Instruction Manual

DS25

All metal variable area flowmeter,

insensitive to viscosity changes

PKP Prozessmesstechnik GmbH

Borsigstraße 24

D-65205 Wiesbaden-Nordenstadt

Tel.: ++49-(0)6122-7055-0

Fax: ++49-(0)6122-7055-50

Email: info@pkp.de

Table of Contents

Safety Information................................................................................................................................2

Device Description...............................................................................................................................4

Installation in the pipeline....................................................................................................................6

Electrical Connection...........................................................................................................................6

Connection Diagrams...........................................................................................................................9

Start of operation................................................................................................................................11

Limit switches.....................................................................................................................................12

Electronic Transmitter........................................................................................................................14

Selection of indication function (F11)................................................................................................18

Setting the unit (F12 / F13).................................................................................................................19

Totalizer reset (F14)...........................................................................................................................21

Selection of temperature unit (F15)....................................................................................................21

Setting of damping (F2-)....................................................................................................................22

Selection / Adjustment 4-20 mA / 0-20 mA (F3-)..............................................................................23

Error messages (F4-)...........................................................................................................................24

Manual adjustment (F5-)....................................................................................................................25

Revision indication (F61/F62)............................................................................................................29

Current output test (F63)....................................................................................................................29

Switching between standard / Indicator on extension (F64)...............................................................30

Master Reset (F65).............................................................................................................................30

Float blocking indication (F7-)...........................................................................................................31

Service and Maintenance....................................................................................................................36

Safety Information

General Instructions

To ensure safe operation, the device should only be operated according to the specifications in the

instruction manual. The requisite Health & Safety regulations for a given application must also be

observed. This statement also applies to the use of accessories.

Every person who is commissioned with the initiation or operation of this device must have read

and understood the operating instructions and in particular the safety instructions!

The liability of the manufacturer expires in the event of damage due to improper use, nonobservance of this operating manual, use of insufficiently qualified personnel and unauthorized

modification of the device.

DS25 Instruction Manual 08/2018 page 2

Proper Usage

The variable area flow meter DS25 are designed to measure and monitore continuous flow rates of

liquids or gases which do not attack the device materials. All other usage is regarded as being

improper and outside the scope of the device.

In particular, applications in which shock loads occur (for example, pulsed operation) should be

discussed and checked in advance with our technical staff.

The series DS25 flow meter devices should not be deployed as the sole agents to prevent dangerous

conditions occurring in plant or machinery. Machinery and plant need to be designed in such a

manner that faulty conditions and malfunctions do not arise that could pose a safety risk for

operators.

Dangerous substances

For dangerous media such as e.g. Oxygen, Acetylene, flammable or toxic substances as well as

refrigeration systems, compressors, etc. must comply with the relevant regulations beyond the

general rules.

Qualified Personnel

The DS25 devices may only be installed by trained, qualified personnel who are able to mount the

devices correctly. Qualified personnel are persons, who are familiar with assembling, installation,

placing in service and operating these devices and who are suitably trained and qualified.

Inward Monitoring

Please check directly after delivery the device for any transport damages and deficiencies.

Additional with reference to the accompanying delivery note the number of parts must be checked.

Claims for replacement or goods which relate to transport damage can only be considered valid if

the delivery company is notified without delay.

DS25 Instruction Manual 08/2018 page 3

Device Description

Explanations of specifications on flanges

• type of flange e.g. DIN

• size of flange e.g. DN15

• Pressure range of flange and measuring tube e.g. PN40

• Material of wetted parts e.g. 1.4404

• Manufacturing code of flange manufacturer

• Lot. No.

DS25 Instruction Manual 08/2018 page 4

Scale example for Display

Scale example for Display with electronic transmitter

DS25 Instruction Manual 08/2018 page 5

Installation in the pipeline

• Be sure to remove the transport lock card-board strip from the measuring tube. Check that

no cardboard remains in the tube.

• The DS25 flow rate meter must be installed in a vertical pipeline, in which the medium

flows upwards. The vertical position has to be checked at the outer edge of the flanges.

• Bigger nominal diameters (DN 80 / DN 100) require straight pipe sections of at least 5D in

front and behind the DS25.

• The nominal diameter of the DS25 should correspond to the nominal diameter of the

pipeline.

• To avoid stress in the connecting pipes, the connecting flanges must be aligned in parallel

and axial direction.

• Bolts and gaskets have to be selected according to the maximum operating pressure, the

temperature range and corrosion conditions.

• Center gaskets and tighten nuts with a torque appropriate for the pressure range.

• If contamination or soiling of the DS25 is to be expected, a bypass should be installed to

allow the removal of the instrument without interruption of the flow.

Tightening of the flange threads for DS25 with PTFE- liner with the following torques:

