Page 1

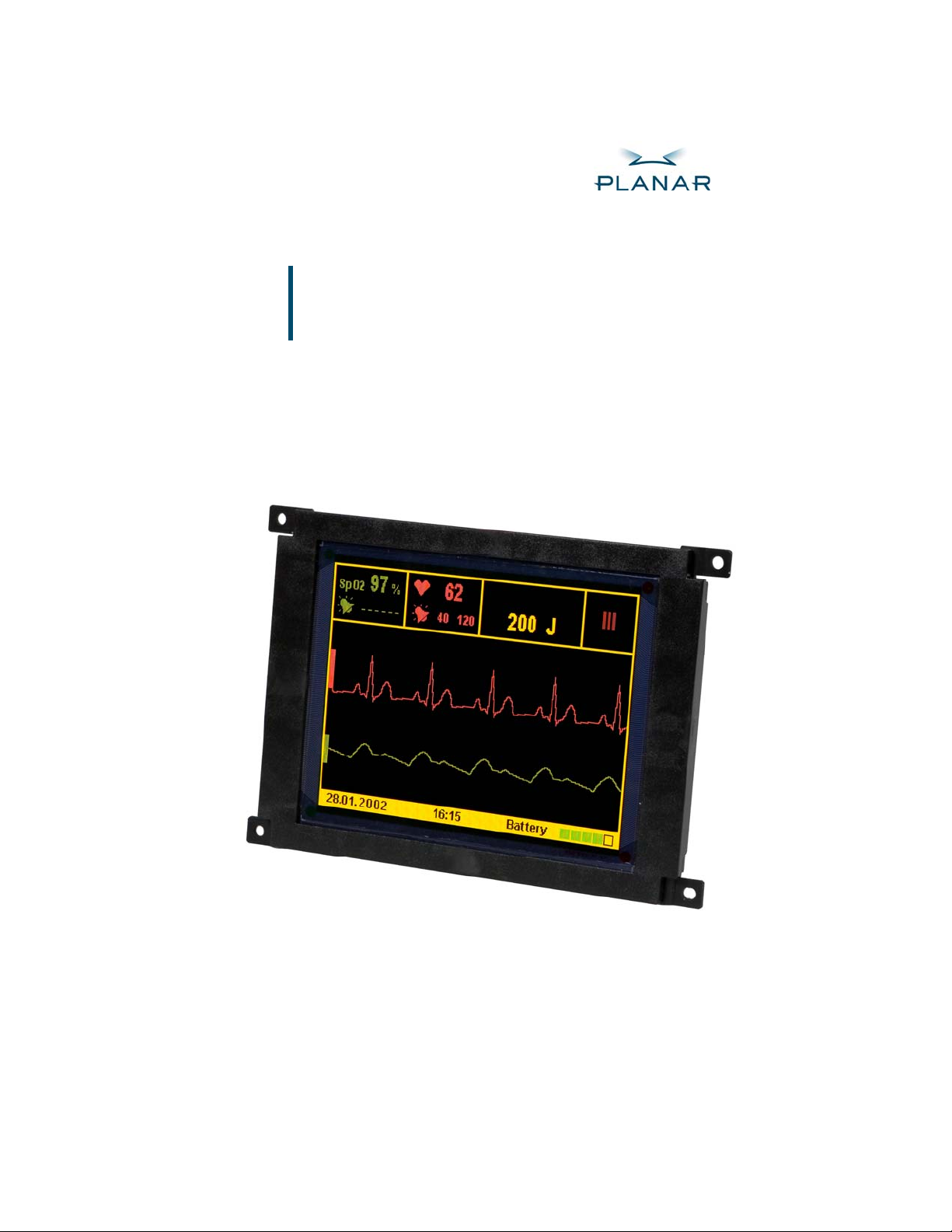

EL320.240-FA3

Multi-Color QVGA EL Display

OPERATIONS MANUAL

www.planar.com

Page 2

Revision Control

Date Description

February 2007 Initial release, 020-0591-00 Rev A

EL320.240-FA3 Operations Manual Page 2 of 25

Page 3

Table of Contents

EL320.240-FA3 Multi-Color QVGA Display………………………………...…………...…4

Features and Benefits…………………………………………………………………….…4

Installation and Set-up…………………………………………………………...………..5

Mounting Considerations…………………………...………...…..…………………………5

Cable Length…………………………………………………...……………………………5

Cleaning………………………………………………………...……………………………5

Avoiding Image Burn-in………………………………………..……………………………6

Power Supply and Video Sequencing………...…………...……...…………………………6

VH Overcurrent Protection……………...……………………...……………………………6

Internal Frame Buffer…………………………………...………………...………….………6

Color Bit Mapping……................………………………...………………...………….………6

Display Overlay Considerations……...............……………...……………...………….………7

Specifications and Operation………………………...……………………………..……..8

Environmental……………………………………………...……………………………...…8

Over-temp Condition………………………………………...…...…………………...…8

Optical……………………………………………...…………………………………...….…9

Displayed Colors……………………………………………...……………….…………9

Power…………………………………...…………………………………………………...10

Display Interface……………………..………………...……………………………..……..11

Video Mode Selection…………………………………...……………………………..11

Connector…………………………………...………………………………...………...12

Display Input Descriptions…………………………………...……………….………...13

