Page 1

<R42-105-O>

Sn*ice%/lon*0

STEREO

TAPE

DECK

T-

6600/F

T-

61o,o^

/F

<7OJO2E31T>

TJIONEEfiI

All manuals and user guides at all-guides.com

all-guides.com

Page 2

:l

I

't

:I

1.

SPECIFICATIONS

Drive and control

Center

capstan drive with automatic

reverse recordings

and

playbacks,

and automatic

repetition

playbacks

by

sensing foil or by manual operation.

Track

4-track

2-channel

stereo

4-track 1-channel mono

Recording compensation

characteristics

NAB

Erasing

AC system

Reel

Up to 7

inches

Motor

Hysteresis

synchronous motor

Heads

Two 4-track

2-channel heads

for

recording and

play-

back

Two

4-track 2-channel heads for

erasing

Tape

speeds

7'1l2ips

(19cm/s)

3-3/4 ips

(9.Scm/s)

Fast winding time

Approx. 1

10 seconds

(1200ft/370m

tape)

Wow and

flutter

Less than

O.12%

at7-1

12ips

(19cm/s)

Less

than Q.2O% at 3-3/4 ips

(9.5cm/s)

Frequency response

30 to 20,000H2

(So

to 15,000H2,

12dB)

at7'1l2ips

(19cm/s)

30

to 13,000H2 at 3-3/4 ips

(9.5cm/s)

SN Ratio

More than 55dB

lnput

Microphone .....0.3mVto240mV/50kSl

Line input

30mV

to 24Vl330kQ

Output

Lineoutput

.....0.775Vl50kO

Headphone

output

0.2mW/8O

Connector

REC/P.B. DIN type

Lineinput .....

Pinjack

Lineoutput .....

Pinjack

Microphone ..... Standardjack

Headphones ..... Standardstereojack

Built-insemiconductors

Transistors .....14

Diodes ........4.

Powerrequirement AC 110V, 117V, 130V, 22OV and

240V

(50H2

or

60Hz)

Maximum

power

consumption

70VA

Overalldimensions

17"3/16(W) X

17"(H) X 7"5132(Dl

(including

dust

cover

and

foot)

437mm(W)

X 434mm(H)

X

182mm(D)

(including

dust cover

and

foot)

All manuals and user guides at all-guides.com

Page 3

Weight

Furnished

accessories

NOTE:

Specifications

and the

due

to improvements.

T-EiCiOO

With

package

38 lb 11

oz

(17.6kg)

Without

package

28 lb

9 oz

(13k9)

PR-T0emptyreel

(easy-loadingreel)

. . .

. .1

Dustcover .........1

Reelcap .....2

Connectioncord..

....2

Splicingtape..

......1

Sensingfoil

.. .......1

Cleanrngkit...

......1

Fuse(1A)

..........1

Motorpulley(50Hzor60Hz) .

........1

design subject to

possible

modification

without notice

All manuals and user guides at all-guides.com

Page 4

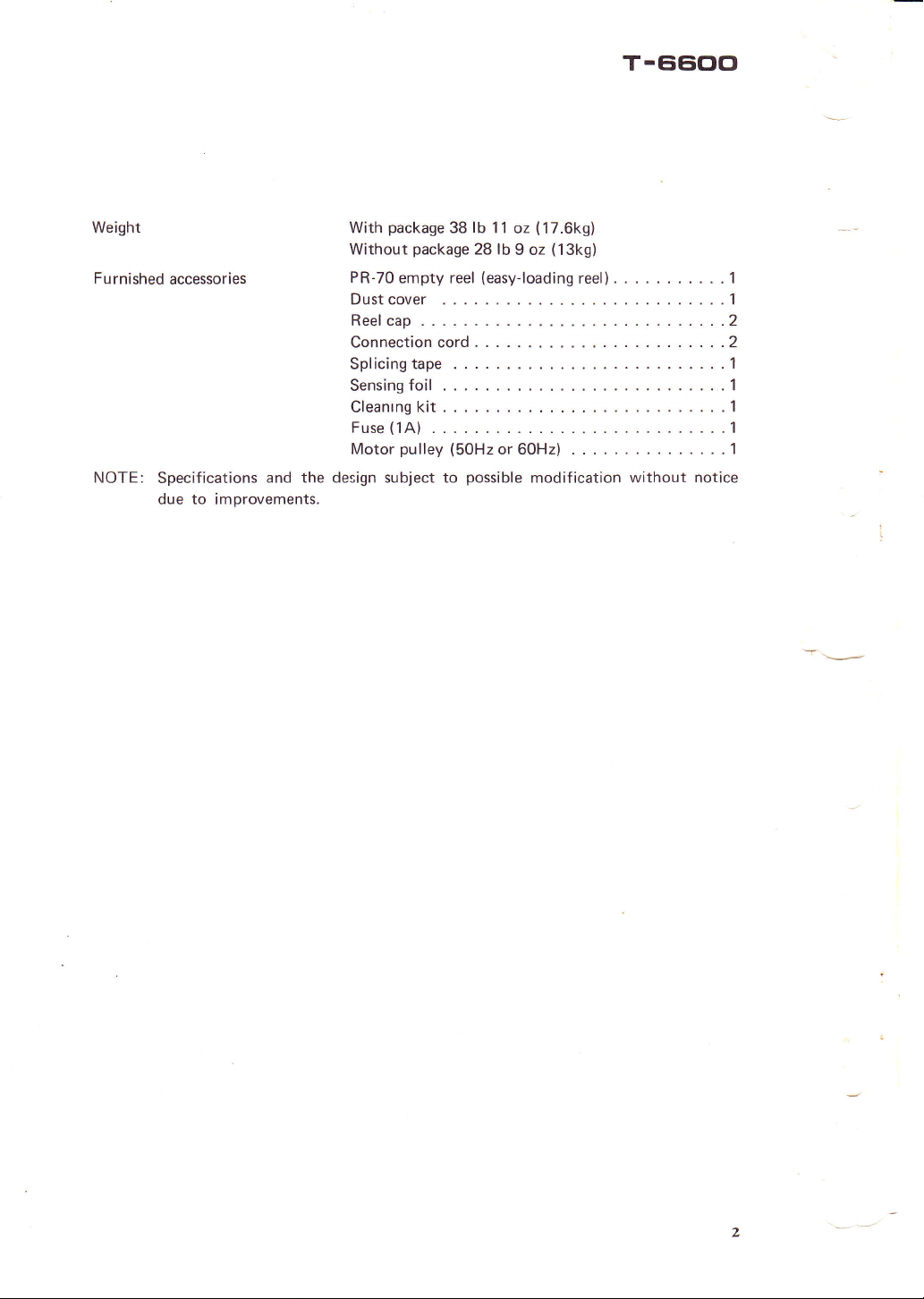

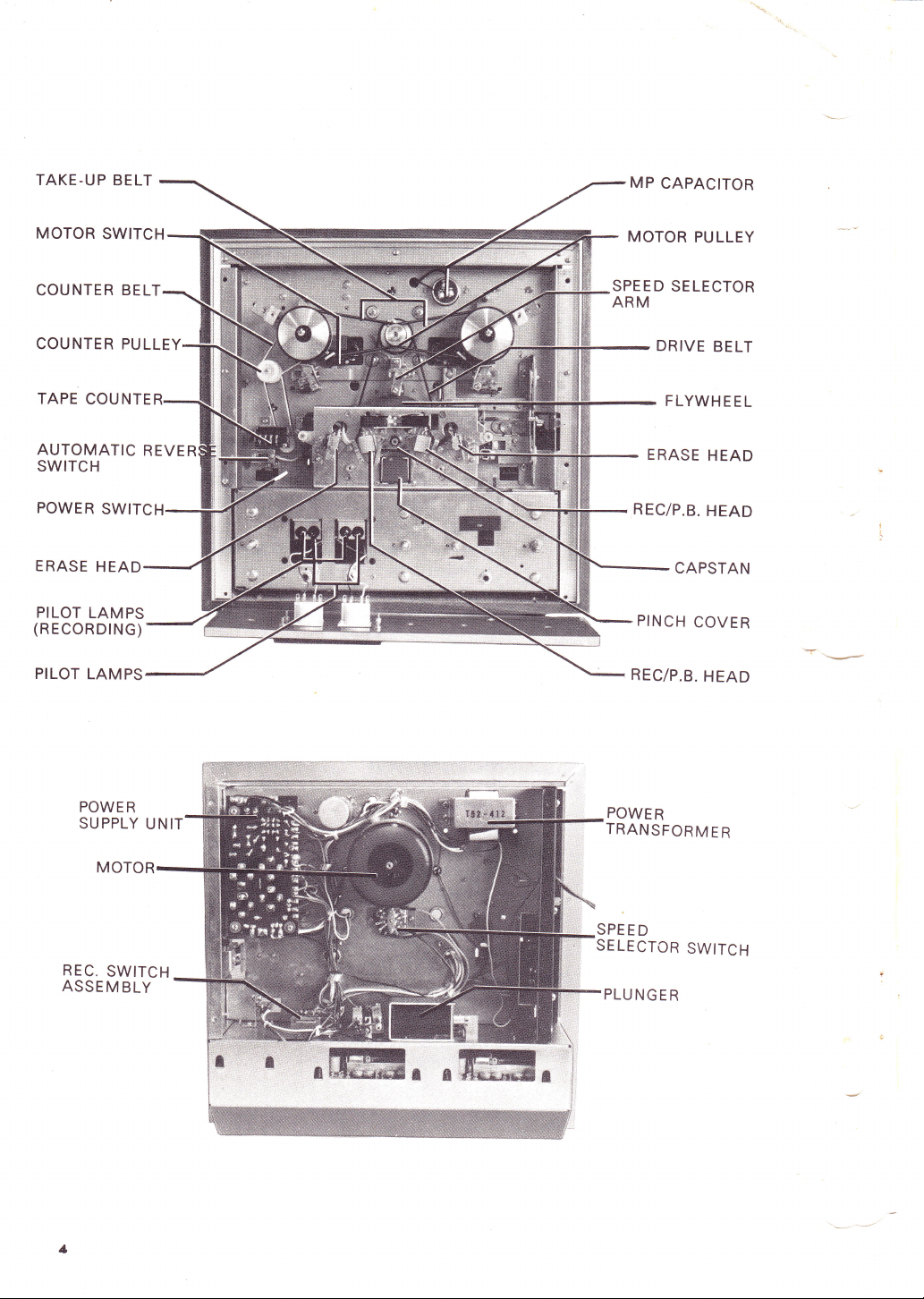

2.

PARTS

I DE

NTI

FICATION

SPE

E

D

KNOB

SE

LECTOR

REEL

BASE

TAPE

COU

NTE R

AUTOMATIC

R

EVE

RSE

SWITCH

POWE

R

SWITCH

RECORDING

LEVEL

CoNTROL

(LE

FT)

LEVEL

METER

M

ICROPHON

E

JACKS

RECORDING

LEVEL

CoNTROL

(R

tc

HT)

MODE

SWITCH

REEL

CAP

REC/P.

B.

CON N ECTOR

LIN

E VOLTAG

E

SELECTOR

8

FUSE

AC

POWER

CORD

GROUND

REEL

BASE

D IR

E

CTION

SELECTOR

BUTTON

S

HEAD HOUSING

PAU

SE

LEVE

R

U

NCTION

LEVE

R

PLAYBACK

LEVE

L

CONTROL

RECORDING

LEVER

H

EADPHON

E

S

JACK

LINE

INPUT

JACKS

LINE

OUTPUT

JAC

KS

TE

RM INAL

All manuals and user guides at all-guides.com

Page 5

TAKE.UP

BELT

MOTOR

SWITCH

COU

NTE

R

COU NTE

R

BELT

PU

LLEY

TAPE

COU NTE

AUTOMATIC

R

EVE

R

SWITCH

POWE

R

SWITCH

E

RASE

H EAD

PILOT

LAM

PS

(R

E

COR DtN

G)

PILOT

LAM

PS

POWE

R

SUPPLY

UNIT

MOTOR

R

E

C

SWITCH

ASSE

M

BLY

MP

CAPACITOR

MOTOR

PU LLEY

SPE E

D

SE LE

CTOR

ARM

DRIVE

BELT

FLYWHEEL

E

RASE

H EAD

R

ECIP.B.

HEAD

CAPSTAN

PINCH

COVER

REC/P.B.

HEAD

POWE

R

TRANSFORM

E

R

SPEED

SELECTOR

SWITCH

PLUNGER

All manuals and user guides at all-guides.com

Page 6

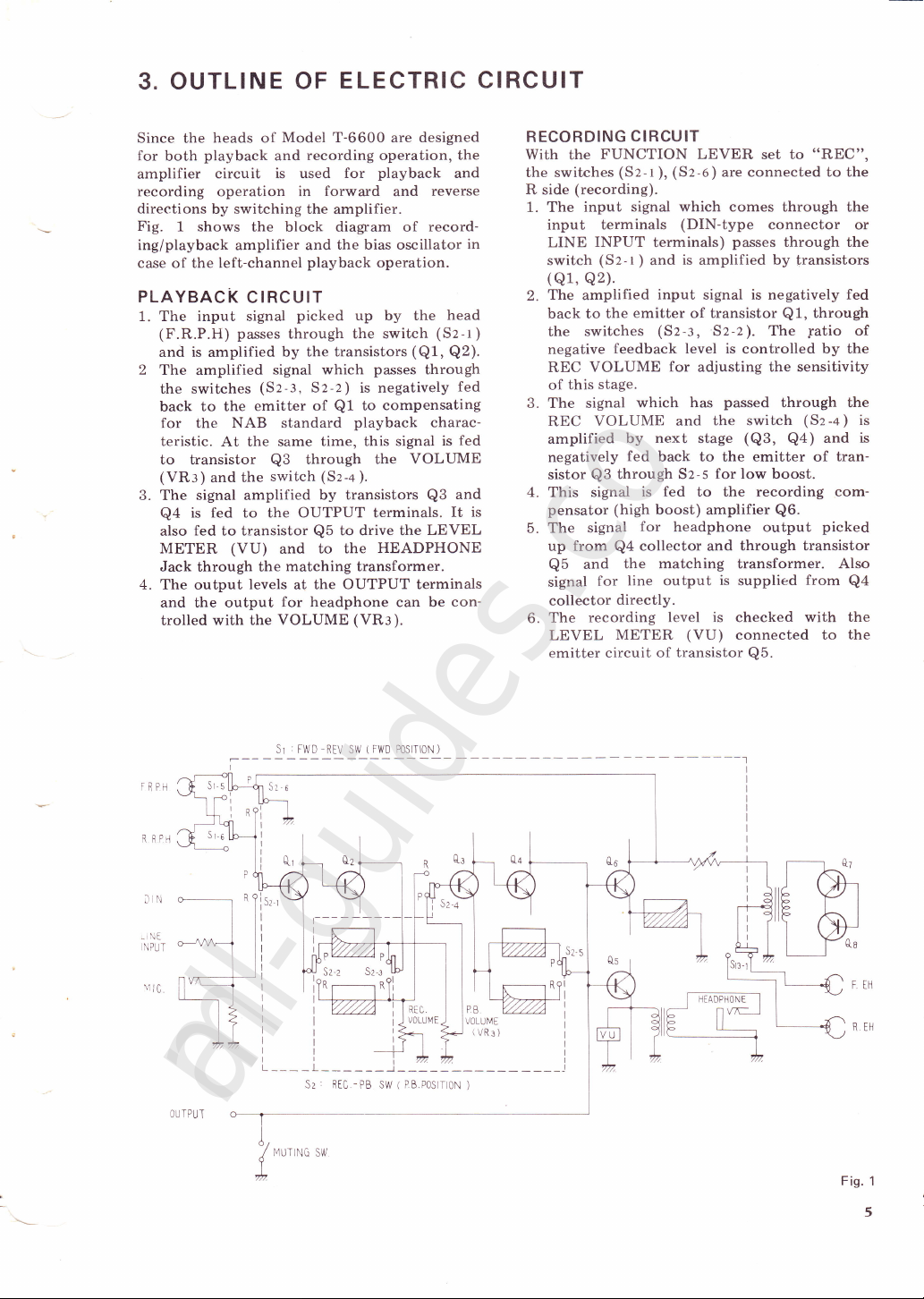

3.

