Pioneer WYD-GLFI SERIES, WD Series, YN Series Service Manual

Troubleshooting and Repair Guideline for

WD Indoor / YN Outdoor Units

Series DC Inverter Air Conditioner

WYD-GF16-S1-1714

SERVICE MANUAL

DC INVERTER

SPLIT WALL-MOUNTED

DUCTLESS HEAT PUMPS

WYD-GLFI SERIES

16 SEER VERSIONS

1

Contents

I. Electrical Control of Inverter Air Conditioner········································································2

1. Main compositions of the electrical control of inverter air conditioner·······························2

2. Wiring of Inverter AC Unit ································································································3

3. Current Flow ······················································································································4

4. Computer Control Function Flow Chart for Inverter AC Unit ············································5

5. Protection and Fault Codes·································································································5

II. Troubleshooting····················································································································8

1. According to the fault code ································································································8

(1) Display E1 or E2:·············································································································8

(2) Display E6························································································································9

(3) Display E3, E7, E8 ···········································································································10

(4) Display E4························································································································11

(5) Display EC ·······················································································································13

(6) Display EP························································································································14

(7) Display EA·······················································································································16

(8) Display EU·······················································································································17

(9) Display E9 (Firstly display P0 or P9, then change to E9)··················································18

(10) Display E0、E5··············································································································20

(11) Display EE ·····················································································································22

(12) Display P0······················································································································23

(13) Display P1······················································································································24

(14) Display P2······················································································································24

(15) Display P4······················································································································25

(16) Display P5······················································································································25

(17) Display P6······················································································································26

(18) Display P7······················································································································27

(19) Display P8······················································································································27

(20) Display P9······················································································································28

2. Other faults ························································································································29

1) The indoor unit works normally but the outdoor unit does not work.·································29

2) The outdoor unit is stopped when the air conditioner has run for a period of time ·············29

3) The air conditioner is tripped when it is started.·································································30

4) The complete unit does not work·······················································································30

Appendix 1································································································································31

Appendix 2································································································································34

Appendix 3································································································································36

Cautions on Replacement of PCB Boards··················································································37

2

I. Electrical Control of Inverter Air Conditioner

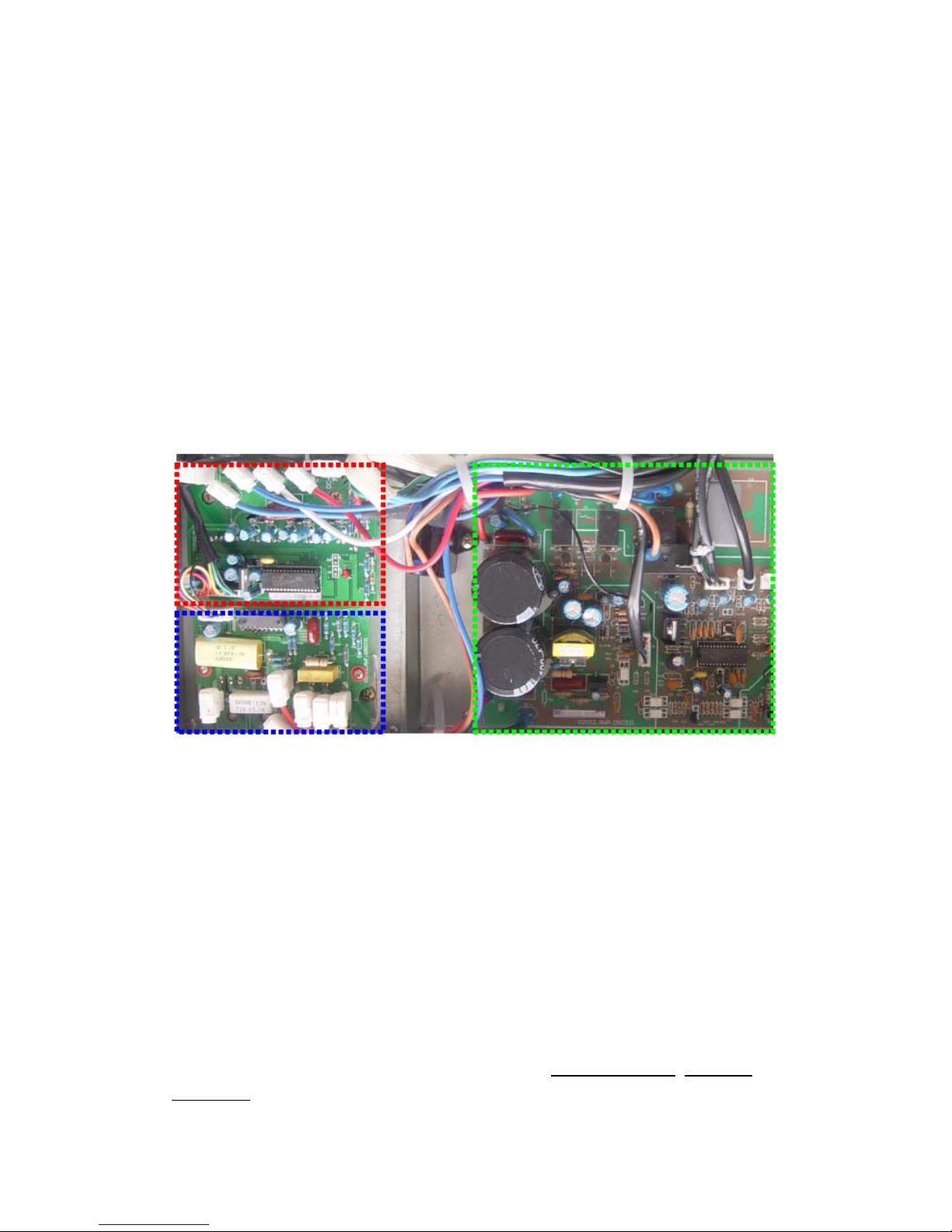

1. Main compositions of the electrical control of inverter air conditioner

The electrical control of inverter air conditioner is divided into indoor control system and outdoor

control system.

Relative to the fixed-speed air conditioner, the indoor control system is added with one

communication circuit, but removed of the control circuits for compressor, 4-way valve and

outdoor fan. The other circuits are basically the same.

