Bulletin M0188A EN - Rev. 1

CONTROL PANEL

FOR DISPENSERS

CONTROL PANEL

FOR DISPENSERS

MC BOX

MC BOX

ENGLISH

USE AND

MAINTENANCE MANUAL

2

EN

3

TABLE OF CONTENTS

A. EC DECLARATION OF

CONFORMITY ...............................

B. FIRST AID RULES .........................

C. GENERAL ......................................

D. SAFETY INSTRUCTIONS ..............

D.1 SAFETY RULES ........................

D.2 TRANSPORT, HANDLING

AND UNPACKING .....................

D.3 DISPOSAL ................................

E. USING AND LOOKING AFTER

THE MANUALS ..............................

E.1 IDENTIFICATION PLATE ..........

F. DESCRIPTION OF MAIN PARTS ..

F.1 CONTROL SYSTEM .................

G. TECHNICAL SPECIFICATIONS ....

G.1 PERMITTED USES ...................

G.2 CONTROL SYSTEM

PERFORMANCE .......................

G.2 METERING PRECISION............

G.3 ABSORBED POWER ................

4

5

5

6

6

7

7

8

8

9

10

10

10

10

10

10

H. INSTALLATION ..............................

H.1 GENERAL .................................

H.2 ELECTRICAL CONNECTIONS..

I. COMMISSIONING .........................

I.1 ELECTRICAL POWER SUPPLY..

I.2 STATION CONFIGURATION ....

I.3 DISENGAGING THE

“MC” SYSTEM ..........................

I.4 METER CALIBRATION ..............

L. EVERY DAY USE ............................

L.1 FUEL DISPENSING ..................

M.ROUTINE MAINTENANCE ............

M.1 “MC” CONTROL SYSTEM ........

M.2 TROUBLESHOOTING ..............

N. SPECIAL MAINTENANCE .............

N.1 CHECKING AND REPLACING

FUSES ......................................

O. MC BOX SPARE PARTS ................

P. MANUFACTURER AND

SERVICE DATA ..............................

10

10

10

16

16

16

17

18

18

19

20

20

20

22

22

23

23

EN(Translated from Italian)

4

The MC BOX dispensing units described in this manual are for professional use

only.

A EC DECLARATION OF CONFORMITY

EN (Translated from Italian)

- Machine Directive 2006/42/EC

- Low-Voltage Directive 2006/95/EC

- Electromagnetic Compatibility Directive 2004/108/EC

Description:

Model:

Serial number:

Year of manufacture:

DIESEL FUEL DISPENSER

MC BOX

refer to Lot Number shown on CE plate affixed to the

product

refer to the year of production shown on the CE plate

affixed to the product

HEREBY STATES

The undersigned:

under its own responsibility, that the equipment described below:

PIUSI S.p.A

Via Pacinotti c.m. z.i.Rangavino

46029 Suzzara - Mantova - Italy

EC DECLARATION OF CONFORMITY

Suzzara 29/12/2009

is in conformity with the legal provisions indicated in the directives:

The documentation is at the disposal of the competent authority following motivated

request at Piusi S.p.A. or following request sent to the email address: doc_tec@piusi.com

The person authorised to compile the technical file and draw up the declaration is

Otto Varini as legal representative.

the legal representative

5

B FIRST AID RULES

C GENERAL

Persons who have ingested toxic liquids.

Whenever fuel has been swallowed, do not induce vomiting, but have the

injured person drink large quantities of milk or water.

MC BOX Electronic Panels are designed for the private distribution of fuel (or other

liquids).

All of the models in the series are characterised by the same form for which the MC BOX

is known: a solid metal structure, high-accuracy measurements in the dispensed

product and PC software that is designed for simplicity.

This electronic panel allows you to control and monitor private use fuel consumption via

a fuel dispenser with pump and flow meter.

The MC system consists of a multi-user panel, dedicated software and the option to

connect to a PC.

Persons who have suffered electric shock.

Disconnect the power source, or use a dry insulator to protect yourself while

you move the injured person away from any electrical conductor.

Avoid touching the injured person with your bare hands until he is far away

from any conductor.

Immediately call for help from qualified and trained personnel.

IN ALL CASES, SEEK MEDICAL ATTENTION IMMEDIATELY

Key

reader

CONTROLLED UNITS

RSC converter

Remote printer

Pulse meter

External nozzle

switch

Tank level

gauge

Pump unit

Remote PC

connection

PC interface

(optional)

DATA MANAGEMENT

UP TO 80 OR 120 USERS

The MC BOX System has the ability to:

• Switch the pump on;

• Recognise authorised users;

• Preset the dispense quantity;

• Manage the pulse meter;

• Manage an external level switch that turns off the pump in the event of minimum

flow level;

• Operate an external nozzle switch;

• Connect directly to a PC;

• Connect to an external printer

EN(Translated from Italian)

The panel is easy to install and is adequately protected. The wiring connections

can be easily accessed.

The group can also be supplied with a meter, to be installed together with

the pump.

Specifications

Panel with dual display, keyboard and i-button reader.

The electric box can be opened, allowing easy access to the wiring.

Maximum power supply: 6.5 amps.

Optional

• PC Software with dedicated RS converter or i-button reader to export data.

• I-button keys for users.