OUTLINE OF

ELECTRIC

CIRCUIT

Since the

heads of

Model

T-6600 are

designed

for

both

playback

and

recording operation,

the

amplifier

circuit is used

for

playback

and

recording operation in

forward

and

reverse

directions

by switching the

amplifier.

Fig.

1 shows

the block diagram of

record-

ing/playback

amplifier

and the bias

oscillator

in

case

of the

left-channel

playback

operation.

PLAYBACK

CIRCUIT

1. The input signal

picked

up

by

the

head

(F.R.P.H)

passes

through

the switch

(Sz-t)

and is amplified

by the transistors

(Q1,

Q2).

2 The

amplified

signal which

passes

through

the

switches

(Sz-:,

Sz-z) is negatively

fed

back

to the

emitter

of

Q1

to compensating

for the

NAB

standard

playback

charac-

teristic.

At the

same time, this

signal is

fed

to transistor

Q3

through

the VOLUME

(VR:)

and

the

switch

(Sz-+

).

3. The signal amplified

by

transistors

Q3

and

Q4

is

fed

to the

OUTPUT terminals.

It

is

also

fed

to transistor

Q5

to drive the

LEVEL

METER

(VU)

and

to the

HEADPHONE

Jack

through

the

matching

transformer.

4.

The output

levels at the OUTPUT terminals

and the output

for headphone

can be

con-

trolled

with the

VOLUME

(VRr).

Sr

'

FWD

-REV

SW

(

FWD

POSITI0N

)

I

FRPH

R

RPil

)N

.NE

]NPUT

v

tC.

P P

Sz

-:

R

RECORDING

CIRCUIT

With the

FUNCTION TEVER

set to

"REC",

the switches

(Sz-t

),

(Sz-0)

are connected to the

R

side

(recording).

1. The input

signal

which

comes through the

input terminals

(DIN-type

connector

or

LINE

INPUT

terminals)

passes

through the

switch

(Sz-t

)

and

is

amplified by transistors

(Ql,

Q2).

2.

The

amplified

input signal is negatively

fed

back to

the

emitter

of transistor

Q1,

through

the

switches

(Sz-:

,

Sz-z\. The

.ratio

of

negative

feedback level is

controlled

by the

REC

VOLUME

for

adjusting the

sensitivity

of

this

stage.

3. The

signal

which has

passed

through the

REC

VOLUMB

and

the switch

(Sz-+)

is

amplified

by

next

stage

(Q3,

Q4)

and

is

negatively

fed

back to

the emitter of

tran-

sistor

Q3

through Sz-s

for low

boost.

4.

This signal

is fed to the recording com-

pensator (high

boost)

amplifier

Q6.

5. The

signal

for

headphone output

picked

up from

Q4

collector and

through transistor

Q5

and

the matching

transformer.

Also

signal

for

line output

is

supplied

from

Q4

collector

directly.

6.

The

recording

level is checked with

the

LEVEL

METER

(VU)

connected

to

the

emitter

circuit

of transistor

Q5.

:-J

ll

f

wf=-

-ri

t<-

L'

Sz-z

REC.

V0tUl'4

E

PB

VOtUI,4E

(VR3)

FEH

R. EH

Fis.

1

5

Sr-s

l!--

4

5,

,

a,

l--

[z

l-,-------- n

a.

l---

aa

1,,

--

0o

O UT

PUI

Sz

'

REC

-

PB

SW

(

P B.

POS]II0N

)

All manuals and user guides at all-guides.com

all-guides.com

Page 7

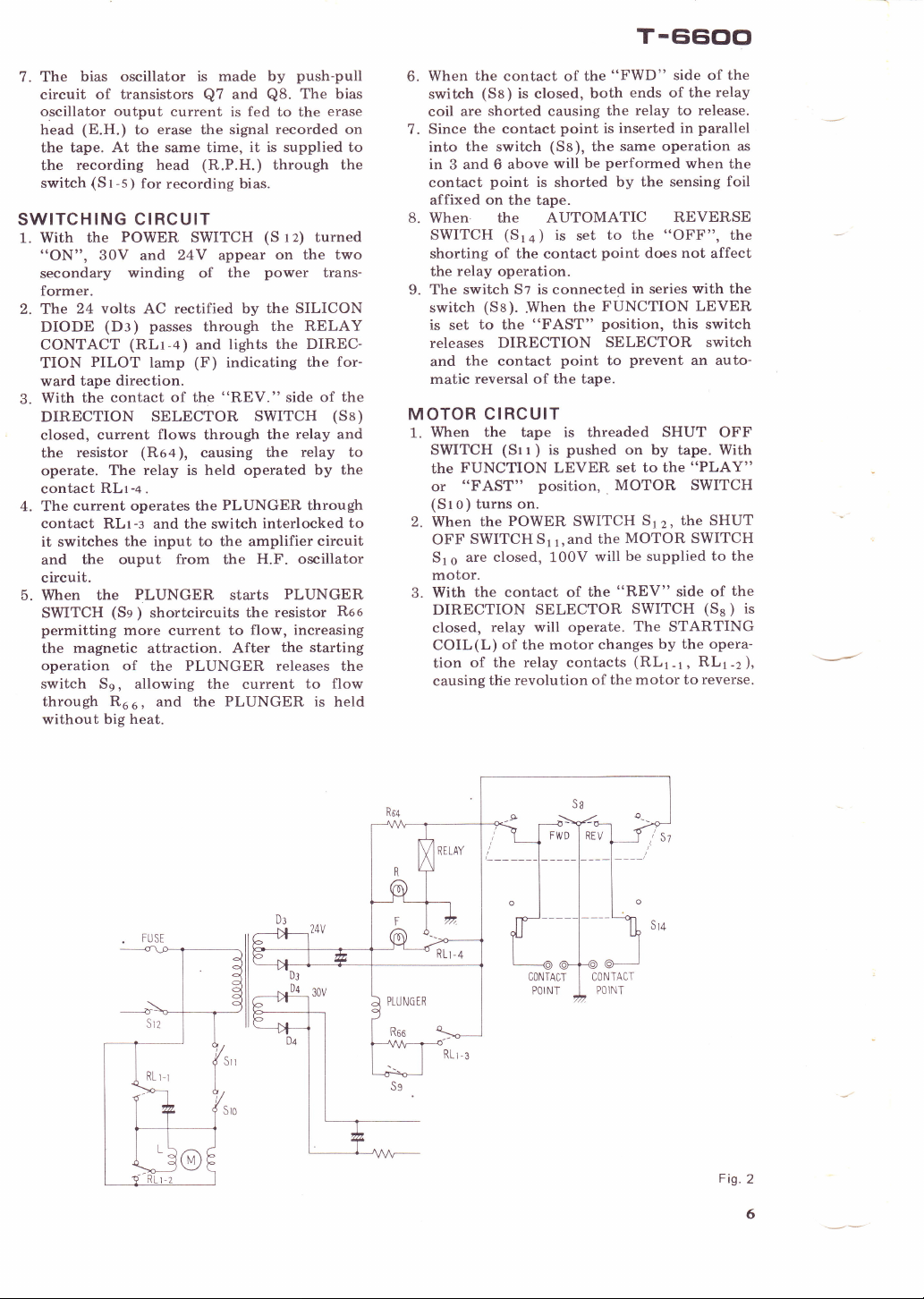

7. The

bias oscillator

is made by

push-pull

circuit

of transistors

Q7

and

Q8.

The bias

oscillator

output

current

is

fed

to the

erase

head

(E.H.)

to

erase

the

signal recorded on

the

tape. At the same time,

it is supplied to

the

recording head

(R.P.H.) through the

switch

(S

t

-s

)

for

recording bias.

SWITCHING

CIRCUIT

1.

With

the

POWER SWITCH

(S

t

z)

turned

"ON",

30V

and

24Y appear

on the two

secondary

winding of the

power

trans-

former.

2. The

24

volts

AC rectified by

the SILICON

DIODE

(Dl

)

passes

through

the

RELAY

CONTACT

(RLt-+)

and

lights the DIREC-

TION

PILOT

lamp

(F)

indicating the

for-

ward

tape direction.

3.

With

the

contact of the "REV." side

of

the

DIRECTION

SELECTOR

SWITCH

(Sa)

closed,

current flows through

the

relay

and

the

resistor

(Ro+

),

causing

the

relay to

operate.

The

relay is held operated

by the

contact RLt-+.

4. The

current operates the

PLUNGER

through

contact

RLr-s

and the switch

interlocked to

it switches

the input to the amplifier

circuit

and

the ouput

from

the

H.F. oscillator

circuit.

5. When

the

PLUNGER

starts

PLUNGER

SWITCH

(Se

)

shortcircuits the

resistor

Roo

permitting

more current to

flow, increasing

the

magnetic

attraction.

After

the starting

operation of

the PLUNGER releases the

switch

Ss, allowing the

current

to flow

through

R6

6

,

and the PLUNGER is held

without big heat.

T-EiCioo

6.

When

the

contact of

the

"FWD"

side of the

switch

(Ss)

is closed, both

ends of the

relay

coil

are shorted causing

the

relay

to

release.

7. Since

the contact

point

is

inserted in

parallel

into

the switch

(Sa),

the

same operation as

in

3

and 6

above

will

be

performed

when

the

contact

point

is

shorted

by the sensing

foil

affixed

on

the

tape.

8. When the

AUTOMATIC

REVERSE

SWITCH

(Sr

+ )

is

set

to the

"OFF",

the

shorting of the contact

point

does not affect

the

relay operation.

9. The

switch St

is

connected

in

series

with

the

switch

(Sa).

.When

the

FUNCTION

LEVER

is set

to the

"FAST"

position,

this

switch

releases

DIRECTION

SELECTOR

switch

and

the contact

point

to

prevent

an

auto-

matic

reversal of

the

tape.

MOTOR

CIRCUIT

1.

When

the tape

is threaded

SHUT

OFF

SWITCH

(St

t

)

is

pushed

on by tape. With

the

FUNCTION LEVER

set to the "PLAY"

or "FAST"

position, MOTOR SWITCH

(St

o)

turns on.

2. When

the

POWER SWITCH

S12, the SHUT

OFF

SWITCH Sr

1,&nd

the

MOTOR

SWITCH

516

are

closed,

100V

will

be

supplied

to the

motor.

3.

With

the contact of

the "REV"

side of

the

DIRECTION

SELECTOR

SWITCH

(Ss

)

is

closed,

relay will operate.

The

STARTING

COIL(L)

of the motor

changes

by

the opera-

tion

of the relay contacts

(RLr-r,

RLr-z),

causing

the

revolution of

the motor

to reverse.

Fig.2

6

CONTACT

POINT

All manuals and user guides at all-guides.com

Page 8

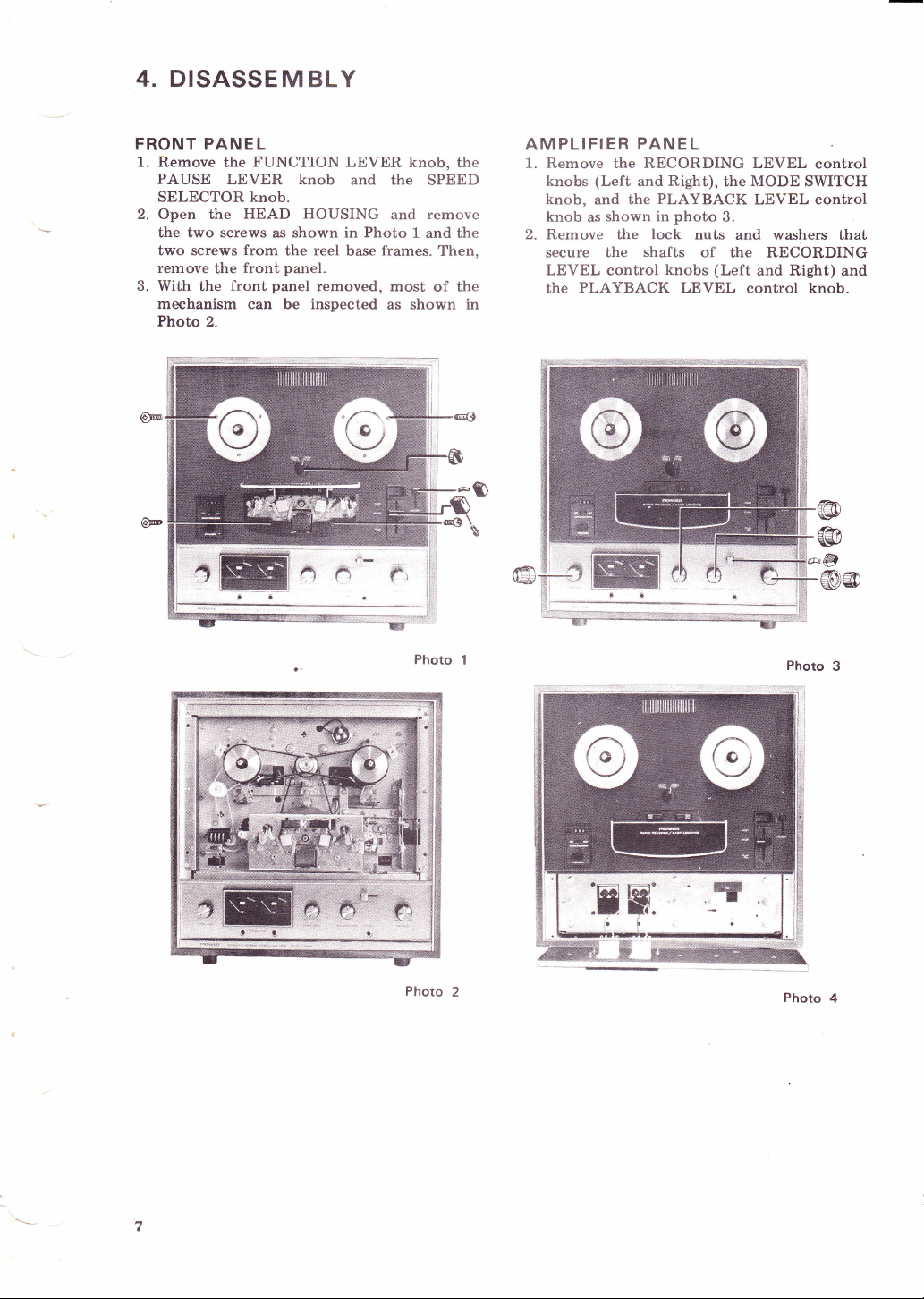

4.

