Flight manual and

Maintenance manual

applies to Taurus ELECTRO G2

WARNING!

This booklet MUST be present inside the cockpit at all times!

Should you be selling the aircraft make sure this manual is handed over to the new owner.

REV. 0

(9 March, 2011)

This is the original manual of Pipistrel d.o.o. Ajdovščina

Should third-party translations to other languages contain any discreptancies,

Pipistrel d.o.o. Ajdovščina denies all responsibility.

2

TAURUS ELECTRO

www.pipistrel.si

REV. 0

Taurus model:

Factory serial number:

Date of manufacture:

Aircraft empty weight (kg):

Available crew weight (no front ballast):

Available crew weight (9 kg front ballast):

Available luggage weight:

List of equipment included in aircraft empty weight:

Date and place of issue: Ajdovščina,

To log into the Owner’s section, receive updates and Service Bulletins, go to: www.pipistrel.si and log in

the top right corner of the page with:

Username: owner1

Password: ab2008

THANK YOU!

3

TAURUS ELECTRO

www.pipistrel.si

REV. 0

Flight manual and

Maintenance manual for

Model: Taurus ELECTRO

Data Sheet:

Factory serial number:

Registration number:

Date of Issue: March, 2011

Pages signed under “Approval” in section Index of revisions and List of valid pages

(pages 4 and 5 of this manual) are approved by:

Authority: SLO.DOA.002

Signature:

Stamp:

Original date of Approval: March, 2011

This aircraft is to be operated in compliance with information and limitations contained herein.

The original English Language edition of this manual has been approved as operating instruction

according to “Pravilnik o ultralahkih letalnih napravah” of Republic of Slovenia.

Approval of translation has been done by best knowledge and judgement.

Pipistrel d.o.o. Ajdovščina, Goriška cesta 50a, SI- 5270 Ajdovščina, Slovenija

tel: +386 (0)5 3663 873, fax: +386 (0)5 3661 263, e-mail: info@pipistrel.si

www.pipistrel.si

Taurus ELECTRO

4

TAURUS ELECTRO

www.pipistrel.si

REV. 0

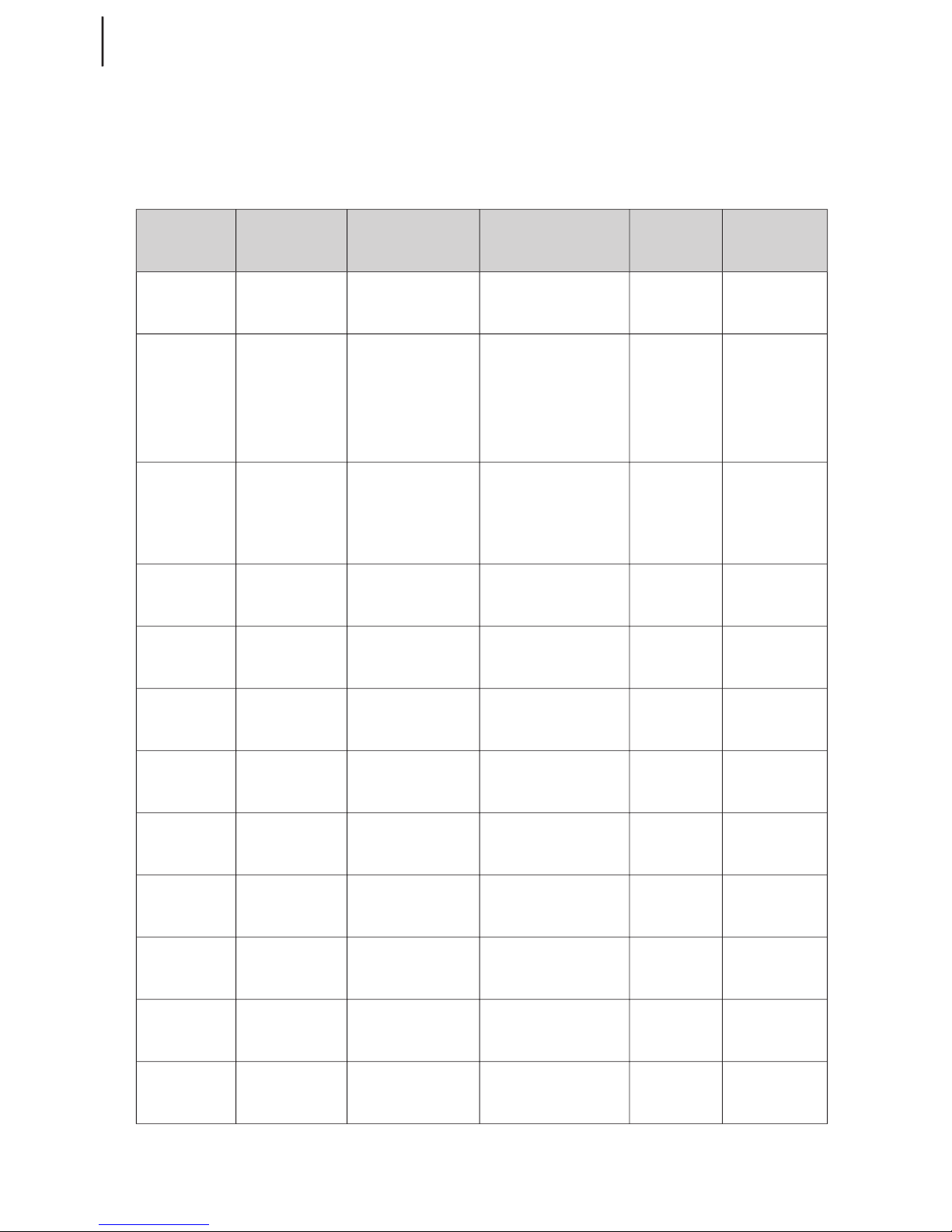

Index of revisions

Enter and sign the list of revised pages in the manual into the spaces provided below. All revised pages

should be clearly designated in the upper right corner of the page, also, any changes in page content

should be clearly visible (e.g. marked with a bold black vertical line).

Name of

revision

Reason for

Revision:

Revision no.,

date:

Description:

Affected

pages:

Approval,

signature:

Original /

Rev. 0

9 March, 2011

First original release. / Tomazic

5

TAURUS ELECTRO

www.pipistrel.si

REV. 0

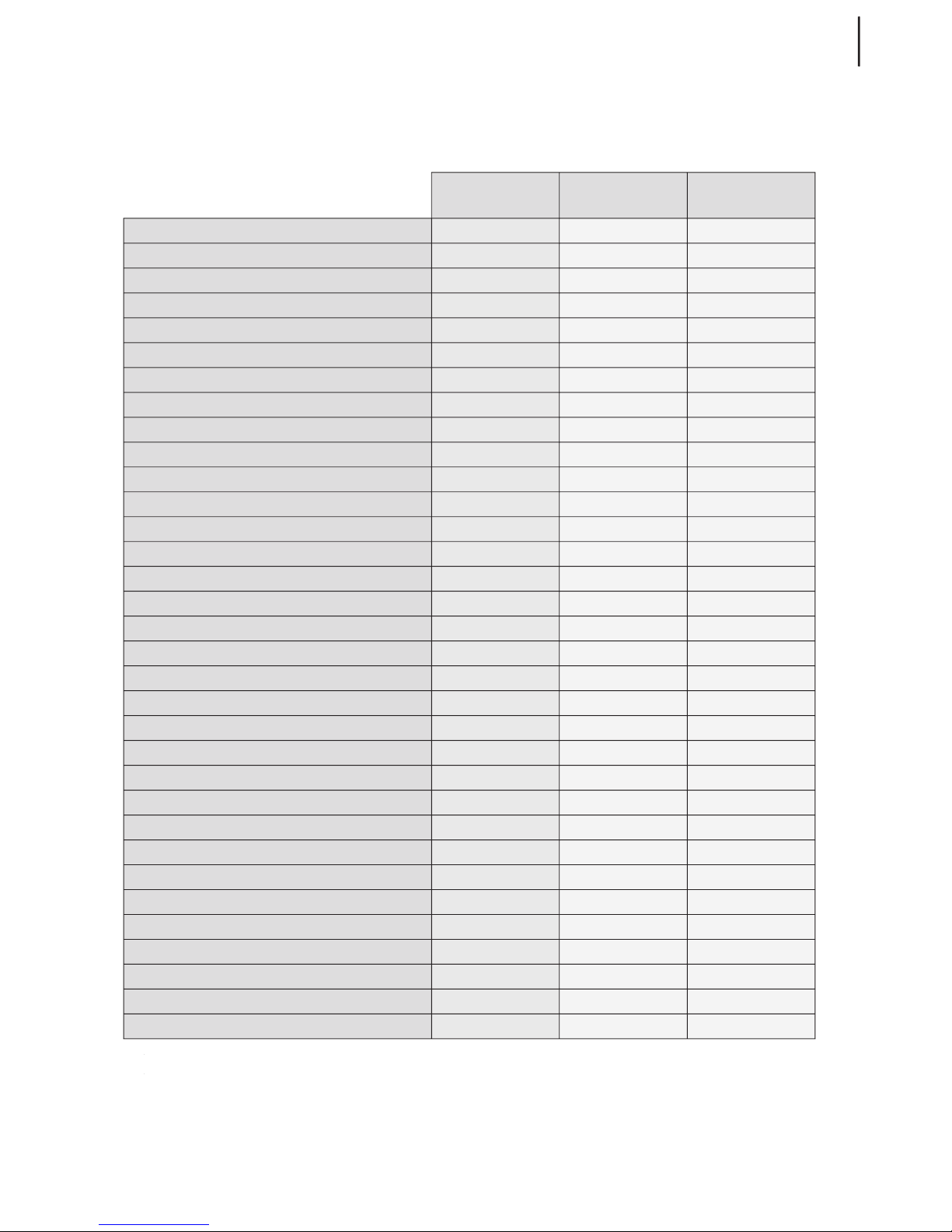

List of valid pages

This manual contains 96 original and revised pages listed below.

Pages

State

(Revision)

Approval:

Cover

REV. 0

Page numbering

REV. 0

Authority approval sheet

3 REV. 0

Index of revisions

4 REV. 0

List of valid pages

5 REV. 0

Table of contents

7 REV. 0

General

9 - 12 REV. 0

Limitations

13 - 20 REV. 0

Emergency procedures

21 - 28 REV. 0

Normal procedures

29 - 42 REV. 0

Performance

43 - 51 REV. 0

Weight and balance

53 - 59 REV. 0

Aircraft and systems on board

61 - 73 REV. 0

Handling and maintenance

75 - 84 REV. 0

Appendix

85 - 93 REV. 0

CAUTION!

This manual is valid only if it contains all of the original and revised pages listed above.

6

TAURUS ELECTRO

www.pipistrel.si

REV. 0

This page is intentionally left blank.

7

TAURUS ELECTRO

www.pipistrel.si

REV. 0

Table of contents

General

Limitations

Emergency procedures

Normal procedures

Performance

Weight and balance

Aircraft and systems on board

Handling and maintenance

Appendix

8

TAURUS ELECTRO

www.pipistrel.si

REV. 0

This page is intentionally left blank.

9

TAURUS ELECTRO

www.pipistrel.si

REV. 0

Introduction

Notes and remarks

Technical data

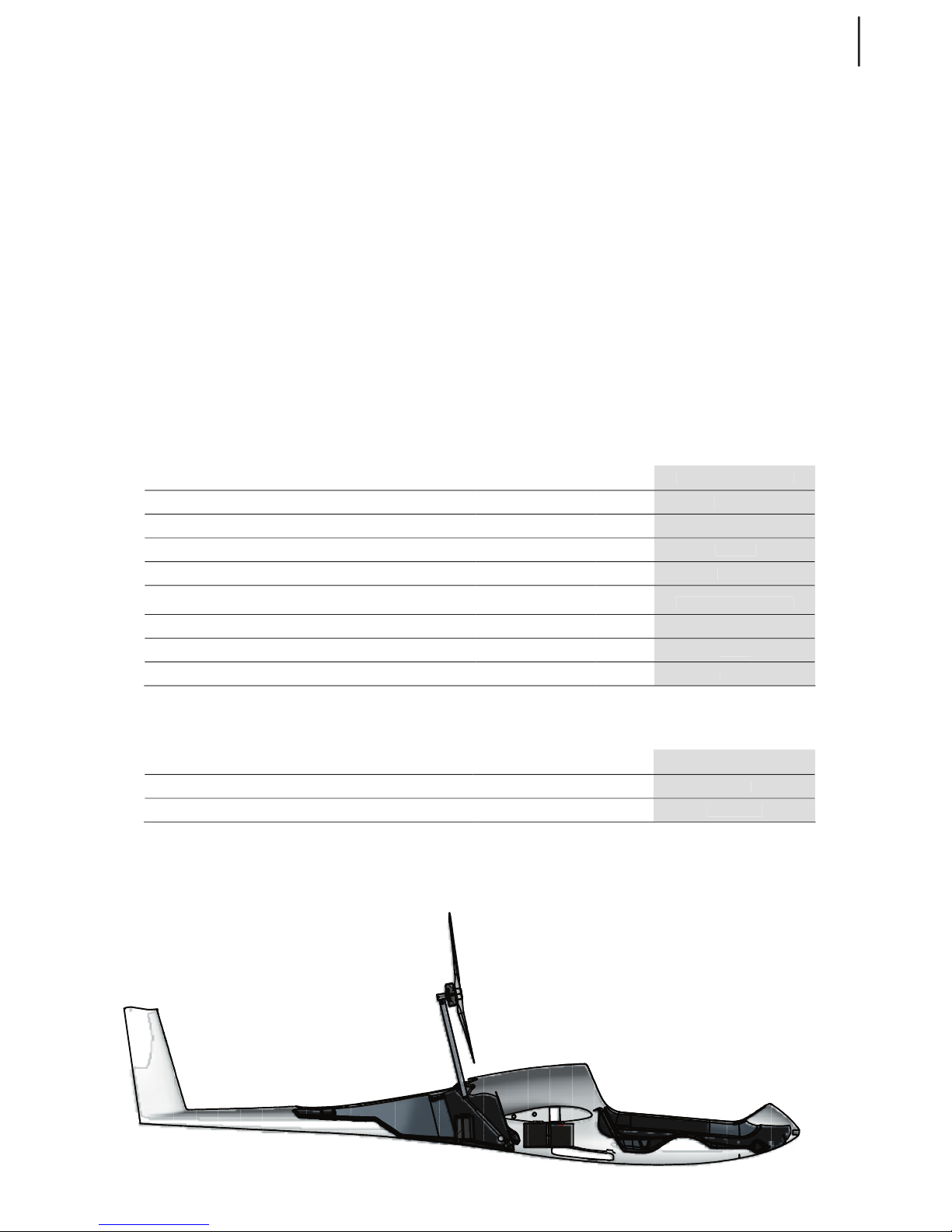

3-view drawing

General

General

TAURUS ELECTRO

www.pipistrel.si

Introduction

This manual contains all information needed

for appropriate and safe use of Taurus Electro

IT IS MANDATORY TO CAREFULLY

STUDY THIS MANUAL PRIOR TO USE

OF AIRCRAFT

In case of aircraft damage or people injury

resulting form disobeying instructions in the

manual PIPISTREL d.o.o. Ajdovscina denies all

responsibility.

All text, design, layout and graphics are

owned by PIPISTREL d.o.o. Ajdovscina

Therefore this manual and any of its contents

may not be copied or distributed in any manner (electronic, web or printed) without the

prior consent of PIPISTREL d.o.o. Ajdovscina

Notes and remarks

Safety definitions used in the manual:

WARNING! DISREGARDING THE FOLLOWING INSTRUCTIONS WILL LEAD TO SEVERE

DETERIORATION OF FLIGHT SAFETY AND HAZARDOUS SITUATIONS, INCLUDING SUCH

RESULTING IN INJURY AND LOSS OF LIFE.

CAUTION! DISREGARDING THE FOLLOWING INSTRUCTIONS WILL LEAD TO SERIOUS

DETERIORATION OF FLIGHT SAFETY.