• High-accuracy oval gear flow meters.

Performance

• 80 or 120-user capacity (depending on model), managed via password or i-button key.

• Total consumption calculation for defined periods for each user.

• Local memory that can store data until the last 255 dispenses.

• Vehicle identification and mileage tracking option.

• Dispensing date and time control.

• Dedicated software that allows you to print dispense data for each user.

• Ability to manage up to 16 control panels with one single software.

• Key reader with USB plug for exporting data.

• RS converter with USB plug for direct connection to the PC via cable (up to 1000 m).

D SAFETY INSTRUCTIONS

All the MC BOX models have been designed and built according to applicable EEC

directives relating to essential safety and health requirements.

Page 4 of this manual shows a copy of the manufacturer's DECLARATION OF

CONFORMITY.

6

D.1 SAFETY RULES

Electrical Precautions.

There are dangerously high voltages inside the unit. Only qualified and

authorized technical personnel are allowed to open the fuel unit.

Permitted Uses.

The unit must always be used for the purpose intended. Follow the

instructions listed in the chapter Instructions for Use.

Service.

Service of the dispenser must be performed by qualified personnel.

EN (Translated from Italian)

When the machine is not used, whether it is packed or unpacked, it must be stored in a

place protected from the weather (rain, damp, sun, etc.) and from dust.

To remove the cardboard packaging, use a pair of scissors or cutters, being careful not

to damage the appliance. Fully open the packaging and take out the MC BOX so that it

can be taken to the place of final installation.

Packaging parts (cardboard, wood, cellophane, etc...) must be placed in specific

containers and not left lying around or within reach of children, as these represent a

potential risk hazard.

They must be disposed of according to the regulations applicable in the country of use.

Check the integrity of the machine by making sure the shipped parts are not damaged

in any way that could affect safety and operation. In case of any doubts, do not start the

appliance but contact the manufacturer's after-sales service.

Should the device be demolished, its parts and components should be entrusted to a

firm that specialises in the disposal and recycling of industrial waste. Please note:

DISPOSAL OF PACKING MATERIAL:

the packaging is made of biodegradable cardboard and can be sent to companies for

the normal recovery of cellulose-based packaging.

DISPOSAL OF METAL COMPONENTS:

metal parts, whether paint-finished or in stainless steel, can be consigned to scrap metal

collectors.

DISPOSAL OF ELECTRIC AND ELECTRONIC COMPONENTS:

these have to be disposed by companies that are specialised in the disposal of

electronic components, in accordance with the instructions of 2002/96/EC (see text of

Directive below).

INFORMATION REGARDING THE ENVIRONMENT FOR CLIENTS RESIDING

WITHIN THE EUROPEAN UNION:

D.2 TRANSPORT, HANDLING AND UNPACKING

D.3 DISPOSAL

7

172

260 146

256

22

MC BOX is shipped inside stackable

cardboard packaging.

DIMENSIONS OF

PACKAGING:

TOTAL WEIGHT:

WEIGHT OF

PACKAGING:

h=400 mm/

l = 290 mm/

p=200 mm

5.386 Kg

0.482 Kg

European Directive 2002/96/EC requires that all equipment marked with this

symbol on the product and/or packaging not be disposed of together with

non-differentiated urban waste. The symbol indicates that this product should

be disposed of separately from regular household waste streams.

It is the responsibility of the owner to dispose of these products as well as other

electric or electronic equipment by means of the specific refuse collection

structures indicated by the government or the local governing authorities.

DISPOSAL OF OTHER PARTS:

Other components, such as pipes, rubber gaskets, plastic parts and wires, must be

disposed of by companies specialising in the disposal of industrial waste.

EN(Translated from Italian)

E USING AND LOOKING AFTER THE MANUALS

This manual is common to all MC box models and illustrates the main characteristics of

the various models, providing information on:

• electrical and mechanical installation

• first start up operations

• daily use

This manual DOES NOT cover other aspects such as:

• configuration and operation of the Control system

For these aspects, refer to the specific manuals which accompany each station

model.

For the installer's convenience, all supplied manuals are grouped together in an

envelope. This collection of manuals represents an integral and essential part of the

product and, according to the provisions of directive EEC 89/392, must be given to

operators and maintenance staff in order to comply with the obligations relating to

training/information referred to in directive EEC 89/391.

Carefully read the instructions contained in these manuals, as these are most important

for installation safety, operation and maintenance.

The manufacturer shall not be responsible for damage caused to persons, to property

or to the product that derive from improper use.

Look after this manual carefully in a place protected from damp, heat, dust, oils,

greases, etc., as it will be useful for future reference and consultation. Do not remove,

tear or amend any parts of the manual for any reason. In case of loss or damage, ask

the manufacturer for a copy, quoting the manual code.

This manual must always remain with the machine; in the event of the machine being

sold, it must be given to the new user.

The MC BOX has an identification plate that reads:

• Model

• Serial number / Year of manufacture

• Technical Specifications

• CE mark

8

E.1 IDENTIFICATION PLATE

MANUFACTURER

PRODUCT CODE

(see table)

YEAR OF MANUFACTURE

TECHNICAL

SPECIFICATIONS

(see table)

“CE” MARK

SERIAL NUMBER

PRODUCT NAME

MC BOX

Vn: 230 V

Fn: 50/60

In stand-by: 40 mA

Pulser Max. Freq.: 60 Hz

Pulser Duty Cycle: 20%-80%

IMotor Max: 6.5 A

IP 55

YEAR 2008

Read instruction

M0187 - M0188

CODE F1398000B

LOT NUMBER

0000001

CERTIFIED COMPANY

UNI-EN ISO 9001

PIUSI S.P.A.

