PixelVision, Inc. PMD-004-00012-00

Rev: C

SPECTRAVIDEO

™

CAMERA USER’S MANUAL

DOCUMENT CHANGE NOTICE

REV DATE DCN ORIGINATOR SUMMARY OF CHANGES

A 2/8/98 n/a T. Nebeker Original Document

B 4/15/99 n/a T. Nebeker Updates/Edits

C 2/15/00 n/a T. Nebeker Updates/Edits

S

PECTRAVIDEO™ CAMERA

USER’S MANUAL

LIMITED WARRANTY

PixelVision of Oregon, Inc. warrants that The SpectraVideo™ series of cameras

(the “camera”) will perform essentially in accordance with the accompanying

documentation for a period of one (1) year from date of receipt. If there are

physical defects in workmanship or materials in the camera or documentation that

are not associated with normal use and service, PixelVision, Inc. will replace or

repair camera or documentation free of charge within the period of one (1) year

from the date of receipt. The limited warranty is void if failure of the camera has

resulted from accident, abuse or misapplication on the part of the user.

If the camera must be returned to PixelVision, Inc. for replacement or

repair, it must be packed in its original material, as it was shipped to you.

The limited warranty may be voided if the camera is not returned in its

original packing material.

Some states do not allow exclusions or limitations of implied warranties, so the

above limitations or exclusions may not apply to you. This warranty gives you

specific legal rights and you may also have other rights that vary from state to

state.

DAMAGE DISCLAIMER

At no time will PixelVision, Inc. be liable for direct, indirect, incidental or

consequential damage to hardware or software, loss of business profits, loss of

clients (potential and existing) or loss of information arising from the use or

inability to use the SpectraVideo™ series cameras, PixelView™ software program

or pertaining documentation. PixelVision, Inc. has no liability for any data stored

or processed with this software, including any costs for recovery of such data.

Copyright © 1998 PixelVision of Oregon, Inc. All Rights Reserved PMD-004-00012-00 Rev. C

Table of Contents

1. INTRODUCTION............................................................................................ 1

2. GENERAL DESCRIPTION OF CAMERA............................................................ 2

2.1. DIGITAL DATA ACQUISITION BOARD....................................................................3

2.2. PIXELVIEW SOFTWARE.......................................................................................3

2.3. SOFTWARE DEVELOPER’S KIT............................................................................3

2.4. SYSTEM REQUIREMENTS....................................................................................3

3. SPECTRAVIDEO CAMERA SETUP ................................................................. 5

3.1. PRECAUTIONS ...................................................................................................5

3.2. SETUP ..............................................................................................................5

3.3. SPECTRAVIDEO FAMILY GENERAL SPECIFICATIONS.............................................9

4. CAMERA EXPOSURE CONTROL.................................................................. 10

4.1. EXTERNAL EXPOSURE CONTROL ......................................................................10

4.2. SOFTWARE TRIGGERED EXPOSURE CONTROL ...................................................11

5. ANALOG SIGNAL PROCESSING BOARD ...................................................... 12

5.1. OVERVIEW.......................................................................................................12

5.2. ANALOG SIGNAL PROCESSING BOARD CONNECTIONS........................................12

5.2.1. GAIN SELECTION .........................................................................................................12

5.2.2. ANALOG OUTPUT ........................................................................................................13

5.2.3. BOARD TO BOARD SIGNAL CONNECTIONS .....................................................................14

5.2.4. DIGITAL INPUT/OUTPUT................................................................................................15

5.2.5. RS232 INPUT..............................................................................................................15

6. DIGITAL CONTROL BOARD ........................................................................ 17

6.1. OVERVIEW.......................................................................................................17

6.2. TIMING SEQUENCE...........................................................................................17

6.2.1. FLUSH MODE ..............................................................................................................18

6.2.2. EXPOSURE MODE ........................................................................................................19

6.2.3. AFTER EXPOSURE MODE..............................................................................................19

6.2.4. READOUT MODE..........................................................................................................19

6.2.5. CLOCKING PARAMETERS..............................................................................................19

6.2.6. DIGITAL CONTROL BOARD CONNECTIONS......................................................................19

6.2.6.1. Scope Triggers...............................................................................................................................................19

6.2.6.2. Control Input/Output .....................................................................................................................................20

6.2.6.3. Analog to Digital Board Connections .........................................................................................................20

6.2.6.4. Socket Board Signals....................................................................................................................................21

7. SERIAL INTERFACE BOARD ....................................................................... 22

8. SHUTTER AND COOLING CONTROL BOARD................................................. 24

9. DATA ACQUISITION BOARDS ..................................................................... 25

9.1. LYNXPCI DATA ACQUISITION BOARD................................................................25

SpectraVideo Camera User’s Manual Table of Contents

9.1.1. FEATURES ..................................................................................................................25

9.1.2. GENERAL DESCRIPTION ...............................................................................................25

9.1.3. ARCHITECTURE ...........................................................................................................26

9.1.4. GENERAL SPECIFICATIONS ...........................................................................................27

10. BOARD TO BOARD ELECTRICAL CONNECTIONS ..................................... 28

11. SOFTWARE DEVELOPMENT................................................................... 29

11.1. SPECTRAVIDEO SERIAL PORT INTERFACE.........................................................29

11.1.1. REBOOT COMMANDS ...................................................................................................30

11.1.2. REGION OF INTEREST (ROI) IMPLEMENTATION................................................................30

11.1.3. COMMAND SUMMARY...................................................................................................31

12. SUPPORTING SOFTWARE...................................................................... 34

12.1. COMMTEST

12.2. PIXLOAD

12.2.1. TEXT FILE FORMAT......................................................................................................35

12.2.2. SAMPLE TEXT FILE ......................................................................................................36

™

SOFTWARE USER’S GUIDE...........................................................34

™

SERIAL PORT CONTROL SOFTWARE.................................................35

13. APPENDICES........................................................................................ 38

13.1. APPENDIX A....................................................................................................38

13.1.1. HEAD ASSEMBLY MECHANICAL DRAWING......................................................................38

13.2. APPENDIX B....................................................................................................39

13.2.1. CAMERA CONTROL BOX MECHANICAL DRAWING............................................................39

13.3. APPENDIX C....................................................................................................40

13.3.1. SPECTRAVIDEO 1 CAMERA LOW LEVEL COMMAND SUMMARY .........................................40

13.3.2. DSP CONTROL OUTPUTS.............................................................................................43

GLOSSARY OF ACRONYMS AND TERMS........................................................... 44

INDEX OF CONTENTS...................................................................................... 46

SpectraVideo Camera User’s Manual Table of Contents

1. I

NTRODUCTION

The SpectraVideo™ series of high performance, charge-coupled device (CCD)

cameras, manufactured by PixelVision, Inc., offer excellent sensitivity and low

noise throughout the visible and ultra-violet spectral regions. The affordable

SpectraVideo series cameras use Scientific Imaging Technologies, Inc. (SITe)designed CCDs. The camera’s back-illuminated CCD detector has as high as

ninety-nine percent quantum efficiency in the visible spectral region.

An optional ultra-violet, anti-reflective coating allows for excellent sensitivity

throughout the visible and ultra-violet spectral regions.

Thinned, back-illuminated CCDs overcome the performance limits of the

conventional front-illuminated CCDs by illuminating and collecting charge

through the back surface away from the polysilicon gate electrodes on the front

surface. The image photons enter the CCD back surface unobstructed, allowing

for high quantum efficiency visible and ultra-violet light detection. Software gain

and shutter control allow variable exposure, binning, region of interest (ROI) and

timing.

The camera is delivered with a head assembly, camera control box, data

acquisition board and PixelView™ (PixelVision, Inc.’s easy-to-use Microsoft

Windows®-based software package). The head assembly and camera control box

provide all of the necessary circuitry to operate the CCD array and provide low

noise signals to the computer interface. A LynxPCI™ data acquisition board

acquires the images. The detector head is adaptable to most popular lens mounts,

with an ‘F’ mount standard. Exposure, temperature, gain and pixel binning are

controlled using PixelView.

SpectraVideo Camera User’s Manual Introduction

1

2. G

0000000000000000000000000000000000000000000000000000000000000000

0000000000000000000000000000000000000000000000000000000000000000

0000000000000000000000000000000000000000000000000000000000000000

0000000000000000000000000000000000000000000000000000000000000000

0000000000000000000000000000000000000000000000000000000000000000

ENERAL DESCRIPTION OF CAMERA

The SpectraVideo series camera is a two-piece camera design. A schematic

representation of the camera is shown in Figure 1 The CCD, thermoelectric

cooler, and pre-amplifier are all contained in the head assembly. The amplified

output of the CCD is transmitted over coaxial cable to the SpectraVideo camera

control box.

CCD Analog

Signal Cable

Drive Cable

Head

Assembly

Control Box

Figure 1 Schematic Representation of the SpectraVideo camera electronics

Data Cable

Serial Cable

Camera

Data

Acquisition

Board

PixelView™

Software for

Windows

3.1x, 95/98 or NT

User

supplied PC

The CCD clock and bias signals are provided to the head from the camera control

box through the drive cable. The pre-amplified CCD signal is returned through

the CCD analog signal cable. The camera control box houses: 1) the power

supplies necessary to operate the camera and thermoelectric cooler; 2) the digital

control board that generates the clocking to operate the CCD; 3) the analog signal

processing board; and 4) the shutter and cooler control board. On those cameras

using a PCI bus data acquisition card and fiber optic data link, a serial to parallel

converter board is also contained in the camera control box.

The digital control board contains the sequencer which generates the logic signals

for all time critical tasks associated with the CCD readout, the drivers which clock

the CCD gates, and the bias supplies for the driver rails. The sequencer is a

programmable digital signal processor (DSP) and many timing parameters are

controlled through its serial port. The analog signal processing board contains the

correlated double sampled (CDS) analog signal chain, the 16 bit, analog-to-digital

converter (ADC) and optical isolation from the PC to improve noise immunity.

SpectraVideo Camera User’s Manual General Description of Camera

2

2.1. DIGITAL DATA ACQUISITION BOARD

SpectraVideo cameras are shipped with a 16 bit digital input interface to a

LynxPCI data acquisition board that acquires the images. The data acquisition

board receives digital signals from the SpectraVideo camera and the PixelView

software program captures the data that corresponds to the image’s pixel intensity

values and places the image into the PC memory, pixel-by-pixel. For more

detailed information on the data acquisition board, see Section 1.

