Page 1

© 2020 Activated Research Company, LLC | 1

Polyarc® System v2.0 Installation Manual

Agilent 7890, 7820, 6890 or equivalent

Manual ID: PA-MAN-IM38

Page 2

© 2020 Activated Research Company, LLC | 2

Quick Start Guide

Installation

1. Shut down GC completely: Turn off oven and detector temperatures and allow to cool; unplug

power supply. (page 6)

2. Install CO2 trap on the air supply to your flow controller (do not purify FID air supply). (page 12)

3. Plumb 1/8” tubing lines from air and H2 supplies to Polyarc flow controller.

4. Place the Polyarc onto the GC with the capillary lines extending into the oven. (page 7)

5. Connect the heater assembly from the Polyarc system to the GC motherboard or external PID

controller. (page 8)

6. Connect the Polyarc outlet to the FID. (page 9)

NOTE: Trim at least 0.5 inch of protruding tubing after putting on the 0.8mm graphite

ferrule to remove any debris from the graphite ferrule (consult Agilent website tube cutting

guide for information on how to properly cut tubing).

7. Connect the Polyarc inlet to the capillary column using a zero-dead volume union.

NOTE: Consult Agilent website for proper swaging instructions and to ensure the right

ferrule is being used. Improper swaging can lead to leaky connections and bad

chromatography.

8. Connect Polyarc air and H2 inlets to their respective flow controller outlets. (page 11)

9. Power on GC; ensure carrier gas is flowing through column.

10. Turn on Polyarc air and H2 flows and measure the flows independently out of the FID to confirm

2.5 sccm and 35 sccm, respectively; adjust if necessary. (page 11)

11. Configure the Polyarc heater

12. Identify the heater type. This will be indicated on the packaging and packing list, but the following

can be used as a reference.

a. PT-100 RTDs will have a blue heater cable and/or a black Molex connector. They will

display the actual temperature at room temperature.

b. ARC RTDs will have a tan heater cable and a white Molex connector. There will be an

offset in the temperature readout, and you will see a negative readout at room

temperature.

13. Condition the Polyarc depending at 350°C setpoint for one hour with an ARC RTD and at a 450

°C for two hours with a PT-100 RTD

14. Set the Polyarc temperature to the operating temperature using the following settings depending

on heater cable:

a. PT-100: 450 °C

b. ARC RTD: 293 °C

Operation

1. Always turn the column carrier gas and air & hydrogen supplies on before heating the Polyarc.

2. Double check and leak test all connections.

3. Ensure the Polyarc is operating with gas flow rates of 2.5 sccm air and 35 sccm H2. (pg 14)

4. Configure GC methods with aux temperature (293 °C for ARC RTD, 450 °C for PT-100 RTD) and

FID H2 flow rate to 1.5sccm. (page 14)

a. NOTE: if using hydrogen as a carrier gas, see important note in the Appendix.

b. Limit the on column injection amount to 0.1uL (i.e., 1 uL volume 10:1 split or lower).

5. Run your method. Avoid injecting more than 1,000 ppm sulfur and large amounts of silicon

containing compounds such as BSTFA or TMS.

Shut Down or GC Maintenance

1. Shut off the FID.

2. Cool the reactor to room temperature (turn off the auxiliary temperature).

3. Shut off the air and H2 flows to the reactor.

4. Perform maintenance or shut down GC.

Page 3

© 2020 Activated Research Company, LLC | 3

Safety Notices

Throughout this manual, different signal words are used to indicate hazards in the installation

process of a Polyarc® system in an Agilent 7890, 7820, and 6890 GC. Failure to follow the safety

messages accompanying the signal words can result in damage to the Polyarc system and GC

systems, injury, or death.

DANGER indicates a hazardous situation which, if not avoided, will result in

death or serious injury.

WARNING indicates a hazardous situation that, if not avoided, could result in

death or serious injury.

CAUTION indicates a hazardous situation that, if not avoided, could result in

minor or moderate injury.

NOTICE is used to address practices not related to physical injury.

Page 4

© 2020 Activated Research Company, LLC | 4

Contents

Quick Start Guide ....................................................................................................................... 2

Installation .............................................................................................................................. 2

Operation ............................................................................................................................... 2

Shut Down or GC Maintenance .............................................................................................. 2

Introduction ................................................................................................................................ 5

Required Tools ....................................................................................................................... 5

Troubleshooting ......................................................................................................................... 6

Part I – Gas Chromatograph Preparation ................................................................................... 6

Part II – Location of the Polyarc® System ................................................................................... 7

Part III – Polyarc® System Gas Connections .............................................................................. 9

Part IV – Connecting Gas Flows to Polyarc® System ................................................................11

Part V – Final Configuration ......................................................................................................12

Heater Configuration .............................................................................................................12

Clean-up ................................................................................................................................14

Test Fittings ...........................................................................................................................14

Initial Catalyst and GC Treatment ..........................................................................................14

