Page 1

REV COUNTER RCX

(RCX As of Octo ber, 2013 No.1)

USER’S MANUAL

REV COUNTER

SHIFT LAMP & REV COUNTER for Pros

Thank you for purchasing this PIVOT product.

Please read this manual carefully and keep it for future

reference.

●If this product is given to

another u ser, make sure to

include this User’s Manual.

Product

+

Contents Please check the contents of the package

Contents / WARNING / CAUTION ……… 1 Features …………………………………… 1 Connecting The Wires …………………… 2 Installing The Product …………………… 3 Settings……………………………………… 3 Basic Operation …………………………… 4 Display The Peak Value and Reset …… 4 Troubleshooting …………………………… 4

WARNING

●Do not work in areas where there is excessive exhaust.

Due to vehi cle exhau st emission poi soning or fire may re sult in a damage to

humans.

●Please securely fasten the product to a stable place.

It is very d angero us if, whil e in use, the p roduc t falls of f and interferes w ith brak ing.

●Do not crush the cable.

Please be careful t hat the ca ble doe s not get cr ushed by t he seat rail or car do or

steel pl ate, nor cut by any sharp s teel plate as this may cause a po or connection or

an elec tric sho rt lead ing to fire or other danger.

●Do not op erate while driving.

Operat ing or checking the disp lay during drivi ng may caus e an acci dent; please use

with the u tmost c onsideration for safety.

●Please be sure to store bundle away all wires with tape, etc...

It is very danger ous to pull tangle d wires by force or all ow tangl ed wires to interfe re

with driving.

Improp er use or di sregar d of these w arning s may

result i n the injury or death of peop le.

OBD2

Shift Lamp

Cut Connectors

× 4

Controller

Double-sided

Tape

CAUTION

●This product is for DC12V cars;

Installation cannot be carried out on cars with other voltage batteries.

●Just after installation do not exert any strong force on the product.

When double- sided t ape is used for an ins tallation be warned that wh en hot the

tape temporarily losses adhesiveness.

●Do Not Use Chemical Cleansers.

If the uni t gets dir ty please wipe with a sof t cloth to remove any dirt. Do n ot use

chemical cleansers such as thinner, benzene, or alcohol.

●Do not install the product in any place subject to high temperature

or any place where water may be splashed.

●Make sure to replace all screws and parts to their original place.

●Do not install the product in a place where it will cause distraction.

●Do not, in any manner, process, take apart, or make changes to

this product.

Power Cable

with fuse 3A

Allen

Wrench

Improp er use or di sregar d of these warning s may

cause in jury to p ersons , damage t he product and

other things.

extension

Zip Ties

× 5

White

cord

Earth

terminal

User’s guide

ECU wiring

diagram list

Features

Shift Lamp

■

Shift lamp lights up when the set rpm is reached.

Ultra bright LED is easy to see even in full daylight.

・

For night driving select auto low light ing or synchronize w ith parking lights.

・

High quality aluminum machined body with swivel neck.

・

Digital Tachometer

■

High precision display for setting shift lamp and viewing rpm.

High precision display of engine rpm up to 9999 in 1 rpm units.

・

Shift lamp settings can be made in units of 100 rpm.

・

View real time and peak engine rpm.

・

Compac t design needs no space.

・

Alarm

■

Alarm sounds at shift point for 0.5 seconds.

Easy Installation

■

Can be easily installed in some model TOYOTA and DAIHATSU cars

directly by connecting to the diagnostics connector. Other models can be

connected to the ECU.

Compatible Vehicles

■

12 V Gasoline Engine Cars (some diesel engine models)

For 1・2・3・4・5・6・8 cylinder models.

