Page 1

Page 2

User’s Manual of IGSW-24040T

Trademarks

Copyright © PLANET Technology Corp. 2016.

Contents are subject to revision without prior notice.

PLANET is a registered trademark of PLANET Technology Corp. All other trademarks belong to their respective owners.

Disclaimer

PLANET Technology does not warrant that the hardware will work properly in all environments and applications, and makes no

warranty and representation, either implied or expressed, with respect to the quality, performance, merchantability, or fitness for

a particular purpose. PLANET has made every effort to ensure that this User's Manual is accurate; PLANET disclaims liability

for any inaccuracies or omissions that may have occurred.

Information in this User's Manual is subject to change without notice and does not represent a commitment on the part of

PLANET. PLANET assumes no responsibility for any inaccuracies that may be contained in this User's Manual. PLANET makes

no commitment to update or keep current the information in this User's Manual, and reserves the right to make improvements to

this User's Manual and/or to the products described in this User's Manual, at any time without notice.

If you find information in this manual that is incorrect, misleading, or incomplete, we would appreciate your comments and

suggestions.

FCC Warning

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC

Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated

in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and

used in accordance with the Instruction manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in which case the user will be required to correct the

interference at his own expense.

CE Mark Warning

This is a Class A product. In a domestic environment, this product may cause radio interference, in which case the user may be

required to take adequate measures.

Energy Saving Note of the Device

This power required device does not support Standby mode operation. For energy saving, please remove the power cable to

disconnect the device from the power circuit. In view of saving the energy and reducing the unnecessary power consumption, it

is strongly suggested to remove the power connection for the device if this device is not intended to be active.

WEEE Warning

To avoid the potential effects on the environment and human health as a result of the presence of

hazardous substances in electrical and electronic equipment, end users of electrical and electronic

equipment should understand the meaning of the crossed-out wheeled bin symbol. Do not dispose of

WEEE as unsorted municipal waste and have to collect such WEEE separately.

Revision

User's Manual of PLANET Industrial L2+ Multi-port Full Gigabit Managed Switch

FOR MODEL: IGSW-24040T

REVISION: 3.0 (March, 2016)

Part No: EM-IGSW-24040T_v3.0

2

Page 3

User’s Manual of IGSW-24040T

TABLE OF CONTENTS

1. INTRODUCTION..................................................................................................................10

1.1 Packet Contents.........................................................................................................................................10

1.2 Product Description...................................................................................................................................11

1.3 How to Use This Manual............................................................................................................................15

1.4 Product Features........................................................................................................................................16

1.5 Product Specifications ..............................................................................................................................19

2. INSTALLATION ................................................................................................................... 22

2.1 Hardware Description................................................................................................................................22

2.1.1 Physical Dimensions ...........................................................................................................................................22

2.1.2 Front Panel ..........................................................................................................................................................22

2.1.3 LED Indications ...................................................................................................................................................25

2.1.4 Wiring the AC Power Input...................................................................................................................................26

2.1.5 Wiring the DC Power Input ..................................................................................................................................27

2.1.6 Wiring the Faulty Alarm Contact ..........................................................................................................................28

2.1.7 Wiring the Digital Input/Output.............................................................................................................................29

2.2 Installing the Managed Switch..................................................................................................................32

2.2.1 Desktop Installation .............................................................................................................................................32

2.2.2 Rack Mounting.....................................................................................................................................................33

2.3 Cabling ........................................................................................................................................................34

2.3.1 Installing the SFP Transceiver .............................................................................................................................36

2.3.2 Removing the Module..........................................................................................................................................38

3. SWITCH MANAGEMENT.................................................................................................... 40

3.1 Requirements..............................................................................................................................................40

3.2 Management Access Overvi ew.................................................................................................................41

3.3 CLI Mode Management..............................................................................................................................42

3.4 Web Management.......................................................................................................................................44

3.5 SNMP-based Network Management.........................................................................................................45

3.6 PLANET Smart Discovery Utility ..............................................................................................................46

3

Page 4

User’s Manual of IGSW-24040T

4. WEB CONFIGURATION...................................................................................................... 48

4.1 Main Web page ...........................................................................................................................................51

4.2 System.........................................................................................................................................................53

4.2.1 System Information..............................................................................................................................................54

4.2.2 IP Configuration...................................................................................................................................................55

4.2.3 IP Status ..............................................................................................................................................................57

4.2.4 Users Configuration .............................................................................................................................................58

4.2.5 Privilege Levels ...................................................................................................................................................61

4.2.6 NTP Configuration ...............................................................................................................................................63

4.2.7 Time Configuration ..............................................................................................................................................64

4.2.8 UPnP ...................................................................................................................................................................65

4.2.9 DHCP Relay ........................................................................................................................................................67

4.2.10 DHCP Relay Statistics .......................................................................................................................................68

4.2.11 CPU Load ..........................................................................................................................................................70

4.2.12 System Log........................................................................................................................................................71

4.2.13 Detailed Log ......................................................................................................................................................72

4.2.14 Remote Syslog ..................................................................................................................................................73

4.2.15 SMTP Configuration ..........................................................................................................................................74

4.2.16 Digital Input/Output ............................................................................................................................................75

4.2.17 Fault Alarm ........................................................................................................................................................77

4.2.18 Web Firmware Upgrade.....................................................................................................................................78

4.2.19 TFTP Firmware Upgrade ...................................................................................................................................79

4.2.20 Save Startup Config...........................................................................................................................................80

4.2.21 Configuration Download ....................................................................................................................................80

4.2.22 Configuration Upload .........................................................................................................................................81

4.2.23 Configuration Activate........................................................................................................................................81

4.2.24 Configuration Delete ..........................................................................................................................................82

4.2.25 Image Select......................................................................................................................................................82

4.2.26 Factory Default ..................................................................................................................................................83

4.2.27 System Reboot ..................................................................................................................................................84

4.3 Simple Network Management Protocol....................................................................................................85

4.3.1 SNMP Overview ..................................................................................................................................................85

4.3.2 SNMP System Configuration ...............................................................................................................................86

4.3.3 SNMP Trap Configuration....................................................................................................................................88

4.3.4 SNMP System Information ..................................................................................................................................90

4.3.5 SNMPv3 Configuration ........................................................................................................................................91

4.3.5.1 SNMPv3 Communities ..............................................................................................................................91

4.3.5.2 SNMPv3 Users ..........................................................................................................................................92

4.3.5.3 SNMPv3 Groups........................................................................................................................................93

4

Page 5

User’s Manual of IGSW-24040T

4.3.5.4 SNMPv3 Views..........................................................................................................................................94

4.3.5.5 SNMPv3 Access........................................................................................................................................95

4.4 Port Management.......................................................................................................................................97

4.4.1 Port Configuration................................................................................................................................................97

4.4.2 Port Statistics Overview.......................................................................................................................................99

4.4.3 Port Statistics Detail...........................................................................................................................................100

4.4.4 SFP Module Information ....................................................................................................................................102

4.4.5 Port Mirror..........................................................................................................................................................103

4.5 Link Aggregation......................................................................................................................................106

4.5.1 Static Aggregation..............................................................................................................................................108

4.5.2 LACP Configuration ...........................................................................................................................................109

4.5.3 LACP System Status ......................................................................................................................................... 111

4.5.4 LACP Port Status...............................................................................................................................................112

4.5.5 LACP Port Statistics........................................................................................................................................... 113

4.6 VLAN..........................................................................................................................................................114

4.6.1 VLAN Overview ................................................................................................................................................. 114

4.6.2 IEEE 802.1Q VLAN ........................................................................................................................................... 115