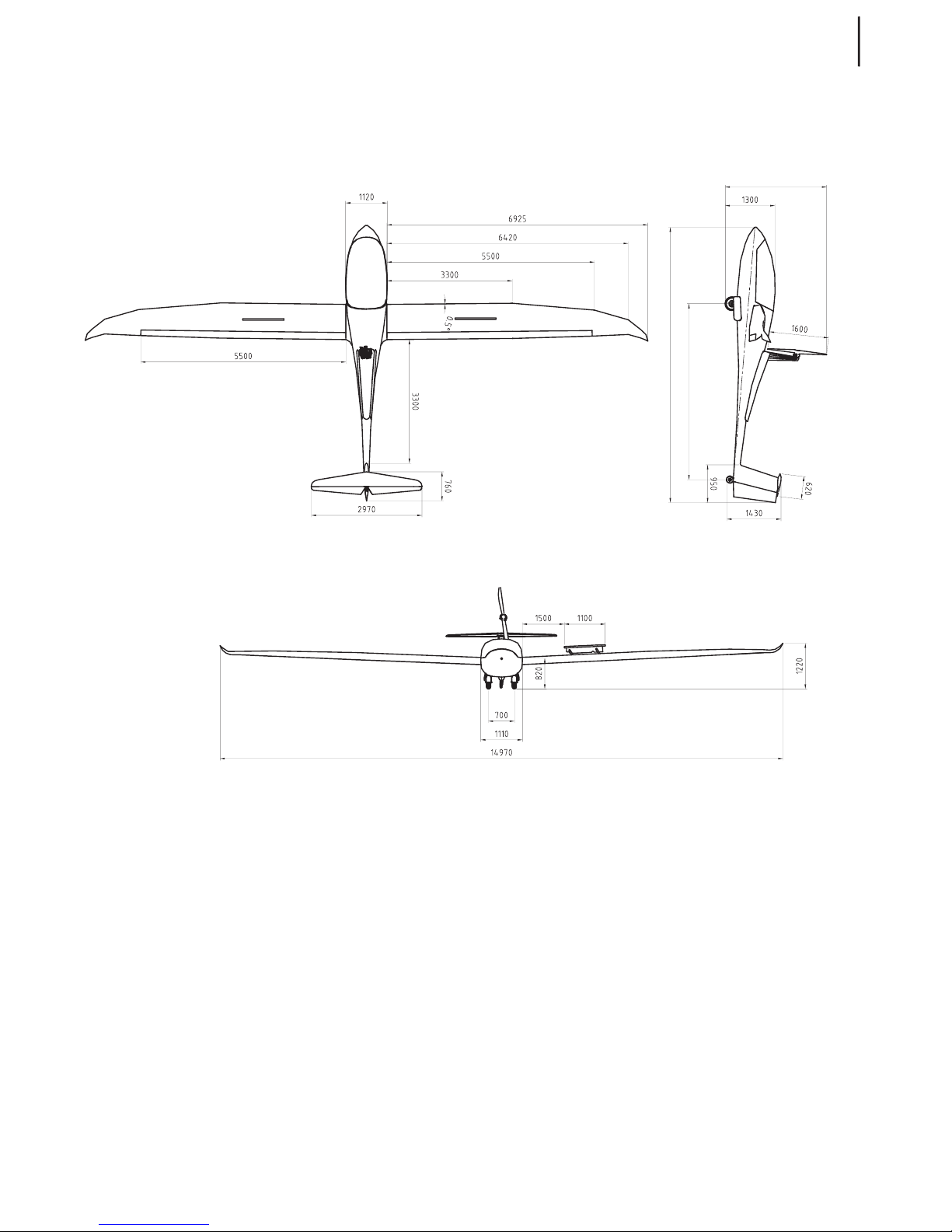

Technical data

PROPORTIONS ELECTRO

wing span 14.97 m

length 7.30 m

height (propeller extended)

2.7 m

wing area

12.26 m

2

vertical tail area 0.86 m

2

horizontal stabilizer and elevator area 1.275 m

2

aspect ratio 18.30

positive flap deflection (down)

5°, 9 °, 18 °

negative flap deflection (up)

-5°

centre of gravity (% of MAC)

23% - 45%

General

TAURUS ELECTRO

www.pipistrel.si

3-view drawing

General

TAURUS ELECTRO

www.pipistrel.si

This page is intentionally left blank.

TAURUS ELECTRO

www.pipistrel.si

Introduction

Operational velocities

Motor, fuel, oil

Weight limits

Centre of gravity limits

Manoeuvre limits

G-load factors

Cockpit crew

Types of operations

Minimum equipment list

Other restrictions

Warning placards

Limitations

TAURUS ELECTRO

www.pipistrel.si

Operational velocities

Speed limits

Velocity

Velocity never to be

exceeded

Never exceed this speed. Should the VNE be

exceeded, land as soon as possible and have

the aircraft verified for airworthiness by authorised service personnel.

extended.

VPO

or retract powerplant

this speed.

VRA

Also known as Vb. Turbulence penetration

speed.

VA

VFE

extended

extended.

airbrake extention

speed. Once fully extended, VNE is the limit.

VLO

above this speed

Airspeed indicator markings

white arc

Speed range where flaps may be extended. Lower end is de-

fined as 110% of VS (stall speed in landing configuration at

green arc

Speed range of normal operation. Lower end is defined as

sition), upper end is limited by VRA (see above).

yellow arc

Y

)

Introduction

This chapter provides information about operational restrictions, instrument markings and basic

knowledge on safe operation of aircraft, motor and on-board appliances.

WARNING! ABOVE PRESSURE ALTITUDE OF 1000 METERS 3300 FT ALL SPEED LIM

ITS MUST BE TREATED AS TRUE AIRSPEED TAS.

INDICATED AIRSPEED IAS MUST BE REDUCED ACCORDINGLY!

TAURUS ELECTRO

www.pipistrel.si

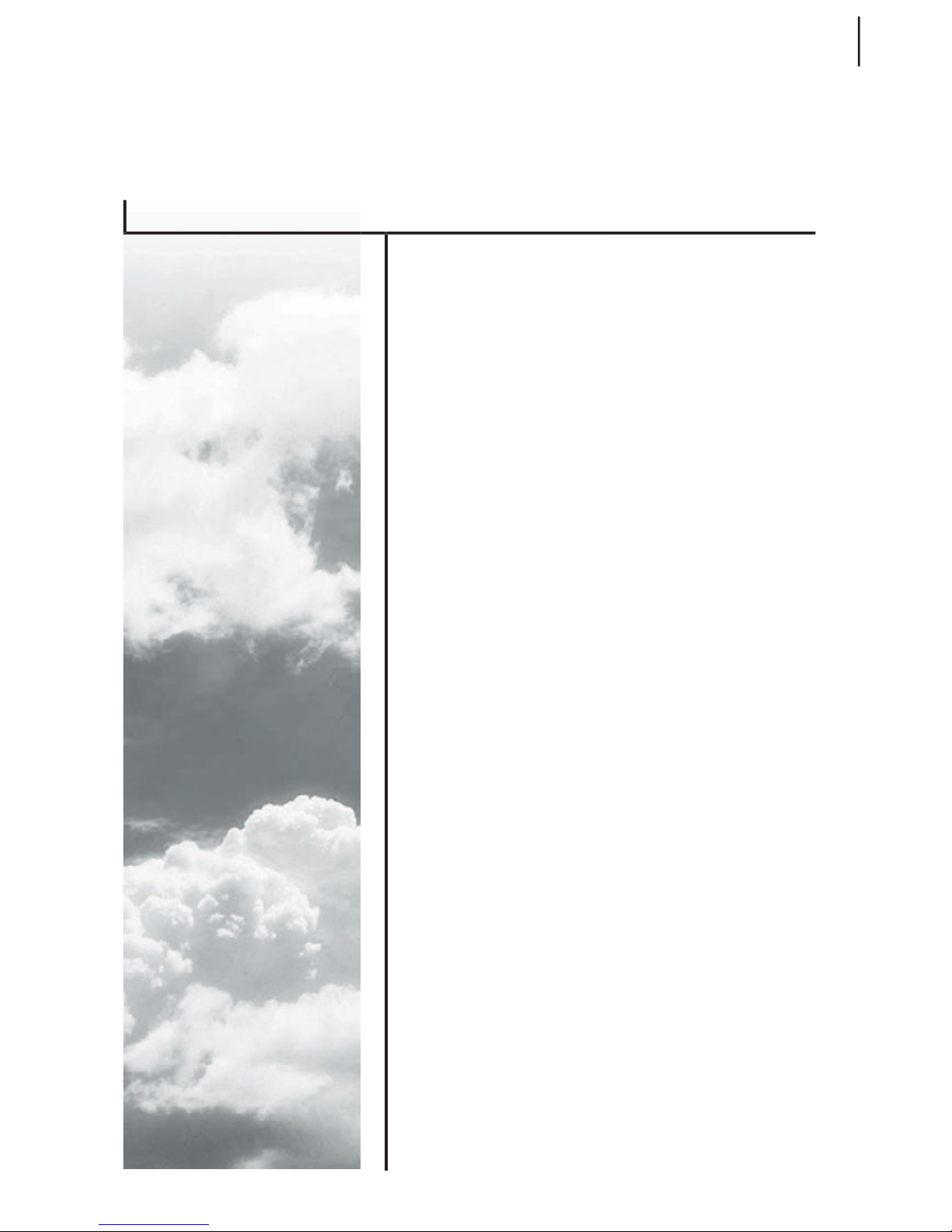

VNE at altitude (standard ICAO atmosphere)

The tables below indicate IAS to TAS relation for an altitude span of 0 - 5000m (0 - FL165) in different

atmospheres (variable is temperature). TAS is a constant of 225 km/h (122 kts) - VNE for the entire tables.

Altitude (meters)

Altitude (meters)

0

500

2000

2500

3000

3500

4000

4500

5000

Altitude (flight level)

0

VNE IAS (km/h)

VNE IAS (km/h)

225

225

223

218

213

209

203

VNE IAS (kts)

Altitude (meters)

Altitude (meters)

0

500

2000

2500

3000

3500

4000

4500

5000

Altitude (flight level)

0

VNE IAS (km/h)

225

219

209

205

VNE IAS (kts)

98

Altitude (meters)

Altitude (meters)

0

500

2000

2500

3000

3500

4000

4500

5000

Altitude (flight level)

Altitude (flight level)

0

VNE IAS (km/h)

225

220

215

210

205

201

VNE IAS (kts)

98

96

Altitude (meters)

Altitude (meters)

0

500

2000

2500

3000

3500

4000

4500

5000

Altitude (flight level)

0

VNE IAS (km/h)

220

215

206

202

VNE IAS (kts)

999794

:

Altitude (meters)

Altitude (meters)

0

500

2000

2500

3000

3500

4000

4500

5000

Altitude (flight level)

0

VNE IAS (km/h)

216

207

202

VNE IAS (kts)

999794

92

Note how VNE decreases at higher altitudes!

WARNING! RESPECT THE LISTED VALUES AT ALL TIMES, NOT TO EXCEED FLUTTER CRITI

CAL SPEED.

Indicated airspeed (IAS) to true airspeed (TAS) relation

Airspeed indicator measures the difference between total and static pressure (also called dynamic

pressure), which does not only change as speed increases, but is also linked with altitude. Flying at

high altitudes, where the air is getting thinner, results in misinterpreting airspeed which is being

indicated. The indicated airspeed value is actually lower than the true airspeed to which the aircraft

is exposed. The higher you fly, the bigger the difference between IAS and TAS. Be aware of this effect

especially when flying at high altitude at high speeds, not to exceed VNE unawarely. Bear in mind

this can happen even with the indicator still pointing within the yellow arc!

TAURUS ELECTRO

www.pipistrel.si

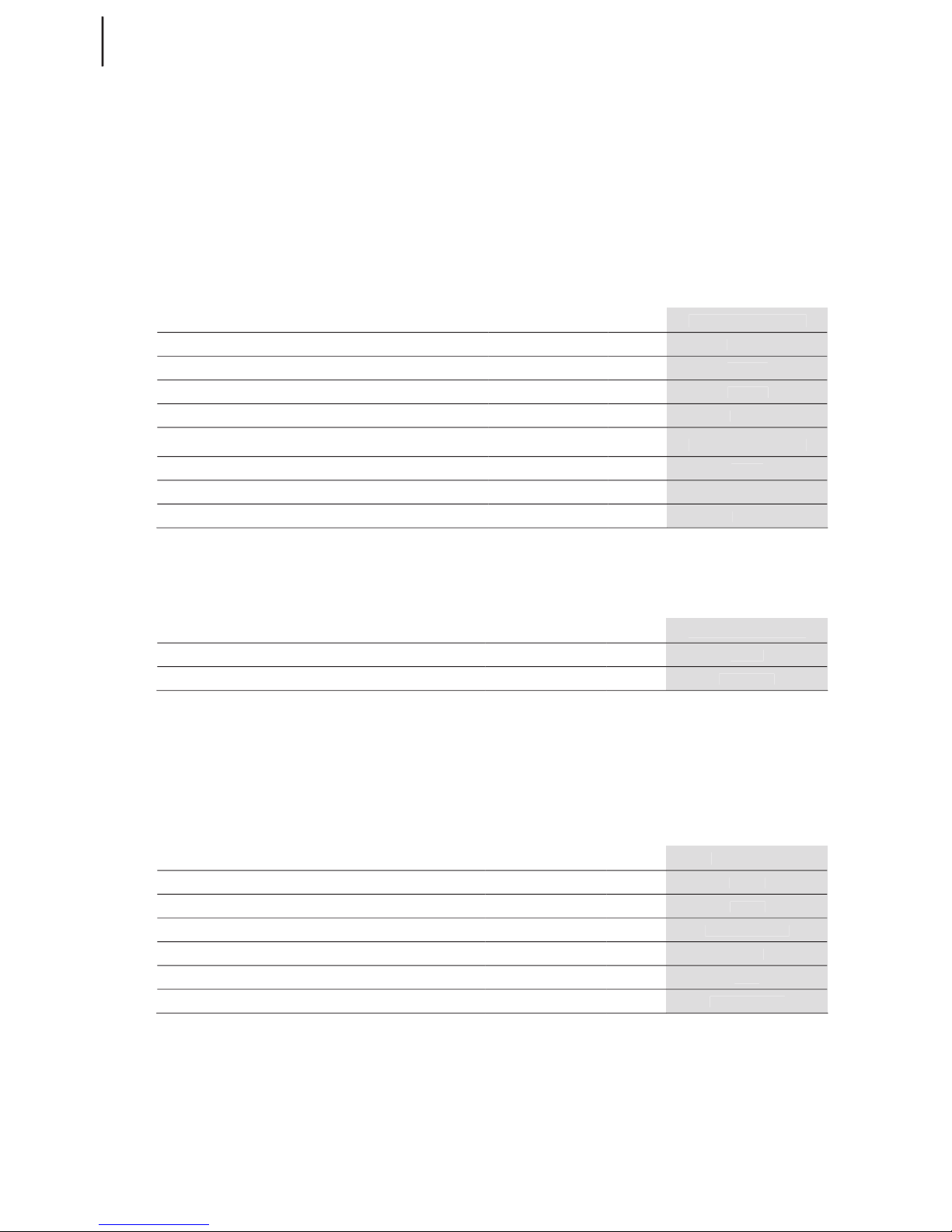

Motor/controller, Battery System

Motor types: ELECTRO40/30

WARNING! The motor is not certified for aviation use, therefore, there is no assur-

ance it cannot fail in its operation at any given moment, without prior notice.

The motor

TEMPERATURE °C / ELECTROMOTOR

40 kW

30 kW

40° C

2200

take-off rpm (typical)

2150

climb rpm (typical)

Controller

45-55° C

WARNING! DO NOT, UNDER ANY CIRCUMSTANCES, ATTEMPT TO USE ANY OTHER

BATTERIES, OTHER THAN PIPISTREL FACTORY ORIGINAL BATTERY SYSTEM, WITH THIS MOTOR/

CONTROLLER

Battery system

Standard

270 V

230 V - 250 V

5° C

Allowable temperature range for storage

CAUTION! TEMPERATURES BELOW 10°C WILL RESULT IN DECREASE OF BATTERY CAPACITY.

PLAN YOUR FLIGHT ACCORDINGLY.

WARNING! DO NOT, UNDER ANY CIRCUMSTANCES, ATTEMPT TO CHARGE THE BATTERIES

WITH ANY THIRD PARTY CHARGERS. ONLY PIPISTREL ORIGINAL EQUIPMENT MUST BE USED.

WARNING! RESPECT OPERATING AND STORAGE TEMPERATURE LIMITS AT ALL TIMES.

FAILURE TO DO SO MAY RESULT IN BATTERY DAMAGE.

TAURUS ELECTRO

www.pipistrel.si

Propeller

TAURUS

fixed pitch (wooden or composite)

Motor instrument markings

WARNING! USER IS TO FILL IN MOTOR SPECIFIC VALUES.

Green arc

Yellow arc

Tachometer (RPM)

Controller temp. (°C)

/

/

5

0-2150

5-55

2150-2200

55-70

50-70

2200

Weight limits

Taurus electro basic model weights

WEIGHT

empty aircraft weight (incl. parachute rescue system), std battery system

306 kg

empty aircraft weight (incl. parachute rescue system), optional batteries sys.

323 kg

472.5 kg

see p. 55

see p. 55

water ballance reservoir (max weight)

9 kg

allowable luggage weight

WARNING! SHOULD ONE OF THE ABOVELISTED VALUES BE EXCEEDED, OTHERS MUST BE

REDUCED IN ORDER TO KEEP MTOM BELOW 472.5 KG. MAKE SURE MAXIMUM AND MINIMUM

COCKPIT CREW WEIGHT AS WELL AS AVAILABLE LUGGAGE WEIGHT ARE ALWAYS KEPT WITHIN

ALLOWABLE LIMITS. FAILING TO COMPLY WITH ANY OF THE WEIGHT LIMITATIONS MAY RESULT

IN AIRCRAFT BEING UNCONTROLLABLE ON GROUND AND/OR IN FLIGHT DUE TO EXTREME

CENTRE OF GRAVITY POSITION.

WARNING! CHECK THE WATER BALANCE RESERVOIR IN FRONTCABIN AND VERIFY

CREW’S WEIGHT BEFORE EVERY FLIGHT AS IT MAY INFLUENCE THE CENTRE OF GRAVITY OF

AIRCRAFT TO THE POINT WHERE IT IS NO LONGER CONTROLLABLE!

TAURUS ELECTRO

www.pipistrel.si

Centre of gravity limits

•

Aircraft's safe centre of gravity position ranges between 23% and 45% of MAC (Mean

Aerodynamic Chord)

•

C.G. point ranges between 238 mm and 429 mm aft of datum, datum is leading edge

of wing root.

Manoeuvre limits

Taurus Electro is certified as an Ultralight aircraft. Therefore, no aerobatic manoeuvers

are permitted.

WARNING! FLYING IN CONSIDERABLE SIDESLIP WHEN THE MOTOR IS EXTENDED AND

RUNNING MAY DAMAGE THE MOTORPROPELLER ASSEMBLY. YOU ARE STRONGLY DISCOUR

AGED FROM SIDESLIPPING WHEN MOTOR IS EXTENDED AND RUNNING!

G-load factors

at VA at VNE

max. positive wing load:

+ 5.3 G + 4.0 G

max. negative wing load:

– 2.65 G – 1.5 G

Cockpit crew

•

Actual minumum and maximum combined cockpit crew weight heavily depend on the

centre of gravity of an empty aircraft. Minumum and maximum combined cockpit crew

weight is determined after weighing the aircraft each time. Procedure for the determination of minimum and maximum combined cockpit crew weight can be found on

page 57 of this manual. Inside the cockpit, there must be a clearly visible placard stating

the minimum and maximum combined weight of the crew.

•

Maximum takeoff weight (MTOW) MUST NOT, under any circumstances, exceed 472.5

kg.

Types of operations

Taurus Electro is built to fly under day visual flight rules

(day VFR). Flight into known icing conditions or rain is prohibited.

