Plasmon LF 6602 User Manual

THE PLASMON INFINITY

LF 6602

OPTICAL DISK DRIVE

User Manual

P/N 97654438 E

New features and changes to information in this document are indicated by change bars. Revision level is

indicated by the letter following the eight-digit document number. If a document has undergone major

modifications, change bars will not be inserted in the document.

Reproduction of this manual, or any portion of this manual, is prohibited without the express permission of

Plasmon Laser Magnetic Storage (LMS). Plasmon LMS reserves the right to make changes in this

document and the product referred to herein without prior notice.

© 1999 Plasmon Laser Magnetic Storage

WARNING

Always observe the following when installing, operating or maintaining

this product:

• This unit must be connected to a power distribution system that has a

direct connection to earth ground (Terminated Terra [TT] network/

ground connected). This unit is not suitable for use on a floating

ground (Interrupted Terra [IT]) network.

• The AC input power cord must be shielded and must have a minimum

current rating of 10 A with a nominal cross-section area of 0.75 sq mm

(reference: AWG #18) per conductor, 2 wires plus ground and product

safety approvals as required for use in the country in which the unit is

installed.

• When the unit is mounted in an equipment rack or cabinet, be certain

that the internal temperature within the rack or cabinet does not

exceed the limits defined in the Product Specification or this

document.

• To ensure the integrity of safety features of this unit, maintenance must

be performed only by qualified service personnel using designated

Plasmon LMS parts.

• In case of fire or other emergency, isolate the units from the main

power by disconnecting the power plugs from their site power

receptacles. In situations where disconnecting the plugs is not

possible or practical, use the system main power disconnect to isolate

the units from the main power.

• To prevent fire or shock hazard, do not expose this unit to rain or

moisture. Refer servicing to qualified technicians.

(German Translation)

• Bei der Installation, Bedienung und Wartung dieses Produkts, bitte

immer die folgenden Vorsichtsmaßnahmen treffen:

• Dieses Gerät muß an ein Stromversorgungssystem angeschlossen

werden, das direkt mit einem Erdungsanschluß verbunden ist

(Terminated- Terra-Netz [TT]/mit Erdanschluß). Dieses Gerät kann

nicht an ein ungeerdetes Netz (Interrupted Terra [IT]) angeschlossen

werden.

• Die Verbindungsschnur des Wechselstromeingangs muß entstört sein

und ihr Minimalstrom unter folgenden Bedingungen bei 10 A liegen:

Der Nennquerschnitt beträgt 0,75 mm je Leiter (Referenz: American

Wire Gauge Nr. 18), es bestehen 2 Drähte plus ein Erdanschluß und

das Produkt entspricht den im Land, in dem es aufgestellt wird,

geltenden Sicherheitsvorschriften.

WARNUNG

• Wird das Gerät in ein Gerätegestell oder einen Geräteschrank

eingebaut, ist darauf zu achten, daß die interne Temperatur im Gestell

oder Schrank nicht über die in den Produktspezifikationen oder

diesem Dokument angegebenen Grenzwerte hinausgeht.

• Um ein ordnungsgemäßes Funktionieren der Sicherheitsmerkmale

dieses Gerätes zu gewährleisten, dürfen Wartungsarbeiten nur von

qualifiziertem Fachpersonal ausgeführt werden. Es sind darüber

hinaus nur Ersatzteile zu verwenden, die von der Firma Plasmon LMS

angegeben werden.

• Im Falle eines Feuers oder in einem anderen Notfall sind die Geräte

vom Hauptnetz zu trennen, indem die Netzstecker aus den

Steckdosen am Einbauort gezogen werden. Ist ein Herausziehen der

Stecker nicht möglich oder zu umständlich, trennen Sie die Geräte mit

Hilfe des System- Hauptnetzabschalters vom Hauptnetz.

• Um Feuer- oder Stromschlaggefahr zu vermeiden, ist dieses Gerät

niemals Regen oder Feuchtigkeit auszusetzen. Wartungsarbeiten

sind qualifiziertem technischen Personal zu überlassen.

Radio/TV Interference (USA)

The information in this section applies only to units in use within the United States:

This equipment generates and uses radio frequency energy and, if not installed and used properly, that is,

in strict accordance with the manufacturer's instruction, may cause interference to radio and television

reception. It has been type tested and found to comply with the limits for a Class A computing device in

accordance with the specifications of Part 15 of FCC Rules, which are designed to provide reasonable

protection against such interference in a residential installation. However, there is no guarantee that

interference will not occur in a particular installation. If this equipment does cause interference to radio or

television reception, which can be determined by turning the equipment off and on, the user is encouraged

to try to correct the interference by one or more of the following measures:

• reorient the receiving antenna

• relocate the equipment away from the receiver

• plug the equipment into a different outlet so that equipment and receiver are on different branch

circuits.

If necessary, the user should consult the dealer or an experienced radio/television technician for additional

suggestions. A pamphlet by the FCC ‘How to Identify and Resolve Radio-TV Interference Problems' is

available from the US Government Printing Office, Washington, D.C., 20402, Stock No. 044-000-00345-4.

CDRH COMPLIANCE

LF 6602 contains a Class 1 Laser Product. This product complies with 21CFR Chapter 1, Subchapter J,

applicable at date of manufacture.

CANADIAN EMI COMPLIANCE

Canadian Department of Communications standards require that the following statement appear in

operating manuals for any digital apparatus imported into Canada:

This digital apparatus does not exceed the Class A limits for radio noise for digital apparatus set out in the

Radio Interference Regulations of the Canadian Department of Communications.

FRENCH TRANSLATION

Cet équipement digital ne dépasse pas les limites de la Classe A pour les interférences radioélectriques

des systémes digitaux fixées par les Réglements concernant les Interférences Radioélectriques établis par

le Ministére des Communications du Canada.

All Plasmon LMS products comply with the requirements of this standard.

Agency Compliance and Approval

For details on Agency Compliance and Approval refer to the LF 6602 Product Specification Manual.

TABLE OF CONTENTS

SCOPE 9

RELATED PUBLICATIONS 9

GENERAL DESCRIPTION 11

DRIVE CHARACTERISTICS 13

FRONT PANEL 13

REAR PANEL 14

DIMENSIONS AND WEIGHT 15

TEMPERATURE, HUMIDITY AND ALTITUDE 16

SHOCK AND VIBRATION 17

AC POWER REQUIREMENTS 17

AC GROUND 18

AC POWER CORD 18

TILT RANGE 18

HEAT DISSIPATION 18

PARTICULATE LIMITS 18

WARNING LABELS 19

UNPACKING AND REPACKING INSTRUCTIONS 21

UNPACKING THE LF 6602 21

INSPECTING THE LF 6602 27

REPACKING THE LF 6602 27

INSTALLATION 33

INSTALLATION REQUIREMENTS 33

SCSI BUS CONSIDERATIONS 34

CONNECTING POWER AND SCSI CABLING 37

SINGLE-DEVICE CONFIGURATION 38

MULTIPLE-DEVICE CONFIGURATION 39

CONNECTOR VERIFICATION 39

EXTENSION PROCEDURES 40

OPERATING INSTRUCTIONS 43

CONTROLS AND INDICATORS 43

POWER-ON PROCEDURE 45

MODES OF OPERATION 46

OPERATING MODE 46

CONFIGURATION MODE 48

TEST MODE 70

MEDIA CARTRIDGE HANDLING 71

SETTING THE WRITE PROTECTION SWITCH 73

AFFIXING LABELS 74

MEDIA INSERTION AND REMOVAL 74

MEDIA ACCESS DOOR 74

CARTRIDGE INSERTION 76

CARTRIDGE REMOVAL 77

MANUAL CARTRIDGE RELEASE MECHANISM 78

MEDIA LOADING 82

OPERATOR MAINTENANCE 83

ACCESSING DRIVES 83

INSPECTING AND CLEANING FAN

AND BLOWER FILTERS 85

REPLACING FUSES 86

MEDIA CLEANING 87

MEDIA CLEANING USING

CLEANING KIT P/N 97662550 87

ACCESSORIES 89

APPENDIX A 93

GERMAN TRANSLATIONS/

ÜBERSETZUNGEN INS DEUTSCHE 93

SCOPE

This User Manual describes unpacking, installing, operating, and maintaining the Plasmon Infinity LF 6602

RapidChangert High-Performance Optical Disk Drive.

RELATED PUBLICATIONS

Publication Part Number

LM 6000 Media Product Specification 97647044

LF 6600 User Manual 97653976

LD 6100/LF 6600 SCSI Interface Specification 97653978

LD 6100 Hardware Maintenance Manual 97653979

LF 6600/LF 6602 Hardware Maintenance Manual 97653980

LD 6100 User Manual 97654437

WARRANTY STATEMENT

The LF 6602 is warranted as stated in the purchase agreement between Plasmon and it’s customer,

or the Plasmon sales order acknowledgment, whichever is applicable.

The Plasmon LMS quality system is in compliance and registered to ISO 9001. The LF 6602 is

manufactured from new parts, or remanufactured parts.

LF 6602 warranty does not cover defects or damage caused by the use of unauthorized parts or

repairs or improper use or maintenance. Repairs or replacements not covered by the warranty will

be invoiced at LMS’ then current prices.

The warranty is void when installation, service or repairs are performed by unauthorized

personnel; when the product is affected by unauthorized alterations, modifications or other

tampering or misuse; when the product is incorporated into a system which causes or involves

any changes in the physical, mechanical or electrical arrangement of the product; or when the

product is not used in accordance with its applicable specifications.

The term, authorized personnel, is defined as those persons who have been trained by Plasmon

LMS Technical Services.

