LC640.480.21-065

HIGH PERFORMANCE 6.5" COLOR TFT AMLCD

Operations Manual

The Definition of Quality

®

Copyright © 2000 by Planar Systems, Inc.

Planar and The Definition of Quality are registered trademarks.

ColorBrite is a trademark of Planar Systems, Inc.

This document is subject to change without notice. Planar provides this information as reference only and does not imply any

recommendation or endorsement of other vendor’s products.

Revision Control

Date Description

September 2000 Document number OM610-00

Contents

LC640.480.21-065 Display ............................................................................................................. 1

Features and Benefits................................................................................................................... 1

Installation and Handling................................................................................................................. 2

Mounting the Display .................................................................................................................. 2

Mounting Display Face Down.................................................................................................2

Mounting Display Face Up ..................................................................................................... 2

Thermal Control...................................................................................................................... 2

Isolation and Air Gap..............................................................................................................2

Ambient Light Sensor Clearance.............................................................................................3

Cable Length................................................................................................................................3

Cleaning....................................................................................................................................... 3

Avoiding Image Retention........................................................................................................... 3

Specifications .................................................................................................................................. 4

Environmental Characteristics..................................................................................................... 4

Safety and EMI Certifications................................................................................................. 4

Reliability and Backlight Life.................................................................................................. 4

Mechanical Characteristics..........................................................................................................5

Optical Characteristics................................................................................................................. 6

Viewing Angles........................................................................................................................ 7

Response Times ....................................................................................................................... 7

Interfacing and Operation................................................................................................................ 8

Control Basics.............................................................................................................................. 8

Power Requirements................................................................................................................8

Power Sequencing (LCD)........................................................................................................ 9

Video Signals...............................................................................................................................9

Video Signal Characteristics................................................................................................... 9

Signal Timing......................................................................................................................... 10

Video Characteristics................................................................................................................. 14

Pixel Position......................................................................................................................... 15

Warmup Characteristic ......................................................................................................... 16

Connectors................................................................................................................................. 17

Video Input and Backlight Control Connector (J1).............................................................. 17

Backlight Inverter and Heater Connector (J2) ..................................................................... 19

Ambient Light Sensor (Tethered Option) (J3)....................................................................... 19

Luminance Features....................................................................................................................... 20

Backlight Dimming.................................................................................................................... 20

Manual Dimming...................................................................................................................20

Automatic Dimming (Ambient Light Sensor) ........................................................................ 22

Automatic Dimming (Manual Offset)....................................................................................23

Controlled Luminance Mode................................................................................................. 23

Backlight Enable........................................................................................................................ 24

LC640.480.21-065 Operations Manual (OM610-00) i

Temperature Considerations...................................................................................................... 24

Luminance Variation Due to Ambient Temperature ............................................................. 24

Temperature Sensors............................................................................................................. 25

Heater Operation and Over Heat Status Lines ..................................................................... 25

Backlight Heater................................................................................................................ .... 25

Cell Heater ............................................................................................................................ 28

High Temperature Control.................................................................................................... 30

Defects........................................................................................................................................... 31

Emissive Defects ....................................................................................................................... 31

Cosmetic Defects....................................................................................................................... 32

Display Dimensions....................................................................................................................... 33

Figures

Figure 1. Viewing Angles............................................................................................................ 7

Figure 2. Response Times............................................................................................................ 7

Figure 3. Power Sequencing........................................................................................................ 9

Figure 4. Timing Diagram. ........................................................................................................ 11

Figure 5. Timing Diagram. ........................................................................................................ 12

Figure 6. Timing Diagram. ........................................................................................................ 13

Figure 7. Pixel Position of Input Data. ...................................................................................... 15

Figure 8. Warmup Curve. .......................................................................................................... 16

Figure 9. Connector Locations. ................................................................................................. 17

Figure 10. Dimming Voltage Input on J1 (DIM)....................................................................... 20

Figure 11. Luminance vs. Dimming Voltage: Manual Dimming.............................................. 21

Figure 12. Luminance Levels: Automatic Dimming (Ambient Light Sensor).......................... 22

Figure 13. Luminance Levels: Automatic Dimming (Manual Offset). ..................................... 23

Figure 14. Backlight Power Consumption.................................................................................24

Figure 15. Sensor Temperature vs. Lamp Heater (Inverter Startup Time Delay) ..................... 26

Figure 16. Sensor T emperature vs. Lamp Heater Duty Cycle................................................... 27

Figure 17. Display Warmup Performance................................................................................. 27

Figure 18. Cell Heater Response Time Performance. ............................................................... 28

Figure 19. Cell Heater Maximum Power Time. ........................................................................ 29

Figure 20. Cell Heater Duty Cycle. ........................................................................................... 29

Figure 21. Temperature Control: Maximum Pulse Width Modulation Duty Cycle.................. 30

Figure 22. Diameter Calculation................................................................................................ 32

Figure 23. Display Dimensions. ................................................................................................ 33

LC640.480.21-065 Operations Manual (OM610-00)ii

LC640.480.21-065 Display

The LC640.480.21-065 is a 6.5-inch diagonal VGA active matrix liquid crystal display

(AMLCD) designed to meet the demanding SAE specifications for the transportation

industry. This display is ideal for a variety of industrial applications, such as point-ofsale and outdoor kiosks. With a typical brightness of 1000 nits, this sunlight-readable

display offers high contrast in bright environments along with a wide dimming range for

nighttime operation. With its modular design, this display is perfect for mobile

computing and rugged applications where a high-performance embedded display is

required.

AMLCD Panel: The panel is a color active matrix LCD module incorporating

amorphous silicon TFT (thin film transistor) technology with wide viewing angle

characteristics. The video interface is digital, 6-bits per color, which allows up to

262,144 different colors.

Backlight Module: The backlight assembly contains six high-efficiency cold cathode

fluorescent lamps (CCFL), temperature sensors, and lamp heaters. All the components

are mounted to a single circuit board. The CCFLs are heated at low temperatures to

increase their luminance and extend their life. Located in front of the backlight module

are several diffusing and brightness-enhancement films.

Inverter Module: This assembly contains the backlight inverter electronics,

microprocessor, heater control circuitry, and input/output connectors. All the

components are mounted to a single circuit board. The microprocessor controls the

inverter, heater, and dimming functions. The dimming functions include manual analog

and automatic control based upon ambient light.

Ambient Light Sensor: The ambient light sensor can remain attached to the display or

mounted remotely using a cable.

Video Interface: Standard VGA TFT interface is digital 6-bit RGB.

Features and Benefits

♦ 1000 cd/m2typical luminance for sunlight-readability

♦ 3:1 contrast @ 100K Lux ambient for outdoor daylight use

♦ Wide +35/-45° vertical / ±50° horizontal viewing angle

♦ 300:1 digital dimming for efficient control over a wide range of ambient light

♦ 18-bit ( 6 bits per color) video interface for wide color range (262,144 colors)

♦ 30,000 hours MTBF for long service-free operating life

♦ Durable and lightweight for rugged conditions

♦ Convection cooling for operation without cooling fans

♦ Modular design for easy field replacement of backlight and inverter

♦ Automatic thermal management at low and high temperature extremes

LC640.480.21-065 Operations Manual (OM610-00) 1

Installation and Handling

Do not drop, bend, or flex the display. Do not allow objects to strike the surface of the

display.

Mounting the Display

To maximize shock and vibration performance, the display must be properly mounted

using all four mounting hole locations. There are two recommended mounting

configurations. Appropriate changes to these mounting configurations may be needed to

meet specific requirements or applications. Table 1 below lists the recommended

mounting hardware.

