Page 1

INSTALLATION INSTRUCTIONS

Universal Low Prole Flat Mount

Model: FWM-MXL

U.S.

Toll Free: 1-866-752-6271

Outside N. America: 1-503-748-5799

E-mail: ts@planar.com

9531-033-O03-01

FRANCE

Phone: +33 5 6378 3810

E-mail: emeats@planar.com

Page 2

FWM-MXL

Contents

Weight Limit. ................................................................................................................................................................................. 2

Warning Statements. .................................................................................................................................................................... 2

Installation Tools. .......................................................................................................................................................................... 3

Parts List....................................................................................................................................................................................... 3

Mounting Hardware. ..................................................................................................................................................................... 4

Features. ...................................................................................................................................................................................... 5

Installing the Wall Plate. ............................................................................................................................................................... 6

Installing the Mounting Bracket. ..................................................................................................................................................11

Lock-It™ Security Barrel Installation (Optional).......................................................................................................................... 14

Mounting Bracket Adjustments. .................................................................................................................................................. 15

Technical Specications. ............................................................................................................................................................ 16

Disclaimer ................................................................................................................................................................................... 17

Introduction. ................................................................................................................................................................... 6

Determining the Mounting Surface................................................................................................................................. 6

Wood Stud Installation. .................................................................................................................................................. 6

Concrete Installation. ..................................................................................................................................................... 8

Steel Stud Installation. ................................................................................................................................................... 9

Selecting the Mounting Hardware. ................................................................................................................................11

Universal Washer Installation. ...................................................................................................................................... 12

Universal Spacer Installation........................................................................................................................................ 12

Locking and Leveling Screw Installation. ..................................................................................................................... 13

Attaching the Mounting Bracket to the Flat Panel. ....................................................................................................... 14

Attaching the Flat Panel to the Wall Plate. ................................................................................................................... 15

Leveling Screw Adjustment. ......................................................................................................................................... 15

Locking Screw Adjustment. .......................................................................................................................................... 15

Utilizing the Security Barrel. ......................................................................................................................................... 16

Weight Limit

THE WALL STRUCTURE MUST BE CAPABLE OF

Maximum Flat Panel Weight:

175 lbs.

SUPPORTING AT LEAST FIVE TIMES THE WEIGHT OF

THE FLAT PANEL. IF NOT, THE WALL STRUCTURE MUST

BE REINFORCED.

Warning Statements

PRIOR TO THE INSTALLATION OF THIS PRODUCT, THE INSTALLATION INSTRUCTIONS MUST BE READ AND

COMPLETELY UNDERSTOOD. KEEP THESE INSTALLATION INSTRUCTIONS IN AN EASILY ACCESSIBLE LOCATION

FOR FUTURE REFERENCE.

PROPER INSTALLATION PROCEDURE BY A QUALIFIED SERVICE TECHNICIAN MUST BE FOLLOWED, AS OUTLINED

IN THESE INSTALLATION INSTRUCTIONS. FAILURE TO DO SO COULD RESULT IN PROPERTY DAMAGE, SERIOUS

PERSONAL INJURY, OR EVEN DEATH.

SAFETY MEASURES MUST BE PRACTICED AT ALL TIMES DURING THE ASSEMBLY OF THIS PRODUCT. USE

PROPER SAFETY EQUIPMENT AND TOOLS FOR THE ASSEMBLY PROCEDURE TO PREVENT PERSONAL INJURY.

PLANAR SYSTEMS DOES NOT WARRANT AGAINST DAMAGE CAUSED BY THE USE OF ANY PLANAR SYSTEMS

PRODUCT FOR PURPOSES OTHER THAN THOSE FOR WHICH IT WAS DESIGNED OR DAMAGE CAUSED BY

UNAUTHORIZED ATTACHMENTS OR MODIFICATIONS, AND IS NOT RESPONSIBLE FOR ANY DAMAGES, CLAIMS,

DEMANDS, SUITS, ACTIONS OR CAUSES OF ACTION OF WHATEVER KIND RESULTING FROM, ARISING OUT OF OR

IN ANY MANNER RELATING TO ANY SUCH USE, ATTACHMENTS OR MODIFICATIONS.

At least two qualied people should perform the assembly procedure. Personal injury and/or property damage can result

from dropping or mishandling the at panel.

If mounting to wall studs or ceiling studs, make sure that the mounting screws are anchored into the center of the wall studs

or ceiling studs. Use of an edge-to-edge stud nder is recommended.

It is recommended that a maximum of ⅝″ plaster board be used when mounting to wooden studs.

Be aware of the mounting environment. If drilling and/or cutting into the mounting surface, always make sure that there

are no electrical wires in wall. Cutting or drilling into an electrical line may cause serious personal injury.