TAURUS ELECTRO

www.pipistrel.si

WARNING! SHOULD YOU FIND WATER DROPS ON THE AIRFRAME DURING PREFLIGHT

CHECKUP AT TEMPERATURES CLOSE TO FREEZING, YOU MAY EXPECT ICING TO APPEAR IN

FLIGHT. AIRBRAKES ARE ESPECIALLY PRONE TO ICING UNDER SUCH CIRCUMSTANCES. AS

WATER MAY ACCUMULATE UNDERNEATH THE TOP PLATES, SPOILERS MAY FREEZE TO THE

WING SURFACE. SHOULD THIS OCCUR, YOU WILL MOST DEFINITELY BE UNABLE TO EXTEND

SPOILERS BEFORE THE ICE MELTS. THEREFORE, FLYING UNDER CIRCUMSTANCES MENTIONED

ABOVE, IT IS RECOMMENDED TO EXTEND AND RETRACT THE SPOILERS IN FLIGHT FREQUENT

LY TO PREVENT ITS SURFACE FREEZING TO THE AIRFRAME.

Minimum equipment list

• Airspeed indicator (functional)

• Altimeter (functional)

• Compass (functional)

• Electric System Manager instrument (ESYS-MAN)

• Battery Management System (BMS, functional)

• Parachute rescue system (where required legally)

Other restrictions

Due to flight safety reasons it is forbidden to:

•

fly in any rainfall;

•

fly during thunderstorm activity;

•

fly in a blizzard;

•

fly according to instrumental flight rules (IFR) or attempt to fly in zero visibility conditions (IMC);

•

fly when outside air temperature (OAT) reaches 40°C or higher;

•

perform any form of aerobatic flying;

•

take off and land with flaps retracted or set to negative (-5°) position;

•

take off with spoilers extended.

•

store the aircraft outside in the rain.

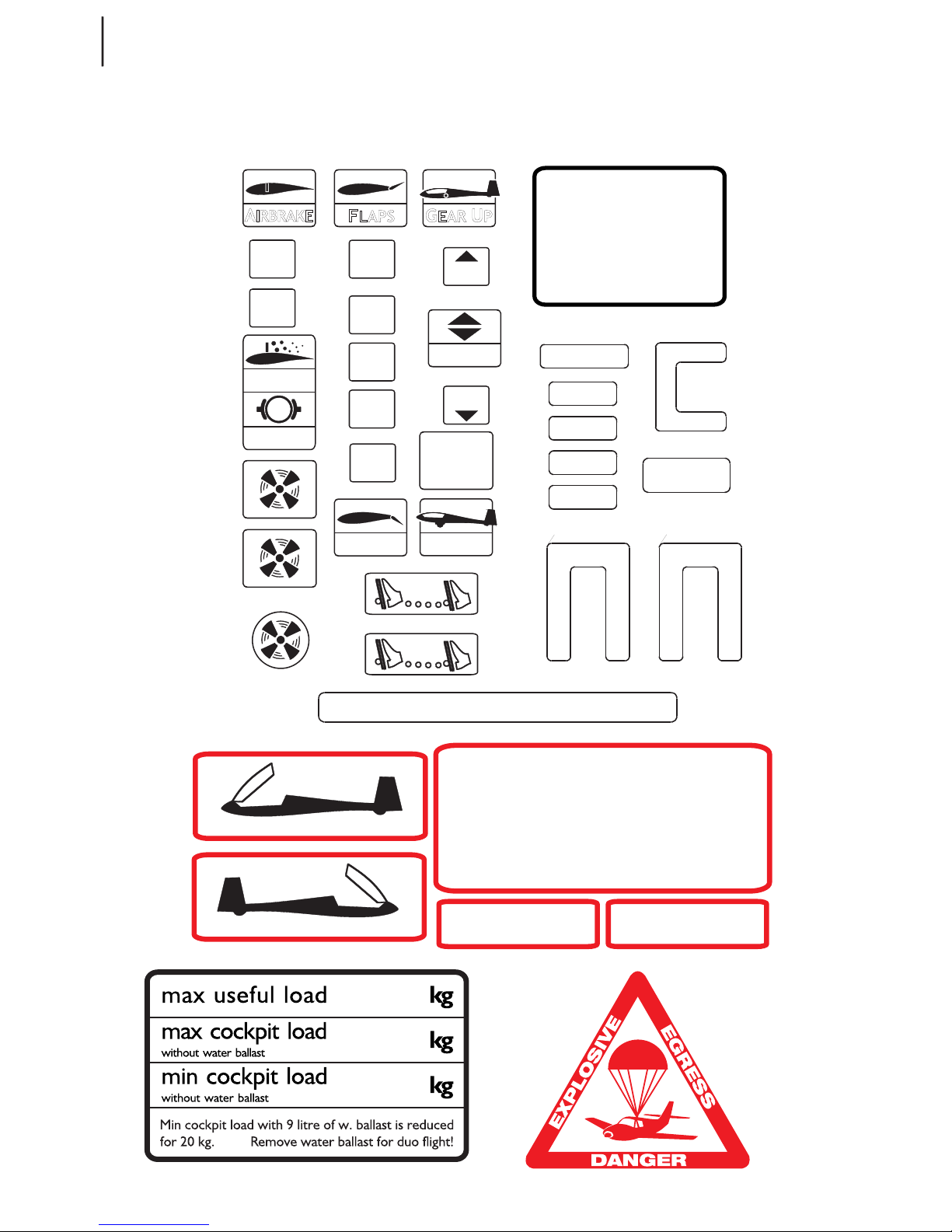

Warning placards

Taurus Electro is categorised as an Ultralight aircraft and must wear a

warning placard as such. The placard indicates the

aircraft is not certified according to EASA standards and is therefore flown

completely at pilot’s own risk

.

20

TAURUS ELECTRO

www.pipistrel.si

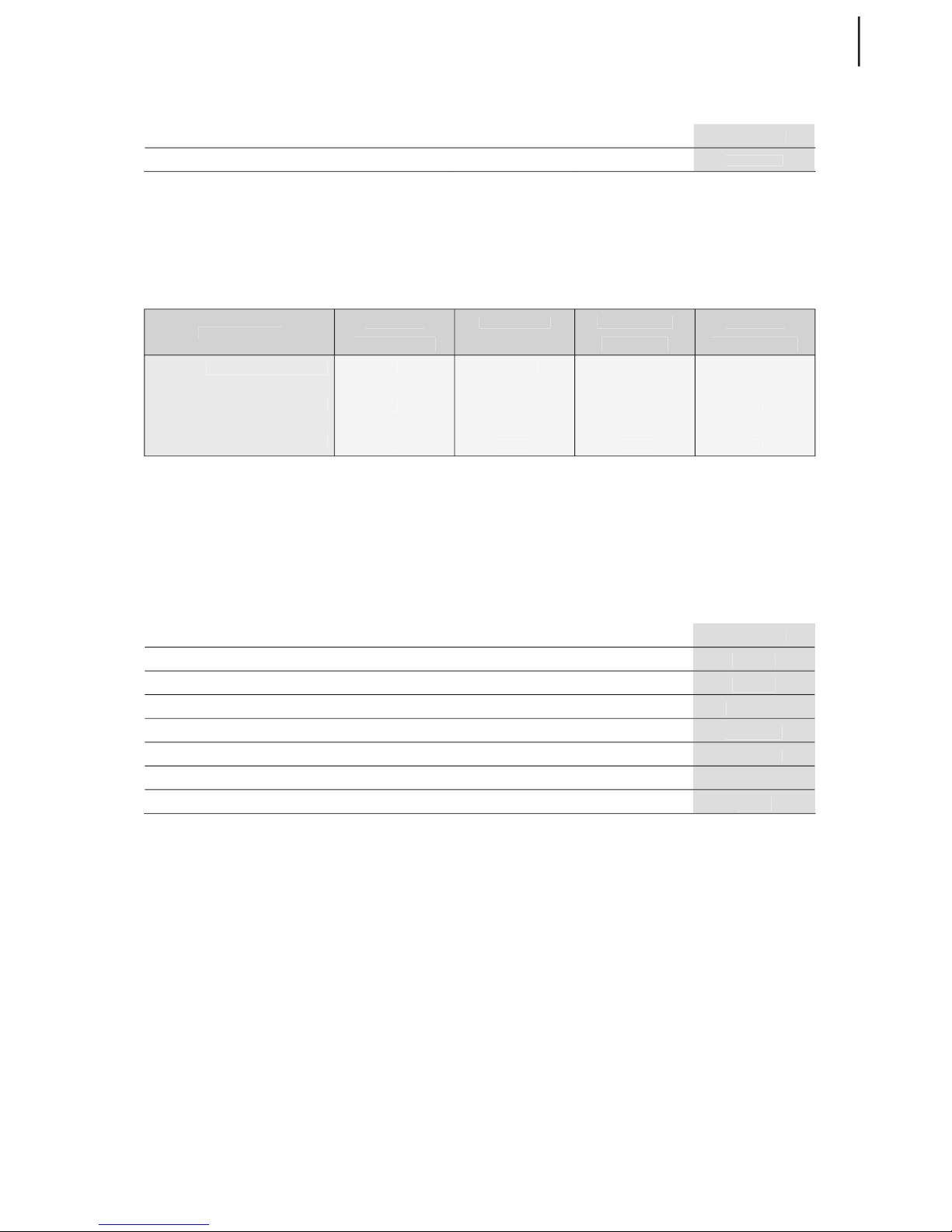

Placards

G

E

A

R

U

P

A

I

R

B

R

A

K

E

GEAR DN

F

L

A

P

S

FLAPS

TRIM

UP

DN

OUT

IN

0°

+5°

L

-5°

AIRBRAKE

GEAR BRK

pilot min. kg

pilot max. kg

EN GI N E RE TR A C T IO N

1. throttle idle, ignition off

2. reduce IAS to 75 km/h

3. after prop. stops IAS 90 km/h,

- engine DOWN

4. when prop. retracted

- master switch I

VARIO

RADIO AUX

XPDR

12V

socket

ENG

INST

ENG

SYSTEM

T

INTERCOM

ON

OFF

L MAGNETOS R

P

R

I

M

E

R

ON

OFF

THROTTLE

ON

OFF

F

U

E

L

SC MODE

ON

OFF

with 9kg nose ballast kg

with 9kg nose ballast kg

pilot min. kg

WARNING!

If battery is removed

M I C

HEADSET

ON

OFF

F

U

E

L

21

TAURUS ELECTRO

www.pipistrel.si

Introduction

Stall recovery

Spin recovery

Motor failure

Landing out

Motor fire

Smoke in cockpit

ESYS-MAN failure

Landing gear failure

Flutter

Exceeding VNE

Parachute rescue system

22

TAURUS ELECTRO

www.pipistrel.si

Introduction

This chapter provides information on how to react when confronted with typical flight hazards.

Stall recovery

First reduce angle of attack by easing-off on the control stick, then

1. If the motor is running, add full power.

2. Resume horizontal flight.

Spin recovery

Taurus Electro is constructed in such manner that it is difficult to be flown into a spin. However, once

spinning, react as follows:

1. If the motor is running, set throttle to idle (lever in full back position).

2. Apply full rudder deflection in the direction opposite the spin.

3. Lower the nose towards the ground to build speed (stick forward).

4. As the aircraft stops spinning neutralise rudder deflection.

5. Slowly pull up and regain horizontal flight.

Taurus Electro tends to re-establish rightened flight by itself usually after having spun for a mere 90°.

WARNING! KEEP THE CONTROL STICK CENTRED ALONG ITS LATERAL AXIS NO AILERON

DEFLECTIONS THROUGHOUT THE RECOVERY PHASE! DO NOT ATTEMPT TO STOP THE AIR

CRAFT FROM SPINNING USING AILERONS INSTEAD OF RUDDER!

WARNING! AFTER HAVING STOPPED SPINNING, RECOVERING FROM THE DIVE MUST BE

PERFORMED USING GENTLE STICK MOVEMENTS PULL, RATHER THAN OVERSTRESSING THE

AIRCRAFT. HOWEVER, VNE MUST NOT BE EXCEEDED DURING THIS MANOEUVRE.

When the aircraft is straight and level resume normal flight.

Motor failure

Motor failure during takeoff or initial climb

Ensure proper airspeed by lowering the nose and land the aircraft in runway heading, avoiding eventual obstacles in your way. Set master switch to OFF position (key full left).

Land straight ahead.

WARNING! DO NOT CHANGE COURSE OR MAKE TURNS IF THIS IS NOT OF VITAL

NECESSITY! AFTER HAVING LANDED SAFELY, ENSURE PROTECTION OF AIRCRAFT AND VACATE

THE RUNWAY TO KEEP THE RUNWAY CLEAR FOR ARRIVING AND DEPARTING TRAFFIC.

DO THIS CALMLY AND CAREFULLY NOT TO CAUSE DAMAGE TO YOURSELF AND EQUIPMENT.

23

TAURUS ELECTRO

www.pipistrel.si

Motor failure in climb

First ensure proper airspeed by lowering the nose, then start scanning the terrain underneath and

choose the most appropriate site for landing out.

WARNING! THE DECISION WHERE TO LAND WHEN LANDING OUT IS FINAL! CHANGING

YOUR MIND EVEN IF YOU HAPPEN TO COME ACROSS A DIFFERENT, PERHAPS MORE APPROPRI

ATE LANDING SITE, SHOULD BE YOUR LAST RESORT.

Provided the motor fails aloft, first retract the propulsion unit and prepare for an

emergency landing if the conditions prevent you from gliding to the airport.

Emergency landing

Propulsion unit retracted

1. Master switch OFF (key in full left position).

2. Fasten your seat belts tightly.

3. Approach and land with extreme caution with +10 km/h (+5 kts) airspeed reserve if

the chosen landing terrain lenght permits.

4. After having landed abandon the aircraft immediately.

Propulsion unit extended or refusing to retract

1. Your first priority is to fly the aircraft! Atempt to retract the propulsion unit by

setting the retraction switch up and back down IF your height is 300 m or higher.

Otherwise, proceed with emergency landing.

2. Fasten your seat belts tightly.

3. Master switch OFF (key in full left position).

4. Should the propulsion unit remain extended or partially retracted land the aircraft

onto the main wheels first in order to minimise vertical impact onto the propeller arm.

5. Fly no faster than minimum sink speed (94 km/h - 51 kts) during the approach as

more speed will only increase your rate of descent and use up to+10 km/h (+5 kts) airspeed reserve only before touchdown if the chosen landing terrain lenght permits.

The landing out manoeuvre MUST be preformed with regard to all normal flight parameters.

24

TAURUS ELECTRO

www.pipistrel.si

Fire

WARNING! USE ONLY WATERLESS FIRE EXTINGUISHING AGENTS TO EXTINGUISH ANY

FIRE ON THE AIRCRAFT!

Motor fire on ground

Should you encounter motor fire on ground, react as follows:

1. Come to a complete standstill, master switch OFF immediately and pull out the red

connector on the battery box behind the cockpit to disconnect the battery system.

Keep powerplant extended.

3. Abandon the aircraft and start fire extinguishing with a waterless agent.

WARNING! AFTER THE FIRE HAS BEEN EXTINGUISHED DO NOT ATTEMPT TO RESTART THE

MOTOR.

Motor fire in flight

1. Swich System enable swith off.

2. Open slide windows and set all ventilation devices to ON.

3. Perform side-slip (crab) manoeuvre in direction opposite the fire.

4. Perform emergency landing procedure and abandon the aircraft immediately.

Battery system fire

Land and abandon the aircraft as soon as possible.

WARNING! USE ONLY WATERLESS FIRE EXTINGUISHING AGENTS TO EXTINGUISH ANY

FIRE ON THE AIRCRAFT!

Smoke in cockpit

1. Leave the motor extended and set master switch to OFF.

2. Open slide windows and set all ventilation devices to ON for adequate breathing.

3. Land as soon as possible.

ESYS-MAN failure

With the motor retracted: Continue flying as a sailplane.

With the motor extended and not running: Look for a landing field to do a safe outlanding.

With the motor extended and running: Do not stop the motor. Fly to the next airfield and land.

25

TAURUS ELECTRO

www.pipistrel.si

Landing gear failure

Should the landing gear fail to lower, fasten your seatbelts tightly and perform a landing procedure

as normal. Use full flaps to have the minimum possible speed at touch-down.

Flare at the same altitude like you would normally and in the same manner. Avoid eventual obstacles

(bumps, fences etc. on the runway or strip where you are landing.

Flutter

Flutter is described as the oscillation of control surfaces. In most cases it is caused by abrupt control

deflections at speeds close or in excess of VNE. As it occurs, the ailerons, elevator or even the whole

aircraft start to vibrate violently.

Should flutter occur, pull on the stick (and reduce power immediately)!

WARNING! FLUTTERING OF AILERONS OR TAIL SURFACES MAY CAUSE PERMANENT

STRUCTURAL DAMAGE AND/OR INABILITY TO CONTROL THE AIRCRAFT.

AFTER A SAFE LANDING, THE AIRCRAFT MUST UNDERGO A SERIES OF CHECKUPS PER

FORMED BY AUTHORISED SERVICE PERSONNEL TO VERIFY AIRWORTHINESS.

Exceeding VNE

Should the VNE be exceeded, reduce airspeed slowly and continue flying using gentle control deflections. Land safely as soon as possible and have the aircraft verified for airworthiness by

authorised service personnel.

Parachute rescue system

Upon pulling the rescue system handle, the whole electrical system, including the propulsion

system, of the aircraft is disengaged immediately. See next page for further instructions.

26

TAURUS ELECTRO

www.pipistrel.si

Parachute rescue system

System description

Depending on the canopy size, the main canopy system is open and fully inflated above the aircraft

between 1.5 - 6.0 seconds after being fired with regard to the flight speed. This means that a rescue

can be successful from as little as 30 m to 150m over the ground, depending on the installation, position of the aircraft, its speed and trajectory. The necessary height needed for a rescue is deduced

from measured figures in horizontal flight up to the stated VNE of aircraft in its MTOW. These figures

are stated in the technical parameters of the system. It is possible to aim the rocket in any direction

but, the best direction is vertical to the lengthwise axis of the plane in an upward or slightly oblique

aft direction. The rocket system has been designed with sufficient power reserve so that it can pull

out the chute even under extreme conditions ranging in temperatures from -40°C up to +60°C.