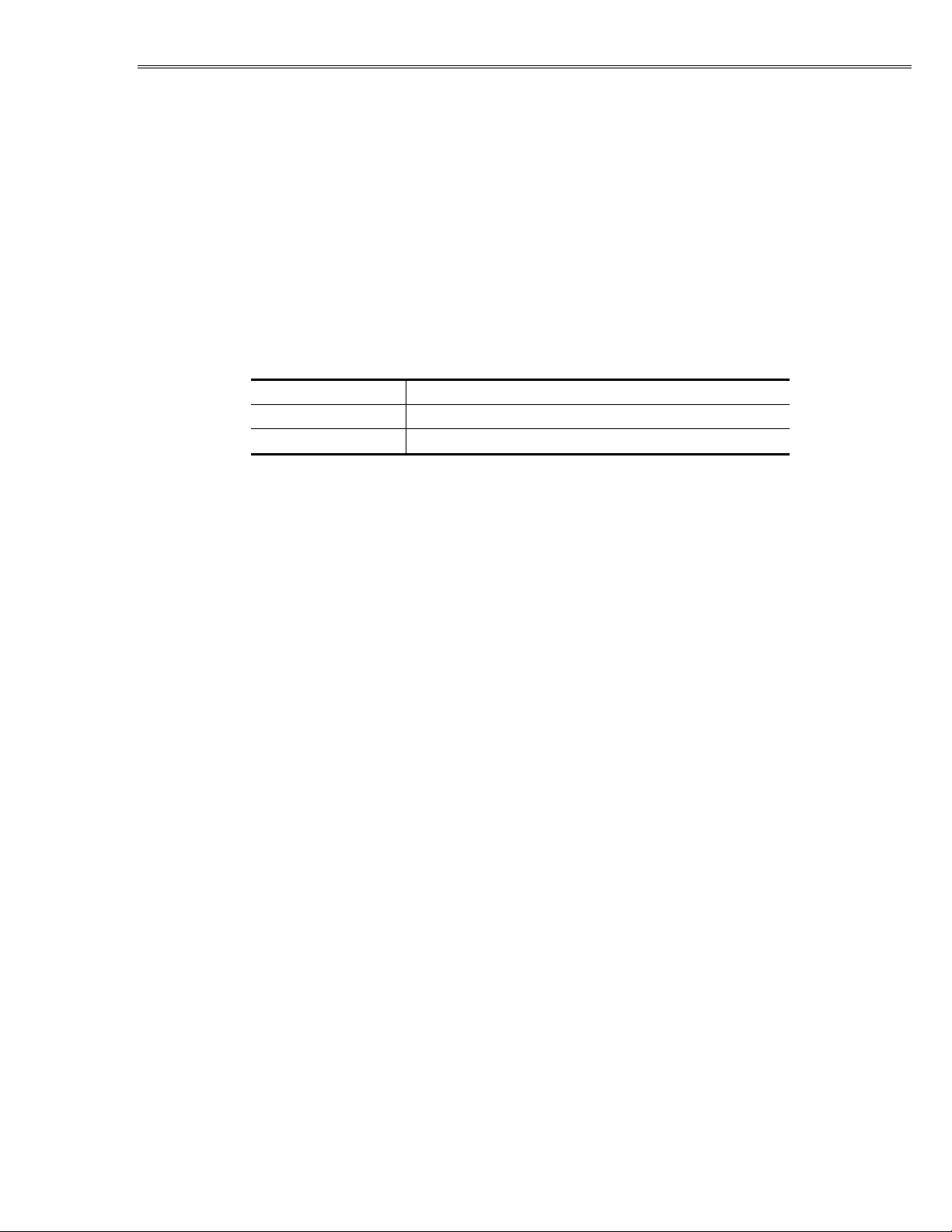

Table 1. Mounting Hardware.

Screw

Washer

Tightening torque

M2.5 SS phillips-head or #4 SS phillips-head

Lockwasher, split type

4oz-in \ 2.8x105dyne – cm

Mounting Display Face Down

Standoff spacers or bosses with a minimum height of 3.0 mm must be used at all four

mounting locations to prevent binding and deflection of the display.

Mounting Display Face Up

Standoff spacers or bosses with a minimum height of 33.0 mm must be used at all four

mounting locations to prevent binding and deflection of the display.

Thermal Control

Several thermal sensors located on the backlight module allow the display to operate

safely at temperature extremes. At low ambient temperatures, heaters on the backlight

module warm t he lamps to a safe temperature before energizing the lamps. This coldstart routine extends the life of the lamps and increases the luminance at low

temperatures. During the warm up period, pin 39 on the input connector is set low.

At high ambient temperatures, the luminance will gradually be reduced to maintain

acceptable temperatures on the inverter module. If the temperatures remain above the

acceptable level after the luminance has been totally reduced, then the inverter will shut

down. During the luminance reduction period, pin 40 on the input connector (J1) is set to

low.

Isolation and Air Gap

The display generates high voltage AC to drive the CCFL tubes. High voltage is present

at numerous points on the backlight and inverter module that forms the rear surface of

the display, so your application should not place metal too near the module. In the

interests of both high voltage isolation and airflow for cooling, it is recommended that an

air gap of .197" (5 mm) or greater be maintained behind the display.

LC640.480.21-065 Operations Manual (OM610-00)2

Ambient Light Sensor Clearance

Two backlight dimming modes utilize automatic brightness control. If the display is to be

operated in either of these modes, the ambient light sensor located on the front bezel

must be unobstructed. If the sensor is placed behind the same protective window as the

display active (viewing) area, the sensor operation may be affected due to light scattering

and reflections from display-generated light coupling to the sensor via the window.

Cable Length

Due to the high frequencies present on the video interface, unterminated video cable

lengths of more than 12 inches (300 mm) are discouraged.

Cleaning

Care should be taken to minimize scratching. Clean the display front with a dry, soft

cloth such as a professional photographic lens cleaner. Disposable cleaning cloths are

recommended to minimize the risk of inadvertently scratching the display with particles

embedded in a re-used cloth. Particular care should be taken when cleaning displays with

polarizers or anti-glare and anti-reflective films. These films may delaminate if exposed

to certain chemicals.

Avoiding Image Retention

Image retention may occur when a fixed pattern is displayed for a long time. Use a

screen saver or image inversion to avoid image retention on the display.

LC640.480.21-065 Operations Manual (OM610-00) 3

Specifications

Performance characteristics are guaranteed with the display at room temperature (25 °C)

and with the operating voltage within specifications, unless otherwise specified. Optical

performance is referenced to screen center at normal i ncidence with a full white screen

display and the backlight at maximum luminance, 60Hz LCD frame rate, unless

otherwise specified.

Environmental Characteristics

Table 2. Environmental Characteristics.

Temperature

Operating

Operating survival

Storage

Humidity

Operating

Non-operating

Altitude

Operating

Non-operating

Vibration (random)

Operating/Non-operating 0.02 g2/Hz, 5-500 Hz, 30 min. ea. axis, per IEC 68-2-34

Shock

Operating/Non-operating 100 g, 6 ms, half sine wave, 3 shocks per surface, per IEC 68-2-27

-20 to +71 °C (-40 to +71°C with cell heater/version -01)

-40to+85°C,2hrs.maximum

-45to+90°C,24hrs.maximum

93% RH @ 40 °C, non-condensing, 10 days per IEC 68-2-3

0 to 95% RH @ 25-55 ºC, 6 days per IEC 68-2-30

0 to 10k ft. per IEC 68-2-13

0 to 40k ft. per IEC 68-2-13

Specific profiles for each axis, SAE J1455, section 4.9

Safety and EMI Certifications

The display will not inhibit the end product from compliance with UL1950, CSA22.2,

and IEC950. When housed in a suitable enclosure, the display will not inhibit the end

product from complying with FCC Part 15, Subpart J Class B, EN55022 Class B, or

SAE-J-1113.

Reliability and Backlight Life

The demonstrated system MTBF is to be greater than 30,000 hours with a 90%

confidence level at 25 °C. Refer to Table 3 for backlight life.

