Strona 1 z 11

User manual and operating instruction of

standard radial fans series : WPL, WPM, WPH

Imielin, lipiec 2014

Copyright by Planetfan Sp. z o.o. sp. k

User manual and operating instruction of standard centrifugal fans:

WPL, WPM, WPH

PLANETFAN Sp. z o.o. sp. k. Tel.: 32 225 88 81; 32 318 34 42 www.planetfan.pl

41-407 Imielin, ul. Przemysłowa 5 Fax: 32 225 88 85 e-mail: info@planetfan.pl

Strona 2 z 11

Producer:

Company name:

Adress:

Internet:

Customer service:

Fax:

PLANETFAN Sp. z o.o. sp. k.

ul. Przemysłowa 5, 41-407 Imielin

biuro@planetfan.pl, www.planetfan.pl

+48 32 225 88 94

+48 32 318-34-42

+48 32 225-88-85

Distribution:

Thank you for purchasing product of Planetfan Sp. z o.o. sp. k.

Before installing and starting up the fan, please read the user's manual installation of fans. Following

the guidance and recommendations of this manual will allow for safe and trouble-free use of the

delivered product.

User manual and operating instruction of standard centrifugal fans:

WPL, WPM, WPH

PLANETFAN Sp. z o.o. sp. k. Tel.: 32 225 88 81; 32 318 34 42 www.planetfan.pl

41-407 Imielin, ul. Przemysłowa 5 Fax: 32 225 88 85 e-mail: info@planetfan.pl

Strona 3 z 11

Spis treści

1. INTRODUCTION ............................................................................................................................................ 4

1.1. SYMBOLS USED IN THE INSTALLATION MANUAL OF STANDARD FANS PLANETFAN 4

1.2. INTRODUCTION TO INSTALLATION 4

1.3. ERP DIRECTIVE 5

2. SAFETY. ......................................................................................................................................................... 5

3. TECHNICAL DATA, PRODUCT DESCRIPTION, FLOW PARAMETERS ............................................... 5

3.1. DESCRIPTION OF PRODUCTS. 5

3.2. DELIVERY / PACKAGING, COLLECTION / TRANSPORT AND STORAGE. 6

4. INSTALLATION, ELECTRICAL CONNECTION ......................................................................................... 6

4.1. FAN INSTALLATION 6

5. START UP ...................................................................................................................................................... 7

5.1. FIRST START UP 8

6. OPERATION / MAINTENANCE. .................................................................................................................. 8

WHILE THE FAN IS WORKING IT IS ABSOLUTELY FORBIDDEN TO PERFORM ANY WORK WITHIN

THE ROTOR AND MOTOR. ................................................................................................................................. 8

7. TROUBLESHOOTING ................................................................................................................................... 9

8. SPARE PARTS .............................................................................................................................................. 9

9. HANDLING AFTER OPERATION ................................................................................................................ 9

10. DECLARATION OF CONFORMITY. .......................................................................................................... 10

11. WARRANTY. ................................................................................................................................................ 11

User manual and operating instruction of standard centrifugal fans:

WPL, WPM, WPH

PLANETFAN Sp. z o.o. sp. k. Tel.: 32 225 88 81; 32 318 34 42 www.planetfan.pl

41-407 Imielin, ul. Przemysłowa 5 Fax: 32 225 88 85 e-mail: info@planetfan.pl

Strona 4 z 11

1. INTRODUCTION

1.1. Symbols used in the installation manual of standard fans produced by Planetfan

Caution! Preliminary safety and preparation of equipment for installation and operation of the

installation instructions standard fans Planetfan.

Caution! Electrical device, install the device by qualified personnel. Connecting accordance with the

instructions or performed by unqualified personnel may result in electric shock.

Caution! Rotating device - rotor does not stop immediately after switching off the device. Before

maintenance work, make sure that the rotating parts are not moving, and whether the device is

disconnected from the power supply.

