Page 1

SERVICE SECTION

Service, Parts, and Schematics

For Gas Fryers With Solo Filter

Models:

SF14 UFM & SF14R UFM

Pitco Frialator, Inc., P.O. Box 501, Concord, NH 03302-0501 • 509 Route 3A, Bow, NH 03304

(800) 258-3708 * (603) 225-6684 • FAX (603) 225-8497 A

BLODGETT Company

Page 2

Table of Contents (Service)

413 Replacin

g the Heat Baffles

4-1

416 Thermopile Replacement

4-4

42 TROUBLESHOOTING PILOT LIGHTS

4-7

43 TROUBLESHOOTING FRYERS WITH UNITROL VALVES

4-8

Section

Table of Contents (Service) i

List of Figures ii

Chapter 4: Service

41 REPLACEMENT PROCEDURES 4-1

411 Main Burner Removal and Replacement 4-1

412 Changing the Main Burner Orifice 4-1

414 Pilot Burner Removal and Replacement 4-2

415 Pilot Orifice Replacement 4-2

4151 Pilot Flame Adjustment 4-2

417 Thermostat Replacement 4-4

418 Limit Control Replacement 4-5

419 Calibrating the GS Thermostat 4-6

44 TROUBLESHOOTING FILTER UNITS 4-10

Chapter 5: Parts

Title Page

4-1

5-1

Chapter 6: Schematics

ALPHABETICAL PART LIST 5-6

NUMERICAL PART LIST 5-9

6-1

i

Page 3

List of Figures and Tables

Figure No Title Page

5-1

5-2 Filter Pan Assembly 5-5

Table No

5-1

5-2 Filter Pan Assembly 5-4

Overall Exploded View

Overall Exploded View

5-3

Title Page

5-2

ii

Page 4

Chapter 4: Service

This chapter provides the qualified technician with the replacement and troubleshooting procedures

necessary to service the Pitco fryer.

4.1 REPLACEMENT PROCEDURES

These procedures are provided to the qualified technician as a guide to removal and replacement of

various fryer components. If a test is required to verify component operation after installation, it

will be referenced.

WARNING

To prevent bums, always ensure the fryer is completely SHUT DOWN and

COOLED down before working on the fryer. Do not break any fryer gas

connections while the unit is connected to a gas supply line.

WARNING

The power supply must be disconnected before servicing or cleaning the

appliance.

4.1.1 Main Burner Removal and Replacement

a. Loosen the set screw in the base of the burner casing.

b. Unscrew and remove the two hex head screws at the top of the burner.

c. Loosen the set screw on the air collar. Lift the burner and air collar up to clear the top of

the burner fitting. Remove the burner from the fryer.

d. To re-install the burner, reverse the procedure.

4.1.2 Changing the Main Burner Orifice

a. Unscrew the orifice with a 3/8" wrench and remove the orifice.

b. Insert the new orifice and tighten with the 3/8" wrench. Ensure the orifice is tight

enough to prevent gas leakage around the orifice.

4.1.3 Replacing the Heat Baffles

a. Remove the Main Burner as described in 4.1.1.

4-1

Page 5

b. The heat baffles are located inside the heat tubes. They are attached to the rear of the

baffle supported by tack welds. Using a chisel, break away the baffle support and

remove the old baffles. Be careful not to puncture the heat tubes because this will require

complete tank replacement.

c. Insert the new baffles in the tubes in the original position. The new baffles sit in position

and do not require welding.

d. Install the main burners.

4.1.4 Pilot Burner Removal and Replacement

a. Unscrew the tubing nut from the pilot tubing connection at the gas valve. Disconnect the

thermopile from the connection on the gas valve.

b. Unscrew and remove the two screws that attach the pilot assembly to the fryer tank. Lift

the entire pilot assembly out of the fryer.

c. To replace the pilot assembly, reverse the procedure.

4.1.5 Pilot Orifice Replacement

a. Remove the pilot assembly as described in 4.1.4.

b. Unscrew the tubing nut from the pilot tubing connection at base of the pilot burner. The

pilot orifice is located inside the tubing connection.

c. Remove the orifice and replace with the new orifice. Ensure the orifice is tight enough to

prevent gas leakage around the orifice.

d. Replace the tubing nut in the pilot tubing connection and tighten enough to prevent gas

leakage.

e. Replace the pilot assembly and adjust the pilot flame as described below.