97654438 E

Page 9

PLASMON LASER MAGNETIC STORAGE - LF 6602 USER MANUAL

Page 10

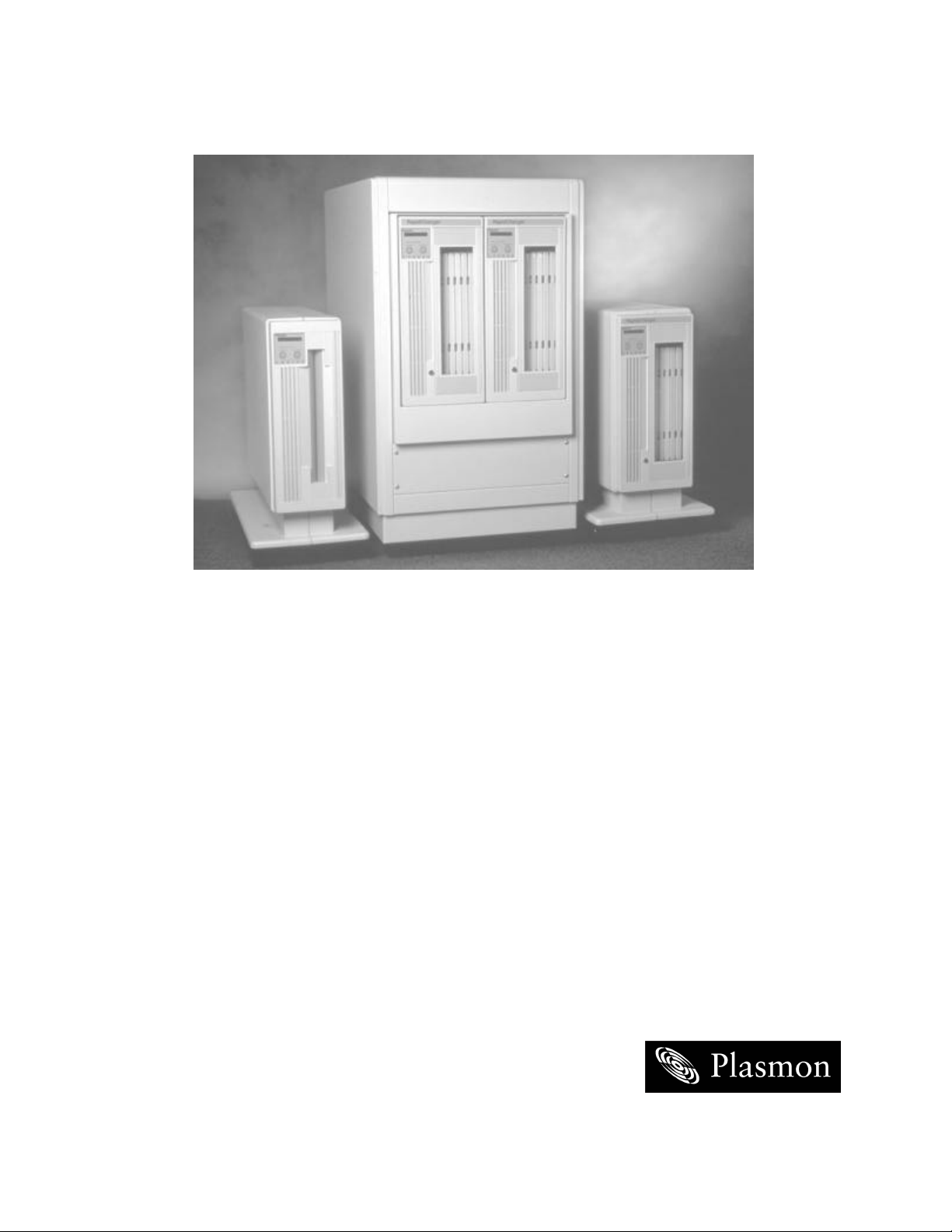

GENERAL DESCRIPTION

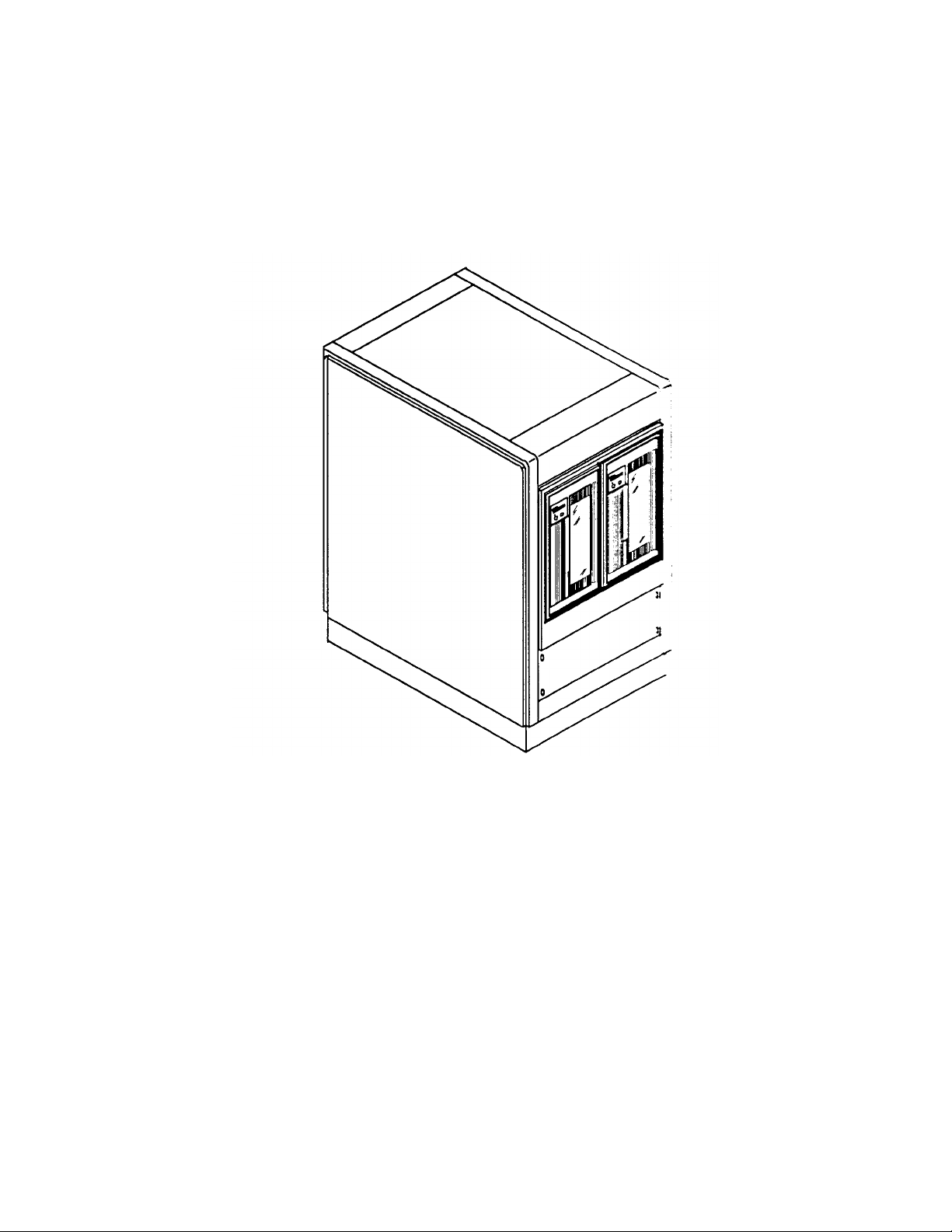

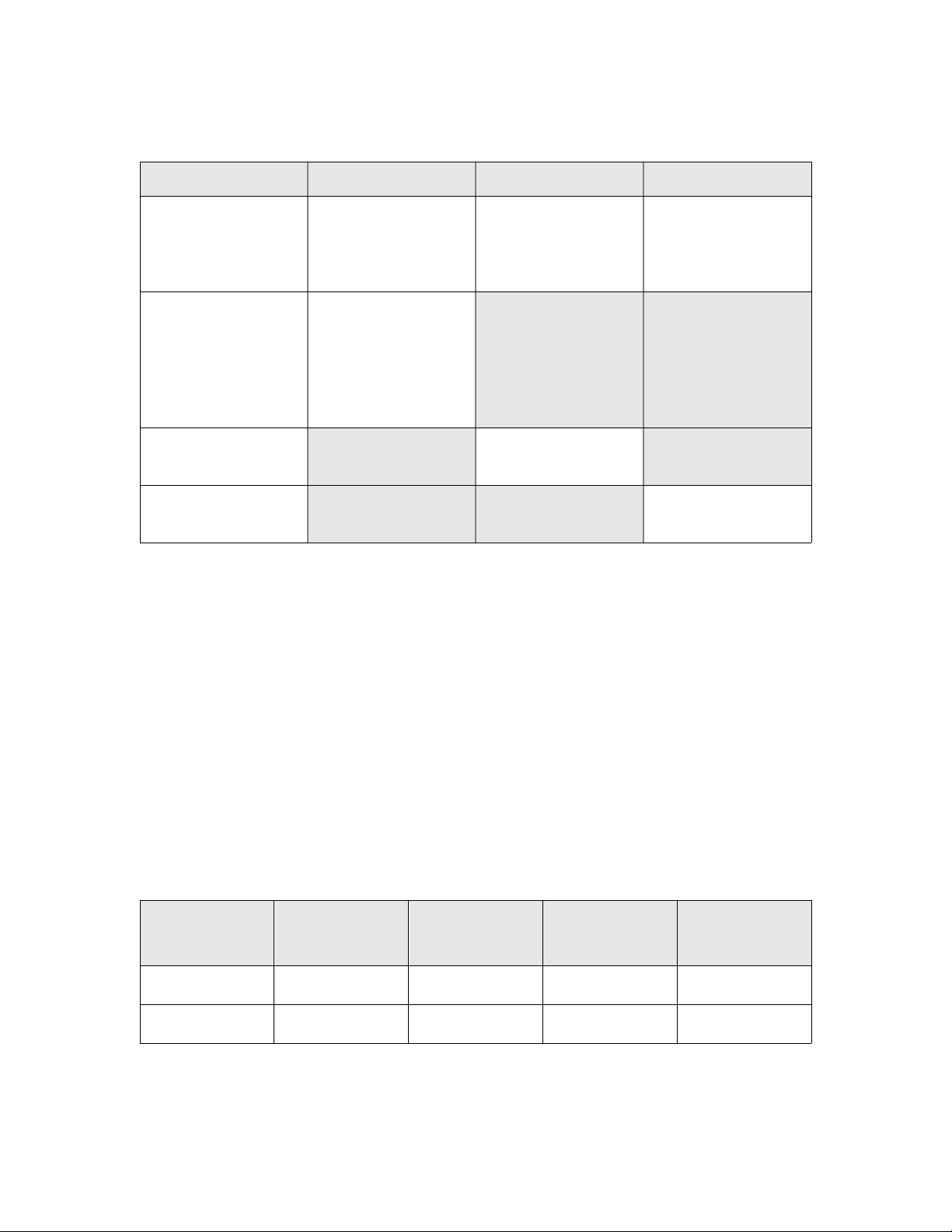

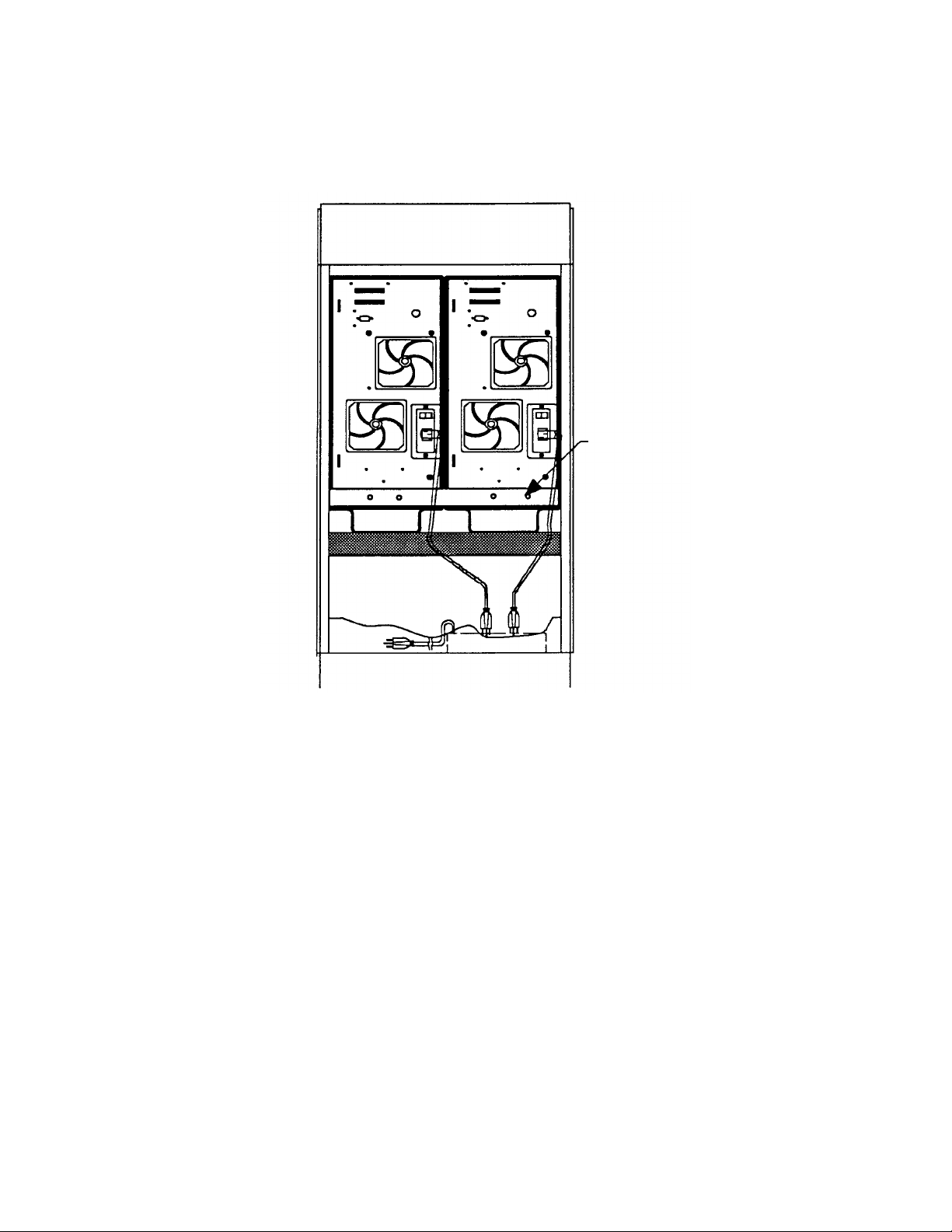

The Plasmon Infinity LF 6602 RapidChanger is a cabinet configuration, housing two LF 6600

RapidChanger drives side-by-side, as shown in the next figure.

LF 6602 Configuration

Each LF 6600 drive is a write once read many (WORM), high-capacity, optical disk drive with an integral

shuttle, capable of holding up to six LM 6000/LM 4000 media cartridges. The integral shuttle moves

laterally to position one of the media cartridges for automated loading and unloading into the optical drive.

The LF 6602 provides 24 GBytes of online storage and up to 144 GBytes of nearline storage. Each LF

6602 provides 12 GBytes of online storage and up to 72 GBytes of nearline storage. Each LM 6000 media

cartridge has a capacity of 12 GBytes.

A Drive Operator Console (DOC) located on the front panel of each drive provides user control of drive

operation and configuration as explained in the Operating Instruction section of this manual. Operating

messages are presented on the alphanumeric display in English, French or German. The language used is

selectable.

Each drive's front panel includes a lockable media access door to provide operator access to the shuttle

and media cartridges.

EP006028

97654438 E

Page 11

The Auxiliary Diagnostic Port (ADP), located on the rear panel of each drive, can be used to download

updates to the drive firmware in the field. Refer to the LD 6100/LF 6600/LF 6602 Product Specification

(P/N 97653977) for more information.

Each LF 6602 drive supports a sustained read transfer rate of 2.7 MBytes/sec with error correction and

defect management capabilities to maintain data integrity and manage media flaws. Each LF 6600

implements the Small Computer System Interface (SCSI) via standard SCSI-2 micro-connectors located

on the rear panels. Single-ended and differential interface options are available, and the interface can be

changed in the field. Both the single-ended and differential controllers support asynchronous or

synchronous data transfer operations.

Preventive maintenance for the LF 6602 is minimal (refer to the Operator Maintenance section). Corrective

maintenance is simplified by internal diagnostic firmware which detects, isolates, and reports malfunctions

to the operator and identifies the faulty Field Replaceable Unit (FRU).

LM 6000 media is interchangeable between the LF 6602, LF 6600 and the LD 6100. The 6000 series of

drives will also read LM 4000 media written by the Plasmon LMS 4000 series of optical drive products

(except for media with serial numbers less than X0010000, where X designates an A or B).