4.6.3 VLAN Port Configuration ...................................................................................................................................118

4.6.4 VLAN Membership Status..................................................................................................................................124

4.6.5 VLAN Port Status...............................................................................................................................................125

4.6.6 Private VLAN .....................................................................................................................................................126

4.6.7 Port Isolation......................................................................................................................................................128

4.6.8 VLAN setting example: ......................................................................................................................................130

4.6.8.1 Two Separate 802.1Q VLANs..................................................................................................................130

4.6.8.2 VLAN Trunking between two 802.1Q aware switches .............................................................................132

4.6.8.3 Port Isolate .............................................................................................................................................. 135

4.6.9 MAC-based VLAN .............................................................................................................................................136

4.6.10 Protocol-based VLAN ......................................................................................................................................138

4.6.11 Protocol-based VLAN Membership..................................................................................................................140

4.7 Spanning Tree Protocol...........................................................................................................................141

4.7.1 Theory ...............................................................................................................................................................141

4.7.2 STP System Configuration ................................................................................................................................147

4.7.3 Bridge Status .....................................................................................................................................................149

4.7.4 CIST Port Configuration.....................................................................................................................................150

4.7.5 MSTI Priorities ...................................................................................................................................................153

4.7.6 MSTI Configuration............................................................................................................................................154

4.7.7 MSTI Ports Configuration ..................................................................................................................................155

4.7.8 Port Status.........................................................................................................................................................157

5

Page 6

User’s Manual of IGSW-24040T

4.7.9 Port Statistics.....................................................................................................................................................158

4.8 Multicast....................................................................................................................................................159

4.8.1 IGMP Snooping ................................................................................................................................................. 159

4.8.2 Profile Table .......................................................................................................................................................163

4.8.3 Address Entry ....................................................................................................................................................164

4.8.4 IGMP Snooping Configuration ...........................................................................................................................165

4.8.5 IGMP Snooping VLAN Configuration.................................................................................................................167

4.8.6 IGMP Snooping Port Group Filtering .................................................................................................................169

4.8.7 IGMP Snooping Status ......................................................................................................................................170

4.8.8 IGMP Group Information....................................................................................................................................171

4.8.9 IGMPv3 Information...........................................................................................................................................172

4.8.10 MLD Snooping Configuration........................................................................................................................... 173

4.8.11 MLD Snooping VLAN Configuration.................................................................................................................174

4.8.12 MLD Snooping Port Group Filtering.................................................................................................................176

4.8.13 MLD Snooping Status......................................................................................................................................177

4.8.14 MLD Group Information ...................................................................................................................................178

4.8.15 MLDv2 Information ..........................................................................................................................................179

4.8.16 MVR (Multicast VLAN Registration).................................................................................................................180

4.8.17 MVR Status......................................................................................................................................................183

4.8.18 MVR Groups Information .................................................................................................................................184

4.8.19 MVR SFM Information .....................................................................................................................................185

4.9 Quality of Service.....................................................................................................................................186

4.9.1 Understanding QoS ...........................................................................................................................................186

4.9.2 Port Policing ......................................................................................................................................................187

4.9.3 Port Classification..............................................................................................................................................188

4.9.4 Port Scheduler...................................................................................................................................................190

4.9.5 Port Shaping......................................................................................................................................................191

4.9.5.1 QoS Egress Port Schedule and Shapers ................................................................................................192

4.9.6 Port Tag Remarking ...........................................................................................................................................194

4.9.6.1 QoS Egress Port Tag Remarking............................................................................................................. 195

4.9.7 Port DSCP .........................................................................................................................................................196

4.9.8 DSCP-based QoS .............................................................................................................................................198

4.9.9 DSCP Translation ..............................................................................................................................................199

4.9.10 DSCP Classification.........................................................................................................................................200

4.9.11 QoS Control List...............................................................................................................................................201

4.9.11.1 QoS Control Entry Configuration ...........................................................................................................203

4.9.12 QCL Status ......................................................................................................................................................205

4.9.13 Storm Control Configuration ............................................................................................................................207

4.9.14 QoS Statistics ..................................................................................................................................................208

6

Page 7

User’s Manual of IGSW-24040T

4.9.15 Voice VLAN Configuration ...............................................................................................................................209

4.9.16 Voice VLAN OUI Table..................................................................................................................................... 211

4.10 Access Control List................................................................................................................................212

4.10.1 Access Control List Status ...............................................................................................................................212

4.10.2 Access Control List Configuration ....................................................................................................................214

4.10.3 ACE Configuration ...........................................................................................................................................216

4.10.4 ACL Ports Configuration ..................................................................................................................................226

4.10.5 ACL Rate Limiter Configuration .......................................................................................................................228

4.11 Authentication.........................................................................................................................................229

4.11.1 Understanding IEEE 802.1X Port-based Authentication .................................................................................. 230

4.11.2 Authentication Configuration ............................................................................................................................233

4.11.3 Network Access Server Configuration..............................................................................................................234

4.11.4 Network Access Overview ...............................................................................................................................245

4.11.5 Network Access Statistics ................................................................................................................................246

4.11.6 RADIUS ...........................................................................................................................................................253

4.11.7 TACACS+ ........................................................................................................................................................ 255

4.11.8 RADIUS Overview ...........................................................................................................................................256

4.11.9 RADIUS Details ...............................................................................................................................................258

4.11.10 Windows Platform RADIUS Server Configuration..........................................................................................264

4.11.11 802.1X Client Configuration ...........................................................................................................................269

4.12 Security ...................................................................................................................................................272

4.12.1 Port Limit Control.............................................................................................................................................272

4.12.2 Access Management .......................................................................................................................................276

4.12.3 Access Management Statistics ........................................................................................................................277

4.12.4 HTTPs .............................................................................................................................................................278

4.12.5 SSH .................................................................................................................................................................279

4.12.6 Port Security Status .........................................................................................................................................279

4.12.7 Port Security Detail..........................................................................................................................................282

4.12.8 DHCP Snooping ..............................................................................................................................................283

4.12.9 Snooping Table ................................................................................................................................................285

4.12.10 IP Source Guard Configuration...................................................................................................................... 285

4.12.11 IP Source Guard Static Table.........................................................................................................................287

4.12.12 Dynamic IP Source Guard Table....................................................................................................................288

4.12.13 ARP Inspection ..............................................................................................................................................289

4.12.14 ARP Inspection Static Table ...........................................................................................................................290

4.12.15 Dynamic ARP Inspection Table ......................................................................................................................291

4.13 MAC Address Table................................................................................................................................293

4.13.1 MAC Table Configuration .................................................................................................................................293

7

Page 8

User’s Manual of IGSW-24040T

4.13.2 MAC Address Table Status ..............................................................................................................................295

4.14 LLDP........................................................................................................................................................297

4.14.1 Link Layer Discovery Protocol .........................................................................................................................297

4.14.2 LLDP Configuration .........................................................................................................................................297

4.14.3 LLDP MED Configuration ................................................................................................................................300

4.14.4 LLDP-MED Neighbor .......................................................................................................................................307

4.14.5 Neighbor .......................................................................................................................................................... 311

4.14.6 Port Statistics...................................................................................................................................................312

4.15 Network Diagnostics..............................................................................................................................314

4.15.1 Ping .................................................................................................................................................................315

4.15.2 IPv6 Ping .........................................................................................................................................................316

4.15.3 Remote IP Ping Test ........................................................................................................................................317

4.15.4 Cable Diagnostics............................................................................................................................................318

4.16 Loop Protection......................................................................................................................................320