DISASSE

M BLY

FRONT

PAN E

L

1. Remove

the

FUNCTION LEVER

knob, the

PAUSE

LEVER knob

and the SPEED

SELECTOR knob.

2. Open the

HEAD HOUSING

and

remove

the two screws as shown in

Photo

1 and the

two screws from

the

reel

base

frames.

Then,

remove

the

fronf

panel.

3. With

the

front

panel

removed, most

of the

mechanism

can be

inspected

as shown in

Photo

2.

AMPLIFIER

PANEL

1.

Remove the RECORDING LEVEL

control

knobs

(Left

and

Right),

the

MODE

SWITCH

knob,

and

the

PLAYBACK

LEVEL

control

knob

as

shown

in

photo

3.

2.

Remove the

lock

nuts

and

washers

that

secure

the shafts of

the RECORDING

LEVEL control

knobs

(Left

and Right) and

the

PLAYBACK LEVEL

control knob.

All manuals and user guides at all-guides.com

Page 9

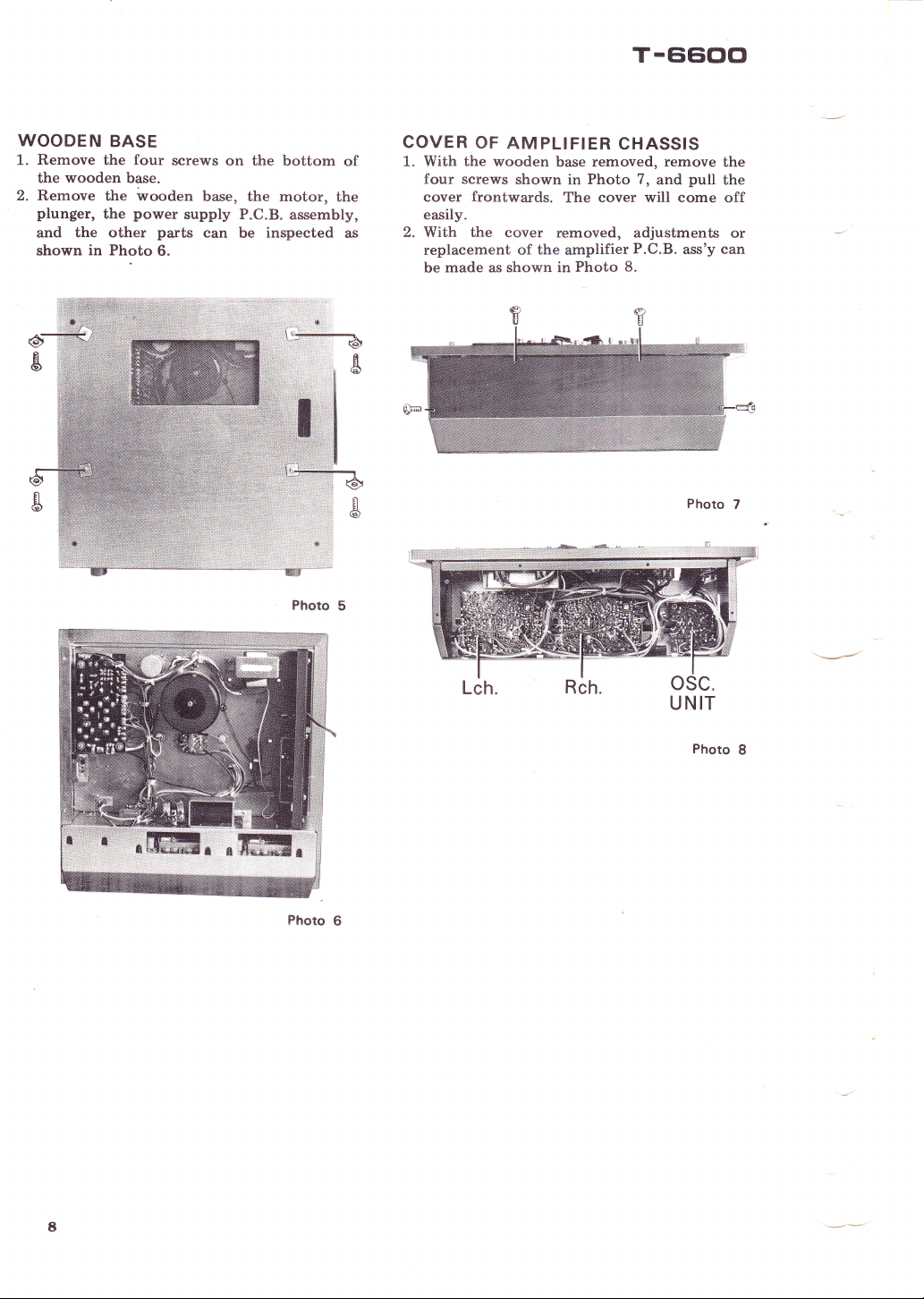

WOODEN

BASE

1. Remove

the

four

screws

on the

bottom

of

the

wooden

base.

2. Remove

the

wooden

base, the

motor,

the

plunger,

the

power

supply

P.C.B.

assembly,

and

the

other

parts

can

be

inspected

as

shown

in

Photo

6.

$$WIi*

Photo

5

Photo

6

T-CiCiO(f,

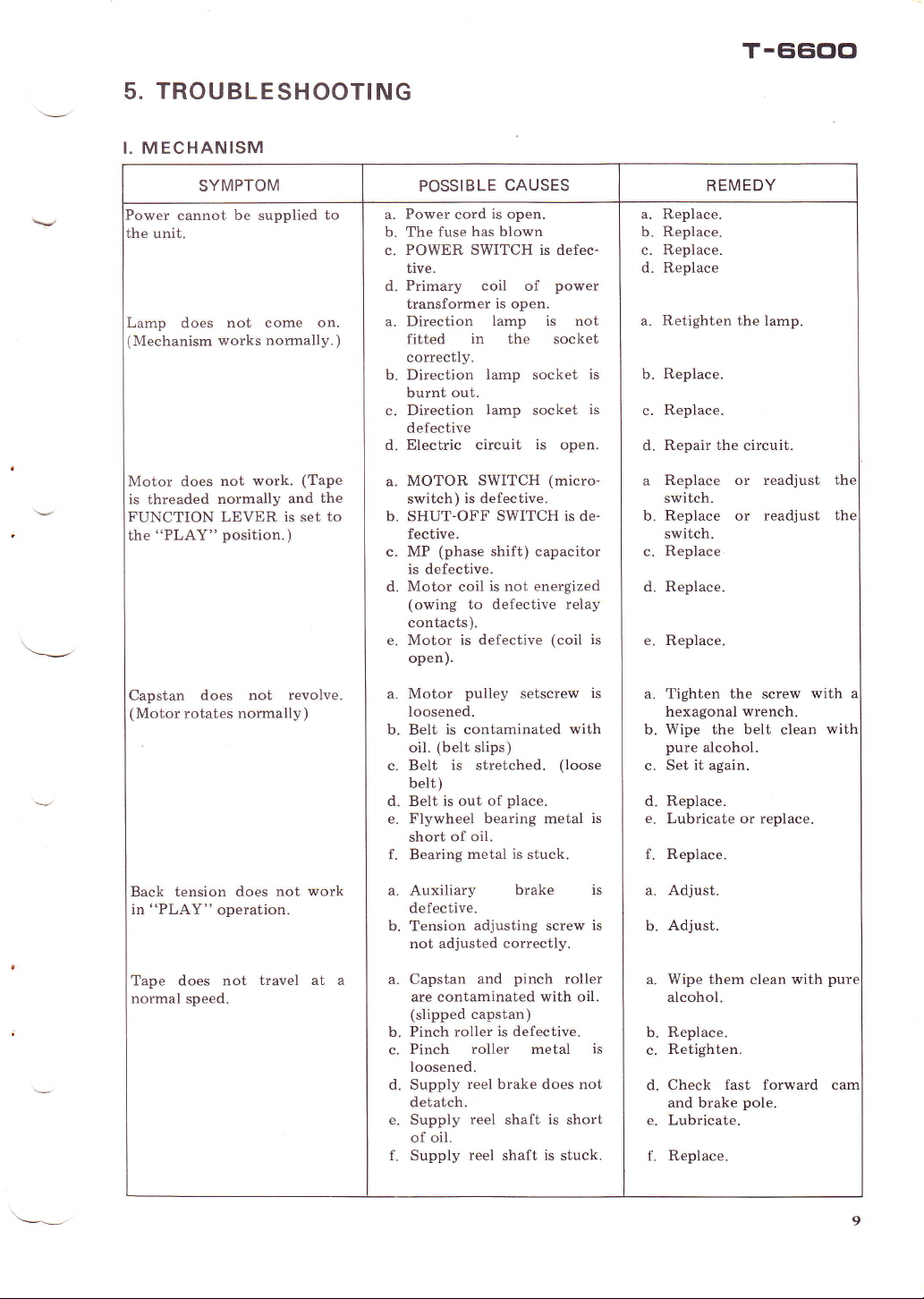

COVER

OF

AMPLIFIER

CHASSIS

1. With the wooden

base

removed, remove

the

four

screws

shown in

Photo

7,

and

pull

the

cover

frontwards.

The

cover will

come off

easily.

2. With

the cover

removed, adjustments

or

replacement of the

amplifier

P.C.B.

ass'y

can

be

made

as

shown

in

Photo

8.

Photo

7

Lch.

Rch.

osc.

UNIT

Photo

I

?

All manuals and user guides at all-guides.com

Page 10

T-EiEiclcl

5.

TROUBLESHOOTING

I. MECHANISM

SYMPTOM POSSIBLE

CAUSES REMEDY

Power

cannot

be

supplied

to

the unit.

Lamp does

not come on.

(

Mechanism

works

normally.

)

Motor does

not work.

(TaPe

is threaded

normally

and

the

FUNCTION LEVER is set

to

the

"PLAY"

position.)

Capstan

does not

revolve.

(Motor

rotates normally

)

Back tension does

not work

in

"PLAY" operation.

Tape does not

travel at

normal

speed.

a.

Power

cord

is open.

b. The fuse

has

blown

c.

POWER SWITCH is defec-

tive.

d.

Primary

coil of

power

transformer

is

open.

a. Direction

lamp is not

fitted

in

the socket

correctly.

b. Direction

lamp

socket

is

burnt

out.

c.

Direction

lamp socket

is

defective

d. Electric

circuit is open.

MOTOR

SWITCH

(micro-

switch)

is defective.

SHUT-OFF

SWITCH

is de-

fective.

MP

(phase

shift)

capacitor

is

defective.

Motor coil

is not energized

(owing to defective

relay

contacts).

Motor

is defective

(coil is

open).

a.

Motor

pulley

setscrew

is

loosened.

b. Belt

is contaminated with

oil.

(belt

slips)

c. Belt

is stretched.

(loose

belt)

d. Belt

is

out

of

place.

e. Flywheel bearing metal

is

short

of oil.

f. Bearing

metal is

stuck.

b.

Auxiliary

brake

defective.

Tension

adjusting screw

not adjusted correctly.

a.

Capstan and

pinch

roller

are contaminated

with oil.

(slipped capstan)

b.

Pinch roller

is

defective.

c.

Pinch

roller

metal

is

loosened.

d. Supply

reel brake does not

detatch.

e.

Supply

reel

shaft

is

short

of oil.

f.

Supply

reel

shaft

is

stuck.

b.

c-

d.

e.

ls

a.

a. Replace

b. Replace

c.

Replace

d. Replace

Retighten

the lamp.

b. Replace.

c.

Replace.

d. Repair

the

circuit.

a Replace

or readjust

switch.

b. Replace or

readjust

switch.

c. Replace.

d.

Replace.

Replace

a.

Tighten the

screw

with

a

hexagonal

wrench.

b.

Wipe the

belt clean

with

pure

alcohol.

c. Set

it again.

d. Replace.

e. Lubricate or replace.

f.

Replace.

a.

Adjust.

b.

Adjust.

a. Wipe them clean

with

pure

alcohol.

b.

Replace.

c.

Retighten.

d. Check

fast forward cam

and brake

pole.

e. Lubricate.

f. Replace.

the

the

9

All manuals and user guides at all-guides.com

Page 11

SYMPTOM

POSSIBLE CAUSES

REMEDY

Fast forward

operation

does

not start.

DIRECTION

SELECTOR

BUT'IONS

operate

errone-

ously.

Brake

does not work.

Tape is

slackened.

g.

Supply reel Aux. brake

shoe

is defective.

h.

Supply reel

clutch is

defective.

i. Take-up belt

is

con-

taminated with oil.

j.

Take-up belt

is stretched.

k.

Take-up belt

is

out of

place.

l. Take-up reel clutch is

defective.

m. Take-up reel brake cannot

be released.

a.

Take-up

belt

is con-

taminated with oil.

b. Take-up belt

is stretched.

c. Take-up belt

is

out of

pIace.

d. Tension adjusting screw is

maladjusted.

e. Supply

reel

brake shoe is

not released.

f.

Supply reel auxiliary brake

is not released.

g.

Take-up reel brake shoe is

not released.

h. Tension

brake

is too

strong.

c.

DIRECTION SELECTOR

switch

is defective.

DIRECTION SELECTOR

switch

has

poor

contact.

Preset release

switch

(Ss

)

is

defective.

d. Contacts of relay

(RL1)

are defective.

e.

Coil of relay

(RLt

)

is

open.

f. Contact

pole

is shorting

to

pole

mounting

plate.

a.

Brake

shoe

is unstuck

or

out of

place.

b. Brake spring

is

out

of

place.

c. Brake mechanism

is

maladjusted.

d. Side

of reel base or the

brake shoes are

dirty.

a. Brake

is

defective.

b. Brake mechanism

is

maladjusted.

c. Supply and take-up

ten-

sion are not

proper,

a.

b.

g.

Replace.

I

h. Replace reel

pulley.

I

i. Wipe the belt clean

with

pure

alcohol.

j.

Replace.

k.

Set it

again.

l.

Replace reel

pulley.

m.

Check fast forward

cam

and brake

Pole.

a.

Wipe

the belt clean with

pure

alcohol

b.

Replace.

c.

Set it agein.

d.

Readjust.

e. Check fast forward

cam

and brake

pole.

f. Check

coupling

condition

of brake arm

and Aux.

brake

arm.

g.

Check fast forward

cam

and brake

pole.

h. Readjust the

brake.

a.

Repair

or replace

the

switch.

b.

Clean its

contacts or

replace.

c.

Replace

and

readjust

the

switch.

d. Replace the relay,

or

replace the

power

supply

unit.

The

same

as in

"d".

Readjust.

a.

Fix

brake shoe

properly

b.

Hook

the spring

again.

c. Readjust.

d. Wipe

them

alcohol.

a.

Replace.

b.

Readjust.

c.

Readjust

or

base.

with

pure

replace

reel

e

f.

10

All manuals and user guides at all-guides.com

all-guides.com

Page 12

T-6EiOO

SYMPTOM

POSSIBLE

CAUSES

REMEDY

Can not

change tape

speed.

FUNCTION

LEVER can not

be

set to "PLAY"

position.

Does not work.

TAPE

COUNTER

does not

work.

Much

mechanical

noise.

Wow is noticeable.

PAUSE

LEVER does

turn

smoothly.

not

a.

