Pioneer RSP-99 Service manual

ORDER NO.

PIONEER CORPORATION 1-1, Shin-ogura, Saiwai-ku, Kawasaki-shi, Kanagawa 212-0031, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION 2010

CRT4559

RS-P99/EW5

OPTICAL DIGITAL REFERENCE SYSTEM UNIVERSAL DIGITAL PREAMP

RS-P99

/EW5

For details, refer to "Important Check Points for Good Servicing".

K-ZZZ. JUNE 2010 Printed in Japan

1234

1234

C

D

F

A

B

E

SAFETY INFORMATION

Where in a manufacturer’s service documentation, for example in circuit diagrams or lists

of components, a symbol is used to indicate that a specific component shall be replaced only

by the component specified in that documentation for safety reasons, the following symbol shall

be used:

This service manual is intended for qualified service technicians; it is not meant for the casual do-it-yourselfer.

Qualified technicians have the necessary test equipment and tools, and have been trained to properly and safely repair

complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may void the warranty.

If you are not qualified to perform the repair of this product properly and safely, you should not risk trying to do so

and refer the repair to a qualified service technician.

2

RS-P99/EW5

5 678

56

7

8

C

D

F

A

B

E

[Important Check Points for Good Servicing]

In this manual, procedures that must be performed during repairs are marked with the below symbol.

Please be sure to confirm and follow these procedures.

1. Product safety

Please conform to product regulations (such as safety and radiation regulations), and maintain a safe servicing environment by

following the safety instructions described in this manual.

1 Use specified parts for repair.

Use genuine parts. Be sure to use important parts for safety.

2 Do not perform modifications without proper instructions.

Please follow the specified safety methods when modification(addition/change of parts) is required due to interferences such as

radio/TV interference and foreign noise.

3 Make sure the soldering of repaired locations is properly performed.

When you solder while repairing, please be sure that there are no cold solder and other debris.

Soldering should be finished with the proper quantity. (Refer to the example)

4 Make sure the screws are tightly fastened.

Please be sure that all screws are fastened, and that there are no loose screws.

5 Make sure each connectors are correctly inserted.

Please be sure that all connectors are inserted, and that there are no imperfect insertion.

6 Make sure the wiring cables are set to their original state.

Please replace the wiring and cables to the original state after repairs.

In addition, be sure that there are no pinched wires, etc.

7 Make sure screws and soldering scraps do not remain inside the product.

Please check that neither solder debris nor screws remain inside the product.

8 There should be no semi-broken wires, scratches, melting, etc. on the coating of the power cord.

Damaged power cords may lead to fire accidents, so please be sure that there are no damages.

If you find a damaged power cord, please exchange it with a suitable one.

9 There should be no spark traces or similar marks on the power plug.

When spark traces or similar marks are found on the power supply plug, please check the connection and advise on secure

connections and suitable usage. Please exchange the power cord if necessary.

a Safe environment should be secured during servicing.

When you perform repairs, please pay attention to static electricity, furniture, household articles, etc. in order to prevent injuries.

Please pay attention to your surroundings and repair safely.

2. Adjustments

To keep the original performance of the products, optimum adjustments and confirmation of characteristics within specification.

Adjustments should be performed in accordance with the procedures/instructions described in this manual.

4. Cleaning

For parts that require cleaning, such as optical pickups, tape deck heads, lenses and mirrors used in projection monitors, proper

cleaning should be performed to restore their performances.

3. Lubricants, Glues, and Replacement parts

Use grease and adhesives that are equal to the specified substance.

Make sure the proper amount is applied.

5. Shipping mode and Shipping screws

To protect products from damages or failures during transit, the shipping mode should be set or the shipping screws should be

installed before shipment. Please be sure to follow this method especially if it is specified in this manual.

RS-P99/EW5

3

1234

1234

C

D

F

A

B

E

CONTENTS

SAFETY INFORMATION..................................................................................................................................... 2

1. SERVICE PRECAUTIONS............................................................................................................................... 5

1.1 SERVICE PRECAUTIONS ........................................................................................................................ 5

1.2 NOTES ON SOLDERING .......................................................................................................................... 5

2. SPECIFICATIONS............................................................................................................................................ 6

2.1 SPECIFICATIONS ..................................................................................................................................... 6

2.2 CONNECTION DIAGRAM ......................................................................................................................... 7

3. BASIC ITEMS FOR SERVICE.......................................................................................................................... 9

3.1 CHECK POINTS AFTER SERVICING....................................................................................................... 9

3.2 JIGS LIST .................................................................................................................................................. 9

4. BLOCK DIAGRAM.......................................................................................................................................... 10

5. DIAGNOSIS.................................................................................................................................................... 14

5.1 OPERATIONAL FLOWCHART................................................................................................................ 14

5.2 CONNECTOR FUNCTION DESCRIPTION............................................................................................. 15

6. SERVICE MODE ............................................................................................................................................ 15

7. DISASSEMBLY .............................................................................................................................................. 16

8. EACH SETTING AND ADJUSTMENT ........................................................................................................... 19

9. EXPLODED VIEWS AND PARTS LIST.......................................................................................................... 20

9.1 PACKING ................................................................................................................................................. 20

9.2 EXTERIOR............................................................................................................................................... 22

10. SCHEMATIC DIAGRAM............................................................................................................................... 24

10.1 CONTROL UNIT(1/2)(GUIDE PAGE) .................................................................................................... 24

10.2 CONTROL UNIT(2/2)(GUIDE PAGE) .................................................................................................... 30

10.3 DSP UNIT(1/2)(GUIDE PAGE) .............................................................................................................. 36

10.4 DSP UNIT(2/2)(GUIDE PAGE) .............................................................................................................. 42

11. PCB CONNECTION DIAGRAM.................................................................................................................... 48

11.1 CONTROL UNIT .................................................................................................................................... 48

11.2 DSP UNIT............................................................................................................................................... 52

12. ELECTRICAL PARTS LIST .......................................................................................................................... 56

4

RS-P99/EW5

5 678

56

7

8

C

D

F

A

B

E

1. You should conform to the regulations govering the product (safety, radio and noise, and other regulations),

and should keep the safety during servicing by following the safety instructions described in this manual.

2. Be careful in handling ICs. Some ICs such as MOS type are so fragile that they can be damaged by

electrostatic induction.

3. "When you carry out the diagnosis and the repair in the cover (CNN3484: spacer, CNN3485: sheet) of this

sound master clock part, remove the cover carefully not to damage it and reuse it after the diagnosis and

the repair."

For environmental protection, lead-free solder is used on the printed circuit boards mounted in this unit.

Be sure to use lead-free solder and a soldering iron that can meet specifications for use with lead-free solders for repairs

accompanied by reworking of soldering.

Compared with conventional eutectic solders, lead-free solders have higher melting points, by approximately 40 C.

Therefore, for lead-free soldering, the tip temperature of a soldering iron must be set to around 373 C in general, although

the temperature depends on the heat capacity of the PC board on which reworking is required and the weight of the tip of

the soldering iron.

Compared with eutectic solders, lead-free solders have higher bond strengths but slower wetting times and higher melting

temperatures (hard to melt/easy to harden).

The following lead-free solders are available as service parts:

Parts numbers of lead-free solder:

GYP1006 1.0 in dia.

GYP1007 0.6 in dia.

GYP1008 0.3 in dia.