Method Configuration and Testing .........................................................................................15

Part VI – Polyarc Replacement .................................................................................................16

Thanks and Feedback ...............................................................................................................16

Appendix ...................................................................................................................................17

Using Hydrogen as a Carrier Gas ..........................................................................................17

Adjusting Gas Flow Rates .....................................................................................................17

1. Manual Flow Control Module ......................................................................................17

2. Electronic Flow Control Module...................................................................................18

3. Calibrating the Agilent Auxiliary Electronic Pressure Control (EPC) ............................20

Page 5

© 2020 Activated Research Company, LLC | 5

Introduction

This manual will guide you through the Polyarc® system installation process into an Agilent 7890,

7820, or 6890 GC. The installation is estimated to take two hours to complete (not including initial

catalyst treatment).

This manual is intended for use by those familiar with GC operation and

installations, as well as those familiar with and competent using compressed

gases including He, H2, and air. Do not attempt installation if you are uncomfortable. Comply with

all local and national safety requirements and be aware of the safety systems and procedures for

the facility in which you are installing the system. Wear gloves and appropriate personal protection

equipment.

Required Tools

1. T-15 and T-20 Torx drivers

2. 2 x 5/16” wrench

3. 2 x 1/4” wrench

4. 2 x 7/16” wrench

5. 3/8” wrench

6. 1.8 mm slotted screwdriver

7. Volumetric flowmeter (bubble-type or digital)

8. Leak detector (do not use liquids such as soapy water on GC components)

9. Ceramic column cutting tool

10. OPTIONAL: Column pre-swaging tool (e.g., pre-swaging wrench or pre-swaging nut;

metal ferrules can also be tightened on the fitting without pre-swaging; recommend Agilent

part G3440-80227)

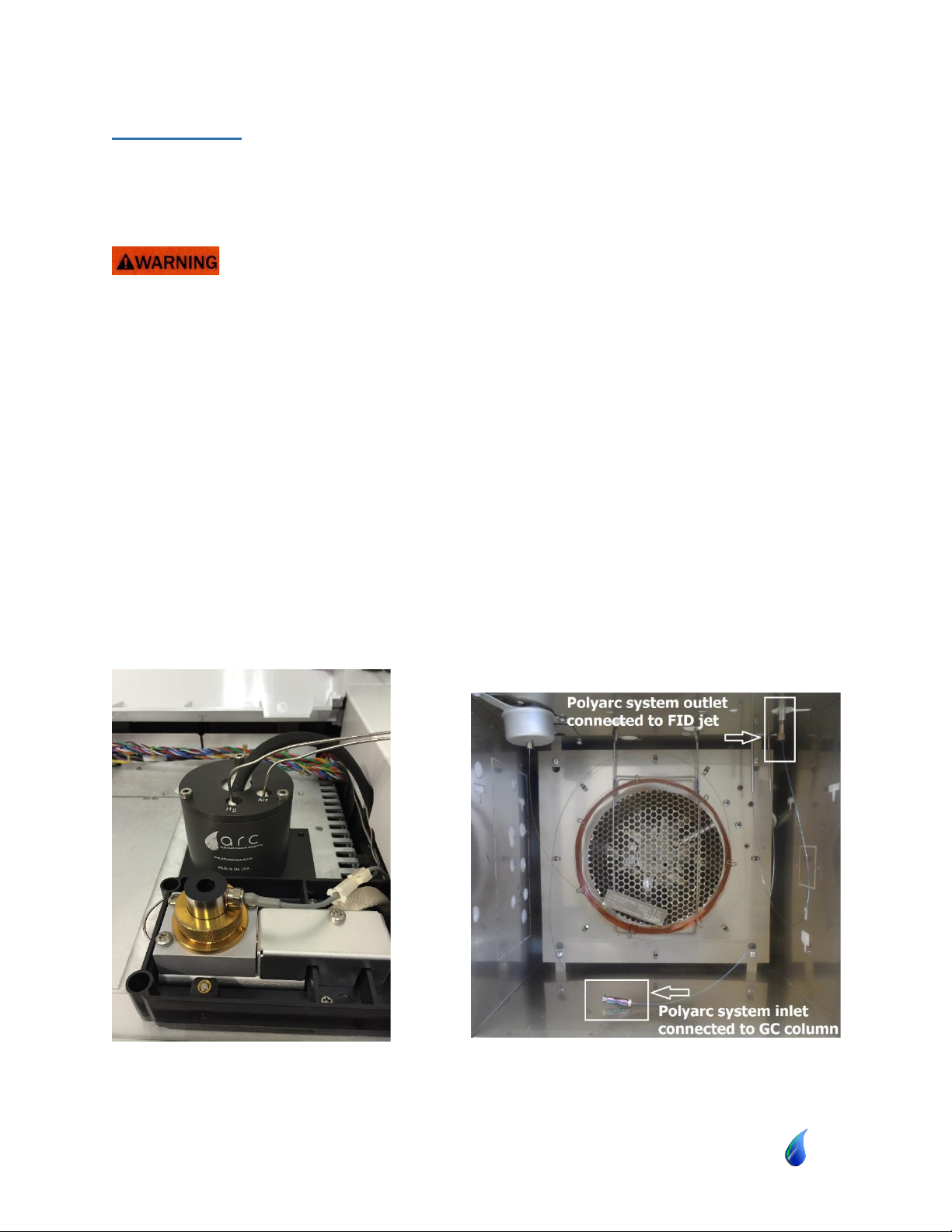

Figure 2. (A). Polyarc® system installed in back detector position of Agilent 7890.