WARNING! ACTIVATION HANDLE SAFETY PIN SHOULD BE INSERTED WHEN THE

AIRCRAFT IS PARKED OR HANGARED TO PREVENT ACCIDENTAL DEPLOYMENT.

HOWEVER, AS SOON AS THE PILOT BOARDS THE AIRCRAFT, SAFETY PIN MUST BE REMOVED!

Use of parachute rescue system

In situations such as:

•

structural failure

•

mid-air collision

•

loss of control over aircraft

•

motor failure over hostile terrain

•

pilot incapacitation (incl. heart attack, stroke, temp. blindness, disorientation...)

the parachute SHOULD be deployed.

Prior to firing the system:

•

shut down the motor and set master switch to OFF (key in full left position)

•

fasten safety harnesses tightly

•

protect your face and body.

To deploy the parachute jerk the activation handle (located above and between pilots)

hard for a length of at least 30 cm towards the instrument panel.

Once you have pulled the handle and the rocked is deployed, it will be less than two seconds before

you feel the impact produced by two forces. The first force is produced by stretching of all the system. The force follows after the inflation of the canopy from opening impact and it will seem to you

that the aircraft is pulled backwards briefly. The airspeed is reduced instantly and the aircraft now

starts do descent to the ground underneath the parachute.

As a pilot you should know that the phase following parachute deployment may be a great unknown and a great adventure for the crew. You will be getting into situation for the first time, where

27

TAURUS ELECTRO

www.pipistrel.si

a proper landing and the determination of the landing site are out of your control.

CAUTION! SHOULD YOU END UP IN POWER LINES CARRYING ELECTRICAL CURRENT, DO

NOT UNDER ANY CIRCUMSTANCES TOUCH ANY METAL PARTS INSIDE OR OUTSIDE THE COCK

PIT. THIS ALSO APPLIES TO ANYONE ATTEMPTING TO HELP OR RESCUE YOU. BE AWARE THAT

ANYONE TOUCHING A METAL PART WHILE STANDING ON THE GROUND WILL PROBABLY SUF

FER MAYOR INJURY OR DIE OF ELECTROCUTION. THEREFORE, YOU ARE STRONGLY ENCOUR

AGED TO CONFINE YOUR MOVEMENTS UNTIL QUALIFIED PERSONAL ARRIVE AT THE SITE TO

ASSIST YOU.

After the parachute rescue system has been used or if you suspect any possible damage to the system, do not hesitate and immediately contact the manufacturer!

Handling and maintenance of Parachute rescue system

Prior to every flight all visible parts of the system must be checked for proper condition. Special attention should be paid to eventual corrosion on the activation handle inside the cockpit. Also, main

fastening straps on the inside of the fuselage must remain undamaged at all times.

Furthermore, neither the system, nor any of its parts should be exposed to moisture, vibration and

UV radiation for long periods of time to ensure proper system operation and life.

CAUTION! IT IS STRONGLY RECOMMENCED TO THOROUGHLY INSPECT AND GREASE THE

ACTIVATION HANDLE, PREFERABLY USING SILICON OIL SPRAY, EVERY 50 FLIGHT HOURS.

All major repairs and damage repairs MUST be done by the

manufacturer or authorised service personnel.

For all details concerning the GRS rescue system, please see the “GRS - Galaxy Rescue System Manual

for Assembly and Use”.

28

TAURUS ELECTRO

www.pipistrel.si

This page is intentionally left blank.

29

TAURUS ELECTRO

www.pipistrel.si

Introduction

Assembling and

disassembling the

aircraft

Daily check-up

Preflight check-up

Normal procedures and

recommended speeds

30

TAURUS ELECTRO

www.pipistrel.si

Introduction

This chapter provides information on everything needed to fly Taurus Electro safely.

Assembling and disassembling the aircraft

CAUTION! PRIOR TO EACH ASSEMBLING OR DISASSEMBLING ACTION THE TAURUS Electro

SHOULD NOT BE PLACED UNDER STRONG SUNSHINE, AS COMPOSITE PARTS EXPAND AND

CONTRACT AND YOU MAY NOT BE ABLE TO ASSEMBLE OR DISASSEMBLE THE AIRFRAME. UNDER

NO CIRCUMSTANCES ATTEMPT TO ASSEMBLE OR DISASSEMBLE ANY PARTS OF THE AIRCRAFT

FURCEFULLY!

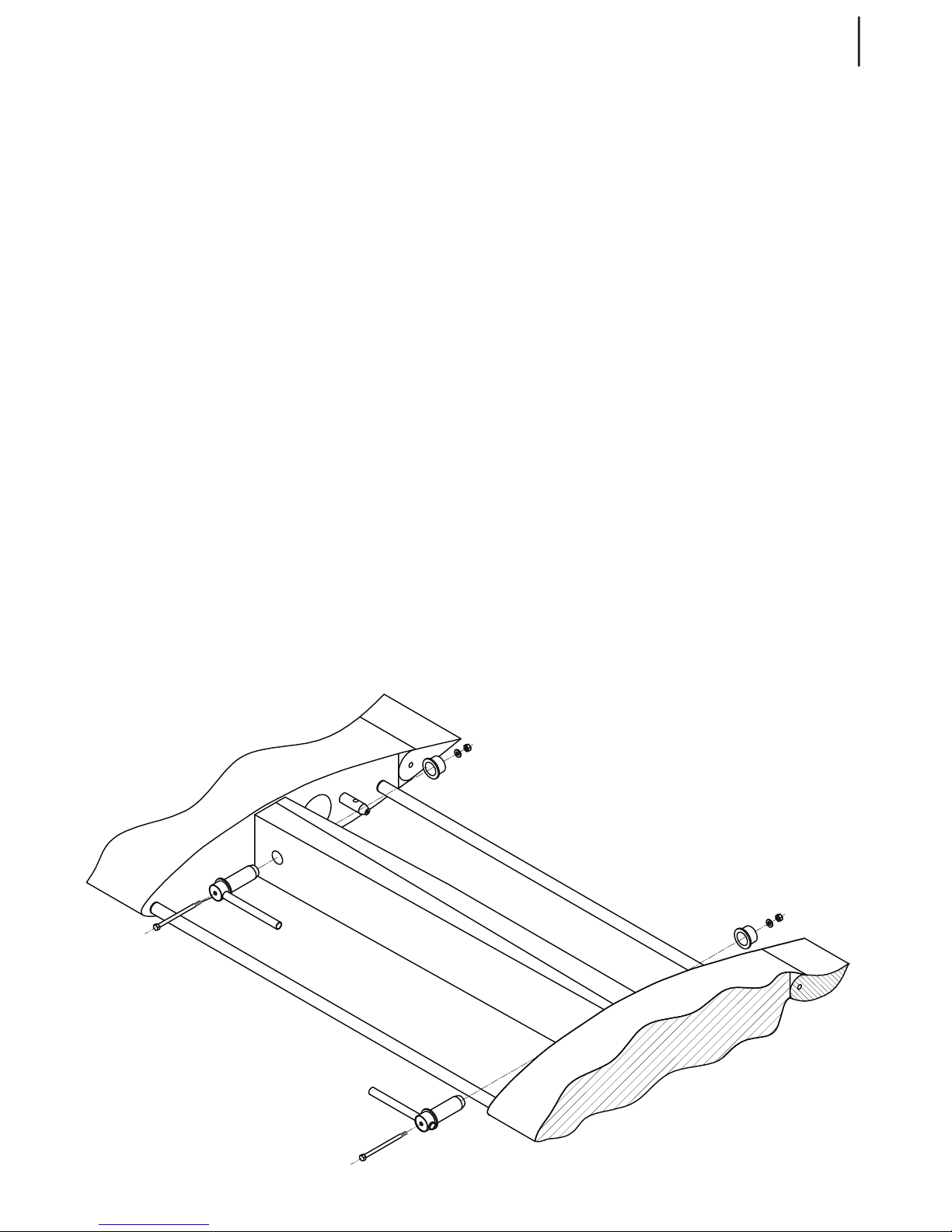

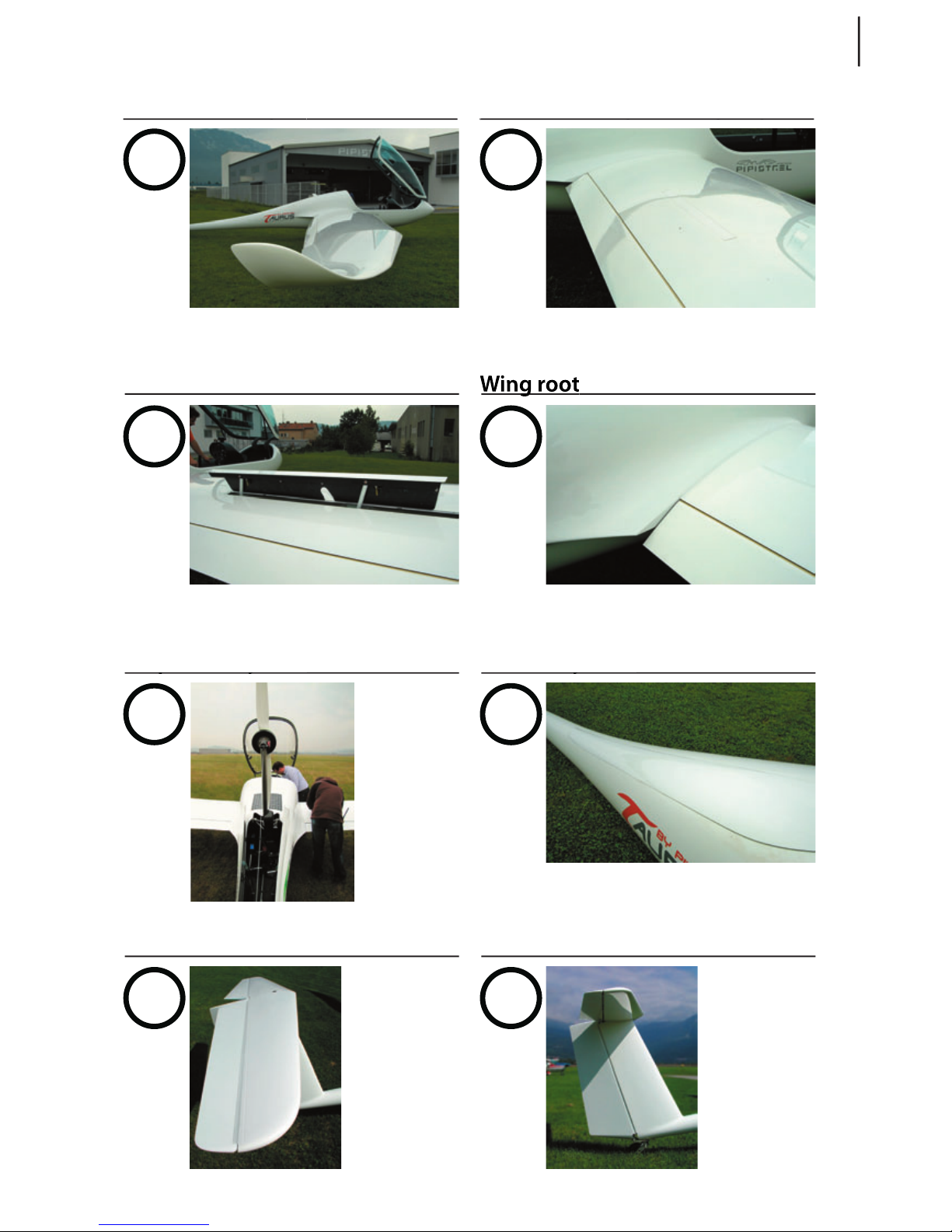

Assembling the wings

Three people (or two with a stand) are needed

to assemble the wings to the fuselage.

First block all three wheels for the fuselage to

stay in position.

Clean and grease the main wing pins and insertion openings. Open the canopy. Inside the

cockpit set the flap handle to neutral position

and unlock the spoilers’ handle. Make sure

you have all bolts, nuts, washers and spanners

needed within reach of a hand.

Lift one wing-half (one person at each end)

and bring it closer to the fuselage. While the

two are holding the wing-half high up, the

third person directs their movement to put the

wing’s main spar into the opening on the adjacent side of the fuselage.

Now push the wing-half into its final position

slowly. The person closest to the fuselage must

make sure the spoiler and flap connectors have

fitted into adequate fuselage fittings properly. At the same time, the person holding the

wingtip must start with slight circular movements (1cm each direction) in order to assure a

tight fit of the wing and its adequate bushings.

As this is done the person at the wingtip must

remain in positon holding the wing, whereas

the other two move over to the other winghalf, lift it and bring it closer to the fuselage.

Do not forget to make sure the spoiler and flap

connectors have fitted into adequate fittings

properly on this wing-half as well.

Both wing-halfs should now be in their final

position but still being held at wingtips. The

person not holding the wings must now insert

both pre-greased spar pins. First insert the pin

on the right-hand side of the cockpit because

of easier insersion (thinner spar infront), then

the pin on the lefe-hand side of the cockpit.

If necessary, the two at the wingtips can assist

by rocking the wings a couple of

millimeters up and down.

Only when both spar pins have been inserted

and secured, wingtips may be released.

Now check all control deflections as well as

flap and spoilers’ extensions for smooth,

unobstructed movement.

Insert all bolts and pins and secure them with

self-locking nuts. Do not forget to put aluminium washers underneath the nuts!

Connect all electical clables and fuel hoses to

their correct fittings.

Finally tape the gap between the fuselage and

the wing using self-adhesive tape.

31

TAURUS ELECTRO

www.pipistrel.si

Three people again are needed to disassemble

the wings.

First block all three wheels for the fuselage to

stay in position.

Disassemble the horizontal tail surfaces, disconnect all eventual electrical cables, then unscrew and remove both pin bolts.

WARNING! Do not remove spar pins yet!

Two people must now lift the wingtips (one

wingtip each) and the person in the cockpit remove the main spar pins, one by one,

smoothly.

Forcing pins out of their position may result

in structural damage, therefore the wingtip

holders must hold the wing-halfs precisely at

certain height!

Using slight circular movement at the wingtip,

the wing-halfs must now be pulled out of the

fuselage slowly. On pulling, each wing-half

must be held by two, one at the wingtip and

one near the spar.

As the wing-halfs have been pulled out, place

them onto a soft surface to prevent their

damage.

