OPERATOR'S MANUAL

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

For

Models

IL,

5821

TX24KWA, TX24KWAE, TX24KWC, TX24KWCE

S828KWA, S828KWAE, 5828KWC, S82BKWCE

KWA,

5821

KWAE,

1-----PROPANE

5821

KWC,

5821

KWCE

BURNISHER----1

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

DATE OF PURCHASE

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

PURCHASED FROM

RECORD THIS IMPORTANT INFORMATION

CITY---------

PHONE

MACHINE MODEL

MACHINE SERIAL NUMBER

-,~GINE

ENGINE SERIAL NUMBER

_________

IMPORTANT PHONE NUMBERS

Medical Emergency

STATE

_

_____________

_____

CONTACT---------~

ZIP

_____

_

_

Police

Fire Department

_________________

______________

_

_

SAFE OPERATING PRACTICES

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

for Pioneer Eclipse® Propane Powered Burnishers and Strippers

• Allow only qualified and trained personnel to operate equipment.

• Follow closely maintenance and operating instructions.

• Keep accurate records of maintenance and service

• Remember, routine maintenance

• Always check oil level before starting.

• Keep nuts and bolts tightened and hose connections snug.

• Refer to engine manufacturer's service manual

adjustments not listed

• Never alter or reconstruct the fuel system. To do so may be dangerous and will void the factory

warranty.

• Always use U.L.,

• Be careful not to cross thread the Rego·coupling on the fuel cylinder.

• Always store the fuel cylinder outside away from heat and direct sunlight.

• Never leave the machine running unattended.

• Always operate in a well ventilated area. (C.atalytic mufflers need to warm up before

are effective. Failure to do so may cause nausea or carbon monoxide poisoning.)

• Check pad holder for cracks each time the pad is changed.

• Have the machine serviced by a certified technician, including

three (3) months.

in

this manual.

C.T.C./0.0.T

NOW

listed Safe Fill cylinders supplied by Pioneer Eclipse.

will prevent a breakdown LATER.

in

the provided log book.

or

contact Pioneer Eclipse for engine repairs

an

emission check, every

or

they

• Before attempting any service on the machine, turn the ignition switch "OFF" and remove the key

to

avoid accidental start-up.

WARNING: Keep hands and feet clear

fractured pad holder may result

in

pad fragments causing injury.)

WARNING: Failure to follow the instructions and warnings appearing

or

manual

possibly to other persons and property.

on machine labels may result

of

rotating pad! Inspect pad holders regularly. (A

in

this operating

in

serious injury to the person using the machine and

NOTE: This machine is manufactured for commercial use only.

Propane powered floor burnishers are designed and manufactured for ultra high speed

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

commercial floor burnishing only. These machines are designed to burnish most modern

types of floors including composition tile, stone, marble, terrazzo, and resilient floor covering

using floor coatings designed for ultra high speed burnishing.

to

Even though NFPA 58 8-4.5 says ... "these machines shall be permitted

the

buildings frequented by

the public," Pioneer Eclipse suggests usage when occupancy of a given work area is

minimal.

public, including the times when such buildings are occupied by

be used in

These machines should

• in nursing homes, hospitals, day-care centers, etc.

•

by

unqualified or untrained personnel.

• unless properly maintained and adjusted.

• on areas with obstructions such

• in areas where loose tile or other objects are present.

• in rooms without proper ventilation.

not

be used:

as

thresholds, floor outlet boxes, etc.

These machines should not be left.running unattended.

It is recommended to start burnishing on the right side of the aisle, turn and come back down

the aisle in the opposite direction, overlapping the previous path slightly. Continue this pattern

until the floor area to be burnished

of

the

machine. The forward speed is generally at normal walking speed.

CAUTION:

Do

not allow the burnisher to operate without moving. It may burn the

has·been covered with the last pass being

on

the right side

floor and damage the floor covering.

SPECIFICATIONS:

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

SB21KWA(EVKWC(E)

21"

Pad

Size

Pad

Speed

Width

Length

Engine

Starting

Weight

Handle

Deck

Vibration

Sound Level

(53,3 cm)

2000RPM

22.75" (57,8 cm)

51.5" (130,8 cm)

Kawasaki 17

12

V Battery

192

lbs.

Welded Steel Adjustable

Cast Aluminum Alloy

Less than

87dB(A)

TX24KWA(EVKWC(E)

24"

Pad

Size

Pad Speed

Width

Length

Engine

Starting

Weight

Handle

Deck

Vibration

Sound Level

(61

1800 RPM

26.25"

58.5" (148,6 cm)

Kawasaki 17

12 V Battery

215

lbs. (97,5 kg)

Welded Steel Adjustable

Cast Aluminum Alloy

Less than

87dB(A)

(87 kg)

2.5

cm)

(66,

7 cm)

2.5

HP

m/s

HP

m1s2

2

SB2BKWA(EVKWC(E)

Pad Size

Pad Speed

Width

Length

Engine

Starting

Weight

Handle

Deck

Vibration

Sound Level

28"

(71,

1700RPM

30" (76,2 cm)

58.25" (148 cm)

Kawasaki 17

12

V Battery

215

Welded Steel Adjustable

Cast Aluminum Alloy

Less than

87dB(A)

1 cm)

HP

lbs. (97,5 kg)

2.5

m/s

2

TABLE

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

,

I.

PROPANE MACHINE SAFETY

A Purpose ....................................................................................................................................................................................

B.

Refueling

C.

Safety

D.

Use

E.

Canadian Safety Regulations .................................................................................................................................................... 1

F.

Operator-Ear

G.

Hand-Arm Vibration .................................................................................................................................................................... 2

and

Storage

in

Engineering ................................................................................................................................................................. 1

and

Care

............................................................................................................................................................................. 1

Sound

of

Fuel Cylinders .................................................................................................................................. 1

Pressure

Level

.......................................................................................................................................... 1

OF

CONTENTS

II. MACHINE PREPARATION

A Adding Oil ................................................................................................................................................................................... 2

B.

Connecting Battery ..................................................................................................................................................................... 2

C.

Adjusting the Handle ................................................................................................................................................................. 2

D.

Filling the

E.

Installing the

Fuel

Cylinder ............................................................................................................................................................. 2

Fuel

Cylinder ........................................................................................................................................................ 2

Ill. OPERA TING INSTRUCTIONS

A Starting Instructions ................................................................................................................................................................... 3

B.

Operation ................................................................................................................................................................................... 3

C.

Idling

and

Stopping the Machine .............................

D.

Installing

E.

Storage ............................................................................. , ......................................................................................................... 4

F.

Repacking ................................................................

G.

Transportation ......................................................

and

Changing Burnishing

Pad

.................................................................................................................................. 3

.'

................................................................................................................. 3

,_.

.••............................................................................................................. 4

-;

..

:,

..

;,;

............................................................................................................. 4

..

IV. SCHEDULED MAINTENANCE

...................................................................................................................................

GENERAL MAINTENANCE PROCEDURES

A

Fuel

System ............................................................................................................................................................................... 6

1. Adjusting the Regulator ........................................................................................................................................................ 6

2. Engine Dust Filter ................................................................................................................................................................. 6

3.

Carburetor

4.

Fuel

8.

Engine

1.

Cooling Fins .......................................................................................................................................................................... 7

2.

Head Bolts ............................................................................................................................................................................. 7

3. Changing Oil ......................................................................................................................................................................... 7

C.

Belt

Maintenance ....................................................................................................................................................................... 7

D.

Adjusting the Handle .................................................. , .............................................................................................................. 8

E.

Battery Maintenance and Replacement .................................................................................................................................... 9

VI.

TROUBLESHOOT/NG ................................................................................................................

VII.

ORA WING

Safe-Fill Cylinder Head Layout ....................................................................................................................................................... 10

Wiring

Diagram/Schematic .............................................................................................................................................................

Deck Sub-Assembly and Parts List

SB21KWA(E), SB21KWC(E) ....................................................................................................................................................

TX24KWA(E), TX24KWC(E) .....................................................................................................................................................