(B). Polyarc® system installed, view from inside oven.

A

B

Page 6

© 2020 Activated Research Company, LLC | 6

Troubleshooting

Please view our troubleshooting guide at http://www.activatedresearch.com/documents for

instructions on how to troubleshoot a Polyarc system that is not functioning properly.

Part I – Gas Chromatograph Preparation

Hydrogen (H2) is a flammable, colorless, odorless, compressed gas. It poses an

immediate fire and explosive hazard when concentrations exceed 4% in air. Higher

concentrations can also cause suffocation. In any application using H2, turn off the supply at its

source before working on the instrument and purge the lines to remove H2. Failure to follow these

precautions could result in explosion, fire and/or suffocation.

Compressed air poses a pressure hazard. The high pressure gas coming out

could rapidly pressurize an enclosed space or send particles rapidly out the tube. Turn off air at

the source and depressurize the lines using an appropriate relief valve.

Column bleed from silicon containing columns (e.g., polydimethylsiloxane, or

PDMS, and 5% Phenyl columns) can cause irreversible deposition of silica in the reactor leading

to poor peak shapes and inaccurate peak quantification. High temperature, air/water leaks, old

columns and large film thicknesses can all contribute to excessive column bleed rates. For the

best performance operate all silicon-containing columns below 250C and maintain a leak free

system or avoid silicon-containing columns altogether.

Prepare your Agilent 7890, 7820, or 6890 (if you are using an Agilent 5890 or any other

manufacturer’s GC please contact ARC prior to installation) gas chromatograph (GC) using the

steps below.

1. Shut-down the GC and unplug the power cable. Allow all detectors, inlets and the oven

to cool completely.

2. Detach the side panel on the detector side of the GC.

3. Detach the top covers of the GC.

4. Turn off the air supply to the GC and vent/depressurize the line (gas supply must be

free of CO2).

5. Turn off the H2 supply to the GC and vent/depressurize the line.

6. The Polyarc flow controllers should be placed in a relatively isothermal area that is

safe and level. We recommend setting on the top right or side of the GC.

7. Attach air and H2 supply lines to Polyarc flow controller. For the manual or electronic

flow controllers provided by ARC, attach copper lines to 1/8” Swagelok compression

fittings by using supplied nuts and back/front ferrules, tightening as appropriate (3/4

turns past finger tight).

Page 7

© 2020 Activated Research Company, LLC | 7

NOTE: Only use regulated and pure gas supplies. Supported supply pressures are

indicated on flow controller inlets (60-80 psi is advisable). Fluctuations in the pressure

of the gas supply will cause fluctuations in the flow rates of gases to the Polyarc system

and could damage the catalyst. Activated Research Company is not responsible for

damage to the Polyarc system from fluctuations due to negligent use.

8. Reconnect any tubes that were disconnected and make sure the shut-off valves are

in the off position.

Part II – Location of the Polyarc® System

The Polyarc system is designed to be located in a variety of locations on the GC depending upon

the specifics of each GC configuration. The location needs to house the enclosure, which can

reach temperatures of 100 °C, and allow for the Polyarc

system inlet/outlet tubes to connect into the GC oven.

The Polyarc system is optimally placed in the back (Figure

2) or front detector positions. Placement of the system

elsewhere may result in sub-optimal separation

performance (such as peak broadening and/or tailing) if the

transfer lines become cold enough to cause condensation

or large interactions with eluents. If the two detector

positions are full please contact us at

contact@activatedresearch.com for other options.

For the remainder of the installation procedure we will

assume the Polyarc system is located in an otherwiseunused back detector position of an Agilent 7890.

Note: Do not place the electronic flow controller (EFC) on

top or near the FID electrometer (see Figure 2)! This can

lead to RF interference with the detector leading to a noisy

baseline

1. Clear a space for the system enclosure in the

back detector opening (or other selected

location). This may require that the aluminum

cap is removed and the insulation cleared out.

Be sure to clear out enough insulation to make

room for the transfer lines (the final shape

should look like a keyhole; see Figure 4 below).

2. Feed the two capillary transfer tubes into the

GC while inserting the system enclosure in the

back detector opening (or other selected

location). Be careful not to bend or score the

capillary tubes (they are flexible, but tight bends

can destroy the tube).

Figure 4. Keyhole shape within

detector position for transfer

lines of Polyarc® system.

