Instruction Manual

DB04A

Thermal Mass Flowmeter for Gases

without auxiliary Power

PKP Prozessmesstechnik GmbH

Borsigstraße 24

D-65205 Wiesbaden-Nordenstadt

Tel.: ++49-(0)6122-7055-0

Fax: ++49-(0)6122-7055-50

Email: info@pkp.de

Manual Version Page

DB04A EN A1-9 PKP Prozessmesstechnik 02

Version : DB04A EN A1-9

For the latest information on our products, see our website at www.pkp.de

PKP Prozessmesstechnik GmbH, Borsigstraße 24, D-65205 Wiesbaden-Nordenstadt

Operating instructions

DB04A

Manual Version Page

DB04A EN A1-9 PKP Prozessmesstechnik 03

Copyright and Liability Disclaimer

All rights reserved. No part of this publication may be reproduced in any form or by any means

without the publisher's prior written permission.

The content of this manual is provided for information only and may be altered without prior notice.

PKP Prozessmesstechnik assumes no responsibility or liability for any errors or inaccuracies in

this manual.

This symbol alerts the user to important operating, maintenance and service

information.

Important instructions

•

Do not remove the electronics housing. A damaged hologram seal will void the warranty.

•

There are no serviceable parts inside the unit.

•

Repairs must only be performed by qualified personnel

Attention

This unit has several power supply possibilities. If you use the external 24 Vdc power supply, it is

strongly recommended to have this device grounded.

Subject to change

Due to our policy of ongoing product development, we reserve the right to change the information

in this manual without notice.

Recycling

Note the existing regulations of your country.

Toxic, flammable gases and ATEX

In the case of toxic and flammable gases, the respective safety guidelines in each country must be

followed. This DB04A device is NOT Ex certified. In the case of flammable and toxic gases, fittings,

cable glands and pipes intended for that purpose must be used. The responsibility for safe

operation lies with the user and designer of the facilities.

Manual Version Page

DB04A EN A1-9 PKP Prozessmesstechnik 04

Oxygen service

PKP is not liable for any damage or personal injury, whatsoever, resulting from the use of our

standard mass flow meters or controllers for oxygen gas. You are responsible for determining if

this mass flow meter or controller is appropriate for your oxygen application. You are responsible

for cleaning the mass flow meter or controller to the degree required for your oxygen flow

application.

Trademark

DB04A is a Trademark of PKP. Other product and company names listed in this manual are

trademarks or trade names of their respective manufacturers.

Receipt of your instrument

When receiving the instrument, carefully check the outside packing carton for damage that may

have incurred during shipment. If the carton is damaged, notify the local carrier and submit a report

to the factory or distributor. Remove the packing slip and check that all ordered components are

present and match your specifications (as ordered). Make sure any spare parts or accessories are

not discarded with the packing material. Do not return any equipment to the factory without first

contacting PKP:

E-mail Customer Service:

info@pkp.de

Installation

Please note before the start-up:

•

Do not use sealing tape or liquid sealant

•

Piping must be cleaned before installation of instrument.

Products in this manual may contain metal or elastomer seals, gaskets, o-rings or valve seats. It is

the “user’s” responsibility to select materials that are compatible with their process and process

conditions. Using materials that are not compatible with the process limitations of the device, may

result in equipment damage and/or personnel injury or death.

It is recommended that the user check the devices on a regular schedule to ensure that it is leak

free as both metal and elastomer seals, gaskets, o-rings and valve seats may change with age and

exposure to process gas.

Power

If it becomes necessary to remove the instrument from the system or change a battery, the power

to the device must be disconnected. Always switch off the power before you disconnect terminal

connections in potentially dangerous surroundings to avoid sparks.

Manual Version Page

DB04A EN A1-9 PKP Prozessmesstechnik 05

Table of contents

1. Introduction 7

1.10. Features of DB04A thermal mass flow meters 7

1.11. Scope of warranty 7

1.12. Instructions and warnings 8

1.13. Documentation and cables supplied 8

1.14. The measurement principle 8

1.15. Real, Standardized and Normalized flow 9

1.16. CMOS technology 10

1.17. Block diagram 11

2. General device specifications 12

2.10. Safety 13

2.11. Electrical data 13

2.12. Measurement ranges (air) 13

2.13. USB interface 14

2.14. Battery 14

2.15. Optional Modules 14

2.16. Calibration 15

2.17. Operation with other gases 16

2.18. Pressure loss 16

2.19. Temperature compensation 16

2.20. Pressure compensation 16

2.21. Response time 16

2.22. Filter settings 16

3. Installation and commissioning 17

3.10. Scope of delivery 17

3.11. Mounting position and mounting location 17

3.12. Requirements for pipework 17

3.13. Fittings and filters 18

3.14. Filters / Gas cleanliness 18

3.15. Electrical power supply 19

3.16. How to replace the battery? 20

3.17. Warm-up time 21

4. Operation 21

4.10. Introduction 21

4.11. Main Menu 24

4.12. Settings 31

Manual Version Page

DB04A EN A1-9 PKP Prozessmesstechnik 06

5. Maintenance 35

5.10. Cleaning to remove contamination 35

5.11. Returns 36

6. Appendix 37

6.10. Troubleshooting 37

6.11. Pressure loss 39

6.12. Dimensional drawings ¼” in mm 41

6.13. Dimensional drawings ¼” in inches 42

6.14. Dimensional drawings ½” in mm 43

6.15. Dimensional drawings ½” in inches 44

6.16. Wetted parts DB04A series 45

6.17. Contamination statement 46

6.18. Overview Default settings 47

Manual Version Page

DB04A EN A1-9 PKP Prozessmesstechnik 07

1. Introduction

Thank you for choosing devices from the DB04A series. These operating instructions will help you

to install and operate the measuring devices. Please read through these instructions carefully

before installing the devices. Our aim has been to write a full and practical guide. We would be

grateful if you would notify us of any shortcomings or mistakes.

Please contact PKP if you have questions about any aspect of the products.

The DB04A is a thermal based mass flow meter that can measure the mass flow of gases. The

core element of the DB04A thermal mass flow meter is a CMOS sensor chip. The sensor and parts

of the electronics are on one board and offer a number of advantages for the user.

1.10. Features of DB04A thermal mass flow meters

In developing and manufacturing the devices, we have focused primarily on customers and their

applications. Our aim is to implement customers' requirements in the form of new developments or

enhancements on an ongoing basis. The essential features are:

Compact design

Battery operated optional (Portable)

Dot-matrix LCD touch screen

Multiple gases possible (3 gases)

Flexible due to the many different settings accessible through the touch screen

Back-light screen in USB and 12-30 Vdc power mode

Power also possible with USB micro-B connector or external 12-30 Vdc (Separate module)

Optional alarm module with power, 3 contacts and 2 inputs

Display can be rotated 180 degrees

Fast and accurate measurement and control

Integrated temperature compensation and flow totalizer (standard)

Easy to maintain and service

Firmware upgradable through USB connection

3-year warranty

1.11. Scope of warranty

Warranty for the DB04A product line extends to material and manufacturing defects only.

Maximum warranty covers product replacement free of charge. The following causes of

faults/damage are not covered under warranty:

Use outside the operating limits

Damage due to corrosion

Damage due to leaking batteries

Mechanical damage in general

Contamination due to improper sealing

Contamination due to impure gases or penetration of liquids

Damage to electronic components due by over-voltage or electrostatic discharges, and

corrosion damage due to aggressive environments.

Functional failure due to incorrect operation or faulty parameterization

If the unit has been opened or otherwise tempered with.

Drift in the calibration

Manual Version Page

DB04A EN A1-9 PKP Prozessmesstechnik 08

1.12. Instructions and warnings

Read all of the operating instructions thoroughly before installing and commissioning equipment.

Misconceptions and incorrect use can lead to breakage of the measuring device or risk of personal

injury.

The installation, commissioning and operation and maintenance must be done by appropriately

qualified personnel.

1.13. Documentation and cables supplied

Every unit comes with a USB A to USB Micro-B cable. This cable can be used to power the unit

and to upgrade the firmware.

1.14. The measurement principle

The thermal mass flow measurement principle is particularly suitable for the measurement and

control of clean and dry gaseous media. The most significant advantage is that the measurement

process measures the real mass flow and is largely independent of temperature and pressure.

Stated simply, the thermal measurement principle measures the heat transport by gas flowing past.

In the case of DB04A mass flow measuring instruments, a constant heat input gives a flowdependent temperature difference (∆T). Two temperature sensors are positioned in the measuring

channel (T1, T2), one before the heating system (H) and one after it.

If there is no flow, the heat spreads symmetrically in directions T1 and T2. The temperature

difference T1-T2 is therefore zero.

Flow rates > 0 create a temperature difference.

The sensor T1 at the inlet is cooled by the gas flowing past it, and the temperature of the second

sensor T2 rises due to the heat drawn from the heating system.

The temperature difference is related non-lineary to the mass flow, with very high repeatability. The

electronics will, based on the calibration, convert this temperature difference in a linear and

proportional indication of the mass flow of the gas.