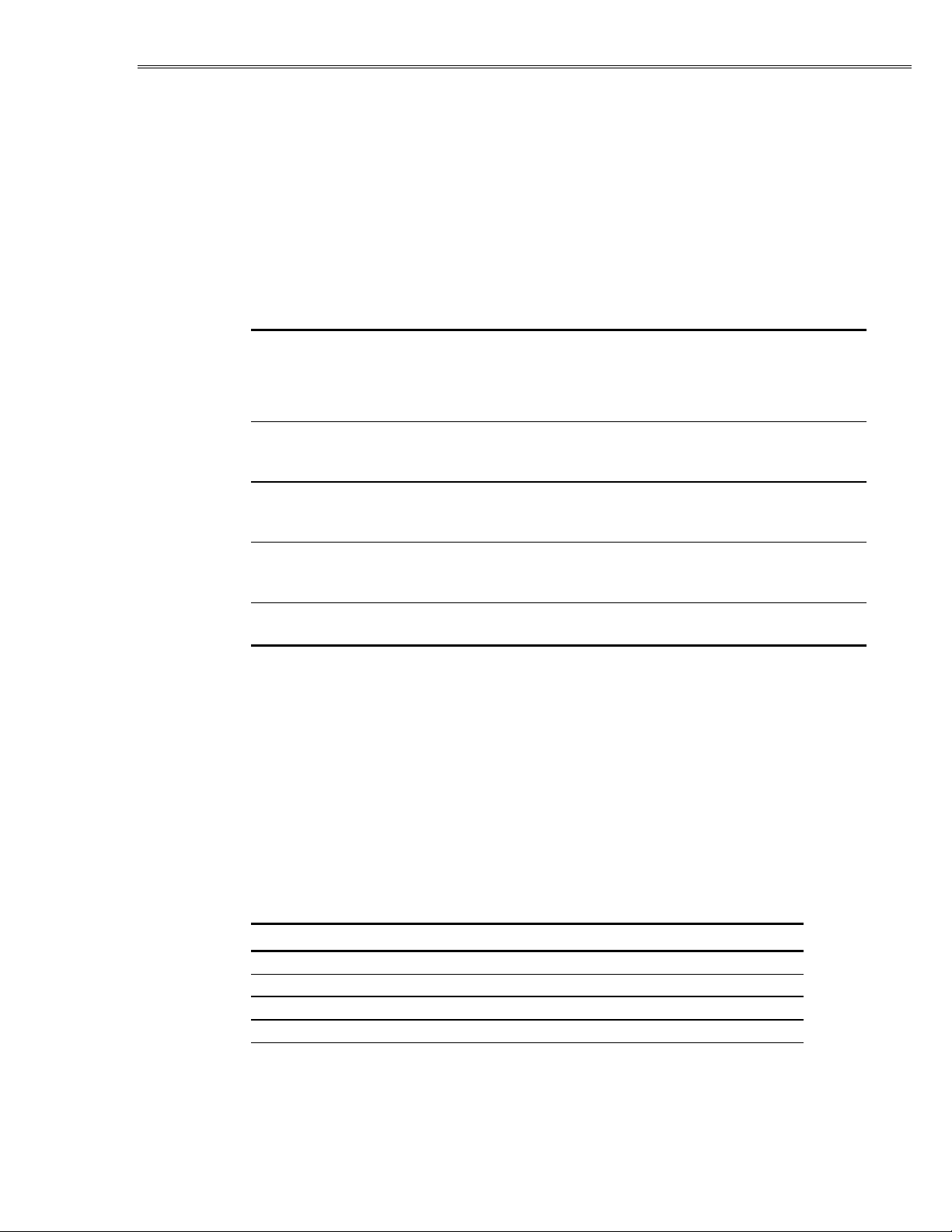

Table 3. Backlight Life.

Usage Backlight life (typical to 50% of initial luminance)

Continuous at full luminance 20K hours

Continuous at half luminance 60K hours

Typical use using CBM* 50K hours @ 700 cd/m

* Controlled luminance mode

2

LC640.480.21-065 Operations Manual (OM610-00)4

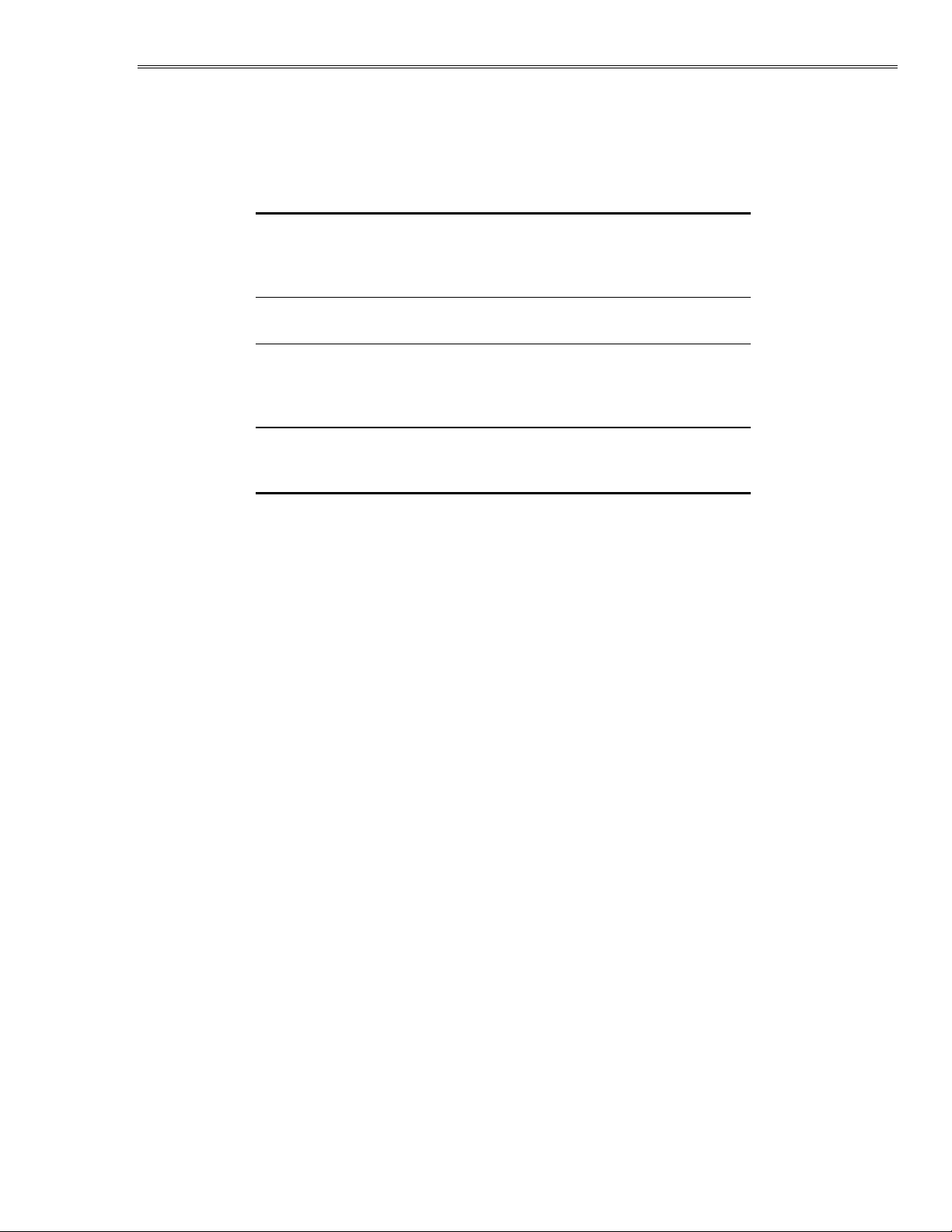

Mechanical Characteristics

Refer to mechanical outline drawing in Figure 23 on page 33. All size measurements

shown in Table 3 are in millimeters (inches).

Table 4. Mechanical Characteristics.

Display External Dimensions

width

height

depth

Weight (normal)

Display Active Area

width

height

diagonal

Pixel Pitch

width

height

178.8 (7.04 ) nominal

126.8 (4.99) nominal

38.3 (1.51) nominal

470 g (1.05 lbs.)

132.48 (5.22) nominal

99.36 (3.91) nominal

165.10 (6.5)

.207 (0.008) nominal

.207 (0.008) nominal

LC640.480.21-065 Operations Manual (OM610-00) 5

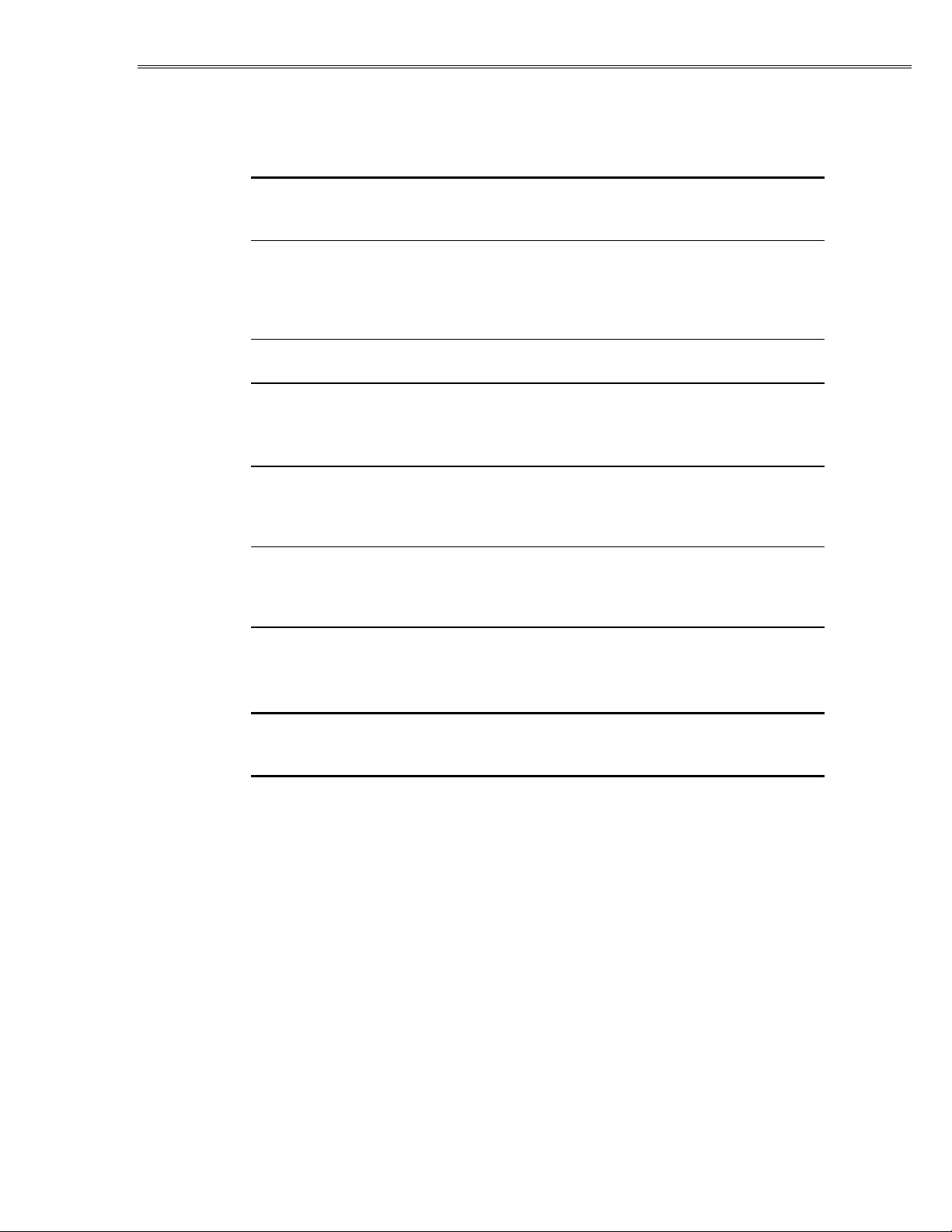

Optical Characteristics

Table 5. Optical Characteristics.