Make sure there are no water or natural gas lines inside the wall where the mount is to be located. Cutting or drilling into a

water or gas line may cause severe property damage or personal injury.

This product is intended for indoor use only. Use of this product outdoors could lead to product failure and/or serious

personal injury.

Do not install near sources of high heat. Do not install on a structure that is prone to vibration, movement or chance of

impact.

Contact Planar Systems with any questions:

1-866-752-6271

ts@planar.com

Page 2 Installation Instructions

Page 3

FWM-MXL

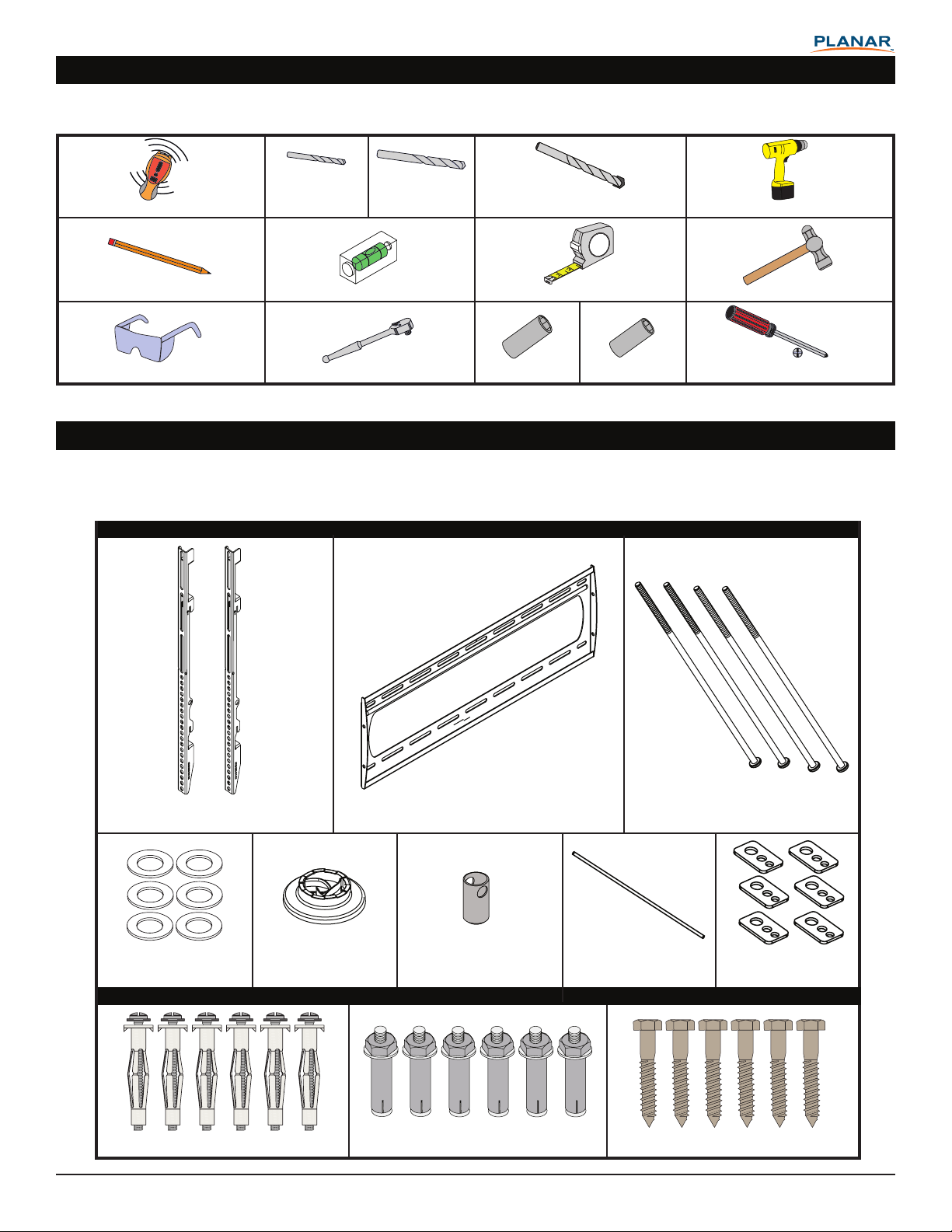

Installation Tools

The following tools may be required, dependent upon your particular installation. These tools are not provided, but you

can purchase them at your local hardware store.

7

Electronic Stud Finder

Pencil

¼˝ Drill Bit for

Wood Stud

/16˝ Drill Bit for

Steel Stud*

Level

5

/16˝ Concrete Drill Bit**

2

1

Tape Measure

Hand Held Drill

Hammer**

Protective Eyewear

Socket Wrench

½˝ Socket

M10 Socket*

Phillips Tip Screwdriver

* Optional tools for steel stud installations.