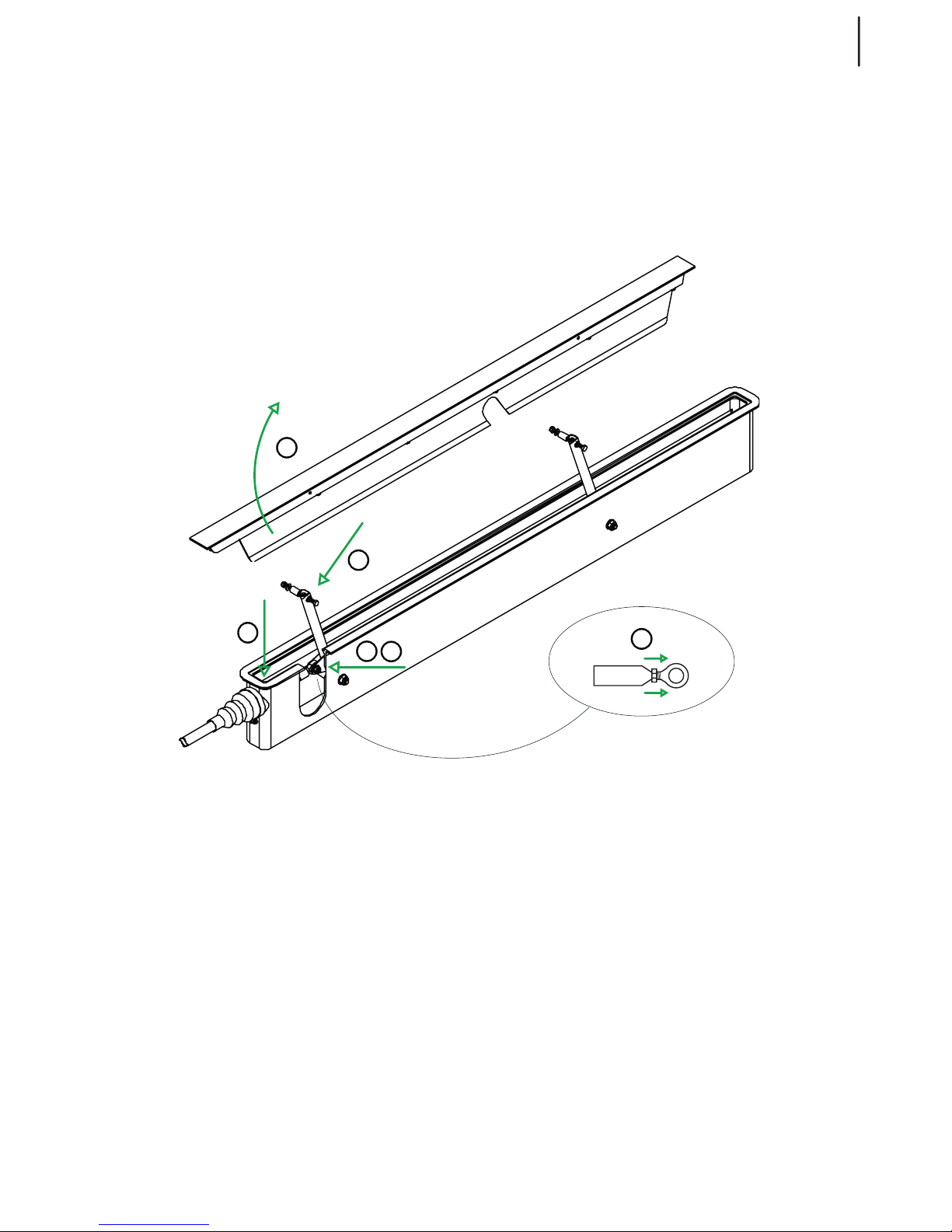

Schematic of wing (dis)assembly

Disassembling the wings

32

TAURUS ELECTRO

www.pipistrel.si

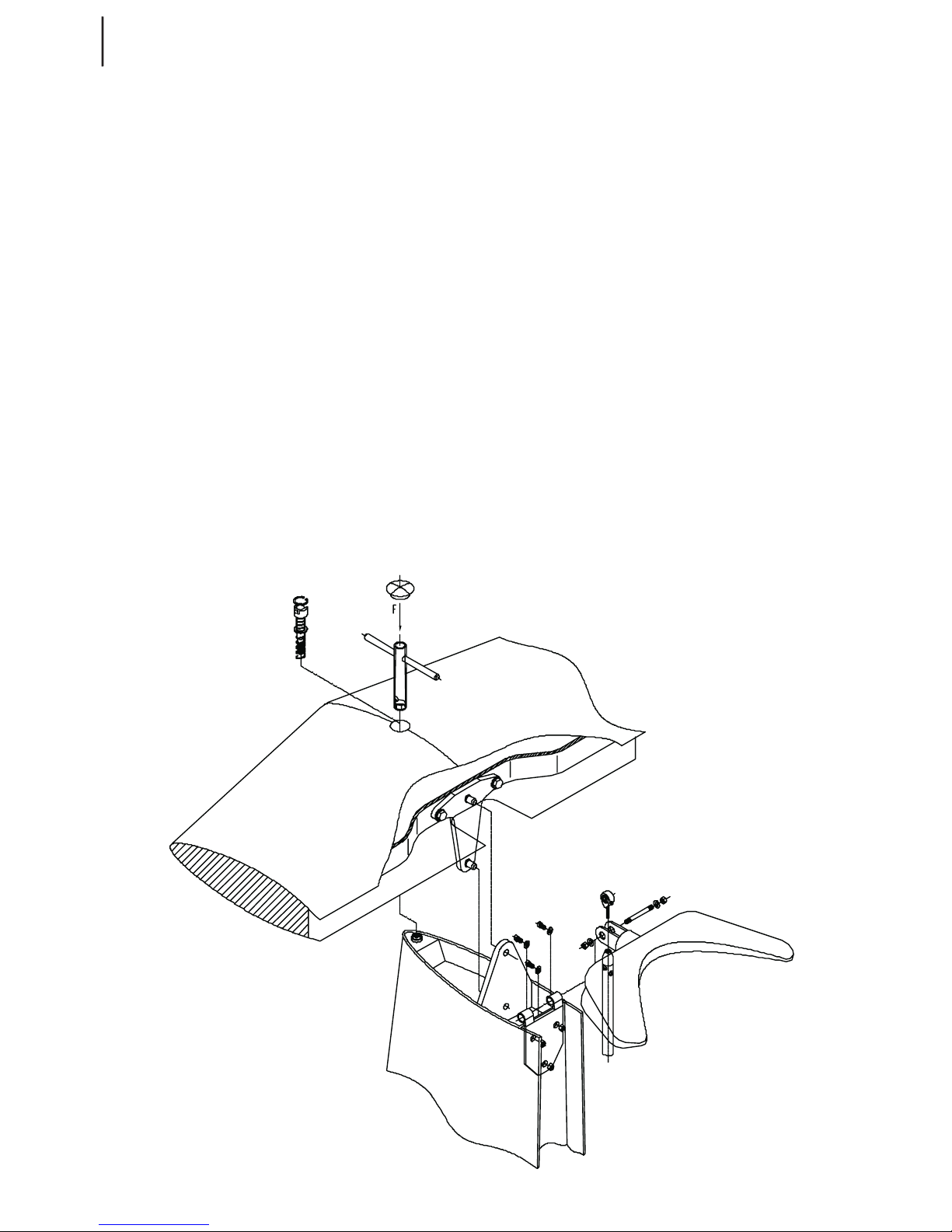

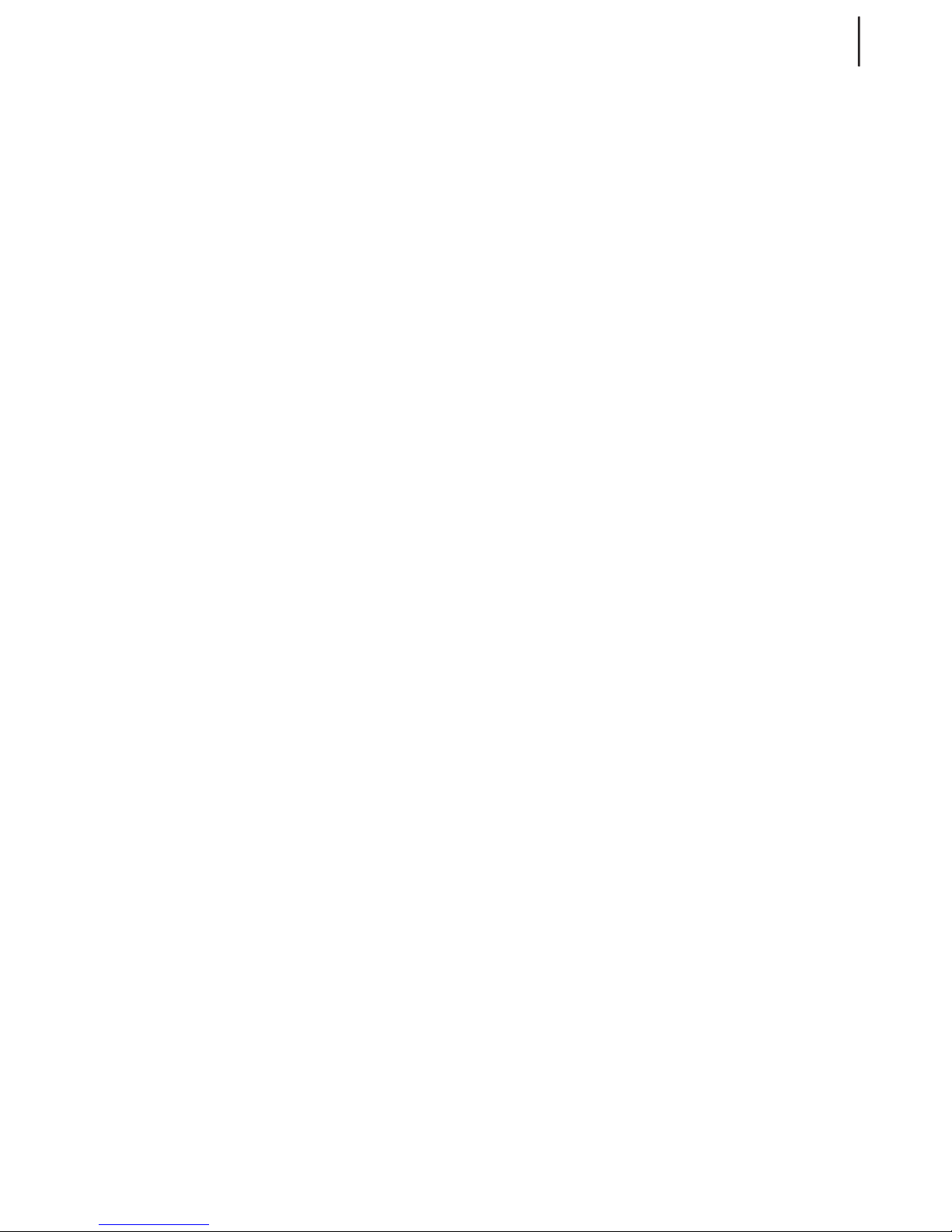

Set the trim handle to full forward position and remove the safety sticker covering the hole on top of

the horizontal stabilizer and the tape covering the gab between horizontal and vertical tail surfaces.

Now use the enclosed “T” key to push the safety pin screw down while spinning it counter-clockwise

until it is completely loose. To detach the horizontal tail unit push it forward using firm palm strokes

until the unit pops out.

When detached, always place the horizontal tail unit onto a soft surface to prevent damage.

Fitting the horizontal tail surfaces

Horizontal stabilizer and elevator MUST be united during the following procedure. To fit the horizontal tail surfaces first set the trim handle inside the cockpit to full forward position. Make sure the pins,

their holes and bushings have been cleaned and greased!

Lift the joint stabilizer and elevator and slide them into position by pushing them backwards. Now

use the enclosed “T” key to push the security screw down while spinning it clockwise until the screw

is completely tightened. Pull the “T” key out and make sure the safety pin holds the head of the

screw, so that eventual unscrewing will not occur.

At the end tape the gap between horizontal and vertical tail surfaces and cover the hole on top of

the vertical stabilizer with a sticker. Check control deflections for smooth, unobstructed movement.

Detaching the horizontal tail surfaces

Schematic of horizontal tail surfaces (dis)assembly

33

TAURUS ELECTRO

www.pipistrel.si

Bring the rudder close to fuselage and fit it first onto the top and then to the bottom hinge.

The rudder must then be fully deflected to one side to provide access to the rudder bolts. Use a selfsecuring, pre-glued M6 nut together with a washer and gently screw them onto the bolt using size

10 spanner. To reach the other rudder bolt deflect the rudder to the opposite direction and repeat

the up-stated procedure.

With both nuts tightened check full rudder deflections for smooth, unobstructed movement.

Detaching the rudder

Deflect the rudder to one side fully and unscrew the nut of the bolt with which the rudder is attached to the bottom hinge. This is the bolt located in-between the central bolt (axis of rotation) and

the bolt holding the metal ropes. DO NOT touch these two bolts - unscrew the nut of the middle bolt

ONLY. Now deflect the rudder to the opposite direction and repeat the up-stated procedure.

After both bolts have been unscrewed, lift the rudder and detach it first from the bottom, then from

the top hinge.

Schematic of rudder (dis)assembly

Attaching the rudder

34

TAURUS ELECTRO

www.pipistrel.si

Daily check-up

The daily check-up matches the preflight check-up.

Preflight check-up

WARNING! EVERY SINGLE CHECKUP MENTIONED IN THIS CHAPTER MUST BE PER

FORMED PRIOR TO EVERY FLIGHT, REGARDLESS OF WHEN THE PREVIOUS FLIGHT TOOK PLACE!

THE PERSON RESPONSIBLE FOR THE PREFLIGHT CHECKUP IS THE PILOT FROM

WHOM IT IS REQUIRED TO PERFORM THE CHECKUP IN THE UTMOST THOROUGH

AND PRECISE MANNER.

PROVIDED THE STATUS OF ANY OF THE PARTS AND/OR OPERATIONS DOES NOT COMPLY WITH

CONDITIONS STATED IN THIS CHAPTER, THE DAMAGE MUST BE REPAIRED PRIOR TO MOTOR

STARTUP. DISOBEYING THIS INSTRUCTIONS MAY RESULT IN SERIOUS FURTHER DAMAGE TO

THE PLANE AND CREW, INCLUDING INJURY AND LOSS OF LIFE!

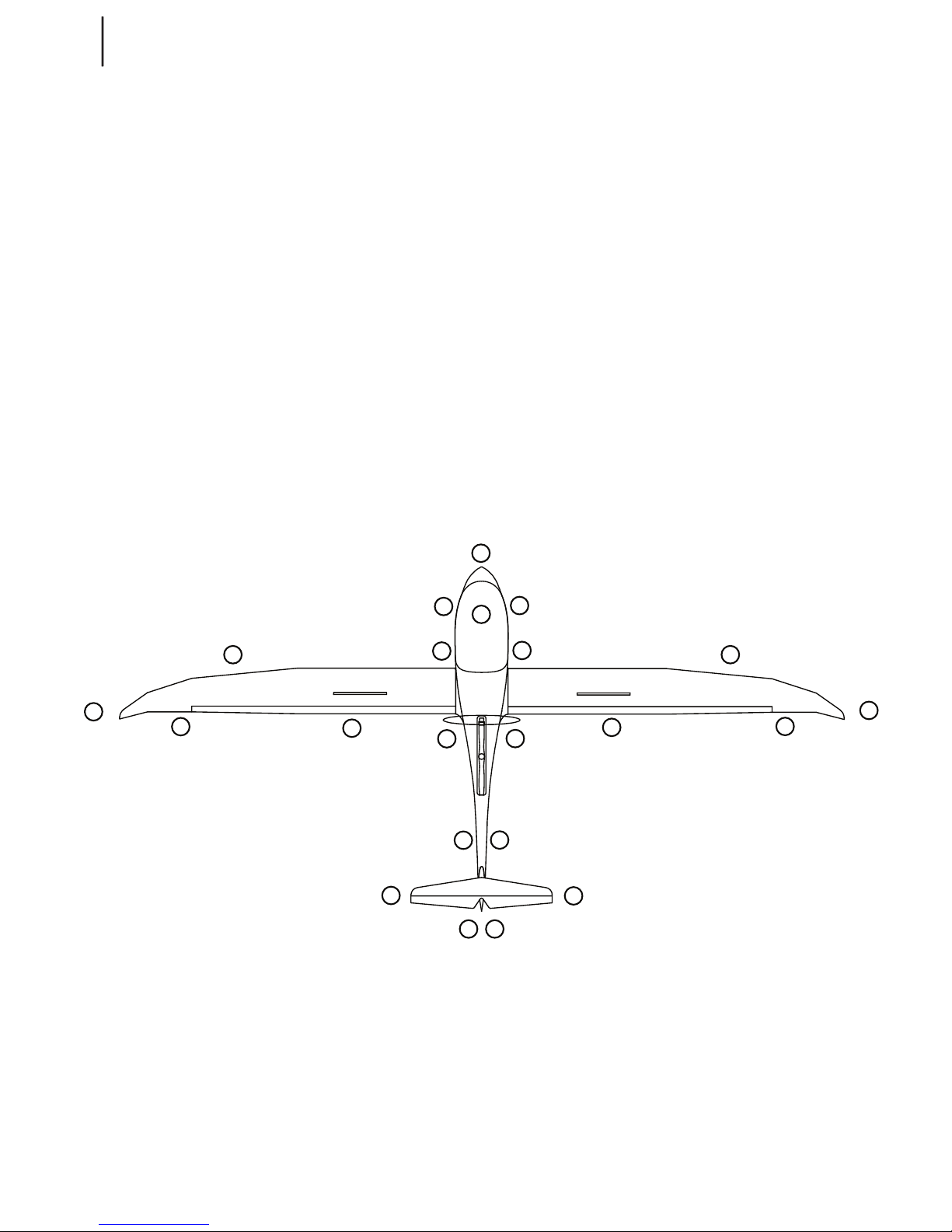

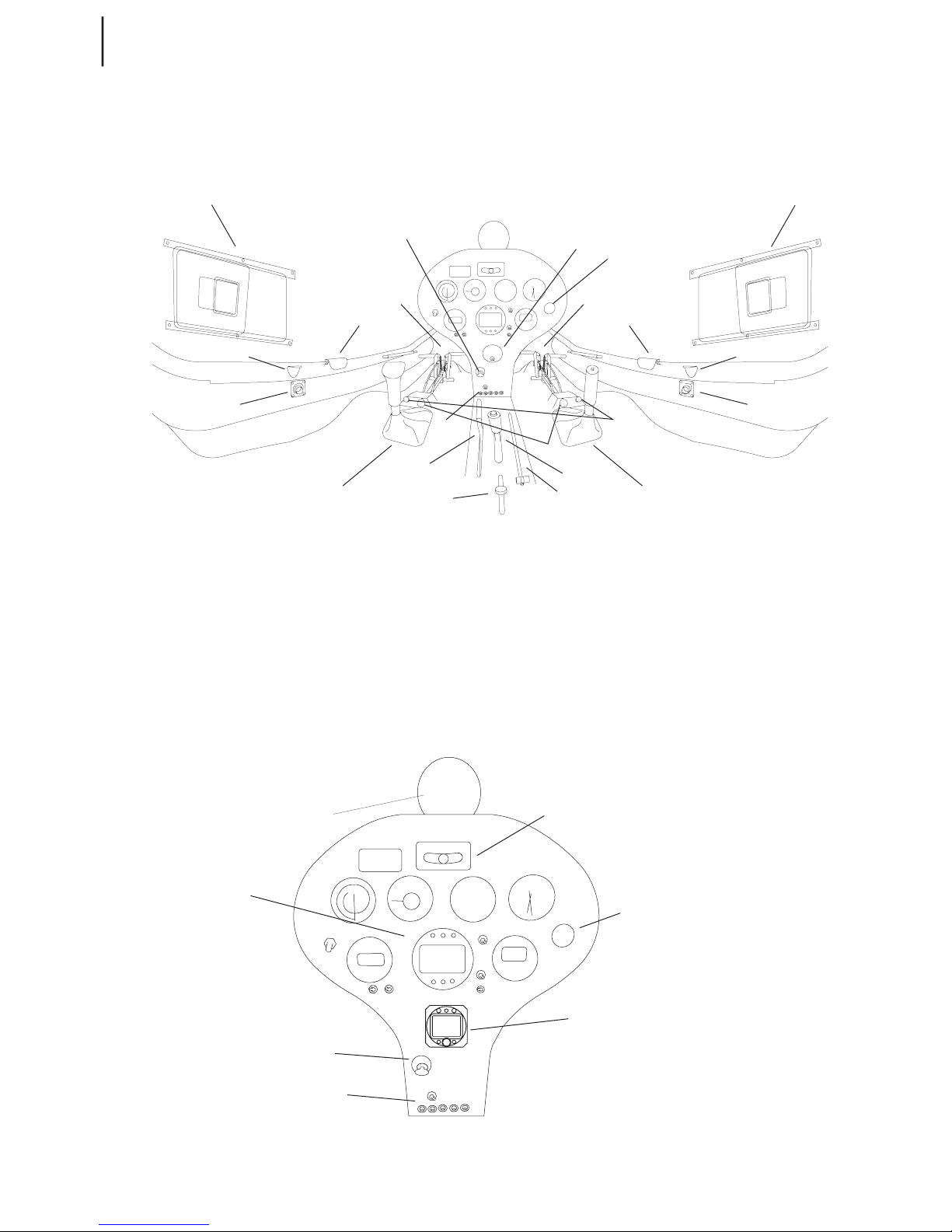

Schematic of preflight check-up

12

1

2

3

4

5

6

7

8

9

10

11

13

14

15

16

17

18

19

20

21

22

1 Glass cannopy 8 Right wing - trailing edge 15 Hor. tail surfaces (left)

2 LH flank 9 Right airbrake 16 Fuselage, continued (left)

3 Nose tip 10 Motor, propeller (RH side) 17 Motor, propeller (LH side)

4 RH flank 11 Fuselage, continued (right) 18 Left spoiler

5 Undercarriage, RH wheel 12 Hor. tail surfaces (right) 19 Left wing - trailing edge

6 Right wing - leading edge 13 Vert. tail surfaces (right) 20 Left wingtip

7 Right wingtip 14 Vert. tail surfaces (left) 21 Left wing - leading edge

22 Undercarriage, LH wheel

35

TAURUS ELECTRO

www.pipistrel.si

Glass cannopy

Surface condition: clear, no cracks, no wavy patterns, impact spots

Attachment fork: perfect closure, no deformations

De-fogging frame holes: clear for adequate airflow

Locking levers: check for correct and smooth operation, locking pin and bushing clean and greased

Water ballast reservoir: inserted and filled-up as required

LH flank

Surface condition: clear, no cracks, no wavy patterns, impact spots

Fuselage - cannopy frame joint: equal spacing, perfect closure

Nose tip

Pitot tube: firmly attached, no mechanical damage or bendings. Remove protection cover and make

sure it is not blocked or full of water.