Figure 1: Measurement principle

Figure 2: Sensor operation

Manual Version Page

DB04A EN A1-9 PKP Prozessmesstechnik 09

1.15. Real, Standardized and Normalized flow

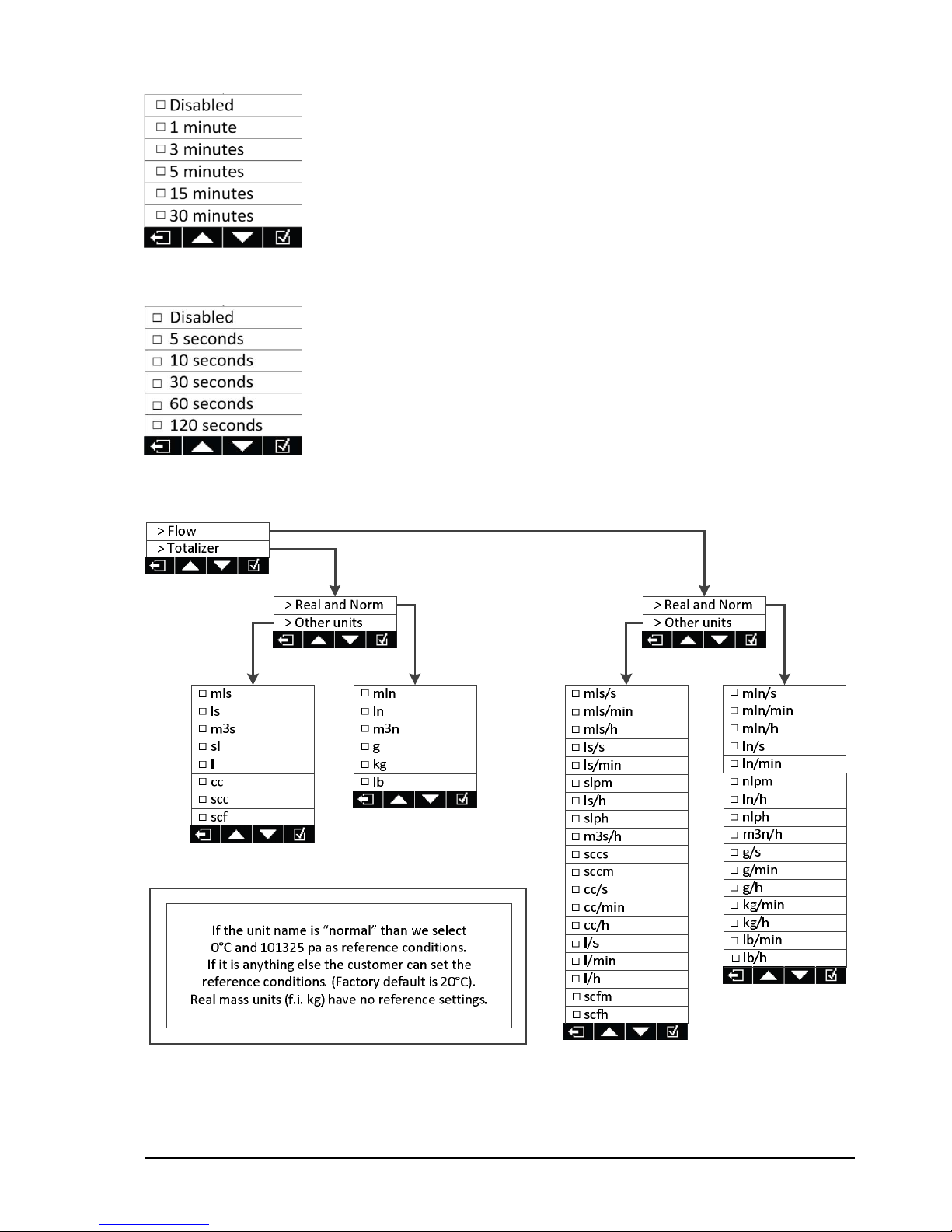

The user-selectable engineering units of the DB04A has been divided in two groups: “Real and

Normal” units and “Other units”

This separation is not only there to find the unit you want to select quicker, it also separated the

“Normalized flow” from the “Standardized flow”

Figure 3: Units menu

The DB04A has basically 2 reference conditions: One for “Real and Normal” units and one for

“Other units”

The factory setting is as follows:

1) For all units that are used in "normal" (like ln/min), the reference conditions are always 0°C

and 1013.25 mbara. This cannot be adapted.

2) For all the other units that are “standard” (like ls/min and sccm) and the l/min the reference

conditions has to be be defined when the unit is ordered.

The reference value for all units that are not “Normal” or “Real” it has to be defined with the

purchase order. It cannot be changed after the units has been delivered.

On the sticker of the DB04A we will mention a reference condition. This reference condition is for

the “Standard” units only. The “normal” units will always be 0°C and 1013.25 mbara.

In future version of the firmware the reference conditions will be adjustable in the menu.

Manual Version Page

DB04A EN A1-9 PKP Prozessmesstechnik 10

Gas flow in general can be expressed in one of the following:

•

Volumetric flow: (f.i. l/min). This theoretically cannot be measured by the DB04A because it

is volume. The DB04A measures mass flow. However, due to regional requirements we

still have it as a flow unit that is selectable. Units shown as volume (l/min) refer to the

customer defined reference conditions (Same as “standard”)

•

Real Mass flow: (f.i. Kg/hr). This refers to true mass units per time unit. The DB04A can

measure this and you can select this type of unit from the menu.

•

Normalized volumetric flow: Normalized means that the units are “translated” to predefined

pressure and temperature conditions. Normalized or Normal Conditions refers to 0°C and

1013.25 mbar absolute. You can select this type of unit from the menu of the DB04A.

These units are mostly used in Europe and China.

•

Standardized volumetric flow: Standardized means that the units are “translated” to

predefined pressure and temperature conditions. Standardized or Standard conditions

refers to 20°C (68°F) and 1013.25 mbar (=760 mmHg) absolute. You can select these type

of units from the menu of the DB04A. These units are mostly used in the USA.

Standardized can also refer to other reference conditions (f.i. Natural Gas industry often

uses 15°C and 1013.25 mbar absolute. In the semicon world they often use 25°C and

1013.25 mbara. Please define and mention these reference condition at the time of your

order.

Please note that reference condition relating to Normalized or Standardized volumetric flow are

NOT the operating conditions. According to the ideal gas law, the gas volume will change by

0.35% per K.

Please note that PKP standard uses the following densities for their main 3 gasses:

Air: 1.293 gr/m3, N2: 1.2504 gr/m3, O2: 1.429 gr/m3 (All at 0°C and 1013.25 mbar absolute). If you

use other densities or need additional information for other gasses, please contact the factory.

Densities need to be defined before manufacturing and cannot be adjusted once the unit has been

delivered.

1.16. CMOS technology

The DB04A measuring and control devices are equipped with an innovative CMOS semiconductor

sensor that sets new standards for accuracy, speed and measurement dynamics.

With our CMOS technology the sensor element, amplifier and A/D converter form a single silicon

chip.

Manual Version Page

DB04A EN A1-9 PKP Prozessmesstechnik 11

1.17. Block diagram

The following GCM block diagram shows the structure of the device. The block diagram does not

show the optional manual control/needle valve (Model GCR) that would normally be placed on the

outlet of the unit.

Figure 4: Block diagram

Manual Version Page

DB04A EN A1-9 PKP Prozessmesstechnik 12

2. General device specifications

Media (real gas calibration): Air, O2*, N2*, He, Ar, CO2, H2, CH4, C3H8

(other gases and gas mixtures on request)

*O2 & N2 are calibrated with air.

Accuracy:

Standard: ±2.0% of full scale; Ranges > 200 ln/min ±3.0% of full scale

Option G: ±1.0% of full scale (only G¼” instruments and real gas calibrations)

Dynamics:

Standard: 1:50 (Meter reads zero if flow is less than 1.7% of full scale)

Option G: 1:100 (Meter reads zero if flow is less than 0.83% of full scale)

Response time: Maximum 300 msec (filter setting dependend)

Flow update by sensor 40 ms (Battery mode 500 ms)

Display update 240 ms (Battery mode 500 ms)

Repeatability: ±0.5% of full scale

Long-term stability: < 1% of reading / year

Temperature coefficient: < 0.025% FS measuring range type per °C

< 0.012% FS measuring range type per 1°F

Pressure coefficient: < 0.2% / bar of reading (typical N2)

< 0.014% / psi of reading (typical N2)

Working pressure range: 0.2 - 11 bara(3-160 psia)

Test pressure: 16 bara (232 psia)

Storage conditions: -20 to 80°C (-4 to 176°F), 0-95% RH, non-condensing

Temperature range: 0 – 50°C (32 bis 122°F), 0-95%, RH, non-condensing

Do not expose device to direct sun light.

