Page 1

Mariner

LX0801PTI/ LX1201PTI/ LX1501PTI

IP-65 Touch Monitors

USER’S GUIDE

www.planar.com

Page 2

The information contained in this document is subject to change without notice. This document

contains proprietary information that is protected by copyright. All rights are reserved. No part of

this document may be reproduced, translated to another language or stored in a retrieval system,

or transmitted by any means, electronic, mechanical, photocopying, recording, or otherwise,

without prior written permission.

Windows® is a registered trademark of Microsoft, Inc.

Other brands or product names are trademarks of their respective holders.

Important Recycle Instruction:

LCD Lamp(s) inside this product contain mercury. This product may contain other

electronic waste that can be hazardous if not disposed of properly. Recycle or dispose

in accordance with local, state, or federal Laws. For more information, contact the

Electronic Industries Alliance at HYPERLINK “http://WWW.EIAE.ORG”

For lamp speci c disposal information check WWW.LAMPRECYCLE.ORG.

2 LX0801PTI/ LX1201PTI/ LX1501PTI - IP-65 Touch Monitors User’s Guide (020-0512-01A)

Page 3

Table of Contents

Usage Notice

Precautions .................................................................................................................................... 5

In a Watercraft or Vehicle ...................................................................................................... 5

Cleaning the Monitor ............................................................................................................. 5

Introduction

About the Product ...................................................................................................................... 6

Front View .................................................................................................................................. 6

Rear View with Connector Information ........................................................................... 7

Features....................................................................................................................................... 8

Package Overview ....................................................................................................................... 9

Installation

Before Installing .........................................................................................................................10

Step 1 - Mounting the Monitor.........................................................................................11

Step 2 - Connecting the Monitor .....................................................................................12

Step 3 - IRtouch Software Installation ...........................................................................13

User Controls

Front Panel Controls .................................................................................................................17

Turning the Monitor On and O .......................................................................................... 18

Using the Touchscreen ............................................................................................................ 18

Navigating the Touchscreen .................................................................................................. 18

Cleaning the Monitor ...............................................................................................................18

Appendix

Troubleshooting the Monitor ...............................................................................................20

Speci cations ............................................................................................................................21

LX0801PTI/ LX1201PTI/ LX1501PTI - IP-65 Touch Monitors User’s Guide (020-0512-01A) 3

Page 4

Addendum A .................................................................................................................................... 24

USB Control of OSD Functions ............................................................................................... 24

Addendum B ................................................................................................................................... 24

Wiring the IP-67 sealed eld installable connector manufactured by LTW

(p/n LTWCD-07 BFFA-LL 7001) .......................................................................... .................... 24

Addendum C ................................................................................................................................... 24

Mechanical Drawing for LX0801 PTI- (not available at time of print) ...................... 24

Addendum D ................................................................................................................................... 25

Mechanical drawing for LX1201PTI ..................................................................................... 25

Addendum E .................................................................................................................................... 26

Mechanical Drawing for LX1501PTI ..................................................................................... 26

Support and Service ...................................................................................................................... 27

4 LX0801PTI/ LX1201PTI/ LX1501PTI - IP-65 Touch Monitors User’s Guide (020-0512-01A)

Page 5

Usage Notice

WARNING – Please do not open or disassemble the product as this may

!

cause electric shock. Doing so will void the warranty.

ATTENTION – Do not plug the touchscreen in yet! Install the touchscreen

!

driver rst!

Precautions

To maximize the life and safe use of your unit, always be sure to follow the

warnings, precautions and maintenance recommendations in this user’s guide.

In a Watercraft or Vehicle:

The monitor should be visible to the driver only if it is used for navigation, or •

system control. Care should be taken to ensure distraction does not occur.

Review all applicable federal, state and local laws and regulations to make sure •

the monitor is used properly and safely.

Avoid using the monitor for extended times while the charging system is not •

running, or the monitor could drain the watercraft’s battery.

Cleaning the Monitor:

Use a soft cloth moistened with mild detergent, isopropyl alcohol, or window •

cleaners to clean the display housing.

Never use abrasive cleaners, waxes or solvents to clean the unit.•

LX0801PTI/ LX1201PTI/ LX1501PTI - IP-65 Touch Monitors User’s Guide (020-0512-01A) 5

Page 6

Introduction

About Planar’s Mariner Touch Monitors

The LX0801PTI, LX1201PTI and LX1501PTI are high-performance, rugged touch

monitors intended for demanding environments, such as those aboard a watercraft.