SB28KWA(E), SB28KWC(E) .................................................................................................................................................... 16

Kawasaki Engine Sub-Assembly and Parts List ...........................................................................................................................

Handle Sub-Assembly and Parts List .....................................................................................................................................•...... 20

Air

Filter

............................................................................................................................................................... 6

Hose

and

Connections ................................................................................................................................................. 6

Maintenance .................................................................................................................................................................. 7

AND

PARTS

LIST

s

10

11

12

14

18

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

I.

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

PROPANE MACHINE SAFETY

A. Purpose

The accepted demand for and use of propane powered floor machines underscores the need for responsible manufacturers

users

to

stress the importance

use of propane powered floor machines.

In

addition, we recommend operators

for the safe operation

Technician Training.

of

safety. This manual is designed to provide the information

of

propane powered floor machines complete a program of training and certification

of

this equipment. Contact Pioneer Eclipse

you

at

1-800-334-2246 for informaflon

need to ensure proper and safe

on

Factory Certified

and

B. Refueling

Propane cylinders should only be filled by

an

upright position

at

least five feet (1.5

The National Fire Protection Association (NFPA) Standard for Storage

propane use. A copy of this publication is available through the National Fire Protection Association

(1-800-334-3555).

C.

Safety

Pioneer Eclipse engineers and manufactures machines utilizing U.L. (Underwriters Laboratories)

Association) approved components where possible. When a tag or tags bearing the U.L.,

to the machine,

having met all

In

some cases, the tag will be affixed to a particular component. This means that only the component

recognition for the following parts

you

use only machines meeting the above minimum

Even

though propane powered floor machines manufactured

(TWA) standard for noise,

D.

Use

All machines manufactured by Pioneer Eclipse come with a detailed Operator's Manual. Safety dictates that before using any new

equipment,

E.

Canadian Safety Regulations

1.

A sign indicating "NO SMOKING" shall

sign required

2.

When the cylinder

for short periods of time such

3.

The requirements of

4.

A floor maintenance machine shall only be used

a)

provided with continuous mechanical ventilation that removes the products

300 CFM for each 10,000 Btuh input or traction thereof.

b)

provided with natural ventilation of not less than 300 CFM for

maximum of one quarter air exchange per hour for the net building volume.

5.

The owner

manufacturer of the unit

6.

The owner of a floor maintenance machine shall ensure that the unit is maintained in accordance with the manufacturer's

recommended maintenance procedures

for a period

7.

Before transporting a floor maintenance machine, the cylinder shall

cylinder shall be located

and

in

Engineering

it

of

and

Care

it

is

important

in

of

of

Storage

in

a secure, tamper-proof, steel

m)

of

space between the cabinet and the nearest building opening (door or window).

indicates that the entire machine has been researched, tested,

their safety criteria.

to

Clause 10.12.3

is

attached to the floor maintenance machine for

1.10.1

a floor maintenance machlne shall ensure that the operator has participated in a course authorized

two years.

of

Fuel Cylinders

an

authorized propane dealer. When not

mesh

storage cabinet. This cabinet may be located next

and

is

important: fuel cylipders, couplings, regulators,

r6qUii"ements.

by

Pioneer Eclipse meet the 0.S.H.A. Time Weighted Average

we

still recommend that hearing protection be worn by the operator.

read

and

understand the Operator's Manual. We strongly recommend this practice.

be

permanently displayed

of

CAN/CGA-B149.2-M91, Propane Installation

as

rest stops, washroom or meal stops.

(e)

and

(g)

do

not

apply in industrial buildings.

in

buildings:

on

the safe handling of propane and the sate operation of the machine.

in

a safe operating condition and the owner shall maintain a record

in

a well ventilated space.

at

the storage area. The sign shall be

use,

the operator shall not leave the unit unattended except

each

10,000

be

securely fastened with the system valve closed,

in

Handling of

and

and

Code.

of

combustion

Btuh

use,

LP

is listed by

fuel lines. We strongly recommend that

input or fraction thereof, based

they

shOuld

always

be

stored outside

to

the building but

Gas is the appropriate authority for sale

in

Qµincy, Massachusetts

and

C.G.A. (Canadian Gas

CE

and/orC.G.A. insignia is/are affixed

one

or both organizations as

is

listed. Component

in

accordance with the

to

the outdoors of not less than

of

the maintenance

on

by

a

the

and

in

with

the

F.

Test

for

Operator-Ear

Pioneer Eclipse measures and rates the operator-ear sound pressure level for hand-guided floor treatment and floor

cleaning machines for industrial

• Outdoor test area consists of a flat open space tree from effects

ft) from the center of the test surtace. Indoor tests are conducted

Sound

use.

Pressure

All tests are perlormed

Level

in

accordance with European Machinery Directive (98/37/EC).

of

signboards, buildings or hillsides for

in

a semi-anechoic or sound_deadening

at

least 15m (50

room.

• The test surtace is a single sheet of floor covering at least 1 m (3.3

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

order to not affect the sound reading, the observer taking readings is at least 2 m (6.6

standing directly behind the operator.

• All machines are tested while stationary and centered

the test is conducted with the machine at maximum engine or motor speed as

• The operator is located

machine, 1,68 m (66 in) above the test

cm

(8

in)

to

the rearmost point of the handle, with the handle in the most forward position.

• The sound !eve! meter

repeatable sound level observed during the test at each microphone position

G.

Test

for

Hand-Arm Vibration

Pioneer Eclipse measures and rates the vibration at the machine-hand contact surface of hand-guided machines that are

provided with handles in accordance with European Machinery Directive (98/37/EC).

• The Test area consists of a flat open floor area that allows the machine to be operated normally.

• The transducer is mounted firmly at a point halfway along the length of the handle where the handle would normally be held.

• Machines are tested while stationary, with all mechanisms necessary for the equipment to pertorm its intended functions

engaged

specified

• The measurements are recorded from the dominant axis.

II.

MACHINE PREPARATION

and the traction drive

by

the manufacturer of the subject machine.

in

the normal operating position with the microphone or meter supported independent

surtace,

is

observed for a minimum

at

the

Grip

in

neutral (if applicable). The machine will be tested

on

the test surface. With the traction drive

25

cm

(10 in) to the right and left centerline of the operator's position, and 20

of

5 seconds or until a stabilized reading

Surface

fl)

wider and longer than the equipment being tested. In

fl.)

from the equipment being tested, or

in

specified by the manufacturer.

is

recorded and documented.

of

Hand-Guided Machinery

at

maximum engine or motor speed as

neutral (where applicable)

is

obtained. The maximum

of

the

Adding

A.

When the Burnisher is shipped by

machine

The

machine

When filling a "dry" burnisher or changing oil,

changing

necessary but DO NOT OVERFILL!

operator's

-c1oth,

then insert dipstick into tube without screwing in. Check oil level. ALWAYS make sure

when

checking

B.

Connecting

Connect the RED positive battery cable FIRST.

Connect the

C.

Adjusting

The burnisher handle adjusts for comfort and optimum control. Height may be changed

D.

Filling

Pioneer Eclipse uses the

also listed by U.L. Filling should be done ONLY by a qualified propane dealer. FILL THROUGH THE SERVICE

(See page 13) A properly filled cylinder should not exceed 80% of the rated capacity.

DO NOT attempt safe-fill cylinder repair. Return the cylinder to your propane dealer

regulations prohibit shipping of cylinders after the cylinder has been filled with propane.

E.

Installing

Align the slot in the top flange

the

toggle assembly to the cylinder band. Adjust the toggle assembly by screwing

Connect the fuel hose coupling

is

not

cross threaded and check for leakage by noting any propane odors immediately after cylinder is connected. (It is sometimes

easier to install

TO

REMOVE THE SAFE-FILL CYLINDER, reverse above procedure.

