Page 1

Industrial 10/100Base-TX to

100Base-FX Media Converter

IFT-802

User's Manual

Page 2

Trademarks

Copyright © PLANET Technology Corp. 2006.

Contents subject to which revision without prior notice.

PLANET is a registered trademark of PLANET Technology Corp. All other trademarks belong to their

respective owners.

Disclaimer

PLANET Technology does not warrant that the hardware will work properly in all environments and

applications, and makes no warranty and representation, either implied or expressed, with respect to the

quality, performance, merchantability, or fitness for a particular purpose.

PLANET has made every effort to ensure that this User's Manual is accurate; PLANET disclaims liability

for any inaccuracies or omissions that may have occurred.

Information in this User's Manual is subject to change without notice and does not represent a

commitment on the part of PLANET. PLANET assumes no responsibility for any inaccuracies that may be

contained in this User's Manual. PLANET makes no commitment to update or keep current the

information in this User's Manual, and reserves the right to make improvements to this User's Manual

and/or to the products described in this User's Manual, at any time without notice.

If you find information in this manual that is incorrect, misleading, or incomplete, we would appreciate

your comments and suggestions.

FCC Warning

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

Instruction manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in which case the user will be

required to correct the interference at whose own expense.

CE Mark Warning

This is a Class A product. In a domestic environment, this product may cause radio

interference, in which case the user may be required to take adequate measures.

WEEE Warning

To avoid the potential effects on the environment and human health as a result of the

presence of hazardous substances in electrical and electronic equipment, end users of electrical and

electronic equipment should understand the meaning of the crossed-out wheeled bin symbol. Do not

dispose of WEEE as unsorted municipal waste and have to collect such WEEE separately.

Revision

PLANET Industrial Fast Ethernet Media Converter User's Manual

For model: IFT-802

Revision: 1.0(February.2006)

Part No. EM_IFT802(2081-AH0010-000)

Page 3

Table of Contents

1. INTRODUCTION................................................................................................................... 4

1.1 Packet Contents.............................................................................................................. 4

1.2 How to Use This Manual ................................................................................................. 4

1.3 Product Feature............................................................................................................... 4

1.4 Product Specification....................................................................................................... 5

2. INSTALLATION..................................................................................................................... 7

2.1 Product Description......................................................................................................... 7

2.2 Mounting Installation ......................................................................................................11

3. Hardware Installation........................................................................................................ 14

4. TROUBLESHOOTING........................................................................................................ 16

4.1 Incorrect connections.................................................................................................... 16

4.2 Diagnosing LED Indicators............................................................................................ 16

Appendix A Networking Connection ................................................................................... 18

A.1 Switch‘s RJ-45 Pin Assignments .................................................................................. 18

A.2 RJ-45 cable pin assignment ......................................................................................... 18

Page 4

1. INTRODUCTION

1.1 Packet Contents

Check the contents of your package for following parts:

▫ Industrial Media Converter x1

▫ DIN-Rail kit (screwed on the switch)

▫ Wall-mount kit (wall-mount plate with 6 screws)

▫ CD-ROM user's manual x1

If any of these are missing or damaged, please contact your dealer immediately, if possible, retain the

carton including the original packing material, and use them against to repack the product in case there is

a need to return it to us for repair.

1.2 How to Use This Manual

This User Manual is structured as follows:

Chapter 2, HARDWARE NSTALLATION

The chapter explains the functions of the Converter and how to physically install the Converter.

Chapter 3, NETWORK INSTALLATION

The chapter explains how to install the Converter in the network.

Chapter 4, TROUBLE SHOOTING

The chapter explains how to trouble shooting of the Converter.

Chapter 5, APPENDIX A Networking Connection

The chapter contains cable information of the Converter.

1.3 Product Feature

Hardware Feature:

▫ UTP to Fiber Media Converter

▫ Auto Negotiation Speed and Half / Full Duplex

▫ Support 12 to 48VDC power inputs

▫ TX port support Auto MDI/MDI-X

▫ Relay alarm output for port link failure

▫ IEEE 802.3x flow control support

▫ Flow control on full-duplex

▫ Back pressure on half-duplex

▫ Built-in Link Lose Forwarding Technology

Page 5

▫ DIN-Rail or wall mountable

▫ DIP-switches to set the operation mode and Link- Lost-Forwarding function.