The outdoor circuit is generally divided into three parts, i.e. outdoor power source board, Power

Factor Correction (PFC) board and Intelligent Power Module (IPM). The details are as follows:

PFC board Outdoor power source board

WT/WL-LI Inverter Air Conditioner Model 1 – 1.5P has been developed for four generations.

The 1

st

generation (V1) applies 120° square wave control plan and the all PFC plan is used for

power treatment.

The 2nd generation (V2) remains to apply 120° square wave control plan, but the partial PFC plan

is used for power treatment. This product is never put into batch production.

The 3

rd

generation (V3) applies 180° sine wave plan and partial PFC plan. This model is also few.

The 4

th

generation (V4) remains to apply 180° sine wave plan (including 2P unit), where only

significant adjustment is made to the function architecture. That is, the indoor control plan applied

for the 1

st

and 2nd generation is changed to outdoor control (For details on the function distribution,

please refer to the Control Function Chart below.

The 5

th

generation(V5), the function is same as V4, but the Power source board, PFC board and

IPM board

have already integrated onto one board (All-In-One) for easily installation and

IPM board

3

repairing.

The products 2P and higher are mainly developed for two generations.

The 1

st

generation (VP1) applies NEC 180° sine wave plan and indoor control.

The 2

nd

generation (VP2) applies TI DSP 180° sine wave plan and outdoor control. (Exclusive of

2P unit).

There are derivative models, e.g. full DC inverter unit, inverter floor-standing unit and LC plan.

See Appendix 1 for details.

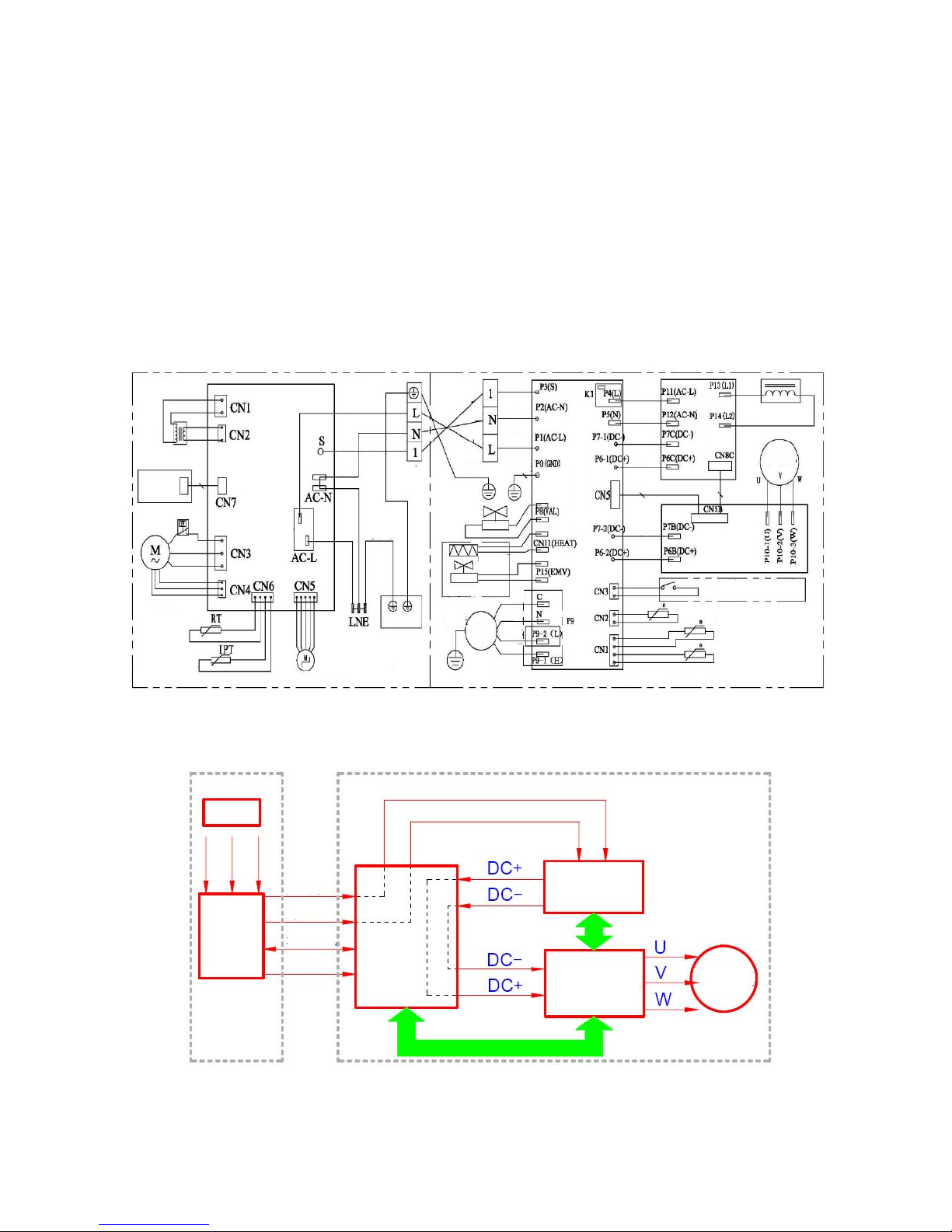

2. Wiring of Inverter AC Unit

3. Current Flow

Power

supply

Live

N

eutral

Ground

Live

N

eutral

Communicati

on wire

Ground

Main

control

board

Indoor

unit

Outdoor

power

source

Live

N

eutral

Outdoor

Unit

PFC board

IPM board

Compressor

Tran sforme r

Display circuit

board

Motor

protector

Fan Motor

Room temperature

sensor

Coil temperature

sensor

Main control

board

Rela

y

Guide louver

moto

r

Y/G

B

rOr

BL

BL

BR

Indoor uni

t

Y/G

Heat exchange

r

Wh

BL

B

r

Y/G

O

r

BL

Y/G

4-way Valve

BL

Electric

Heater

Solenoid

valve

Optional

Y/G

Outdoor uni

t

Fan

motor

O

r

BL

Re

BL

N

ote: There is no LOW FAN for single-speed motor P9-2

B

r

BL

Re

BL

Outdoor power source boar

d

BL

Re

Re

Re

Reactor

Compressor

Re

Wh

BL

Module board

Compressor top protection switch

(Optional)