Luminance (at screen center)

Standard (typical)

1

Controlled (typical)

Contrast Ratio

Dark room ambient

500 Lux ambient

5K Lux ambient

20K Lux ambient

Color Coordinates

2

3cd/m

3cd/m

minimum, 1000 cd/m2maximum (initial)

2

minimum, 700 cd/m2maximum

150: 1 typical, 80:1 minimum

92:1 typical

12:1 typical

4:1 typical

White field x = .362 typical; y = .370 typical

Luminance Non-uniformity

25% maximum With a white screen, max difference between any 2 of 5

points is defined as follows:

Lnu (%) = (1- (Lmin/Lmax)) x 100%

Luminance Control (typical))

Dimming range 50:1 initial, 300:1 stabilized (Lmax after > 15 minutes

at max. lum., then Lmin at min. lum; dimming range =

Lmax/Lmin)

Ambient Light Sensor

Response

Field of view

Dynamic range

Viewing Angles

Horizontal

Vertical

Visible light filtered ~420 to 675nm @ 50% pts.

±50 degrees typical to half sensitivity

0 to 3000 Lux typ.; assumes 18% scene reflectance

±50 degrees typ., White/black CR ≥ 10

+35/-45 degrees typ., White/black CR ≥ 10

(See Figure 1)

1

The contrast brightness mode regulates backlight luminance via feedback over the life

of the lamps. The lamp and luminance life will vary depending on the chosen controlled

luminance level. For more information, see “Backlight Dimming” on page 20.

LC640.480.21-065 Operations Manual (OM610-00)6

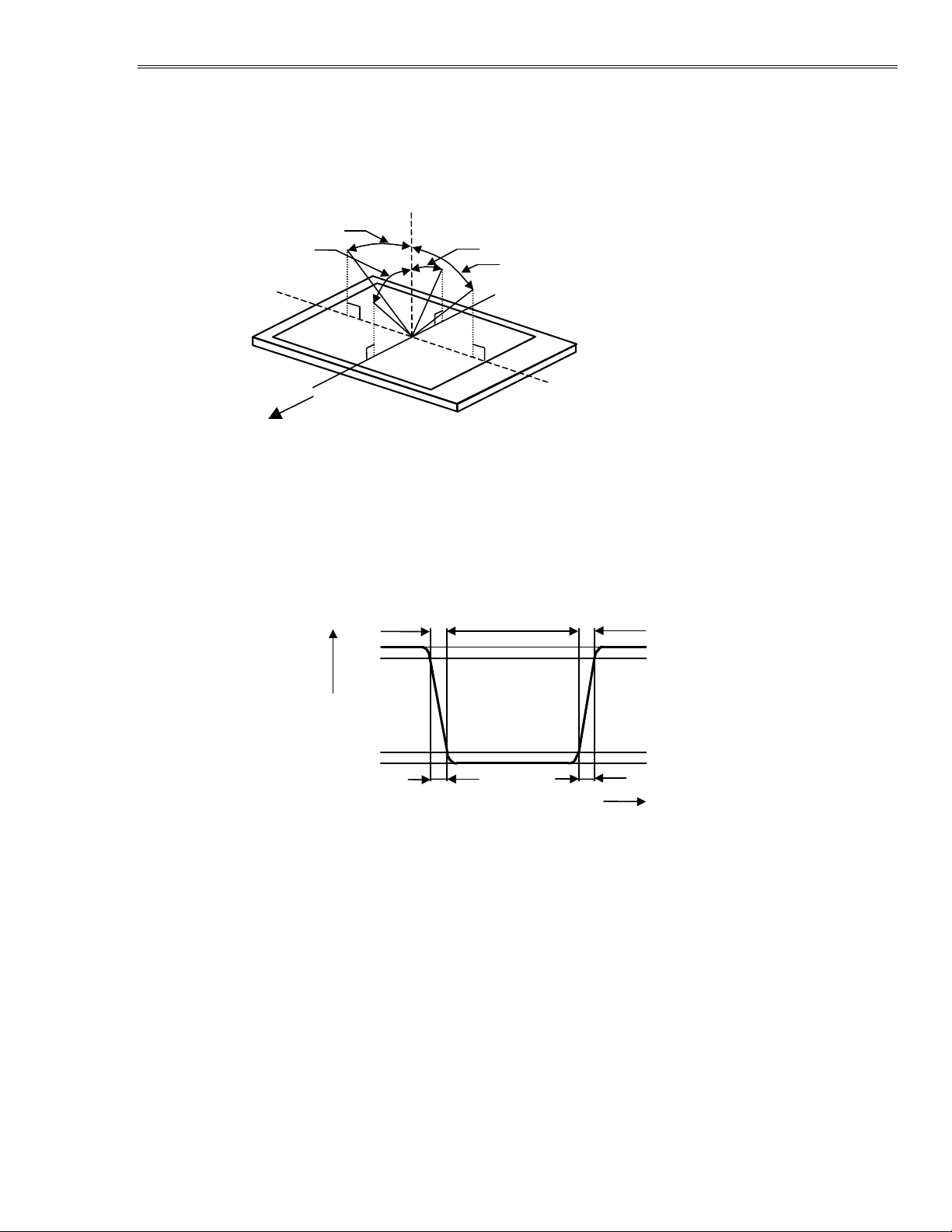

Viewing Angles

-

-

+

+

w

Figure 1. Viewing Angles.

Normal Line

θ

H

θ

V

θ

V

θ

H

where:

θ

+Horizontal angle (+50)

+H

θ

-Horizontal angle (-50)

-H

+Vertical angle (+35)

θ

+V

θ

-Vertical angle (-45)

