Page 1

Service Manual

for the

Pitco Frialator

Literature # L20-155 Rev 0 Patent Pending Manufactured in

Printed 9 May 1997 The United States of America

Page 2

FOR YOUR SAFETY :

Do not store gasoline or other flammable vapors

or liquids in the vicinity of this or any other appliance.

TO THE PURCHASER

POST IN A PROMINENT LOCATION INSTRUCTIONS TO BE FOLLOWED IN THE

EVENT THAT AN OPERATOR SMELLS

GAS. OBT AIN THIS INFORMATION FROM

YOUR LOCAL GAS SUPPLIER.

WARNING:

IMPROPER INSTALLATION, ADJUSTMENT , AL TERA TION, SERVICE OR MAINTENANCE CAN CAUSE PROPERTY DAMAGE, INJURY OR DEATH. READ THE INSTALLATION, OPERATING AND MAINTENANCE MANUALS THOROUGHLY BEFORE INSTALLING OR SERVICING THIS

EQUIPMENT.

WARNING

DO NOT use an open flame to check for gas leaks!

Keep all open flames away from the machine at all

times.

WARNING

Ensure that the machine can get enough air to keep

the flame burning correctly . If the flame is starved

of air it can give off a dangerous carbon monoxide

gas. Carbon Monoxide is a clear odorless gas that

can cause suffocation.

WARNING

Blocking the flue will also cause the unit to overheat. DO NOT obstruct the flow of combustion/

ventilation or air opening around the machine. Ensure that you meet the minimum clearances specified in the installation instructions. Adequate clear ance around the unit is necessary for servicing and

proper burner operation.

WARNING

The power supply must be disconnected before servicing or cleaning the unit.

WARNING

DO NOT supply the fryer with a gas that is not

identified on the data plate, located on the inside of

one of the doors of the machine. If you need to

convert the machine to another type of fuel, contact your dealer or Authorized Blodgett Service

Agency.

WARNING

Machines equipped with casters and a flexible

power cord, must be connected to a gas supply with

a Quick-Disconnect device. This quick disconnect

must comply with ANSI Z24.41. T o limit the movement of the unit without depending on the connector or quick disconnect, a restraining cable must

also be installed.

WARNING

Use only a B/C or A/B/C extinguisher that contains the dry chemical Sodium Bicarbonate or

Potasium Bicarbonate should be used to extinguish

any fires.

WARNING

When the fryer is in its operating location, lock the

casters and reattach the restraining device to the

rear of the machine.

WARNING

Shortening, when it is at cooking temperatures, is

very HOT and DANGEROUS! Use extreme caution when handling! Use the proper protective gear

such as insulated gloves, aprons, face shield and

sleeves when handling hot shortening. DO NOT

attempt to move any machine that has hot oil in it.

Allow the oil to cool to room temperature or drain

the oil into a suitable container before moving the

fryer.

i

Page 3

ORIGINAL EQUIPMENT LIMITED WARRANTY - TURBOFRY 2000

General Warranty

Pitco Frialator, Inc. warrants to the original user of its T urbofry 2000 cooking appliance that said appliance and related equipment will be free from

defects in material and workmanship under normal use for a period of one (1) year from the date of installation, with appropriate documentation, subject

to the following additions, exceptions, exclusions and limitations.

What is covered

This warranty is limited to the repair or replacement at the Company’s option, without charge, of any part found to be defective within the warranty

period and reasonable expenses incurred for freight and material for the installation of such part; in addition, the Company’s obligation shall be limited to

reimbursement for normal labor on such parts.

Pitco Frialator, Inc. agrees to pay the G.S. Blodgett Corporation Authorized Service and Parts Distributor, for any labor and material required to

repair or replace, at the Company’s option, any part which may fail due to defects in material or workmanship during the above general warranty period.

Fry T anks

In addition, the Company warrants to the original user of any fry tank to be free from defects for a period of ten (10) years from the date of

manufacture. Labor and freight shall be the responsibility of the user. This shall only obligate the Company to repair or replace, at its option, any fry tank

which it determines to be defective. Claims under this item shall be supported by a statement detailing the defect, and the Company may require the return

of the fry tank claimed to be defective.

Computer or Digital Cooking Controller

In addition, the Company warrants to the original user of any Cooking Computer or Digital Controller to be free from defects for a period of two (2)

years,from the date of manufacture. During the two (2) year period all charges involved in the replacement of a Pitco Computer or Digital Controller will

be the responsibility of Pitco Frialator Inc.

How to Keep Your Warranty in For ce

€ Make sure any shipping damages are reported immediately. Damages of this nature are the responsibility of the carrier.

€ Install the unit properly. This is the responsibility of the installer and the procedures are outlined in the manual. Do not install it in a home

or residence.

€ Maintain the unit properly. This is the responsibility of the user, the procedures are outlined in the manual.

What is NOT covered under this Warranty

€ Adjustments, such as calibration, leveling, tightening of fasteners or plumbing or electrical connections normally associated with initial

installation are not covered under this warranty. These procedures are outlined in the installation manual.

€ Damaged due to flood, fire or other acts of Nature are not covered under this warranty.

€ If the unit is used for a purpose other than for which it was intended or designed, resulting damages are not covered under the warranty .

€ Failures due to erratic voltage or gas supplies are not covered under the warranty.

€ Material alterations or modifications from the condition in which the unit left the factory are not covered under the warranty.

€ Units with unreadable, obliterated or removed serial number rating plates are not covered by the warranty.

€ Any parts other than Genuine OEM parts from Pitco Frialator, Inc. or its Authorized Parts and Service Distributors are not covered by the

warranty.

€ Any other failure which is not attributable to a defect in materials or workmanship is not covered bt the warranty.

This warranty specifically excludes parts which wear or would be replaced under normal usage, including, but not limited to, electric lamps, fuses,

interior or exterior finishes and gaskets.

Limits to the Warranty

Outside the United States of America and Canada, this warranty is limited to the replacement of parts and Pitco Frialator , Inc. will not bear any other

expense be it labor, mileage, freight or travel.

Charges for mileage over one hundred (100) miles, travel time over two (2) hours, overtime, and holiday charges are not covered under this warranty .

These charges are the responsibility of the individual or firm requesting these services.

If any oral statements have been made regarding the appliance, these statements do not constitute warranties and are not part of the contract of sale.

This limited warranty constitutes the complete, final and exclusive statement with regard to warranties.

THIS LIMITED WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ALL OTHER WARRANTIES WHETHER WRITTEN, ORAL OR IM-

PLIED, INCLUDING, BUT NOT LIMITED TO ANY WARRANTY OF MERCHANT ABILITY OR FITNESS FOR A PARTICULAR PURPOSE OR

W ARRANTY AGAINST LATENT DEFECTS.

Limitations of Liability

In the event of a warranty or other claim, the sole obligation of Pitco Frialator, Inc. will be the repair or replacement, at the Company’ s option, of the

appliance or the component part. This repair or replacement will be at the expense of Pitco Frialator, Inc. except as limited by this warranty statement. Any

repair or replacement under this warranty does not constitute an extension in time to the original warranty. Parts covered under this warranty will be

repaired or replaced, at the Company’s option, with new or functionally operative parts. The liability of Pitco Frialator, Inc. on any claim of any kind,

including claims based on warranty, express or implied contract, negligence, strict liability or any other legal theories will be exclusively the repair or

replacement of the appliance. This liability will not include, and the purchaser specifically renounces any right to recover special, incidental, consequential or other damages of any kind, including, but not limited to, injuries to persons, damage to property, loss of profits or anticipated loss of the use of this

appliance.