Motor has

much end

play.

b. Tape speed

selector

arm

is maladjusted.

c. Tape speed

selector

stopper is maladjusted.

a. Slide stopper spring is

out of

place.

b. Tape speed

selector

stopper

is

bent.

a. Counter belt is

out of

place

or snapped.

b. TAPE COUNTER

is

defective.

a.

Motor

is defective.

b. Driving belt touches

tape

speed selector arm..

c.

Revolving

parts

are

short

of oil.

d. ReeI base

pully

ass'y

is

defective.

a. Back tension is

too

strong.

b. Dusty capstan.

c. Capstan

surface is

scratched

or deformed.

d. Dusty

pinch

roller.

e.

Pinch roller is

scratched

or deformed.

f. Pinch roller

pressure

is

not enough.

g,

Driving

belt

is

defective.

h. Driving

belt is contami-

nated with oil

i. Flywheel

ass'y

is defec-

tive.

j.

Motor is

defective.

a. Spring is out of

place.

a. Replace.

b.

Readjust the

arm.

c. Readjust

the stopper.

Hook

the spring

again.

Straighten.

Set it

replace.

Replace

again

a.

Replace.

b.

Readjust.

c.

Lubricate.

d. Replace.

a. Readjust.

b. Wipe

the capstan

clear

with

pure

alcohol.

c. Replace.

d. Wipe the

roller clean

with

pure

alcohol.

e. Replace.

f.

Readjust.

g.

Replace.

h. Wipe it

clean.

i. Replace.

j.

Replace.

a.

Hook

the

spring

again.

a,

b

a.

b

All manuals and user guides at all-guides.com

Page 13

II. ELECTRIC CIRCUITS

SYMPTOM

POSSIBLE CAUSES

REMEDY

The

unit

will

not

play

back.

Sound is too

low.

Distortion

noticeable.

of sound

Drop-out sound.

Poor treble.

Poor

base.

Too much hum.

Too much nolse.

a.

Connecting cord

is

disconnected or

has

poor

contact.

b.

R: s

is

not

soldered or

open.

c. If

no

B+

voltage on the

each stage, rectifier diode

(1S1849),

power

trans-

former,

or

resistors

R

r s

&

Re z defective.

d.

Head is open.

c.

Poor

contact of

switches

Sr &

Sz.

f. VR:

&

VR4

have

poor

contact.

g.

Muting SW

(Se

)

has

poor

contact.

VRs or VR+

has high

resistance or

has

poor

contact.

Head wear out

or

dusty.

Transistor is defective.

a. Dr

and

Dz

are

shorted.

b.

Too much

input is

supplied to

connected

amplifier.

The head is dirty.

b. The tape in use it too

old

a.

The head is dirty

Angle

adjustment

is

insufficient.

Equalizer

is maladjusted.

a. Resistance of

R+ +

is

lowered.

b. Coupling capacitor

or

emitter capacitor of each

transistor is defective.

a.

Connecting

cord is

poor

connection or equipment

is froating from

gtound.

b. Co

t

and Co

s

are

defec-

tive.

Transistors

Qt

and

Qz

are

defective.

Resistors Rr

,

Rz, Rr r

,

Rl

z

or

Rr r

are

responsi-

hle for noise.

a.

b.

a.

b.

c.

Check connecting cord.

Solder again or

replaee.

Replace defective

parts.

d.

Replace.

e.

Replace amplifier

P.C.B.

ass'y.

f. Replace.

g.

Replace.

Adjust

or replace.

b.

Replace

or

clean with

pure

alcohol.

c,

Replace.

a.

Replace the diode.

d.

Adjust the output.

a.

Wipe with head cleaning

ribbon or

clean

with

pure

alcohol.

b. Replace.

a.

Wipe

the

head

clean with

pure

alcohol.

b.

Readjust heads

by

using

Test Tape.

c.

Readjust equalizer

by

using Test Tape.

a.

Replace R++

and

just

with the Test Tape.

b.

Replace

defective capa-

citor.

a. Check connections

and

make

ground

completely.

b.

Replace.

Replace.

Replace

defective

parts.

a.

a.

b.

t2

All manuals and user guides at all-guides.com

Page 14

T-CiEioo

SYMPTOM

POSSIBLE

CAUSES

REMEDY

Occasionally

noisy.

The

unit does not

record.

The

sound is

distorted and

the

sound level is

too

low.

Does not erase,

Much

crosstalk.

Recording

and

playback

are

good,

but LEVEL METER

does not deflect.

Head

is magnetized.

a If noise

comes out

when

body is vibrated,

bad

soldering

or

poor

con-

tact.

b. Transistors

of

Qr

and

Qz

are defective.

a. Connection

to

LINE

INPUT

and MICRO-

PHONE

jacks

incomplete.

b. Inside

of

pin

jacks

con-

nection

are disconnected

or

shorted.

c.

Poor

contact of

switches

St

and

Sz.

d. Head

is defective.

e.

Oscillator circuit

does

not work.

a. The

head

is

dirty.

b. Bias

current is

not cor-

rect.

c. Recording

amplifier

circuit has

trouble.

d. Oscillator transformer

Tz

is broken.

e.

Cs r

&

Csz

defective

or

VRr &

VRa are malad-

justed.

a.

Erasing

head

is

open.

b.

Switches

S+-l

& S+-c

defective.

c. Oscillator

circuit

not

work.

does

a. Head height

ed.

b.

Tape

does

smoothly.

is

maladjust-

not

run

LEVEL METER

defective.

VRs

is maladjusted.

ls

b.

c. Demagnetize

eraser-

by head

a. Solder

defective

points

again or replace.

b. Replace

a. Check

connections

b. Check

and repair

the

pin

jacks.

c.

Replace amplifier

P.C.B.

ass'Y.

d.

Replace.

e. Check

and repair.

a. Wipe

the

head

clean

with

pure

alcohol.

b. Readjust.

c. Replace

printed

circit

board

ass'y.

d, Replace.

e. Replace

defective

parts

or readjust.

a. Replace.

b.

Replace.

c. Check

the

circuit

repair.

a.

Readjust

the

level

of

heads.

b.

Readjust.

a. Replace.

b. Readjust.

and

the

13

All manuals and user guides at all-guides.com

Page 15

6.

AD.'USTMENTS

OF

MECHANISM

ADJ

USTM E

NT

OF

BAC K TE NSION AT

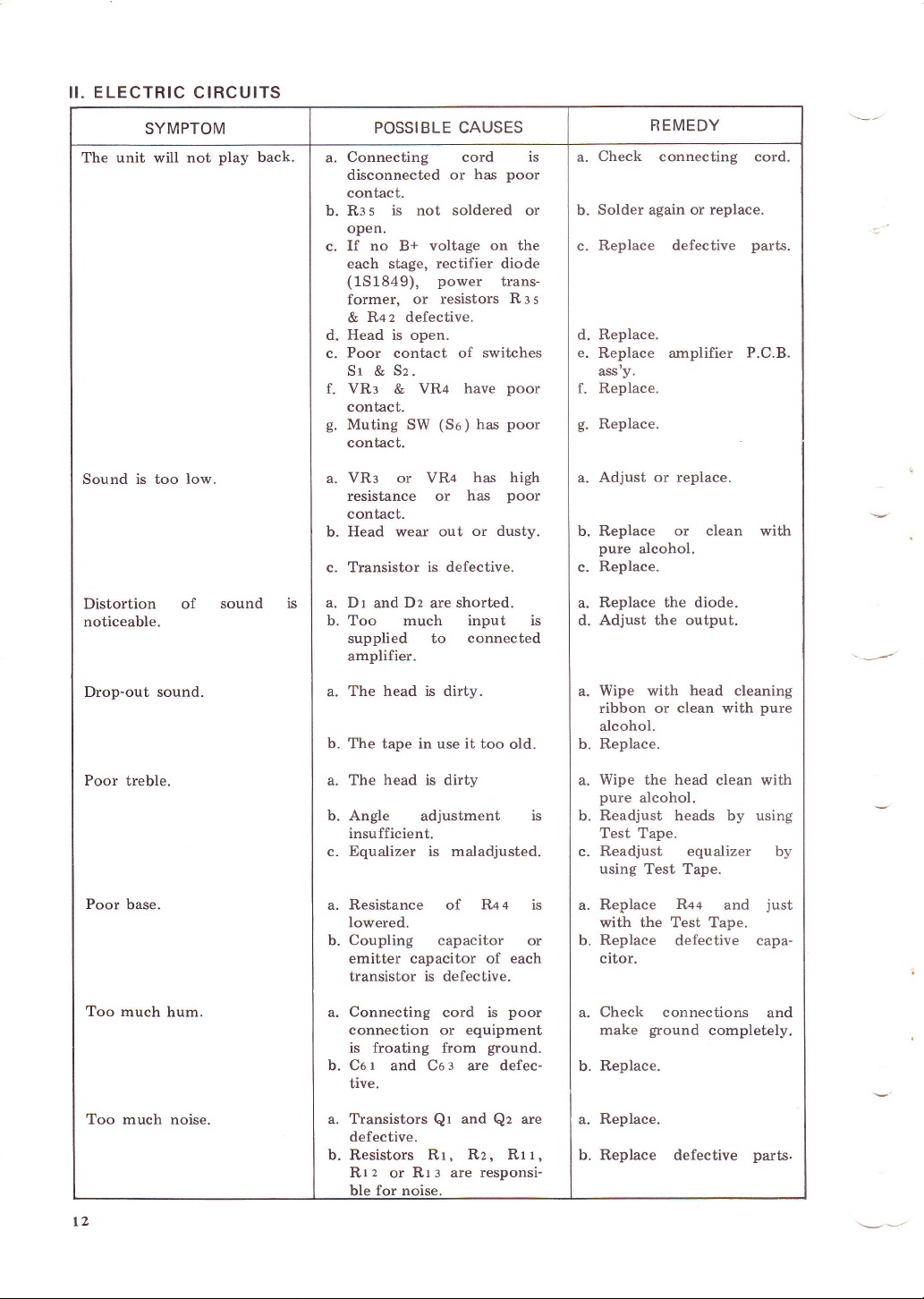

1) Switch

the

power

"OFF"

and

fix

one end of

the

tape to

the reel.

2) Set

the

FUNCTION

L,EVER

to

the "PLAY"

position.

Hook

a tension

gauge

at

the

end

of

the tape. Pull

the

gauge

at

a speed

of

about

7-712 ips (19

cm/s), and

read

the

gauge.

Note:

A

thread

may be

used

instead of tape"

3

)

When

the

reel

hub

is 2-318"

(60

m/m),

normal

back tension

should

be 2.1 oz

(60

g)

to

2.8

oz

(80

g).

4)

If the

indicated back tension

is

more

or less

than

the

specified

value,

adjust

the

tension

adjusting

spring.

Refer to

Photo

9.

Notes:

o

The

tension

adjusting

spring

is

secured

by double

nuts.

Make

ad-

justment

of

the

spring after

remov-

ing

the upper

nut.

o

With

the

nut

tightened,

the back

tension will

become

larger;

with

the

nut

loosened, the tension

will be-

come smaller.

5

)

Repeat

this adjustment

several

times

for

right

and left

reels

until

the value

of back

tension

remains within the

specified

range.

Note:

After

adjustment,

replace

and tight-

en

the upper nut

and

lock

it with

paint

so that

the

lower

nut should

not

be

loosened.

NORM

AL

SPE

E D

2+

"

(6omm)

TENSION

GAUGE

Pull

the

tension

gauge

at a

speed of

7%n9cm/s)

Fis.

3

ADJ

USTM E NT

OF

TAKE

-U

P TE NSION

AT

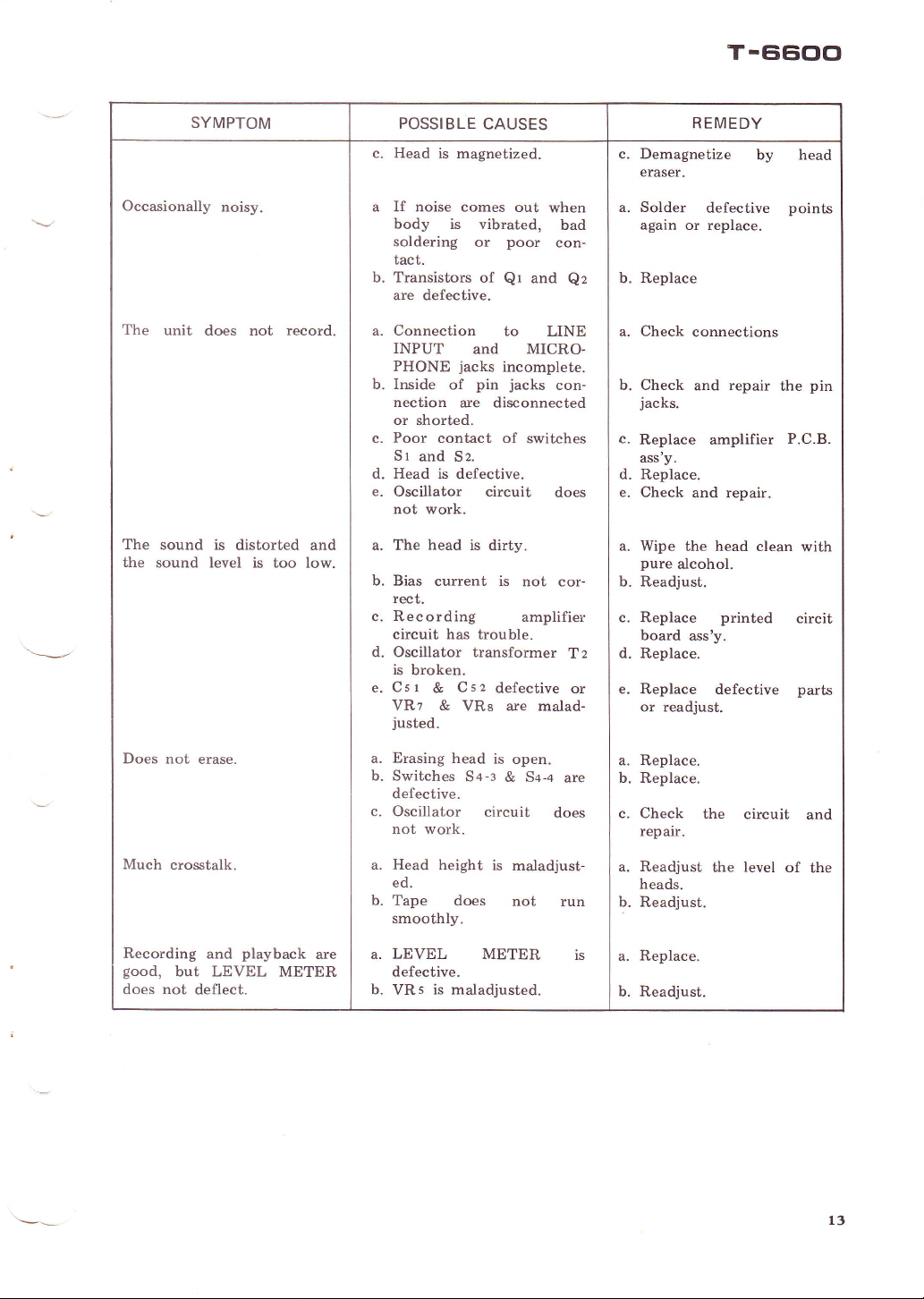

1)

Switch

the

power

"ON".

Hook

a tension

gauge

at the end of

the

tape.

2) Set

the

FUNCITON

LEVER

to

the

"FAST"

position.