The monitors feature a AMLCD TFT display with IR touchscreen, bright enough to

be read in daylight. The monitors include several mounting points for front or rear

mounting. The monitors are to be powered directly from circuit breaker protected

and switched 8-32 VDC power aboard the watercraft. The metal enclosure is IP-65,

designed to withstand liquid and dust intrusion. An optional cosmetic bezel is

included with each monitor.

1

3

2

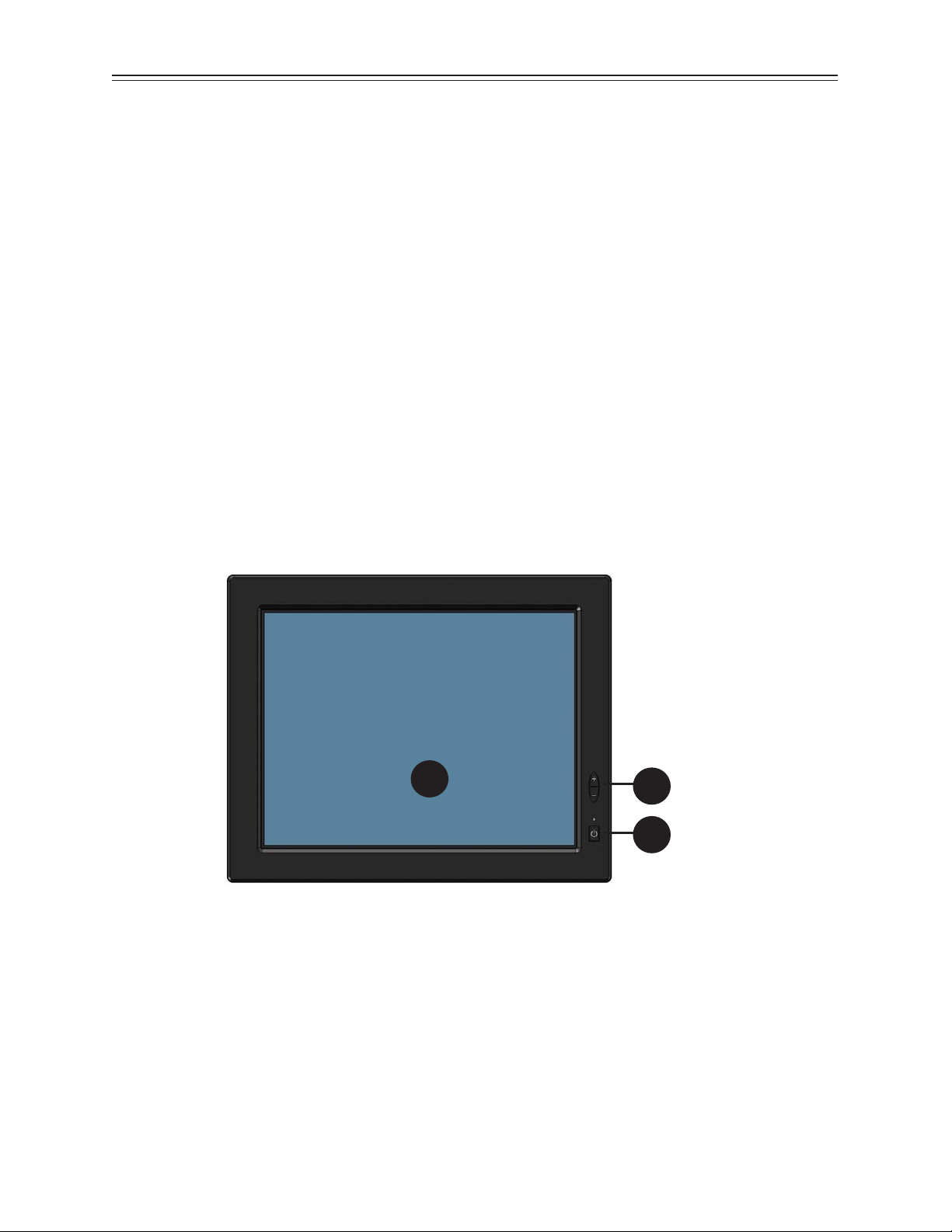

Front Views:

AMLCD TFT with Touchscreen1.

Auxiliary power switch2.

Brightness adjust/auto sync buttons3.

