Page 1

23x Indoor Speed Dome Camera

CAM-ISD48

User’s Manual

. .

User’s manual 1

Page 2

CONTENTS

1. Safety Information..............................................................................4

2. Preface...............................................................................................5

3. Features.............................................................................................6

4. Appearance........................................................................................7

4.2 DIP switches................................................................8

4.3 Set Up Device ID Number ...........................................9

4.4 Control Protocol and Baud Rate................................12

4.5 RS-485 Network and Impedance...............................13

5. Mount The Speed Dome Camera....................................................16

5.1 Mounting Accessory...................................................17

5.2 Surface mount............................................................18

5.3 Embed Camera Into Ceiling.......................................19

5.4 Ceiling-drop mount (with CAM-CM)...........................20

5.5 Wall mount (with CAM-WM).......................................21

5.6 Use External Housing (with CAM-OH).......................23

6. Connecting Wires.............................................................................26

6.1 Power.........................................................................26

6.2 Video..........................................................................27

6.3 RS-485.......................................................................28

6.4 Alarm Input and Alarm Output...................................28

7. Applications......................................................................................31

7.1 Controllers and RS-485.............................................31

7.2 Connect single dome to console................................32

7.3 Connect two or more domes to console....................35

8. Camera setup --- OSD functions .....................................................37

8.1 OSD operation...........................................................37

. .

User’s manual 2

Page 3

8.2 OSD function List....................................................... 37

8.3 OSD function description...........................................39

9. Pre-defined System Functions ........................................................45

10. Specification...................................................................................46

. .

User’s manual 3

Page 4

1. Safety Information

Federal Communication Commission (FCC) Statement

NOTE: This equipment has been tested and found to comply

with the limits of a Class B digital device, pursuant to Part 15 of

the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is

operated in a commercial environment. This device generates,

uses and can radiate radio frequency energy and, if not installed

and used in accordance with the instruction manual, may caus e

harmful interference to radio communications. However, there is

no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference,

the user is encouraged to try to correct the interference by on or

more of the following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and

receiver.

Correct the equipment into an output o a circuit different

from that to which the receiver is connected

Consult the dealer or an experienced radio / television

technician for help

FCC Caution: To assure continued compliance, any change

or modification not expressly approved by the

party responsible for compliance could void the

user’s authority to operate this equipment.

Notice for customers in Canada

. .

User’s manual 4

CAUTION

This Class B digital apparatus meets all requirements of the

Canadian Interference Causing Equipment Regulations.

ATTENTION

Cet appareil numerique de laclasse B respects toutes les

exigencies du Reglement sur le materiel brouilleur du

Canada

Page 5

2. Preface

Congratulations for the purchasing of the world most compact PTZ (Pan, Tilt

and Zoom) camera. The camera is designed and manufactured not just to

meet the requirements for traditional CCTV and modern digital surveillance,

but also increase the systems’ overall performance.

This camera line incorporates high resolution color CCD, with two types of

lens available: power zoom or vari-focal. Some image and special effect

functions are related to the type of lens, while other functions are the same

across the line.

The PT mechanism provides controllable panning (360

auto-rotation (180

o

) functions, giving users the capability to manipulate the

camera for precise locating on target. The built-in micro-controller allows users

to program up to 64 presets for quick and accurate capture to specific view

positions. Moving speed, ranging from 0.25 to 300 degrees per second and is

selectable to controller, is variable in 16 optional levels. Dwell time of each

view position is also selectable from 1second up to 255 seconds.

System function includes I/O for alarm function for intrusion management, ID

(maximum to 128) and impedance matching option for multiple node

setup

system, 3 control protocols, 3 options of baud rates, RS-485 communication

format. This device is driven by DC12V power. It can be controlled by

keyboard, PC, video server or standalone DVR.

For the power zoom version, a number of image related functions (such as

DSP functions, lens functions, special effects of video…) are managed via

OSD (On-Screen-Display) menu. These functions are explained in the section

of OSD with details. The CCD can be set up for automatic switching to

black-white mode for night-vision ready when illumination is low.

This camera is designed to be water-resistant for outdoor use, under the

condition of normal temperature range from -10

outdoor housing is also available for severe weather condition (extreme low or

high temperature environment).

o

) and tilting (90o)+

o

to 50o C. A companion

. .

User’s manual 5

Page 6

3. Features

High resolution color CCD 480 TV lines

23x optical / 10x digital zoom

Continuous panning for 360o; Tilt for 90o +auto-rotation (180o )

Fast rotation speed, up to 300o per second

RS-485 digital control, supporting multi-nude topology

BNC connector for video output

Programmable for view position, speed and dwell

View position preset, up to 64 points

Auto-pan and 4 groups of tour

3 alarm inputs and 1 alarm output

Compatible with Pelco D and Pelco P protocols

Internal ID setup function, maximum to 128

Compatible with keyboard and DVR for CCTV system

Compatible with PC and video server for WAN / LAN surveillance

For embedded, surface, wall and ceiling mount

External housing for severe outdoor environment (Option)

. .

User’s manual 6

Page 7

4. Appearance

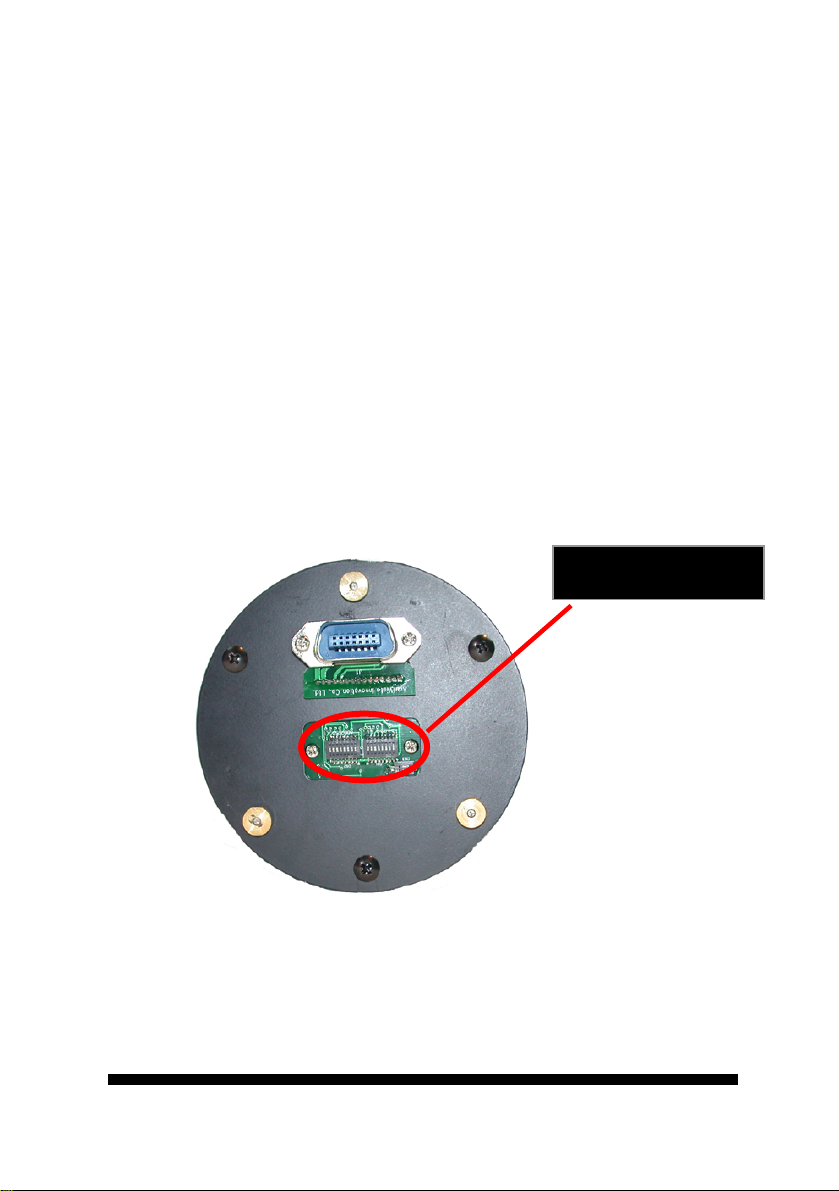

4.1 To Access DIP Switches

Before the camera is mounted in place, be sure the following four settings are

properly executed, or the camera may fail the control:

Camera ID setup

Protocol selection

Baud rate selection

Termination impedance

Tools:

Use pencil, pincer, paper clip or small flat screw driver, to move the lever of DIP

switch

Access points:

The DIP switches are located on the bottom of the dome cameras:

DIP switches

. .