Size

■

[Unit:mm]

(Shift Lamp) (Controller)

46

32

20

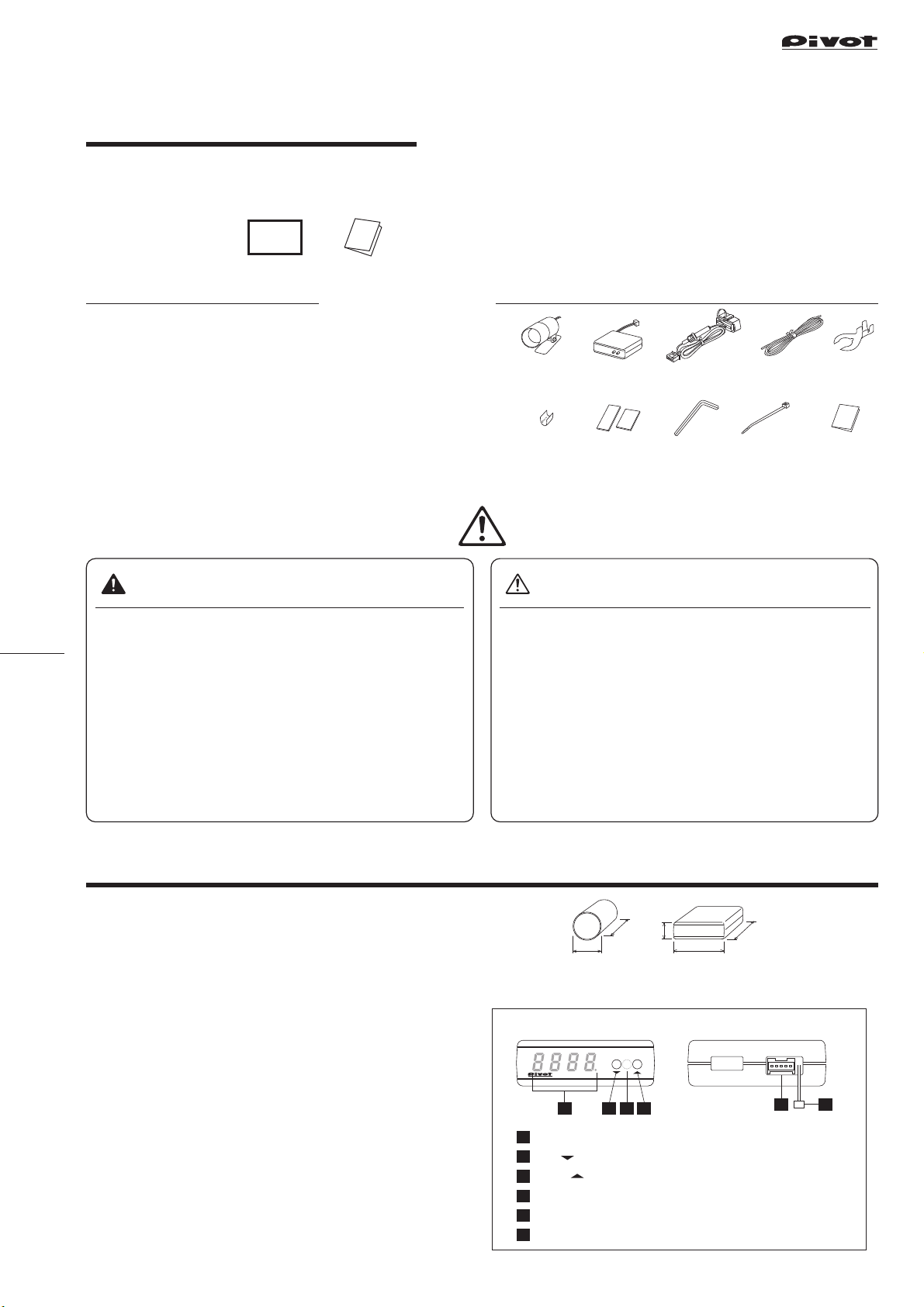

Part Names of the Controller

(Front) (Backside)

REV COUNTER

12634

Display

1

SET( ) switch

2

PEAK( ) switch

3

Light sensor

4

5-pin Connector

5

2-pin Connector

6

SET

PEAK

rpm

RPM and eac h setting disp lay

Change each setting

Peak and change each sett ing

For Automatical ly low lighting

Connect to the 5 -pin Co nnecto r of Power cab le

Connect to the 2-p in Connector of Sh ift Lamp

60

50

5

1

Page 2

Connecting the Wires

Red

Red

Black

Black

White

White

Red

Black

White

1

Type

Backside of the controller

Type

Connect to the Power and RPM signal

Car models with a ● or ◎ mark in the

“ECU Wiring Diagram List”

:

A

(Some of TOYOTA, DAIHATSU and MINI)

Connect to the diagnostic

monitor connector

OBD2

5-pin

connector

: If you are not using the diagnostic monitor connector

C

Connector

Backside of the controller

Type

:For Popular Models (other than TOYOTA, DAIHATSU and MINI)

B

5-pin

connector

If you are wiring directly cut off and insulate all wires at the base of the OBD2 connector.