Video Mode Timing ………………………………………...………………...……...…14

Dimming…………………………………...……………………………………………….19

Self Test Mode…………………………………...……………………………………….....20

Reliability………………………………………...…………………………………...…...…21

Safety and EMI Performance…………………………………...……………………...……21

Mechanical Characteristics…………………………………...……………………...……...21

Display Dimensions and Component Envelope …………………………………...…22

Warranty…………….…………………………………………………………….…...…23

Ordering Information…………………………………………………………..……...…23

RoHS……………………………………...……………………………………….…...….24

Support and Service…………………………………………………….………..……....24

EL320.240-FA3 Operations Manual Page 3 of 25

Page 4

EL320.240-FA3 Multi-Color QVGA Display

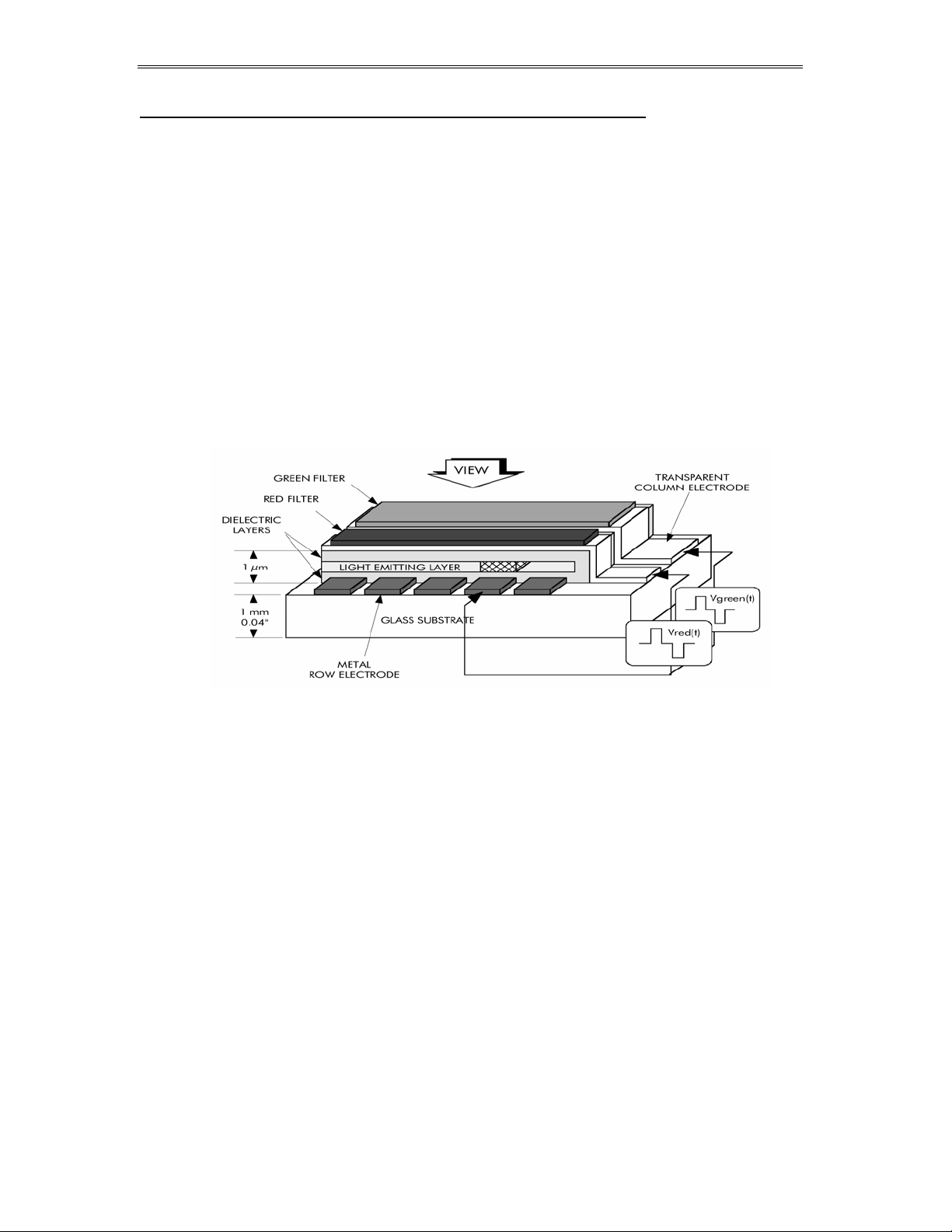

The EL320.240-FA3 thin film electroluminescent (EL) multi-color display is a

high-performance alternative to QVGA (320 x 240) LCDs and is the ideal

solution in demanding applications where superior visual performance,

extreme temperature range, and environmental ruggedness are critical.

The EL320.240-FA3 utilizes Planar’s proprietary Integral Contrast Enhancement

technology combined with red and green filters patterned over Planar’s

industry-leading yellow phosphor to achieve unparalleled image quality in

hues of red, green and yellow. Three intensity levels in each of the red and

green sub-pixels generate sixteen distinct colors (nine chromatically different

colors, black, and two mid-levels of red, green, and yellow.)