Oil

3.8

overland

with

US

pints

to

be

shipped without oil.

is

also

the

oil

filter,

manual.

oil.

shipped

or

IMPORTANT: When checking oil

the Battery

BLACK

negative battery cable LAST.

the Handle

the Safe-Fill"' Fuel

20

lb. capacity aluminum safe-fill cylinder which meets the D.O.T. 4E240 standards. These cylinders are

the

Safe-Fi/I'M

of

the cylinder with the locating pin on the machine. Strap the safety fill cylinder in place

to

the service valve by turning to the right (clockwise). HAND TIGHTEN ONLY. Make sure coupling

if the connection to the service valve

freight,

the

battery

(1,8 L)

ALWAYS

the.correct arilOunt of oil

disconnected.

for

the

Kawasaki

when

the

CHECK OIL BEFORE USING THE MACHINE. Refer

on

Cylinder

Fuel Cylinder

is

made before strapping the cylinder

is

in

the engine.

engine

add

no

more than 1.5

oil

filter

is

changed, then check the dip stick

Kawasaki models, remove oil filler cap and clean dipstick with clean

if

repair is necessary. Please note that

in

or out

Always

connect or change cylinders in a well ventilated area.

Air

freight

quarts

the

machine

to

suit the individual operator. (See page 8)

in

orderto keep the tank firmly secured.

in

place.)

shipments require the

(1,4 L)

when

not

in

the fill cap. Add oil if

to

the

engine

is

sitting

level

VALVE

ONLY.

0.0.T.

by

clamping

2

Ill. OPERATING INSTRUCTIONS

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

,j

A. Starting

1.

Check oil and fuel levels

2.

Check and clean engine air filter

NEVER RUN

FILTER. (See "Scheduled Maintenance")

3.

Check

4.

Turn propane service valve counterclockwise to open.

NOTE: ALWAYS OPEN

FLOWCHECKVALVETO

5. Allow machine to tilt backward (pad off floor) and move

6. Engage starter

ignition switch return to the run position (Do

(NOTE: Do not engage starter for more than 1 O seconds. Allow a 60 second cool-down period

cycle.)

7.

SAFE

(The machine

as

the machine

Instructions

CONTINUOUSLY

carburetor air filter. Change

SLOWL

by turning the key-switch to

SENSE

ONLY:

may

be operated during this

is

running safely.

FOR

YTO

ENGAGE, LIMITING FUEL FLOW.

After engine starts, a GREEN light will flash for a 3 minute

MORE

if

necessary. (See "Scheduled Maintenance")

ALLOW

THAN

PRESSURE

the

starting position

not

turn off).

warmMup

1 HOUR WITHOUT

TO

EQUALIZE IN HOSES. OPENING QUICKLY

the

throttle to the

for

Wait

approximately 5 seconds and

period.) After the

SLOW

approximately 5 seconds. If the machine fails to start, let the

warmMup

CLEANING

position.

B. Operation

After engine

Lower the burnishing head to the floor while moving the

CAUTION! DO

OR

FLOOR FINISH

To

stop burnishing, push down on handle to raise th~ burnishing head off the floor.

SAFE

muffler.

Upon

continuously

the

green

machine

WARNING!

of

proper

has

SENSE

starting

light

will

ventilation

started, allow approximately

NOT

RUN

THE

BURNISHER

MAY

OCCUR.

ONLY:

the

unless a warning

shut

Catalytic

NOTE: This burnisher is equipped with the SAFE SENSE emjssjon monitoring system and catalytic

engine,

will

down

the

go

out

and

within 1 minute.

mufflers

during

this

GREEN

is

being

the

RED

require a few

warm-up

30

WITHOUT

LED

light

sl.gnaled.

LED

period!

secoads.

will

light

will

minutes

f0rthe

engine to warm up. Advance the throttle to operating speed.

!Tlachine forward slowly.

MOVING.

flash

If

the

start

to

IF

ALLOWED

for 3 minutes

carbon

monoxide

flashing.

warm

up

before

during a warm-up

When

TO

in

the

the

red

effectively

OR CHANGING ENGINE DUST

MAY

CAUSE

try

again for another 5 seconds.

for

each 1 O second start-up

warm-up

cycle, the green light will remain on as

RUN IN

exhaust

light

cycle

of

the

SAFE

ONE

SPOT

DAMAGE TO

period.

becomes a continuous

removing

After

that,

is

approaching a hazardous

harmful

SENSE

THE

it

will

red,

emissions.

be

THE

system.

Jong

FLOOR

on

level

the

Make

sure

C.

Stopping

To

stop the engine, close the service valve

used up).

D.

Installing/Changing

1.

With engine

accomplished by pushing down on the right handle grig with some force while the machine

machine

2.

Remove centering device (if used) and carefully pull old

3.

CAREFULLY

NOTE: A damaged

4. Pull center from

center ring.

5. Press pad onto velcro.

6.

Return machine to upright position.

the Machine

After

the

engine

OFF

and in the operating position, turn the machine over

over

on

INSPECT

pad

new

stops,

turn

Burnishing

the

carburetor

THE

PAD

holder

rotating

pad, center pad on pad holder and secure with centering device (if used) or tuck the center

on

the fuel cylinder by turning it clockwise. (The engine will stop when the fuel in the lines

the

key

switch

to

the

"OFF"'

position.

Failing to turn the

key

OFF

may

drain

Pad

on

side

as

HOLDER

at

high speeds

this

will

FOR

may

the RIGHT

fill

the

carburetor

pad

off the velcro pad holding material.

CRACKS

be

OR

an extreme hazard if it should come apart.

with

DAMAGE!

3

or

starter side. This can

is

tilted back.

oil.)

Replace

if

Be

necessary.

be

sure

under

easily

not

the

to

the

battery.

turn

the

plastic

is

E.

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

Storage

Only authorized, trained personnel should have access to propane cylinders and machines.

1.

Remove

Section

Please consult your local Fire Marshal

2. Store machine away from objects that may fall and damage

3. Never store burnisher or fuel cylinders near

4.

Make sure burnisher is cleaned properly before storing.

5.

Never store burnisher with cylinders installed, or store spare cylinders

F.

Repacking

1.

Use shipping and package

information attached to packing slip to

repack machine.

2.

Store

Temperature not

propane

5

or

Subsection

machine

fuel

cylinder

in

a dry location.

to

exceed S0°C.

9.5.2

when

not

in

use and

of

CAN/CG A 8149.2. Do

to

ensure that you are

an

open flame or heat producing devices.

store

not

it

outside

release

in

it.

in a storage cage

or

bleed

propane

compliance with local fire codes.

in

an enclosed van or trailer.

in

accordance

inside

the

with

building.

NFPA

G.

Transportation

When

transporting a propane powered floor burnisher with the fuel cylinder installed,

be

with the service valve closed and the burnisher should

should

be

securely

with cylinders installed, or store spare cylinders in an enclosed van

for

overfilling

outside

in a

fastened to avoid movement and damage.

before

safe

transporting them. If overfilled, correct before loading them in

area using the bleeder valve.

secured in the vehicle. Any propane fuel cylinders not installed

The

service valves should

or

SCOTCH BLOCKS

the

cylinder should

be

closed. Never store burnishers

trailer. It is a good practice to check propane cylinders

the

vehicle

by

be

securely fastened

venting the excess propane

4

IV.

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

SCHEDULED MAINTENANCE

Following proper scheduled maintenance procedures will provide years of uninterrupted service.

KAWASAKI ENGINE

or

ITEM

TYPE of SERVICE

Engine Oil

Oil Filter

Engine Dust Filter

Carburetor Air Cleaner

Clean Pre-Foam Element 2

Belt

Fuel Hose

& Connections

Cooling Fins

Check Level 2

Change

Change 4,5

Inspect

Clean/Change 1,2

Inspect 2

Clean/Change Element

Inspect

AdjusVReplace As Required

Inspect

Replace

Clean 2

REGULAR SERVICE PERIOD

(Periormed At Indicated Hour Intervals)

Break

In

Each

25 hrs.

8 hrs. Use

2,4,5 2,4,5

1

•

2

2

2

2

M Signs of Wear are Present (3,5 below)

50 hrs. 100 hrs.

2,4,5

(5

below)

300 hrs.