6 LX0801PTI/ LX1201PTI/ LX1501PTI - IP-65 Touch Monitors User’s Guide (020-0512-01A)

Page 7

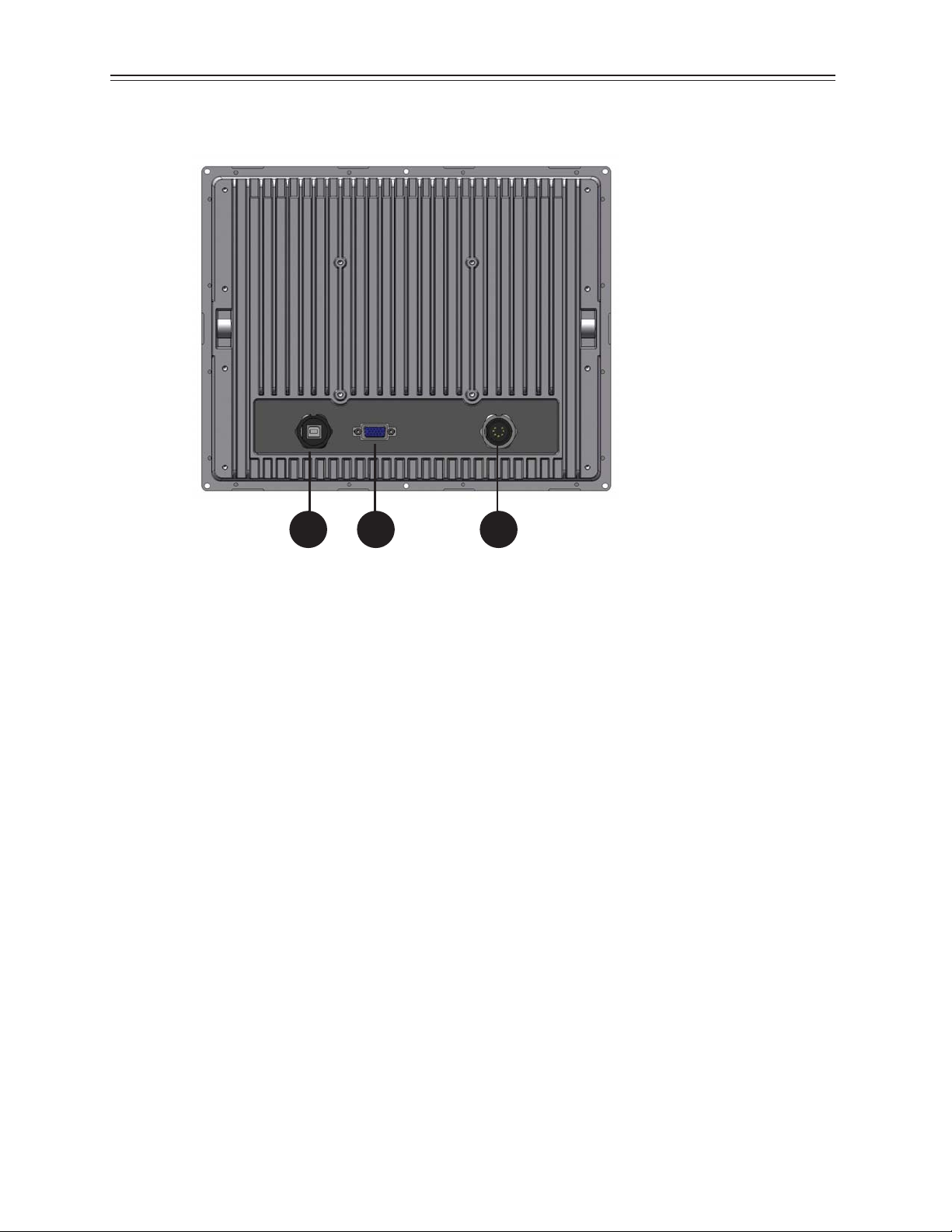

1 2 3

Rear View (Descriptions):

USB port (Type B) for connecting the touchscreen to the remote computer1.

VGA Signal Input2.

8-32 VDC Internally Regulated Power Input3.

Modular, removable connector plate for customizing I/O (not available on 12" 4.

model at time of print)

Mating Connectors (sourced from http://www.ltw-tech.com):

USB Cable Assembly: 1 to 5 meter available. LTWWUB-20BFM-A7Axx (01, 02,

...05 for meter length)

VGA: The VGA connector located inside the monitor is waterproof.

The connector style is standard 15-pin VGA.

DC Power Connector Only: LTWCD-07BFFA-LL 7001

DC Cable Assembly: LTWCD07AFFM-LL7Axx (01, 02, ... 99 meter length)

LX0801PTI/ LX1201PTI/ LX1501PTI - IP-65 Touch Monitors User’s Guide (020-0512-01A) 7

Page 8

Features

Brightness control• allows you to easily adjust the display to match the

ambient light, from full sunlight to night.