The company Planetfan Sp. o.o. sp. k. is not responsible for any damages caused by improper assembly,

installation, operation or maintenance contrary to the instructions below standard installation of fans

Planetfan.

1.2. Introduction to installation

Centrifugal fans series WPL, WPM, WPH has been designed for industrial use in general and local

ventilation systems. Fans are intended to pump fresh air at a temperature of -20 to + 40 ° C. Fans may run

in duct systems with connected channels for suction and discharge sides. In the case of installation of the

fan with a free inlet or outlet it must be protected from getting into the zone of the working rotor foreign

bodies. Fans WPL, WPM, WPH are designed as standard to draw fresh air from the ambient air and

discharge it into the channel connected on the outlet side. Fans series WPL, WPM, WPH can be made in

two versions: stationary - marking WPL, WPM, WPH and mobile - marking WPL, WPM, WPH ... /./ M. The

mobile version is equipped with wheels for easy transportation of the fan between the positions of work.

If you need to connect the channel on the suction side the fan should be equipped with an additional fan

tailpiece available as an option from the manufacturer of the fan. Fans WPL, WPM, WPH normally are

protected against corrosion by powder painting. Optionally, the fan can be made of galvanized steel.

This manual contains information and notes for the safe installation and commissioning of the fan.

Installation instructions do not take into account local conditions, laws and regulations, compliance with

which is the responsibility of the user.

Centrifugal fans type: WPL, WPM, WPH do not belong to the ready-to-use products are developed

only in the form of components, equipment of ventilation systems. Fans can be operated only when

installed in accordance with their intended purpose.

Do not use the above mentioned fans in places with high humidity entrusted to above 80% at 20°C, the air

with particles of high-viscosity liquids (edible oils, lubricants, etc.), caustic gases or gases, vapors, dust that

can create an explosive atmosphere.

The fans can be installed in facilities located at a height of up to 1000 [m] above sea level.

CAUTION! It is forbidden to place any objects on the fan.

You can adjust the performance of radial fan with the dampers on ducts intake or discharge of fan. Adjusting

the throttle should not result in unstable operation of the fan in terms of flow.

CAUTION! Fans can be operated only if they have been installed in accordance with their purpose and

security is guaranteed by the use of security according to EN13857 or other building protective measures.

User manual and operating instruction of standard centrifugal fans:

WPL, WPM, WPH

PLANETFAN Sp. z o.o. sp. k. Tel.: 32 225 88 81; 32 318 34 42 www.planetfan.pl

41-407 Imielin, ul. Przemysłowa 5 Fax: 32 225 88 85 e-mail: info@planetfan.pl

Strona 5 z 11

1.3. ErP Directive

Due to the EU Commission Regulation No. 327/2011 of 30 March 2011 in order to implement Directive

2009/125 / EC, the scope of some fans in the EU is associated with certain conditions. The fan can be

used in the EU only if they are satisfied for him ErP requirements of the Regulation. If the fan does not

have the CE marking is not approved for use in the EU.

2. SAFETY.

CAUTION! The electrical connection must be made by qualified personnel in accordance with these

instructions and applicable regulations.

Observe the instructions for operating the motor issued by the motor manufacturer, which is attached to the

delivery.

Before starting any electrical work related to the fan motor, junction box, and in particular the protective

covers against direct contact with live parts, make sure the device is properly disconnected from the power

supply voltage. Moreover, all additional and support circuits should also be disconnected.

CAUTION! Before connecting, make sure that the voltage and frequency of the mains correspond to the

data on the rating plates. In the case of non-compliance, do not connect the device.

CAUTION! The fan is a rotating device - impeller does not stop immediately after switching off the device.

Before maintenance work, and in particular against touching the rotating elements, make sure the device

is not working properly and that it is disconnected from the power supply voltage.