SUZZARA

(MN) ITALY

EN (Translated from Italian)

The company reserves the right to change MC BOX features and specifications

at any time.

! WARNING

9

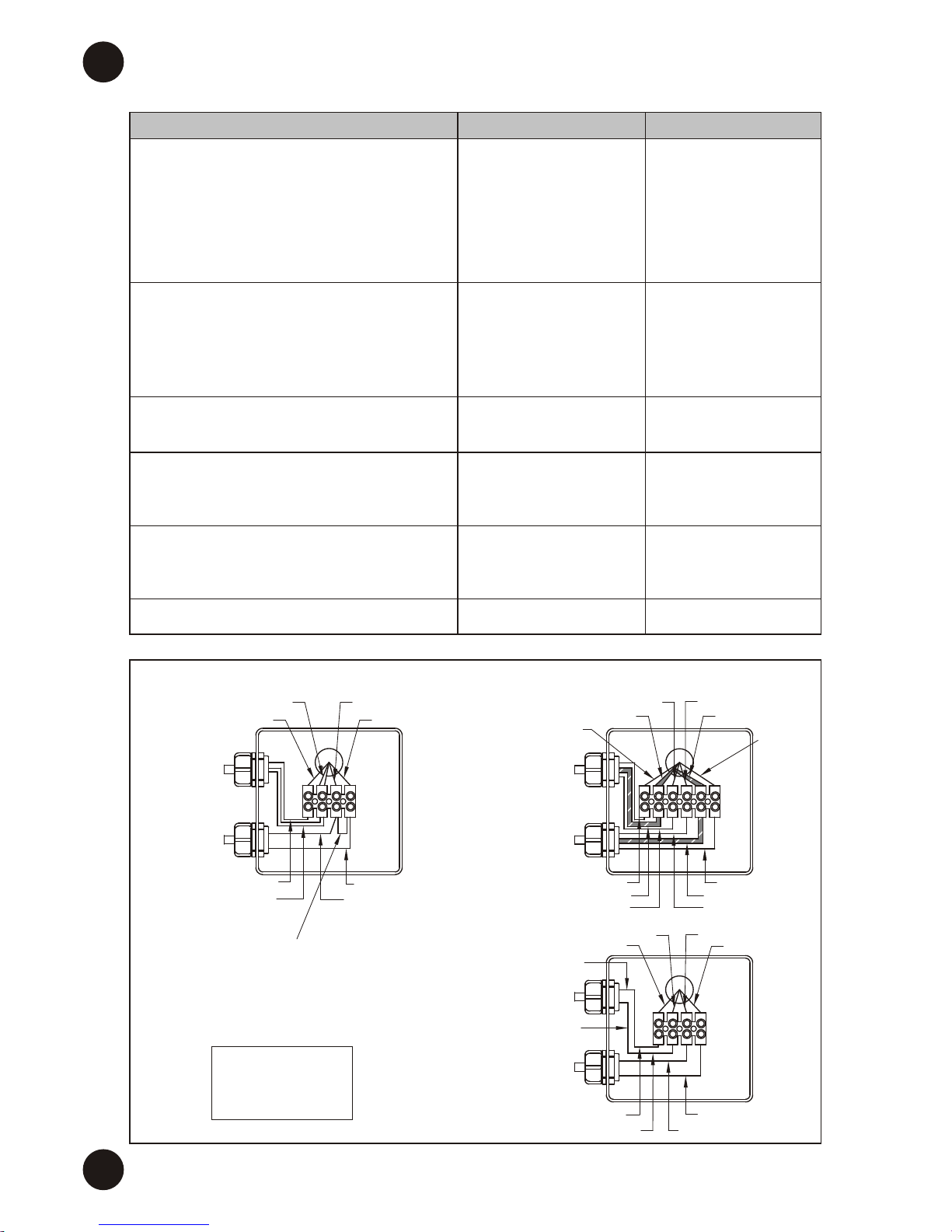

Client

reference

code

Description

Nominal current

consumption in

stand-by mode

at 25°C ambient

temperature

Power supply

fuse on

electronic

board

Nominal

power supply

(Voltage)

Nominal

frequency (Hz)

Max. motor

current (A)

Motor fuse

F1398000B

MC BOX 230V

80 USER

40 mA

100 mA T (Rit.)

40 mA

100 mA T (Rit.)

80 mA

200 mA T (Rit.)