Exhaust temperature senso

r

Outdoor temperature sensor

Outdoor coil temperature sensor

Port: P9 pair port for dual-speed moto

r

4

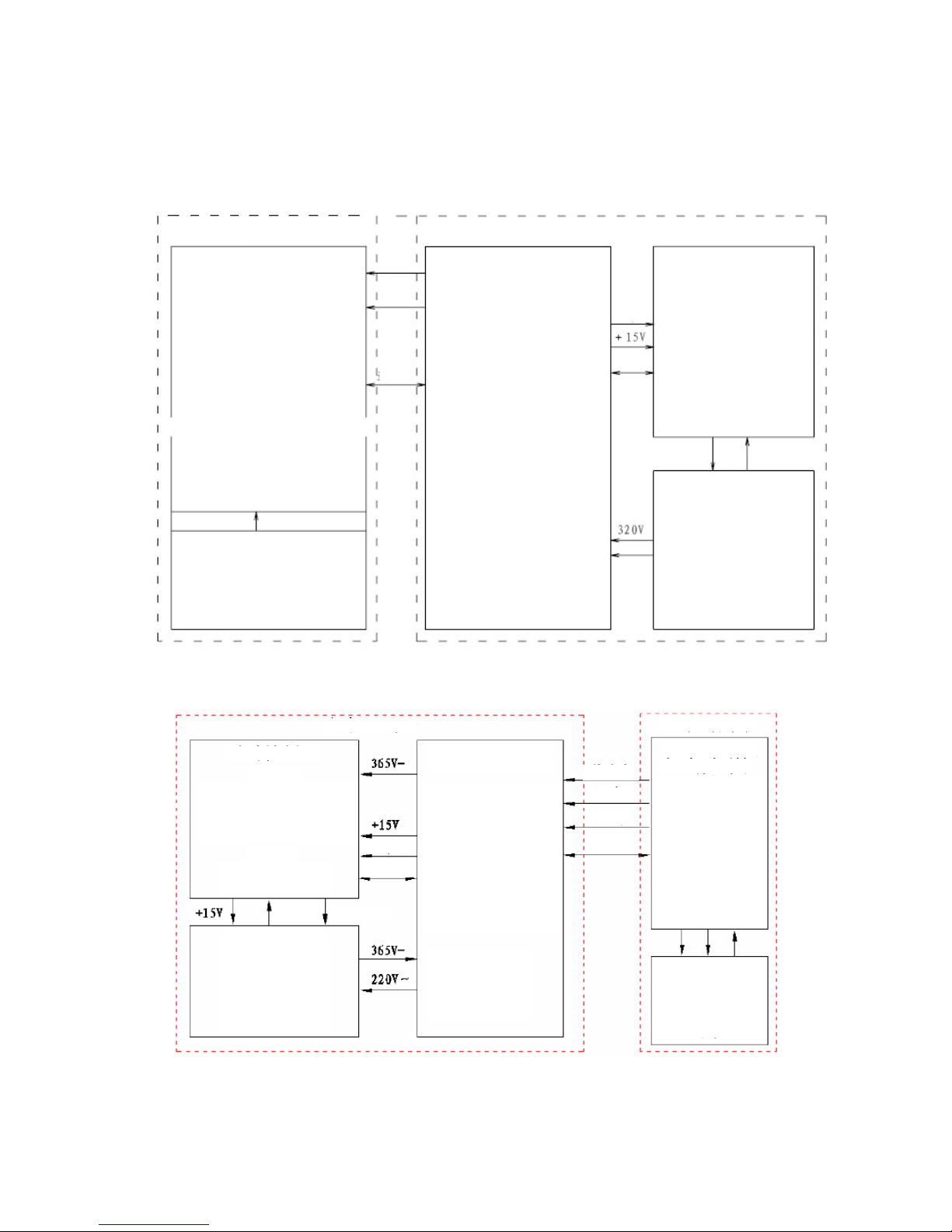

4. Computer Control Function Flow Chart for Inverter AC Unit

1) Outdoor control plan

2) Indoor control plan

Indoor control system

Indoor control board

Communication with outdoor unit

Indoor fan control

Louver motor control

Health assembly control

Temperature detection

Fan speed feedback

Electric heater control

Selection of cool-heat and cool-only

model

Selection of data sheet

Selection of Fahrenheit and

Centigrade temperature

Selection of LED OR without LED

display

Signal input

Display board

Temperature or fault code display

Emergencyl Switch signal input

Remote signal input

Live

N

eutral

Communi

cation

wire

Outdoor control system

Outdoor power source board

Storage of working parameters

Frequency generation

Outdoor temperature detection

Communication with indoor unit

Outdoor fan control

4-way valve control

Outdoor power treatment

Power ON/OFF

Communication with IPM

Fault and compressor state

indication

Switch signal on top of the

compressor

Chassis heating control

Electronic expansion valve control

Pressure switch signal processing

Voltage sampling

Signal

wire

Commu

nication

IPM module

Communication with power

source board

Compressor drive

IPM fault output

PFC control DC power

Outdoor PFC board

AC rectifier

Power factor adjustment

Protection current sampling

Outdoor control

IPM module

ST72141

Communication with power source

board、PFC control、IPM drive、Current

sampling and processing 、 Voltage

sampling and signal processing 、

Detection of compressor feedback signal

PS21865

Compressor inverter drive

IPM fault signal output

Signal

wire

PFC control

Signal wire

Outdoor PFC board

AC rectifier

Power factor adjustment

Boosting of DC voltage

Protection current sampling

Harmonic inhibition

Outdoor power source

b

oar

d

TMP86F807N

Temperature detection

Communication with indoo

r

unit

Outdoor fan control

4-way valve control

Communication with module

board

Power source indication

Repair key signal processing

Compressor top temperature

protection

BMC processing

AC voltage sampling

