Shockwave

Starter Package

User Guide

Shockwave Starter Package 33102 V1114 1

33102 V1114

Cautionary and Warning Statements

• This kit is designed and intended for educational purposes only.

• Use only under the direct supervision of an adult who has read and understood the instructions

provided in this user guide.

• Read warnings on packaging and in manual carefully.

• Always exercise caution when using sharp tools

• Do not mix old and new batteries.

• Do not mix alkaline, standard (carbon-zinc), or rechargeable (nickel-cadmium) batteries.

Introduction

The Shockwave Electric Dragster helps teachers get extra mileage out of their electronic CO2 race

systems featuring launch pods. It’s a fun activity that encourages students to look at electric cars as

an exciting option from the world of alternative energy.

This guide shows you how to put together and use all the parts of the Shockwave Starter Package.

The individual parts of the Shockwave will not work independently. For example, the Shockwave Car

Kit will not work without the Shockwave Module.

History of Electric Vehicles

While electric cars are in the spotlight today as an environment-friendly alternative to the gasolinepowered internal combustion engine, the concept has been around for more than 150 years. The

rst electric carriage – though crude – was built in the 1830s in Scotland by Robert Anderson. Some

credit Thomas Davenport as the rst, but his work was around the same time.

At the bridge between the nineteenth and twentieth centuries, electric cars actually outsold the

gas and steam versions – largely because they did not

require dicult shifting or a manual crank start nor

did they require passengers to smell gas fumes and

exhaust.

However, the improvement of the gasoline engine

and the roads, which allowed longer trips (electric was

good for short trips), and the reduced price of gasoline

combined to help gas-powered vehicles take the lead.

Between 1935 and 1960, the electric car was all but

forgotten.

The Tesla Roadster is an electric car built

by Tesla Motors. The company is trying to

change the perception of electric cars. Photo

courtesy of Tesla Motors.

several manufacturers oered electric vehicles. Even the United States Post Oce tested out electric

jeeps.

During the 1960s and ‘70s, air pollution and

dependency on foreign oil companies prompted

engineers to take a fresh look at the electric car. Many

were developed over the next several decades, and

At the beginning of the twenty-rst century, the electric car still faced problems with production

and aordability. The organization Plug In America promotes the use of electric vehicles and lobbies

manufacturers to keep producing electric vehicles.

2 Shockwave Starter Package 33102 V1114

A popular alternative to the completely electric or gasoline car is the hybrid-electric vehicle, which

combines the two technologies to reduce fuel consumption.

Materials Included

Note: All materials except the Starting Blocks should be divided in half as these parts make up two

car kits.

• 2 sheets of laser-cut basswood parts

• 2 hooks

• 2 screw eyes

• 8 axle bushings

• 8 wheels

• 2 – 2-1/2" axles (front)

• 2 – 2-3/4" axles (rear)

• 2 gear fonts

• 2 motors with prewired connectors

• 2 motor mounts

• 4 screws

• 4 hex nuts

• 2 – 9 V batteries

• 2 Shockwave Modules

• 2 rubber bands

• Shockwave Starting Blocks, set of 2

Items Required (not included)

• White glue, such as Pitsco’s HD Bond II

• Small Phillips screwdriver

• Acrylic paint in color of choice (optional)

• Pitsco Wheel Deal (optional)

Note: The following instructions are for one car; there are enough materials in this package for two

cars.

• Hobby knife or sandpaper

• Tape, preferably double-stick (optional)

• Electronic CO2 race system with launch pods

Building the Car Body

1. Pop out the laser-cut parts from the basswood sheet. Find the

two Part 7s and Part 4. Glue one of the Part 7 pieces into a slot

on Part 4. Take the hook and insert one side of its T-shaped

end into the hole on the glued Part 7. Maneuver the other

side of the T end into the hole of the second Part 7. Glue that

Part 7 into the remaining slot on Part 4 (Figure 1). Let this

assembly dry.

2. Lay a Part 1 piece at on its side. In the rst slot on the

Figure 1

dragster’s front, glue Part 5. Moving toward the back of the

dragster one slot at a time, glue in one Part 2, the Part 3,

and then the second Part 2. Finally, glue in the

assembly from Step 1 so Part 4 is glued in the

dragster’s side with the pin on the underside of

the car (Figure 2).

3. Place glue on the other side of all the pieces

perpendicular to Part 1. Place the second Part 1

on top of these parts, tting the notches into the

side evenly and so the parts are all straight and t

snugly (Figure 2).