The display consists of a solid state EL glass panel, depicted below, with

a124mm diagonal active area, and control electronics assembled into a

space-saving, rugged package for easy mounting.

Features and Benefits

• Excellent visual performance:

Unparalleled crisp, clear image

Excellent contrast

Unbeatable viewing angle of > 160° for all colors in all directions

No off-axis color or contrast shift

• Extremely wide operation temperature range: -50 to 85C

• Instant turn on at -50C: no heaters needed, no warm up time

• Long life phosphor: allows >11 years of continuous operation

• Wide dimming range via digital control and analog voltage input

• Rugged solid state construction

• Great reliability: MTBF > 50,000 hours demonstrated

• Low cost of ownership: no maintenance, no lamps to replace

• AMLCD-type panel interface, 3V and 5V logic compatible

• RoHS compliance

EL320.240-FA3 Operations Manual Page 4 of 25

Page 5

Installation and Set-up

Do not drop, bend, or flex the display. Do not allow objects to strike the

surface of the display.

CAUTION: The display uses CMOS and devices. These components are

electrostatic-sensitive. Unpack, assemble, and examine this assembly in a

static-controlled area only. When shipping, use packing materials designed

for protection of electrostatic-sensitive components.

Mounting EL Displays

Properly mounted, EL displays can withstand high shock loads as well as

severe vibration found in demanding applications. However the glass panel

used in an EL display will break if subjected to bending stresses, high impact,

or excessive loads.

Avoid bending the display. Stresses are often introduced when a display is

mounted into a product. Ideally, the mounting tabs of the display should be

the only point of contact with the system. Use a spacer or boss for support;

failure to do so will bend the display and cause the glass to break. The

instrument enclosure or frame should not flex or distort in such a way that

during use the bending loads might be transferred to the display. The

EL320.240-FA3 mounting tabs were designed for a 3 mm screw. Mounting

surfaces should be flat to within ±0.6 mm (±0.025"). Use all the mounting holes

provided. Failure to do so will impair the shock and vibration resistance of the

final installation.

WARNING: These products generate voltages capable of causing personal

injury (high voltage up to 140 Vac ). Do not touch the display electronics

during operation.

Cable Length

A cable length of 0.5 m (20 inches) or less is recommended. Longer cables may

cause visual artifacts such as pixel “jitter” due to data transfer problems

between the host and the display.

Cleaning

As with any glass surface, care should be taken to minimize scratching. Clean

the display glass with mild, water-based detergents only. Apply the cleaner

sparingly to a soft cloth, then wipe the display. Disposable cleaning cloths are

recommended to minimize the risk of inadvertently scratching the display

with particles embedded in a re-used cloth.

EL320.240-FA3 Operations Manual Page 5 of 25

Page 6

Avoiding Image Burn-In

As with other light emitting displays, displaying fixed patterns on the screen

may cause burn-in, where luminance variations can be noticed after hundreds

of hours of operation. To avoid image burn-in, use a screen saver or use

periodic image inversion if possible. Note that the rate of image burn-in will

slow over time such that most of the burned-in image effect occurs in the first

1000 hours of operation.

Power Supply and Video Sequencing

Any combination or sequencing in the application or removal of VH (12VDC

input power)and/or video signals will not result in abnormal display operation

or display failure

.

VH Overcurrent Protection

There is no overcurrent protection on VH, the 12V power input. To protect

against catastrophic faults, Planar recommends the use of a fuse or similar

protection on the VH input to the display.

Internal Frame Buffer

This display includes an internal frame buffer, which is required to transform

the incoming video data into the desired displayed data. The display frame

rate (the rate at which the phosphor is scanned) and thus the display

brightness are independent of the frame rate of the user-supplied input data.

Video data need not be continuously sent to the display since previously sent

data is stored indefinitely until new data is received.

CAUTION: Some third-party video controllers use frame dithering algorithms

to produce gray scale images. If such algorithms are used, the internal frame

buffer may cause objectionable visual artifacts.

Color Bit Mapping

The EL320.240-FA3 utilizes standard AMLCD-type video interface timing. Thus

it is possible that a video source will be chosen which provides 18 bits of data

per pixel (six bits each for red, green, and blue) as is common for AMLCD

displays. Because the EL320.240-FA3 requires just 4 bits (two each for red and

green), the 18 bits would need to be mapped into 4 bits.

One option is to use just the two most significant bits of red and green and

leave the rest open or terminated. This is the easiest approach and will work

well if the user is developing their own content and can refrain from using

patterns containing dim colors since these would likely be displayed as black.

EL320.240-FA3 Operations Manual Page 6 of 25

Page 7

Another option is to electrically “OR” the 3 red MSBs together and route the

result to R1, OR the 3 red LSBs together and route to R0, and do the same for

G1 and G0. Additionally the bits of blue could be OR’d together with either

the red or green bits depending on the characteristics of the images that need

to be displayed.

If upgrading from a monochrome EL320.240 display model and using the SGD

timing mode, some engineering will be required to map the monochrome

SGD data into the color data required by the EL320.240-FA3. SGD data is one

bit per pixel, and 4 pixels of data are latched per video clock edge. The

EL320.240-FA3 is 4 bits per pixel with one pixel of data latched per clock edge.

Display Overlay Considerations

Though not a requirement, often the end system will employ some type of

transparent cover over the front the display. The purpose and construction of

the cover varies depending on the application and economical constraints.

The cover may be used to improve contrast under certain lighting conditions

by reducing reflections, to provide additional impact protection, to provide a

more seamless enclosure appearance, or to protect against fluids. See

Application Note AN117-01 at planar.com for details. Some leading suppliers

of various display overlays are: EyeSaver International, Cyro Industries, and

Dontech Incorporated.

EL320.240-FA3 Operations Manual Page 7 of 25

Page 8

Specifications and Operation

Environmental

Environmental Characteristics

Temperature

Operating -50°C to +85°C

Storage -50°C to +105°C

Humidity

Non-condensing,

operating

Condensing,

non-operating

Altitude

Operating/non-operating 0 to 18 km (58k ft) per IEC 68-2-13

Vibration

Random

Operating/non-operating

93% RH max at +40°C, per IEC 68-2-3

95% RH max at +55°C, per IEC 68-2-30

0.05 g2/Hz, ASD level, 5-500 Hz

per IEC 68-2-36, test Fdb.

Shock

Operating/non-operating 100 g, 6 ms, half sine wave on each of six surfaces per

Over-temp Condition

The display contains a temperature sensor which measures the temperature of the circuit board at the lower left corner as viewed from the component side of the board.

If the board temperature exceeds approximately 100C, the display will

automatically operate at its lowest luminance setting (as if LUM0 was low and LUM1

was high) to reduce the board temperature. At no point will the display be shut

down. The content of the pattern will be unaffected.

After surpassing 100C, once the board temperature drops below approximately 92C

or the power is cycled, the display will resume normal operation as defined by the

LUM0 and LUM1 settings. Typically, the 100C limit may be reached if the 12V input

power exceeds 6W when the ambient temperature for the display electronics is

85C.

IEC 68-2-27, test Ea.

EL320.240-FA3 Operations Manual Page 8 of 25

Page 9

Optical

Optical Characteristics

Luminance

Guaranteed

Typical

Guaranteed

Typical

Black luminance

Luminance Non-uniformity

Typical 5% Maximum difference two of five points (center plus

Luminance Variation across Temperature

Maximum

Luminance Decrease over Time

Typical 6% 10,000 hours

Typical 15% 100,000 hours (> 11 years)

Viewing Angle

Minimum

>75 cd/m²

95 cd/m²

>41 cd/m²

53 cd/m²

<0.2 cd/m²

±15%

>160° in all directions; no change to contrast, color, or luminance

max frame rate (LUM0=LUM1=0), yellow, center

max frame rate (LUM0=LUM1=0), yellow, center

min frame rate (LUM0=0, LUM1=1), yellow, center

min frame rate (LUM0=0, LUM1=1), yellow, center

max frame rate, 5 points: center plus four corners

four corners), using the formula:

BNU%=[1- (min_lum/max_lum)] x 100%

Deviation from 25°C to the operating extremes

Contrast Ratio (typical)

1000:1

Displayed Colors

The display is capable of displaying 16 hues based on the red and green sub-pixels

and frame dithering (utilizing a three frame period with either a 33% or 66% duty

cycle) generated by the display.

Color

Level

R1 R0 G1 G0 Pixel Color

0 0 0 0 0 Black n/a Off Off

1 0 0 0 1 Dim Green .450,.546 Off 1/3

2 0 0 1 0 Medium Green .450,.546 Off 2/3

3 0 0 1 1 Green .450,.546 Off On

4 0 1 0 0 Dim Red .606,.393 1/3 Off

5 0 1 0 1 Dim Yellow .497,.498 1/3 1/3

6 0 1 1 0 Greenish Yellow .481,.514 1/3 2/3

7 0 1 1 1 Reddish Green .471,.524 1/3 On

8 1 0 0 0 Medium Red .606,.393 2/3 Off

9 1 0 0 1 Reddish Yellow .524,.473 2/3 1/3

10 1 0 1 0 Medium Yellow .497,.498 2/3 2/3

11 1 0 1 1 Yellowish Green .486,.509 2/3 On

12 1 1 0 0 Red .606,.393 On Off

13 1 1 0 1 Greenish Red .535,.462 On 1/3

14 1 1 1 0 Yellowish Red .511,.485 On 2/3

15 1 1 1 1 Yellow .497,.498 On On

2.5:1

1.5:1

Description

@ 0 lux ambient (dark room), maximum frame rate

@ 20k lux ambient (daylight), maximum frame rate

@ 75k lux ambient (direct sun), maximum frame rate

Typical Chromaticity

(x, y coordinates)

FA1 Red

Intensity

FA1 Green

Intensity

EL320.240-FA3 Operations Manual Page 9 of 25

Page 10

Power

The supply voltage and power requirements are shown in the table below. The

power will vary greatly depending on the number of pixels lit and depending

on the chosen luminance level (see graph below.) Power levels will vary up to

+/-15 % from display to display due to brightness variation.