PLASMON LASER MAGNETIC STORAGE - LF 6602 USER MANUAL

Page 12

DRIVE CHARACTERISTICS

FRONT PANEL

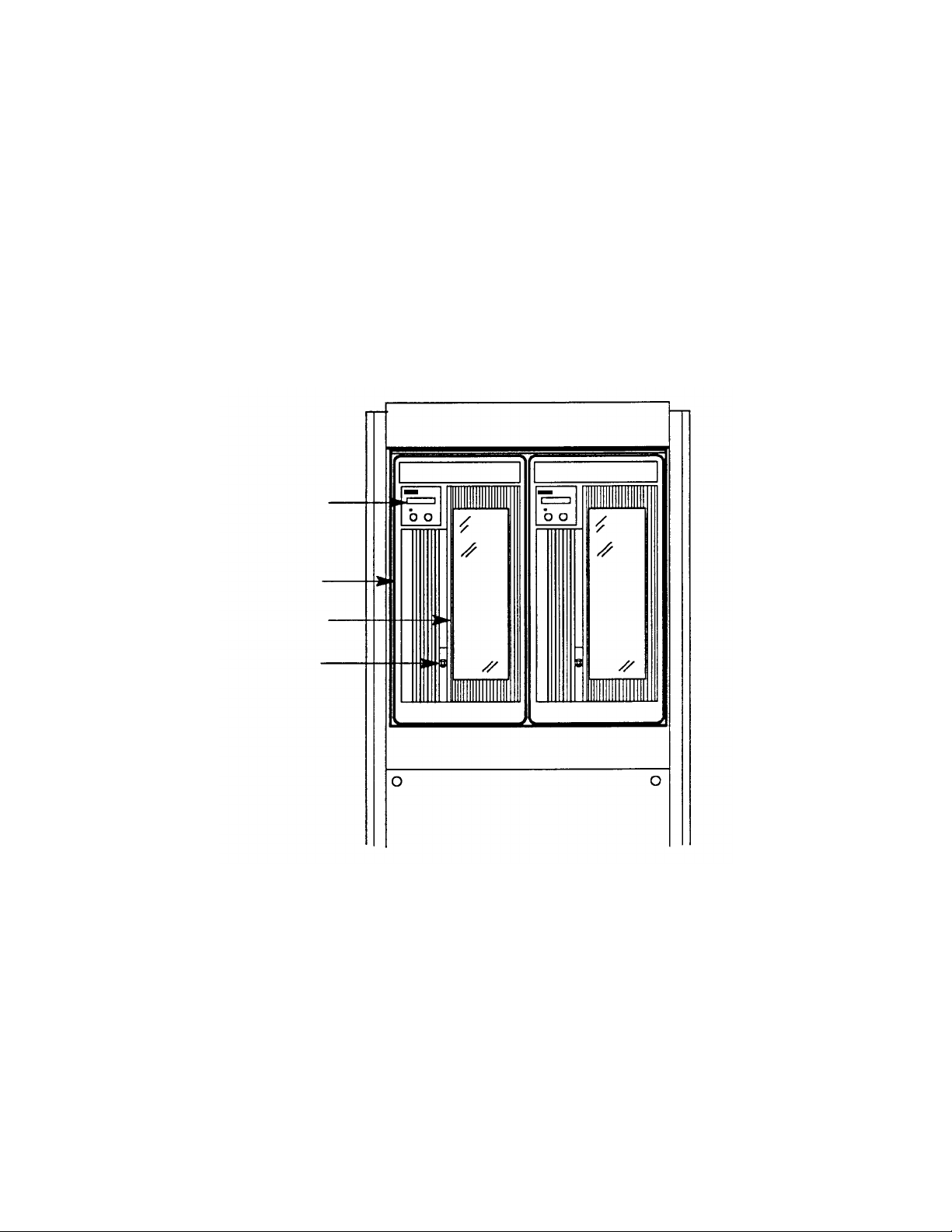

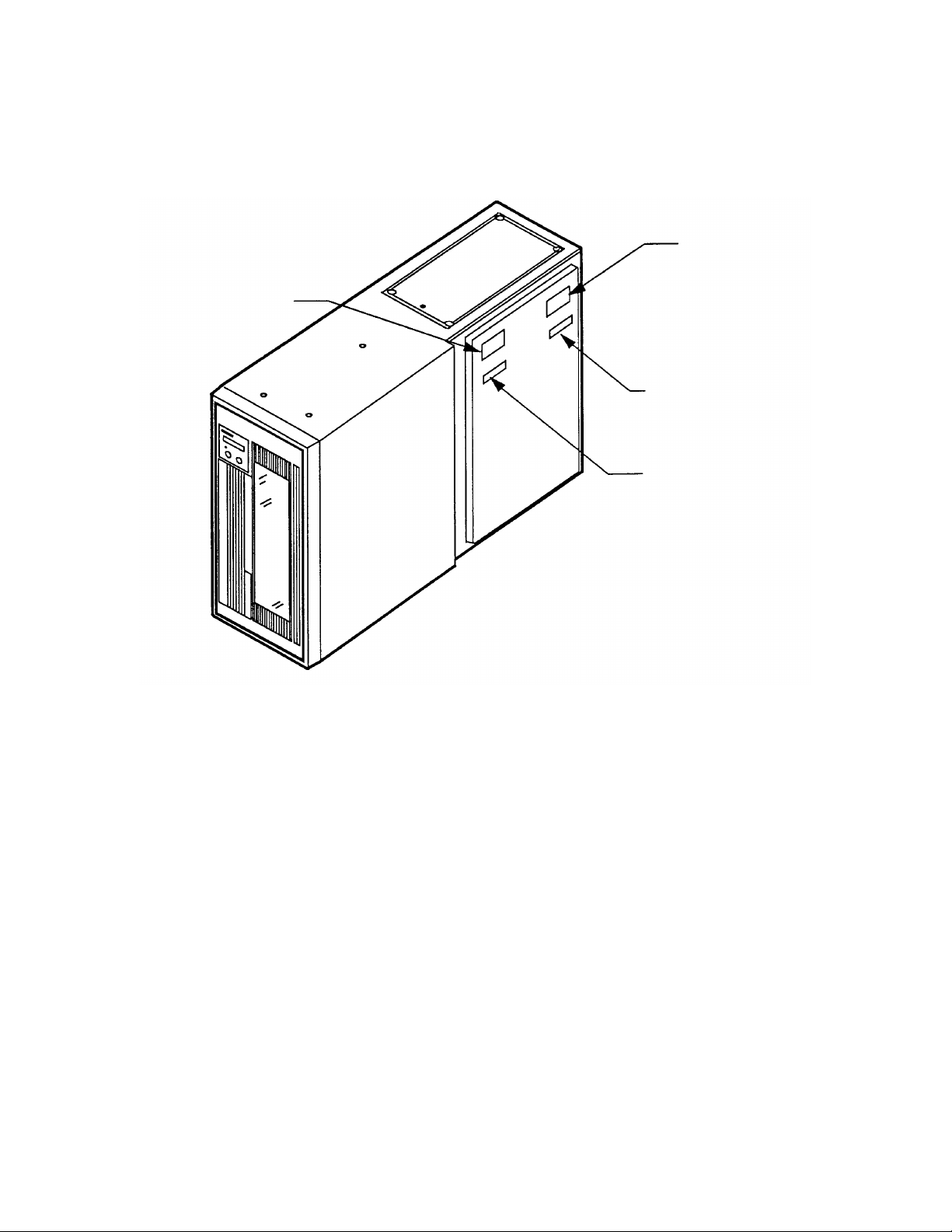

The LF 6602 front panel is shown in the figure below. The LF 6600 bezels, which contain the Drive

Operator Console (DOC), media access door and door lock, protrude through a frame in the cabinet. A

drive's bezel can be removed to gain access to that drive.

Refer to the Operating Instruction section for a detailed description of the DOC.

DOC

BEZEL

MEDIA ACCESS

DOOR

DOOR LOCK

LF 6602 Front Panel

EP006030

97654438 E

Page 13

REAR PANEL

On the rear of the LF 6602 cabinet, a louvered door with a latch and a key lock covers the access to the

rear of the LF 6600 drives (refer to figure below).

To gain access to the drives' power switches, ADP and SCSI interface connectors, unlock the door, press

up on the latch and open the door. The drives' AC power source is provided by the power socket strip,

located on the bottom of the rear panel within the cabinet. The primary AC cord for the LF 6602 is

connected to the power socket strip.

KEY LOCK

LATCH

POWER

SOCKET

STRIP

LF 6602 Rear Panel

PLASMON LASER MAGNETIC STORAGE - LF 6602 USER MANUAL

Page 14

EP006031

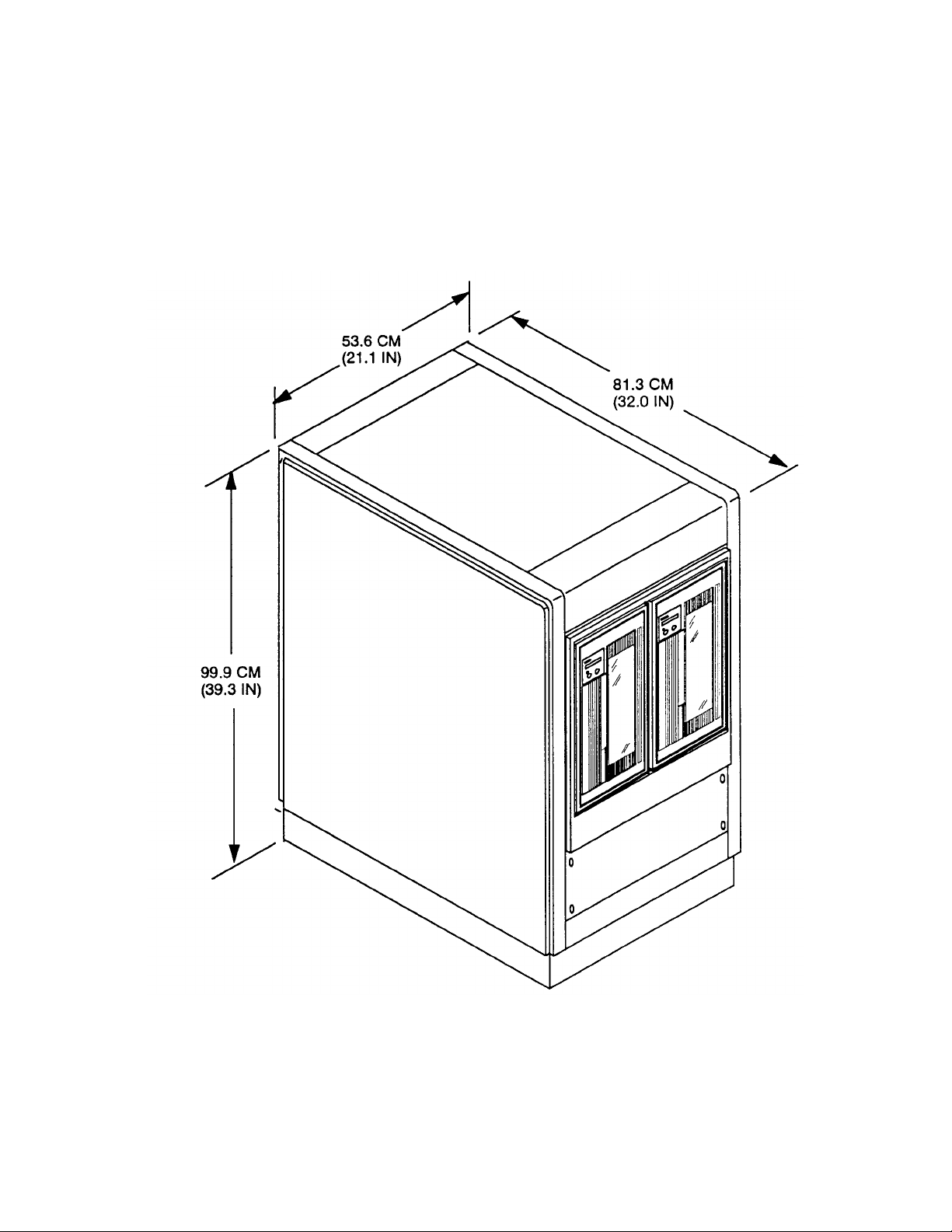

DIMENSIONS AND WEIGHT

The LF 6602's reference dimensions, are shown in the next table.

Height: 99.9 cm (39.3 in)

Width: 53.6 cm (21.1 in)

Depth: 81.3 cm (32.0 in)

Weight: 204 kg (450 lb)

LF 6602 Dimensions

EP006029

97654438 E

Page 15

TEMPERATURE, HUMIDITY AND ALTITUDE

The following table lists the temperature, humidity and altitude limits for the LF 6600 drives installed in the

LF 6602.

