Page 1

Industrial 8-Port 10/100/1000BASE-T

+ 2-Port 100/1000BASE-X SFP Ethernet Switch

IGS-1020TF

User’s Manual

Page 2

Table Of Contents

1. Package Contents ............................................................. 3

2. Hardware Introduction ...................................................... 4

2.1 Physical Dimensions ................................................ 4

2.2 Switch Front Panel................................................... 5

2.3 LED Indicators ........................................................ 6

2.4 Switch Upper Panel ................................................. 8

2.5 Wiring the Power Inputs .......................................... 8

2.6 Wiring the Fault Alarm Contact ............................... 10

2.7 Product Specications ............................................ 10

3. Installation ..................................................................... 14

3.1 DIN-rail Mounting Installation ................................. 14

3.2 Wall-mount Plate Mounting ..................................... 16

3.3 Installing the SFP Transceiver ................................. 17

3.4 Removing the Transceiver Module ........................... 19

4. Troubleshooting .............................................................. 20

APPENDIX A: Networking Connection .................................... 21

A.1 Switch’s RJ45 Pin Assignments ................................... 21

A.2 RJ45 Cable Pin Assignments ...................................... 22

A.3 Fiber Optic Cable Connection Parameter ..................... 23

APPENDIX B: Approved PLANET SFP Transceivers .................. 25

Page 3

1. Package Contents

Thank you for purchasing PLANET industrial 10-port Gigabit

Ethernet Switch, IGS-1020TF. In the following section, the term

“Industrial Gigabit Ethernet Switch” means the IGS-1020TF.

Open the box of the Industrial Gigabit Ethernet Switch and

carefully unpack it. The box should contain the following items:

Industrial Gigabit Ethernet Switch x 1 User’s Manual x 1

Wall-mount Kit x DIN Rail Kit x 1

If any of these are missing or damaged, please contact your

dealer immediately; if possible, retain the carton including the

original packing material, and use them again to repack the

product in case there is a need to return it to us for repair.

3

Page 4

2. Hardware Introduction

Side View

2.1 Physical Dimensions

IGS-1020TF Industrial Gigabit Ethernet Switch dimensions (W

x D x H): 135 x 87.8 x 50mm

DIN-Rail Kit

Mounting Kit

Mounting Kit

Dimensions ( unit = mm )

Top View Rear View

109

864

1 2 3 4 5 6

V1+ V1- V2+V2-

PWR1

ACT

ACT

ACT

ACT

LNK

1000 LNK

10/100

LNK

LNK

100/1000X SFP

9 10

100

1000

Input

PWR2Fault

DC12~48V, AC 24V

P1 P2 FAULT

753

2

IGS-1020TF

1

Bottom View Front View

4

Page 5

2.2 Switch Front Panel

The front panel of the Industrial Gigabit Ethernet Switch consists

of 8 auto-sensing 10/100/1000Mbps Ethernet RJ45 ports and

2 dual speed 100/1000BASE-X SFP slots. The LED Indicators

are also located on the RJ45 ports and SFP slots of the Gigabit

Ethernet Switch.

Figure 2-1 shows the front panel of Industrial Gigabit Ethernet

Switch.

P1 P2 FAULT

ACT

LNK

100

1000

LNK

ACT

9 10

109

100/1000X SFP

ACT

1000 LNK

LNK

10/100

ACT

7

5

3

1

Figure 2-1: IGS-1020TF Front Panel

Gigabit TP Interface

10/100/1000BASE-T Copper, RJ45 Twisted-pair: Up to 100

meters.

SFP Slot

100/1000BASE-X mini-GBIC slot, SFP (Small-form Factor

Pluggable) transceiver module: From 550 meters to 2km

(multi-mode ber) and 10/20/30/40/50/70/120 kilometers

(single-modeber).