If any provision of this warranty is unenforceable under the law of any jurisdiction, that provision only will be inapplicable there, and the remainder

of the warranty will remain unaffected. The maximum exclusion or limitation allowed by law will be substituted for the unenforceable provision.

How to Obtain W arranty Service

First direct your claim to the G.S. Blodgett Corporation Authorized Service and Parts Distributor closest to you giving complete model, serial and

code numbers, voltage, gas type, and description of the problem. Proof of the date of installation and/or the sales slip may also be required. If this

procedure fails to be satisfactory, write the National Service Manager , Pitco Frialator, Inc., P. O. Box 501, Concord, NH. 03302-0501. USA

This warranty gives you certain specific legal rights; you may have other rights which vary from state to state.

ii

Page 4

Table of Contents

ORIGINAL EQUIPMENT LIMITED WARRANTY ................................ ii

TABLE OF CONTENTS ......................................................................... iii

SPECIFICATIONS and DATA ................................................................. iv

INTRODUCTION ..................................................................................... 1

How does it work? ................................................................................ 1

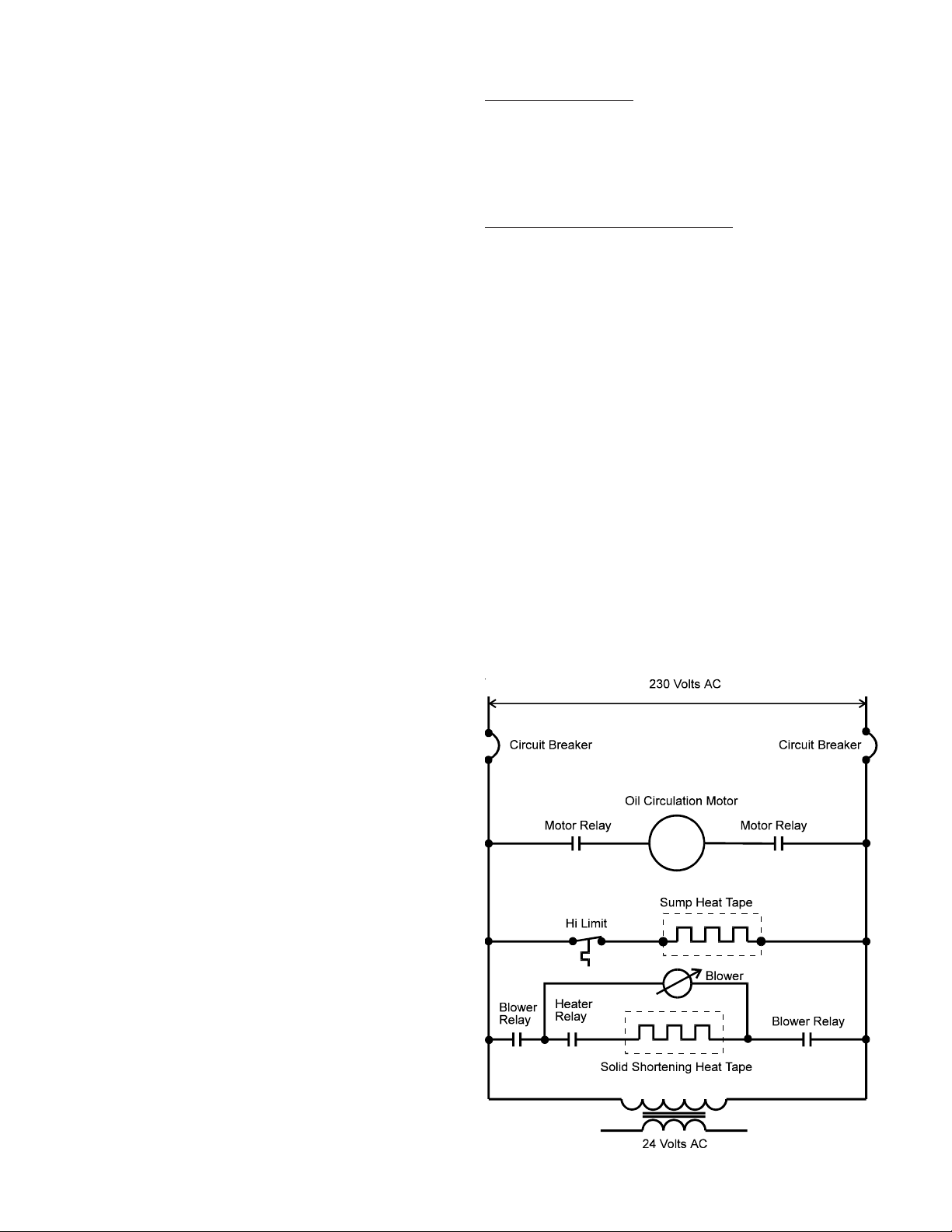

230 VAC, High Voltage System ............................................................ 1

24 VAC, Low Voltage System............................................................... 2

Component Recognition - Fry T ank...................................................... 5

Component Recognition - Controls...................................................... 6

PREVENTATIVE MAINTENANCE ....................................................... 7

Daily Cleaning ...................................................................................... 7

W eekly Cleaning................................................................................... 7

Vacuum Gauge Inspection .................................................................... 7

Boil Out Procedure ............................................................................... 7

Air Filter Inspection .............................................................................. 9

Inspect O-Rings .................................................................................. 10

Service T echnician Inspection ............................................................. 10

TROUBLESHOOTING........................................................................... 11

COMPONENT TROUBLESHOOTING ................................................ 12

T emperature Probe .............................................................................. 12

Relays ................................................................................................. 12

Hi Limits ............................................................................................. 12

Drain Valve & Return Valve Switches................................................. 12

Transformer......................................................................................... 12

Blower ................................................................................................ 13

Pressure Switch ................................................................................... 13

Ignition Control Modules .................................................................... 13

Ignitors ................................................................................................ 13

PARTS ...................................................................................................... 15

General................................................................................................ 15

Entrance Box Assembly............................................................... 16 - 17

SCHEMATICS..................................................................................18 - 20

700268 Rev C - Page 1, Left Side of schematic.................................. 18

700268 Rev C - Page 1, Right Side of schematic ............................... 19

700268 Rev C - Page 2 ....................................................................... 20

iii

Page 5

SPECIFCA TIONS and DAT A

Gas Consumption................................................................................................ 240 kbtu/hr

Efficiency ..................................................................................................................71-73%

Cooking capacity , fries ............................................................................................ 260 lb/hr

Supply V oltage .............................................................................................. 208 - 230 VAC

Control V oltage ........................................................................................................ 24 VAC

Heat up time - Liquid ................................................................................................20 mins

Heat up time - Solid ..................................................................................................25 mins

Minimum melt time - Solid only................................................................................10 mins

Sump Thermostat temp ..................................................................................Open at 135°F

Close at 105°F

Spark Gap ........................................................................... 0.1 ± 0.005" (2.54 ± 0.127mm)

Hi Limit specs .................................................................................................... 435 - 465°F

Burner flame color .........................................................................................Yellowish blue

Blower speed ....................................................................................... Set by Speed control

Ignition lockout time ..................................................................................................15 secs

Pressure switch.................................................................... Open below 0.8" WC (0.2 kPa)

Close above 0.1" WC (0.325 kPa)

Blower Air High Fire Pressure ...............................................................Nat - 5.5 - 5.6" WC