Shockwave Starter Package 33102 V1114 3

Figure 2

4. Take Part 8 and insert it through the

small notch below Part 3. This part

should extend a quarter inch from

either side of the dragster. Push it

slightly o center. Apply glue on Part

8 where it will touch the sides when

recentered (Figure 3). Recenter it.

5. Find Part 6 and glue it at on top of Part

5 so the small holes in both parts are

aligned. You could use a paper clip or a

piece of wire to hold the pieces in place

while they dry. Let the car dry.

6. If you wish to paint the dragster, do

Figure 3

that at this time. When any nishes on

the car are dry, turn the car upside down. Keeping the screw eye

straight, screw it into the small hole on the underside of Part 5.

Make sure the hole on the screw eye is facing the front and back

of the dragster (not the sides).

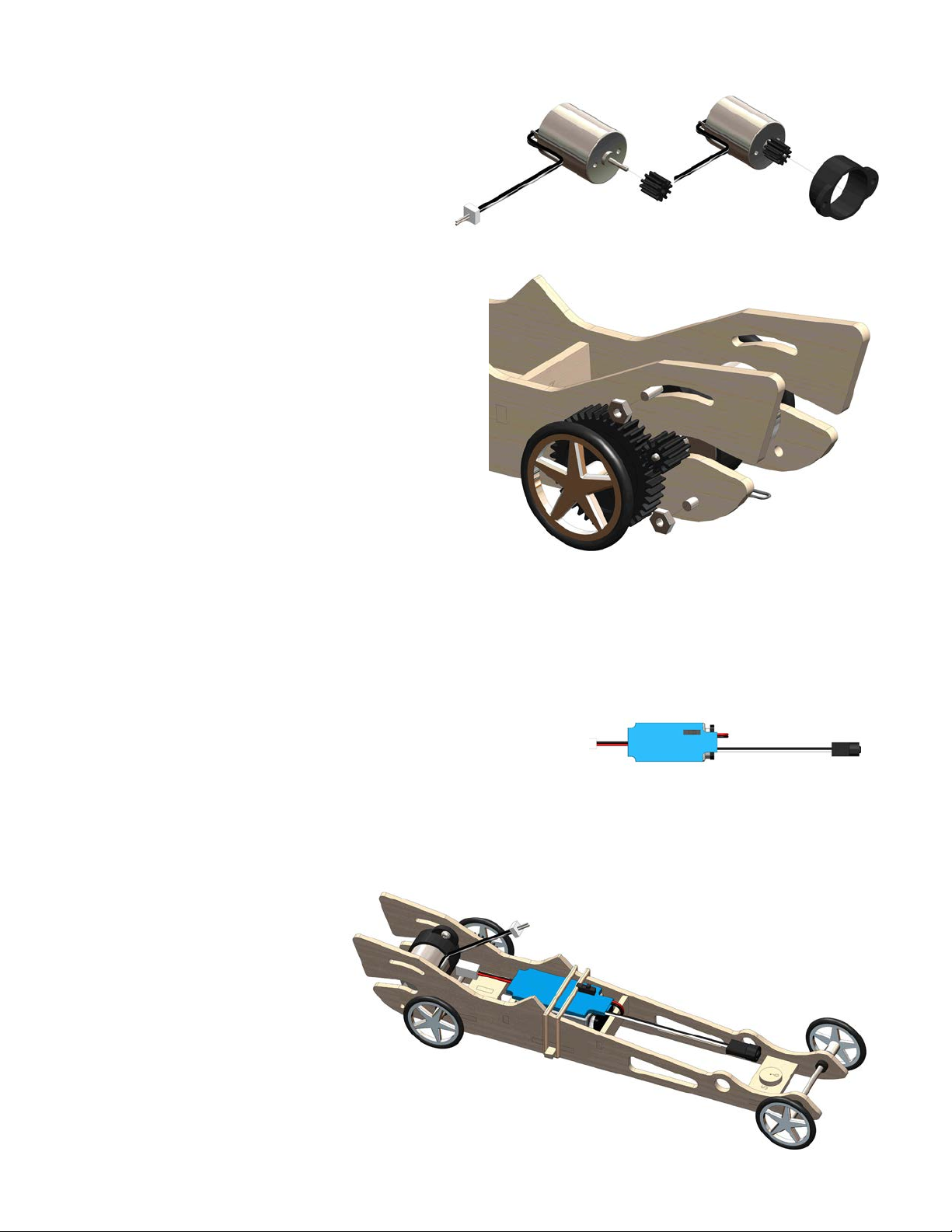

Adding the Wheels, Gears, and Motor

1. In the axle holes, push in the axle

bushings; the wide edge of the

bus hings should be on the outside

of the car body (Figure 4).