150 mA

1 A T (Rit.)

75 mA

1 A T (Rit.)

230 Vac 230 Vac 110 Vac 12 Vdc 24 Vdc

50/60 Hz

6.5 A

8 A T (Rit.)

50/60 Hz

6.5 A

8 A T (Rit.)

50/60 Hz

7.0 A

8 A T (Rit.)

50 A

Sized according

to the power

of the connected

DC 12V motor,

but must NOT

exceed 60 A

(automotive)

Sized according

to the power

of the connected

DC 24V motor,

but must NOT

exceed 30 A

(automotive)

25 A

MC BOX 230V

120 USER

MC BOX 110V

120 USER

MC BOX 12V

120 USER

MC BOX 24V

120 USER

F1398005A F1398003A F1398001A F1398002A

MC BOX

230 Vac - 50/60 Hz

80 user

MC BOX

230 Vac - 50/60 Hz

120 user

MC BOX

110 Vac - 50/60 Hz

MC BOX

12 Vdc

MC BOX

24 Vdc

F DESCRIPTION OF MAIN PARTS

The MC BOX is designed for the private dispensing of fuel.

Recognised for their ease of use and maximum safety, MC BOX dispensers are reliable,

high-performing, quick to install and ready-to-use.

Equipment and features are:

• Sturdy, lockable metal box with hinged door;

• Electronic Control Panel with:

- Dual display

- Membrane keyboard

- Recognition and access control system with electronic key, allowing for a

simple man-machine interface.

The electronic panel is also equipped with other out-facing interfaces, such as:

- Pump ignition control

- Nozzle contact input command

- Level contact input command

- RS485 output for PC connection

(subject to software installation and available drivers)

EN(Translated from Italian)

Before installing, always make sure the dispenser model is correct and suitable

for the available power supply (voltage / frequency).

! WARNING

G TECHNICAL SPECIFICATIONS

10

The performance of the MC control system is detailed in the M0187 manual supplied

together with the MC BOX.

Implementation of a fluid dispensing system, intended for private use, not subject to

special regulations (e.g. ATEX) for potentially explosive environments.

Mainly influenced by the pulsation type used.

For further details, please refer to the specific user manual for the pulsation type used.

The MC BOX can be installed outdoors. Nevertheless, it is advisable to locate it under

the shelter of a roof to ensure the dispenser's longevity and provide greater comfort

during refueling in the event of bad weather.

The installation of the dispenser must be carried out by skilled personnel and performed

according to the instructions provided in this chapter.

The power connections must be workmanlike performed by skilled personnel, in strict

compliance with the laws applicable in the country of installation and with the

instructions on the wiring diagrams in this manual.

G.2 CONTROL SYSTEM PERFORMANCE

G.1 PERMITTED USES

G.3 METERING PRECISION

H.1 GENERAL

H.2 ELECTRICAL CONNECTIONS

G.4 ABSORBED POWER

H INSTALLATION

See table, paragraph E.1.

The maximum acceptable variations from the electrical parameters are:

• Voltage +/-10 % for AC versions

• Voltage +/-15 % for battery-operated DC versions

• Frequency +/-1% (+/-2% for short periods) (for AC versions)

The electronic control system -MC- ensures the dispenser can only be used by

authorised personnel.

All the data relating to each dispensing operation are stored and can be transferred

to a PC (optional).

F.1 CONTROL SYSTEM

EN (Translated from Italian)

11

The MC BOX is equipped with 3 junction boxes. These can easily be accessed

by opening the door to where the screw terminals for the external cable connections

are located.

The connections that need to be made vary according to the model (AC or DC):

AC :Versions

EN

Inputs Outputs Note

AC mains supply

AC motor power the same

voltage as the mains

The RS 485 data line

to the PC (optional)

Nozzle contact:

clean contact: Open with nozzle replaced

and Closed when nozzle dispensing

Level contact:

clean contact: Open with nozzle in normal

conditions and Closed below the minimum

flow level

Pulse meter input:

clean contact or Open Collector output signal,

with 60 Hz maximum frequency and between

20% and 80% duty cycle

Voltage: 230Vac or

110Vac, depending

on the maximum

power of the

pluggable motors:

• 230Vac version

= 1400 W

• 110Vac version

= 750 W

(Translated from Italian)

- The MC BOX Electronic Panel does NOT come with protective switches;

it is therefore mandatory that the MC BOX be installed with an electrical panel

that is suitable to the individual MC BOX and has a differential power switch or,

at the very least, a fast-access device such as a socket/plug, to be used in the

event of anomalies;

- All the electronic components found within the MC BOX container have been

pre-wired and tested at the factory; as such, it is NEVER necessary to have the

MC BOX opened by the person who installed it or the plant operator, unless the

fuse protection on the I/O card needs to be replaced;

- The installer should carry out a plug/socket connection for a quick sectioning of

the electric system in case of failures.

! WARNING

Before accessing the electrical parts, be sure that you have

disconnected all of the general switches that power the device.

! WARNING

DC :Versions

Inputs Outputs Note

DC Power Supply

DC motor power

is the same as the

supply voltage

The RS 485 data line

to the PC (optional)

Voltage: 12Vdc or

24Vac, depending on

the maximum power of

the pluggable motors:

• 12Vdc version

= 600 W

• 24Vdc version

= 600 W

By removing a jumper

and inserting the

“in ignition” contact in

its place, the electronics

can be powered only

when the vehicle is

switched on

Power input WITH IGNITION ON.

