Page 1

TECHNICAL MANUAL (Ver.2.0)

MULTI PROJECTION UNIT

RM-V2550BU

RM-V2550E

PROJECTION SCREEN KIT

RM-V2550S

RM-V2550S2

MULTI VIDEO PROCESSOR

RMD-V3104U

RMD-V3104A

PROJECTION STAND

RMA-V5020

Caution

This symbol refers to a hazard or unsafe

practice which can result in personal in-

jury or property damage.

Notes:

Pioneer will accept no responsibilities for damages re-

•

sulting from problems with parts other than those supplied by Pioneer.

•

Performance shall be guaranteed solely when assembly

and adjustment is performed as prescribed in this technical manual.

•

For improvement purposes, the specifications and de-

sign described in this technical manual are subject to

change without notice.

1

Page 2

PIONEER RM-V2550

MANUAL.

This Acrobat (IE: a PDF file) version of the Pioneer manual was made from

the original digital document and has had some updated pages added into it. Because of this

some of the page numbers may be out of order.

As Pioneer is constantly working towards providing the best possible documentation for our

products, there may be an improved version of this document available. Please contact your

Pioneer representative for additional information.

Josh Kairoff

Pioneer New Media Technology.

Augest 7, 2000

Page 3

CONTENTS

CHAPTER 1 FEATURES .......................................................................................................... 5

1. FEATURES OF THE MULTI PROJECTION UNIT (hereinafter referred to as the “MPJ”) ............. 5

2. FEATURES OF THE MULTI VIDEO PROCESSOR (hereinafter referred to as the “MVP”)............ 6

3. FEATURES OF THE PROJECTION STAND (hereinafter referred to as the “Stand”).................... 6

CHAPTER 2 GENERAL SPECIFICATIONS .............................................................................7

1. SPECIFICATIONS OF THE DIFFERENT UNITS ................................................................................. 7

(1) Multi Projection Unit (RM-V2550BU, RM-V2550E) ................................................................... 7

(2) Projection Screen Kits ................................................................................................................. 8

(3) Multi Video Processor (RMD-V3104U, RMD-V3104A) ............................................................ 14

(4) Multi Video Processor (RMD-V3216/V3109/3000X) ................................................................ 19

(5) Projection Stand (RMA-V5020) ................................................................................................ 20

(6) Adjustment Control Unit (RU-V107) Option ............................................................................ 21

2. Diagram of system dimensions ....................................................................................................... 22

(1) Single panel ................................................................................................................................ 22

(2) 2 x 2 (100 inch) ............................................................................................................................ 23

(3) 3 x 3 (150 inch) ............................................................................................................................ 23

CHAPTER 3 INSTALLATION AND ASSEMBLY .................................................................. 24

1. INSTALLATION CONDITIONS......................................................................................................... 24

(1) Weight-tolerant ......................................................................................................................... 24

(2) Ceiling height ............................................................................................................................ 24

(3) Front space ................................................................................................................................ 24

(4) Rear space ................................................................................................................................. 24

(5) Stacking stages ......................................................................................................................... 24

(6) Installation work to prevent toppling ...................................................................................... 25

(7) Heat value calculation ............................................................................................................... 26

(8) Temperature and humidity conditions .................................................................................... 26

(9) Condensation ............................................................................................................................ 26

(10)Visual field angles, visible range ............................................................................................. 27

(11)Lighting ...................................................................................................................................... 30

(12)Effects of earth magnetism ...................................................................................................... 30

(13)Backyard ventilation .................................................................................................................. 30

(14)Power supply ............................................................................................................................. 31

(15)Cables used ............................................................................................................................... 32

(16)Semi-outdoor installation ......................................................................................................... 32

(17)Caution for use of user-prepared parts ................................................................................... 32

(18)Ventilation .................................................................................................................................. 33

2. INSTALLATION AND ASSEMBLY................................................................................................... 34

(1) Confirmation .............................................................................................................................. 34

(2) Unpacking .................................................................................................................................. 34

(3) Carrying the units after opening packaging ........................................................................... 37

3. PRECAUTIONS FOR TRANSPORTATION ...................................................................................... 39

4. ASSEMBLING THE SYSTEM ........................................................................................................... 40

(1) System assembly flowchart ..................................................................................................... 40

(2) Assembling the system ............................................................................................................ 41

(3) Installation without using stands (Direct floor installation) .................................................. 72

(4) Fixation using anchors ............................................................................................................. 73

(5) Connections (for 4 screen system) .......................................................................................... 75

5. SPECIAL INSTALLATION................................................................................................................. 76

(1) Wall inset ................................................................................................................................... 76

(2) Diagonal installation ................................................................................................................. 76

(3) Architrave processing ............................................................................................................... 76

(4) Upside down installation .......................................................................................................... 76

(5) Hanging from ceiling ................................................................................................................ 76

CHAPTER 4 ADJUSTMENTS ............................................................................................... 77

1. ADJUSTMENT PREPARATIONS ..................................................................................................... 77

(1) Wiring ......................................................................................................................................... 77

(2) Processing of wires ................................................................................................................... 78

(3) Aging .......................................................................................................................................... 78

(4) Adjustment signals ................................................................................................................... 78

(5) Equipment required for adjustments ...................................................................................... 79

2

Page 4

CONTENTS

2. BEFORE ADJUSTMENTS ................................................................................................................ 80

(1) Convergence adjustment memory .......................................................................................... 80

(2) TV system .................................................................................................................................. 81

(3) White balance adjustment memory ........................................................................................ 82

(4) Combined use of remote control and personal computer .................................................... 82

(5) Memory of adjustment data and settings ............................................................................... 82

(6) Assigning ID numbers .............................................................................................................. 83

(7) Focus adjustment ...................................................................................................................... 88

3. GENERAL EXAMPLES OF MULTI PROJECTION PRESENTATIONS ............................................ 89

(1) Switching between enlarged/individual display on the multi video processor ................... 89

(2) Switching the sources input to the multi video processor .................................................... 89

4. SCREEN ADJUSTMENTS ................................................................................................................ 90

(1) Adjustment flowchart ............................................................................................................... 90

(2) Convergence adjustment flowchart ........................................................................................ 91

(3) Convergence adjustment contents .......................................................................................... 92

(4) White balance adjustment flowchart ..................................................................................... 110

(5) White balance adjustment ...................................................................................................... 111

(6) External control by MPJ RS-232C .......................................................................................... 117

(7) Adjustments by remote control ............................................................................................. 129

CHAPTER 5 OPERATION AND MAINTENANCE ...............................................................144

1. MAINTENANCE .............................................................................................................................. 144

(1) Re-adjustments after 3 months .............................................................................................. 144

(2) Periodic maintenance ............................................................................................................. 144

(3) Replacement of parts .............................................................................................................. 144

2. CAUTIONS DURING PRESENTATIONS ....................................................................................... 145

3. SERVICING SYSTEM ..................................................................................................................... 146

4. CAUTIONS ON ASSEMBLY AND MAINTENANCE ..................................................................... 146

CHAPTER 6 PRECAUTIONS ...............................................................................................147

1. PRECAUTIONS ON FUNCTION AND PERFORMANCE OF SYSTEM ......................................... 147

2. NOT MALFUNCTION ..................................................................................................................... 148

3. CHECKING THE ADJUSTMENTS.................................................................................................. 149

4. CAUTION AND NOTES ON THE MPF INSTALLATION ............................................................... 150

5. NOTE IN USE OF THE OPTIONAL JOINT-LESS SCREENS......................................................... 150

6. TROUBLESHOOTING..................................................................................................................... 151

CHAPTER 7 MVP MANUAL ...............................................................................................152

1. INTRODUCTION ............................................................................................................................. 152

2. CONNECTION WITH MVP EXTERNAL COMPUTER .................................................................... 153

3. INSTRUCTIONS FOR USING A COMPUTER AS A TERMINAL .................................................. 154

4. OPERATING MODES ..................................................................................................................... 155

5. MVP VIDEO OUTPUT MODES ...................................................................................................... 157

6. ADJUSTMENT FUNCTIONS ......................................................................................................... 158

7. PICTURE FRAME ADJUSTMENT PROCEDURES ........................................................................ 159

1. Command reference ............................................................................................................... 159

(1) To shift to the operation mode [! command] ................................................................... 159

(2) To set different screens for adjusting convergence [DFFC command] .......................... 159

(3) To set the system back to 4-screen magnification [@ command] ................................. 160

2. Adjusting the picture frame ................................................................................................... 160

(1) To perform fine adjustment of the picture frame [&G command] ................................. 160

(2) To perform coarse adjustments of the picture frame [&P2, &Q2 commands] ............. 161

(3) To store the picture frame data [&W command] ............................................................. 162

(4) To load the picture frame data [&L command] ................................................................ 162

3. To switch the image input [IFF command] ........................................................................... 163

4. To indicate the current MVP state [SYS command] ............................................................. 164

5. To perform NTSC input board picture quality adjustment .................................................. 165

(1) To set the adjustment mode [AJYC command] ............................................................... 165

(2) To exit the adjustment mode [AJN command] ............................................................... 165

(3) Bright compensation [BRT command] ............................................................................. 166

(4) Color compensation [COL command] .............................................................................. 166

(5) Tint adjustment [TNT command] ...................................................................................... 167

3

Page 5

CONTENTS

6. Controls the panel switch function ........................................................................................ 167

(1) To set the manual mode [MNL command] ...................................................................... 167

(2) To set the remote mode [RMT command] ....................................................................... 167

(3) To select composite video input [CIC command] ............................................................ 167

(4) To select YC separation input [YIC command] ................................................................ 167

(5) To set the output to the NTSC mode [NT command] ..................................................... 168

(6) To set the output to standard RGB mode [NTR command] ............................................ 168

(7) To set the output to the double-speed RGB mode [NTD command] ............................. 168

(8) Optional variable scan board adjustment mode settings [:A command] ...................... 168

8. DEMO PATTERN SETTINGS AND CAUTIONS ............................................................................ 169

9. INSTALLING AND REMOVING BOARDS ..................................................................................... 170

10. RMD-V3020 COMMAND REFERENCE .......................................................................................... 172

(1) Outline of the RMD-V3020 ...................................................................................................... 172

(2) VS board command rules ....................................................................................................... 173

(3) Tracking adjustment [TRK command] ................................................................................... 175

(4) Contrast adjustment [CNT command] .................................................................................. 175

(5) R, G, B gain adjustment [RGN, GGN, BGN commands] ...................................................... 175

(6) Brightness adjustment [BRT command] ............................................................................... 175

(7) B, R clamp adjustment [BLV, RLV commands] ..................................................................... 176

(8) Blanking window level adjustment [BKL command] ........................................................... 176

(9) Horizontal, vertical direction screen display position adjustment [HPS, VPS commands] .. 176

(10)Horizontal, vertical blanking window position adjustment [HWN, VWN commands] ...... 177

(11)Horizontal, vertical blanking window width adjustment [HWD, VWD commands] .......... 177

(12)Full dot number compensation [HFD command] ................................................................. 178

(13)Freeze frame Y:ON N:OFF [FZY, FZN commands] ............................................................... 178

(14)Vertical filter ON/OFF [DSY, DSN, DSX commands] ............................................................ 178

(15)Vertical compression filter conversion rate input [LCV command] .................................... 179

(16)Program ROM version display [VER command] .................................................................. 179

(17)To indicate the current function setting [STS command] ................................................... 179

(18)To select preset model [M command] .................................................................................. 180

(19)Model fresh [F command] ...................................................................................................... 181

(20)Measurement data display [FRQ command] ........................................................................ 181

(21)Model table reference [TBL command] ................................................................................. 182

(22)Horizontal frequency input [HFQ command] ........................................................................ 183

(23)Vertical frequency input [VFQ command] ............................................................................. 184

(24)Vertical full-line input [VLN command] ................................................................................. 184

(25)All reset [ARS command] ....................................................................................................... 184

11. MODE 99 ......................................................................................................................................... 185

12. VS BOARD MODEL SELECTION ................................................................................................... 186

13. USING METHODS OF HFQ, VFQ, VLN ......................................................................................... 186

14. SELECTING THE SYNC SIGNAL ................................................................................................... 187

15. RMD-V3104J additional commands ............................................................................................. 188

WARNING

• prevent injuries and physical damages, always read and observe this manual and all labels on the system before

assembly, construction, and adjustments.

• Do not use the system outdoors to prevent fire hazards and electric shocks caused by water entering the system.