DC Input Voltage and Power Requirements

Parameter Minimum Typical Maximum Abs Max

Display supply voltage, VH 8 V 12 V 18V

Supply current at +12 V 0.45 A 0.95 A 1.09 A

Power consumption @ maximum

luminance (LUM0=LUM1=0)

Power consumption @ minimum

luminance (LUM0=0, LUM1 =1)

Quiescent power consumption

(SHUTDOWN = 1)

Note: 1) Maximum power: 90% of pixels lit (yellow) per row

2) Abs Max power: 90% of pixels lit (yellow) per row, worst case display sample

2) Typical power: pattern with 10% of pixels lit per row, typical display

3) All power numbers are for LUMA open (no analog dimming)

5.4 W 11.4 W 13.1 W

3.5W 6.9 W

0.5 W

EL320.240-FA 3 Power vs. Percent of Pi xel s O n, for A ll Three

Lumi n anc e Settings , Typical

12

10

8

6

4

Power Consumption, watts

2

0

0 20406080100

Pe rcenta ge of pixels turne d on (yell ow) per row

Max l um inance, 325 Hz

Med lum i nanc e, 240 Hz

Min l um inance, 180 Hz

EL320.240-FA3 Operations Manual Page 10 of 25

Page 11

Display Interface

The display supports five video interface modes: SGD timing as used on the

Planar EL320.240.36-HB (though with video data differences to denote colors)

and the four AMLCD timing modes used on Sharp and Kyocera QVGA color

displays (though using only two bits of red and green data). Four bits of data

per pixel are provided. The data is clocked to the display with a video clock,

VCLK. Frame and line synchronization is provided by the VS, HS and (if needed)

DE signals.

Video mode detection is performed automatically. The display evaluates the

timing of the incoming video approximately every 25 msec and will shift “on

the fly” between video modes as required.

The internal display controller utilizes a frame buffer to provide the display

with the appropriate modulation on a line by line and frame by frame basis to

implement the color generation, including frame dithering algorithms. Thus

the input frame rate and the display scan rate, in general, will not be the same

and will not be synchronous.

Video Mode Selection

Inputs LUM0 and LUM1 must be set to attain the desired video mode as shown

in the following table.

LUM0 and

LUM1 = 1?

No 0 Active AMLCD,Q

No 0 0 AMLCD,

No 1 Active AMLCD,

No 1 0 AMLCD,

No X 1 SGD SGD timing. Horizontal start of valid data is

Yes X X Self test Displays various patterns at the maximum

V/Q

Input

DE

Input

Mode

Name

VGA

QVGA,

Fixed

VGA

VGA,

Fixed

Mode Description

(refer to Video Mode Timing for details)

AMLCD timing. DE determines the

horizontal location of data.

AMLCD timing. Horizontal start of valid

data is a predetermined number of VCLKs

from HS.

AMLCD timing. Displays upper left

quadrant of a VGA (640x480) input signal

with DE determining the horizontal

location of data.

AMLCD timing. Displays upper left

quadrant of a VGA (640x480) input signal

with the horizontal start of valid data

predetermined.

the first VCLK after HS.

refresh rate regardless of video input data.

Useful for verifying display functionality.

Note:1) DE is considered active if more than eight logic transitions are detected

2) SGD mode is similar to that of the Planar EL320.240.36 and EL320.240-HB

displays but with required changes to the video data content to represent color

3) The AMLCD modes are compatible with those found on the following QVGA

displays though the video data content of 4 bits/pixel is a subset of the typical

18 bits/pixel: Sharp LQ057Q3DC12, Sharp LQ057Q3DC02, Kyocera

TCG057QV1AC

EL320.240-FA3 Operations Manual Page 11 of 25

Page 12

Connector

K

The display uses the Samtec EHT-110-01-S-D or equivalent 2mm locking

connector. The mating connector is in the Samtec TCSD family of cable strips.

The proper connector, user-specified cable length and connector

configuration is supplied as a single unit. Consult your Samtec representative

(1-800-SAMTEC9) for the cable/connector options. Compatibility with nonSamtec equivalents should be verified before use.

Pin 19

(Viewed from

back of display)

Pin 1

J1

ey

Pin 1

Pin 2

(Viewed from top of connector)

Figure: Data/Power Connector

J1 Connector Pin Assignment

Signal Pin Pin Signal

VH 1 2 VH

V/Q 3 4 DE

LUMA 5 6 LUM0

VS 7 8 LUM1

HS 9 10 GND

VCLK 11 12 GND

R0 13 14 GND

R1 15 16 GND

G0 17 18 GND

G1 19 20 SHUTDOWN

EL320.240-FA3 Operations Manual Page 12 of 25

Page 13

Display Input Descriptions

y

y

p

y

Signal Description

VH Power supply voltage for display functions. 12 VDC nominal.

V/Q Format selection: in AMLCD timing modes, selects between VGA mode (high) and

QVGA mode. In VGA mode the upper left quadrant of data will be displayed.

Internall

DE Data Enable: in AMLCD non-fixed timing modes, the rising edge identifies the data

for the first pixel of each row and must stay high until the data for the last pixel of

each row is clocked. DE is also used to determine the video timing mode.

Internally pulled high to 3.3V.

LUMA Analog Luminance Control: used to reduce the display luminance by reducing the

voltage applied to the display phosphor. If left open, defaults to the luminance set

b

LUM0, LUM1 Digital Luminance Controls: used to reduce the luminance of the display by

reducing the frequency at which the display is scanned.

VS Vertical Sync: identifies the start of each frame (entire screen) of data. Internally

ulled low.

