Page 1

IMPORTANT FOR FUTURE REFERENCE

Please complete this information and retain this

manual for the life of the equipment:

Model #:________________________

Serial #: ________________________

Date Purchased: _________________

14R & 18 WKS

KENTUCKY FRIED CHICKEN

EQUIPPED WITH A FAST COOKING

COMPUTER: EM99 or VC210

FRONT PANEL SUPPLIED BY PITCO

TROUBLESHOOTING

MANUAL

PITCO FRIALATOR, INC

P.O. BOX 501

CONCORD, N.H. 03301

PHONE 603-225-6684

SERVICE DEPT. 603-225-5688

L20-310 R1 (02/15)

Page 2

SERVICE MANUAL

14R & 18 WKS

KENTUCKY FRIED CHICKEN

CONTENTS

Section 1S Service Procedures

- Burner Flow Drawing

Section 2S Troubleshooting Charts

Section 3S Parts List

Section 4S Front Panel Bezel

- Orifice Tips & Burner Pressure

Section 5S Entrance Box

L20-310 R0 (02/15)

Page 3

Pitco Frialator, Inc.

P.O. Box 501, Concord, New Hampshire

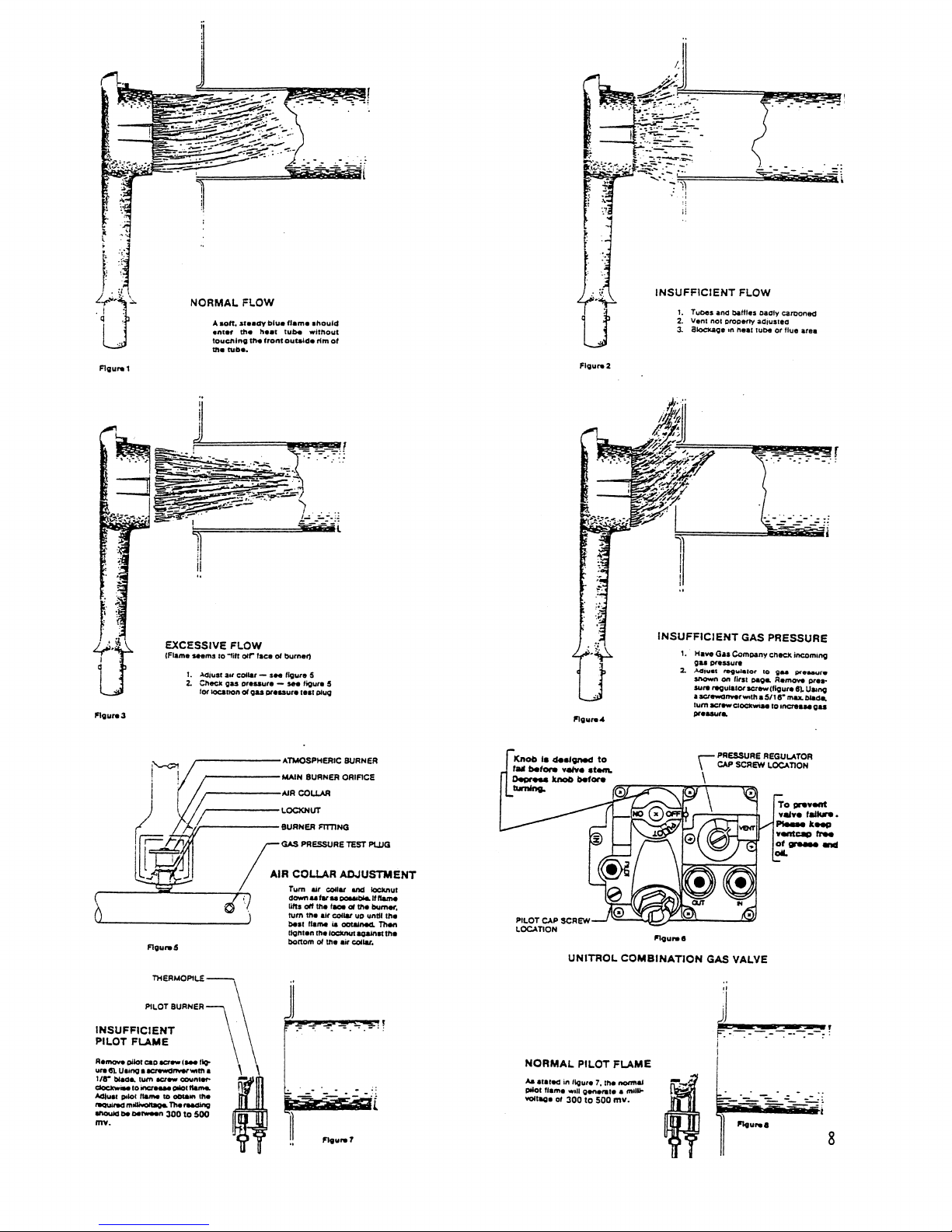

SECTION 1S SERVICE PROCEDURES

Parts can be identified from diagrams on Parts List page for each model.

1.1 TO REMOVE MAIN BURNER

Turn Unitrol knob to “OFF" position.

a.

b.

Loosen set screw in base of burner casting.

Unscrew and remove two hex head screws at top of burner.

c.

d.

Unscrew and remove air collar from burner.

e.

Lift burner up to clear top of burner fitting and remove from fryer.

Reverse procedure to remount burner.

f.

1.2 TO CHANGE MAIN BURNER ORIFICE

Follow procedure in Section 1.1.

a.

b.

After burner has been removed, unscrew orifice with 3/8” wrench.

Screw in new orifice – tighten gas tight.

c.

d.

Remount burner and air collar.

1.3 TO REPLACE HEAT TUBE BAFFLES

a.

Remove main burners: follow procedure in Section 1.1.a. through e.

b.

Baffles are fastened to the inside of the heat tube by a small tack weld on the right

hand front baffle support. Break leg away from weld with a chisel or solid steel bar.

c.

Remove old baffles and insert new ones in tubes in original position.