• To prevent injuries, take note of the sharp edges of this system.

• When performing setup work at high places, to prevent the falling down of the system and damages caused by

falling objects, set the Keep Out area.

• To prevent fire hazards and electric shocks, do not place foreign objects in the system nor remodel it.

• To prevent fire hazards, observe the following using environment.

Temperature : 5 to 35 °C

Humidity : 20 to 80%

• Perform ventilation with the fan etc. and observe the operating environment conditions even after completing assembly.

• Never install the system tilted.

4

Page 6

Page 7

Page 8

Page 9

Page 10

Page 11

Page 12

Page 13

Page 14

Page 15

CHAPTER 1. FEATURES

FEATURES

1. FEATURES OF THE MULTI PROJECTION UNIT

(hereinafter referred to as the “MPJ”)

¶ Thin, space-saving design (75 cm deep), and installable flush against the wall (when stacked in two levels in

a 4-screen configuration, etc.)

¶ Split structure for easy carrying and assembly

The structure is split by screen, making it easy to carry and assemble the system.

¶ Excellent features with a reasonable price

¶ Can be stacked in up to three levels

¶ Under 2 meters high when stacked in two levels, allowing installation in stores with low ceilings

¶ Improved adjustment procedures

• Uniform, simplified ABL level adjustment using ABL control voltage indication.

• Lists of main deviation and white balance adjustment values can be displayed when performing adjustments

with the remote control unit, making it simple to check adjustment values and compare with other screens.

¶ Variety of screens available

1. Screw width approx. 4mm (RM-V2550S)

2. Screw width 1mm (RM-V2550S2)

¶ Usable in bright places

High screen brightness (420 ft-L), allowing use in lobbies exposed to external light and bright offices.

¶ Full of functions for providing high picture quality with enlarged images and a strong sense of picture unifor-

mity

• Though the peripheral brightness is sufficient for multi-screen images, a “multi” function is also included for

activating a peripheral light compensation circuit and achieving enlarged pictures with even more uniform

brightness. There is also a function for achieving the optimum contour compensation level with enlarged

images, thereby providing natural, high quality enlarged pictures.

• An auto white balance function and ABL (Auto Brightness Limiter) linking function suppress differences in

colors and brightness on the different screens.

¶ Convergence memory function

Up to three sets of adjustment data in addition to the standard factory default settings can be stored in the

memory.

5

Page 16

FEATURES

¶ “Color mode selection function” for convenient camera reshooting

The MPJ is equipped with a “color mode selection function” allowing the selection of two white balance data

settings. When used for example in a broadcast station’s studio for reshooting, the colors will be unnatural if

a camera suited to the brightness in the studio is used, but if one color temperature is set to 4500°K, natural

colors can be reproduced at the touch of a button.

¶ On-screen display function

Adjustment values and various settings can be displayed on the screen.

¶ External control function

The MPJ is equipped with an RS-232C external control terminal. This makes it possible to use a computer to

perform the various adjustments, and provides possibilities for various types of visual presentations. Transfer of control signals to the individual multi projection units is possible in daisy chain format by connecting

the combination terminals using interconnection control cables (DIN 6-pin connectors, included). No complicated connections are necessary. The multi projection units can be assigned ID numbers and still be adjusted

individually after the system is expanded.

¶ Dual NTSC/PAL compatibility

The individual multi projection units display high quality pictures with either NTSC or PAL inputs.

¶ Wired remote control unit (RU-V107, sold separately) available for adjustments

The wired remote control unit can be used for adjusting the convergence, white balance and other settings

while watching the picture from the front when setting up the multi picture system.

2. FEATURES OF THE MULTI VIDEO PROCESSOR

(hereinafter referred to as the “MVP”)

¶ Multi video processor for 4-screen enlarged images

¶ Compact, space-saving design

¶ Adjustment remote control unit/computer relay function considering system installation

¶ Expandable through the addition of an option board (one)

3. FEATURES OF THE PROJECTION STAND

(hereinafter referred to as the “Stand”)

¶ EIAJ rack mount function

¶ Casters for easy moving

¶ Built-in adjuster for level adjustment

6

Page 17

CHAPTER 2. GENERAL SPECIFICATIONS

GENERAL SPECIFICATIONS

1. SPECIFICATIONS OF THE DIFFERENT UNITS

(1) Multi Projection Unit (RM-V2550BU, RM-V2550E)

TV format ............... NTSC/PAL, automatic switching

(fixed mode available)

Projection tubes..........................................7" CRT x 3

Horizontal resolution ..... 800 TV lines (with video input)

Brightness (at white peak) .....................420 ft-L (50")

Practical angle of vision 150° horizontal, 60° vertical

Input signal:

Video input

...... Standard input level (75-ohm load) 1 Vp-p

Input terminal: BNC connector x 1

Y/C isolated inputs

.................. Standard input level (75-ohm load)

Brightness (Y) signal 1 Vp-p

Color (C) signal ... 286 mVp-p (burst signal, NTSC)

300 mVp-p (burst signal, PAL)

Input terminals: BNC connectors

(one each for Y and C)

RGB input ............................ Analog R.G.B signals

(NTSC/PAL R.G.B)

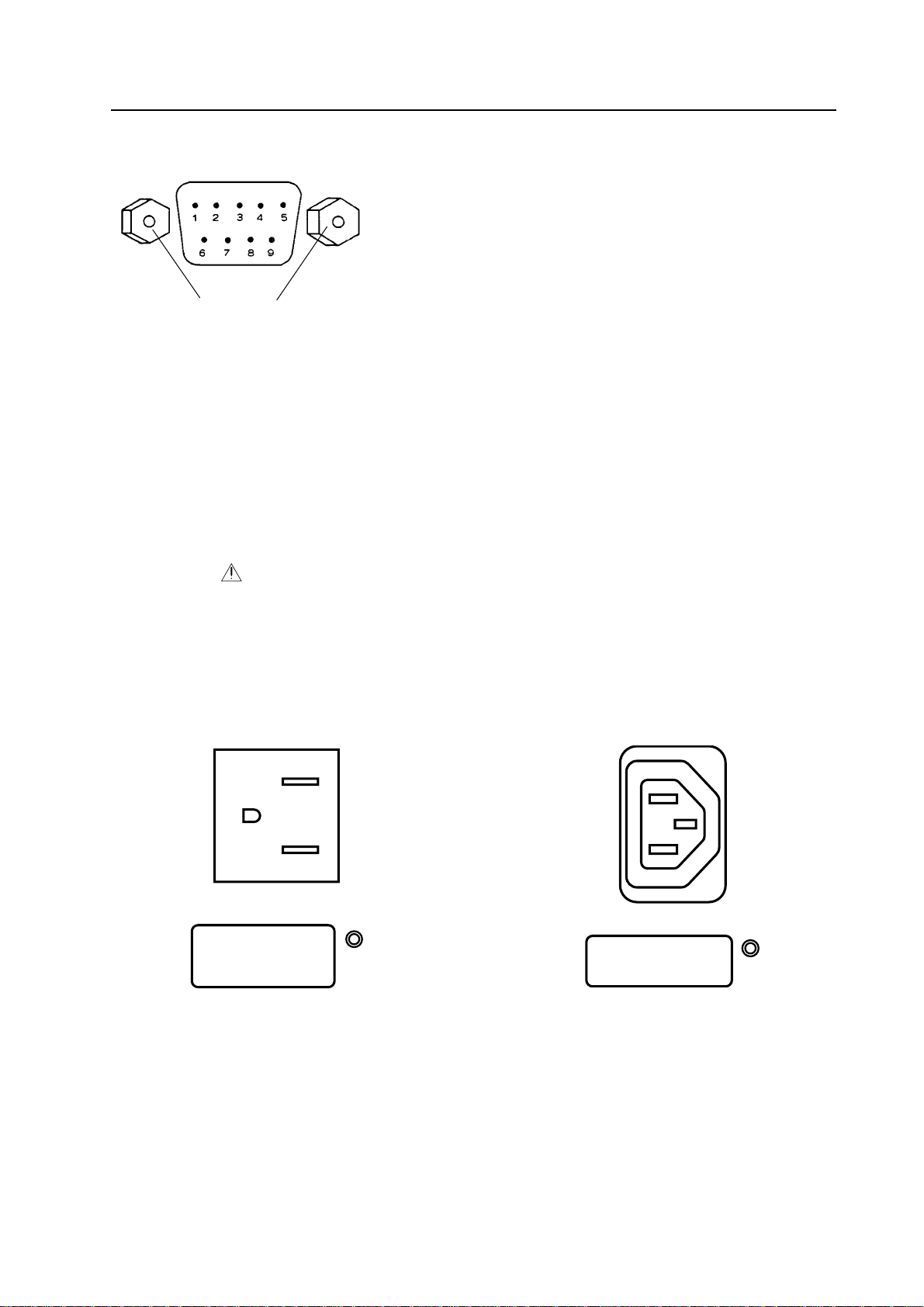

RGB-1: D-Sub 9-pin terminal x 1 *2

RGB-2: BNC connector x 5 *2

R: Red input, 0.7 Vp-p ±2 dB, 75-ohm terminal,

positive polarity

G/G on SYNC: Green input, 0.7 Vp-p ±2 dB,

75-ohm terminal, positive polarity

Green input with synchronization,

1.0 Vp-p±2 dB, 75-ohm terminal, positive polarity

B: Blue input, 0.7 Vp-p ±2 dB, 75-ohm terminal,

positive polarity

HD/SYNC: Horizontal synchronization input,

0.3 to 4 Vp-p, 75-ohm terminal,

negative polarity

Composite synchronization input,

0.3 to 4 Vp-p, 75-ohm terminal,

negative polarity

VD: Vertical synchronization input, 0.3 to 4 Vp-p,

75-ohm terminal, negative polarity

Synchronizing signal frequency: Standard NTSC

or PAL frequency

EXT control: BNC connector

Remote input: Mini-jack

Auto input: 6-pin DIN connector

Output signal:

Video output .... Standard level (75-ohm load) 1 Vp-p

Outputs input signals from input terminals

Remote output ...................... 6-pin DIN connector

Computer control:

Method ........................... RS-232C (D-SUB 25-pin)

Speed .........1200, 2400, 4800, 9600, 19200 bps *1

Power supply voltage

for RM-V2550BU ......... AC 100V to 120V, 50/60 Hz

for RM-V2550E ............ AC 220V to 240V, 50/60 Hz

Normal power consumption

for RM-V2550BU ........................ approx. 300W *3

for RM-V2550E ........................... approx. 300W *3

Maximum power consumption

for RM-V2550BU .......................................... 400VA

for RM-V2550E ............................................. 400VA

AC outlet (Max. 8A, AC 100V to 120V)

for RM-V2550BU ................................................... 1

AC outlet (Max. 550W/A, AC 220V to 240V)

for RM-V2550E ...................................................... 1

External dimensions

.............. 1030.8 (W) x 1115 (H) x 665.2 (D) mm

(when RM-V2550S or RM-V2550 S2 fitted:)

1030.8 (W) x 1115.5 (H) x 750 (D) mm

Weight ................................................................. 74 kg

(87kg when RM-V2550S fitted)

(82kg when RM-V2550S2 fitted)

Accessories

(RM-V2550BU, RM-V2550E)

Power cord ................................................... 1 *4

Control cable..................................................... 1

Used to control multiple multi projection units.

Hexagonal bolt w/ washer (M8x65) ................ 2

Hexagonal bolt w/ washer (M8x45) ................ 3

Hexagonal nut (M8).......................................... 5

Light shield (black) ........................................... 4

*1 The RS-232C baud rate is set at 4800 bps upon

shipment from the factory. The setting can be

changed by remote control or from a computer.

*2 Only RGB-1 or RBG-2 can be used (selected by

switch).

*3 NTSC color bar signal input and other adjustment

data as set upon shipment from the factory.