Industrial Conformance:

▫ 12~48V DC, redundant power with polarity reverse protect function and connective

removable terminal block for master and slave power

▫ 0 to 60 Degree C operation temperature

▫ IP-30 Aluminum case

▫ EMI complies with FCC Class A, CE EN6100-4-2, CE EN6100-4-3, CE EN6100-4-4, CE

EN6100-4-5 and CE EN6100-4-6

▫ Stability testing with IEC60068-2-32(Free fall), IEC60068-2-27(Shock) and

IEC60068-2-6(Vibration)

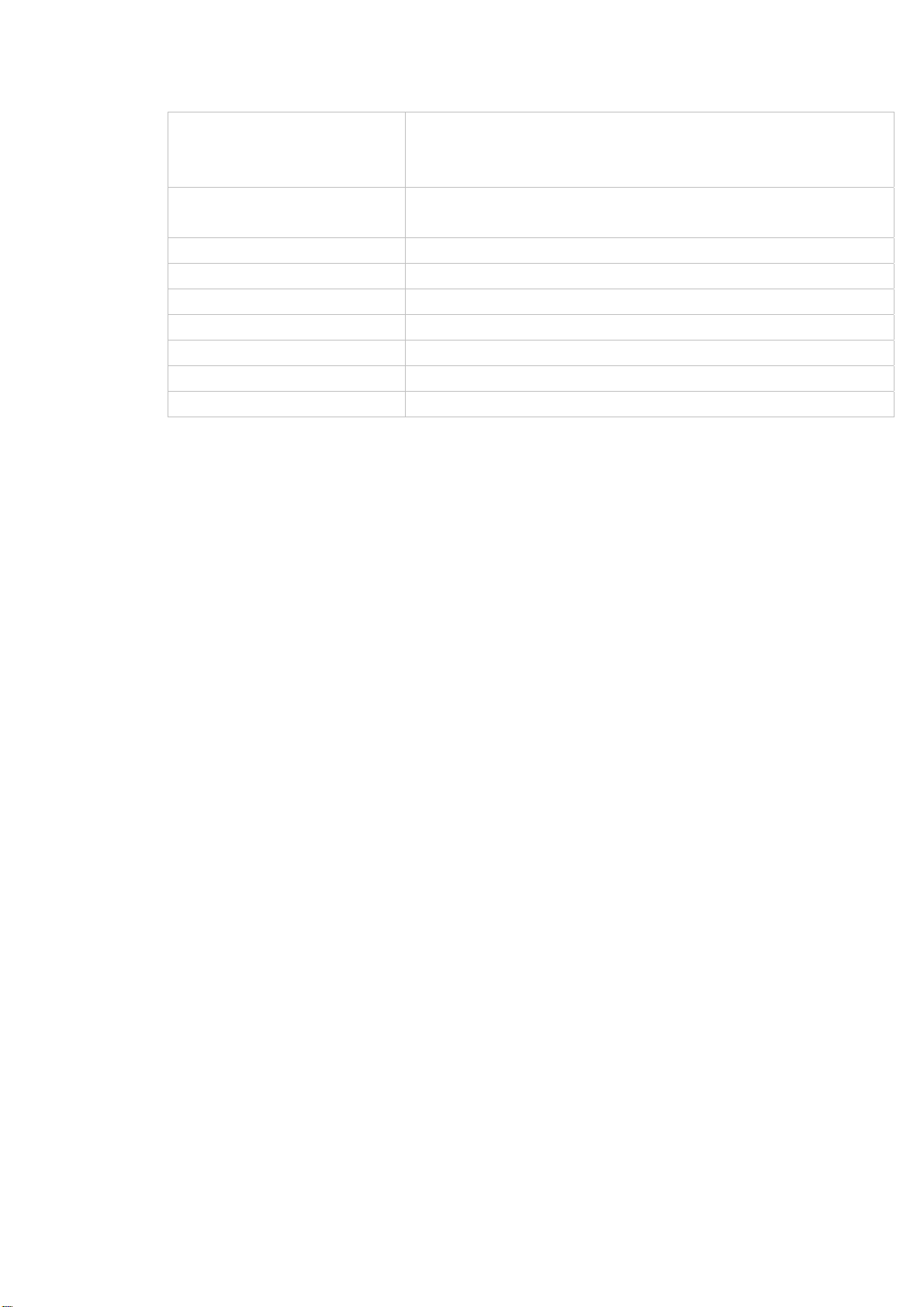

1.4 Product Specification

Model IFT-802

Standard IEEE 802.3 10BASE-T

IEEE 802.3u 100BASE-TX / 100BASE-FX

IEEE 802.3x Flow Control and Back pressure

10/100Mbps TP CAT-3/5 (10/100Mbps) Twisted Pair cable Auto MDI/MDI-X and Auto-Negotiation

