Instruction Manual

DG04

Flow Sight Class

for Installation between two Flanges

PKP Prozessmesstechnik GmbH

Borsigstraße 24

D-65205 Wiesbaden-Nordenstadt

Tel.: ++49-(0)6122-7055-0

Fax: ++49-(0)6122-7055-50

Email: info@pkp.de

Table of Contents

Safety Information..................................................................................................................2

Assembly instructions and tightening torques.......................................................................3

Maintenance and care...........................................................................................................3

Safety Information

General Instructions

To ensure safe operation, the device should only be operated according to the specifica tions in the instruction manual. The requisite Health & Safety regulations for a given

application must also be observed. This statement also applies to the use of accessories.

Every person who is commissioned with the initiation or operation of this device must have

read and understood the operating instructions and in particular the safety instructions!

The liability of the manufacturer expires in the event of damage due to improper use, nonobservance of this operating manual, use of insufficiently qualified personnel and unauthorized modification of the device.

Proper Usage

The sight class of the DG04 series are used for the optical control monitoring of liquids.

Any other use of the device is prohibited and outside the scope of application.

In particular, applications in which shock loads occur (for example, pulsed operation)

should be discussed and checked in advance with our technical staff.

The devices of the DG04 series should not be used as sole monitoring devices in order to

detect or even avoid dangerous operating states in plants and machines. The plant or

machine itself must be planned and constructed in such a way that critical conditions

which pose a danger to man and the environment are excluded from the outset

Dangerous substances

For dangerous media such as e.g. Oxygen, Acetylene, flammable or toxic substances as

well as refrigeration systems, compressors, etc. must comply with the relevant regulations

beyond the general rules.

Qualified Personnel

The devices of the DG04 may only be installed by trained, qualified personnel who are

able to mount the devices correctly. Qualified personnel are persons, who are familiar with

assembling, installation, placing in service and operating these devices and who are suit ably trained and qualified.

DG04 Instruction manual 04/2019 page 2

Inward Monitoring

Please check directly after delivery the device for any transport damages and deficiencies.

Additional with reference to the accompanying delivery note the number of parts must be

checked.

Claims for replacement or goods which relate to transport damage can only be considered

valid if the delivery company is notified without delay.

Assembly instructions and tightening torques

Attention:

• Tighten flange screws evenly.

• Avoid shock loads.

• Mount flat gaskets and sight glass centred.