LP - 4.8 - 4.9" WC

Blower Air Low Fire Pressure ....................................................................... Nat - 0.4" WC

LP - 0.4" WC

Gas Pressure at Tap in High Fire Gas Line ....................................................... Nat - 4" WC

LP - 3.5" WC

Heat Time from 250°F to 300°F.................................................................. 2:25 - 3 Minutes

Pump Rate, clean oil, Full Pan to Fry T ank................................... 5 - 5:45 Minutes/Seconds

Pump Rate, clean oil, to empty Circulating System............................................. 45 Seconds

(This is done after the T ank has been cleaned, drained and the filters removed)

Low Fire Orifice Size................................................................... Nat & LP - #54 Drill Size

Hi Fire Orifice Size ........................................................................................... Nat - 0.328"

LP - 0.302"

Air Bleed T ip Orifice ............................................................................. Nat - #52 Drill Size

LP - #45 Drill Size

Air collar Size ..................................................................................................... Nat - 1.06"

LP - 1.165"

Minimum Gas Pressure Requirments ................................................... Nat & LP - 5.0" WC

Maximum Gas Pressure Requirements.................................................. Nat & LP - 14" WC

iv

Page 6

v

Page 7

INTRODUCTION

How does it work?

The development of the TURBOFRY 2000 fills the

needs of the food industry that have been, until now ,

unattainable. They are:

1. Continuous filtration of the food oil.

2. Crispier than ever fried food coatings due to convection currents.

3. High production from a high efficiency heat transfer system.

Continuous filtration of the cooking oil provides clean,

clear oil, even through busy periods. This means

breaded particles do not settle on heating surfaces and

burn, which in turn means longer oil life and lower

oil costs. The clean oil produces foods with coatings

free of burnt food particles that look and taste more

appetizing. Turbofry 2000 has an advanced filter system that makes clean up quick and easy. The main

filters trap the larger crumbs and can be lifted out for

easy cleaning and replacement.

The Turbofry 2000 uses a heating process, within the

cooking area, known as "Convection", foods cook

with crisper coatings because hot oil is forced between

the individual pieces of food, the breading or outer

coating gets seared quickly before the food can absorb as much oil as with a standard fryer. This will

produce a finished product that is much lower in absorbed oils.

There are two parts to the control system in the Tur bofry 2000 fryer, the 230 VAC or high voltage circuit and the 24 VAC or low voltage circuit.

230 VAC, High Voltage System:

230 VAC is applied to the machine -

• The Pump Motor Relay switch contact are supplied with 230 VAC.

• The Sump Heat System is supplied with 230

V AC. When the Sump T emperature Switch closes

the Sump Heat Tape will start to heat.

• The Motor Relay switch contacts will be supplied with 230 VAC. This relay will be explained

later in this manual.

• On machines equipped with the Solid Shortening Option the switch contacts of the Heat Tape

Relay will also be supplied with 230 VAC. This

relay is controlled by the Pipe Temperature

Switch.

• The primary coils of the Transformer will be supplied with 230 VAC. At this point the 24 VAC,

low voltage circuit will become energized.

The Turbofry 2000 has a high efficiency gas combustion system that transfers heat more efficiently than

regular fryers. The high input rate in conjunction with

a large heat transfer surface area give this fryer the

ability to cook high capacity loads effortlessly .

When installing the Turbofry 2000 follow the instructions in the Installation and Operating Manual.

1

Page 8

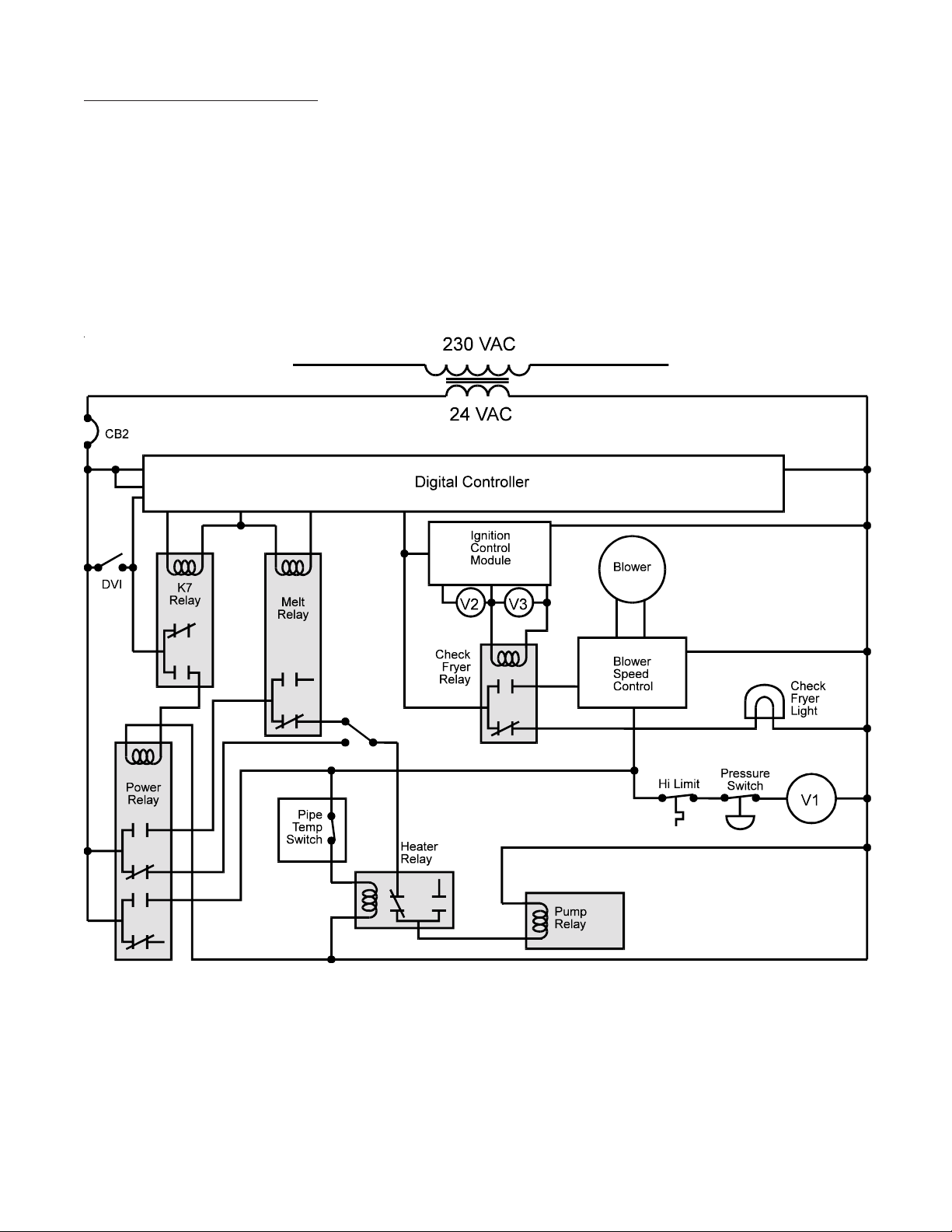

24 VAC, Low Voltage System:

Digital Control Condition - Power supply ON Digital Control OFF.

• 24 VAC is supplied to the Digital Temperature Controller.

• The Drain Valve Switch is supplied with 24 VAC. If the Drain Valve is closed the switch will allow 24

VAC to be supplied to the Drain Interlock connection at the Controller .

• The Power Relay switch contacts will also be supplied with 24 VAC.

2

Page 9

Condition - Digital control is switched ON but there is NO demand for heat:

• 24 VAC is supplied to the On Relay (K7) relay which energizes and supplies 24 VAC to the coil of the

Power Relay (K1).

• The Power Relay (K1) energizes and supplies 24 VAC to following places:

→ Hi Limit Switch (S2) - If the Hi limit (S2) is closed 24 VAC is supplied to the Pressure Switch (PS1),

the Pressure Switch (PS1) will close and supply 24 VAC to the Gas Valve (V1) when the Blower

(M2) comes up to speed.

→ Melt Relay (K2) - if the Digital Control (A1) is in Melt Cycle the Melt Relay (K2) is energized and

the circuit will be open. If the Digital Control (A1) has completed the Melt Cycle the Melt Relay (K2)

will be de-energized and the Pump Override Switch (S1) will be supplied with 24 VAC.

→ Blower Speed Control (VR1) - the Blower Speed Control (VR1) will cause the Blower (M2) to run

in Low Fire mode until it receives a signal from the Check Fryer Relay (K5) to tell it to run in the

High Fire mode.

→ Pipe T emperature Switch (TS1) - When the temperature in the filter piping falls below a certain level

the Pipe Temperature Switch (TS1) will close and supply 24 VAC to the Heater Relay (K6). In this

state the Heat Tape (HR2-HR6) will be supplied with 230 VAC and will continue to heat until the

Pipe T emperature Switch Opens at its designed temperature.

Condition - Demand for heat (All Controls):

• 24 VAC is supplied to the switch points of the Check Fryer Relay (K5). Since the Check Fryer Relay is

energized by the Ignition Control Module when it runs in High Fire Mode it will remain de-energized and

the Check Fryer Light (DS1) will be illuminated.

• 24 VAC is supplied to the Ignition control Module at terminal #6. The Ignition Control Module will cause

a spark at the Ignitor (PR1) and supply the Gas Valve (V2) with 24 VAC. At this time the Low Fire flame

will ignite. The Ignition Control Module will seek a flame sense signal from the Ignitor (PR1). The

Ignition Control Module will then supply 24 VAC to the Gas Valve (V3) and the High Fire Flame will

run. (Under normal working conditions it should take 2.6 - 4 seconds for the High Fire Flame to light.)

The same 24 VAC signal supplied to the Gas Valve (V3) is also supplied to the Check Fryer Relay (K5).

When the Check Fryer Relay energizes it will stop supplying 24 VAC to the Check Fryer Light and start

supplying 24 VAC to the Blower Speed Control. The Blower speed will then increase to High Fire speed

which will sustain the air demand for High Fire.

Condition - Auto Pump start (All Contr ols):

• The Pump Relay (K4) is supplied with 24 VAC from the Heater Relay (K6) and, if all of the following

conditions are met, the Circulation Pump (M1) will begin to run:

• When the Controller is turned off the Power Relay (K1) is de-energized which supplies 24 VAC to one

side of the Pump Override switch (S1). If the pump is NOT running the Pump Override Switch (S1) will

be in the open condition. In the open position the Pump Override Switch will be in the correct position for

Automatic Pump Start. When the Control is first turned on it will send a 24 VDC signal to the coil of the

Melt Relay (K2). This will energize the relay and open the circuit to the Pump Override Switch. When

the Control has exited the Melt Cycle or run past the Minimum Melt Time it will stop supplying the Melt

Relay (K2) with 24 VDC and the Pump Override Switch will be supplied with 24 VAC At this time,

assuming the Sump T emperature is above 135°F (57°C) and the Heater Relay is de-energized the Pump

Relay (K4) will be supplied with 24 VAC and the Circulation Pump will be supplied with 230 VAC.

3

Page 10

Condition - Computer Control Option:

• In order to supply power to the computer the OFF/ON ST ART Switch (S6) must be in the ON position.

The following conditions must be met before the machine can begin heating:

→ The Drain Valve Interlock Switch (S3) must be closed.

→ The Interlock Relay (K10) must have been energized by pressing the OF/ON/ST AR T Switch (S6) to

the ST AR T position and releasing. The Interlock Relay (K10) will stay latched until the Drain V alve

Switch (S3) is opened or the power is cut to the machine. When the Interlock Relay (K10) is latched

it will supply a continuous 24 VAC to the Power Relay (K1). When the Computer Control (A2) is

supplied with 24 VAC it will supply the Control Transfer Relay (K8) with 24 VDC, if there is an open

circuit condition on the Probe (PR1) the Computer Control (A2) will stop supplying the Control

Transfer Relay (K8) with 24 VDC causing it to de-ener gize and allowing the Alternate Thermostat

(S5) to control the Heating of the oil. When the Computer Control (A2) calls for heat it will supply 24

VDC to the coil of the Heat Demand Relay (K9) which will cause the machine to heat in a manner

previously described.

4

Page 11

Component Recognition - Fry tank:

The Turbofry 2000 uses a new frying and filtering

technology , therefore it is important that you become

familiar with the major components inside and outside of the fry tank. The following drawing and index shows these components and their uses:

1. Flue opening - The HOT exhaust gases from combustion will rise from this opening.

2. Burner Heat Tube - Combustion takes place

within this tube. The heat radiates out from this

tube and from the sides of the fry tank.

3. Hi Limit Probe - The Hi Limit is the safety device that will shut the machine down should the

temperature become excessively high.

4. T emperature Sensing Probe - This probe is used

by the Digital/Computer Control to sense the

actual temperature of the oil.

5. Oil Circulation Tube Assembly - The filtered oil

is returned to the fry tank through this tube. It

has many orifices along the underside to direct

the oil streams into the bottom of the fry tank.

There is a handle welded to the end of the tube.

6. Filter Bag Retainers - The Filter Bags "Hang"

on the retainer which fits snugly in the Filter Bag

Housing.

7. Drain - Oil will drain from this opening when

the Drain Valve Handle is opened.

8. Filter Bag Housing Lifting Points - Use the supplied lifting tool to lift the Housing out.

5

Page 12

Component Recognition - Controls:

1. Gas Shut Off Valve.

2. Master Circuit Breaker - Protects all circuits in

the machine.

3. Pump Override Switch - Manually turns the filter pump ON or OFF independently of the current operation mode. This switch is locked out

while the control is in the melt cycle mode.

4. Control Circuit Breaker - Protects the control

circuit only.

5. Check Fryer Indicator Light - Indicates burner

ignition status.

6. Flush Hose Connector - When needed the Flush

Hose is connected here.

7. Pump Outlet Selector - Used to direct the oil to

the Fry Tank or the Flush Hose.

8. Drain Outlet Pipe - Allows the oil to be drained

into the Lower Pan or a high temperature disposal container.

9. Drain Valve Handle - Green.

10. Lower Pan Pick Up Assembly - Connects the

Lower Pan to the Pump Suction Connection.

11. Pump Suction Connection.

12. Sump Screen Assembly - This Screen prevents

any debris from getting into the pump during a

Filter Bag Change procedure.

13. Sump Drain Handle - When this is pulled away

from the Sump Screen Assembly it opens a valve

to drain the Sump so that it can be removed from

the machine safely.

14. Lower Pan Assembly - Holds the cooking oil

while the filter bags are being changed.

15. Digital/Computer Control - Controls operating

and cooking functions (Digital Control shown.)

16. Vacuum Gauge - Shows the status of the main

filters.

17. Pump Inlet Selector Knob - Used to change the

pump inlet from Main Filter to the Lower Pan

Assembly.

18. Oil Circulation Tube Gauge - Indicates when the

Oil Circulation Tube needs cleaning.

6

Page 13

PREVENT A TIVE MAINTENANCE:

In order to keep your new Pitco Frialator Turbofry

2000 operating and looking in top condition it is

necessary to perform a few simple tasks on a daily,

weekly , monthly and quarterly basis. Follow the chart

below to find the frequency at which these Preventative Maintenance Items should be performed:

Cleaning Daily and Weekly

Vacuum Gauge Inspection Daily

Boil Out Monthly or when needed

Air Filter Inspection Every 3 months

Inspect O-Rings on-

Filter Bag Housing Every 3 months

Oil Circulation Tube Every 3 months

Sump Screen Every 3 months

Service T ech Inspection Yearly

Follow the directions outlined below for the instructions on how to perform the given task:

Daily Cleaning:

Bag Removal Tool to lift the complete Filter Bag

Housing out of the machine. Wash the Filter Bag

Housing with soap and water to remove all debris.

Dry thoroughly and install in the machine. Make sure

the Housing is seated correctly before installing the

Filter Bags.

Pump Suction Screen - Follow the instructions outlined in the Main Filter Bag Changing Procedure. Use

an abrasive, NON metallic, scouring pad on persistent stains.

Oil Circulation Tube - Grasp the Oil Circulation

Tube Handle and pull to the right until it is free from

the housing. Lift the Oil Circulation Tube from the

fry tank. The Oil Circulation Tube may be washed

with soap and water. Use a toothpick or similar tool

to push the crumbs and debris out of the circulation

holes. Thoroughly dry the Oil Circulation T ube and

reinstall by carefully aligning the end in the housing,

lower the handle until it is seated on the bracket. Push

the Oil Circulation Tube into the housing until it seats.

It is recommended that, in addition to filtering, the

external components of the fryer be cleaned in the

following manner.

Turn the fryer OFF by pressing the key on the

Digital Control panel, or pressing the power switch

to the OFF position. Using a soft clean cloth to wipe

the exterior surfaces until they are free of oil. A small

amount of non abrasive cleaner may be used on stubborn stains.

Weekly Cleaning:

At least once a week the following preventative maintenance procedures should be performed:

Clean Filter Bag Housing

Clean Pump Suction Screen

Clean Oil Circulation Tube

Clean Fry T ank using the Boil Out procedure

Follow the instructions below for instructions on each

of these items:

Filter Bag Housing - After the oil has been drained

from the Filter Bag Housing use the supplied Filter

Vacuum Gauge Inspection:

Each time that the pump is switched off or the machine shuts the pump off during a Filter Bags Change,

check the Vacuum Gauge to make sure the needle

points to the zero mark. The Vacuum Gauge will only

point to zero when the pump is NOT running. If it

does not point to the zero or very close call an Authorized Service Agency to have the Vacuum Gauge

checked.

Boil Out Procedure:

Periodically it will be necessary to perform what is

known as a Boil Out. This removes baked on frying

oil from the inner surfaces of the fry tank. The best

time to accomplish this is when the oil is ready to be

replaced.

Due to the unique design of the TURBOFRY 2000,

the Boil Out procedure is more involved than that of

a regular fryer. Always use Pitco Fryer Cleaner to

boil out the TURBOFRY 2000. Other cleaners not

approved by Pitco may be harmful to materials used

in the construction of the TURBOFRY 2000. Any

7

Page 14

damage done by the use of other cleaners will not be

covered by the Pitco warranty .

The Procedure has 3 main parts - Cleaning, Neutralization and Rinsing:

Cleaning:

1. Check that the controller is programmed to heat

with a melt cycle, the Digital display will show

. (The Computer display will show

or .)

2. Check the current Set T emperature setting of the

controller. Reprogram the controller to a temperature setting of 200° F . (Follow the instructions in

the appropriate section of this manual.)

Notice - Even though we call this a Boil Out, there is

no need to boil the water . 200°F is hot enough for the

cleaner to work and will prevent the mess and hazards of a boil over .

3. Shut the fryer OFF by pressing the key on

the Digital controller . (Press the OFF/ON/ST ART

switch to the OFF position on Computer controlled machines.)

4. Drain all of the oil from fry tank and filter bags

into the lower pan by opening the Green Drain

Valve (#9, page 6). Remove any pieces of food

that may have accumulated on the bottom of the

fry tank or in the Sump and Sump Screen. Remove the Sump Screen assembly (#12, page 6)

and clear any particles from it. Return the Sump

Screen assembly to its housing and make sure it

is seated. Remove the soiled Filter Bags and install clean ones.

5. Fill the fry tank with water to the OIL LEVEL

mark on the inside of the fry tank.

6. Turn the fryer ON by pressing the key on the

Digital control. (Press the OFF/ON/START

switch to the ON position on Computer controlled

machines.)

Notice - Allow the fryer to heat for 10-15 minutes

until the Digital display changes to (Com-

puters will show ), before adding Pitco

cleaner . Adding cleaner while the fryer is heating up

could cause a boil over . At this time the pump should

have started to circulate the water.

7. Add 8 Ounces by weight of Pitco Fryer Cleaner

to the water. (4 sample packets, supplied with your

new fryer .)

8. Allow the Pitco Fryer Cleaner and hot water to

soak with the pump running for 45 minutes, the

fryer will hold the cleaning compound at 200°F .

9. While the cleaner is soaking, use the white fryer

cleaning brush to scrub all the inner surfaces of

the fry tank, splashback, basket hanger, and the

fry baskets.

10. After 45 minutes, turn the fryer OFF by pressing

and holding the key on the Digital control.

(Press the OFF/ON/START switch to the OFF

position on Computer controlled machines.)

11. Rotate the Drain Outlet Pipe (#8, page 6) to point

outward. Place a heat resistant 3-5 gallon container under the Drain Outlet Pipe. The water

should be disposed of in a responsible manner.

12. Drain the fry tank by slowly opening the Green

Drain Valve Handle (#9, page 6). The used Boil

Out water and Pitco cleaner is safe to pour down

a sink drain.

Notice - The water from the fryer could be hot enough

to damage plastic drain systems. Run cold tap water

as you pour the hot cleaner down the drain to protect

plastic drain systems.

13. Turn the pump on by pressing the Pump Override Switch (#3, page 6) to drain the filters. Allow the pump to run until the Filter Bags are empty

of water. Remove and dispose of the soiled Filter

Bags.

14. Use a Green Scouring Pad or similar Non Metallic abrasive cleaning pad to remove any carbonized deposits from the inner surfaces of the fry

tank. Rinse all surfaces after scrubbing.

15. Remove the Oil Circulation Tube Assembly (#5,

page 5) and rinse it. Rinsing should be done from

the outside of the Circulation holes to the inside

of the tube to prevent plugging the holes, a toothpick or similar tool may be used to clear any

blockages in the holes.

16. If after completing the previous steps, the fry tank

8

Page 15

is not cleaned to your satisfaction, repeat steps 5

through 15. If the fry tank is clean go to step 17.

If the fryer cleaner did not clean the fryer adequately, then Boil Outs should be performed

more frequently to prevent heavy build up.

17. Use clean water to rinse the fryer cleaner out of

the fry tank. Use the brush or a clean towel to

rinse all surfaces that were contacted by the fryer

cleaner. Repeat the rinsing until all surfaces are

free of cleaner residue.