Function Support

Fiber Connector Multi-Mode SC connector

Architecture Store and forward

Fiber Parameters Fiber Core: Multi-Mode (62.5/125µm, 50/125µm). Wavelength: 1310nm

Fiber Distance: Multi-Mode Fiber, up to 2Km

Link Lost Forward TX to Fiber: If TX port link down, the media converter will force Fiber port to link down

Fiber to TX: If Fiber port link down, the media converter will force TX port to link down.

DIP Switch DIP Switch 1:

ON: Enables Port Alarm

OFF: Disables Port Alarm

DIP Switch 2:

ON: Enables LLF (Link Lose Forwarding)

OFF: Disables LLF (Link Lose Forwarding)

DIP Switch 3:

ON: 100Base-FX Half-mode

OFF: 100Base-FX Full-mode

DIP Switch 4:

ON: 100Base-TX Full-duplex mode

OFF: Auto-Negotiation

LED Power (Green), Power1 (Green), Power2 (Green), Fault (Orange)

Fiber: Link/Activity (Green)

Half/Full Duplex (Orange)

Page 6

TX: 10/100(Green)

Link (Green)

Half/Full Duplex (Orange)

Power Supply 12~48 VDC, Redundant power with polarity reverse and overlap current protection

function

Power Consumption 4.6 Watts

Installation Provide DIN rail kit and wall mount plate for 3-way installation

Operating environment 0~60 Degree C, 5%~90%RH (Non-condensing)

Storage environment -40~85 Degree C, 5%~90%RH (Non-condensing)

Dimension (W x D x H) 54 × 105 × 155 mm

Emission FCC Class A, CE mark

Stability testing IEC60068-2-32(Free fall), IEC60068-2-27(Shock), IEC60068-2-6(Vibration)

Page 7

2. INSTALLATION

This section describes the functionalities of the Converter’s components and guides how to install it on

the rack or mount to the wall. Basic knowledge of networking is assumed. Please read this chapter

completely before continuing.

2.1 Product Description

2.1.1 Product Overview

The PLANET IFT-802 industrial 10/100BaseTX to 100BaseFX Media Converter is a cost- effective

solution for the converting 10/100Base-TX (Auto MDI/MDIX) to 100Base-FX cabling. It provides two

power inputs that can be connected simultaneously to the DC power sources. If one power input fails, the

other one acts as a backup.

The PLANET IFT-802 also provides relay alarm outputs to warn when the port link failure, so the

technician can respond quickly with appropriate emergency operation procedures. Also, there are DIP-

switches to set the operation mode for relay alarm, Fiber ports, link loss forwarding function, and UTP

operation mode.

2.1.2 Switch Front Panel

Figure 2-1 shows the front panel of the converter.

Figure 2-1 IFT-802 Front Panel

Page 8

2.1.3 LED Indications

There are 9 diagnostic LEDs located on the Front panel of industrial media converter. They provide

real-time information of system and optional status. The following table provides description of the LED

status and their meanings for the industrial media converter.

LED Status Meaning

Green When the IFT-802 has power input s the LED will light on

Power

Off No any power inputs

Green Power on

Power 1

Off No power inputs

Green Power on

Power 2

Off No power inputs

Orange Power failure or UTP port failure or Fiber port failure

Fault

LNK/ACT(Fiber)

FDX (Fiber)

10/100(UTP)

LNK/ACT(UTP)

Off

No Power failure or UTP port failure or Fiber port failure occurs or the

port alarm disable

Green The port is linking with its link partner.

Blinks The port is transmitting or receiving packets from the FX device.

Off No device attached

Orange The port is operating in full-duplex mode.

Off Half-duplex mode or no device attached

Green In 100Mbps transmitting speed

Off In 10Mbps transmitting speed

Green The port is linking with its link partner.

Blinks The unit is transmitting or receiving packets from the devices.

Off No device attached

FDX (UTP)

Orange The port is operating in full-duplex mode.

Off Half-duplex mode or no device attached

Page 9

2.1.4 DIP-Switch

The DIP-switch is used to configure operation mode for LLF (Link Lost Forwarding) operation mode for

UTP/Fiber port and relay alarm operation mode. The factory default mode of DIP switch is OFF.