4.16.1 Configuration ................................................................................................................................................... 320

4.16.2 Loop Protection Status.....................................................................................................................................321

4.17 RMON.......................................................................................................................................................323

4.17.1 RMON Alarm Configuration .............................................................................................................................323

4.17.2 RMON Alarm Status.........................................................................................................................................325

4.17.3 RMON Event Configuration .............................................................................................................................326

4.17.4 RMON Event Status.........................................................................................................................................327

4.17.5 RMON History Configuration ...........................................................................................................................328

4.17.6 RMON History Status.......................................................................................................................................329

4.17.7 RMON Statistics Configuration ........................................................................................................................330

4.17.8 RMON Statistics Status....................................................................................................................................331

4.18 PTP...........................................................................................................................................................333

4.18.1 PTP Configuration ...........................................................................................................................................333

4.18.2 PTP Status.......................................................................................................................................................337

4.19 Ring..........................................................................................................................................................338

4.19.1 MEP Configuration...........................................................................................................................................339

4.19.2 Detailed MEP Configuration ............................................................................................................................340

4.19.3 Ethernet Ring Protocol Switch .........................................................................................................................343

4.19.4 Ethernet Ring Protocol Switch Configuration...................................................................................................345

4.19.5 Ring Wizard .....................................................................................................................................................348

4.19.6 Ring Wizard Example: .....................................................................................................................................349

5. SWITCH OPERATION ....................................................................................................... 352

8

Page 9

User’s Manual of IGSW-24040T

5.1 Address Table...........................................................................................................................................352

5.2 Learning ....................................................................................................................................................352

5.3 Forwarding & Filtering.............................................................................................................................352

5.4 Store-and-Forward...................................................................................................................................352

5.5 Auto-Negotiation ......................................................................................................................................353

6. TROUBLESHOOTING....................................................................................................... 354

APPENDIX A: Networking Connection............................................................................... 355

A.1 Switch's Data RJ45 Pin Assignments - 1000Mbps, 1000BASE-T........................................................355

A.2 10/100Mbps, 10/100BASE-TX..................................................................................................................355

APPENDIX B : GLOSSARY.................................................................................................. 357

9

Page 10

User’s Manual of IGSW-24040T

1. INTRODUCTION

Thank you for purchasing PLANET IGSW-24040T Industrial L2+ Managed Ethernet Switch, which comes with multiple Gigabit

Ethernet copper and SFP fiber optic connectibility and robust layer 2 and layer 4 features in a 19” rack-mountable chassis. The

configuration of this model is shown below:

Model Name Gigabit RJ45 Ports Gigabit SFP Slots

IGSW-24040T 24 4 shared

“Industrial Managed Switch” is used as an alternative name for the above models in this user’s manual.

1.1 Packet Contents

Open the box of the Industrial Managed Switch and carefully unpack it. The box should contain the following items:

Model Name

The Industrial Managed Switch

Quick Installation Guide

DB9 to RJ45 Consol Cable

Rubber Feet

Rack Mount Accessory Kit

AC Power Cord

SFP Dust-proof Cap

RJ45 Dust-proof Cap

If any of these are missing or damaged, please contact your dealer immediately; if possible, retain the carton including the

original packing material, and use them again to repack the product in case there is a need to return it to us for repair.

IGSW-24040T

x 1

x 1

x 1

x 4

x 1

x 1

x 4

x 25

10

Page 11

User’s Manual of IGSW-24040T

1.2 Product Description

PLANET IGSW-24040T, a new industrial Layer 2+ managed Gigabit Switch, features 24 10/100/1000Mbps ports and 4 shared

SFP ports, and supports static Layer 3 routing in a 1U case. With a total switch fabric of 48Gbps, the IGSW-24040T can

handle large amounts of data in a secure topology linking to an industrial backbone or high capacity servers. The

IGSW-24040T is capable of providing non-blocking switch fabric and wire-speed throughput in the temperature range from -40

to 75 degrees C without any packet loss and CRC error. It greatly simplifies the tasks of upgrading the industrial LAN for

catering to increasing bandwidth demands. Furthermore, it adopts user-friendly “Front Access” design for easy wiring and

maintenance of the IGSW-24040T when placed in the cabinet.

AC and DC Redundant Power to Ensure Continuous Operation

The IGSW-24040T possesses a 100~240V AC power supply and dual 36~60V DC power supply utilized as redundant power

supply to ensure its continuous operation. Its redundant power system is specifically designed to handle the demands of

high-tech facilities requiring the highest power integrity. Furthermore, with the 36~60V DC power supply implemented, the

IGSW-24040T can be applied as the telecom level device and placed in almost any difficult environment.

Digital Input and Digital Output for External Alarm

The IGSW-24040T helps the network administrators efficiently manage the unexpected network situations by providing Digital

Input and Digital Output for external alarm device on the front panel. The Digital Input can be used to detect and log the status of

the external devices such as door intrusion detector. The Digital Output could be used to send alarm whenever the

IGS-W-24040T has port link-down or power failure.

11

Page 12

User’s Manual of IGSW-24040T

Effective Alarm Alert for Better Protection

The IGSW-24040T supports a Fault Alarm feature which can alert the users when there is something wrong with the switches.

With this ideal feature, the users would not have to waste time to find where the problem is. It will help to save time and human

resource.

12

Page 13

User’s Manual of IGSW-24040T

IPv6/IPv

Supporting both IPv6 and IPv4 protocols, the IGSW-24040T helps data centers, campuses, telecoms, and more to experience

the IPv6 era with the lowest investment as its network facilities need not be replaced or overhauled if the IPv6 FTTx edge

network is set up.

4 Dual Stack

Layer 3 IPv4 and IPv6 VLAN Routing for Secure and Flexible Management

The IGSW-24040T offers IPv4/IPv6 VLAN routing feature which allows to crossover different VLANs and different IP addresses

for the purpose of having a highly-secured, flexible management and simpler networking application.

Robust Layer 2 Features

The IGSW-24040T can be programmed for advanced switch management functions such as dynamic port link aggregation,

Q-in-Q VLAN, private VLAN, Multiple Spanning Tree Protocol (MSTP), Layer 2 to Layer 4 QoS, bandwidth control and

IGMP/MLD Snooping. Via the link aggregation of supporting ports, the IGSW-24040T allows the operation of a high-speed

trunk to combine with multiple fiber ports and supports fail-over as well.

Powerful Security

The IGSW-24040T offers a comprehensive layer 2 to layer 4 Access Control List (ACL) for enforcing security to the edge. It

can be used to restrict network access by denying packets based on source and destination IP address, TCP/UDP ports or

defined typical network applications. Its protection mechanism also comprises 802.1X P ort-based and MAC-based user, and

device authentication. With the private VLAN function, communication between edge ports can be prevented to ensure user

privacy. The IGSW-24040T also provides DHCP Snooping, IP Source Guard and Dynamic ARP Inspection functions to

prevent IP snooping from attack and discard ARP packets with invalid MAC address. The network administrators can now

construct highly-secure corporate networks with considerably less time and effort than before.

Excellent Traffic Control

The IGSW-24040T is loaded with powerful traffic management and QoS features to enhance connection services by telecoms

and ISPs. The QoS features include wire-speed Layer 4 traffic classifiers and bandwidth limit that are particularly useful for

multi-tenant units, multi-business units, Telco and network service providers’ applications. It also empowers the industrial

environment to take full advantage of the limited network resources and guarantees the best performance in VoIP and video

conferencing transmission.