Warm-up time: < 5 sec. for full accuracy

Materials

Electronics housing: ABS (Acrylnitril-Butadien-Styrol)

Body Material: Anodized aluminium or stainless steel 1.4404 (316L)

Sensor area: Silicon, glass, epoxy

Seal material: FKM, optional EPDM (FDA compatable)

Wetted parts: See appendix (see chapter Wetted Parts List)

Integration

Display:

Touch display 128x64 px

Backlighted only with external power supply (Micro-USB or 24 Vdc)

Process connection:

G¼" (BSPP* female) up to 60 ln/min,

G½" (BSPP* female) up to 450 ln/min

*British Standard Pipe Parallel

Inlet section: None required

Mounting orientation: Any position (consult manufacturer above 5 bara (72 Psia) if the

DB04A will be mounted vertical)

Connection cable: For external power supply: 2 m with loose ends (fly leads)

Manual Version Page

DB04A EN A1-9 PKP Prozessmesstechnik 13

2.10. Safety

Test Pressure: 16 Bara (232 psia)

Leak rate: 1 x 10-6mbar*l/s He

Protection class: IP-50

EMC EN 61326-1

2.11. Electrical data

Supply voltage:

Power supply DB04A meter & regulator Standard AA battery or

USB micro-B power supply (DIN 62684)

Option: External power 12...30 Vdc (required current power

supply 120 mA. We recommend a power supply with a minimum

current of 150 mA)

(Power supply hereafter refered to as the 24 Vdc power supply)

2.12. Measurement ranges (air)

The DB04A has 4 different flow elements. Each element has a defined maximum operating flow

range that will be defined during calibration. The flow ranges selectable below are the maximum

flow ranges for air/O2 and N2 only. For other gasses consult the factory.

These ranges are adjustable electronically during factory configuration to your desired full scale

range.

Measurement full scale (air) scale freely selectable

DB04A: from 50 mln/min to 600 mln/min

from 600 mln/min to 6000 mln/min

from 6 ln/min to 60 ln/min

from 60 ln/min to 450 ln/min

Manual Version Page

DB04A EN A1-9 PKP Prozessmesstechnik 14

2.13. USB interface

The unit has an female USB micro-B connection (DIN 62684) that can be used as an external

power supply and to upgrade the firmware (USB micro-B is the same connector you find on most

Android and Windows portable phones, you can use the charger of your telephone to power the

DB04A). It is not possible to read data from the flow meter through the USB connection.

2.14. Battery

The battery operated DB04A can operate on any common AA battery. The lifetime is strongly

dependent on the usage and the quality of the battery. In general we can state that the battery

lasts for about 3-6 months under non-continuous use.

We recommend to use external power (USB micro-B or 24 Vdc) if you application needs

continuous measurement like measuring totalized flow. To extend the lifetime of the battery, the

back-light is disabled during battery operation, you cannot activate it. We strongly recommend to

use the “auto power off” in the menu for battery driven devices.

More information on the battery in chapter 3.15 Electrical power supply and 3.16 How to replace

the battery?.

Note: When we supply the unit, the “auto power off” will be set to 15 minutes

2.15. Optional Modules

As an additional option you can purchase a power supply or an alarm module. See our website or

contact your local distributor for additional information.

The power supply module, is provided with a voltage from 12 to 30 Vdc, will power the unit. The

unit comes with a 2 meter cable.

Manual Version Page

DB04A EN A1-9 PKP Prozessmesstechnik 15

The alarm module can in addition to the

above power module, provide 3 customer

individually settable alarms and 2 inputs. The

module is supplied with a 2 meter fly-lead

cable.

Each of the 3 alarm contacts can be

configured as high, low, window and totalizer

alarm. Once the alarm becomes active, the 3

potential free alarm contacts can be reset in

many different ways. Automatic, through the

touch screen or with one of the 2 input

signals. Other options like hysteresis settings

and delays are also available.

For detailed information see 4.11.2 Alarm

Menu in this manual.

Both the power and the alarm module are

mounted similar to the battery module (see

3.16 How to replace the battery). They

replace the battery module, so you cannot

use these modules in combination with

battery power.

Generic specifications optional alarm module

Power input:

Voltage supply range : 12 - 30 VDC (Power supply hereafter refered to as the 24 Vdc power

supply)

Max. current : 300 mA

Protection input: Polyfuse (trip current > 500mA) and reverse polarity protected

Switch ratings switch 1 + 2 (SPST hard contact):

Maximum current 0.5 A

Maximum voltage 30 Vdc

Switch ratings switch 3 (DPST contact):

Maximum current 1 A

Maximum voltage 30 Vdc

Inputs 1 + 2 (Opto-couplers):

Voltage range (polarity sensitive): 5 – 30 Vdc (@ 5mA max)

Min. recommended pulse width 100 msec (Sample interval: 20 msec)

2.16. Calibration

Each measuring device is supplied with a factory calibration report. The calibration is traceable to

American and/or European standards. On request we can also provide DAkkS calibration (German

Accreditation Body).

Figure 5: Power and Alarm module wiring

Manual Version Page

DB04A EN A1-9 PKP Prozessmesstechnik 16

2.17. Operation with other gases

Each measuring device can store data for up to 3 types of gas or operational states that need to be

defined at the time of purchase.

CMOS gas flow sensors are not linear (The output is linearized) and respond different to each gas.

If the gas or gas composition is different than the gas that the unit was calibrated for, the unit will

not measure accurately. It is possible to program up to 3 different gases and gas mixtures, but this

needs to be done at the factory. Please contact PKP for additional information.

Note:

Please note that, among other effects, the zero-point error (offset display) will be higher if the

device is not operated with the type of gas, for which it had been calibrated. A difference in zero

indication is also possible if the used pressure is different than specified.

2.18. Pressure loss

Our thermal mass flow meters have a low pressure drop. The pressure drop depends mainly on

the medium, the pressure conditions and the flow rate. In chapter 6.11 Pressure Loss you find the

pressure drop for the most common gases. PKP has a calculation program for the other gases.

Please note that the size of the pipes has a large effect on the pressure loss. For example from

around 60 ln/min, we recommend a pipe inside diameter of at least 10 mm.

Please also note that some fittings have a reduced diameter and can cause considerable pressure

drop in your system. Be especially careful with vacuum applications, please select a relative big

pipe diameter).

2.19. Temperature compensation

The DB04A thermal mass flow meters measure the mass flow of gases, the result being largely

independent of pressure and temperature. In addition to the fundamental principle an internal

sensor measures the gas temperature and, with the help of a 3-dimensional table of interpolation

values, a correction factor is calculated automatically. The flow indication is thus temperaturecompensated.

2.20. Pressure compensation

During calibration, the specified operating pressure is taken into account. Changes to the pressure

conditions may introduce an additional error. This is around ±0.2% per bar.

Please note that the control behavior is influenced by substantially different pressure conditions.

(relevant for units with an intergrated needle valve only)

2.21. Response time

The response time is time required to display 98% of its final value after a sudden change in flow.

This response time for the DB04A 2 is around 300 ms but is dependent on your filter settings.

2.22. Filter settings

The filter settings smoothens the reading of pulsating or noisy flows. It can be set through the setup menu.

Manual Version Page

DB04A EN A1-9 PKP Prozessmesstechnik 17

Higher filter settings will slow down the response time of the unit.

(Please always first try to find and remove the cause of your noisy or pulsating flow e.g. add

volume to your system). More information on the filter settings in chapter 4.12.3 Filter

3. Installation and commissioning

3.10. Scope of delivery

We ship the device with the following accompanying documentation:

With each device, USB cable + 1 x AA battery (if battery powered)

3.11. Mounting position and mounting location

Although the recommend mounting position is horizontal, the unit can used be upright, vertical or

upside down. With a vertical mounting position, dependent on the type of gas and at pressures

above 5 bara (72 psia, 500 kPa(abs)), a zero-point offset can be possible. This effect is caused by

convection in stationary media.

With regard to mounting location, the following situations can cause problems:

Strong heat sources, or ambient temperatures outside the specification

Strong sources of electromagnetic radiation such as spark discharges

Humid environments and the associated condensation lead to damage of the electronic

components

In general, aggressive environments reduce the service life.

Liquid running backwards can penetrate into the measuring instrument. An elevated

mounting location generally helps, or using check valves.

If your ambient air contains high humidity and at night the temperature goes down, it is

possible that you will get some condensation inside the unit. Please take precautions to

avoid this.

3.12. Requirements for pipework

The most common causes of faults concern the way that devices are connected to the gas supply.

Please note the following points:

The pipes must be absolutely clean. Please flush them

before

installing the measuring

instruments!

Please ensure there are no pieces of thread sealant (f.i. Teflon tape) in the piping!

Use appropriate pipe materials (pressure rating, durability)

Even when connected to fixed pipework, we recommend that the devices are mounted

using the appropriate mounting holes

From 50 ln/min, we recommend the following flow-calming sections of straight and

unobstructed straight tubing: Inlet: 10 x diameter; outlet: 5 x diameter

Use appropriate fittings (see chapter 3.13 Fittings and Filters).