Figure 2. Improperly placed EFC

Page 8

© 2020 Activated Research Company, LLC | 8

3. Secure the Polyarc with

the supplied enclosure

screws to attach the

Polyarc enclosure to the

top of the GC oven.

4. Connect the heater

assembly (4-pin Molex

connector) from the

Polyarc system to the

back detector port as

indicated in Figure 5

located on the detector

side of the GC (behind

the plastic panel). If the

Polyarc is installed in an

inlet position, use the

inlet heater port located

on the inlet side of the

GC. If installing the Polyarc in a valve box or MS position, refer to Step 5 for

instructions to connect to an auxiliary heater cable assembly.

5. If using an an Agilent 6890 GC or if performing an installation on an Agilent 7890 GC

in a position other than an inlet or detector position, follow this step for connection of

the heater cable to a heater cable assembly. Otherwise, proceed to Step 6. Check to

see that an auxiliary heater cable assembly (shown in Figure 6) is connected to the

GC power board on the detector side of the GC. If the assembly is not present, install

a cable assembly (specified during order; Figure 6). Feed heater assembly through

side of GC down to its existing cable assembly. Perform step ‘a’ or ‘b’ below depending

on cable assembly configuration.

a. Using Existing Cable Assembly: Connect the heater assembly (4-pin Molex

connector) from the system to the cable assembly in the first (A1) or last (A2)

position as indicated in Figure 6 located on the detector side of the GC (behind

the plastic panel). Record its position (A1/A2).

Figure 6. Heater connection to A1 port on assembly cable of Agilent 6890 GC

(electronics located behind plastic panel on detector side of GC).

Figure 5. Heater connection to back detector port on

Agilent 7890 GC (electronics located behind plastic

panel on detector side of GC).

Page 9

© 2020 Activated Research Company, LLC | 9

b. Using Cable Assembly Supplied in Kit: Connect the heater assembly to the

cable assembly and the cable assembly to the main power board (Figure 7)

Figure 7. Heater assembly connection with ARC cable assembly on Agilent

7890 GC (electronics located behind plastic panel on detector side of GC).

6. Close and fasten the GC side cover.

Part III – Polyarc® System Gas Connections

The following steps connect the GC column and FID to the Polyarc system.

NOTE: Procedure is the same for both capillary optimized and adaptable FID inlets.

Use gloves to avoid contamination of the column

1. Connect the larger ID metal capillary tube (the outlet of the Polyarc system) to the FID

following the steps below.

Page 10

© 2020 Activated Research Company, LLC | 10

a. Remove the existing capillary column from the FID and cut

the column to remove the nut to reuse it for the next step.

b. Place the larger metal capillary tube from the system

through the FID nut (removed above) and through the included

0.8 mm graphite ferrule.

c. Trim 0.5” of the tubing using a ceramic scribe to remove any

debris which may have accumulated during shipping and

installation. Information about how to cut metal capillary tubing

can be found online (http://www.agilent.com/en-

us/video/properlycuttubing).

d. Insert the column up into the flame detector jet (you may

need to gently move the tube around to find the jet hole) until it

stops, then pull the column back out ~1-2 mm. Tighten the nut

and ferrule onto the FID fitting by turning the nut about 90° past

finger tight to secure the column (Figure 8).

NOTE: If you are having problems finding the jet hole and you

have an adaptable FID inlet, try removing the 1/4” fitting.

2. Connect the smaller ID metal capillary tube (the inlet to the Polyarc system) to the

outlet of the capillary column using a zero-dead volume union by following the steps

below. More detailed instructions can be found on the Agilent website:

https://www.agilent.com/cs/library/usermanuals/public/G3182-90580.pdf.

Table 1: Agilent Ferrules

Item

Agilent Part No.

Ferrule Description

Degrees to tighten

internal nut

1

G3188-27501

0.1 – 0.25 mm column ID

50-100

2

G3188-27502

0.32 mm column ID

30-70

3

G3188-27503

0.45 – 0.53 mm column ID

20-50

4

G3188-27504

Plug

60

5

G3188-27505

0.25 – 0.32 mm UltiMetal column ID

(Polyarc inlet)

40-90

6

G3188-27506

0.53 mm UltiMetal column ID

(Polyarc outlet)

20-50

Figure 8. Outlet of the

Polyarc® system inserted

into the FID jet.

Page 11

© 2020 Activated Research Company, LLC | 11

a. The smaller ID metal capillary tube should have a column nut and ferrule

attached to a zero-dead volume union (Agilent ferrule Part No. G318827505).

If these are not attached swage the ferrule onto the column following the

procedure below (Steps c-f). Then tighten the nut and ferrule onto the zerodead volume union by tightening the nut 5-10° past finger tight (Figure 9b).

b. Pass the GC capillary column

(supplied by customer) through

the supplied column nut, metal

ferrule (with correct column I.D.,

Figure 9a) and swaging tool

(wrench or nut). The union can be

used as a swaging tool if no

swaging tool is available. After

swaging, the column must

protrude 0.1-0.5 mm from the

ferrule, or leaks and column

breaks can occur.

c. Tighten the column nut on the

swaging tool in 10-20°

increments using a wrench until

the column just begins to grip.