-V

and R/L and U/D = default

6o’clockdirection

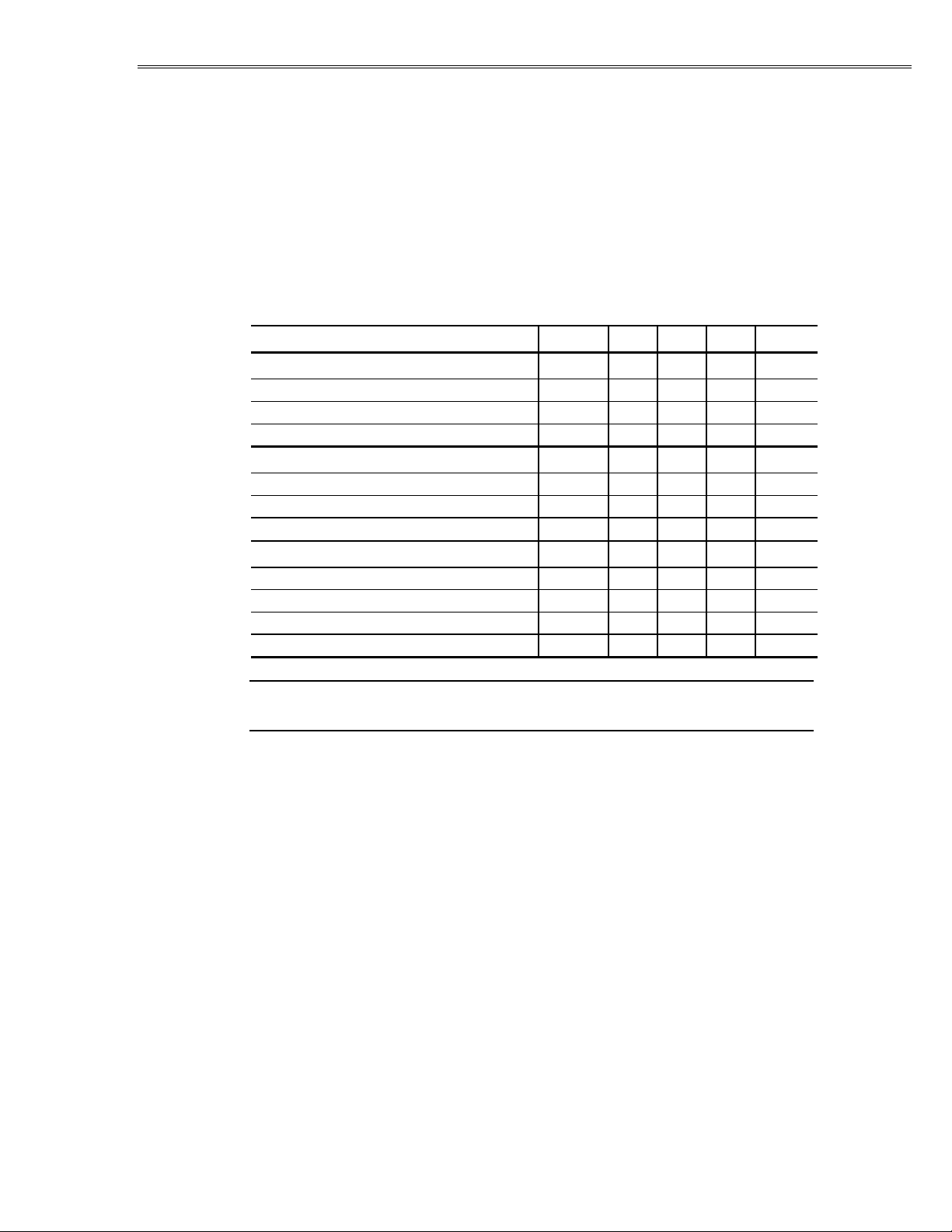

Response Times

As shown in Figure 2, the rise response time (from white to black) is 40 ms typical and

the fall response time (from black to white) is 50 ms typical.

Figure 2. Response Times.

Photo-

detector

output

(Relative Value)

100%

90%

10%

0%

blackwhite

hite

τr = Rise (wht to blk): 40 ms typ

τf=Fall(blktowht): 50mstyp

τr

f

τ

time

LC640.480.21-065 Operations Manual (OM610-00) 7

Interfacing and Operation

Control Basics

Power Requirements

The LC640.480.21-065 display requires two power supplies: +5 Vdc for the LCD logic

and +12 Vdc for the backlight. In Table 6 below, the backlight current and power are

referenced to maximum luminance, 25 °C ambient temperature.

Table 6. Input Pow er

Panel

Panel voltage (nominal = 5.0V) V

Absolute max. V

ICC(VCC=5.0V) I

Inverter

Inverter voltage (nominal = +12.0V) V

Absolute max. voltage V

Current (V

Backlight

Backlight heater voltage V

Backlight heater current I

Cell heater voltage V

Cell heater current I

CC

= 8.0V, max. luminance) I

INV

Symbol Min Typ Max Units

4.75 5.0 5.25 Vdc

-0.3 – 6.5 Vdc

– 470 640 mAdc

8.0 12.0 18.0 Vdc

– – 20.0 Vdc

– 1.6 1.8 Adc

8.0 12.0 18.0 Vdc

– 2.0 3.0 Adc

8.0 12.0 18.0 Vdc

– 1.0 1.5 Adc

V

CC

CC

CC

INV

INV

INV

LH

LH

LH

LH

CAUTION: Absolute maximum ratings are those values beyond which damage to

the device may occur.

LC640.480.21-065 Operations Manual (OM610-00)8

Power Sequencing (LCD)

Power-on

Power-off

When performing power sequencing:

• Ensure the supply voltage for input signals is the same as for VCC.

• Apply VCC within the LCD operation period. When the backlight turns on before

LCD operation or the LCD operation turns off before the backlight turns off, the

display may momentarily become white.

• When the power is off, keep whole signals (Hsync, Vsync, CLK, DE, and DATA)

low level or high impedance.

Figure 3. Power Sequencing.

SUPPLY VOLTAGE SEQUENCE

VCC

Signal

*1 The supply voltage for input signals should be the same as VCC.

*2 Apply VDD within the LCD operation period. When the backlight turns on before LCD operation or the LCD

operation turns off before the backlight turns off, the display may momentarily become white.

*3 When the power is off, please keep whole signals (Hsync, Vsync, CLK, DE, and DATA) low level or high

impedance.

4.75 V

0V

0V

0<t<35ms 0<t<35ms

mst<150

VALID

4.75 V

Video Signals

Video Signal Characteristics

Video signal inputs on J1 are digital inputs and are compatible with CMOS logic.

Table 7. Video Signal DC Characteristics.

Description Symbol Minimum Maximum Units

Absolute maximum input voltage V

Low-level input voltage V

High-level input voltage V

I

max

IL

IH

-0.3 6.5 Vdc

00.8Vdc

2.2 5.25 Vdc

LC640.480.21-065 Operations Manual (OM610-00) 9

Signal Timing

Video signal timing diagrams are shown in Figures 2 through 4 on the following pages.

Table 8 refers to these diagrams.

Table 8. Video Signal Timing.

Parameter Symbol Min. Typ. Max. Unit

CLK Frequency

Duty tch/tc 0.4 0.5 0.6 –

Rise, fall t crf – – 10 ns

Hsync

Period

Display period t hd 640 CLK

Front-porch t hf 2 16 – CLK

Pulse width t hp 10 96 – CLK

CLK-Hsync timing t hch 12 – – ns

Hsync-CLK timing t hcx 8 – – ns

Hsync-Vsync timing t vh 15 – – ns

Vsync-Hsync timing t vs 15 – – ns

Rise, fall t hrf – – 10 ns

Vsync

Display period t vd 480 H

Front-porch t vf 1 12 – H

Pulse width t vp 2 2 – H

Rise, fall – – – 10 ns

DATA

R0-R5

G0-G5

CLK-DATA timing t ds 8 – – ns

DATA-CLK timing t dh 12 – – ns

Rise, fall t drf – – 10 ns

B0-B5

DE

DE-CLK timing t es 8 – – ns

CLK-DE timing t eh 12 – – ns

Rise, fall t erf – – 10 ns

1

39.722 ns (Typ.)

1

2

1/tc 21.0 25.175 29.0 MHz

th

30.0 31.778 33.6

µs

– 800 – CLK

thb 5 48 – CLKBack-porch

*)thp+thb 64 144 – CLK

3

tv

16.1 16.683 17.2 msPeriod

– 525 – H

tvb 4 31 – HBack-porch

*)tvp+tvb 6 33 – H

2

31.468 kHz (Typ.)

3

59.94 Hz (Typ.)

Note: Keep all parameters within the specified range. Do not operate the LCD

module without an input DE signal.

LC640.480.21-065 Operations Manual (OM610-00)10

CLK

(R0toR5)

(G0toG5)

(B0toB5)

Figure 4. Timing Diagram.

tch

IH

V

1.5 V

V

IL

INVALID INVALIDDATA

V

IH

1.5 V

V

IL

tc

tcrftcrf

tds tdh

tdrf tdrf

DE

CLK

Hsync

V

IH

1.5 V

V

IL

1.5 V

V

IH

1.5 V

V

IL

1.5 V

teh tes

thch thcs

thrf

teh tes

terf terf

V

IH

1.5 V

V

IL

tvh tvs

tvrf

LC640.480.21-065 Operations Manual (OM610-00) 11

Figure 5. Timing Diagram.

LC640.480.21-065 Operations Manual (OM610-00)12

Figure 6. Timing Diagram.

Hsync

LC640.480.21-065 Operations Manual (OM610-00) 13

Video Characteristics

Colors are developed in combination with 6-bit signals (64 steps in grayscale) of each

primary red, green, and blue color. This process can result in up to 262,144 (64x64x64)

colors. The mapping of the eighteen video data inputs is shown in Table 9.

Table 9. Video Data Color and Grayscale Map.

Display colors

Basic

colors

Red

grayscale

Green

grayscale

Black

Blue

Red

Magenta

Green

Cyan

Yellow

White

Black

dark

↑

↓

bright

Red

Black

dark

↑

↓

bright

Green

Data signal (0: Low level, 1: High level)

R5 R4 R3 R2 R1 R0 G5 G4 G3 G2 G1 G0 B5 B4 B3 B2 B1 B0

000000

000000

111111

111111

000000

000000

111111

111111

000000

000001

000010

↑

↓

111101

111110

111111

000000

000000

000000

↑

↓

000000

000000

000000

000000

000000

000000

000000

111111

111111

111111

111111

000000

000000

000000

↑

↓

000000

000000

000000

000000

000001

000010

↑

↓

111101

111110

111111

000000

111111

000000

111111

000000

111111

000000

111111

000000

000000

000000

↑

↓

000000

000000

000000

000000

000000

000000

↑

↓

000000

000000

000000

Black

dark

Blue

grayscale

LC640.480.21-065 Operations Manual (OM610-00)14

↑

↓

bright

Blue

000000

000000

000000

↑

↓

000000

000000

000000

000000

000000

000000

↑

↓

000000

000000

000000

000000

000001

000010

↑

↓

111101

111110

111111

Pixel Position

The position of pixel data, relative to t he color filter orientation and scan direction

inputs is shown in Figure 7 below. Refer to Table 10 to see the relations between the

scan direction and the viewing direction.