DC harmonics

Supply DC power

Ground wire

Communic

ation wire

Communic

ation wire

L wir e

N

wire

Indoor control

Indoor main PCB

TMP86PH46NG

Working frequency control

Indoor fan control

Swing motor control

Temperature detection

Storage of model

p

arameters

Operating signal processing

Outdoor power supply

Audio indication fo

r

operation

Communication with

outdoor unit

Other optional functions

Indoor display panel

Remote signal acceptance

Preset temperature display

Protection and fault display

Key operation

5

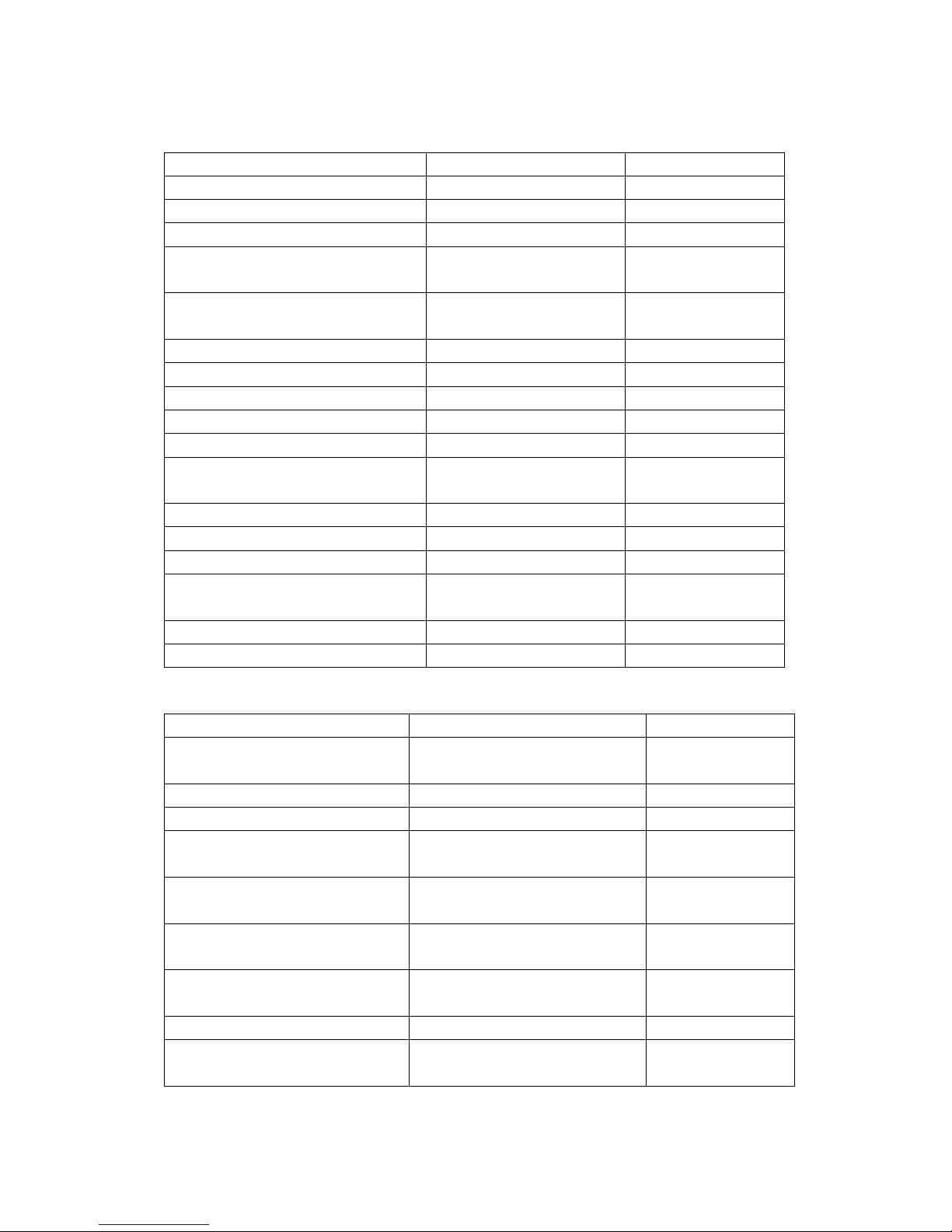

5. Protection and Fault Codes

Fault Code

Fault Type

Function Indicator (flash) Digital LED display

Indoor/outdoor communication fault RUN & TIMER: Blink E0

outdoor communication fault RUN & TIMER: Blink EC

Room temperature sensor (IRT) RUN-1/8 sec. E1

Indoor pipe (coil) temperature sensor

(IPT)

RUN-2/8 sec. E2

Outdoor pipe (coil) temperature sensor

(OPT)

RUN-3/8 sec. E3

System abnormal RUN-4/8 sec. E4

Model configuration wrong RUN-5/8 sec. E5

Indoor fan motor fault RUN-6/8 sec. E6

Outdoor temperature sensor RUN-7/8 sec. E7

Exhaust temperature sensor RUN-8/8 sec. E8

Intelligent power module of drive and

module fault

RUN-9/8 sec. E9

Outdoor fan motor fault (DC Motor) RUN-10/8 sec. EF

Current sensor fault RUN-11/8 sec. EA

EEPROM fault RUN-12/8 sec. EE

Temperature switch fault (on top of the

compressor)

RUN-13/8 sec. EP

Voltage sensor fault RUN-14/8 sec. EU

Intake temperature sensor RUN-15/8 sec. EH

Protection Code

Protection Type Function Indicator (flash)

Digital LED display

Overvoltage /

undervoltage protection

RUN: Blink; TIMER: 1 blink /8 sec P1

Overcurrent protection RUN: Blink; TIMER: 2 blink /8 sec P2

Exhaust overtemperature protection RUN: Blink; TIMER: 4 blink /8 sec P4

Subcooling protection

under cooling mode

RUN: Bright; TIMER: 5 blink /8

sec

P5

Overheating protection

under cooling mode

RUN: Bright; TIMER: 6 blink /8

sec

P6

Overheating protection

under heating mode

RUN: Bright; TIMER: 7 blink /8

sec

P7

Outdoor overtemperature

/ undertemperature protection

RUN: Bright; TIMER: 8 blink /8

sec

P8

Drive protection (software control ) RUN: Blink; TIMER: 9 blink /8 sec P9

Module protection (hardware

control)

