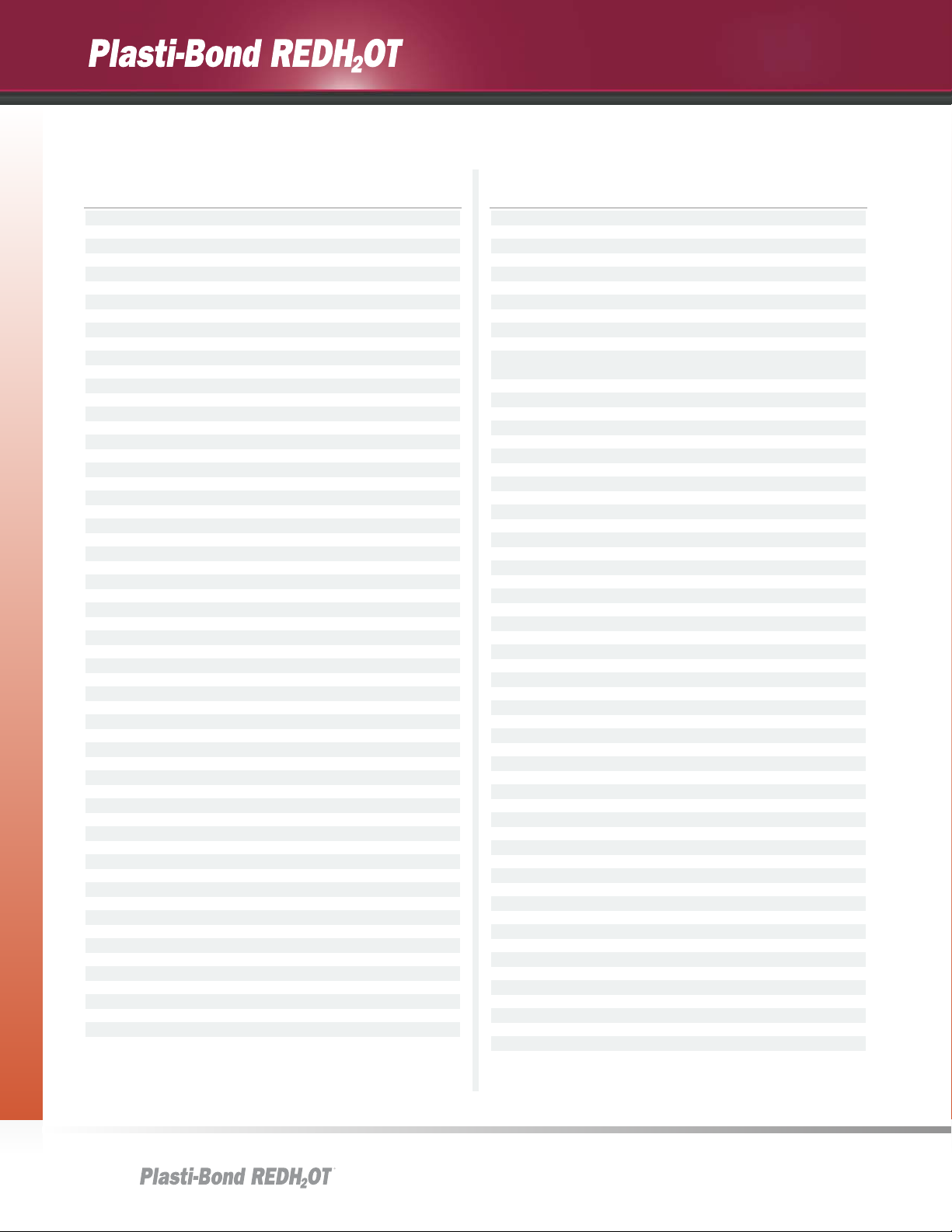

Plasti-Bond, a RobRoy Company all products Technical Data

Technical Information

Urethane Interior Coating Chemical Resistance Chart

RECOMMENDED

EXPOSURE

SOLUTIONS CONC. TEMP. FUMES SPLASH IMMERSION

Acetic Acid 10% 75˚ F YES YES NO

Acid Copper Plating Sol. Any 75˚ F YES YES NO

Alkaline Cleaners Any 75˚ F YES YES NO

Aluminum Chloride Sat’d 75˚ F YES YES NO

Aluminum Sulfate Sat’d 75˚ F YES YES NO

Alums Sat’d 75˚ F YES YES NO

Ammonium Chloride Sat’d 75˚ F YES YES NO

Ammonium Hydroxide 28% 75˚ F YES YES NO

Ammonium Hydroxide 10% 75˚ F YES YES NO

ium Sulfate

Ammon

Ammonium Thiocyanate Sat’d 75˚ F YES YES NO

Amyl Alcohol Sat’d 75˚ F YES YES YES

Arsenic Acids Any 75˚ F YES YES NO

Barium Sulfide Sat’d 75˚ F YES YES NO

Black Liquor Sat’d 75˚ F YES YES NO

Benzoic Acid Sat’d 75˚ F YES YES NO

Brass Plating Solution Sat’d 75˚ F YES YES NO

Bromine Water Sat’d 75˚ F YES YES NO

Butyl Alcohol Any 75˚ F YES YES NO

Cadmium Plating Sol.