12

←To controller

Cut off at the base

RedRed

BlackBlack

WhiteWhite

OBD2

connector

■ Explanation of wires

Color

Red

Black

White

Orange

Wiring place

IGN

GND

TA

Illumi

Details

12V with key switch ON (or Normal power)

Screw to ga in eart h, etc

RPM signal

12V with park ing light s ON

Backside of the controller

5-pin

connector

●

⇒

●Automatically low lighting

⇒ No need to make wiring

IGN (or Normal power)

BlackBlack

WhiteWhite

Orange wire

Synchronize wit h parkin g lights

Need to make wiring

RedRed

※1

Connect to the diagnostic

monitor connector

Engine Computer,

Earth

= Use cut connector (or solder)

OBD2

Connector

Cut off

WhiteWhite

at the base

Insulate the cut

off part with tape

RedRed

BlackBlack

White ※1

If the white wire is not long

※1

enough, please use the

white wire provided in this package to extend the length.

ECU

etc.

See 【Reference 2】

Cut connector

TA

Backside of the controller

5-pin

connector

Cut the black tube of the wire tip and connect.

Orange

ECU

Engine Computer,

etc.

TA

White

extension wire

Insulate the cut off

part with tape

Parking

light

When another device is already

connected to the RPM signal

from the ECU

●To get the RPM signal from diagnosis

To get the RPM

signal from other

than the ECU

2

Connect to the Shift Lamp

(check connector)

Ex : in ca se of

MAZDA EUNOS

ROADSTER

(NA6C)

←To controller

... and that device works properly keep that wiring.

... and the meter or other device stops working properly or sometimes becomes unstable disconnect from

the ECU wire and get the RPM from the minus terminal of ignition coil or diagnosis. (Follow the directions

as written below)

Location of the

RPM sign al (IG − )

White wire

Insert the 2-pin connector from the shift lamp into the 2-pin connector at the back

of the controller.

Backside of the controller

Shift Lamp

2-pin connector

【Reference 1】Notes about using the OBD 2 Connector

Make sure to g rip the

distended portions when

pullin g it out or inserti ng it.

CAUTION

Do not pul l on the wires

when tr ying to remove the

conne ctor; th e wires may

become disconnected.

If you unable to get a gripon the distended portions.

With some car mod els

it may be difficu lt to

get a goo d grip on the

connector.

●To get the RPM signal from

the igni tion coil

White wire

←To controller

Ignition coil

ー

About Using OBD2 Products in Combination

If you wish to use REV COUNTER in combination with products in

our 3- drive S eries (FLAT or COMPACT) or other OBD 2 products, th e

“OBD2 W iring Kit OBD- EH” (sold separately ¥ 3,2 00) mak es

installation a snap.

For more d etail s about using combinations of pro ducts s ee here.

⇒

http://pivotjp.com/o bd- e/

When usi ng REV COU NTER with p roduc ts menti oned above, they can

*

only be us ed toget her in com patibl e model ve hicles for both products.

When co nnect ing the RPM signal to the

igniti on coil or d iagnos is and th e indica ted

rpm on the meter may be obvio usly lowe r

than th e actual rpm as show n on tach omete r

Ex : For a 6 cyli nder car, th e reading s hould be 3 000

rpm, but d isplay sh ows 500 rp m.

This may be c aused by th e indivi dual wir ing system

of that mod el of car. Chan ge the cyl inder set ting to

“1”. (See page 3 “SE TTING S A” for detail s.)

In such c ase, pull

out the connector by

pullin g on the end of

the zip ti e.

【Reference 2】How to use the Cut Connectors

10 mm

1

Peel off of t he vinyl

cover at connection.

When cri mping, p lease us e crimper s or use pli ers to ben d and then s older tog ether.

*

10 mm

2

Peel off of t he vinyl

cover at the e nd of

the prod uct’ s wire.

3

Wrap around both

wire coils.

2

4

Close ti ghtly wi th

cut connector.

5

Insulate with

vinyl tape.