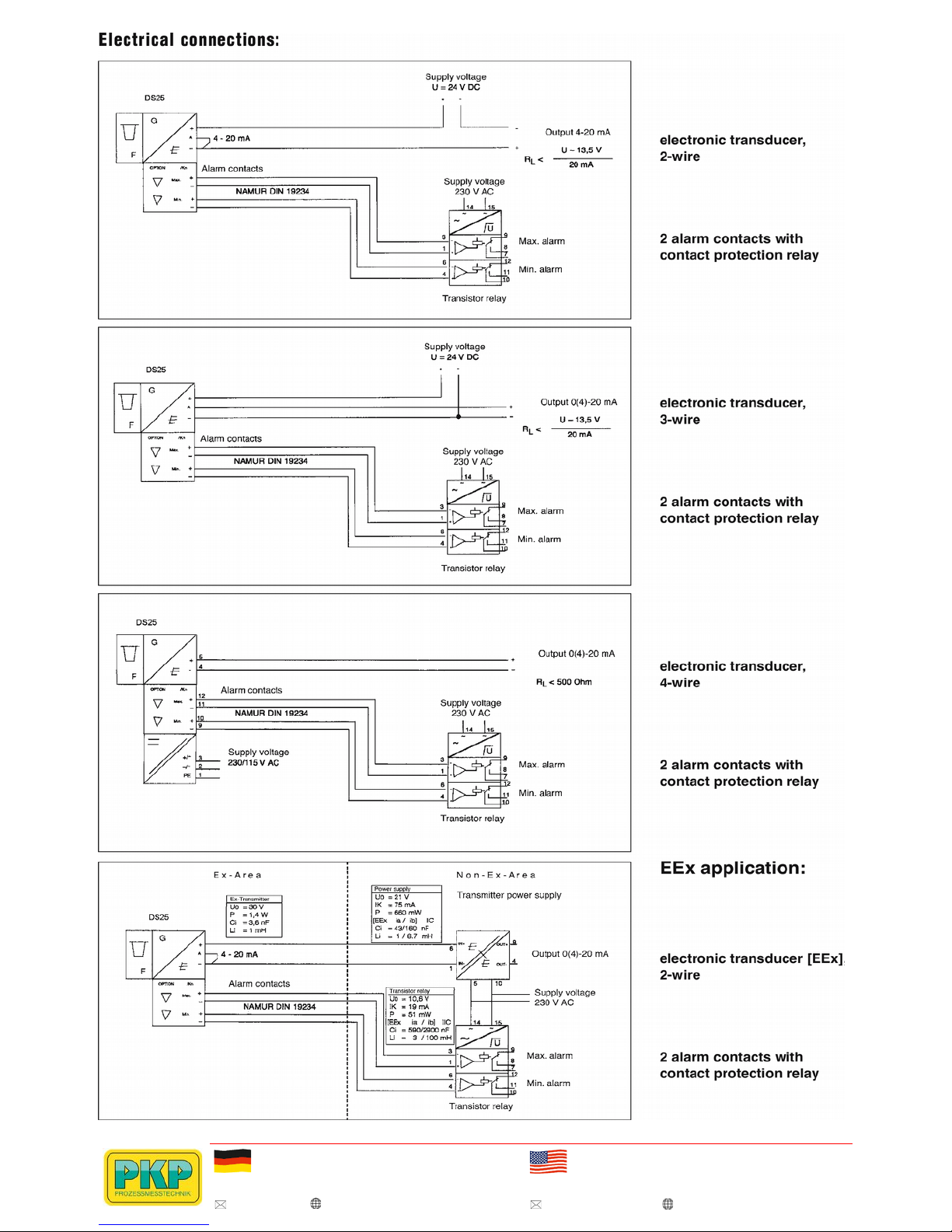

Electrical Connection

Please regard the drawings on the following pages.

• On the rear of the DS25 are two cable glands for round cables with a diameter of 6 to 9 mm

• Unused glands must be closed with a blind plug M16x1.5.

• Wires should not be bent directly at terminal screws.

• Do not expose wires to mechanical pressure.

• Wires must be arranged according to common installation rules, especially signal and power

lines must not be bundled together.

• Cables should not be bend directly after the cable gland. Do not fix cable at the measuring

tube.

• The DS25 terminals accept wires with a maximum sectional area of 1.5 mm²

DS25 Instruction Manual 08/2018 page 6

• The attached ferrite core must be mounted

on the cable as shown on the below

picture. Distance "L" < 2 cm.

• Measuring and indicating instruments,

connected in series to the output of the

electronic transmitter, must not exceed a

load impedance of

RL = (U - 13.5 V) / 20 mA

for 2-/3-wire or 500 Ω for 4-wire

• 2- or 3-wire units are connected to the

terminals marked “+”, “-” and “A” of the

power connector.

• For 2-wire instruments the terminals “-”

and “A” have to be shorted with a jumper.

Take care not to loose that jumper when mounting wires.

• Wiring inside the case should be kept as short as possible to avoid that moving parts are

blocked.

Attention: Hints for Unit Safety (according DIN EN 61010-1)

• Do not connect cables outdoors in wet weather in order to prevent damage from

condensation and to protect the insulation, e.g. inside the terminal box of the flowmeter.

• Heed the nominal voltage indicated on the scale.

• Use the cables which fulfill specification and check before wiring.

• The electrical connections have to be executed according to VDE0100 “Errichten von

Starkstromanlagen mit Nennspannungen bis 1000 V” (Installation of high current assemblies

with nominal voltages of up to 1000 V) or equivalent national regulations.

• For units with a nominal voltage of 115 V or 230 V the correspondingly marked terminal

has to be connected to protective earth (PE).

• Units with a nominal voltage of 24 V may only be connected to a protected low voltage

circuit (SELV-E according to VDE0100/VDE 0106 or IEC 364/IEC 536).

• The DS25 indicator housing must be grounded to ensure electromagnetic interference

protection. This can be done by grounding the pipeline.

• Once all wiring is complete, check the connections before applying power to the instrument.

Improper arrangements or wiring may cause a unit malfunction or damage.

• This unit does not include a power switch. Therefore, a switch has to be prepared at the

installation location in the vicinity of the unit. The switch should be marked as the power

separation switch for the DS25.

DS25 Instruction Manual 08/2018 page 7

2 wire unit:

4 wire unit:

DS25 Instruction Manual 08/2018 page 8

Connection Diagrams

DS25, 2-wire unit with limit switches and transmitter relay:

DS25, 3-wire unit with limit switches and transmitter relay:

DS25 Instruction Manual 08/2018 page 9

DS25, 4-wire unit with pulse output:

DS25, 2-wire unit with HART-communication, with limit switches and transmitter relay:

DS25 Instruction Manual 08/2018 page 10

Start of operation

Hints on flow rate measurement:

The measured fluid should neither consist of a multi-phase mixture nor contain ferrite ingredients or

large solid mass particles.

Hints on scale:

The DS25 scale is adjusted to the state of operation/aggregation of the measured fluid by the

manufacturer. If the state of operation changes, it might become necessary to establish a new scale.

This depends on several factors:

• If the DS25 is operated in the given viscosity independent range, only the density of the float

as well as the operational density of the previous and new substance have to be considered.

• In case the operational density only changes marginally (≤ 0.5 %), the present scale can be

used.

• If the DS25 is operated outside the given viscosity independent range, the viscosities at the

previous and new state of operation as well as the mass and diameter of the float have to be

taken into account.

Pulsation and pressure shock:

Pressure shock waves and pulsating flow influence measurement significantly or can destroy the

meter. Surge conditions should be avoided. (open valves slowly, raise operating pressure slowly)

If float bouncing occurs in gases increase the line pressure until the phenomena stops. If this is not

possible provide the float with a damper. A damping kit is available as spare part.

Start of operation of electronic transmitter:

Ensure that the device has been connected correctly and that the used power supply meets the

requirements indicated on the scale.

Switch on the power supply.

The digital display gives the totalizer value in the measuring unit, indicated on the right side of the

display.

The DS25 is now ready for operation.

Unit graduation, measuring unit, damping, etc. can be adjusted by an operating menu.

In case of an error, the bars beneath the 8 digits of the display will flash. The corresponding error

message can be checked using the operating menu and then taking the appropriate counter measures

(refer to section “Error Messages”).

The transmitter has been prepared and calibrated according to the model code as a 2-, 3- or 4-wire

unit.

DS25 Instruction Manual 08/2018 page 11

In 2-wire units, a jumper connects “A” and “-”. When switching from a 2- to a 3-wire configuration,

this jumper should be removed. The current output should then be adjusted.

When changing from a 3- to 2-wire configuration, the jumper should be set in place, and the current

output has to be adjusted.

Limit switches

The optional limit switches are available as maximum or minimum type switches. They are

proximity switches according to EN 60947-5-6 (NAMUR). Maximum two switches can be

installed. As transmitter relay we recommend our model P+F.

The limit switches have to be connected to the transmitter relays.

The terminals for the limit switches are on a small board on top of the transmitter case.

Use of 2 standard limit switches:

The MIN-MIN and MAX-MAX functions have been integrated at the factory as MIN-MAX

switches in the DS25.

The MIN-MIN or MAX-MAX function is set by adjusting the switching direction of the transmitter

relay.

The following table shows the assignment:

Function

Switching direction of transmitter relay

Chanel 1 Chanel 2 Chanel 1 Chanel2

MIN MAX S1 position I S2 position I

MIN MIN S1 position I S2 position II (ON)

MAX MAX S1 position II (ON) S2 position I

DS25 Instruction Manual 08/2018 page 12

Adjusting the switching points:

To adjust the switching points, loosen set screws 1 and 2 and move them in the guide rail. The small

red pointers (Limit switch MAX and Limit switch MIN) indicate the set value on the scale.

