Plasma Air 200 SERIES, 201D, 202E, 201E, 203D Installation, Operation & Maintenance Manual

...

INSTALLATION, OPERATION

& MAINTENANCE MANUAL

PLASMA AIR

MODEL 200 SERIES

(MODELS 201D, 201E, 202D, 202E, 203D, 203E)

REV 02/2018

INTRODUCTION

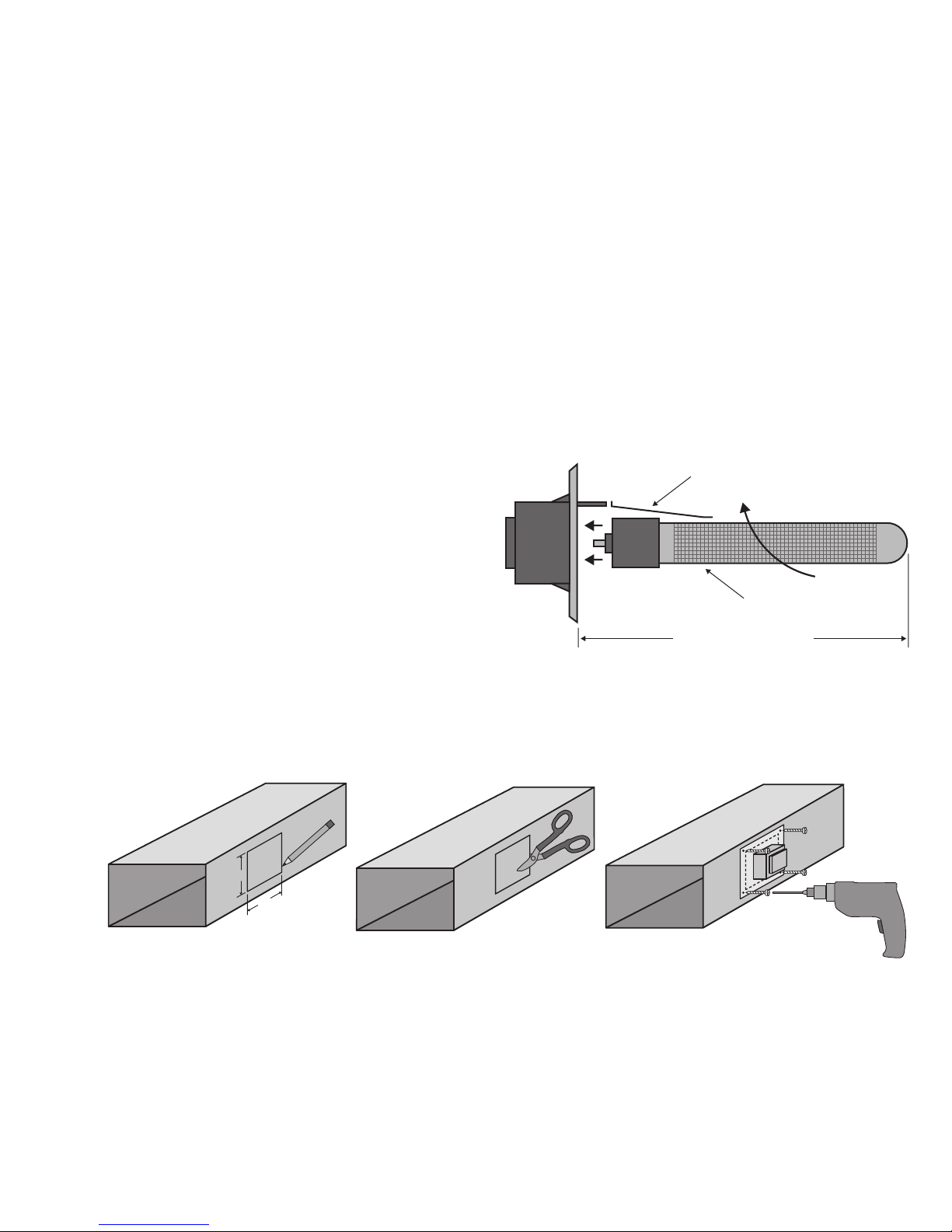

IONIZATION TUBE

GROUNDING CLIP

TUBE CLEARANCE

D=10½”, E=14½”

FIGURE 1 – MODEL 200 AND IONIZATION TUBE

5½ ”

5½ ”

Plasma Air model 200 series air ion generators are two tube commercial quality units intended for installation in air

handling units (AHU), furnaces, or duct systems for residential and commercial applications.

This ionization equipment is effective in reducing harmful pollutants and odors by introducing positive and negative ions

into the system airflow. The number of units and the size of the ionization tubes are dependent on the airflow in the system

and the severity of the pollution problem. See chart on the back of this manual for selection criteria.

MECHANICAL INSTALLATION INSTRUCTIONS

GENERAL MOUNTING LOCATION CRITERIA:

Warning: To reduce the risk of fire, this unit should not be installed downstream of a humidifier or exposed to other

sources of moisture.

Caution: This product is suitable for mounting into duct of metallic construction only. Installation must be such that the

structural integrity of the ducting is not compromised.

Mount units to allow access to the ionization level adjustment knob and for general maintenance. This product shall not

be installed behind a suspended floor/ceiling or a structural wall, ceiling, or floor.

This product should not be mounted in a location where the air

temperature exceeds140°F. This usually means that it should

not be installed at the outlet of a gas or oil fired furnace.

1) Screw the ionization tubes into the back of the transformer

while gently holding the grounding clip away from the tube.

2) For residential installations, the preferred location is in the

supply air duct leaving the AHU. Be sure to pick a location

before any branch duct take-offs.Verifythat there is sufficient

duct depth to allow clearance for the tube – see figure 1.

To mount the units in a duct:

a) Trace a 5½“ by 5½“ square on the surface of the duct onto

which you are mounting the model 200. The units have a

flange gasket that forms a seal between the duct and the mounting plate.

b) Cut out the traced portion of the duct using snips or sheet metal shears.

c) Screw the model 200 onto the duct using sheet metal screws.

(a)

(c)(b)

3) If the unit cannot be installed in the preferred location due to space or temperature limitations, see Figure 2 for

alternate locations. Units can be installed using “L” shaped brackets available from many hardware suppliers or by

cutting a hole in the AHU or furnace casing.

For commercial applications, the units are not typically mounted in the supply air duct as these ducts may not be easily

4)

accessible for tube replacement or other service. Units are commonly mounted inside a roof top AHU using “L” shaped

brackets available at many hardware suppliers. Be sure to select a location within the air handling unit where there is

good air flow. One such location is immediately next to the fan inlet.

PLASMA AIR INTERNATIONAL 35 MELROSE PLACE STAMFORD, CT 06902 203-662-0800 info@plasma-air.com www.plasma-air.com PLASMA AIR INTERNATIONAL 35 MELROSE PLACE STAMFORD, CT 06902 203-662-0800 info@plasma-air.com www.plasma-air.com

Loading...

Loading...