User’s manual 7

Page 8

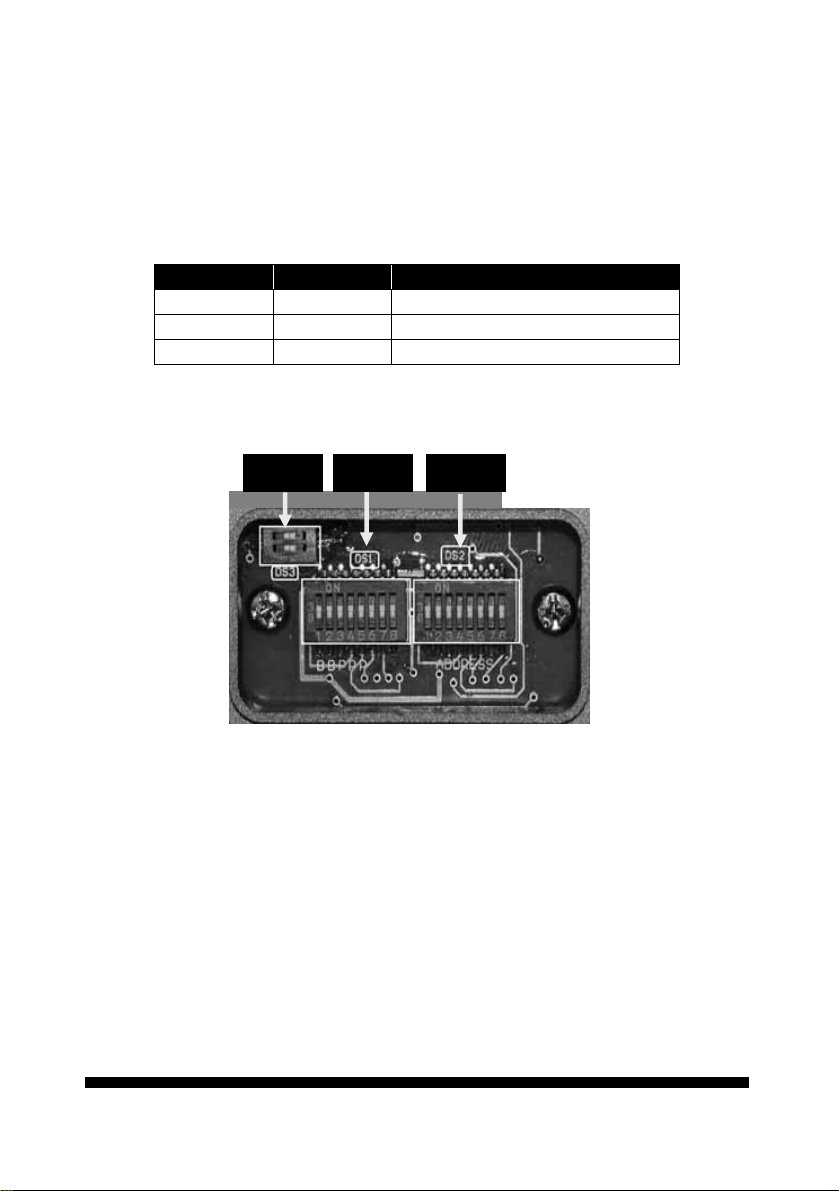

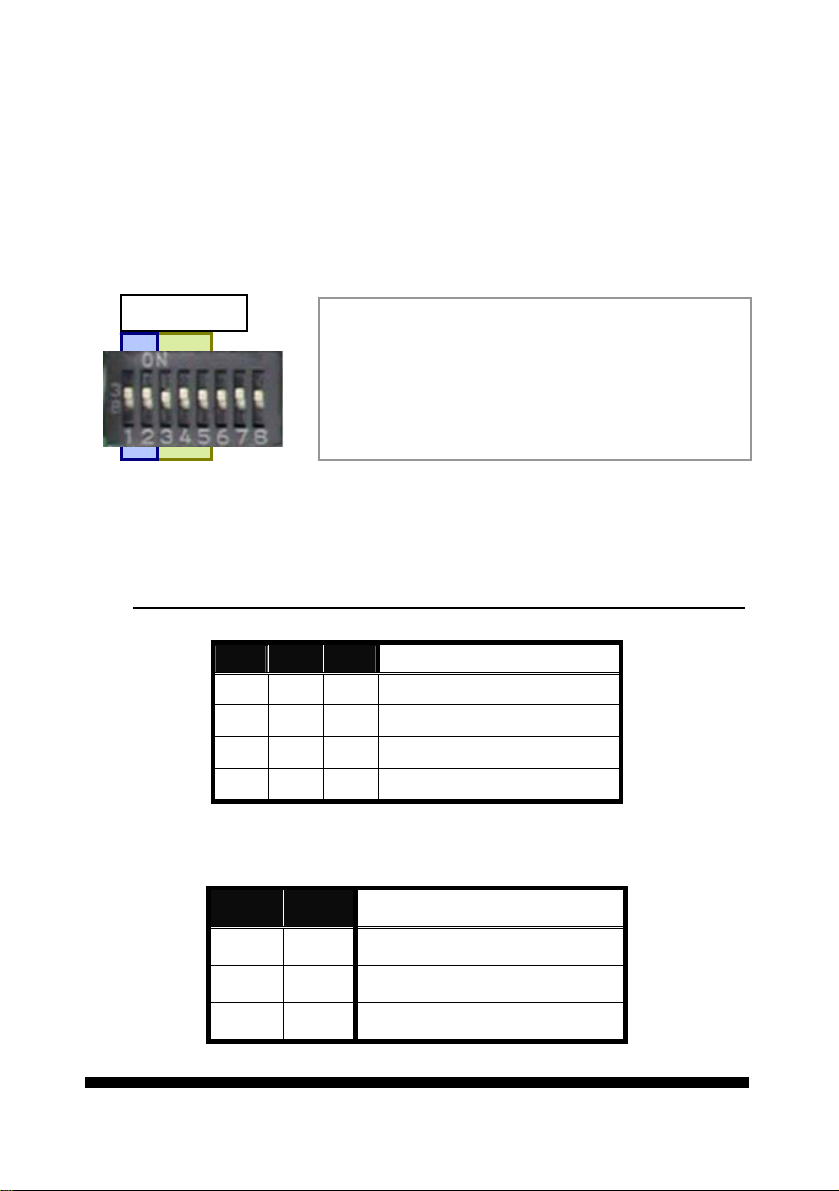

4.2 DIP switches

Overview of DIP switches

There are three sets of DIP switch on board for different setup purposes.

location # bit quantity used for

DS1 8 Protocol / baud rate setup

DS2 8 Device ID setup

DS3 2 Network impedance

Refer to the picture on below for DIP switch locations.

In the following paragraphs are the detail descriptions of the three main setups the

installer must do, before hardware mounting and cabling work should begin.

DS3 DS1 DS2

. .

User’s manual 8

Page 9

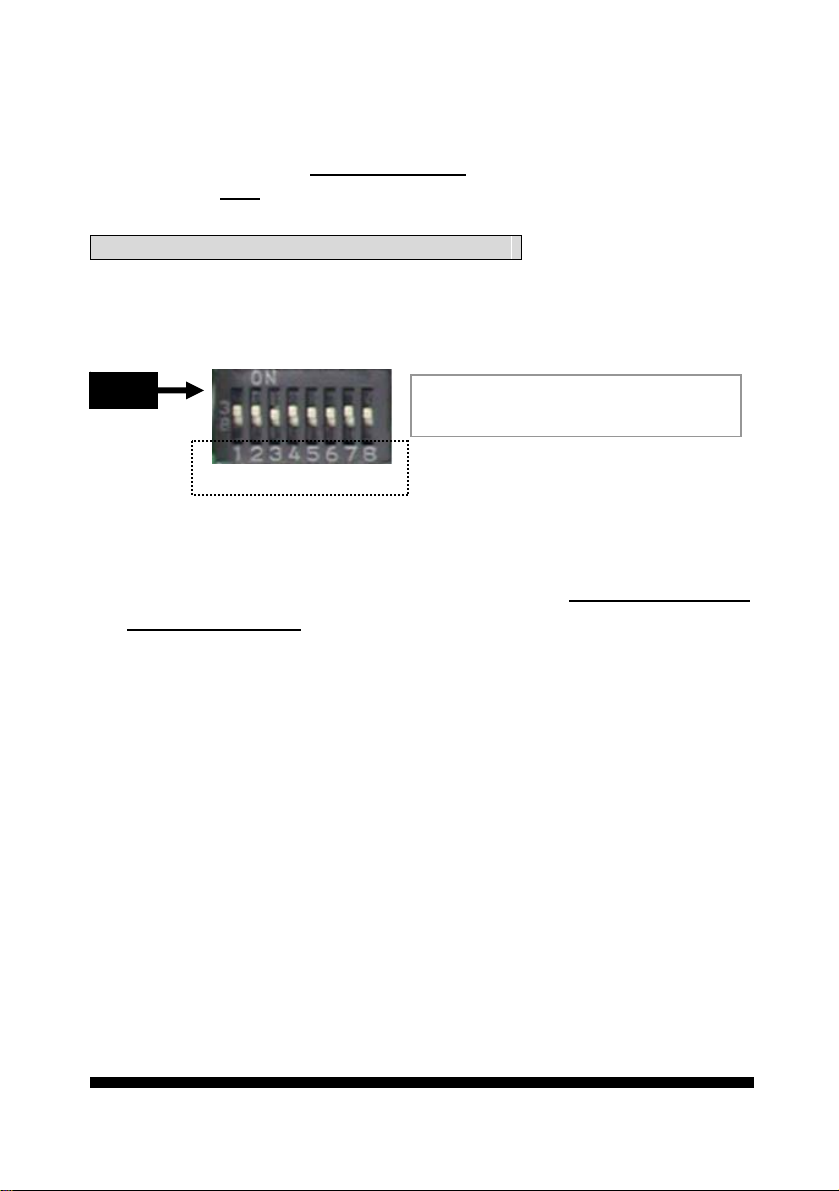

4.3 Set Up Device ID Number

To build correct network for control communication, every speed dome camera in

the network must have an unique ID number

8-bit DIP switch DS2.