** Optional tools for concrete installations.

Parts List

Your product is shipped with all proper installation hardware and components. Make sure that none of these parts are

missing and/or damaged before beginning installation. If there are parts missing and/or damaged, please stop the

installation and contact Planar at 1-866-752-6271 (U.S.) or +33 5 6378 3810 (France).

FWM-MXL Universal Low Prole Flat Mount Assembly Components

Mounting Brackets

(Qty 2)

Wall Plate

(Qty 1)

M6 x 120mm Screws

(Qty 4)

5

/16˝ Flat Washers

(Qty 6)

M6 Steel Stud Anchors (Qty 6)

Universal Spacers

(Qty 24)

Security Barrel

(Qty 1)

Pro Mounting Hardware

5

/16˝ Concrete Wedge Anchors (Qty 6)

Thread Depth Indicator

(Qty 1)

5

/16˝ x 3˝ Lag Bolts (Qty 6)

Universal Washers

(Qty 6)

Installation Instructions Page 3

Page 4

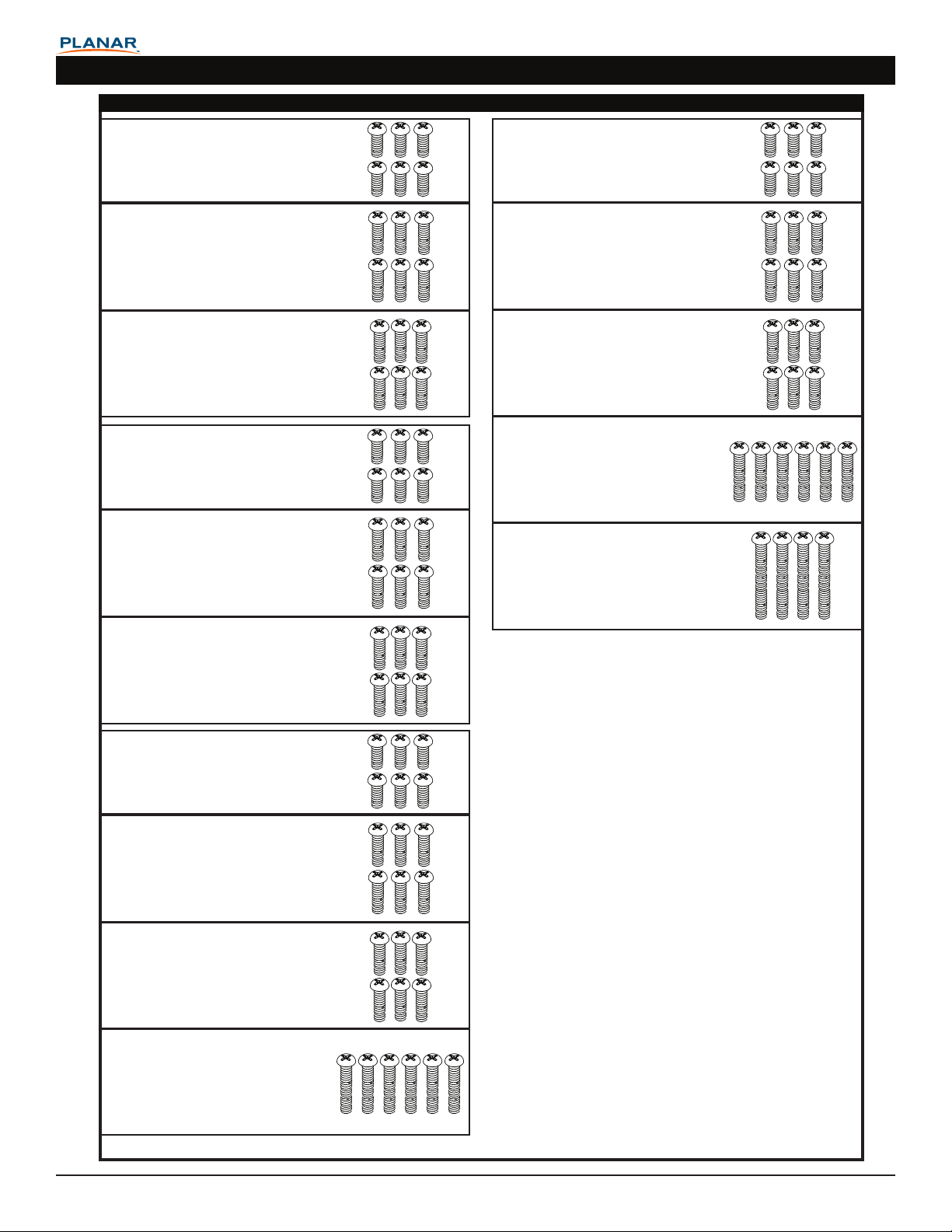

Parts List (cont’d)