Burnishing Head Assembly

Pad Holder

Inspect

6

Inspect When Chanaina Pads

Replace If Cracks Appear (2 below)

& Connections

Bolts

Inspect

Tighten

6

6

Spark Plug Clean/Replace 5,6 4,5

Battery

Exhaust Emissions

Check

& Battery Cables Inspect 2

Check 3,5

& Adjust Valve Clearance 5,6,7

Retorque Heads

1.

Perlorm

2. Refer to Section

3.

These

4. Refer to Engine Manufacturer's "OWNER'S MANUAL" for recommended replacement.

5.

Always enter maintenance performed

6.

Routine

7.

Refer

after

each

items

should

maintenance.

to

Engine

hour

of

operation.

V"GENERAL

be

serviced

Service

Manual.

MAINTENANCE PROCEDURES".

by

an

authorized

in

"SERVICE LOG BOOK".

Pioneer

Eclipse

Service

Center.

5

V.

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

GENERAL MAINTENANCE PROCEDURES

A.

Fuel

System

The

fuel system

for

system

1.

Adjusting

NOTE:

The

authorized personnel, trained and certified in

N.F.P .A.

Gas

engine

2.

Engine

The

engine dust filter should be

Squeeze

engine

works

from vacuum created

flow to the carburetor once the

the

Regulator

regulator and carburetor have been factory pre-set and should not require any modification. Only Pioneer Eclipse

58

8-1.4 states, "In the interest

fuel system shall

Dust

Filter

out

the excess water (do not wring). Allow the filter to air dry.

to

overheat. Also, it may cause

be

properly trained in the necessary procedures."

cleaned

by

the engine running. Turning the fuel cylinder service valve ON pressurizes the

engine

starts

to

crank.

propane

of

safety, each person engaged in installing, repairing, filling, or otherwise servicing an LP-

each

the

systems, should

hour

and after each use

exhaust

emissions

modify

or

adjust the system

by

shaking out the dust and then rinsing with mild detergent.

Failure

to

elevate

to

maintain

to

harmful levels.

or

a clean

its setting.

engine

filter

will

cause.the

3. Carburetor

a. Loosen wing

b. Remove foam pre-cleaner and

c.

Clean foam pre-cleaner using

ct.

Clean filter seal, making sure

e.

Inspect paper element. Replace if dirty, bent

f.

Install the clean paper element, pre-cleaner, air filter. cover and wing nut.

SAFE

SENSE

emissions

4.

Hose

a. Inspection

(1) Inspect hoses

(2) Check for gas leaks by spreading soapy water solution around all

and the fuel system is pressurized.

Air

Filter

nut

on top

of

the air cleaner cover.

paper

filter element.

the

ONLY:

NOTE:

same procedure as

no

dust is allowed in,!he carburetor inlet.

or

Failure

to

service

#2

damaged.

the

carbu.retor

and cause the SAFE SENSE systerri t~-shut the-engine

and Fuel Connections

for

abrasions and other signs of wear; replace all worn

above.

air

cleaner

b. Fixing Leaking Joints

(1) Uncouple

the clean joint.

(2) Recouple

(3)

Recheck

turned

bad

joint and clean it. Then apply pipe sealing compound (Loc-Tite Pipe Sealant with Teflon or equivalent) to

the

joint finger tight plus 1/2 tum.

for

leaks

using

soapy

water

on and

the

fuel system pressurized.

solution.

Watch

for

bubbles

may

produce

down.

or

damaged hoses.

the

connections while

at

the

joint

with

excessive

the

service valve is turned ON

the

fuel

cylinder

carbon

monoxide

service

valve

6

B.

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

Engine Maintenance

1,

Cooling Fin Maintenance

a.

Remove

b.

Clean

c.

Reinstall

2. Head Bolt Maintenance

a.

Refer

3.

Changing

a.

Run

by itself. Turn the key OFF. (Failing to turn the key OFF

SAFE SENSE ONLY: NOTE:

b.

Locate

c.

Remove

d.

Allow

e.

Replace

t.

Remove oil fill cap. Slowly add no more than 1 1/2 quarts (1,4

quarts

g. Check oil level with dip stick in oil fill cap. Add additional oil if necessary.

DO NOT OVERFILL AND NEVER RUN

IMPORTANT:ALWAYSMAKESURETHEMACHINEISSIITINGLEVELWHENCHECKINGOIL.

h.

Replace fill cap. Hand tighten only.

the

the

all

to

Engine

the

engine

the

the

oil

to

the

(1,8

cooling

oil

blower

housing

fins

housings

Manufacturer's

for 5 minutes

oil

drain

pipe

cap

by

turning

dra!n

completely

cap

by

turning

L)

when

the

and

as

necessary

and

shrouds.

to

warm

Must

located

it

with a wrench.

into

clockwise.

oil

filter

other

using

Service

oil,

be

running

on

the

the

receptacle.

is

changed.

ENGIN~

cooling

compressed

Manual.

then

stop

above

right

shrouds.

side

Refer

LOW

the

engine

may

2150 RPM

of

the

to

engine

ON

Olli

air

or

pressure

by

closing

run the battery down.)

or

SAFE SENSE

machine.

L)

of motor oil when not changing the oil filter, or 1 3/4

Owner's

washer.

the

Manual

fuel

service

will

for

valve,

allowing

shut

the

engine

recommended

down.

oil.

the

engine

to

stop

C.

Belt Maintenance

,nside V-Groove Idler System --

To

inspect

the

belt

it

is

necessary

can

easily

be

accompllshed

badly

cracked

To check

Always

To change belt:

1.

Turn

2.

Remove the pad holder

counterclockwise.

3.

Use the 3/4" wrench to turn the end of the spindle shaft on top

4.

Finish

5.

Check engine pulley for correct alignment with the spindle pulley. Check hardware attaching pulleys for proper tightness.

6.

Install the new belt onto the engine pulley.

7.

Reinstall the new belt onto the spindle pulley using the 3/4" wrench

placed on the idler pulley.

8.

Reinstall the pad holder onto the spindle shaft.

9.

Turn

10. Check belt

or

worn

for

the proper tightness squeeze the belt together. The belt should depress between 1/4" (,6 cm) and 1/2" (1,3 cm).

use

the

recommended

the

machine

removing

the

machine

over

the

upright

for

correct operation. Check all hardware

by

pushing

it

should

belt

on

the

by

holding the end of

belt

from

the

in

the

be

right

5821

to

turn

the

down

replaced.

size.

side.

engine

pulley,

burnishing

KWA(E)IKWC(E}, SB28KWA(E}IKWC(E)

machine

on

the

position.

over.

The

machine

the

handle

grip

with

shaft on the top of the machine with a 3/4'' wrench and turn the pad holder

of

the machine while removing the old belt from the spindle pulley.

if

necessary.

for

proper tightness.

should

be

turned

to

the

right

some

force

while

the

machine

to

turn the spindle clockwise. Make sure the belt is correctly

is

side

tilted

(starter

back.

side).

If

the

This

belt

is

7

V-Groove Idler System -- TX24KWA(E), TX24KWC(E) Only

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

To

inspect

the

belt

it

is

necessary

can

easily

be

badly cracked

To

check for the proper tightness squeeze the belt together. The belt should depress between 1/4 and 1/2 inch (,6 - 1,3 crn).

To

tighten

accomplished

or

worn it should be replaced.

follow#

9 of this section.

by

pushing

to

turn

the

down

machine

on

the

over.

handle

The

grip

machine

with

some

should

force

be

turned

while

the

to

the

machine

right

is

side

tilted

(starter

back.

To Tighten Belt

Push

belt

outer

edge

tensioner

of

deck

to

add

bolt

more

toward

tension.

Deck Edge

---

To Change Belt:

1. Remove the pad holder

counterclockwise.

2. Use

the

3/4" wrench to

3.

Finish

removing

4.

Check

engine

pulley

5. Install the

6.

Reinstall

placed on

7.

Reinstall

8.

Turn

9. Check for propertightness. Tighten the belttension by pushing

tighten with a 9/16" wrench. Loosen the belt tension by pushing

a 9/16" wrench.