2. Push one wheel on the end of a

front axle (a 2-1/2" axle). Slide the

other end through the front axle

bushings. Carefully, place a second

wheel on the free end of the axle.

(If available, use the Wheel Deal to

push the wheels onto the axle.) Be

sure the wheels aren’t on so tight

that they cannot spin.

3. Remove from the gear font the

40T gear with a 1/8" axle hole.

Using a hobby knife or sandpaper,

remove any burrs from the gear.

This is the drive gear. Push the gear

onto the end of the rear axle so

3/8" of the axle extends from one

side of the gear.

Figure 4

Figure 4 - Top View

4. Place a wheel on the short end of

the axle. Push the other end through the back bushings on the

car’s left side – the left side if you were looking at the car from

behind (Figure 4). Place a fourth wheel on that end.

4 Shockwave Starter Package 33102 V1114

5. Remove from the gear font the pinion

gear, which is the smallest gear with a

2 mm hole. Place this on the end of the

motor post (Figure 5).

6. Slide the motor mount over the motor

post and onto the motor; the sides of

the motor and motor mount should be

ush (Figure 6). Place the motor into

the slot on the back of the dragster

with the motor post facing the drive gear.

With one screw and hex nut, attach one

side of the motor mount to the hole below

the motor slot.

7. Maneuver the top of the motor until the

pinion gear meshes into the drive gear

about halfway. Make sure the gears spin

freely and – without moving the gears

– use the second screw and hex nut to

secure the top of the motor mount in

place (Figure 7).

Figure 5

Figure 7

Figure 6

Attaching the Module

1. Make sure the module is turned o; it is o when the switch

is facing away from the battery connector (Figure 8).

2. Connect the module to the battery. Fold the assembly so

the battery is under the module with the switch facing up.

Place this into the center area of the dragster between the

Part 2 pieces (Figure 9). Make sure the motor connector is

hanging free behind the module and battery (toward the

motor). The wire with the infrared (IR) detector also hangs

free but in front of the module.

3. Take the rubber band and hook one end over the end of

Part 8. Stretch the rubber band over the module and hook

the other end on the other side of Part 8 (Figure 9).

4. Connect the motor to the

module (Figure 9). This only

ts one way; if it doesn’t go

in, turn it and try again.

Figure 8

Figure 9

Shockwave Starter Package 33102 V1114 5

5. At this time, determine in which lane your

dragster will race. If you are using the Impulse

GII or Impulse race systems, determine what

side of your dragster will be near the middle of

the track (see Figure 10a). Place the IR detector

so it ts in the hole facing the middle of the

track.

If you are using the i-race or Palm Racer

systems, determine what side of your dragster

will be facing the outside of the track (see

Figure 10b). Place the IR detector so it ts in the

hole facing the outside of the track.

Tip: To make sure everything is set up properly

before putting the dragster on a track, test it with

a 60-watt incandescent light. Simply turn the

module switch to the on position (toward the

Figure 10a

motor connector), and hold the IR detector under the light. The motor should turn on. When it does,

set the car on the oor and it should move forward (be sure someone is ready to pick up the car

before it runs into anything). Hold the detector under the light again and the motor will turn o.

If the car moves backward, the motor post and gears are probably placed on the wrong (right) side

of the Shockwave.

Placing the Starting Blocks and Running the Race

Note: You can use either manual or auto mode when racing the Shockwave.

1. Set up your race system as usual except do not attach the launch pods. In the ports for the launch

pods, plug in the starting blocks instead.

2. For the Impulse GII or Impulse race systems,

place the starting blocks in the center of the

track at the starting line (Figure 10a). The IR

emitters (the small bulb inset on one side of

each starting block) should face away from

the center of the track. You might need to

tape them down to the track to make them

stay in place.

For the i-race or Palm Racer systems, place

the starting blocks on the outside edges of

the track – one on each side (Figure 10b).

The IR emitters should face toward the

center of the track. You might need to tape

them down to the track to make them stay

in place.