CAUTION! Before fitting the fan, make sure that the safety distances are maintained according to

EN13857. If the fan is located in the area of threats, the manufacturer of the installation or the user must

ensure that the protection / example. safety nets / both at an inlet side and an outlet to eliminate the threat.

Security elements of the fan, protective devices may not be dismantled, circumvented or denied their

functions. Failure can cause injury damage to the fan or installation.

CAUTION! Centrifugal fans standard series: WPL, WPM, WPH cannot be operated in the explosive

atmosphere - the danger of ignition and explosion hazard!

3. TECHNICAL DATA, PRODUCT DESCRIPTION, FLOW PARAMETERS

Detailed flow data of supplied fan are shown in the Certificate of Quality Control.

For fans series: WPL, WPM, WPH to determine the energy efficiency category measuring B category

performance has been used: total. In the calculation of the efficiency of the fan does not include the use of

the control system of rotation, this unit is not a part of the fan structure.

3.1. Description of products.

Centrifugal standard fan series: WPL, WPM, WPH consist of the following elements:

- Impeller, - motor, - steel casing.

Fans can operate in temperatures ranging from -20 to + 40 ° C, optionally up to + 60 ° C.

Used motors have degree of protection IP54 or IP55.

Rotors of all fans are dynamically balanced in class G6.3 according to PN-N-01359: 1993.

Used motors: three-phase.

Any information regarding the type of fan, power supply, motor power, year of manufacture are indicated

on the rating plate of the fan.

User manual and operating instruction of standard centrifugal fans:

WPL, WPM, WPH

PLANETFAN Sp. z o.o. sp. k. Tel.: 32 225 88 81; 32 318 34 42 www.planetfan.pl

41-407 Imielin, ul. Przemysłowa 5 Fax: 32 225 88 85 e-mail: info@planetfan.pl

Strona 6 z 11

The fan is made with standard outlet of rectangular cross section. In the case of the need to connect the

circular duct should be installed special connector on the outlet that meets the connection dimensions.

Such connectors are not in the standard delivery, these elements represent the standard offer

manufacturers of ventilation ducts.

3.2. Delivery / packaging, collection / transport and storage.

Fans and accessories are supplied in boxes, pallets EURO or on special pallets adapted to the dimensions

of the product. In the case of delivery of products on pallets wrapped in protective foil.

Receipt of goods / transport.

- During transportation, loading and unloading, observe safety rules in the field of personal protective

equipment (shoes and gloves) and safety rules governing the manual handling and mechanical (information

on the weight of the fan on the nameplate!).

- Before commissioning, make sure that the packaging of the fan is not damaged. If you notice any damage

to the packaging - must file a complaint with a company that provided transport service and notify the

manufacturer. After unpacking, make sure the fan was not damaged during transport. Each fan is

recommended to unpack in the presence of the driver of the transport company. If you notice any damage,

report it to the driver and noted in the letter forwarding the transport company and contact the manufacturer

of the fan.

If in doubt, do not use the device. You should contact the manufacturer.

- Fans are transported in the assembled state. Each delivery is accompanied by fan documentation. The

recipient is obliged to check compliance with the delivery documentation.

- Avoid impacts and shocks.

Storage.

- Fans should be stored under cover in a dry place, preferably in the warehouse adapted for storage of

industrial products.

- The fan should be stored in its original packaging, so as not to affect its functional properties and

performance.

- Avoid exposure to extreme heat and cold.

- Avoid too long period of storage, follow the recommendations of the motor manufacturer.

- Each time before starting the buildings and the user must check the correct mounting of the motor and

the rotor inside the fan housing.

4. Installation, electrical connection

4.1. Fan installation

Centrifugal fans type: WPL, WPM, WPH are not ready-to-use products. These are industrial products

manufactured on the basis of the customer's order, they can be operated only when installed as intended.

Keep in mind that:

- You have to follow the safety instructions, also in the field of personal protective equipment,

- Manufacturer of ventilation system is responsible for the compliance of the typical installation instructions

and safety regulations in accordance with current norm.