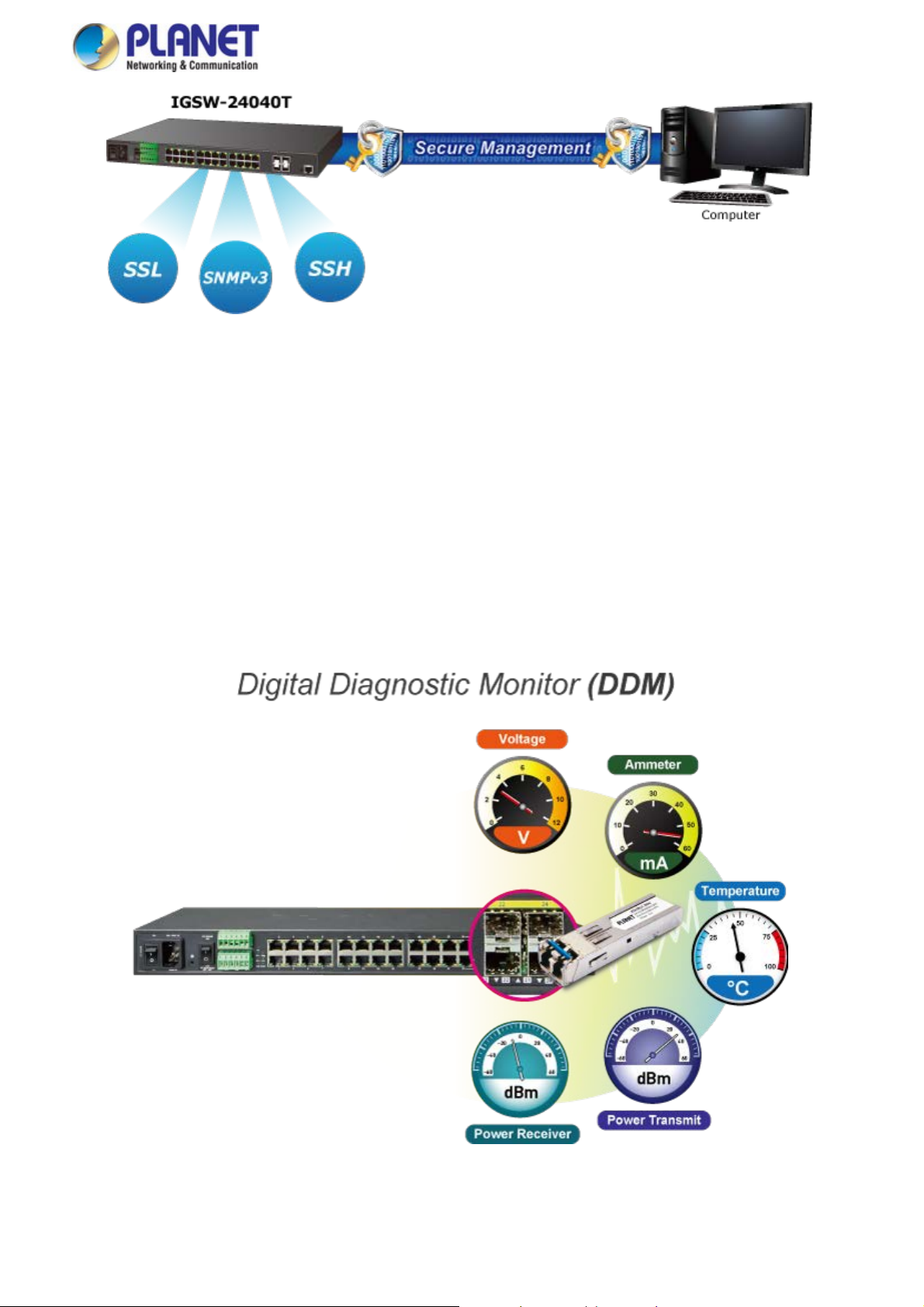

Efficient and Secure Management

With built-in Web-based management interface, the IGSW-24040T L2+ Managed Switch offers an easy-to-use,

platform-independent management and configuration facility which includes Console, Web and SNMP management interfaces.

The SNMP can be managed via any management software based on the standard of SNMP Protocol. For reducing product

learning time, it offers Cisco-like command via Telnet or console port and customer does not need to learn new console

command. Moreover, it also offers secure remote management by supporting SSH, SSL and SNMP v3 connections which

encrypt the packet content at each session.

13

Page 14

User’s Manual of IGSW-24040T

Flexibility and Extension Solution

The four mini-GBIC slots built in the IGSW-24040T support dual speed as it features 100BASE-FX and 1000BASE-SX/LX SFP

(Small Form-factor Pluggable) fiber-optic modules. Now the administrator can flexibly choose the suitable SFP transceiver

according to not only the transmission distance, but also the transmission speed required. The distance can be extended from

550 meters to 2km (multi-mode fiber) or up to 10/20/30/40/50/70/120 kilometers (single-mode fiber or WDM fiber). They are well

suited for applications within the industrial data centers and distributions.

Intelligent SFP Diagnosis Mechanism

The IGSW-24040T supports SFP-DDM (Digital Diagnostic Monitor) function that greatly helps network administrator to easily

monitor real-time parameters of the SFP, such as optical output power, optical input power, temperature, laser bias current, and

transceiver supply voltage.

14

Page 15

User’s Manual of IGSW-24040T

1.3 How to Use This Manual

This User’s Manual is structured as follows:

Section 2, INSTALLATION

The section explains the functions of the Industrial Managed Switch and how to physically install the Industrial

Managed Switch.

Section 3, SWITCH MANAGEMENT

The section contains the information about the software function of the Industrial Managed Switch.

Section 4, WEB CONFIGURATION

The section explains how to manage the Industrial Managed Switch by Web interface.

Section 5, SWITCH OPERATION

The chapter explains how to do the switch operation of the Industrial Managed Switch.

Section 6, TROUBLESHOOTING

The chapter explains how to do troubleshooting of the Industrial Managed Switch.

Appendix A

The section contains cable information of the Industrial Managed Switch.

Appendix B

The section contains glossary information of the Industrial Managed Switch.

15

Page 16

User’s Manual of IGSW-24040T

1.4 Product Features

Physical Port

24-port 10/100/1000BASE-T RJ45 copper

4 100/1000BASE-X mini-GBIC/SFP slots, shared with Port-21 to Port-24 compatible with 100BASE-FX SFP

RJ45 to RS232 DB9 console interface for basic management and setup

Hardware Conformance

One 100 to 240V AC or dual 36 to 60V DC power input, redundant power with polarity reverse protection function

Active-active redundant power failure protection

Backup of catastrophic power failure on one supply

Fault tolerance and resilience

19-inch rack-mountable design

IP30 metal case

Supports EFT protection for 4000V DC power and 6000V DC Ethernet ESD protection

-40 to 75 degrees C operating temperature for DC power input

-10 to 60 degrees C operating temperature for AC power input

Digital Input & Digital Output

2 Digital Input (DI)

2 Digital Output (DO)

Integrates sensors into auto alarm system

Transfers alarm to IP network via email and SNMP trap

Layer 3 IP Routing Features

Supports maximum 32 static routes and route summarization

Layer 2 Features

Prevents packet loss with back pressure (half-duplex) and IEEE 802.3x pause frame flow control (full-duplex)

High performance of Store-and-Forward architecture, and runt/CRC filtering eliminates erroneous packets to optimize

the network bandwidth

Storm control support

Broadcast/Multicast/Unknown unicast

Supports VLAN

IEEE 802.1Q tagged VLAN

Up to 255 VLANs groups, out of 4095 VLAN IDs

Provides Bridging (VLAN Q-in-Q) support (IEEE 802.1ad)