Malfunctions can be caused by unstable pressure controllers, pumps that oscillate, and

volumes before and/or after the measuring device that are generally too small. Install an air

reservoir with 2 liter volume in the feed pipe (2 liter is an example, the volume depends on

the application).

Manual Version Page

DB04A EN A1-9 PKP Prozessmesstechnik 18

The size of the pipe must be matched to the measuring/control device. A diameter that is

too small results in an increased pressure drop.

Check for any leaks before commissioning the devices.

For maintenance work, we recommend that a bypass system is used. This is particularly

important where the gas supply must not be interrupted.

Sealants

The design of the devices enables sealing at the ends with O-rings or flat seals. It is essential that

you avoid:

the use of sealing tape to seal threads. Small pieces can cause incorrect measurements

and control-valve malfunctions. As well as that, if the device has to be checked or

recalibrated, there will be an extra charge for the additional cleaning work.

sealing with liquid sealants will incur a higher cleaning charge for cleaning the device in an

ultrasonic tank.

3.13. Fittings and filters

We recommend fittings which are sealed with O-Rings. Than sealing agents or Teflon tape are not

necessary. Some compression fittings are available with an internal 50µ filter.

Please also consider that fittings and filters can create additional pressure drops over the flow

meter.

Please note that the length of the tread on you fitting that is screwed inside the body is for the G¼˝

no longer than 10mm (⅜”) and for the G½˝ no longer than 13mm (½˝) to avoid internal damage.

Installation

The fittings are normally supplied in pairs: they preferably should be installed with filter at the inlet

and without filter at the outlet. The fitting with a filter must be installed at the inlet (as determined by

the flow direction). The sealing rings (O-rings) must not be damaged during assembly.

3.14. Filters / Gas cleanliness

We always recommend that a filter, or at least a fine-mesh sieve (50 microns), is installed before

the measuring devices. It often happens that solid matter such as welding residues, metal or

plastic chips, rust, sealing tape, etc. affect the function.

In pressurized-air applications using compressors, the air must be dry and free of oil. Please

ensure that a suitable processing unit is located before the devices. In the case of gases from

cylinders, in general no filter is needed. For more information, see chapter 5. Maintenance.

Manual Version Page

DB04A EN A1-9 PKP Prozessmesstechnik 19

3.15. Electrical power supply

The DB04A can be provided with power from a standard AA battery or from a common USB microB charger that you typically use for the changing of your phone. There are optional modules by

which you can apply a 12 to 30 Vdc external power.

The lifetime of the battery strongly depends on the type and quality of the AA battery you use. We

recommend (and determine the specifications with) an Alkaline-Manganese Dioxide Battery with a

capacity of 3000 mAh (ANSI: 15A IEC: LR6)

Other types of batteries (for instance Zinc Carbon, Zinc Chlorine, NiCd, NiMH or Li-ion) can be

used, as long as the voltage is 1.2 to 1.8 Vdc. Using other batteries will influence the life of the

battery when used in the DB04A flow meter.

It is also possible to use rechargeable batteries, but the unit will however not charge the battery if

powered by the USB micro-B.

We strongly recommend to remove the battery from the case if you do not use the meter for longer

periods of time to avoid damage to the flow meter in case the battery starts to leak. The unit will

retain its settings so when you re-insert the battery the settings will be the same as when you took

it out. (The totalizer will be stored to the non-volatile memory once every 10 minutes, so the stored

value will never be older than 10 minutes)

There is no need to remove the battery if you connect the USB power supply. When you run the

unit on power from the USB micro-B and have a battery inserted, you can remove the USB

connector and the battery automatically takes over.

When the unit is powered by the battery you will not see the backlight to conserve energy. The

backlight is only operational when there is a power supply other than a battery.

When you replace or install a battery, all power to the unit should be disconnected.

Manual Version Page

DB04A EN A1-9 PKP Prozessmesstechnik 20

3.16. How to replace the battery?

When you replace or install a

battery, all power to the unit should

be disconnected.

The battery is in plastic compartment

mounted above the body and connected to

the main display/electronics housing. This

plastic part has 3 notches on each side. With

one hand hold the housing on the sides of

the display and with your other hand grab the

side where the plastic notches are located.

Pull the battery compartment from the main

housing. Replace the battery and push the

battery compartment back on the main

housing.

By pushing the battery compartment into

place you automatically connect the battery

to the electronics. It will take a few seconds

for the meter to start up.

You have to press the screen for about 3

seconds in order to switch the unit on.

Replacing the battery will not automatically

turn on the unit.

Inserting the battery incorrectly will not

damage the unit.

Please dispose of the

battery on an

environmental

friendly way

Manual Version Page

DB04A EN A1-9 PKP Prozessmesstechnik 21

3.17. Warm-up time

All instruments of DB04A line are ready for use within seconds of connecting the power. There is

no significant warm-up time (<5 sec).

4. Operation

4.10. Introduction

The DB04A has a touch screen based on pressure. You can operate the screen with your finger or

an object that does not create any scratches on the display.

The display has a backlight that only operates if the unit is powered by an external power source.

To start the unit, insert a battery or connect an external power supply (USB or 24 Vdc). Press the

screen for at least 3 seconds until the unit switches on. When connecting the unit to an external

power source it will be turned on automatically.

Once you switch the unit on you are able to access a menu structure with which you can adjust the

meter for your specific applications and preferences.

Before you put the unit into operation verify that the unit is suitable for your application (gas, range,

pressure and temperature). You find these details on the supplied calibration sheet. If any of these

details deviate from your application please contact the factory.

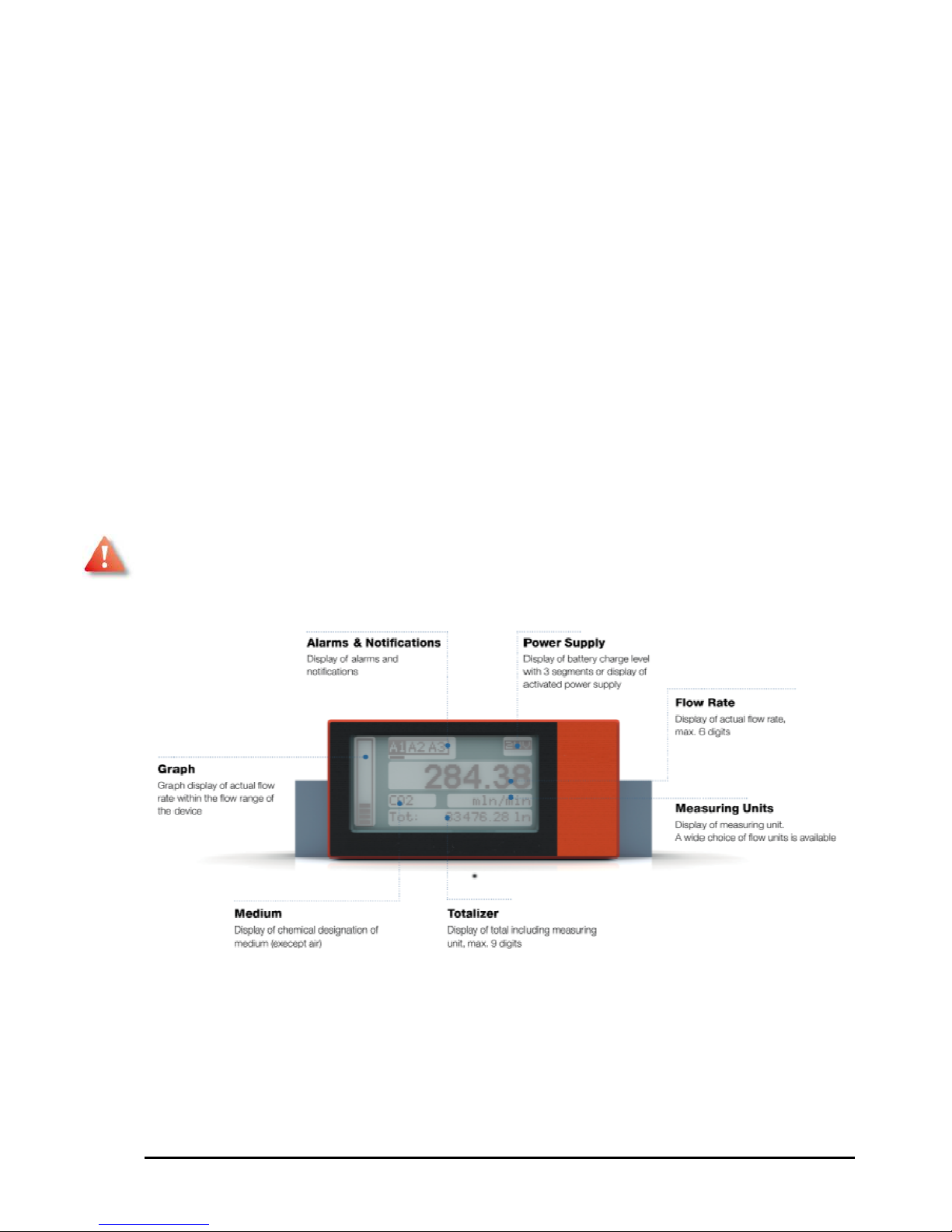

Figure 7: Display main home screen overview

4.10.1. Start-up screen

When the unit starts up, it will show a startup screen for 4 seconds (Screen name: Sensor mode).