RUN: Blink; TIMER: 10 blink /8

sec

P0

6

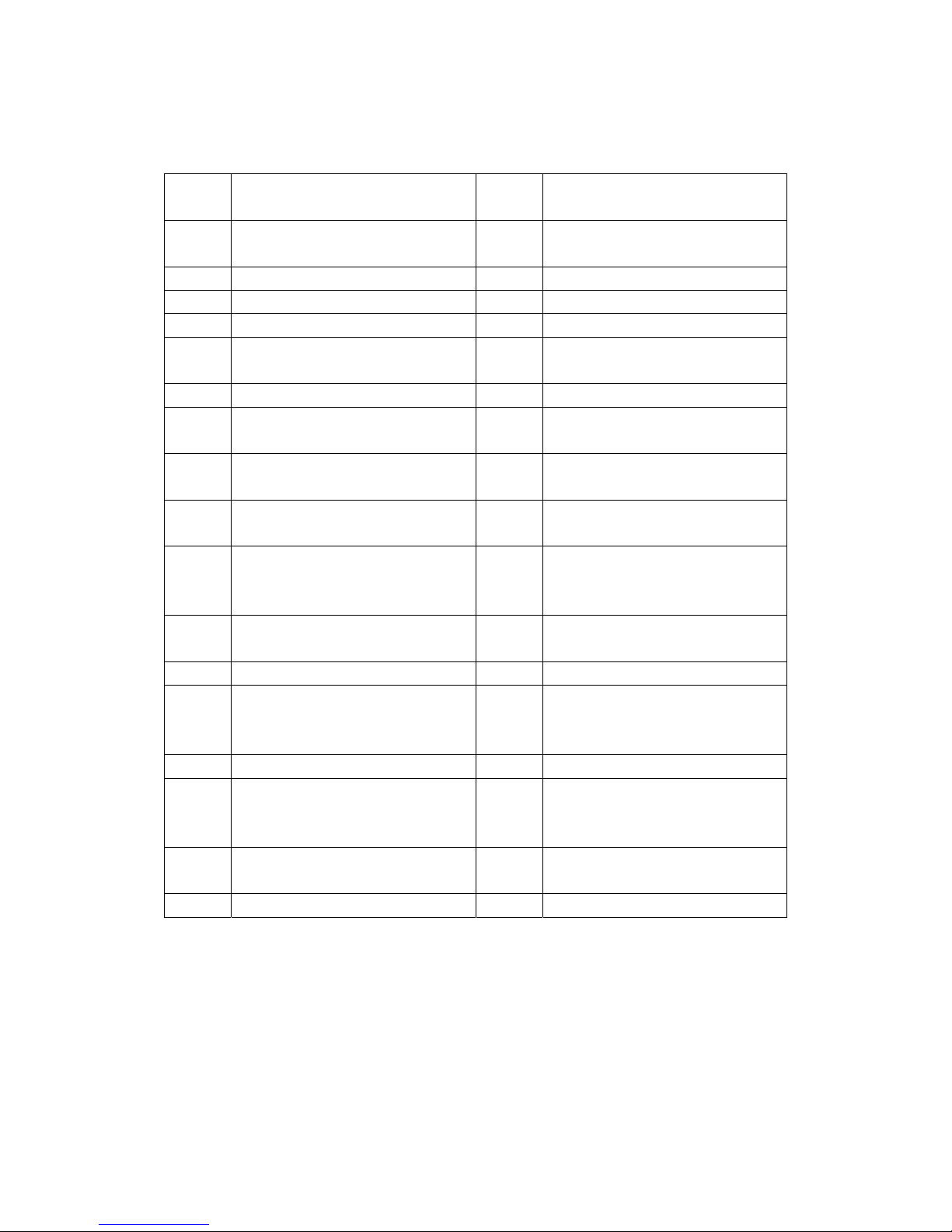

Display on outdoor power source board: The indicator alerts the fault in a cycle as such that it is

bright for 0.5 seconds, dark for 0.5 seconds, blinks “n” times and then dark for 3 seconds.

Blink

times(n)

Fault Message

Blink

times(n)

Fault Message

1 IPM protection 18

Short-circuit / open-circuit fault of

intake temperature sensor

2 Overvoltage / undervoltage 19 Outdoor EEPROM fault

3 Overcurrent 20 Outdoor fan motor protection

4 Exhaust overtemperature protection 21 Indoor fan motor protection

5

Outdoor coil overtemperature

protection

6 Drive fault and protection (V1,VP1) 23 System in shortage of Freon

7

Communication fault with indoor

unit

24 Model configuration wrong

8

Compressor overheat fault

(compressor top switch)

25 Indoor sensor fault

9

Short-circuit / open-circuit fault of

outdoor temperature sensor

26 Indoor coil sensor fault

10

Short circuit / open-circuit fault of

outdoor heat exchanger temperature

sensor

27 Indoor EEPROM fault

11

Short-circuit / open-circuit fault of

exhaust temperature sensor

28 Indoor fan motor fault

12 Voltage sensor fault 30 drive fault(V4、VP2)

13 Current sensor fault 31

Outdoor environmental

overtemperature /

undertemperature protection

14 IPM fault 32 Indoor coil deforst prevention

15

communication fault between power

source board and intelligent power

module

33 Indoor coil overheating protection

16

No feedback from DC fan

motor(outdoor unit)