Private VLAN Edge (PVE)

Protocol-based VLAN

MAC-based VLAN

IP subnet-based VLAN

Voice VLAN

Supports Spanning Tree Protocol

IEEE 802.1D Spanning Tree Protocol (STP)

IEEE 802.1w Rapid Spanning Tree Protocol (RSTP)

16

Page 17

IEEE 802.1s Multiple Spanning Tree Protocol (MSTP), spanning tree by VLAN

BPDU Guard

Supports Link Aggregation

802.3ad Link Aggregation Control Protocol (LACP)

Cisco ether-channel (static trunk)

Maximum 12 trunk groups, with 8 ports for each trunk

Up to 16Gbps bandwidth (full duplex mode)

Provides port mirror (many-to-1)

Port mirroring monitors the incoming or outgoing traffic on a particular port

Loop protection to avoid broadcast loops

Supports E.R.P.S. (Ethernet Ring Protection Switching)

IEEE 1588 and Synchronous Ethernet network timing

Quality of Service

Ingress shaper and egress rate limit per port bandwidth control

8 priority queues on all switch ports

Traffic classification

- IEEE 802.1p CoS

- ToS/DSCP/IP precedence of IPv4/IPv6 packets

- IP TCP/UDP port number

- Typical network application

Strict priority and Weighted Round Robin (WRR) CoS policies

Traffic-policing policies on the switch port

User’s Manual of IGSW-24040T

DSCP remarking

Multicast

Supports IGMP snooping v1, v2 and v3

Supports MLD snooping v1 and v2

Querier mode support

IGMP snooping port filtering

MLD snooping port filtering

MVR (Multicast VLAN Registration)

Security

Authentication

- IEEE 802.1x port-based/MAC-based network access authentication

- IEEE 802.1x authentication with guest VLAN

- Built-in RADIUS client to cooperate with the RADIUS servers

- RADIUS/TACACS+ users access authentication

Access Control List

- IP-based Access Control List (ACL)

- MAC-based Access Control List (ACL)

Source MAC/IP address binding

DHCP Snooping to filter distrusted DHCP messages

Dynamic ARP Inspection discards ARP packets with invalid MAC address to IP address binding

17

Page 18

IP Source Guard prevents IP spoofing attacks

IP address access management to prevent unauthorized intruder

Management

IPv4 and IPv6 dual stack management

Switch Management Interfaces

- Console/Telnet command line interface

- Web switch management

- SNMP v1, v2c, and v3 switch management

- SSH/SSL secure access

IPv6 address/NTP management

Built-in Trivial File Transfer Protocol (TFTP) client

BOOTP and DHCP for IP address assignment

System Maintenance

- Firmware upload/download via HTTP/TFTP

- Reset button for system reboot or reset to factory default

- Dual images

User’s Manual of IGSW-24040T

DHCP relay and option 82

User privilege levels control

NTP (Network Time Protocol)

Link Layer Discovery Protocol (LLDP) and LLDP-MED

Network diagnostic

- SFP-DDM (Digital Diagnostic Monitor)

- Cable diagnostic technology provides the mechanism to detect and report potential cabling issues

- ICMPv6/ICMPv4 remote ping

SMTP/Syslog remote alarm

Four RMON groups (history, statistics, alarms and events)

SNMP trap for interface link up and link down notification

System Log

PLANET Smart Discovery Utility for deployment management

18

Page 19

1.5 Product Specifications

Product IGSW-24040T

Hardware Specifications

Hardware Version

Copper Ports

SFP/mini-GBIC Slots

Console

Switch Architecture

Switch Fabric

Throughput

Address Table

Shared Data Buffer

Flow Control

Jumbo Frame

Reset Button

Dimensions (W x D x H)

Weight

LED

3

24 10/100/1000BASE-T RJ45 auto-MDI/MDI-X ports

4 100/1000BASE-X SFP interfaces, shared with Port-21 to Port-24

Compatible with 100BASE-FX SFP transceiver

1 x RS232-to-RJ45 serial port (115200, 8, N, 1)

Store-and-Forward

48Gbps/non-blocking

35.71Mpps@64Bytes

8K entries, automatic source address learning and aging

4M bits

IEEE 802.3x pause frame for full-duplex

Back pressure for half-duplex

9K bytes

< 5 sec: System reboot

> 5 sec: Factory default

440 x 200 x 44.5 mm, 1U height

2788g

System:

AC (Green), DC1 (Green), DC2 (Green), Fault (Red)

Ring (Green), R.O. (Green), DI/DO (Red)

10/100/1000T RJ45 Interfaces (Port 1 to Port 24):

1000Mbps LNK/ACT (Green)

10/100Mbps LNK/ACT (Orange)

100/1000Mbps SFP Combo Interfaces (Port 21 to Port 24):

1000Mbps LNK/ACT (Green)

100Mbps LNK/ACT (Orange)

User’s Manual of IGSW-24040T

Power Consumption

Power Requirements – AC

Power Requirements – DC

DI

DO

EFT Protection

ESD Protection

Layer 2 Management Functions

Port Configuration

Port Status

Port Mirroring TX/RX/Both

Max. 19.7 watts/67.2 BTU

AC 100~240V, 50/60Hz 0.5A

DC 36~60V, 0.7A

2 Digital Input (DI):

Level 0: -24~2.1V

Level 1: 2.1~24V

Max. input current: 10mA

2 Digital Output (DO): Open collector to 24VDC, 100mA

6KV DC

6KV DC

Port disable/enable

Auto-negotiation 10/100/1000Mbps full and half duplex mode selection

Flow control disable/enable

Display each port’s speed duplex mode, link status, flow control status,

auto-negotiation status, trunk status

19

Page 20

VLAN

Link Aggregation

Spanning Tree Protocol

QoS

IGMP Snooping

MLD Snooping

Access Control List

Bandwidth Control

Layer 3 Functions

User’s Manual of IGSW-24040T

Many-to-1 monitor

802.1Q tagged based VLAN

Q-in-Q tunneling

Private VLAN Edge (PVE)

MAC-based VLAN

Protocol-based VLAN

Voice VLAN

IP Subnet-based VLAN

MVR (Multicast VLAN registration)

Up to 255 VLAN groups, out of 4095 VLAN IDs

IEEE 802.3ad LACP/static trunk

12 groups with 8 port per trunk

IEEE 802.1D Spanning Tree Protocol (STP)

IEEE 802.1w Rapid Spanning Tree Protocol (RSTP)

IEEE 802.1s Multiple Spanning Tree Protocol (MSTP)

Traffic classification based, strict priority and WRR

8-level priority for switching:

- Port number

- 802.1p priority

- 802.1Q VLAN tag

- DSCP/ToS field in IP packet

IGMP (v1/v2/v3) snooping, up to 255 multicast groups

IGMP querier mode support

MLD (v1/v2) snooping, up to 255 multicast groups

MLD querier mode support

IP-based ACL/MAC-based ACL

Up to 256 entries

Per port bandwidth control

Ingress: 100Kbps~1000Mbps

Egress: 100Kbps~1000Mbps

IP Interfaces Max. 8 VLAN interfaces

Routing Table Max. 32 routing entries

Routing Protocols

Management

Basic Management Interfaces Console/Telnet/Web browser/SNMP v1, v2c

Secure Management Interfaces SSH, SSL, SNMPv3

SNMP MIBs

Standards Conformance

IPv4 software static routing

IPv6 software static routing

RFC 1213 MIB-II

RFC 1493 Bridge MIB

RFC 1643 Ethernet MIB

RFC 2863 Interface MIB

RFC 2665 Ether-Like MIB

RFC 2819 RMON MIB (Group 1, 2, 3

and 9)