Given the DC systems' high power

absorption, the motor should be powered

while the battery is being recharged

Nozzle contact:

clean contact: Open with nozzle replaced

and Closed when nozzle dispensing

Level contact:

clean contact: Open with nozzle in normal

conditions and Closed below the minimum

flow level

Pulse meter input:

clean contact or Open Collector output signal,

with 60 Hz maximum frequency and between

20% and 80% duty cycle

12

POWER

INPUT

230V/110V

TO MOTOR

11

BROWN

GREEN/YELLOW

BLUE

GREY or

BLACK

GREEN/YELLOW

BLACK

BROWN

GREEN/YELLOW

BLUE BLUE

GREEN/YELLOW

BROWN

RS485,

PC/PRINTER OUTPUT

(OPTIONAL)

TO LEVEL

PROBE CONTACT

(OPTIONAL)

3

RS485+

RS485 -

RED

ROSE

GREY

YELLOW

RED

ROSE

GREY

YELLOW

Max. current Motor

Imax = 6.5A (230 Vac)

Max. current Motor

Imax = 7A (110 Vac)

MC BOX 230Vac - 110Vac: EXTERNAL ELECTRICAL CONNECTIONS DIAGRAM

TO

PULSER

K600

TO NOZZLE

CONTACT

22

BROWN

WHITE

GREEN

BLUE

BROWN

WHITE

BROWN

BLUE

Apply a bridge

to the contacts

in the event that

there is no nozzle

contact

EN (Translated from Italian)

13

MC BOX 12Vdc - 24Vdc: EXTERNAL ELECTRICAL CONNECTIONS DIAGRAM

12V version MOTOR 12V

24V version MOTOR 24V

12V version 12V BATTERY

24V version 24V BATTERY

BLUE

BLACK

BROWN

BLUE

BLUE

YELLOW

12V version: TO POWER12V

RED

BLACK

YELLOW

RED

NOZZLE

CONTACT

85

86

87

30

YELLOW

BLUE

RED

BLACK

+

-

BATT IN

+

BATTERY

MOTOR

+

-

R-C

FILTER

If you want to use

the nozzle contact,

remove the jumper

If you wish to turn

the device on and off

with the vehicle key,

replace the jumper

with an ignition switch

The fuse (max. 40A @ 24V and max. 60A @ 12V)

can be placed on the motor or inside the electrical

box as shown. (See "Electrical Power" chapter).

Choose fuse size in accordance with the motor's

absorption level (See "Electrical Power" chapter).

24V version: TO POWER 24V

12V version: TO POWER RELAY 12V

24V version: TO POWER RELAY 24V

WHITE

RED

BROWN

ROSE

GREY

YELLOW

BROWN

WHITE

RED

ROSE

RS-485 +

RS-485 -

TO

K600

PULSER

RS485

PC/PRINTER

OUTPUT

(OPTIONAL)

LEVEL

CONTACT

ON-OFF

key

FUSE

XX

FUSE

XX

85

86

87

30

FUSE

XX

MOTOR

FUSE

XX

Max. current Motor

Imax = 50A (12 V)

Max. current Motor

Imax = 25A (24 V)

EN(Translated from Italian)