The monitor’s • TFT display is optically bonded to the Touchscreen to

increase contrast ratio. Increased contrast ratio makes it easier to

read information displayed on the monitor.

The monitor’s • autosync function eliminates the need for adjusting the

monitor for the best image - the monitor automatically makes any needed

adjustments whenever it is powered up or the display mode is changed.

The monitor supports • standard VGA signal input:

LX0801PTI is 800 x 600 SVGA (native) and 640 x 480. •

LX1201PTI and LX1501PTI are 1024 x 768 (native), 800 x 600 and •

640 x 480.

The monitor’s IP-65 • enclosure protects from splashed water and dust. It

is designed to withstand shock and vibration for greater endurance and

reliability.

There are several mounting point features incorporated in the design of •

the enclosure to enable installation exibility.

Note: The LX0801PTI/LX1201PTI/LX1501PTI monitors do not have OSD controls

available from the front buttons. All OSD commands can be controlled via USB

cable from the host CPU (see Addendum A).

8 LX0801PTI/ LX1201PTI/ LX1501PTI - IP-65 Touch Monitors User’s Guide (020-0512-01A)

Page 9

Package Overview

The following items are shipped with the display. If any of these items are not in the

shipping container, please contact Planar.

LX080PTI/ LX1201PTI/ LX1501PTI

Touch Monitor

(Bezel is attached for shipping.)

Quick Start Guide

2M Power Cord

Note: Mounting hardware (M4 Screws), mounting brackets, power supply,

USB and video cables are sold separately.

Software drivers can be downloaded from www.Planar.com/downloads

LX0801PTI/ LX1201PTI/ LX1501PTI - IP-65 Touch Monitors User’s Guide (020-0512-01A) 9

Page 10

Installation

Before Installing

Keep the following in mind while installing the monitor:

The monitor should be visible to the driver only if it is used for navigation, •

system control or vehicle information. If the monitor will be used for other

purposes, it should be installed in such a way that it will only operate while the

watercraft is not moving.

Review all applicable federal, state and local laws and regulations to make sure •

the monitor is used properly and safely.

The installed monitor must not interfere with the driver’s vision.•

Installing the monitor consists of three steps:

Attaching the monitor using one of the mounting interfaces built into the 1.

monitor’s enclosure.

Connecting the monitor to the computer and power source.2.

Installing the touchscreen driver software. 3.

10 LX0801PTI/ LX1201PTI/ LX1501PTI - IP-65 Touch Monitors User’s Guide (020-0512-01A)

Page 11

Step 1 - Mounting the Monitor

The back and sides of the monitor include mounting points that you can use to

mount the monitor as your installation requires.

Mounting holes on the LX0801PTI, LX1201PTI and LX1501PTI allow the monitor

to be mounted :

Front mounted using corner mounting holes•

Rear mounted using either VESA or edge mounting holes•

Side mounted using variegated bosses•

1

4

3

Mounting from front:

2

4 corner mounting non-tapped holes in 1.

ange (clearance for M4 fastener).

Mounting from rear:

100mm VESA (4 hole pattern). Accepts 2.

M4x0.7 up to 8mm depth.

Edge casting holes (8 hole pattern) 3.

Accepts M4x0.7 up to 8mm depth.

Mounting from side:

Variegated mounting bosses Accepts 4.

M8x1.25 up to 8mm depth.

Mounting monitor to be mounted :

Rear using rear peripheral mounting bosses•

Side points•

Side bosses•

Panel points•

Use the proper M4 screws for attaching the monitor to the mounting xture.

Removing Bezel:

If you are ange mounting the monitor, it •

will be necessary to remove the decorative

bezel from the enclosure. As shown, insert a

narrow straight blade screw driver between

the bezel and enclosure near one of the

friction points. Pry upwards gently.

LX0801PTI/ LX1201PTI/ LX1501PTI - IP-65 Touch Monitors User’s Guide (020-0512-01A) 11

Page 12

Step 2 - Connecting the Monitor

Once the monitor is mounted in place, connect it to the computer (or other

video source) and the regulated DC power supply as follows. Planar does not supply

a power supply. The monitor is intended to be powered from the watercraft’s DC

power system. Power to the monitor (and CPU) is hard switched from the line power

that should be protected by a magnetic hydraulic circuit breaker. DO NOT connect

the USB cable at this time!

Note: This procedure refers to connections to and from the computer.

However, depending on your particular hardware con guration, these

connections may be to a dock or other device rather than directly to

the computer.

Install IRtouch software on computer.1.

As needed, route any data and power cables from the computer to the 2.

monitor.