Notice - If you are using the recommended Pitco Fryer

Cleaner (Pitco part Number P6071397) which is a

“Non Caustic” cleaner or another brand Non Caustic

cleaner skip the Neutralization steps (18 through 23).

Neutralization:

18. Fill the fryer with fresh water to the OIL LEVEL

line on the rear of the fry tank. Add 1/2 gallon of

white vinegar to the water.

19. Connect the flush hose to the flush hose fitting.

Start the pump by pressing the Pump Override

Switch (#3, page 6). Let the pump run for 1-2

minutes. Stop the pump. Pull the Pump Outlet

Selector (#7, page 6) to the Flush Hose position,

place the end of the hose nozzle into the fry tank,

and start pump by pressing the Pump Override

Switch. This will neutralize the cleaner in the flush

hose lines. Use the brush or a clean towel to wipe

the neutralizer solution over all the parts that were

cleaned with the fryer cleaner. Once the entire

fryer has been neutralized, drain the fry tank and

filter sump by following steps 12 and 13.

20. Close the Green Drain Valve Handle (#9, page 6)

and fill the fryer with fresh water to the OIL

LEVEL line on the rear of the fry tank. Rinse the

fry tank, splashback, basket hanger, and the fry

baskets. Operate the pump as in step 19.

21. Drain the fry tank and filter sump of all water, by

opening the Green Drain Valve Handle (#9, page

6). This includes removing the Sump Screen Assembly (#12, page 6) and allowing all water to

drain from the sump housing. Replace the Sump

Screen Assembly in the sump housing and return

the Sump Drain Handle (#13, page 6) to its normal operating position.

22. Wipe the fry tank, splashback, basket hanger , and

the fry baskets with clean dry towels to remove

all water. Install the Oil Circulation Tube Assembly (#5, page 5). This completes the neutraliza-

tion part of the Boil Out procedure.

23. Install new filters in the filter sump. Pull the Pump

Inlet Selector Knob (#17, page 6) to the “ Lower

Pan” position.

24. Turn the Drain Valve Handle (#9, page 6) counter

clockwise to the “Closed” position. Use the Pump

Override Switch to start the pump and pump all

of the oil from the lower pan to the fry tank to a

level ½" below the OIL LEVEL mark at the rear

of the fry tank.

CAUTION:

The next step will be very noisy as the fryer evaporates the remaining water in the fry tank and pump

lines. Allow the pump to run the entire time it takes

to evaporate the residual water. If the pump is not

left running, there is a chance that steam could build

up in the unit and discharge hot oil.

25. Turn the fryer on using the key. Enter the program mode to reset the temperature to the original setting as shown in the Operating Manual. The

fryer will now heat the oil and evaporate any remaining moisture.

26. Allow the fryer to heat the oil until all the moisture from the boil out is evaporated. The amount

of time required to do this will vary with the degree of dryness that was achieved during the wipe

down after rinsing, generally it takes 15 -20 min-

utes to dry the oil.

Notice -The best way to tell if the system has dried

out is by the appearance of the oil. When the oil is

dry , there will be no small bubbles visible in the oil.

At this point the fryer can be shut down.

27. Shut the fryer OFF by pressing the key on

the Digital controller. (Press the OFF/ON/START

switch to the OFF position on Computer controlled machines.) Drain fry tank and filter sump

and dispose of the used oil.

28. Fill the fryer with new cooking oil. The Boil Out

is now complete.

Air Filter Inspection:

Remove the 8 screws that hold the Air Filter cover in

place (see page 6), grasp the handle and pull outward

until the entire Air Filter extends out of its housing.

9

Page 16

Inspect the air Filter for dirt and debris. If the Air Filter has a light coating of dust, it may be removed and

cleaned by gently tapping it against a hard surface so

that the particles fall out of the filter material. Check

for anything that may obstruct air flow. If, for any

reason, the Air Filter requires changing pull it out of

the housing by lifting upwards and install a new Air

Filter.

Notice - The Air Filter has a directional arrow on it.

Make sure the arrow is pointing in the direction of

the air flow .

sure the O-Ring has seated in the bottom of the groove

and reinstall the Oil Circulation T ube.

Sump Screen - Unscrew the Sump Screen (#12, page

6) as described in the Operation Manual. Inspect it

for Dry , Cracked or Flat surfaces. T o reinstall the ORing place the O-Ring in its groove making sure it is

has not twisted during the installation. If it did twist

gently untwist it and replace it in the groove. Make

sure the O-Ring has seated in the bottom of the groove

and reinstall the Sump Screen Assembly.

Service Technicians Inspection:

Push the Air Filter Housing in until it stops and the

cover seats, replace ALL of the screws and tighten

them. T ake care not to overtighten.

Inspect O-Rings:

Choose a time when the machine has been cleaned

and allowed to cool to perform any O-Ring inspection (see page 5). T ake great care NOT to stretch the

O-Ring.

Filter Bag Housing - Lift the Filter Bag Housing out

as described in the Operation Manual. Using a small

Dental Pick or Flat Tipped Screwdriver carefully lift

the O-Ring out of its groove. Inspect the O-Ring for

any Dry , Cracked or Flat surfaces, if the O-Ring has

any of these symptoms it should be replaced.

T o install the O-Ring, first clean the groove to make

sure it is clear of any debris or pieces of old O-Ring.

Cover the new O-Ring in a little cooking oil which

will make the installation a little easier. Place the ORing in its groove making sure it is has not twisted

during the installation. If it did twist gently untwist it

and replace it in the groove. Make sure the O-Ring

has seated in the bottom of the groove and reinstall

the Filter Bag Housing.

Oil Circulation Tube - There is an O-Ring inside

the housing where the Oil Circulation Tube seats. Use

a Curved Dental Pick to extract the O-Ring. Inspect

it for Dry, Cracked or Flat surfaces. To reinstall the

O-Ring Place the O-Ring in its groove making sure it

is has not twisted during the installation. If it did twist

gently untwist it and replace it in the groove. Make

On a yearly basis an Authorized Parts and Service

Technician should perform the following Preventative Maintenance checks:

1.* Remove and clean or replace the Air Filter .

2. Perform recovery test.

3. Check input gas pressure.

4. Remove burner and inspect for sooting or other

damage.

5. Check calibration of controls.

6. Remove and replace the Pump Suction Connection O-Ring, Oil Circulation Tube O-Ring and

the Sump Screen O-Ring.

7.* Inspect the Filter Housing O-Ring, replace when

needed.

8. On machines equipped with Heaters, check to

make sure they are heating correctly .

9.* Inspect the Vacuum Gauge to make sure it is returning to zero.

* These are steps which the end user will normally

perform, however, during the T echnician' scheduled visit they are performed as part of the overall

Preventative Maintenance (PM) service.

It is estimated that this should take approximately 2 -

2.5 hours.

10

Page 17

TROUBLESHOOTING:

Symptom Cause Repair

V acuum Gauge in black area. Filter Bags are clogged or are old. Install new filters bags. Filters can be reused for up to

2 days. After 2 days, the fibers are saturated and the

material is hardened, dispose of filters, replace.

High vacuum gauge reading. Cold oil. Allow the oil to rise to operating temp and recheck

the V ACUUM GAUGE.

Clogged Sump Screen. Caused by a failure to clear the area around the

filter bags before changing. Clean the Filter Bag

Housing.

Incorrect Filter Bag installation, Remove the Filter Bags and Filter Bag Housing,

debris has clogged the Filter Bag clean and reinstall.

Housing.