Table 10. Display Positions.

Normal scan: DPS = “L” or “OPEN”

D (0,0) D (1,0) D (X,0) D (638,0) D (639,0)

D (0,1) D (1,1) D (X,1) D (638,1) D (639,1)

(D 0,Y) D (1,Y) D (X,Y) D (638,Y) D (639,Y)

D (0,478) D (1,478) D (X,478) D (638,478) D(639,478)

D (0,479) D (1,479) D (X,479) D (638,479) D(639,479)

Reverse scan: DPS = “H”

D (639,479) D (638,479) D (X,479) D (1,479) D (0,479)

J3

J1

D (639,478) D (638,478) D (X,478) D (1,478) D (0,478)

D (639,Y) D (638,Y) D (X,Y) D (1,Y) (D 0,Y)

D (639,1) D (638,1) D (X,1) D (1,1) D (0,1)

D (639,0) D (638,0) D (X,0) D (1,0) D (0,0)

Figure 7. Pixel Position of Input Data.

Normal Scan Reverse Scan

D (0,0) D (639,0)

D (0,479) D (639,479)

D (0,0) D (639,0)

D (0,479) D (639,479)

J1

J3

LC640.480.21-065 Operations Manual (OM610-00) 15

Warmup Characteristic

L

Some time after startup is required to allow the CCFL tubes to reach their normal

operating temperature. The graph in Figure 8 shows the typical room temperature

warmup curve for the LC640.480.21-065 when set to maximum luminance.

Figure 8. Warmup Curve.

uminance VS Time

(warm-up curves)

100.00%

90.00%

80.00%

70.00%

60.00%

50.00%

40.00%

PERCENT OF MAX. LUMINANCE

30.00%

20.00%

10.00%

0.00%

0 10203040506070

TIME (min)

LC640.480.21-065 Operations Manual (OM610-00)16

Connectors

J

The LC640.480.21-065 display has four connectors on the back near one side of the

display. J1 is the video input and backlight control connector, J2 is the backlight inverter

and heater connector, and J3 and J8 are the connectors for tethering t he ambient light

sensor.

Figure 9. Connector Locations.

Pin 1

J2

Pin 1

J1

J1

ON

J3

Pin 1

SW1

1

Video Input and Backlight Control Connector (J1)

The video input and backlight control signals are connected to the display through

a 40-pin, dual-row, 1.27 mm pitch, square pin, locking connector (Samtec

FTSH-120-01-L-DV-EJ-A). The mating connector is available through Samtec as

a cable assembly (FFSD series). Consult your Samtec representative (1-800SAMTEC) for cable and connector options. Table 11 on the following page lists

the pin assignments for the J1 connector.

8

LC640.480.21-065 Operations Manual (OM610-00) 17

Table 11. Video Input and Backlight Connector (J1) Pinouts.

Pin Signal Description Pin Signal Description

1 GND Ground 2 CLK Video clock

3 HSync Horiz. sync 4 VSync Vert. sync

5 GND Ground 6 R0 Red data (LSB)

7 R1 Red data 8 R2 Red data

9 R3 Red data 10 R4 Red data

11 R5 Red d ata (MSB) 12 GND Ground

13 G0 Green data (LSB) 14 G1 Green data

15 G2 Green data 16 G3 Green data

17 G4 Green data 1 8 G5 Green data (MSB)

19 GND Ground 20 B0 Blue data (LSB)

21 B1 Blue data 22 B2 Blue data

23 B3 Blue data 24 B4 Blue data

25 B5 Blue data (MSB) 26 GND Ground

27 DE Data Enable 28 V

29 V

CC

AMLCD and fan power 30 GND Ground

CC

AMLCD power

31 DPS Display scan select 32 /CBM Controlled luminance

33 DIM Analog dimming control 34 DIMREF Dim reference

35 INV Inverter control 36 GND Ground

37 ALS Ambient light sensor 38 TS1 Temperature sensor

39 /HT Heater indicator 40 /OHT Overtemp indicator

Signal I/O Description

CLK I Video Clock

HSync I Horizontal Sync

Vsync I Vertical Sync

R0-R5 I Red Data

G0-G5 I Green Data

B0-B5 I Blue Data

GND I Ground – Signal return for logic and power supplies. Isolated from the

display metal bezel.

DE I Data Enable

DPS I Display Scan - Low or open = normal; High = image upside down

V

CC

I AMLCD power supply: +5 Vdc

INV I Inverter - High or open = enable; Low = disable (backlight off)

/CBM I Controlled Luminance Mode - High or open = normal; Low = enabled

DIM I AnalogDimmingControl-0to+5Vdc;+5Vdcismaximumluminance

DIMREF O Dimming Reference - +5 Vdc reference for analog dimming

ALS O Ambient Light Sensor - signal to microprocessor: 0 to +5 Vdc; +5 Vdc is

lowest ambient light level

TSI O Temperature Sensor (no. 1) - signal to microprocessor: 0 to +5 Vdc, with

0C = 0.5 Vdc, and 10 mv/

°C

/HT O Heating Indicator - Low = display is heating and backlight is turned off

/OHT O Over-temp Indicator - Low = display temperature is at maximum and

luminance is reduced

LC640.480.21-065 Operations Manual (OM610-00)18

Backlight Inverter and Heater Connector (J2)

This connector supplies 12 Vdc nominal to the inverter to operate the backlight inverter

and backlight heater. The connector is a M olex Micro-Fit 3.0 Wire-to-Board Header

(# 43045-0600). The mating connector is a Molex Micro-Fit 3.0 Wire-to-Wire

Receptacle (#43025-0600, crimp # 43030-0007).

Table 12. Backlight Inverter and Heater Connector (J2) Pinouts.

Pin Function

1 VDD, inverter

2 Inverter ground

3 VLH, backlight heater

4 Backlight heater ground

5 VCH, cell heater

6 Cell heater ground

Ambient Light Sensor (Tethered Option) (J3 and J8)

This connector is used when the ambient light sensor is tethered. The connector is a

3-pin Molex part number 22-03-5035. The mating connector is Molex part number

50-37-5033 with 5263 crimps (Molex # 08-70-1040).

Table 13. Ambient Light Sensor (J3 and J8) Pinouts.

Pin Symbol Function

1 PDANODE Photo diode anode

2 PDCATH Photo diode cathode

3 GND Po wer ground

Tethering the Light Sensor

The protruding circuit board area containing the light sensor is designed so it can be

snapped off and removed from the main interface board. Once the ambient sensor is

removed it will require the addition of a cable between J3 and J8 in order to function.

With the cable installed the sensor can be remotely positioned. The sensor may be

discarded if the ambient sensing capability is not required.

To remove the light sensor, place the thumb of your right and left hand on the

corresponding front surfaces of the sensor circuit board. Place the index fingers of both

hands on the display’s rear circuit board just above the sensor. With a f irm quick action,

push the sensor circuit board back. This will cause the circuit board to snap along the

perforation. Now rock the sensor circuit board back and forth several times until it is free

from the main interface board.

Connect a cable from J8 on the rear of the sensor circuit board to J3 on the rear of the

display. The ambient light sensor should now function normally.

LC640.480.21-065 Operations Manual (OM610-00) 19

Luminance Features

Backlight Dimming

Control for backlight dimming is performed by several methods depending on how the

switches on switch block SW1 (see Figure 9) are set as shown in Table 14 below. These

selections are available for both standard and controlled luminance mode.

Table 14. Backlight Dimming Control.

Luminance Control Switch1Switch2Switch

Manual control off off –

3

ON

Automatic control with ambient light sensor on off –

Automatic control with manual offset and

ambient light sensor

Note: Because Switch 3 is not used, its position has no effect.

off on –

ON

ON

Manual Dimming

This mode allows the user to adjust the luminance by varying the input from 0 to +5 Vdc

on pin 33 (DIM) of the video input connector (J1). See Figures 10 and 11.

Table 15. Manual Dimming Specifications.

Description Specification

Dimming range Approximately300:1

Analog voltage input (DIM) Compatible with voltage and potentiometer (3 terminal)

No connection results in maximum luminance

Voltage range: 0 to +5V (+5V equals maximum luminance)

Dimming method Pulse width modulation (period = 100 millisecond, 256

discrete steps, linear)

Recommended pot value 10K ohm

DIM REF High side pot reference output provided, short-circuit

protected

SWI Setting Switch 1 = OFF, Switch 2 = OFF

Figure 10. Dimming Voltage Input on J1 (DIM).