After this screen you will see the main home screen that indicates the flow and totalized value.

On the right top you see the battery icon or the symbol for external power. The bar graph on the

left of the display represents the current flow graphically. The display also shows the selected gas

Manual Version Page

DB04A EN A1-9 PKP Prozessmesstechnik 22

and the selected measuring units. Note: If you hold the screen too long during start up, you

get into the “service mode”. Hold the display for 6 seconds to leave the service mode.

4.10.2. Display flow reading resolution

The DB04A has the ability to show the actual flow in many different engineering units. This means

that the number of digits in the readout can change a lot. In automatic resolution mode the DB04A

calculates the required number of digits depending on the range and selected units. This resolution

is however adjustable by the user (See chapter 4.12.4 Resolution)

4.10.3. Alarms and notifications on home screens

Flow Rate

If the flow is higher than 108% of the calibrated full scale, the message: “Overflow” will be

shown in the “Alarms and notification” section in the top of the screen.

If you select an engineering unit for the flow indication that has too many digits to display for

the range of the unit, the area where the flow is normally displayed, will show: “Out of

range”. Select a different flow unit in section 4.12.2 Units

Totalizer

If the totalized value exceeds the 8 available digits or you selected a totalized unit that

exceeds the current totalized flow, the totalizer will show all 9’s on it display. (9999999)

You will have to select an engineering unit for the totalizer indication that is big enough to

show all totalized flow (for instance m3n or kg). Select a different flow unit in section 4.12.2

Units

Alarm notifications

If you make use of the optional alarm module you will see the status on the main screen.

More information on the Alarm module see chapter 4.11.2 Alarm Menu.

4.10.4. Home screens and Menu access

The DB04A has customer selectable “home screens”:

•

Overview: Shows flow + flow totalizer + bar graph

•

Flow: Shows flow in big digits

•

Total: Shows the totalized flow in big digits

•

Alarms: Alarm screens 1 to 3 (or notification if no alarm module is connected)

** only active with alarm module

You can switch between the home screens by touching the screen for less than one second. It is

possible to hide screens with the display menu. (See compact manual 4.12.1.1 Home screen)

Manual Version Page

DB04A EN A1-9 PKP Prozessmesstechnik 23

Home screen 1: Screen which shows both the actual flow and the totalizer in

smaller digits. The bar graph represents 0-100% of the maximum flow range.

The A1, A2 and A3 represent the alarms and only show when you have

installed the optional alarm module.

Home screen 2: Screen which shows the actual flow.

Home

screen

3:

Screen which shows the totalized flow in big digits.

Home screen 4 to 6: Screens dedicated to the individual alarm (Each alarm

has its own page. Here you can read the main settings of an alarm. If the

alarm is activated you can reset it here if the manual reset is activated. These

screens are only relevant if the alarm module is installed.

If you touch any of the home screens longer than one second

you will access the Main Menu. You will see the screen

shown on the right.

From this menu you can modify your preferences and access

the alarm settings menu.

If you have the password activated, you have to enter your

passcode before you have access to the Main menu (See

4.12.5 Security).

4.10.5. Buttons and selection

Each menu has a name (See top inverted bar) and on the upper right you see 2 numbers (example

1/6). The first number shows which item you selected, the second number how many items there

are in the menu you selected.

At the bottom of most screens you find the inverted buttons. Meaning of buttons:

Return: Return to the previous menu. If you hold it for longer than 0.5 sec you return to

the home screen

Up/down: increase/decrease (you can also select a menu item by touching

the relevant line)

Select/confirm: Store selected value

Manual Version Page

DB04A EN A1-9 PKP Prozessmesstechnik 24

4.11. Main Menu

Below is an overview of the main menu structure.

4.11.1. Main Menu

In the main menu you have access to the Alarms, totalizer settings, gas

selection, settings, information about the status and settings of your unit. If

your unit is battery powered, it will give the option “Power off” on the bottom

line. If the unit is externally powered it will give you the option to “Reboot” the

unit.

**Alarms will be visible but if the Alarm module is not installed this menu option cannot be used.

Manual Version Page

DB04A EN A1-9 PKP Prozessmesstechnik 25

4.11.2 Alarm Menu

If you have installed the optional alarm module and once the alarm function is selected from the

main menu, you can select which of the 3 alarms (A1, A2 or A3) you want to configure. Please

note that alarm 3 has a different contact type and capacity than alarms 1 and 2 (see diagram in

2.15 Optional Modules). If an alarm has already been configured the primary function is mention

behind the Alarm (f.i. A1: flow high).

4.11.2.1 Select Alarm Menu

Once you selected A1, A2 or A3, you go into the specific alarm menu. You have the following

options:

Enable:

If you active this, the alarm becomes operational. You can

see that an alarm is enabled on any home screen. If an alarm has

been enabled the corresponding alarm name is shown underlined

(see picture on the right).

Reset: If applicable you can manually reset an alarm here (The other reset location is on

the alarm home screen). If the alarm is enabled you see a star ( ) behind the word “Reset”.

Function: With this submenu you can set the function of the alarm (Options: Flow high, low

or window and totalizer). For more details see chapter 4.11.2

Manual Version Page

DB04A EN A1-9 PKP Prozessmesstechnik 26

Configure: In this menu item you can set the details of the alarm like it alarm value(s), how

the alarm is reset, Alarms delays, hysteresis and more. For more details see chapter

4.11.2.3

4.11.2.2 Function Alarm Menu:

Under the function alarm item you define the functionality of the alarm

Flow high: with this function the alarm gets activated if the flow goes over a

predefined value set in the threshold by the customer.

Flow low: with this function the alarm gets activated if the flow is under a

predefined value set in the threshold by the customer

Flow window: with this function the alarm gets activated if the flow is outside a “Window”

that is predefined by the customer. For example if upper threshold is set to 5 and lower

threshold to 4 the alarm will get active if flow is lower than 4 or higher than 5.

Totalizer: The DB04A has 2 build in totalizer. One is permanent and non-resettable. The

second one is a resettable totalizer. You can bring it back to zero.

The totalizer alarm works with the resettable totalizer. You enter a value in the threshold

and once that value is reached the alarm goes on.

4.11.2.3 Configure Alarm Menu:

Once you defined the function of an alarm you can define the details of the operation in this menu

Numerical entry screen: If you have to enter numeric values (Like an alarm value

(Threshold)) you will see a little keyboard on the screen where you can enter a numerical

value.

Manual Version Page

DB04A EN A1-9 PKP Prozessmesstechnik 27

The decimal point is located behind the number display field. Once you entered a decimal

point followed by another number, the dot changes into an “E”. If you press this you can

enter the scientific notation, for instance 1.0E-3 = 0.001 or 2.2E2=220.

Threshold: Threshold is the activation value. If f.i. you selected a high alarm, the alarm will

be active when the flow value comes over the Threshold value. The value is entered in flow

engineering values that the unit is set for at that moment (f.i. in mln/min). If you change the

engineering units of the unit in a later stage, the Threshold value will automatically adjust

itself to the new flow unit.

Please note that there is no limit to the value you can enter as a threshold. Please

double check your entered value.

Hysteresis: The hysteresis

is the difference between

the value where the alarm

turns ON from turning OFF

and the value where it turns

OFF from turning ON.

This difference is defined in

% of full scale. In figure 9

an example of a 50%

threshold value high alarm

with a 10% hysteresis. The

blue line in the top graph

reflects the gas flow, the

vertical dotted lines the

switching points.

The blue area’s in the

graph below is where the

alarm is activated.

The reset is set to

automatic.

Please note that you can enter a value of 100% as hysteresis value. If you do that the

alarm will no longer switch off.

Alarm delay: The alarm delay is a delay in milliseconds between the moment the alarm

situation occurs to the moment that the alarm is activated. It can be set from 20 to 9999999

msec (=2.777 hr).

Alarm duration: (Note: This function is only active if the reset is set to automatic)

The alarm duration is minimum time that the alarm is active after it is activated. It can be set

from 100 to 9999999 msec (=2.777 hr)

Reset source: The alarm can be reset in different ways. Below a list of the 4 possible

settings:

Figure 8: Explanation hysteresis

Manual Version Page

DB04A EN A1-9 PKP Prozessmesstechnik 28

Automatic: The alarm is reset the moment the alarm situation is no longer valid.

This unless you programmed an alarm duration. For a totalizer alarm this setting will

reset the totalizer as soon as the threshold has been exceeded.

Manual: The alarm stays active until you manually reset the alarm through the touch

screen of the flow meter.

Input 1: The alarm stays active until you activate input 1

Input 2: The alarm stays active until you activate input 2

Reset trigger: (Note: this function only relates to alarm reset by input 1 or 2).