Temperature, Humidity and Altitude Limits

CONDITION OPERATING NONOPERATING

Temperature

Maximum Rate of

Change

Humidity

10° to 42° C

(50° to 108° F)

11° C/hr

(20° f/hr)

10 to 90% 5 to 95% 5 to 95%

2

-40° to 66° C

(-40° to 151° F)

20° C/hr

(36° F/hr)

(Noncondensing)

Maximum Rate of

10%/hr 10%/hr 10%/hr

Change

Maximum Wet

Bulb

28° C

(82° F)

46°C

(115° F)

Temperature

Minimum Dew

Point

Altitude -300 to 3,000 m

2° C

(35.6°)

(-984 to 9840 ft)

2° C

(35.6°)

-300 to 3,000 m

(-984 to 9840 ft)

without Media

-300 to 2,000 m

(-984 to 6562 ft)

with Media

STORAGE/TRANSIT

-40° to 66° C

(-40° to 151° F)

20° C/hr

(36° F/hr)

46°C

(115° F)

2° C

(35.6°)

Storage

-300 to 3,000 m

(-984 to 9840 ft)

Transit

-300 to 12,000 m

(-984 to 40,000 ft)

with Media

1

1 Storage specifications are for 90 days maximum in Plasmon LMS packaging. No condensation is permitted. Transit spec-

ifications are based on a maximum 1-week period in a factory-sealed container.

2 Maximum operating temperature is 42 _C for a free-standing drive at sea level unless otherwise stated. Maximum oper-

ating temperature is derated linearly above 300 m altitude to 38 _C at 2,000 m altitude.

3 See the LD 6100/LF 6600/LF 6602 Product Specification (P/N 97653977) for more information concerning the tempera-

ture and humidity operating range.

4 Media limits maximum operating altitude to 2000 m. For conditions and limits pertaining to the media, refer to the LM

6000 Media Specification (P/N 97647044).

PLASMON LASER MAGNETIC STORAGE - LF 6602 USER MANUAL

Page 16

SHOCK AND VIBRATION

The table below lists the conditions and limits for shock and vibration for the LF 6602.

Shock and Vibration Criteria and Limits

CONDITION OPERATING

Swept Vibration

(Bidirectional)

1 Octave/Min

3

Shock

(Host Retries May

5 to 22 Hz 0.01 in

Double Amplitude,

22 to 500 Hz

10 - msec Half Sine

Pulse of 5.0 g Peak

0.25 g Peak

NONOPERATING

5 to 44 Hz, 0.03 in

Double Amplitude,

44 to 500 Hz

3.0 g Peak

4

1

STORAGE/TRANSIT

5 to 44 Hz, 0.03 in

Double Amplitude,

44 to 500 Hz

3.0 g Peak

2

Be Required and

Drive Performance

May Degrade During

Test

Unpacked (3 Axis) 5 - msec Half Sine

Pule of 5.0 g Peak

Packed on Pallet 31 - cm (18 - in)

Drop Test Flat

1 With media removed 2 In LMS-approved packaging 3 Shock repetition rate should be limited to allow mechanical

system transients to subside between pulses. 4 Limit at 5.0 g peak for LF 6602 cabinet. Limit at 3.0 g peak in

LF 6600/LF 6602 in front-to-back axis because media in shuttle will be displaced. The drive is not designed for prolonged operation at these shock levels.

AC POWER REQUIREMENTS

The primary AC power cord type will depend on the LF 6602 configuration ordered. The primary AC power

cord supplies power to the power socket strip located within the LF 6602 cabinet. Each LF 6602 is

connected to the power socket strip with a grounded AC power cord. The power connector of each

LF 6600 is integrated into the AC power receptacle. Over current protection is provided by two fuses,

which are also integrated into the receptacle with two spare fuses. Refer to the Replacing Fuses section

for the fuse replacement procedure.

Each drive's power supply accepts the input line voltages listed in Table 3. The power supply is

autoranging and does not require mechanical switching for input voltage or frequency selection.

AC Power Requirements

MINIMUM

SERVICE

RATINGS

FREQUENCY AC VOLTAGE

47 to 66 Hz 86.7 to 128 V 3.0 A 10.0 A 15 A

47 to 66 Hz 173.4 to 268 V 1.5 A 5.0 A 15 A

1 Less than 1 sec, cold start

After the power has been turned off, the operator must wait 1 second

before turning on the power again

CURRENT

(TYPICAL)

NOTE

SPIN - UP

SURGE

1

97654438 E

Page 17

AC GROUND

The LF 6602 chassis must be connected to earth ground for operator safety. The AC power cord has a

grounding conductor which connects the LF 6602 chassis to safety ground through the site AC power

system. If the site AC system ties its ground wire connection to earth ground, then the LF 6602 chassis will

also be tied to earth ground. All site AC power connections must be maintained on the same safety

ground.

A line grounding connector located on the rear panel of each LF 6600 can also be used to tie the drive

chassis to earth ground. These ground connectors are 6-mm (0.24-in.) M4 with a nut and lock washer.

AC POWER CORD

The type of AC power cord supplied with the LF 6602 will depend upon the configuration ordered.

POWER SUPPLY OUT-OF-RANGE PROTECTION FEATURES

Each LF 6600 power supply provides over and under voltage protection, over current protection, power

failure detection and over temperature protection. Should an out-of-range condition occur, each LF 6600

detects it and shuts down the DC outputs of the power supply.

NOTE

After the situation is corrected, power can be restored by turning the

AC power switch to the off position, waiting 1 sec and then turning the

power switch to the on position again.

TILT RANGE

The LF 6602 is not designed for use when tilted from the vertical position.

HEAT DISSIPATION

The LF 6602 cabinet will typically represent a heat load of 292 kg-calories/hr (1160 BTU/hr) during a read/

write operation. When media cartridges are inserted, loaded, spun up, spun down, unloaded and removed

at each drive's maximum rate, the LF 6602 will typically represent a heat load of 364 kg-calories/hr (1450

BTU/hr).

PARTICULATE LIMITS

The LF 6602 is designed for use in an office or computer room. The environment must have a low dust

level. Each drive filters incoming air for cooling to reduce the quantity of particles entering the drive;

however, the filters are not effective against small particles (including tobacco smoke). These particles will

become deposited on optical components and media, causing a degradation in drive performance. Refer

to the Operator Maintenance section for media cleaning and air filter cleaning instructions.

PLASMON LASER MAGNETIC STORAGE - LF 6602 USER MANUAL

Page 18

WARNING LABELS

The LF 6602 is classified as a laser product. As such it is subject to United States federal requirements

covering laser products. The warning labels shown in the next figure are required to ensure compliance

with federal regulations and must not be removed from the LF 6600 drives within the cabinet.

LASER CLASS

LABEL

LASER DANGER

LABEL

CANADIAN CLASS A

COMPLIANCE LABEL

FCC CLASS A

LABEL

Location of LF 6600 Warning Labels

EP006043

97654438 E

Page 19

PLASMON LASER MAGNETIC STORAGE - LF 6602 USER MANUAL

Page 20

UNPACKING AND REPACKING

INSTRUCTIONS

If the Laser Drive’s shipping carton shows evidence of rough handling or damage, return the unit in it’s

carton to your supplier and request a replacement.

UNPACKING THE LF 6602

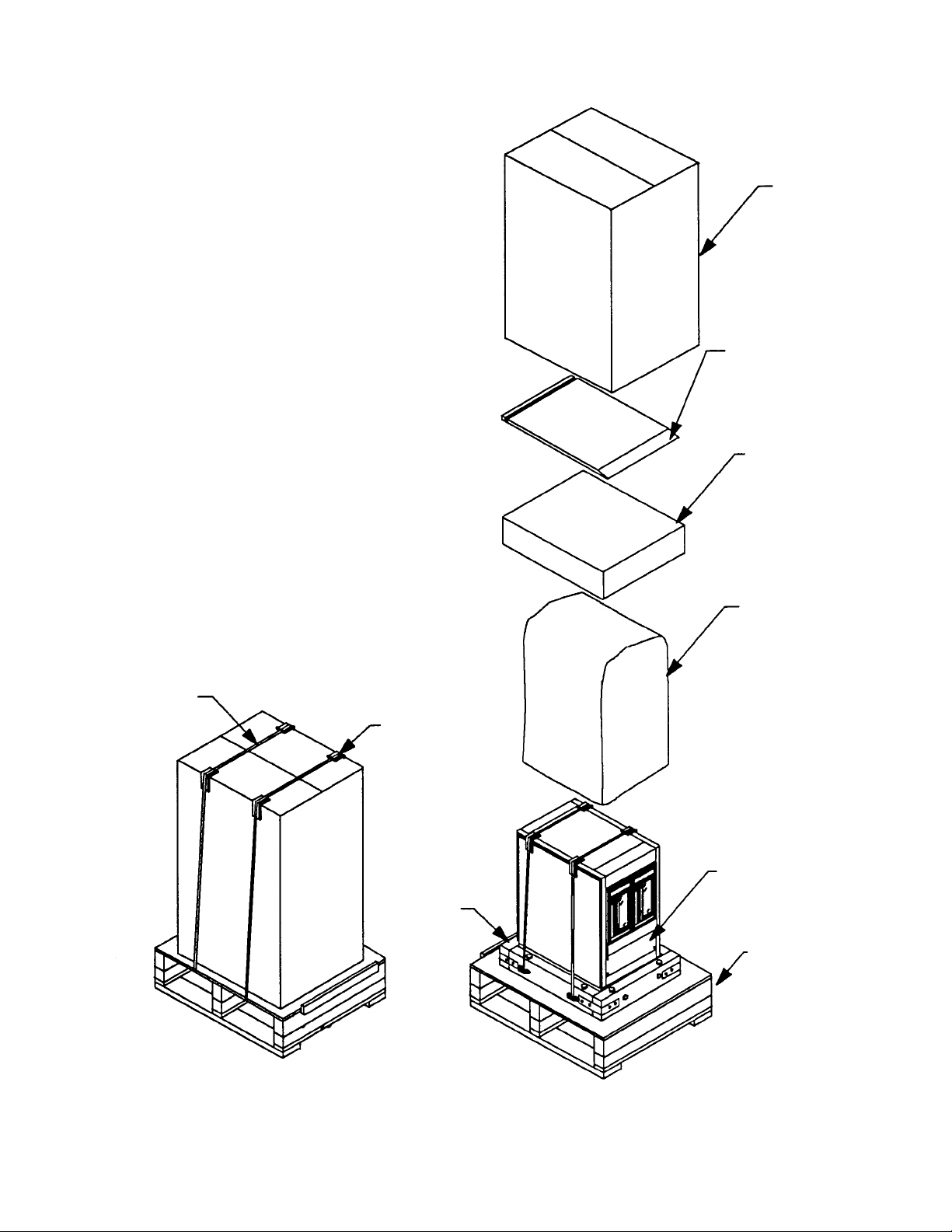

The LF 6602 is shipped with foam packing material which protects the unit from shock and vibration. After

you receive your LF 6602, inspect the shipping carton for damage before unpacking the unit to

substantiate a claim with the carrier if the unit is damaged. Retain all original packing materials for possible

reshipment.