FWM-MXL

Mounting Hardware

M4 x 16mm Screw

(Qty 6)

M4 x 25mm Screw

(Qty 6)

M4 x 30mm Screw

(Qty 6)

M5 x 16mm Screw

(Qty 6)

M5 x 25mm Screw

(Qty 6)

M8 x 16mm Screw

(Qty 6)

M8 x 25mm Screw

(Qty 6)

M8 x 30mm Screw

(Qty 6)

M8 x 45mm Screw

(Qty 6)

M8 x 70mm Screw

(Qty 4)

M5 x 30mm Screw

(Qty 6)

M6 x 16mm Screw

(Qty 6)

M6 x 25mm Screw

(Qty 6)

M6 x 30mm Screw

(Qty 6)

M6 x 45mm Screw

(Qty 6)

Page 4 Installation Instructions

Page 5

FWM-MXL

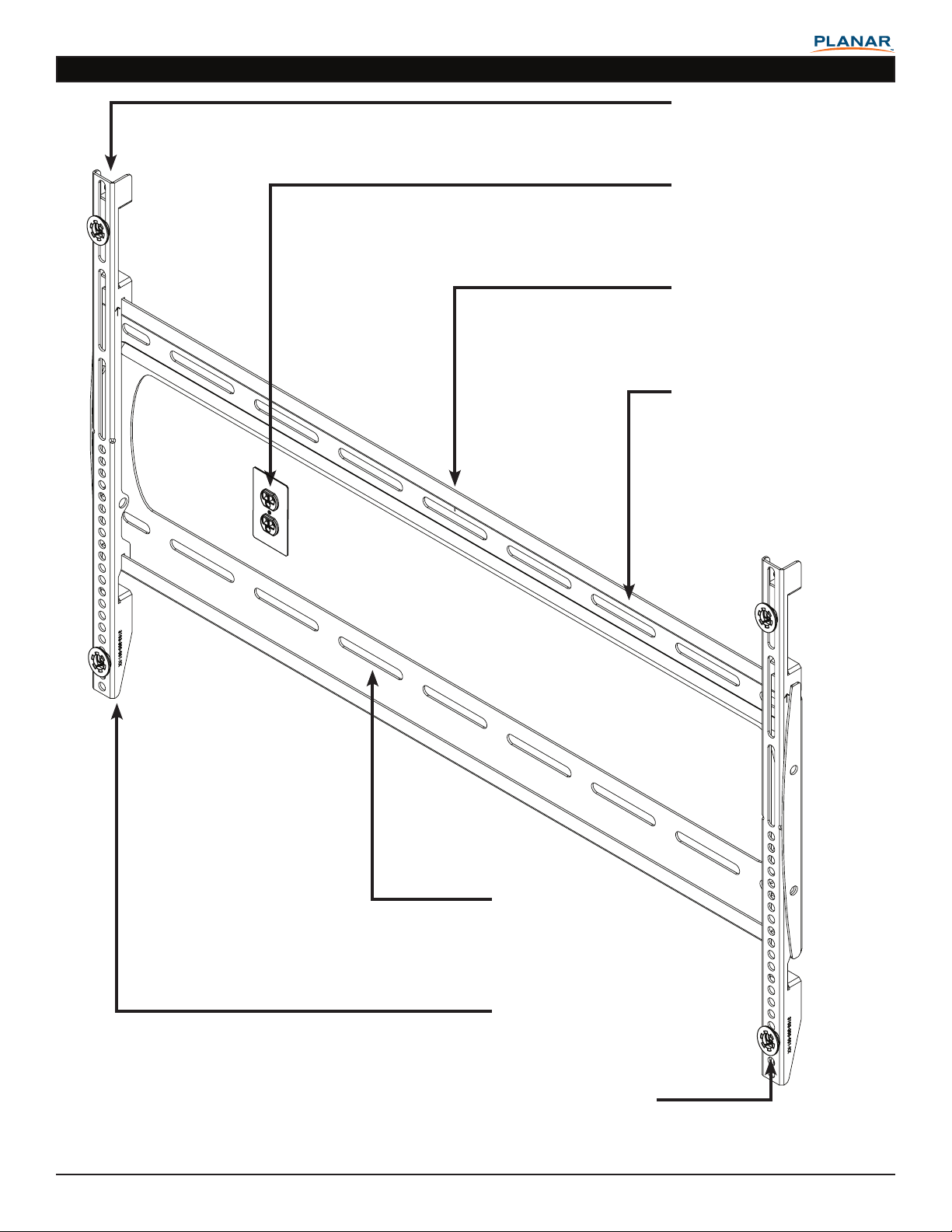

Features

Leveling Screws

Allows for leveling

adjustments of the at panel

after mounting.