- Before installing the fan at the final destination, check that the fan has not been damaged during

transport, paying particular attention to the fan propeller: slightly rotate impeller inside the casing and check

whether the impeller blades do not touch the fan casing, then check the equal gap between the blade tip

and the casing . You should also pay attention to any obstacles in the inlet and outlet, if so remove it.

- Fan must be mounted the without any additional stresses, paying attention to the correct direction of

rotation and flow direction according to the arrows located on the fan casing. Install the fan using screws in

strength class 8.8. Permissible tightening torques: M6 = 9,5Nm, M8 = 23 Nm, M10 = 47Nm, M12 = 81 Nm.

The fan is not equipped with a plug for direct plugging into the power supply. The power cables must be

connected to the terminals on the motor in a place of installation. Pay attention to the proper selection of

cables. When installed cable is long with a small cross-section it may cause the drop of tensions hindering

motor starting.

When connecting rigid or flexible duct, remember not to add any additional load to the fan inlet/ outlet

connectors.

User manual and operating instruction of standard centrifugal fans:

WPL, WPM, WPH

PLANETFAN Sp. z o.o. sp. k. Tel.: 32 225 88 81; 32 318 34 42 www.planetfan.pl

41-407 Imielin, ul. Przemysłowa 5 Fax: 32 225 88 85 e-mail: info@planetfan.pl

Strona 7 z 11

CAUTION! Each motor must be protected against overload and short circuit with appropriate safety device

chosen by the installer in accordance with PN-89 / E-05012.

Do not use the motor without neutralization or without earthing system, as this may cause electric shock

and can lead to accumulation of dangerous electrostatic charges on the propeller blades.

CAUTION! In case of free inlet use the fan inlet guard protection!

In case when the fan is mounted at the beginning or end of the ventilation system to avoid any unwanted

object getting to the working space of impeller also use guard protection. The decision to mount safety

guards is the responsibility of the installer.

4.2. Electrical connection

All work associated with connecting the fan should be conducted by trained professionals, adhering to

regulations and safety rules.

Before connecting the motor the data connection has to be compared to the information on the nameplate

of the fan. 3-phase motors connected to 3 phases with phase to phase voltage U = 400V, 50Hz, according

to the connection diagram section on the motor terminal box and the motor manufacturer's instructions

contained in the Manual of the motor.

Check the standard wiring diagrams below.

4.2.1. Connection of 3-phase motor.

3-phase motor must be connected according to information provided on the nameplate of the fan motor.

The standard single speed motors are connected in either star or delta. Connection diagrams below.

Delta Star

CAUTION!

Exceeding the maximum allowable RPM (round per minute) of fan it is prohibited.

5. START UP

Before starting, check that:

the impeller rotates freely without friction,

fan is properly installed and adjusted,

fan is properly connected to the mains,

motor is electrically protected by:

• overload protection,

• short circuit protection,

• neutralization or protective earth,

elements have been installed to prevent direct touch moving parts and are under the voltage,

all electrical connections, mounting screws and connecting elements are properly adjusted and

tightened,

residual fixing and other foreign bodies were removed from the interior of the fan.

Commissioning can take place only after checking all safety hazards and exclusion.

W2

U2

V2

U1

V1

W1

L1

L2

L3

PE

W2

U2

V2

U1

V1

W1

L1

L2

L3

PE

User manual and operating instruction of standard centrifugal fans:

WPL, WPM, WPH

PLANETFAN Sp. z o.o. sp. k. Tel.: 32 225 88 81; 32 318 34 42 www.planetfan.pl

41-407 Imielin, ul. Przemysłowa 5 Fax: 32 225 88 85 e-mail: info@planetfan.pl

Strona 8 z 11

CAUTION!

It should be noted that the permissible fluctuations in input voltage for 3-phase motor is no greater than

+/- 10% of nominal voltage.