1. SERVICE PRECAUTIONS

1.1 SERVICE PRECAUTIONS

1.2 NOTES ON SOLDERING

RS-P99/EW5

5

1234

1234

C

D

F

A

B

E

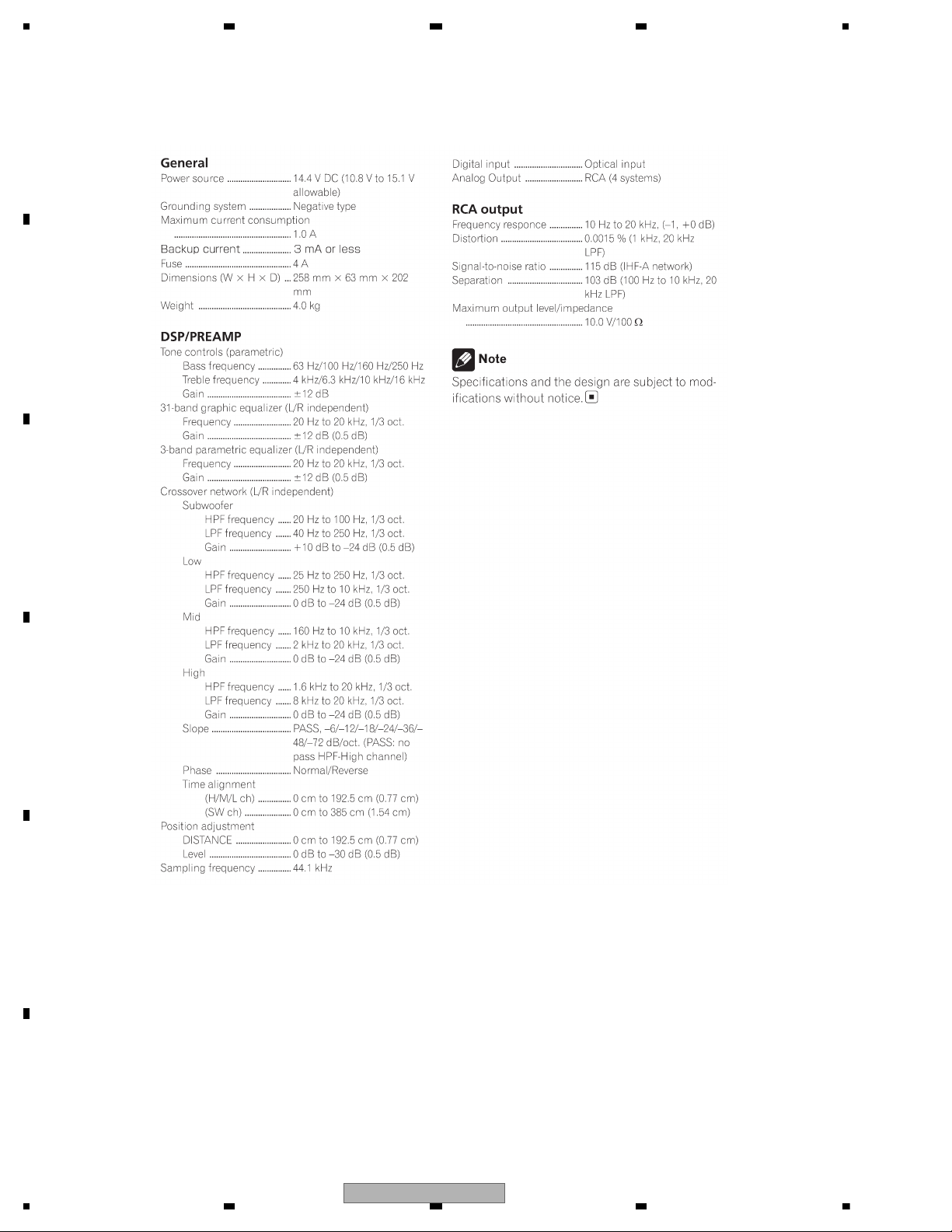

2. SPECIFICATIONS

2.1 SPECIFICATIONS

6

RS-P99/EW5

5 678

56

7

8

C

D

F

A

B

E

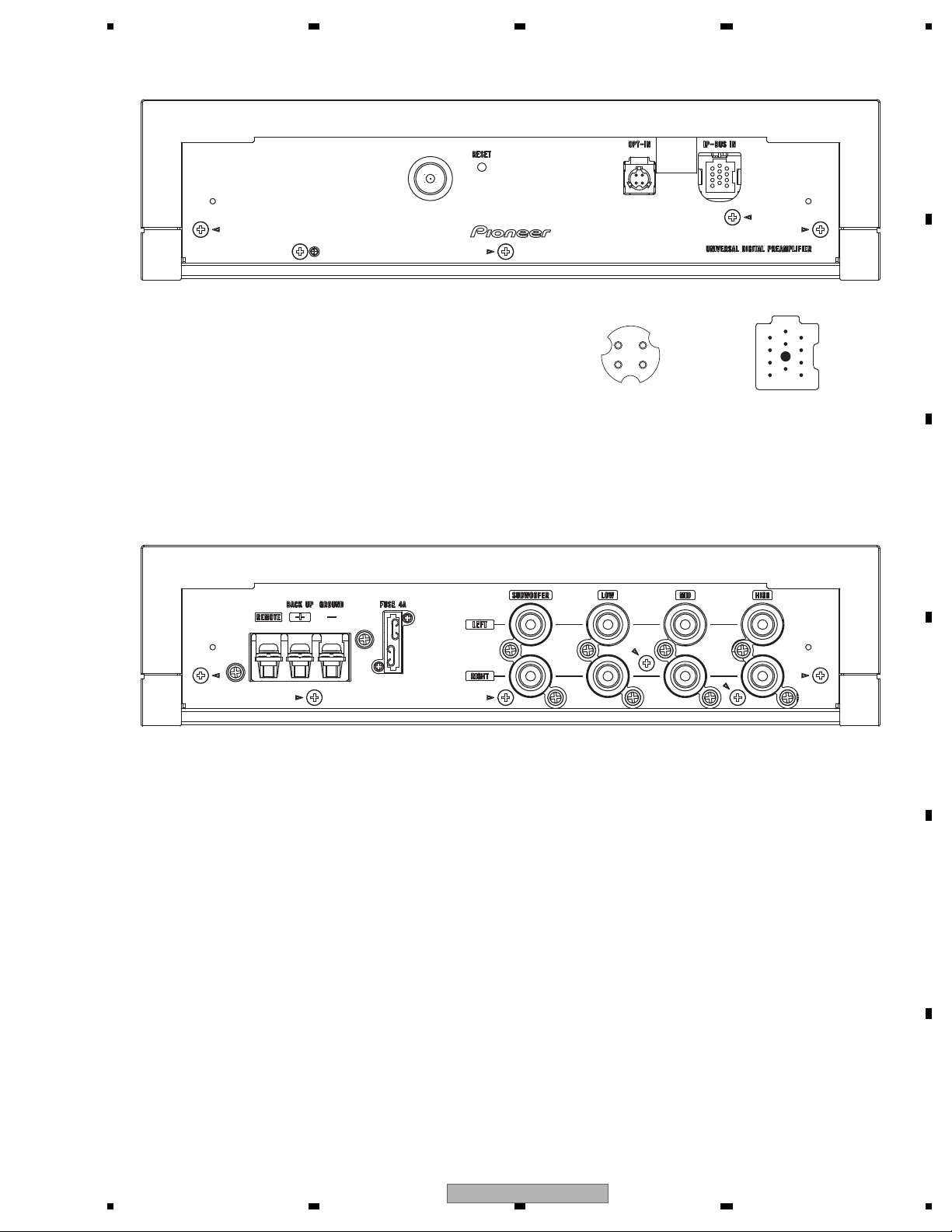

Optical input

(blue)

IP-BUS input

(blue)

IP-BUS cable

(supplied)

optical cable

(supplied)

RS-D7R

(sold separately)

To IP-BUS output

(black)

To optical output

(black)

Fuse (4A)

Right side

Left side

Fuse holder

(4A)

RCA output

Power terminal

Blue/white lead

Connect to system control

terminal of the power amp

(max. 300 mA 12 V DC).

Clear/red lead

Connect to the constant

12 V supply terminal.

Clear/black lead (chassis

ground)

Connect to a clean,

paint-free metal location.

Connection diagram

2.2 CONNECTION DIAGRAM

RS-P99/EW5

7

1234

1234

C

D

F

A

B

E

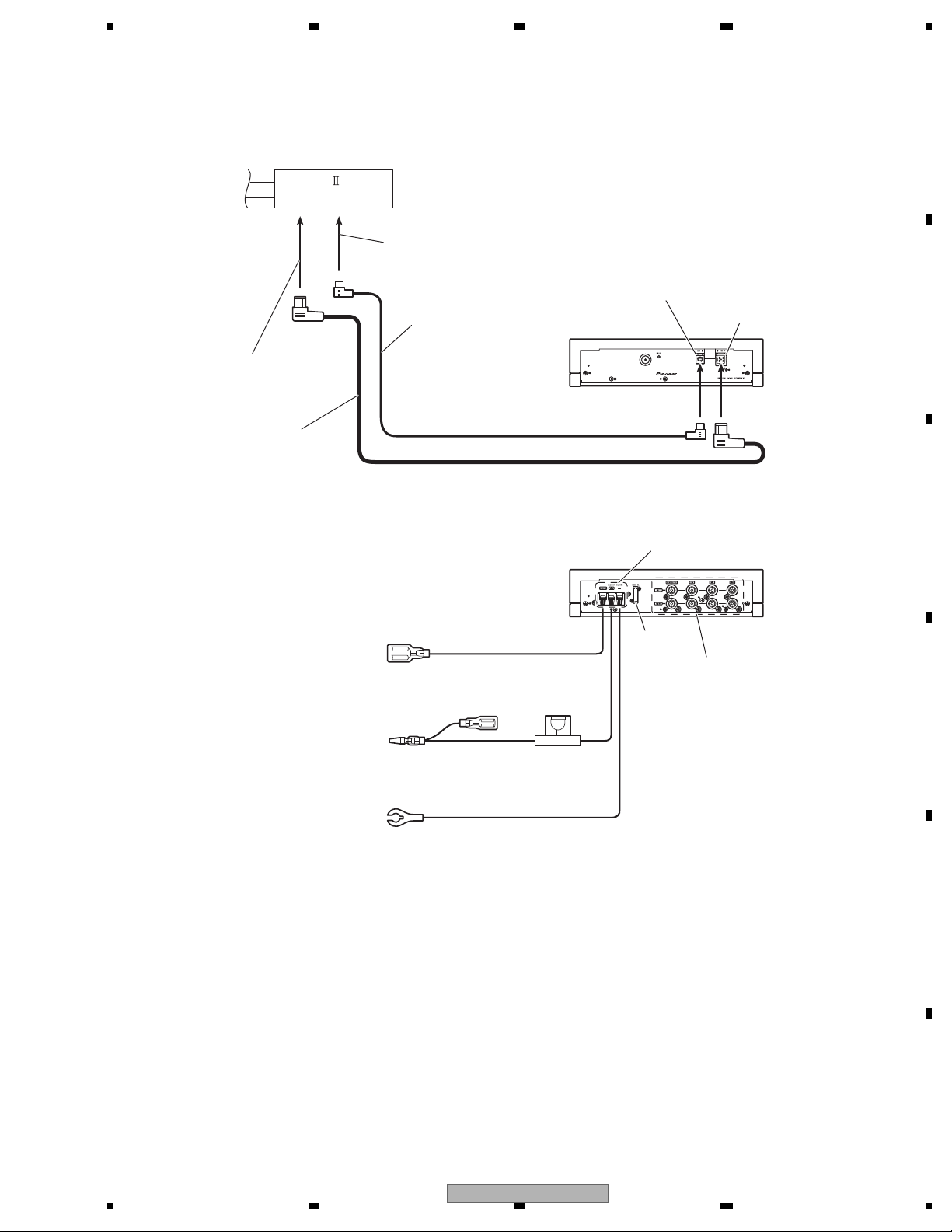

Connecting the RCA input amplifier

White (Left)

Red (Right)

Blue/whiteBlue/white

system remote control

Tweeter

Mid range

Woofer

Subwoofer

Power

amplifier

(sold separately)

Power

amplifier

(sold separately)

Power

amplifier

(sold separately)

Power

amplifier

(sold separately)

White (Left)

Red (Right)

8

RS-P99/EW5

5 678

56

7

8

C

D

F

A

B

E

To keep the product quality after servicing, please confirm following check points.

demrifnoc eb ot metIserudecorP.oN

1 Confirm whether the customer complain has

been solved.

The customer complain must not be

reappeared.

Audio and operations must be normal.

2 Check the output sound. Audio and operations must be normal.

retfa ecnaraeppa sti no trid ro sehctarcs oNkcehc ecnaraeppA3

receiving it for service.

See the table below for the items to be checked regarding audio:

Item to be checked regarding audio

Distortion

Noise

Volume too low

Volume too high

Volume fluctuating

Sound interrupted

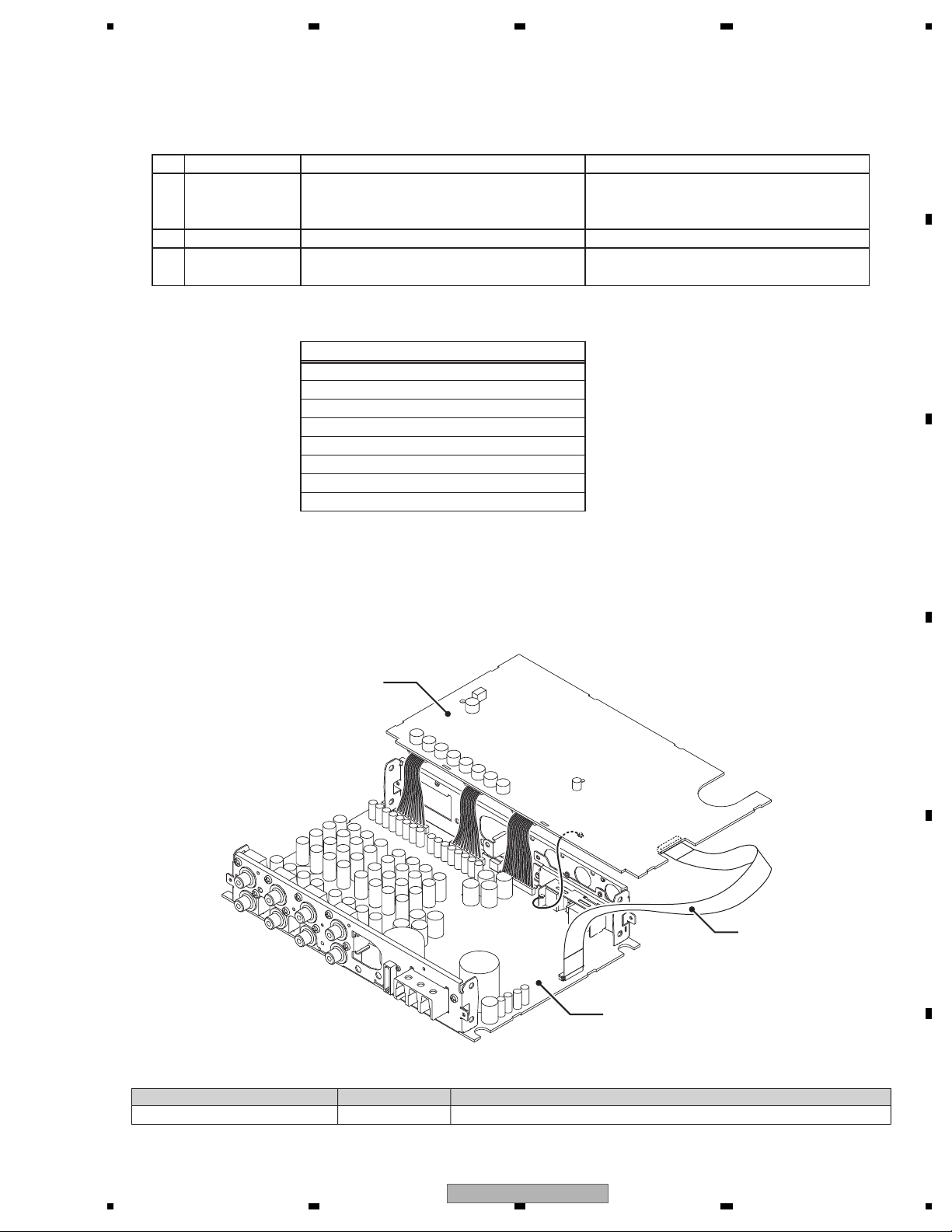

DSP Unit

Control Unit

GGD1262

- Jigs List

Name

Extension cable

Jig No.