2.2. PIXELVIEW SOFTWARE

PixelView software is provided with every SpectraVideo camera. PixelView is an

easy-to-use Windows-based image acquisition and analysis software package that

supports the features of the SpectraVideo camera. The software also includes

many intuitive image processing and analysis tools. Through the data acquisition

board, PixelView captures the 16 bit data that corresponds to the image’s pixel

intensity values and places the image into the PC memory, pixel-by-pixel.

PixelView has an intuitive structure where images and graphics are associated

with windows. The Shortcut Key feature (a combination of mouse drags and key

pushes) makes graphics and analysis just a touch away. Some of the most

commonly used analysis and display tools are accessible from toolbox buttons.

The pull down menu system is user friendly and easy to learn.

For detailed information on the functions of the PixelView software program,

please refer to the PixelView Software User’s Manual.

2.3. SOFTWARE DEVELOPER’S KIT

PixelView uses device drivers that are loaded at system boot. These drivers can

also be accessed from the user’s software through provided DLLs.

2.4. SYSTEM REQUIREMENTS

The recommended hardware system to run your SpectraVideo camera is a 233

MHz Pentium processor with at least 64 MB of RAM and 5 MB of available disk

space.

PixelView is compatible with Windows 95/98/NT. It is not compatible with

earlier versions of Window. The program also requires a display adapter that

supports at least 256-color displays.

PixelView supports 1-, 2-, or 4-channel versions of the LynxPCI data acquisition

board with either a parallel or fiber optic interface. In addition, PixelView

supports controlling a single camera using two LynxPCI cards, but does not

support controlling multiple cameras with multiple boards.

SpectraVideo Camera User’s Manual General Description of Camera

3

The camera determines the data acquisition rate and you must ensure that your

computer has sufficient resources to keep up with the rate at which the camera

transmits data. Computers operating with higher clock speeds will not acquire

images faster than the rate determined by the camera; however, as bus and

microprocessor clock speeds improve the efficiency in which the computer

handles background tasks, a faster computer increases the reliability of acquiring

images.

PixelView does not interface directly with any other program; however, the

software reads and writes files that can be shared with other programs. PixelView

uses TIFF as its default file format.

SpectraVideo Camera User’s Manual General Description of Camera

4

3. S

3.1. PRECAUTIONS

PECTRAVIDEO CAMERA SETUP

CAUTION! Charge-Coupled Devices (CCDs) are extremely sensitive to

electrostatic discharge (ESD) damage. The CCD may be damaged by

discharges of as low as 50 Volts. Do not unplug the head assembly unless at an

ESD safe workstation.

Your camera may have been shipped with the Head Assembly separate from the

camera control box. If so, the Head Assembly will have a shorting bar on its 37pin connector. Do not remove the shorting bar unless at an ESD safe workstation.

Connect the Head Cable to the camera control box. Remove the shorting bar and

replace it with the Head Cable. Be sure the Head Cable connectors are screwed in

at both ends.

The computer +5 Volt supply is available on pin 37 of the D37 connector of

parallel data acquisition board. It is highly recommended that the computer be

turned off when connecting the data cable on these cameras. The PCI data

acquisition board has a fuse on this supply voltage pin. A damaged fuse on a PCI

board can cause a serial port command upload failure error message.

Please save all packing material! If the camera must be returned to

PixelVision, Inc. for replacement or repair, it must be packed in its original

material, as it was shipped to you. The limited warranty may be voided if the

camera is not returned in its original packing material. If you need new

packing material, please contact PixelVision, Inc.

3.2. SETUP

Your SpectraVideo camera is shipped prepared for easy integration and operation.

Included in your shipment is a Packing List. Please verify that all parts have been

received. If any parts listed in the Packing List are not received with this package,

please contact PixelVision, Inc. Immediately.

Start by plugging the power cord into the power supply box then into a grounded

power source (a grounded wall socket is preferred). Leave the camera and

computer off until all the cabling is connected.

CAUTION! The camera is shipped with the drive cable from the camera control

box to the head assembly connected. DO NOT REMOVE THIS CABLE.

Removal will expose the static-sensitive CCD to possible electrostatic discharge

(ESD) damage.

SpectraVideo Camera User’s Manual SpectraVideo Camera Setup

5

For the camera control box to communicate with your PC, the data acquisition

board must be installed, if there is not one already installed. To install the board:

1. Make sure the computer is turned off.

2. Leave your computer plugged into a grounded power source, if it is

not already plugged in (a grounded wall socket is preferred).

3. Remove the computer’s chassis cover and locate a free PCI expansion

slot.

4. Remove the protective plate covering that corresponds to the chassis

slot, saving the machine screw.

5. Dissipate any static electricity by touching a bare-metal portion of the

PC chassis.

6. Remove the data acquisition card from the anti-static bag, holding the

board’s edge (do not touch the board’s back or the connectors

because these areas are more susceptible to retained static charge).

7. Insert data acquisition board into the free PCI expansion slot, making

sure that the board is fully seated.

8. Secure the board bracket using the machine screw from the chassis slot

plate.

9. Replace the chassis cover.

If you are not using a PCI bus data acquisition board with fiber optic links, you

must connect the 9-pin serial data cable from the port on the back of the camera

control box marked “serial control” to a free serial (COM) port on your PC. Note

which serial (COM) port you are using for setup of PixelView. Then connect the

parallel cable from the port marked “Parallel Data” to the parallel port on the data

acquisition card. Figure 2 shows the camera setup with serial/parallel cabling. If

you are using a fiber optic link, install the fiber optic cables from the data

acquisition board to the camera control box.

CAUTION! When inserting or detaching the fiber optic cables, grasp the

metal nut at the end of the cable. Do not push or pull on the cable itself.

When removing the plastic cover at the tip of the cable, grasp the metal nut,

not the cable. DO NOT tie the fiber optic cable in a knot. Bending the cable

in a circle with a radius smaller than four inches can damage the cable.

To connect the fiber optic cables:

1. Remove the fiber optic port plugs by turning counter-clockwise ¼ turn and

then pulling out.

2. The first fiber optic cable goes from the port labeled “FO1” on the back of the

camera control box to the top fiber optic port on the data acquisition board.

The “top” port is the port farthest away from where the board is plugged into

the extension slot. Remember to loosen or tighten the cable using the metal

nut. Do not push or pull the cable itself. Rotate the metal nut clockwise until

the key slot drops into place.

SpectraVideo Camera User’s Manual SpectraVideo Camera Setup

6

3. The next cable goes from the port labeled “FO2” on the back of camera

NOTE: If the camera control box has more than two fiber optic ports, continue to

☞

use the next available port on the data acquisition board for each cable coming

from the camera control box, in order from top to bottom on the board.

Once the cables are connected, restart your computer. If you are running

PixelView and a LynxPCI data acquisition board, when you restart your

computer, Windows 95 should inform you that it has detected new hardware, and

ask you for a driver disk for this hardware. Insert the disk label “PCI Driver Disk”

into your 3½" floppy drive, select that drive, and click “OK.” Follow any

instructions Windows 95 presents. Some PC systems may prompt you for a file

name or directory in the C

to your floppy drive (i.e. ‘a:’) and press enter. You may have to direct the search

to your floppy drive more than once on some systems, especially if your system

has a CD-ROM drive.

For “internal exposure” use the short coaxial “exposure control loop back” cable

provided to connect the “Exposure Out” connector on the back of the camera

control box to the “Exposure In” connector (see Figure 2). For external exposure,

disconnect this cable and provide a TTL gate to the “Exposure In” connector (see

Section 4.1 for detailed information). In internal exposure, the camera controls the

exposure start and exposure duration; but, while in external exposure mode,

exposure is slaved to the gate pulse provided by the user.

control box to the next available port on the data acquisition board (again, in

order from top to bottom on the board).

opy files from: box. If this occurs, type the correct path

SpectraVideo Camera User’s Manual SpectraVideo Camera Setup

7

Figure 2 SpectraVideo Camera with Serial/Parallel Cable Interface

The camera head is provided with a Nikon lens mount standard. A C-mount or

Canon lens mount is optional. A ¼ inch – 20 tpi mounting hole is provided in the

camera head.

For specific information on the installation of the PixelView software program,

please refer to the PixelView Software User’s Manual.