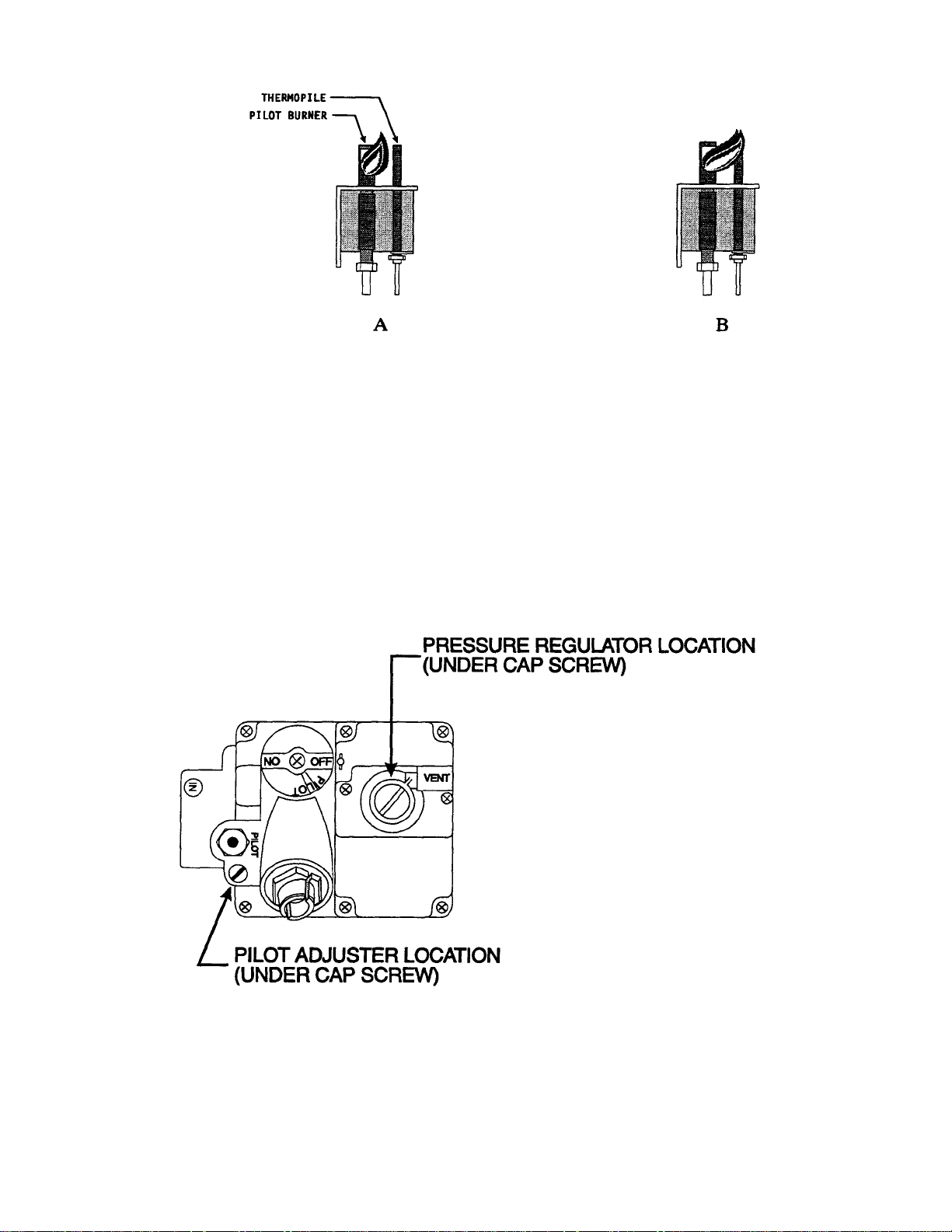

4.1.5.1 Pilot Flame Adjustment - The pilot flame should be adjusted to produce the proper millivolt

output from the pilot sensing device. Millivolt output for the thermopile should be between 300 and

500 millivolts. Figure 4-1 shows the pilot assembly with examples of the incorrect and correct pilot

size. Example A illustrates a pilot flame size that is too small to produce sufficient millivolt output.