Remount main burners.

d.

1.4 TO REMOVE PILOT BURNER

a.

Follow procedure in Section 1.1 and remove main burner to the right of the pilot

burner.

b.

Unscrew and remove tubing nut from pilot tubing connection on Unitrol.

Unscrew and remove thermopile or thermocouple from connection on Unitrol.

c.

d.

Unscrew and remove the two screws holding the pilot to the bracket on the fry tank

and lift the entire pilot assembly out of the fryer.

1.5 TO CHANGE PILOT BURNER ORIFICE

a.

Follow procedure in 1.4.

Unscrew tubing nut in fitting in base of pilot burner.

b.

c.

Unscrew fitting in the base of pilot burner and withdraw orifice from inside the fitting.

Insert new orifice and reverse procedure to re-assemble.

d.

e.

Tighten all screws and connections and test for gas leaks.

Page 4

Pitco Frialator, Inc.

P.O. Box 501, Concord, New Hampshire 03301

SECTION 1S SERVICE PROCEDURES (Cont’d)

1.6 TO REPLACE THERMOPILE OR THERMOCOUPLE

a. Follow pro

Unscrew and remove thermopile or thermocouple from pilot burner and bracket.

b.

c.

Replace with new thermopile or thermocouple.

Reverse procedure to re-assemble.

d.

e. Tighten all screws and connections and test for gas leaks.

1.7 TO ADJUST PILOT FLAME

a. Mak

b.

Remove screw cap underneath pilot supply tubing connection to Unitrol valve.

Insert long handled screwdriver with 1/8” wide blade in adjusting screw slot inside this

c.

pilot supply fitting.

d. Turn adjusting screw clockwise to decrease or counterclockwise to increase pilot

flame. Watch size of pilot flame while turning adjusting screw.

e

. Replace scre

f.

Replace pilot orifice if desired flame cannot be obtained by adjustment. See

procedure 1.5.

1.8 TO REPLACE LIMIT CONTROL

cedure in 1.4.

e this adjustment with pilot burner lit.

CAUTION DO NOT REMOVE ADJUSTING SCREW

w cap when desired flame size is obtained.

a. Turn Unitrol

Drain all shortening from fry tank. Remove tube screen.

b.

c.