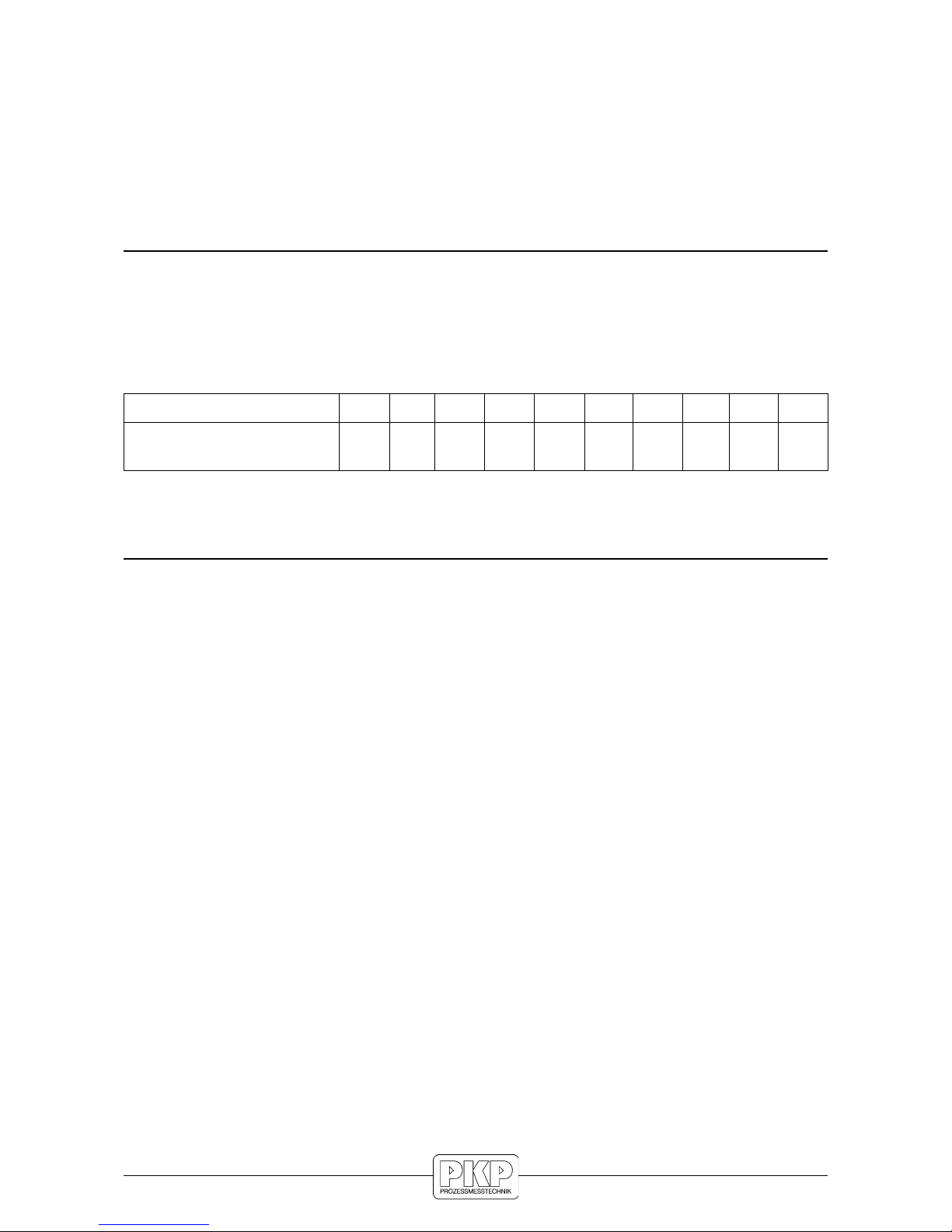

Nominal size DN 25 40 50 80 100 125 150 200 250 300

max. tightening torque

(Nm)*

12 21 28 20 26 32 47 63 63 63

*for lubricated torques µ = 0,1

Maintenance and care

The sight glasses are insensitive to contamination, as the inner surface is flushed by the

flowing medium.

The sight glasses have no dead spaces, so that the sight glass can be flushed or cleaned

together with the pipeline when changing the product.

DG04 Instruction manual 04/2019 page 3

Flow Measurement and Monitoring

DG04

Flow Sight Glass for

Installation between Two Flanges

• for liquids and gases

• 360° all round visibility

• easy installation between two DIN-

or ANSI-flanges

• design in borosilicate glass for

aggressive media, until 300 °C

media temperature

• quartz glass-design for mediatemperatures until 1100 °C

• insensitive to contamination

• maximum pressure 16 bar

Description:

Model series DG04 sight glasses are distinguished by their

rugged construction and wide range of applications. They feature 30, 50 or 100 mm long transparent cylinders made of

acrylic, soda-lime or borosilicate glass with very high wall

thickness. These cylinders are intended to be clamped

between two existing flanges. Their dimensions match those

of the sealing face on the raised area of the flange. This sizing

makes support from a separate metal housing unnecessary.

In addition, this design allows the flow to be viewed and

monitored from any direction. The flange screws provide addi-

tional protection against mechanical damage.

The sight glass has no dead spaces, so that it can be

flushed / cleaned together with the pipeline when changing

products.

There are no deposits in the sight glass when the pipeline is

drained, because the inner diameter of the sight glass corresponds to the inner diameter of the pipeline. The DG04 are

therefore also ideally suited for sterile and antiseptide applications.

Typical applications:

The flange bolts also offer additional protection against mech anical damage. The borosilicate glass version can be installed

in devices used with very caustic / corrosive liquids. They are

insensitive to contamination because the inner surface is constantly being rinsed by the flowing liquid.

In particular, the larger nominal sizes are very cost effective

solutions since they only require the transparent cylinder and

no metal housing with flanges.

PKP Prozessmesstechnik GmbH

Borsigstr. 24 • D-65205 Wiesbaden

S +49 (0) 6122-7055-0 • T +49 (0) 6122 7055-50

info@pkp.de • www.pkp.de

PKP Process Instruments Inc.