HS Horizontal Sync: identifies the start of each horizontal row of data.

VCLK Video Clock: the falling edge latches the video data (R0, R1, G0, and G1)

R0 Video data: Least significant bit for red sub-pixel

R1 Video data: Most significant bit for red sub-pixel

G0 Video data: Least significant bit for green sub-pixel

G1 Video data: Most significant bit for green sub-pixel

SHUTDOWN Display Shutdown: when high, will disable the display, thus rendering the display

black and minimizing power. All display data will be stored but no new data

accepted when SHUTDOWN is high. Internall

GND Signal return for power and logic

pulled low.

LUM0 and LUM1.

pulled low.

Display Input Signal Requirements

Description Min Max Units Notes

Input Voltage Range -0.3 5.5 V

Video logic high voltage 2.0 5.0 V All input thresholds are TTL

Video logic low voltage 0 0.8 V

LUMA input voltage 0 5.5 V

LUMA input current –250 0 uA

Note: 1. All inputs (except LUMA input) are 5V tolerant, with 270 ohm series resistors.

2. Input capacitance for all inputs except LUMA is 8 pF typical.

3. DE, LUM0, and LUM1 have > 20kohm pull-up resistors to 3.3V.

4. VS, SHUTDOWN, and V/Q have > 20kohm pull-down resistors to ground

EL320.240-FA3 Operations Manual Page 13 of 25

Page 14

EL320.240-FA3 Operations Manual Page 14 of 25

Page 15

Video Mode Timing—SGD Video Mode

0

K

a

l

g

Item Description Min. Max. Units

1 HS high time 30 nsec

2 Last VCLK fall to HS fall 20 nsec

3 HS to VCLK rising edge 10 nsec

4 R/G data setup to VCLK 10 nsec

5 R/G data hold from VCLK 10 nsec

6 VCLK period 100 nsec

7 VCLK low width 30 nsec

8 VCLK high width 30 nsec

9 VS high setup to HS low 140 nsec

10 VS hold after HS 140 nsec

11 VS low setup to HS high 140 nsec

12 HS period 34 usec

VS period 240 HS periods

VS frequency 120 Hz

Notes: 1) The first HS falling edge occurring when VS is high indicates the first row