GGD1262

Remarks

Flexible extension

3. BASIC ITEMS FOR SERVICE

3.1 CHECK POINTS AFTER SERVICING

3.2 JIGS LIST

RS-P99/EW5

9

1234

1234

C

D

F

A

B

E

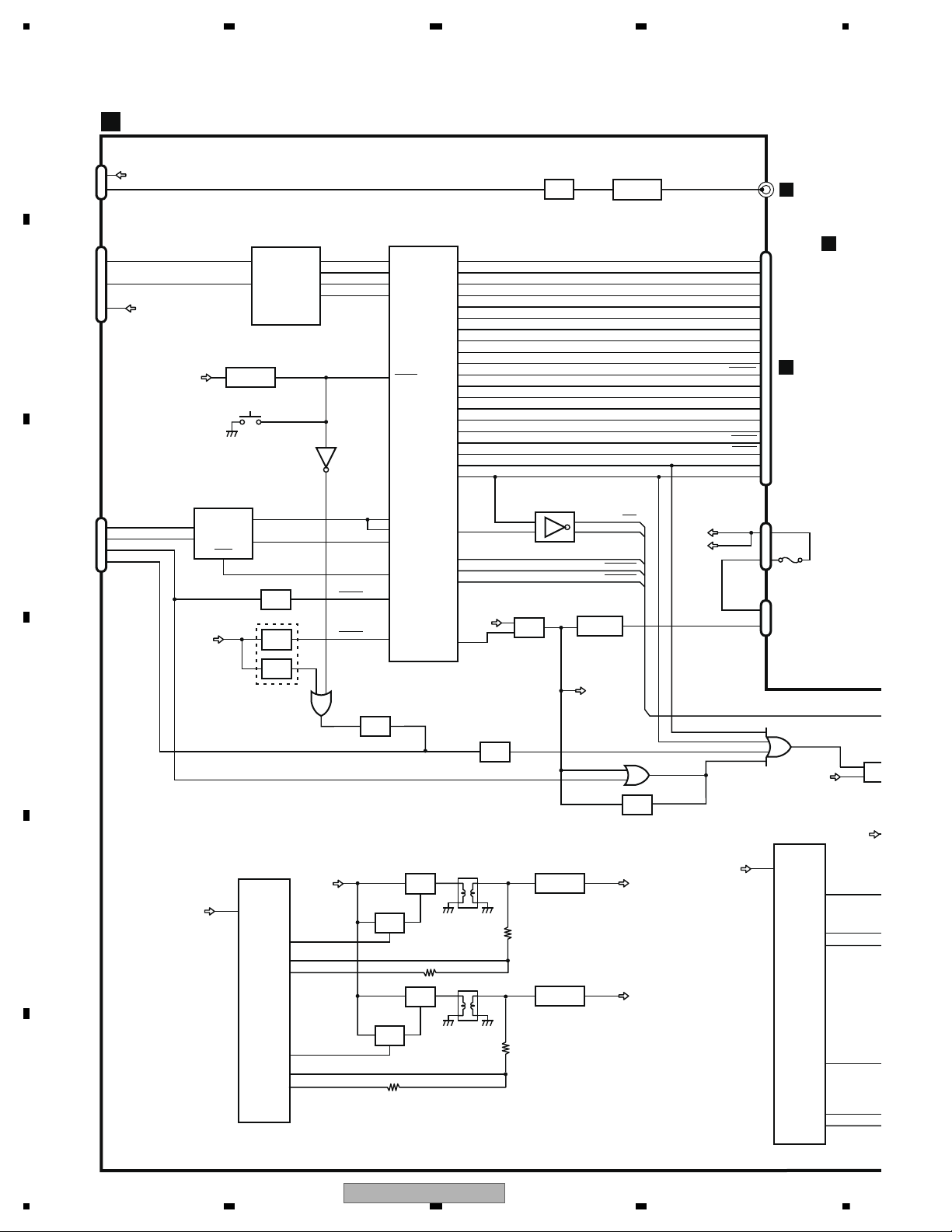

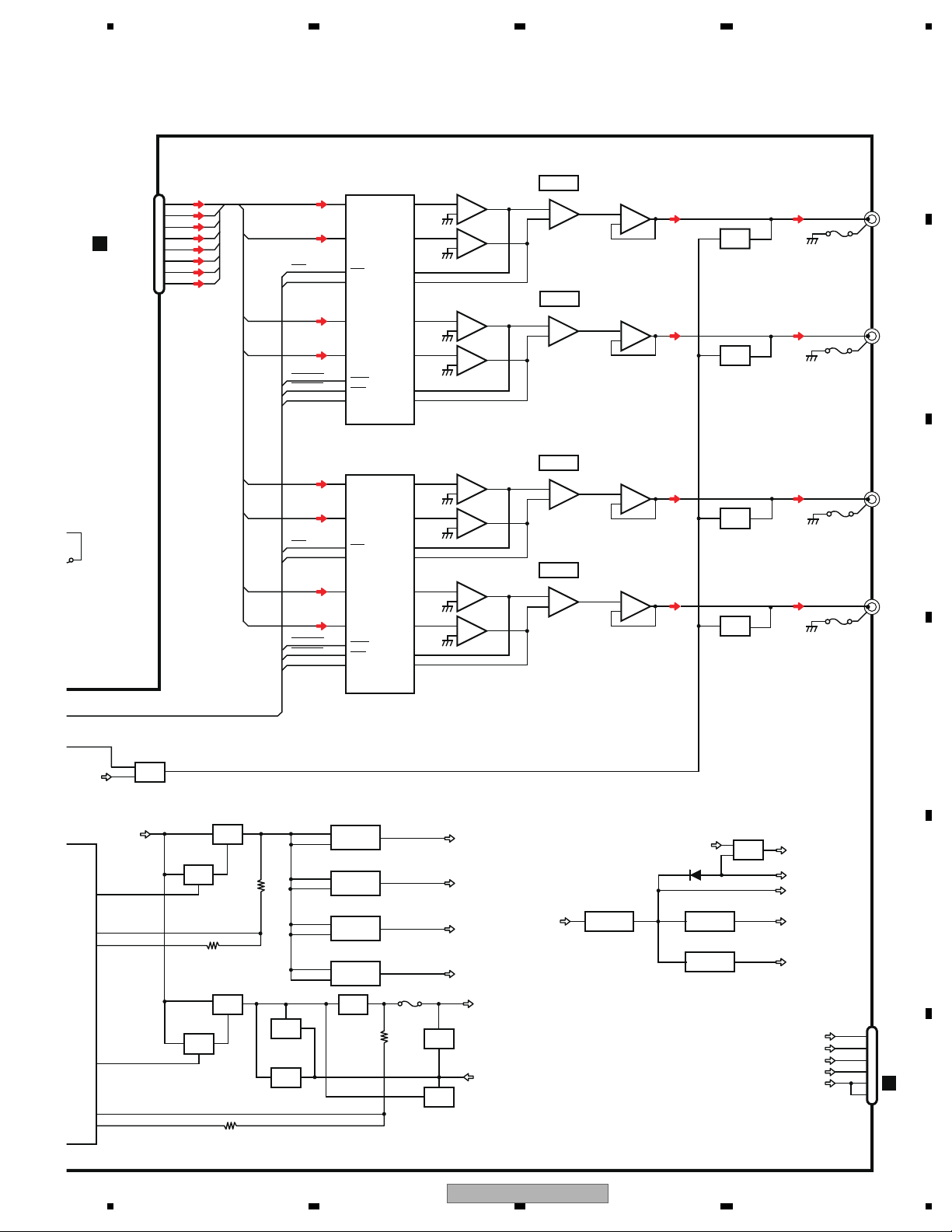

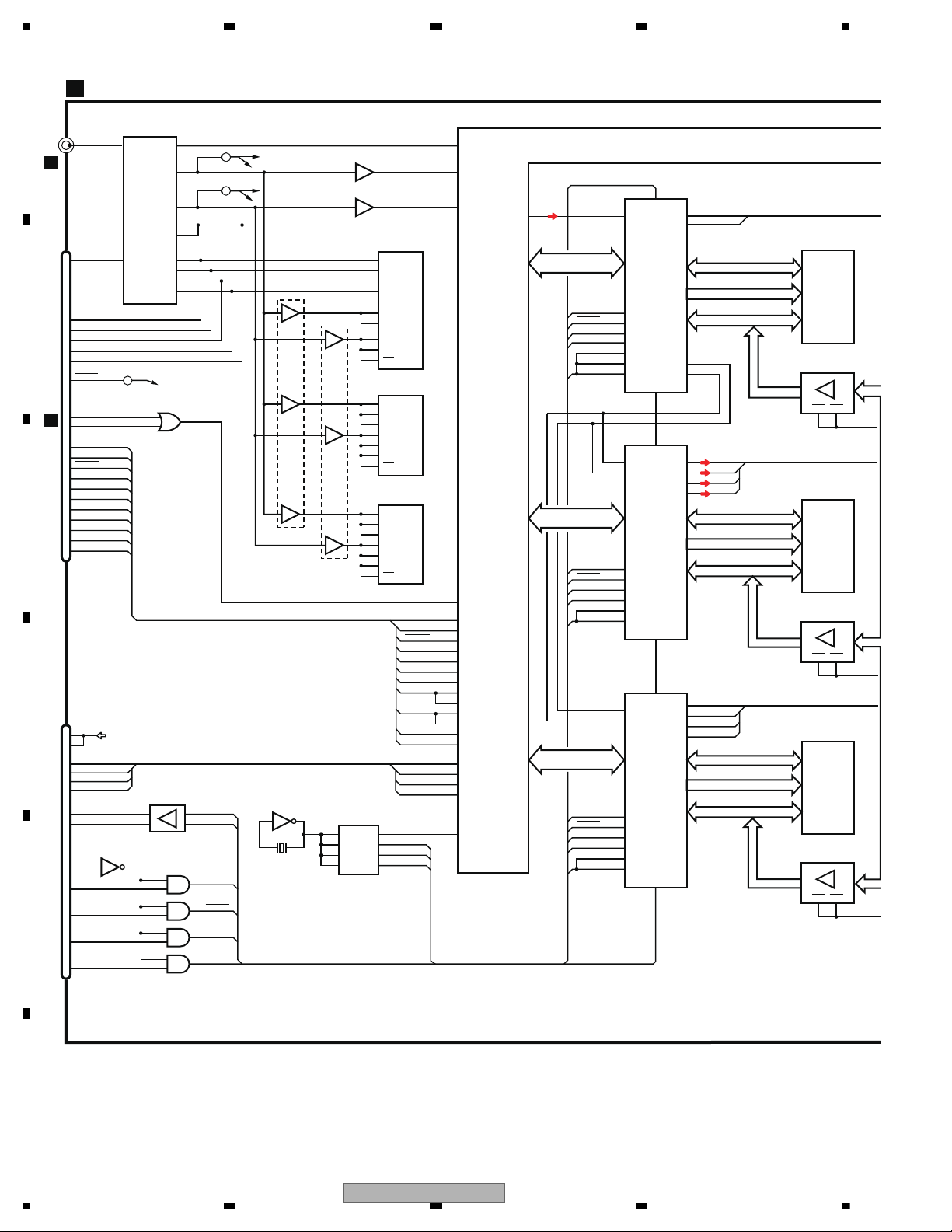

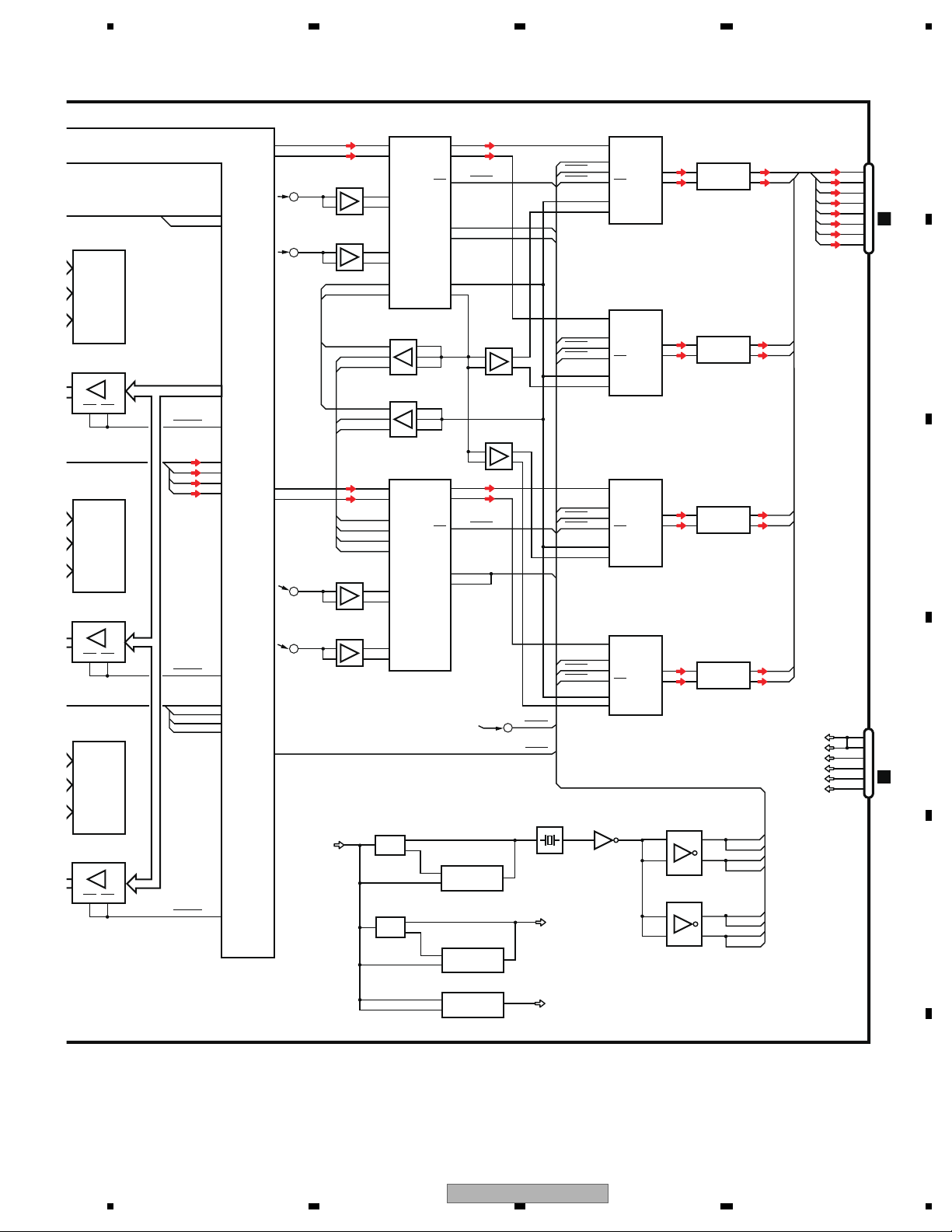

4. BLOCK DIAGRAM

OPT-IN

IP-BUS IN

2

4

5

YA

1

DATA IN

D5V

CONTROL UNIT

TC7WH157FU

1

3

2

D+

2

1

2

1

REM1

B.U

SWBU

BATT

VP15L

±17V REGULATOR

AN8011S

9

OUT2

7

4

IN-2

VCC

T851

OUT1

10

IN+

14

VREF

16

T852

3

OUTIN

1

NJM78M15DL1A

3

OUTIN

2

NJM79M15DL1A

SWBU

3V/6V REGULATOR

AN8011S

9

OUT1

10

13

IN-1

VCC

OUT2

7

4

IN-2

5

8

4

1

BUS+

ASENB

BMUTE

US+5V

USB MICRO

COMPUTER

CY7C68013A-100AXC

18

RXD0

41

40

TXD0

DMINUS

17

DPLUS

37

PB3/FD3

45

PB5/FD5

PEG169A

TC7WH04FU

TXD1

24

25

RXD1

27

P64

6

67

66

1

80

CNVSS

22

P71

23

RX

TX

P70

21IPPW

P76

15

P84

P00

P01

CLK4

Sout4

79

62

61

53

Sin4

P05

P06

P26

43

51

65

63

P40

P30

P02

P04

50

49

46

45

P31

P32

P35

P36

44

47

48

42

1

35

7

5 CLKIN

P37

P34

P33

P41

CLK3

M3.3V

BATT

BATT

SWBU

4

3

5

6

7

8

9

18

20

2

10

12

14

16

22

24

26

28

30

32

DIRRST

DITRST

DIRBRATE1

DIRBRATE0

DIRADFLG

DIREMFLG

DIRUNLOCK

nCONFIG2

nCONFIG1

UMUTE

4 ELDATA

SOUT3

3

P93

2

P94

40

SWBU

ASENM

P43

CONFDONE

PLDRST

DSPERR

DSPSTOP

nSTATUS

PLDIN

PLDOUT

PLDCLK

PLDSEL1

PLDSEL0

EVOLENB

EVOLSTB

ASENS

CLR

4.0A

BATT

VBUM

VBUM

1

OUTIN

6

TPD1018F

19

2

4

OUTVDD

2

POWER ON RESET

S-80827CNUA-B8M

2

ROUT

5

16

P83

BSENS

6

8

1

DIN1

HA12241FP

TC7SET04FUS1

RESET

STBY

RESET

VM15L

BATT

JA301

IC301

CN904

IC851

IC952

IC954

IC801

JA701

IC651

IC601

IC150

IC552

IC621

IC701

IC631

CN302

CN901

H902

CN601

CN5101

CN3001

CN2101

Q541

Q502

Q501

Q511

Q932

Q512

Q311

Q521

Q853

Q851

Q854

Q852

Q52

S401

Q931

B

B

B

Q52

D-

A

BUS-

BUS+

BUS-

OPI1

S/PDIF SELECTOR

SYSTEM MICRO

COMPUTER

IP-BUS DRIVER

18

P81

ACC SENSE

BACK UP SENSE

5

FB2

12

FB1

5

FB2

10

RS-P99/EW5

5 678

56

7

8

C

D

F

A

B

E

1

7

8

4

5

6

2

3

HLP

HLM

MLP

MLM

LLP

LLM

SLP

SLM

12bit DACx4

AD7564BRS

LT1358CS8

LT1358CS8

LT1358CS8

6

EVOLENB

EVOLSTB

CLR

SDIN

CLKIN

15

16

LDAC

13

FSIN

CLR

12

14

IOUT1C

46

7

8

5

HLP

HLO

MLO

HLM

ELDATA

CLKIN

IOUT1D

13

2

8

5

14

11

RFBC

5

9

RFBD

VREFC

10

VREFD

D3.3V

D5V

DAC5V

VP15L

23MLP

MLM

VREFB

19

VREFA

2

1

3

5

7

6

LT1358CS8

IOUT1B

25 2

1

21

3

IOUT1A

RFBB

24

20

RFBA

6

7

5

3

1

2

12bit DACx4

AD7564BRS

LT1358CS8

6

EVOLENB

EVOLSTB

CLR

SDIN

CLKIN

15

16

LDAC

13

FSIN

CLR

12

14

IOUT1C

46

7

8

5

LLP

LLO

LLM

ELDATA

CLKIN

IOUT1D

RFBC

5

9

RFBD

VREFC

10

VREFD

23SLP

SLM

VREFB

19

VREFA

2

1

3

LT1358CS8

IOUT1B

25 2

1

21

3

IOUT1A

RFBB

24

20

RFBA

6

7

5

SLO

DAC5V

OUT1

10

13

IN-1

OUT2

7

4

IN-2

D5V

4

VOUT

VIN

5

NJM2880U1-05

4

VOUT

VIN

5

NJM2880U1-05

V5DAVOR

4

VOUT

VIN

5

NJM2880U1-05

V5DAVOL

N3.3V

D3.3V

4

VOUT

VIN

5

NJM2880U1-05

N3.3V

VDD5V

VBUM

3

VOUTVIN

2

S-812C33AMC-C2N

M3.3V

3

VOUT

VIN

2

S-812C33AMC-C2N

US3.3V

N3.3V

MUTE

VBUM

Hi-Lch

Mid-Lch

Low-Lch

Sw-Lch

5

7

6

LT1358CS8

(1/2)