Make sure the computer is turned o . Connect video cable and USB cable.3.

Connect to the monitor’s power supply.4.

Note: Use a appropriately sized fuse in line to the power source. Also, to

prevent the watercraft’s battery from draining in standby mode, you

should install a device that shuts o power to the monitor while the

monitor is inactive. (An example is Lind Electronic’s Vehicle Battery

Voltage Shutdown Timer - www.lindeletronic.com).

12VDC system: 4A slow blow fuse

24VDC system: 2A slow blow fuse

Turn on power to the computer and monitor. The monitor then turns on as 5.

soon as it receives a video signal from the computer, and its LED turns green.

Also, the rst time the monitor is powered up, it automatically displays a test

pattern of repeating colored screens (black, white, red, green, and blue) until a

video signal is detected.

Note: For best results, adjust the display mode of the computer to a resolution

of 800 x 600 (LX0801PTI) or 1024 x 768 (LX1201PTI and LX1501PTI) and a

refresh rate of 60 Hz.

12 LX0801PTI/ LX1201PTI/ LX1501PTI - IP-65 Touch Monitors User’s Guide (020-0512-01A)

Page 13

Step 3 - IRtouch Software Installation

IMPORTANT – Do not plug in the touchscreen yet! Install the driver rst.

!

Run IRtouch driver setup1.

Accept user agreement2.

3. Install in default location

LX0801PTI/ LX1201PTI/ LX1501PTI - IP-65 Touch Monitors User’s Guide (020-0512-01A) 13

Page 14

Click Install4.

Click continue, you can trust Planar and IRtouch5.

Click on Finish6.

Attach the Planar monitor to the system or install the computer to a

docking station. Attach the USB cable. After the USB cable from the

monitor is attached to the computer it will recognize the touchscreen for

the rst time.

14 LX0801PTI/ LX1201PTI/ LX1501PTI - IP-65 Touch Monitors User’s Guide (020-0512-01A)

Page 15

7. Continue

Click Finish8.

Click the IRtouch icon located on your desktop to calibrate the touch 9.

monitor.

Click Calibrate10.

LX0801PTI/ LX1201PTI/ LX1501PTI - IP-65 Touch Monitors User’s Guide (020-0512-01A) 15

Page 16

Set Modes11.

When used in rugged environments with software written for touchscreens,

you may nd it easier to use the ‘click on release’ radio button.

Beep 12.

You can set the computer to beep on touch activation if needed.

16 LX0801PTI/ LX1201PTI/ LX1501PTI - IP-65 Touch Monitors User’s Guide (020-0512-01A)

Page 17

User Controls

Front Panel Controls

3

2

1

CONTROL FUNCTION

Auxiliary Power Switch Turns the CPU o and sends signal to host PC through

power cable.

Brightness Adjust Switches Enables brightness adjustment by depressing

one or the other button. Depressing both buttons

simultaneously enables auto sync of the monitor to

the video source.

Touchscreen Enables user to control software and computer with a

touch

Note: The Mariner design does not have a power switch that turns o the power to

the monitor. This is because the vast majority of marine installations utilize a

circuit breaker to turn power on/o to electrical devices.

LX0801PTI/ LX1201PTI/ LX1501PTI - IP-65 Touch Monitors User’s Guide (020-0512-01A) 17

Page 18

Turning the Monitor On and Off

The monitor’s power button can control power to the display and CPU. It is

not designed to electrically isolate the monitor or CPU from the supply. Use

an appropriately sized (4A slow blow 12VDC/2A slow blow 24VDC) magnetic

hydraulic circuit breaker to switch line power on/o .

Note: Be sure to con gure the computer’s power options, including how the

computer responds, when the button is pressed. See Windows on-line

help for details. The monitor goes into standby whenever the computer is

put into sleep or into hibernation.

Using the Touchscreen

The touchscreen allows you to operate the computer by touching

the screen with a nger or stylus, rather than using a mouse or keyboard.

Navigating the Touchscreen

To click an item, tap the item once.•

To double-click an item, tap the item twice rapidly.•

To drag an item, touch the item, and then drag it along the screen to the •

new location.

To move the cursor, touch the screen and move the cursor as needed.•

Cleaning the Monitor

Clean the monitor’s touchscreen periodically to keep the display image bright

and sharp, and to keep the touchscreen functions working properly.

• Always turn o the monitor before cleaning.

• Clean the touchscreen with a dry soft cloth. If this does not clean

the screen adequately, preferably use Sparkle or Glass X cleaners.