2) The video data for a given row is clocked in prior to the falling edge of HS

3) The first 320 VCLK falling edges after the fall of HS clock in the valid data

4) If video inputs are halted, the previously clocked in data will be displayed

5) Video frame dithering/gray scale may cause artifacts due to the frame buffer

6) All timing measurements are made at 1.6V

Horizontal Tim ing

HS

VCL

R/G dat

Vertical Tim in

VS

HS

2

3

4 5

7

6

8

Da ta f o r F irst P ix e l

10

9

1

11

1

First Line of

Data

Pixe

EL320.240-FA3 Operations Manual Page 15 of 25

Second Line of Pixel Data

Page 16

Video Mode Timing—AMLCD Video Mode, QVGA

K

a

g

4

Item Description Min. Max. Units

1 HS low time 2 200 VCLK periods

2 HS to VCLK phase difference 10 VCLK period - 10 nsec

3 HS to DE phase difference 2 HS period - 340 VCLK periods

4 DE set up time 5 VCLK period - 10 nsec

5 VCLK frequency 7 MHz

6 R/G data set up to VCLK 5 nsec

7 R/G data hold from VCLK 10 nsec

8 VS low width 2 34 HS periods

9 VS to HS phase difference 0 HS period – HS low

10 Vertical start position After 7 HS rising edges

DE high time 2 HS period - 10 VCLK periods

HS period 50 usec

VS period 251 280 HS periods

H orizontal Tim ing

HS

VCL

R/G dat

time

1

2

horizontal invalid data period

nsec

5

6 7

DE

V ertical T im in

VS

HS

R/G data

3

da ta for first pix el

8

9

Line 1

Line 2

Line N

10

vertical invalid data period

data fo r first lin e

EL320.240-FA3 Operations Manual Page 16 of 25

Page 17

Video Mode Timing—AMLCD Video Mode, QVGA, Fixed

a

g

Item Description Min. Max. Units

1 HS low time 2 200 VCLK periods

2 HS to VCLK phase difference 10 VCLK period - 10 nsec

5 VCLK frequency 7 MHz

6 R/G data set up to VCLK 5 nsec

7 R/G data hold from VCLK 10 nsec

8 VS low width 2 34 HS periods

9 VS to HS phase difference 0 HS period – HS low

time

10 Vertical start position After 7 HS rising edges

HS period 50 usec

VS period 251 280 HS periods

Horizontal T iming

HS

VCLK

R/G dat

1

first v a lid c loc k =

2

clock edge C 1

clock edge C 52

horizontal invalid data period

nsec

5

6 7

Vertical Tim in

VS

HS

R/G data

da ta fo r firs t p ix el

8

9

Line 1

Line 2

Line N

10

ve rtic a l in va lid d ata p e rio d

da ta fo r firs t lin e

EL320.240-FA3 Operations Manual Page 17 of 25

Page 18

Video Mode Timing—AMLCD Video Mode, VGA

K

g

Item Description Min. Max. Units

1 HS low time 2 200 VCLK periods

2 HS to VCLK phase difference 10 VCLK period - 10 nsec

3 HS to DE phase difference 44 HS period - 664 VCLK periods

4 DE set up time 5 VCLK period - 10 nsec

5 VCLK frequency 28.33 MHz

6 R/G data set up to VCLK 5 nsec

7 R/G data hold from VCLK 10 nsec

8 VS low width 2 34 HS periods

9 VS to HS phase difference 0 HS period – HS low time nsec

10 Vertical start position After 34 HS rising edges

DE high time 2 HS period - 10 VCLK periods

HS period 30 usec

VS period 515 560 HS periods

Horizontal Tim ing

HS

VCL

R/G data

1

2

horizontal invalid data period

5

6 7

DE

Vertical Timin

VS

HS

R/G data

3

8

9

Line 1

vertical invalid data period

EL320.240-FA3 Operations Manual Page 18 of 25

Line 2

10

4

Line N

da ta fo r firs t pix e l

da ta fo r fir st lin e

Page 19

Video Mode Timing—AMLCD Video Mode, VGA, Fixed

a

g

Item Description Min. Max. Units

1 HS low time 2 200 VCLK periods

2 HS to VCLK phase

difference

5 VCLK frequency 28.33 MHz

6 R/G data set up to VCLK 5 nsec

7 R/G data hold from VCLK 10 nsec

8 VS low width 2 34 HS periods

9 VS to HS phase difference 0 HS period – HS low time nsec

10 Vertical start position After 34 HS rising edges

HS period 30 usec

VS period 515 560 HS periods

10 VCLK period - 10 nsec

H orizontal T im in g

HS

VCLK

R/G dat

Vertical Timin

VS

1

2

clock edge C1

horizontal invalid data period

8

9

first v a lid c loc k =

clock edge C 104

5

6 7

da ta fo r f irst p ix e l

HS

Line 1

Line 2

Line N

10

R/G data

vertical invalid data period

da ta fo r first lin e

EL320.240-FA3 Operations Manual Page 19 of 25

Page 20

Dimming

Dimming is used to reduce the display luminance to better match ambient

conditions or to reduce power consumption. There are two methods for

dimming the EL320.240-FA3 display.

The preferred method is digital dimming, where the internal display frame rate

is controlled using the LUM0 and LUM1 inputs. The internal frame rate is the

frequency at which the drive voltage is applied to the display phosphor and

thus impacts luminance and power consumption. Note that the internal

display frame rate is unrelated to the frame rate defined by the VS input.

(For normal operation, LUM0 and LUM1 must not be open or both high. When

LUM0 and LUM1 are high or open, the display enters self test mode where predetermined patterns are displayed. )

Using the combination of the two inputs LUM0 and LUM1, the following

display luminance settings are obtained:

Digital Luminance Control Characteristics

LUM0 logic level 0 1 0

LUM1 logic level 0 0 1

Approximate Frame Rate, Hz 325 240 180

Approximate Relative

Luminance

100% 74% 55%

If the dimming obtained from digital dimming is insufficient, analog

luminance control (the LUMA input) may be used to adjust the luminance

further downward. Connection of a 50 kohm variable resistor between LUMA

and GND will give a brightness range of approximately <5% to 100% of the full

luminance value (see dimming curve below). Alternatively, an external voltage

or D/A converter may be used to sink current from LUMA to GND.

Analog Luminance Control Characteristics

Max luminance, LUMA open 100% (no dimming)

Max luminance, 50kohm from

LUMA to GND

Min luminance, 0 ohm from

LUMA to GND

LUMA open circuit voltage 4 V, nominal

LUMA maximum sink current 250 uA

100%

0.2% typical,

5% maximum

When using LUMA for dimming, visual artifacts such as brightness nonuniformity and image burn-in may become more noticeable especially at low

dimming levels. To minimize the visual artifacts, analog dimming should be

employed with LUM0 and LUM1 set for the minimum frame rate. See the

following graph for the typical analog dimming response. Note that the actual

response will vary depending on individual display characteristics.

EL320.240-FA3 Operations Manual Page 20 of 25

Page 21

EL320. 24 0- FA3 Anal og Dimming Res ponse, Typical

120

100

80

60

40

20

Percentage of full lum i nance

0

01234

Self Test Mode

The display contains a self test mode composed of patterns displayed at the

maximum frame rate for approximately four seconds each. Self test mode can

be useful for verifying operation of the display.

The self test patterns are as follows: yellow diagonal lines with a one sub pixel

wide perimeter box, all pixels red, all pixels green, and all pixels yellow. Upon

power up when in self-test mode, the pattern sequences are repeated three

times and then the pattern remains in the all pixels yellow state. The self test

mode is entered by leaving LUM0 and LUM1 disconnected or logically high.

LUMA voltage, volts

EL320.240-FA3 Operations Manual Page 21 of 25

Page 22

Reliability

The display MTBF is to be greater than 50,000 hours at maximum luminance

and maximum input power with a 90% confidence level at 25°C.

Safety and EMI Performance

The display will not inhibit the end product from obtaining these certifications:

IEC 60101-1; UL60950; CSA 22.2 #950; FCC Part 15, Subpart J, Class B; EN55022

Class B.