(1/2)

3

1

2

LT1358CS8

(2/2)

(2/2)

LT1358CS8

LT1358CS8

5

7

6

3

1

2

5

7

6

LT1358CS8

(1/2)

(1/2)

3

1

2

LT1358CS8

(2/2)

(2/2)

3

VOUTVIN

1

BD3931FP

5V REGULATOR

VM15L

BATT

IC974

IC973

IC972

IC971

IC921

IC931

Q699

IC911

CN101

IC101

IC102

IC104

IC104

CN801

IC103

IC201

IC202

IC203

IC105

IC105

JA102

JA101

IC204

IC204

IC205

IC205

JA202

JA201

P202

P201

CN5101

CN1001

CN3001

CN2101

P102

P801

Q804

Q802

Q813

Q810

Q803

Q811

Q815

Q812

Q523

Q236

Q235

Q136

Q135

B

B

Q522

P101

+

-

+

-

-

+

+

-

+

-

-

+

-

+

-

+

+

-

+

-

-

+

+

-

+

-

-

+

-

+

-

+

Q698

Q814

12

FB1

Q801

5

FB2

CONT

1

CONT

1

CONT

1

CONT

1

PREOUT

BUFFER

BAL→UNBAL

BAL→UNBAL

BAL→UNBAL

BAL→UNBAL

PREOUT

BUFFER

PREOUT

BUFFER

PREOUT

BUFFER

+15VL

-15VL

US+5V

RS-P99/EW5

11

1234

1234

C

D

F

A

B

E

(IAD

0-9

)2,IAD132,ISDA102

(IDAT

0-31

)2

(IDAT

0-7

)2

DATA IN

B

DOUTRXIN

DIR

DIR9001IPWRQ1

Rch EQ DSP

ADSP-21065LCS240S1

TC7WZ34FU

TC7WZ34FU

TC7WZ34FU

TC7SH32FUS1

12

BCKO

11 1 7

BCKO

20

21

4

3

5

6

7

8

9

18

20

2

10

12

14

16

22

24

26

28

30

32

DIRRST

DIRBRATE1

DIRBRATE0

DIRADFLG

DIREMFLG

DIRUNLOCK

nCONFIG2

nCONFIG1

2

nCONFIG

4

1

UMUTE

CONFDONE

PLDRST

DITRST

RST

DSPERR

DSPSTOP

nSTATUS

PLDIN

PLDOUT

PLDCLK

PLDSEL1

PLDSEL0

2

21

23

19

6

8

10

TDI

JTD1

JRST

25

JTCK

27

JTMS

JTEMU

JTD4

31

4

JEMU

JTTD4

JTTRST

JTTD1

JTTCK

JTTMS

TMS

TDO

TCK

JTEMU

JTTD4

JTTRST

JTTMS

JTTCK

UMUTE

CONFDONE

PLDRST

PLDOUT

PLDCLK

DSP UNIT

TC7WZ34FU

LRCKO

10

ERROR

27 DIRUNLOCK

CKSEL

28

EMPH

17 DIREMFLG

FSOUT1

3 DIRBRATE1

FSOUT0

2 DIRBRATE0

AUDIO

1 DIRADFLG

TFS0

7

2

18

RFS0

TFS1

TCLK0

8

4

19

RCLK0

TCLK1

TC74VHC541FK

9

A8

A6

7

6

42

8

11

13

14

12

DSP0CLK

DSP2CLK

DSP1CLK

A5

A7

Y8

Y6

Y5

Y7

IS45S32200E-7TLA1

TC74LCX541FK

146

19 1

TDO

TDI

CLKIN

TMS

149

147

151

23

12

11

22

INSR

INMR

INHR

INLR

TRST

145

TCK

DT1B

TD0B

DT0A

DT1A

PLDDATA

PLD

EPF6016ATI144-3S1

21

PLDBCK

20

PLDLRCK

17

DIRUNLOCK

59

nCONFIG

53

MUTERQ

63

CONF_DONE

105

RESET

89

DSPERR

62

DSPSTOP

60

nSTATUS

56

PLDIN

123

PLDOUT1

124

PLDOUT2

128

PLDCLK1

130

PLDCLK2

125

PLDSEL1

129

PLDSEL0

131

13

TDI

73

TMS

TDO

27

TCK

34

CLK30

92

6

5

17

LRCKO

62

TC7SZU04FU

62

Lch EQ DSP

ADSP-21065LCS240S1

TFS0

7

2

18

RFS0

TFS1

TCLK0

8

4

19

RCLK0

TCLK1

35

35

COEFFICIENT DSP

ADSP-21065LCS240S1

TFS0

7

2

205

RFS0

TCLK0

8

4

RCLK0

76

FLAG11

FLAG8

80

79

78

FLAG9

FLAG10

17

17

30MHz

17

62

JTAG

24

2

1

5

10

13

4

9

12

3

6

8

11

TC7WZ34FU

TC7SH04FUS1

TC74VHC08FK

OE2 OE1

EMU

DR0B

DR0A

(IAD

0-9

)1,IAD131,ISDA101

(IDAT

0-31

)1

(IDAT

0-7

)1

JTEMU

JTTRST

JTTMS

JTTCK

DSP1CLK

IS45S32200E-7TLA1

TC74LCX541FK

30

146

148

TDI

148

19 1

TDO

CLKIN

15

RCLK1

TMS

149

147

151

23

12

11

22

INSL

INML

INHL

INLL

TRST

145

TCK

DT1B

TD0B

DT0A

DT1A

6

5

OE2 OE1

EMU

DR0B

DR0A

(IAD

0-9

)0,IAD130,ISDA100

(IDAT

0-31

)0

(IDAT

0-7

)0

JTEMU

JTTRST

JTTMS

JTTCK

OUTL

JTTD1

DSP0CLK

ADSP-21065

IS45S32200E-7TLA1

TC74LCX541FK

30

146

19 1

TDO

CLKIN

15

RCLK1

19

TCLK1

TMS

149

147

151

23

12

11

22

DS0DT1B

DS0DT1A

TRST

145

TCK

DT1B

TD0B

DT0A

DT1A

OUTL

37 5

OE2 OE1

EMU

DR0A

TDI

148

A

B

C

IRQ0

AA

DSP2CLK

30

15

RCLK1

(1/2)

(1/2)

(1/2)

(2/2)

LCS240S1

CN2101

IC2001

IC2111

IC2101

IC2161

IC3051

CN3001

CN4951

IC2171

IC4901

IC4902

IC4951

IC4953

IC4952

CN601

IC4803

IC4751

IC3001

IC4501

IC4451

IC4201

IC4151

IC4601

IC4301

IC4001

IC4001

Lch EQ DSP

ADSP-21065

(2/2)

LCS240S1

IC4301

Rch EQ DSP

ADSP-21065

(2/2)