17 Defrost state

7

Display on V5 All-in-one board

Blink

Counts

Fault Message

Blink

Counts

Fault Message

1 IPM fault 2

Short-circuit / open-circuit fault of

outdoor temperature sensor

3 Outdoor coil sensor fault 4 Absorption temperature sensor fault

5 Exhaust temperature sensor fault 6 Current sensor fault

7 Compressor drive fault 8 Compressor drive protection

9 Outdoor overheat protection 10 IPM protection

11 AC overcurrent protection 12 Exhaust Temperature Protection

13 Compressor top temperature protection 14 Exhaust Overtemperature Protection

15 Voltage protection 16 Exhaust underpressure protection

17 Exhaust Overpressure Protection 18 Indoor antifreeze protection

19 Indoor overheat protection 20 Indoor / outdoor communication fault

21 Outdoor EEPROM fault 22

Outdoor ambient overtemperature

protection

23 Outdoor DC fan fault 24 Outdoor coil overheat protection

25 Model configuration wrong 26 Indoor fan fault

27 Reserved 28 Reserved

29 Reserved 30 Reserved

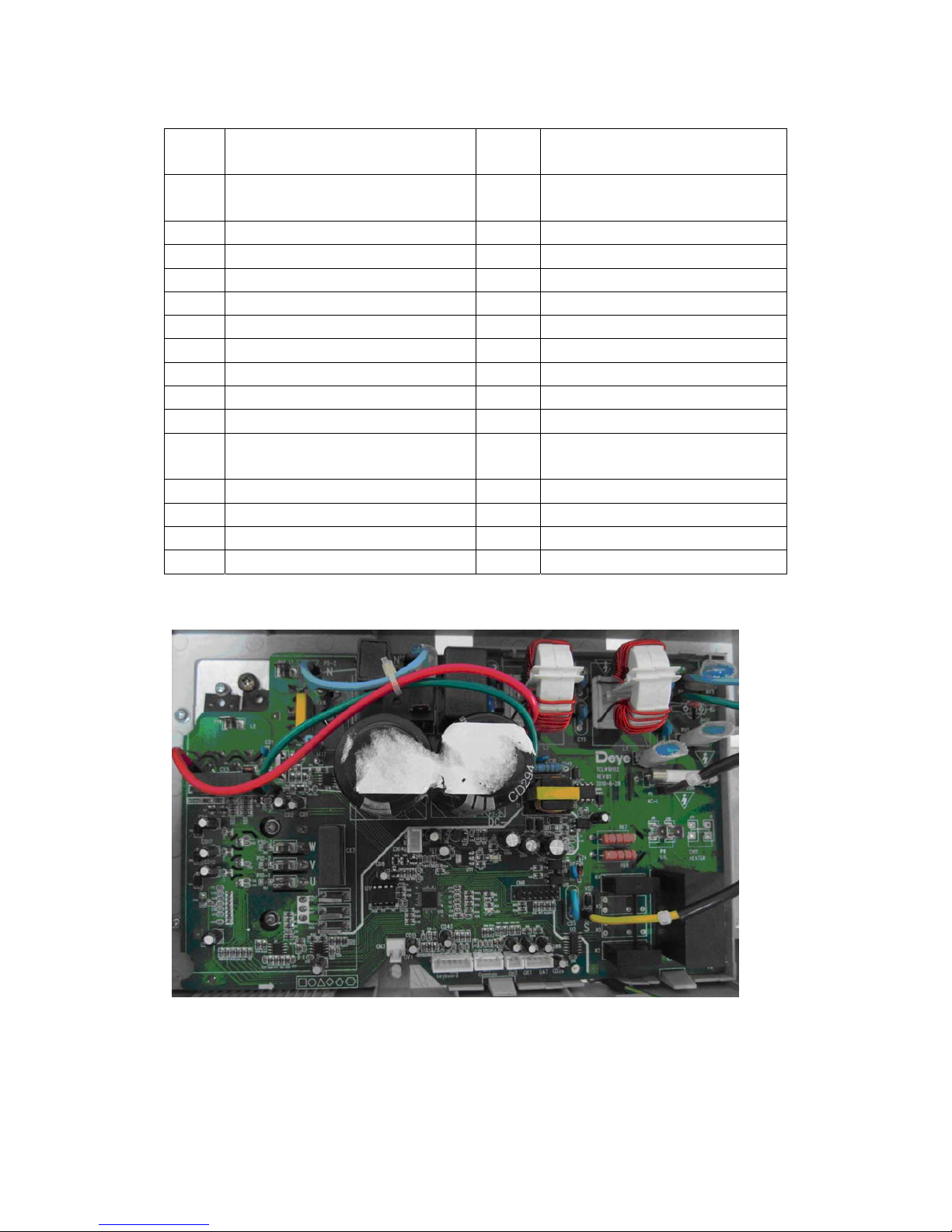

V5 All-in-one board

8

II. Troubleshooting

1. According to the fault code

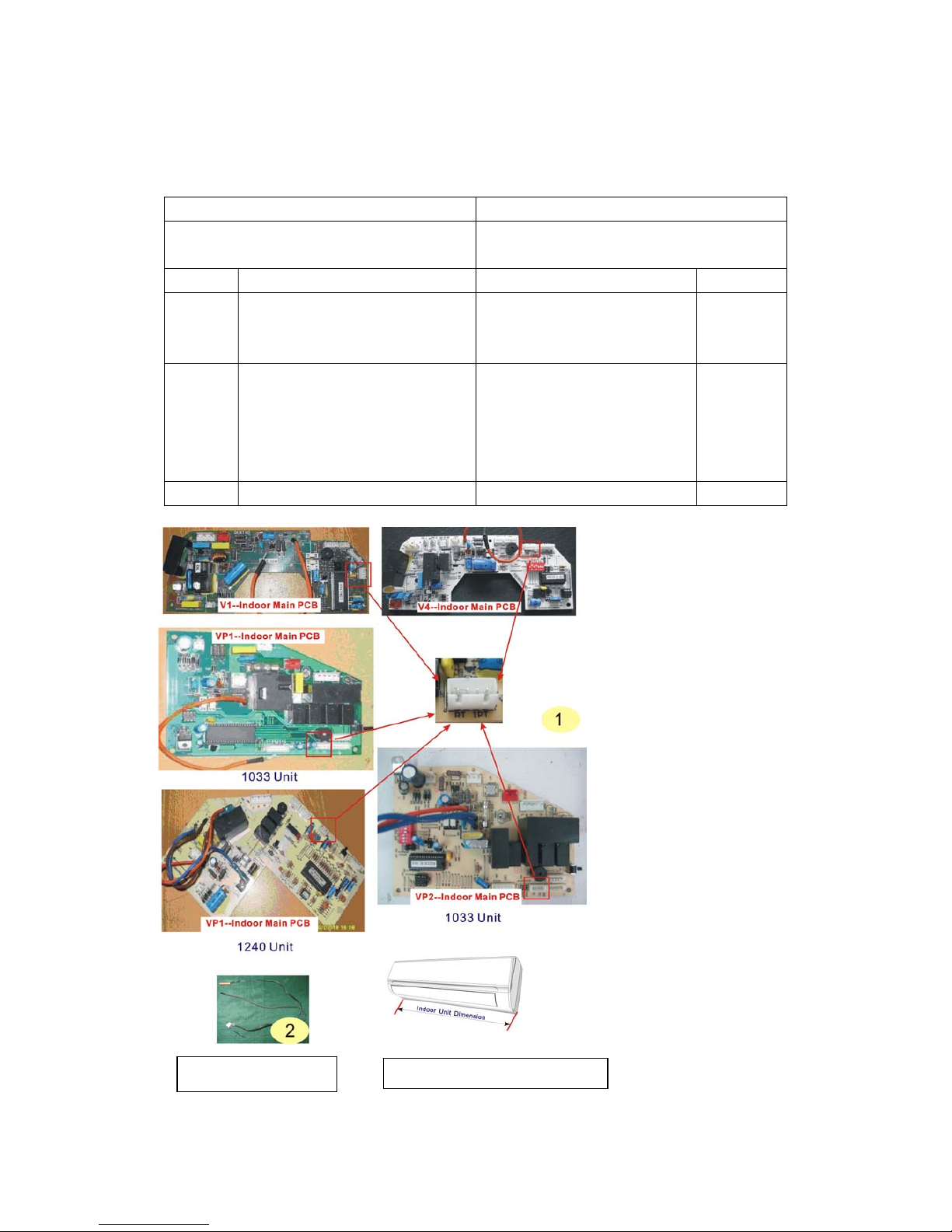

(1) Display E1 or E2:

Symptom Display E1 or E2

Cause

Room temperature sensor (IRT) and Indoor