18 LX0801PTI/ LX1201PTI/ LX1501PTI - IP-65 Touch Monitors User’s Guide (020-0512-01A)

Page 19

If these optimal cleaners are not available use water or mild glass or window cleaner

(that does not contain ammonia) applied to the cloth and not to the display.

• Clean the monitor housing with a soft cloth moistened with mild

detergent.

• Never apply abrasive cleaners, waxes or solvents to the monitor.

LX0801PTI/ LX1201PTI/ LX1501PTI - IP-65 Touch Monitors User’s Guide (020-0512-01A) 19

Page 20

Appendix

Troubleshooting the Monitor

If you are experiencing trouble with the monitor, refer to the following. If the

problem persists, please contact your local dealer or our service center.

Problem: No image appears on screen

Make sure the brightness is not turned all the way down.•

Make sure all data and power cables are properly connected to the •

monitor and to the computer and power supply.

Make sure the pins on the cables and connectors are not crooked or •

broken.

Make sure the computer is functioning properly, and has not entered •

power-saving mode. (You may also want to disable the computer’s

power-saving feature.)

Problem: Partial image or incorrectly displayed image

Make sure the computer’s image resolution is set to one of these •

resolutions: 1024 x 768 (XGA) (LX1201PTI only), 800 x 600 (SVGA) or 640

x 480 (VGA).

Problem: Image is scrolling

Check and make sure the VGA signal cable (or adapter) is securely •

connected at both ends.

Initiate an auto-sync to solve the problem.•

Problem: The monitor does not appear to respond to the touchscreen

Make sure the USB cable to the computer is securely connected at both •

ends.

20 LX0801PTI/ LX1201PTI/ LX1501PTI - IP-65 Touch Monitors User’s Guide (020-0512-01A)

Page 21

Specifi cations

Parameter LX1501PTI - 15"

Display Type

Full Color TFT AMLCD

Display Viewing Area

Diagonal Viewing Area

Display Color

Resolution

Contrast Ratio

Response Time

Luminance

Horizontal Viewing Angle (CR>5)

Vertical Viewing Angle (CR>5)

Video Input

Backlight

Backlight Adjustment

Backlight Inverter

Power Consumption

Touch screen

Touch screen Interface

Cover Glass

304 (w) x 228 (h) mm

15" (381 mm)

262 K (6 bit/color); 16.7 m (8 bit)

1024 (H) x 768 (V) pixels XGA

650:1 (typical)

25 ms (on/off)

1200 Nits (typical)

80° (right), 80° (left)

80° (down), 70° (up)

VGA

6 CCFLs

0-100% dimmable

Pizeoelectric, dims to o

<45 Watts (total), 4.2W standby typical with USB

connected; 3.6W standby typical without USB.

Infrared, 4096 points of resolution

USB

AG etched, direct bonded

Operating Survival Temp Range

Operating Temperature

Storage Temperature

Shock

Vibration, Endurance

Vibration, Operating

Humidity

Emission

Immunity

Reverse Polarity Protection

Regulatory and Safety

Enclosure Including Front Bezel

Input/Outputs

-40° C to + 70° C

-20° C to + 70° C

-20° C to + 80° C

30 Gs, Half Sine Wave, 11 ms

10-500 Hz, 2 Gs rms, 1hr/axis

10-500 Hz, 2 Gs rms, 1hr/axis

90% RH @ 40° C, Non-condensing

EN 55022, EN6100-3-2, -3

IEC 6100-4-2, -3, -4, -5, -6, -8, -11: 1995

Protected

FCC Class B, CE, UL/CUL, TUV

IP-65 (Waterproof)

Power On/O Button

Dimming/Auto Sync rocker switch

Watertight USB “B” Type

Watertight VGA 15-Pin

Watertight Power Connector (LTW p/n LTWCD-07BFFALL7001 is eld installable mating connector)

LX0801PTI/ LX1201PTI/ LX1501PTI - IP-65 Touch Monitors User’s Guide (020-0512-01A) 21

Page 22

Parameter LX1201PTI - 12.1"

Display Type

Full Color TFT AMLCD

Display Viewing Area

Diagonal Viewing Area

Display Color

Resolution

Contrast Ratio

Response Time

Luminance

Horizontal Viewing Angle (CR>5)

Vertical Viewing Angle (CR>5)

Video Input

Backlight

Backlight Adjustment

Backlight Inverter

Power Consumption

Touch screen

Touch screen Interface

Cover Glass

246 (w) x 184.5 (h) mm

12.1" (307 mm)

262 K (6 bit/color); 16.7 m (8 bit)

1024 (H) x 768 (V) pixels XGA

650:1 (typical)

25 ms (on/off)

>800 Nits (typical)

65° (right), 65° (left) (CR>1)

80° (down), 70° (up) (CR>1)

VGA

4 CCFLs

0-100% dimmable

Pizeoelectric, dims to o

<30 Watts (total), 4.2W standby typical with USB

connected; 3.6W standby typical without USB.