SpectraVideo Camera User’s Manual SpectraVideo Camera Setup

8

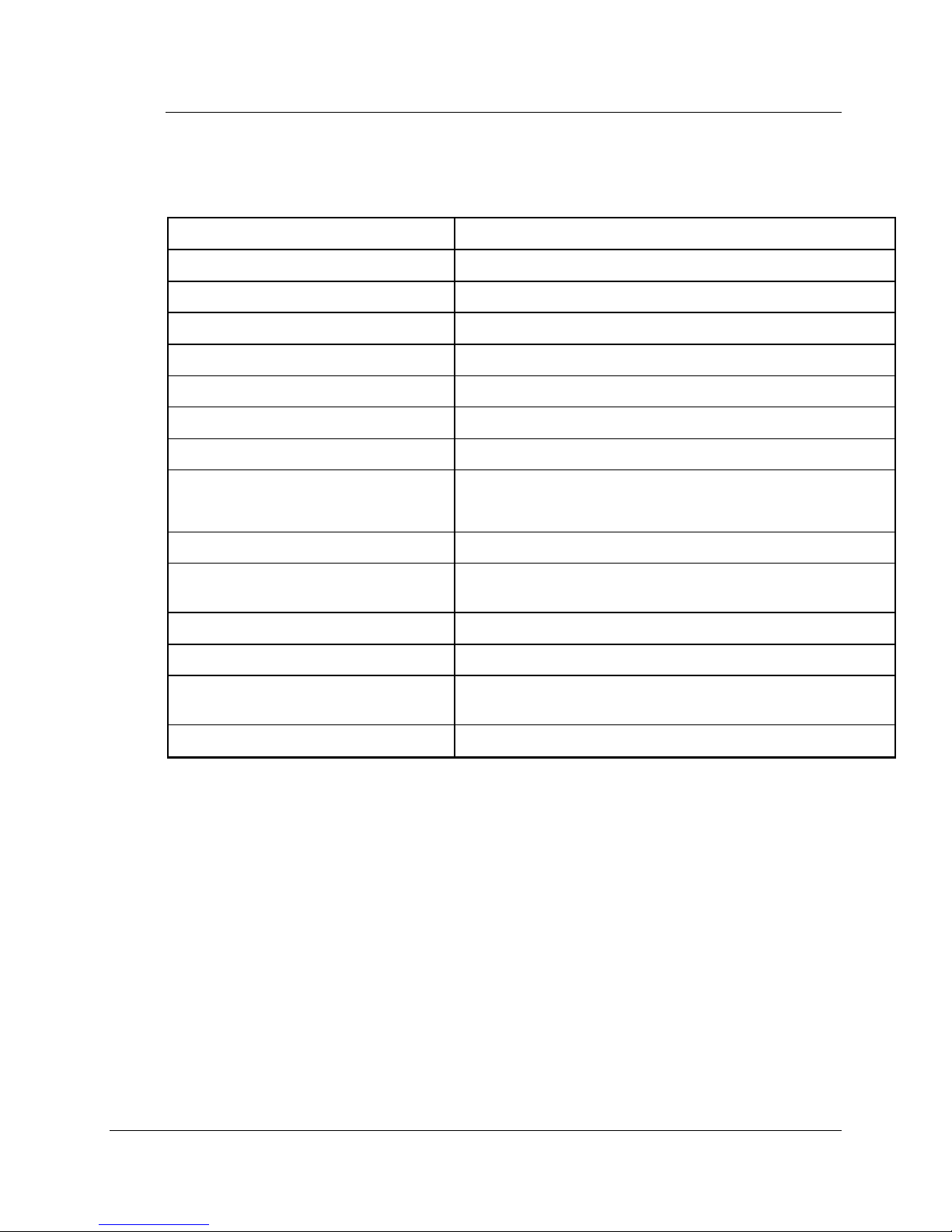

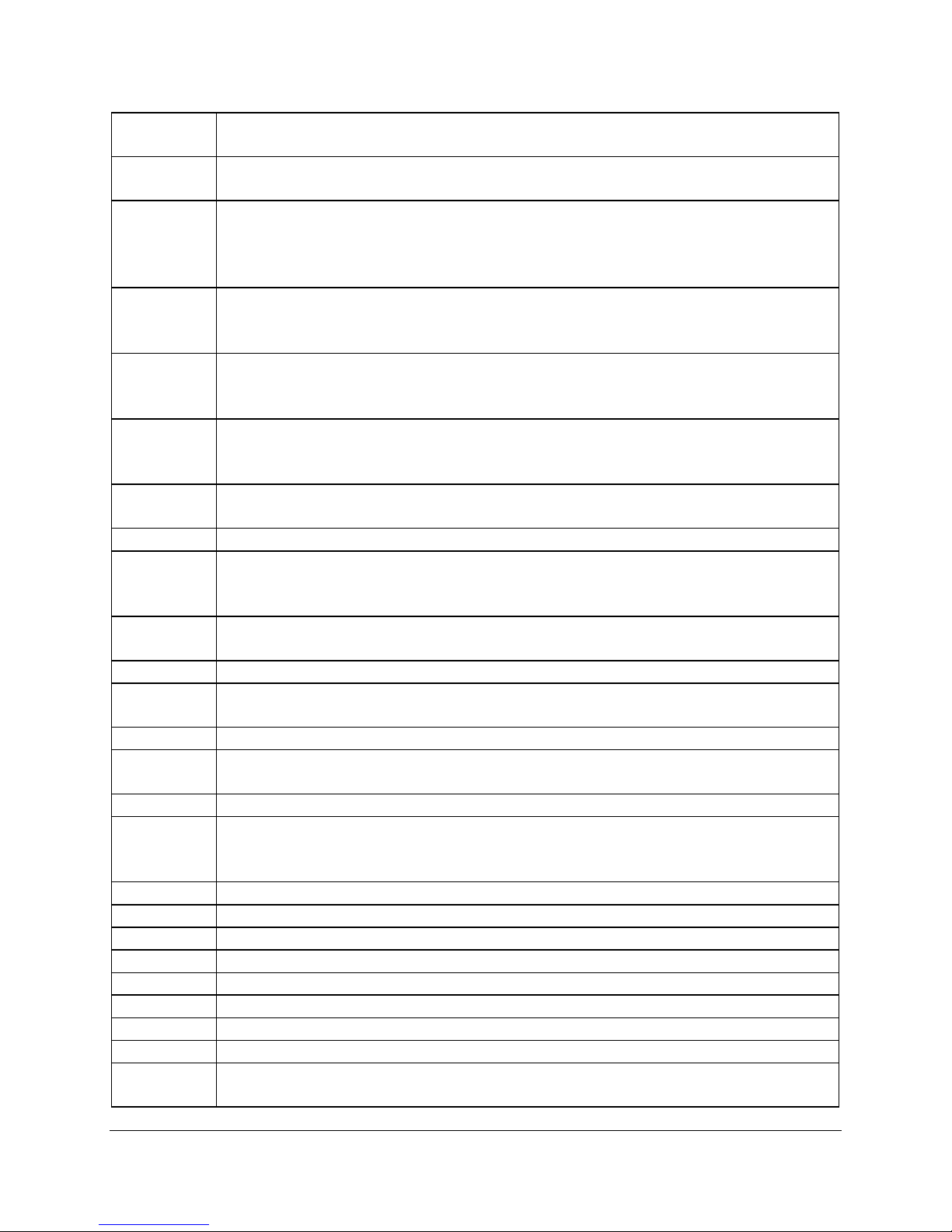

3.3. SPECTRAVIDEO FAMILY GENERAL SPECIFICATIONS

Below are the general specifications for the SpectraVideo family.

Full Well Capacity

Readout Amplifier Noise

A/D Conversion

Readout Rate

Shutter

Row Shift Period

Gain Settings

Binning and Region-of-Interest (ROI)

Cooling Capacity

Electrical Input

Computer Interface

Camera Head Dimensions

Operating Mode

80,000 – 1,200,000 e–

4 - 9 e–/per readout @ -45°C., 50kpix/sec

16 bit

50 - 450 kpix/sec (1 Mpix/sec optional)

DC to 50 milliseconds, software or external sync control

24 – 60 µsec

Software select, High (app. 4.5 e–/ADU) or Low (app. 9 e–/ADU)

Binning and ROI is software selectable in X and Y coordinates

2-stage TE Vacuum Module -45 – -60°C from ambient

3-stage TE O-ring Dewar -70°C from ambient

100 VAC - 240 VAC 50 - 60Hz

Serial port and PCI bus (fiber optic cabling available with PCI

bus)

4.0"(w) x 4.0"(h)

Software selectable via serial port or fiber optic link

Recommended Computer System

Requirements

Software

Table 1 SpectraVideo Family General Specifications

233MHz Pentium processor with at least 64 MB of RAM and

5MB of available disk space

PixelView is provided with each camera

SpectraVideo Camera User’s Manual SpectraVideo Camera Setup

9

4. C

4.1. EXTERNAL EXPOSURE CONTROL

AMERA EXPOSURE CONTROL

Exposure may be controlled externally by supplying a TTL level to the “Exposure

In” connector on the back of the camera control box, with “Exposure Out”

disconnected. The TTL level is normally high; exposure will occur while the level

is pulled low. With a brief delay (typically 15 µs), as soon as the level goes low,

the camera will go into exposure mode and communication with the camera will

be suspended until exposure is discontinued and a frame readout is complete.

If you are running PixelView, exposure must be set to Externally Gated in the

Exposure Tab within the “Camera Setup” dialog box under the Control menu.

A new frame must then be acquired. The software will wait until an exposure has

occurred and will capture the frame. Pressing the Escape key will cancel the

acquisition. Once a single frame has been acquired, selecting the Continuous

(Ctrl-C) item from the Acquire menu makes continuous acquisitions.

The entrance into exposure mode may be delayed for as long as it takes the

parallel gate drivers to fall, typically 15 µs. Consequently, the exposure gate

should precede the external event by at least 15 µs.

After the exposure gate rises, the CCD will continue to expose to allow time for a

shutter to close, phosphor to decay, etc. The length of time is determined by the

value entered in the “After Exposure” box within the Rate Tab of the “Camera

Setup” dialog box under the Control menu. After exposure wait can also be

accessed by the user’s software. Figure 3 below shows the relationships between

the various waveforms.

Figure 3 Exposure Timing Relationships

SpectraVideo Camera User’s Manual Camera Exposure Control

10

When using an external exposure gate, the beginning of exposure will not be

synchronized with the end of a CCD line and there will be a slight difference in

dark current between two frames with the same exposure. This results from the

dark current accumulated during the uncertainty in one line. This effect should be

small for cooled CCDs running at high speeds.

When externally gated exposure mode is selected, the Digital Signal Processor

(DSP) stops the parallel gates for the duration of the low level on the exposure

gate (± ½ row readout + one parallel shift).

NOTE: When using a PCI data acquisition board, the 100 µs signal is the signal

☞

4.2. SOFTWARE TRIGGERED EXPOSURE CONTROL

that is generated by the PCI board. The signal goes to the DSP that controls CCD

shifting. This DSP acts on the falling edge.

To use software triggered exposure control, the connector on the camera control

box labeled “Exposure Out” must be looped back to the connector labeled

“Exposure In.” A short coaxial cable is provided with each camera for this use. If

PixelView used, exposure must be set to Software Trigger in the Exposure Tab

within the “Camera Setup” dialog box under the Control menu.

Internal exposure timing is handled by the DSP and when a new frame is

requested, the camera will complete clearing the serial register before beginning

the exposure. A TTL level that is low while the camera is exposing is available at

the Sync connector on the front panel of the camera control box.

Internal exposure duration may be set from 25 µs to over 100 hours with a

granularity of 100 ns or 62.5 ns, depending on the frequency of the system clock.

When externally triggered exposure mode is selected, the DSP stops the CCD

parallel gates for the programmed exposure time, starting on the falling edge of

the Exposure In signal.

SpectraVideo Camera User’s Manual Camera Exposure Control

11

5. A

5.1. OVERVIEW

NALOG SIGNAL PROCESSING BOARD

The analog signal processing board is used to amplify the output signal from the

CCD and digitize it. The analog processing board contains the clamp/sample

correlated double sample circuit, the analog signal chain, the analog-to-digital

converter, and the optical isolation circuitry that provides noise immunity from

the PC.

Figure 4 SpectraVideo Analog Processing Board Layout

One of two gain settings can be selected on the analog signal processing board. A

buffered analog output is also available for troubleshooting and for external signal

processing.