*4 Bolts for connecting the MPJ to a stand are not

included with the MPJ (they are included with the

standard stand)

7

Page 18

GENERAL SPECIFICATIONS

(2) Projection Screen Kits

1 4mm-screw screen (RM-V2550S)

External dimensions ....... 1030.8 x 768.5 x 84.8mm

Weight ................................................................ 13kg

Accessories

Hook fitting (left) ................................................. 1

Hook fitting (right) .............................................. 1

Screen frame fastener ........................................ 1

Cross-recessed tap tight screws

(wood screws, nominal diameter 4, length 18) .. 2

(nominal diameter 4, length 8) ........................ 18

Cross-recessed small screw (M6x10) ................ 1

Cross-recessed tap tight screw with metal washer

(nominal diameter 4, length 12) ........................ 1

2 1mm-screw screen (RM-V2550S2)

External dimensions ....... 1030.8 x 768.5 x 84.8mm

Weight .................................................................. 8kg

Accessories

Hook fitting (left) ................................................. 1

Hook fitting (right) .............................................. 1

Screen frame fastener ........................................ 1

Connector ............................................................ 1

Cross-recessed tap tight screws

(nominal diameter 4, length 10) ...................... 10

(nominal diameter 4, length 12) ........................ 1

(nominal diameter 4, length 18) ........................ 2

Cross-recessed tap tight screws

(M4, length 25) .................................................... 3

(M6, length 10) .................................................... 1

Pin ........................................................................ 1

*1 When either above-mentioned 1 or 2 is used as

a single-panel screen, you will need one more set

consisting of a screen frame fastener etc., and so

you should obtain the following service parts set:

AAX1056

8

Page 19

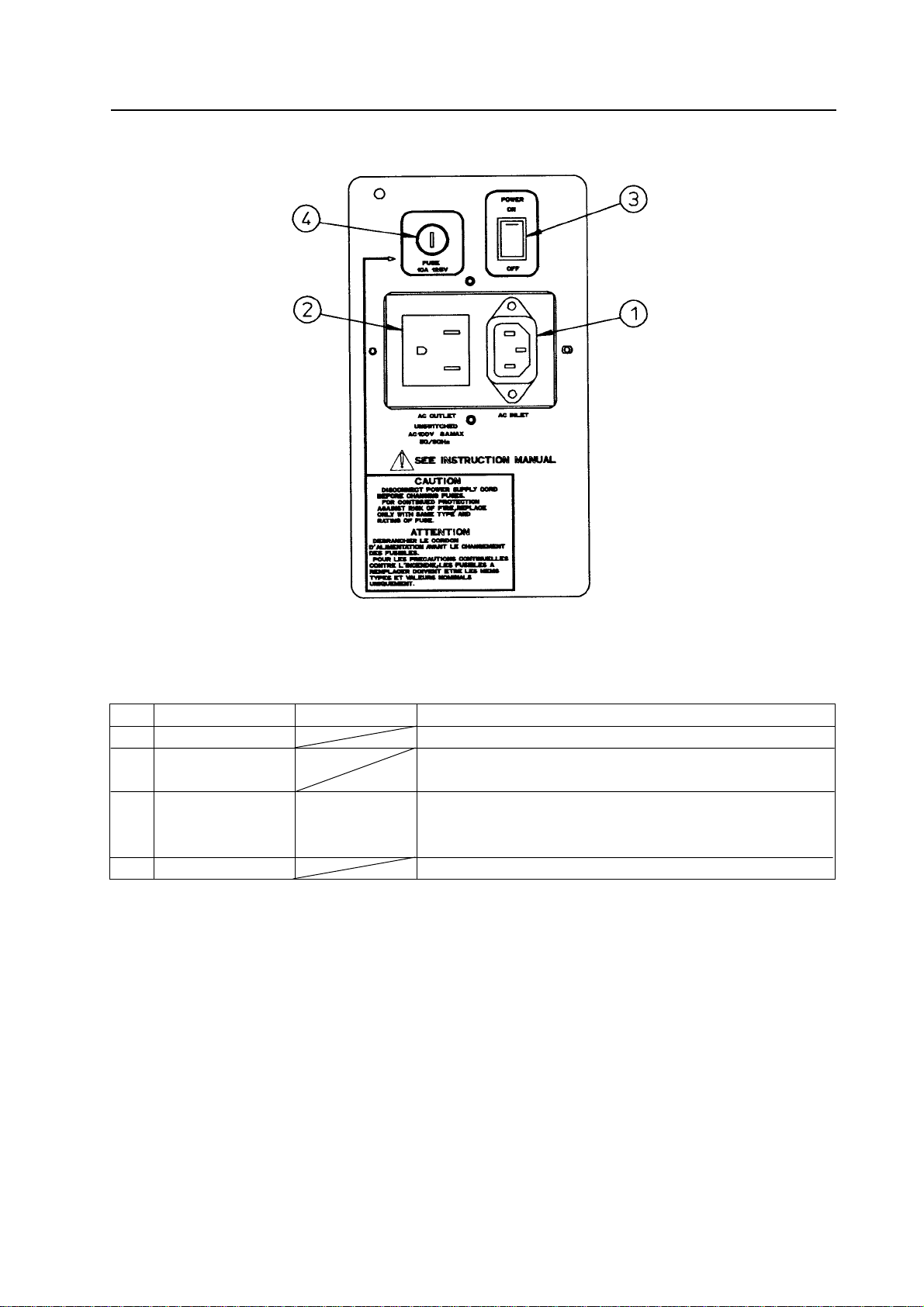

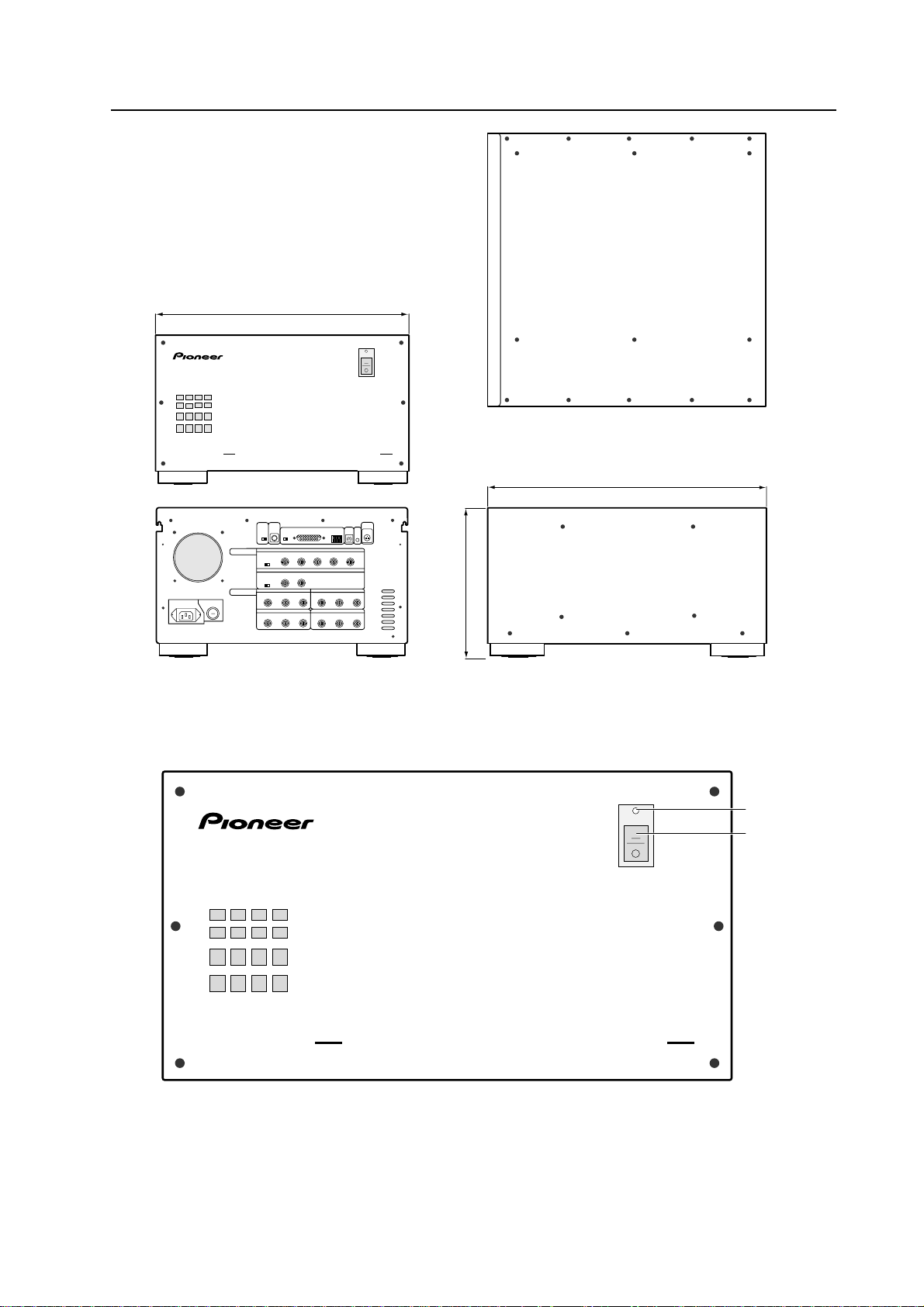

Power Supply Panel

GENERAL SPECIFICATIONS

[Fig. 2-1-1]

No. Name Type Function

1 AC inlet Connect the power cord here.

2 AC outlet Connect other multi projection units here. Not linked to main

power switch. (*1)

3 Main power switch Seesaw switch Turns the power supply to the set on and off. When on, the set

is set to the mode stored in the last memory (standby or

power on).

4 Fuse holder The fuse is in here. Only service personnel should touch this.

NOTE) 1. Refer to “(13) Power supply 3 connection”.

9

Page 20

GENERAL SPECIFICATIONS

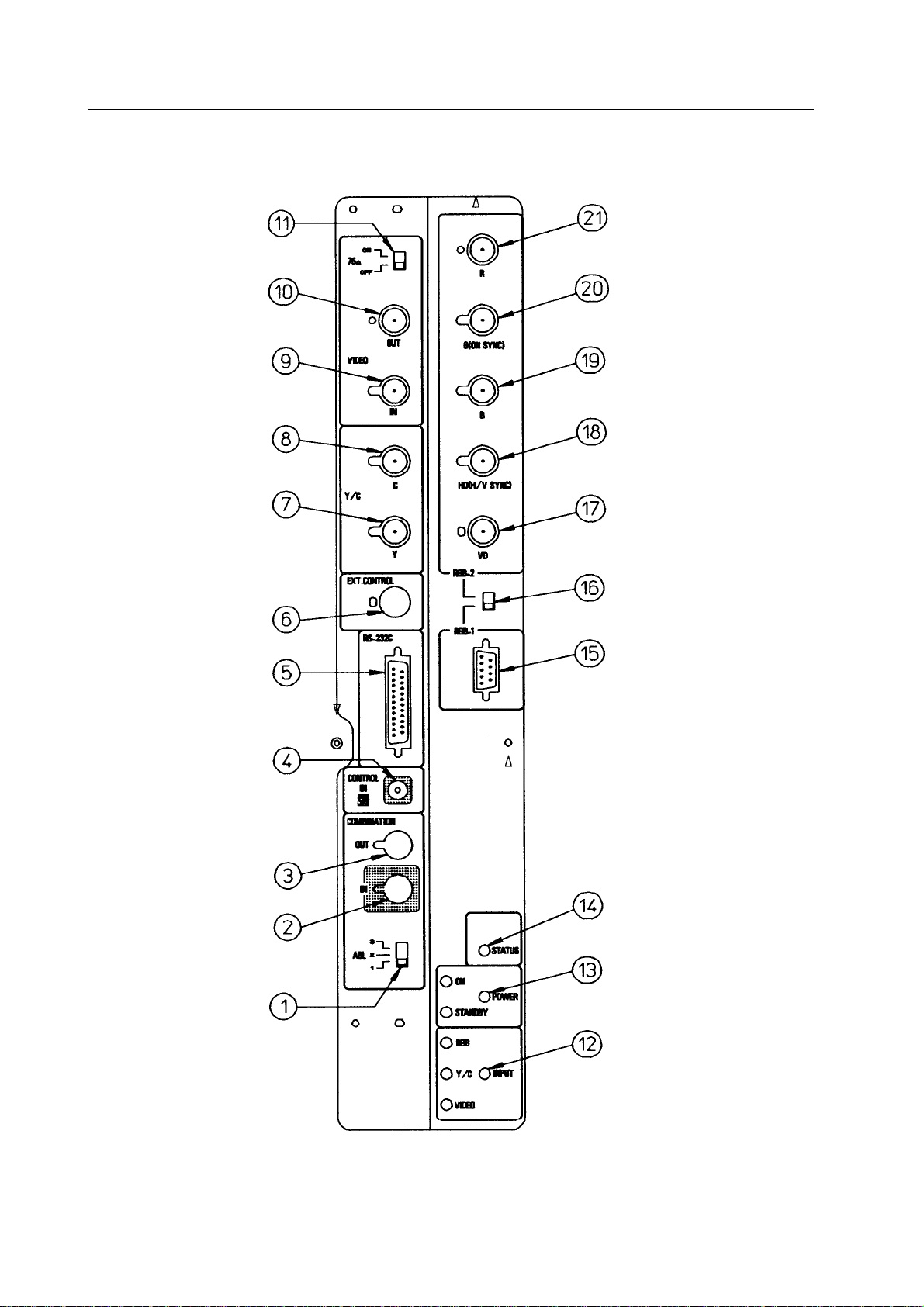

Control Panel

10

[Fig. 2-1-2]

Page 21

GENERAL SPECIFICATIONS

No. Name Type Function

1 ABL linking switch Slide switch When ABL linking is on, the ABL linking control

voltage’s control quantity can be switched

2 Linked input terminal DIN 6-pin ABL, remote control signal and RS-232C signal input

terminal

3 Linked output terminal DIN 6-pin ABL, remote control signal and RS-232C signal output

terminal

4 Remote control connector Mini jack Jack for connecting adjustment remote control unit

(sold separately)

5 RS-232C port D-sub 25-pin RS-232C communications connector

(female)

6 Control input terminal BNC connector Video input and Y/C input external switching control

signal input terminal

7 Y (brightness) BNC connector Brightness signal input terminal

input terminal

8 C (color) input terminal BNC connector Color signal input terminal

9 Video input terminal BNC connector Video signal input terminal

0 Video output terminal BNC connector Video input terminal 9 through out terminal

- Terminating switch Slide switch Turn on to terminate video input terminal 9 at 75 ohm

= Input selector switch Tact switch Video input, Y/C input, RGB input selector switch.