DS25 Instruction Manual 08/2018 page 13

Electronic Transmitter

Operation principle:

The position of the float is magnetically transferred to a magnetic follow up system. The position

angle of this magnetic rocker is detected by magnet sensors. A micro controller determines the angle

by means of a combining reference value table in the memory and calculates the flow rate by the

angle with calibration and operation parameters the calibration EEPROM.

The flow rate is given as a current, either 0-20 mA or 4-20 mA, and, in addition, indicated on the

digital display (refer also to section 6-2). The electronic transmitters have been electronically

adjusted before shipping and, therefore, are mutually exchangeable.

Calibration data of the metering tube as well as customer specific data are entered into a calibration

EEPROM, inserted on the board. This calibration EEPROM and the indication scale are assigned to

the respective metering tube.

When replacing an indicator (e.g. because of a defect) the scale and calibration EEPROM of the old

unit have to be inserted in the new unit. Then, no calibrations or adjustments are necessary.

If an indicator with electronic transmitters is installed to a new metering tube, the calibration

EEPROM of that tube has to be inserted into the transmitter and the indicator scale for that

particular tube has to be mounted.

A change in the fluid data (e.g. specific gravity, pressure, etc.) requires the preparation and

mounting of a new calibration EEPROM and scale.

Normally the range of the current output is equal to the rounded measuring range of the tube (end

value on scale). The customer can position the 20 mA point between 60 % and 100 % of the end

value on scale. The set of the 20 mA point is shown on the scale. The flow cut off is positioned at

5 % of the end value. Below 5 % flow the current output shows 0 mA (4 mA).

DS25 Instruction Manual 08/2018 page 14

Parameter setting:

The displays allows indication of various parameters:

• Flow rate (8 mass or volume units in combination with 4 time units)

• Counter (8 mass or volume units)

• Flow rate indication in percent

• Special functions

• Setting of different damping times

• Switching of current output 0-20 mA / 4-20 mA or vice versa

• Indication of error messages

• Manual adjustment

• Service functions

• Detection of float blockage

The setting of these parameters is done by two buttons.

DS25 Instruction Manual 08/2018 page 15

The buttons access three functions:

• upper button ( ↑ ) : Exit setting mode

• lower button ( → ) : Scroll through menu/selection of parameters

• both buttons ( ↑ + → ) = Enter : Entering parameters/selecting setting mode

If no button is pressed for one minute while the operating menu is active, the indication reverts to

the measuring indication. This does not apply to subfunctions F32, F33, F52, F63.

For indication of volume or mass values at maximum 6 digits in front of the decimal point and 7

decimals are used. This format allows an indication range for flow rates from 0.0000001 unit/time

to 106000 unit/time.

Flow rate values exceeding 106000 are shown as ‘————’ on the display. In this case the next

bigger flow rate unit (next smaller time unit) has to be selected.

For the indication of totalizers values 8 digits are used at maximum of which 7 digits can be

assigned for decimal values. The decimal point setting is determined by selecting the unit.

Therefore, possible totalizer offsets are:

Unit x 1 Unit x 1/10 Unit x 1/100

The totalizer counts up to 99999999 or 9999999.9 or 999999.99 and is reset to zero.

The next page shows the operating menu.

The following describes selection and execution of functions.

Menu:

DS25 Instruction Manual 08/2018 page 16

DS25 Instruction Manual 08/2018 page 17

Selection of indication function (F11)

The function F11 selects the display’s indication function.

The following indications can be set: flow rate, totalizer, % value or temperature.

At the factory the display is preset to totalizer indication.

Note:

If you press “↑” instead of “Enter”, you can return from the selected point to the previous menu

without activating the displayed parameter.

When selecting “Flow rate” the measuring unit is set with function F12 and F13. When selecting

“Totalizer” the measuring unit is set with F12. If % indication is selected, F12 and F13 have no

effect. The internal totalizer is updated, if “Flow rate” or “Counter” is selected. In case of setting to

“%” the internal counter is not updated and keeps its previous value.

If "Temperature" is selected the unit can be set by function F15. The indicated value is the

temperature in the indication unit.

After changing the indicating function and measuring units the corresponding measuring unit label

should be fixed on the right side next to the display.

DS25 Instruction Manual 08/2018 page 18

Setting the unit (F12 / F13)

When ordering the transmitter two sets of metering units are available. It is not possible to switch

between them.

These two sets comprise the following metering units:

DS25 Instruction Manual 08/2018 page 19

With functions F12 and F13, the measuring unit for displayed value is selected.

F12 selects volume and mass units, while F13 sets the corresponding time unit.

When selecting the indication function “totalizer” the set time unit is not taken into account and

only the selected mass or volume unit is effective. When choosing the “%” indication F12 and F13

have no effect.

The selection of the measuring unit is performed as follows:

Note:

If you press “↑" instead of “Enter”, you can return from the selected point to the previous menu

without activating the displayed parameter.

After changing the measuring unit the corresponding measuring unit label should be fixed on the

right side

next to the display. A sheet with stickers is included.

Attention:

When switching the mass/volume unit the totalizer is reset to zero.

When changing the time unit the totalizer value remains unchanged.

DS25 Instruction Manual 08/2018 page 20

Totalizer reset (F14)

Function F14 resets the totalizer to zero.

The counter reset is performed as follows:

Note:

If you press “↑" instead of “Enter”, you can return from the selected point to the previous menu

without activating the displayed parameter.

Selection of temperature unit (F15)

The function F15 sets the unit of temperature indication.

The following indications can be set: degC (Celsius) or degF (Fahrenheit).

At the factory the display is set to degC indication.

The selection of the indication is as follows:

Note:

If you press “↑" instead of “Enter”, you can return from the selected point to the previous menu

without activating the displayed parameter.

DS25 Instruction Manual 08/2018 page 21

Setting of damping (F2-)

Function F21 allows damping the output with a certain time constant (63 % value). Normally the

time constant is set to 1 sec.

The selection of the time constant is as follows:

Note:

If you press “↑" instead of “Enter”, you can return from the selected point to the previous menu

without activating the displayed parameter.

DS25 Instruction Manual 08/2018 page 22

Selection / Adjustment 4-20 mA / 0-20 mA (F3-)

Function F3- sets the current output to 4-20 mA or 0-20 mA. In addition, offset and span have to be

readjusted. Offset compensation is for fine tuning the 0 or 4 mA point. Span or range compensation

is for precise adjustment of the 20 mA point.

For compensating the output, an ampere metre (mA) should be connected to the circuit loop. For

wiring refer to the diagrams in chapter 3.

The current output is set according to customer specifications at the factory.

Switching the output is executed as follows:

An adjusting step corresponds to 20 μA. The complete adjusting range is ± 0.62 mA (31 steps).

If the adjusting range does not suffice, change to display F32 or F33 by pressing ENTER when

display shows F32 31 or F33 31, press ENTER again and continue adjusting at F32 00 or F33 00.

DS25 Instruction Manual 08/2018 page 23

3 wire connection:

At this the ranges 0-20 mA and 4-20 mA are possible.

At a switch over between the two ranges with F31 the current output is automatically adjusted at

equipment as of firmware version 1.4 . (s.F 61). A perhaps necessary fine adjustment can be carried

out with F32 or F33.

2 wire connection:

At this only the range of 4-20 mA is meaningful. The range of 0-20 mA is not closed however.