5.2. ANALOG SIGNAL PROCESSING BOARD CONNECTIONS

5.2.1. GAIN SELECTION

Two analog gain settings, HIGH and LOW, are used to set the gain of the analog

channel on the analog signal processing board.

Unless otherwise specified by the customer, the HIGH gain setting is used to

adjust the dynamic range of the analog-to-digital converter (ADC) so that the

SpectraVideo Camera User’s Manual Analog Signal Processing Board

12

upper end of the dynamic range is set to the full well potential of the CCD’s

parallel pixel charge sites and so that 2 bits are used to sample the noise floor of

the camera. The LOW gain setting is used to match the upper end of the ADC’s

dynamic range to the full well potential of the CCD’s serial pixels. Under typical

operating conditions, gain setting is performed by the PixelView software

package.

NOTE: If you are running a two-speed camera, the HIGH gain setting is used for

☞

high speed operation, and the LOW gain is used for low speed operation.

5.2.2. ANALOG OUTPUT

Buffered analog output (0 to -10V range) taken just prior to input to the analog to

digital converter is available on J7 outer most pin. DC offset may be adjusted on

R11 of the clamp sample piggyback board.

J7 pin 2 J7 pin 2

Analog output GND

Table 2 Analog Output on the PMB-003

J5 pin Function J5 pin Function

1 -15V 2 Last Gate

3 GND 4 Vrd

5 GND 6 Vdd

7 +15V 8 GND

9 GND 10 Analog Signal

Table 3 Low Noise Cable Connection to Socket Board

SpectraVideo Camera User’s Manual Analog Signal Processing Board

13

5.2.3. BOARD TO BOARD SIGNAL CONNECTIONS

Control signals from the DSP digital board control. Analog signal processing for

noise reduction and data conversion.

J1 pin Function J1 pin Function

1 -15Vdc 2 ~Sample/Hold 1

3 GND 4 ~Start Convert

5 +5Vdc 6 ~Output Enable

7 +15Vdc 8 ~Sample/Hold2

9 GND 10 Expo_Gate

11 GND 12 Gain

13 GND 14 Serdatain

15 GND 16 Serdataout

17 GND 18 Frame blank

19 serclk 20 Line blank

Table 4 Analog Board to Digital Board Control Cable Connections

SpectraVideo Camera User’s Manual Analog Signal Processing Board

14

5.2.4. DIGITAL INPUT/OUTPUT

J3 pin Function J3 pin Function (with Serial I/O)

1 Data 0 (LSB)

3 Data 1 4 n/c

5 Data 2 6 PC GND

7 Data 3 8 Line Blanking pulse

9 GND 10 Frame Blanking pulse

11 Data 4 12 ~ Output enable 0

13 Data 5 14 PC GND

15 Data 6 16 ~ Output enable 1

17 Data 7 18 n/c

19 GND 20 Data Valid strobe

21 Data 8 22 ~ Output enable 2

23 Data 9 24 PC GND

25 Data 10 26 ~ Output enable 3

27 Data 11 28 n/c

29 GND 30 n/c

31 Data 12 32 n/c

33 Data 13 34 n/c

35 Data 14 36 +5V from PC

37

39 Serial clock 40 TTL out

Data 15

(MSB)

2 n/c

38 TTL in

Table 5 PMB-003 Data I/O Connector

5.2.5. RS232 INPUT

RS232 control of DSP parameters is accessible through the RS232 connector.

This connector can be connected straight across to a DB9 connector. These

RS232 connections also appear in the data I/O connector (J3) for convenience.

Parallel SpectraVideo cameras use an RS232 port. CommTest is a program used

to exercise the serial port of the Imaging Module in order to determine the health

of the link. For more information on the CommTest program see Section 12.1.

SpectraVideo Camera User’s Manual Analog Signal Processing Board

15

J4 pin Function J4 pin Function

1 NC 2 nc

3 RS232 input 4 nc

5 RS232 output 6 nc

7 NC 8 nc

9 GND 10 nc

Table 6 PMB-003 RS232 Connector

SpectraVideo Camera User’s Manual Analog Signal Processing Board

16

6. D

6.1. OVERVIEW

IGITAL CONTROL BOARD

The SpectraVideo digital control board generates the clock signals used to operate

the CCD. High performance clock drivers generate the clock signals. A digital

signal processor (DSP) controls the clock waveforms. Using a DSP allows users

flexibility in operating and optimizing the CCD. Readout rates, pixel binning, and

region of interest readout are all easily modified using the DSP.

J3J2

Figure 5 SpectraVideo Digital Control Board Layout

6.2. TIMING SEQUENCE

The DSP program has four basic modes: flush, exposure, after exposure and

readout. During the flush mode the CCD is cleared as quickly as possible and the

data is not transferred to the PC. Exposure mode is entered from the flush mode.

During the exposure interval the CCD central array is not shifted to avoid blurring

of the image. An after exposure delay can be set through the serial port to allow

time for the shutter to close or a phosphor to decay before readout. The readout

mode is entered from the after exposure mode. During readout the charge in the

CCD pixels is clocked out, amplified, processed and digitized. A Data Valid

strobe is active for those pixels that will be transferred to the computer. If region

of interest readout is active, only the data from the region will have Data Valid

strobes.

SpectraVideo Camera User’s Manual Digital Control Board

17

An Exposure Gate pulse of 25 µs minimum width must be provided to this board

to trigger exposure as discussed below.

A Line Blank and Frame Blank pulse are provided in addition to the Data Valid

strobe. The Line Blanking pulse is high for the parallel shifts. Line Blanking is

only active with a Region of Interest (ROI) selected. Frame Blanking is low

during the exposure period, high during the after exposure delay and then low

during the readout. In this way the I/O channel to the PC can sense the internal

exposure gate timing.

EG=Exposure Gate

DV=Data Valid

LB=Line Blanking

FB=Frame Blanking

Figure 6 Camera Control Timing for Internal Exposure Mode

NOTE: For external exposure mode, EG must be high the entire exposure period.

☞

SpectraVideo Camera User’s Manual Digital Control Board

Parallel mode is used with the parallel data input option and serial mode is used

with the serial fiber optic input option.

6.2.1. FLUSH MODE

After readout or after rebooting the DSP, the CCD is kept flushed of charge

indefinitely by a parallel transfer, serial readout sequence. The only way to get out

of this mode is to trigger an exposure.

18

6.2.2. EXPOSURE MODE

CCD exposure is controlled by a user provided external gate (input through the

digital I/O connector on PMB-003). Internal or External exposure timing may be

selected through the serial port as explained under the software development

section. Exposure begins on the falling edge of the exposure gate. The exposure

gate should stay low or high for a minimum of 25µs. For internal exposure mode

the DSP handles the exposure duration after an exposure is triggered. For external

exposure mode, the exposure gate must be held low through the entire exposure.

6.2.3. AFTER EXPOSURE MODE

After the exposure has finished, the DSP will keep the CCD in exposure mode

longer to allow time for a shutter to close, phosphor to decay, etc. The after

exposure wait can be set through the serial port.

6.2.4. READOUT MODE

After every exposure, a CCD readout occurs with the data valid strobe active. The

readout may not be interrupted, except by DSP reset.

The rising edge of the data valid strobe occurs after valid data appears on the data

bus. There is a pipeline delay of 3 pixels. The first three pixels after a parallel

shift are discarded by the warm-up sequence because the first two were in the

pipeline during the shift plus the third is slewing back to baseline conditions. The

data valid pulse is blanked except for unblanked pixels.

6.2.5. CLOCKING PARAMETERS

The serial port may be used to change several counters used in the DSP program

as well as to control the exposure and readout modes. See Section 1 on software

development for details.

6.2.6. DIGITAL CONTROL BOARD CONNECTIONS

6.2.6.1. Scope Triggers

Pixel, line and frame triggers are available. Pixel clock is high for the reset

gate period of the serial pixel shift sequence, line clock is high during

parallel shift and shutter is high during exposure.

J1 pin # Function

1 GND

2 Pixel clock (reset gate logic)

3 Line clock (parallel shift period)

4 Shutter

Table 7 PMB-001 Scope Trigger Outputs

SpectraVideo Camera User’s Manual Digital Control Board

19

6.2.6.2. Control Input/Output

Power and shutter logic (high during exposure) are available for use by

other equipment. ~DSP reset is a logic input which causes the DSP to boot

from PROM page 0 when pulled low and released. Aux data is an 8 bit

word that may be written by the DSP with accompanying CLK and write

signals. This port is used by the Aux board for temperature control and by

the Jaguar serial interface board for receipt of channel enable pulses.

J2 Pin # Function J2 Pin # Function

1 -15V 2 ~DSP reset

3 GND 4 Shutter

5 +5V 6 Aux dat 1

7 +15V 8 Aux dat 2

9 GND 10 Aux dat 3

11 GND 12 Aux dat 4

13 GND 14 Aux dat 5

15 GND 16 Aux dat 6

17 Clockout 18 Aux dat 7

19 Aux1_write 20 Aux dat 8

Table 8 Control Input/Output on PMB-001 Analog to Digital Board Connections

6.2.6.3. Analog to Digital Board Connections

The digital DSP board controls the digitization and analog signal

processing through a board to board ribbon cable.

J3 pin # Function J3 pin # Function

1 -15Vdc 2 ~SH1

3 GND 4 ~SC

5 +5Vdc 6 ~OE

7 +15Vdc 8 ~SH2

9 GND 10 Expo_Gate

11 GND 12 Gain

13 GND 14 Serdatain

15 GND 16 Serdataout

17 GND 18 ~frmvalid

19 serclk 20 ~linvalid

Table 9 Digital to Analog Board Control Cable Connections

SpectraVideo Camera User’s Manual Digital Control Board

20

6.2.6.4. Socket Board Signals

The digital DSP board contains the gate drivers used to clock the CCD.

The drive signals are sent to the socket board.

J6 Pin # Function J6 Pin # Function

1 GND 2 SWout

3 GND 4 S1out

5 GND 6 S2out

7 GND 8 S3out

9 GND 10 ~Reset Logic

11 GND 12 P1out

13 GND 14 P2out

15 GND 16 P3out

17 GND 18 Tgout

19 Reset gate

High rail

voltage

Table 10 Socket Board Connector on PMB-001

20 TGbias

On PMB-001AC circuit boards, pin 19 is a reset gate dc voltage level and

pin 10, Rsout, is the TTL reset circuit signal contained on the socket card.