8

6

4

2

IGS-1020TF

5

Page 6

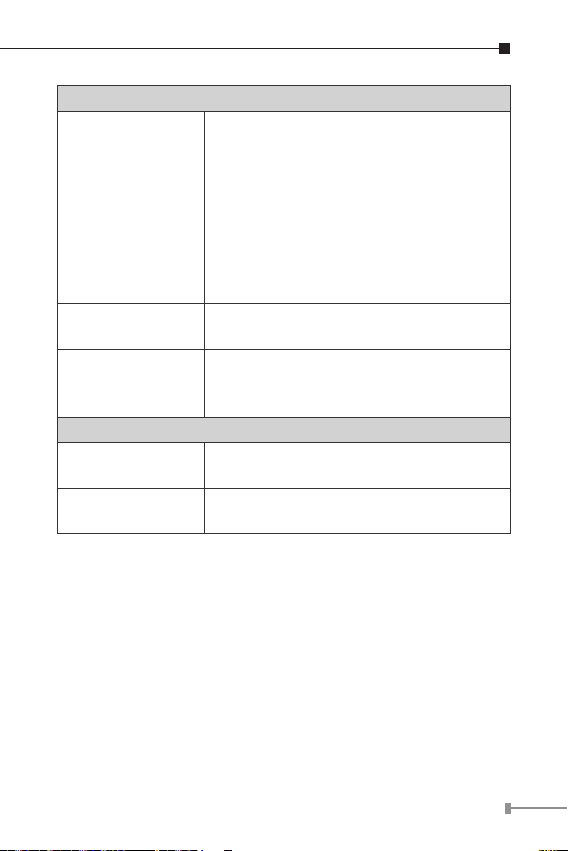

2.3 LED Indicators

System

LED Color Function

P1 Green Lit: indicates power 1 has power.

P2 Green Lit: indicates power 2 has power.

FAULT Red

Per 10/100/1000T Port

LED Color Function

100

LNK/ACT

1000

LNK/ACT

Lit: indicates either power 1 or power 2 has

no power.

Lit: indicates the link through that port is

successfully established at 100Mbps

or 10Mbps.

Orange

Green

Blinking: indicates that the Switch is

actively sending or receiving data

over that port.

Off: indicates the link through that port is

successfully established at 1000Mbps.

Lit: indicates the link through that port is

successfully established at 1000Mbps

or 10Mbps.

Blinking: indicates that the Switch is

actively sending or receiving data

over that port.

Off: indicates the link through that port is

successfully established at 100Mbps.

6

Page 7

Per 100 / 1000X SFP Slot

LED Color Function

Lit: indicates the link through that port is

successfully established at 100Mbps.

100

LNK/ACT

1000

LNK/ACT

Orange

Green

Blinking: indicates that the Switch is

actively sending or receiving data

over that port.

Off: indicates the link through that port is

successfully established at 1000Mbps.

Lit: indicates the link through that port is

successfully established at 1000Mbps

or 10Mbps.

Blinking: indicates that the Switch is

actively sending or receiving data

over that port.

Off: indicates the link through that port is

successfully established at 100Mbps.

7

Page 8

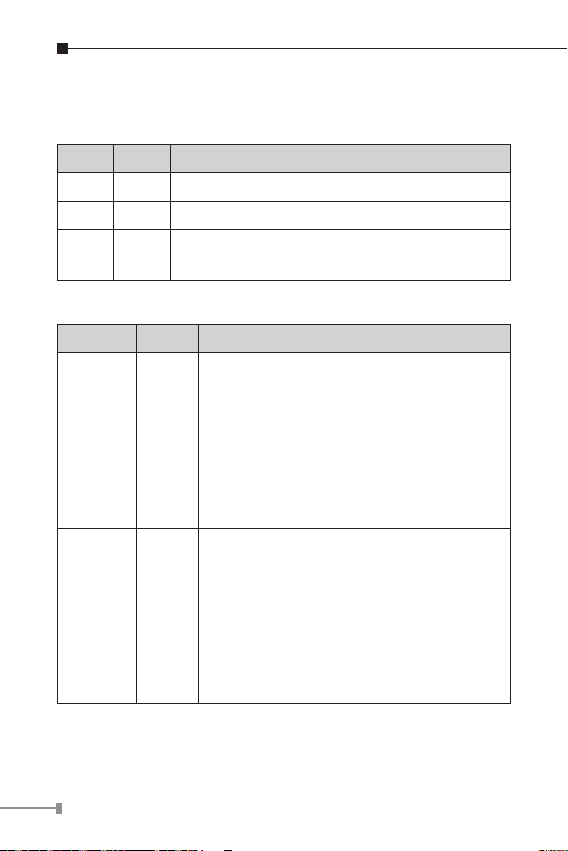

2.4 Switch Upper Panel

The upper panel of the Industrial Gigabit Ethernet Switch

consists of one terminal block connector within two DC power

inputs,

Figure 2-2 shows the upper panel of the Industrial Gigabit

Ethernet Switch.