At the change to 0-20 mA with F31 the equipment assumes a remodelling on 3 wire connection and

the current output is adjusted according to this. A perhaps necessary fine adjustment can be carried

out with F32 or F33.

WARNING:

Since PKP doesn’t have any influence on the custom-designed connection the current output is not

automatically adapted, if the connection is changed from 2 wire to 3 wire or vice versa .

This must be manually carried out with the functions F32 and F33.

Preset values :

Error messages (F4-)

If the 8 bars beneath the digits start flashing, an error has occurred in the measuring

transmitter/current output. Since the pointer indication is independent from the electric measuring

transmitter, it may show the correct measuring value even if the transmitter is defective. Function

F41 allows checking of assigned error codes.

Error codes are called onto the display as follows:

DS25 Instruction Manual 08/2018 page 24

List of error massages:

In case of error the appropriate remedy has to be taken.

Manual adjustment (F5-)

During manufacturers adjustment and calibration process the relation between flow rate with water

(or with air) and float position (indicated as angle on the mm-scale) is determined. Based on the

properties of the customers fluid at expected operating conditions the flow scale and the

corresponding EEPROM is then calculated.

If the fluid properties are changing (by change of the fluid or by change of the process conditions)

the scale as well as the EEPROM has to be adapted. Easiest and recommended way to do this is to

order new scale and EEPROM for the new properties from manufacturer and to replace both.

A second possibility is to readjust the meter by the user. This readjustment procedure will only

adjust the current output and the display indication (but only in % of the new flow range), At least

the readjustment by the user is possible by two different procedures:

1. Manual “dry” readjustment based on recalculated original scale:

The following steps have to be performed:

a) Calculate the new of flow rate to mm (on scale) relation based on original manufacturers

calibration certificate.

b) Place the DS25 (with the measuring tube) horizontally on a table (Note: the distance to any

ferromagnetic parts must be at least higher than 25 cm!).

c) Go to menu function F51 and press ENTER to switch to manual adjustment mode.

(Switching back to the original adjustment is possible by pressing ENTER again).

d) Go to menu function F52 in order to start the manual adjustment.

e) Move the float to a position where the pointer is indicating on mm-scale the mm-value

belonging to 5 % of the new flow rate (Note: these values have to be calculated in step a

first!)

DS25 Instruction Manual 08/2018 page 25

f) Press ENTER to adjust the first 5 % point.

g) Repeat steps 1.e) to 1.f) for the 15 %; 25 %; 35 %; 45 %; 55 %; 65 %; 75 %; 85 %; 95 %

and 105 % points. (Note: The whole loop from 5 % to 105 % has to be adjusted in the

requested order without interruption. It is not possible to skip or stop and restart the

adjustment.)

h) The adjustment has to be finished and stored by pressing “ ↑ “.

After storage the new adjustment is permanently available and can be switched “on” or “off” by

function F51.

Note:

When manually adjustment is active, the user is responsible for the measurement accuracy.

Activating/deactivating manual adjustment table (F51)

(*) -1 : manual adjustment OFF; -2 : manual adjustment ON

DS25 Instruction Manual 08/2018 page 26

Input of manual adjustment table (F52)

The manual adjustment table is input as follows:

2. Manual “wet” adjustment by comparison to a reference master meter with the real process

fluid at operating conditions:

This adjustment is useful under the following conditions:

• The original manufacturer’s calibration is not available or needs to be renewed.

Or

• The user is not able to recalculate the new mm to flow rate table.

And

• The user has the possibility to compare the meter indication with a master meter with the

process fluid at process conditions.

In these cases the following steps have to be performed:

a) Place the DS25 in line with the master meter in an installation allowing controlled flow with

the process fluid at process conditions in a flow range from 5 % to 105 % of the expected

flow range.

b) Go to menu function F51 and press ENTER to switch to manual adjustment mode.

(Switching back to the original adjustment is possible by pressing ENTER again).

c) Go to menu function F52 in order to start the manual adjustment.

d) Set the flow to 5 % of the new flow rate indicated by the master.

e) Press ENTER to adjust the first 5 % point.

f) Repeat steps 2.d) to 2.e) for the 15 %; 25 %; 35 %; 45 %; 55 %; 65 %; 75 %; 85 %; 95 %

and 105 % points. (Note: The whole loop from 5 % to 105 % has to be adjusted in the

requested order without interruption. It is not possible to skip or stop and restart the

adjustment.)

g) The adjustment has to be finished and stored by pressing “ ↑ “.

After storage the new adjustment is permanently available and can be switched “on” or “off” by

function F51.

DS25 Instruction Manual 08/2018 page 27

For the manual adjustment procedure according to the two cases described the following remarks

have to be taken into account:

• After manual adjustment the flow-scale of the indicator is no longer valid.

• The display will only indicate in % of the new flow range.

• Switching of units is impossible.

• The indicator can be always resetted to the original adjustment according to manufacturers

calibration at any time.

• The given procedures will only adjust the current output and the display to the new

measuring range for a different fluid and/or new process conditions.

• The result of this adjustment is NOT a calibration! If proof of the new adjustment is

requested a real calibration by comparison to a standard has to be made after adjustment!

• The following interactions with other functions apply:

Interaction with other functions:

Due to the limitations described it is strongly recommended to order a new scale and EEPROM

from manufacturer (this gives a real new flow scale without new calibration) or to order a new

calibration by the manufacturer together with a new scale and EEPROM for the new fluid and/or

new process conditions (this gives new adjustment plus new calibration).

DS25 Instruction Manual 08/2018 page 28

Revision indication (F61/F62)

Functions F61 and F62 enable the indication of revision states for hardware, software of calibration

EEPROM and internal EEPROM.

The indication is called up as follows:

1

H = Hardware 2F = Firmware 3A = Internal EEPROM 4C = Calibration-EEPROM

Current output test (F63)

Function F63 sets the output current to 0/4 mA or 20 mA respectively.

With this you can determine whether output current correction by function F32 is required.

The adjustment of the current output is as follows:

Note:

During selection you can switch between 0/4 mA and 20 mA with the"→"-key.

If you press “↑” instead of “Enter”, you can return from the selected point to the previous menu item

without activating the displayed parameter.

DS25 Instruction Manual 08/2018 page 29

Switching between standard / Indicator on extension (F64)

F64 allows switching between the standard calibration table and a calibration table of the remote

version (option /A16 for high temperatures). The adjustment has to be performed according to the

DS25 type (MS code).

This is done as follows:

Note:

If you press “↑" instead of “Enter”, you can return from the selected point to the previous menu

without activating the displayed parameter.

Master Reset (F65)

If the unit shows aberrant behavior or does not execute functions any longer, function F65 allows a

master reset of the micro controller.

Attention:

All parameter settings are reset to factory settings (see operation menu).

The master reset is executed as follows:

Note:

If you press “↑" instead of “Enter”, you can return from the selected point to the previous menu

without activating the displayed parameter.

DS25 Instruction Manual 08/2018 page 30

Float blocking indication (F7-)

Function

Float

Pulsating movements of the flow medium (gasses, liquids) lead to fluctuations of the float and with

that to fluctuations of the tap system/pointer. Therefore the electrical measuring signal permanently

changes and with that the display value and the output current value.

The fluctuations can be reduced with the help of the damping function “F21”. That shows however

that the medium still flows and the float/the tap system is not blocked. This means that in most

applications there is a permanently changing measuring signal which can be used for the recognition

of the movement or the blockade of the float.