At the VIDEO position, switching between the video

input and Y/C input is possible with the external control

signal 6.

~ POWER switch Tact switch When power off: STANDBY (red LED) lights

When power on: ON (green LED) lights

! STATUS indicator switch Tact switch Switch for displaying the total power on time (*), switch

settings, etc., on the screen

@ RGB input terminal D-sub 9-pin (male) RGB signal input terminal

# RBG input selector switch Slide switch Switch for selecting the RGB signal input terminal

format

$ RGB input terminal BNC connector RGB signal vertical synchronization input terminal

(vertical synchronization)

% RGB input terminal BNC connector RGB signal horizontal synchronization and composite

(horizontal synchronization synchronization (for only input signal H/V synchronization)

/composite synchronization) input terminal

^ RGB input terminal (B) BNC connector RGB signal B input terminal

& RBG input terminal BNC connector RGB signal G or G on Sync input terminal

(G/G on Sync)

* RBG input terminal (R) BNC connector RGB signal R input terminal

¶ Turn the power off with the POWER switch ~ on the set, through RS-232C control or with the wired remote

control unit (sold separately). (If the power supply is interrupted with the main power switch or if the power

cable is disconnected from the outlet, the switch settings in ! above, the TV system and the convergence

memory settings will not be stored in the last memory.)

Thus, for permanent installations, to start up and stop the entire system by turning the AC power on and off,

the power must first be turned off as described above in order to store the settings in the last memory.

(Refer to “Chapter 4, 2 (5) Last memory of adjustment data and settings “.)

* Total power on time

Only counted when power is set to ON.

11

Page 22

GENERAL SPECIFICATIONS

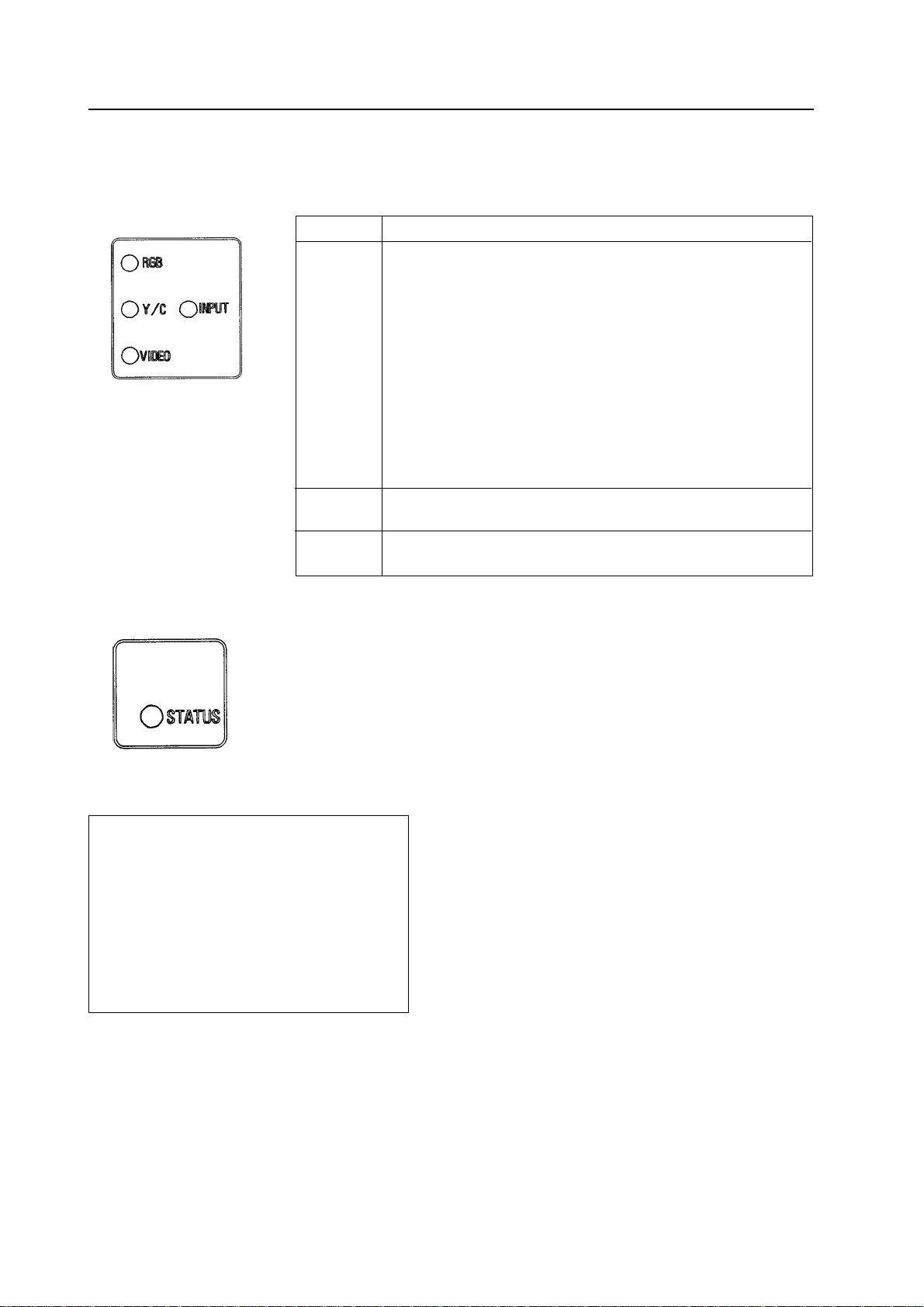

Control Panel Mode Switches

¶ INPUT SELECT switch

Position Function

VIDEO Selects the VIDEO input terminal. When selected, the VIDEO LED

¶ The input switches each

time the switch is pressed.

Y/C The Y/C input terminal is selected.

RGB The RGB input terminal is selected.

lights. This position is also used for switching the input between

VIDEO and Y/C by inputting a control signal to the EXT. CONTROL terminal.

< EXT. CONTROL >

The input switches between VIDEO and Y/C when a control signal is input to the EXT. CONTROL terminal (BNC).

In this case, the VIDEO LED remains lit, regardless of which input

is selected.

Control signal Open : VIDEO

Low : Y/C

When the control input terminal is open (normal mode), the

open mode is set and the VIDEO input signal is selected.

When selected, the Y/C LED lights.

When selected, the RGB LED lights.

¶ STATUS indicator switch

Display example)

1.HOUR

2.INPUT

3.MULTI

4.COLOR MODE

5.COMBI.

6.VIDEO MODE

7.BAUD RATE

8.TV SYSTEM

9.CONV. DATA

1000 H

VIDEO

ON

1

ON

ON

4800BPS

AUTO/NTS

MEMO-1

¶ The display of the various settings turns on and off when the

switch is pressed.

1: Indicates the total power on time. (Only counted

when power is set to ON.)

2: Indicates the selected input.

3: Indicates the MULTI ON/OFF mode.

4: Indicates the COLOR MODE 1/2 mode.

5: Indicates the COMBINATION ON/OFF mode.

6: Indicates the picture muting on/off mode when

the input function is switched.

7: Indicates the transfer speed for computer con-

trol.

8: Indicates the TV system mode.

9: Indicates the memory area status for the selected

convergence data.

12

Page 23

GENERAL SPECIFICATIONS

AC OUTLET

»

UNSWITCHED

AC220-240V~ 550W

[RGB-1 terminal]

Analog RGB : 0.7 Vp-p (75 ohm)

Synchronizing signal : 0.3 Vp-p to 4 Vp-p (75 ohm)

Connection terminal : 9-pin D SUB (male)

Pin layout 1 : R 6 : GND

2 : G/G on Sync 7 : VD

3 : B 8 : NC

M2.6 inner thread screw

4 : Signal GND 9 : NC

5 : HD/Sync

[VIDEO input]

The video output terminal outputs the signal input to the input terminal (through out). When connecting other

devices, terminate the other device at 75 ohm and set the unit’s 75-ohm terminating switch to “OFF “ (open).

When not connecting other devices, always set the terminating switch to “ON”.

Power outlet

¶ Power outlet (unswitched)

RM-V2550BU ...... MAX. 8A/AC 100V to 120V

RM-V2550E ......... MAX. 550W/AC 220V to 240V

This outlet is for adding multi projection units. Do not use it for other purposes.

¶ Power outlet power consumption

Up to two other multi projection units can be connected after one multi projection unit.

AC OUTLET

UNSWITCHED

AC100-120V 8AMAX

50/60Hz

»

RM-V2550BU

RM-V2550E

13

Page 24

GENERAL SPECIFICATIONS

(3) Multi Video Processor (RMD-V3104U, RMD-V3104A)

Input signal

Input video signal

1 set ............................................... BNC connector

for RMD-V3104U .................................... NTSC

for RMD-V3104A .............................. NTSC/PAL

(One set of RGB inputs can be added by adding an

optional variable scan board.)

1 Composite video signal....................... 1.0 V (p-p)

(75-ohm terminated)

2 Isolated Y/C signal

Y (with synchronization) ..... 1.0 V (p-p) (75 ohm)

C ...................................... 0.286 V (p-p) (75 ohm)

* Signal format 1 or 2 selectable

3 Optional RGB input signal

RGB signal ............................0.7 V (p-p) (75 ohm)

H.V ........................................................... TTL level

C SYNC ................ 0.3 to 4 V (p-p), negative logic

Green (G on Sync) ............... 1.0 V (p-p) (75 ohm)

SYNC section ....................................... 0.3 V (p-p)

SYNC order of priority

H.V > C SYNC > Green (G on Sync)

RS-232C control input 25-pin D-sub

Output signal

Output video signal

4 sets ...............................................................BNC

1 Composite video signal...... 1.0 V (p-p) (75-ohm)

2 Isolated Y/C signal

Y (with synchronization) ..... 1.0 V (p-p) (75 ohm)

C ......................................0.286 V (p-p) (75 ohm)

* Simultaneous output of 1 and 2

3 RGB signal

Green (Sync on Green) ........................ 1.0 V (p-p)

SYNC section ....................................... 0.3 V (p-p)

Blue ....................................................... 0.7 V (p-p)

Red ........................................................ 0.7 V (p-p)

* PAL output is available for only signal 3.