Overtightening can cause leaks

and potential damage to the

column. Remove the swaging

tool.

d. If the column does not extend 0.1-0.5 mm from the ferrule then trim the excess

column using a cutting tool leaving 0.3 mm of column extending from the

ferrule. Make sure no cracks extend into the ferrule or leaks may occur.

e. Connect the column to the union and tighten 5-10° past finger tight (Figure 9b).

Part IV – Connecting Gas Flows to Polyarc® System

Hydrogen (H2) is a flammable, colorless, odorless, compressed gas. It poses an

immediate fire and explosive hazard when concentrations exceed 4% in air. Higher

concentrations can also cause suffocation. In any application using H2, turn off the supply at its

source before working on the instrument and purge the lines to remove H2. Failure to follow these

precautions could result in explosion, fire and/or suffocation.

Compressed air poses a pressure hazard. The high-pressure gas coming out

could rapidly pressurize an enclosed space or send particles rapidly out the tube. Turn off air at

the source and depressurize the lines using an appropriate relief valve.

(b)

Figure 9. Inlet of the Polyarc® system

connected to GC capillary column. (a)

From left to right: column nut, capillary

metal ferrule for GC column, zero-dead

volume union. (b) Completed

connection of components.

(a)

Page 12

© 2020 Activated Research Company, LLC | 12

Always measure air and H2 flow rates from the FID outlet while the Polyarc

system is at room temperature for accurate readings. Flow rates measured while the Polyarc

system is warm are incorrect due to the reaction of oxygen and hydrogen to form water.

The following instructions can be used to connect and check the flow rates of air and H2 to the

Polyarc system. The electronic flow module supplied by ARC does not require any calibration.

1. Install a CO2 trap on the air supply line to your flow controller. Split the air supply line

so that one side goes to the FID and the other to the CO2 trap and Polyarc system.

This will prolong the life of the trap.

2. Measure and cut appropriate lengths of the supplied 1/16” OD tubing to connect your

chosen flow controller to the Polyarc system for air and H2 gases. The tubing can be

routed through the back of the GC under the back cover.

3. Connect the 1/16” tubing to the flow controller ‘air outlet’ using two wrenches to tighten

the nut without torqueing on the body of the flow controller. Connect the other side of

the 1/16” tubing to the supplied 1/16” union.

4. Repeat Step 2 for H2.

5. Turn on the H2 at the source and adjust the flow rate to 35 (± 1.0) (see Adjusting Gas

Flow Rates) as measured through the FID outlet. Check all fittings for leaks and adjust

as needed. NOTE: If you are using hydrogen as a carrier gas, see important note

with modified hydrogen flow rates in the Appendix.

6. Turn off the H2 and turn on the air at the source and adjust the flow rate to 2.5 (± 0.5)

sccm (see Adjusting Gas Flow Rates). NOTE: If you are using hydrogen as a carrier

gas, see important note with modified air flow rate in the Appendix. Check all

fittings for leaks and adjust as needed. NOTE: Ensure the Polyarc system is not

heated for this step as the flow rate will be inaccurate.

Note: Do not place the electronic flow controller (EFC) on top or near the FID electrometer (see

Figure 2)! This can lead to RF interference with the detector leading to a noisy baseline.

Part V – Final Configuration

Heater Configuration

1. Plug the GC into the wall outlet. Turn on the GC.

2. Turn configuration lock ‘Off’ under the following menu: Options/Keyboard &

Display/Hard Configuration Lock.

3. Use Option ‘a’ or ‘b’ below depending on GC type

Page 13

© 2020 Activated Research Company, LLC | 13

a. For an Agilent 7890/7820, restart the GC and then;

i. Install cartridge heater/sensor as a ‘Heater’ in Thermal Aux 1, 2, or 3

(see step iii to determine Thermal Aux Number).

ii. Scroll to Config/Aux Temp#/

iii. Use the following table do determine which Thermal Aux number to

install the Polyarc heater cartridge:

Heater Installation Location

Thermal Aux Number

Auxiliary Heater 1 (A1)

Thermal Aux 1

Auxiliary Heater 2 (A2)

Thermal Aux 2

Back Detector

Thermal Aux 2a

Front Detector

Thermal Aux 3

Front Inlet

Thermal Aux 3

Back Inlet

Thermal Aux 1b

a

If there is currently a heater connected to A2 it will need to be reconfigured as

Thermal Aux 3.

b

If there is currently a heater connected to A1 it will need to be reconfigured as

Thermal Aux 3.

iv. Select the Thermal Aux number determined above.