Basic noise

Since it is an electronic evaluation circuit, permanently minimal fluctuations of the measuring signal

appear. The basic noise is caused by vibrations in the plant as well as by temperature influences or

external magnetic fields. The basic noise also appears, if

• no medium flows through the measuring pipe

• the float and with that the tap system are in the rest position

• the float/the tap system is blocked.

Float-Blocking-Indication

The function of the Float-Blocking-Indication allows the electronic transmitter to distinguish the

fluctuations, which are caused by a moving float, with the fluctuations of the basic noise to state a

fault status. If the measuring signal does not exceed the autozero value during a defined supervision

time, this is recognized as blockade and an error condition is shown.

Operation

Switching on

At delivery of the equipment the Float-Blocking-Indication is turned off. By the function “F71 2”

the Float- Blocking-Indication can be activated.

Autozero function

The autozero function is called to find out the level of basic noise in the application. This is started

with the function “F74 1” and lasts for 90 seconds. While the autozero function is running the value

“0.000” is displayed and the 4 bars will flash below the numbers. After approx. 80 seconds the

current autozero value appears on the display. This value gets stored and will not be lost after power

off / on the DS25 or after switching off / on the Float-Move-Detection-function. The stored value is

typed over first after a renewed autozero.

DS25 Instruction Manual 08/2018 page 31

Autozero without flow

To execute the autozero function the following expiry is recommended:

• Plant in operation (measuring tube filled with medium)

• Drive flow to zero (place float into rest position)

• Raise the pointer to 10 % to 20 % of the flow and fix it on the scale with adhesive tapes or

underlayed paper stripe

• Start Autozero function by menu.

• Check Autozero value after approx. 80 seconds.

During the Autozero function it absolutely has to be respected that:

• the DS25 is not moved by touching or using the 2 buttons.

• the pointer is protected against slipping.

• the tube is not exposed to strong tremors

If these prerequisites are not adhered, it comes to the inquiry of too high autozero results. This leads

that a relatively quiet flow can trigger the Float-Blocking-Indication.

Autozero with flow

The Autozero function can be carried out also under flow, if the flow cannot be switched off. To

this the following expiry is recommended:

• Plant in operation (measuring tube filled with medium)

• Move flow to constant value (preferably between 10 % and 40 %)

• Fix pointer on the oriented scale factor with adhesive tapes or underlayed paper stripe

• Start Autozero function by menu.

• Check Autozero value after approx. 80 seconds.

It has to be respected on this absolutely, for this the flow is constant during the Autozero duration!

Normally at this variant higher Autozero results must be expected !

Autozero range

The factory default autozero value is zero (0.000).

At the inquiry of the autozero value it has to be respected that the pointer / tap system are not in the

rest position. In this case the autozero value is zero and the Float-Move-Detection does not work.

Normally the autozero value is smaller than 0.200. If higher results should appear in the application,

a multiple inquiry of the autozero value is recommended to confirm the value.

Supervision range (measuring range)

The measuring range in which Float-Move-Detection is active lies between 5 % and 105 % of the

maximum flow Qmax (Factory Setting). With the help of the function “F72” this range can be

reduced if a supervision is not possible or not desired in the lower flow range. The range can be

restricted to 15 % or 30 % to 105 % (see point 3.1 to 3.3).

DS25 Instruction Manual 08/2018 page 32

Supervision time (Time Out)

The supervision time of the measuring signal is 5 minutes (Factory Setting). If the measuring signal

should not exceed the autozero value during this period, this is recognized as blockade and an error

condition is shown. The supervision time can be increased with the function “F73” up to 15

minutes.

Indication of a blocking condition

After the recognition of the blockade the error code “08” is produced and the bars under the

displayed measurement value are flashing (see fault behavior). Simultaneously the current output is

set to a value, which enables a clear fault detection of a connected evaluation unit:

• 2 - wire 4-20 mA: Error condition: IA (IG) < 3.6 mA

• 3 - wire 4-20 mA: Error condition: IA < 0.0 mA

• 3 - wire 0-20 mA: Error condition: IA = 0.0 mA

Unsuitable applications

It is possible, that the Float-Blocking-Indication - Function does not work satisfactory. This can be

caused with different factors which are explained briefly here. In these cases the function of the

Float-Blocking-Indication is not suitable for the respective application and it should be turned off.

Applications with gases

At applications with gases and float-damping it can happen, that the pulsating movements of the

medium (and with that of the float) are damped so strongly in the measuring tube, that the

measuring signal lies under the autozero value and a Float-Blocking-Indication is not possible.

Applications with high viscous media

If a high viscous medium should be used in the plant, the damping can get so high by the high

viscosity of the flow that the measuring signal lies below the autozero value, and a Float-BlockingIndication is not possible.

Applications with quiet flow

If the plant has an extremely quiet flow (gases or liquids) ,the supervision range can be limited in

the lower flow range. Normally greater flow (> 30 %) causes greater medium flow deviations. The

duration of the supervision can be put to 15 minutes to reach a longer supervision time.

DS25 Instruction Manual 08/2018 page 33

Parameter setting

Error message (F41)

Factory defaults / Master Reset (F65)

The DS25 is adjusted at delivery (Factory Setting):

• F71 - 1 Float-Move-Detection OFF

• F72 - 1 Lower limit value of the supervision area 5 %

• F73 - 1 Supervision time (Time Out) 5 min

• F74 Autozero inactive Autozero value = 0

After Master Reset the following attitudes are given:

• F71 - 1 Float-Blocking-Indication OFF

• F72 - 1 Lower limit value of the supervision area 5 %

• F73 - 1 Supervision time (Time Out) 5 min

• F74 Autozero inactive Autozero value not changed

Damping (F21)

The selection of the damping value has no influence on the autozero value or the measurement

value of the Float-Blocking-Indication!

DS25 Instruction Manual 08/2018 page 34

Float-Blocking-Indication (F7x)

Function F71: On-/Off- switching of the float-blocking-indication

Function F72: Selection of the lower limit value of the supervision range

Function F73: Selection of the supervision time

Function F74: Start Autozero function and storage

DS25 Instruction Manual 08/2018 page 35

Service and Maintenance

Function test

Checking free movement of pointer:

• Remove housing cover.

• After deflecting the pointer by hand, it must return to measurement value. If the pointer

pivots to different values upon repeated deflections, there is too much friction in the

bearings. In this case, send indication unit to service.

Checking free movement of float:

• First, free movement of pointer has to be ascertained.

• Check visually if pointer follows each flow rate change. If not, clean float and measuring

tube.

Unit with electronic transmitter:

• The display must show values corresponding to indication function and measuring unit

settings.

• The bars under the 8 digits must not flash. If an error occurs, the corresponding

countermeasure (refer to chapter 6.2.8 error messages) has to be taken or the unit has to be

sent to service.

• Without flow, the output current must be 0 or 4 mA. At a flow rate of 100 % the current

must be 20 mA.

Measuring tube, float

The DS25 is maintenance-free. If contamination of the measuring tube impairs the mobility of the

float, the tube and the float have to be cleaned. To do this, the DS25 has to be removed from the

pipe.

Replacement or cleaning of the float:

• Remove DS25 from the pipe.

• Remove upper retainer from metering tube.

• Take float stopper and float out through the top of metering tube.