1 2 3 4 5 6

V1+ V1- V2+ V2-

PWR1

PWR2Fault

Input

DC12~48V, AC 24V

Figure 2-2: Industrial Gigabit Ethernet Switch Upper Panel

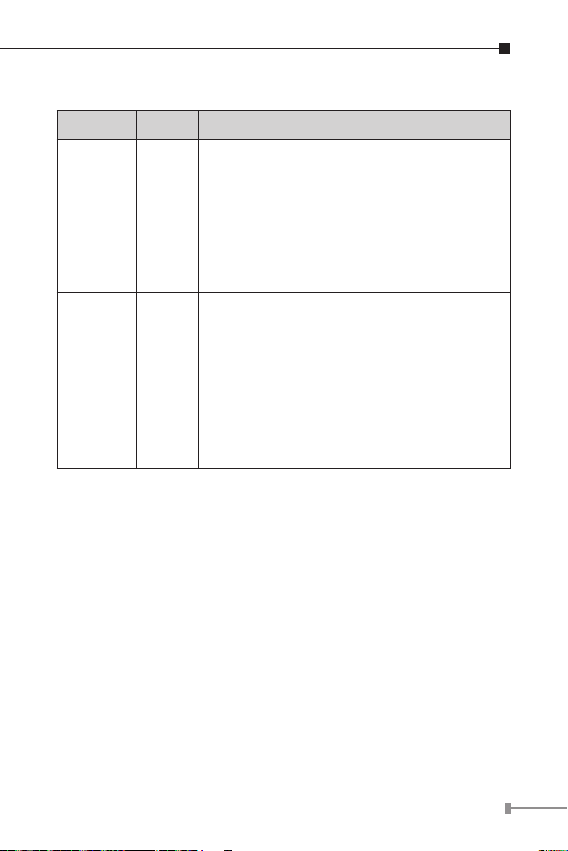

2.5 Wiring the Power Inputs

The 6-contact terminal block connector on the top panel of

Industrial Gigabit Ethernet Switch is used for two DC redundant

power inputs. Please follow the steps below to insert the power

wire.

When performing any of the procedures like

inserting the wires or tightening the wire-clamp

screws, make sure the power is OFF to prevent

from getting an electric shock.

8

Page 9

1. Insert positive and negative DC power wires into contacts 1

and 2 for POWER 1, or 5 and 6 for POWER 2.

1 2 3 4 5 6

V1+ V1- V2+ V2-

PWR1

PWR2Fault

Input

DC12~48V, AC 24V

2. Tighten the wire-clamp screws for preventing the wires from

loosening.

1 2 3 4 5 6

Power 1 Fault Power 2

+ - + -

1. The wire gauge for the terminal block should be

in the range between 12 and 24 AWG.

Note

2. The DC power input range is 12V ~ 48V DC.

9

Page 10

2.6 Wiring the Fault Alarm Contact

The fault alarm contacts are in the middle of the terminal block

connector as the picture shows below. Inserting the wires, the

Industrial Gigabit Ethernet Switch will detect the fault status of

the power failure and then forms an open circuit. The following

illustration shows an application example for wiring the fault

alarm contacts.

1 2 3 4 5 6

The Fault Alarm Contacts are

energized (CLOSE) for normal

Fault Alarm Contacts

Fault

operation and will OPEN when

failure occurs

Insert the wires into the fault alarm contacts

1. The wire gauge for the terminal block should be

in the range between 12 and 24 AWG.

Note

2. Alarm relay circuit accepts up to 30V, max. 3A

currents.