DIM

(PIN 33)

DIMREF

(PIN 34)

LC640.480.21-065 Operations Manual (OM610-00)20

GND

(PIN 36)

Figure 11. Luminance vs. Dimming Voltage: Manual Dimming.

LUMINANCE VS DIMMING VOLTAGE

100.00

80.00

60.00

40.00

20.00

0.00

PERCENT OF MAX. LUMINANCE (%)

0123456

DIMMING VOLTAGE

LC640.480.21-065 Operations Manual (OM610-00) 21

Automatic Dimming (Ambient Light Sensor)

Lamp luminance varies depending on ambient light levels. An off-board light sensor is

used to determine the level. See Figure 12 below.

Table 16. Automatic Dimming (Ambient Light Sensor) Specifications.

Description Specification

Sensor type Photodiode, visible light filtered

Sensor sensitivity 10 nA/lux

Dynamic range 3000 lux ambient = maximum display luminance

0 lux ambient = minimum display luminance

Ambient to display luminance Approximately linear relationship

1 second averaging

Field of view

Response Visible light filtered, 420 to 675 nm @ 50% points

SWI Setting Switch 1 = ON, Switch 2 = OFF

Figure 12. Luminance Levels: Automatic Dimming (Ambient Light Sensor).

MAX

± 50 degrees typical to half sensitivity

DISPLAY

LUMINANCE

MIN

0

AMBIENT LIGHT LEVEL

3000

(lux)

LC640.480.21-065 Operations Manual (OM610-00)22

Automatic Dimming (Manual Offset)

Lamp luminance varies depending on ambient light levels. An off-board light sensor is

used to determine the level. The user can adjust the l uminance offset by varying the input

from 0 to 5 Vdc on pin 33 (DIM) of the video input connector (J1). See Figure 13 below.

Table 17. Automatic Dimming (Manual Offset) Specifications.

Description Specification

DIM function 0 Vdc = max. negative offset (display always at min. luminance)

+2.5 Vdc = no offset

+5 Vdc = max. positive offset (display always at max. luminance)

DIM voltage to offset % Linear relationship

SWI Setting Switch 1 = OFF, Switch 2 = ON

Figure 13. Luminance Levels: Automatic Dimming (Manual Offset).

Max.

d

V

5

.

4

=

M

I

D

M

I

D

DISPLAY LUMINANCE

Min.

c

c

d

V

0

.

4

=

D

c

d

V

5

.

3

=

M

I

D

c

d

V

0

.

3

=

M

I

D

c

d

V

5

.

2

=

M

I

D

c

d

V

0

.

2

=

M

I

D

c

d

V

5

.

1

=

M

I

D

c

d

V

0

.

1

=

M

I

D

c

d

V

5

.

0

=

M

I

1200 1800 2400 3000 3600

42000 600

AMBIENT LIGHT LEVEL (lux)

Controlled Luminance Mode

This function compensates for the luminance degradation of the lamps over time and

constrains the maximum display luminance to approximately 700 cd/m

sensor that measures the lamp luminance inside the light box, the microcontroller adjusts

the lamp current to maintain constant luminance at the desired luminance level. For

example, if DIM = 2.5V (corresponding to a 50% luminance level) in analog dimming

mode, then the display luminance will be maintained at approximately 350 cd/m

controlled luminance mode is enabled when pin 32 (/CBM) on J1 is low.

LC640.480.21-065 Operations Manual (OM610-00) 23

2

. Using a light

2

.The

Backlight Enable

The INV input on pin 35 of the backlight control connector (J1) directly shuts down the

inverter output.

Table 18. Backlight Enable Specifications.

Description Specification

Input characteristic CMOS logic-compatible; open circuit defaults to high state

State definition INV low state turns backlight off

Temperature Considerations

The LC640.480.21-065 display is designed to operate over a wide temperature range. To

accomplish this, the display must be heated at low t emperatures and the power level

reduced at high temperatures. At l ow temperatures, the lamps are heated using nichrome

wires. At high temperatures, the internal temperature is lowered by reducing the

backlight luminance. Two sensors located on the lamp circuit board monitor the internal

temperature. The 996-0406-01 product incorporates a cell heater to warm the AMLCD

cell at cold temperatures.

Luminance Variation Due to Ambient Temperature

Although the inverter features regulated lamp current drive, luminance will vary across

the temperature range due to the characteristics of the CCFL tubes. Lamp luminance

decreases at low t emperatures as the mercury condenses out of the gas and it decreases

again at high temperatures as the tube phosphors become less efficient. The

LC640.480.21-065 has been designed to provide peak luminance at normal room

temperatures without using a heater, and at low temperatures with a heater for the CCFL

tubes.

Backlight power consumption decreases as temperatures climb and the working voltage

of the CCFL tubes decreases. The graph in Figure 14 indicates typical performance

across temperatures.

Figure 14. Backlight Power Consumption.

Luminance vs. Temperature

(steady state luminance, standard luminance mode, display enclosed)

100.00%

90.00%

80.00%

70.00%

60.00%

50.00%

40.00%

30.00%

PERCENT OF MAX. LUMINANCE

20.00%

10.00%

0.00%

-60 -40 -20 0 20 40 60 80 100

TEMPERATURE (°C)

LC640.480.21-065 Operations Manual (OM610-00)24

Temperature Sensors

The temperature sensors are located at opposite corners of the backlight module, just

outside the active area of the display. T he output of the sensors are sent to the

microprocessor on the inverter module through a board-to-board connector.

Heater Operation and Over Heat Status Lines

There are two situations when the inverter controller will override the external control of

the backlight:

1. At cold temperatures, the backlight will not turn on until it is warmed up.

2. At high temperatures, the luminance will be reduced until the temperature drops to a

safe level.

Two digital status signals notify the user computer of these conditions. These CMOSlevel outputs sink up t o 20 mA to accommodate an LED load.

Table 19. Heater Operation and Over Heat Status Line Parameters.

Parameter Value Units

Heater status (/HT, pin 39, J1) 0 = heating, +5 = normal Vdc

Over heat status (/OHT, pin 40, J1) 0 = over heat, +5 = normal Vdc

Backlight Heater

The backlight heater consists of nichrome wire wrapped around each lamp. The purpose

of the heater is to vaporize the mercury at low temperatures providing proper lamp

emission color and extending lamp life.

When the inverter is first powered up it checks the backlight cavity temperature. If the

temperature is below +10° C, the lamp heaters are turned on at 100% duty cycle and the

inverter is disabled for a specific time period as shown in Figure 15 on page 26. After the

time delay, the inverter is enabled and the heater duty cycle is set t o the value shown in

Figure 16 on page 27. The heater continues to operate until the sensor temperature

reaches +10° C. See Figure 17 on page 27 for actual display warm-up performance.

LC640.480.21-065 Operations Manual (OM610-00) 25

Table 20. Backlight Heater Parameters.

Parameter Value

Type Resistive wire (nichrome: NiCrA – 80% Ni 20% Cr, 39 AWG,

53 ohms/foot)

Length/Lamp ~ 200 mm (7.87 inches)/lamp, 8 revolutions around each lamp,

resistance/wire = 36 ohms, total heater resistance = 6 ohms

Active temperature sensor Monitor temperature sensor with the highest reading

Control Duty cycle and maximum power time delay are stepped as shown

in Figures 15 and 16

Inverter enable Inverter is enabled as shown in Figure 15.

If the temperature is below +10°C, inverter is turned off until the

lamps are heated.

Status indicator Set the status indicator when the inverter is disabled. See “Heater

Operation and Over Heat Status Lines.” On page 25.

Hysteresis 3.0 °C

Heater voltage 8-18 Vdc

Power 10.6 W (@ 8 V), 54W (@18 V)

Figure 15. Sensor Temperature vs. Lamp Heater (Inverter Startup Time Delay)

SENSOR TEMPATURE VS

LAMP HEATER(@ FULL POWER) & INVERTER STARTUP TIME DELAY

35

30

25

20

15

(SEC)

10

5

0

-5

LAMP HTR/INVTR STARTUP DELAY

-10

-50 -40 -30 -20 -10 0 10 20 30 40 50

SENSOR TEMPERATURE (C)

LC640.480.21-065 Operations Manual (OM610-00)26

Figure 16. Sensor Temperature vs. Lamp Heater Duty Cycle

SENSOR TEMPERATURE VS LAMP HEATER DUTY CYCLE

110

100

90

80

70

60

50

(%)

40

30

20

LAMP HEATER DUTY CYCLE

10

0

-10

-50 -40 -30 -20 -10 0 10 20 30 40 50

SENSOR TEMPERATURE (C)

Figure 17. Display Warmup Performance.