• Clean float and metering cone.

• Insert float and float stopper into the metering tube.

• Set retainer into tube.

• Check float for free movement.

• Install DS25 to the pipe.

Attention:

Do not expose float to strong alternating magnetic fields. The float and especially its measuring

edge must not be damaged.

DS25 Instruction Manual 08/2018 page 36

Electronic transmitter

The electronic transmitter is maintenance-free. The electronic section is sealed and cannot be

repaired. Since the transmitter has been adjusted fully to the mechanical components at the factory,

single components can only be replaced with a reduction of the accuracy.

Solely the display and operation unit (LCD PCB) can be replaced. For this the unit has to be sent to

service.

The current output can be adjusted by means of software. The current output test in chapter “Current

output test” determines whether an adjustment is necessary. The adjustment is carried out according

to chapter “Selection / Adjustment 4-20 mA / 0-20 mA”.

The power supply PCB of 4-wire units includes a fuse. For fuse replacement be sure to switch off

the power supply. Only use fuses with the capacity and characteristic as imprinted on the fuse

holder.

DS25 Instruction Manual 08/2018 page 37

Flow Measurement and Monitoring

DS25

All-Metal Variable Area Flowmeter,

Insensitive to Viscosity Changes

• for liquids, gases and steam

• operating pressure PN 40 and PN 100

(standard), higher pressures

up to 320 bar on request

• operating temperature up to 370 °C

• float- blockade detection

• scales for all operating conditions

individual calibrated

• local display, Min.-/Max.-contacts

or analogue output

• Measuring tube completely of

stainless steel 1.4404

• PTFE-coating for wetted parts optionally

• Ex-Version acc. to ATEX

Description:

The Flowmeter DS25 work according to the proven variable

area principle. The float is guided in a conical measuring tube.

The flowing medium moves the float in the flow direction.

An externally mounted pointer indicator is magnetically

coupled to the float and thus, following the float position,

indicates the flow rate on a scale. This indicator assembly is

equipped with a scale calibrated to the operating conditions in

the system and additionally may contain alarm contacts or an

analogue output.

Typical application:

The variable area flowmeter model DS25 is used for

measuring and monitoring the flow of all kinds of liquids or

gases.

By using only stainless steel 1.4404 for the wetted parts the

meter is especially suited for aggressive media.

PKP Prozessmesstechnik GmbH

Borsigstr. 24 • D-65205 Wiesbaden

S +49 (0) 6122-7055-0 • +49 (0) 6122 7055-50

info@pkp.de • www.pkp.de

PKP Process Instruments Inc.

10 Brent Drive • Hudson, MA 01749

S +1-978-212-0006 • +1-978-568-0060

info@pkp-usa.com • www.pkp-usa.com

180614

Flowmeter selection procedure:

1. Define materials of wetted parts

2. Select process connection

(table “process connections“)

3. Select measuring range

(table “measuring ranges”)

4. Select indicator and output signals

5. Select options

2. Process connections:

Nom.

pipe

size

[DN]

Process connection Meas.

tube

No.

Conn.

code

No.

Length

L [mm]

15

(1/2“)

flange DN 15 PN 40

flange ANSI 1/2“ 150 Ibs.

flange ANSI 1/2“ 300 Ibs.

G 1/2 female

1/2“ NPT female

flange DN 15 PN 40

flange ANSI 1/2" 150 lbs.

flange ANSI 1/2" 300 lbs.

1

1

1

1

1

2

2

2

101

102

103

104

105

206

207

208

250

250

250

295

295

250

250

250

20

(3/4“)

flange DN 20 PN 40

flange ANSI 3/4" 150 lbs.

flange ANSI 3/4" 300 lbs.

flange DN 20 PN 40

flange ANSI 3/4", 150 lbs.

flange ANSI 3/4", 300 lbs.

G 3/4 female

3/4" NPT female

1

1

1

2

2

2

2

2

111

112

113

216

217

218

219

220

250

250

250

250

250

250

250

250

25

(1“)

flange DN 25 PN 40

flange ANSI 1" 150 lbs.

flange ANSI 1" 300 lbs.

threaded spigot DN 25 PN 40 (female)

acc. to DIN 11851

Tri-clamp DN 25 / 1

flange DN 25 PN 40

flange ANSI 1" 150 lbs.

flange ANSI 1" 300 lbs.

threaded spigot DN 25 PN 40 (female)

acc. to DIN 11851

Tri-clamp DN 25 / 1

flange DN 25 PN 40

flange ANSI 1", 150 lbs.

flange ANSI 1", 300 lbs.

G 1 female

1" NPT female

1

1

1

1

1

2

2

2

2

2

3

3

3

2

2

121

122

123

126

127

228

229

230

233

234

335

336

337

338

339

250

250

250

275

250

250

250

250

275

250

250

250

250

250

250

Flange for nominal pipe size DN 125 / 5" and DN 150 / 6"

on request.

1. Material version (wetted parts):

The flow meters model DS25 may be supplied either completely

in stainless steel 1.4404 (DS25.1) or with PTFE- coating

(DS25.2).

Nom.

pipe

size

[DN]

Process connection Meas.

tube

No.

Conn.

code

No.

Length

L [mm]

32

(1 1/4“)

flange DN 32 PN 40

Tri-clamp DN 32

flange DN 32 PN 40

flange ANSI 1 1/4" 150 lbs.

flange ANSI 1 1/4" 300 lbs.

Tri-clamp DN 32

flange DN 32 PN 40

flange ANSI 1 1/4", 150 lbs.

flange ANSI 1 1/4", 300 lbs.

G 1 14 female

1 1/4" NPT female

1

1

2

2

2

2

3

3

3

3

3

140

141

242

243

244

245

346

347

348

349

350

250

250

250

250

250

250

250

250

250

250

250

40

(1 1/2“)

Tri-clamp DN 40 / 1 1/2"

Tri-clamp DN 40 / 1 1/2"

flange DN 40 PN 40

flange ANSI 1 1/2", 150 lbs.

flange ANSI 1 1/2" 300 lbs.

G 1 1/2 female

1 1/2" NPT female

1

2

3

3

3

3

3

151

252

353

354

355

364

365

250

250

250

250

250

250

250

50

(2“)

flange DN 50 PN 40

flange ANSI 2" 150 lbs.

flange ANSI 2" 300 lbs.

threaded spigot DN 50 PN 25 (female)

acc. to DIN 11851

Tri-clamp DN 50 / 2"

flange DN 50 PN 40

flange ANSI 2" 150 lbs.

flange ANSI 2" 300 lbs.

flange DN 65 PN 40

flange ANSI 2 1/2" 150 lbs.

flange ANSI 2 1/2" 300 lbs.

3

3

3

3

3

4

4

4

4

4

4

356

357

358

359

360

461

462

463

469

470

471

250

250

250

275

250

250

250

250

250

250

250

65

(2 1/2“)

threaded spigot DN 65 PN 25 (female)

acc. to DIN 11851

G 2 1/2 female

2 1/2" NPT female

4

4

4

466

467

468

275

250

250

80

(3“)

threaded spigot DN 80 PN 25 (female)

acc. to DIN 11851

Tri-clamp DN 80 / 3"

flange DN 80 PN 40

flange ANSI 3", 150 lbs.

flange ANSI 3", 300 lbs.