pipe (coil) temperature sensor (IPT) fault

S/N Inspections How to Solve Remarks

1 Contact between indoor

temperature sensor CN6 (RT, IPT)

and slot

Insert again if loose. Photo 1

2 Measure the resistance on the two

ends of indoor temperature sensor:

(25 / 5KΩ). For other resistance, ℃

please refer to the Temperature –

Resistance Sheet (Appendix 1).

Replace the temperature sensor

if the resistance is incurred to

drift, open or short circuiting.

Photo 2

3 If the above testing is normal Replace the indoor control board

Position and marking of temperature sensors

CN6 (RT, IPT) on indoor control board

1033 Unit and 1240 Unit

indicate the dimensions of indoor unit.

Measure the resistance of

indo or temperature sensor

9

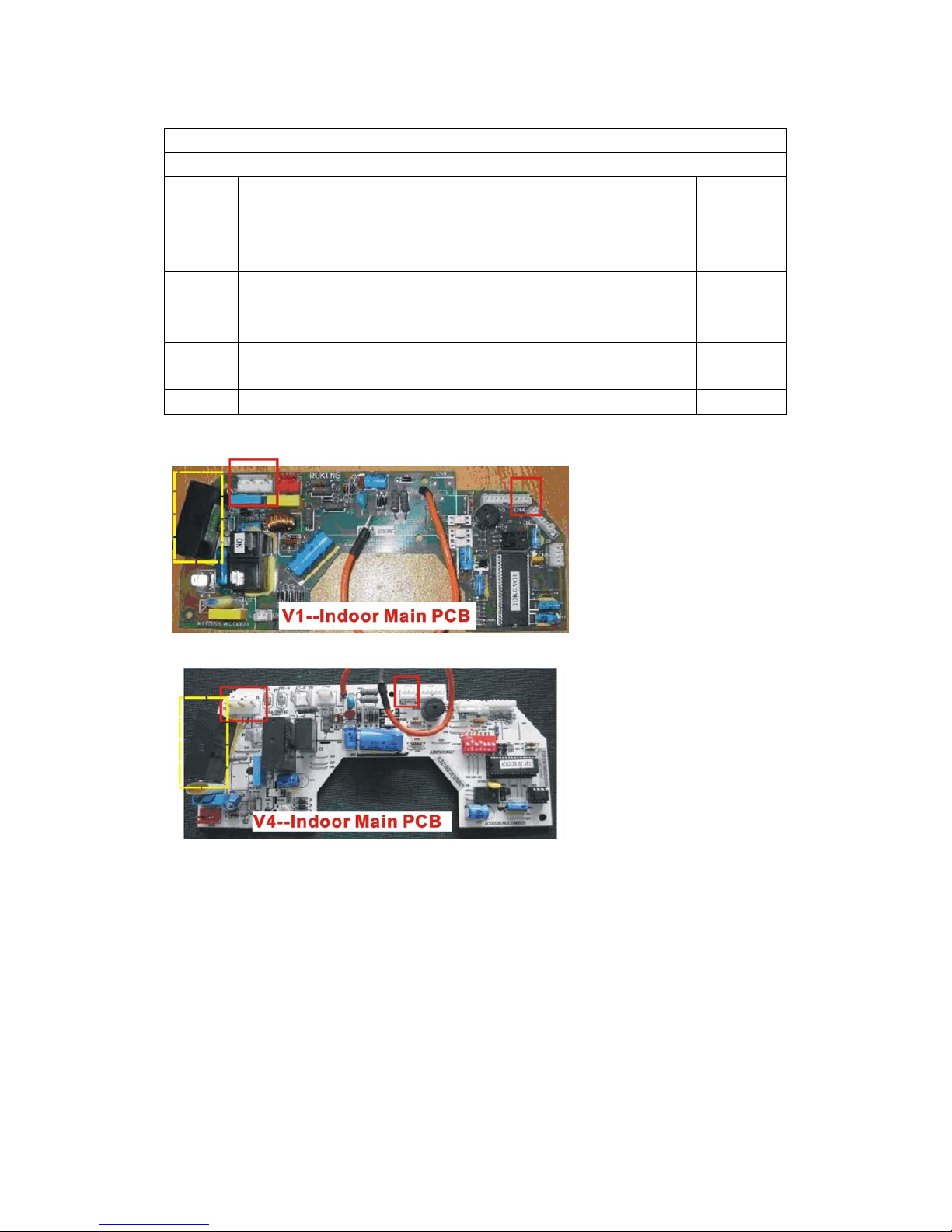

(2) Display E6

Symptom Display E6

Cause Indoor fan motor fault

S/N Inspections How to Solve Remarks

1

Check the indoor cross-flow fan

blade

If the fan does not run, readjust

the fan position until it can run

smoothly.

2

If the motor insert (CN3, CN4) on

indoor main PCB is in good contact

with the slot

Insert again if loose.

Red-line

part

3 Startup capacitance value

Capacitance incorrect. Replace

with a new capacitor.