SpectraVideo Camera User’s Manual Digital Control Board

21

7. S

ERIAL INTERFACE BOARD

The Serial Interface Board provides a serial interface to the PCI-based data

acquisition card. The card is located in the camera control box and has a standard

form-factor of 4" x 4". In both serial modes up to 4 channels can be multiplexed

in the same serial line at speeds of ≤ 454 kpix.

Figure 7 PMB-007 Serial Interface Board Layout

The card employs a Lattice ispLSI-2032 In-System programmable PLD as a

service controller. It provides:

• 4-channel serial transmitter control

• clock divider

• violation control

A “transparent” AMD TAXI transmitter Am7968 and a receiver Am7969 are

used in the serial link between the PMB-007 and the PCI bus data acquisition

board. They are able to send, asynchronously via differential PECL lines, 8 bit

data and 3 bit commands providing auto-synchronization and error checking.

Receivers on the host interface side can be configured such that only one link with

time-multiplexed data from 4 outputs can be used, providing 16Kx16K total

resolution.

SpectraVideo Camera User’s Manual Serial Interface Board

22

Although the link is error-free, every 8 bit word in the RS232 emulation stream is

checked for errors and should they happen, a violation flag will be raised and an

on-board LED will be lit.

Up to four Analog boards can be used to provide an input signal to the board.

They all share the same 16 bit bus. Additional write enable signals are provided

by the Digital Control Board to latch every channel in its own latch to read later

by the controller. The card provides loop back of these 4 enable signals to the

Analog Signal Processing Board.

Software for RS232 serial emulation and board status mailbox message handling

is provided in PVLYNXX.DLL.

Figure 8 Serial Interface Board Timing

SpectraVideo Camera User’s Manual Serial Interface Board

23

8. S

100

HUTTER AND COOLING CONTROL BOARD

The shutter and cooler control board provides the drive circuitry to control the

shutter as well as temperature control for the thermoelectric cooler (TEC) and

CCD. The shutter supply circuit operates from the +15V power supply to make

+70V for the shutter. During exposures, closing a switch between the supply and

the shutter opens the shutter. Immediately after exposure, the shutter supply

recharges. The Camera External Sync output is low during the time the shutter is

open and +5V otherwise.

PixelView uses two constants called TempGain and TempOffset. These values

are used to convert a temperature to a binary value to send after the ‘x’ command:

TempGain

256x −∗∗=

The TempGain and TempOffset constants are CCD package and camera specific,

they are calibrated for each camera. A temperature sensor inside the TEC package

converts temperature to current. The current passes through a resistor and the

voltage on the resistor (representing CCD temperature) is displayed by a

Voltmeter LCD display. Temperature can be set in PixelView in Control,

Camera Setup… (Ctrl-C), by using the CCD temperature slider in the CCD tab

within the “Camera Setup” dialog box.

)TempOffsetKelvin_in_ccdtemp(

Figure 9 SpectraVideo Shutter and Cooler Control Board Layout

SpectraVideo Camera User’s Manual Shutter and Cooler Control Board

24

9. D

9.1. LYNXPCI DATA ACQUISITION BOARD

ATA ACQUISITION BOARDS

The LynxPCI data acquisition board can be used for 8-, 12-, and 16 bit input from

scientific and non-standard digital cameras. With the serial input option, the board

can accommodate the input simultaneously from up to four data streams.

9.1.1. FEATURES

• PCI bus data transfer rates greater than 80 Mbytes/second

• Single 16 bit parallel acquisition or up to four 16 bit serial fiber optic

channels

• Master Mode PCI Plug-and-Play compatible

• Fiber optic serial input option available to reduce environmental

corruption of data

• Software drivers available for Microsoft Windows 95, Windows NT,

or Windows 3.1

• Uses system memory

• Fiber optic transmission option allows cameras to be “remoted” up to

two kilometers away

9.1.2. GENERAL DESCRIPTION

Specifically designed for use with digital camera systems, the LynxPCI data

acquisition board captures and stores the parallel or serial data from digital

cameras to system memory.

The LynxPCI can accommodate up to four digital serial data streams, and when

implemented with other LynxPCI boards, can accommodate an unlimited number

of serial inputs. ‘Plug-and-Play’ PCI operation allows users to easily add

LynxPCI boards to expand the number of captured channels. No special

configuration file is required. This makes it ideal for multiple camera head

systems or for camera systems that have multiple output data streams. By using

fiber optic serial cables, the LynxPCI overcomes the limitation of SCSI type data

transmissions, and allows operation of your camera up to 2 kilometers from the

host computer system.

LynxPCI’s specially designed line buffering architecture eliminates the need for

costly full frame memory and reduces system complexity and size.

SpectraVideo Camera User’s Manual Data Acquisition Boards

25

9.1.3. ARCHITECTURE

The LynxPCI data acquisition board is a PCI-compliant card providing a parallel

or serial interface to digital cameras from PixelVision and other manufacturers. A

serial wire interface can be used for short distance transfers. A fiber optic cable

option is available for long distance data transfer and high data integrity.

Taking advantage of the PCI Bus speed in DMA master mode, the LynxPCI can

transfer to host RAM an unlimited number of consecutive frames across the bus

in real time. Because system resources are not involved in transferring data, the

computer’s CPU is free to perform other tasks such as image processing or

network transfers of the acquired data.

Unlike other popular data acquisition boards that use costly full frame memory to

buffer images, LynxPCI uses doubled FIFO or dual-port memory buffers.

LynxPCI writes incoming data into one memory buffer while another is read by

the PCI controller – guaranteeing uninterrupted data acquisition. The LynxPCI is

a very versatile data acquisition board that uses the Taxi™ serial transmission

standard. The LynxPCI can be configured to receive data in parallel single ended

or parallel mode. It can also receive multiplexed data over a serial data cable that

can then be de-multiplexed on the LynxPCI board so that the image is correctly

placed into memory.