Cable/Electrical Cut Out

A large cut out on the wall

plate allows for easy cable

access and power

distribution installations.

Directional Mounting Arrow

Directional Mounting Arrow

lets you know which edge is

up.

Low Prole Design

Holds the at panel less

than 1˝ from the wall.

Mounting Slots

Allow for a variety of stud

congurations and lateral

shift adjustments when

mounting your at panel.

Locking Safety Screws

Prevents the at panel from

being removed or dislodged

from the wall plate.

Universal Spacers

Uniquely designed spacers that t

multiple screw sizes.

Installation Instructions Page 5

Page 6

Installing the Wall Plate

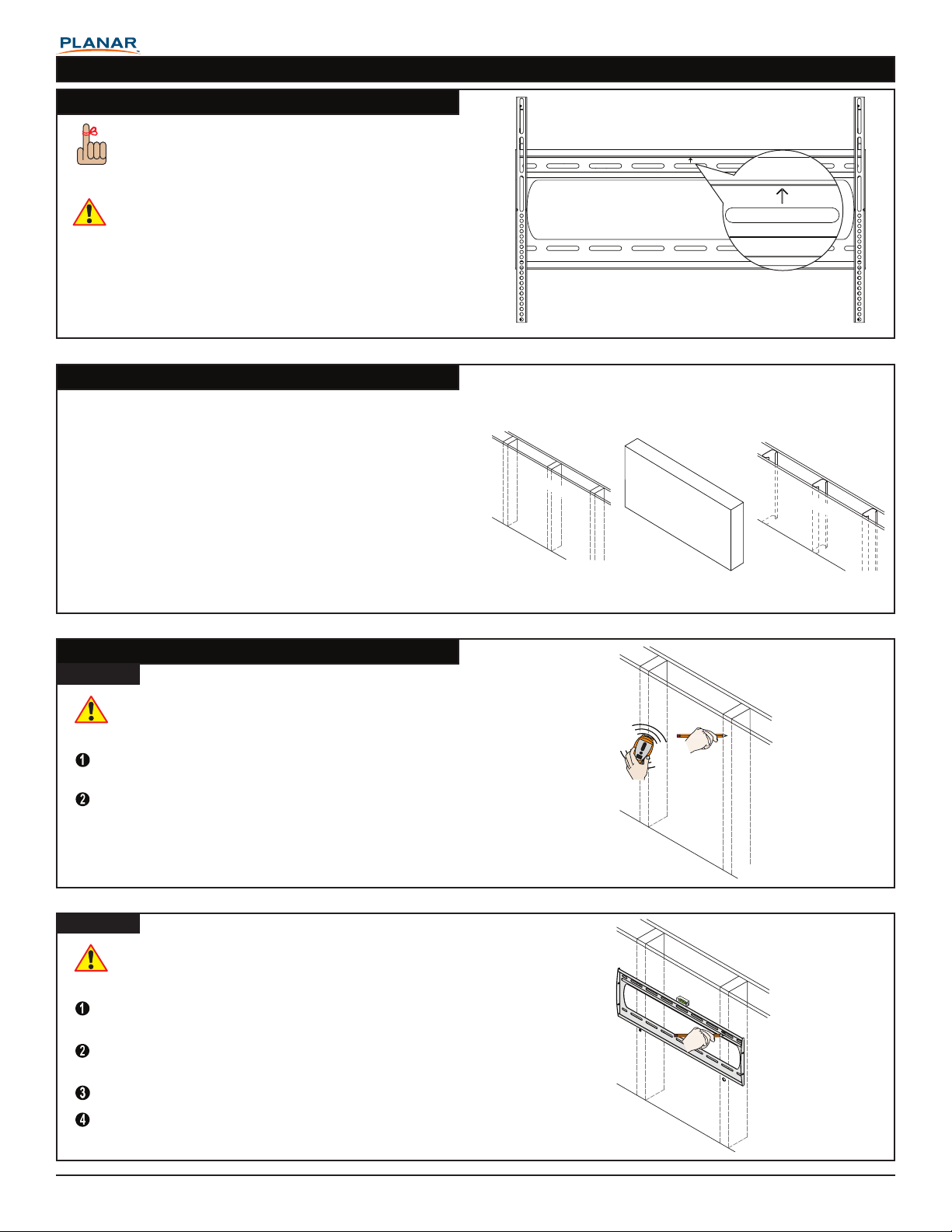

Introduction

Directional Mounting Arrow

The Directional Mounting Arrow stamped into the

top of the wall mount indicates which edge is the

top.

Mounting Safety

Two people are recommended for the installation

of this mount.

Determining the Mounting Surface

If you will be installing your mount to wood studs,

proceed to the “Wood Stud Installation” section.

If you will be installing your mount to a concrete wall,

proceed to the “Concrete Installation” section.

If you will be installing your mount to a steel frame,

proceed to the “Steel Stud Installation” section.

Wo

FWM-MXL

C

o

d

St

u

d

onc

rete

St

e

e

l

St

u

d

Wood Stud Installation

Step 1

You must secure the wall plate to two (2) wall

studs with a minimum of four (4) lag bolts (2 lag

bolts for each stud found).

Use a stud nder to determine the exact center of

wall studs in the vicinity of the wall plate.

Use a pencil to mark the exact center of each of the

wall studs.

Step 2

Two people are recommended for this step; one

person to level the wall plate and another person

to mark the wall stud location.

Place the wall plate against the wall in the desired

viewing location.

Adjust the wall plate to align the mount slots in the

wall plate with the center of the wall studs.

Level the wall plate.

X

X

Use a pencil to mark the upper right mounting

location along the center of the wall stud.

Page 6 Installation Instructions

Page 7

FWM-MXL

Installing the Wall Plate (cont’d)

Step 3

Drill a “pilot hole” in the center of the upper right mark

using a ¼˝ drill bit and power drill.

Only use a ¼˝ drill bit when drilling the pilot holes.

Step 4

Place the wall plate against the wall and align it with

the pilot hole.

Insert one (1) 5/16˝ x 3˝ lag bolt and one (1) 5/16˝

washer into the upper right mounting hole and

tighten using a socket wrench and ½˝ socket.

Do not overtighten the lag bolt.

Step 5

Level the wall plate.

Use a pencil to mark the remaining three (3)

mounting locations along the center of each wall

stud.

Step 6

Two people are recommended for this step; one

person to level the wall plate and another person

to drill the pilot holes.

Drill a “pilot hole” in the center of each of the marks with

a power drill and a ¼˝ drill bit.

Only use ¼˝ drill bit when drilling the pilot holes.

Installation Instructions Page 7

Page 8

Installing the Wall Plate (cont’d)

Step 7

Insert one (1) 5/16˝ x 3˝ lag bolt and one (1) 5/16˝ washer

into each pilot hole.

Tighten all lag bolts using a socket wrench and ½˝

socket.

Do not overtighten the lag bolts when attaching the

mount to the wall. Improper installation may result in

personal injury or property damage.

Proceed to the “Installing the Mounting Bracket” section.

Concrete Installation

The supplied 5/16˝ concrete wedge anchors must be

used for concrete installation.

You will need a 5/16˝ concrete drill bit, which is

available at your closest hardware store.

FWM-MXL

Concrete Wedge Anchors

Step 1

Two people are recommended for this step; one

person to level the wall plate and another person

to mark the mounting locations.

Place the wall plate against the wall in the desired

viewing location.

Level the wall plate.

Use a pencil and mark 2 upper and 2 lower

mounting locations where you will be drilling holes

for the concrete wedge anchors. Each horizontal

location cannot be closer than 12˝ apart.

Set the wall plate to one side in a safe location.

Step 2

Use a power drill and 5/16˝ concrete drill bit to drill a hole

at each of the marks.

Example of

5

/16˝ Concrete Drill Bit (Not Included)

>12”

Page 8 Installation Instructions

Page 9

FWM-MXL

Installing the Wall Plate (cont’d)

Step 3

Insert a concrete wedge anchor into each hole.

If necessary, lightly tap each concrete wedge anchor

into place with a hammer.

Remove the nuts and washers from all four (4)

concrete wedge anchors.

Step 4

Place the wall plate against the wall over the

threaded shafts of the concrete wedge anchors.

Replace the washers which you removed from

the concrete wedge anchors with the 5/16˝ washers

shown in the parts list on Page 3.

Attach the nuts and 5/16˝ washers to each of the

concrete wedge anchors and tighten using a socket

wrench and an M10 socket.

Do not overtighten the wedge anchor nuts.

Proceed to the “Installing the Mounting Bracket”

section.

Steel Stud Installation

The supplied M6 steel stud anchors must be used

to install your mount to steel studs. Do not use

lag bolts or wood screws.

Step 1

Identify the general location on the wall where you

will be mounting your at panel.

Steel Stud Anchor Screw Steel Stud Anchor Sleeve

Use a stud nder to determine the exact center

of each steel stud in the vicinity of the mounting

location.

Use a pencil and mark the exact center of each

steel stud.

Installation Instructions Page 9

X

Page 10

Installing the Wall Plate (cont’d)

Step 2

Place the wall plate against the wall in the desired

viewing location.

Adjust the wall plate to match the locations of the

steel studs.

Level the wall plate.

Use a pencil and mark 2 upper and 2 lower

locations where you will be drilling holes for the steel

stud anchors.