DIP Switch No Status Description

1

2

3

4

Link Lose Forwarding:

When LLF is enabling, allow UTP link failures to be reported to the fiber side and also allow Fiber link

failure to be reported to the UTP side. Therefore, a link lost forward feature is provided in both UTP and

Fiber side.

ON Enable Port Alarm. If the port’s link fails, the fault LED will light up.

OFF Disable Port Alarm

ON LLF Enable

OFF LLF Disable

ON 100Base-FX Half Duplex mode

OFF 100Base-FX Full Duplex mode

ON 100Base-TX Full Duplex mode

OFF UTP Auto-Negotiation

#Notice:

Please don't change the DIP-switch setting when UTP or fiber port is transmitting or receiving data. It

may cause some data error. After change the DIP-switch setting, must execute Power OFF/ON to enable

new configures.

2.1.5 Converter Bottom Panel

The bottom panel of the Converter consist one terminal block connector within two DC power inputs and

one DC IN power jack for extra AC/DC power adapter. Figure 2-2 shows the bottom panel of the switch.

Figure 2-2 IFT-802 Bottom Panel.

Page 10

2.1.6 Wiring the Power Inputs

Please follow below steps to insert the power wire.

V - V + V - V +

1. Insert the positive and negative wires into the V+ and V- connector on the terminal block connector.

2. To tighten the wire-clamp screws for preventing the DC wires to loose.

2.1.7 Wiring the Fault Alarm Contact

The fault alarm contact is in the middle of terminal block connector as below figure shows. By inserting

the wires and set the DIPswitch at "ON" status, it will detect when power is failure or port link failure and

form an open circuit. And, the following figure shows an application example for the fault alarm contact.

Inset the wires into the falult alarm contact

Power Notice:

The wire range of terminal block is from 12~ 24 AWG.

Page 11

Fault Alarm Contact

The open circuit will form

when the power failure or

port link failure.

24V DC Buzzer 24V Battery

The fault alarm device will

send a warning signal t

warn the user, ex: alarm

sound or flash light.

2.2 Mounting Installation

This section describes how to install the Converter and make connections to it. Please read the following

topics and perform the procedures in the order being presented.

2.2.1 DIN-Rail mounting

The DIN-Rail is screwed on the Converter when out of factory. If the DIN-Rail is not screwed on the

Converter, please see the following figure to screw the DIN-Rail on the switch. To hang the Converter,

follow the below steps:

Page 12

Step1: Insert the top of DIN-Rail into the track.

Step2: Lightly push the button of DIN-Rail into the track.

Step3: Check the DIN-Rail is tightly on the track.

Step4: To remove the Converter from the track, reverse steps above.

2.2.2 Wall Mount Plate Mounting

To install the converter to the wall, please follows the instructions described below.

Step1: Remove the DIN-Rail from the industrial switch; loose the screws to remove the DIN-Rail.

Step2: Place the wall mount plate on the rear panel of the industrial switch.

Page 13

Step3: Use the screws to screw the wall mount plate on the Converter.

Step4: Use the hook holes at the corners of the wall mount plate to hang the Converter on the wall.

Step5: To remove the wall mount plate, reverse steps above.

Page 14

3. Hardware Installation

In this section, we will describe how to install the 10/100BaseTX to 100BaseFX Media Converter and the

installation points for the attention. In Figure G, it is an example application for the Converter.

Installation Steps

Step1: Unpacked the Industrial media converter.

Step2: Check the DIN-Rail is screwed on the Industrial media converter. Please refer to DIN-Rail

Mounting section for DIN-Rail installation if the DIN-Rail is not screwed on the Industrial media converter.

If you want to wall mount the Industrial media converter, then please refer to Wall Mount Plate Mountin g

section for wall mount plate installation.

Step3: To insert the Industrial media converter into the track or hang on the wall, please refer to the

Mounting Installation section.

Step4: Power on the Industrial media converter. The power LED on the Industrial media converter will

light up. Please refer to the LED Indicators section for meaning of LED lights.

Step5: Prepare the twisted-pair, straight through Category 5 cable for Ethernet connection and optic fiber

cable for fiber connection.

Page 15

#Notice:

The Fiber port has single-mode and multi-mode. To check your Industrial media converter fiber connector

type, look for the sticker on the Industrial media converter.