Dirty or clogged Filter Bags. New Filter Bags should be used to prevent the

introduction of debris to the system.

Filter Bag has a hole in it. Install a new Filter Bag.

Mechanical Problems. The V acuum Gauge may be defective.

Low oil flow in cook zone, Filter Bags are becoming full. Install new Filter Bags (Page 12).

gauge needle in Yellow.

Bubbles coming from the right Product has a high moisture content. This is a normal reaction to high moisture

rear corner of the fry tank. content.

Filter Bags are filling. Check the Vacuum Gauge for Filter Bag status.

Oil level is low. Add cooking oil as needed.

Pump Inlet Selector set to PAN. Push the Pump Inlet Selector Knob in to select the

MAIN FILTERS position.

Low oil flow in cook zone, Large amounts of high moisture content This is normal and will dissipate shortly.

filter bags are clean. foods are being cooked.

High pressure reading on OIL CIRCULA TION TUBE is Remove the OIL CIRCULATION TUBE as and clean

PRESSURE GAUGE. becoming blocked. the orifices with a toothpick or similar item.

FLUSH HOSE valve not in fry pot Place the PUMP OUTLET SELECTOR in the FRY

position. TANK position.

Cooking controller displays DRAIN HANDLE is in open position or Close DRAIN HANDLE and refill the fry tank.

"drn" "trn" "off". has not been closed fully. Check the DRAIN HANDLE by pushing closed. The

machine will have to be shut down and started up again

as described Operating Manual.

No oil is coming out of the flush PUMP OUTLET SELECTOR is not set Check the position of the PUMP OUTLET

hose. on FLUSH HOSE. SELECTOR and change as needed.

No oil in LOWER PAN. Follow the directions outlined in the Operating Manual.

LOWER PAN PICK UP ASSEMBLY Remove the LOWER PAN PICK UP ASSEMBLY

not connected properly. and install it into the LOWER PAN PICK UP

CONNECTION until it seats properly.

11

Page 18

COMPONENT TROUBLESHOOTING

Temperature Probe:

plied to the coil. When energizing, the relay Switching Contacts will close, thus connecting the Common and Normally Open terminals.

The resistance of the probe decreases as the temperature rises. The lower the temperature the greater

the resistance change will be per degree of temperature change, as the temperature approaches the working range of the probe, the resistance change will

slow and become more linear. If the probe is suspect, check its resistance and the oil/air temperature

at which it was taken. Compare these values on the

chart below .

TEMP RESISTANCE TEMP RESISTANCE

ºF Ohms Ω ºF Ohms Ω

60° 139055 Ω 330° 1192 Ω

80° 84644 Ω 335° 1123 Ω

100° 53146 Ω 340° 1058 Ω

120° 34328 Ω 345° 998 Ω

140° 22755 Ω 350° 942 Ω

160° 15446 Ω 355° 890 Ω

180° 10716 Ω 360° 841 Ω

200° 7586 Ω 365° 795 Ω

210° 6427 Ω 370° 752 Ω

220° 5470 Ω 375° 712 Ω

240° 4013 Ω 380° 675 Ω

260° 2991 Ω 385° 640 Ω

280° 2262 Ω 390° 607 Ω

300° 1734 Ω 395° 576 Ω

320° 1347 Ω 400° 547 Ω

325° 1267 Ω

Hi Limits:

A Hi - Limit switch is a normally closed switch until

the temperature at its probe reaches 435ºF ± 15°

(225ºC ± 15º). In order to test this switch it will be

necessary to bypass the Heat Demand Relay. This

will cause the fryer to heat until the temperature of

the oil reaches the necessary temperature to trip the

Hi Limit.

WARNING

Do NOT leave the machine during this test. This

test will cause the oil to heat past the normal operating temperature and can cause damage to the

machine and its operator. Always use an external

temperature probe to observe the oil temperature

during this procedure

In order to cause the oil to reach a temperature where

the Hi Limit will trip it will be necessary to bypass

the T emperature Controls.

If the switch does not trip between the prescribed

limits it is defective and should be replaced. Once

tripped, the switch cannot be reset until the oil has

cooled to approximately 400°F (204ºC). If the switch

cannot be reset it is defective.

Drain Valve & Return Valve Switches:

If the probe returns an open circuit or 0 Ohms reading it should be replaced. If the resistance varies more

than 20 Ohms from the above chart when being

checked between 325 - 375°F (162ºC - 190ºC) the

probe will give a false temperature reading on the

computer and should be replaced. However, it will

continue to operate at a slightly higher or lower temperature. Allow the oil to cool and check the probe

resistance at a lower temperature. As can be seen

from the chart a greater degree of offset can be allowed at a lower temperature.

Relays:

Relays will energize when the correct voltage is sup-

These switches are magnetically operated Reed

switches. When the Drain Valve handle is moved to

the open position, the Actuator will move away from

the switch causing the Reed switch to open. When

the Drain Valve is closed the Reed switch will close.

This switch can also be checked with an Ohm meter.

The normal gap between the Actuator and the Sensor switch on the Drain Valve handle is 1/8" - 1/4" (3 6 mm).

Transformer:

Transformers are multiple input voltage, 24 volt out

put voltage and can be checked by reading the input

and output voltages.

12

Page 19

Blower:

Check the voltage between the wires going to the

Blower. If 230 VAC is found at the blower connection and the Blower is NOT turning it is defective.

Pressure Switch:

As the blower speed rises the amount of vacuum on

the suction side of the pressure switch rises past approximately 1.3" WC (0.325 kPa) and the Pressure

Switch will close. When the vacuum falls below approximately 0.8" WC (0.2 kPa) the Pressure Switch

will open. With the Blower running, check the IN

and OUT voltage of the Switch. If 24 VAC can be

found on one side but NOT the other, the Pressure

Switch is defective.

Ignition Control Modules:

When the Ignition Control Module is supplied with

24 VAC from the temperature control system at the

TH terminal it will send a signal to the Ignitor which

will begin to spark. At the same time the Ignition

Control Module will also have a 24 VAC output signal on the PV terminal sending 24 VAC to V2. At

this time the Low-Fire flame will light and produce

a flame sense signal. When the Ignition Control Module is supplied with a flame sense signal it will send a

second 24 VAC signal on the MV terminal which will

cause the V2 gas valve to open and thus create the

Hi-Fire flame. If a flame sense signal is NOT received

the Ignition Control Module will spark for 15 seconds before it "Locks Out". If the machine is running on High Fire flame and looses the flame for any

reason the Ignition Control will "Lock Out" in 0.8

seconds.

Ignitors:

When an Ignitor is supplied with power and does

NOT spark the Spark Gap should be checked. The

distance between the Ignitor and the Ground post

should be approximately 1/8" ± 1/32".