Set the wall plate to one side in a safe location.

Step 3

Use a power drill and 7/16˝ drill bit to drill a hole at

each of the marks.

Insert a steel stud anchor into each hole.

If necessary, lightly tap each steel stud anchor into

place with a hammer.

FWM-MXL

Step 4

Use a Phillips screwdriver to tighten each steel

stud anchor screw until the legs have completely

compressed against the back of the steel stud.

The steel stud anchor screw will feel tight when

you rst begin to turn it until the legs begin to

compress. The steel stud anchor screw will then

turn easier for several turns. The steel stud anchor

screw will again feel tight when the legs have

completely compressed against the back of the

drywall. Stop turning the steel stud anchor screw

at that point.

Do not overtighten the steel stud anchor screw.

Remove the steel stud anchor screws and set them

aside.

Steel stud anchors may come with small paper

washers. You may leave them on the screw or

discard them. These small paper washers do not

replace standard 5/16˝ washers.

Page 10 Installation Instructions

Page 11

FWM-MXL

Installing the Wall Plate (cont’d)

Step 5

Align the wall plate over the steel stud anchor sleeves.

Insert a steel stud anchor screw and a 5/16˝ washer into

each steel stud anchor sleeve.

X

Use a Phillips screwdriver and tighten each steel stud

anchor screw until it is just snug.

Do not overtighten the steel stud anchor screws.

Do not use a power drill to tighten the steel stud anchor

screws.

Proceed to the “Installing the Mounting Bracket” section.

Installing the Mounting Bracket

Selecting the Mounting Hardware

Insert a small straw or toothpick into the threaded

inserts found on the back of the at panel.

Use a pencil to mark the depth of the threaded

insert on the small straw or toothpick.

Mark the straw or toothpick 1/8” above the depth of

the threaded insert, as shown in Figure 1.

Insert the small straw or toothpick into the remaining

threaded inserts to compare and verify their depth

using the straw or toothpick’s 1/8” allowance mark.

Locate the correct diameter screw for the threaded

insert.

If the screw you selected is longer than the 1/8”

allowance mark on the small straw or toothpick,

as shown in Figure 2 and Figure 3, do not use

this screw. The screw length must not bypass the

mark.

Test each size of the screws provided.

The correct screws should thread easily into the

mounting point and not pull out when tension is

applied.

Small Straw or Toothpick

X

Marking the 1/8”

Allowance

Proceed to the “Universal Washer Installation”

section.

Small Straw

or Toothpick

Depth Plus 1/8” Allowance

Mark

Small Straw

or Toothpick

Depth Plus 1/8” Allowance

Mark

Installation Instructions Page 11

Page 12

Installing the Mounting Bracket (cont’d)

Universal Washer Installation

FWM-MXL

Universal Washers are designed to accommodate the

various M4, M5, M6 and M8 hole sizes required by at

panels.

Do not place excessive pressure on the back of

the at panel, as this may damage your at panel.

The Universal Washer must be installed between

the head of the mounting screw and the mounting

bracket as shown.

Does your at panel have:

● Recessed mount points?

● Uneven mount points?

● A curved back?

● Any obstruction near the mount point?

If Yes, you must install Universal Spacers. Remove the

mounting brackets, Universal Washers, and mounting

screws from the back of the at panel. Proceed to the

“Universal Spacer Installation” section.

If No, skip to the “Leveling and Locking Screw

Installation” section.

Universal Spacer Installation

Universal Spacers allow you to attach the mounting

bracket to at panels which have recessed or uneven

mount points. Each Universal Spacer adds ¼˝ to the

distance between the mounting bracket and your at

panel.

M8

M5, M6

M4

Mounting Screw

Universal Washer

Mounting Bracket

Flat Panel

Universal Spacer

Mount Point

The Universal Spacers must be stacked and

oriented as shown.

The Universal Spacers must only be installed

between the mounting bracket and your at panel.

The Universal Spacers will t M4, M5, M6 and M8

screw sizes.

Proceed to the “Locking and Leveling Screw

Installation” section.

1˝ ¼˝

Page 12 Installation Instructions

Page 13

FWM-MXL

Installing the Mounting Bracket (cont’d)

Locking and Leveling Screw Installation

Leveling Screw Installation

You must install the leveling screws before you

attach the mounting bracket to the back of the at

panel. The leveling screws consists of two (2)

M6 x 120mm screws.

Thread one (1) leveling screw into the top mounting

hole on each of the mounting brackets. Make sure the

leveling screw is securely threaded into the mounting

tab before proceeding.

Do not thread the leveling screw any further once

it is even with the mounting tab. Threading the

leveling screw any further will prevent you from

safely attaching the at panel to the wall plate.