5.1. First start-up

Turn on temporarily fan to verify the correct direction of rotation, and thus the correct direction of air flow.

When during this test the motor shaft rotates in the opposite direction to a predetermined, in three-phase

motors change two phase conductors in single-phase motors is needed to change places bridges

according to the attached diagram.

After starting the fan, check that the current consumption does not exceed the rated value shown on the

nameplate of the motor. You should also pay attention to the smooth operation of the fan. Strong vibrations

due to unstable work / unbalance / caused for instance by damage during transportation, may cause

damage to the fan and / or motor.

CAUTION!

It is not allowed to operate the fan in the opposite direction to that intended. Such operation is incorrect

and may cause damage to the fan. Such damage is not considered as a warranty claim.

5.2. Quiet and stable work

When installing the fan on the floor, use the appropriate mounting lugs, frame or in the case of higher

powers - concrete foundations. When the fan is equipped with a motor - mounting position IM B3 - should

always be placed horizontally to the ground and the motor resting on the base. The use of dampers is

permitted for fixing the legs to fan frames / floors / ceilings.

6. OPERATION / MAINTENANCE.

While the fan is working it is absolutely forbidden to perform any work within the rotor and motor.

Before maintenance work, perform the following steps:

- check whether the impeller is not rotating,

- make sure that the power supply was cut off electric motor,

- remove the fan from the place where it is operated,

- transport fans to the place where the service work is carried out,

- service work to be performed only by trained personnel.

- follow the rules and safety standards.

It is recommended:

- once per quarter to control construction of the fan to detect symptoms of possible irregularities, in order

to avoid any serious fault,

- Once every 6 months to check if there are mechanical vibrations. The maximum allowable vibration

velocity is 2.8 mm / s / according to DIN ISO 10816-1 /,

- Maintenance of the motor, including the replacement of motor bearings in accordance with the

manufacturer's motor technical data - the information in the manual of motors.

Impellers are made of steel and are protected against corrosion by painting. In case of getting into the fan

dust or abrasive materials such as sand which can lead to premature removal of surface protection of the

rotor, prevent corrosion of the rotor by painting. It should be remembered that after dismounting and

remounting of the impeller, it is necessary to re-balance in accordance with PN-N-01359!

Operations rely on to clean the entire device. Regular inspections are necessary for any deposits to prevent

unbalancing the rotor. The frequency depends on the degree of contamination of the fan impeller. The

entire fan can be cleaned with a damp cloth. You cannot use any aggressive cleaning agents, which could

cause the dissolution of the paint. For cleaning do not use pressure washer or a strong stream of water.

CAUTION! Wet cleaning of the fan can cause electric shock - mortal danger!

User manual and operating instruction of standard centrifugal fans:

WPL, WPM, WPH

PLANETFAN Sp. z o.o. sp. k. Tel.: 32 225 88 81; 32 318 34 42 www.planetfan.pl

41-407 Imielin, ul. Przemysłowa 5 Fax: 32 225 88 85 e-mail: info@planetfan.pl

Strona 9 z 11

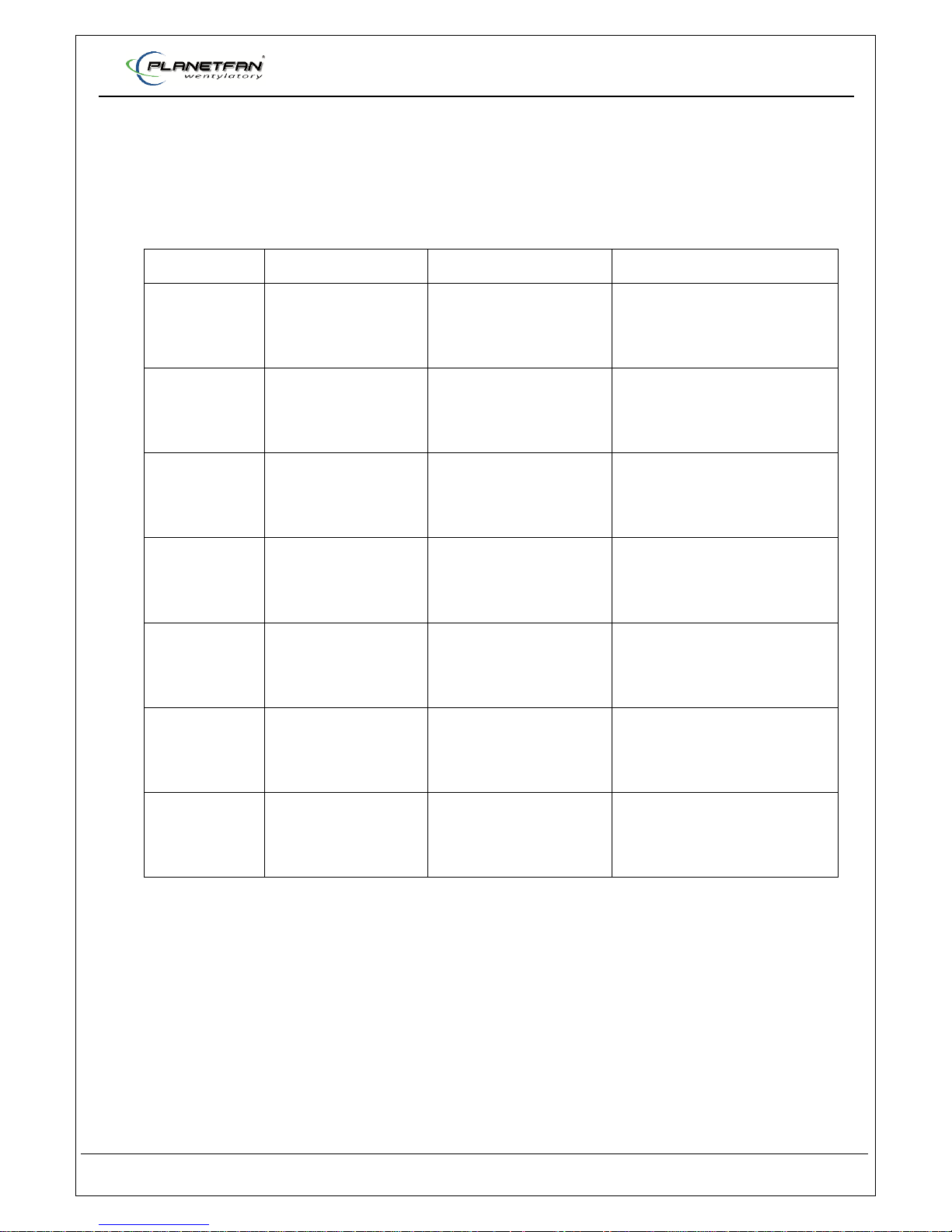

7. Troubleshooting

Radial Fans series: WPL, WPM, WPH

Lp.

Problem/ status:

Solution

1

The is a voltage on fan casing.

Immediately turn off the fan, check the

correct connection of neutralization or

earthing system.

Earthing system - ok, correctly connected

power supply – still there is a voltage on the fan

casing.

Immediately turn off the fan Disconnect

from the main power supply to protect

against accidental turning on. Contact

the manufacturer.

2

The fan is not working after connecting the

power supply.

Check the input terminals.

The fan is not working – there is a voltage on the

input terminals.

3-phase motor, check the correct

connection of the motor.

The fan is still not working.

Contact the manufacturer.

3

The fan is operating - the airflow direction other

than the required flow and motor rpm

incompatible with the arrows on the housing.

Change the direction of rotation of the

rotor in accordance with the wiring

diagram of the motor.

4

The fan generates high vibrations.

Check the impeller blades for the

presence of raid. If yes, remove the raid

from the blades.