LCS240S1

IC4601

X4901

CN302

PLD BCK

PLD LRCK

205

IRQ0

DSP BCK

DSP LRCK

5

7

B33V

JTAG

OSCILLATOR

30MHz CLOCK

DSPCLK/PLDCLK

30MHz

DSP CONTROL

DATA0

COEFFICIENT

DSP

CONTROL DATA

SDRAM

DSP CONTROL

DATA1

CONTROL DATA

SDRAM

SDRAM

CONTROL DATA

205

IRQ0

DSP CONTROL

DATA2

12

RS-P99/EW5

5 678

56

7

8

C

D

F

A

B

E

4

10

9

5

8

7

3

6

HLP

HLM

MLP

MLM

LLP

LLM

SLP

SLM

SDOUTASDINA

SRC0

SRC4184IPAG

DAC-High

I/V CONVERTER

I/V CONVERTER

I/V CONVERTER

I/V CONVERTER

PCM1794ADB

LT1358CS8

TC7WZ34FU

64 558HDATA22

RST

DMUTE

RCKIA

RCKIB

SCK

MUTE

BCKOA

LRCKOA

19 1

DS1BFEN

DMUTE

OE2 OE1

19 1

OE2 OE1

BDAT0-7

TC74LCX541FK

19 1

DS0DT1B

DS0DT1A

OE2 OE1

15

10

8

12

INSL

INML

INHL

109

64

DSP1BFEN

MUTE

INLL

DS2BFEN

16

11

9

14

INSR

INMR

INHR

108

DSP2BFEN

INLR

DS0BFEN

60

53

3

1

5

7

TC7WZ34FU

1

2

7

5

66

67

DSP0DT1B

LRCK2 51

LRCKOB

BCK2

LRCK2

BCK2

LRCK3

BCK3

LRCK4

BCK4

TC7WZ34FU

3

2

5

7

50 62

63 BCK

49

20

29

7

10

S0K5

RST

21

S0K6

SOK4

BCK

6

LRCK

4LRCK5

14

BCKOB

BCKIA

BCKIB

TC7WZ34FU

59

54

3

1

5

7

TC7WZ34FU

3

5

7

TC7WZ34FU

3

5

7

LRCKIA

LRCKIB

DSP0DT1A

110

DSP0BFEN

BCKO

LRCKO

A

B

OUTHLR

SDINB SDOUTB

IOUTL-

26

25

HLP

HLM

IOUTL+

OUT_A

1

7

2

6

OUT_B

55MDATA24

OUTMLR

1

13

7

10

2

4

SDOUTASDINA

SRC1

SRC4184IPAG

TC7WZ34FU

6458LDATA25

RCKIA

RCKIB

60

53

3

1

5

7

LRCK4 62

LRCKOA

LRCK3

51

49

20

29

MCK18

LRCKOB

BCK3 63

BCKOA

BCK4 50

BCKOB

BCKIA

BCKIB

TC7WZ34FU

59

54

3

1

5

7

LRCKIA

LRCKIB

BCKO

LRCKO

A

B

C

OUTLLR

SDINB SDOUTB

55SDATA26

OUTSLR

DATA

DAC-Mid

PCM1794ADB

LT1358CS8

5

RST

DMUTE

DITRST

SCK

MUTE

7

10

SOK3

BCK

6

LRCK

4LRCK6

14

IOUTL-

26

25

MLP

MLM

IOUTL+

OUT_A

1

7

2

6

OUT_B

DATA

DAC-Low

PCM1794ADB

LT1358CS8

5

RST

DMUTE

DITRST

SCK

MUTE

7

10

SOK2

BCK

6

LRCK

4LRCK7

14

IOUTL-

26

25

LLP

LLM

IOUTL+

OUT_A

1

7

2

6

OUT_B

DATA

DAC-Sw

PCM1794ADB

LT1358CS8

5

RST

DMUTE

DITRST

SCK

MUTE

7

10

SOK1

BCK

6

LRCK

4LRCK8

14

IOUTL-

26

25

SLP

SLM

IOUTL+

OUT_A

1

7

2

6

OUT_B

DATA

DSP33V

B33V

D5V

A5V

-15VL

+15VL

TC7WH04FU

1

4234

7

5

SOK1

SOK2

SOK3

SOK4

TC7WH04FU

5

7

SOK5

MCK18

3

TC7SH04FUS1

X1001

24.576MHz

A

A

DITRST

D5V

5

4

NJM2880U1-33

LM4120AIM5-3.3

+3.3V

DAC3.3V

LM4120AIM5-3.3

DITRST

RST

21

DITRST

3

IC4803

IC4751

IC4501

IC4451

IC4201

IC4151

CN5101

IC2501 IC5101

IC5151

IC2121

IC2911

IC2921

IC2141

IC2931

IC2941

CN1001

IC2551

IC2131

IC2151

IC5201

IC5251

IC5301

IC5351

IC5401

IC5451

IC1101

IC1153

CN101

CN801

IC1001

IC1051

IC5501

IC1152

DITRST

-IN_A

-IN_B

-IN_A

-IN_B

-IN_A

-IN_B

-IN_A

-IN_B

SDRAM

SDRAM

SDRAM

SRC BCK

SRC LRCK

6

3

1

1

6

1

MCK20

SRC BCK

SRC LRCK

Q1001

VIN

ENABLE

VOUT

5

4

3

Q1051

VIN

ENABLE

VOUT

BCK

BCK

BCK

BCK

3

SOK6

MCK20

1

4

5

1

VIN

CONTROL

VOUT

IVM15L

IVP15L

SPXO

RS-P99/EW5

13

1234

1234

C

D

F

A

B

E

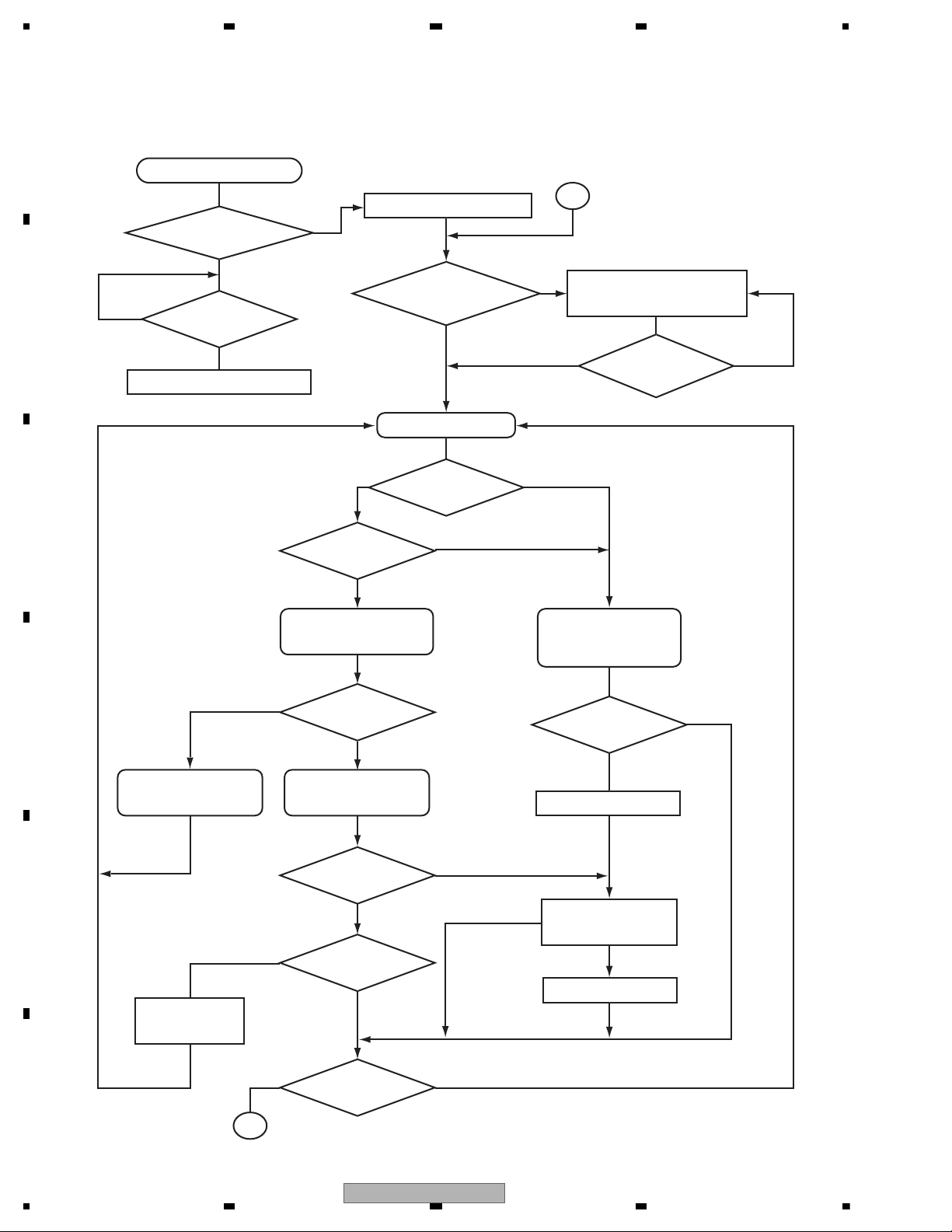

5. DIAGNOSIS

Herdware reset release

Initialization of reset release

Bus communication

System power on

DSP Initialization OK

DSP error

Pin51:H

Un lock

Pin48:H?

Bup or Acc off

DSP initialization failure

DSP initialization

failure

Pin16:Low and Pin15:Low

Error

ON

DSPPW on (Pin40:H)

Normal

Mute OFF(Pin42:L)

PLD,DSP initialization

About 3 seconds

Mute off (Pin42:L)

DSPPW on (Pin40:H)

OFF

DSPPW off (Pin40:L)

Mute on (Pin42:H)

Power on commond

DSP error

PW lamp on and off

DIT reset

Pin47 = L

Main loop

-SYSTEM RESET

Bup,Acc check

Acc:Pin15,Bup:Pin16

Microcomputer dispatch stop

Power saving mode

Pin16:Low

and

Pin15:Low

Pin16:Low

and

Pin15:Low

Unit check program start

Test program mode

Pin39 = Low

Pin39 = High

Low

Hi

Yes

Yes

OFF

ON

No

Pin48 = H

No

No

AbnormalitiesNormal

1

Yes

1

No

5.1 OPERATIONAL FLOWCHART

14

RS-P99/EW5

5 678

56

7

8

C

D

F

A

B

E

1. BUS+

2. BUSG

3. BUSG

4. BMUTE

5. BUS-

6. BUSG

IP-BUS INPUT

7. NC

8. ASENB

9. NC

10. NC

11. NC

1

2

3

4

8

9

10

11

5

6

7

1 : OPIG

2 : OPI

3 : GND

4 : OPI5V

4

2

3

1

OPTICAL INPUT

5.2 CONNECTOR FUNCTION DESCRIPTION

6. SERVICE MODE

There is not information to be shown in this chapter.