When you use input 1 or 2 as an alarm reset, you can set exactly on

which action the alarm is reset. If for example the input is a manual

push button, the rising edge is the moment that you push the button

and the falling edge the moment when you let go of the push button.

Please note that the reset overrides the alarm. Even if the alarm is

still valid, if you set this reset trigger to high level, the alarm is ignored until the level

becomes low again.

If the blue represents the input being active you can see the different trigger points below.

Output driver: the output driver setting offers the possibility to invert the action from the

alarm switch and set the alarm to a predefined state which is convenient for testing systems.

The “Always low” and “Always high” override all alarm settings and flow signals. Please

make sure that you take precautions before you use these options in a “life” system.

4.11.3. Totalizer

The totalizer calculates how much gas has totally passed through the flow meter based on the

measured flow and the factor time. The instrument has 2 totalizers. Each can display a maximum

Figure 9: Explanation trigger points

Manual Version Page

DB04A EN A1-9 PKP Prozessmesstechnik 29

of 8 digits. The totalizer value will be stored internally as a IEEE 754 floating point number. The

internal totalizer will never roll-over, the maximum value far exceeds the lifetime of the instrument.

One of the two totalizers is resettable, the other can never be reset and always continues to count

for the lifetime of the instrument. Both the totalizer values are stored every 10 minutes in a

permanent memory so even if there is no power supply the last stored value will still be kept. If you

apply power again the saved value will be restored (Unless you activated the “reset on start”

feature).

Please note that if the flow rate exceeds the full scale of the unit (overflow), the totalized value will

not be correct. Even if there is an overflow the totalizer operation will continue normally. However

since the flow value is limited the totalizer is totalizing the limited flow value only.

If the totalizer value exceeds the possible 8 digit display, you can set the totalizer engineering units

to a suitable unit that can display the value within the 8 digits, for instance m3n or kg. See section

4.12.2 Units.

Resettable

Non-Resettable□

□

-> N: 123456 ln

-> R: 1.23 ln

> Read

> Home screen view

> Reset

Reset totalizer?

Reset manual

Reset on start

□

Reset: Reset the resettable totalizer to zero

Reset manual: Select this option to manually reset the resettable totalizer

Reset on start: Activate this option if you want that the resettable totalizer is set to zero every

time you switch the unit on. Please note: Upon startup the totalizer will be silently reset without

asking for confirmation. It simply resets the resettable totalizer to zero every time you switch

the unit on.

Remark: With the alarm module it is possible to reset the totalizer with an external remote switch

or signal.

Read: Read the totalizers (for instance in-case you only activated the flow screen).

N: is the non-resettable totalizer, R: is the current value of the resettable totalizer.

Home screen view: Here you can select if you want to read the Non-resettable or Resettable

totalizer on the main screen.

Manual Version Page

DB04A EN A1-9 PKP Prozessmesstechnik 30

4.11.4. Gas selection

The DB04A can store up to 3 different curves for different gases or gas

mixtures in its memory. If you have ordered more than one gas when you

purchased this unit, you can select the required gas here. The locations

that do not have a gas programmed are marked with “N/A”.

Behind the gas name you see the maximum flow you can measure in

your selected units.

4.11.5. Settings

In this menu you can adjust your preferences. See section 4.12 Settings for

details.

4.11.6. Info

Info brings you to menu that informs you about the current configuration of the unit. When you

select “Software” under the Info menu you can see the current firmware version and the date that

this version was released.

Under “Configuration” you see the active settings for the flow and the totalizer. The temperature

and pressure refer to the reference conditions for the selected flow units. (See 1.15 Real,

Standardized and Normalized flow)

4.11.7. Reboot or Power off

If your unit is battery powered, it will give the option “Power off” in the main

menu. You can switch the unit on again by touching the display for 3

seconds.

If the unit is externally powered it will give you the option to “Reboot” the

unit. “Reboot” restarts the unit. If you select one of these options the unit will ask you to confirm

your selection.

> Units

> Filter

> Display

> Security

Factory reset

> Battery auto off

> Resolution

Manual Version Page

DB04A EN A1-9 PKP Prozessmesstechnik 31

4.12. Settings

In the settings menu you can adjust the user variables. See the chapters

below for more details.

4.12.1. Display

In the display menu you can configure the settings for the display

4.12.1.1. Home screen

There are 6 different home screens (See chapter 4.10.4 Home screens)

and in this menu you can deactivate up to 5 of the home screens.

Deactivated screens do not show up as a home screen

4.12.1.2. Backlight

In this menu you can select the brightness of the backlight. The backlight is

only available if you use an external power (USB or 24 Vdc).

4.12.1.3. Orientation

The screen can be orientated upside down (180 degree turned). If this

menu is set to Auto, the unit will do this automatically. A sensor

determines it’s orientation. The sensor can be overridden with the 0 or

180 degrees settings. This is very convenient if you want the gas inlet to

be on the right side of the flow meter.

Manual Version Page

DB04A EN A1-9 PKP Prozessmesstechnik 32

4.12.1.4. Display auto off

The display can be set to switch off after a defined time following your last

touch event. If you set the “Display auto off” to “Disabled”, the display stays

on till the power is switched off. When the display is switched off, the

backlight will also switch off. The totalizer is still working.

You can activate the display again by touching it.

4.12.1.5. Light auto off

In this menu you can define a time before the backlight automatically

switches off (after the last touch event). The backlight goes on again when

you touch the display. When the setting is “Disabled” the light is

continuously on.

When the backlight is switched off you can still read the display. The

backlight only works if there is an external power connected. On battery

power supply the backlight is not operational.

4.12.2. Units

In the Units menu you can set the required engineering units for the totalizer and the flow indication.

If there is a unit selected with too many digits, the device will show: “Out of range” on the display.

If you select a totalizer unit that would create too many digits the totalizer will show 9999999.

Manual Version Page

DB04A EN A1-9 PKP Prozessmesstechnik 33

Low

Off

Medium

High

□

□

□

□

Very high

□

Maximum

□

Low

Off

Medium

High

□

□

□

□

Maximum

□

> Dynamic

> Averaging

More information in section 4.10.3 Alarms and notifications on home screens

For more information on “normal” and “standard” flow units see chapter 1.15 Real, Standardized

and Normalized flow of this manual.

4.12.3. Filter

With the filter settings you adjust the reading of

quickly changing flows. The filter basically averages

the readings from the sensor. More information can

be found in chapter 2.22 Filter Settings.

There are two separate filters that are adjustable and

independent of each other.

Dynamic and Averaging filter:

Dynamic

Filter:

The dynamic filter will increase the number of

readings that are averaged when the flow is less

dynamic and decrease the number of readings that

are averaged when the flow shows quick changes. So when the flow is quickly rising or falling it

will take less averages in it calculations. On this way the unit will react faster to changes in the

flow.

Averaging filter:

The averaging filter is a “moving average filter”. It calculates the average value of a number of

measurements and shows the average on the display. As you increase the filter setting from off

to maximum, you increase the number of measurements the average is calculated from.

Before you apply higher filter values, please try to identify the cause of the flow pulsations. This

could be a compressor, pressure amplifiers, incorrectly sized fittings, non-return valves or pressure

regulators. Sometimes creating more “dead volume” before of behind your flow meter could solve

the problem.

Manual Version Page

DB04A EN A1-9 PKP Prozessmesstechnik 34

4.12.4. Resolution

In this menu you can adjust the resolution of your flow and totalizer values

shown on the display.

The DB04A has the ability to show the actual flow and the totalizer in

many different engineering units. This means that the number of digits in

the readout can change a lot. In automatic resolution mode (menu option

"Auto") the number of digits are computed depending on range and

current selected unit.

The minimum number of digits is 4, the maximum 6 (Excluding the

decimal point). Below you find the table on how many digits will be visible

in this auto mode.

Notes:

1. Because the value is right-aligned, it is possible that depending on the actual flow you can

see a change in the number of digits behind the decimal point. For example if the flow is

changing from 2 to 2.01 and then 2.1 you can see: 2.0, 2.01 and 2.1 on the display.

2. If the maximum number of digits is exceeded you see out of range on the display. In that

case select another unit (see chapter 4.12.2 Units).

3. The step size in auto mode between each reading is depending on the range but it is

always well within the accuracy of the flow meter. For other setting mentioned below, this

does not have to be the case.

The other settings are the minimum step that the value will take between values.

Example: If you have a flow of 189.673 mln/min than the unit will show 189.6 in auto mode.

When selecting the other settings you would see:

Resolution setting Flow Displayed Remarks

0.0001

189.673

189.673

The display cannot show more than 6 digits

0.001 189.673

0.01 189.67

0.1 189.6

auto 189.6

1 189

10 180

100 100

1000 0.0

10000 0.0

Range Examples display values Display resolution

from until from until

0.01 0.09 0.01 0.09999 0.00001

0.1 0.9 0.1 0.9999 0.0001

1 9 1 9.999 0.001

10 99 10 99.99 0.01

100 999 100 999.9 0.1

1000 9999 1000 9999 1

10'000 99'999 10'000 99'990 10

100'000 999'999 100'000 999'900 100

Manual Version Page

DB04A EN A1-9 PKP Prozessmesstechnik 35

Note: The numbers are not rounded off, but they are made invisible (also called a floor function)

The totalizer and the bar graph will not be effected by this setting and will also work based on the

real high resolution flow.