Example B is the correct size for proper millivolt output.

4-2

Page 6

Figure 4-1 Pilot Assembly, Flame Adjustment

a. This test requires a DC millivolt meter set to a scale of 0-l000mv.

b. Locate the thermopile wires coming from the thermostat/High Limit box going to the

gas shut off valve. The wire insulation size decreases near the gas valve connections.

c. Connect the negative (-) test probe to pilot bracket.

d. Connect the positive (+) test probe to one of the High Limit terminal connections

e. Remove the pilot flame adjustment cover.

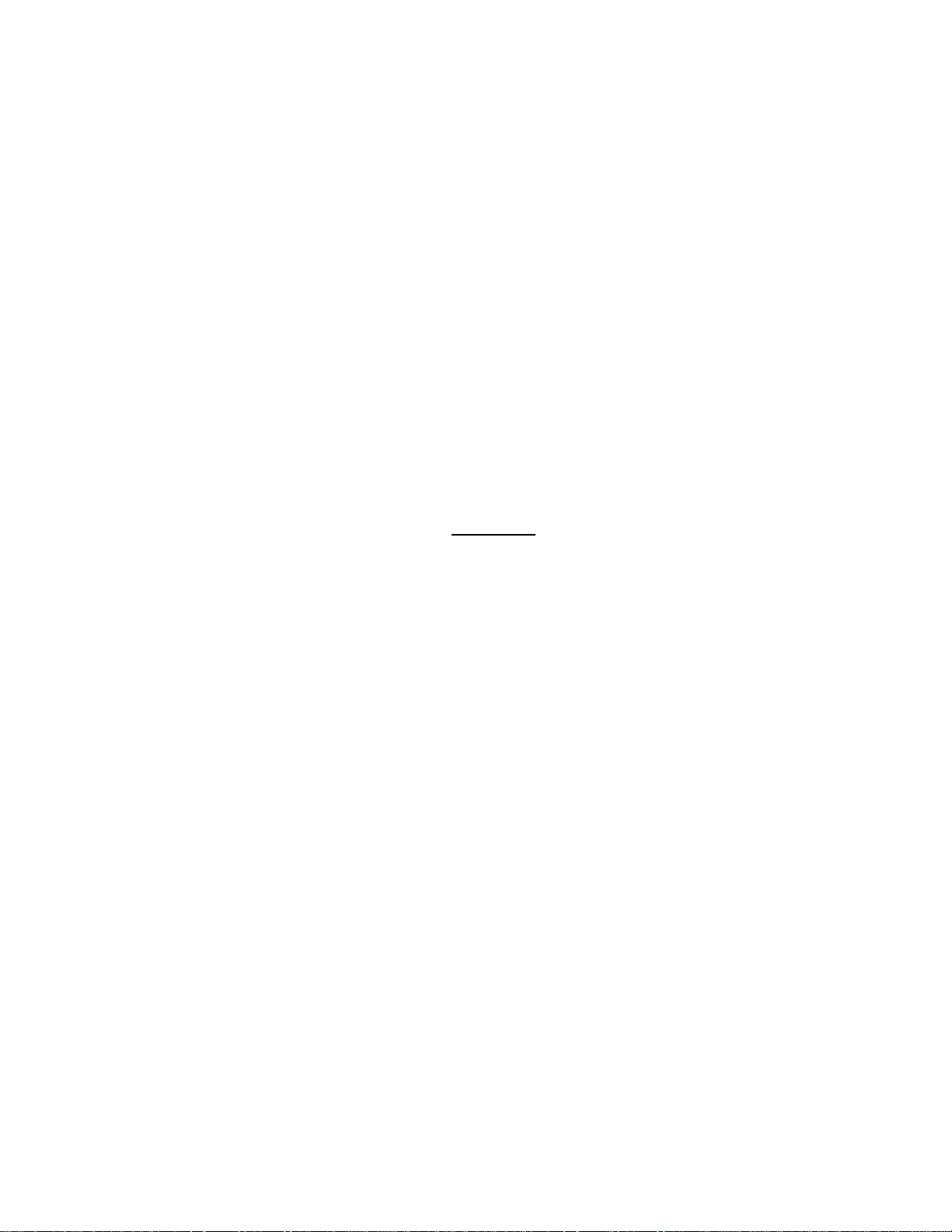

Figure 4-2 Gas Valve Showing Location of the Pressure Regulator and Pilot Adjusters

f. Turning the flame adjusting screw clockwise lowers the flame and the millivolt output.