Others

Power supply

for RMD-V3104U ................... AC 100V (50/60 Hz)

for RMD-V3104A ......... AC 220 – 240V (50/60 Hz)

Maximum Power consumption...................... 100 W

for RMD-V3104U ..............................100W/200VA

for RMD-V3104A .............................. 100W/200VA

Operating temperature/humidity range .......... 5 to 35°C

85% or less (without condensation)

External dimensions

.....................377 (W) x 382 (D) x 204 (H) (mm)

Weight .............................................................12.0 kg

14

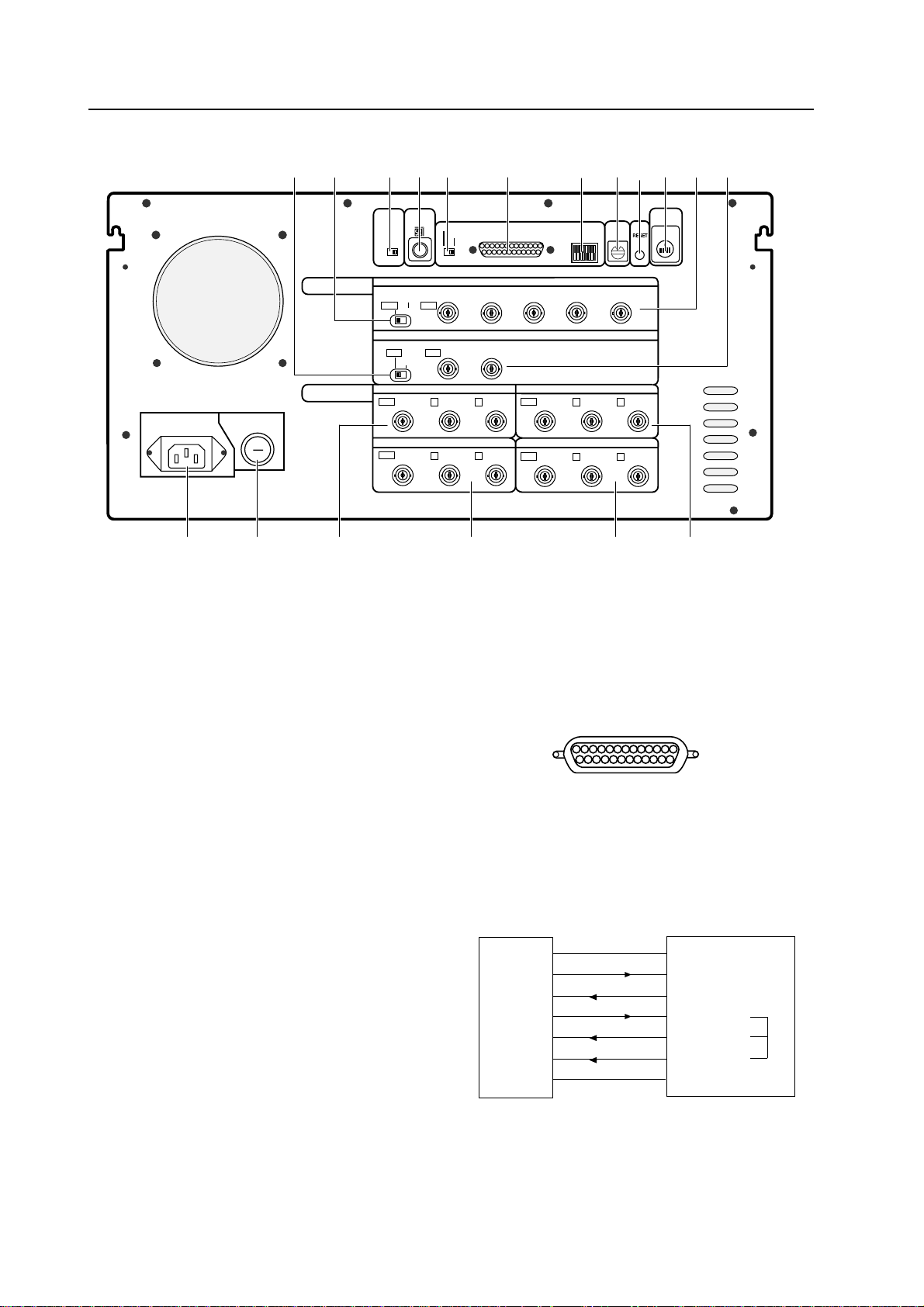

Page 25

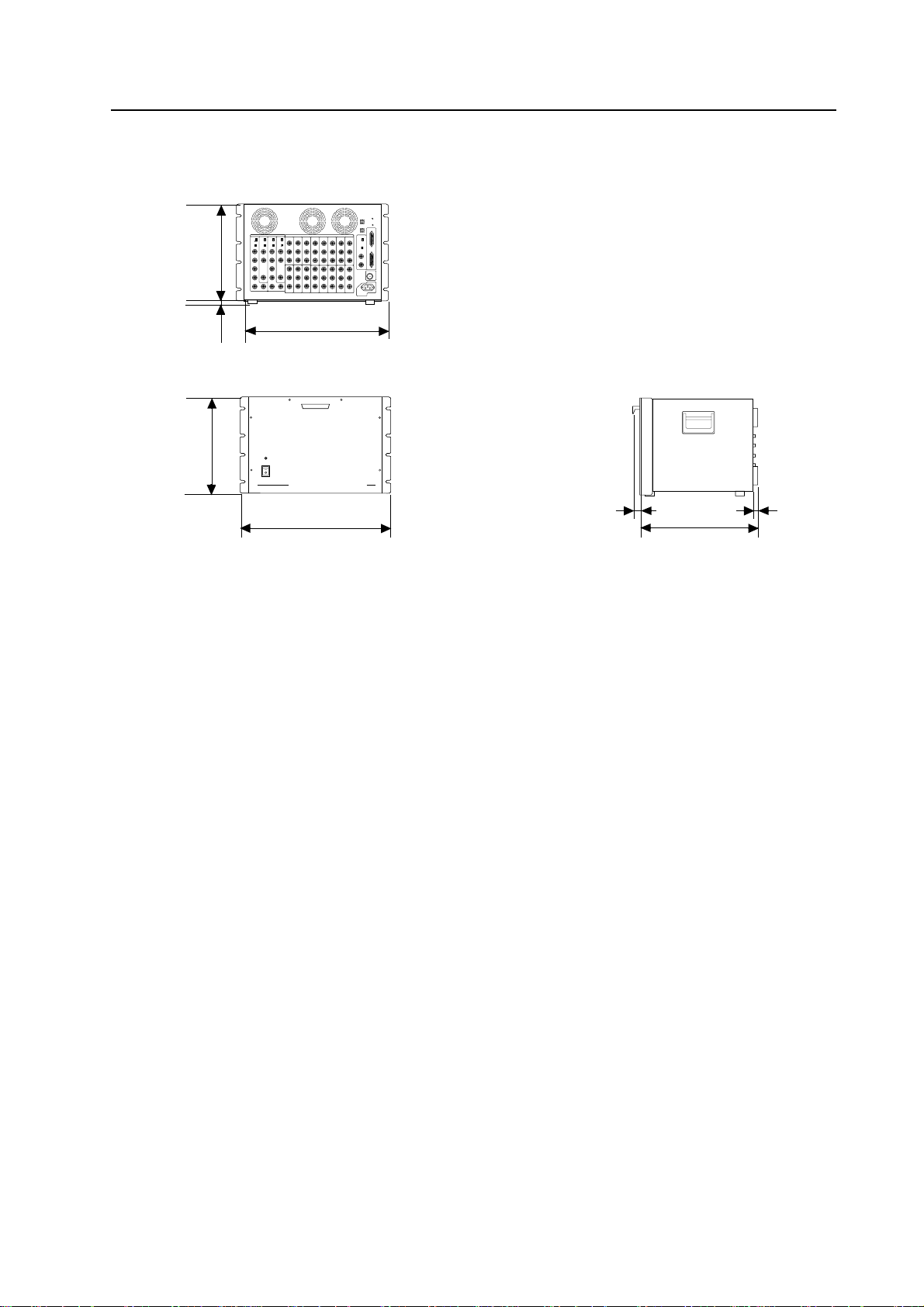

External Dimensions

377

MULTI VIDEO PROCESSOR RMD-V3104J

GENERAL SPECIFICATIONS

382

Front Panel

INPUT

OUTPUT

204

POWER

ON

OFF

Unit: mm

1

2

1 POWER indicator

Lights when the power is ON.

2 POWER switch

Press to switch the power ON/OFF.

MULTI VIDEO PROCESSOR RMD-V3104J

15

Page 26

GENERAL SPECIFICATIONS

Rear Panel

~

9

2134

INPUT

OPTION

V IN

INPUT

OUTPUT

FUSE 125V 3.15AAC INLET

!

@

ON OFF

( )

VBS

VBS VBS

VBS

GBR

VBS

GBR

5

CONTROL

IN

DISPLAY

MVP RATERS-232C MODE

V.FIL

G

( )

VBS

(Y)

(Y/C)

Y/C

YC

V OUT1 V OUT2

Y C

V OUT3 V OUT4

Y C

6

OPTION

B

(C)

V IN

#

R H/CS

VBS

GBR

VBS

GBR

8

7

V

Y C

Y C

0-

COMB

OUT

%$

=

1 VBS/ Y/C switch

Selects whether the VBS (video signal) or Y/C

signals are input to the V IN (Video) input.

The factory preset is VBS (video signal).

2 V.FIL (Vertical interpolation filter) ON/

OFF switch

When the optional variable scan board (RMDV3020) is installed, use this switch to switch the

vertical interpolation filter ON/OFF. Set this

switch to ON if the top and bottom of the computer screen image cannot be accommodated

entirely by the screen.

The factory preset is set to ON.

3 INPUT switch

Selects whether the V IN (Video) or OPTION input

is enlarged into 4 screens.

The factory preset is set to V IN.

* Always press the reset button after changing

the position of this switch.

4 Remote control input connector

Connects the display’s remote control unit.

(Adjustment or changes to the settings of the

unit cannot be accomplished with the remote

control unit.)

6 RS-232C connector

Connects RS-232C cable.

< RS-232C connector diagram >

RS-232C pin layout

13 1

25 14

< RS-232C connection diagram >

Use an RS-232C straight cable for connection.

<External computer> <MVP unit>

RS-232C RS-232C IN connector

FG 1 1 FG

TxD 2 2 RxD

RxD 3 3 TxD

RTS 4 4 RTSI

CTS 5 5 CTSI

DSR 6 6 DSRI

SG 7 7 SG

straight cable

* Pins 4, 5 and 6 are internally shorted.

5 RS-232C switch

When performing adjustments from a computer,

use this switch to switch between this unit (MVP)

and display (DISPLAY).

16

• Pins which are not shown in the diagram are not

used.