10 Brent Drive • Hudson, MA 01749

S +1-978-212-0006 • T +1-978-568-0060

info@pkp-usa.com • www.pkp-usa.com

180723

Models:

DG 04.A: material: acrylic

max. temperature: +80 °C

max. pressure: 16 bar

DG 04.B: material: borosilicate glass

max. temperature: -200...+300 °C

max. pressure: 16 bar

for aggressive medias and high temperatures

DG 04.Q: material: quartz glass-

max. temperature: +1100 °C

max. pressure: 16 bar

for aggressive medias and very high temperatures

Assembly / Mounting:

Dimensions:

Nominal

sizes

DG04 for

DIN-flanges

diameters

[mm]

DG04 for

ANSI-flanges

diameter

[mm]

Permitted

process

pressure [bar]

with 150 °C and

borosilicate glass

outside inside outside inside

DN 10

DN 15

DN 20

DN 25

DN 32

DN 40

DN 50

DN 65

DN 80

DN 100

DN 125

DN 150

DN 200

DN 250

40

45

58

68

79

88

102

122

138

158

188

212

268

320

14

18

23

29

38

44

55

71

83

108

132

160

208

261

40

35

43

50

63

73

92

105

127

157

186

216

270

324

14

16

21

27

35

41

53

63

78

102

128

154

203

255

16

16

16

16

16

16

16

16

16

16

16

16

16

10

Larger nominal sizes and higher pressures on request.

Order Code:

Order number: DG04.

Flow sight glass for installation

between two flanges

A. 50. D. 025. 0

Models:

A = acrylic

B = borosilicate glass

Q = quartz glass

Length:

030 = 30 mm (DG04.B only)

050 = 50 mm

100 = 100 mm (DG04.A only)

Connection:

D = flange, max. PN 16

A = ANSI-flange, max. 150 lbs.

Nominal size:

010...250 = nominal size appropriate table „Dimensions“

Options:

0 = without

1 = please specify in plain text

Advice:

The flanges, screws and gaskets are not included

in the delivery.

Weights:

Nominal

sizes

DG04 for

DIN-flanges weight

[Kg]

DG04 for

ANSI-flanges weight

[Kg]

Borosilicate

glass

Acrylic Borosilicate

glass

Acrylic

L

[mm]

30

L

[mm]

50

L

[mm]

50

L

[mm]

100

L

[mm]

30

L

[mm]

50

L

[mm]

50

L

[mm]

100

DN 10

DN 15

DN 20

DN 25

DN 32

DN 40

DN 50

DN 65

DN 80

DN 100

DN 125

DN 150

DN 200

DN 250

0,08

0,1

0,16

0,22

0,28

0,33

0,42

0,56

0,7

0,76

1,03

1,11

1,64

1,97

0,13

0,16

0,27

0,36

0,46

0,56

0,71

0,94

1,16

1,27

1,71

1,85

2,73

3,28

0,07

0,08

0,14

0,18

0,23

0,28

0,36

0,47

0,59

0,64

0,86

0,93

1,38

1,65

0,14

0,16

0,27

0,36

0,46

0,56

0,71

0,95

1,17

1,28

1,73

1,87

2,75

3,31

0,06

0,08

0,1

0,16

0,21

0,32

0,4

0,58

0,82

1,05

1,32

1,82

2,29

-

0,09

0,13

0,17

0,26

0,35

0,54

0,67

0,96

1,36

1,74

2,19

3,03

3,82

-

0,05

0,07

0,09

0,13

0,18

0,27

0,34

0,48

0,69

0,88

1,11

1,53

1,93

-

0,09

0,14

0,17

0,26

0,35

0,55

0,68

0,97

1,37

1,76

2,21

3,06

3,85

-

PKP Prozessmesstechnik GmbH

Borsigstr. 24 • D-65205 Wiesbaden

S +49 (0) 6122-7055-0 • T +49 (0) 6122 7055-50

info@pkp.de • www.pkp.de

PKP Process Instruments Inc.

10 Brent Drive • Hudson, MA 01749

S +1-978-212-0006 • T +1-978-568-0060

info@pkp-usa.com • www.pkp-usa.com

Flow

Loading...

Loading...