RFC 2737 Entity MIB

20

RFC 2618 RADIUS Client MIB

RFC 2863 IF-MIB

RFC 2933 IGMP-STD-MIB

RFC 3411 SNMP-Frameworks-MIB

RFC 4292 IP Forward MIB

RFC 4293 IP MIB

RFC 4836 MAU-MIB

IEEE 802.1X PAE

LLDP

Page 21

Regulatory Compliance FCC Part 15 Class A, CE

User’s Manual of IGSW-24040T

Standards Compliance

Environment

Operating

Storage

IEEE 802.3 10BASE-T

IEEE 802.3u 100BASE-TX/100BASE-FX

IEEE 802.3z Gigabit SX/LX

IEEE 802.3ab Gigabit 1000T

IEEE 802.3x flow control and back

pressure

IEEE 802.3ad port trunk with LACP

IEEE 802.1D Spanning Tree Protocol

IEEE 802.1w Rapid Spanning Tree

Protocol

IEEE 802.1s Multiple Spanning Tree

Protocol

IEEE 802.1p Class of Service

Temperature: -10 ~ 60 degrees C for AC power input

Temperature: -40 ~ 75 degrees C for DC power input

Relative Humidity: 5 ~ 95% (non-condensing)

Temperature: -40 ~ 80 degrees C

Relative Humidity: 5 ~ 95% (non-condensing)

IEEE 802.1Q VLAN tagging

IEEE 802.1x Port Authentication Network

Control

IEEE 802.1ab LLDP

IEEE 1588v2

RFC 768 UDP

RFC 793 TFTP

RFC 791 IP

RFC 792 ICMP

RFC 2068 HTTP

RFC 1112 IGMP version 1

RFC 2236 IGMP version 2

RFC 3376 IGMP version 3

RFC 2710 MLD version 1

FRC 3810 MLD version 2

21

Page 22

User’s Manual of IGSW-24040T

2. INSTALLATION

2.1 Hardware Description

The Industrial Managed Switch provides three different running speeds – 10Mbps, 100Mbps and 1000Mbps and automatically

distinguishes the speed of incoming connection.

This section describes the hardware features of Industrial Managed Switch. For easier management and control of the Industrial

Managed Switch, familiarize yourself with its display indicators and ports. Front panel illustrations in this chapter display the unit

LED indicators. Before connecting any network device to the Industrial Managed Switch, read this chapter carefully.

2.1.1 Physical Dimensions

IGSW-24040T

Dimensions (W x D x H) : 400 x 200 x 44.5mm

2.1.2 Front Panel

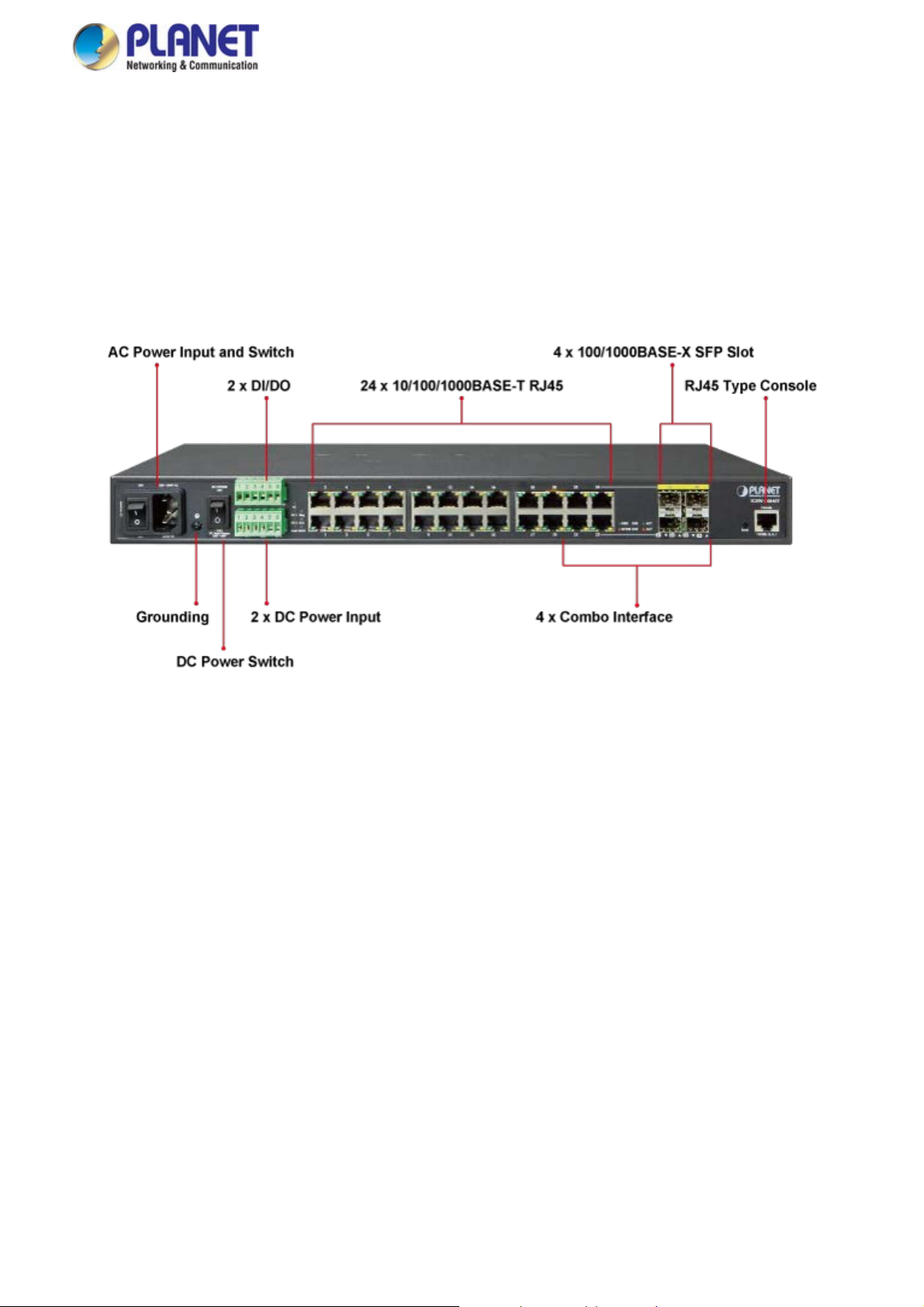

The front panel provides a simple interface monitoring the Industrial Managed Switch. Figures 2-1 show the front panel of the

Industrial Managed Switch.

22

Page 23

IGSW-24040T Front Panel

User’s Manual of IGSW-24040T

IGSW-24040T Front Panel

Figure 2-1: IGSW-24040T Switch Front Panel

■ Gigabit TP I

10/100/1000BASE-T copper, RJ45 twisted-pair: Up to 100 meters.

■ SFP Slot

100/1000BASE-X mini-GBIC slot, SFP (Small-form Factor Pluggable) transceiver module: From 550 meters to 2km

(multi-mode fiber), up to 10/20/30/40/50/70/120 kilometers (single-mode fiber).

■ Console Port

The console port is an RJ45 port connector. It is an interface for connecting a terminal directly. Through the console port, it

provides rich diagnostic information including IP address setting, factory reset, port management, link status and system

nterface

setting. Users can use the attached DB9 to RJ45 console cable in the package and connect to the console port on the

device. After the connection, users can run any terminal emulation program (Hyper Terminal, ProComm Plus, Telix,

Winterm and so on) to enter the startup screen of the device.