Page 27

GENERAL SPECIFICATIONS

Signal name

FG ............................. Frame Ground

TxD ...................... Transmitted Data

RxD ............................ Received Data

RTS ........................ Request to Send

CTS ............................. Cleat to Send

DSR .......................... Data Set Ready

SG ............................. Signal Ground

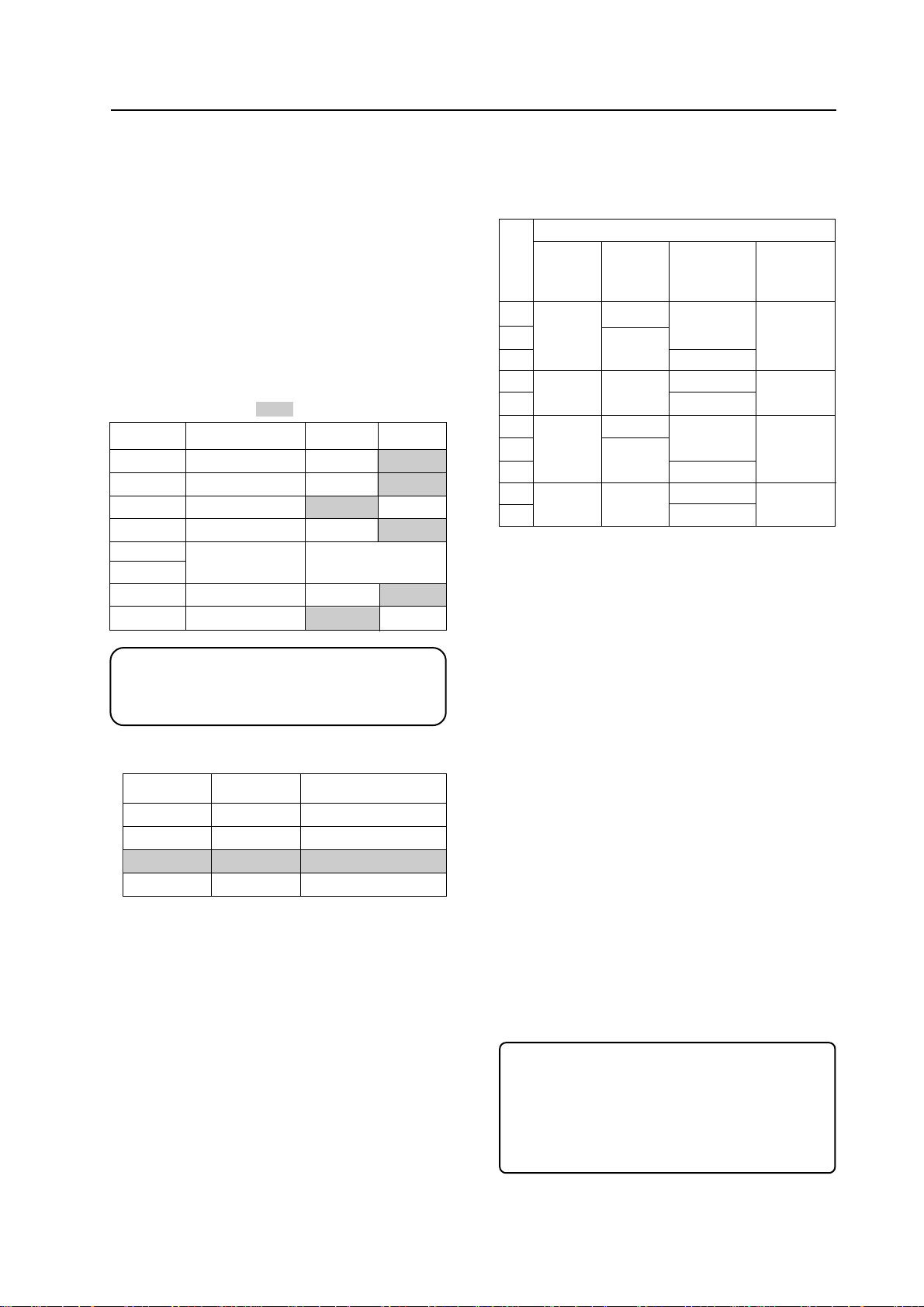

7 Baud rate switch

Selects the baud rate for the RS-232C.

Baud rate switch (8-bit DIP switch)

Functions of bits : Factory preset values

Switch No. Function ON OFF

1 Parity Yes No

2 Parity polarity Even Odd

3 Character bits 8 bits 7 bits

4 Stop bits 2 bits 1 bit

5

Baud rate setting See table below.

6

(Note)

7 Reserved

(Note)

8 Reserved

8 MODE switch

Selects the video output mode.

MODE switch details

SW

Frequency

No.

mode

NTSC

0

1

2

PAL

4

5

NTSC

8

9

A

PAL

C

D

• The factory preset is “8” for RMD-V3104U.

• Frequency mode

NTSC ........................ Vertical refresh rate 59.94Hz

PAL ........................... Vertical refresh rate 50.00Hz

Output Mode Details

Output

mode

VBS,Y/C

Standard/

Double scan

Standard

RGB

Double scan

RGB

Standard

Double scan

VBS,Y/C

Standard

RGB

Double scan

RGB

Standard

Double scan

Middle cut

recovery

mode

OFF

OFF

ON

ON

(Note)

SW7 should always be set to OFF.

SW8 should always be set to ON.

Baud rates available with SW 5 and 6

SW5 SW6 Baud rate (bps)

ON ON 19200

OFF ON 9600

ON OFF 4800

OFF OFF 2400

• Output mode

VBS (Video signal), Y/C or RGB is able to selected.

Yet, VBS, Y/C output are useful is only NTSC Standard

mode.

• Standard / Double scan

Standard (Interlace) ................................................

................. Horizontal frequency 15.625kHz(PAL),

.............. Horizontal frequency 15.734 kHz(NTSC)

Double scan (Non-interlace) ..................................

................ Horizontal frequency 31.250 kHz(PAL),

.............. Horizontal frequency 31.468 kHz(NTSC)

• Output mode

It is the function that mitigates the trunk piece

phenomenon by multiple visions unique scanning line

structure. There is a difference in an effect by the

magnification ratio and it is more effective as smaller of

the magnification ratio. Yet, it does not work in vertical

magnification ratio X 1.

CAUTION:

The Frequency mode for each input board is as follows.

Variable scan board ................................. NTSC, PAL

PAL / NTSC input board .............................................

.................. NTSC (NTSC source), PAL (PAL source)

In the case that a MODE NO other than the above is

set up, a proper picture is not output.

17

Page 28

GENERAL SPECIFICATIONS

CAUTION:

MVP has each separete position data in PAL and

NTSC. When a mode is changed between PAL and

NTSC, a video image position is initialized to data that

was preserved with each mode before. Do so that you

preserve adjustable data with &W1 without fail, in

the case that a mode is changed after video image

position adjustment. (Refer to &W command)

9 Reset button

Press this button to reset the system. After the

button is pressed, the system enters the manual

mode. In manual mode, this unit can be controlled

using the rear panel switches, without using a

computer.

When the reset button is pressed, this unit

functions in the modes selected by the rear panel

switches.

0 COMB cable connector

Connects the interlock cable (cord with 6P miniDIN plugs) provided with the display.

- OPTION video input connectors

These input connectors are used when an option

board is installed.

When the RMD-V3020 variable scan board is used,

their functions operate as shown below.

~ AC INLET

Connects the power cord to the unit.

! FUSE

Use only a fuse with the specified capacity.

Unplug the power cord before replacing the fuse.

@~% V OUT connectors 1 to 4

These video output connectors output enlarged

video image signals for the 4 screens.

VBS/G ...... Output terminal of the composite video

signal or the G signal of RGB separate

signals. (Also outputs the G On Sync

signal while it outputs the G signal.)

Y/B ........... Output terminal of the Y signal or the

B signal of RGB separate signals.

C/R ........... Output terminal of the C signal or the

R signal of RGB separate signals.

The correspondence between these outputs and

a 4 displays is shown below.

V OUT1

V OUT2

G .................... Input terminal for the G signal

of RGB separate signals.

B .................... Input terminal for the B signal

of RGB separate signals.

R .................... Input terminal for the R signal

of RGB separate signals.

H/CS .............. Input terminal for the H sync or

C SYNC signal.

V .................... V sync input terminal.

• As the NEC PC-9800

computers use H/V separate sync signals, their

sync signals should be connected to both the H/

CS and V connectors. H and CS use a common

connector.

• Macintosh

which should be connected to the H/CS

connector.

®

computers use the CS sync signal,

®

, IBM PC and DOS/V (VGA)

= V IN (video) input connectors

These connectors receive video data (V IN signal

images).

Apply V IN (Video) input signals to these

connectors.

VBS/Y ...... Input terminal for the composite video

signal or the Y signal of Y/C separate

signals.

C ............... Input terminal for the C signal of Y/C

separate signals.

V OUT3 V OUT4

4 displays (front view)

18

Page 29

(4) Multi Video Processor (RMD-V3216/V3109/V3000X)

Rear

0

0

299

15

GENERAL SPECIFICATIONS

430

unit: mm

SideFront

D

314

POWER

ON

OFF

MULTI VIDEO PROCESSOR RMD-V3216

16

482.6

420

[Fig. 2-1-3]

General Specifications of the Multi Video Processor (RMD-V3216/V3109/V3000X)

Input signal

Input video signal (up to 4 sets can be added)

2 sets (RMD-V3216) or 1 set (RMD-V3109) or

0 set (RMD-V3000) ............................ BNC connector

1 Composite video signal.......................... 1.0 Vp-p

(75-ohm terminated)

2 Isolated Y/C signal

Y (with synchronization) ............. 1.0 Vp-p (75 ohm)

C burst level ............................. 0.286 Vp-p (75 ohm)

* Signal format 1 or 2 selectable

* Input 1 only equipped with terminating

switch, through out

Input reference synchronizing signal ... BNC connector

1 Composite synchronizing signal

............................................... 0.286 to 4.0 Vp-p

2 Composite video signal

Image level............... 0 to 0.714 Vp-p (75 ohm)

Sync. Level ...................... 0.286 Vp-p (75 ohm)

* Equipped with terminating switch, through

out

RS-232C control input 25-pin D-sub

Output signal

Output video signal

16 sets (RMD-V3216) or 9 sets (RMD-V3109) or

0 set (RMD-V3000) ............................ BNC connector

1 Composite video signal ..... 1.0 Vp-p (75-ohm)

2 Isolated Y/C signal

Y (with synchronization) .... 1.0 Vp-p (75 ohm)

C (with burst) burst level.. 0.286 Vp-p (75 ohm)

* Simultaneous output of 1 and 2

3 RGB signal

Green (G on Sync) .............................. 1.0 Vp-p

SYNC section ...................................... 0.3 Vp-p

Blue ...................................................... 0.7 Vp-p

Input reference synchronizing signal BNC connector TTL level

(or input reference synchronizing signal through

out)

Others

Power supply .................AC 100 to 120 V (50/60 Hz)

Power consumption

...... (RMD-V3216, RMD-V3109, RMD-V3000X)

350 W, 700 VA

Operating temperature/humidity range ... 5 to 35°C

85% or less (without condensation)

External dimensions

(RMD-V3216, RMD-V3109, RMD-V3000X)

................. 482.6 (W) x 420 (D) x 314 (H) (mm)

(not including handle)

Weight

RMD-V3216 .................................................... 22.5 kg

RMD-V3109 .................................................... 22.0 kg

RMD-V3000X ................................................. 20.5 kg

Accessories

Rack mount screw M5 ............................................ 8

Rack mount washer ................................................ 8

* Up to 3 units of the RM-V2550BU can be stacked.

4x4 (16-screen) configurations are not possible.

19

19

Page 30

GENERAL SPECIFICATIONS

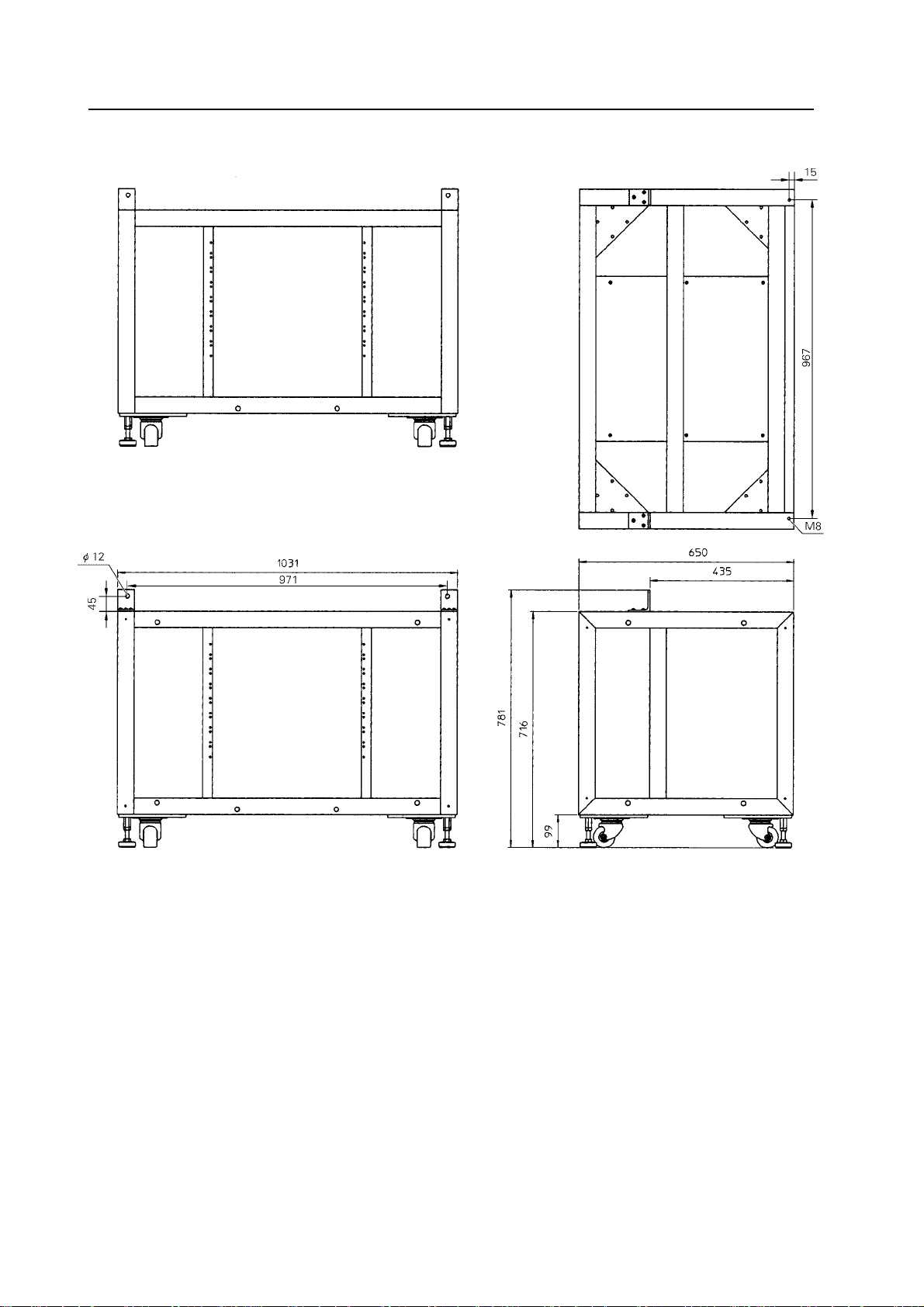

(5) Projection Stand (RMA-V5020)