Turning the screw counterclockwise increases flame size and millivolt output.

4-3

Page 7

g. Rotate the screw in the direction to achieve a reading of 400 ±50 mv for thermopiles.

NOTICE

Allow 3 to 5 minutes between flame adjustments to allow the reading to settle.

h. Replace the pilot flame adjusting screw cover.

4.1.6 Thermopile Replacement

a. Remove the pilot assembly as described in 4.1.4.

b. Unscrew and remove the thermopile from the pilot assembly.

c. Remove from gas valve magnet.

d. Insert the new thermopile in the pilot assembly.

e. Replace the pilot assembly and adjust the pilot flame as described in 4.1.5.1.

4.1.7 Thermostat Replacement

The thermostat includes the temperature adjustment knob, temperature sensor inside the fryer tank,

and connecting capillary tubing. The high limit control also has a temperature sensor in the fryer

tank, so ensure you are removing the correct temperature sensor.

CAUTION

Thermostat capillary tubing is very delicate. Be VERY CAREFUL when

working with the capillary tubing. If the tubing is kinked or broken the

thermostat is no longer usable.

a. Drain the oil from the fryer and remove the heat tube screens. The thermostat probe (heat

sensor) is clamped to the heat tube inside the tank. Unscrew and remove the two screws in

the thermostat probe clamp.

b. Remove the thermostat probe from the clamp and straighten the capillary tubing. Unscrew

the small hex nut inside the cabinet under the tank for the thermostat control.

c. Unscrew the large connector nut from the tank and pull the thermostat probe and capillary

tubes through the opening.

d. Pull the knob off of the thermostat. Remove the two slot head screws from the retaining

plate.

4-4

Page 8

e. Remove the two hex head screws that hold the thermostat control unit in the fryer cabinet.

f. Remove the tubing from the fittings on the thermostat body. Remove the defective thermostat

control unit from the fryer.

g. Install the new thermostat following the above procedures in reverse order. Remember to be

careful with the capillary tubes.

h. Use appropriate pipe joint compound on the large fitting before installing to prevent oil leakage.

DO NOT use joint compound on the small nut.

i. Perform the calibration procedures detailed in section 4.1.9.

4.1.8 Limit Control Replacement

The limit control includes a temperature sensor inside the fryer tank, control unit inside the fryer cabinet,

and connecting capillary tubing. The high limit control temperature sensor looks like the thermostat

temperature sensor, so ensure you are removing the correct temperature sensor clamp.

CAUTION

The limit control capillary tubing is very delicate. Be VERY CAREFUL when

working with the capillary tubing. If the tubing is kinked or broken the limit control

is no longer usable.

a. Drain the oil from the fryer and remove the heat tube screens.

b. The limit control probe (heat sensor) is clamped to the heat tube inside the tank. Unscrew and

remove the two screws in the probe clamp.

c. Remove the probe from the clamp and straighten the capillary tubing. Unscrew the small hex nut

inside the cabinet at the bottom of the tank for the limit control.

d. Unscrew the large connector nut from the tank and pull the pr obe and capillary tubes through the

opening.

e. Remove the two mounting screws from the limit control bracket and remove the limit control

unit. Disconnect the wires from the limit control box.

f. Reverse the procedure to install the new limit control.

g. Use appropriate pipe joint compound on the large fitting before installing to prevent oil leakage.

DO NOT use joint compound on the small nut.

4-5

Page 9

4.1.9 Calibrating the GS Thermostat

To calibrate this thermostat the knob must be removed from the shaft. The adjustment for the

thermostat is inside the shaft.

a. Set the thermostat dial to 325°F.

b. Remove the thermostat knob by pulling the knob straight out. DO NOT rotate the knob.

c. Hold the outside of the shaft so it does not move. Use the tip of a small, flat tip screw

driver to scrape away the sealing compound from the adjustment screw. Turn the

adjustment screw clockwise to lower the temperature setting and counterclockwise to

raise the temperature. One quarter turn will change the temperature approximately 25°F.

d. Turn the adjustment until the burners turn off at 325°F. Replace the knob and allow the

fryer to cycle 4 to 6 times. Check the temperature of the thermometer against the

thermostat knob, if it is greater than 5°P repeat the calibration procedure.

e. When the calibration is correct, remove the thermometer and replace the tube screen.