Cadmium Bisulfate Any 75˚ F YES YES NO

Calcium Chloride Sat’d 75˚ F YES YES NO

Calcium Hypochlorite Sat’d 75˚ F YES YES NO

Carbonic Acid Sat’d 75˚ F YES YES NO

Casein Any 75˚ F YES YES NO

Castor Oil Any 75˚ F YES YES YES

Caustic Soda 35% 75˚ F YES YES NO

Caustic Soda 10% 75˚ F YES YES NO

Caustic Potash 35% 75˚ F YES YES NO

Caustic Potash 10% 75˚ F YES YES NO

Chlorine Water Sat

Chromium Plating Sol. Any 75˚ F YES YES NO

Citric Acid Sat’d 75˚ F YES YES NO

Copper Chloride Sat’d 75˚ F YES YES NO

Copper Cyanide Plating Sol. Any 75˚ F YES YES NO

Copper Sulfate Sat'd 75˚ F YES YES NO

Coconut Oil Sat’d 75˚ F YES YES YES

Cottonseed Oil Sat’d 75˚ F YES YES YES

Disodium Phosphate Sat’d 75˚ F YES YES NO

Ethyl Alcohol Any 75˚ F YES YES NO

Ethylene Glycol Any 75˚

Ferrous Sulfate Sat’d 75˚ F YES YES NO

Fluoboric Acid Any 75˚ F YES YES NO

Formaldehyde 37% 75˚ F YES YES NO

Formic Acid 85% 75˚ F YES YES NO

Gallic Acid Sat’d 75˚ F YES YES NO

Glucose Any 75˚ F YES YES YES

Glycerine Any 75˚ F YES YES YES

Gold Plating Solution Any 75˚ F YES YES NO

Hydrochloric Acid 10% 75˚ F YES YES NO

Hydrochloric Acid 21.5% 75˚ F YES YES NO

Hydrochloric Acid 37.5%

Hydrofluoric Acid 4% 75˚ F YES YES NO

Hydrofluoric Acid 10% 75˚ F YES YES NO

Hydrofluoric Acid 48% 75˚ F YES YES NO

Hydrogen Peroxide 30% 75˚ F YES YES NO

Hydroquinone Any 75˚ F YES YES NO

Indium Plating Solution Any 75˚ F YES YES NO

Lactic Acid Any 75˚ F YES YES NO

Lead Plating Solution Any 75˚ F YES YES NO

Sat’d 75˚ F YES YES NO

Any

75˚ F YES YES NO

’d

75˚ F YES YES NO

F

YES YES YES

75˚ F

YES YES NO

RECOMMENDED

EXPOSURE

SOLUTIONS CONC. TEMP. FUMES SPLASH IMMERSION

Malic Acid Any 75˚ F YES YES NO

Methyl Alcohol Any 75˚ F YES YES NO

Mineral Oils Any 75˚ F YES YES YES

Nickel Acetate Sat’d 75˚ F YES YES NO

Nickel Plating Solution Any 75˚ F YES YES NO

Nickel Salts Sat’d 75˚ F YES YES NO

Nitric Acid 35% 75˚ F YES YES NO

Nitric Acid 40% 75˚ F YES YES NO

Nitric Acid 60% 75˚ F YES YES NO

Nitric/Hydrofluoric Acid 15%/4% 7

Nitric Acid/

Sodium Dichromate Water 16%/13%/71% 75˚ F YES YES NO

Oleic Acid Any 75˚ F YES YES NO

Oxalic Acid Any 75˚ F YES YES NO

Phenol Sat’d 75˚ F YES YES NO

Phosphoric Acid 75% 75˚ F YES YES NO

Phosphoric Acid 85% 75˚ F YES YES NO

Potassium Acid Sulfate Sat’d 75˚ F YES YES NO