4.12.5. Security

To avoid the unauthorized changing of settings in the menu, it is

possible to protect the menu with a self-defined password. If you

enable this option you first have to enter a 4-digit numeric password to

gain access to the menus. In this setting you can also define that

password. You can only activate the password after you have defined

your own personal password under “Set password”

If you forget or lose your password, please contact the factory at:

info@pkp.de

4.12.6. Battery auto off

To extend the battery life to the maximum we recommend that you set

this menu so that, when powered with a battery, the DB04A will switch off

automatically after the indicated number of minutes. Please note that this

menu has no effect if the unit is powered by USB or the external 24 Vdc.

Once the unit is switched off it no longer totalizes the flow.

Note: When we supply the unit, the “auto power off” will be set to 15 minutes

4.12.7. Factory reset

If you activate the factory reset, all variables will be reset to the factory

default (for instance the password protection will be disabled). The

continuous totalizer, however, keeps its value. Only the resettable totalizer

gets reset to zero. The reset takes about 30 seconds.

5. Maintenance

When operated properly and with the use of clean and dry gas, DB04A devices do not require any

routine maintenance. There are no internal moving parts in the measurement part of the device.

However, we recommend that the calibration is checked after 12 months. If your DB04A is still

within tolerance, this time interval can be extended. The timing of the periodic check is the

customer's responsibility.

5.10. Cleaning to remove contamination

Depending on the type of contamination, on-site cleaning of the measuring or control device may

be possible. As a first step, we recommend flushing with N2or dry air. If it is contaminated with

liquids (ex. oil), pure methanol alcohol (100%) can be used. After cleaning, rinse the DB04A with

the optional needle valve position fully open with dry air or nitrogen for approximately 15 minutes to

dry out all liquids.

Manual Version Page

DB04A EN A1-9 PKP Prozessmesstechnik 36

Notes:

The

warranty

is

null

and

void

if

the

housing

was

removed.

Only use the proper tools.

Be careful when handling the device and the individual components.

Make sure that the disassembly environment is clean.

Do not touch the circuit board or electronic components without first grounding yourself

and the surroundings. Electrostatic discharges can destroy components.

After cleaning, you should have the device checked or, if necessary, recalibrated by

PKP at the next opportunity.

5.11. Returns

When returning a DB04A please insure suitable packaging. Please contact us before you return

the unit to us. To repair the unit we require a detailed and accurate description of the problem, the

required service and the possible causes of the faults. You can contact us at: info@pkp.de

Note:

If the device has come into contact with aggressive or toxic gases, please ensure that it is properly

cleaned/flushed before returning the device to us. Please always complete the contamination

declaration form. You will find these in the appendix or in the enclosed CD and in this manual, see

section 6.17 Contamination Statement.

Manual Version Page

DB04A EN A1-9 PKP Prozessmesstechnik 37

6. Appendix

6.10. Troubleshooting

In the following table we have compiled fault symptoms, their possible causes and suitable

measures you can take. If you do not recognize your fault symptom, or the proposed measures

were not successful, please consult PKP.

If you are planning to return a product, please refer to the chapter 5.11 Returns.

If you have to remove the measuring or control device from the pipeline, please observe any

flushing procedures and the relevant safety guidelines. You will find a guide on how to remove and

clean the devices in the chapter 'Operation and Maintenance'.

Error Possible causes Measures

Output indicates high flow

continuously

Flow is too high

(Overflow)

Reduce the flow rate. If necessary, the full scale

can be extended. Please consult PKP

Device is heavily contaminated Please consult PKP

Sensor faulty Please consult PKP

Flow is shown despite

zero flow.

Sensor contaminated Please consult PKP

The device is being operated with a

different gas from its calibration.

For multi-gas instruments, you can set the

appropriate gas type

Offset due to mounting position Particularly with small measurement ranges,

heavy gases and gauge pressures > 5 bar, a

zero-point offset can occur where the mounting

position is vertical >> chimney effect. Where

possible, mount the device horizontally

The manual valve is

leaking

Contaminated valve Flush the valve repeatedly with clean dry

nitrogen

Meter does not indicate

the expected value.

Leakage Flow rate > than reference:

Leakage between measuring device and your

reference

Flow rate < than reference:

Leakage upstream of the measuring instrument

Contamination With contamination by sealing tape, for example,

it is possible that the flow divider is partially

blocked. In this case the device displays more

than the reference. Please consult PKP.

The device is being operated with a

different gas than calibrated.

Connect the intended gas, or change the type of

gas in the 'Calibration' menu

Different reference conditions Verify “Normal” or “Standard” conditions

Inlet pressure is too low Check your inlet and outlet pressures

Pressure drop too high Check for blockage or polution. Check fittings ID

Manual Version Page

DB04A EN A1-9 PKP Prozessmesstechnik 38

Error Possible causes Measures

Unit, backlight or display

unexpectedly switched off

Battery empty Replace battery

Menu settings incorrect Adjust the auto off menu’s

Unit always enters service

mode when switched on

Firmware damaged Perform a firmware upgrade as described in this

manual. If the problem remains please consult

PKP.

Out of Range Wrong unit selection Select a unit that fits better to the current flow.

Forgot Password Contact the factory or distributor Please consult PKP

Totalizer shows 9999999 Overflow totalizer units Select a different unit (try m3n or kg)

If you need any support please contact us by e-mail through Customer Service:

info@pkp.de

Manual Version Page

DB04A EN A1-9 PKP Prozessmesstechnik 39

6.11. Pressure loss

The following figures show examples of the pressure drop of a DB04A (measuring instrument only,

not the valve)

Please note that the curves below are as an indicator only and based on atmopheric outlet

pressure. Especially when the outlet is under vacuum, the pressure drop can be higher.

Heavier gasses like Argon will greate more pressure drop, lighter gasses like helium will create

less pressure drop.

Manual Version Page

DB04A EN A1-9 PKP Prozessmesstechnik 40

Manual Version Page

DB04A EN A1-9 PKP Prozessmesstechnik 41

6.12. Dimensional drawings ¼” in mm

Units with ¼” BSP process connections

“P” referes to the optional fittings length. Fittings are options only. Standard process connection is

female ¼” BSPP tread.

If additional information is needed, please consult PKP.

Manual Version Page

DB04A EN A1-9 PKP Prozessmesstechnik 42

6.13. Dimensional drawings ¼” in inches

Units with ¼” BSP process connections

“P” referes to the optional fittings length. Fittings are options only. Standard process connection is

female ¼” BSPP tread.

If additional information is needed, please consult PKP.

Manual Version Page

DB04A EN A1-9 PKP Prozessmesstechnik 43

6.14. Dimensional drawings ½” in mm

“P” referes to the optional fittings length. Fittings are options only. Standard process connection is

female ½” BSPP tread.

If additional information is needed, please consult PKP.

Manual Version Page

DB04A EN A1-9 PKP Prozessmesstechnik 44

6.15. Dimensional drawings ½” in inches

Units with ½” BSP process connections

“P” referes to the optional fittings length. Fittings are options only. Standard process connection is

female ½” BSPP tread.

If additional information is needed, please consult PKP.

Manual Version Page

DB04A EN A1-9 PKP Prozessmesstechnik 45

6.16. Wetted parts DB04A series

Instrument

InstrumentInstrument

Instrument

Ger

GerGer

Geräääätttt

DB04A

DB04ADB04A

DB04A series

seriesseries

series

Body

Grundkörper

1.4404 (316L) or aluminium

Body: O-Rings

Grundkörper: O-Ringe

FKM (Standard), EPDM (option)

Flow divider

Strömungsteiler

1.4305

Control valve

Regelventil

1.4305/1.4105/1.6908

Control valve: O-Rings

Regelventil: O-Ringe

FKM (Standard), EPDM (option)

Sensor material

Sensormaterialien

Silicon, silicon oxide, silicon nitride

Silizium, Siliziumoxid, Siliziumnitrit

Epoxy

Sensor packaging 1.4305

Abbreviation

AbbreviationAbbreviation

Abbreviation

Kurzbezeichnung

KurzbezeichnungKurzbezeichnung

Kurzbezeichnung

Designation

DesignationDesignation

Designation

Bezeichnung

BezeichnungBezeichnung

Bezeichnung

Remarks

RemarksRemarks

Remarks

Bemerkunge

BemerkungeBemerkunge

Bemerkunge

nnnn

EPDM –

Ethylene-propylene-diene-monomer rubber

Ethylen-Propylen-Dien-Kautschuk

Epoxy –

Adhesive for sensor fixation, protection for wire bonding

Klebstoff für Sensorfixierung, Schutz für Bonddrähte

FKM –

Fluor rubber

Fluor-Kautschuk

For units with EPDM O-rings it is possible to get a FDA compatible materials statement. Please

contact the factory or your local distributor for additional information.