Locking Screw Installation

You must install the locking screws before you

attach the mounting bracket to the back of the at

panel. The locking screws consists of two (2)

M6 x 120mm screws.

Leveling Screw

Correctly Threaded

Leveling Screw

Threaded Too Far

Thread one (1) locking screw into the bottom mounting

hole on each of the mounting brackets. Make sure the

locking screw is securely threaded into the mounting tab

before proceeding.

Do not thread the locking screw any further once

it is even with the mounting tab. Threading the

locking screw any further will prevent you from

safely attaching the at panel to the wall plate.

Proceed to the “Attaching the Mounting Bracket to

the Flat Panel” section.

Locking Screw

Correctly Threaded

Locking Screw

Threaded Too Far

Installation Instructions Page 13

Page 14

Lock-It™ Security Barrel Installation (Optional)

Optional security congurations include:

- PCB-CSL1 (sold separately)

- Padlock (Combination or Keyed; commercially

available)

Please read the following directions to install the

security barrel:

Remove the locking screw from the mounting

bracket.

Place the locking screw into and through the

security barrel (see illustration below).

Re-insert the locking screw and security barrel into

the mounting bracket.

Tighten the locking screw and security barrel until

seated in the mounting tab.

Do not thread the locking screw any further once

it is even with the mounting tab (see illustration to

the right). Threading the locking screw any further

will prevent you from safely attaching the at

panel to the wall plate.

Do not overtighten the locking screw.

FWM-MXL

Mounting Tab

Proceed to the “Attaching the Mounting Bracket to

the Flat Panel” section.

Locking Screw

Lock-It™ Security

Barrel

Attaching the Mounting Bracket to the Flat Panel

This section presumes that you have read and

understood these sections:

● Selecting the Proper Mounting Hardware

● Universal Washer Installation

● Universal Spacer Installation

Place your at panel screen-side down on a soft, at

surface.

Identify the number and location of the thread

inserts on the back of your at panel.

Aligning the holes on each mounting bracket with

the thread inserts on the back of your at panel.

Secure each mounting bracket to your at panel by

inserting a minimum of two (2) screws per bracket.

Do not overtighten the mounting hardware.

Proceed to the “Attaching the Flat Panel to the Wall

Plate” section.

Page 14 Installation Instructions

Page 15

FWM-MXL

Attaching the Flat Panel to the Wall Plate

This section requires two people.

Do not release your at panel until you are certain that top and bottom hooks of both mounting brackets are

securely seated on the upper and lower mounting rails of the wall panel.

Raise the at panel past the top and bottom mounting rails on the wall panel.

Slide the at panel down slowly, keeping it close to the wall.

Engage the top and bottom mounting brackets to the rails of the wall plate.

Proceed to the “Mounting Bracket Adjustments” section.

Mounting Bracket Adjustments

Leveling Screw Adjustment

If your at panel is tilted too far to one side, the leveling

screws will allow you compensate for this tilt by simply

adjusting the screws with a screwdriver.

Loosen both locking screws.

Adjust the tilt of your at panel.

Tighten both locking screws.

Caution!

It is possible to dislodge your at panel while you

level your at panel. Use extreme caution until

you tighten the locking screws.

Locking Screw Adjustment

After you have nished leveling your at panel, be sure

to tighten the two (2) M6 x 120mm locking screws.

Do not overtighten the locking screws.

M6 x 120mm

Leveling Screw

(1 per Bracket)

M6 x 120mm

Locking Screw

(1 per Bracket)

Installation Instructions Page 15

Page 16

Utilizing the Security Barrel

Your mount includes one (1) Security Barrel which can

provide additional theft deterrence for your at panel.

PCB-CSL1 Security Cable -

Thread the cable through the hole on the security

barrel.

Attach the PCB-CSL1 locking mechansim and

secure it using the supplied key.

Padlock -

Place the locking hook through the hole of the

security barrel.

Snap lock and locking hook together.

FWM-MXL

Technical Specications

All measurements are in inches [millimeters].

PCB-CSL1

Padlock

(Combination or Keyed)

Page 16 Installation Instructions

Page 17

FWM-MXL

Disclaimer

Planar Systems intends to make this manual accurate and complete. However, Planar Systems makes no claim that

the information contained herein covers all details, conditions or variations, nor does it provide for every possible

contingency in connection with the installation or use of this product. The information contained in this document

is subject to change without notice or obligation of any kind. Planar Systems makes no representation of warranty,

expressed or implied, regarding the information contained herein. Planar Systems assumes no responsibility for

accuracy, completeness or sufciency of the information contained in this document. This mount is covered under

Planar’s standard warranty terms and conditions found on www.planarcontrolroom.com/support.

©Planar Systems 2010

Installation Instructions Page 17

Loading...

Loading...