4-6

Page 10

4.2 TROUBLESHOOTING PILOT LIGHTS

4-7

Page 11

4.3 TROUBLESHOOTING FRYERS WITH UNITROL VALVES

4-8

Page 12

4-9

Page 13

4.4 TROUBLESHOOTING FILTER UNITS

4-10

Page 14

4-11

Page 15

Chapter 5: Parts

This chapter contains listings of the components used on SF14 UFM series fryers. These components are

listed in two places, with the illustration and in ordered listings. The illustrations in this chapter are provided

to show relative location of components located in the fryer. The fryer you have may not be illustrated in

this chapter, but the part locations should be the same. With each illustration there is a table of components

in numerical order by illustration number. The illustration has numbered lines pointing to components which

are listed in the table.

At the end of this chapter there are alphabetical and numerical listings of all parts used on SF14 UFM series

fryers. The alphabetical part list is arranged in alphabetical order according to the part name. Each part name

also has the Pitco Frialator part number. The numerical list is in Pitco Frialator part number order. A brief

description of each component is provided for each part.

5-1

Page 16

3

4

1 5

1

1

8

1 9

4

1 16

1

1

21

2

27

1

Table 5-1 Overall Exploded View

Item Number

1 PP10194 Heat Tape, 115 2

2 PP10101 Pump and Motor Assembly, 115/230 V 1

6 B1812701 Cabinet CRS 1

7 B7260505 Flue Assembly, 14 1

10 A1401002 damp, T-Stat Bulb 1

11

12 A8000801 Support, Burner Manifold 2

13

14 B3312001 Handle, Drain Valve 1

15

17 A8001001 Air Collar 4

18 B7402240 Quick Disconnect (option) 1

19

20 B8013501 Piping Gas Supply, Complete Assembly, 14 NAT 1

22 PP10834 Knob, Drain Valve 1

23 PP10739 Snap Disk 2

24

25 PP10460 Circuit Breaker, SPST 8 AMP 1

26

28 PP10084 Hi Limit 1

29 A1824001 Bracket, Hi Limit Mounting 1

30

31 B7230202 Hinge, Upper 1

32 B2301108 Door 1

Pitco Frialator Part

Number

PP10588

PP10171

A6688601

P6071493

A1620101

A1620102 Cover SST 1

B1812702

B7260506

B3312101

A1102804

B3311801

B3311802

B3311901 Fat Container, 14R CRS 1

B3311902

P6071051

PP10368

P6071449

P6071450

P6071780

B8013502 Piping Gas Supply, Complete Assembly, 14 LP 1

B8013601 Piping Gas Supply, Complete Assembly, 14R NAT 1

B8013602

P0154100

P0190100

PP10470 Circuit Breaker, DPST 4 AMP (International) 1

A7504901

B3610302

P6094991

Heat Tape, 220/240 (International)

Pump and Motor Assembly, 240 V (International)

Tubing, Pump Discharge

Plug Hole

Cover CRS

Cabinet SST

Rue Assembly, 14R

Backsplash

Basket Hanger

Fat Container, 14 CRS

Fat Container, 14 SST

Fat Container, 14R SST

Burner

Drain Valve

Pilot LP

Pilot NAT

Valve, Oil Return

Piping Gas Supply, Complete Assembly, 14R LP

Pin, Hitch

Pin, Clevis 1/4 x 3/4

Knob, Gas Valve Extension

Front Panel

Pitco Frialator Logo

Description

5-2

Quantity Per

Unit

2

1

1

1

1

1

1

1

1

1

1

1

1

Page 17

2 36

2 37

1

1

1

Table 5-1 Overall Exploded View (Continued)