Yellow-line

part

4 The above inspections are normal Replace the indoor main PCB

10

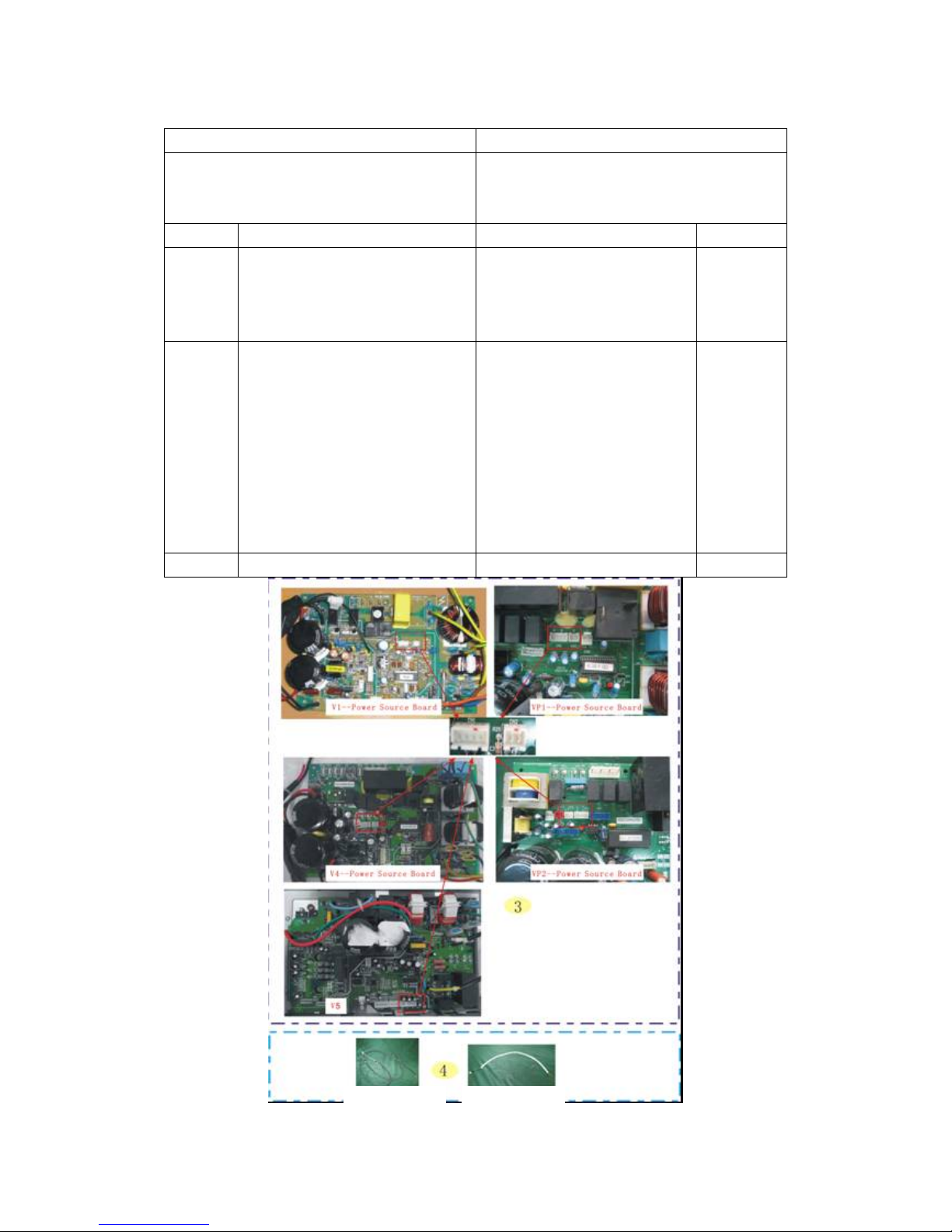

(3) Display E3, E7, E8

Symptom Display E3, E7, E8

Cause

Outdoor pipe (coil) temperature sensor and

outdoor temperature sensor and exhaust

temperature sensor fault

S/N Inspections How to Solve Remarks

1

If the temperature sensor on

outdoor power source board is in

good contact with the slot (CN1,

CN2)

Insert again if loose. Photo 3

2

Measure the resistance on the two ends of

outdoor temperature sensor:

Resistance of CN1 terminal sensor –

(25 / 5KΩ). For other resistance, please ℃

refer to the Temperature – Resistance

Sheet. Resistance of CN2 terminal sensor

– (25 / 20KΩ). For other resistance, ℃

please refer to the Exhaust Temperature

Sensor Resistance Sheet.

Replace the temperature sensor

if the resistance is incurred to

drift, open or short circuiting.

Photo 4

3 If the above testing is normal Outdoor power source board

Position and marking of

temperature sensors (CN1, CN2) on

outdoor power source board

CN1 terminal sensorCN2 terminal senso

r

11

(4) Display E4

Symptom Display E4

Cause

System abnormal: Let the compressor run for 5

minutes. If the indoor coil temperature cannot

be 2 lower than that before the compressor is ℃

started (2 higher for heating mode), it can be ℃

judged that the system is abnormal.

S/N Inspections How to Solve Remarks

1

Check the high-pressure and

low-pressure valves.

If not open, open again to ensure

the system circulation is smooth.

Photo 5

2

Check the system refrigerant (Start

and run under cooling mode. When

the compressor is started, check the

outlet temperature for its change. If

the change is not obvious after 5

minutes)

The system is in shortage of

refrigerant. Test with pressure

gauge, check the leakage point

and recharge the refrigerant.

Photo 6

3

Check the evaporator coil

temperature sensor (25 /5KΩ). ℃

For other resistance, please refer to

the Temperature – Resistance

Sheet.

Replace the temperature sensor

if the resistance is incurred to

drift, open or short circuiting.

Photo 7

1. The flow might be uneven for

indoor system. Short circuit JP4

jumper of the indoor control

board to shield this protection

function (V1 – Indoor Main

PCB).

Photo 8

2. The flow might be uneven for

indoor system. Dial the JP4

switch of the outdoor power

source board to position “1” to

shield this protection function

(V4 – Power Source Board).

Photo 9

4 The above inspections are normal

Replace the indoor main PCB

if the problem cannot be solved

by using the above methods.

Loading...

Loading...