Note: Factory default of device ID is 1

Find 8-bit DIP switch DS2 on the PC board

DS2

Refer to the tables in the next two pages for ID setting (the tables will show the

relation between pin assignments of DIP switch and ID numbers 1 to 128)

Since the highest ID of this camera is 128, maintain the bit number 8 in OFF

position all the time.

All the speed domes in a network must have their unique ID. It is highly

recommended to installers, for future maintenance and users’ convenience, to

mark the ID of each camera onto its corresponding location on the site map,

and make out a list of cameras with their ID numbers.

The DS2 pin assignment for ID setup is in binary format.

Bit number

, which is set by the bit 1 to 8 of a

remark: Dash line “---“ in table means to

set the bit to “OFF” position

. .

User’s manual 9

Page 10

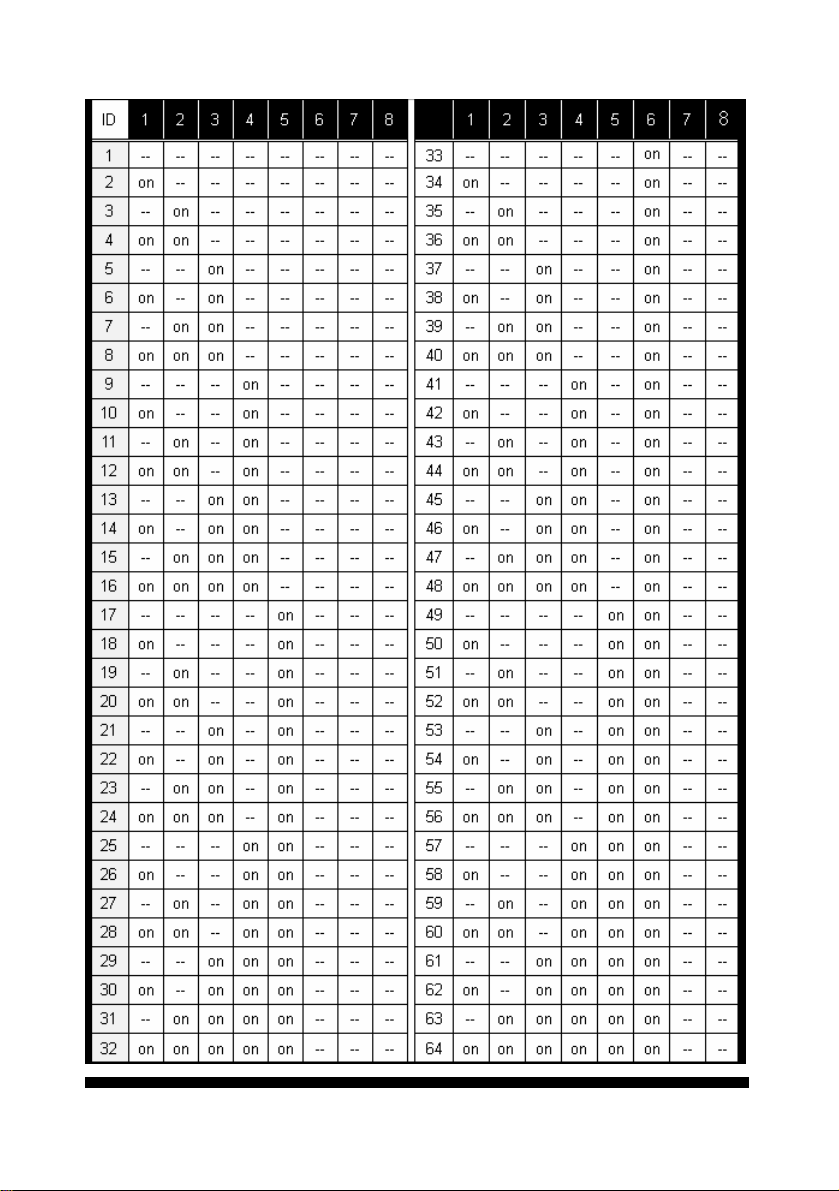

ID table (1 ~ 64)

. .

User’s manual 10

Page 11

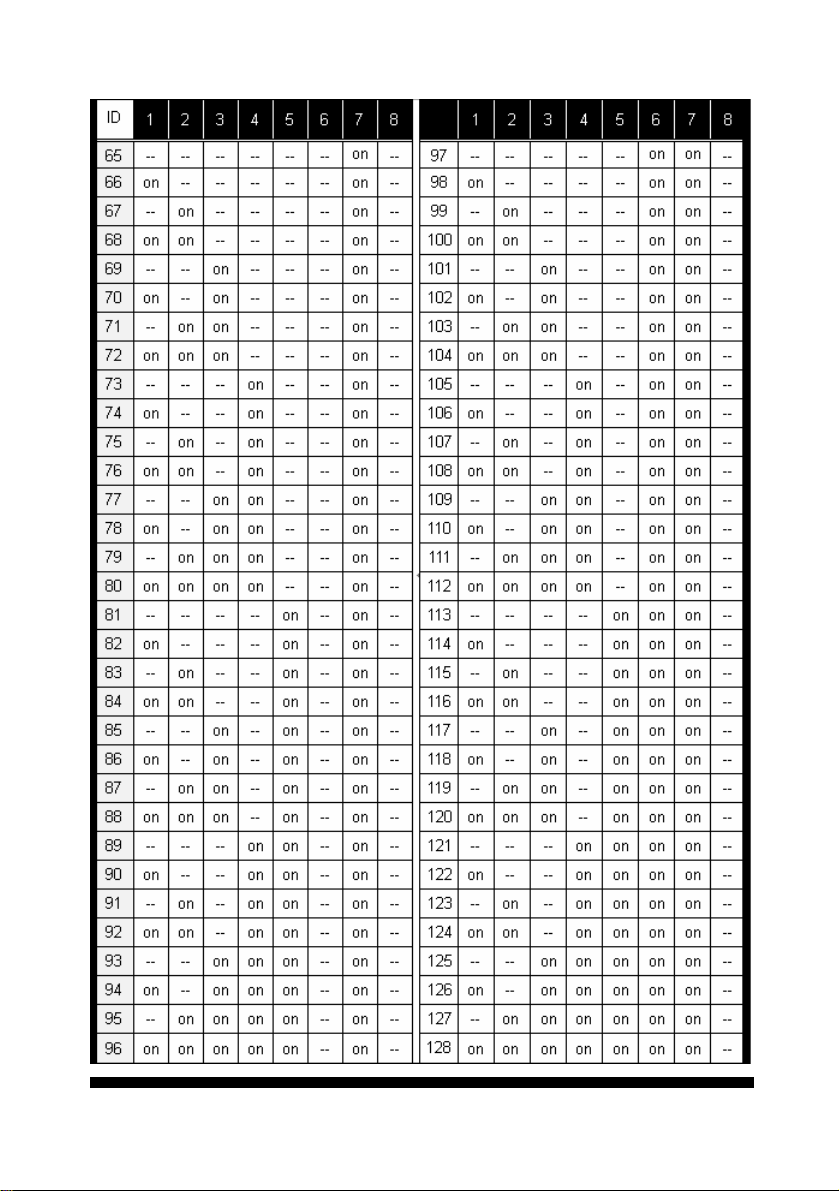

ID table (65 ~ 128)

. .

User’s manual 11

Page 12

4.4 Control Protocol and Baud Rate

Control protocol and baud rate must be set correctly in the dome camera in order to

establish proper control communication between the camera and control device.

Be sure that the same protocol and baud rate must be implemented in control

device, too.

3 types of protocol and 3 levels of baud rate are provided b y this speed dome,

through an 8-bit DIP switch labeled DS1.

First, installer needs to choose a communication protocol with bit number 3, 4

DS 1

and 5. Watch that the same protocol is chosen for speed dome and controller.

The following table shows the three protocols provided in this speed dome.

Check what are available in the controller before choosing the protocol.

remark:

1. “--“ means to set the bit to “OFF” position

2. Bit 1 and 2 are for baud rate setup

3. Bit 3, 4 and 5 are for protocol selection

4. Bit 6 is reserved future use

5. Bit 7 is for firmware upgrade

6. Bit 8 is for cooling fan on / off switching

3 4 5

-- -- --

on -- --

-- on --

on on --

Protocol

Pelco-D

Pelco-P

Reserved

Reserved

Bit 1 and 2 are for baud rate setup. Same baud rate must be set up for the

speed dome and control device, or communication fro control will fail.

. .

User’s manual 12

1 2 Baud rate

-- --

on --

-- on

2,400 bps

4,800 bps

9,600 bps

Page 13

4.5 RS-485 Network and Impedance

Transmission distances of RS-485 Bus

The 0.56mm (24AWG) twisted pair or higher grade wires are recommended for data

transmission cable.