【Reference 3】How to use provided e arth terminal

1.

Peel off a bout 10mm of vi nyl coveri ng from the t ip of

the blac k wire.

2.

Bend the outside wires around the core to

make the wir e thicker.

3.

Crimp down on the earth terminal.

4.

Connec t it to a ear th screw.

Crimp down

Page 3

Fastening the products

On the steering

column cover

Below the

meter hood

On the steering

column cover

On the da shboard

Installation of the Shift Lamp

(Installation Method)

On the da shboard

On the steering

column cover

Adjust to

designed

angle

Double-sided

tape (included)

Clean to remove

oil or dus t

Hexagonal bolt

Fasten using the

①

double-sid ed tape.

(Clean the surfac e;

removing all oil or dust.)

After decidin g the

②

position and angle of

the meter face, fasten

the hexag onal bolts on

both sid es to sec ure.

Settings

SETTING

A

Set the cylinder number for the car being used.

1

2

Patterns for cylinder set tings display

1-cylinder 234568Special A

Cylinder Number Setting

ON

Press the S ET switc h for 5 seco nds

during the key switch ON (engine not running)

Ex)

(The factory d efault se tting i s for a four-c ylinde r engine)

Press the SET

switch for 5 seconds

Cylinder display

3

Down Up

Press the sw itch to ch ange

the patt ern and set t o the

proper one.

Installation of the Controller

(Installation Example)(Installation Example) (Installation Method)

On the

meter hood

Below the

meter hood

On the steering

column cover

SETTING

C

Changes are only necessary for those car models listed below.

NISSAN (FAIRL ADY Z Z33)・MAZDA (after 2002)・

MITSUBISHI (COLT and others)・SUBARU (early t ype of PLEO and others)

※See the “ECU Wiring Diagram List” for details.

1

Press the PE AK switc h for 3 seco nds during

the key switch ON (engine not running)

2

3

Switching the signal level

ON

Press the PEAK switch

for 5 seconds

orDisplay

Press

the PEAK

switch

The display will c hange with each pressin g of the switch.

Fasten using the double-sided tape.

(Clean the s urface; r emoving a ll oil or du st.)

If the

generic car

4

5

Controller

Double-sided tape

(included)

Clean to remove

oil or dus t

With no

operation for

5 seconds

Display off

If the level

is small

4

※ For one and two cylinder engines, set the signal level switch to two.

●The factor y default setting is for a four-cylinder engine. After set ting is

changed, the last setting will be displayed.

●If the engine is a two cycle engine, multiply the number of cylinder by two.

(e.g., For a two- cycle three- cylinder engine the set ting would be six.)

【Reference】

One- cylind er : Some models of NISSAN or MA ZDA

Two-cylinder : Some models of MAZDA or SUBARU

Four-cylinder : Rotary engine (RX-7)

Special A : Some models of NISSAN, etc.

SETTING

B

Make RPM setting for turning on the Shift Lamp.

While di splayi ng RPM,

press th e SET swit ch once.

Ex)

2

The Shif t Lamp d oes not li t during settin g.

3

With no operation

for 5 seconds

⇒ See SETTING C : Sw itching the sign al level for details.

5

RPM Setting

RPM display

Down Up

Press the switch to change

the RPM set ting

Press the

SET switch

Current setting

(Ex; 350 0rpm)

display

Pressin g button one time w ill

decrease the RPM s ettin g by 100 rpm;

pressi ng button will in crease t he

setti ng by 100 rpm.

※Holding down the either button will

rapidly chang e the set ting.

41

5

Display off

With no

operation for

5 seconds

RPM display

SETTING

Alarm Setting

D

Make Alarm setting for the sound during light emission of Shift Lamp.

RPM display

While di splayi ng RPM,

press th e SET swit ch for 3 sec onds.

Ex)

2

3

The display will c hange with each pressin g of the switch.

●Alarm sounds when you make each settings even if Alarm set to OFF.

SETTING

Current setting

display

Press

the SET switch

Alarm ON Alarm OFF

Press the SET

switch

for 3 seconds

(Ex; Alar m on)

41

5

With no

operation for

5 seconds

RPM display

Low lighting setting

E

Make setting of auto low lighting of Shif t Lamp.

RPM display

While di splayi ng RPM,

press th e PEAK swit ch for 3seconds.