Item Number

33 B3801002 Hinge, Lower 1

34 P6071785 Filter Module (See Figure 5-2) 1

35

38 A1823801 Bracket, T-Stat Mounting 1

39

40 PP10220 Caster 8" Ridgid (option) 2

41

42 B6626501 Tubing, Suction 1

Pitco Frialator Part

Number

PP10833

A3901302

PP10537

P5047588

A6685601

Insert, Leg

Leg Cover

Knob, T-Stat

T-Stat

Insulator

Description

Quantity Per

Unit

Figure 5-1 Overall Exploded View

5-3

Page 18

Table 5-2 Filter Pan Assembly

2

B6627201

Crumb Catch

1

4

P6071062

Caster

2

10

PP10668

Acorn Nut

2

Item Number

1 B6627301 Lid 1

3 P0092300 Bolt 10-24 x 3/8 8

5 P0092300 Nut, 10-24 Keep 8

6 B6617002 Clip Screen 1

7 B6620002 Paper Rack 1

8 B6627401 Suction Tube Assembly 1

9 B6626901 Pan Assembly 1

11 A6690502 Axel 1

12 A6690402 Axel Frame 1

13 P0075400 Bolt 10-24 Self Tap 4

14 PP10840 Wheel 2

Pitco Frialator

Part Number

Description

Quantity Per

Unit

5-4

Page 19

Figure 5-2 Filter Pan Assembly

5-5

Page 20

ALPHABETICAL PART LIST

AXEL

A6690502

BASKET HANGER

Al 102804

BOLT 10-24 SELF TAP

P0075400

CABINET CRS

B1812701

CASTER, PMF 2

P6071062

CATCH MAGNET STANDARD

P6071300

CLAMP, T-STAT BULB

A1401002

CLIP SCREEN

B6617002

COVER CRS

A1620101

DRAIN VALVE

PP10368

FILTER ENVELOPE 20.5" X 14.344" CENTER HOLE

A6667103

Part Description

ACORN NUT PP10668

AIR COLLAR 7,12,12D,14,14C,14R,18 A8001001

AXEL FRAME A6690402

BACKSPLASH B3312101

BAFFLE, WELDMENT, 14R,PR14, PM14,14RDI (MODEL SF14 UFM S) B1000801

BAFFLE, WELDMENT, 14R.PR14, PM14,14RDI (MODEL SFR14 UFM S) B1000601

BOLT 10-24 X 3/8 P0092300

BRACKET, HI LIMIT MOUNTING A1824001

BRACKET, T-STAT MOUNTING A1823801

BRUSH, NYLON P6071409

BURNER, PITCO 4" P6071050

BURNER, PITCO 6" P6071051

CABINET SST B1812702

CASTER 8" RIDGID (OPTION) PP10220

Pitco Frialator

Part No.

CIRCUIT BREAKER, SPST 8A, 250V PP10460

CIRCUIT BREAKER, DPST 4 AMP (INTERNATIONAL) PP10470

CORD, POWER SUPPLY-14AWG IEC COLORS PP10615

COVER SST A1620102

CRUMB CATCH B6627201

DOOR B2301108

DOOR, OSD LH/RH B2301208

FAT CONTAINER, 14 CRS B3311801

FAT CONTAINER, 14 SST B3311802

FAT CONTAINER, 14R CRS B3311901

FAT CONTAINER, 14R SST B3311902

FILTER MODULE P6071785

FILTER, HOSE ASSEMBLY B6626001

FILTER, INSULATION PICK-UP A6684601

FILTER, SCREEN INLET B6615301

5-6

Page 21

FRONT PANEL

B3610302

HEAT DEFLECTOR

A3700105

HIGH LIMIT

PP10084

INSULATOR

A6685601

LEG COVER

A3901302

O-RING, VINTON .5 ID X .688 OD

PP10111

PAN ASSEMBLY

B6626901

PILOT LP

P6071449

PITCO FRIALATOR LOGO

P6094991

ALPHABETICAL PART LIST (Continued)

Part Description

FILTER, TUBING PICK-UP WELDMENT B6626401

FLUE ASSEMBLY, 14 B7260505

FLUE ASSEMBLY, 14R B7260506

HANDLE, CHROME 3" CTOC P6071516

HANDLE, DRAIN VALVE B3312001

HANDLE, DRAIN WELDMENT B4001001

HANDLE, VALVE 3/8" COATED RED PP10048

HEAT TAPE 115 PP10194

HEAT TAPE 220/240 (INTERNATIONAL) PP10588

HINGE, LOWER B3801002

HINGE, UPPER B7230202

INSERT, LEG PP10833

KNOB, DRAIN VALVE PP10834

KNOB, GAS VALVE EXTENSION A7504901

KNOB, T-STAT PP10537

Pitco Frialator

Part No.