Figure 10b

6 Shockwave Starter Package 33102 V1114

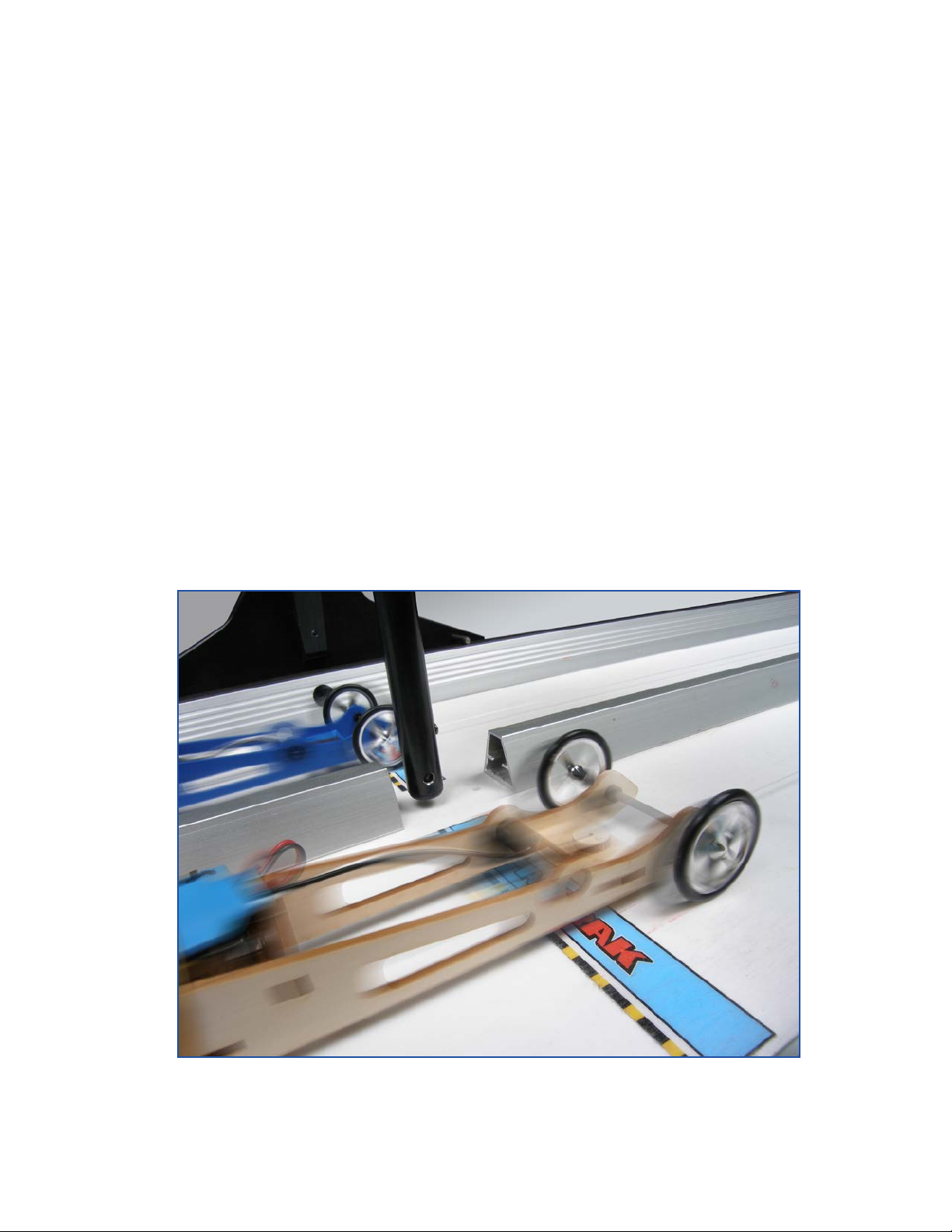

3. Attach the dragsters to the racetrack with monolament line as usual, and then line up the IR

detectors on the cars to the IR emitters on the starting blocks. Without moving the dragsters, turn

on the module.

4. Run the race as normal. When the dragster passes the nish gate, the motor will turn o

automatically. Then, switch o the module and remove the dragster (Figure 11).

Tip: If you have to rerun the same cars and don’t want to remove them from the track’s

monolament line, be sure to turn o the module before rolling them back up the track. If the

module is on and the dragster passes the IR emitter while rolling back, it will turn on automatically.

Activity Ideas

• The gear font in this package features several dierent sizes of gears. Have students study gear

ratios.* Then, have them design dierent gear combinations for the Shockwave and hypothesize

how it will perform with each combination. Students can test each combination on the track,

record the times of each race, and learn if their hypotheses were correct.

• With standard CO2 dragsters, weight is an important variable. Have students think of ways they

can alter the weight of the Shockwave (adding a load, carefully shaving down the wooden body,

and so forth). Race the cars to see the result of the weight changes.

*One way to learn about gear ratios is by experimenting with the Pitsco Gear Factor (32242).

Figure 11

Shockwave Starter Package 33102 V1114 7

P.O. Box 1708 • Pittsburg, KS 66762

www.pitsco.com

Toll-Free Orders 800-835-0686

Loading...

Loading...