Potassium Antimonate Sat’d 75˚ F YES YES NO

Potassium Bisulfite Sat’d 75˚ F YES YES NO

Potassium Ch

Potassium Cuprocyanide Sat’d 75˚ F YES YES NO

Potassium Cyanide Sat’d 75˚ F YES YES NO

Potassium Dichromate Sat’d 75˚ F YES YES NO

Potassium Hypochlorate Sat’d 75˚ F YES YES NO

Potassium Sulfide Sat’d 75˚ F YES YES NO

Potassium Thiosulfate Sat’d 75˚ F YES YES NO

Propyl Alcohol Sat’d 75˚ F YES YES NO

Rhodium Plating Solution Sat’d 75˚ F YES YES NO

Silver Plating Soluti

Soaps Any 75˚ F YES YES NO

Sodium Acid Sulfate Sat’d 75˚ F YES YES NO

Sodium Antimonate Sat’d 75˚ F YES YES NO

Sodium Bicarbonate Sat’d 75˚ F YES YES NO

Sodium Bisulfite Sat’d 75˚ F YES YES NO

Sodium Chloride Sat’d 75˚ F YES YES NO

Sodium Cyanide Sat’d 75˚ F YES YES NO

Sodium Dichromate Sat’d 75˚ F YES YES NO

Sodium Hydroxide 10% 75˚ F YES YES NO

Sodium Hydroxide 35% 75˚

Sodium Hydroxide 73% 75˚ F YES YES NO

Sodium Hypochlorite Sat’d 75˚ F YES YES NO

Sodium Hypochlorite 15% 75˚ F YES YES NO

Sodium Sulfide Sat’d 75˚ F YES YES NO

Sodium Thiosulfate Sat’d 75˚ F YES YES NO

Sulfuric Acid 15% 75˚ F YES YES NO

Sulfuric Acid 50% 75˚ F YES YES NO

Sulfuric Acid 70% 75˚ F YES YES NO

Sulfuric Acid 98% 75˚ F YES YES NO

Sulfurous Acid 2% 75˚ F YES YES NO

Sulfurous

Tannic Acid Sat’d 75˚ F YES YES NO

Tartaric Acid Sat’d 75˚ F YES YES NO

Tin Chloride Sat’d 75˚ F YES YES NO

Tin Plating Solution Sat’d 75˚ F YES YES NO

Triethanolamine Sat’d 75˚ F YES YES NO

Trisodium Phosphate Sat’d 75˚ F YES YES NO

White Liquor Sat’d 75˚ F YES YES NO

Zinc Plating Solution Sat’d 75˚ F YES YES NO

Zinc Sulfate Sat’d 75˚ F YES YES NO

loride

on

Acid

5˚ F

YES YES NO

Sat’d 75˚ F YES YES NO

Sat’d 75˚ F YES YES NO

F

YES YES NO

4% 75˚ F YES YES NO

Technical Information

60

1100 US Highway 271 South

Gilmer, Texas 75644

Phone: 903.843.5591

Fax: 903.843.5595

Technical Information

PVC Exterior Coating Chemical Resistance Chart

RECOMMENDED

EXPOSURE

SOLUTIONS CONC. TEMP. FUMES SPLASH IMMERSION

Acetic Acid 10% 120 NO NO NO

Acid Copper Plating Sol. 160 YES YES YES

Alkaline Cleaners 160 YES YES YES

Aluminum Chloride Sat’d 160 YES YES YES

Aluminum Sulfate Sat’d 160 YES YES YES

Alums Sat’d 160 YES YES YES

Ammonium Chloride Sat’d 160 YES YES YES

Ammonium Hydroxide 28% 120 YES YES YES

Ammonium Hydroxide 10% 120 YES YES YES