Manual Version Page

DB04A EN A1-9 PKP Prozessmesstechnik 46

6.17. Contamination statement

When returning equipment to us, please complete all sections of the following declaration. In

particular, the reason for return, in the case of contamination the nature of the residues and

the cleaning, as well as information on any possible hazards. Include this with shipment.

Device(s)

Model code:

Serial number(s):

Reason for return:

Type of contamination

Device was in contact with:

It was cleaned by us with:

To protect our employees and for general safety during transport, it is vital to clean devices

properly and to use appropriate packaging.

Can you provide further

information on the

contamination?

Inert (no hazard)

Corrosive

Caustic/acid

Must not come into contact with moisture

Oxidizing

Toxic

Other hazards: ___________________________

Legally binding declaration

We hereby confirm the correctness and completeness of the above information.

Company:

Address:

Phone:

Contact person:

e-mail address:

Date:

Signature:

Manual Version Page

DB04A EN A1-9 PKP Prozessmesstechnik 47

6.18. Overview Default settings

No. Group Subgroup Name Options Default Remarks

1 Totalizer Home screen view Non- Resettable

Resettable

2 Gas selection Gas 1

Gas 2

Gas 3

1)

3 Settings Display Home screens

(multiple choice)

Overview

Flow

Totalizer

Alarm (A1)

Alarm (A2)

Alarm (A3)

4 Settings Display Backlight 0% (Off)

20%

40%

60%

80%

100% (Max)

5 Settings Display Orientation Auto

0 degree

180 degree

6 Settings Display Display auto off Disabled

1 minute

3 minutes

5 minutes

15 minutes

30 minutes

7 Settings Display Light auto off Disabled

5 seconds

10 seconds

30 seconds

60 seconds

120 seconds

8 Settings Units Flow Custom 2)

9 Settings Units Totalizer Custom 2), 3)

10 Settings Filter Dynamic filter Off

Low

Medium

High

Very high

Maximum

11 Settings Filter Averaging filter Off

Low

Medium

High

Maximum

12 Settings Resolution Flow 0.0001

0.001

0.01

0.1

Auto

1

10

100

1000

10000

Manual Version Page

DB04A EN A1-9 PKP Prozessmesstechnik 48

13 Settings Resolution Totalizer 0.0001

0.001

0.01

0.1

Auto

1

10

100

1000

10000

14 Settings Security Enable password

15 Settings Battery auto off Disabled

15 minutes

30 minutes

60 minutes

1)

If ordered for air or N2or O2and the unit is calibrated with air and all have the same operating conditions,

range and dynamics, all these 3 gasses will be programmed. The gas is set default on the customer

ordered gas.

2) The reference condition of all units under “Real and Norm” are always 0⁰C and 1013.25 mbara. (Both for

the totalizer and flow units). The reference conditions of all “Other Units” are always defined at the time

of ordering.

3) If no units are specified for the totalizer, it is set it the same as the main unit without the time factor. For

example: ln/min becomes ln, kg/hr becomes kg, etc. The totalizer unit can be changed by the user

anytime. See 4.11.3 Totalizer and 4.12.2 Units.

Flow Measurement an Monitoring

DB04A

Thermal Mass Flowmeter for

Gases without Auxiliary Power

• pressure and temperature

independent measurement

• range: 0,001...450 Nl/min

• indication of flow and total consumption

(totalisator integrated)

• compact design, no need for straight

pipe runs

• touch display for intuitive navigation

• optional with valve, limit switch

• high accuracy +/- 1 %

• battery operated (AA) – no external

power supply needed

Description:

The DB04 thermal mass flowmeter is a modular system for

the measurement of the flow of gases. Due to its being

independent of any power supply because of its integrated

battery, and its excellent cost-effectiveness, the device can

replace conventional variable area flowmeters in many cases.

The DB04 can be supplied in a number of versions:

as a flowmeter with an integrated regulating valve, a totaliser

or with an adjustable limit switch. Depending on the medium,

the device can be made of either stainless steel or aluminium.

The convenient LCD-touch display combines a clear

indication with an easy an self-explanatory programing. The

device operates in any position and can be easily cleaned

without the need for recalibration.

Typical applications:

The DB04A measures flow rates from 0,001...0,05 Nl/min to

9...450 Nl/min.

The standard calibration medium is air, but a large number of

other gases can be measured as well: O2, N2, He, Ar etc.

Because of the totalisator the device can be perfectly use for

consumption measurement of the gases.

PKP Prozessmesstechnik GmbH

Borsigstr. 24 • D-65205 Wiesbaden

S +49 (0) 6122-7055-0 • +49 (0) 6122 7055-50

info@pkp.de • www.pkp.de

PKP Process Instruments Inc.

10 Brent Drive • Hudson, MA 01749

S +1-978-212-0006 • +1-978-568-0060

info@pkp-usa.com • www.pkp-usa.com

180618

Models:

DB04A.1: Mass flowmeter, battery operated

DB04A.2: Mass flowmeter, battery operated

with integrated manual regulating valve

DB04A.3: Mass flowmeter

24 VDC voltage supply

with 3 integrated limit contacts

DB04A.4: Mass flowmeter

24 VDC voltage supply

with manual regulating valve and 3 integrated

limit contacts

Technical Data:

Pressure:

0,2...11 bar abs.

Medium temperature:

0...50 °C

Media:

air, O2, N2, He, Ar Co2 H2 CH4, C3H8

(others on request)

all devices are delivered free from oil

and grease (wetted parts)

Gas/Calibration:

up to 3 Gas/calibrations (optional)

Gas connection:

G ¼ female up to 60 Nl/min

G ½ female up to 450 Nl/min

Accuracy:

(air)

+/- 2 % of full scale,

> 200 Nl/min: +/- 3 % of full scale

optional: +/- 1 % of full scale

(up to 50 Nl/min)

Dynamic:

(measuring range)

1:50,

optional 1:100 (up to 50 Nl/min)

Response time:

500 ms

Repeatability:

+/- 0,5 % of measured value

Power supply:

standard battery AA

micro-USB supply

optional: external supply

12...30 VDC (max. 200 mA)

(standard at devices with limit switch)

2 m cable

Display:

touch display 128x64 px

background light (not at battery

operated use)

Units/scale:

free selectable

Password protection:

for menu available

Installation position:

up to 5 bar: any

from 5 bar: horizontal

Limit output:

potential-free changer (24 V, 1 A)

Function:

MIN or MAX-alarm, switching point,

delay, hysteresis programmable

Protection class:

IP50

Alarm contacts:

3 alarm contacts: 2 n/o: max. current: 0,5 A

max. voltage: 30 VDC

1 spdt: max. current: 1 A

max. voltage: 30 VDC

power supply: 12...30 VDC,

with reverse-pole protection

2 optical separated input chanels:

voltage range: 5...30 VDC, at 5 mA max.

Including 2 m cable connection

Measuring ranges for air and dimensions:

(Standard accuracy and dynamic)

Range

[Nl/min]

Connec-

tion

[G female]A[mm]B[mm]C[mm]D[mm]

0,001...0,05 1/4 114 44 25 44

0,004…0,2 1/4 114 44 25 44

0,01…0,5 1/4 114 44 25 44

0,04…2 1/4 114 44 25 44

0,1…5 1/4 114 44 25 44

0,4…20 1/4 114 44 25 44

0,8...40 1/4 114 44 25 44

1…60 1/4 114 44 25 44

2…100 1/2 160* 54 35 54

4…200 1/2 160* 54 35 54

6…300 1/2 160* 54 35 54

9...450 1/2 160* 54 35 54

refering to 20 °C and 1000 mbar

* 270 with flanged hand valve

Dimensions:

PKP Prozessmesstechnik GmbH

Borsigstr. 24 • D-65205 Wiesbaden

S +49 (0) 6122-7055-0 • +49 (0) 6122 7055-50

info@pkp.de • www.pkp.de

PKP Process Instruments Inc.

10 Brent Drive • Hudson, MA 01749

S +1-978-212-0006 • +1-978-568-0060

info@pkp-usa.com • www.pkp-usa.com

Durchfluss

Materials:

DB04A.x.x.A: housing made of aluminium, anodised,

sensor made of PBT, sealing made of FKM

DB04A.x.x.E: housing made of st.st 1.4404,

electropolished,

sensor made of PBT, sealing made of FKM

Options:

• special measuring ranges

• other media as air, Nitrogen, Oxygen

• sealings EPDM

• power supply 24 VDC for DB04A.1./2.

• high accuracy +/- 1 % of f.s., dynamic: 1:100

• up to 3 types of gases calibrated

• calibration certificate

G 1/4 female connection with regulating valve

G 1/2 female connection, with flanged regulating

valve

G 1/4 female connection, without regulating valve

Order Code: