Page 1

IMPORTANT FOR FUTURE REFERENCE

E N G L I S H

Please complete this information and retain these

instructions for the life of the equipment:

Model #: __________________________

Serial #: __________________________

Date Upgraded: ___________________

Technician: _________________________

Installation Instructions for the

PITCO

Self-Cleaning Burner System

L80-029 Rev 5 10/07

Page 2

appliance containing hot cooking medium; serious personal injury may occur.

RETAIN THESE INSTRUCTIONS FOR FUTURE REFERENCE

WARNING

The power supply to the appliance MUST be disconnected before performing

this procedure.

WARNING

Ensure that the gas supply to this appliance is turned off before performing

this procedure.

WARNING

Use only parts supplied with this kit. Use of any parts other than those

supplied with this kit will void the warranty and could cause unsafe conditions

or improper operation of your appliance.

WARNING

Drain the tank and ensure that appliance has cooled to room temperature

before performing this upgrade. DO NOT work on a hot appliance or an

TO THE PURCHASER

Post in a prominent location the instructions

to be followed in the event that an operator

smells gas. Obtain this information from

your local gas supplier.

WARNING

There is an open flame inside this appliance.

The unit may get hot enough to set nearby

materials on fire. Keep the area around the

appliance free from combustibles.

WARNING

DO NOT use an open flame to check for

gas leaks!

WARNING

Adequate means must be provided to limit the

movement of this appliance without depending on

the gas line connection. If any restraining devices

are disconnected during this procedure, ensure

that they are reconnected before putting the

appliance into service. Failure to do so could

result in a dangerous and unsafe condition.

WARNING

Installation of this upgrade kit should only be

performed by a competent service technician.

WARNING

Do not attempt to move a cooking appliance when

the unit is at operating temperature. Serious

personal injury could result if skin comes in

contact with the hot surfaces.

WARNING

DO NOT sit or stand on this appliance. Serious

injury could result from falling or contact with hot

shortening/oil.

WARNING

Improper installation, alteration, service or

maintenance can cause property damage, injury

or death. Read the installation, operating and

maintenance instructions thoroughly before

installing or servicing this equipment.

WARNING

If gas flow to appliance is interrupted, or pilots

extinguish, wait 5 minutes before attempting to

relight the pilot to allow any residual gas in

appliance to dissipate.

NOTICE

It is recommended that your appliance be

inspected by a qualified technician on a yearly

basis.

L80-029 Rev 5 10/07

Page 3

Theory of Operation:

A natural gas burning appliance requires roughly 10 cubic feet of air to properly combust a single cubic foot of

gas. Minute airborne particles entrained during this process pass through the combustion system and are

incinerated. However, some particles may be trapped within the combustion system, building up over time,

causing an eventual decrease in the operational efficiency of your appliance. The rate at which this build up

may occur varies from kitchen to kitchen and is greatly influenced by the environment (breading, flour etc.) and

kitchen processes (i.e. cleaning). Historically, frequent cleaning of burners and other combustion related

components has been the only way to insure optimal efficiency of your fryer. The Pitco Self Cleaning Burner

System (SCBS) will minimize the cost and inconvenient down time of frequent cleaning of combustion system

components. Each morning when the appliance is turned on, a small amount of gas is momentarily diverted

into a runner tube, which, after passing by the pilot, ignites and causes a short but effective light back at the

main burner orifice. This brief flame bath cleans the inside of the burner face by incinerating any foreign matter

that has accumulated from the previous day’s operation.

The Pitco Self Cleaning Burner System is designed to help maintain proper operation and efficiency of your

appliance’s combustion system by minimizing the build up of any foreign material inside the burner housings.

Proper installation of this upgrade and periodic maintenance of the appliance are critical to safe, reliable and

efficient operation.

Tools required to perform this upgrade:

5/16” (8 mm) wrench 1 1/16” wrench Wire cutters

5/16” (8 mm) nut driver Cordless screwdriver w/ 5/16” bit Pipe joint compound or teflon

7/16“ (12 mm) wrench Phillips screwdriver tape

1/2“ (13 mm) wrench Small flat blade screwdriver

11/16” (18 mm) wrench (or socket) 3/16” (5 mm) hex key

7/8” (23 mm) wrench

Before you begin:

Verify that you have all the parts for the model that you are upgrading by checking the kit number and contents

against the exploded view drawings in the back of these instructions.

WARNING

The power supply to the appliance MUST be disconnected before performing this procedure.

WARNING

Ensure that the gas supply to this appliance is turned OFF before performing this procedure.

WARNING

Drain the tank and ensure that appliance has cooled to room temperature

before performing this upgrade. DO NOT work on a hot appliance or an

appliance containing hot cooking medium; serious personal injury may occur.

1 L80-029 Rev 5 10/07

Page 4

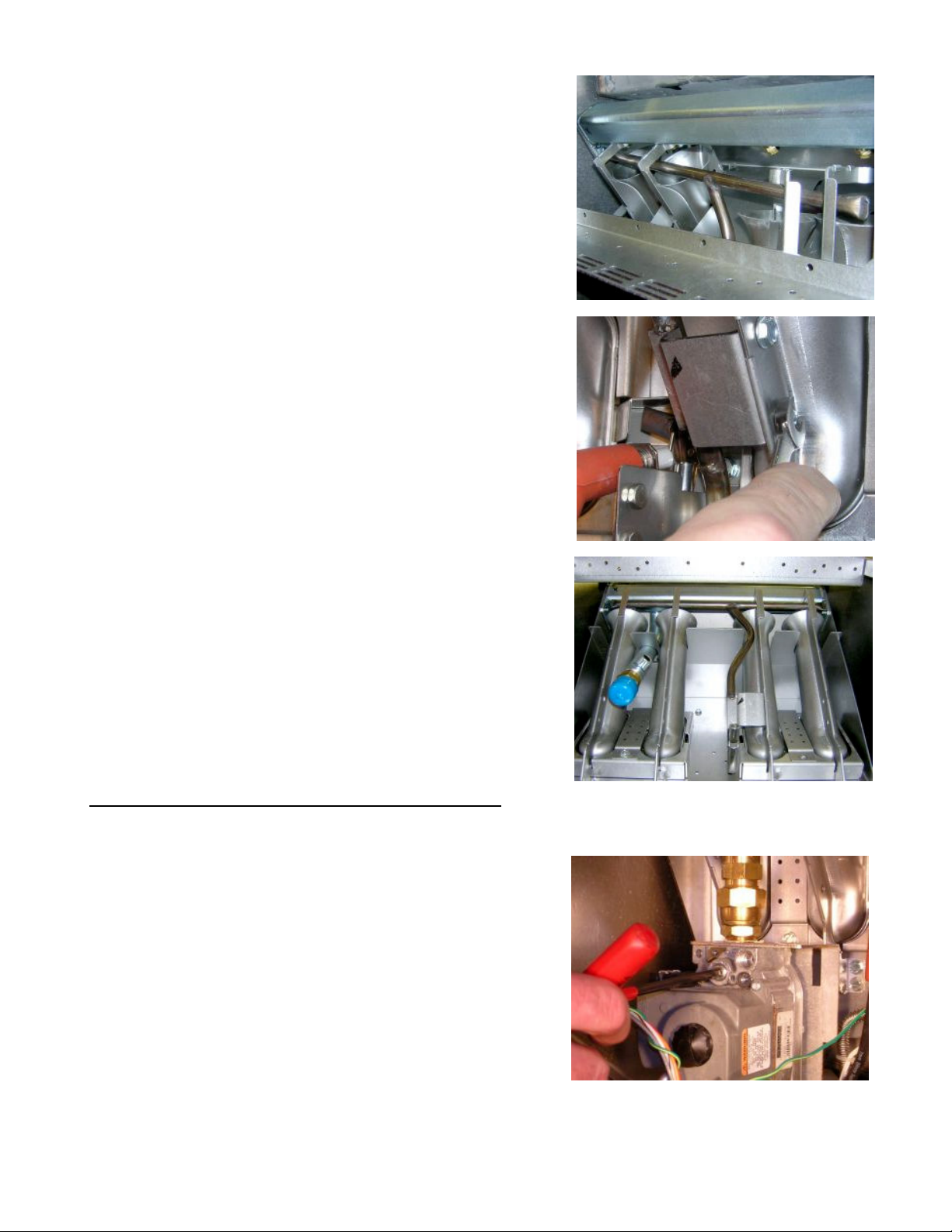

Follow this procedure for Installation of Self Cleaning

burners and SCBS arm:

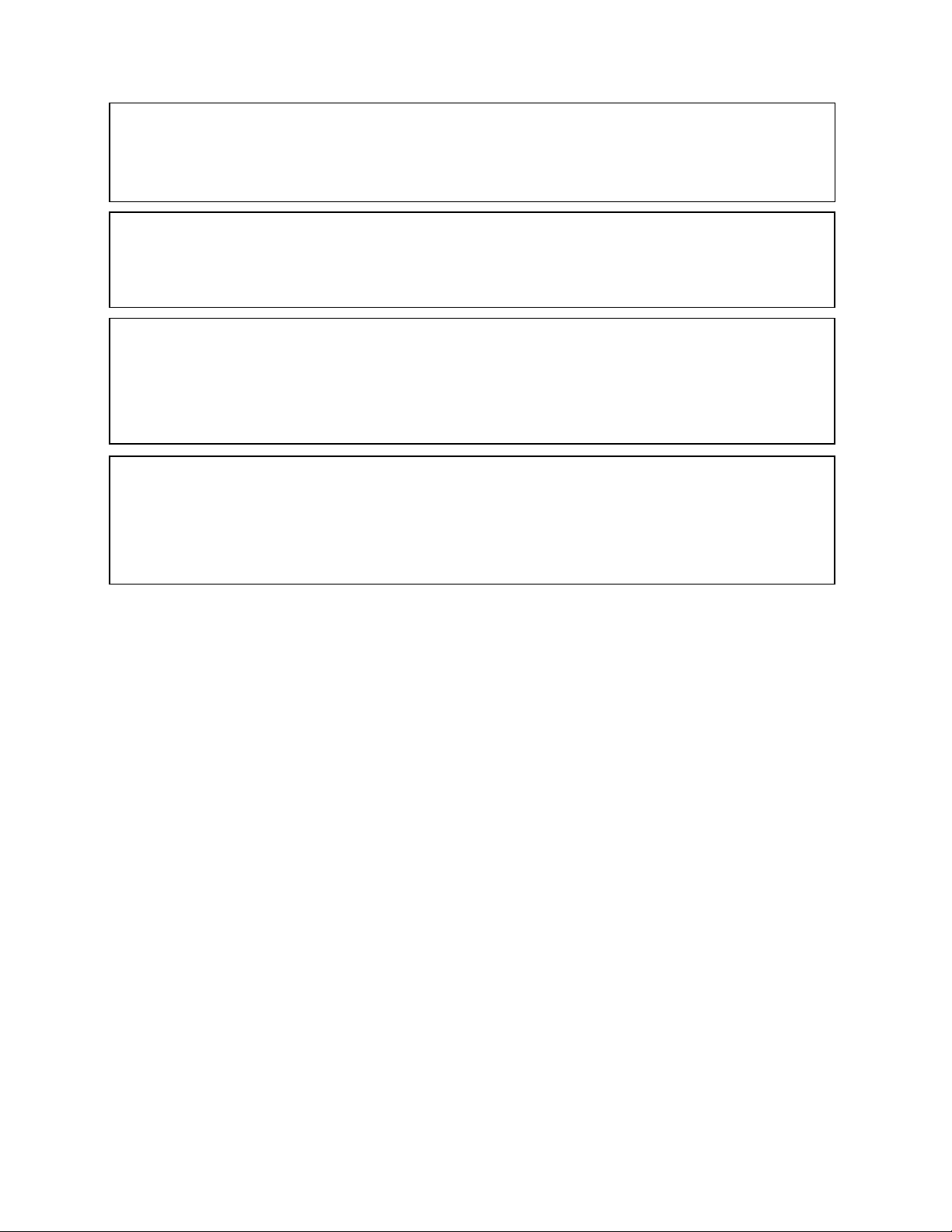

a. Disconnect the control harness from the main gas

valve and tuck it out the way to avoid damaging the

harness during this procedure.

b. If your appliance has a solid-state control (or

auxiliary thermostat) behind the door, remove it at

this time. With a 5/16” nut driver remove the two

self-threading screws that mount the control to the

appliance, disconnect the control harness and tuck

it out of the way to avoid damaging the harness

during this procedure. Be sure to store the control

in a safe place to avoid accidental damage to it.

c. Using a 7/16” wrench, remove the pilot tubing from

the gas valve by turning the brass fitting counter-

clockwise. There is no need to remove the pilot

from the burner assembly.

WARNING

Ensure that the tank contents have been

drained before executing this step!

d. Using an 11/16” wrench or socket, loosen and

remove the drain valve nut and washer, and

remove the blue drain valve handle. Note: You may

want to place the nut and washer back on the valve

stem for safekeeping.

L80-029 Rev 5 10/07 2

Page 5

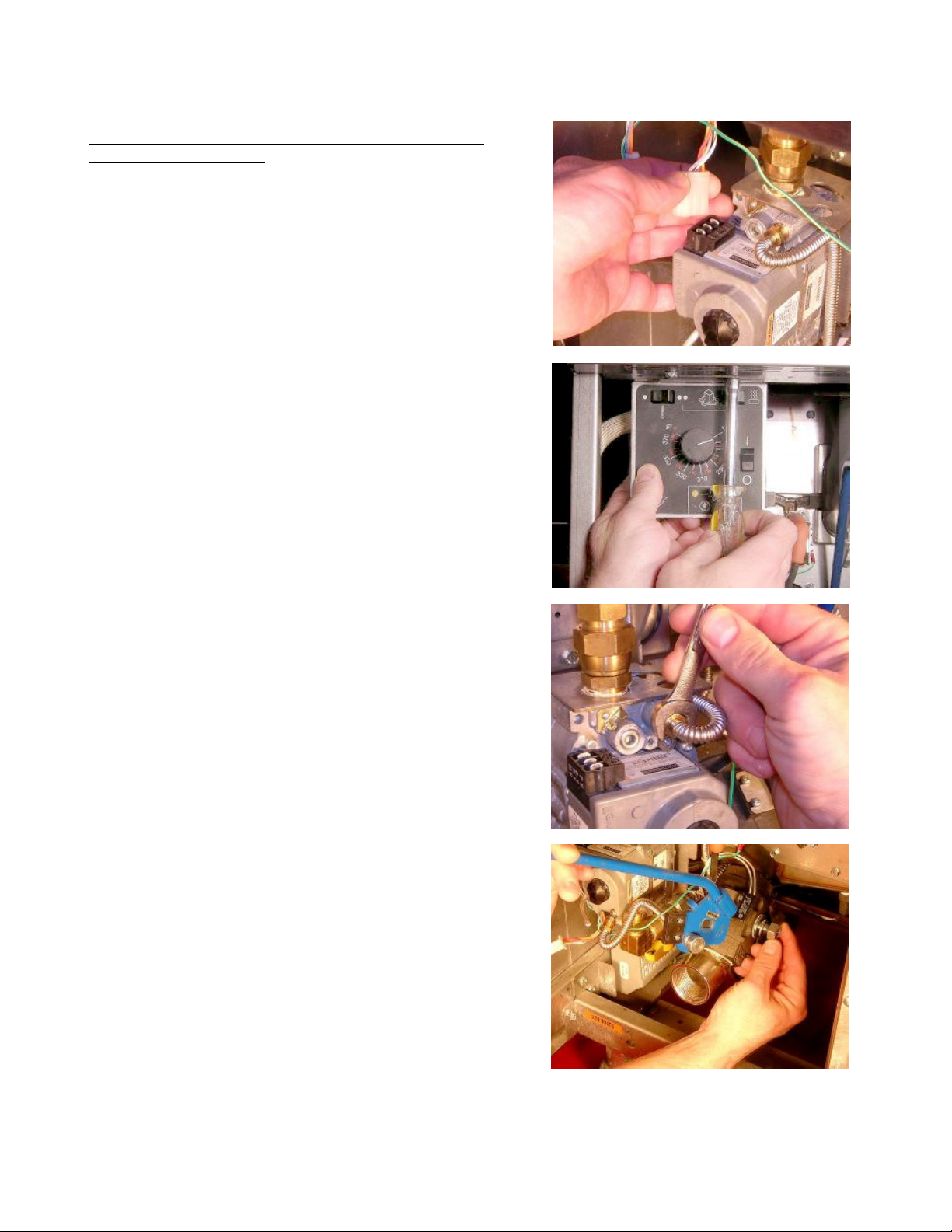

e. Using a 1 1/16” wrench and a 7/8” wrench, loosen

the brass fitting on the top of the gas valve and

disconnect the gas valve from the manifold inlet.

This will allow you to drop the gas valve down

and keep it out of the way during burner

replacement.

f. Using a 5/16” wrench, nut driver or screw gun bit,

remove all burners by removing the (2 ea.) self

threading screws holding them into the burner rack.

Retain these for reinstallation of the new burners.

Note: On models MG2 and SGH50, it will be

necessary to remove the air collars surrounding the

burner head.

WARNING

Be sure to keep the removed burners separate from

burners supplied with the upgrade kit. The existing

burners WILL NOT work with the Pitco Self-Cleaning

Burner System. DO NOT attempt to use the old burners

with the Pitco Self-Cleaning Burner System: an unsafe

condition may occur.

g. Replace the burners to the LEFT of the pilot with

burners supplied with the Pitco Self-Cleaning

Burner System upgrade kit, securing them with the

fasteners removed and retained in step f.

NOTE: Pre-tap the holes on mounting bracket on

the SCBS runner arm with the two self tapping

screws provided in the kit before you install it.

h. With the ports FACING INWARD, insert the SCBS

Arm into the space between the burner venturis

and orifice holders of the newly installed burners.

3 L80-029 Rev 5 10/07

Page 6

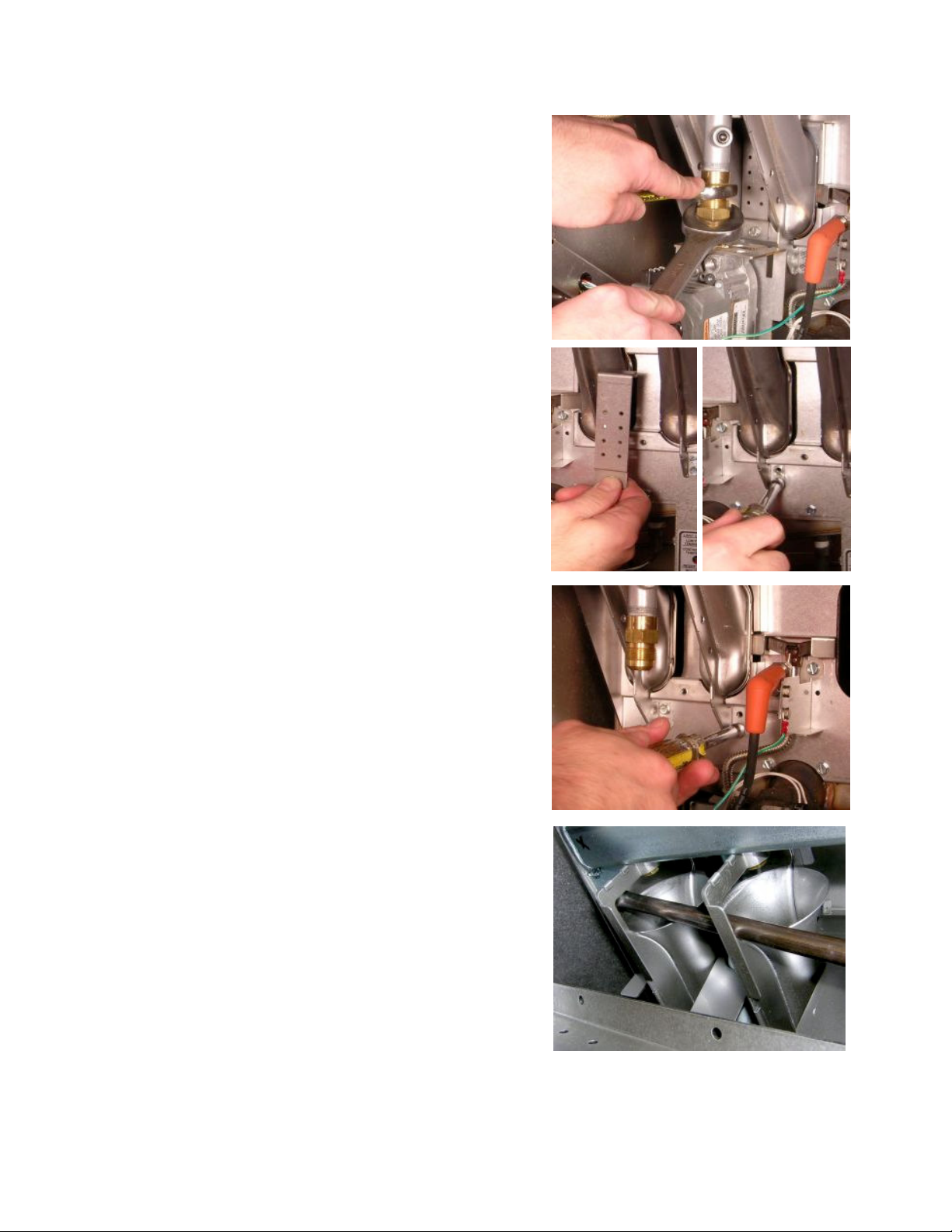

i. Capture the remaining burners on the SCBS Arm in

the same manner as in step h, and secure them into

the appliance, taking care not to strip the pre-threaded

holes.

j. Secure the SCBS Arm to left side of the burner to the

right of the pilot using two 10 X 24 self-threading

screws provided with the Pitco Self-Cleaning Burner

System Upgrade Kit.

The SCBS Arm should now be mounted properly and securely.

Inspect your work to insure that the burners are installed correctly.

Improperly mounted or poorly aligned burners may result in an

unsafe condition or poor appliance performance. They should be

mounted properly on the orifice fittings, facing straight into the

burner tubes and secured tightly to the appliance.

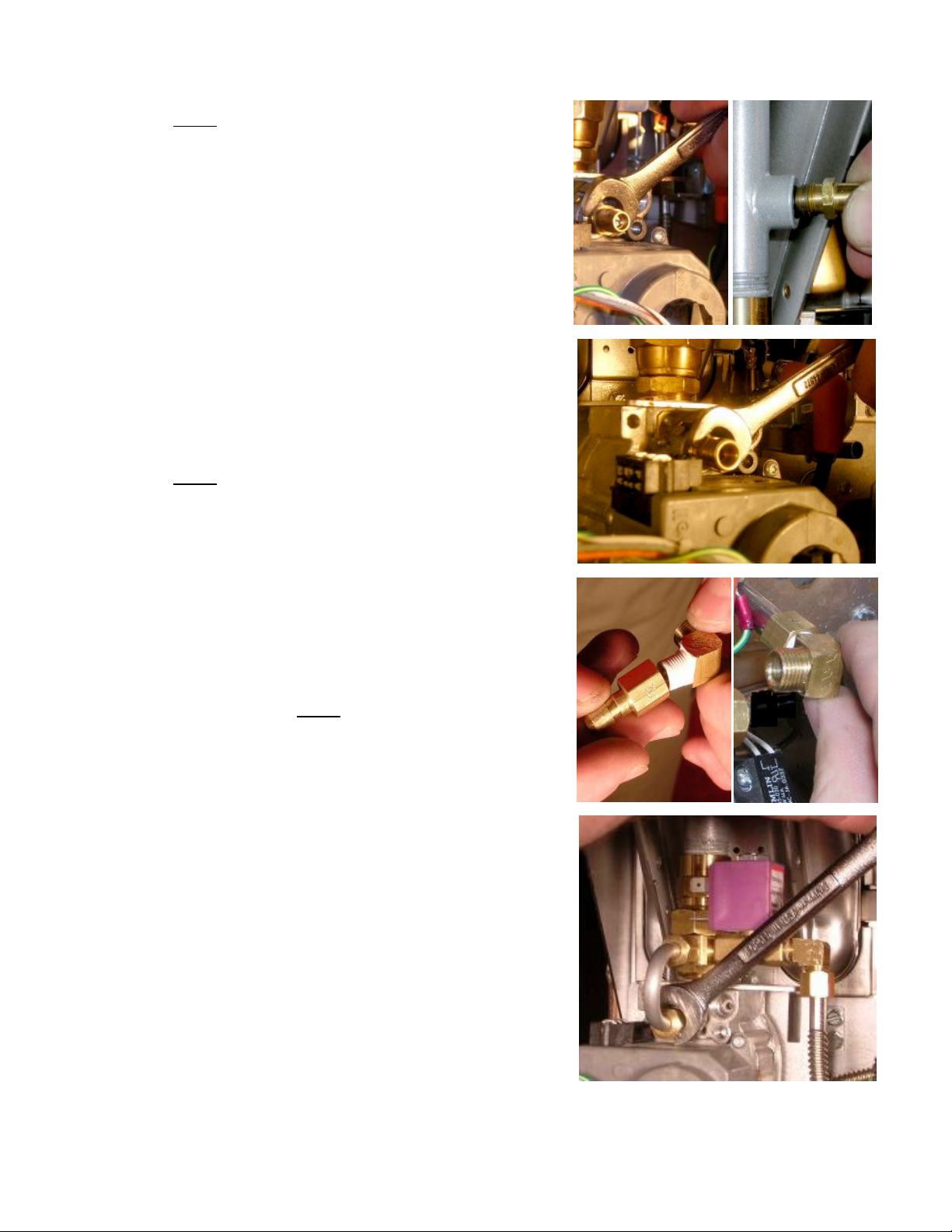

Follow this procedure for installation of the SCBS Valve:

NOTE: The valve type you receive in your kit may differ in appearance slightly from the one shown in these

instructions.

a. Re-attach the gas valve to the manifold inlet using a 1

1/16” wrench and a 15/16” wrench and, with a 3/16” (5

mm) hex key, remove the plug from the pressure tap

port on the TOP portion (Outlet Side) of the valve,

next to the pilot fitting.

L80-029 Rev 5 10/07 4

Page 7

NOTE: CE approved models will have a pressure test

fitting in this location. For CE approved models, remove

this pressure test fitting using a 7/16” (12 mm) wrench.

Using a 3/16” (5 mm) hex key, remove the plug from the

auxiliary pressure tap on the manifold inlet and replace

it with pressure tap fitting that you removed from the

TOP (Outlet side) of the valve. Use teflon tape or apply

pipe joint compound on the threads of the fitting to

ensure a gas-tight seal.

b. Remove the straight 1/8” NPT X ¼” compression fitting

from the U tube end of the SCBS Valve Assembly

provided with the kit and, with a 7/16” wrench, install it

into the recently vacated pressure test port on the TOP

(Outlet Side) of the valve. Use teflon tape or apply pipe

joint compound on the threads of the fitting to ensure a

gas-tight seal.

NOTE: The threads on this fitting (1/8’ NPT and ¼”

compression) are not interchangeable. Be sure to

install the NPT side of this fitting into the gas valve.

Failure to complete this step correctly could damage

the threads of both the fitting and the pressure test

port, and may result in gas leakage at this joint.

c. Remove the 1/8” NPT X 90° ¼” compression fitting from

the other end of the SCBS Valve Assembly provided

with the kit and install the orifice tip, also provided in the

kit, on to the NPT end of the fitting. Insert the orifice end

of this assembly into the runner tube installed previously

in this procedure. NOTE: Check the orifice against the

parts list included in these instructions to insure that it is

the correct size for the gas type of your appliance.

d. Mount the SCBS Valve Assembly into the appliance by

loosely attaching the U tube end of the assembly onto

the straight fitting that you installed into the TOP (Outlet

Side) of the gas valve in step b.

5 L80-029 Rev 5 10/07

Page 8

e. Thread the compression nut on the corrugated tubing

end of the SCBS Valve Assembly onto the orifice

assembly that you inserted into the runner tube in

step c and tighten with a 1/2” (13 mm) wrench.

f. Install the orifice retainer bracket onto the pilot

bracket and SCBS Orifice assembly. This will secure

the orifice assembly into the runner tube.

g. Tighten ALL joints on the SCBS Valve assembly with

a ½” (13 mm) wrench. Reinstall the pilot tubing into

the gas valve.

h. Reconnect the control harness to the main gas valve,

and if you removed a Solid State Control earlier in

this procedure you may re-install it at this time.

Follow this procedure to prepare and install the

SCBS Control Board and Harnesses:

a. Using a phillips head screwdriver, remove the two

screws that secure front panel and rotate the control

assembly down. Disconnect the control harness and

remove the front panel assembly from the appliance.

(This will not be necessary if your model uses a solidstate control). Store the front panel assembly in a safe

place to avoid damaging the control.

L80-029 Rev 5 10/07 6

Page 9

b. Disconnect the wiring harness from the relay board

BOARD SHOWN

NEW REVISION

BOARD SHOWN

BOARD SHOWN

HARNESS

mounted behind the front panel and remove the

relay board and insulation paper. Be sure to retain

the screws. The existing relay board may or may

not have a jumper plug as shown. If it does, remove

it from the old relay board and install it into the

same position on the “new” SCBS relay board

provided.

c. Install the insulation paper provided with the Pitco

Self-Cleaning Burner System Upgrade Kit onto the

backside of the SCBS Control Board and mount the

board in the front panel enclosure, using the same

screws and holes as the old board. Older revision

boards will have wires attached to the board for

the thermal cutout and a two pin connector for

the valve harness; these wires are not present

on newer revision boards, which have the

thermal cutout harness and valve harness

combined into one single harness.

NOTE

It is critical for proper operation that the

insulation paper is installed. Failure to install

the insulation paper may cause soldered joints

on the back of the Control board to short out

and damage the Control board and/or appliance.

OLDER REVISION

d. Plug four-pin connector on SCBS Harness into

SCBS Relay Board and ground as shown, using the

existing fastener to secure ground cable to the

appliance chassis. Older revision models will

have the thermal cutout leads feeding directly

from the board, a two-pin connector for the

valve harness and a separate harness for the

thermal limit assembly. For older revision

boards, plug the two pin connector on the SCBS

Valve harness into the SCBS Relay Board and

ground as shown, using the existing fastener to

secure ground cable to the appliance chassis.

Connect the SCBS Thermal Limit Harness

(supplied with older revision kits only) to the red

and grey leads on the older revision SCBS Relay

Board.

OLD REVISION

OLD REVISION

7 L80-029 Rev 5 10/07

Page 10

e. If the appliance you are upgrading does NOT have a

Solid State Control, proceed to step f in this section.

If the appliance that you are upgrading has a Solid

State Control, feed the other ends of the SCBS

Harness through the unused portion of the strain

relief holding the Solid State Control Harness and

proceed directly to step h in this section.

NOTE: If needed, you can carefully nudge open the

area in the strain relief with a screwdriver to make

additional room to insert the SCBS harness. Take

care not damage the harness during this procedure.

f. Using a 5/16 nut driver, remove the two screws on

the underside of the front panel that hold the slotted

bottom on. Remove the slotted front panel bottom;

this will allow easier access to the cable retainer

plate. Remove the two screws holding the cable

retainer plate onto the appliance and remove the

cable retainer plate, leaving the control cable held in

place by the square strain relief. Replace the cable

retainer plate that you removed with the new one

provided in the kit. Cable retainer plate style varies

from model to model; the one that came with your kit

should look exactly like the one that you removed

with an added hole.

g. Feed the SCBS harness through the hole in the cable

retainer plate. Collect and capture all wires in this

harness into the split grommet provided with the kit

and install the grommet into hole in the cable retainer

plate. The installation of the grommet is critical as it

insures that the wires will not chafe and/or short out

against the metal edge of the hole in the cable

retainer bracket.

h. You may now reconnect the main control harness to

the SCBS board exactly as it was connected to the

previous board, re-attach the front panel bottom and

reconnect, remount and close up the front panel

assembly.

L80-029 Rev 5 10/07 8

Page 11

i. Connect the SCBS Harness to the SCBS Valve as

shown. The red and violet wires must be connected

to the vertically oriented tabs on the valve and the

green (ground) wire must be connected to the

bottom, horizontally oriented tab on the valve. The

grey wires will be connected to the Thermal Limit at

a later point in the upgrade process.

j. Route the SCBS Harness along the main control

harness and wire tie it to the control harness. The

proper wire tie locations are indicated by arrows, see

photo at right. Trim excess from wire ties.

k. Mount the Thermal Limit Switch Assembly with

the flange of the bracket oriented down and facing

inward toward the tank. The switch terminals will then

be facing outward toward the front of the appliance.

Mount the assembly by straddling it on the two

burners on either side of the pilot and positioned up

to where the flange on the assembly meets with the

bottom of the flange on the burner “web”, see photos

at right.

l. Fasten the Thermal Limit Switch to the flange on the

burner web using two self-drilling fasteners provided

in the Pitco Self Cleaning Burner System Kit.

Connect the leads of the SCBS Harness to the tabs

on the Thermal Limit Switch. Re-attach the drain

handle.

You have now successfully installed the Pitco Self-Cleaning Burner system. Apply the schematic label

provided with the kit over the one on the inside of the appliance door. Before proceeding it is highly

recommended that you now thoroughly check the appliance to insure that the procedure was

properly followed. Check that all gas joints are tight, all electrical connections are correct, and

that the appliance is completely and properly reassembled.

9 L80-029 Rev 5 10/07

Page 12

Follow this procedure to check proper operation of the Pitco Self-Cleaning Burner System:

WARNING

Ensure that tank is filled to the level line with oil before turning the

appliance on. Turning the appliance on with an empty or partially filled tank

could cause an unsafe condition, which could lead to damage to the

appliance, property damage or personal injury.

a. Reconnect the power supply and turn on the gas supply to the appliance.

b. Energize the unit and check the gas delivery system and Pitco Self-Cleaning Burner System for

gas leaks by applying liquid leak detector or a solution of soapy water to all gas joints and

watching for bubbles at the joints.

c. If you detect bubbles at any gas joint, turn the appliance off, disconnect the power supply and turn

off the gas supply immediately. Retighten any joints that show signs of leaking and repeat steps a,

b and c until no leakage is detected. If you do not detect any leaks, proceed to step d.

d. Turn appliance on and observe its behavior. The appliance will execute a Cleaning Cycle every

time it is energized from on “OFF” state, so you may turn the appliance off and then on again to

verify proper execution of the Cleaning Cycle. Refer to the below table to verify proper Cleaning

Cycle execution

Event Duration Indication

Turn appliance “ON” N/A

Pre-Purge Pulse 2 seconds Appliance operates briefly and stops. Pilot remains lit.

Interwaiting period 1 5 seconds Appliance does not operate. Pilot remains lit.

Cleaning Pulse 6 seconds

Interwaiting period 2 8 seconds

Normal operation

resumes

N/A

Control Illuminates, pilot sparks and ignites. Pre-Purge

pulse is initiated.

Main valve operates, lighting main burners. SCBS valve

operates, feeding gas to the SCBS Arm. The SCBS arm

ignites, initiating a brief burn at the main burner orifice of

each burner.

The Main and SCBS valves de-energize for this period.

The pilot remains lit.

The appliance operates normally and begins to heat up.

The SCBS Valve remains de-energized until power to

the appliance is recycled. There is no flame on the

SCBS Arm. There is no burn at the main burner orifices.

With the Pitco Self-Cleaning Burner System installed, the appliance should behave as outlined in the above

table. A Cleaning Cycle will execute every time the appliance is turned “ON” from an “OFF” state. The thermal

cut out switch is designed to disable the appliance if the Self Cleaning Burner System malfunctions and

remains activated for an extended period of time or if there is a downdraft into the flue or a blocked flue

situation.

Follow this procedure to adjust and verify proper operation of an appliance using flue baffles

(McDonald’s models MG2 and MG2T):

WARNING

If the appliance you are upgrading is equipped with flue baffles, it may be

necessary to adjust the baffle’s opening to restore proper operation of the

appliance.

If the model you are upgrading is an MG2 or MG2T, it may be necessary to adjust the flue baffle opening to

restore proper operation of the appliance’s combustion system. Flue baffles are used when the appliance is

direct coupled to an exhaust hood, the flue baffle balances the exhaust draw on the combustion system.

When operating properly, the burners should exhibit light blue flame and generate a mild, consistent roar. It is

possible to view the burner flame on the center two burners by peeking sideways into the opening on the air

collars near the pilot. If, during operation the burner flames appear to be lifting or pulsing, the draw of the

hood may be too powerful and the baffle will need to be adjusted to a more restrictive setting. Lifting or

pulsing burners can usually be heard when the

L80-029 Rev 5 10/07 10

Page 13

appliance is in operation, or can be detected visually by watching the burner flame through the air collars. The

sound of the burners will be inconsistent and the flame may appear to ‘peel’ off of the burner face.

A certain amount of flame roll out during ignition is normal. However, excessive flame roll out during burner

operation is abnormal. Excessive flame roll out will cause undue heating in the burner area and will cause the

thermal cut out switch to trip. If there is significant flame roll out upon ignition or during normal operation, the

flue baffle setting may be too restrictive and will need to be adjusted to a more open position.

Determine whether or not the appliance you have upgraded has flue baffles. After performing this upgrade

procedure, observe the appliance during startup and normal operation. If pulsing burners or extreme flame roll

out are detected, adjust the flue baffle according to the following

procedure.

Follow this procedure to verify proper setting of flue baffles

and adjust if necessary:

a. Ensure that the appliance is installed properly under the

hood in the manner in which it is intended to be used.

Turn the appliance on and allow it to execute the

cleaning cycle and go into normal operation. Observe

the operation of the main burners as the appliance

brings the oil to set point, during idling and during

cooking operations.

LESS RESTRICTIVE

b. If the burners appear to pulse or the flame is lifting off of

the burner face proceed to step c of this section of these

instructions. If there appears to be significant roll out

during ignition or any time during operation, proceed to

step d of this section of these instructions.

c. For pulsing/lifting burner flame: Turn the appliance

off and allow it to cool. Pull the appliance out from under

the hood and loosen the screws securing the adjustable

slide plate on the flue baffle. Move the slide plate toward

the rear of the appliance to a more restrictive position

and retighten the screws. Repeat steps a and c until no

pulsing or flame lift is observed.

d. For excessive flame roll out: Turn the appliance off and allow it to cool. Pull the appliance out

from under the hood and loosen the screws securing the adjustable slide plate on the flue baffle.

Move the slide plate toward the front of the appliance to a less restrictive position and retighten the

screws. Repeat steps a and d until flame roll out is minimized.

e. Observe burner operation while allowing the appliance to heat up and during hot operation

(cooking and idling): the flue baffle must be adjusted correctly to allow the appliance to operate

properly during both (cold) start up and normal (hot) use conditions. It may be necessary to fine

tune the flue baffle setting for proper operation under both conditions.