4

4

5

5

5

469

470

571

572

573

275

300

250

250

250

100

(4“)

threaded spigot DN 100 PN 25

(female)

acc. to DIN 11851

Tri-clamp DN 100 / 4"

flange DN 100 PN 16

flange DN 100 PN 40

flange ANSI 4", 150 lbs.

5

5

6

6

6

574

575

676

677

678

300

250

250

250

250

Higher pressures on request

PKP Prozessmesstechnik GmbH

Borsigstr. 24 • D-65205 Wiesbaden

S +49 (0) 6122-7055-0 • +49 (0) 6122 7055-50

info@pkp.de • www.pkp.de

PKP Process Instruments Inc.

10 Brent Drive • Hudson, MA 01749

S +1-978-212-0006 • +1-978-568-0060

info@pkp-usa.com • www.pkp-usa.com

3. Measuring ranges:

Reference conditions: Water: 20 °C

3a) DS25.1. Stainless steel version Air: 0 °C, 1,013 bar abs.

Meas.

tube

Nr.

Meas.range-

code

Water/ Liquids Air/ Gases

Meas. range*

[m³/h]

Meas.-cone

No.

Float

No.

Pressure

drop

[mbar]

Meas. range*

[Nm³/h]

Meas. cone

No.

Float

No.

Pressure

drop

[mbar]

1 101 0,0025- 0,026

43 S0 40

0,075- 0,75

43 S0 45

102 0,004- 0,04 44 S0 40 0,12- 1,2 44 S0 45

103 0,0063- 0,063

47 S0 40

0,18- 1,8

47 S0 45

104 0,01- 0,1 51 S0 40 0,3- 3 51 S0 45

105 0,01- 0,1

53 L1 6

-

- - -

2 206 0,01- 0,1 53 L1 6 0,55- 5,5 53 M1 20

207 0,016- 0,16

53 M1 15

0,4- 4

53 L1 11

208 0,016- 0,16 54 L1 6 0,65- 6,5 54 L1 11

209 0,025- 0,25

53 S1 40

0,75- 7,5

53 S1 45

210 0,025- 0,25 57 L1 6 1- 10 57 L1 11

211 0,04- 0,4

54 S1 40

1,3- 13

54 S1 45

212 0,04- 0,4 61 L1 6 1,6- 16 61 L1 11

213 0,063- 0,63

57 S1 40

2- 20

57 S1 45

214 0,063- 0,63 61 M1 15 2,5- 25 62 L1 11

215 0,1- 1

61 S1 40

3- 30

61 S1 45

216 0,1- 1 62 M1 15 3,5- 35 62 M1 20

217 0,16- 1,6

62 S1 40

-

- - -

218 0,23- 2,3 62 V1 45 - - - -

3 319 0,1- 1

63 L2 7

4- 40

63 L2 12

320 0,16- 1,6 64 L2 7 5- 50 63 M2 22

321 0,25- 2,5

63 S2 41

7- 70

64 L2 12

322 0,25- 2,5 64 M2 16 9- 90 64 M2 22

323 0,4- 4

64 S2 41

13- 130

64 S2 47

324 0,6- 6 64 V2 43 - - - -

4 425 0,25- 2,5

67 L5 8

10- 100

67 L5 14

426 0,4- 4 71 L5 8 13- 130 67 M5 25

427 0,63- 6,3

67 S5 47

16- 160

71 L5 14

428 0,63- 6,3 72 L5 8 20- 200 71 M5 25

429 1- 10

71 S5 47

20- 200

67 S5 54

430 1- 10 72 M5 19 28- 280 72 L5 14

431 1,6- 16

72 S5 47

36- 360

72 M5 25

432 2,3- 23 72 V5 63 50- 500 72 S5 54

5 533 2,5- 25

73 V8 60

50- 500

73 L8 30

534 4- 40 74 V8 60 75- 750 73 V8 65

535 6,3- 63

77 V8 60

85- 850

74 L8 30

536 - - - - 120- 1200 74 V8 65

537 -

- - -

180- 1800

77 V8 65

6 638 10- 100 81 11 70 - - - -

639 15- 130

81 12 -

-

- - -

Measuring range for steam on request

* The specified measuring ranges - in particular for air - serve for orientation.

Please specify the following process conditions for inquiries:

Medium, pressure, temperature

We create an individual scale for you at no extra charge.

PKP Prozessmesstechnik GmbH

Borsigstr. 24 • D-65205 Wiesbaden

S +49 (0) 6122-7055-0 • +49 (0) 6122 7055-50

info@pkp.de • www.pkp.de

PKP Process Instruments Inc.

10 Brent Drive • Hudson, MA 01749

S +1-978-212-0006 • +1-978-568-0060

info@pkp-usa.com • www.pkp-usa.com

3b) DS25.2 – Wetted parts PTFE coated

Meas.

tube

No.

Meas.range-

code

Water/ Liquids Air/ Gases

Meas. range*

[m³/h]

Meas.-

cone

No.

Float

No.

Pressure

drop

[mbar]

Meas. range*

[Nm³/h]

Meas.-

cone

No.

Float

No.

Pressure

drop

[mbar]

2 250 0,01 – 0,1 51 A1 16 0,35- 3,5 51 A1 20

251 0,016- 0,16 52 A1 16 0,5- 5 52 A1 20

252 0,025- 0,25 53 A1 16 0,85- 8,5 53 A1 20

253 0,04- 0,4 54 A1 16 1,3- 13 54 A1 20

254 0,063- 0,63 57 A1 16 2- 20 57 A1 20

255 0,1- 1 61 V1 18 3,4- 34 61 V1 22

3 356 0,16- 1,6 62 A2 20 5- 50 62 A2 25

357 0,25- 2,5 63 A2 20 8,5- 85 63 A2 25

358 0,4- 4 63 V2 22 - - - -

4 459 0,4- 4 64 A5 20 13- 130 64 A5 25

460 0,63- 6,3 67 A5 20 20- 200 67 A5 25

461 1- 10 71 A5 20 35- 350 71 A5 25

462 1,6- 16 71 V5 22 - - - -

5 563 1,6- 16 72 V8 25 50- 500 72 27 12

564 2,5- 25 73 V8 25 85- 850 73 27 22

565 4- 40 74 V8 25 - - - -

6 666 6,3- 63 77 10 30 - - - -

* The specified measuring ranges - in particular for air - serve for orientation.

Please specify the following process conditions for inquiries:

Medium, pressure, temperature

We create an individual scale for you at no extra charge.

Technical Data (Measuring tube):

Measured media: liquids, gases or steam

Measuring ranges: see tables 3a) and 3b)

Turndown ratio: 10:1

Accuracy:

DS25.1: class 1.6

DS25.2: class 2.5

Process connection: see table

„Process connection“

Max. pressure: see table

„Process connection“

Operating temperature:

DS25.1: −180 °C…370 °C

DS25.2: − 80 °C…130 °C

Note max. operating temperatures of the display part and any

options.

Materials:

DS25.1: all wetted parts stainless steel

1.4404, (AISI 316 L)

DS25.2: all wetted parts stainless steel

1.4404, (AISI 316 L) with PTFE

coating

Mounting: vertical

Flow direction: from bottom to top

Mounting length: see table „process connection“

Straight pipe runs:

DN 15-65 none

DN 80-100 min. 5D

protection class: IP66

PKP Prozessmesstechnik GmbH

Borsigstr. 24 • D-65205 Wiesbaden

S +49 (0) 6122-7055-0 • +49 (0) 6122 7055-50

info@pkp.de • www.pkp.de

PKP Process Instruments Inc.