■ Reset Button

On the upper left side of the front panel, the reset button is designed for rebooting the Industrial Industrial Managed Switch

without turning off and on the power. The following is the summary table of reset button functions:

Figure 2-2: Reset Button of IGSW-

Reset Button Pressed and Released Function

24040T Industrial Managed Switch

< 5 sec: System Reboot Reboot the Industrial Managed Switch.

Reset the Industrial Managed Switch to Factory Default

configuration. The Industrial Managed Switch will then reboot

and load the default settings as shown below:

> 5 sec: Factory Default

。 Default Username: admin

。 Default Password: admin

。 Default IP address: 192.168.0.100

。 Subnet mask: 255.255.255.0

。 Default Gateway: 192.168.0.254

23

Page 24

User’s Manual of IGSW-24040T

■ AC Power Receptacle

For compatibility with electrical service in most areas of the world, the Managed Switch’s power supply automatically

adjusts to line power in the range of 100-240V AC and 50/60 Hz.

Plug the female end of the power cord firmly into the receptacle on the front panel of the Managed Switch and the other end

into an electrical outlet, and then the power will be ready.

The device is a power-required device, which means it will not work till it is powered. If your networks

should be active all the time, please consider using UPS (Uninterrupted Power Supply) for your device.

It will prevent you from network data loss or network downtime. In some areas, installing a surge

suppression device may also help to protect your Managed Switch from being damaged by unregulated

surge or current to the Switch or the power adapter.

■ DC Power Connector

The front panel of the Managed Switch contains a power switch and a DC power connector, which accepts DC power input

voltage from -36V to -60V DC. Connect the power cable to the Managed Switch at the input terminal block. The size of the

two screws in the terminal block is M3.5.

■ Digital Input

The digital input of the Managed Switch can be activated by the external sensor that senses physical changes. These

changes can include intrusion detection or certain physical change in the monitored area. For example, the external sensor

can be a door switch or an infrared motion detector.

■ Digital Output

The digital output main function is to allow the Managed Switch to trigger external devices, either automatically or by

remote control from a human operator or a software application.

24

Page 25

User’s Manual of IGSW-24040T

2.1.3 LED Indications

The front panel LEDs indicate instant status of power and system status, fan status, port links and data activity; they help

monitor and troubleshoot when needed. Figures 2-3 shows the LED indications of the Managed Switch

IGSW-24040T LED Indication

Figure 2-3: IGSW-24040T LED on Front Panel

System

LED Color Function

AC Green Lights to indicate AC power input has power.

DC1 Green Lights to indicate DC power input 1 has power.

DC2 Green Lights to indicate DC power input 2 has power.

Fault Red Lights to indicate that Switch AC/DC or port has failed.

Ring Green Lights to indicate that the ERPS Ring has been created successfully.

R.O. Green

DI/DO Red Blinks to indicate that Switch AC/DC or port has failed or DI has event.

Per 10/100/1000BASE-T Port

LED Color Function

1000

Green

LNK / ACT

Lights to indicate that Ring state is in idle mode.

Blinks to indicate that the Ring state is in protected mode.

Lights

Blinks

Indicating the port is running at 1000Mbps speed and successfully established.

Indicating that the switch is actively sending or receiving data over that port.

10/100

LNK/ACT

Orange

Lights

Blinks

Indicating the port is running at 10/100Mbps speed and successfully

established.

Indicating that the switch is actively sending or receiving data over that port.

25

Page 26

Per 100/1000BASE-X SFP Interface

LED Color Function

User’s Manual of IGSW-24040T

1000

LNK / ACT

100

LNK/ACT

Lights

Green

Blinks

Lights

Orange

Blinks

Indicating the port is running at 1000Mbps speed and successfully established.

Indicating that the switch is actively sending or receiving data over that port.

Indicating the port is running at 100Mbps speed and successfully established.

Indicating that the switch is actively sending or receiving data over that port.

2.1.4 Wiring the AC Power Input

The front panel of the industrial managed switch indicates an AC inlet power socket, which accepts input power from 100 to

240V AC, 50/60Hz.

26

Page 27

User’s Manual of IGSW-24040T

2.1.5 Wiring the DC Power Input

The 6-contact terminal block connector on the front panel of industrial managed switch is used for two DC redundant power

input. Please follow the steps below to insert the power wire.

1. Insert positive/negative DC power wires into contacts 1 and 2 for DC POWER 1, or 5 and 6 for DC POWER 2.

Figure 2-4: IGSW-24040T Managed Switch Upper Panel

2. Tighten the wire-clamp screws for preventing the wires from loosening.

1 2 3 4 5 6

DC 1 DC 2

+ - + -

Figure 2-5 6-Pin Terminal Block Power Wiring Input

1. The wire gauge for the terminal block should be in the range of 12 ~ 24 AWG.

2. When performing any of the procedures like inserting the wires or tighten the wire-clamp screws,

make sure the power is OFF to prevent from getting an electric shock.

27

Page 28

User’s Manual of IGSW-24040T

2.1.6 Wiring the Faulty Alarm Contact

The fault alarm contacts are in the middle (3 & 4) of the terminal block connector as the picture shows below. Inserting the wires,

the Industrial Managed Switch will detect the fault status of the power failure, or port link failure (available for managed model)

when Fault Alarm function has been enabled. The following illustration shows an application example for wiring the faulty alarm

contacts

Insert the wires into the faulty alarm contacts

1. The wire gauge for the terminal block should be in the range of 12 ~ 24 AWG.

2. When performing any of the procedures like inserting the wires or tighten the wire-clamp screws, make

sure the power is OFF to prevent from getting an electric shock.

28

Page 29

User’s Manual of IGSW-24040T

2.1.7 Wiring the Digital Input/Output

The 6-contact terminal block connector on the front panel of Industrial Managed Switch is used for Digital Input and Digital

Output. Please follow the steps below to insert wire.

1. The Industrial Managed Switch offers two DI and DO groups. 1 and 2 are DI groups, 3 and 4 are DO groups and 5 and 6

are GND (ground).

Figure 2-6 Wiring the Redundant Power Inputs

2. Tighten the wire-clamp screws for preventing the wires from loosening.

DI DO GND

1 2 3 4 5 6

DI0 DI1 DO0 DO1 GND GND

Figure 2-7 6-Pin Terminal Block DI / DO Wiring Input

3. There are two Digital Input groups for you to monitor two different devices. The following topology shows how to wire DI0

and DI1.

29

Page 30

User’s Manual of IGSW-24040T

Figure 2-8 Wires DI0 and DI1 to Open Detector

4. There are two Digital Output groups for you to sense Industrial Managed Switch port failure or power failure and issue a

high or low signal to external device. The following topology shows how to wire DO0 and DO1.

30

Page 31

User’s Manual of IGSW-24040T

Figure 2-9 Wiring DO0 and DO1 to Open Detector

31

Page 32

User’s Manual of IGSW-24040T

2.2 Installing the Managed Switch

This section describes how to install your Industrial Managed Switch and make connections to the Industrial Managed Switch.

Please read the following topics and perform the procedures in the order being presented. To install your Industrial Managed

Switch on a desktop or shelf, simply complete the following steps.

In this paragraph, we will describe how to install the Industrial Managed Switch and the installation points attended to it.

2.2.1 Desktop Installation

To install the Industrial Managed Switch on desktop or shelf, please follow these steps:

Step 1: Attach the rubber feet to the recessed areas on the bottom of the Industrial Managed Switch.