The maximum theoretical transmitting distances, for the AWG#24, are as follows:

Baud Rate Maximum Transmitting Distance

2400 Bps 1800m

4800 Bps 1200m

9600Bps 800m

If user selects thinner cables, or installs the dome in an environment with strong

electromagnetic interference, or connects lots of equipment to the RS-485 bus, the

maximum transmitting distance will be decreased. To increase the maximum

transmitting distance, do the contrary, i.e. use thicker wire and keep the cable away

from the interference.

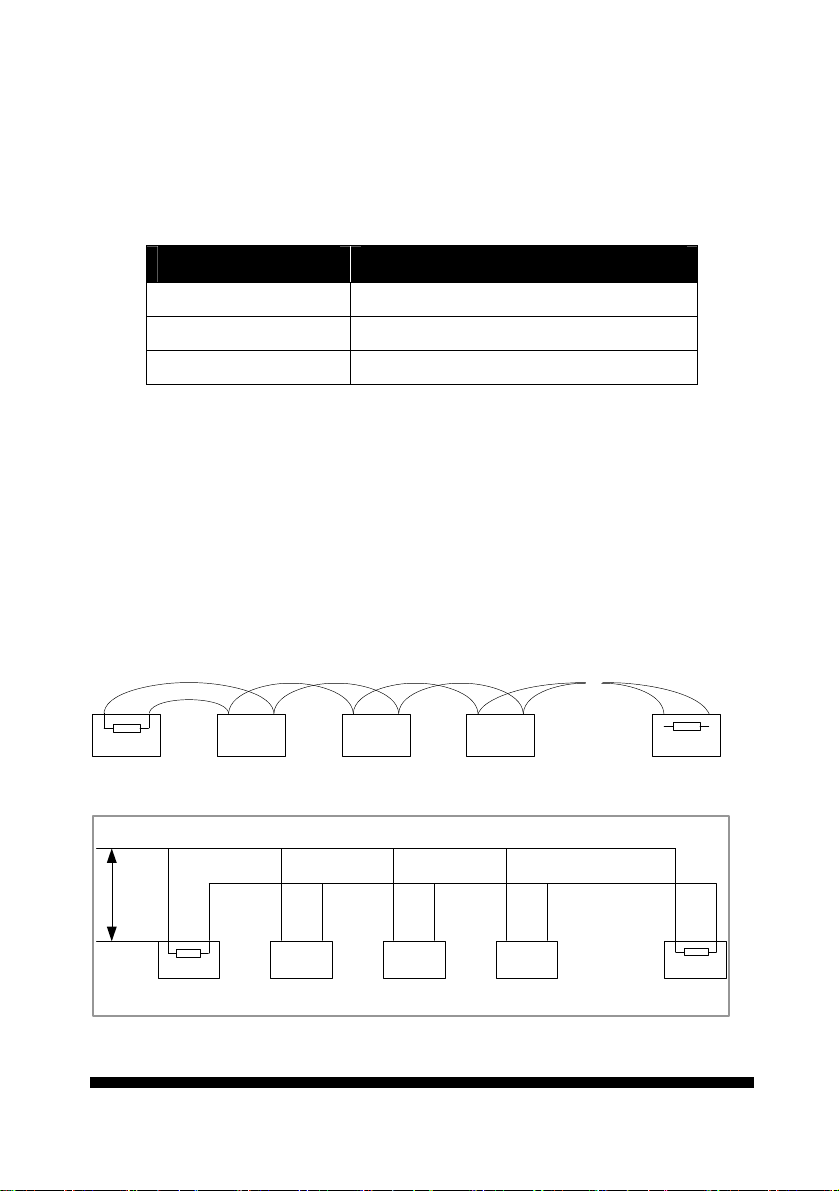

Connection and termination resistor

The RS-485 standard requires a daisy-chain connection among the equipments.

There must be termination resistors of proper impedance (typically 120 ohms,

within the range from 90 to 250 ohms) at both ends of the connection.

120Ω 120Ω

1# 2# 3# 4# 32#

A+

B-

D

A+ B -

120Ω

Main controller

1# 2# 3# 31#

. . . . .

.....

.....

120Ω

. .

User’s manual 13

Page 14

Impedance setup for the speed dome

Each speed dome camera has a termination resistor built in.

In a network of RS-485 chain, the speed domes are classified in two categories:

end unit (such as the #31) and node (such as #1 through #30).

To set up the resistor correctly, installer must decide if the specific dome camera is

the termination device or not, i.e. if it is at the end of the RS-485 chain.

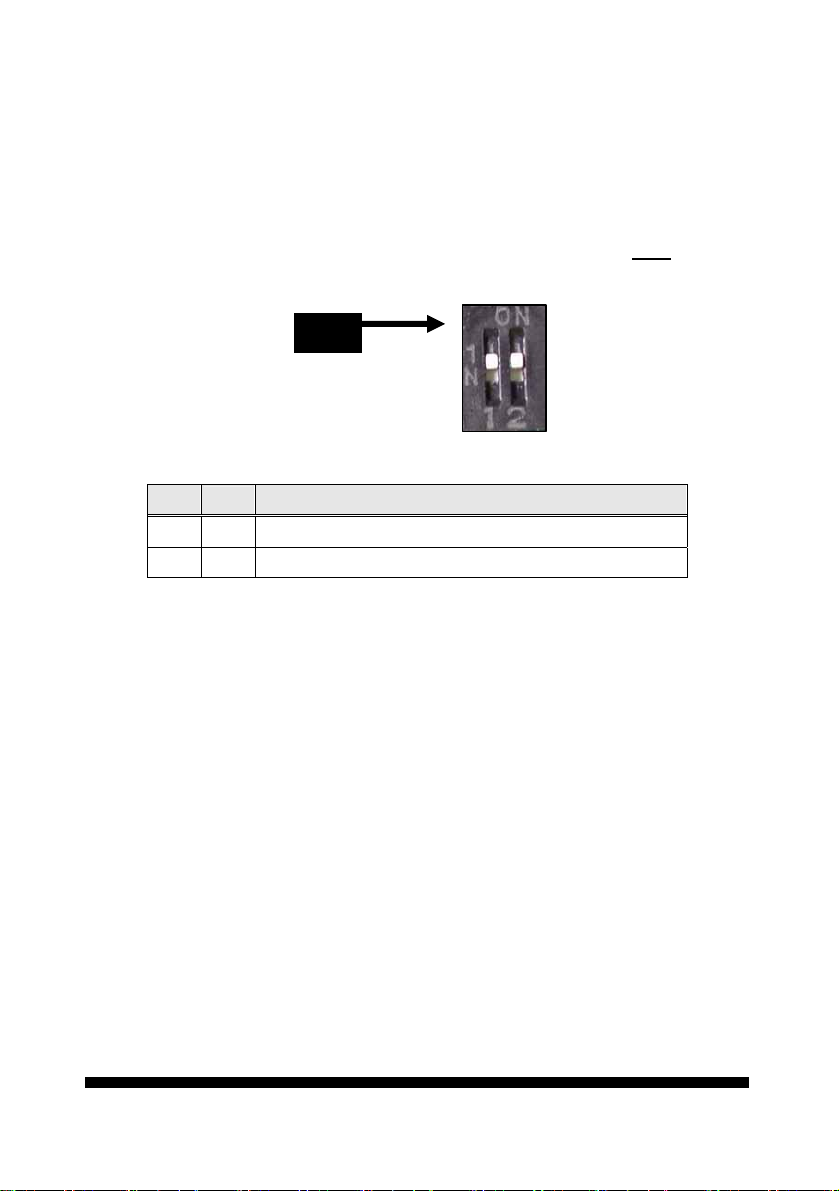

The impedance setup is provided by the bit 1 and bit 2 of DIP switch

DS3 .

DS3

Bit 1

Bit 2

-- --

On On

For nodes: Set both of Bit 1 and Bit 2 to OFF position

For end unit: Set both of Bit 1 and Bit 2 to ON position

Standard 120 ohms ( device at end )

Impedance

Open ( device on node )

Impedance of the control unit

This is generally for two cases: controller with RS-485, and controller with RS-232.

Controller with RS-485:

Most keyboard and video server in market have RS-485, which are equipped with

termination resistor to drive a RS-485 system.

But most PC and notebook sort of devices have RS-232 or USB port but no RS-485.

Therefore, for PC system, a RS-232 or USB to RS-485 converter is required. So

installer must check out if the converter has proper termination resistor.