WARNING

Physical injury will result if you attempt to lift the LF 6602 without

using proper equipment.

When the LF 6602 is being unpacked or transported, ensure that the

unit is tilted no more than 10 degrees from the vertical position. The

LF 6602 weighs more than 181 kg (400 lbs). If the unit is tilted more

than 10 degrees, it can topple over, causing personal injury.

To unpack the LF 6602, you will need the following tools:

• diagonal cutters

• One T-15 screwdriver

• One #2 cross recess screwdriver

• One 1/2-in. socket wrench

To unpack the LF 6602, perform the following procedure:

1) Cut the banding straps and remove the plastic corners.

2) Lift the shipping carton up, off the LF 6602, and remove the ramp and the foam cushion.

3) Remove the protective bag from the unit and then remove all adhesive tape from the unit's

exterior, such as on the key lock on the rear of the cabinet.

97654438 E

Page 21

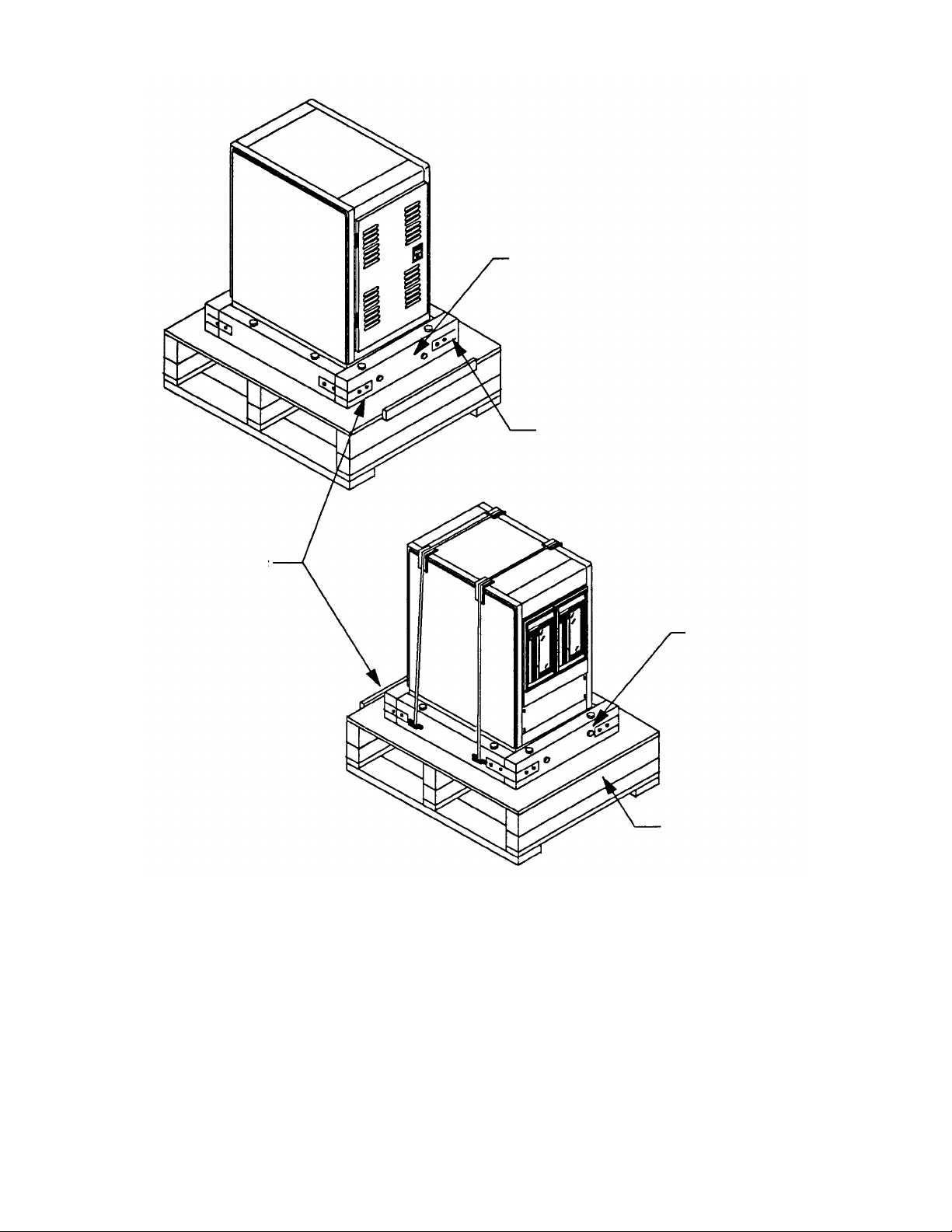

RAMP

CUSHION

BAG

CARTON

BANDING

STRAP

PLASTIC

CORNER

FRONT PANEL

FRAME

PALLET

EP005015

Unpacking the LF 6602

PLASMON LASER MAGNETIC STORAGE - LF 6602 USER MANUAL

Page 22

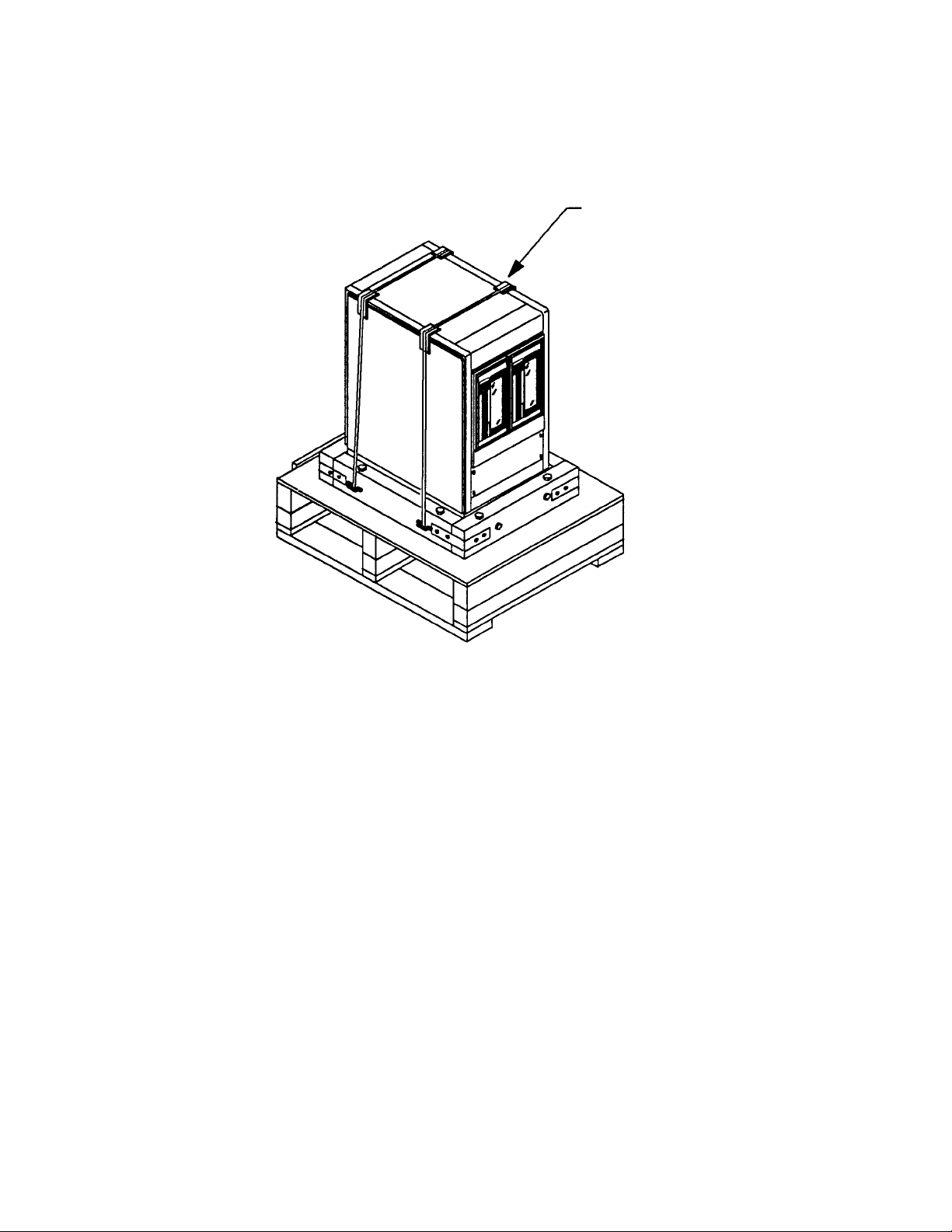

4) Cut the banding straps that secure the unit to the pallet and removes plastic corners.

BANDING STRAP

AND PLASTIC

CORNER

Removing Banding Straps from LF 6602

5) Unlock and unlatch the LF 6602's rear door (see next figure).