RS-P99/EW5

15

1234

1234

C

D

F

A

B

E

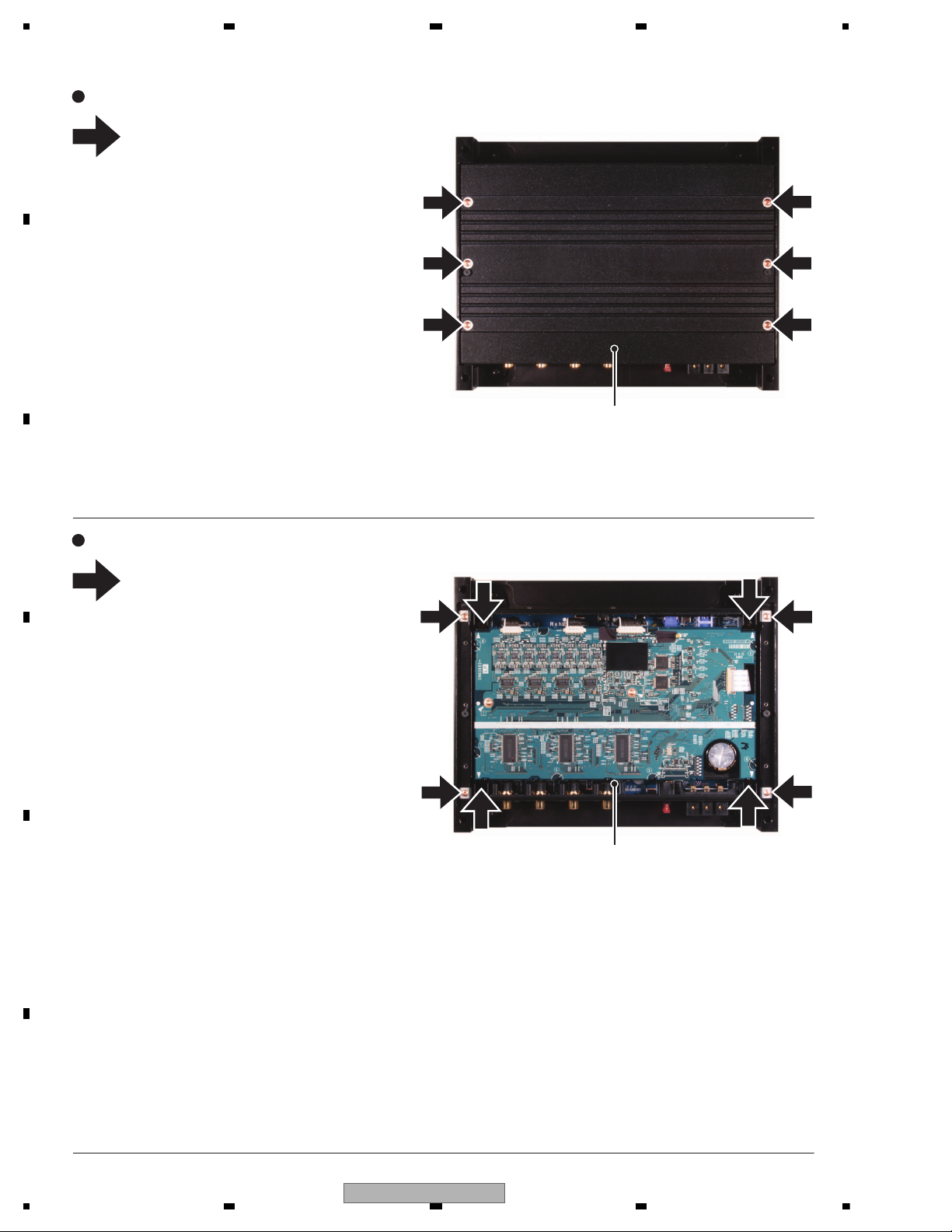

7. DISASSEMBLY

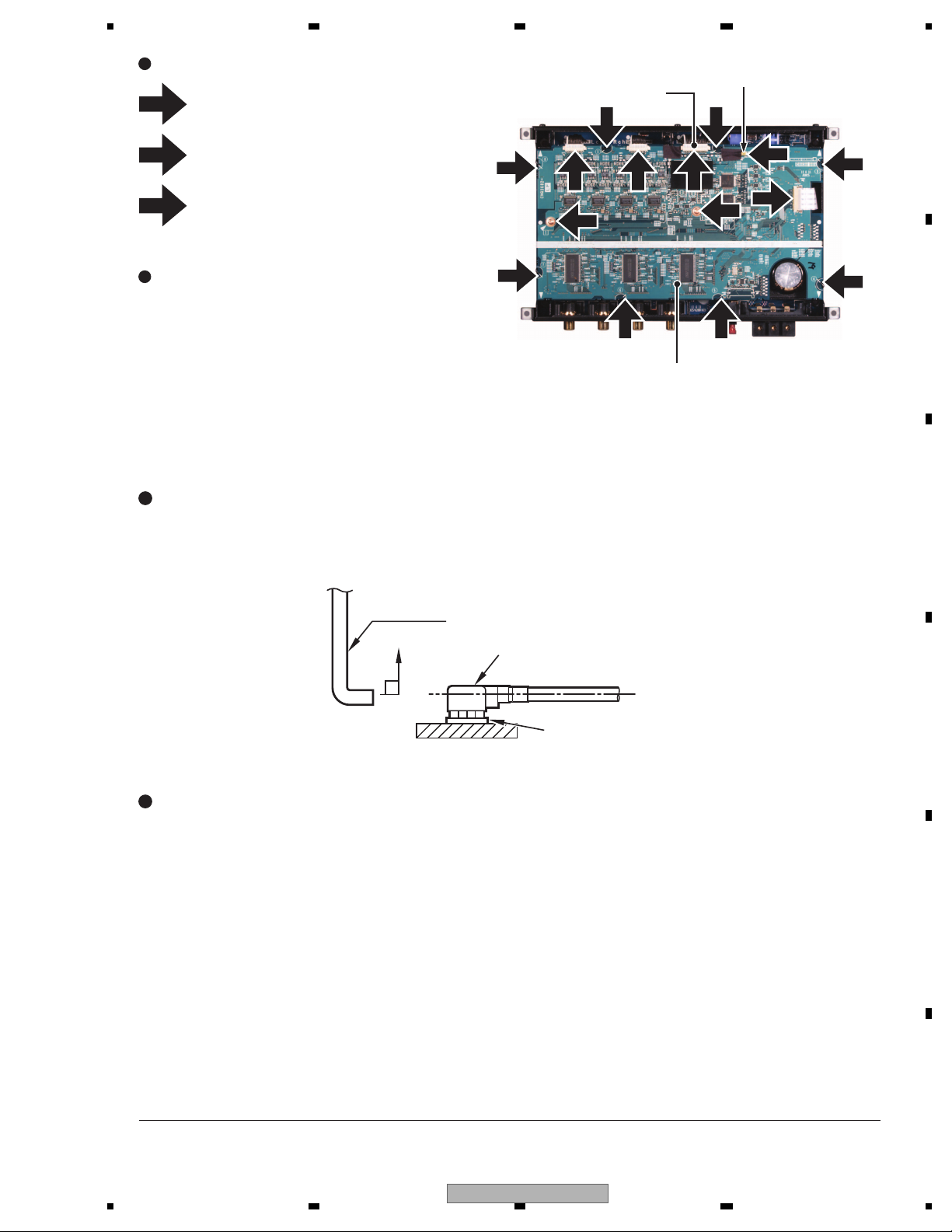

Removing the Lower Case (Fig.1)

Remove the six screws and then remove the

1

Lower Case.

1

1

1

1

1

1

Lower Case

Fig.1

Removing the Control Unit (Fig.2)

Remove the eight screws and then remove the

1

Control Unit.

1

1

1

1

1

1

1

1

Control Unit

Fig.2

16

RS-P99/EW5

5 678

56

7

8

C

D

F

A

B

E

Removing the DSP Unit (Fig.3)

Disconnect the five connectors.

1

Remove the two screws.

2

14P Power Cable

3

1 1 1

3 3

Coaxial Jumper

1

3

Straighten the tabs at eight locations

3

indicated and then remove the DSP Unit.

Precaution for Disconnecting/Connecting the

14P Power Cable in DSP Unit

This connector has been built to fit more tightly

than other connectors. Please use due caution

not to cause damage when disconnecting or

2

2

3

3 3

1

3

connecting it.

DSP Unit

When unplugging the Coaxial Jumper, make sure to use jig GGF1539.

If the Coaxial Jumper is directly unplugged without using jig GGF1539, you might damage your fingertip or fingernail.

- -

How to Remove the Coaxial Jumper

- - When unplugging Coaxial Jumper, hook the point of jig GGF1539 on the lid of Coaxial Jumper

- - and vertically draw out along with the engagement axis of connector.

GGF1539

Coaxial Jumper

How to Attach the Coaxial Jumper

- -

Connector

- - For inserting Coaxial Jumper, adjust cord assy with the engagement axis of connector and insert it as vertically

- - as possible.

- - Do not insert the Coaxial Jumper in extreme slant, as the connector might suffer damage.

Fig.3

RS-P99/EW5

17

1234

1234

C

D

F

A

B

E

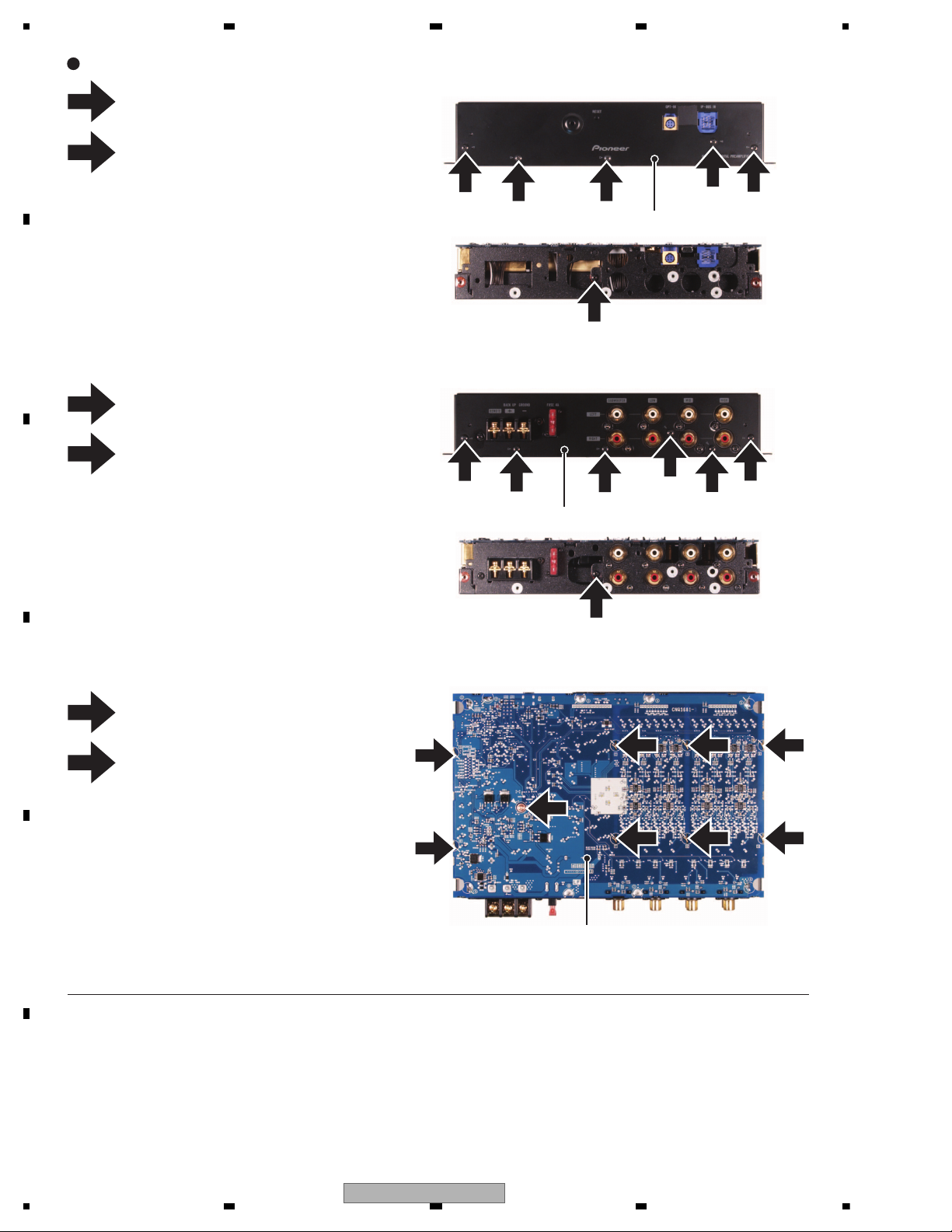

Removing the Control Unit (Fig.4)

(IP-BUS Side)

Remove the five screws and then remove

1

the Panel(IP-BUS Side).

Remove the screw.

2

1

1

1

1

1

Panel

2

(RCA Side)

Remove the six screws and then remove

3

the Panel(RCA Side).

Remove the screw.

4

3

3

3

3

3

3

Panel

4

Remove the screw.

4

Straighten the tabs at eight locations

5

indicated and then remove the Control Unit.