10. Operate

new

belt onto the engine pulley.

the

new

the

idler pulley.

the

pad holder onto the spindle shaft.

the

machine

for

20

minutes

the

belt

for

belt

upright

by

holding the end of the shaft on the top of the machine with a 3/4" wrench and turn

tum

the end of the spindle

from

the

engine

correct

alignment

onto

the

spindle

in

the

burnishing

and

check

belt

pulley,

pulley

tension.

if

with

the

using

position.

Adjust

shaffon

neCessary.

spin91e

the

3/4"

if

top of

p~lley.

wrench

necessary.

the

machine while removing the old belt from the spindle pulley.

Check

hardware

to

turn

the

the

belt tensioner bolt toward the left side of the machine and

the

belttensioner bolt in the opposite direction and tighten with

attaching

spindle

pulleys

clockwise.

for

Make

the

proper

sure

the

pad holder

tightness.

belt

is

side}.

If

the

belt

correctly

This

is

D.

Adjusting the Handle

Insert lever bolt through handle

bracket

and

hinge

bushing

locate

handle

in

operating

to

position.

8

Handle

OJ>erating

Position*

Lever Bolt

Bracket

Hinge Bushing

Shinning

Position

E.

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

Battery Maintenance

The

battery

supplied

When

battery

doubt, contact Pioneer Eclipse Customer Service at 1-800-367-3550. To replace:

1.

Remove

2.

Raise

3.

Disconnect

4.

Remove battery hold-down clamp.

5.

Lift old battery out and replace with new battery.

6.

Reinstall hold-down clamp. NOTE: DO NOT OVER TIGHTEN

to

7.

Connect the RED positive battery cable first.

Connect the

the

battery

rupture.

with

replacement

propane

battery

BLACK

fuel

cover

to

cables

negative battery cable last.

this

machine

becomes

cylinder

expose

from

and

Replacement

is a sealed

necessary,

from

the

battery.

terminals.

gelled

the

replacement

machine.

Always

electrolyte

disconnect

maintenance

should

the

BLACK

HOLD-DOWN

have

free

the

cable

type.

same

specifications

first.

CLAMP.

lt

never

should

need

servicing.

as

the

original.

Doing so may cause the battery

If

in

Dispose of

old

battery in the proper manner.

SAFETY'.

INSTRUCTIONS

RECHARGEABLE BATIERY

! DANGER!

ALL

BATTERIES CONTAIN CORROSIVE ACIDS AND

PRODUCE EXPLOSIVE GASES DURING RECHARGING

GAS EXPLOSION

CAN CAUSE

BLINDNESS

OR

SHIELD EYES

INJURY

BATTERY ACID

CAN CAUSE

BLINDNESS OR

SEVERE BURNS

* Do not make direct contact between battery

terminals as this can cause

an

explosion or

fire.

* Batteries should not be stored discharged.

* Only adults should recharge batteries.

* Keep charger away from children.

* Use only the charger provided by the equip-

ment manufacturer.

* Do not recharge batteries upside down.

* Charging produces explosive gases. Charge

battery

sparks, flames and smoking.

* Disconnect charger

in

a well ventilated area away from

from

batteryafter24 hours.

INTERNAL

TAKE MILK, EGG WHITES,

AND WATER.

DO

NOT

INDUCE VOMITING

CALL PHYSICIAN IMMEDIATELY

EXTERNAL

FLUSH IMMEDIATELY FOR

15 MINUTES IF ACID GETS

IN

EYES

OR

ON SKIN

9

VI.

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

TROUBLESHOOT/NG

SYMPTOM

1. Hard to start

2.

Will not start

3.

Engine lacks power

4.

Smell of burned rubber

5.

Machine vibrates

6.

Machine "Bogs Down" when in use

7. Machine pulls to one side

8.

Engine stops running

POSSIBLE CAUSES

Opening propane cylinder too quickly (OPEN SLOWLY)

Spark plug

Blown head gasket

Insufficient vacuum

Coil, air gap needs adjusting

Low oil

Incorrect spark plug gap (Gap should be .025)

No fuel

Blown head gasket

Insufficient vacuum

Defective spark plug

Defective coil

Dirty air filter

Low oil

Fuse blown in Safe Sense

Wires broken or disconnected

Leaking head gasket

Insufficient vacuum

Governor needs adjusting

No compression

Check air filters

Belt out of adjustment

Loose bolts

Pad not centered

Operator ls bearing down too hard

Dirty air filters

Check for bent wheel bracket

Dirty air filter

High exhaust emissions

Out of fuel

Low oil

or

head bolts loose

w worn rings

VII.

DRAWING AND PARTS LIST

Safe-FilJ'M Cylinder Head

Layout

10

Bleeder

Valve

Liquid

Sight

Pressure

Relief

level

Gauge

Valve

Wiring Diagram/Schematic

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

Oil

PRESSURE

swrrci;

for

Machines with Safe Sense

ELECTRICAL SCHEMATIC

SAFE

SENSE

.....

(fASflCIIIG)

""'

REV.

8

#iring

Diagram/Schematic

for

Machines

SEALED

without

Bl.TIER'!'

Safe Sense

(JX)

.«!OVOC

BLOCl<ING

SAMP

DIODE

11

Deck

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

Sub-Assembly: 5821KWA(E), SB21KWC(E)

12

Deck

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

Sub-Assembly Parts List:

5821

KWA(E},

5821

KWC(E)

REF# PART#

300

301

302 NB3350

303 MP8038

304 TB1012

305 NB5700

306

307

308

309 MP4775

310

311

312

313

314

315

316

317

318

319

"''..10

1 NB6863

322

323

324

325

326

327

328

329

330

PD006021

NB9308

MP8310

MP032600

NB3275

MP7245

NB3260

NB6111

NB3265

MP9420

MP012801

MX1010

NB2643

MP9613

NB6525

NB003100

NB5000

MP9610

NB6044

NB9269

NB5282

NB3450

MP007900

SA003900

MP481001

DESCRIPTION

Pad,

21

",

Blue Blend

Bolt, Button HD 1/4"-20UNC x 1

Washer, Flat 1 /4"

Belt, BX-38

Flexi-Swivel

Washer, S.S

Velcro Stud

Padholder,

Nut, Lock 1/4"

Tensioner, Belt

Spindle Asm., w/BK65 Pulley

Nut, Lock 5/16"-18NC

Washer, Spring Lock 5/6"

Nut, Lock 5/16" -18

Wheel, w/Bracket 5"

Wheel, Caster Rear

Moulding, Bumper

Rivet, Pop 1/8" x 1/4"

Wire, Ground Hour Meter Assembly

Grommet 1/2" x 3/8" x 1"

Nut, Jam 3/8" x 16

Bolt, Hex HD 1/2" x 1" NC

Bolt, Carriage 5/6"-18 x 1"

Meter, Hour (RND)

Screw, Cap 3/8" x 1 1 /4"

Washer, Flat 7/16"

Bolt, Hex HD 5/16"-18 x 1"

Washer, Flat, 3/8

Deck, Resale, 21"

Padholder,

Block, Wheel, 14GA

..

755 x 1.005 x .060

21

",

Complete Asm.