Ventilation ring: firmly attached

Fuselage - cannopy frame joint: equal spacing, perfect closure

RH flank

Surface condition: clear, no cracks, no wavy patterns, impact spots

Fuselage - cannopy frame joint: equal spacing, perfect closure

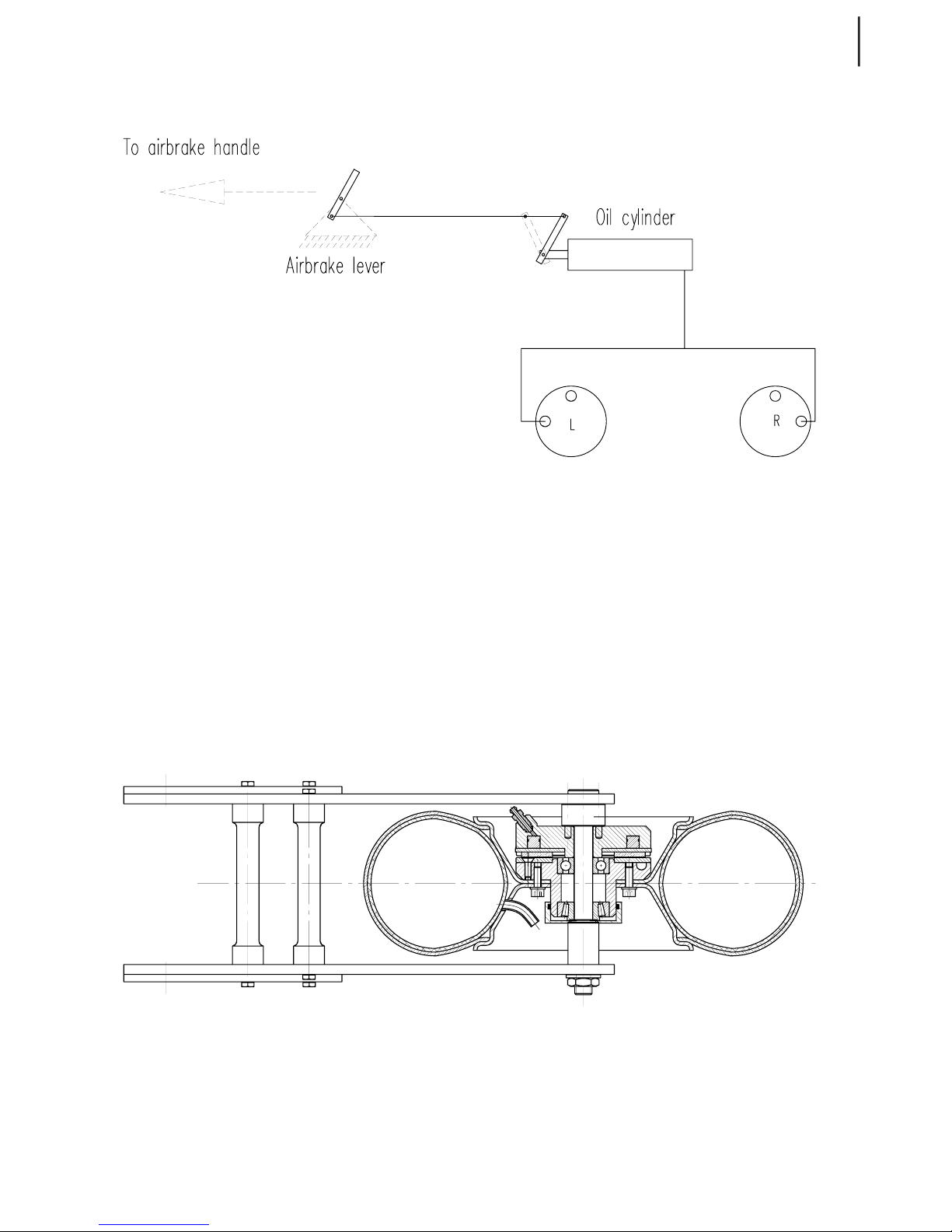

Undercarriage, wheels

Bolts: fastened

Wheel: no mechanical damage (e.g. cracks), clean

Wheel axis and nut: fastened

Oil line (hydraulic brakes): no mechanical damage and/or leakage

Tyre: no cracks, adequate pressure

Wheel fairing: undamaged, firmly attached, clean (e.g. no mud or grass on the inside)

Wheel-bay doors: undamaged, check rubber-rope tension

Retraction mechanism: no visible abnormalities, adequate grease on sliding parts, clean of larger

particles e.g. soil, dirt.

Gear bay: free of larger particles, soil, dirt etc.

Under-belly drain holes: make sure they are not blocked and clean accordingly.

Wings’ leading edge

Surface condition: pristine, no cracks, impact spots, no paint and/or edge separations

Wing drain holes: make sure they are not blocked and clean accordingly.

Wingtip

Surface condition: pristine, no cracks, impact spots or bumps, no paint separations

1

2

3

4

5

6

22

21

7

20

36

TAURUS ELECTRO

www.pipistrel.si

Wings’ trailing edge

Surface condition: pristine, no cracks, impact spots, no paint and/or edge separations

Sealing tape between wing and aileron: undamaged and in position

Aileron: pristine surface, no cracks and/or impact spots, no paint abnormalities and edge separa-

tions, no vertical or horizontal free play, smooth and unobstructed deflections

Airbrakes

Airbrake: firm, smooth, equal and unobstructed extension, tightly fitted when retracted, springs stiff

and intact.

Motor, propeller, rescue parachute hood

Check for smooth propeller rotation, check for motor axle free play. No free play is permitted.

Check for any water or condensation inside the motor compartment, remove it accordingly.

Check battery boxes, connectors (all connected firmly) and exposed wiring.

Check the battery boxes behind the cockpit as well.

Propeller must be clean and undamaged.

Parachute rescue system cover: intact and firmly in place. No deformations whatsoever.

Fuselage, continued

Under-belly drain holes: make sure they are not blocked and clean accordingly

Vertical fin bottom part: no cracks, impact spots or paint separations along main chord

Surface condition: pristine, no cracks, impact spots or bumps, no paint and/or edge separations

Horizontal tail surfaces

Surface condition: pristine, no cracks, impact spots or bumps, no paint and/or edge separations

Hinges: no free play in any direction

Central securing screw on top or the horizontal stabilizer: fastened and secured

Self-adhesive tape covering the gap between horizontal and vertical tail surfaces: in position

Elevator: smooth and unobstructed up-down movement, no side-to-side free play

Vertical tail surfaces

Vertical fin bottom part: no cracks, impact spots or paint separations along main chord

Surface condition: pristine, no cracks, impact spots or bumps, no paint separations

Hinges: no free play in any direction

Rudder metal rope endings: intact, bolts in position

Tail wheel

Shock absorbing rubber: no cracks, firm and clean, check for no deformations

Tire: no cracks, adequate pressure

Wheel fork, fork base and bolt: nut tightened, no abnormalities, bearing in position, bolt attached,

straight and fastened

Lift the tail high enough so that the tail wheel is not touching the ground and make sure the

wheel side-to-side deflections are smooth and unobstructed

CAUTION! Preflight check-up should be performed following stations 1 through 22!

8

19

9

18

10

17

11

16

12

15

13

14

37

TAURUS ELECTRO

www.pipistrel.si

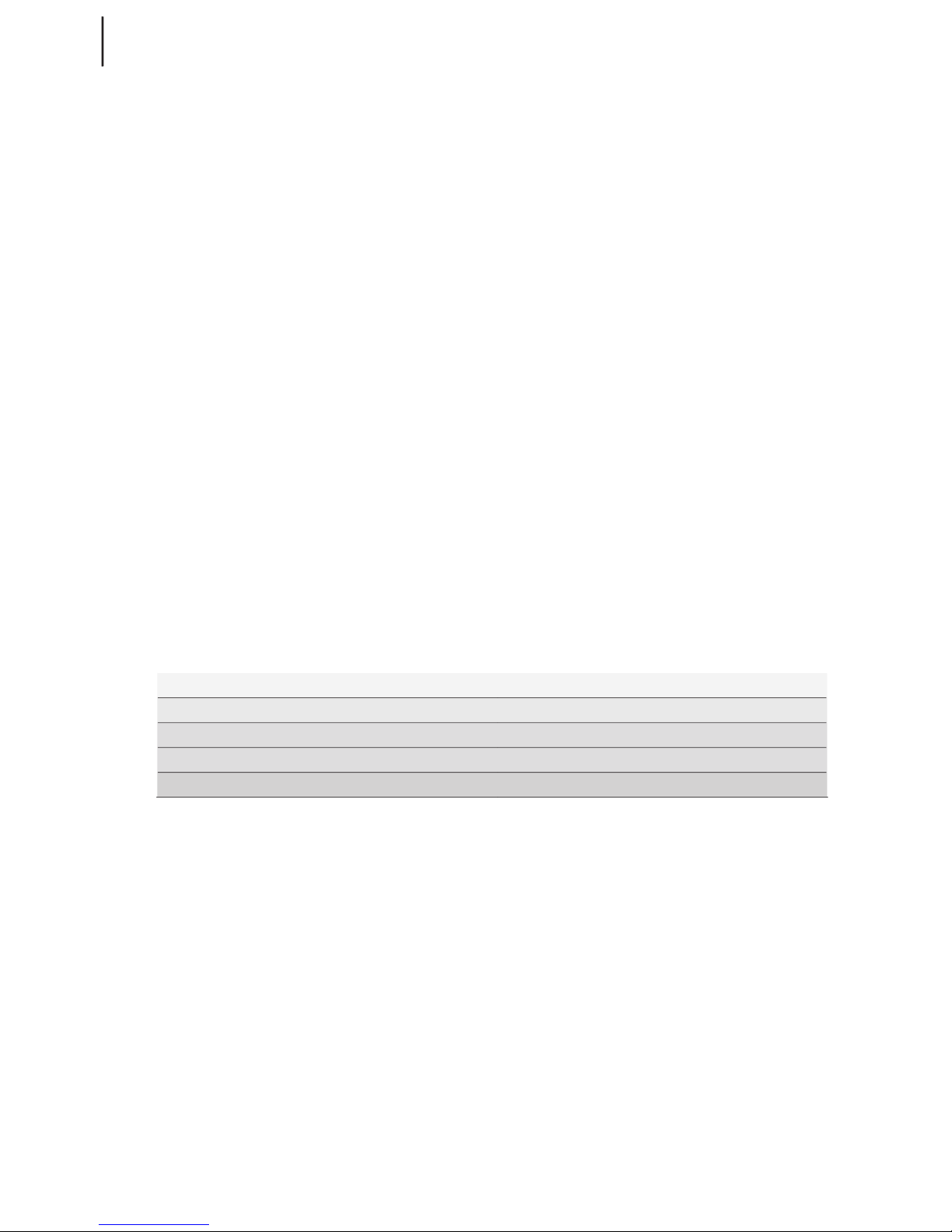

In-cockpit preflight check-up

Instrument panel and instruments: checked, Fuses: pushed in position

Master switch OFF (key in full left position): no control lights and/or electronic instrument activity

Master switch ON (key in full right position): control lights and electronic instrument active

Make sure you have set all instruments to correct initial setting.

Water ballast reservoir (front-cabin): check for water quantity and make sure it is appropriate for

your planned flight. Remove or ad water as necessary to keep the c.g. within limits.

WARNING! CHECK THE WATER BALANCE RESERVOIR IN FRONTCABIN AND VERIFY

CREW’S WEIGHT BEFORE EVERY FLIGHT AS IT MAY INFLUENCE THE CENTRE OF GRAVITY OF

AIRCRAFT TO THE POINT WHERE IT IS NO LONGER CONTROLLABLE!

Main wing spars and connectors: no visible abnormalities of metal parts, spars, pins and bolts; all

bolts and nuts in position and tightened

Electrical cables: correctly connected and in position

Seat belts: undamaged, verify unobstructed harness opening; fastening points intact

Glass cannopy: perfect closing at all points, smooth opening, hinges firmly attached; glass immacu-

lately clean with no cracks.

Flap handle: button spring firm, locking mechanism working properly, smooth movement along full

deflections, no free play or visible damage.

Spoilers (Airbrakes) handle: full forward and locked

Ventilation lever: as required

Radio wiring: test the switches, check connectors and headset, perform radio check

Battery: firmly in position, fittings clean with wires connected

Cockpit mirror: in position and adjusted

Emergency parachute release handle: safety pin removed. Make sure unobstructed access is

provided.

Adjust the rudder pedals according to your required legroom. Sit inside the cockpit and release the

pressure o the pedals. Pull the black knob in front of the control stick to bring the pedals closer to

you. To move the pedals further away, rst release the pressure of the pedals, then pull on the knob

slightly (this will release the lock in the mechanism). Now push the pedals forward using with your

feet, while keeping the black adjusment knob in your hand.

38

TAURUS ELECTRO

www.pipistrel.si

Normal procedures

and recommended speeds

To enter the cabin first unlock the cannopy frame and lift the glass canopy all the way by lifting the

lock levers or lifting pads on each side of the cabin. Sit onto the cabin’s edge and support your body

by placing hands onto this same cabin edge and middle cockpit console. Drag yourself into the seat

lifting first the inner and then the outer leg over the control stick. Immediately after having sat into

the seat, check rudder pedals’ position to suit your size and needs. Bring the pedals closer or further

away by pulling the handle behing the control stick and slide them to the desired position.

To lower the canopy gently hold and pull the metal levers on the side of the cocpit. To lock the cannopy once closed, push the levers forward so that they become parallel to the surface of the glass

frame. Verify that the cannopy is closed by applying upward-pressuse to the cannopy.

Fasten the safety harnesses according to your size.

WARNING! THE SAFETY HARNESS MUST HOLD YOU IN YOUR SEAT SECURELY. THIS IS ES

PECIALLY IMPORTANT WHEN FLYING IN ROUGH AIR, AS OTHERWISE YOU MAY BUMP INTO THE

CANOPY OVERHEAD.

Motor start-up

Before motor start-up

CAUTION! TO ENSURE PROPER AND SAFE USE OF AIRCRAFT IT IS ESSENTIAL FOR ONE TO

FAMILIARISE WITH MOTOR’S LIMITATIONS AND MOTOR MANUFACTURER’S SAFETY WARN

INGS. BEFORE MOTOR STARTUP MAKE SURE THE AREA AROUND THE PROPELLER IS CLEAR.

YOU CAN ALSO CHECK THIS IN THE INSTRUMENT PANEL MIRROR. IT IS RECOMMENDED TO

STARTUP THE MOTOR WITH AIRCRAFT’S NOSE POINTING AGAINST THE WIND.

Make sure the battery charge status will suffice for the planned flight duration.

Make sure the pitot tube is not covered and rescue parachute safety pin removed.

Engage wheel brakes. Hold the control stick in full aft position always when on the ground.

CAUTION! SHOULD YOU NOT BE HOLDING THE CONTROL STICK IN FULL AFT POSITION,

YOU MAY TIP THE NOSE OF THE AIRCRAFT AS THE CENTRE OF PROPULSION IS HIGH ABOVE

THE FUSELAGE.

Motor start

Make sure the master switch is in ON position (key full right).

Extend the propulsion unit (master-on-board-computer: right switch to UP position).

After the propustion unit is extended (indication green), set system enable ON (left switch ON).

The motor is now engaged and the propeller should be stationary in its vertical position. Verify this

in the miror.

CAUTION! THE RPM KNOB IS SENSITIVE, BE CAREFULL WHEN ROTATING IT.

Motor warm-up procedure

The motor does not require any warm-up procedure.

39

TAURUS ELECTRO

www.pipistrel.si

Taxi

Taxing technique does not differ from other taildragging aircrafts. Prior to taxiing it is essential to

check wheel brakes for proper braking action.

CAUTION! TAXI AT AT MOST 10KM/H / 5 KTS, AS THERE ARE NO DIFFERENTIAL BRAKES

AVAILABLE. STEERING IS PROVIDED BY A STEARABLE TAIL WHEEL THROUGH RUDDER INPUT.

Holding point

Make sure the temperatures, particulary battery system temperature is within operational limits.

Make sure the safety harnesses are fastened and canopy closed and secured at both sides.

Set flaps to T position. Power idle.

CAUTION! SHOULD THE MOTOR START TO OVERHEAT BECAUSE OF LONG TAXI AND HOLD

ING, SHUT DOWN THE MOTOR AND WAIT FOR THE MOTOR TEMPERATURES DROP TO REASON

ABLE VALUES. IF POSSIBLE, POINT THE AIRCRAFT’S NOSE TOWARDS THE WIND. THIS WILL PRO

VIDE COOLING MEANS WITH AIRFLOW TO COOL DOWN THE MOTOR FASTER.