Problems in practical connection

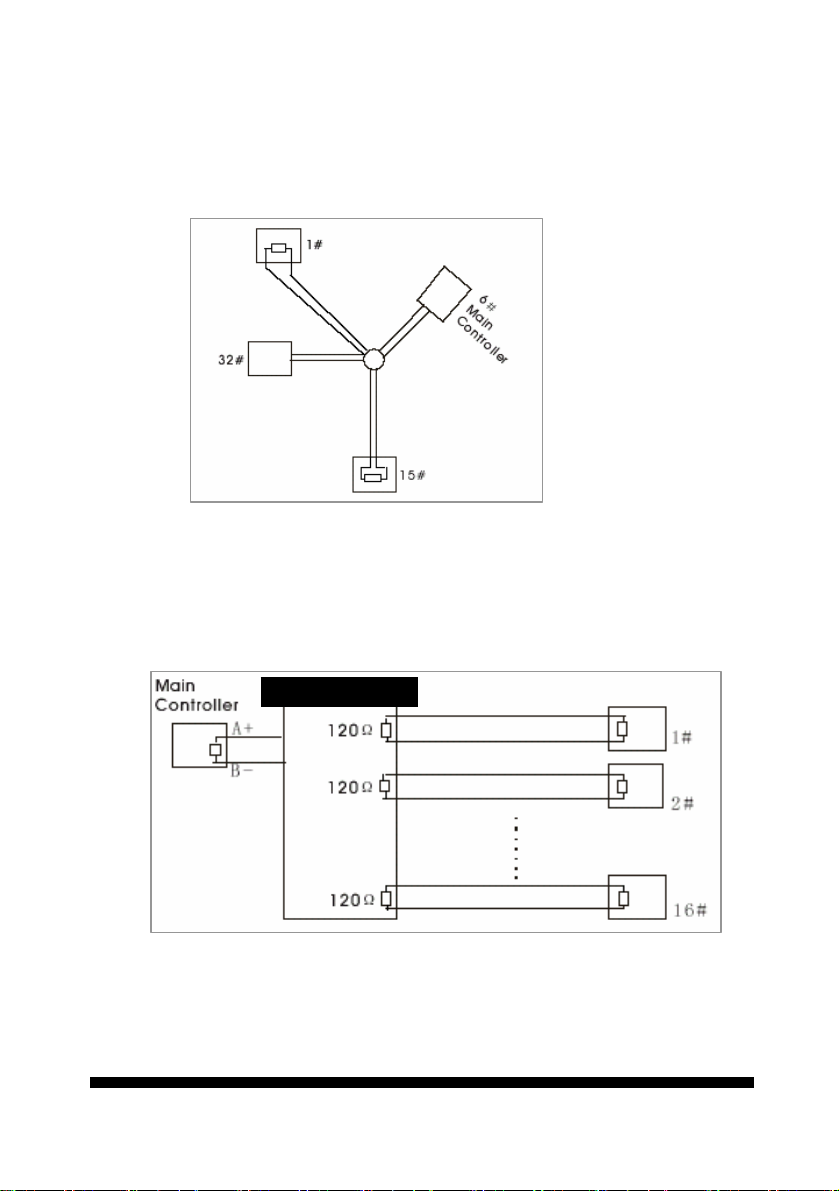

In some circumstances user adopts a star configuration in practical connection. The

termination resistors must be connected to the two equipment that are farthest

away from each other, such as equipment 1# and 15# in the following picture. As

the star configuration is not in conformity with the requirements of RS-485

. .

User’s manual 14

Page 15

standards, problems such as signal reflections, lower anti-interference performance

RS-485 distributor

arise when the cables are long in the connection. The reliabilit y of control signals

could be downgraded with the phenomena that the dome does not respond to or

just responds at intervals to the controller, or does continuous operation without

stop

In such circumstances the usage of RS-485 distributor is recommended. The

distributor can change the star configuration connection to the mode of connection

stipulated in the RS-485 standards. The new connection achieves reliable data

transmission.

. .

User’s manual 15

Page 16

5. Mount The Speed Dome Camera

The camera and its mounting system are designed in modules. There are 5

methods to mount the PTZ camera, which are:

1. Attached to the ceiling surface directly

2. Embedded into ceiling

3. Held to ceiling surface through a bracket (ceiling-drop)

4. Mounted to wall through a bracket

5. Adapted into external housing

For all these five mounting ways, a common mounting base for mechanical locking

and signal interface shall be adapted as below.

In the next page there is a list of all the accessories provided with the camera for

various environments.

. .

User’s manual 16

Page 17

5.1 Mounting Accessory

The following items are supplied with the speed dome for the camera mounting.

Description The look The Use

1

2

Plastic ring

Metal ring

To hold the camera

mbedded on ceiling e

Must be used with the

metal ring together to

hold the PTZ camera..

To hold the camera

mbedded on ceiling e

Must be used with the

plastic decoration ring

together to hold the PTZ

camera.

3

Mounting base

4

Plastic Housing for surface mount

5

Metal Bowl holder

. .

User’s manual 17

The interface for holding

the camera and bridging

signals

To hold the camera on ceiling surface

To work with item 3 for creating ceiling or wall mount

Page 18

5.2 Surface mount

Before installation starts, put mounting base and plastic housing together to

1.

make a base module

2.

Locate the base module onto the place the camera is to be mounted, and fix

the base on the surface completely with screws through the 3 holes on the

base (be sure the cables are well located throughout the cable outlet)

3.

Get the camera and plug it onto the base; watch for the direction of the

connectors on camera and mounting base and be sure they are mated well.

Then rotate the camera body counter-clockwise until it is completely locked

4. Put the safety screw (anti-loss) in locking position and screw it in

Integrate the mounting base and the

plastic housing as a module

Fit the camera into the module and

lock it in position

Mounting the module to the surface

Put the safety screw in place

In case of dealing with a concrete surface:

a. Mark the locations for screw through the holes on the base

b. Make holes on the wall, then insert the supplied plastic plugs into the holes and

squeeze them in until they are flush with the wall surface.

c. Mount the base on the desired place tightly with screws

. .

User’s manual 18

Page 19

5.3 Embed Camera Into Ceiling

Step 1 make holes

To insert the speed dome into the ceiling, first

a hole must be properly made to let the dome

be through for hanging.

The best way to decide the diameter of the

hole, and the spots for mounting screws, is to

use the supplied metal holder.

Put the holder on the surface of the target location and mark a circle with

pencil or color marker

Also mark out the spots for screws with the screw holes on the holder

Cut the camera hole alone with the curve

Drill holes for screw in 6 mm (1/4”) on the three marked spots;

Step 2 Integrate the decoration ring with camera

The decoration ring is not just for nice looking,

but also the piece to hold the camera in place

for embedded mounting.

To integrate the ring to camera:

1. Take the transparent dome cover off

2. Locate the ring to the bottom side of the

cover

3. Put the cover back to the camera

Step 3 Mount the camera through the hole

Take the below steps to make the camera cling

to ceiling:

1. Place the auxiliary metal bracket onto the

top of the ceiling

2. Put the camera through out the hole

3. Align the screw holes of the decoration

ring and the auxiliary bracket

4. Put screws through and tighten the two

brackets, with the ceiling in between

. .

User’s manual 19

Page 20

5.4 Ceiling-drop mount (with CAM-CM)

Pre-assembling of the Bowl Module

Both ceiling-drop and wall-mount needs to have a bowl module, an assembly of the

mounting base and metal bowl supplied in the mounting kit, be built first.

Follow the flow chart on below for building up the bowl module.

Put the base

into the bowl

The mounting base

Metal bowl

To drop camera from ceiling, take the ceiling bracket (option item) and bowl module,

1. put the cables into the tube and have them come out from cable outlet

2. put the bracket on top of the bowl and tight them together with screws

Put the bowl

on bracket

The bowl module

3. Locate the assembled piece ont o the place the camera is

to be mounted, and fix it on the surface completely with

screws through the 3 holes on the bracket

Get the camera and plug it onto the base; watch for the

4.

direction of the connectors on camera and mounting base

and be sure they are mated well. Then rotate the camera

body counter-clockwise until it is completely locked

5. Put the safety screw (anti-loss) in locking position and

screw it in

Make a

module

The bowl module

Make an

assembly

. .

User’s manual 20

Page 21

5.5 Wall mount (with CAM-WM)

Pre-assembling of the Bowl Module

Both ceiling-drop and wall-mount needs to have a bowl module, an assembly of the

mounting base and metal bowl supplied in the mounting kit, be built first.

Follow the flow chart on below for building up the bowl module.

Put the base

into the bowl

The mounting base

Metal bowl

Mount the camera on wall

To mount camera on wall:

1. Take the wall-mount bracket (optional item),

put it on the target place and fix it with the

supplied screws (total of 4)

2.

Take the cover-screw off the bracket, and

remove the cover from bracket

3. Attach the bracket on top of the bowl and

tight them together with screws

4. Put the cables in the trench of bracket, and

all connectors come out through the cable outlet. Then put cover and screw

back.

Make a

module

The bowl module

Remove this screw

. .

User’s manual 21

Page 22

Put the bowl

on bracket

The bowl module

Locate the assembled piece onto the place the

5.

camera is to be mounted, and fix it on the surface

completely with screws through the 4 holes on the

bracket

Get the camera and plug it onto the base; watch for

6.

the direction of the connectors on camera and

mounting base and be sure they are mated well. Then

rotate the camera body counter-clockwise until it is

completely locked

7. Put the safety screw (anti-loss) in locking position.

Make it an

assembly

. .

User’s manual 22

Page 23

5.6 Use External Housing (with CAM-OH)

To operate speed dome cameras and maintain all functions in normal in severe

temperature conditions, i.e. below -10

required.

CAM-OH has included two brackets (Ceiling-mount and Wall-mount bracket). You

can choose which one you will like to used.

Inside the housing, the mounting base (item # 3 in the

accessory list) is already built before it leaves factor.

picture on the right).

Wall mount Inst allation Procedure

1. Take the wall mount bracket, put it on the target place and fix it with the

supplied screws (total of 4).