21

",

W/Studs Only

Q1Y

1

6

12

1

1

50

1

6

1

1

3

2

1

4.8 Ft.

11

1

1

4

1

1

1

4

3

1

1

13

Deck

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

Sub-Assembly: TX24KWA(E), TX24KWC(E)

01M3601

14

Deck

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

Sub-Assembly Parts List: TX24KWA(E), TX24KWC(E)

REF# PART#

301

302

303 NB9308

304

305

306

307

308

309

310

311

312

313

314

315

316

317

318 NB6110 Washer, Lock, 1

319 NB9680 Bolt, Button HD, 1/4-20 x 1-1/2 2

320

8>'1

323

324

325 IN7800

326

327 NB6863

328

329

330

331

332

333 NB9670 Washer, 16M X 28M X 3M, Zinc

334 NB9675 Screw, 5/8-18 x 2-1/2, Cap

335 MP4770

336 TB2040 Guard, Belt, Turbo

337

338

339 NB2463 Screw, Set, 5/16-18 x 3/8, Hex Socket

340

341

342

MP8310

TB1210

NB3350 Washer, Flat, 1 /4

NB3275 Nut, Lock, 1/4

SA009000 Padholder, 24", Vortex, W/Studs only 1

NB5700 Washer, S.S

NB2643

TB9610 Hour Meter

PD006124 Pad, 24" Blue Blend-VTX 1

MP012700 Retainer, Pad, Center-Lok

NB6525 Grommet 1 /2" x 3/8" x 1" 1

NB52816 Bolt, Button HD, 1/4-20 x 1/2

NB003200 Bolt, Hex, HD, 1/4-20 x 5/8 2

MX1035 Bolt, Hex HD, 10-24 UNG 2

TB2489

MP027500

TB2060 Bag, Dust, Turbo

TB2061

TB2050

MP8150 Belt, B-49

TB7230 Spindle Assembly

MP9415 Wheel,

NB9269 Washer, Flat 7/16"

MP7802

MP8300 Velcro, Hook, 1"

TB000100

MP9613

MX1075 Lock Washer

NB1588

MP4805 Spacer

MP007800

MP024600

DESCRIPTION

Velcro Stud

Flexi-Swivel

Bolt, Button HD, 1/4-20 x 1

..

755 x 1.005 x .060 1

Rivet, Pop 1/8" x 1/4"

II

Skirt, Turbo

Caster, 3 1/2 Swivel, Pl~te Mount 1

/4

Hook, Dust Bag

Guard, Dust Bag, Turbo

Pulley

5"

Bolt, Hex HD 1 /2" x 1" NC

Key,

1/4 x 1/4 x 1-1/2

Spacer, Tensioner, Turbo 1

Ground Wire, Hour Meter

Tensioner, Belt

Bolt, Hex HD, 3/8 X 2-1/2 NC

Deck, Resale, 24"

Padholder, 24" Vortex, Complete Asm.

QTY

76

10

16

10

2

1

1

1

2

1

1

1

2

4

4

6 ft.

4

2

1

1

1

1

1

1

15

Deck

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

Sub-Assembly: SB28KWA(E}, SB28KWC(E)

010535Cl!I

~

I

'

01/0fl/H

16

Deck

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

Sub-Assembly Parts List: SB28KWA(E}, SB28KWC(E)

REF#

400

401

402

403

404

405 NB5700 Washer, S.S

406 MP8310 Velcro Stud

407

408

409

410

411

412

413 NB3265 Nut, Lock 5/16"-18 x 1 3

414 MP9420

415

416 MP4810

417

418

419

420 NB6525 Grommet 1/2" x 3/8" x 1" 1

422

423 NB5290 Bolt, Hex HD 5/16"-18 x 1-1/2 3

424 NB6863

425

426 MP9610 Meter,

427 NB6044

428

429

430

431

432

433 SA004000 Padholder, 28", W/Studs only

PART#

PD006028

NB9319 Bolt, Button HD 1/4"-20UNC x 1.25 6

NB3350 Washer, Flat 1 /4" 12

MP008900

TB1210 Flexi-Swivel

MP032500 Padholder, 28" Complete Asm. 1

NB3275 Nut, Lock 1/4" 6

MP4775

MP7240 Spindle Asm.

NB3260 Nut, Lock 5/16"-18NC

NB6111

MP012801 Wheel, Caster Rear 1

MX1010 Moulding, Bumper

NB2643 Rivet, Pop 1 /8" x 1 /4"

NB3450 Washer, Flat 3/8 1

MP012700 Retainer, Pad

NB003100 Nut, Jam 3/8" x

NB5050 Bolt, Carriage 5/6"-18 x 1-1/2 1

NB9269 Washer, Flat 7/16"

MP9613 Ground Wire, Hour Meter 1

MP008200 Deck, Resale, 28" 1

MP481001 Wheel Block, .07 4 Thk. 2

MP481002

DESCRIPTION

Pad, 28", Blue Blend

Belt, BX-52

..

755 x 1.005 x .060

Tensioner, Belt 1

w/

BK-90 Pulley 1

Washer, Spring Lock 5/6" 2

Wheel, w/Bracket 5" 2

Wheel Block

16

Bolt, Hex HD 1 /2" x 1"

Hour

(RND) 1

Screw, Cap 3/8" x 1 1/4"

Wheel Block, 1 /8 Thk. 1

NC

QTY

1

1

70

11

1

4

4

17

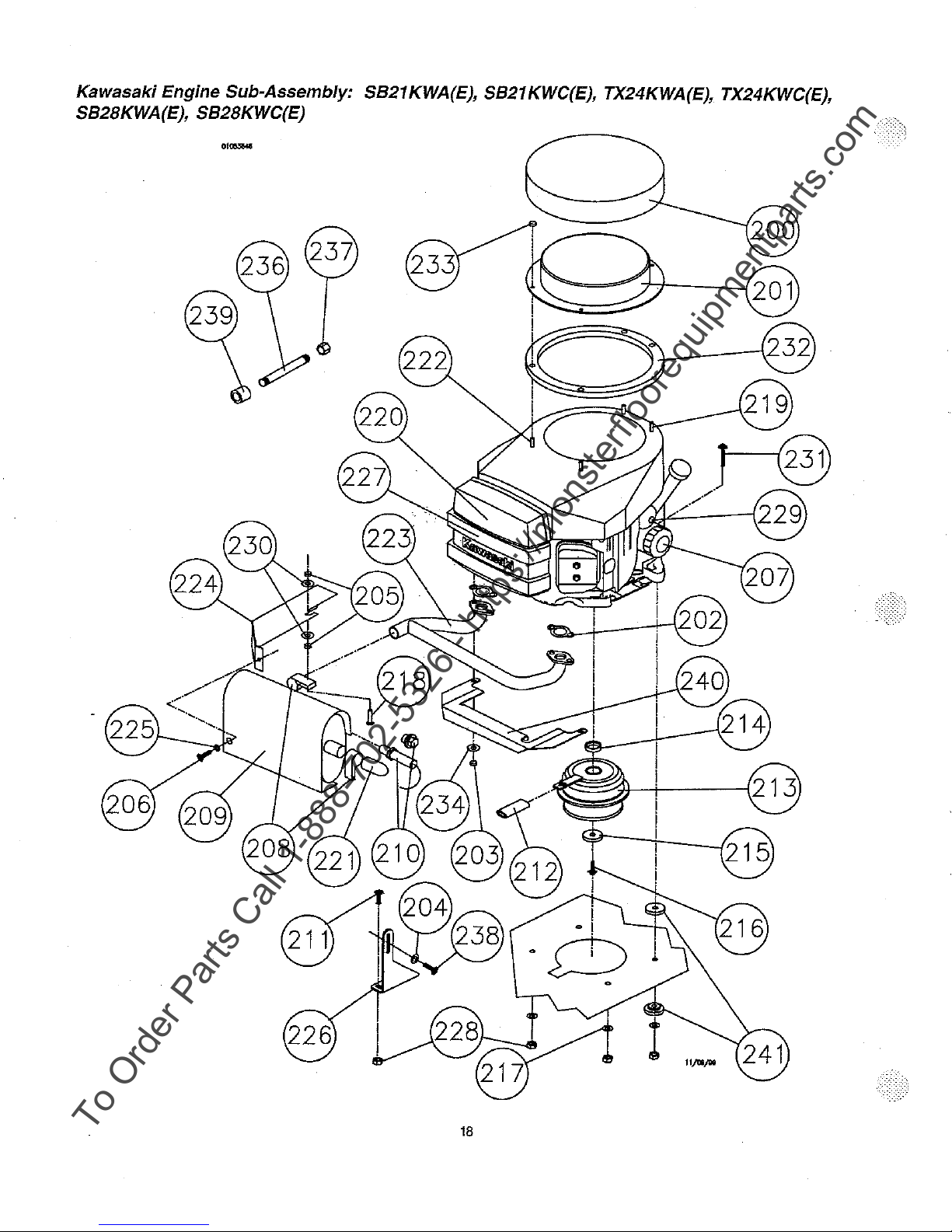

Kawasaki Engine Sub-Assembly:

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

S828KWA(E), S828KWC(E)

........