14

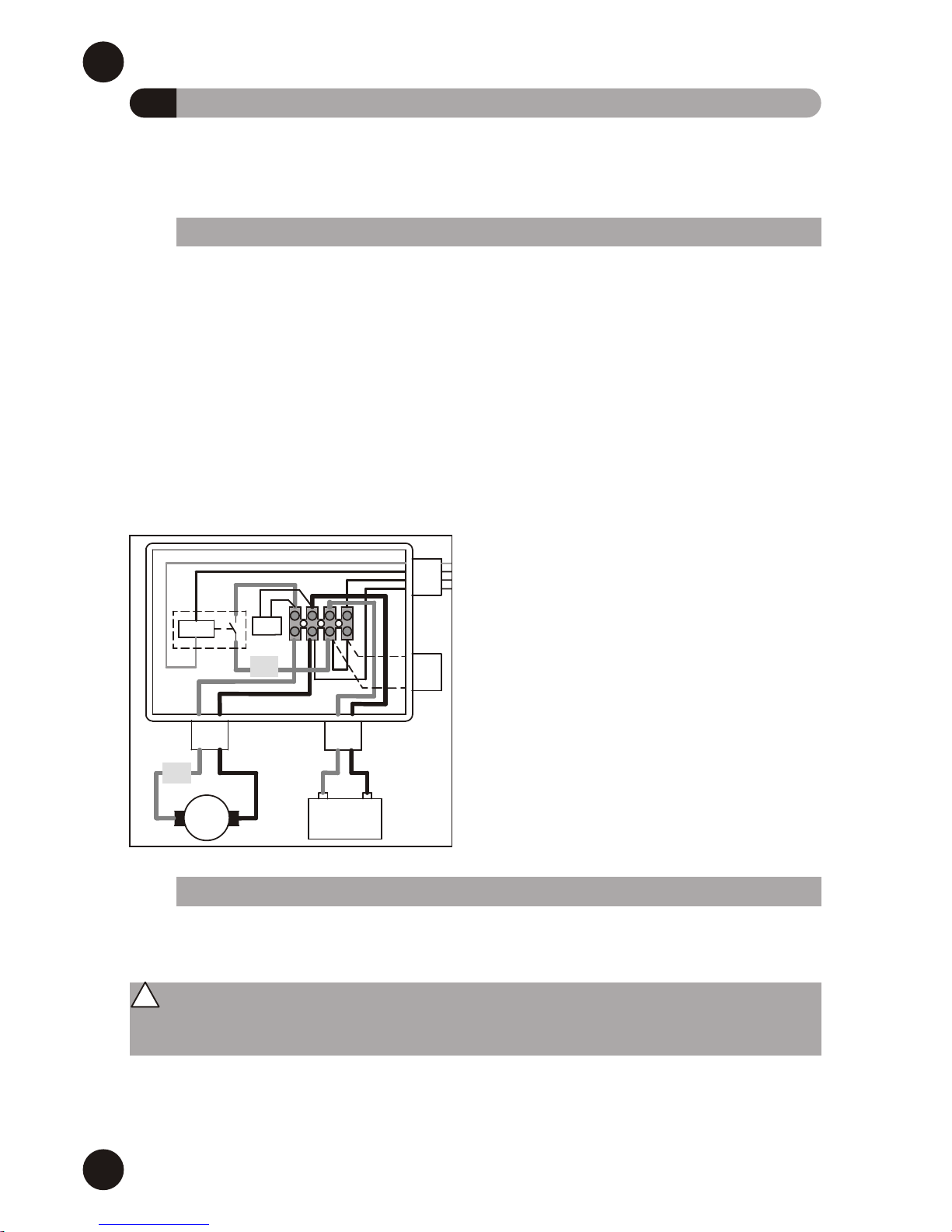

CPU CARD

DISPLAY CARD

KEY

READER

KEYBOARD

I/O CARD

BROWN

RED

GREEN

BLUE

1

2

3

4

5

6

1.

2.

3.

4.

5.

6.

KEY READER (I-BUTTON)

DISPLAY CARD

CPU CARD

KEYBOARD

I/O CARD

ELECTRICAL BOXES

K600

PULSER

NOZZLE

CONTACT

BLACKGREY

RED

ROSE

GREY

YELLOW

BLUE

GREEN

YELLOW

GREY

BROWN

WHITE

RED

ROSE

BLUE

YELLOW/GREEN

BROWN

VERSION 230V:

POWER IN 230V

VERSION 110V:

POWER IN 110V

RS-485 OUT TO

PC/PRINTER

(OPTIONAL)

TO LEVEL

PROBE CONTACT

(OPTIONAL)

BROWN

YELLOW/

GREEN

BLUE

GREY

BLACK

BROWN

WHITE

VERSION 230V: MOTOR 230V

VERSION 110V: MOTOR 110V

MC BOX 230Vac - 110Vac:

INTERNAL ELECTRICAL

CONNECTIONS DIAGRAM

EN (Translated from Italian)

15

CPU CARD

DISPLAY CARD

KEY

READER

KEYBOARD

I/O CARD

VERSION 12V:

POWER INPUT 12V

WHITE

VERSION 12V: MOTOR 12V

VERSION 24V: MOTOR 24V

85

86

87

30

+

-

IN BATT

-

+

BATTERY

MOTOR

+

-

OPTIONAL

(RS485 +

LEVEL PROBE)

K600

PULSER

LEVEL

CONTACT

BROWN

RED

ROSE

GREY

YELLOW

NOZZLE

CONTACT

BLACK

RED

BLUE

YELLOW

BROWN

BLUE

1

2

3

4

5

6

1.

2.

3.

4.

5.

6.

KEY READER (I-BUTTON)

DISPLAY CARD

CPU CARD

KEYBOARD

I/O CARD

ELECTRICAL BOXES

YELLOW

BLUE

BROWN

GREY

YELLOW

BROWN

WHITE

RED

ROSE

RED

BLACK

FILTER

R-C

VERSION 24V:

POWER INPUT 24V

VERSION 12V: BATTERY 12V

VERSION 24V: BATTERY 24V

VERSION 12V: RELAY 12V

VERSION 24V: RELAY 24V

BLUE

MC BOX 12Vdc / 24Vdc: INTERNAL ELECTRICAL CONNECTIONS DIAGRAM

The fuse (max. 40A @ 24V and max. 60A @ 12V)

can be placed on the motor or inside the electrical

box as shown

Choose fuse size in accordance with the motor’s

absorption level (see “Electrical Power” chapter)

(see “Electrical Power” chapter).

If you wish to turn the device on and off

with the vehicle key, replace the jumper

with an ignition switch

ON-OFF Key

FUSE

XX

FUSE

XX

85

86

87

30

FUSE

XX

MOTOR

FUSE

XX

Max. current Motor

Imax = 50A (12 V)

Max. current Motor

Imax = 25A (24 V)

EN(Translated from Italian)

16

I COMMISSIONING

To correctly commission the MC BOX the sequence of operations indicated below

must be followed and the MC control system functions must be known (see attached

manual).

Once the power connections have been made, the MC BOX can be energised by

means of the master switch to be fitted by the installer on the upstream line.

Switching on of the MC system will be indicated by the lighting up of the two backlit

LCDs fitted on the front.

NOTE:

In the event of continuous current power supply (DC), a fuse size that is appropriate

to the DC motor's absorption level should be introduced to the motor

power line.

For example:

• If the connected motor is one that absorbs 10A max then a 12A delay fuse should be

inserted.

• If, however, the motor absorbs 50A max, then a 60A delay fuse should be inserted.