v. Text should say ‘Unconfigured’

vi. Press ‘Mode/Type’

vii. Install as ‘Heater A1’ or ‘Heater A2’, if the heater is installed in the

auxiliary heater zone or ‘Heater B-DET’ if the heater is installed in the

back detector position, by pressing enter over your selection. If the

heater is installed in a different detector position, or an inlet position,

select the appropriate option.

viii. If using a PT-100 Polyarc heater (black connector on heater cable),

proceed as follows:

1. Once the heater has been configured, press [Config], then

select your aux temp #, and press [Enter]

2. Select Auxiliary Type: Unknown and press [Mode/Type]

3. Select User Configurable Heater and press [Enter]

4. Reboot GC by pressing [Options], selecting Communications,

and selecting Reboot GC

5. Press [Config] and select the thermal auxiliary being used

6. Scroll down to Maximum Setpoint, and update the value to 450

°C

7. Reboot GC as in step 3.

b. For an Agilent 6890 (method may vary depending on GC model; the goal is to

configure the heater assembly into the appropriate auxiliary heater port as

some recognizable heater, e.g., the MSD):

i. Install cartridge heater/sensor as a ‘Heater’ in A1 or A2 (determined in

Part II)

ii. Scroll to Config/Aux Temp#/

iii. Select 1 or 2 to install as A1 or A2

iv. Under aux type, select ‘MSD’ using the Mode/Type key

4. Check that the Aux temperature reading is stable (it will be around -35 °C if at room

temperature; the offset is normal).

Page 14

© 2020 Activated Research Company, LLC | 14

Clean-up

Insulation contains particles that are hazardous to your lungs and eyes. Avoid

breathing insulation dust and contact with eyes. Wear long sleeves, gloves, safety glasses, and

a disposable dust/mist respirator. Clean up insulation in the area. Dispose of insulation in a sealed

plastic bag.

1. Clean up air and H2 tubing by coiling or bending into its final location.

2. Clean up any insulation particles and dispose in a sealed plastic bag.

Test Fittings

1. Ensure all gas flows are on.

2. Using a leak detector, check all fittings for leaks.

3. Heat oven to 20 °C below maximum and hold for 10 minutes, cool GC down.

4. Recheck fittings for leaks and tighten as needed.

Initial Catalyst and GC Treatment

1. If not already completed, check and adjust (see “Adjusting Gas Flow Rates” in

Appendix) the air and H2 flow rates through the Polyarc system while the reactor is at

room temperature. Never measure flow rates with the reactor warm and always

measure from the FID outlet to obtain the proper pressure driven flow values. An

electronic flow control module can be purchased from ARC to eliminate this flow

calibration.

2. The Polyarc system requires an initial conditioning to prepare the catalyst and remove

contaminants absorbed during shipping and installation. Leave the air supply and the

H2 supply on.

3. Turn the column carrier gas on before heating the Polyarc system.

DO NOT heat the reactor without the carrier gas flowing through the

inlet capillary of the Polyarc system. The reactor must be first cooled before

disconnecting the column or before turning off the carrier gas supply.

4. Condition the Polyarc with the proper temperature setpoint according to the following

instructions:

a. If your Polyarc is fitted with an ARC RTD (indicated by a tan heater cable and

white Molex connector), condition the Polyarc at a 350 °C setpoint for one hour.

b. If your Polyarc is fitted with a PT-100 RTD (indicated by a blue heater cable

and/or a black Molex connector), condition the Polyarc at a 450 °C setpoint for

at least two hours.

NOTE: The heater has been specially engineered to ensure the Polyarc system runs

at the ideal temperature to maximize analyte conversion. Please contact ARC if there

are any questions about which heater settings should be used.

DO NOT increase heater temperature beyond 350 °C with an ARC

RTD (525 °C with PT-100 heater). Higher temperatures could damage the equipment

and/or lead to fire.

5. Set GC oven temperature to 20 °C below max column/oven temperature.

6. Allow reactor to remain heated under these conditions for 1-2 hours, or until the

baseline stabilizes.

Page 15

© 2020 Activated Research Company, LLC | 15

7. If using an ARC RTD, reduce aux heater temperature setting to 293 °C and wait 30

minutes after temperature has reached 293 °C. Note: When using an ARC RTD, the

293 °C setpoint is not the actual temperature. The actual temperature of the

Polyarc is 450 °C when heated to a setpoint of 293 °C. Use the actual temperature

as a setpoint if using a PT-100 RTD (identified with a black connector and/or blue

heater cable).

8. If the baseline is still decreasing, this procedure can be repeated. This may indicate

oils on the fittings or column.

Method Configuration and Testing

The Polyarc system requires minimal changes to your methods, such as adding the

thermal auxiliary temperature and decreasing H2 flow rates to the FID to compensate for the

addition of H2 to the Polyarc feed stream. Follow these guidelines:

1. Change the Auxiliary temperature setting to 293 °C (450 °C for PT-100 RTD) for all

methods.