5821

KWA(E),

5821

KWC(E), TX24KWA(E), TX24KWC(E),

18

Kawasaki Engine Sub-Assembly Parts List: SB21KWA(E}, SB21KWC{E), TX24KWA(E},

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

TX24KWC(E}, SB28KWA(E}, SB28KWC(E)

REF#

200

201

202 KA

203 KA317R0800 Nut,8mm

204 KCX2578

205 NB3260

206 NB3001

207

208

209

210 MP018000 Oxygen Sensor (KWA models)

210 MP015200 Oxygen Sensor Plug (KWC models)

211

212 MP4790 Norprene Tubing

213

214

215 MP4805 Spacer,

216 NB005800 Screw, Hex

217 NB9267 Washer, Flat 5/16"

218 NB004100 Bolt, Carriage 5/16-18 x

219 KA920042148 Back Stud Long

221

222

223

224 MP017400

225 MX1115 Washer, StarLock, 1/4"

226

227 KA110137002 Air Filter

228 NB3265

229 MP019200 Oil Pressure Switch

230 NB9267

231 NB000100 Screw, Hex HD, 5/16-18 X 1 3/4

232 MP035500 Filter Seal

233

234 KA461F0800 Lock Washer

235

236 MP022200

237 NB006800

238 KCM639016

239 KA590717004

?'"

PART#

MP035200

MP035100 Support, Filter, Kawasaki

11

0607006 Gasket

KA490652078 Oil Filter

MP017000 Clamp, Muffler

MP013501 Muffler, Front Mount, Catalytic

NB5282 Bolt, Button HD, 5/16-18 X 1

MP4787

MP4800

KA110137001

MP016700 Def I ector, Exhaust

KA920042147 Front Stud Short

MP030700

MP030800

MP045200

MP045300

KA920151170 Acorn Nut

NB006400 Washer, Fender 1/4 x 1 1/4

MP022202

MP043400

DESCRIPTION

Filter, Recoil, Kawasaki

Washer

Nut, 5/16-18

Screw, 1/4-20 x 3/4

Clutch, Model 5215-63

Spacer, Clutch Top

Bottom.Clutch Hub Base

HD;

1/16-20 x 17/16 x 1 1/2

2"

Air Precleaner

Manifold (21" models)

Manifold (24" & 28" models)

Shield, Manifold

Muffler Bracket (SB models)

Muffler Bracket (TX models)

Nut, Lock, 5/16-18

Washer, Flat, 5/16

Nipple, Pipe, 4" (21" models)

Nipple, Pipe, 3" (24" & 28" models)

Cap, Pipe

M6

Screw, HH, Flange,

Oil Drain Adapter

Manifold Shield

x 1 x 16

QTY

1

1

2

4

2·

2

6

1

2

1

1

1

3

2.4"

1

1

1

1

3

1

2

1

1

2

1

1

1

5

1

1

1

6

1

2

4

1

4

4

4

1

1

1

1

1

1

19

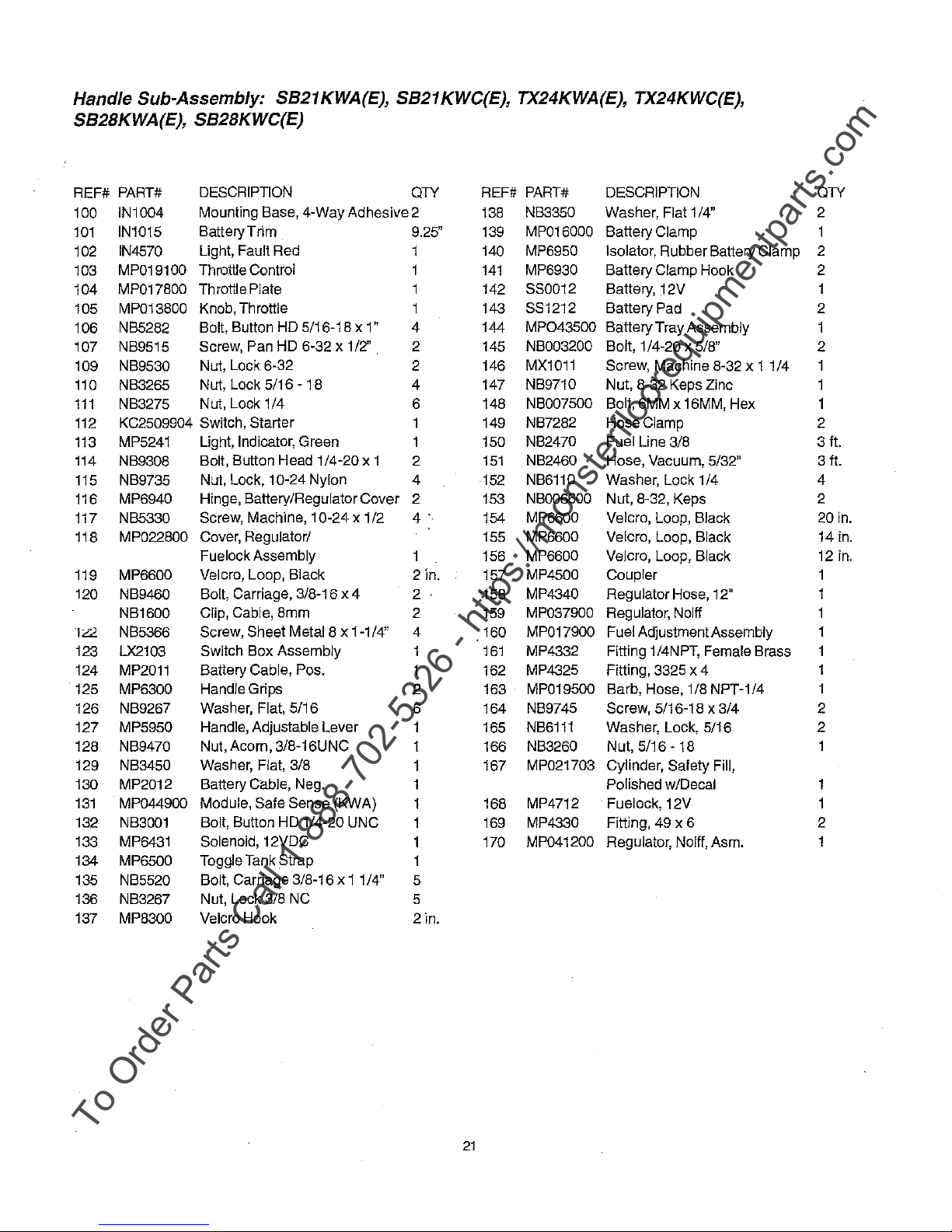

Handle Sub-Assembly:

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

S828KWA(E), S828KWC(E)

5821

KWA(E),

5821

KWC(E), TX24KWA(E), TX24KWC(E),

126

~--------

'

'

""""

20

Handle Sub-Assembly:

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

5821

S82BKWA(E}, S828KWC(E)

KWA(E},

5821

KWC(E}, TX24KWA(E}, TX24KWC(E),

REF# PART#

100 IN1004

101

IN1015

IN4570 Light, Fault Red

102

MP019100 Throttle Control

103

MP017800 Throttle Plate 142

104

MP013800 Knob, Throttle 143

105

NB5282

106

107 NB9515

109 NB9530

110 NB3265 Nut, Lock 5/16 - 18 4 147

NB3275 Nut, Lock 1

111

KC2509904 Switch, Starter 149

112

MP5241 Light, Indicator, Green 150

113

114

NB9308

NB9735

115

116 MP6940

117 NB5330

118 MP022800

MP6600 Velcro, Loop, Black

119

120 NB9460 Bolt, Carriage, 3/8-16 x 4 2

NB1600

"1"2

NB5366

123 LX2103

124

MP2011

125 MP6300

NB9267 Washer, Flat, 5/16

126

127 MP5950

128 NB9470

129 NB3450 Washer, Flat, 3/8

MP2012 Battery Cable, Neg.