2. Take the cover-screw off from the bracket, and remove the cover.

o

C or above 45oC, external housing is

(see

Remove this screw

3.

Please stuff the water proof rub ring into the bracket. Then attach the bracket

and lock it to the housing. Tight them on with screws.

. .

User’s manual 23

Page 24

4. Put the cables in the trench of bracket, and all connectors come out through

the cable outlet. Then put bracket cover and screw back.

5. Load the camera into the housing. Be sur e the connectors are well mated

and then rotate the camera to lock it in position.

6. Put the safety screw in locking position and tight it.

Finished device

. .

User’s manual 24

Page 25

Ceiling mount Installation Procedure

1. Insert the cables pass through the tube. Please also stuff the water

proof rub ring into the iron cover on tube.

2. Close the tube onto the outdoor housing and lock it to the housing.

Tight them on with screws.

3. Finished.

. .

User’s manual 25

Page 26

6. Connecting Wires

The cables, wires and connector attached to the speed dome are categories into 4

major functions of:

1. Power

2. Video

3. RS-485

4. Alarm-in and out

They are easily distinguished from one to another, as being featured with different

connectors. Refer to the picture on below to learn about cable and connector

information.

6.1 Power

The camera will obtain power source from two kinds of power: DC12V or

AC24V.

1. Without outdoor housing, DC12V:

When operated with DC12V, the camera may consume 1000mA DC current in

full load condition. To power the speed dome is simple. Get the DC jack from

the camera, and connect the adapter plug to the jack.

Note: To secure the safety and maintain correct function, always use the

switching DC 12V / 1.5A power adapter. The switching type power adapter

is strongly recommend. Due to switching power adapter can output stable

power source, that can prevent the speed dome camera from damage.

. .

User’s manual 26

DC 12V adapter

(supplied)

Page 27

2. With outdoor housing, AC24V:

An AC adapter of 24V / 1.66A is supplied with the outdoor housing (CAM-OH)

for the AC version. To power the camera, connect adapter to camera’s power

connector.

Power Connector on Speed Dome AC 24V Connector on Adaptor

As soon as power is supplied, the speed dome will enter “initial check” mode with

the following procedures:

Move the lens automatically for system check

Screen comes up with blue picture and will be showing “starting” in white

for around 3 seconds

Then the camera will show normal image and get ready for control

6.2 Video

Video output level of the camera, in standard of 1Vp-p, is delivered with female

BNC connector at 75 ohms impedance. To transmit the video to receiver properly, it

is recommended to use RG-59 A/U coaxial cable with stranded center conductor,

with male BNC connectors on both ends.

RG-59 is also in 75 ohm impedance, which matches the

camera’s output impedance. The A/U version is

recommended, rather than the version B/U, due of its

superior performance on flexibility for resisting severe

twisting, bending and other stresses which occur in many

CCTV installations.

In case the installation distance is over than 500 meters (1,500 feet), additional

amplifier might be needed to keep the video level and image quality.

. .

User’s manual 27

Page 28

6.3 RS-485

The camera adapts RS-485 in half-duplex pattern, which

is a two-pin connectivity, as shown on the right picture.

Installer must pay attention to the polarity of these two

pins – yellow wire is the POSITIVE end, and orange is the

NEGATIVE. Communication between controller and

camera will break and control will not function if they are

reversely connected.

The RS-485 communication may run for 4,000 feet if the system network is properly

built. Two important factors should be handled with care during the system

build-up--- baud rate and termination impedance. More information about RS-485

are in sections “Protocol and Baud rate” and “Applications”.

6.4 Alarm Input and Alarm Output

This camera is equipped with 3 alarm inputs and one alarm output for intrusion

management. Installers may connect the inputs to the various sensors and program

the camera to move and monitor specific spots for monitoring when evens take

place. Dwell time for monitoring is programmable, subject to the system. Refer to

the diagram on right for function assignments of the alarm I/O.

Alarm in Wire Color Alarm GND Wire Color Alarm out Wire Color

Alarm in 1 Black Alarm 1 Brown N.O. Gray

Alarm in 2 Red Alarm 2 Orange N.C. Purple

Alarm in 3 Yellow Alarm 3 Green Com. Blue

Alarm inputs

This speed dome has three alarm inputs, and each input is given by the software a

companion view preset. When trigger single is sent to alarm-in, the following

reactions will be taken by the speed dome:

The pan-tilt mechanism will move lens to the preset.

The alarm-out port will act.

Via RS-485, the console (control un it) will be notified

. .

User’s manual 28

Page 29

The three inputs and their correspondent view presets are independent from one to

another. Therefore, with the connections to three sensors, installer can set up

camera to monitor three different spots with different dwell time.

Presets For Events

Default settings at the alarm-ins activations are:

If setting(s) is / are done to presets 17, 18 and 19 :

At the trigger of alarm-in number 1, lens will move to preset 17.

At the trigger of alarm-in number 2, lens will move to preset 18.

At the trigger of alarm-in number 3, lens will move to preset 19.

If one or more positions of presets 17, 18 and 19 is / are empty:

At the trigger of alarm 1, lens will move to preset 1 (preset 17 is empty)

At the trigger of alarm 2, lens will move to preset 2 (preset 18 is empty)

At the trigger of alarm 3, lens will move to preset 3 (preset 19 is empty)

Note:

All the three alarm inputs are TTL level and triggered by negative signals.

To utilize the default view positions, user must pre-set the desired monitor

spots to presets number 17, 18 and 19 (or 1, 2 and 3).

Alarm-ON Management Protocol

With the presetting of its internal software, the PTZ camera will perform the

following functions automatically at the triggering(s) to alarm-input(s):

Camera is running Auto-pan when alarm signal(s) kicks in

1. When the first alarm signal hits this camera, lens will move to the

corresponding presets (see relative information on above ) at maximum

speed of 300

o

per second

2. Lens will stay at the preset position for 60 se conds

3. Camera will be back to the original auto-pan function after 60 seconds, if

no second alarm-in jumps in this 60 second time frame.

4. In case second and third alarm kicks in during the 60 seconds, camera will

move to the corresponding preset(s) and stay for 10 seconds initially, then

move to the next alarm-preset for 5 seconds and keeps the motion in

cycles until the 60 second time frame is over.

5. Camera will be back to its orig inal auto-pan function after the 60 seconds.

. .

User’s manual 29

Page 30

Camera is in steady mode when alarm signal(s) kicks in

1. When the first alarm signal hits this camera, lens will move to the

corresponding presets (see relative information on above ) at maximum

speed of 300

o

per second

2. Lens will stay at the preset position for 60 se conds

3. Camera will be back to the original position after 60 seconds, if no second

alarm-in jumps in this 60 second time frame.

4. In case second and third alarm kicks in during the 60 seconds, camera will

move to the corresponding preset(s) and stay for 10 seconds initially, then

move to the next alarm-preset for 5 seconds and keeps the motion in

cycles until the 60 second time frame is over.

5. Camera will be back to its original position after the 60 seconds.

Alarm output

The alarm output is a hardware toggle switch of NC (normal close) and NO (normal

open). In the event the camera receives trigger signal from one of the three

alarm-inputs, the output ports will swap their states (i.e. the NC port will turn into

OPEN condition, and the NO port will become CLOSE). The changing state can be

used for activating various external alarm devices, such as siren, recorder,

alarm-light or call-out system.

Alarm-on status will be automatically relieved at the 30

point and PTZ will be back to the original conditions. To relief system the alarm-o n

status earlier, please use the MANUAL OFF on the controller (subject to the

function’s availability to the controller)

th

minute from the triggering

Warning:

The NC/NO port provided by alarm-out is a mechanical contact relay.

Make sure the device connected to the alarm-output does not drain current

over than 0.5A and the voltage is not higher than DC 24V or AC 250V. Any

load over these may damage the output port permanently.

. .

User’s manual 30

Page 31

7. Applications

r

The PTZ camera, by itself alone or encompassed in different numbers of domes

with comprehensive matrix switching, is mainly for link to 4 different control means

(also known in different terms such as controller, console or host):

PC-based system

Keyboard controller

DVR

Video server

While most keyboards, DVRs and video servers are equipped with RS-485 port,

which can be directly connected to speed dome, desk top and notebook computers

usually don’t provide direct output of RS-485. Therefore an interface device (signal

converter) will be needed when computer is used as the controller.

Signal converte

(Digital Video Recorder )

7.1 Controllers and RS-485

Note:

Check the PC first to see if RS-232 port or USB port is available to the specific unit.

Some may have both while others only have one of the two.

. .

User’s manual 31

Page 32

7.2 Connect single dome to console

r

Connect the RS-485 of camera to controller (such as a keyboard) with a pair of

twisted cable. Tele-control is sent via the cable between dome and controller.

Video signal from the dome is sent to multiplexer, monitor, DVR or video server

directly, normally through coaxial cable (usually the RG-59 A/U).

Power (DC12V or AC24V) shall be applied to the camera v ia separate DC or

AC adapter.

Usually the termination resistor in speed dome is set to OPEN when only one

is connected console.

Select a proper protocol and corresponding baud rate for the controller. Be

sure both sides (camera and controller) have the same protocol and baud rate.

Connect to keyboard + monito

Connect to keyboard + MUX

. .