Cold Start Up: Luminance VS Time

100.00%

90.00%

80.00%

70.00%

60.00%

50.00%

40.00%

Luminance (nits)

30.00%

20.00%

(12 VDC, w/o cell heater, full luminance, display enclosed)

-40C ambient

-20C ambient

0 C ambient

10.00%

0.00%

0.00 2.00 4.00 6.00 8.00 10.00 12.00 14.00 16.00 18.00 20.00 22.00

Time (min)

LC640.480.21-065 Operations Manual (OM610-00) 27

Cell Heater (Optional version 996-0406-01)

The cell heater consists of a glass panel with an ITO coating on one side. There are bus

bars along each side of the panel. The heater decreases the response time of the AMLCD

cell at low temperatures by heating the liquid crystal material in the cell. Figure 18

shows the response time performance at different heater voltages.

If the temperature is below +10° C, the ITO heater is turned on at 100% duty cycle for

the time shown in Figure 19 on page 29. The heater duty cycle is then set as shown in

Figure 20 on page 29.

Table 21. Cell Heater Parameters.

Parameter Value Units

Type Resistive: ITO on glass (~ 7.5 ohms/square)

Total resistance ~ 12 ohms

Active temperature sensor Monitor temperature sensor with the highest reading None

Control Duty cycle is stepped as shown in Figure 21 %

Trip point Not applicable C

Hysteresis 3.0 C

Heater voltage 8-18 Vdc

Power 5.3 (@ 8 V), 27 (@18V) Watts

None

Figure 18. Cell Heater Response Time Performance.

(with cell heater, ambient temperature = -40C, Vdim=2.5)

1800

1700

1600

1500

1400

1300

1200

1100

1000

900

800

700

600

RESPONSE TIME (milliseconds)

500

400

300

200

100

0

0 2 4 6 8 10 12 14 16 18

DISPLAY RESPONSE TIME VS TIME

cell heater voltage = 0.0

cell heater voltage = 8.0

cell heater voltage = 12.0

cell heater voltage = 18.0

TIME (minutes)

LC640.480.21-065 Operations Manual (OM610-00)28

Figure 19. Cell Heater Maximum Power Time.

S

SENSOR TEMPERATURE VS MAXIMUM POWER TIME

(ITO CELL HEATER)

6

5

4

3

2

1

0

MAXIMUM POWER TIME (MIN)

-1

-50 -40 -30 -20 -10 0 10 20 30 40 50

SENSOR TEMPERATURE (C)

Figure 20. Cell Heater Duty Cycle.

ENSOR TEMPERATURE VS DUTY CYCLE

(ITO CELL HEATER)

110

100

90

80

70

60

50

40

30

DUTY CYCLE (%)

20

10

0

-10

-50 -40 -30 -20 -10 0 10 20 30 40 50

SENSOR TEMPERATURE (C)

LC640.480.21-065 Operations Manual (OM610-00) 29

High Temperature Control

At high temperatures, thermal control is performed by decreasing the maximum duty

cycle of the backlight inverter. See Table 22 and Figure 21 below.

Table 22. High Temperature Control Parameters.

Parameter Value Units

Active temperature sensor Monitor temperature sensor with the highest reading None

Control Maximum duty cycle is stepped as shown in Figure 21 %

Hysteresis 3.0 C

Figure 21. Temperature Control: Maximum Pulse Width Modulation Duty Cycle.

SENSOR TEMPERATURE VS MAXIMUM PWM DUTY CYCLE

110

100

90

80

70

60

50

40

30

20

10

0

MAXIMUM PWM DUTY CYCLE (%)

-10

80 85 90 95 100 105 110 115 120

SENSOR TEMPERATURE (C)

LC640.480.21-065 Operations Manual (OM610-00)30

Defects

Emissive Defects

Table 23. Emissive Defects.

Item Specification

Line Defect

Luminous Dots

Color Red, Green, Blue

Brightness: F + H

Brightness: F

Dark Dots

Color Red, Green, Blue

1

“F” means full-luminous dot(s), bright point independent from viewing angle.

“H” means half-luminous dot(s), bright point dependent on viewing angle.

2

Dark dots are counted while the screen is illuminated with Red, Green, or Blue dots only.

3

Adjacency is considered separately for each color; adjacency among Red, Green, and Blue is

not considered as adjacent.

4

When the distance b etween two pairs is ≤ 10 mm, this situation is not allowed. If distance is

≤ 10 mm, the quantity is 0 pair.

5

Adjacent two dark dots is counted as one point.

1

23

Not allowed

Distance between same color dot defects Quantity

1

–

R+G+B

≤ 6.5 mm ≤ 6 pairs, each color

Adjacent two dots

Adjacent three or more dots

Distance between same color dot defects Quantity

–

Adjacent three or more dots

≤ 6 pairs, each color

≤ 0 pair, each color

≤ 8, each color

≤ 0 pair, each color

≤ 15

4

5

LC640.480.21-065 Operations Manual (OM610-00) 31

Cosmetic Defects

Table 24. Cosmetic Defects.

Item Measurement Criteria Quantity

Polarizer scratch Remarkable scratches 0 points

Polarizer bubbles, wrinkles,

or dent

Other objects or dust

between polarizer and glass

* The distance between each defect is larger than 6.5 mm.

Figure 22. Diameter Calculation.

Average diameter

Width ≤ 0.05 mm

0.05 mm ≤ Width ≤ 0.1 mm

0.1 mm < Width – 0 point

Average diameter

D

≤ 0.5 mm ≤ 3 points

– All allowed

L<0.7mm

0.7 mm

1.0 mm < L

D

0.2 mm < D < 0.3 mm*

0.3 mm

0.5 mm < D

≤ L ≤ 1.0 mm

≤ 0.2 mm

≤ D ≤ 0.5 mm*

All allowed

≤ 5 points

0 point

All allowed

≤ 11 points

≤ 4 points

0 points

LC640.480.21-065 Operations Manual (OM610-00)32

Display Dimensions

The recommended clearance shown in Figure 23 indicates the distance behind the

display module that should be left to provide free-flow of air for convection cooling. In

Figure 23, dimensions are in millimeters.

Figure 23. Display Dimensions.

Unless specified, tolerances are:

±0.50

.x =

.xx =

±0.25

Note: The dimensions in this drawing are approximate. Please contact Planar

Applications Engineering to request the actual drawing prior to beginning your

design.

LC640.480.21-065 Operations Manual (OM610-00) 33

Description of Warranty

This description is not the full warranty, and should not be construed as a substitute for the full

warranty. A copy of the full warranty is available upon request.

Planar warrants that the goods it sells will be free of defects in materials and workmanship, and that

these goods will substantially conform to the specifications furnished by Planar, and to any drawings or

specifications furnished to t he Seller by the Buyer if approved by the Seller. This warranty is effective

only if Planar receives notice of such defect or non-conformance during the period of warranty, which

begins the day of delivery.

The goods Planar sells are warranted for a period of one year unless otherwise agreed to by Planar and

the Buyer. The Buyer must return the defective or non-conforming goods, upon request, to Planar not

later than 30 days after Planar’s receipt of notice of the alleged defect or non-compliance. Buyer shall

prepay transportation charges, and Planar shall pay for return of the goods to the Buyer. No goods are

to be returned to Planar without prior permission.

The warranty does not apply in cases of improper or inadequate maintenance by the Buyer,

unauthorized modification of the goods, operation of the goods outside their environmental

specifications, neglect or abuse of the goods, or modification or integration with other goods not

covered by a Planar warranty when such modification or integration increases the likelihood of damage

of the goods.

Ordering Information

Product Part Number Description

LC640.480.21-065 996-0406-00 Standard

LC640.480.21-065 HTR 996-0406-01 Cell heater, conformal coating

LC640.480.21-065 CC 996-0406-02 Conformal coating

Design and specifications are subject to change without notice.

Planar Systems continues to provide optional, and in many cases custom, features to address the

specific customer requirements. Consult Planar Sales for pricing, lead time and minimum quantity

requirements.

Support and Service

Planar is a U.S. company based in Beaverton, Oregon and Espoo, Finland, with a world-wide sales

distribution network. Full application engineering support and service are available to make the

integration of Planar displays as simple and quick as possible for our customers.

RMA Procedure: For a Returned Material Authorization number, please contact

Planar Systems, Inc. with the model number(s) and serial number(s). When returning goods for repair,

please include a brief description of the problem, and mark the outside of the shipping container with

the RMA number.

North & South America OEM Sales Europe & Asia-Pacific OEM Sales

Planar Systems, Inc.

1400 NW Compton Drive

Beaverton, OR 97006-1992

Tel. +1 (503) 690 1100

Fax +1 (503) 690 1493

sales@planar.com

app_eng@planar.com

Planar Systems, Inc.

Olarinluoma 9, P.O. Box 46

FIN-02201 Espoo, Finland

Tel. +358 9 42 0010

Fax +358 9 420 0200

intlsales@planar.com

tech_support@planar.com

Visit the Planar web site: http://www.planar.com

OM610-00

Loading...

Loading...