130

131

MP044900

132 NB3001

133 MP6431 Solenoid, 12VDC

134 MP6500 Toggle Tank Strap

135 NB5520

136 NB3267

137 MP8300 Velcro Hook

DESCRIPTION

Mounting Base, 4-Way Adhesive 2

Battery Trim

Bolt, Button HD 5/16-18 x 1"

Screw, Pan HD 6-32 x 1/2'' 2 145 NB003200 Bolt, 1 /4-20 x 5/8"

Nut, Lock 6-32

/4

Bolt, Button Head 1/4-20 x 1

Nut, Lock, 10-24 Nylon

Hinge, Battery/Regulator Cover

10-24

Screw, Machine,

Cover, Regulator/

Fuelock Assembly

Clip, Cable, 8mm

Screw, Sheet Metal 8 x 1-1/4"

Switch Box Assembly

Battery Cable, Pos.

Handle Grips

Handle, Adjustable Lever

Nut, Acorn, 3/8-16UNC

Module, Safe Sense (KWA)

Bolt, Button HD 1/4-20 UNC

Bolt, Carriage 3/8-16 x

Nut, Lock 3/8 NC

x 1/2

11/4"

QTY

9.25" 139

1

4

2 146

6 148

2

4

2

4·

2 in. 157

2 159

4 160

2 163

6 164 NB9745 Screw, 5/16-18 x 3/4

1 165

1 166 NB3260 Nut,

1 167

5

5

2in.

REF# PART# DESCRIPTION

138

140 MP6950 Isolator, Rubber Battery Clamp

141

144 MP043500

151

152

153

154 MP6600

155

156

'158

161

162

168

169

170

NB3350 Washer, Flat 1 /4"

MP016000

MP6930 Battery Clamp Hook

880012

881212

MX1011

NB9710

NB007500

NB7282

NB2470

NB2460

NB6110

NB006600 Nut, 8-32, Keps

MP6600

MP6600

MP4500 Coupler

MP4340 Regulator Hose, 12"

MP037900

MP017900

MP4332

MP4325 Fitting, 3325 x 4

MP019500 Barb, Hose, 1/8 NPT-1/4

NB6111

MP021703 Cylinder, Safety Fill,

MP4712 Fuelock, 12V

MP4330 Fitting, 49 x 6

MP041200

Battery Clamp

Battery, 12V

Battery Pad

Battery Tray Assembly

Screw, Machine 8-32 x 1 1

Nut, 8-32 Keps Zinc

Bolt, 6MM x 16MM, Hex

Hose Clamp

Fuel Line 3/8

Hose, Vacuum, 5/32"

Washer, Lock 1 /4

Velcro, Loop, Black

Velcro, Loop, Black

Velcro, Loop, Black

Regulator, Nolff

Fuel Adjustment Assembly

Fitting 1 /4NPT, Female Brass

Washer, Lock, 5/16

5/16-18

Polished w/Decal

Regulator, Nolff, Asm.

/4

QTY

2

1

2

2

2

2

1

2

3 ft.

3 ft.

4

2

20

14

12

1

1

1

1

2

2

2

in.

in.

in.

21

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

PAC~E~

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

Limited Warranty

Burnishers - Stripping Machines - Scrubbing Machines

To

qualify

for

this

Warranty:

1) Machine must be registered at the time of purchase on a form provided

Pioneer Eclipse Distributor is responsible for the registration of your machine. Please cooperate

Distributor

2) The machine must have been purchased from Pioneer

3) This warranty extends to the original purchaser only and is not transferable to subsequent owners.

TIME PERIODS

TWO (2) YEAR WARRANTY - For the following models: PE1700, Laser X, Magna 2000. Warranted to be free from

defects in material and workmanship for a period

owners. (See Exclusions.)

ONE

('1)

to be free from defects in material and workmanship

the original owners. (See Exclusions.)

in

supplying necessary information on the card.

of

two (2) years from the date

YEAR WARRANTY - For the following models SB,

Eclipse or an authorized Pioneer Eclipse Distributor.

SP,

ST,

for

a period of one

TX, XL,

by

Pioneer Eclipse® Corporation. Your

of

purchase

BA,

and the StarStrip 2400. Warranted

{'1)

year from the date of purchase by

with your

by

the original

L-'°

-,'N.....,.''-.

I

i....:::"""'

°]

EXCLUSIONS

'1)

Parts that fail through normal wear

body molding,

2) This warranty does not extend to parts affected by -misuse, neglect, abuse or improper maintenance.

defective parts must

3) Batteries warranted by battery manufacturer

4) Propane Engine warranted by engine manufacturer for 2 years (Note: The engine warranty period can

extended to a four (4) years

Contact your Pioneer Eclipse distributor for more information regarding this optional extended warranty

program.)

5) Valve train warraned

5) Electric motors warranted by motor manufacturer.

6) Deck Frame warranted

THE OBLIGATION OF PIONEER/ECLIPSE CORPORATION

1) The obligation of Pionee, Eclipse under this warranty is limited to repairing or replacing,

which

above.

2) Warranty repairs

3) Parts repaired or replaced under this warranty are warranted only during the balance of the original warranty

period.

WARRANTY SERVICE

To

obtain warranty service, take your machine and proof

Pioneer Eclipse

Eclipse Customer Service Department at 800 367 3550. If you are dissatisfied

or

write Pioneer Eclipse Customer Service Department for further assistance.

call

DISCLAIMER

PIONEER

MACHINE

APPLICABLE

OTHERWISE

...._

THE

1

COMPANY.

~

(Not

Covered

skirting, squeegees or other consumable parts).

is

proven to

All defective parts replaced ·under these warranties become the property

ECLIPSE

OR

ANY

TO

WARRANTY

be

will

will not reimburse expenses for service calls

OF

CONSEQUENTIAL

DISCLAIMS

OTHER

EACH

MACHINE.

by

Warranty)

by

reason

of

their characteristics (cords, pads, brushes, belts, bumpers,

be

returned

by

by

defective ln material or workmanship under normal use for the applicable period stated

be

made by your Pioneer Eclipse Distributor without charge for parts and labor.

INCIDENTAL

ANY

to

the

Dlstri_butor

on

Kawasaki engines providing the customer uses only approved Kawasaki oil.

Pioneer Eclipse for (1) year.

Pioneer Eclipse for (5) years.

ANY

RESPONSIBILITY

OR

CONSEQUENTIAL

EXCEPT

MACHINE

AS

AND

Copyright 2000 Pioneer Eclipse Corporation

for

('1)

FOR

STATED

NO

WARRANTY,

for ~credit.

year.

of

purchase to any authorized Pioneer Eclipse Distributor.

or

travel. For the Distributor

LOSS

OF

USER

TIME

EXCEPT

WARRANTIES,

IMPLIED

IN

DAMAGE

SUCH

EXPRESS,

at

its option, any part

of-

Pioneer Eclipse.

in

with the service that you receive,

OF

THE

AS

THE

your area, call Pioneer

PIONEER

STATED

COMPANY

OR

STATUTORY

IN

THE

DOES

ECLIPSE

WARRANTY

NOT

IS

~~

All

be

MADE

BY

.ll

~

,-

I

.L..-:.....,~::::~

ifLh (

_

~r

1

\\ 11"

~

Article#

To Order Parts Call 1-888-702-5326 - https://monsterfloorequipmentparts.com

Serial#

DOM:

Place Built: NC. USA

PIONEER ECLIPSE® CORPORATION

ECLIPSE ROAD. SPARTA. NC 28675

PHONE: 1-336-372-8080 OR 1-800-367-3550

______

_

© 2000 Pioneer Eclipse® Corporation

Machine Directive 98/37/EC as amended

Directive 91/368/EEC. Directive 93/44/EEC. and

CE

Certification applies

as indicated

only

to

machines

by

KWAE extension on

by

Directive 89/392/EEC.

by

Directive 93/68/EEC.

for

export

part

with

SafeSense

number.

LT014500-F

4/6/00

Loading...

Loading...