6) With the LF 6602's rear door open, unfasten and remove the two bolts from the front of the

frame using a 1/2 in. socket wrench. Ensure that you pull the bolts completely out of the

frame.

7) Loosen, but do not remove, the two bolts on the back of the frame. Part of the wood frame

will then angle out, thereby lowering the LF 6602 onto its casters.

8) With the #2 cross recess screwdriver, remove the four screws from each bracket on the

front of the frame, and then remove the brackets and the wood support.

EP005016

97654438 E

Page 23

FRONT OF

FRAME

REMOVE BOLTS (2X)

REMOVE SCREWS (4X),

BRACKETS (2X) AND

WOOD SUPPORT

LOOSEN BOLTS

(2X)

Removing Bolts from Front of Frame; Loosening Bolts from Back of Frame

PLASMON LASER MAGNETIC STORAGE - LF 6602 USER MANUAL

Page 24

BACK OF FRAME

EP005017

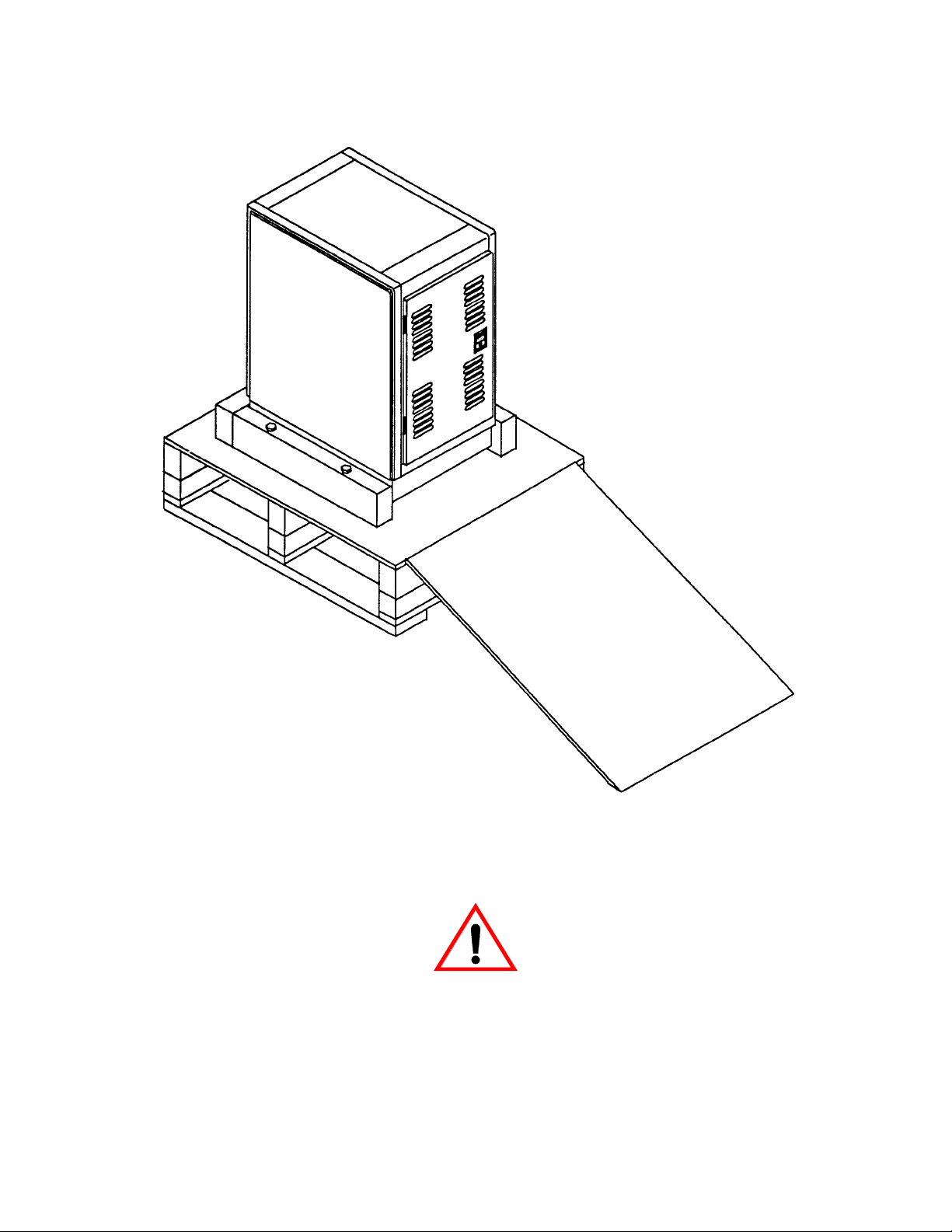

9) Place the ramp on the front lip of the pallet (see figure below).

Positioning Ramp on Pallet

10) With the assistance of a second person, carefully roll the LF 6602 down the ramp.

WARNING

To prevent personal injury, you must have a second person help you

roll the LF 6602 down the ramp.

When the unit is being rolled down the ramp, ensure that it is tilted no

more than 10 degrees in the vertical position. The LF 6602 weighs

more than 181 kg (400 lbs). If the unit is tilted more than 10 degrees, it

can topple over, causing personal injury.

EP005018

97654438 E

Page 25

11) Re-install the front panel onto the LF 6602.

12) Carefully roll the LF 6602 to the selected operating site.

NOTE

Retain and store all fastening hardware and packing materials,

including the wooden ramp.