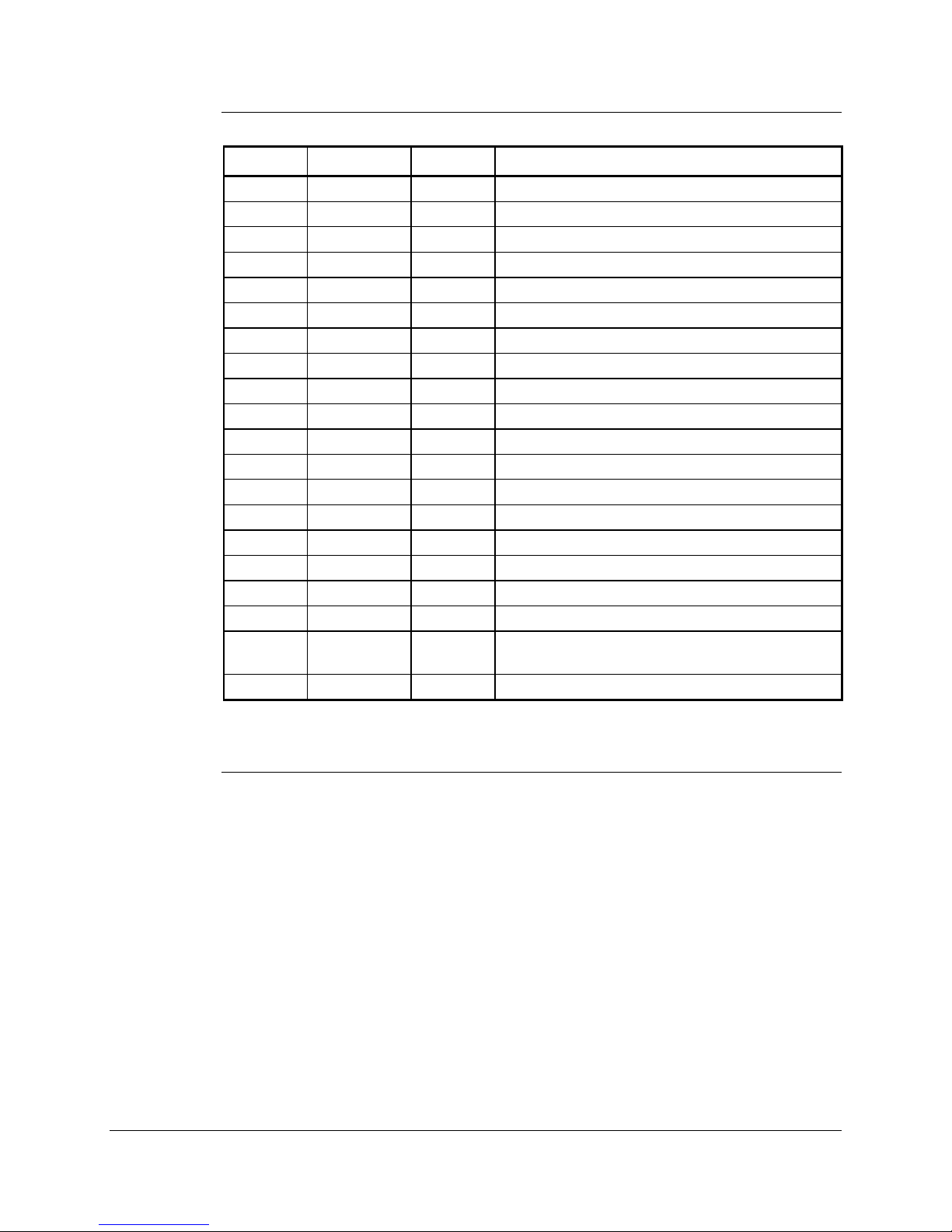

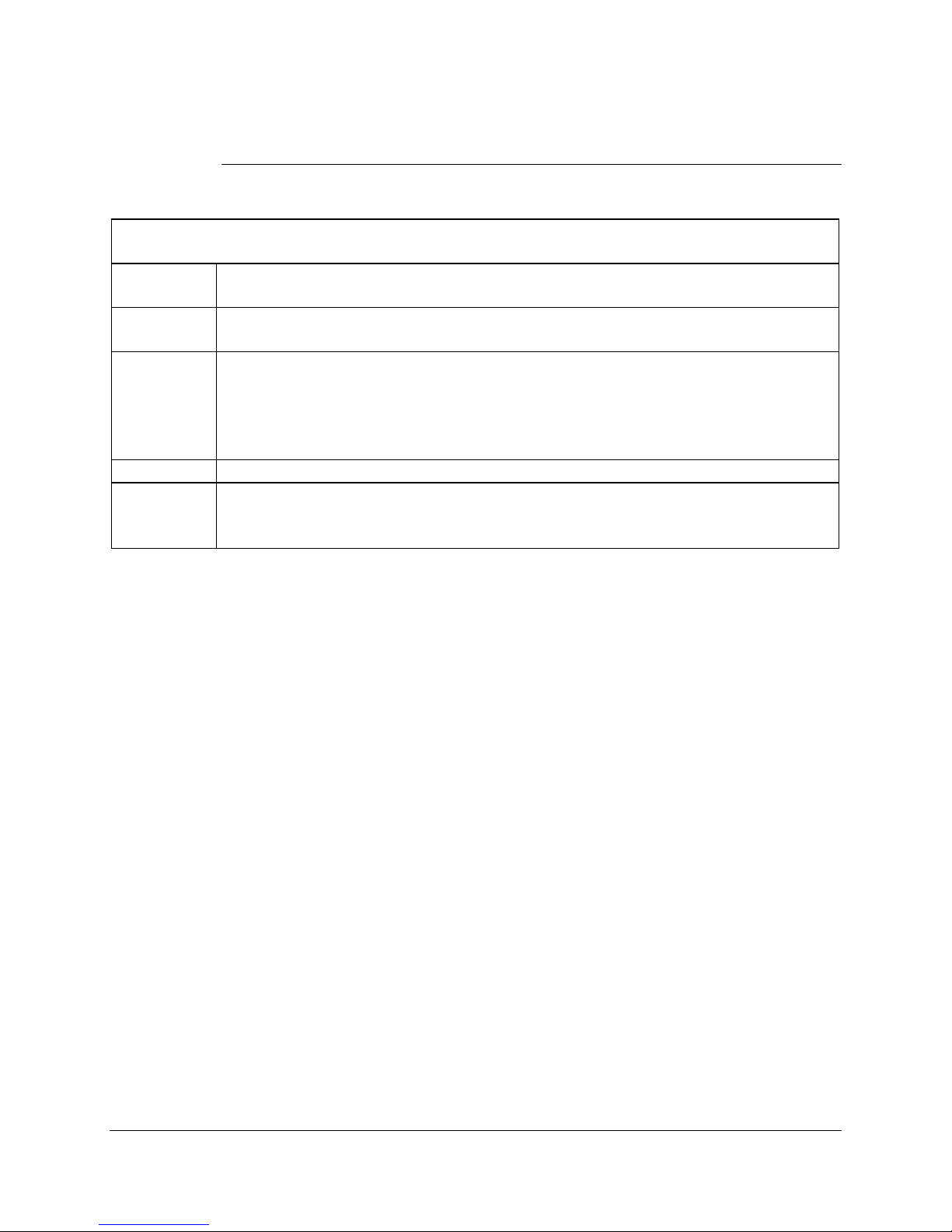

Table 11 shows the different data acquisition configurations for the data

acquisition board.

Mode Configurations 0 1 2 3

1 Parallel Acquisition

2 Serial Acquisition, 1 channel

3 Serial Acquisition, 2 channels de-multiplexed

from a single multiplexed data stream

4 Serial Acquisition, 4 channels de-multiplexed

from a single multiplexed data stream

5 Serial Acquisition, 2 individual channels

6 Serial Acquisition, 4 individual channels

Table 11 LynxPCI Permissible Configurations

LynxPCI

Channel

√

√

√ √

√ √ √ √

√ √

√ √ √ √

SpectraVideo Camera User’s Manual Data Acquisition Boards

26

9.1.4. GENERAL SPECIFICATIONS

LynxPCI Data Acquisition Board

DIGITAL INPUTS 16 bit parallel, 15 MHz Pixel Clock

16 bit serial, 4 MHz Pixel Clock

SYNCHRONIZATION SIGNALS Frame Blank, Line Blank, Data Valid

DIGITAL OUTPUTS “Taxi” Serial 4 bit

CONTROL INTERFACE 8 bit I/O Mapped

ON BOARD MEMORY Each Line: up to Four 16 bit FIFOs (1KB or 4KB)

PCI INTERFACE 32 bit Master Mode, 32 bit Memory Map

POWER +5VDC, 3A (max)

MTBF 30,000 hrs.

OPERATING TEMPERATURE 0 – 70 Degrees Celsius (non-condensing)

STORAGE TEMPERATURE -20 to 85 Degrees Celsius

FO

Tx

Tx

Parallel bus, LB, FB, DV

FO

Rx

Rx

LSB

Rx

Ch.0

MSB

8

8

Service bus

Control bus

FIFO

4Kx16

FIFO

4Kx16

Status bus

Buffers

16

Switch

FIFO

64x16

FIFO

64x16

4

FIFO

bus

16

Service

controller

Data

registers

3

4

Mailbox

interface

Internal

data bus

32

9

PCI

controller

(bus master)

PCI

bus

Pass-thru

Ch.1

Ch.2

Ch.3

Data

FIFO

interface

33 MHz

FIFO

controller

Clock

distribution

interface

PCI FIFO

interface

FIFO 8x32

NV SPROM

Figure 10 LynxPCI Data Acquisition Board PMB-002 Funcitonal Diagram

SpectraVideo Camera User’s Manual Data Acquisition Boards

27

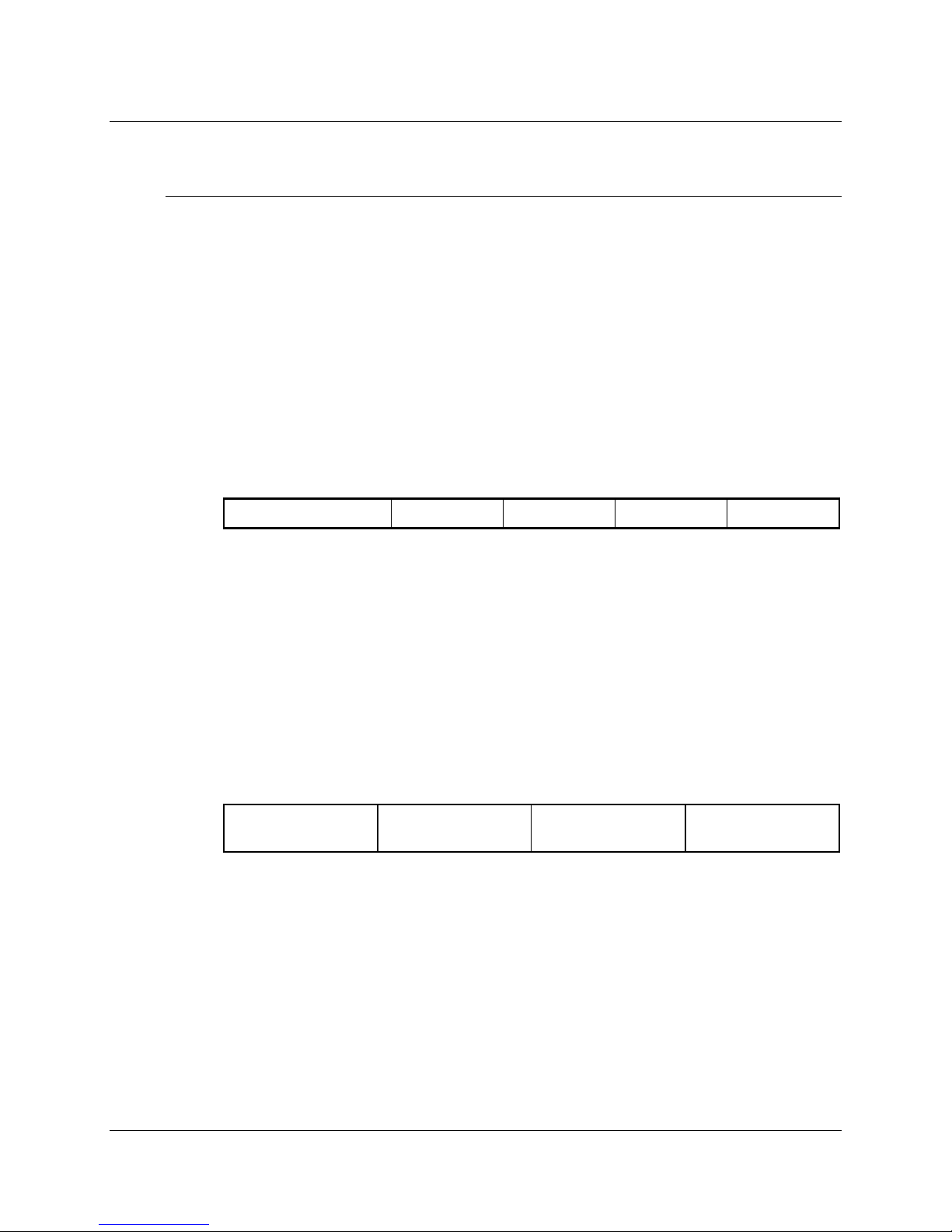

10. B

OARD TO BOARD ELECTRICAL CONNECTIONS

The SpectraVideo camera comes with the head assembly connected to the camera

control box via an umbilical that should not be removed.

If individual boards are purchased, they need to be assembled with the socket

board that holds the CCD.

The digital control board, analog signal processing board, and the CCD socket

boards are connected as shown in Table 12.

Digital Control Board to

J3 J1 pin 1 to pin 1

Digital Control Board to Socket Board

J6 J1 & J2

J6 pin 1 J1 pin 1

Table 12 Board to Board Connections

Analog Signal Processing

Board

Depending on the individual CCD shipped with the socket board, analog signal

processing board may be connected to either one of two sets of connectors. The

data sheet will specify which connectors to use.

Analog Signal Processing

Board

J5 J3 & J4 J5 & J6

J5 pin 1 J3 pin 1 J6 pin 1

Table 13 PMB-003 to Socket Board Connections

to Socket Board OR To Socket Board

SpectraVideo Camera User’s Manual Board to Board Electrical Connections

28

11. S

11.1. SPECTRAVIDEO SERIAL PORT INTERFACE

OFTWARE DEVELOPMENT

The SpectraVideo camera uses a serial interface to control some of the operation

modes and timing parameters involved in image acquisition. A digital signal

processor (DSP) which incorporates a serial port controls timing in the camera.

Mode control and internal counters are set through this port. Serial

communications to the SpectraVideo camera, which uses the PCI data acquisition

board without the fiber optic link, is through the PC’s RS-232 (COM) port. The

port must be set up to use 9600 baud, 1 stop bit, 8 data bits and no parity. This

section of the manual covers serial communication to those cameras that do not

use the serial interface board and fiber optic link to the PCI data acquisition

board. Additional commands are required for the serial interface board / fiber

optic link.

