Page 1

Project

Model SG Tube Fired, Gas Fryer - With SoloFilter

Model SG Tube Fired, Gas Fryer

With SoloFilter

(SG18 SoloFilter with optional I12 computer)

STAND ARD ACCESSOR IES

Choice of basket options

Two nickel-plated, oblong, wire mesh baskets

One nickel-plated , square, wire mesh basket

Built-in filtration system with 3" (7.6 cm) drain line

One nickel-plated tube rack

One drain line clean-out rod

Fryer cleaner sample

Rear gas connection

Manual gas shutoff

1 ¼” (3.2 cm) full port drain valve

Built-in integrated flue deflector

Removable basket hanger for easy cleaning

10” (25.4 cm) adjustable legs front, 10" (25.4 cm) fixed

casters rear.

Cabinet - stainless steel front, door, and sides

Tank - stainless steel

AVAI LABLE OPTIONS

Stainless steel back

Basket lift

Solid state thermostat**

Digital controller**

I12 Intellifry computer controller**

Triple baskets

Tank cover

Back-up thermostat (for use with digital or I12 control)

Item No.

Quantity

STANDARD SPECIFICATIONS

CONSTRUCTION

Welded tank with an extra smooth peened finish

ensures easy cleaning.

Long-lasting, high-temperature alloy stainless steel

heat baffles are mounted in the heat exchanger tubes

to provide maximum heating and comb usti on

efficiency.

Standing pilot light design provides a ready flame when

heat is required.

Stainless steel front, door, side, and splashback.

Heavy duty 3/16” (.48 cm) door hinge.

CONTROLS

Millivolt thermostat maintains selected temperature

automatically between 200°F (93°C) and 400°F (190°CCE).

Integrated gas control valve acts as a manual and

pilot valve, automatic pilot valve, gas filter, pressure

regulator, and automatic main valve.

Gas control valve prevents gas flow to the main burner

until pilot is established and shuts off all gas flow

automatically if the pilot flame goes out.

Temperature limit switch safely shuts off all gas flow

if the fryer temperature exceeds the upper limit.

New Solstice burner/baffle design.***

-Increases cooking production.

-Lowers flue temperature.

-Improves working environment.

-Generates more production per BTU.

***Compared to previous models.

OPERATIONS

Front 1 ¼” (3.2 cm) full port drain for quick draining.

10” (25.4 cm) clearance allows for ease of cleaning.

APPROVALS

CSA Certified

(AGA, CGA)

NSF Listed

MEA Approved

*Only available with digital or computer controls

**Includes matchless ignition, melt cycle, and drain valve interlock

switch.

Pitco Frialator, Inc., P.O. Box 501, Concord, NH 03302-0501 • 509 Route 3A, Bow, NH 03304, USA

Phone (603) 225-6684 • FAX (603) 225-8472 • www.pitco.com

L10-152 Rev 2 (02/07)

Page 2

Model SG Tube Fired, Gas Fryer - With SoloFilter

]

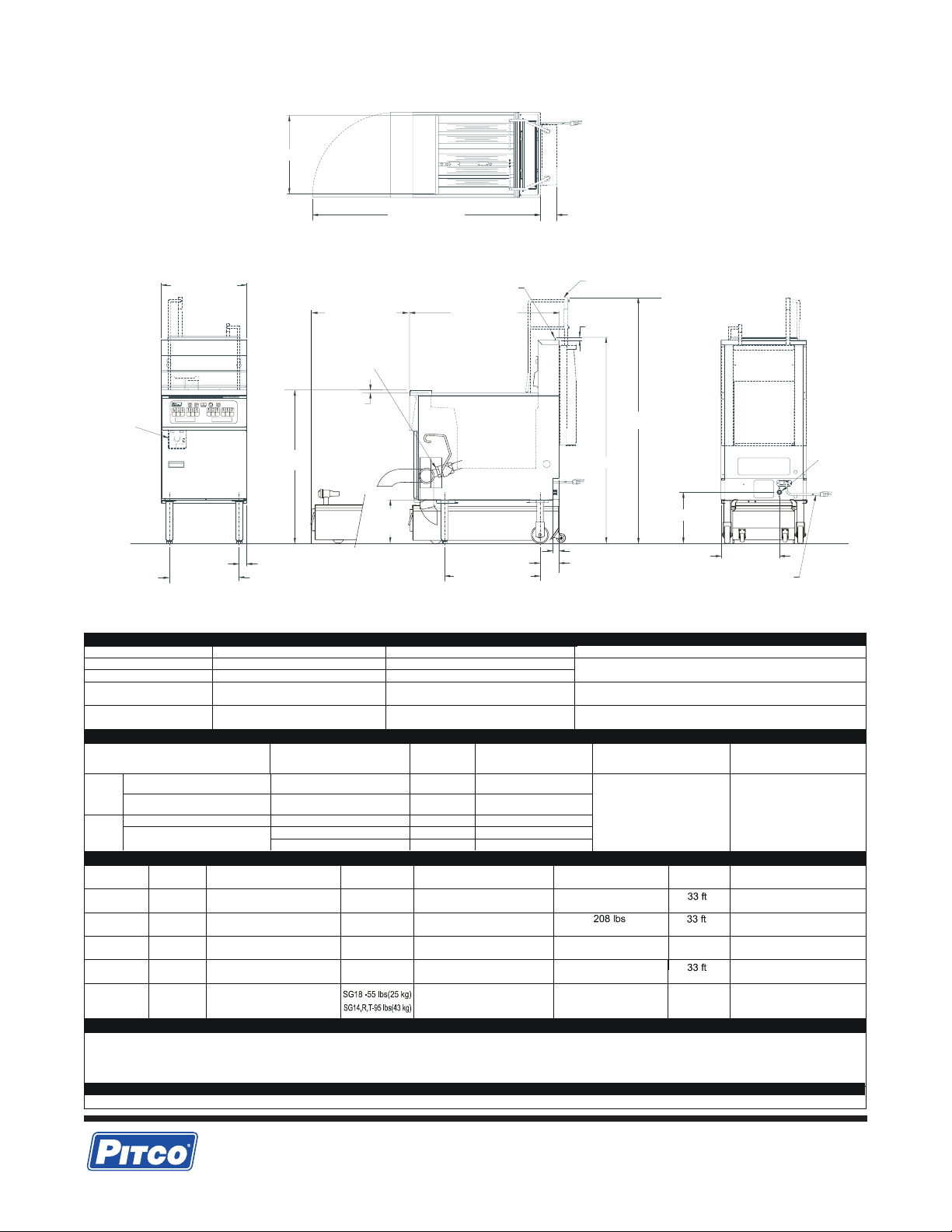

See Cook Area Below

52 5/16 [132.9] 3 27/32 [9.8]

Dim A

OPTIONAL

BACK-UP

THERMOSTAT

Model SG Tube Fired, Gas Fryer - With SoloFilter

INCHES [CENTIMETERS

Gas Type

Natural Gas 7” W.C. / 17.4 mbars / 1.75 kPa

L.P. Gas 13” W.C. / 32.4 mbars / 3.25 kPa

Clearance Information Fryer Front

All Models 30” (76.2 cm) minimum

Options Voltage / Phase / Frequency

Filter

8.0 GPM (30.3 LPM) 1/3 HP 115 / 1 / 60 7 3

6.7 GPM (25.4LPM) 1/3 HP 220-230-240 / 1 / 50

Fryer

Millivolt controls Not Required 0 N/A

Upgrade Controls: Solid state,

Digital, Computer, Basket Lift

Models “A” Dim Cook Area

SG14

SG14R

15-5/8 in

39.7 cm

15-5/8 in

39.7 cm

Store Manifold Pressure* Burner Manifold *Recommended Minimum

14 x 14 x 4 in

35.6 x 35.6 x 10.2 cm

14 x 14 x 4 in

35.6 x 35.6 x 10.2 cm

FLUE DEFLECTOR

35 [88.9]

NOM.