2.7 ProductSpecications

Model IGS-1020TF

HardwareSpecications

Copper Ports

8 x 10/100/1000BASE-T RJ45 TP

Auto-MDI/MDI-X, auto-negotiation

10

Page 11

SFP/mini-GBIC

Slots

Switch Processing

Scheme

Switch Fabric 20Gbps (non-blocking)

Switch Throughput

(packet per

second)

MAC Address Table 4K entries

Flow Control

Jumbo Frame 9216 bytes

Connector

Alarm

LED Indicator

2 1000BASE-SX/LX/BX SFP interfaces

(Port-9 and Port-10)

Compatible with 100BASE-FX SFP

Store-and-Forward

14.88Mpps@64bytes

Back pressure for half duplex

IEEE 802.3x pause frame for full duplex

Removable 6-pin terminal block

Pin 1/2 for Power 1; Pin 3/4 for fault

alarm; Pin 5/6 for Power 2

Provides one relay output for power

failure

Alarm Relay current carry ability: 1A @

DC 24V

3 x LED for System and Power:

Green: DC Power 1

Green: DC Power 2

Red: Power Fault

2 x LED for Per Copper Port (Port1~Port-8):

Green: 1000 LNK/ACT

Orange:100 LNK/ACT

2 x LED for Per mini-GBIC interface

(Port-9 and Port-10)

Green: 1000 LNK/ACT

Orange: 100 LNK/ACT

11

Page 12

ESD Protection 6KV DC

Enclosure IP30 type metal case

Installation DIN rail kit and wall mount ear

Dimensions

(W x D x H)

Weight 540g

Power

Requirements

Power

Consumption/

Dissipation

Twisted-pair

Cable

Fiber-Optic

Cable

56 x 87 x 135 mm

DC 12~48V or AC 24V

Redundant power with polarity reverses

protection function

8.7watts/29.69BTU

10BASE-T: 2-pair UTP Cat. 3, 4, 5, up to

100 meters

100BASE-TX: 2-pair UTP Cat. 5, 5e up to

100 meters

1000BASE-T: 4-pair UTP Cat. 5e, 6 up to

100 meters

1000BASE-SX :

50/125μmor 62.5/125μmmulti-mode

beroptic cable,up to550m

1000BASE-LX :

9/125μmsingle-mode beroptic cable,

up to 10/20/30/40/50/70/120 kilometers

(vary on SFP module)

100BASE-FX :

50/125μmor 62.5/125μmmulti-mode

beroptic cable,up to2 kilometers

9/125μmsingle-mode beroptic cable,

up to 20/40/60 kilometers (vary on SFP

module)

12

Page 13

Standards Conformance

IEEE 802.3 Ethernet/10BASE-T

IEEE 802.3u Fast Ethernet/100BASE-TX

IEEE 802.3ab Gigabit

Standards

Compliance

Regulatory

Compliance

Stability Testing

Environment

Temperature

Humidity

Ethernet/1000BASE-T

IEEE 802.3z Gigabit

Ethernet/1000BASE-SX/LX

IEEE 802.3x Full-Duplex Flow Control

IEEE802.3az EnergyEfcient Ethernet

(EEE)

IEEE 802.1p Cos

FCC Part 15 Class A, CE

IEC60068-2-32 (free fall)

IEC60068-2-27 (anti-shock)

IEC60068-2-6 (anti-vibration)

Operating: -40~75 degrees C

Storage: -40~75 degrees C

Operating: 5~95% (non-condensing)

Storage: 5~95% (non-condensing)

13

Page 14

3. Installation

This section describes the functionalities of the Industrial

Gigabit Ethernet Switch’s components and guides how to install

it on the DIN-rail and wall. Basic knowledge of networking is

assumed. Please read this chapter completely before continuing.

This following picture is telling the user how

to install the device, and the device is not IGS-

Note

3.1 DIN-rail Mounting Installation

The DIN-rail is screwed on the Industrial Gigabit Ethernet Switch

when out of factory. When replacing the wall-mount application

with DIN-rail application, Industrial Gigabit Ethernet Switch

is needed. Please refer to the following gures to screw the

DIN-rail on the Industrial Gigabit Ethernet Switch. To hang the

Industrial Gigabit Ethernet Switch, follow the following steps:

Step 1: Screw the DIN-rail on the Industrial Gigabit Ethernet

1020TF.