Ammonium Sulfate Sat’d 16

Ammonium Thiocyanate Sat’d 160 YES YES YES

Amyl Alcohol Any 90 YES YES YES

Arsenic Acids Any 150 YES YES YES

Barium Sulfide Sat’d 160 YES YES YES

Black Liquor Sat’d 90 YES YES YES

Benzoic Acid Sat’d 160 YES YES YES

Brass Plating Solution Any 160 YES YES YES

Bromine Water Sat’d 120 YES YES YES

Butyl Alcohol Any 90 YES YES YES

Cadmium Plating Sol. Any 150 YES YES YES

Cadmium Bisulfate

Calcium Chloride Sat’d 160 YES YES YES

Calcium Hypochlorite Sat’d 120 YES YES YES

Carbonic Acid Sat’d 160 YES YES YES

Casein Any 90 YES YES YES

Castor Oil Any 90 YES YES YES

Caustic Soda 35% 120 YES YES YES

Caustic Soda 10% 150 YES YES YES

Caustic Potash 35% 120 YES YES YES

Caustic Potash 10% 150 YES YES YES

Chlorine Water Sat’d 90 YES YES YES

Chromium Plating Sol. Any 150 YES

Citric Acid Sat’d 160 YES YES YES

Copper Chloride Sat’d 160 YES YES YES

Copper Cyanide Plating Sol. Any 160 YES YES YES

(High Speed) Any 180 YES YES YES

(with Alkali Cyanides) Sat’d 160 YES YES YES

Copper Sulfate Sat’d 160 YES YES YES

Coconut Oil Sat’d 90 YES YES YES

Cottonseed Oil Sat’d 90 YES YES YES

Disodium Phosphate Sat’d 160 YES YES YES

Ethyl Alcohol Any 90 YES YES YES

Ethylene Glycol

Ferric Chloride 45% 120 YES YES YES

Ferrous Sulfate Sat’d 150 YES YES YES

Fluoboric Acid Any 150 YES YES YES

Formaldehyde 37% 120 YES YES YES

Formic Acid 85% 100 NO NO NO

Gallic Acid Sat’d 150 YES NO NO

Glucose Any 150 YES YES YES

Glycerine Any 90 YES YES YES

Gold Plating Solution Any 150 YES YES YES

Hydrochloric Acid 10% 120 YES YES YES

Hydrochloric Acid 21.5% 120 YES YES YES

ydrochloric Acid

H

Hydrochloric Acid 37.5% 90 YES YES NO

Hydrofluoric Acid 4% 140 YES YES NO

Hydrofluoric Acid 10% 120 YES YES NO

Hydrofluoric Acid 48% 120 YES YES NO

Hydrogen Peroxide 30% 120 YES YES YES

Hydrogen Sulfide Sat’d 120 YES YES YES

Hydroquinone Any 90 YES YES YES

Indium Plating Solution Any 150 YES YES YES

Any

Any

37.5% 120 YES YES NO

0

YES YES YES

150 YES YES YES

YES

90 YES YES NO

YES

RECOMMENDED

EXPOSURE

SOLUTIONS CONC. TEMP. FUMES SPLASH IMMERSION

Lactic Acid 50% 120 YES YES YES

Lactic Acid Any 90 YES YES YES

Lead Plating Solution Any 150 YES YES YES

Malic Acid Any 90 YES YES YES

Methyl Alcohol Any 90 YES YES YES

Mineral Oils Any 90 YES YES YES