• If the fuse is small, it can be fitted along

the cable inside the junction box, in

position (1) (see illustration)

• If, however, the fuse is very big (e.g. 60A)

and cannot physically fit inside the box,

then it can be inserted along the motor’s

power supply cable in position (2) (see

illustration)

I.1 ELECTRICAL POWER SUPPLY

85

86

87

30

+

-

BATT IN

-

+

BATTERY

MOTOR

+

-

FILTER

R-C

(1)

(2)

Every MC BOX station can be adapted to the specific requirements of the station

manager. To do this the MC control system must be CONFIGURED.

After completing configuration, user PIN CODES can be assigned to the persons

charged with using MC BOX, in accordance with the detailed information in the MC

manual.

I.2 STATION CONFIGURATION

EN (Translated from Italian)

MC configuration is crucial and must be done by skilled personnel.

To perform this operation, the MC manual must be carefully and thoroughly read.

! WARNING

17

In MANUAL mode:

• The MC's LCD may be switched off (only the

backlight is clearly visible) or you may continue

to see the indication that was present at the

time of transition from AUTO to MAN.

• No PIN CODE is required to activate the

pump; the pump starts when the dispenser

nozzle is removed from its lodging and stops

when it is put back (naturally this is in the event

that the "nozzle contact" function is used).

• The amount dispensed is not shown in any

way.

All the MC BOX functions are controlled by the MC control system.

The MC system can nevertheless be disengaged for any startup or maintenance

activities requiring repeated pump starting.

In these case, it is often convenient to simplify pump startup by not having to enter any

code and record any dispensing data.

To do this, a JUMPER has been fitted on the card that permits switching from

AUTOMATIC mode (code request to access dispensing) to MANUAL mode (no code

request).

I.3 DISENGAGING THE “MC” SYSTEM

WITHOUT

JUMPER

JUMPER

IN POSIT.

AUTO

EN(Translated from Italian)

The jumper is only accessible by opening the front panel and is positioned as

shown in the photo.

In this operating mode, MC does not record any data relating to performed

dispensing operations.

Before accessing this jumper, the voltage must be removed.

! WARNING

Before accessing the electrical parts, be sure that you have disconnected all of

the general switches that power the device.

! WARNING

L EVERY DAY USE

Thanks to the MC control system, all the MC BOX models provide access to authorised

users only.

MC acknowledges User authorisation by means of two alternative systems:

• The entering of a 4-figure SECRET CODE (PIN CODE)

• The fitting of an electronic key (OPTIONAL)

18

Before using the MC BOX station, check the METER ACCURACY.

For this purpose, proceed as follows:

• Enter a previously enabled USER PIN code;

• Run the fuel into a calibrated container;

• Compare the quantity of dispensed diesel fuel using a calibrated container.

If accuracy is NOT satisfactory, proceed to CALIBRATE THE METER according to the

instructions in the specific manual.

I.4 METER CALIBRATION

EN (Translated from Italian)

To correctly check accuracy, always keep to the following instructions:

• Use a precision sample container, featuring a graduated scale, with a capacity

of at least 20 litres.

• Before making the check, always make sure you have eliminated all the air from

the system and then run the fuel until a full and regular flow is achieved.

• Dispense continuously at MC BOX maximum flow rate.

• Stop the flow by quickly closing the nozzle.

• Reach the graduated area of the sample container, avoiding prolonged

dispensing at low flow rate, but rather performing short dispensing operations

at maximum flow rate.

• Compare the reading provided by the container, with that provided by MC BOX,

after waiting for all the froth to disappear

! WARNING

Differences of up to 1/10 of a litre affecting the dispensing of 20 litres of fluid fall

within the guaranteed precision of +/- 0,5%.

! WARNING

All the users to whom a PIN CODE is assigned must be adequately instructed and

be at least acquainted with the contents of this chapter.

! WARNING

19

The pump will start (if previously enabled) just as soon as the control lever is moved

to ON position, while it switches off as soon as the control lever is moved to

OFF position.

No further manual operation is required to start or stop the pump.

In the case of the simplest configuration (no optional data required), the fuel dispensing

procedure is the following:

• Insert PIN CODE

(or apply the electronic key)

If the MC recognises the activated PIN

(or key), a “GOOD MORNING MANAGER /

USER” message is displayed and the

pump enabled.

For details on dispensing options, please

refer to the M0187 manual.

L.1 FUEL DISPENSING

The configuration of the MC system permits requiring the User to enter further optional

data (vehicle licence plate, mileage, quantity to be dispensed).

For details, see the MC control system manual.

In the event that these options are not set, MC will recognise an activated PIN CODE

and, once the nozzle contact (if applicable) has been closed, the pump is enabled,

allowing it to dispense

EN(Translated from Italian)

Such enabling does not result in immediate pump startup.

The pump is in fact controlled by a switch (positioned in the nozzle seat)

operated by the user.

! WARNING

Fuel MUST ONLY be dispensed under the careful control of the User.

! WARNING

20

M ROUTINE MAINTENANCE

The MC system is maintenance free.

To control it however, refer to the dedicated M0187 manual provided.