5

5

5

5

4

5

5

5

5

18

RS-P99/EW5

Control Unit

Fig.4

5 678

56

7

8

C

D

F

A

B

E

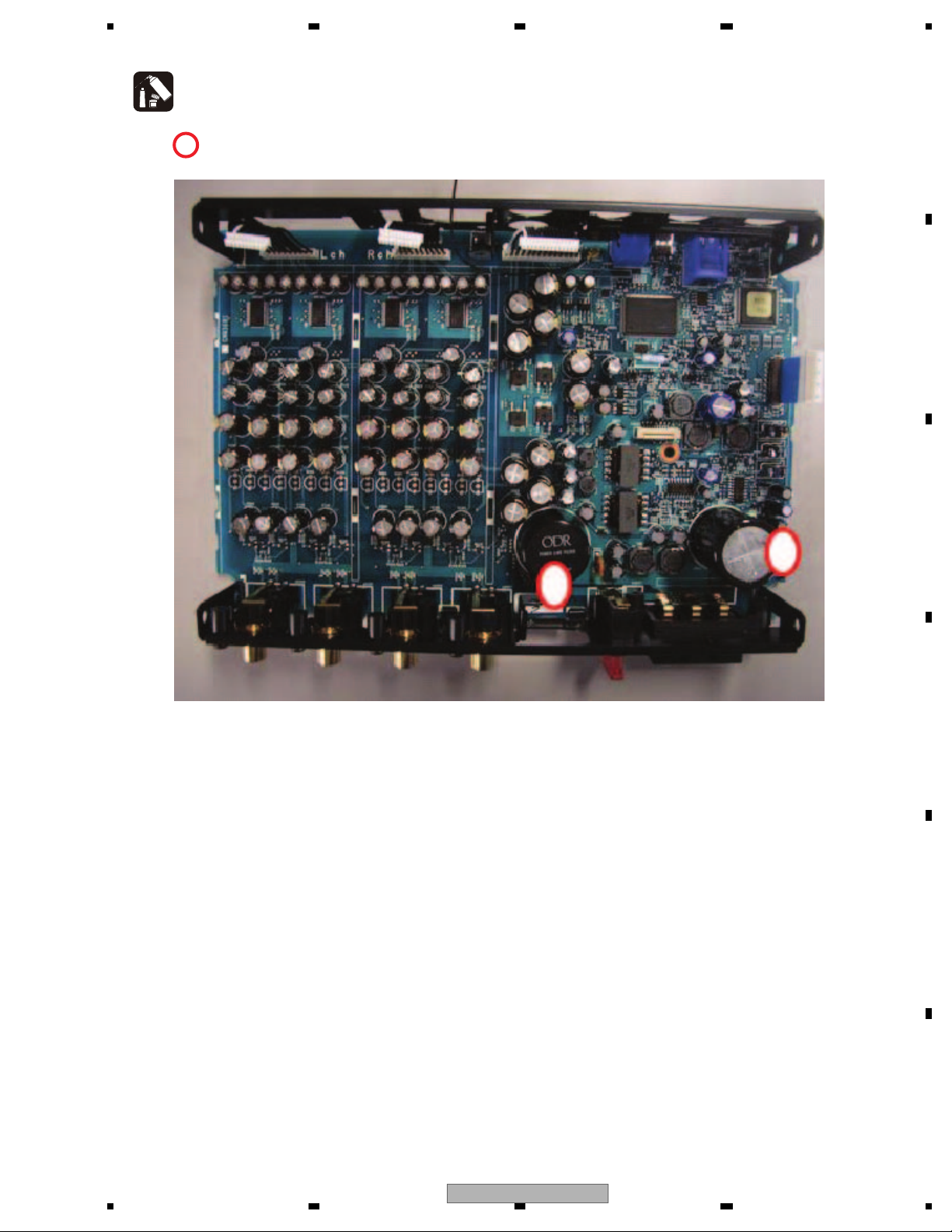

Bonding Position

: GEM1017

8. EACH SETTING AND ADJUSTMENT

There is not information to be shown in this chapter.

RS-P99/EW5

19

1234

1234

C

D

F

A

B

E

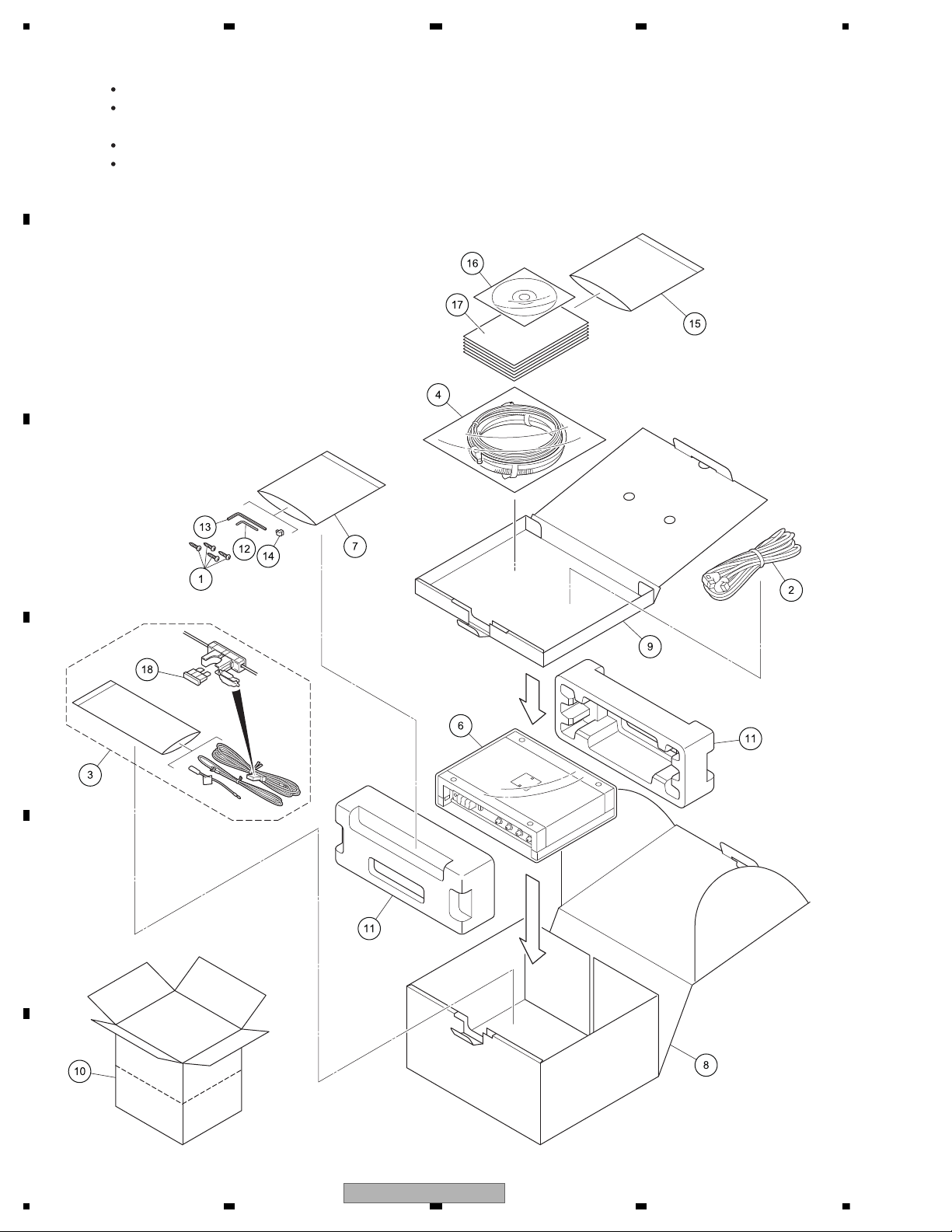

9. EXPLODED VIEWS AND PARTS LIST

NOTES : Parts marked by " * " are generally unavailable because they are not in our Master Spare Parts List.

The > mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

Screw adjacent to mark on the product are used for disassembly.

For the applying amount of lubricants or glue, follow the instructions in this manual.

(In the case of no amount instructions,apply as you think it appropriate.)

""

9.1 PACKING

20

RS-P99/EW5

5 678

56

7

8

C

D

F

A

B

E

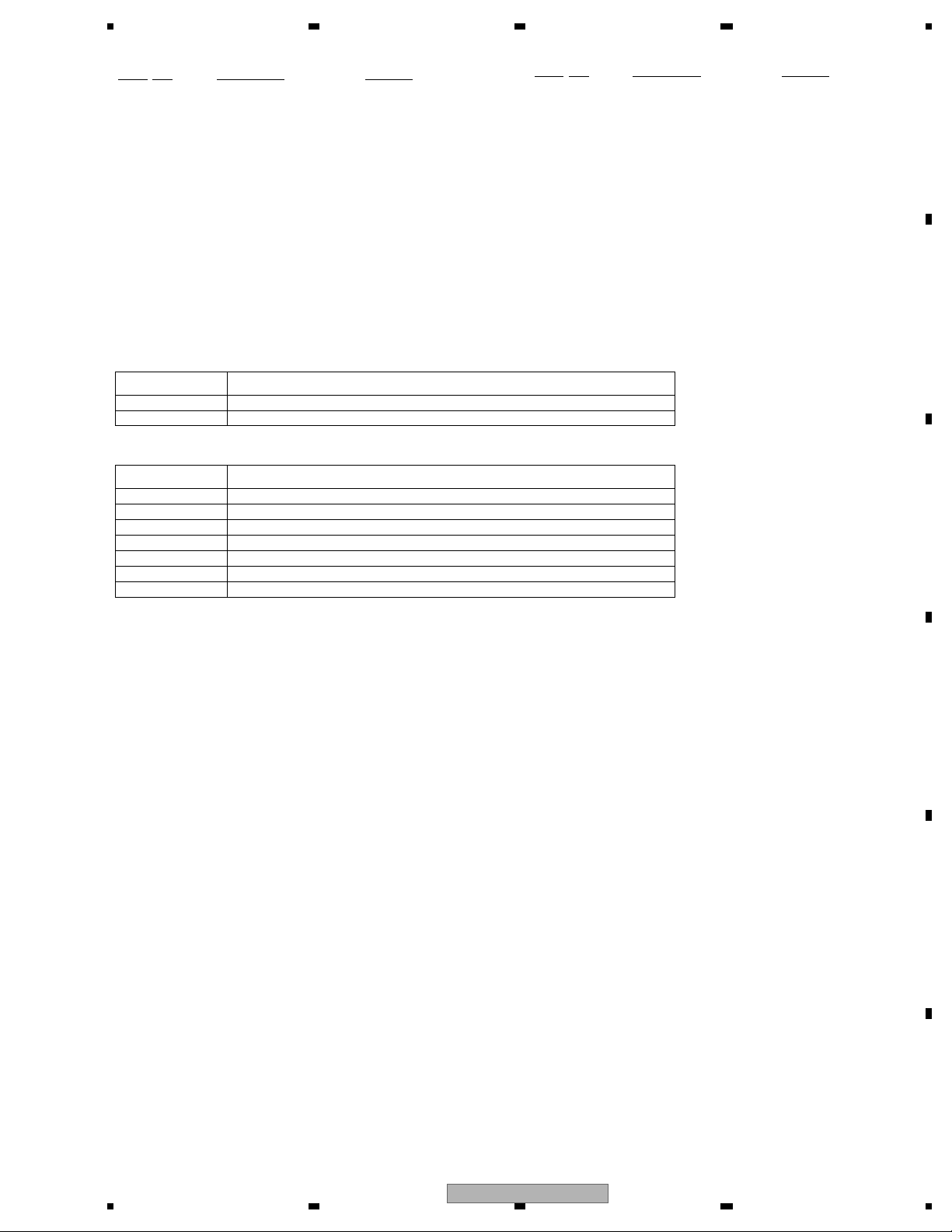

PACKING SECTION PARTS LIST

Mark

Mark No. Description Part No.

1 Screw BNC50P250FTB

2 Cord CDE4167

3 Cord Assy CDE6642

4 Cable CDE6690

5 •••••

6 Cover CEG1057

7 Polyethylene Bag CEG1161

8 Unit Box CHG7379

9 Sub Unit Box CHG7380

10 Contain Box CHL7379

11 Protector CHP4057

No. Description Part No.

* 12 Shaft CLP1100

* 13 Shaft CLP1224

14 Clamper CNV1443

* 15 Polyethylene Bag E36-634

16 IM CD-ROM CPJ1313

17-1 Quick Start Guide CRD4501

17-2 Quick Start Guide CRD4502

* 17-3 Caution Card CRP1389

* 17-4 Caution Card CRP1423

* 17-5 Warranty Card CRY1279

> 18 Fuse(4 A) CEK1001

Quick Start Guide

Part No. Language

CRD4501 English, French, Italian, Spanish(Espanol)

CRD4502 German, Dutch, Russia

CONTENTS OF CD-ROM (Operation Manual), CPJ1313

Part No. Language

*CRB3380 English

*CRB3381 French

*CRB3382 Italian

*CRB3383 Spanish(Espanol)

*CRB3384 German

*CRB3385 Dutch

*CRB3386 Russia

All operation manuals are supplied in PDF files by the CD-ROM.

Regarding the availability of paper manual, contact Pioneer Service representative in your region.

RS-P99/EW5

21

Loading...

Loading...