Unscrew and remove the two screws in the limit bulb clamp on the heat tube inside

the fry tank.

d.

Take sensing bulb out of the clamp and straighten the capillary tubing.

Remove the two burners that are in front of the capillary connector fitting on the

e.

bottom of the fry pot. See procedure 1.1.

f.

Unscrew small hex nut in connector fitting of control to be replaced.

Unscrew large connector nut and withdraw capillary and bulb from fry tank.

g.

h.

Remove the two wires off the limit control terminals.

Unscrew and remove the two mounting screws in the limit control bracket and

i.

remove the limit control from the fryer.

j.

Unpack the new limit control and carefully unroll the capillary tubing and straighten it

out.

k.

Install the new limit control by reversing the procedure. BE CAREFUL NOT TO

BEND, KINK OR TWIST THE CAPILLARY TUBING SHARPLY. THIS WILL

DESTROY THE LIMIT CONTROL.

knob to “OFF.”

Page 5

Page 6

PITCO Frialator, Inc.

P.O. Box 501, Concord, New Hampshire 03301

SECTION 2S TROUBLESHOOTING CHART

TROUBLE POSSIBLE CAUSE REMEDY

Pilot will light but Unitrol

pilot gas valve will not hold

open automatically.

Pilot thermopile or

11

thermocouple not hot enough

to generate required

millivoltage.

22

millivoltage circuit.

Thermopile or thermocouple

producing insufficient

millivoltage.

High limit control may have cut

44

out.

Pilot flame too small.

5

Hold Unitrol knob (in PILOT

position) depressed for 1

minute or longer. Make sure all

air has been purged from gas

line.

Check all wire connections.Loose wire connection in

Check voltage at Unitrol with

33

millivoltmeter, holding pilot

flame on manually as in No. 1

above. Reading should be 500

+/-50 mv. for thermopile.

Reading should be between 25

and 35 mv. for thermocouple.

Check continuity across limit

control terminals with meter. If

limit control has cut off, check

at what temperature it cut off.

Check millivoltage as above;

5

increase size of flame with

Unitrol pilot adjusting screw.

Pilot flame burning yellow.

66

Draft may be pulling flame off

7

thermopile or thermocouple.

Gas pressure too low.

8

Remove and clean pilot and

thermopile or thermocouple;

decrease size of flame with

Unitrol pilot adjusting screw if

over 450 mv. Reading should

be 500 +/-50 mv. for

thermopile. Reading should be

between 25 and 35 mv. for

thermocouple.

Eliminate the draft.

7

Pressure at burner manifold

8

should be 4.0" w.c. for natural

gas and 10.0" w.c. for propane

with all equipment on line in

full operation. If this cannot be

maintained, consult gas

company.

Page 7

PITCO Frialator, Inc.

P.O. Box 501, Concord, New Hampshire 03301

SECTION 2S TROUBLESHOOTING CHART (Cont'd)

TROUBLE POSSIBLE CAUSE REMEDY

Pilot will light but Unitrol pilot

gas valve will not hold open

automatically.

Pilot flame lit but burners will

not light.

99

10 10

11

Defective thermopile or

thermocouple

Defective thermopile or

thermocouple

Unitrol valve handle not turned

to ON.

Replace thermopile or

thermocouple

Replace magnet

Turn handle counter clockwise

as far as it will go.

Pilot flame and main

burners cut off while

cooking.

Fryer temperature recovery

too slow.

Float switch bulb off or stuck

22

down.

Supply cord may not be

33

plugged in or switch may not be

turned on.

44

Defective probe.

55

Defective computer. Replace Computer.

Defective Unitrol. Replace Unitrol.

66

Hi-Limit tripped

11

Dirty burners.

1

Low gas pressure.

22

Install float switch bulb and new

clip.

Check electric supply circuit

Replace probe.

Reset

Clean.

1

Minimum operating pressure:

Natural Gas- 4.0" w.c.;

Propane Gas- 10.0" w.c.

33

4

55

Pilot flame is yellow.

11

22

Incorrect burner orifices.

Carbon build-up on heat tubes. Clean fry tank and tubes.

Baffles in heat tubes may be

burned out.