M.1 “MC” CONTROL SYSTEM

M.2 TROUBLESHOOTING

EN

PROBLEM POSSIBLE CAUSES SOLUTIONS

AUTO/MAN jumper in the MAN.

position

The user has not yet been

configured by the system

MANAGER

The key has not been linked to

the User by the system

MANAGER

The electronic key is damaged

and is no longer recognised by

the system

The keyboard is damaged and

does not insert the data properly

The MC BOX does

not switch on

The MC BOX turns on

and the displays light

up but no words

appear

The MC BOX turns on

and the displays light

up but the words that

appear are irregular

and the system does

not respond to any

commands

The system does not

recognise the “USER”

with PIN CODE or

Electronic key

• Check connections

• Ensure disconnect switch is in

the ON position

• Check fuse

• Turn the vehicle key to the

ON position

Put the jumper to the AUTO

position

The system MANAGER sets up a

New User

The system MANAGER links the

key to the User

Change electronic key (contact

technical support)

Change keyboard (contact

technical support)

Power supply has failed due to:

• The power leads being

connected incorrectly

• The upstream circuit switch

being in the OFF position

• The power supply fuse being

interrupted

• For DC versions: vehicle key in

the OFF position (if the

“ignition on” power supply

option has been adopted)

(Translated from Italian)

21

PROBLEM POSSIBILE CAUSES SOLUTIONS

It has not been connected

properly to the set terminals

The Pulser that emits the count

signals has not been connected

properly

The Pulser that emits the count

signals is NOT compatible with

the electronics

The signal sent by the Pulser is

outside the acceptable electronic

ranges

Action not permitted by nozzle

contact

The MOTOR

will NOT START

DOES NOT COUNT

when dispensing

The count is

INACCURATE

The count remains

INACCURATE even

after calibration, or it

is accurate but only

for low flow rates

It DOES NOT

COMMUNICATE with

the PC

Check connections

Verificare collegamenti

An incoming electronic signal,

namely “clean contact” or

“OpenCollector”, should be

received.

If the input signal is an

incompatible voltage signal, the

electronic board is likely to be

damaged, in addition to the

malfunction

The maximum pulsation

frequency must be 70 Hz and

between 20% and 80% duty

cycle. The system does not

process received data correctly

outside the acceptable electronic

ranges.

The system must adapted to fit

within the correct ranges,

possibly by interposing other

electronic interface devices

(please contact Technical

Support for options)

Check how the nozzle contact

option has been set (YES/NO)

and the status of the relevant

jumper

The system is NOT calibrated

The RS485 connection is not

correct

The driver on the PC is not

installed properly or the version

is not compatible with the PC’s

Operating System

The RS232 or USB converter is

damaged

The PC's USB or RS232 port is

damaged

Calibrate the system according

to the procedure

Check the connections

Check the versions of the drivers

and the Operating System.

Contact Technical Assistance

Try with a different converter: if

the problem disappears, replace

the converter

Try a different port or try it on a

different PC to check the rest of

the device: if it works on another

PC, then the problem is with the

PC

EN(Translated from Italian)

22

85

86

87

30

+

-

BATT IN

-

+

BATTERY

MOTOR

+

-

FILTER

R-C

Fuse

XX

Fuse

XX

N SPECIAL MAINTENANCE

To check and replace contained fuses

• on the electronic boards

and/or

• in the junction box (for DC versions):

1) Remove voltage from the device;

2) Open the door to the MC BOX with the special key;

3) Open the junction box that contains the motor fuse (DC only) for verification and

possibly replacement;

4) Unscrew the metal back panel to access the electrical boards compartment;

5) Check the condition of the fuses and replace if necessary

6) Shut down everything and restore power.

N.1 CHECKING AND REPLACING FUSES

MOTOR FUSES

(AC Motors)

• 8 A T (Rit)

MOTOR FUSES

(DC Motors)

• The fuse (max. 40A @ 24V and

max. 60A @ 12V) can be placed

on the motor or inside the electrical

switch box (see “Electrical Power”

chapter)

Choose fuse size in accordance

with the motor’s absorption level

(see “Electrical Power” chapter).

POWER FUSE

• 100 mA T (Rit)

for the 230V / 50 Hz version

• 200 mA T (Rit)

for the 110V / 60 Hz version

• 1 A T (Rit)

for versions DC 12 Vdc and 24 Vdc

EN (Translated from Italian)

I

23

EN

The information contained in this manual is provided by the Manufacturer, who reserves

the right to make changes without prior notice

P MANUFACTURER AND SERVICE DATA

O MC BOX SPARE PARTS

5

15

3

14

6

1

4

4

8

2

2

7

9

10

11

12

13

7

13

MANUFACTURER:

DOCUMENT TYPE:

EDITION:

PRODUCT:

MODEL:

CONFORMITY:

TECHNICAL SUPPORT:

PIUSI S.p.A.

General Description and Instructions for Its Installation,

Activation, Use and Maintenance

Bullettin M0188A EN - Rev. 1

Diesel fuel dispenser for private use with meter

All the models of the MC BOX range, with singlephase/three-phase mechanical/electronic meter, with

various voltages/frequencies

CE Mark

(see Declaration of conformity, page 4)

Provided by the Service Departments of our Authorized

Resellers

(Translated from Italian)

Authorized reseller’s stamp

M0188A EN - Rev. 1

Loading...

Loading...