Mechanical Characteristics

Mechanical Characteristics

Display External Dimensions

millimeters (inches)

Weight (typical)

Display Active Area

millimeters (inches)

Pixel Size

millimeters (inches)

Pixel Pitch

millimeters (inches)

width 150.3 (5.92)

height 104.8 (4.13)

depth 20.56 max (0.81)

198 g

width 99.15 (4.05)

height 74.36 (2.93)

diagonal 123.94 (4.88)

width 0.265 (0.010)

height 0.265 (0.010)

width 0.31 (0.012)

height 0.31 (0.012)

EL320.240-FA3 Operations Manual Page 22 of 25

Page 23

Display Dimensions and Component Envelope

The Figure below shows the display dimensions. For additional details the

Mechanical Outline drawing is available at www.planar.com.

Note the 20.56 mm component envelope. This is the depth required by the

display to ensure no interference with display board components, which are

up to 12.19 mm in height. While tall components are the minority, Planar

reserves the right to relocate components

component envelope without prior customer notification. For this reason,

Planar advises users to design enclosure components to be outside the

component envelope.

Device designers will need to consider their specific system requirements to

determine the spacing necessary to maintain the specified ambient temperature

for the display electronics.

Air flow and the thermal properties of surrounding components will impact the

required depth of the air gap. In addition, electrical spacing must be considered

to accommodate the high voltage (up to 200 VDC) present on the display

electronics.

Figure: Display Dimensions (millimeters, ±0.25 mm)

within

the constraints of the

EL320.240-FA3 Operations Manual Page 23 of 25

Page 24

Warranty

Seller warrants that the Goods will conform to published specifications and be free from defects in

material for 12 months from delivery.

Warranty repairs shall be warranted for the remainder of the original warranty period. Buyer shall

report defect claims in writing to Seller immediately upon discovery, and in any event, within the

warranty period. Buyer must return Goods to Seller within 30 days of Seller’s receipt of a warranty

claim notice and only after receiving a Returned Material Authorization number from the Seller.

Seller shall, at its sole option, repair or replace the Goods.

If Goods were repaired, altered or modified by persons other than Seller, this warranty is void.

Conditions resulting from normal wear and tear and Buyer's failure to properly store, install, operate,

handle or maintain the Goods are not within this warranty. Repair or replacement of Goods is

Seller’s sole obligation and Buyer's exclusive remedy for all claims of defects. If that remedy is

adjudicated insufficient, Seller shall refund Buyer's paid price for the Goods and have no other

liability to Buyer.

All warranty repairs must be performed at Seller’s authorized service center using parts approved by

Seller. Buyer shall pay costs of sending Goods to Seller on a warranty claim and Seller shall pay costs

of returning Goods to Buyer. The turnaround time on repairs will usually be 30 working days or less.

Seller accepts no added liability for additional days for repair or replacement.

If Seller offers technical support relating to the Goods, such support shall neither modify the

warranty nor create an obligation of Seller. Buyer is not relying on Seller’s skill or judgment to select

Goods for Buyer’s purposes. Seller’s software, if included with Goods, is sold as is, and this warranty

is inapplicable to such software.

SELLER DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO, IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

Ordering Information

Product Part Number Description

EL320.240-FA3

EL320.240-FA3 CC

Design and specifications are subject to change without notice.

Planar Systems continues to provide optional, and in many cases custom, features to address the

specific customer requirements. Consult Planar Sales for pricing, lead time and minimum quantity

requirements.

997-3377-00LF Standard FA3 display.

997-3377-01LF Same as standard FA3 but with the electronics conformal

coated (acrylic material: HumiSeal p/n 1B73) to minimize

the effects of moisture and conductive debris

EL320.240-FA3 Operations Manual Page 24 of 25

Page 25

European Union 2002/95/EC Directive on the

Restriction of Hazardous Substances (RoHS)

In February 2003, the European Union issued Directive 2002/95/EC on the Restriction of

Hazardous Substances, commonly known as RoHS, in certain electrical and electronic

equipment. It restricts the use of six hazardous substances, including lead (Pb).

The Directive states that all new products within its scope, placed on the European market

after July 1, 2006 must be compliant with its requirements.

Planar Systems Inc. is fully in support of and compliant with EU Directive 2002/95/EC for

applicable products within its scope.

Planar part number will be modified with an “LF” suffix designation to indicate RoHS

compliance, as shown on the part number label affixed to the display and on the box

containing the display.

Support and Service

Planar is a U.S. company based in Beaverton, Oregon and Espoo, Finland, with a world-wide sales

distribution network. Application engineering support and service are available to make the

integration of Planar displays as simple and quick as possible for our customers.

RMA Procedure: For a

with the model number(s) and serial number(s). Contact may be made via our website,

(www.planar.com

Returned Material Authorization

), by faxing a request to 503-748-1493, or by phoning 503-748-1100.

Planar Systems, Inc. Customer Service

24x7 Online Technical Support: http://www.planar.com/support

World-Wide Support

Tel: 1-866-752-6271

Hours: M-F, 5am - 5pm Pacific Time

© 2007 Planar Systems, Inc. Planar is a registered trademark of Planar Systems, Inc.

Technical information in this document is subject to change without notice.

number, please contact Planar Systems, Inc.

EL320.240-FA3 Operations Manual Page 25 of 25

Loading...

Loading...