Rear

Top

Front

[Fig. 2-1-4]

Specifications

External dimensions (max.) .......................... 1031 (W) x 781 (H) x 650 (D) mm

(For 100-inch 4-screen systems, system height is 2600 mm)

Weight ............................................................ 51.5 kg

Accessories

Main unit mount bolt M8x30 ........................ 2

Main unit mount bolt M8x60 ........................ 2

Side coupling bolt M10x120 ......................... 4

Side coupling washer (for M10 bolt) ............ 8

Side coupling nut (for M10 bolt) .................. 4

Package dimensions .......................................... 1165 (W) x 800 (H) x 840 (D) mm

Package weight................................................... 63 kg

20

Side

unit: mm

Page 31

(6) Adjustment Control Unit (RU-V107) Option

84

GENERAL SPECIFICATIONS

unit: mm

POWER

0

13

46

79

D

ADJUSTMENT CONTROL UNIT

ADJ IN

2

5

8

Î

ABC

DEF

ADJ ADJ ADJ

RGB

ON/OFF ON/OFF ON/OFF

INPUT SEL

2//3

–+

DISP CALL

MAIN MENU

ADJ OUT

187

Cable length : 5m

[Fig. 2-1-5]

Accessories

AA dry battery (IEC R6P) ..................................................................................... 2

Cable (5m) ............................................................................................................ 3

29

21

Page 32

GENERAL SPECIFICATIONS

2. Diagram of system dimensions

* For the detailed system dimensions, please refer to chapter 3.

* External dimensions do not include protuberances such as screw heads etc.

(1) Single panel

RM-V2550BU, RM-V2550E + (RM-V2550S, RM-V2550S2)

(Bolt mounting

hole pitch)

[Fig. 2-2-1]

(Surface)

unit: mm

22

Page 33

(2) 2 x 2 (100 inch)

GENERAL SPECIFICATIONS

(3) 3 x 3 (150 inch)

[Fig. 2-2-2]

unit: mm

[Fig. 2-2-3]

unit: mm

23

Page 34

CHAPTER 3. INSTALLATION AND ASSEMBLY

INSTALLATION AND ASSEMBLY

1. INSTALLATION CONDITIONS

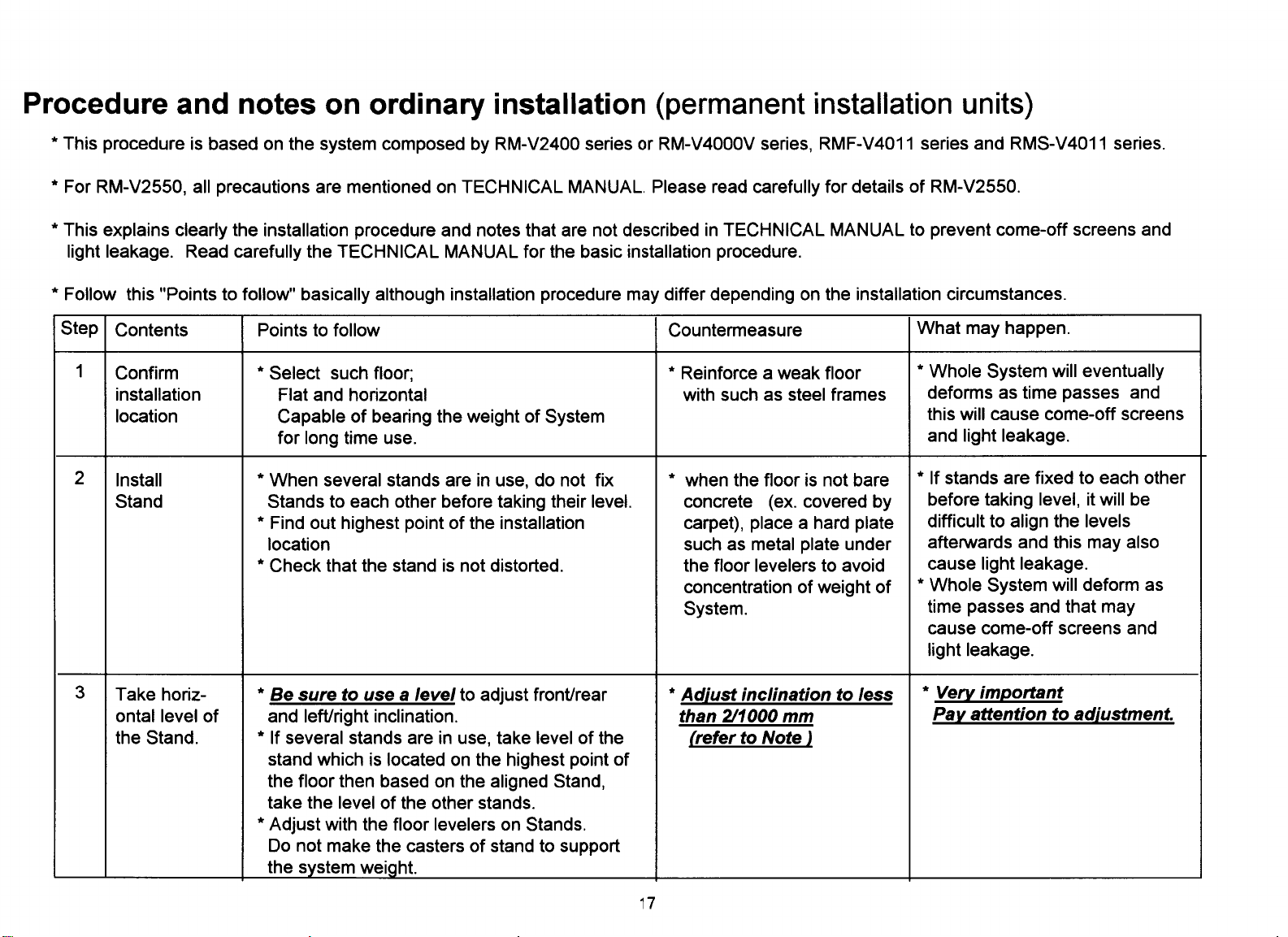

(1) Weight-tolerant

The ground must be flat and horizontal. It should be able to bear the weight of the system.

For wooden floors, if the part receiving the weight of the system lies at the center between the reinforcement

beams below the floor, the floor may become deformed or may curve inwards. Moreover, in the case of a carpet

etc., the part bearing the load may sink with time, meaning that the horizontal balance of the system may shift

out of place after installation. In such cases, lay a more than 12 mm thick board below the system to distribute

the weight of the system on the floor.

For concrete floors, it may not be possible to install the system horizontally due to the roughness of the floor. In

such cases, do the same as above.

(2) Ceiling height

¶ Reserve a headroom of at least about 10 cm (4 inches) between the top of the system and the ceiling. If an air

conditioner outlet or illumination lamp is located above the system, use special care to prevent troubles due

to dust, temperature, humidity and dew condensation. In case the system is covered by interior furnishings,

be sure to take measures to ventilate Floor leveler tends to pool above the top of the system. Otherwise

troubles may result.

(3) Front space

¶ Finger and hand prints form easily on the face of the screen. Therefore make sure viewers cannot touch it

directly.

Leave workspace in front for replacing the screen.

(4) Rear space

¶ The system can be installed up against the wall when the projection units are stacked in two stages. When

they are stacked in three stages, reserve a rear clearance of at least 5 cm (2 inches). However, remember that

a space of at least 50 cm (20 inches) is required in the maintenance operation and install the system by taking

later maintenance in consideration.

(5) Stacking stages

¶ The projection units can be stacked in up to three stages.

¶ They cannot be stacked in four stages or more.

Otherwise troubles may result in relation with the cabinet strength or stagnation of heat.

¶ Up to 4 columns of RM-V2550S2 screens can be placed in a row.

(Maximum number of screens is thus 12 [3 x 4])