Switch.

14

Page 15

Step 2: Lightly insert the bottom of the switch into the track

1

2

Step 3: Make sure if the DIN-Rail is tightly secured on the

track.

Step 4: Please refer to the following procedures to remove the

Industrial Gigabit Ethernet Switch from the track.

1

2

15

Page 16

Step 5: Lightly pull out the bottom of the switch for removing

it from the track.

3.2 Wall-mount Plate Mounting

To install the Industrial Gigabit Ethernet Switch on the wall,

please follow the instructions described below.

Step 1: To remove the DIN-Rail from the Industrial Gigabit

Ethernet Switch, loosen the screws to remove the

DIN-rail.

Step 2: Place the wallmount plate on the rear panel of the

Industrial Gigabit Ethernet Switch.

Step 3: Use the screws to screw the wallmount plate on the

Industrial Gigabit Ethernet Switch.

Step 4: Use the hook holes at the corners of the wallmount

plate to hang the Industrial Gigabit Ethernet Switch on

the wall.

Step 5: To remove the wallmount plate, reverse the steps

above.

16

Page 17

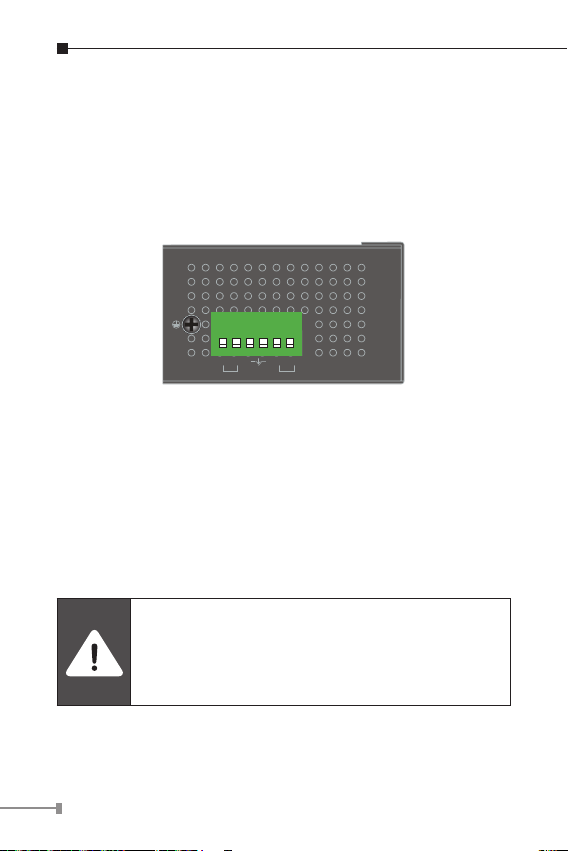

3.3 Installing the SFP Transceiver

The sections describe how to insert an SFP transceiver into an

SFP slot.

The SFP transceivers are hot-pluggable and hot-swappable.

You can plug in and out the transceiver to/from any SFP port

without having to power down the Industrial Gigabit Ethernet

Switch as Figure 2-3 shows.

MGB/MFB

Series Module

Figure 3-1: Plug-in the SFP Transceiver

PLANET Industrial Gigabit Ethernet Switch supports 100/1000

dual mode with both single mode and multi-mode SFP

transceivers.

1. Before we connect Industrial Gigabit Ethernet Switch to the

other network device, we have to make sure both sides of

the SFP transceivers are with the same media type, for

example, 1000BASE-SX to 1000BASE-SX, 1000BASE-LX to

1000BASE-LX.

17

Page 18

2.Check whether the ber-optic cable type matches with the

SFP transceiver requirement.

To connect to 1000BASE-SX SFP transceiver, please use

the multi-mode ber cable with one side being the male

duplex LC connector type.

To connect to 1000BASE-LX or 1000BASE-BX SFP trans-

ceiver, please use the single-mode ber cable with one

side being the male duplex LC connector type.