Pilot flame too large. Adjust Unitrol pilot adjustment

Carbon build-up on thermopile

or thermocouple.

Call factory to learn proper

sizes.

4

Replace baffles.

screw.

Remove and clean.

Page 8

PITCO Frialator, Inc.

P.O. Box 501, Concord, New Hampshire 03301

SECTION 2S TROUBLESHOOTING CHART

TROUBLE POSSIBLE CAUSE REMEDY

Burner flames will not enter

heat tubes.

11

22

33

Downdraft on fryer flue

opening, or vent not turned on.

Orifices may be incorrect size.

Gas pressure too high/low.

Protect flue opening from

downdrafts, breezes or air

flows from blowers.

a. Turn Vent on.

Call factory to learn proper

sizes.

On natural gas adjust Unitrol

pressure regulator to 4.0" w.c

operating pressure. On

propane gas have gas supplier

adjust tank pressure to provide

10.0" w.c. operating pressure

at the fryer. (See Orifice and

Burner pressure chart)

Main burners will not shut

off automatically.

Main burner flames are

yellow.

when burners are on.

44

Burners out of alignment.

Clogged vent cap on Unitrol.

11

Defective Unitrol.

2

Improper air collar adjustment

11

Main burners dirty.

2

Improper gas pressure.

3

Orifices are too large.

44

Gas pressure too high. Adjust pressure regulator.

11Howling or screeching noise

Loosen burner mounting

screws and line up burners.

Remove and clean cap.

Replace Unitrol.

2

Remove and clean cap.

Remove burners and clean.

2

On natural gas adjust Unitrol

3

pressure regulator to 4.0" w.c

operating pressure. On

propane gas have gas supplier

adjust tank pressure to provide

10.0" w.c. operating pressure

at the fryer. (See Orifice and

Burner pressure chart)

Call factory to learn proper

sizes.

22

Dirt or burr on burner orifice. Clean orifice or replace.

Page 9

NOTES

Page 10

SECTION 3S PARTS LIST MODEL 14R & 18 WKS

Page 11

SECTION 3S PARTS LIST MODEL 14R & 18 WKS

ITEM # PART NUMBER ITEM DESCRIPTION

1

3 P5047210 Hi limit Control

4

5

6 B6779850 Unitrol Limit Wire

7

8 P6071269 Unitrol Knob

9 Contact Factory Data Plate

10 P6071051 Main Burners

11

12 A8001001 Air Collar

14 A8001101 Burner Fittings

15 B8005601 Manifold

17 PP10025 Main Burner Bolt

18 PP10368 Drain Valve 1 1/4"

20

21 PP11006 Door Handle

22 P6071496 Snap Buttons

23 PP11261 Burner Mounting Bolts

24 P6071300 Magnetic Door Catch

26 A1400202 Probe and Limit Bulb Clamp

27 A3301001 Clean Out Rod

28

29

30 A2510101 Drain Extension

31

32 P6072145 Basket (14R)

33 Front Bezel Assembly See Section 4S Front Bezel Assembly

37

38 A8000801 Manifold Bracket

39 Entrance Box Assembly See Section 5S Entrance Box

B3309902 Stainless Steel Fat Container (14R)

B3307201 Stainless Steel Fat Container (18)

P5047541 Thermopile

P5047540 Thermocouple

P6071450 Pilot Burner Natural

P6071449 Pilot Burner Propane

P5045650 Unitrol Natural 120V (Thermopile)

P5045652 Unitrol Propane 120V (Thermopile)

P5045638 Unitrol Natural 24V (Thermopile)

P5045639 Unitrol Propane 24V (Thermopile)

PP10777 Unitrol Natural 24V CE (Thermocouple)

PP10778 Unitrol Propane 24V CE (Thermocouple)

P6071338 Burner Orifices Natural (14R)

P6071309 Burner Orifices Propane (14R)

P6071339 Burner Orifices Natural (18)

P6071353 Burner Orifices Propane (18)

See Orifice Chart See Section 3S Burner Orifices chart (CE)

B2301105 Door Assembly RH (14R)

B2301106 Door Assembly RH (18)

B1000601 Heat Tube Baffles (14R)