User’s manual 32

Page 33

R

Connect Speed dome to standalone DV

Connect the RS-485 of camera to controller (in this case, the DVR) with a pair of

twisted cable. Tele-control is conducted from the DVR via the cable between

the PTZ device and DVR.

Video signal from the dome is sent to DVR also, then forwarded to monitor

through the multiplexer inside the DVR. Usually RG59 A/U coaxial cable is

recommended for the video connection.

Power (DC12V or AC24V) shall be applied to the camera v ia separate DC or

AC adapter.

Set the termination resistor in speed dome to OPEN mode (disconnected) if

only one speed dome is connected console.

If two or more speed domes are in the system, the termination resistor of END

unit should be loaded (more information is in the next section).

Select a proper protocol and corresponding baud rate for the DVR. Be sure

both sides (PTZ camera and DVR) have the same protocol and baud rate.

In case the DVR does not have PTZ control function, use a separate

keyboard for the PTZ controlling. Protocol shall be properly selected, too.

. .

User’s manual 33

Page 34

r

Connect Speed dome to video serve

Video server, the contemporary device for transmitting video throughout LAN and

WAN, can also be the controlling tool for this speed dome camera.

Most video servers in market are built with RS-485 communication port, and single

video input for connecting one camera. To work with this PTZ camera, installer

must connect both signals (video and RS-485) from the server to the camera, as

the picture shown on below.

First of all, the camera ID should be kept on number “0” (zero) or 1 (one)

is linked to a video server, unless your video server requires different ID. Be sure

the RS-485 polarity is correctly handled. Once the connectivity is completed, start

the video server control panel on computer and follow the instructions on below

during the video server setup

when it

Choose Pelco D as the control protocol

choose RS-485 as the communication format

baud rate matches the setting in camera; “2400” is recommended

parity is set to “0” (zero) or “None”

Data bit is “8” (eight)

Stop bit is “1” (one)

You may conduct control to the speed dome after these are correctly set up. For

advanced functions, you must follow the instructions given by the video server

manual.

. .

User’s manual 34

Page 35

7.3 Connect two or more domes to console

As the RS-485 supports multi-drop topology, two or more domes can be connected

to one controller in a system. For such application, the following rules must be kept:

All the speed domes should be connected to host in daisy chain pattern. Star

type of configuration should be prohibited to avoid system instability.

Each dome must have unique ID so communication data can be delivered to

the correct target device.

Impedance-match setup is also required to keep communication quality.

Connect the other end of the cable to a phone jack box with extension outlet of

two. Installer must pay attention to the pins

connection is correct.

To connect more cameras, copy the same procedure on

above. You may continue extending the quantity of camera

to its maximum number of 128 per network, if the control

device has the capability of addressing that many ID..

of the extension box to ensure the

Extension box

The extension wire and box are available in general electronic and phone shops.

. .

User’s manual 35

Page 36

Connect Speed Dome and PC (Capture Card)

When PC is used as the console, installer needs to connect both of video

and RS-485 signals to PC separately.

Most capture cards have 4 video input per card, and normally each PC c an

handle 4 cards, meaning up to 16 cameras can be hooked to one PC.

Video: connect the camera video to the video-in of capture card.

RS-485: the RS-485 shall be connected to the RS-232 or USB port

through an signal converter. Refer to the previous section for

the establishment of the RS-485 network ( watch the

different ways of impedance setup for terminal device, for

single or multiple domes per network )

Power: camera’s power is to be connected locally with the

supplied DC or AC adapter.

. .

User’s manual 36

Page 37

8. Camera setup --- OSD functions

For the version with Power Zoom, many functions are available to users for setup

and fine tune through controllers. To access the functions and make adjustment,

follow the instructions on below:

(NOTE: all the procedure in this paragraph is NOT applied to the version of vari-focal lens)

8.1 OSD operation

1. To initiate the OSD setup function, exercise “preset 88” ( a simulated function

call) at keyboard. Due to the procedure may vary from one keyboard to

another, please read the keyboard manual first.

2. After menu is displayed, use up and down controls (joystick or arrow keys)

to locate the target item. The under-seized item will blink, and screen will

move to next or previous page if moving forward over the end.

3. When the item is captured, move joystick to the right-hand direction or press

the “right” button (normally is marked as ►) to confirm setting and update

memory, or enter the sub-menu.

4. To exit menu, move joystick to left-hand direction, or press the “left” button

(sometimes is marked as ◄) in each pag

5. To close the OSD control, exercise “call preset number 88” again.

Warning:

OSD setup and control are relatively sophisticated. T o make proper adjustments, it

is suggested to consult with the original installer or experienced technician.

In case of getting lost or mess in setting, find the “Default” option, activate it and

you will retrieve the factor settings and get back to the original status.

In the next page there will be more information about what are available for camera

setup through OSD, and how to do.

8.2 OSD function List

Total 30 items are included in the OSD menu. Each has two or multiple sub-items

for selection or adjustment. All functions are listed in the tables on next page:

. .

User’s manual 37

e.

Page 38

OSD functions list (1) OSD function list (2)

1 Camera ID Off

On On

2 SENSE UP 26 AF SLEEP Off

3 AISHUT AUTO. On

FIX. 27 SCALE Off

4 AES FIX.

AUTO.

5 BLC OFF

On

6 AGC 29 WINKER Off

7 WHITE BAL ATW.

AWB. 30 MISC H-REVERS

8 SYNC Off

On

9 ZOOM

10

DIGITAL ZOOM

11

FOCUS

12

AUTO FOCUS Off

On

13

POSITION LOAD.

SAVE.

ALARM

OSD

14

H-GAIN

15

V-GAIN

16

MOTION Off

On

17

IR Off

On

18

INITIAL Off

On

19

DEFAULT

OK

20

FREEZE Off

On

21

FREEZE MODE FIELD

FRAME

22

ZOOM SPEED

23

FOCUS SPEED

24

GAMMA GAMMA.1

GAMMA.2

Cancel

25

ZOOM+AF Off

On

LANGUAGE ENGLISH

28

DEUTSCH

ITALIANO

On

V-REVERS

POSI/NEGA

PRIORITY

MASK A

MASK B

. .

User’s manual 38

Page 39

8.3 OSD function description

1. Camera ID Î 2 sub-items

This is for setting up number or name for camera, providing the convenience

to user for distinguishing one camera from others by specific name.

Off is not used for putting the number or name on screen.

On is for giving the number or name to the camera.

Edit: When Edit is selected, the screen of string of 20 characters will be

display, ready for alpha-numeric setting. Push the joystick right-ward for

the second time will pop the alpha-numeric list for selection. The

character currently located is displayed on above of the line in larges

scale

2. Sense up Î is the abbreviation of sensitivity. It gives user the ability to set up

3. AISHUT Î Auto or Fix

4. AES Î Auto or Fix

. .

User’s manual 39

Position: is to choose the position for camera name to be displayed.

sensitivity for AGC function (AGC function is for controlling dynamic

headroom). 9 options are available in this item, with default of “OFF”.

Auto

When auto mode is chosen, there will be a number shown on the right

hand side of the word “Auto”. The number is the output level set for this

mode. If “Auto” is not the selected mode, then the number will not show,

and entering to the level adjustment will be prohibited.

To make adjustment, use up / down of joystick or arrow keys. Use visual

feedback from screen, which will change during the adjustment, until the

desired outcome is reached. Default level is +4.

Fix

Like the auto mode, the output level setting will be shown in the line of

this item on the screen. The adjustment procedure is the same as Auto

mode. Default level is also +4.

AES. AES means Auto-Electronic-Shuttle, which controls the CCD e xposure

in electronic way. It also has two optional modes of Auto and Fix. The longer

the exposure time is chosen (for instance, 1/100 is 8 times longer than

1/10000), the brighter the picture will be. However, it also takes the risk of

over-exposure in strong light environments.

Default is Fix mode and in OFF position, to obtain maximum exposure.

Page 40

5. BLC Î On or Off

Back-Light-Compensation, a function used for adjusting the e xposure level

automatically in the conditions that lens is facing strong spot light source,

which normally drives AES or AISHUT too much and cause object too dark.

Off :To utilize this function, turn it on with the ON/OFF selection firstly

On : BLC AREA, make proper mask to block the light source. To do that,

user must situate the lens to cover the target precisely

BLC LEVEL, choose an appropriate sensitivity for the function

6. AGC Î AGC stands for Automatic Gain Control. It maintains video level as

constant against variable input levels, therefore keeps the brightness of

image stable.

There are 9 optional levels of headroom for the AGC setting. Factory default

is set to the maximum level of 18dB which gives the maximum dynamic

headroom. The smaller number, while has less dynamic range, responds

faster to get stable image during the changes of brightness.

7. White BALÎ ATW / AWB and related adjustments

Color tone function is mainly about color temperature setup. Two options are

offered to users, with default of

ATW

ATW function, standing for Auto-Tracking-White balance, will monitor the

ambient color temperature and makes adjustment to the white balance of

video output automatically by the internal microprocessor. The operation

range of color temperature is from 2,500 to 9,500

User may decide the preferred color temperature with AT W le v el function.

ATW level allows user to choose more blue or more red the background is.

o

K.