3

)

Pull

the tension

gauge

until

the reel

stops

rotating.

4

)

When

the reel hub is 2-3

18"

(

60

mm

),

normal

take-up

tension should be

7

.05

oz

(200

g)

to 8.I oz

(230

g).

5

)

If

the

indicated

take-up

tension is more

or

less

than the

specified value,

adjust

the

tension

by

controlling

the tension

adjusting

screw.

See

Photo

10.

Notes:

o

If

the 4O

nut

is

loosened

before-

hand,

adjusting

screw

may

be easily

moved.

o

With

the

screw tightened, the ten-

sion will

become

larger; with

the

screw

loosened,

the

tension

will

become

smaller.

6

)

Repeat

this

adjustment

several

times for

right

and left

reels,

until the value of the

take-up tension remains

within

the

specified

range.

Note:

After

adjustment, tighten the

40

nut

and lock it with

paint

so

that

the

adjusting

screw

should

not be

loosened.

FAST

FORWARD

7

"

REEL

2+

"

(6omm)

TENSION

GAUGE

Pull

the

tension gauge

until

the

reel

stops

rotating

Fis.4

Photo I

7

"

REEL

r4

Photo

10

\\--J

All manuals and user guides at all-guides.com

Page 16

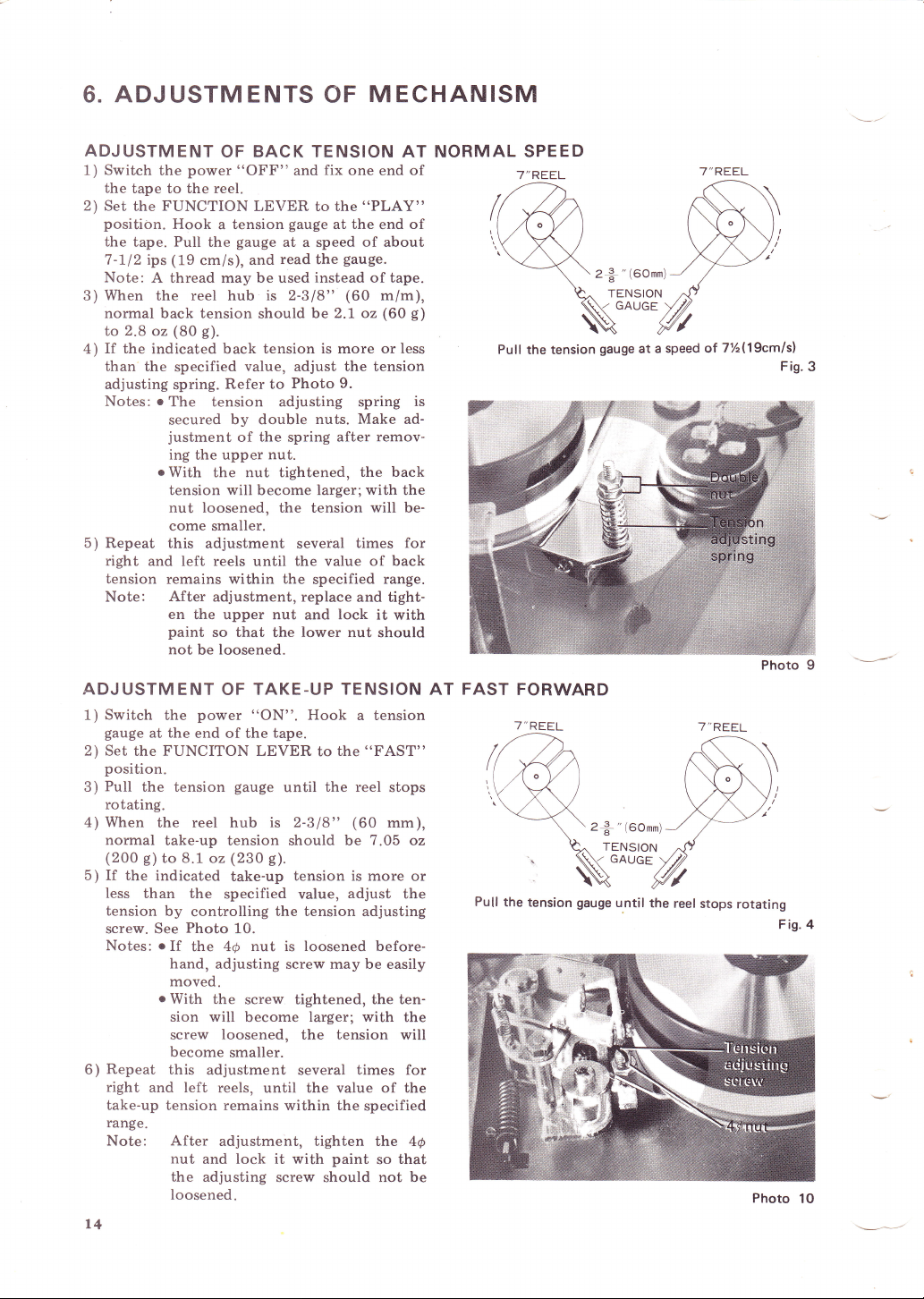

ADJUSTMENT

OF

BACK TENSION

AT

FAST

1)

Switch

the

power

"ON".

Place

a reel to

which

the

tape is

fixed

on the left-hand

side

reel

base.

2)

Set

the

FUNCTION

LEVER

to the

"FAST"

position.

Hook

a

tension

gauge

at

the

end

of

the

tape

and

pull

it

until the

reel

starts

rotating

Note:

Measure

the

back

tension

of the

left-hand

side

reel

while

the take-up

reel is rotating

at a

high

speed.

3

)

When

the reel

hub is 2-3

18"

(

60

mm

),

normal

back

tension should

be

L

14

oz

(7

S)

to

7

lLO

oz

(20il.

4)

It

the

indicated

back

tension is

more

or less

than

the

specified

value,

adjust the

tension

with the

tension brake which

is in

contact

with

the reel

base.

Notes:

o

If

the tension

brake is

pressed

harder

to the reel

base,

the

back

tension will

become larger.

o

Since the tape

counter is loaded

on

the

left reel

base,

the

contact

pres-

sure

of the tension

brake

to the left

reel

base can be

smaller than that to

the

right reel

base.

o

Setting the

FUNCTION

LEVER

to

the

"STOP"

position

will

make

an

adjustment of

the tension

brake

easier.

5

)

Repeat

this

adjustment

several times for

right

and

left reels

until

the

value

of back

tension

remains

within

the

specified

range.

ADJ

USTM

E NT

OF

BRAKE

1)

Bend

the brake

pole

slightly so

that

the

brake

shoe detaches from

the

reel

base

in

"PLAY"

and

"FAST"

operations.

2) Bend

the

pawl

of

the

auxiliary brake

arm so

that

the

auxiliary brake

contacts

the reel

base

pulley

in

"PLAY"

operation,

and

detaches from

the

pulley

in

"FAST"

opera-

tion.

3

)

Repeat

this

adjustment for right

and

left reel

bases.

4

)

The

brake assembly

should

be adjusted as

shown

in

the

table below.

FORWARD

T-EiEioo

Fig.5

Photo

11

Photo

12

"

(6Omm)

TANSION

(-

GAUGE

Pull

the

tension

gauge

,,.!i&,

'&:

f:"

M

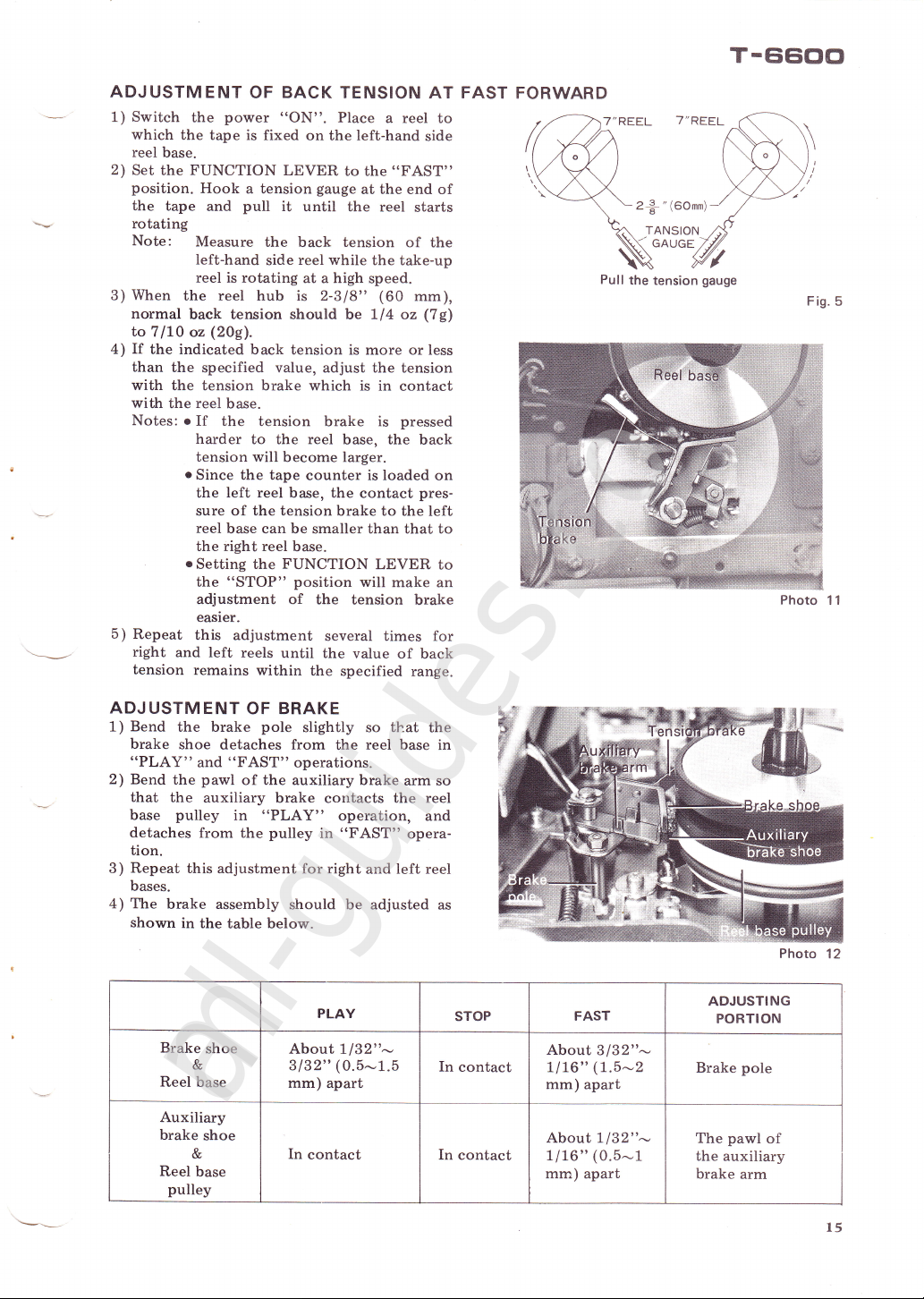

PLAY

STOP

FAST

ADJUSTI

NG

PORTION

Brake

shoe

&

Reel

base

About

I

f

32"-

3132"

(0.5-1.5

mm)

apart

In

contact

About

3132'

-

1176"

(1

.5-2

mm)

apart

Brake

pole

Auxiliary

brake

shoe

&

Reel

base

pulley

In

contact

In

contact

About

L

f

32"-

L116"

(0.5^,1

mm)

apart

The

pawl

of

the

auxiliary

brake

arm

\\---

t5

All manuals and user guides at all-guides.com

all-guides.com

Page 17

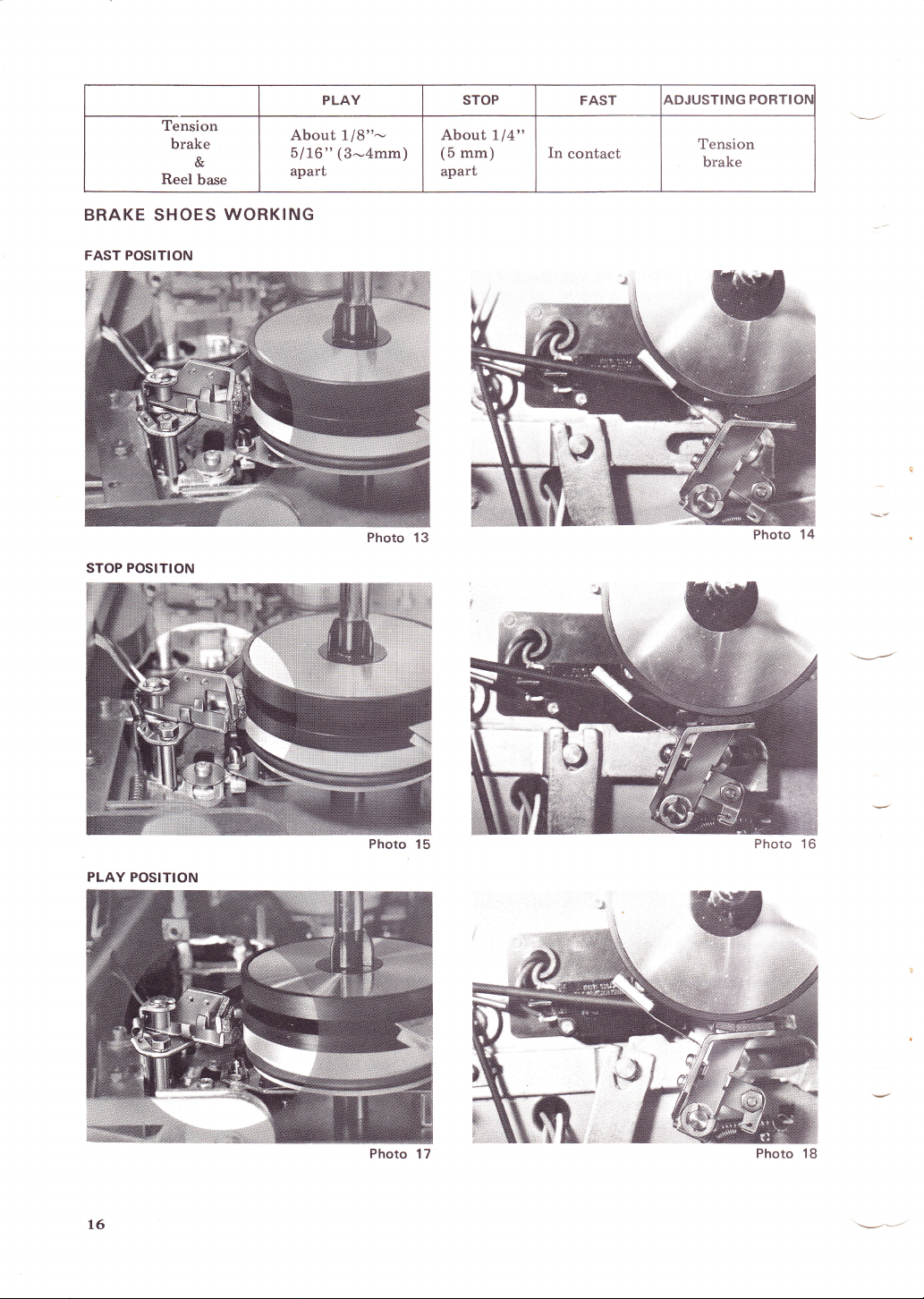

PLAY STOP

FAST

ADJUSTING

PORTION

Tension

brake

&

Reel

base

About t

f

8"^'