Take-off and initial climb

Before lining-up verify the following:

Spoilers: retracted and secured

Battery charge status and health: sufficient and OK

Safety belts: fastened

Cabin: closed securely

Trim handle: in neutral position or slightly backward

Flap handle: T position

Runway:

clear

Now pull the stick to full aft position, line up and add full power.

Verify motor for sufficient RPM at full power.

CAUTION! KEEP ADDING POWER GRADUALLY.

WARNING! SHOULD MOTOR RPM NOT REACH SUFFICIENT RPM WHEN AT FULL THROT

TLE, ABORT TAKEOFF IMMEDIATELY, COME TO A STANDSTILL AND VERIFY THE PROPUSTION

UNIT.

Start the takeoff roll pulling the elevator full aft, then slowly ease on the sitck the lift the tail wheel of

the ground as you accelerate. Reaching Vr (between 70 -75 km/h; 38-42 kts), pull on the stick to get

the aircraft airborne.

CAUTION! CROSSWIND MAX 28 KM/H 15 KTS TAKEOFF SHOULD BE PERFORMED WITH

AILERONS DEFLECTED OPPOSITE THE DIRECTION OF THE WIND. SPECIAL ATTENTION SHOULD

BE PAID TO MAINTAINING RUNWAY HEADING AND NOT LOWERING THE WINGTIP TOO MUCH!

40

TAURUS ELECTRO

www.pipistrel.si

Climb

When airborne, accelerate at full power. As you reach 90 km/h (52kts) at a height above 50 meters

(165 ft), retract flaps to neutral position. and retract the landing gear. Reduce power to 30 kW.

WARNING! ALWAYS MOVE THE LANDING GEAR COCKPIT HANDLE STRONGLY, WITHOUT

HESITATION AND WITH ONE SINGLE CONTINUOUS MOVEMENT TOWARDS THE DESIRED

POSITION.

Adjust the trim to neutralise the stick force if necessary.

Remember to keep the temperatures and RPM within operational limits during this manoeuvre.

WARNING! FULL POWER CAN BE UTILISED FOR A MAXIMUM 1 MINUTE. AFTER THIS, RE

DUCE POWER TO 30 KW AND VERIFY THIS WITH ESYSMAN.

Level flight

Taurus Electro is not desinged to be a cruising aircraft, however you may be able to maintain level

cruise flight should this be required. To cover distances, saw-tooth flight with interchanging climbs

and glides are an established common practice. When saw-toothing, plan your flight well and always

restart the motor over a landable terrain.

Flights in rough atmosphere

Should you experience turbulence, reduce airspeed and continue flying with flaps set to neutral

position.

CAUTION! IN ROUGH AIR EXTEND AIRBRAKES UNPOWERED FLIGHT FOR SHORT TIME IF

NECESSARY TO KEEP AIRSPEED BELOW VRA.

Descent and final approach

Landing the Taurus Electro with the motor out should be strongly avoided due stress on the propeller mast. It will decrease the life-time of critical component as well. Therefore it is recommended

that you conduct the approach and landing like a glider - with the propulsion unit in its retracted

(DOWN) position.

On downwind (150-200 m, 500-700 ft), maintain a speed of 100 km/h (55 kts) and lower and secure

the landing gear. Before turning base, set the flaps to T stage, and reduce your speed to 90-95 km/h

(48-51 kts). Set trim to neutralise stick force if necessary.

CAUTION! WHEN DESCENDING, MAKE SURE THE PROPULSION UNIT IS RETRACTED.

CAUTION! WITH FLAPS IN L POSITION ONLY HALF WAY AILERON DEFLECTIONS ARE

PERMITTED.

On final, set flaps to L position only if the runway is very short and a steep angle of arrival is

required. Align with the runway and extend airbrakes while maintaining an airspeed of 90-95 km/h

(48-51 kts). Use airbrakes to control your approach glide path.

CAUTION! CROSSWIND LANDINGS REQUIRE HIGHER FINAL APPROACH SPEEDS TO ENSURE

AIRCRAFT’S SAFE MANOEUVRABILITY.

41

TAURUS ELECTRO

www.pipistrel.si

Roundout and touchdown

CAUTION! See chapter “Performance” for landing performance.

Final roundout (flare) and touchdown should be performed at following airspeeds:

Calm air, aircraft at MTOM 75 km/h (40 kts) IAS

Rough air, aircraft at MTOM (incl. strong crosswinds up to 28 km/h

(15 kts)) 78 km/h (42 kts) IAS

CAUTION! LAND THE AIRCRAFT IN SUCH A MANNER THAT ALL THREE WHEELS TOUCH THE

GROUND AT EXACTLY THE SAME TIME. WHEN TOUCHING DOWN, RUDDER MUST NOT BE DE

FLECTED IN ANY DIRECTION RUDDER PEDALS CENTRED.

When on ground, start braking action holding the control stick in full back position. Stear the aircraft

by using rudder inputs. Provided the runway length is sufficient, come to a complete standstill without engaging the brakes to ensure their long life.

WARNING! AFTER TOUCHDOWN, DO NOT RETRACT SPOILERS IMMEDIATELY, AS THIS

CAUSES SUDDEN LIFT INCREASE AND THE AIRCRAFT MAY REBOUND OFF THE GROUND.

SHOULD THIS OCCUR, HOLD THE ELEVATOR STEADY; UNDER NO CIRCUMSTANCES ATTEMPT

TO FOLLOW AIRCRAFT’S MOVEMENT WITH ELEVATOR DEFLECTIONS, SINCE TAURUS ELECTRO

TENDS TO ATTENUATE REBOUNDING BY ITSELF. HOWEVER, IT IS IMPORTANT TO MAINTAIN

RUNWAY HEADING USING THE RUDDER AT ALL TIMES. TO PREVENT THIS, RETRACT SPOILERS

ONLY AFTER THE AIRCRAFT HAS COME TO A COMPLETE STANDSTILL.

WARNING! TOUCH AND GOES ARE NOT POSSIBLE!

Having reached a complete standstill, extend the motor (Motor start-up) and taxi (Taxi) off the runway.

Crosswind approach and roundout

CAUTION! CROSSWINDS PROLONG LANDING RUNWAY LENGTH SEE CHAPTER

“PERFORMANCE”.

Performing a crosswind landing, the wing-low method should be used. When using the wing-low

method it is necessary to gradually increase the deflection of the rudder and aileron to maintain the

proper amount of drift correction.

WARNING! IF BY CHANCE THE CRAB METHOD OF DRIFT CORRECTION HAS BEEN USED

THROUGHOUT THE FINAL APPROACH AND ROUNDOUT, THE CRAB MUST BE REMOVED THE

INSTANT BEFORE TOUCHDOWN, BY APPLYING RUDDER TO ALIGN THE AIRCRAFT’S LONGITU

DINAL AXIS WITH ITS DIRECTION OF MOVEMENT.

42

TAURUS ELECTRO

www.pipistrel.si

Parking

Come to a complete standstill by engaging brakes. Set the system enable switch OFF, then master

switch OFF. Unlock airbrakes (handle lifted slightly) and insert paracute rescue system handle’s safety

pin. Open the cannopy, unfasten safety belts and exit the cockpit. Close and lock the cannopy after

you have left the aircraft. When closing the canopy, make sure that the lock-handles are in OPEN position not to damage the locking pins. Also, block the wheels if parking on a slope.

CAUTION! WHENEVER YOU LEAVE THE AIRCRAFT MAKE SURE THE CANNOPY IS CLOSED

AND LOCKED. SHOULD YOU FORGET TO DO THIS THE CANNOPY FRAME MAY NOT FIT THE FU

SELAGE FRAME ANY MORE WHEN YOU RETURN, SINCE THE STRETCH COEFFICIENT OF FIBRE

GLASS AND PLEXIGLASS ARE SIGNIFICANTLY DIFFERENT. ALSO, COVER THE CANNOPY WITH A

FABRIC COVER, TO PREVENT THE CABIN FROM OVERHEATING PROTECTOIN TO INSTRUMENTS

AND SYSTEMS.

Retracting & Extending propulsion unit in flight

This procedure applies only for retracting/extending the propulsion unit as an intentional event, be

aware you may lose up to 100m (300ft) of altitude during this procedure.

If under power, set rpm to minimum (rotate knob left) and select engine DOWN. Reduce speed to 80

km/h (43 kts) and set flaps to 1st stage. Continue decellerating towards 70 km/h (40 kts).

The system will complete the retraction/extension by itself. Once retracted (confirmed by green

LED status light), select System enable OFF. For more details please consult the ESYS-MAN section in

chapter Aircraft and Systems on board in this manual.

To restart the motor in-flight follow the same procedure as for Motor startup (page 34) while maintaing level flight at 80 km/h (43 kts) with flaps in 1st stage.

WARNING! ALWAYS WAIT BEFORE THE SYSTEM CONFIRMED IN FULL EXTENDED OR FULL

RETRACTED POSITION BEFORE OPERATING THE MASTER SWITCH OR THE SYSTEM ENABLE

SWITCH! THE PROPELLER BRAKE IS ELECTRIC AND DOES NOT WORK WITHOUT POWER IN

FLIGHT AND WITH THE SYSTEM IN THE MIDDLE OF RETRACTION, CUTTING THE POWER WILL

RESULT IN PROPELLER DAMAGE!

WARNING! BEFORE YOU ENABLE THE MOTOR, MAKE SURE THE PROPELLER IS IN

THE FULLY EXTENDED AND UPRIGHT POSITION GREEN LIGHT INDICATION!

Should the batteries cool down during unpowered flight, use up to 1000 RPM until the battery temperature recovers to operating range.

CAUTION! DO NOT ADD FULL POWER WHILE THE BATTERIES ARE STILL COLD. KEEP FLYING

AT 80 KM/H 43 KTS WITH FLAPS IN L STAGE AND NOT MORE THAN 1000 RPM TO WARMUP

THE BATTERIES FIRST IF COLDER THAN 5°C.

NOTE: IT IS NOT REQUIRED TO COOL DOWN THE SYSTEM BEFORE RETRACTION.

43

TAURUS ELECTRO

www.pipistrel.si

Introduction

Airspeed indicator

calibration

Take-off performance

Climb performance

Cruise

Descent

Landing performance

Maneuver & gust

envelope

Speed polar

Additional technical data

Performance

TAURUS ELECTRO

www.pipistrel.si

Introduction

This chapter provides information on aircraft’s airspeed calibration, stall speeds and general performance. All data published was obtained from test flight analysis. Test pilots were instructed to

control the plane simulating average pilot’s flying skills.

Airspeed indicator calibration (IAS to CAS)

Pitot tube’s ingenious mounting and construction makes IAS to CAS correction values insignificant.

Therefore pilots should regard IAS to be same as CAS. IAS = CAS.

Stall speeds

Stall speeds at MTOM are as follows:

flaps in negative position; -5° (up): 75 km/h (40.5 kts)

flaps in neutral position; 0° (neutral): 71 km/h (38.3 kts)

flaps in 1st position; +5° (down): 68 km/h (36.7 kts)

flaps in T position; +9° (down): 65 km/h (35.0 kts)

flaps in L position: +18° (down): 63 km/h (34,0 kts)

Take-off performance

All data published in this section was obtained under following conditions:

aircraft at MTOM

runway elevation: 100 meters (330 feet)

wind: calm

runway: dry grass runway with low-cut grass, no significant up- or downslope

ICAO standard atmosphere

Taurus Electro

takeoff runway length at MTOM

160 m (530 ft)

takeoff runway length (over 15m (50 ft) obstacle) 245 m (800 ft)

Note: in order to meet the data for takeoff runway lenght over 15 m obstacle maintain Vx

after take-off.

Takeoff runway length may vary depending on the wind, temperature, elevation and

wing & propeller surface condition.

45

TAURUS ELECTRO

www.pipistrel.si

Effect of elevation

The table below provides data about the effect of elevation on takeoff runway length.

elevation (m) 0 500 1000 1500

atmosph. pressure (hPa)

1012 954 898 845

outside temperature (°C)

15.0 11.7 8.5 5.2

Takeoff runway length [m

(ft)]

Electro

160 (530) 185 (610) 232 (765) 275 (910)

WARNING: If the outside temperature is higher than the standard value it is mandatory to

consider the takeoff runway length prolongs as follows:

L = 1,10 • (Lh + Lt - L0).

Abbreviations are as follows:

Lh = takeoff runway length at present elevation,

Lt = takeoff runway length at sea level at same atmospheric conditions,

L0 = takeoff runway length at 15°C.

The graph below indicates how takeoff runway length changes as altitude increases.

Effect of the wind

Wind (head, cross or downwind - also called tailwind) affects aircraft’s ground speed (GS).

Headwind on takeoff and landing causes the Takeoff and Landing runway length to shorten as the

GS is smaller during these two flight stages. The opposite stands for tailwind on takeoff and landing

as tailwind prolongs Takeoff and Landing runway length significantly.

The data on the next page was obtained through testing and therefore serve as informative values

only.

Headwind shortens Takeoff and Landing runway length by 8 meters (25 feet) with every 5 km/h

(3 kts) of wind increase (e.g. provided there is a 10 km/h (6 kts) headwind on takeoff and landing, dis-

tances will be approximately 16 meters (50 feet) shorter then ones published in the manual).

150 500

200 650

250 820

takeoff runway length

elevation (m)

elevation (ft)

650

1300

2000

2600

3200

4000

4600

m f

t

0

200 400

600 800 1000 1200

1400

46

TAURUS ELECTRO

www.pipistrel.si

Tailwind prolongs Takeoff and Landing runway length by 18-20 meters (60-65 feet) with every 5

km/h (3kts) wind increase (e.g. provided there is a 10 km/h (6kts) tailwind on takeoff and landing, distances will be approximately 36-40 meters (120-130 feet) longer then ones published in the manual).

3x

WARNING! TAILWIND AFFECTS TAKEOFF AND LANDING PERFORMANCE BY MORE THAN

TWICE AS MUCH AS HEADWIND DOES.

The table below provides data about the effect of headwind (+) and tailwind (-) on takeoff runway

length.

windspeed (m/s) -3 -2 -1 0 2 4 6

windspeed (kts) -6 -4 -2 0 4 8 12

Takeoff runway length [m (ft)]

Electro

297 (975) 243 (800) 205 (670) 160 (520) 154 (505) 147 (480) 122 (400)

The graph below indicates how takeoff runway length changes when affected by wind.

Effect of outside temperature

The table below provides data about the effect of outside temperature on takeoff runway length.

temperature (°C) 13 20 25 30 35

Takeoff runway length [m (ft)]

Electro

180 (590) 197 (645) 215 (705) 237 (780) 255 (836)

50 160

150 500

200 650

100 330

250 820

m

ft

0

-4

0

4

8

12

16

-8

kts

takeoff runway length

m/s

-4 -2

0

2

4

6

8

47

TAURUS ELECTRO

www.pipistrel.si

The graph below shows how takeoff runway length changes when affected by temperature chances.

Climb performance

Taurus Electro

best climb speed Vy 100 km/h

(54 kts)

best climb rate at MTOM 2.9 m/s (580 fpm)

Effect of elevation

The table below provides data about the effect of elevation on climb rate at best climb speed Vy.

Taurus Electro

0 m (0 ft) 3.1 m/s (620 fpm)

500 m (1600 ft) 2.9 m/s (580 fpm)

1000 m (3300 ft) 2.7 m/s (540 fpm)

1500 m (5000 ft) 2.5 m/s (500 fpm)

The graph below indicates how climb rate changes as altitude increases.

outside temperature (°C)

5

10

15

20

25

30

35

0

50 160

150 500

200 650

100 330

250 820

m f

t

takeoff runway length

0

m/s fpm

650

1300

2000

2600

3300

4000

4600

m

ft

4 800

2 400

climb rate

200

400 600 800

1000

1200 1400

elevation

48

TAURUS ELECTRO

www.pipistrel.si

Descent

The rate of descent and glide path are adjusted using airbrakes (spoilers).

Typical sink rate, with flaps set to L position and spoilers fully extended, measures

4,5 m/s (900 fpm) at 90 km/h (48 kts) and 6,0 m/sec (1200 fpm) at 100 km/h (62 kts).

Taurus Electro

max. sink rate, spoilers extended, flaps at L and at flap speed limit

5.8 m/sec

(1160 fpm)

Landing performance

PRECISE DATA WILL BE PUBLISED AFTER DEDICATED TEST FLIGHTS! PRESENT DATA IS

SUBJECT TO CHANGE WITHOUT NOTICE!!!

Landing length will vary depending on the elevation, gross weight, touchdown velocity, wind direction and how aggressive the braking action is. In following conditions: aircraft at MTOM, airport

elevation 100 meters

(300 feet), wind calm; the landing length measures 110 meters (330 feet). Should

you be flying solo, the length shortens by another 10 meters (30 feet).

WARNING! RUNWAY PROPORTIONS MUST BE IN EXCESS OF 400 X 30 METERS (1300 X 100

FEET) WITH NO OBSTACLES IN A 4° RANGE OFF RUNWAY HEADING IN ORDER ENSURE SAFE

FLYING ACTIVITY. USE OF SHORTER STRIPS SHOULD BE CONSIDERED A MAJOR EXCEPTION AND

SHOULD ONLY BE ATTEMTED BY EXPERIENCED PILOTS AND AT OWN RISK.

Crosswind landing limitations

Maximum allowed crosswind speed for landing with flaps in L position as well as take-off with flaps

in T position is 28 km/h (15 kts).

Gliding performance

The glide is defined as unpowered straight and level flight at a speed providing best lift over

drag ratio or minimum sink rate.

Should the motor become inoperative in flight, as a result of either intended or unintended action,

and it cannot be restarted, react as follows:

establish straight and level flight at the speed providing best lift over drag ratio, if you desire

to overcome greatest distance at reach from initial altitude.

establish straight and level flight at speed providing minimum sink rate, if you desire do stay

airborne the longest. This may come in handy in case you are forced to give way to other aircraft or if

you simply need time to determine the most appropriate site to land.