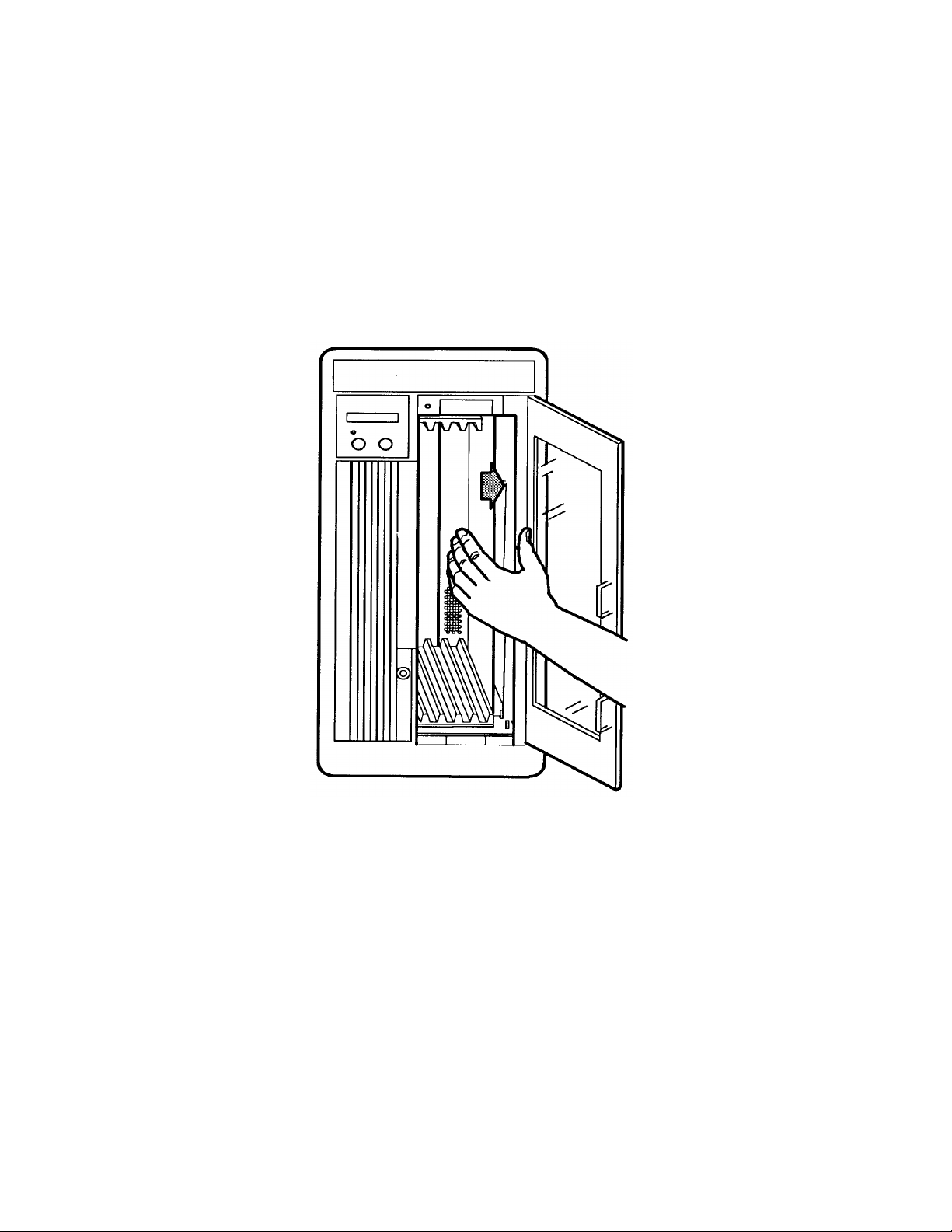

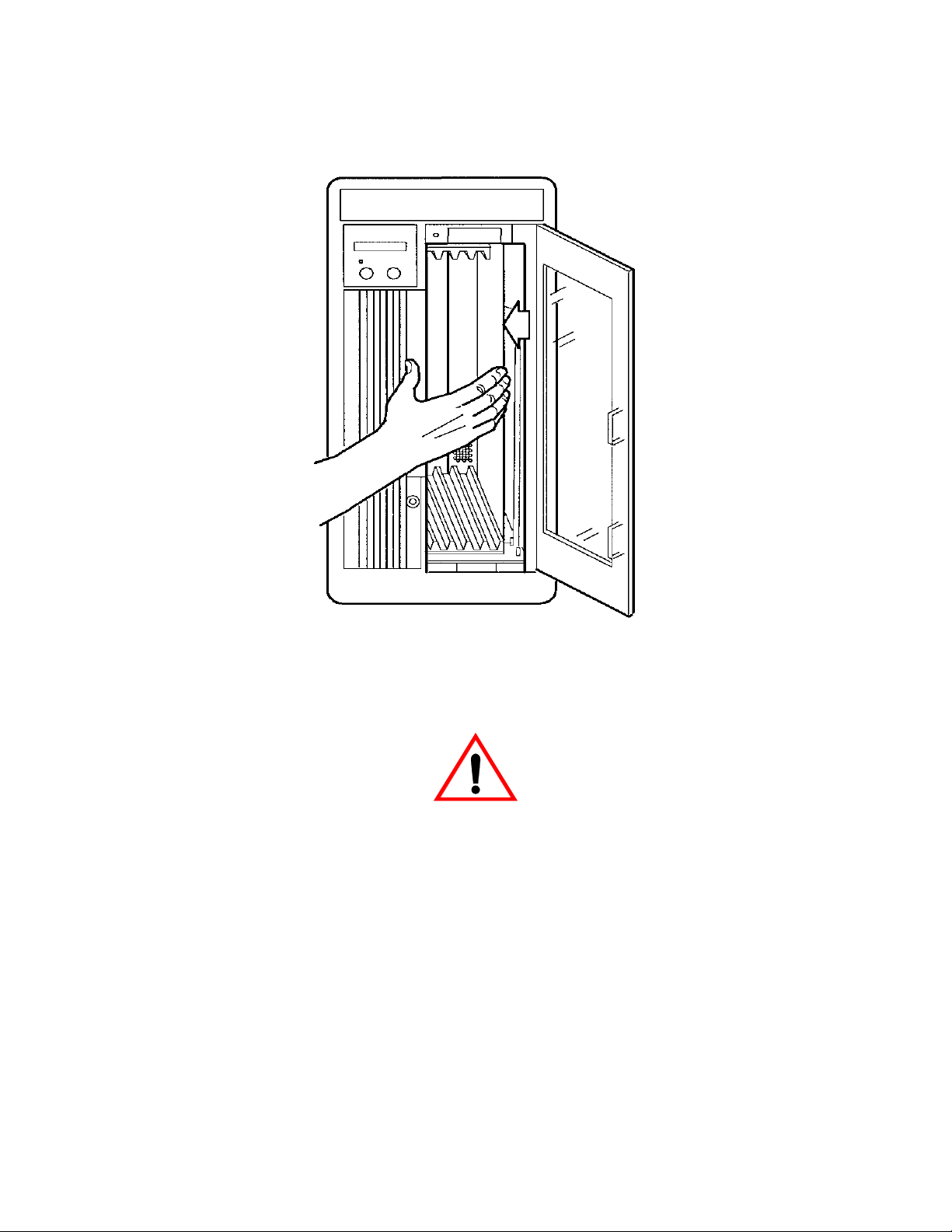

13) Open the drives' media access doors and remove the small foam blocks. Manually move

the shuttles all the way to the right to the home position, as shown in the next figure.

Moving the Shuttle to the Home Position

PLASMON LASER MAGNETIC STORAGE - LF 6602 USER MANUAL

Page 26

EP006042A

INSPECTING THE LF 6602

The following items should be included in the LF 6602 carton:

• One LF 6602

• One daisy chain SCSI cable

• One primary AC cord

• One User Manual

• One Manual Release Tool

Accessories such as a SCSI terminator, a SCSI cable and optional LM 6000 media cartridges, if ordered,

will accompany the LF 6602 in a separate carton.

After unpacking the LF 6602, check for:

• damage to the cabinet

• dislocated or broken controls and indicators

Report all discrepancies, missing items and damaged equipment to your supplier. If condensation exists

on the drive, allow the moisture to evaporate by exposing the LF 6602 to the operating environment for at

least 6 hrs before powering on the unit.

REPACKING THE LF 6602

The LF 6602 should be repacked using the original packing materials. Close the baseplates of each drive

before repacking the LF 6602 as explained in step 2) of the following procedure.

CAUTION

Shipping the LF 6602 without closing the drives' baseplates may

result in damage to the drives which is not covered under warranty.

1) Ensure that the media cartridge is unloaded from the drive into the shuttle. Remove all

cartridges from the shuttle.

2) On each drive's DOC, select the "Park Drive" option, as explained in the Viewing

Diagnostic section, to prepare the LF 6602 for shipment.

If the drive is not functional, follow these steps to manually close the baseplates:

a.) Ensure that the primary AC power cord is disconnected from the wall outlet

and that the power switch on each drive is set to the OFF position ( O ).

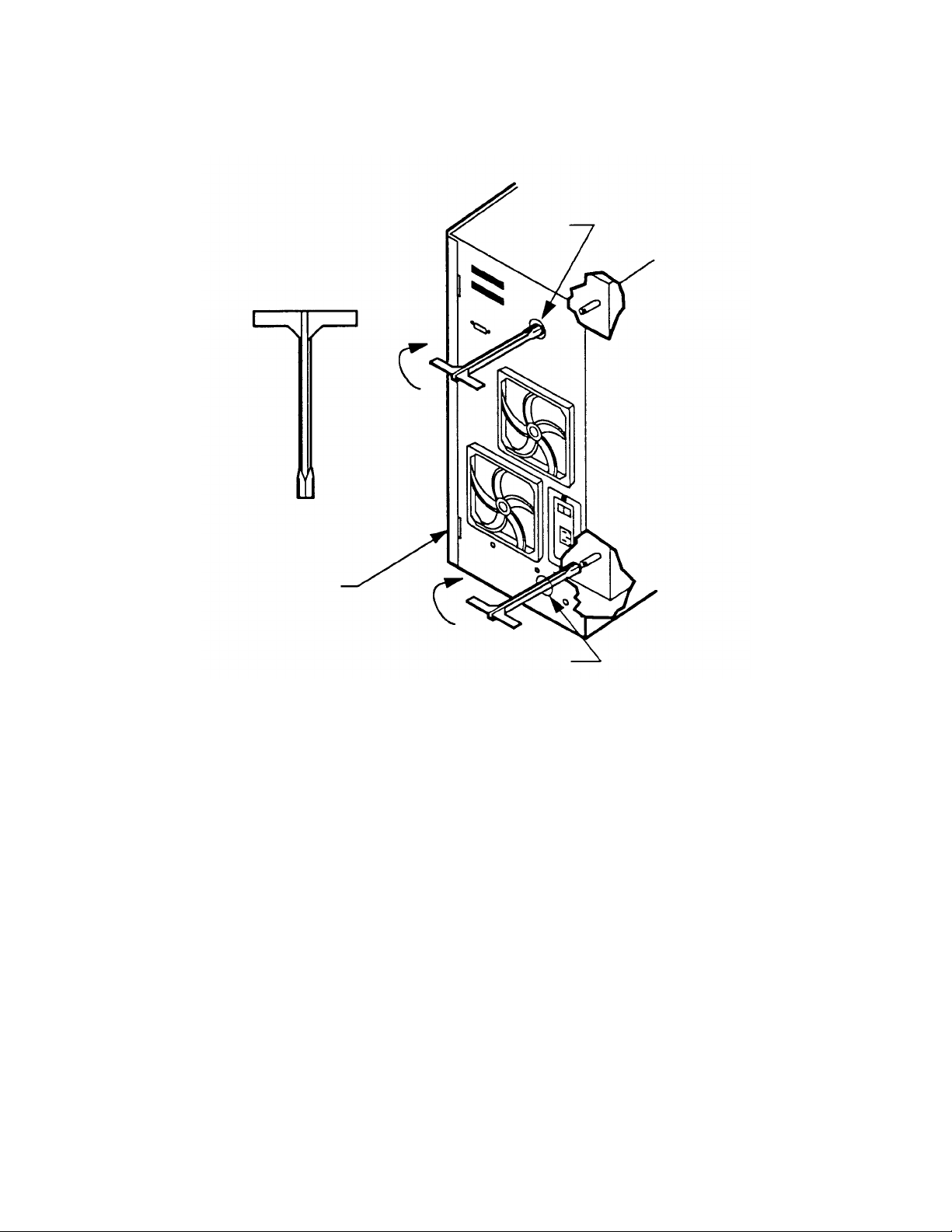

b.) With a T-15 screwdriver, loosen the four screws that secure the shipping

bracket to the LF 6602 chassis (see next figure).

97654438 E

Page 27

SHIPPING

BRACKET

Shipping Bracket on Rear of LF 6602 Cabinet

c.) At the rear panel of each drive, insert the manual release tool into the upper

access hole and engage the recessed D-shaped shaft. Turn the tool handle

clockwise as far as it will turn, closing the upper baseplate.

d.) Repeat step c) at the lower manual release access hole to close the lower

baseplate.

e.) Reposition the shipping bracket and secure it to the LF 6602 chassis by reinstalling the four screws.

EP006031A

PLASMON LASER MAGNETIC STORAGE - LF 6602 USER MANUAL

Page 28

MANUAL RELEASE

TOOL

REAR PANEL

UPPER

ACCESS

HOLE

LOWER

ACCESS HOLE

Manually Closing the Drive's Baseplates

3) Ensure that the primary AC power cord is disconnected from the wall outlet and that the

power switch on each drive is set to the OFF position ( O ).

4) Open each drive's media access door. Manually push each shuttle all the way to the left as

shown in the next figure and insert the small foam shipping blocks to hold the shuttle in

place. Close each media access door.

NOTE

If a media access door is locked, refer to the Removing the Bezel

procedure to manually override the door lock solenoid.

EP006047

97654438 E

Page 29

Moving the Shuttle Assembly to the Shipping Position

WARNING

Do not attempt to lift the LF 6602 without using proper equipment.

5) Position the ramp on the front lip of the pallet.

6) With the assistance of a second person, carefully roll the LF 6602 up the ramp.

EP006041A

PLASMON LASER MAGNETIC STORAGE - LF 6602 USER MANUAL

Page 30

Loading...

Loading...