WARNING

If the flue baffle CANNOT be adjusted properly, the facility must have the

ventilation system checked immediately to be sure that it is operating within

normal specifications. After the ventilation system is corrected, the baffle

setting must be rechecked. Failure to correct ventilation problems or

properly set flue baffles will result in extremely poor appliance operation

and possible equipment damage.

MORE RESTRICTIVE

11 L80-029 Rev 5 10/07

Page 14

B.

Gas supply turned OFF.

B.

Turn on gas supply to appliance.

C.

Appliance unplugged.

C.

Plug appliance power cord into wall outlet.

D.

Blown control fuse.

D.

E.

Faulty transformer.

E.

A.

Tripped hi limit

A.

Depress red button and reset hi limit.

B.

Controller is not turned on

B.

Turn controller on.

C.

C.

D.

Faulty temperature probe

D.

A.

A.

B.

B.

C.

Faulty SCBS Board

C.

Replace SCBS Board.

D.

Faulty SCBS Valve

D.

Replace SCBS Valve.

E.

Clogged SCBS Orifice

E.

Clean debris from SCBS orifice opening.

F.

F.

B.

Pilot is mounted improperly.

B.

Ensure that pilot is mounted properly.

C.

Flame sensor is misaligned.

C.

Ensure that the flame sensor is properly aligned.

D.

Low Pilot

D.

Ensure that pilot is adjusted to provide adequate flame.

E

Clogged Pilot orifice

E

Ensure that pilot orifice is clear of debris.

F.

Damaged or defective Pilot.

F.

Replace pilot if necessary.

A.

Blockage in burner tubes.

A.

Ensure that burner tubes are free of obstructions.

B.

Flue is blocked

B.

Ensure that flue is free of obstructions.

Check ventilation hood for improper operation, down draft

beyond normal cycle

Check that the SCBS Lighter arm has been properly

Poorly aligned or faulty SCBS

Refer to Service and Parts manual to diagnose and correct

SCBS thermal limit switch has

Verify that all wires and harnesses are plugged in properly

Reset Thermal Limit switch. On models MG2 and MG2T,

operation, down draft or blockage.

TROUBLESHOOTING

Should there be a problem with your appliance, use the following tables to isolate possible faults before calling Pitco

Technical Support.

PROBLEM

Appliance will not

run, front panel

lights are not ON.

Appliance will not

run, front panel

lights are ON.

Appliance is ON, but

a Cleaning Cycle

does not execute

SCBS energizes

parameters (during

cooking, idling, etc.)

POSSIBLE CAUSES CORRECTIVE ACTION

A. Main breaker in OFF position. A. Turn on Circuit Breaker to appliance.

Refer to Service and Parts manual for your appliance to

F. Defective controller. F.

tripped

E. Defective controller. E.

Unplugged wire harness.

Improper wiring.

Lighter arm.

A. Faulty SCBS Board A. Replace SCBS Board.

B. Faulty SCBS Valve B. Replace SCBS Valve.

properly diagnose and correct these problems.

Depress button on thermal limit switch and reset.

these problems.

to the correct component.

Verify that the wiring steps in this instruction have been

followed correctly. Correct any faulty wiring.

installed. Replace if faulty.

Appliance will not

run, control flashes

ignition failure

Appliance will not

maintain

temperature

properly.

Thermal Limit

Switch trips after

short period of

operation.

A. Pilot tubing is loose. A. Ensure pilot tubing is tight and properly connected.

SCBS Thermal Limit switch has

G.

tripped.

A. A.

Faulty temperature probe

B. B

Faulty hi limit switch

Model MG2 or MG2T flue baffle

C. C.

is set too restrictively.

D. D.

Ventilation hood malfunction

verify that flue baffles.are properly adjusted per these

G.

instructions. Check ventilation hood for improper

Refer to Service and Parts manual to diagnose this problem

and replace temperature probe.

Refer to Service and Parts manual to diagnose this problem

and replace hi limit switch.

Refer to flue baffle adjustment procedure in these

instructions to set flue baffle to a less restrictive setting.

or blockage.

L80-029 Rev 5 10/07 12

Page 15

13 L80-029 Rev 5 10/07

Page 16

L80-029 Rev 5 10/07 14

Page 17

15 L80-029 Rev 5 10/07

Page 18

L80-029 Rev 5 10/07 16

Page 19

17 L80-029 Rev 5 10/07

Page 20

L80-029 Rev 5 10/07 18

Page 21

19 L80-029 Rev 5 10/07

Page 22

L80-029 Rev 5 10/07 20

Page 23

Before and After: Visual Aid

The below images show a typical model SG14 burner assembly before and after the installation of the SCBS

upgrade. Wire harnesses and pilot tubing are omitted to provide better clarity. In order to give the installer a

sense of part orientation and location, the gas piping parts (valve, tubing, runner arm and fittings) of the SCBS

system are shaded. For clarity, the thermal limit switch assembly is not shaded.

21 L80-029 Rev 5 10/07

Page 24

In the event of problems with or questions about

your order, please contact the Pitco Frialator

factory at:

(800) 258-3708 US and Canada only or

(603) 225-6684 World Wide

MAILING ADDRESS – P.O. BOX 501, CONCORD, NH 03302-0501

SHIPPING ADDRESS – 10 FERRY ST., CONCORD, NH 03301

In the event of problems with or questions about

your equipment, please contact the Pitco Frialator

Authorized Service and Parts representative

(ASAP) covering your area, or contact Pitco at the

numbers listed to the left.

Loading...

Loading...