Connect the Fiber Cable

1. Insert the duplex LC connector into the SFP transceiver.

2. Connect the other end of the cable to a device with SFP

transceiver installed.

3. Check the LNK/ACT LED of the SFP slot on the front of the

Industrial Gigabit Ethernet Switch. Ensure that the SFP transceiver is operating correctly.

4. Check the Link mode of the SFP port if the link fails.

It is recommended to use PLANET SFPs on the

Industrial Gigabit Ethernet Switch. If you insert an

Note

SFP transceiver that is not supported, the Industrial Gigabit Ethernet Switch will not recognize it.

18

Page 19

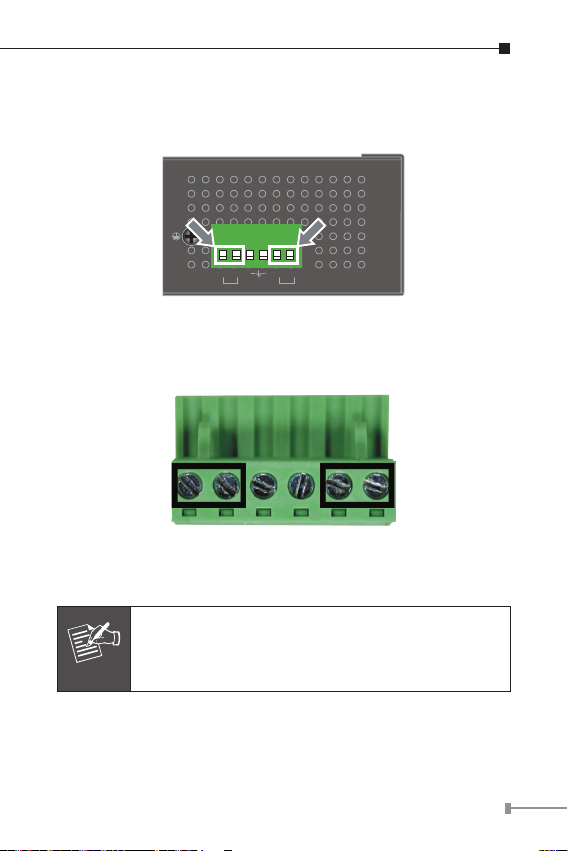

3.4 Removing the Transceiver Module

1. Make sure there is no network activity by consulting or

checking with the network administrator. Or through the

management interface of the switch/converter (if available) to

disable the port in advance.

2. Remove the Fiber Optic Cable gently.

3. Turn the lever of the MGB/MFB module to a horizontal position.

4. Pull out the module gently through the lever.

MGB/MFB

Series Module

12

Figure 3-2: Pull Out from the Transceiver

Never pull out the module without pulling the

lever or the push bolts on the module. Directly

pulling out the module with force could damage

Note

the module and the SFP module slot of the

Industrial Gigabit Ethernet Switch.

19

Page 20

4. Troubleshooting

This chapter contains information to help you solve issues.

If the Industrial Gigabit Ethernet Switch is not functioning

properly, make sure the Industrial Gigabit Ethernet Switch was

set up according to instructions in this manual.

The per port LED is not lit

Solution:

Check the cable connection of the Industrial Gigabit Ethernet

Switch.

Per port LED is lit, but the trafc is irregular

Solution:

Check whether the attached device is not set to dedicated full

duplex. Some devices use a physical or software switch to

change duplex modes. Auto-negotiation may not recognize this

type of full-duplex setting.

Why the Industrial Gigabit Ethernet Switch doesn’t

connect to the network

Solution:

Check each port LED on the Industrial Gigabit Ethernet Switch.

Try another port on the Industrial Gigabit Ethernet Switch. Make

sure the cable is installed properly and the right type. Turn off

the power. After a while, turn on the power again.

Can I install MGB-SX or other non wide temperature

SFP module into SFP slot of Industrial Gigabit Ethernet

Switch?

Solution:

Yes, you can. However, the MGB-SX and the other non wide

temperature SFP module cannot operate under -40 to 75

degrees C.