No raid on the blades – check the

motors bearings.

The fan generates high vibrations, no raid on the

blades

Check the motor bearings (axial and

radial play).

5

Impeller rubs against the housing

Make sure that the casing has not been

damaged.

6

Impeller rubs against the housing. Casing is not

damaged.

Change the position of inlet element.

7

Impeller rubs against the housing

Contact the manufacturer.

8

Fan casing is damaged.

Contact the manufacturer.

9

Impeller blade is damaged

Contact the manufacturer.

10

Missing blades in the impeller

Contact the manufacturer.

8. SPARE PARTS

Components such as rotors, casings, motors, which are parts of the fans are available from the

manufacturer. To order the appropriate parts the type of fan and its serial number shall be given.

9. HANDLING AFTER OPERATION

Disposal must be carried out in a proper and environmentally friendly in accordance with the law.

User manual and operating instruction of standard centrifugal fans:

WPL, WPM, WPH

PLANETFAN Sp. z o.o. sp. k. Tel.: 32 225 88 81; 32 318 34 42 www.planetfan.pl

41-407 Imielin, ul. Przemysłowa 5 Fax: 32 225 88 85 e-mail: info@planetfan.pl

Strona 10 z 11

mgr inż. Daniel Komraus

Prezes Zarządu Komplementariusza

Component Name, detail

Where to go

Metal casing, hub, protection guard, fasteners,

steel rotor

Iron scrab

Aluminum hubs, aluminium rotors, aluminium

parts of motors

Aluminum scrab – after melting

Cast-iron elements (casing, bearing discs,

covering, etc.)

Cast-iron scrab

Steel parts of motor (shaft, ventilating fan,

fasteners)

Steel scrab

Motor bearings

Steel scrab after grease removal (grease

disposal in specialized company)

Winding, cables

Copper scrap (removal and disposal of

insulation in a specialized company)

Cable inserts

Ferrous metals scrap

Rubber parts (gaskets, rings)

Disposal in specialized company

10. DECLARATION OF CONFORMITY.

The company Planetfan Sp. o.o. sp. k. declares that the following equipment meet the requirements of both

health and safety requirements set out in standards and EU directives. Devices that built these products should

have a declared compliance with the provisions of this Directive. Please also note that any interference buyer

products without consulting the manufacturer is synonymous with the loss of validity of this document.

Description of equipment:

10.1. Radial fan series: WPL, WPM, WPH

The above-described products are in accordance with:

Dokument nr

Title

1.

2006/42/WE

Directive of the European Parliament and of the Council on machinery.

17th of May 2006 r. (UE L 157/24).

2.

PN-EN 602041:2010

Safety of machinery - Electrical equipment of machines - Part 1: General

requirements.

3.

PN-M-43011:1992

Fans. Classification and Terminology.

4.

PN-EN ISO

12100:2011

Safety of machinery - General principles for design - Risk assessment and risk

reduction.

5.

PN-EN ISO

5801:2008

Industrial fans - Study of the performances of the standard positions

6.

PN-EN ISO

13351:2010

Fans - Dimensions.

7.

PN-M-43023:1997

Fans. Nameplates and directional.

8.

PN-EN 600341:2011

Rotating electrical machines - Part 1: Rating and performance

Imielin, 01.07.2014r.

Certifies compliance as above:

User manual and operating instruction of standard centrifugal fans:

WPL, WPM, WPH

PLANETFAN Sp. z o.o. sp. k. Tel.: 32 225 88 81; 32 318 34 42 www.planetfan.pl

41-407 Imielin, ul. Przemysłowa 5 Fax: 32 225 88 85 e-mail: info@planetfan.pl

Strona 11 z 11

11. WARRANTY.

Planetfan Sp. o.o. sp. k. The warranty on the products delivered for a period of 12 months from the date of

sale.

Serial number

Purchase date

Signature and stamp of

the seller

Fault description

Loading...

Loading...