10 Brent Drive • Hudson, MA 01749

S +1-978-212-0006 • +1-978-568-0060

info@pkp-usa.com • www.pkp-usa.com

4. Indicator:

The indicator part of the DS25 consists of an aluminium or

stainless steel housing with a pointer assembly magnetically

coupled to the float.

The scale may be calibrated in flow units or in percent.

Additionally, transducers and alarm contacts may be mounted in

the indicator housing.

4a. Housing versions

Material: Code No.

Aluminium, round, d = 160 mm

Stainless steel, round, d = 160 mm

2

3

4b. Alarm contacts

Contact version: Code No.

without

1 min.-contact

1 max.-contact

1 min.-contact + 1 max.-contact

2 Min.-contacts

2 Max.-contacts

0

1

2

3

4

5

4c. Analogue output signals

Type: Code No.

without

electrical transmitter

electrical transmitter (Ex)

0

1

2

4d. Power supply and output signals

Type: Code No.

without

115 VAC, 0…20 mA, 4-wire

115 VAC, 4…20 mA, 4-wire

230 VAC, 0…20 mA, 4-wire

230 VAC, 4…20 mA, 4-wire

24 VDC, 0…20 mA, 3-wire

24 VDC, 4…20 mA, 2-wire (standard)

24 VDC, 4…20 mA, 3-wire

24 VDC, 4...20 mA, 2- wire HART

®

9-32 VDC, PROFIBUS, 2-wire

00

01

02

03

04

07

08

09

10

11

Technical Data (Indicator Assembly):

Mechanical indicator assembly:

Ambient

temperature:

-25 °C...130 °C, for higher or lower

operating temperature use option

“temperature isolation

Alarm contacts:

Type: inductive proximity switch SJ 3,5-N

acc. to DIN 19234 (NAMUR)

Ambient

temperature:

−25 °C …100 °C (for higher or lower

operating temperatures use option

“temperature insolation”)

Rated voltage: 8 VDC (Ri = 1 kOhm)

Output signal: ≤ 1 mA = 0

≥ 3 mA = 1

Explosion

protection:

EEx ia IIC T6,

group II category 2G (on request)

Dust- explosion

protection:

EEx iaD 20 T 108 °C,

group II category 1D

Recommended

accessories:

contact protection relay type

KFA/KFD (see chapter supplies)

Electrical transmitter:

Output signal:

0…20 mA, 4 - 20 mA

Display:

LCD, 8-digits, (programmable for

indication of flow rate or as non

resettable totalizer)

Power supply:

see table 4d

Max. Load:

4-wire: ≥ 500 Ohm

2/3-wire: (U-13,5 V) 20 mA

Operating

temperature: 0 °C…100 °C (for higher or lower

operating temperatures use option

“temperature insolation”)

Electrical

connection: M16 x 1,5 or 1/2" NPT

Intrinsically safe electronic transducer:

Technical Data as standard unit, but:

Output signal: 4…20 mA

Operating

temperature:

−25 °C…70 °C (for higher or lower

operating temperatures use option

“temperature insolation”)

Ex-protection: EEx nL IIC T6; protection „nL“;

group II; category 3G

EEx ia IIC T6 Gb; protection ia;

group II; category 2G

Dust explosion

protection:

EEx II 3D; group II; category 3D,

max: surface temperature: 80 °C

PKP Prozessmesstechnik GmbH

Borsigstr. 24 • D-65205 Wiesbaden

S +49 (0) 6122-7055-0 • +49 (0) 6122 7055-50

info@pkp.de • www.pkp.de

PKP Process Instruments Inc.

10 Brent Drive • Hudson, MA 01749

S +1-978-212-0006 • +1-978-568-0060

info@pkp-usa.com • www.pkp-usa.com

5. Options:

Temperature insolation IA:

For media temperatures outside the limits given in the technical

specifications for the indicator assembly the measuring tube and

the indicator assembly may be temperature isolated by mounting the indicator at a distance of 95 mm apart from the measuring tube. This ensures that the unit may be operated at media

temperatures as high as stated in the specifications for the

measuring tube.

Damping SD:

A float damping is recommended for gas applications to prevent

an up and down movement (only for DS25.1).

Heating H...:

Heating assemblies (steam jackets) are used to keep the

medium in the measuring tube at a required temperature. Steam

jackets are available with three different process connections:

H.1: DIN flanges DN 15 PN 40

H.2: DIN flanges DN 25 PN 40

H.3: Threaded connection R 1/4”

Oil and grease free OF:

For use with oxygen the meters may be supplied oil- and

grease- free.

Certifications:

on request

Tags, customer specified scales:

Stainless steel tags with customer specified text are optionally

available

Order Code:

Order number: DS25.

Variable Area Flowmeter

1. 121. 1. 321. 1. 0. 104

Material version:

1 = stainless steel

2 = wetted parts PTFE-coated

Process connection:

101…678= process connection acc. to

table 2

999 = special connection

(please specify in plain text)

Medium:

1 = water / liquids

2 = air / gases

3 = steam

Measuring range:

101…666 = measuring range acc. to table 3a or 3b

999 = special range (please specify in plain text)

Housing version: (acc. to table 4a)

2 = aluminium, round, d = 160 mm

3 = stainless steel, round, d = 160 mm

Alarm contacts:

0…5 = contacts acc. to table 4b

Analogue output and power supply:

1st. digit:

0…3 = analogue output acc. to table 4c

2nd.–3rd. digit:

00…13 = power supply and output signal acc. to table 4d

Options: please specify in plain text

Ordering information:

for complete identification of the meter the following

information must be specified:

1. order no. acc. to table above

2. a. name of medium

b. temperature

c. pressure

d. viscosity (for liquids only)

e. density

3. for gases only: reference conditions

4. options:

a. model number acc. to section “Options”

b. additional customer specific information

PKP Prozessmesstechnik GmbH

Borsigstr. 24 • D-65205 Wiesbaden

S +49 (0) 6122-7055-0 • +49 (0) 6122 7055-50

info@pkp.de • www.pkp.de

PKP Process Instruments Inc.

10 Brent Drive • Hudson, MA 01749

S +1-978-212-0006 • +1-978-568-0060

info@pkp-usa.com • www.pkp-usa.com

PKP Prozessmesstechnik GmbH

Borsigstr. 24 • D-65205 Wiesbaden

S +49 (0) 6122-7055-0 • +49 (0) 6122 7055-50

info@pkp.de • www.pkp.de

PKP Process Instruments Inc.

10 Brent Drive • Hudson, MA 01749

S +1-978-212-0006 • +1-978-568-0060

info@pkp-usa.com • www.pkp-usa.com

PKP Prozessmesstechnik GmbH

Borsigstr. 24 • D-65205 Wiesbaden

S +49 (0) 6122-7055-0 • +49 (0) 6122 7055-50

info@pkp.de • www.pkp.de

PKP Process Instruments Inc.

10 Brent Drive • Hudson, MA 01749

S +1-978-212-0006 • +1-978-568-0060

info@pkp-usa.com • www.pkp-usa.com

Loading...

Loading...