Nickel Acetate Sat’d 160 YES YES YES

Nickel Plating Solution 160 YES YES YES

Nickel Salts Sat’d 160 YES YES YES

Nitric Acid 35% 120 YES YES NO

d

Nitric Aci

Nitric Acid 60% 120 YES YES NO

Nitric/Hydrofluoric Acid 15%/4% 140 YES YES YES

Nitric Acid/Sodium

Dichromate Water 16%/13%/71% 130 YES YES YES

Oleic Acid Any 90 YES YES YES

Oxalic Acid 90 YES YES YES

Phenol Sat’d 120 NO NO NO

Phosphoric Acid 75% 150 YES YES YES

Phosphoric Acid 85% 120 YES YES YES

Potassium Acid Sulfate Sat’d 150 YES YES YES

Potassium Antimonat

Potassium Bisulfite Sat’d 90 YES YES YES

Potassium Chloride Sat’d 160 YES YES YES

Potassium Cuprocyanide Sat’d 150 YES YES YES

Potassium Cyanide Sat’d 160 YES YES YES

Potassium Dichromate Sat’d 160 YES YES YES

Potassium Hypochlorate Sat’d 90 YES YES NO

Potassium Sulfide Sat’d 150 YES YES YES

Potassium Thiosulfate Sat’d 150 YES YES YES

Propyl Alcohol Sat’d 150 YES YES YES

odium Plating Solution

Rh

Silver Plating Solution Sat’d 150 YES YES YES

Soaps Any 90 YES YES YES

Sodium Acid Sulfate Sat’d 160 YES YES YES

Sodium Antimonate Sat’d 150 YES YES YES

Sodium Bicarbonate Sat’d 160 YES YES YES

Sodium Bisulfite Sat’d 90 YES YES YES

Sodium Chloride Sat’d 160 YES YES YES

Sodium Cyanide Sat’d 160 YES YES YES

Sodium Dichromate Sat’d 160 YES YES YES

ydroxide

Sodium H

Sodium Hydroxide 35% 120 YES YES NO

Sodium Hydroxide 73% 160 NO NO NO

Sodium Hypochlorite Sat’d 90 YES YES NO

Sodium Hypochlorite 15% 120 YES YES NO

Sodium Sulfide Sat’d 150 YES YES YES

Sodium Thiosulfate Sat’d 150 YES YES YES

Sulfuric Acid 15% 120 YES YES YES

Sulfuric Acid 50% 120 YES YES YES

Sulfuric Acid 70% 90 YES YES NO

Sulfuric Acid 98% 100 YES NO NO

Sulfurous Aci

Sulfurous Acid 6% 120 YES YES NO

Tannic Acid Sat’d 90 YES YES YES

Tartaric Acid Sat’d 90 YES YES YES

Tin Chloride Sat’d 150 YES YES YES

Tin Plating Solution Sat’d 150 YES YES YES

Triethanolamine Sat’d 150 YES YES YES

Trisodium Phosphate Sat’d 150 YES YES YES

White Liquor Sat’d 90 YES YES YES

Zinc Plating Solution 160 YES YES YES

Zinc Sulfate Sat’d 160 YES YES YES

e

d

40% 90 YES YES NO

Sat’d 150 YES YES YES

Sat’d 150 YES YES YES

10% 150 YES YES NO

2% 120 YES YES NO

Technical Information

Contact us:

customerservice@plastibond.com

Visit www.plastibond.com

For more information

61

Loading...

Loading...