LEG, ADJUSTABLE 8" ALL SS B7472909

LID, FILTER PAN B6627301

O-RING, VINTON .688 ID X .875 OD PP10409

ORIFICE, #38 (MODEL SFR14 UFM S) P6071338

ORIFICE, #40 (MODEL SF14 UFM S) P6071340

PAPER RACK B6620002

PG, FITTING, BURNER 7,12,12D,14,14C,14R,18* A8001101

PILOT NAT P6071450

PIN, CLEVIS 1/4 X 3/4 P0190100

PIN, HITCH P0154100

PIPING GAS SUPPLY, COMPLETE ASSEMBLY, 14 NAT B8013501

PIPING GAS SUPPLY, COMPLETE ASSEMBLY, 14 LP B8013502

PIPING GAS SUPPLY, COMPLETE ASSEMBLY, 14R NAT B8013601

PIPING GAS SUPPLY, COMPLETE ASSEMBLY, 14 LP B8013502

PLUG HOLE P6071493

PUMP & MOTOR ASSEMBLY 1/3 HP, 115/230V, 50/60 HZ. PP10101

5-7

Page 22

ROD, CLEAN-OUT

A3305701

SNAP DISK

PP10739

SUCTION TUBE ASSEMBLY

B6627401

THERMOPILE CP2 24"

P5047541

ALPHABETICAL PART LIST (Continued)

Part Description

PUMP & MOTOR ASSEMBLY 1/3 HP, 240V, 50/60 HZ. (INTL.) PP10171

QUICK DISCONNECT (OPTION) B7402240

SUPPORT, BURNER MANIFOLD A8000801

T-STAT, GAS GS-A6-030-1800 P5047588

TUBING, PUMP DISCHARGE A6688601

TUBING, SUCTION B6626501

VALVE, BALL, 3/8" P6071780

VALVE, GAS 1/2 BMSGOR TPILE NAT P5045642

WHEEL, 2" HARD RUBBER PP10840

WIRE RADIX ASSEMBLY B6779850

Pitco Frialator

Part No.

5-8

Page 23

NUMERICAL PART LIST

Pitco Frialator

Part No.

A1102804 BASKET HANGER

A1401002 CLAMP, T-STAT BULB

A1620101 COVER CRS

A1620102 COVER SST

A1823801 BRACKET, T-STAT MOUNTING

A1824001 BRACKET, HI LIMIT MOUNTING

A3305701 ROD, CLEAN -OUT

A3700105 HEAT DEFLECTOR

A3901302 LEG COVER

A6667103 FILTER ENVELOPE 20.5" X 14.344" CENTER HOLE

A6684601 FILTER, INSULATION PICK-UP

A6685601 INSULATOR

A6688601 TUBING, PUMP DISCHARGE

A6690402 AXEL FRAME

A6690502 AXEL

A7504901 KNOB, GAS VALVE EXTENSION

A8000801 SUPPORT, BURNER MANIFOLD

A8001001 AIR COLLAR 7,12,12D,14,14C,14R,18

A8001101 PG, FITTING, BURNER 7,12,12D,14,14C,14R,18*

B1000601 BAFFLE, WELDMENT, 14R,PR14, PM14,14RDI

(MODEL SFR14 UFM S)

B1000801 BAFFLE, WELDMENT, 14R, PR14, PM14,14RDI

(MODEL SF14 UFM S)