Infrared, 4096 points of resolution

USB

AG etched, direct bonded

Operating Survival Temp Range

Operating Temperature

Storage Temperature

Shock

Vibration, Endurance

Vibration, Operating

Humidity

Emission

Immunity

Reverse Polarity Protection

Regulatory and Safety

Enclosure Including Front Bezel

Input/Outputs

-40° C to + 70° C

-20° C to + 70° C

-20° C to + 80° C

18 Gs, SAE J1455

100-1100 Hz, 4 Gs rms, 1hr/axis

5-150 Hz, 4 Gs rms, 1hr/axis

95% RH, Non-condensing

-

-

Protected

FCC Class A, CE, UL/CUL, TUV

IP-65 (Waterproof)

Power On/O Button

Dimming/Auto Sync rocker switch

Watertight USB “B” Type

Watertight VGA 15-Pin

Watertight Power Connector (LTW p/n LTWCD-07BFFALL7001 is eld installable mating connector)

22 LX0801PTI/ LX1201PTI/ LX1501PTI - IP-65 Touch Monitors User’s Guide (020-0512-01A)

Page 23

Parameter LX0801PTI - 8.4"

Display Type

Full Color TFT AMLCD

Display Viewing Area

Diagonal Viewing Area

Display Color

Resolution

Contrast Ratio

Response Time

Luminance

Horizontal Viewing Angle (CR>5)

Vertical Viewing Angle (CR>5)

Video Input

Backlight

Backlight Adjustment

Backlight Inverter

Power Consumption

Touch screen

Touch screen Interface

Cover Glass

170 (w) x 127 (h) mm

8.4" (213 mm)

262 K (6 bit/color); 16.7 m (8 bit)

1024 (H) x 768 (V) pixels XGA

650:1 (typical)

-

700 Nits (typical)

80° (right), 80° (left)

60° (down), 80° (up)

VGA

2 CCFLs

0-100% dimmable

Pizeoelectric, dims to o

<15 Watts (total), 4.2W standby typical with USB connected; 3.6W standby typical without USB.

Infrared, 4096 points of resolution

USB

AG etched, direct bonded

Operating Survival Temp Range

Operating Temperature

Storage Temperature

Shock

Vibration, Endurance

Vibration, Operating

Humidity

Emission

Immunity

Reverse Polarity Protection

Regulatory and Safety

Enclosure Including Front Bezel

Input/Outputs

-40° C to + 70° C

-20° C to + 60° C (-4° to 140° F)

-20° C to + 85° C (-4° to 185° F)

18 Gs, SAE J1455

100-1100 Hz, 4 Gs rms, 1hr/axis

5-150 Hz, 4 Gs rms, 1hr/axis

95% RH, Non-condensing

-

-

Protected

FCC Class A, CE, UL/CUL, TUV

IP-65 (Waterproof)

Power On/O Button

Dimming/Auto Sync rocker switch

Watertight USB “B” Type

Watertight VGA 15-Pin

Watertight Power Connector (LTW p/n LTWCD-07BFFALL7001 is eld installable mating connector)

LX0801PTI/ LX1201PTI/ LX1501PTI - IP-65 Touch Monitors User’s Guide (020-0512-01A) 23

Page 24

Addendum A

An interconnection to the host PC with USB can be exploited by the customer to

create an OSD. Planar has utilized a powerful Pixelworks video IC to enable this

functionality should customers desire increased control functions. Planar does

not provide the programming to do this. Please consult with Planar’s application

engineering team if you have questions about the scale of this undertaking.

Contact sales@planar.com.

Addendum B

Pins 4 and 5 are the switch connections. These are connected to our front bezel

button so when the button is depressed these signals will be shorted together for

as long as you hold the button. When you release the button the connection will

be open.

Addendum C

Note, this manual has been published prior to the release of LX0801PTI, please

consult factory for additional information.

24 LX0801PTI/ LX1201PTI/ LX1501PTI - IP-65 Touch Monitors User’s Guide (020-0512-01A)

Page 25

Addendum D

186

(TOUCH

262

SCREEN

OPENING)

325

(TOUCH SCREEN OPENING)

247

BRIGHNESS

CONTROL

35

61

75

REMOTE CPU POWER SWITCH

(NOT DISPLAY POWER)

142

275.025

8X M4x0.7

MOUNTING HOLES

7MM MIN THREAD

DEPTH

2X M8.0x1.25

10MM MIN THREAD

DEPTH

210.0 100.0

FEATURE ALLOWS

FOR TILTING AND

LOCK DOWN

MOUNTING. SEE

CAD DATA.