Comm settings:

9600 Baud 1 stop bit 8 data bits No parity

There are two types of commands: reboot commands and data commands. Reboot

commands consist of a single character (byte). Data commands are three

characters sent without pause between them; first is the control character to tell

the DSP which function is being accessed, and the second two are combined to

form an integer. The port can be tested by sending single characters using a

simple terminal emulator program, but typically these simple programs do not

send characters quickly enough in succession to be able to address any of the data

commands. Data command interpretation in the DSP is timed to look for the

second and third bytes at a particular rate and if no data is present it will read the

hexadecimal numbers 0xFF, 0xFF and interpret them as the hexadecimal integer

0xFFFF.

Data command

syntax:

Control character Data high byte Data low byte

After every three-character command sequence, the DSP will respond over the

serial port by sending back the three characters it received. If the control character

is not recognized, it will also send back the ASCII character ‘?’. This feature is

useful for determining whether the DSP is responding to serial port commands.

With fiber optic links, an ACK is not returned if an invalid command sequence is

sent.

There is an eight-page PROM in the camera that contains the DSP code. The DSP

is booted from PROM page 0 on power-up. Although the same basic DSP code is

used in all eight PROM pages, the actual timing sequences in each page differs to

accommodate the different clock timing patterns required for different CCD

SpectraVideo Camera User’s Manual Software Development

29

outputs. Depending on the CCD output used in a particular camera and the analog

gain state desired, the DSP may have to be rebooted after power-up but before

doing anything else. The PROM pages to be used with a particular camera are

highlighted in bold on the camera data sheet sent with the hardware.

All data commands must be in the range 0 to 16383 due to counter size limitations

in the DSP except as noted. Some values will cause loops to be very long.

Rebooting the camera from the power switch will clear this condition.

The DSP runs off a master clock and all timing is in units of master clock periods,

referred to below as CLK. The actual clock period of a particular camera may be

found on the data sheet and in the registry or pixview.ini shipped with the camera.

11.1.1. REBOOT COMMANDS

Control Character

(ASCII)

0 to 7 Prom Page

Function Discussion

Reboots the DSP from the selected PROM

Reboot

page. The pages for use with a particular

camera are noted on the camera data

sheet in bold.

11.1.2. REGION OF INTEREST (ROI) IMPLEMENTATION

The SpectraVideo camera supports Region-of-Interest (ROI) readout of the CCD.

Both single ROI and multiple ROIs up to a maximum of 16 are supported. The

ROI parameters are set through the serial port interface. The order in which the

parameters are sent is important, depending on whether no ROI, single ROI or

multiple ROI is desired—this order is elaborated below.

Single ROIs may be anywhere on the CCD, up to the edge of the device. Figure

11 shows the parameter names schematically for single ROI readout.

SpectraVideo Camera User’s Manual Software Development

30

n

l

m

k

n = Lines before ROI

k = Pixels before ROI

r = Lines after ROI

m = Pixels after ROI

l = Width of ROI

p = Height of ROI

p

ROI

r

Figure 11 Single ROI Parameters

11.1.3. COMMAND SUMMARY

Control

Character

(ASCII)

a

b

c

Function Discussion

Pixels per line

Lines per frame

Serial pixels

binned minus 1.

Sets the number of pixels per line in the digitized

frame when ROI is disabled. This number must be

greater than the number of serial shifts needed to

fully clear the CCD serial register plus four to

accommodate pipeline delays in the analog to

digital conversion. It must be large enough to clear

the lead-in pixels in the imager as well as the

active pixels. If serial binning is used, this number

may be divided by the number of serial pixels

binned, but the extra 4 pixels for pipeline delay

must still be added. Min = 1.

Sets the number of lines in the digitized frame

(minus one) when ROI is disabled. This number

must be large enough to clear the entire active

area of the CCD plus one to clock the last line into

the PCI data acquisition board. If parallel binning is

used, this number may be divided by the number

of lines binned, but one must be added to clock

the last line in. Min = 1.

Sets the number of serial pixels that are binned

into summing well. Setting this number to 0 turns

off serial binning; setting it to 1 bins two serial

pixels, etc. Min = 0.

SpectraVideo Camera User’s Manual Software Development

31

Control

Character

(ASCII)

d

e

f

g

h

i

j

k

l

m

n

p

Function Discussion

This number divided by eight sets the number of

Lines binned

times num Y

states

lines binned into the CCD’s serial register. This

number must be a multiple of num Y states. This

command is for use with ROI disabled or single

ROI. Min = 1.

Sets the period of the unbinned serial readout

pixel to:

Serial wait count

2

Min = 1.

Set the parallel state time (there are num Y states

per parallel shift). Sets the parallel state time to

Parallel wait count

(5+ParallelWaitCount)*CLK. The parallel gate

drivers typically do not support state times shorter

than 15 µs.

Min = 1.

This wait occurs after parallel shift but before serial

shift. It serves to extend the period between lines.

Disking wait count

Time waited is in units of unbinned serial pixel

periods.

Min = 1.

This wait occurs after exposure but before readout,

in effect, extending the integration time after the

TTL ‘sync’ output on the camera has gone high to

After exposure

count

allow time for the shutter to close, or phosphor to

decay, etc. The serial register of the CCD is kept

flushed during this period. The wait time is set to

AfterExposureWait squared, times the unbinned

serial pixel period. Min = 1.

Setting this to one enables single region of interest

clocking (ROI), setting it to 0 disables it and sets

ROI enable

the readout mode back to full frame. Setting it to a

number greater than one enables multiple ROI

readout, where the number designates the number

of regions. Min = 1.

Sets the serial pixel period for serial shifts used to

Serial flush wait

count

Serial pixels

before ROI

ROI pixels per line

Serial pixels after

ROI

Lines before ROI

flush the CCD (not during readout). Sets the period

of the unbinned serial flush pixel to (CLK*(base

Num Serial states+3*SerialFlushWaitCount)). Min

Sets the number of unbinned serial pixels to clear

every line before the ROI.

Sets the number of digitized pixels per line in the

ROI. Serial binning parameters are used. Min = 1.

Sets the number of unbinned serial pixels to clear

after the ROI. This number should be high enough

to clear the entire serial register.

Sets the number of imager lines to skip before

reading out the ROI.

Sets the number of digitized lines in the ROI for

ROI lines

single ROI readout only. Parallel binning

parameters are used. Min = 1.

= 1.

∗+∗

CountSerialWait3tateNumSerialSbaseCLK

SpectraVideo Camera User’s Manual Software Development

32

Control

Character

(ASCII)

r

s

t

v

w

x

A

B

D

Function Discussion

Lines after ROI

Exposure timer

mode

Internal timer

inner loop counter

Internal timer

middle loop

counter

Internal timer

outer loop

counter.

CCD Temperature

Reset multi ROI

pointer

Enter multi ROI

parameter

Lines binned

times num Y

states before

multiple ROI

Sets the number of imager lines to clear after

reading out the ROI. For use with single ROI only.

When set to 1, internal timing is used for exposure,

when set to 0, exposure time is set by the low

portion of exposure gate. When internal timing is

used, exposure start is synchronized to the

beginning of a serial shift.

Counter for internal exposure time loop. Exposure

time equals

(ReadoutSerialPixelPeriod*InnerLoopCounter*

MiddleLoopCounter*OuterLoopCounter). Minimum

InnerLoopCounter = 1.

See discussion for t above. Minimum

MiddleLoopCounter = 1

See discussion for t above. Minimum

OuterLoopCounter = 1

See discussion in the Shutter and Cooler control

board section

Resets the multiple ROI pointer (internal to the

DSP) in order to begin loading multiple ROI

parameters.

Enters the next multiple ROI parameter. The

parameters are entered in order:

1) ROI lines in first ROI

2) Lines binned in first ROI * num Y states

3) Lines skipped to next ROI

4) Lines binned in lines skipped above * num Y

n) ROI lines in last ROI

n+1) Lines binned in last ROI * num Y states

n+2) Lines skipped to finish clearing CCD

n+3) Lines binned in the last lines skipped * num Y

Same as d except it only sets the binning of the

lines before the first region of interest in multiple

ROI readout.

states

...

states

SpectraVideo Camera User’s Manual Software Development

33

12. S

UPPORTING SOFTWARE

12.1. COMMTEST

CommTest is a program used to exercise the serial port of the Imaging Module.

The Imaging module expects 9600 baud, 1 start bit, 8 data bits (lsb first), 1 stop

bit, and no parity bit. This program is written to use Serial Port 2; Port 1 can be

used by invoking Commtest /p1 on the run option command line.

Applicable files are:

commtest.exe

bwcc.dll

Commands for the Imaging Module are entered in the space beside the button

Send. The format is:

char[hh][hh]CR

where:

char is the single ASCII character detailed in the Imaging Module manual for the

particular command.

h is a hexidecimal character from 0 to f and the 2 characters must be inside

brackets as shown.

™

SOFTWARE USER’S GUIDE

☞

CR is a carriage return.

The Clear button clears the response space in the window.

The Send button works the same as a carriage return if the Send button is

highlighted.

The RS232 lines are optically isolated on the analog board before being fed to the

DSP on the digital board. For the RS232 opto-islators to function, the data cable

of the I/O board must be connected to the data connector on the analog board.

This I/O card provides +5V GND to the PC side of the optical isolators on the

analog board. Plus five volts and GND must be supplied to the analog board data

connector if an alternative I/O card is used.

The RS232 serial port connector is detailed in the Imaging Module manual.

The Imaging module will reply by echoing the characters sent to it. If it does not

recognize a character it will return a ‘?’. A ‘u’ or ‘U’ alone is a useful command

to find if the RS232 serial port is active since these are non-commands to the

Imaging Module.

NOTE: The Imaging Module only accepts commands sent during flush mode,

which, its normal idle state.

SpectraVideo Camera User’s Manual Supporting Software

34

The imaging module expects all three 8 bit characters as above. If only the first is

sent, the Imaging Module will fill in ff ff for the missing characters. If the

Imaging module needs only a single character, as in the case of rebooting to a

prom page, only one character needs to be sent.

12.2. PIXLOAD

The PixLoad software is a DOS executable program used to write serial port

command sequences to the SpectraVideo camera. It is copied to the PixView

directory during software installation. This program allows a series of commands

to be written to the camera from a text file and checks for errors in the response.