B1000801 Heat Tube Baffles (18)

A4500201 Tube Screen (14R)

P6072186 Tube Screen (18)

A1100108 Basket Hanger (14R)

A1100110 Basket Hanger (18)

PP10810 7" Caster-Swivel Non-Locking-Rear

B3900408 7" Leg-Front

B3901401 8" Caster/Leg Set-Swivel Non-Locking-Rear

Page 12

SECTION 3S PARTS LIST MODEL 14R & 18 WKS ORIFICE

(mm)

(

)

(mm)

(

)

(

)

l

l

TIPS & BURNER PRESSURE

14R Natural

GAS CATEGORY

I2H,

I2E

I

2L

I

, I

2E+

2ESI

I

2ELL

18 Natural

GAS CATEGORY

I2H, I2E, I

I

I

2ELL

2L

2E+

, I

ORIFICE TIP

SIZE (mm)

2.44/2.79

ORIFICE TIP

SIZE

2ESI

2.38/2.58

2.44

2.79

1.17(4)

2.38

2.58

MODEL

14R

18

14R Propane

GAS

CATEGORY

I

3P

I

3P

I

3P

I

3P

I

3B/P

GAS

CATEGORY

I

3P

I

3P

Domestic/International Operational Information

GAS TYPE

Natura

Propane

Natura

Propane

Supply Pressure

(mbars)

37

50

37

50

50

18 Propane

Supply Pressure

mbars

50

37

ORIFICE TIP

SIZE

#38

0.0625"

39

53

Governor on

Gas Valve?

Yes

Yes

No

No

No

Governor on

Gas Valve?

No

No

BURNER

PRESSURE

in. WC

4.0 7.0

10.0 12.0

4.0 7.0

10.0 12.0

ORIFICE TIP

SIZE (mm)

1.51

1.51

1.4

1.32

1.25

ORIFICE TIP

SIZE

1.15

1.25

MIN. INLET

PRESSURE

in WC

Page 13

NOTES

Page 14

SECTION 4S FRONT PANEL BEZEL ASSEMBLY MODEL 14R & 18 WKS

Back View of Front Panel Bezel Assembly

ITEM #

Schematic

Symbol

See Schematic 700131 Schematic

2 DS2 P5045044 Lamp

3

S2 PP10093 Switch On/Off

S3 PP10559 Switch Start/On/Off DVI (drain switch)

4 K2 PP11124 Relay 24V SPDT DC

10 K3 P5046686 Relay 24V DPDT AC

Harness Not Shown

Computer Type

Not Shown

Part

Number

B6711702 Harness

B6711703 Harness DVI (drain switch)

Contact FAST for

Replacement

Fast Computer -EM99

Fast Computer -VC210 KFC

ITEM DESCRIPTION

Page 15

SECTION 4S FRONT PANEL BEZEL SCHEMATIC MODEL 14R & 18 WKS

Page 16

SECTION 4S FRONT PANEL BEZEL SCHEMATIC MODEL 14R & 18 WKS

Page 17

SECTION 5S ENTRANCE BOX ASSEMBLY MODEL 14R & 18 WKS

r

r

Item Numbe

1

Qty. Part Numbe

1

1 P5045794 Fuseholder

2

1

3

(See Note 1)

4

5

1 P5045794 Fuseholder

1 PP10122 1 Amp Fuse - 115V

1 PP10210 40VA Transformer

1

NOTE 1: ITEM 3 NOT USED ON 220-240V MODELS

Description

B2904502 Entrance Box 115V

B2904504 Entrance Box 220-240V

PP10122 1 Amp Fuse - 115V

P5045717 2 Amp Fuse - 220-240V

B6713901 Wire Harness 115V

B6713902 Wire Harness 220-240V

Page 18

SECTION 5S ENTRANCE BOX ASSEMBLY MODEL 14R & 18 WKS

ENTRANCE BOX SCHEMATIC OF 700131

Page 19

SECTION 5S ENTRANCE BOX ASSEMBLY MODEL 14R & 18 WKS

ENTRANCE BOX SCHEMATIC OF 700131

Page 20

L20-310 R1 (02/15)

Loading...

Loading...