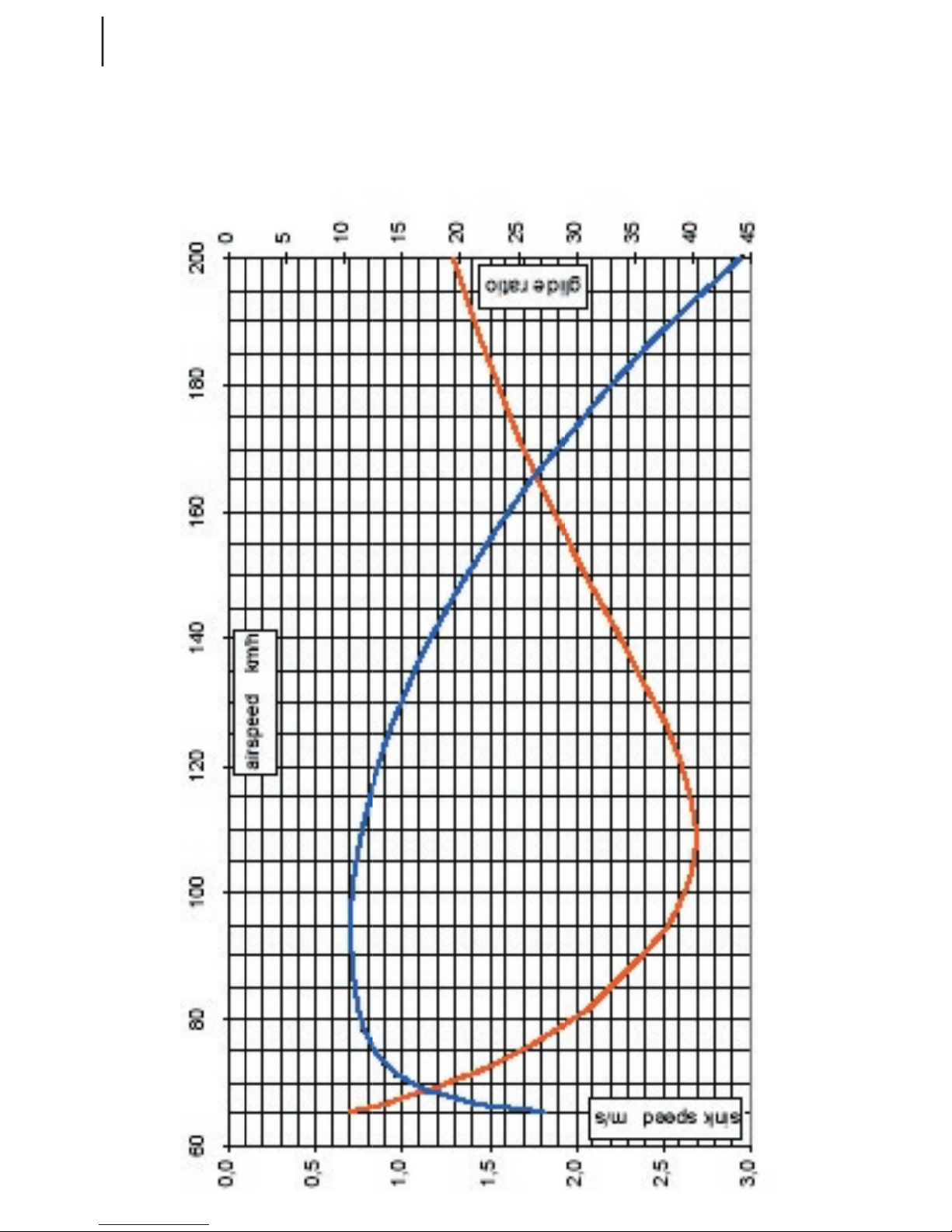

Taurus Electro

minimum sink speed 94 km/h (51 kts)

minimum sink rate (prop.unit., gear retracted) 0.70 m/s (140 fpm)

minumum sink rate(prop.unit extended.) 1.52 m/s (270 fpm)

best lift/drag ratio speed 108 km/h (58 kts)

best lift/drag ratio (prop.unit., gear retracted) 1:41

best lift/drag ratio (prop.unit extended.)

1:25

L/D ratio at 150 km/h

(80 kts) 1:32

49

TAURUS ELECTRO

www.pipistrel.si

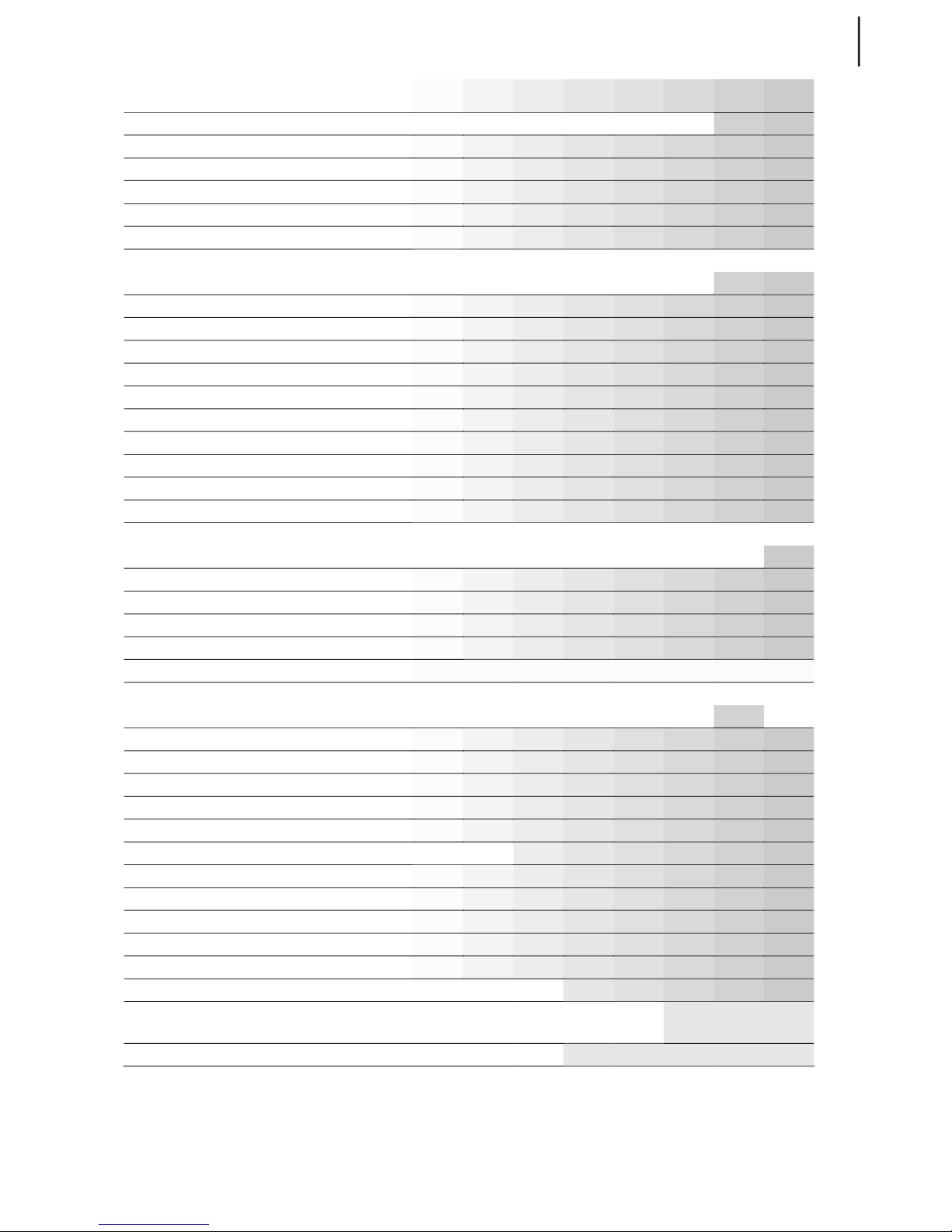

Maneuver & gust envelope

manouever and gust

TAURUS 472,5kg flap 0

5,30

4,00

-1,50

-2,65

-2,04

4,81

-2,81

4,04

-4

-3

-2

-1

0

1

2

3

4

5

6

0 20 40 60 80 100 120 140 160 180 200 220 240 260 280 300

EAS km/h

load factor

manouever and gust

TAURUS 360kg flap 0

6,96

5,25

-1,97

-3,48

-2,68

5,61

4,68

-3,61

-4

-3

-2

-1

0

1

2

3

4

5

6

7

0 20 40 60 80 100 120 140 160 180 200 220 240 260 280 30

0

EAS km/h

load factor

50

TAURUS ELECTRO

www.pipistrel.si

Speed polar

(472 kg, prop.unit & landing gear retracted, optimal flap settings)

51

TAURUS ELECTRO

www.pipistrel.si

Additional technical data

Taurus Electro

stall speed (flaps extended) 63 km/h

(34.0 kts)

stall speed (flaps retracted)

71 km/h

(38.3 kts)

max. speed of spoiler extension 163 km/h (188 kts)

max. speed with flaps in +5° position 130 km/h (70 kts)

max. speed with flaps in T position 130 km/h (70 kts)

max. speed with flaps in L position 110 km/h (59 kts)

manoeuvring velocity Va 163 km/h (88 kts)

maximum rough air speed Vb (gusts 15 m/s) 163 km/h (88 kts)

max. speed with powerplant extended 120 km/h

(65 kts)

max. speed in tow (where permitted legally) 150 km/h (80 kts)

VNE 225 km/h (121 kts)

Vx - best climb-over-distance ratio speed 85 km/h (46 kts)

Vy - best climb rate speed 100 km/h (54 kts)

max. climb rate at MTOM 3.1 m/s (620 fpm)

minimum sink speed 94 km/h (51 kts)

minimum sink rate 0.70 m/s (140 fpm)

max. sink rate with spoilers extended 5.8 m/s (1160 fpm)

best glide ratio speed 108 km/h (58 kts)

takeoff runway length at MTOM 160 m (525 ft)

takeoff runway length at MTOM over 15 m obst. 245 m (800 ft)

best glide ratio 1:41

glide ratio at 150 km/h

1:32

45° left to 45° right - bank to bank time

3.5 s

battery capacity (standard configuration) 4.75 kWh

battery capacity (optional configuration) 7.10 kWh

useful battery capacity (recommended, standard) 3.8 kWh

useful battery capacity (recommended, optional) 5.7 kWh

max. wing load factors

+5.3 G -2.65 G

WARNING! Wing and propeller surfaces must be immaculately clean, dry and undamaged at

all times. As all airfoils are laminar any impact spots, bumps and even a dirty (incl. water, snow...)

surface may significantly lower flight performance. Stall speed, takeoff and landing runway

length, sink rates and energy consumption increase, while climb rates, ceiling, lift-over-drag ratio

and endurance decrease by as much as 30%. Please consult a Pipistrel representative for

high-altitude performance ratings.

52

TAURUS ELECTRO

www.pipistrel.si

This page is intentionally left blank.

53

TAURUS ELECTRO

www.pipistrel.si

Weight and balance

Introduction

Weighing and centre of

gravity calculation for

empty mass

Weight and Balance

report - including:

Useful load distribution

Definitions and

explanations

54

TAURUS ELECTRO

www.pipistrel.si

Weight and balance

Introduction

This section contains the payload range within which the aircraft may be safely operated.

Weighing procedure and procedure for calculating the in-flight c.g. are also provided.

Refer to equipment list for the installed equipment and accessories.

Weighing and c.g. calculation - empty mass

1. Completely assemble the aircraft, in closed space without any wind disturbance, and with:

- gear down

- motor, flaps and airbrakes retracted,

- control surfaces neutral,

- equipment and accessories in accordance with equipment list.

2. Remove all foreign objects, e.g. tools, maps, ...

3. Empty the water ballast tank, remove baggage.

4. Insert scales under main and a scale with support under tail wheel in order to level the

airplane as follows:

- the slope of upper and lower contour of fuselage tailcone in front of fin must be equal, check

with water scale,

- wings level.

5. Read scale readings, subtract eventual tare weight in order to get net weight.

NOTE: IF ACCURATE HIGH RANGE SCALES FOR MAIN WHEELS ARE NOT AVAILABLE, AIR

CRAFT EMPTY MASS MAY BEDETERMINED BY ADDING UP MASSES OF ALL COMPONETS: LEFT

HAND WING, RIGHTHAND WING, FUSELAGE, HORIZONTAL TAIL.

6. Measure distances »a« and »b« between verticals through axis of main wheels, tail wheel

and datum.

Use plumb line to mark verticals at the floor.

For main wheels and wing leading edges take average of Left-hand and Right-hand verticals.

NOTE: DISTANCES A AND B MAY CHANGE WITH AIRCRAFT WEIGHT DUE TO DEFLEC

TION OF LANDING GEAR THEY MUST BE MEASURED AT EACH WEIGHING.

7. Calculate c.g. of empty mass as follows:

X

CG.empty

= (G2.b) / G

empty

- a

G

empty

[kg] Empty mass (with equipment and accessories in accordance with equipment

list, but without occupant(s), baggage and water ballast).

G

2

[kg] Load on tailwheel.

X

CG.empty

[mm] Location of empty mass c.g., positive aft of datum.

a

[mm] Distance between main wheel axis and datum, positive for main wheel forward

of datum.

b

[mm] Distance between main and tail wheel axis, always positive.

Datum

Leading edge of wing root section..

55

TAURUS ELECTRO

www.pipistrel.si

Weight and balance

NOTE: WEIGHING AND C.G. CALCULATION OF FLIGHT MASS CAN BE DONE AS ABOVE, BUT

WITH THE FOLLOWING REMARKS:

FLIGHT MASS INCLUDES EMPTY MASS, OCCUPANTS, BAGGAGE AND WATER BALLAST.

RUDDER PEDALS AND SEATING POSITION MUST BE ADJUSTED AS IN FLIGHT.

However, flight mass and c.g. are normally calculated as shown in “Flight mass and c.g.”.

Weight and balance report

(including: Useful load distribution)

Fill-up »Weight and Balance« report on the next page.

“Empty mass c.g. limits” diagram is used to find out maximum and minimum cockpit load with

respect to mass and centre of gravity of empty aircraft.

Each weighing and centre of gravity calculation has to be entered in the »Weight and Balance«.

If minimum and maximum cockpit load change with respect to last weighing, cockpit placard must

be changed or corrected as well.

After installation or removal of equipment or accessories, repair, painting, or any change which

affects weight and balance, a new »Weight and Balance« (weighed or calculated, whatever is more

appropriate) must be accomplished.

56

TAURUS ELECTRO

www.pipistrel.si

Pipistrel d.o.o.

Ajdovš

čina

Weight and Balance -

Serial Number Registration

Weighing and C.G. calculation - empty mass

1

date of weighing /

1. example 2. example 3. example

2

acomplished by /

3

date of "Equipment list" /

4

main wheel Lh G

1 Lh

kg 123,0 123,4 122,0

5

main wheel Rh G

1 Rh

kg 124,4 124,8 123,5

6

main wheel total G

1

kg 247,4 248,2 245,5

7

tail wheel G

2

kg 49,6 48,8 47,5

8

distance a mm 22 24 23

9

distance b mm 4402 4406 4400

10

empty mass =(6+7) G

empty

kg 297,0 297,0 293,0

11

empty mass C.G. X

CG.empty

mm 713 700 690

12

max cockpit load

without w.ballast

(from "Empty mass c.g. lim its" diagram)

kg 180,0 175,5 169,0

Component

mass

kg kg kg kg

Lh wing

incl.flaperon

Rh wing

incl.flaperon

Fuselage -

complete

Horiz. tail

Empty mass

Empty mass is with equipment and accesories per equipment list, and without occupants, fuel, baggage and water ballast.

X

CG.empt

y

= (G2.b)/G

empt

y

- a

Useful load distribution

13

5,2745,2745,2745,2745,2745,2745,274gkssamxam

14

max useful load = (13-10) kg 175,5 175,5 179,5

15

max cockpit load

without w.ballast

(declared, see Notes)

kg

175,5

less fuel

less bagage

175

,5

less fuel

less bagage

169,0

16

min cockpit load

without w.ballast

(from "Empty mass c.g. lim its" diagram)

kg 86,0 82,0 78,0

17

Inspector

signature & stamp

/

Notes:

● Declared max cockpit load without water ballast is: 14 - fuel - baggage, if 14 is less than, or equal to, 12.

12, if 14 is more than 12.

● Water ballast is installed for solo flight with lightweight pilot for not to exceed aft c.g. limit.

Min cockpit load may be reduced for 2,3 kg per each litre of water ballast.

● If water ballast is left in the tank for duo flight, max cockpit load must be reduced for 2,3kg per each litre of water ballast.

● Influence of fuel and baggage on aircraft c.g. (and corresponding cockpit load) is neglectable.

● Max mass of single occupant (due to structural load per seat) is 110kg.

● Fuel [kg] = 0,76 kg/litre × litres.

a

X

cg

b

Weight and balance

TAURUS ELECTRO

57

TAURUS ELECTRO

www.pipistrel.si

Definitions and explanations

Empty mass and c.g.

Empty mass is mass of empty aircraft with equipment and accessories in accordance with equipment list. Refer to Weight and Balance report for actual value.

»Empty mass c.g. limits« diagram provides empty mass c.g. limits within which flight mass c.g. is kept

in limits. Or differently, the diagram is used to find out cockpit load with respect to mass and c.g. of

empty aircraft.

Minimum cockpit load is obtained as follows:

1. Locate c.g. of empty mass X

CG.empty

[mm] at the Left-hand vertical axis and draw a horizontal line

through it.

2. Locate empty mass G0 [kg] at the bottom horizontal axis and draw a vertical line through it.

3. The intersection of two lines drawn determines minimum cockpit load. Interpolate between lines

of constant minimum cockpit load (RED - 65, 70, 75 kg, ...), if necessary.

NOTE: MIN. COCKPIT LOAD MAY BE REDUCED FOR 2.3 KG PER EACH LITRE OF W. BALLAST.

Empty mass c.g. limits

Cockpit load in kg with respect to