13

Page 20

14

Page 21

PARTS:

General Parts:

Basket, #18 .................................................... P6072184

Blower, Variable Speed 240V 50/60HZ .......... PP11091

Brush, Cleaning ............................................... PP10056

Burner, Nat Gas .............................................B8021001

Burner, LP Gas ..............................................B8021002

Burner Gasket ............................................... A8019401

Capacitor, Motor Starting ................................PP11196

Caster, Swivel .................................................. PP11113

Caster, Locking................................................ PP11114

Caster, Filter .................................................. P6071062

Circuit Breaker, 8 Amp Rocker ....................... PP10460

Circuit Breaker, 15 Amp .................................. PP11074

Circulation Tube Assembly ........................... B6651001

Clamp, Filter Bag ..........................................B6646701

Computer ......................................................... PP11235

Contactor, Motor Starting - 24VAC................. PP11102

Controller Digital T-Stat ................................. PP11O82

Controller, Fan - 2 Speed................................. PP11099

Door Assembly - RH .....................................B2302501

Door Assembly - LH .....................................B2302502

Drain Fitting Screen ......................................B3319601

Filter, Air .........................................................PPl 1072

Filter Bags (64 Count) .................................. A7011101

Filter Removal Tool ...................................... A4018002

Flush Hose Assembly ....................................B6602501

Gasket ........................................................... A8019401

Gauge, Pressure ............................................... PP11223

Gauge, Vacuum................................................ PP11073

Handle Assy , Drain V alve ..............................B4002201

Handlo, Door ................................................. P6071516

Handle, Flush Hose Assembly.......................B4002501

Handle, Pump Inlet Selector..........................B4002701

Handle, Filter Bag Removal ......................... A4018002

Hanger, Basket.............................................. A1105002

Harness, Control Cable.................................. B6733001

Hinge, Door - Bottom Left .............................. PP10895

Hinge, Door - Bottom Right............................ PP10896

Hinge, Door - Top Left .................................... PP10893

Hinge, Door - Top Right .................................. PP10894

Hi Limit- Snap Disc - 425 Deg........................ PP11064

Holder, Filter Bag..........................................B6646901

Hose, T eflon...................................................B6647501

Hose, Flush ....................................................B6602405

Insulator, O-Ring Fitting .............................. A7005601

Knob, Thermostat ............................................ PP10539

Knob, Plastic 1" ............................................... PP11218

Main O-Ring Fitting ......................................B6646801

Module, Ignition Cotrol - 24VAC.................... PP11096

Motor, Filter Pump - 230V 1 Ph....................B5304701

O-Ring, 0.5" ID ............................................... PP10111

O-Ring, 0.688 ID x 0.875 OD, Pick Up .......... PP10409

O-Ring, 1" ID .................................................. PP11104

O-Ring, 1.25" ID ............................................. PP11188

O-Ring, 13" ID ................................................ PP11105

Orifice, Burner.............................................. A8002721

Orifice, Main Burner ..................................... P6071336

Pan Assembly ................................................B6645801

Probe, Temperature ........................................ P5044876

Probe, Ignition/Flame Sensor ..........................PP11100

Pump, Gear Oil w/relief valve.......................B6646301

Pump Selector Rod ....................................... A4018602

Pump Strainer ................................................B6646601

Rack, Tube.....................................................B4511301

Regulator, Gas Pressure................................... PP11093

Relay, 24 VAC DPDT .................................... P5046686

Relay, 24 VDC SPDT...................................... PP11124

Relay DPDT-24VDC ....................................... PP11068

Relay, Over Load............................................. PP11103

Retainer, Filter Bag ........................................B6652701

Screen Assembly, Filter Pickup.....................B6646501

Skimmer, Mesh ................................................ PP10725

Snap Ring, Pick Up Tube ................................ PP10842

Spider Bushing ................................................ PP11080

Spider Coupling............................................... PP11089

Strainer, Pump ...............................................B6646601

Switch, Motor Starter ...................................... PP11195

Switch, Off/On/Start........................................ PP10559

Switch, Pressure Sensing................................. PP10925

Switch, Proximity Actuator .............................PP10263

Switch, Proximity Sensor ................................ PP10262

T ank Assembly ..............................................B3319101

T ape, Heat 240VAC ......................................... PP10298

T ape, Heat 240 V AC 165 Watt - 1/2" x 79" ..... PP10080

T ape, Heat 240 VAC - 48" ...............................PP10588

Thermostat, Alternate .................................... P5047587

Thermostat, Snap Disk .................................... PP10739

Transformer , 230 - 24 VAC.............................. PP10429

Tube Assembly , Pickup ................................. B6646401

Tube, Recirculation .......................................B6651001

Tube Rack......................................................B4511301

Valve 3/8" W/O Handle ................................. P6071780

Valve, Drain ................................................... P6071769

Valve, Gas 1" -24VAC NA T/LP....................... PP11092

Valve, Gas Poppet............................................ PP11094

Valve, Manual Shut Off ................................... PP11095

Vibration Pad................................................ A7010701

Vibration Washer .......................................... A7010801

Wire, Ignition with Boot.................................. PP11200

15

Page 22

Entrance Box Assembly:

# DESCRIPTION PART #

1 Cover, Top ............................................................................................... A2951601

2 Cover, Rear .............................................................................................. A2951701

3 Body......................................................................................................... A2951801

4 Guide, Air Filter ...................................................................................... A2951901

5 Bracket, Blower Mounting ...................................................................... A2952001

6 Bracket, Relay Mounting......................................................................... A2952101

7 Slide, Air Filter.........................................................................................B2911301

8 Plate, Front............................................................................................... A2952301

9 Cover , Air Filter Access .......................................................................... A2952401

10 Tray, Component Mounting..................................................................... A2952501

11 Cover, Component Access....................................................................... A2952601

12 Blower ........................................................................................................PP11091

13 Air Filter .....................................................................................................PP11072

14 Handle....................................................................................................... P6071516

15 Switch, Rocker - SPDT ..............................................................................PP10093

16 Contactor, 24 VAC 3 pole...........................................................................PP10560

17 Cicuit Breaker, Control - 8 A, 250 VAC.....................................................PP10460

18 Heater, Overload Relay............................................................................... PP11103

19 Contactor, Motor Starter ............................................................................. PP11102

20 Relay - DPDT, 10A 24 VDC ...................................................................... PP11068

21 Relay - DPDT, 24 VAC............................................................................. P5046686

22 Ignition Control Module .............................................................................PP11096

23 Clamp, Ground ......................................................................................... P5045241

24 Circuit Breaker, Master - DPST 250 VAC.................................................. PP11074

25 Switch, Pressure..........................................................................................PP10925

26 Bushing, Strain Relief.................................................................................PP10914

27 Lamp, 28 V Amber ................................................................................... P5045044

28 Transformer, 80 VA Multi Tap to 24 ..........................................................PP10429

29 Control, 2 Speed Fan ..................................................................................PP11099

30 Label, Switch Cover ................................................................................ A6071501

31 Wiring Harness .........................................................................................B6727401

32 Nutsert, 10-24 ........................................................................................... P0092500

33 Nutsert, 6-32 ............................................................................................. P0091400

34 Screw, 6-32 x 5/16" ....................................................................................PP10687

35 Screw, 6-32 x 7/8" .................................................................................... P0006100

36 Screw, 10-24 x 3/8" ....................................................................................PP10693

37 Screw, 10-32 x 1/2" ....................................................................................PP10752

38 Switch, Pump Motor Starter ....................................................................... PP11195

39 Capacitor, Pump Motor Starter................................................................... PP11196

40 Ignition Wire............................................................................................... PP11200

41 Screw, M4 ...................................................................................................PP10303

42 Clip, Spring................................................................................................. PP11234

43 Connector, Plug 5 Pin................................................................................. PP11098

44 Adaptor, Ignition Wire ................................................................................ PP11263

16

Page 23

171819

Page 24

Page 25

Page 26

20

Page 27

21

Page 28

In the event of problems with or questions about your order, please contact the Pitco Frialator factory,

from 8:00 a.m. - 5:00 p.m., Eastern Standard T ime, Monday through Friday, toll-free at:

(800)258-3708 US and Canada only

(603)225-6684 W orld Wide

Loading...

Loading...