1 25/32 [4.5]

16 1/16 [40.8]

31 1/8 (79) minimum

aisle space required

to remove filter pan.

1-1/4 INCH (3.2 CM) NPT

FULL PORT DRAIN VALVE

5/8 [1.6]

11

[27.9] NOM.

4” W.C. / 10 mbars / 1 kPa

10” W.C. / 25 mbars / 2.5 kPa

Fryer Sides, Rear, Bottom

to any combustible material

6” (15.2 cm)

Do not Curb Mount

ELECTRICAL REQUIREMENTS

Amps

3.6 1.5

115 / 1 / 60 1.7 N/A

220-230-240 / 1 / 50 0.9 N/A

GAS REQUIREMENTS

Oil

Capacity

40-50 lbs

18-23 kg

40-50 lbs

18-23 kg

Input / Hour

110,000 BTU

33 kW (CE) / 119 mJ (AuGA)

122,000 BTU

36 kW (CE) / 129 mJ (AuGA) 94kg

INTEGRAL

34 3/8 [87.3]

21 29/32 [55.6]

Additional Amps

for Filter Heater

Gas

OPTIONAL

BASKET LIFT

11/16 [1.8]

47 1/8 [119.7]

1 13/32 [3.6]

4 3/8 [11.1]

55 7/16 [140.8]

1 15/32 [3.7]

13 3/8 [34.0]

6 FOOT (183 CM) POWER CORD SUP PLIED

(NEMA 5-15 PLUG ON 115VAC UNITS ONLY)

GAS

CONNECTION

¾ INCH NPT.

Check plumbing/gas codes for proper gas supply line sizing.

Fryer Flue Area

Do not block or restrict flue gasses from flowing into

ventilation system.

Number

of Power cords

Power

Cord Locations

1 Back Left

Shipping

Weight / Unit

200 lbs

91kg

Shipping

Cube

3

.93 m

3

.93 m

Shipping Dimensions

3

3

58 x 22½ x 43½ in

147.3 x 57.2 x 110.5 cm

58 x 22½ x 43½ in

147.3 x 57.2 x 110.5 cm

H x W x L

SG18

SoloFilter N/A

19-5/8 in

49.8 cm

N/A

18 x 18 x 4 ~ 4 ¾ in

45.7 x 45.7 x 10.2 ~12.1 cm

70-90 lbs

32-41 kg

140,000 BTU

40 kW (CE) / 145 mJ (AuGA)

N/A

226 lbs

103 kg

100 lbs / 46 kg

3

3

.93 m

N/A

Ships with

fryer

58 x 22½ x 43½ in

147.3 x 57.2 x 110.5 cm

N/A

SHORT FORM SPECIFICATION

Provide Pitco FD (Filter Drawer) Solstice filter system. Drain line shall be 3” (7.6 cm) diameter with a swivel drain spout for oil disposal. Filter pickup assembly shall have

handles and

and SG14T. Filter pump shall pump 8 GPM, 60 Hz (25.4 LPM, 50 Hz). Filter piping to be self-aligning for easy

of use. Filter pan shall have front stabilizer legs and rear rigid casters for portability. Provide accessories as follows.

utilize envelope type filter paper with 475 sq in (3,065 sq. cm.) of filter area for model SG18 and 310 sq in (2,000 sq cm) of filter area for model SG14, SG14R

assembly. Filter lid shall be attached to the cabinet for ease

TYPICAL APPLICATIONS

Space saving filter capable of filtering heavy to light breaded products fast and conveniently.

Pitco Frialator, Inc., P.O. Box 501, Concord, NH 03302-0501 • 509 Route 3A, Bow, NH 03304, USA

Phone (603) 225-6684 • FAX (603) 225-8472 L10-152 Rev 2 (02/07) Printed in USA

We reserve the right to change specifications without notice and without incurring any obligation for equipment previously or subsequently sold.

Loading...

Loading...