5176"

(3-4mm)

apart

About

I14"

(5

mm)

apart

In

contact

Tension

brake

BRAKE

SHOES

WORKING

FAST POSITION

Photo

13

STOP

POSITION

Photo

15

Photo

14

Photo 16

PLAY

POSITION

L6

Photo

17

Photo 18

All manuals and user guides at all-guides.com

Page 18

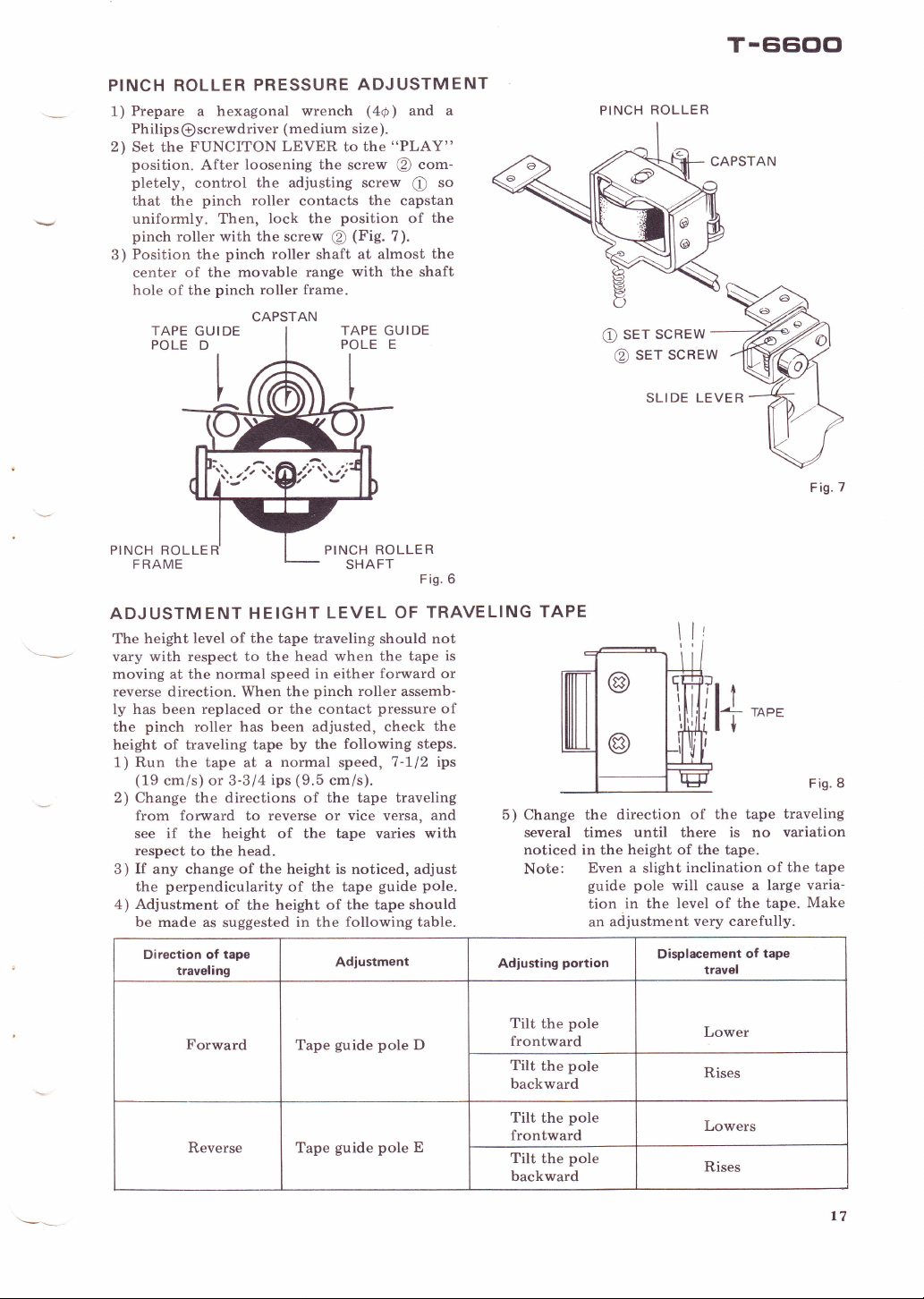

PINCH ROLLER

PRESSURE

ADJUSTMENT

1)

Prepare

a hexagonal

wrench

(40\

and

a

Philips

@screwdriver

(med

ium size

).

2)

Set the

FUNCITON

LEVER

to

the

"PLAY"

position.

After

loosening the

screw

@

com-

pletely,

control

the adjusting screw

C

so

that the

pinch

roller

contacts

the

capstan

uniformly.

Then,

lock

the

position

of

the

pinch roller with the screw

@

(Fig.

7).

3)

Position the

pinch roller

shaft at almost

the

center

of the movable

range

with the

shaft

hole of the

pinch

roller

frame.

GUIDE

E

T-8i600

CAPSTAN

c

sET

SCREW

€)

sET

scREW

SLI

DE

Fig.7

Fig.8

5) Change the

direction

of the tape

traveling

several times

until

there

is no

variation

noticed in the

height

of the tape.

Note:

Even a

slight

inclination

of the

tape

guide pole

will

cause

a large

varia-

tion

in the level of

the tape.

Make

an

adjustment

very carefully,

TAPE

POLE

t

PINCH ROLLE

FRAME

PINCH

ROLLER

SHAFT

Fis. 6

ADJUSTMENT HEIGHT

LEVEL OF

TRAVELING

TAPE

The height

level of

the tape

traveling should not

vary with

respect to the head

when the tape

is

moving

at the

normal

speed

in

either

forward

or

reverse

direction. When

the

pinch

roller

assemb-

ly has been

replaced or the

contact

pressure

of

the

pinch

roller has been adjusted, check

the

height of traveling tape

by

the

following steps.

1) Run

the

tape

at

a normal speed,

7-tl2 ips

(19

cm/s)

or 3-314

ips

(9.5

cm/s).

2) Change the directions of

the tape traveling

from forward

to

reverse or vice versa,

and

see if the

height

of the tape varies

with

respect

to

the

head.

3

)

If

any

change of the height is

noticed, adjust

the

perpendicularity

of the tape

guide

pole.

4) Adjustment

of the

height of the tape

should

be made

as suggested

in the

following table.

PINCH

ROLLER

CAPSTAN

TAPE

GUIDE

POLE

D

I

I

I

_1_

I

Direction of

tape

traveling

Adjustment

Adjusting

portion

Displacement

of

tape

travel

Forward

Tape

guide

pole

D

Tilt

the

pole

frontward

Lower

Tilt

the

pole

backward

Rises

Reverse Tape

guide pole

E

Tilt the

pole

frontward

Lowers

Tilt the

pole

backward

Rises

t7

All manuals and user guides at all-guides.com

Page 19

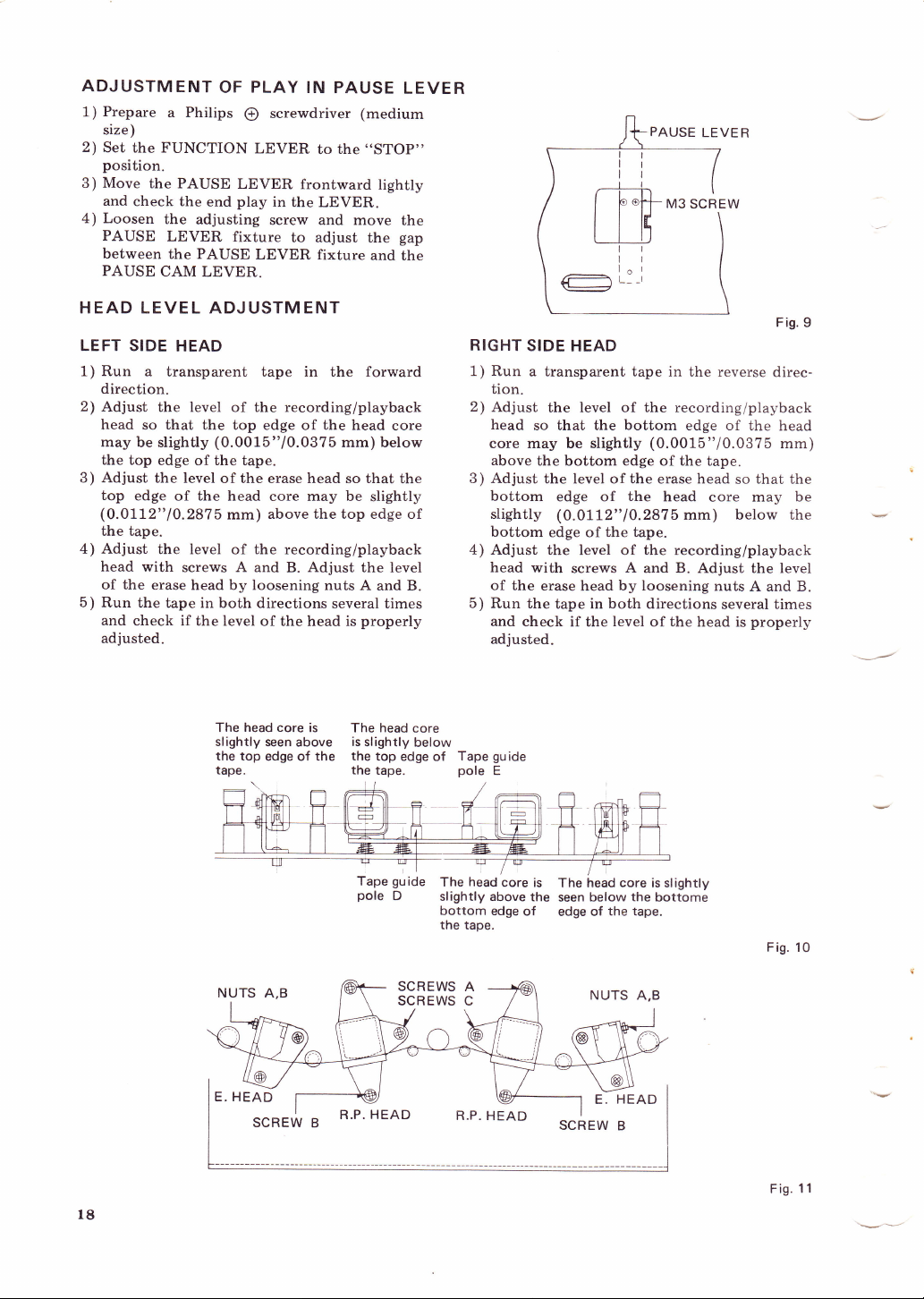

ADJUSTMENT

OF

PLAY

IN

PAUSE

LEVER

1)

Prepare

a

Philips

@

screwdriver

(medium

size)

2)

Set

the FUNCTION

LEVER

to

the

"STOP"

position.

3) Move

the PAUSE

LEVER

frontward

lightly

and

check

the end

play

in

the LEVER.

4) Loosen

the

adjusting

screw and

move the

PAUSE

LEVER fixture

to adjust

the

gap

between

the PAUSE

LEVER fixture

and

the

PAUSE

CAM

LEVER.

HEAD LEVEL ADJUSTMENT

LEFT

SIDE HEAD

1)

Run

a transparent

tape in the forward

direction.

2)

Adjust the level

of the

recording/playback

head so

that

the top edge

of

the

head

core

may

be slightly

(0.0015"/0.0375

mm) below

the top

edge

of

the

tape.

3)

Adjust

the level

of the erase head

so

that

the

top

edge

of the head

core may be

slightly

(0.0112"/0.2875

mm)

above the top edge of

the tape.

4) Adjust

the level

of the recording/playback

head

with

screws

A

and B.

Adjust

the level

of

the

erase head by loosening

nuts A

and B.

5

)

Run

the tape in

both directions

several times

and

check if the level

of the head is

properly

adjusted.

Fis.

9

RIGHT

SIDE HEAD

1) Run

a transparent tape in

the reverse

direc-

tion.

2)

Adjust

the

level of the recording/playback

head

so that the

bottom

edge of

the head

core may be slightly

(0.0015"/0.0375

mm)

above

the

bottom

edge

of

the

tape.

3) Adjust

the level of the

erase

head

so

that the

bottom

edge of the head

core may be

slightly

(0.0112"/0.2875 mm) below the

bottom

edge

of

the tape.

4)

Adjust

the level of the recording/playback

head

with

screws

A

and B. Adjust

the level

of the

erase

head

by loosening

nuts

A and B.

5)

Run the

tape in both directions

several

times

and

check if the

level

of the head

is

properly

adjusted.

The

head core

is

The head core

slightly

seen above

is

slightly

below

the top

edge of the

the

top

edge of

Tape

guide

tape. the

tape.

pole

E

Tape

guide

/

The head

core is

pole

D

slightly

above the

bottom

edge of

the

tape.

The head

core is

slightly

seen below

the

bottome

edge of

the tape.

Fis.

10

PAUSE

LEVER

NUTS

A,B

R.P. HEAD

R.P.

HEAD

Fis.

11

All manuals and user guides at all-guides.com

Page 20

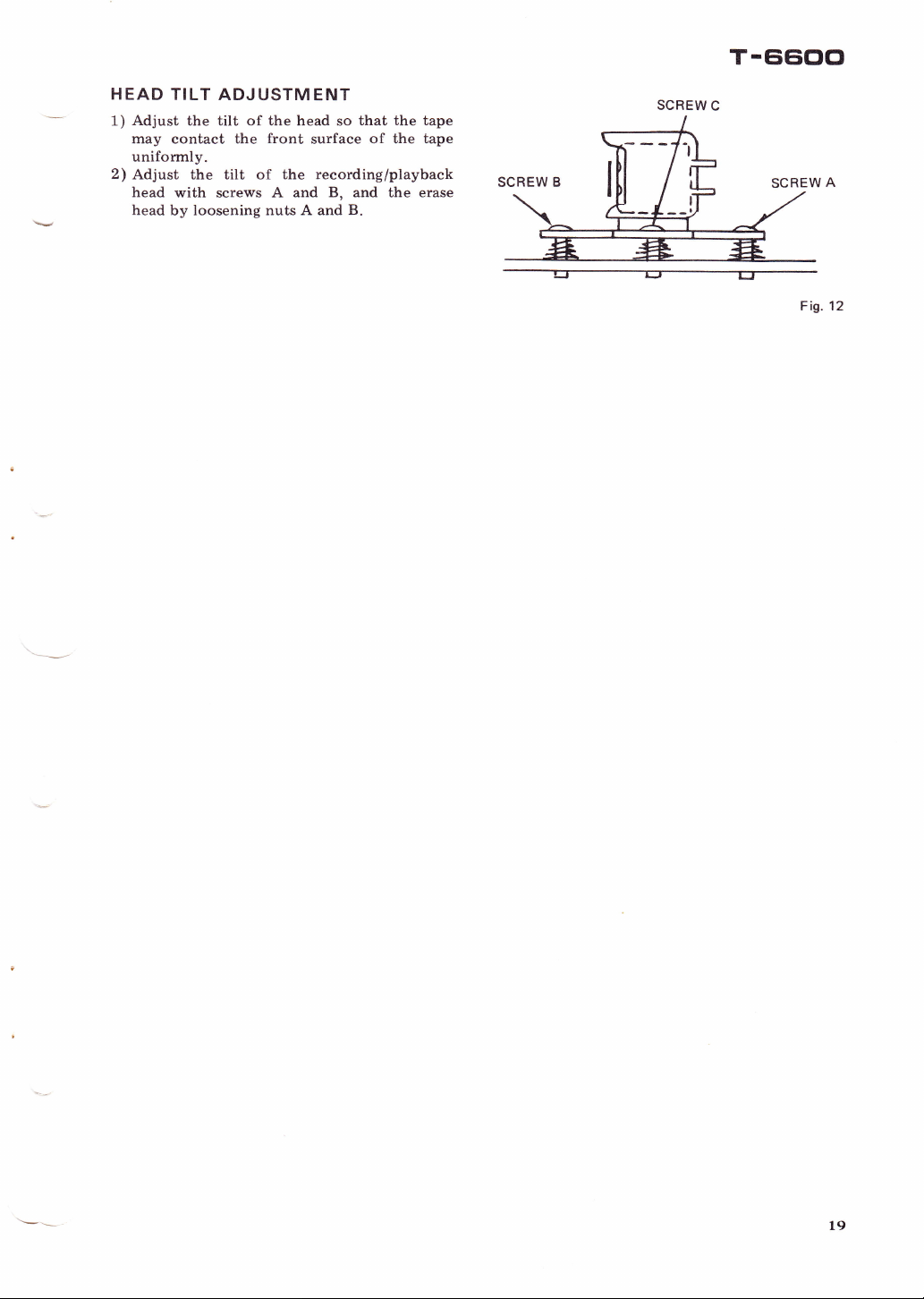

T-Ci600

H E AD

TI LT ADJ

USTM E NT

1)

Adjust

the tilt of the head

so

that

the

tape

may

eontact

the front

surface

of the tape

uniformly.