20

Page 21

APPENDIX A: Networking Connection

A.1 Switch’s RJ45 Pin Assignments

1000Mbps, 1000BASE-T

Contact MDI MDI-X

1 BI_DA+ BI_DB+

2 BI_DA- BI_DB-

3 BI_DB+ BI_DA+

4 BI_DC+ BI_DD+

5 BI_DC- BI_DD-

6 BI_DB- BI_DA-

7 BI_DD+ BI_DC+

8 BI_DD- BI_DC-

10/100Mbps, 10/100BASE-TX

RJ45 Connector pin assignment

MDI

Contact

1 Tx + (transmit) Rx + (receive)

2 Tx - (transmit) Rx - (receive)

3 Rx + (receive) Tx + (transmit)

4, 5 Not used

6 Rx - (receive) Tx - (transmit)

7, 8 Not used

Media Dependent

Interface

MDI-X

Media Dependent

Interface -Cross

21

Page 22

A.2 RJ45 Cable Pin Assignments

The standard RJ45 receptacle/connector

There are 8 wires on a standard UTP/STP cable and each wire is

color-coded. The following shows the pin allocation and color of

straight-through cable and crossover cable connection:

Straight Cable

12345678

12345678

Cross Over Cable

12345678

12345678

SIDE 1

SIDE 2

SIDE 1

SIDE 2

SIDE 1

1 = White/Orange

2 = Orange

3 = White/Green

4 = Blue

5 = White/Blue

6 = Green

7 = White/Brown

8 = Brown

SIDE 1 SIDE 2

1 = White/Orange

2 = Orange

3 = White/Green

4 = Blue

5 = White/Blue

6 = Green

7 = White/Brown

8 = Brown

SIDE 2

1 = White/Orange

2 = Orange

3 = White/Green

4 = Blue

5 = White/Blue

6 = Green

7 = White/Brown

8 = Brown

1 = White/Green

2 = Green

3 = White/Orange

4 = Blue

5 = White/Blue

6 = Orange

7 = White/Brown

8 = Brown

Figure A-1: Straight-through and Crossover Cable

Please make sure your connected cables are with the same pin

assignment and color as the above picture before deploying the

cables into your network.

22

Page 23

A.3 Fiber Optic Cable Connection Parameter

The wiring details are shown below:

100FX Fiber Optic Cables:

Standard Fiber Type CableSpecications

100BASE-FX

(1300nm)

100BASE-FX

(1310nm)

100BASE-BX-U

(TX:1310/RX:1550)

100BASE-BX-D

(TX:1550/RX:1310)

Multi-mode

Multi-mode

Single-mode 9/125μm

Single-mode 9/125μm

1000X Fiber Optic Cables:

Standard Fiber Type CableSpecications

1000BASE-SX

(850nm)

1000BASE-LX

(1300nm)

Multi-mode 50/125μmor62.5/125μm

Multi-mode 50/125μmor62.5/125μm

Single-mode 9/125μm

50/125μmor

62.5/125μm

50/125μmor

62.5/125μm

23

Page 24

Wiring Distances:

Standard Fiber

1000BASE- SX MM

1000BASE- LX

MM

SM 9 N/A 5000*

Diameter

(micron)

62.5

62.5

50

50

62.5

50

50

Modal

Bandwidth

(MHz * km)

100

200

400

500

5

4

5

Max. Distance

(meters)

220

275

500

550

550

24

Page 25

APPENDIX B: Approved PLANET SFP

Transceivers

The following list of approved PLANET SFP transceivers is correct

at the time of publication:

Gigabit SFP Transceiver Modules

MGB-GT SFP-Port 1000BASE-T Module - 100m

MGB-SX SFP-Port 1000BASE-SX mini-GBIC module - 550m

MGB-SX2 SFP-Port 1000BASE-SX mini-GBIC module – 2km

MGB-LX SFP-Port 1000BASE-LX mini-GBIC module - 10km

MGB-L30 SFP-Port 1000BASE-LX mini-GBIC module - 30km

MGB-L50 SFP-Port 1000BASE-LX mini-GBIC module - 50km

MGB-L70 SFP-Port 1000BASE-LX mini-GBIC module - 70km

MGB-L120 SFP-Port 1000BASE-LX mini-GBIC module - 120km

MGB-LA10

MGB-LB10

MGB-LA20

MGB-LB20

MGB-LA40

MGB-LB40

SFP-Port 1000BASE-LX (WDM, TX:1310nm) miniGBIC module - 10km

SFP-Port 1000BASE-LX (WDM, TX:1550nm) miniGBIC module - 10km

SFP-Port 1000BASE-LX (WDM, TX:1310nm) miniGBIC module – 20km

SFP-Port 1000BASE-LX (WDM, TX:1550nm) miniGBIC module - 20km

SFP-Port 1000BASE-LX (WDM, TX:1310nm) miniGBIC module - 40km

SFP-Port 1000BASE-LX (WDM, TX:1550nm) miniGBIC module - 40km

25

Page 26

MGB-LA60

MGB-LB60

MGB-TSX

MGB-TLX

MGB-TL30

MGB-TL70

MGB-TLA10

MGB-TLB10

MGB-TLA20

MGB-TLB20

MGB-TLA40

MGB-TLB40

MGB-TLA60

MGB-TLB60

SFP-Port 1000BASE-LX (WDM, TX:1310nm) miniGBIC module - 60km

SFP-Port 1000BASE-LX (WDM, TX:1550nm) miniGBIC module - 60km

SFP-Port 1000BASE-SX mini-GBIC module - 550m

(-40~75°C)

SFP-Port 1000BASE-LX mini-GBIC module - 10km

(-40~75°C)

SFP-Port 1000BASE-LX mini-GBIC module - 30km

(-40~75°C)

SFP-Port 1000BASE-LX mini-GBIC module - 70km

(-40~75°C)

SFP-Port 1000BASE-LX (WDM, TX:1310nm) miniGBIC module - 10km (-40~75°C)

SFP-Port 1000BASE-LX (WDM, TX:1550nm) miniGBIC module - 10km (-40~75°C)

SFP-Port 1000BASE-LX (WDM, TX:1310nm) miniGBIC module – 20km (-40~75°C)

SFP-Port 1000BASE-LX (WDM, TX:1550nm) miniGBIC module - 20km (-40~75°C)

SFP-Port 1000BASE-LX (WDM, TX:1310nm) miniGBIC module - 40km (-40~75°C)

SFP-Port 1000BASE-LX (WDM, TX:1550nm) miniGBIC module - 40km (-40~75°C)

SFP-Port 1000BASE-LX (WDM, TX:1310nm) miniGBIC module - 60km (-40~75°C)

SFP-Port 1000BASE-LX (WDM, TX:1550nm) miniGBIC module - 60km (-40~75°C)

26

Page 27

Fast Ethernet SFP Transceiver Modules

MFB-FX SFP-Port 100BASE-FX Transceiver (1310nm) - 2km

MFB-F20

MFB-F40

MFB-F60

MFB-F120

MFB-FA20

MFB-FB20

MFB-TFX

MFB-TF20

MFB-TFA20

MFB-TFB20

MFB-TFA40

MFB-TFB40

SFP-Port 100BASE-FX Transceiver (1310nm) 20km

SFP-Port 100BASE-FX Transceiver (1310nm) 40km

SFP-Port 100BASE-FX Transceiver (1310nm) 60km

SFP-Port 100BASE-FX Transceiver (1550nm) 120km

SFP-Port 100BASE-BX Transceiver (WDM,

TX:1310nm) - 20km

SFP-Port 100BASE-BX Transceiver (WDM,

TX:1550nm) - 20km

SFP-Port 100BASE-FX Transceiver (1310nm) - 2km

(-40~75°C)

SFP-Port 100BASE-FX Transceiver (1310nm) 20km (-40~75°C)

SFP-Port 100BASE-BX Transceiver (WDM,

TX:1310nm) - 20km (-40~75°C)

SFP-Port 100BASE-BX Transceiver (WDM,

TX:1550nm) - 20km (-40~75°C)

SFP-Port 100BASE-BX Transceiver (WDM,

TX:1310nm) - 40km (-40~75°C)

SFP-Port 100BASE-BX Transceiver (WDM,

TX:1550nm) - 40km (-40~75°C)

27

Page 28

Loading...

Loading...