12.2.1. TEXT FILE FORMAT

PixLoad reads a text file and sends the commands in the text file to the

SpectraVideo camera over an RS232 serial port. Commands are sent to the

camera at the DOS command line by typing the text file name as a command line

argument to PixLoad. An example would be:

PIXLOAD file.clk

Where ‘file.clk’ is a file containing the alphabetic commands and their numeric

values. A sample text file is included. The text file name must conform to the

DOS filename format. The text file format must conform to the rules described in

this section for the DSP commands to be sent appropriately. PixLoad depends on

the text file to be left justified with ‘=’ signs separating the command character

and the decimal data. PixLoad reinterprets the decimal data to hexadecimal

format.

™

SERIAL PORT CONTROL SOFTWARE

It is recommended that every command character in each line of ‘file.clk’ should

be completed so that the camera is completely configured with a full command set

each time PixLoad is invoked. Some of the values may be “don’t-cares” in some

modes of clocking operation. In this case, a value of 1 or 0 is sufficient as the

numeric value.

The text file may have any number of lines. The first line of the file must be

present to select the PC Serial Port to be used. The first line must say:

port=x

where x is the number of the serial port being used.

Additional lines are text characters of the form ‘char=number’. The number is in

decimal integer format. A DSP command character must be the first character in

the line. The next character must be an ‘=’ sign with the data number immediately

following with no spaces. Comments may also be added to the end of a command

by placing an apostrophe at least two spaces away from the command string. All

text after the apostrophe is considered a comment. Comments are allowed

SpectraVideo Camera User’s Manual Supporting Software

35

between command lines only if the first character is left justified and is an

apostrophe ( ‘ ).

Imaging Module PROM pages are accessed by loading different ‘files.clk’ which

have a numeric first character rather than an alphabetic command character. The

PROM pages control the direction of CCD clocking and hence, are designed

specifically for selecting individual amplifiers unique to each SpectraVideo

system. PROM pages are also used to select the gain characteristics of the

correlated double sample analog signal chain on the analog board. High gain and

low gain for each of 4 outputs are generally programmed in the DSP PROM.

Consult the Data Sheet received with the SpectraVideo camera for choice of

PROM page numbers (0 through 7).

The PixLoad program converts the decimal value to a hexadecimal format used

by the DSP. See Section 11.1 on the SpectraVideo serial port interface for details

on the serial port command syntax.

12.2.2. SAMPLE TEXT FILE

The following is a sample listing of the ‘file.clk’ contents with typical values:

port=2 ‘ MUST be on first line, left justified

‘pc serial port, 9600 baud, 1 start, 1 stop bit, no parity, 8 data bits, set internally.

‘ must be first line of text file.

‘

‘ Next is the commands,

‘ The first character is the prom page from which to boot, the numbers after the =

are

‘ don’t cares but necessary.

0=00 ‘ prom page for gain and amplifier selection

‘ next is pixels per line

a=1044 ‘ pixels per line = lead in pixels + central array pixels + 2

‘

b=1024 ‘ lines per frame = central array rows

c=0 ‘ serial pixels binned minus 1, pixels group size = c+1.

d=8 ‘ parallel states used per parallel shift, rows binned = d/8.

e=32 ‘ serial wait count, pixel period = (19+e*3)*100ηs. (10mhz DSP

clocks)

f=150 ‘ parallel wait count, wait = f*100ηs.

g=600 ‘ discing wait count, wait = g*pixel period.

h=200 ‘ after exposure wait count, h*h*pixel period.

SpectraVideo Camera User’s Manual Supporting Software

36

i=0 ‘ (1) region of interest mode switch, (0) no roi.

j=15 ‘ serial flush wait count = j*pixel period.

k=18 ‘ pixels skipped before region of interest.

l=1024 ‘ unblanked pixels in region of interest.

m=0 ‘ pixels skipped after region of interest.

n=0 ‘ lines skipped before region of interest.

p=1024 ‘ unblanked lines in region of interest.

r=0 ‘ lines skipped after region of interest.

s=0 ‘ (1) internal/ (0) external exposure control.

t=1000 ‘ internal exposure counter, inner loop.

v=1 ‘ internal exposure counter, middle loop.

w=1 ‘ internal exposure counter, outer loop.

‘ exposure period = W*(V*(T*pixel period)+0.3µs)+0.3µs)+0.4µs

x=48128 ‘ TE cooler controller command word. 8 bits used in MSByte (256

‘ to 65535 modulo 256)

‘ only the MSByte is sent to the TE cooler controller hence the modulo function ‘ example given is

‘ [78][BC][00] hexadecimal bytes or x[BC][00]

SpectraVideo Camera User’s Manual Supporting Software

37

13. A

13.1. APPENDIX A

PPENDICES

13.1.1. HEAD ASSEMBLY MECHANICAL DRAWING

Head Assembly Mechanical Specifications:

Weight: 2.5 lbs.

SpectraVideo Camera User’s Manual Appendices

38

13.2. APPENDIX B

13.2.1. CAMERA CONTROL BOX MECHANICAL DRAWING

Camera Control Box Mechanical Specifications:

Weight: 7.0 lbs.

SpectraVideo Camera User’s Manual Appendices

39

13.3. APPENDIX C

Command

Name

port=2

Typical values X size Y size

SI502 3+15+512 512

SI003 3+15+1024+15 1024

1100*165 3+15+1100+15 165

masterClock, 100ns or 62.5ns, this is the master oscillator in the camera

baseNumSerialStates, i.e. 19, used with ‘e’ and ‘j’ to calculate pixel period.

parallel shift state period, A minimum value set by the camera or by the CCD

13.3.1. SPECTRAVIDEO 1 CAMERA LOW LEVEL COMMAND SUMMARY

SpectraVideo 1 Camera Control commands

This command is used with pixload.exe. Other programs specify the serial port

in their own ways.

pc serial port, using 9600 baud, 1 start, 1 stop, no parity, and 8 data bits.

Only parallel output cameras use the PC’s serial port. Cameras using serial PCI

I/O boards use the serial control port on the PCI I/O board.

The SpectraVideo camera stays in flush mode until it receives an exposure

trigger. The camera then enters the exposure mode. At the end of the exposure

period, the camera enters the readout mode. At the end of readout, the camera

returns to flush mode.

The camera ignores the serial control port except when in flush mode.

The first camera control character is the prom page from which to boot, the

numbers after the ‘=’ are don’t cares but necessary.

This file requires the user/host to do some calculations based on constants

associated with the camera. These constants are in pixview.ini or are listed on a

separate data sheet sent with the camera.

prom page, used to configure the camera characteristics, CCD output, analog

gain or bandwidth, custom characteristics.

X size of CCD, serial pixels per row. At least this number of serial pixels plus

lead-in and lead-out pixels + 2 must be shifted out of the CCD on each row.

Y size of CCD, number of CCD rows. At least this number of rows must be

shifted out of the CCD for each frame.

pixel period is a parameter of the camera to support the analog board CDS

circuit.

numYStates, i.e. 6, the number of parallel shift states per row.

parallel states = CCD rows to be binned to one group * numYStates

CCD rows = binned row groups * rows per frame

SpectraVideo Camera User’s Manual Appendices

40

Command

Name

SpectraVideo 1 Camera Control commands

row shift period = parallel shift state period * numYStates

tempGain, a number used in CCD temperature calculation.

tempOffset, a number used in CCD temperature calculation.

s=1 Timed internal exposure mode. Not needed at this point for SV 1 cameras.

This command unlocks the control port and returns ACK. This command is

U=5555

always sent after the camera has booted such as at power up or a commanded

boot as in the next command.

0=0000 Boot to this prom page (0 through 7)

External exposure. The camera waits in flush mode. Exposure starts on the

s=0

falling edge of Expo In. Exposure ends on the rising edge of Exposure In.

Internally timed exposure. The camera waits in flush mode. Exposure starts on

s=1

the falling edge of Exposure In. Exposure duration is calculated from pixel

period and the values of t, v, and w.

s=2 Video mode is not supported.

digital value for CCD temperature control.

x=47995

x = 256 * tempGain / 100 * (CCD temperature in Kelvin - tempOffset)

Region of Interest mode switch,

i=0

(0) no region of interest (roi),

(1) 1 roi

(n) n ROIs with n rods see discussion at ‘B’.

a=number

b=number

z=3

pixels per row (line) = lead in pixels + central array pixels + 2. This is the

number of pixels per row (line) in the image when i = 0.

rows (lines) per frame, i must be set first. When i=0 or 1, b is the number or

rows in the readout frame. When i>1, b is ignored.

warm-up pixels shifted out before ‘a’ pixels (default = 3). These pixels fill the

pipe line in ADC and are binned as readout pixels. ROD pixels are not reduced.

E=1537 Not used as CCD’s have full frame readout

F=64 Not Used

n=0 lines skipped before region of interest, requires i > 0 to activate.

number of lines in single region of interest. i must be set to 1 before entering p

p=number

or r commands, otherwise they will be ignored. p and r are retained for

backward compatibility and for simplicity. When using p and r commands the r

command must immediately follow p.

r=number

d=6

D=6

number of lines in region of disinterest following the single region of interest set

by p. i must be set to 1 first.

parallel states in flush mode and if i=0 it is also used for readout.

rows binned = d / numYStates.

parallel states used per row shift in rod before first roi, requires i > 0 to activate.

rows binned = D / numYStates.

SpectraVideo Camera User’s Manual Appendices

41

Command

Name

A=00

sets a pointer to a data structure. Must appear immediately before group of ‘B’

statements.

SpectraVideo 1 Camera Control commands

Use of B is safer than use of b, p, r since the camera must store b, p, r into the

B=165

structure used for B.

if i = 0, this is rows (lines) per frame.

if i > 0, B = lines in first roi.

the number of parallel states associated with B above.

B=6

rows binned = B / numYStates.

CCD rows = binned rows * rows per frame

if i = 0, this is not used.

B=0

if i > 0, B = lines in first rod.

This B may equal 0.

the number of parallel states associated with B above.

B=6

rows binned = B / numYStates.

CCD rows = binned rows * rows per frame

Add a group of 4 Bs for each additional roi greater than 1 (i=n). The sum of all

roi rows (lines) = number of lines in the image

c=0 serial pixels binned minus 1, pixels group size = c + 1.

serial wait count,

e=20

pixel period = (baseNumSerialStates + e * 3) * masterClock.