67

135.0

75.0

26

TOUCH SCREEN

CONNECTOR

LTWUB-20PMFP-SC8002

POSSIBLE MATING CABLES

LTWUB-20BFM-A7A02 (2m LONG)

LTWUB-20BFM-A7A05 (5m LONG)

112 100.0

USB TYPE B

VGA CONNECTOR

LTWHDB-15PFFP-SA8001

POSSIBLE MATING CABLES

LTWHDB-15AMMM-SL7A02 (2m LONG)

LTWHDB-15AMMM-SL7A05 (5m LONG)

FIELD INSTALLABLE CONNECTOR

LTWHDB-15BMMA-SL7001

A

4X M4x0.7

MOUNTING HOLES

7MM MIN THREAD

DEPTH

81

LOCKING POWER

INPUT CONNECTOR

LTWCD-07PMMS-LC7001

POSSIBLE MATING CABLE

LTWCD-07AFFM-LL7A02 (2m LONG)

FIELD INSTALLABLE CONNECTOR

LTWCD-07BFFA-LL7001

LX0801PTI/ LX1201PTI/ LX1501PTI - IP-65 Touch Monitors User’s Guide (020-0512-01A) 25

Page 26

Addendum E

231

(TOUCH

317

SCREEN

OPENING)

392

307

(TOUCH SCREEN OPENING)

BRIGHNESS

CONTROL

64

90

104

REMOTE CPU POWER SWITCH

(NOT DISPLAY POWER)

171

336.028

4X M4X0.7

MOUNTING HOLES

5MM MIN THREAD

DEPTH

260

28

TOUCH SCREEN

CONNECTOR

75

POSSIBLE MATING CABLES

LTWUB-20BFM-A7A02 (2m LONG)

LTWUB-20BFM-A7A05 (5m LONG)

USB TYPE B

LTWUB-20PMFP-SC8002

146

VGA CONNECTOR

LTWHDB-15PFFP-SA8001

POSSIBLE MATING CABLES

LTWHDB-15AMMM-SL7A02 (2m LONG)

LTWHDB-15AMMM-SL7A05 (5m LONG)

FIELD INSTALLABLE CONNECTOR

LTWHDB-15BMMA-SL7001

100.0

A

LOCKING POWER

INPUT CONNECTOR

LTWCD-07PMMS-LC7001

POSSIBLE MATING CABLES

LTWCD-07AFFM-LL7A02 (2m LONG)

FIELD INSTALLABLE CONNECTOR

LTWCD-07BFFA-LL7001

4X M4X0.7

MOUNTING HOLES

5.5MM MIN THREAD

DEPTH

100.0

128

26 LX0801PTI/ LX1201PTI/ LX1501PTI - IP-65 Touch Monitors User’s Guide (020-0512-01A)

Page 27

Support and Service

Planar is a US company based in Beaverton, Oregon and Espoo, Finland, with a

world-wide sales distribution network. Full application engineering support and

service are available to make the integration of Planar displays as simple and quick

as possible for our customers.

RMA Procedure: For a Returned Material Authorization number, please contact Planar

Systems, Inc. with the model number(s) and serial number(s). When returning goods

for repair, please include a brief description of the problem, and mark the outside of

the shipping container with the RMA number.

Planar Systems, Inc.

Customer Service

24x7 Online Technical Support: http://www.planar.com/support

Email: PlanarSupport@planar.com

Americas Support

1195 NW Compton Drive

Beaverton, OR 97006-1992

Tel: 1-866-PLANAR-1 (752-6271) (US only)

1-503-748-5799 (outside the US)

Hours: M-F, 8am - 8pm Eastern Time | 5am - 5pm Paci c Time

Europe and Asia-Paci c Support

Olarinluoma 9 PO Box 46

FIN-02201 Espoo, Finland

Tel: +358-9-420-01

Hours: M-F, 7am - 4pm CET

© 2008 Planar Systems, Inc. 8/08 Planar is a registered trademark of Planar Systems, Inc.

Other brands and names are the property of their respective owners.

Technical information in this document is subject to change without notice.

Document No. 020-0512-01A

LX0801PTI/ LX1201PTI/ LX1501PTI - IP-65 Touch Monitors User’s Guide (020-0512-01A) 27

Loading...

Loading...