Step 2: Place the Industrial Managed Switch on the desktop or the shelf near an AC power source, as shown in Figure 2-2-1.

Figure 2-11 Place the Industrial Managed Switch on the Desktop

Step 3: Keep enough ventilation space between the Industrial Managed Switch and the surrounding objects.

When choosing a location, please keep in mind the environmental restrictions discussed in Chapter 1,

Section 4, and specifications.

Step4: Connect the Industrial Managed Switch to network devices.

Connect one end of a standard network cable to the 10/100/1000 RJ45 ports on the front of the Industrial Managed

Switch.

Connect the other end of the cable to the network devices such as printer server, workstation or router.

32

Page 33

User’s Manual of IGSW-24040T

Connection to the Managed Switch requires UTP Category 5e network cabling with RJ45 tips. For more

information, please see the Cabling Specification in Appendix A.

Step 5: Supply power to the Industrial Managed Switch.

Connect one end of the power cable to the Industrial Managed Switch.

Connect the power plug of the power cable to a standard wall outlet.

When the Industrial Managed Switch receives power, the Power LED should remain solid Green.

2.2.2 Rack Mounting

To install the Industrial Managed Switch in a 19-inch standard rack, please follow the instructions described below.

Step 1: Place the Industrial Managed Switch on a hard flat surface, with the front panel positioned towards the front side.

Step 2: Attach the rack-mount bracket to each side of the Industrial Managed Switch with supplied screws attached to the

package.

Figure 2-2-2 shows how to attach brackets to one side of the Industrial Managed Switch.

Figure 2-2-2 Attach Brackets to the Industrial Managed Switch.

You must use the screws supplied with the mounting brackets. Damage caused to the parts by

using incorrect screws would invalidate the warranty.

Step 3: Secure the brackets tightly.

Step 4: Follow the same steps to attach the second bracket to the opposite side.

Step 5: After the brackets are attached to the Industrial Managed Switch, use suitable screws to securely attach the brackets to

the rack, as shown in Figure 2-2-3.

33

Page 34

User’s Manual of IGSW-24040T

Figure 2-2-3 Mounting the Industrial Managed Switch on a Rack

Step6: Proceed with Steps 4 and 5 of session 2.2.1 Desktop Installation to connect the network cabling and supply power to the

Industrial Managed Switch.

2.3 Cabling

10/100/1000BASE-T and 100BASE-FX/1000BASE-SX/LX

All 10/100/1000BASE-T ports come with auto-negotiation capability. They automatically support 1000BASE-T,

100BASE-TX and 10BASE-T networks. Users only need to plug a working network device into one of the

10/100/1000BASE-T ports, and then turn on the Industrial Managed Switch. The port will automatically run in 10Mbps,

20Mbps, 100Mbps or 200Mbps and 1000Mbps or 2000Mbps after the negotiation with the connected device. The

Industrial Managed Switch has SFP interfaces that support 100/1000Mbps dual speed mode (Optional

multi-mode/single-mode 100BASE-FX/1000BASE-SX/LX SFP module)

Cabling

Each 10/100/1000BASE-T port uses RJ45 sockets -- similar to phone jacks -- for connection of unshielded twisted-pair

cable (UTP). The IEEE 802.3/802.3u 802.3ab Fast/Gigabit Ethernet standard requires Category 5 UTP for 100Mbps

100BASE-TX. 10BASE-T networks can use Cat.3, 4, 5 or 1000BASE-T use 5/5e/6 UTP (see table below). Maximum

34

Page 35

User’s Manual of IGSW-24040T

distance is 100 meters (328 feet). The 100BASE-FX/1000BASE-SX/LX SFP slot is used as LC connector with optional SFP

module. Please see table below and know more about the cable specifications.

Port Type Cable Type Connector

10BASE-T Cat 3, 4, 5, 2-pair RJ45

100BASE-TX Cat.5 UTP, 2-pair RJ45

1000BASE-T Cat.5/5e/6 UTP, 2-pair RJ45

100BASE-FX

1000BASE-SX/LX

Any Ethernet devices like hubs/PCs can be connected to the Industrial Managed Switch by using straight-through wires.

The two 10/100/1000Mbps ports are auto-MDI/MDI-X, which can be used on straight-through or crossover cable.

50/125µm or 62.5 / 125µm multi-mode 9/125µm single-mode

50/125µm or 62.5 / 125µm multi-mode 9/125µm single-mode

LC (multi/single mode)

LC (multi/single mode)

35

Page 36

User’s Manual of IGSW-24040T

2.3.1 Installing the SFP Transceiver

The sections describe how to insert an SFP transceiver into an SFP slot. The SFP transceivers are hot-pluggable and

hot-swappable. You can plug in and out the transceiver to/from any SFP port without having to power down the Industrial

Managed Switch, as the Figure 2-3-1 shows:

Follow all the SFP installation steps as shown in the example.

Figure 2-3-1: Plugging in the SFP Transceiver

Approved PLANET SFP Transceivers

PLANET Industrial Managed Switch supports both single mode and multi-mode SFP transceivers. The following list of

approved PLANET SFP transceivers is correct at the time of publication:

Fast Ethernet Transceiver (100BASE-X SFP)

Model Speed (Mbps) Connector Interface Fiber Mode Distance Wavelength (nm) Operating Temp.

MFB-FX 100 LC Multi Mode 2km 1310nm 0 ~ 60 degrees C

MFB-F20 100 LC Single Mode

MFB-F40 100 LC Single Mode

MFB-F60 100 LC Single Mode

MFB-F120 100 LC Single Mode 120km 1550nm 0 ~ 60 degrees C

MFB-TFX 100 LC Multi Mode 2km 1310nm -40 ~ 75 degrees C

MFB-TF20 100 LC Single Mode

20km 1310nm 0 ~ 60 degrees C

40km 1310nm 0 ~ 60 degrees C

60km 1310nm 0 ~ 60 degrees C

20km 1550nm -40 ~ 75 degrees C

36

Page 37

User’s Manual of IGSW-24040T

Fast Ethernet Transceiver (100BASE-BX, Single Fiber Bi-directional SFP)

Model Speed (Mbp s) Connector Interface Fiber Mode Distance Wavelength (TX/RX) Operating Temp.

MFB-FA20 100 WDM(LC) Single Mode 20km 1310nm/1550nm 0 ~ 60 degrees C

MFB-FB20 100 WDM(LC) Single Mode 20km 1550nm/1310nm 0 ~ 60 degrees C

MFB-TFA20 100 WDM(LC) Single Mode 20km 1310nm/1550nm -40 ~ 75 degrees C

MFB-TFB20 100 WDM(LC) Single Mode 20km 1550nm/1310nm -40 ~ 75 degrees C

MFB-TFA40 100 WDM(LC) Single Mode 40km 1310nm/1550nm -40 ~ 75 degrees C

MFB-TFB40 100 WDM(LC) Single Mode 40km 1550nm/1310nm -40 ~ 75 degrees C

Gigabit Ethernet Transceiver (1000BASE-X SFP)

Model Speed (Mbps) Connector Interface Fiber Mode Distance Wavelength (nm) Operating Temp.

MGB-GT 1000 Copper -- 100m -- 0 ~ 60 degrees C

MGB-SX 1000 LC Multi Mode 550m 850nm 0 ~ 60 degrees C

MGB-SX2 1000 LC Multi Mode 2km 1310nm 0 ~ 60 degrees C

MGB-LX 1000 LC Single Mode 10km 1310nm 0 ~ 60 degrees C