2. Reduce the H2 flow rate to the FID to 1.5 sccm (most of the H2 is now supplied by the

Polyarc system). In some cases, this H2 flow rate may need to be higher than 1.5 sccm.

3. Change the FID air flow rate to 350 sccm (this can be adjusted slightly to tune the FID

for optimal performance). NOTE: If you are using hydrogen as a carrier gas, see

important note about FID air flow rate in the Appendix.

4. Please note that the oven temperature should be kept above 30 °C when using

standard Polyarc air and hydrogen flow rates, to prevent condensation in the Polyarc

outlet and extinguishment of the FID flame. NOTE: If you are using hydrogen as a

carrier gas, see important note about minimum oven temperature in the

Appendix.

5. The column inlet pressure (flow rate) may need to be increased slightly to account for

the slight increase in pressure drop due to the presence of the micro-channel reactor.

An increase of ~10% is advised, but larger increases may be required for flow rates

above 2 sccm.

6. Test the Polyarc system with a well characterized mixture such as the supplied Polyarc

Test Mix. Use our one of our online calculators to determine the concentrations of

components in the mixture to validate Polyarc system performance.

7. Compounds containing sulfur at a concentration higher than 1,000 ppm can quickly

contribute to catalyst poisoning, so limit the amount on column to below that

concentration and/or below a 1 μL,10:1 split injection.

8. Compounds that contain silicon (e.g., BSTFA, TMS) lead to irreversible deposition of

silica in the combustion chamber of the reactor resulting in peak tailing and broadening

over time. In large amounts, single injections can lead to peak tailing, which is

especially noticeable with sticky (those that bind strongly to silanols) molecules such

as amines.

Page 16

© 2020 Activated Research Company, LLC | 16

Part VI – Polyarc Replacement

Users typically replace the Polyarc every six months or more, depending on the analysis. When

a replacement Polyarc is purchased, ARC will send a new unit to replace the existing one, and

the replacement procedure is as follows:

1. Cool the existing Polyarc and FID to room temperature.

2. Once cool, disconnect the two Swagelok supply lines for air and hydrogen from the

Polyarc, leaving the union connected to the lines for use with the next Polyarc.

3. Disconnect the Polyarc inlet transfer line from the Agilent Ultimate union. Keep the

analytical column connected to this union.

4. Disconnect the Polyarc from the FID. The FID column nut and graphite ferrule can be

re-used.

5. Disconnect the Polyarc heater cable from the GC or ARC Temperature Controller.

6. Carefully remove the Polyarc from its position on the GC.

7. Unpack the replacement reactor from its box and carefully place it onto the GC,

taking care to avoid crimping or bending the transfer lines as they’re guided into the

GC.

8. Connect the air and hydrogen supply lines using the Swagelok unions. Ensure the

proper gases are connected to the proper lines.

9. Connect the Polyarc inlet transfer line to the Agilent Ultimate union. This line will

already have a nut and ferrule swaged on.

10. Connect the Polyarc outlet to the FID, re-using the existing 0.8mm graphite ferrule if

possible.

11. Connect the Polyarc heater cable to the GC or ARC Temperature Controller.

12. Heat the Polyarc. The Polyarc may need to be conditioned for an hour to remove any

residual buildup from shipping.

Thanks and Feedback

Thank you for your purchase and congratulations on your successful installation of the Polyarc

system for quantitative carbon detection. The Polyarc system will eliminate standard time

consuming and costly calibrations while enabling you to analyze your compounds with greater

accuracy and ease than ever before. We are constantly demonstrating new uses for the Polyarc

system and would love to hear how the Polyarc system has helped you. Please email any

testimonials, technical literature or examples to contact@activatedresearch.com and we will

include them on our website.

We at the Activated Research Company strive to bring you the best products with the ultimate

customer experience. If you have any questions which aren’t answered in the FAQ,

troubleshooting or learning center sections of our website (www.activatedresearch.com), please

contact us at contact@activatedresearch.com or call 612-787-2721.

Page 17

© 2020 Activated Research Company, LLC | 17

Appendix

Using Hydrogen as a Carrier Gas

Because hydrogen reacts with air in the Polyarc system, the flows supplied to the Polyarc

system must be modified from the typical operating flows when using hydrogen as a carrier gas.

The following flow rates have been optimized for use with hydrogen as a carrier gas:

1. For hydrogen carrier gas flow rates up to 1.05 sccm:

a. Set the Polyarc system air flow rate to 5.0 sccm.

b. Set the Polyarc system hydrogen flow rate to 40 sccm.

c. Set the FID air flow rate to 400 sccm.

d. Note: The minimum oven temperature that should be used with these conditions

is 40 °C. Operating at a temperature below this recommendation will lead to

condensation of water in the Polyarc system outlet, and extinguishment of the

FID flame. Contact ARC to obtain a cryo assembly if you are interested in

operating at a lower oven temperature.