AWB standing for Auto-White-Balance, is a conventional way which

requires a reference target in white color to be shot for white balancing. The

drawback of it is, if the color temperature keeps on changing, such

adjustment will be needed frequently. Like ATW, the AWB also provides

option to user for more blue or red.

For advanced color adjustments, use options R-Y and B-Y. Ho wever, these

will demand more practical experience, so it is suggested not to make such

change on these unless skilled advisor is available.

To switch between ATW and AWB, enter White Balance to make the change

. .

User’s manual 40

Page 41

8. SYNC Î On or Off

This is to give installer the option of using internal synchronization or external

(usually the AC24V).

Since this device does NOT work with AC voltage, always keep this in Off

mode.

9. Zoom Î 1~23 Times

To let user do zoom in and out. Usually this is replaced by hardware buttons

on control device

10. Digital Zoom Î On or Off

To set up digital zoom function, Factory default setting is OFF.

11. Focus Î

To let user make focus adjustment. Usually this is replaced by hardware

buttons on control device

12. Auto Focus Î On or Off

To enable or disable the Auto-Focus function. Factory setting is Off.

Î In low light condition

or when target to be focused is in low-contrast,

the auto-focus function may fail to deliver well focuse d image. In this case,

use manual focus controls on the controlling device

FOCUS-IN / FOCUS-OUT)

to obtain clear picture with visual judgment

(normally labeled as

13. Position Î (reserved function)

(The POSITION function is to let user to preset up to 64 groups of parameters like

zoom, focus…etc.)

14. H-gain Î

The enhancement function is for changing sharpness of the object contour by

controlling horizontal gain.

15. V-gain Î

The enhancement function is for changing sharpness of the object contour by

controlling vertical gain.

16. Motion Î On / Off, Area, Level, Time, OSD

Motion is the short word of “Motion Detection”, a function used for detecting

moving article in specific zone. Such detection is executed by digital signal

processor in the camera.

To engage it, turn on the DETECTION with the ON/OFF selection.

. .

User’s manual 41

Page 42

Secondly, make proper mask to block the light source. To do that, the

target area must be located precisely to cover the target zone.

rd

3

step is to choose an appropriate sensitivity for the function. This is an

important item, and the suggestion is to make test to the sensitivity

setting with various moving objects (particularly the size) in different

moving speeds, to avoid or reduce unnecessary faulty function.

th

4

step is to decide how long the alarm signal should be retained on

screen after an event is detected. Options are 10, 30 and 60 seconds.

The last item is to decide whether warning signal will be dis played on scr een

at event. This is set up with the OSD option

17. IR Î On or Off

To remove the IR cut filter and turn on the viewing capability in dark where is

IR illumination is provided

IR cut filer is commonly used in most color cameras in order to gain the

maximum quality of color image. However, the use of IR-cut filter also

prohibits CCD from receiving IR illumination – the light source that assists

camera to see in dark. Therefore, IR filter must be removed in dark to retrieve

camera’s visual ability in dark.

The function is in options of on and off.

18. Initial Î On or Off

When this function is set off, the control system will lock the zoom, focus and

iris in their current positions. Before the function is switched on again, control

panel will not make change to those. It is useful, for example, when making

continuous monitor with auto-pan

To change the setup, enter “initial” and select the wanted option. The lens

will perform a short journal of zooming when changing setting from OFF to

ON (not for process from ON to OFF).

19. Default Î OK or Cancel

This is to turn all settings to factory preset condition.

To retrieve defaults, first enter the “Default”, and choose “OK”. After the

function is activated, screen will turn into blue for few second and back to

live picture with factory settings.

Refer to the table in Appendix 2 for factory default value.

20. Freeze Î On or Off

Freeze function is used for grabbing and displaying a picture in still

condition.

. .

User’s manual 42

Page 43

21. Freeze mode Î Field / Frame

To choose whether a field or frame of picture shall be frozen.

22. Zoom speed

To choose the zooming speed. If fast zooming is desired, increase the zoom

speed. If more accurate image size is required, choose medium or lower

speed for zooming.

23. Focus speed

To tune focusing speed. Higher speed shall provide you a quicker stable

picture, while medium or lower focusing speed is for acquiring better

focusing in bad condition

(see related information in “Auto-Focus” on above).

24. Gamma Î Gamma 1 / Gamma 2

Gamma correction is to correct the brightness seen by the camera to match

the brightness displayed on monitor, which makes the monitor show the

correct level of contrast.

Gamma 1 has wider contrast range, good for most indoor conditions.

Gamma 2 has compressed contrast range, which is normally used in

outdoor where the light variation is very dynamic.

The default setting is Gamma 1.

25. Zoom+AF

This is to drive lens to carry out auto- focusing after making control of

zoom-in or zoom-out. However, this function is not the guarantee of the best

focusing result. Use manual focus control buttons on controller to fine tune

the focus on specific target.

(refer to “Auto-Focus” on above)

Default setting is the Off position

26. AF Sleep Î On or Off

The image change less than auto focus range in five minutes; the auto focus

will sleep in AF Sleep on mode. Then the image change more +-6dB than

auto focus range, the auto focus will wake up.

27. Scale

To switch the OSD function on or off

28. Language Î 3 sub-items

Three options of English, Deutsch and Italiano.

29. Winker Î On or Off

When winker is set on position, the round blinker will be display on the screen

of top-right, The blinker means the camera is in normal operation.

. .

User’s manual 43

Page 44

30. MISC Î

H-Revers Î On or Off

This is for turning picture from left to right, or called “Mirror”

To activate it, first enter the “H-reverse”, and choose “ON” in sub-menu.

V-Revers Î On or Off

This is for turning picture up side down, or called “Flip”

To activate it, first enter the “V-reverse”, and choose “ON” in sub-menu.

Posi/NEGA Î To change image to positive or negative mode

Priority Î is to choose the determining item between AGC (headroom )

and sensitivity for internal circuit to follow.

MASK A

Mask function is to provide privacy protection to special object. A rectangular

shadow in black color with programmable size will block the object

considered as privacy from being displayed on monitor or recorded by DVR.

This camera offers two masks --- MASK A and B. These two are identical in

function and operation, but can be set up and enable / disable separately.

To enable this function, first turn the function on by entering the sub-item

“MASK 1” and choosing ON.

nd

The 2

“H-position” and “V-position”.

The last step is to define the mask area, which is composed with the “H-size”

and “V-size”; Use joystick or arrow key to make up the shadow area.

step is to move the shadow to the position, with functions of

The “Connected” function appeared in sub-menu is to stick the mask in

proportion to the protected object(s) when object size is enlarged or

shrunk with zoom

function, or re-positioned with reverse functions.

MASK B

The secondary Mask function. Operation is the same as MASK A.

. .

User’s manual 44

Page 45

9. Pre-defined System Functions

Power-up action

After the power is first applied to a dome it will perform a self-test procedure. This

calibrates and checks the basic functions of the dome. External controls are

overruled during this self-test period.

After the self-test, the PTZ camera will be ready for control. If the device was

running the Auto-pan function before power was broken, the speed dome will

retrieve Auto Scan function until new control is given by an operator.

Tour group

The speed dome software automatically groups the first 16 presets into 4 tour

groups. i.e. presets 1 ~ 4 is owned by group 1; Preset number 5 to 8 belong to

group 2… etc.

When tour function is initiated, the P/T mechanism will start scanning automatically

around all the presets included in the group.

How to initiate tour function is subject to controllers.

. .

User’s manual 45

Page 46

10. Specification

Camera Module and Lens

CCD Manufacturer Sony

Resolution 480 TV lines

Size 1/4”

Image control OSD menu

Zoom Optical 23x

Digital 10x

Focal length 3.6 ~ 82.8 mm

Aperture size F 1.6 ~ 3.8

Light sensitivity Color mode 0.5 lux

Black / white 0.1 lux

Pan / Tilt Functions

PT driving system Stepping motors

Scan / Search Navigation range Pan 360

Tilt (90

Navigation speed 0.25 ~ 240

Preset Search 300

Preset Quantity Max to 64 positions

Dwell time 1 ~ 255 seconds

Tour group 4

o

per second

Auto-pan Yes

Communication RS-485

Protocol Pelco D, Pelco P,

Baud rate 2400, 4800, 9600

Camera ID 1 ~ 128

Miscellaneous

Video Format NTSC or PAL (optional)

Output Level 1.0 V (typical)

Alarm function Input 3 sets

Input level TTL 5V; Negative trigger

Output 1 set; NC / NO

Max. load of O/P port DC24V / 1A or AC120V / 0.5A

Connectivity Video BNC female

RS-485 Terminal block

Power DC input jack

Power consumption DC 12V / 1.5A

Operation Temperature -10 ~ 50℃

Humidity 20 ~ 85% RHD

. .

User’s manual 46

o

/ continuous

o

)+ auto-rotation (180o)

o

/ sec; programmable

Page 47

Storage Temperature -20℃ ~ 60℃

Humidity 20 ~ 100% RHD

Certification FCC, CE

Inside the box Dome camera 1 set

User’s manual 1 set

(Option)

Installation Kit Screw Pack 1 set

Installation base 1 piece

Plastic Housing for surface mount 1 piece

Metal bowl holder 1 piece

. .

User’s manual 47

Loading...

Loading...