The multi-mode connector type must use 50 or 62.5/125 µm multi-mode fiber cable. The connect

distance between two devices is up to 2Km.

Step6: Insert one side of Category 5 cables into the Industrial media converter Ethernet port (RJ-45 port)

and another side of category 5 cables to the network switch's Ethernet port (RJ-45 port). The UTP port

(RJ-45) LED on the Industrial media converter will light up when the cable connected with the switch.

Please refer to the LED Indicators section for LED light meaning.

#Notice:

Be sure the connected local switch's Ethernet port support MDI/MDI-X. If it does not support then use the

crossover category 5 Cable.

Step7: Insert one side of fiber cable into the Industrial media converter fiber port and another side to the

convert in the opposite side connection. The fiber port LED on the converter will light up when the cable

connected. Please refer to the LED Indicators section for LED light meaning.

Step8: When all connections are all set and LED lights all show in normal, the installation is complete.

Page 16

4. TROUBLESHOOTING

This section is intended to help you solve the most common problems on the Industrial Media Converter.

4.1 Incorrect connections

The switch port can auto detect straight or crossover cable when you link switch with other Ethernet

device. For the RJ-45 connector should use correct UTP or STP cable, 10/100Mbps port use 2-pairs

twisted cable. If the RJ-45 connector is not correct pin on right position then the link will fail. For fiber

connection, please notice that fiber cable mode and fiber module should be match.

4.1.1 Faulty or loose cables

Look for loose or obviously faulty connections. If they appear to be OK, make sure the connections are

snug. IF that does not correct the problem, try a different cable.

4.1.2 Non-standard cables

Non-standard and miss-wired cables may cause numerous network collisions and other network problem,

and can seriously impair network performance. A category 5-cable tester is a recommended tool for

every 100Base-T network installation.

4.1.3 Improper Network Topologies

It is important to make sure that you have a valid network topology. Common topology faults include

excessive cable length and too many repeaters (hubs) between end nodes. In addition, you should make

sure that your network topology contains no data path loops. Between any two ends nodes, there should

be only one active cabling path at any time. Data path loops will cause broadcast storms that will severely

impact your network performance.

4.1.4 Incorrect Power Input

Verify that you are using the right power cord/adapter (DC 12-48V), please don't use the power adapter

with DC output bigger than 48V, or it will burn this converter down.

4.2 Diagnosing LED Indicators

The Switch can be easily monitored through panel indicators to assist in identifying problems, which

describes common problems you may encounter and where you can find possible solutions.

IF the power indicator does turn on when the power cord is plugged in, you may have a problem with

power outlet, or power cord. However, if the Switch powers off after running for a while check for loose

Page 17

power connections, power losses or surges at power outlet. IF you still cannot resolve the problem,

contact your local dealer for assistance.

4.2.1 Cabling

RJ-45 ports: use unshielded twisted-pair (UTP) or shield twisted-pair (STP) cable for RJ-45 connections:

100Ω Category 3, 4 or 5 Cable for 10Mbps connections or 100Ω Category 5 cable for 100Mbps

connections. Also be sure that the length of any twisted-pair connection does not exceed 100 meters

(328 feet).

Diagnosing LED Indicators: the Switch can be easily monitored through panel indicators to assist in

identifying problems, which describes common problems you may encounter and where you can find

possible solutions.

IF the power indicator does not turn on when the power cord is plugged in, you may have a problem with

power cord. Than check for loose power connections, power losses or surges at power outlet. IF you still

cannot resolve the problem, contact your local dealer for assistance.

If the Industrial switch LED indicators are normal and the connected cables are correct and the packets

still cannot transmit. Please check your system's Ethernet devices' configuration or status.

Page 18

Appendix A Networking Connection

A.1 Switch‘s RJ-45 Pin Assignments

Contact MDI MDI-X

1 1 (TX +) 3

2 2 (TX -) 6

3 3 (RX +) 1

6 6 (RX -) 2

4, 5, 7, 8 Not used Not used

A.2 RJ-45 cable pin assignment

2 1

3 6

2 1 3 6

6

3

2

1

There are 8 wires on a standard UTP/STP cable and each wire is color-coded. The following shows the

pin allocation and color of straight cable and crossover cable connection:

Figure A-1: Straight-Through and Crossover Cable

Please make sure your connected cables are with same pin assignment and color as above picture

before deploying the cables into your network.

2081-AH0010-000

Loading...

Loading...