2)

Adjust the tilt of

the recording/playback

head

with serews A and

B,

and the erase

head

by

loosening nuts A and B.

Fis.12

SCREW

C

SCREW B

SCREW

A

l9

All manuals and user guides at all-guides.com

Page 21

7. ADJUSTMENT

OF

ELECTRIC CIRCUITS

RECORDING BIAS ADJ

USTM

ENT

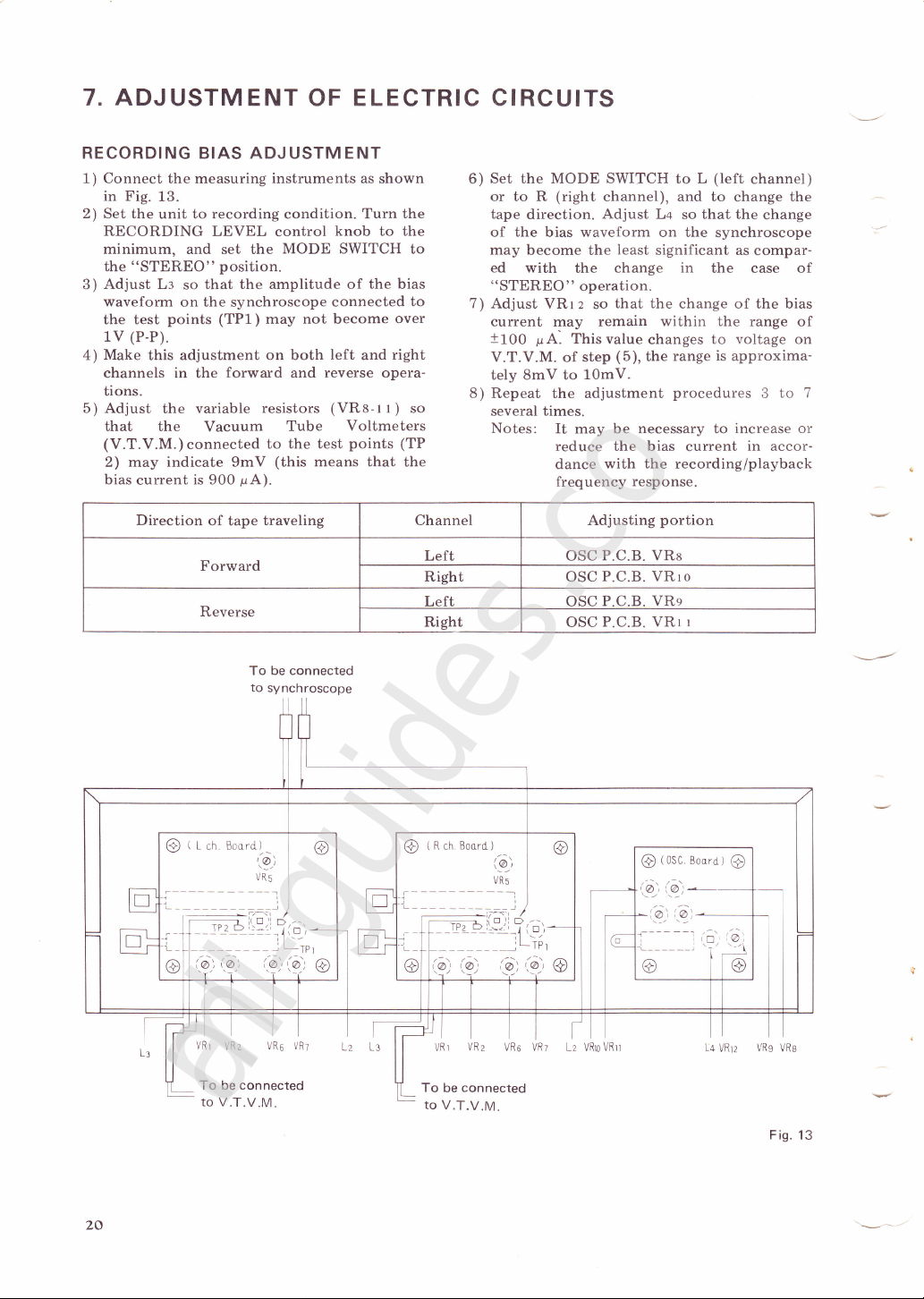

1)

Connect

the measuring

instruments

as shown

in Fig.

13.

2)

Set the unit to recording

condition.

Turn

the

RECORDING

LEVEL

control

knob to the

minimum,

and

set

the

MODE SWITCH to

the

"STEREO"

position.

3)

Adjust

L:

so

that the amplitude of

the bias

waveform

on

the synchroscope

connected

to

the test

points (TP1)

may not become

over

1v (P-P).

4) Make

this adjustment

on

both

left

and

right

channels in the

forward

and

reverse opera-

tions.

5) Adjust

the

variable

resistors

(VRa-t

t

)

so

that the

Vacuum

Tube

Voltmeters

(V.T.V.M.)connected to

the test

points (TP

2) may

indicate 9mV

(this

means that

the

bias

current

is 900

pA).

6)

Set the MODE SWITCH

to

L

(left

channel)

or

to R

(right

channel),

and to

change

the

tape

direction.

Adjust L+

so

that the

change

of the bias waveform on the

synchroscope

may

become the

least

significant as

compar-

ed with

the change

in

the case of

"STEREO"

operation.

7)

Adjust VRrz

so

that the

change of the bias

current may remain

within the range of

1100

pA.

Thisvalue

changes

to voltage on

V.T.V.M. of

step

(5),

the

range

is

approxima-

tely 8mV to

10mV.

8) Repeat the adjustment

procedures

3

to 7

several

times.

Notes:

It

may be

necessary to

increase or

reduce the bias

current

in

accor-

dance

with

the

recording/playback

frequency

response.

Direction

of tape traveling

Channel Adjusting

portion

Forward

Left

OSC

P.C.B. VRs

Right

OSC

P.C.B. VRro

Reverse

Left OSC P C.B. VRs

Right

OSC

P.C.B.

VRr

r

To

be connected

to

synchroscope

To be connected

to V.T.V.M.

To

be

connected

tO

V.T.V.M.

Fig.

13

All manuals and user guides at all-guides.com

all-guides.com

Page 22

HEAD

AZIM

UTH

ADJUSTMENT

With

the

mechanical

adjustments

of

the heads

and their

environments

completed,

following

adjustments

should be made.

READJUSTMENT

OF

R/P

HEAD LEVEL

1)

Connect

the

V.T.V.M.'s

to the right

and

left

channels

of the

OUTPUT

terminal

respec-

tively.

2) Load

the test tape

(TT-5000A)

to the unit

and run

the tape

at

7-Il2

ips

(19cm/s.)

3) Playback

Zone

No.

1 of the

test tape

(700

Hz,

0

dB, 1 & 3 tracks)

and adjust screws A

and B

so that

the

pointer

of the V.T.V.M.

may

deflect

to the "maximum".

Notes: oThe

balance of

the outputs

of the

left

and

right

channels must

not

necessarily

be

considered.

o

Set

the

P.B.

LEVEL

knob

to the

middle

positon.

o

It is

enough

to adjust

the

erase head

under

"Adjustment of

Head

Level

Adjustment"

but

re-check

at the

end of

this

adjustment

by recording

and

erasing

operation.

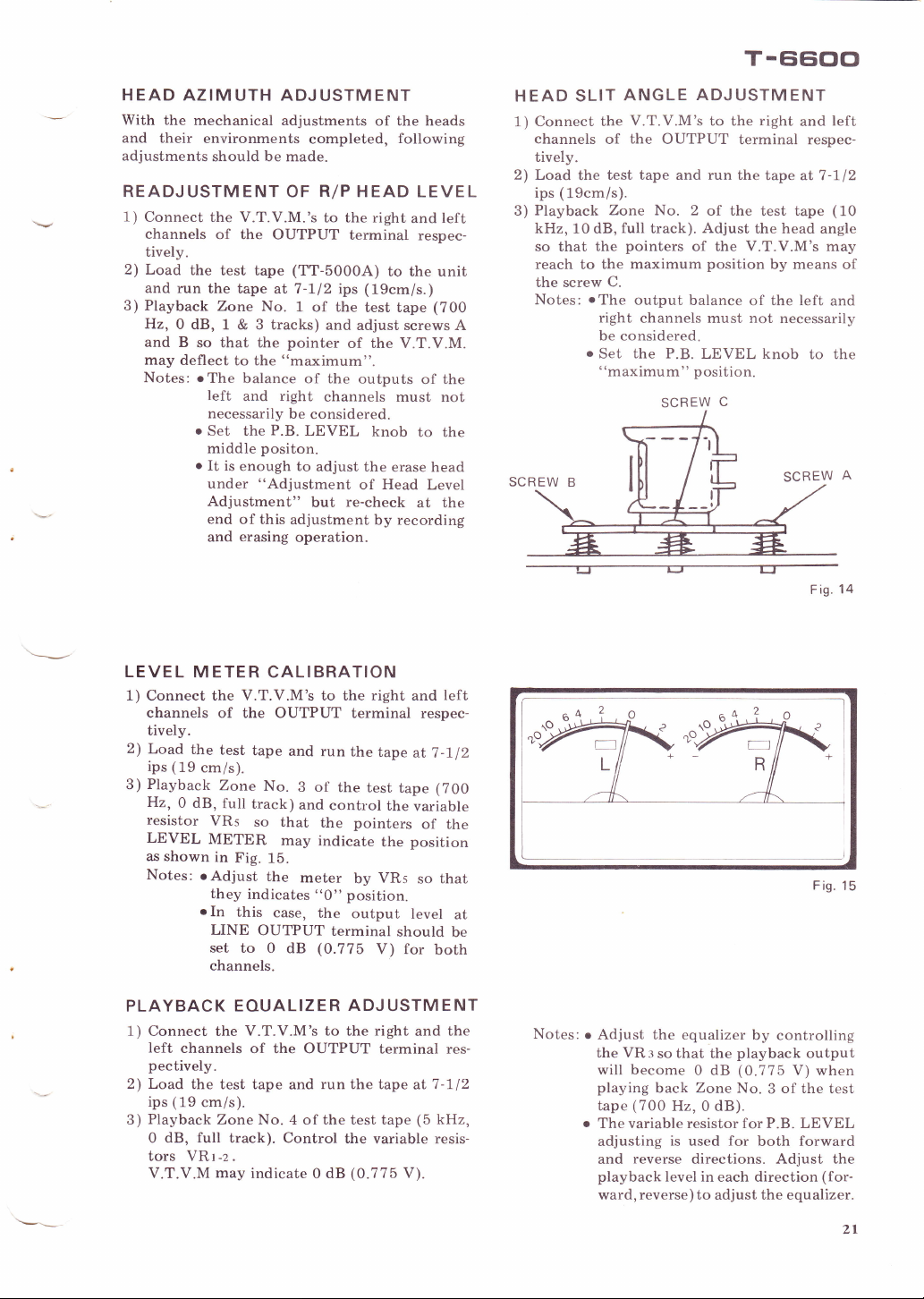

LEVEL

M ETER

CALIBRATION

1)

Connect the

V.T.V.M's to the right

and

left

channels of

the OUTPUT terminal respec-

tively.

2)

Load

the

test

tape

and

run

the

tape

at

7-llz

ips (

19

cm/s).

3)

Playback

Zone

No.

B of

the

test

tape (700

Hz,

0 dB,

full

track)

and

control

the

variable

resistor

VRs

so that

the pointers

of the

LEVEL

METER

may indicate

the

position

as

shown

in

Fig.

1b.

Notes:

oAdjust

the

meter

by

VRs

so

that

they

indicates

"0"

position.

o

In

this

case,

the

output

level

at

LINE

OUTPUT

terminal

should

be

set

to

0 dB

(0.775

V) for

both

channels.

PLAYBACK EOUALIZER

ADJUSTM ENT

1)

Connect the

V.T.V.M's to the right

and

the

left

channels

of the OUTPUT

terminal res-

pectively.

2)

Load the

test tape and

run the tape

at

7-712

ips

(

19 cm/s).

3)

Playback Zone

No. 4 of the test tape

(5

kHz,

0 dB,

full

track). Control

the

variable resis-

tors VRr

-z

.

V.T.V.M

may

indicate 0 dB

(0.775

V).

T-Ei600

HEAD SLIT

ANGLE ADJUSTMENT

1) Connect

the

V.T.V.M's to

the

right

and

left

channels

of

the

OUTPUT

terminal respec-

tively.

2) Load

the

test tape and run

the tape at 7-712

ips

(19cm/s).

3)

Playback Zone No. 2

of the

test tape

(10

kHz,

10 dB,

full

track).

Adjust

the head angle

so that

the

pointers

of the V.T.V.M's may

reach

to

the

maximum

position

by means of

the screw

C.

Notes:

oThe

output

balance

of the left

and

right

channels must not necessarily

be considered.

o

Set the

P.B.

LEVEL

knob

to

the

"maximum"

position.

Fis.

14

Fis.

15

Notes: o

Adjust the

equalizer

by

controlling

the

VR:

so that the

playback

output

will become

0 dB

(O.77

5

V) when

playing

back Zone

No.

3

of the

test

tape

(700

Hz,

0

dB).

o

The variable resistor for P.B. LEVEL

adjusting

is used for

both

forward

and

reverse

directions.

Adjust the

playback

level

in

each direction

(for-

ward,

reverse)

to adjust the equalizer.