B1812701

B1812702 CABINET SST

B2301108 DOOR

B2301208 DOOR, OSD LH/RH

B3311801 FAT CONTAINER, 14 CRS

B3311802 FAT CONTAINER, 14 SST

B3311901 FAT CONTAINER, 14R CRS

B3311902 FAT CONTAINER, 14R SST

B3312001 HANDLE, DRAIN VALVE

B3312101 BACKSPLASH

B3610302 FRONT PANEL

B3801002 HINGE, LOWER

B4001001 HANDLE, DRAIN WELDMENT

B6615301 FILTER, SCREEN INLET

B6617002 CLIP SCREEN

B6620002 PAPER RACK

CABINET CRS

Part Description

B6626001 FILTER, HOSE ASSEMBLY

5-9

Page 24

B6626901

PAN ASSEMBLY

B6627401

SUCTION TUBE ASSEMBLY

B7260506

FLUE ASSEMBLY, 14R

B7472909

LEG, ADJUSTABLE 8" ALL SS

P0075400

BOLT 10-24 SELF TAP

P5047541

THERMOPILE CP2 24"

P6071300

CATCH MAGNET STANDARD

P6071449

PILOT LP

P6071785

FILTER MODULE

P6094991

PITCO FRIALATOR LOGO

PP10084

HIGH LIMIT

NUMERICAL PART LIST (Continued)

Pitco Frialator

Part No.

B6626401 FILTER, TUBING PICK-UP WELDMENT

B6626501 TUBING, SUCTION

B6627201 CRUMB CATCH

B6627301 LID, FILTER PAN

B6779850 WIRE RADIX ASSEMBLY

B7230202 HINGE, UPPER

B7260505 FLUE ASSEMBLY, 14

B7402240 QUICK DISCONNECT (OPTION)

B8013501 PIPING GAS SUPPLY, COMPLETE ASSEMBLY, 14 NAT

B8013502 PIPING GAS SUPPLY, COMPLETE ASSEMBLY, 14 LP

B8013601 PIPING GAS SUPPLY, COMPLETE ASSEMBLY, 14R NAT

B8013602 PIPING GAS SUPPLY, COMPLETE ASSEMBLY, 14R LP

P0092300 BOLT 10-24 X 3/8

P0154100 PIN, HITCH

P0190100 PIN, CLEVIS 1/4 X 3/4

P5045642 VALVE, GAS 1/2 BMSGOR TPILE NAT

Part Description

P5047588 T-STAT, GAS GS-A6-030-1800

P6071050 BURNER, PITCO 4"

P6071051 BURNER, PITCO 6"

P6071062 CASTER, PMF 2

P6071338 ORIFICE, #38 (MODEL SFR14 UFM S)

P6071340 ORIFICE, #40 (MODEL SF14 UFM S)

P6071409 BRUSH, NYLON

P6071450 PILOT NAT

P6071493 PLUG HOLE

P6071516 HANDLE, CHROME 3" CTOC

P6071780 VALVE, BALL, 3/8"

PP10048 HANDLE, VALVE 3/8" COATED RED

PP10101 PUMP AND MOTOR ASSEMBLY 1/3 HP, 115/230V, 50/60 HZ.

5-10

Page 25

PP10194

HEAT TAPE, 115

PP10368

DRAIN VALVE

PP10460

CIRCUIT BREAKER, SPST 8A, 250V

PP10537

KNOB, T-STAT

PP10615

CORD, POWER SUPPLY-14AWG IEC COLORS

PP10668

ACORN NUT

PP10834

KNOB, DRAIN VALVE

NUMERICAL PART LIST (Continued)

Pitco Frialator

Part No.

PP10111 O-RING, VINTON .5 ID X .688 OD

PP10171 PUMP & MOTOR 240 VAC (INTERNATIONAL)

PP10220 CASTER 8" RIDGID (OPTION)

PP10409 O-RING, VINTON .688 ID X .875 OD

PP10470 CIRCUIT BREAKER, DPST 4 AMP (INTERNATIONAL)

PP10588 HEAT TAPE, 220/240 (INTERNATIONAL)

PP10739 SNAP DISK

PP10833 INSERT, LEG

PP10840 WHEEL, 2" HARD RUBBER

Part Description

5-11

Page 26

Chapter 6: Schematics

SCHEMATIC, SOLOFILTER 240V

700166

Schematic Description Schematic Number

SCHEMATIC, SOLOFILTER 115V 700165

SCHEMATIC, SOLOFILTER 220V 700167

6-1

Page 27

6-2

Page 28

6-3

Page 29

6-4

Loading...

Loading...