Ex)

2

3

The display will c hange with each pressin g of the switch.

●This functio n doesn’t work if the Shift L amp synchronizes with par king lights

with connecting to Orange code.

●If the controll er is inst alled dark place and the light sensor of controller could

not sense the change of lights, the Shift Lamp might keep low lighting.

Current setting display

(Ex; Low lig hting ON)

Press

the SET switch

Low lighting ON Low lighting OFF

Press the PEAK

switch

for 3 seconds

41

5

With no

operation for

5 seconds

RPM display

3

Page 4

Operation

ENGINE START Key switch ON (engine not running)

Display: Lamp offDisplay : Engine Revolution display

Press

theSET

switch

SETTING

RPM

Setting

B

For details about settings see each [SETTINGS] on page 3.

*

Press

the PEAK

switch

PEAK Value

Display

SETTING

D

With no operation

for 5 seconds

Press the

SET switch

for 3 seconds

Alarm

Setting

SETTING

Low lighting

E

Press the

PEAK switch

for 3 seconds

Setting

SETTING

A

Peak Display and Reset the Peak Value

Display the Peak value Reset the Peak value

RPM display

1

While di splayi ng RPM,

press th e PEAK swit ch once.

Ex)

2

While di splayi ng Peak valu e, maximum of dot wi ll light .

3

With no operation

for 5 seconds

Peak value display

(Ex; Peak val ue= 685 0rpm)

Press the

PEAK switch

4

1

RPM display

Press the PEAK switch

for 3 seconds

While di splayi ng Peak valu e, press th e PEAK switch for 3 sec onds to reset

the Peak value and go b ack to RPM di splay.

Press the

SET switch

for 5 seconds

Cylinder

Number Setting

With no operation

for 5 seconds

SETTING

C

Press the

PEAK switch

for 5 seconds

Switching

the signal level

Troubleshooting

Tro uble

With the engine running the controller does

not show the rpm.

The displayed values are very different from

the stan dard meter and others.

The Shif t Lamp does not light up.

Even with the parkin g lights o n, brightness of

the shif t lamp does not decrease.

The Shift Lamp keeps low lighting. Please move the controller to w here it can sense the change

The display of the controll er is operating even

when the engine has been stopped.

The auto-power window fun ction and/or oth er

electronic devices are re-set.

Poor connection of each wire.

Poor connection of OBD2 connector.

The signal detection level is not correct.

The cylinder set ting is wrong.

The signal detection level is not correct.

The engine rpm has not reach ed the set s hift

point.

Poor connectio n of 2-pin connector.

Poor connection of orang e wire.

Poor wiring of orange wire.

The controller is installed a dark place.

Noise from the car (door locks and so on) may

cause it to temporar ily operate.

This is due to the minus terminal on the

batter y being d isconnected.

Possible Causes Possible Solutions

Please re confir m whether wiring and conne ction s are correct

or not.

See page 3 [SETTING C] and [ECU Wiring Diagram List],

make any nec essar y chang es.

Due to dif ferenc e in accuracy, readings may not be the same

as those o n the standard tachometer.

See page 3 [SETTING A] and make any necessary cha nges.

See page 3 [SETTING C] , make any necessar y changes.

See page 3 [SETTING B] , make any necessar y changes.

Please re confir m whether wiring and conne ction s are correct

or not.

Please re confir m whether wiring and conne ction s are correct

or not.

Please re confir m whether wiring and conne ction s are correct

or not.

of lights.

If the operation is only temporary it is not a malfunct ion; but if

it still causes worry cut the red wire in the OBD2 connec tor

and connect it to IGN.

Re-c onnect the minus termina l and follow re-setting

instructions for any affe cted devices.

※Our products have already been reco gnized as our Industrial Propert y or are in the process of receiving Industrial Proper ty status.

※We plan in the near future to take all possible legal measures to protect against unfair competition from look-alike products using similar designs, regulating

characteristi cs, circuitry and circuitry layout.

※We strictly prohibit the unlicensed use of the PIVOT trad emark and the unau thorize d use of PIVOT User’s Manual.

4

PIVOT CORPORATION 87-3, Shimookad a Okada, Matsumoto-shi, Nagano, 390-0313 JAPAN http://pivotjp.com/

Loading...

Loading...