2. For hydrogen carrier gas flow rates from 1.05 to 2.1 sccm:

a. Set the Polyarc system air flow rate to 7.5 sccm.

b. Set the Polyarc system hydrogen flow rate to 40 sccm.

c. Set the FID air flow rate to 400 sccm.

d. Note: The minimum oven temperature that should be used with these conditions

is 50 °C. Operating at a temperature below this recommendation will lead to

condensation of water in the Polyarc system outlet, and extinguishment of the

FID flame. Contact ARC to obtain a cryo assembly if you are interested in

operating at a lower oven temperature.

3. For hydrogen carrier gas flow rates above 2.1 sccm, contact ARC.

Adjusting Gas Flow Rates

1. Manual Flow Control Module

The manual flow control module consists of two pressure regulators (bottom; Figure

A1), one each for hydrogen and air, which supply gas at a constant pressure to two

needle valves (top; Figure A1). The regulators are pre-set at the factory and should

not need to be adjusted. If adjustment is necessary, the pressure supply to the needle

valves can be increased/decreased by turning the respective regulator knob

clockwise/counterclockwise. The needle valves are responsible for controlling the flow

rate after a constant supply pressure has been set by the regulators. The needle

valves have a knob to turn the flows off and on, and an inset screw for adjusting the

flow rate. The knob can be turned clockwise to turn off gas flows. The knob should be

completely open when adjusting flows and operating the flow controller. The inset

screw is used to increase/decrease the flow rate by turning

counterclockwise/clockwise.

The procedure for adjusting flows includes turning the valve knob counterclockwise

completely (full open) and adjusting the inset valve screw until the desired flow rate is

obtained. The flow controller is designed to be operated continuously without

interference, but small adjustments may be necessary over time to correct for drift.

Page 18

© 2020 Activated Research Company, LLC | 18

The pressure regulators mitigate changes in upstream gas pressures that could affect

flows.

There are two options for checking the flow rates on the manual flow control option; a

flow meter can be used for both options. The first option (recommended) is checking

the flow rates out of the FID; it is important to note that the reactor must be cooled

down, otherwise, water will be formed and consistent flow rates won’t be obtained.

The second option, if cooling the reactor isn’t possible, is to disconnect the air and

hydrogen fittings and measure the flow rates from the manual flow control module

itself; this option is not as accurate as the first because it does not account for the

pressure drop when the system is connected.

Figure A1. Schematic of manual flow control module.

2. Electronic Flow Control Module

NOTE: The flow rates on the electronic flow control module are pre-set at the factory.

The supplied Electronic Flow Control Communication Package (USB cable and

software) can optionally be used to monitor flows, tare the device, and adjust flow

rates (e.g., based on the carrier gas). The device should be tared every 6 months to

correct for electrical drift. Instructions are included in the software manual.

The electronic flow control module consists of two mass flow controllers in a

convenient enclosure (Figure A2 & A3). The enclosure is equipped with a power plug,

a communication port and two on/off switches in addition to the supply and outlet

fittings. Only use the supplied power plug (Figure A4). To operate the controllers,

connect the appropriate air and hydrogen gases at supply pressures ideally between

60-100 psig. Plug in the device and turn the switches in the back from off (o) to on (|).

Page 19

© 2020 Activated Research Company, LLC | 19

Flow can be turned off or on at any time as required for the operation of the Polyarc

System. No calibration is necessary as the controllers are pre-set at the factory to the

appropriate air and hydrogen flow rates for the Polyarc system. However, if switching

from an inert carrier gas to hydrogen, or vice versa, see the important note in

the Appendix regarding the recommended flows when using hydrogen as a carrier

gas.

Figure A2. Schematic of front of

electronic flow control module.

Figure A2. Schematic of back of

electronic flow control module.

Figure A3. Schematic of EFC software communication cable.

Page 20

© 2020 Activated Research Company, LLC | 20

Figure A4. Schematic of supplied power plug for electronic flow control module.

3. Calibrating the Agilent Auxiliary Electronic Pressure Control (EPC)

NOTE: When measuring these flow rates, ensure that the Polyarc reactor is cold.

Otherwise, water will be formed and accurate flow rates won’t be obtained.

First, connect the hydrogen and air to separate auxiliary channels on the EPC; the

hydrogen should use a medium-flow frit and the air should use a low-flow frit (frits

can be purchased from Agilent). The exact pressure setting required for these flow

rates can vary from system to system, however, most users have found that around

26.5 psi and 20.8 psi work for air and hydrogen, respectively. To measure the flow

rates, with all fittings of the Polyarc reactor connected, connect a flow meter to the

outlet of the FID. Start the hydrogen flow and measure the flow out of the FID,

adjusting the pressure to obtain 35 sccm. Turn off hydrogen, start the air flow, and

measure the flow out of the FID to obtain 2.5 sccm. Re-start the hydrogen flow to the

set pressure. NOTE: If you are using hydrogen as a carrier gas, see important

note with modified air and hydrogen flow rates in the Appendix.

Loading...

Loading...