SCREW

C

2l

All manuals and user guides at all-guides.com

Page 23

Direction

of

tape traveling

Ghannel

Adjusting

portion

Forward

Left VRr of L

ch.

amplifier

Right VRr of R

ch.

amplifier

Reverse

Left VRz of

L

ch. amplifier

Right VRz of R

ch.

amplifier

PLAYBACK FREOUENCY RESPONSE

CHECK

Playback

Zones No. 5

to

No.

11

of the test

tape. See if

the

frequency response

ranges

as

shown

in Fig. 16-.4, when the tape

travels

at

7-ll2 ips, it ranges as shown

in

Fig. 16-8

when

the

tape

travels at3-314

ips

(9.5m/s).

frequency

response

is out-

range, adjust the

head

slit

When the

playback

side the

specified

angle again.

50Hz

RECORDING

LEVEL

CALIBRATION

After

the

bias

circuit

and the

playback

sensi-

tivity

have

been

adjusted

or

calibrated,

the

adjustment

of the recording

circuit sensitivity is

to

be

performed.

Use

a

new

Scotch No.

111

tape

for

adjustment

of

recording

level.

1) Connect

an audio

oscillator to

LINE

INPUT

terminal

and

a

V.T.V.M.

to LINE

OUTPUT

terminal.

2)

Run

the

tape at

7

-l12

ips (19

cm/s).

3)

Supply

signal of

1

kHz (-18

dB, about 100

mV)

to LINE

INPUT

terminal

and

record

it.

Adjust

the recording

level

by means

of the

RECORDING

LEVEL knobs

so that it

may

become

0 dB

(0.775

V)

on the LEVEL

METER.

Note:

Once

the recording

level

has been

set with the knob,

don't touch

the

kriob

hereafter.

4)

Playback

the tape

recorded

through

the

step

3. If

V.T.V.M.

voltage

reading

is less

than

0

dB

(0.775

V),

turn the

variable

resistors

15000H2

7500H2

Fig.

16

VR

e

-r

to

the

right

a

little,

and

reading is

more

than 0 dB,

turn them to the

left

a

little.

Do not

turn

the

playback

output

level

too much

to avoid

changing the

level with

V.T.V.M.

5)

Try

recording according

to

step 3

once

more,

and

re-playback

this

recorded

tape,

then

check

playback

level again,

reading

value

should

get

close

to

0

dB

(0.775V).

€.)

Repeat

this adjustment of

both recording

and

playback

several

times

so

that the

playback

output

level may become 0 dB

(0.775

V).

Note: During

this

adjustment,

the

P.B.

LEVEL

control

knob

(VRt

in

both L and

R

channels) is

set

at the

position

when the

playback

sensi-

tivity is

calibrated. In other

words,

the

playback

output is

0

dB

(O.775

V)

when the

Zone No.

3

of

the test

tape

(700 Hz,

O dB)

is

played

back.

37a ips

(9.Scm/s)

7% ips

(19cm/s)

Direction of

tape traveling Ghannel

Adjusting

portion

Forward

Left VRo

of the

L ch.

amplifier

Right

VRo of

the

R ch.

amplifier

Reverse

Left VRz of

the L

ch.

amplifier

Right

VRz of

the

R ch.

amplifier

All manuals and user guides at all-guides.com

Page 24

VR2

VR2

R E

COR DIN

G COM

PE NSATOR ADJ

USTM

E NT

1)

Connect

a

V.T.V.M.

to

the

test

point (TP

2).

4)

2) Set

the

tape

speed

at 7

-Ll2

ips

(19

cm/s) and

pull

RECORDING LEVER

only.

Note:

If

the

FUNCTION

LEVER

is set to

bhe

"PLAY"

position,

too,

bias cir-

cuit

will

operate.

Make

sure

to

pull

bhe

recording

lever only.

3

)

Supply

the

signal of 2O

k}Iz

(-40

dB,

about

7.8

mV)

through

the

LINE

INPUT

terminals

and

adjust

Lz

so

that

the

pointer

of

the

V.T.V.M. may

indicate the

maximum.

T-CiEiOCl

VR5

(Rch.)

Photo

19

If

the

unit

is

operated

at

the tape

speed

of

3-3

I

4 ips

(

9.5

cm

/s

),

this

adjustment

is

not

always

necessary.

Check

that

the deflection

of

the

pointer

on the

V.T.V.M.

stays

on

about

11

kHz

by changing the frequency

of

the

audio

oscillator.

Note:

This adjustment has

been

carried

out at the

factory.

It

is

necessuuy

only

when

the recording frequency

response is deviated

extremely.

VRs

(Lch.)

aa

\--._--

Photo 20

All manuals and user guides at all-guides.com

Page 25

RECORDING/PLAYBACK

FREOUENCY

RESPONSE

CH

ECK

1)

Adjust

the recording

level and

set

the

level

of

the

line

output

to 0

dB

(0.775

V=0

VU).

2)

Run the

tape

at

7-ll2

ips

(19

cm/s)

and

supply

the signal

of

-38

dB

(10

mV)

to the

LINE

INPUT

and

record

it.

3

)

Change the recording

frequency

response

from 50-15 kHz

and continue

recording.

4)

When

a recorded

tape

is

played

back

the

frequency should

range

as shown

in

Fig.18-A

with the

tape

traveling at

7-112

ips

(19

cm/s);

it ranges

as

shown

in

Fig. 18-B with

the tape

haveling

at

3-314 ips

(9.5 cm/s).

5) When the

frequency

response

is outside

the

specified

value, adjust

the

bias current.

Note:

.

If the

bias

current

is

too

small,

distortion

increases.

So don't

change

bias too

much.

With

the

bias current

changed,

the

frequency

response

in high

fre-

quency range

varies.

A7%

ips

(19cm/s)

3%

ips

(9.5cm/s)

o

I

z

Fig.

17

10000H2

3dB

-F

3dB

1 5000H2

3dB

-+

3dB

SoHz

7sooHz

8.

LINE VOLTAGE

SELECTION

AND FUSE

Fig.

18

o

SWITCHING LINE VOLTAGE

SETTING

AND

FUSE

To

remove

the

fuse,

turn the

fuse

cap located

on the line voltage selector switch

in the

direction indicated by the arrow,

then remove

the fuse

plug

from

the

unit.

Put

the

fuse

plug

back so that

the

proper

line voltage

marking

can be

seen through the cut on the

edge

of the

plug.

Whenever the

position

of the selector

switch is

changed, check the

rating of

the

fuse.

A

0.5-ampere fuse is

to be

used for either 22OV

or 24OV

operation

and a 1-ampere

fuse for

110V,

117V

or 130V operation. If the rating of

the

fuse

is

correct, replace cap.

(Refer

to

Fig.

19).

'

o

FUSE

REPLACEMENT

If

the

fuse

blows,

remove

the

fuse

cap and

replace

the fuse with

a

new one.

^p

@@'

SMALL BIAS

FREOUENCY

-

24

Fis.

19

All manuals and user guides at all-guides.com

Page 26

9.

SELECTION

OF POWER

LINE

1)

Remove

the

front

panel

by making

reference

to the item

of

DISASSEMBLY

on

page

7.

2)

Remove

the drive

belt

and

the take-up

belts

from

the

motor

pulley.

3) Remove

the

screw

which

secures the

motor

pulley

and changes

the

pulley.

Note: There is

a

groove

provided

on the

pulley

for

60

Hz.

4) Secure

the

motor

pulley

for 50

Hz

or

60

Hz

to

the

motor

shaft temporarily.

Place

the

motor pulley

about Lll6"(2mm)

from

the

chassis

as shown in Fig.

21

and tighten

it

to

the

motor

shaft

by the

setscrew.

5)

Load

the

drive

belt and the

take-up

belt.

Operate

the

unit in both

directions

and see

if

the

speed selector knob functions

correctly.

6)

If

oil or

grease

is adhered

on the

drive belt or

the

take-up

belts,

wipe it clean

with

pure

alcohol.

7)

Change

the

connection

of the

MP

(phase-

shift)

capacitor.

x

When

changing 5O Hz

to

60

Hz

Open

the connection between

the termi-

nals

of 1pF

and

3prF,

and leave the

3pF

only.

*When

changing

6OHz

to 5OHz

Connect

the 1

pF

and 3

pF

in

parallel

obtain

a

total of 4

pF.

FREOUENCY

60Hz

T-Ei600

5OHz

TAKE,UP

BELT

HEXAGONAL

WRENCH

TAKE-UP BELT

DRIVE

BELT

MP

(phase-shift)

CAPACITOR

Fig.22

MOTOR

PULLEY

161'Tif

Fig.21

All manuals and user guides at all-guides.com

all-guides.com

Page 27

tl)Cdc!

:1

c!

E

(f)

L(2

E

L(?

(9

Gi

ca

E

o)

(-..1

ct

1

CD

E

t:

q

t

(o

ct;

sf,

C.!

c-j

c13

._i

E

=

F

E

cr-)

LO

E

LO

(\J

.--:

|t:

ca

c\l

@OC\

E

<o.

CA

E

O

(o

O

>

L/).

co

l

@

F

F

O

E

(,

-

o

UJ

o

F

J

o

o

z

F

z

lr|

E

t

=)

O

3

26

All manuals and user guides at all-guides.com

Page 28

11.

LEVEL DIAGRAMS

RE

CORDI NG

@-aas

@-rsao

T-6CiO(]

@-zraa

REC

CURRENT

50uA

+10

0dB

-10

-20

-30

-40

-50

-60

-10

NFB

12d

I

(0775V)

MAX INPUT

-10d8(240mV)

@

oas

NFB

t9sdB

VR

ATT,

11.5

dB

x

(

g.BdB

VOLUME ATT

-43d8

t

=--

/'lt)-tsae

L

VOLUME

ATT IdB

@-rstao

@-zs

zae

HEAD PHONE

OUTPUT

LEVEL

(ot

B"t lood)

X'(

I

:

T-6100

-bBdB

(

1mV

)

MIN iNPUT

-6BdB(03mV)

All manuals and user guides at all-guides.com

Page 29

PLAY BAC K

0dB

-10

-20

-30

-40

-50

-60

@

o

dB

(

o.77sv )

NFB

21.

3 dB

@

-

zsas

NF8

37

dB

)vorur',tE

ATT.

-BdB

C

-37d8

O

rrupur

-5BdB

(

tmv)

28

All manuals and user guides at all-guides.com

Page 30

All manuals and user guides at all-guides.com

Page 31

:<

@

(cJ

c!

.+

o_

O

|t*

c!

@

rD

C,

YZZ

gEU

=

LN

cr)

E

Hurs0/zr-,

lilfh_D

890

0

s0c

tr)

c\l

\t

To-

O

E o-)

c)

cr)

r)

(,)

coC)

J

O

\t

C!

G

E

)l0't

oru

)6t

80u

,--------L/

.@-{>

!?

=

:9

sf

Rr

c-:l

I

+

)i06t

18u

}Z

Z

q?U

o-

a

o-)

aa

'-*

(a

(-)

O

o

t

:<

c-)

cD

a

(o

=

cn

c)

(o

(f)LOt

)

tl

zeg

:<

O

O

<o

@

d

lo-

I o

1(r).

l-.

lN

lc:

I

I

i

9I

3+

Ir)

cl

O

@

N

(J

g9/00t

sz3

YO

6ZU

)t89

ez!

\LV

8ZA

0/t

szu

)J9'9

/zu

)Ig

IZU

O9g

ZZU

AJIN

(n

O

O

cr)

=

(Y'

c

t'9/00t

/13

:<

t

-<r

c!

d

>

reif!

)IZ

B]U

*r

----t

=-

;tl

)l'z

lru

){0zl

0ru

y9l

ilu

)l0t

zlu

0'9/gg

rt3

9t/0r

zt3

d00l

e

rc

==

aa

EEooFF

OO

UJ

lrJ

JJ

Ld Lrj

aa

fro

co-

ll

oc)

3

trr

aLE

UJ

I-trl

() aaF

=

(.f)

OO

t_

t_

oo

MO

C'

J

33

\t.f,

sf

,\,\ ro

\J \-'

9aaz

6NN

F

O

no

(o

-ogo

6

r

r

.. O

-

s}

a=dc'o

trJ

tri

FAoz

(\J

C\I

rf,

I

I

=

F

2

f

(L

.Ar

C\

(\

$

I

ro

F'

=

\/

F

z

f

E,

UT

E

TL

=

o-

=

31

All manuals and user guides at all-guides.com

Page 32

All manuals and user guides at all-guides.com

Page 33

T-EiCiOO

osc.

uNrT

(w37-4o2)

O SC

UNIT

w37

-

402

t3

t4

l5

t6

VRe

150 K

VRro

150K

I

VRr

l50K

Cso

0 01

8o

2SC|O6l

Cs:

10/35

I

Y,l

\it'-.

--

All manuals and user guides at all-guides.com

Page 34

REC.SWITCH

UNlr

(W1

8-442)

REC

SWITCH

UNIT

wlg

-

442

LN

N

o

wl8-442

Y

All manuals and user guides at all-guides.com

Page 35

PO\trrER

SUPPLY UNIT

wl6-

409

r

I

l.

I

rl

L

O

Cv

<i

<f,

a.v

d

r

l'

l.

I

t:

t_

a

c{

d

r

t'

l.

I

t.

L

Rot

150 3tU

l

lat

l\

I

t--

--

J

Cos

0.1

T-EiEiOO

Povl/ER

SUPPLY

UNrr

(W1

6-408)

All manuals and user guides at all-guides.com

Page 36

c;

z

o

o-

VvVv

v

VTIVJY

YYY.'YY

96!?-u

uuv6vv

IctIctct

etiooN(oo

COCTCOCDO OTFFSF

t^

rnAAU)A(h

o-Lo-o-6i 6:>>>il>

It!l!LLu

It!LILLL

T.E.EEtr.

T.EE.E.Etr.

.9

I

o

o

.,!.,Jy

*O*oi

TJTOJJ

'l

Cf,'1 cO

Ct c9

LO O N @

O

C9c9ctetco ctrFF()F

!!_E_E!

!!!!!!

.;G.;;+

.;.;,;E:;

ctrcEEcccccc

ooooo

oooooo

_o _o _o

.o

-o

_o

-o

l)

-o

_o _o

ooooooaooGo

OOOOO

O()OOOO

o

-o

tJ)

-NeC$tO

rNCt$ll)

(OFFF-r

ccccccEE.

trEClEtrct

)lilI

-ci

o

o

c

o

;

o

!

o

J

o

O

c

|U)-.s

ov

F;e

oo

Oj

l!e

Ec

o

z

o-

u-

vvv>

S$sfO

ooooY

YY

FFrro,)

cto

<<<x3

9?

EEE=$ NN

O(J()OO

OC.)

ooo o

ebLO

6

LLvv

v

Bfr8q?c?S

@@@r

x<<8888<

frEEssEsE

OOOOO(JOCJ

oooo

ro l.f,

to Lc)

o

'i

I

o

o

OOOll)66LnO OOOO\.

rl)ro

-Lr)tOc,s)ccCOIO

lf)lOlOLOe

NN

(.)

o

6

oE-8888'. '-.:-85

-ooFFFFo

oooro

rcc

.o

.o

.o

.9

.9

.c

E

oobo

E:

L=L!LLLLI

5Y-96EEE.

oooEE

^.^

o>>oooo>>>>o:+t

r!

o)

>

r.Lr

ur

uJ r! > ) )

)

Lu

O

E

E

a

\i'tO(OrNCt$Lc)

(oN@o)O

FN

LOr$LO@@@@@