24

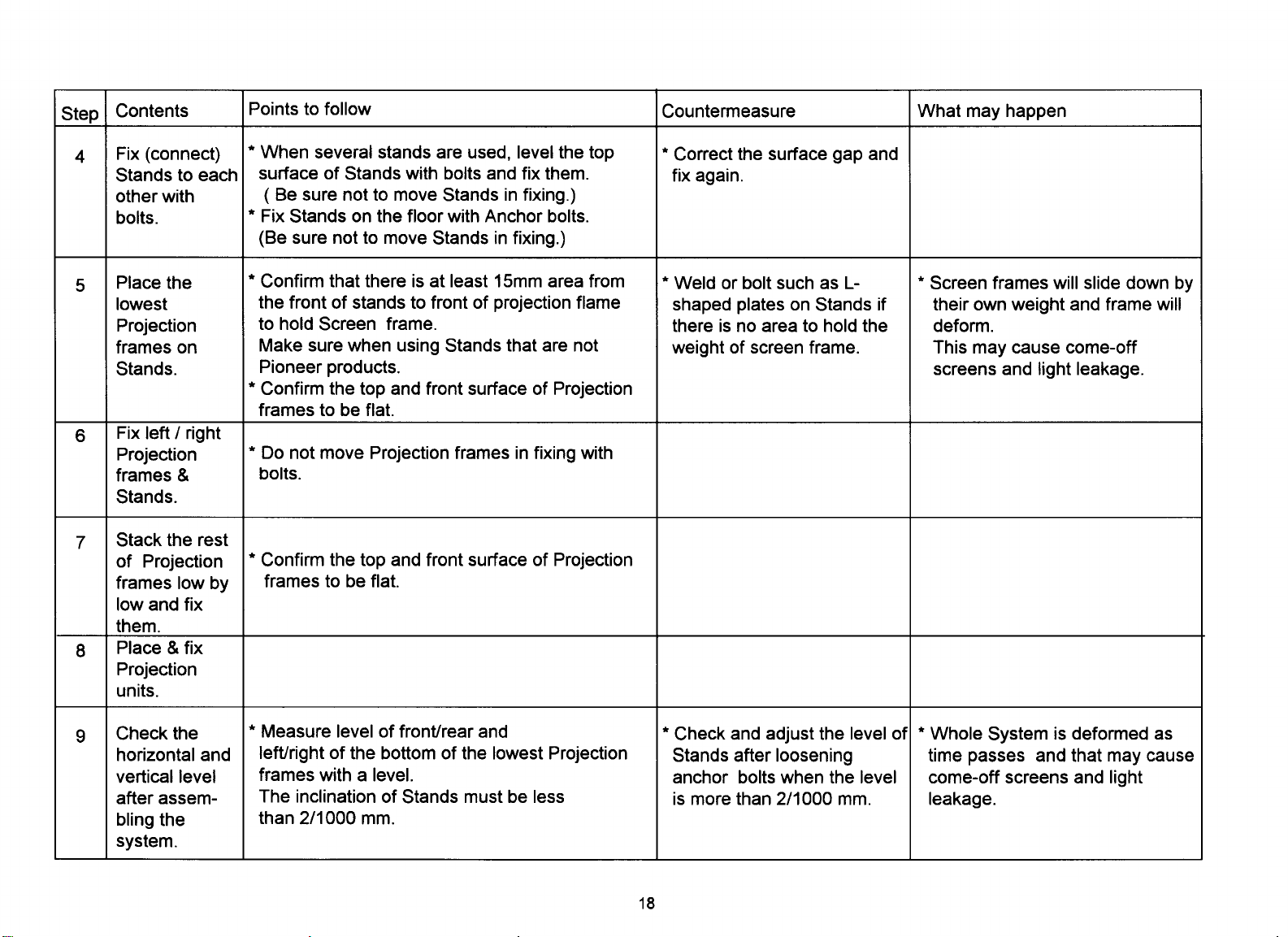

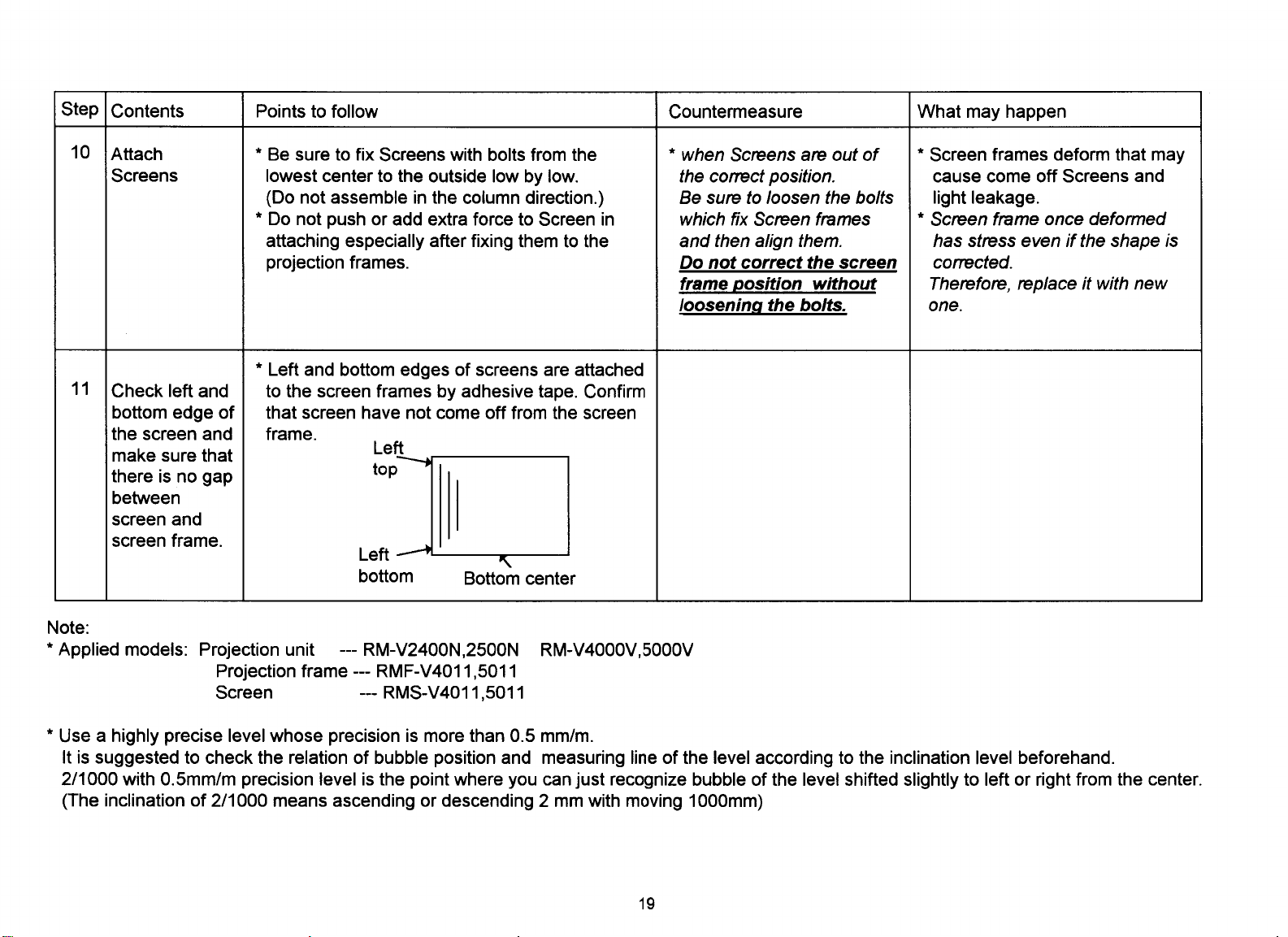

Page 35

INSTALLATION AND ASSEMBLY

(6) Installation work to prevent toppling

¶ Make sure that you carry out the following work after installing the system in order to prevent toppling etc.

1 Lower all of the floor levelers until the system comes into contact with the floor.

2 Anchor the system to the floor.

3 Fix the system to the wall etc. using wires etc., following the points in the diagram below.

NOTE) 1. Always use wires etc. that are a little stronger than necessary.

2. Always use the points designated in the diagram below for attaching the wires etc. Do not use

other holes, since they are not strong enough and their surroundings may be damaged.

¶ The method for fixing the system to the floor or wall depends on the material that the floor or wall is made of.

You should get a specialist contractor or your dealer to do this work.

¶ Make sure that you read the section ‘Fixation using anchors ’ on P74.

Bolt

Wire rope

Fix on the wall, etc.

Must not be used.

Part A Enlarged View (2 points)

Nut

Fix on the

wall, etc.

Wire rope

Part B Enlarged View (2 points)

Nut

Must not be used.

Bolt

Example of tumbling prevention of a system with 4-screen configuration

Use the points indicated by arrows

(4 points).

[Fig. 3-1-1a]

Wire rope attaching points for tumbling

prevention of a system with 9-screen configuration

Use the points indicated by arrows (4 points).

[Fig. 3-1-1b]

25

Page 36

INSTALLATION AND ASSEMBLY

(7) Heat value calculation

¶ In the calculation, assume that the maximum power consumption per multi-projection unit is 300 W by re-

serving a certain headroom. As most of the consumed power becomes heat, the power consumption can be

regarded to be proportional with the calorific value.

1 Conversion into calorific value (kcal/h)

[W] x 0.86 = [kcal/h]

Calorific value per multi-projection unit

300 x 0.86 = 258 (kcal/h)

2 Conversion into British thermal unit

[W] x 3.41 = [B.t.u./h]

Calorific value per multi-projection unit

300 x 3.41 = 1023 (B.t.u./h)

Projection units Calorie (kcal/h) British (B.t.u./h)

1 screen 258 1023

4 screens 1032 4092

9 screens 2322 9207

(8) Temperature and humidity conditions

¶ Closely observe the following conditions on the temperature and humidity of the location of installation.

(1)Operating temperature : 5 to 35 degC (No condensation)

(2)Operating humidity : 20 % to 80 %

(3)Storing temperature : –10 to 45 degC

¶ The lenticular sheet will stretch and consequently the center of the screen will rise if the humidity is relatively

high. In this case, the focus may slightly change and therefore readjustments in the installing conditions of

the location must be performed when your system arrives.

¶ Avoid wetting the system at all times. Due to the shape of the product, it is easily affected by external condi-

tions. Especially to be avoided is wetting the MPJ and screen. Thorough water-proof measures must be taken

when installing them in locations where there is a high level of moisture in the air such as near air-conditioning vents and water sprays.

* Take note that in new buildings, moisture is frequently produced from the concrete and the humidity level

subsequently rises.

¶ Electrical equipment such as this system should not be installed in high humidity environments. Follow the

precautions below when high humidity is expected.

• Never install the MPJ and screen in locations that do not meet their respective specifications.

• Ground the units.

• Ensure that there is no condensation.

• Install the units where no one can touch them.

• Ensure that water droplets do not fall onto the units.

(9) Condensation

One problem that occurs in the winter season is “Condensation”. When the temperature of the room in which

this system is installed rises suddenly, condensation occurs on the screen and lens, thereby the system cannot

display its best performance. In such cases, turn off the power once, leave the system off for one hour, and turn

on the power again. Increasing the room temperature gradually is another method.

26

Page 37

INSTALLATION AND ASSEMBLY

(10) Visual field angles, visible range

¶ Uniform images can be obtained by installing the system in any of the ranges shown below.

Vertical field angle

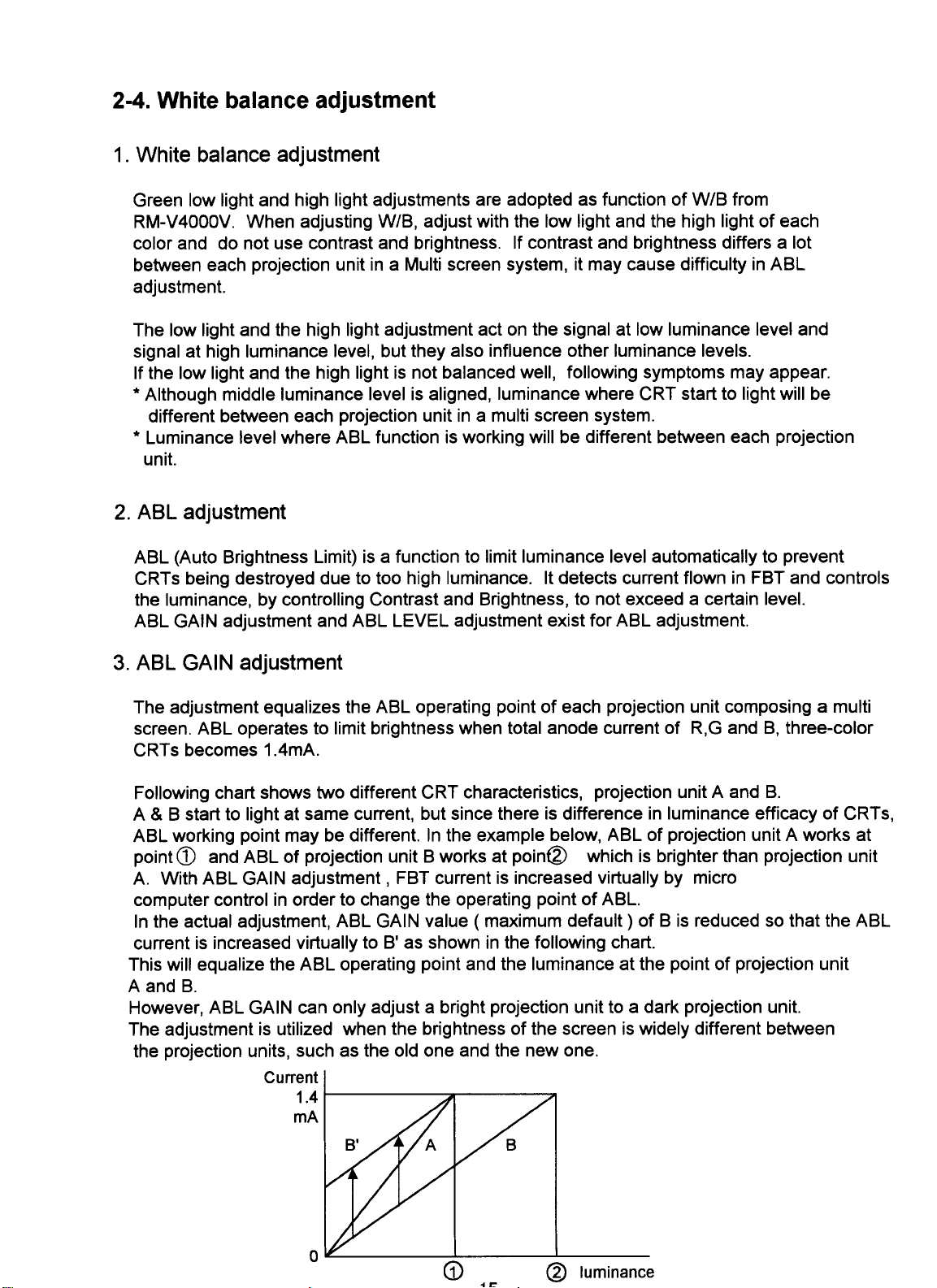

¶ 2-stage configuration

1.6m

¶ 3-stage configuration

1.6m

1.2m

[Fig. 3-1-2]

1.2m

[Fig. 3-1-3]

27

Page 38

INSTALLATION AND ASSEMBLY

¶ 2-stage configuration using stands (RMA-V5020)

1.6m

1.2m

¶ 3-stage configuration using stands (RMA-V5020)

1.6m

1.2m

[Fig. 3-1-4]

28

[Fig. 3-1-5]

Page 39

Horizontal field angle

¶ 2 horizontal screen configuration

INSTALLATION AND ASSEMBLY

¶ 3 horizontal screen configuration

[Fig. 3-1-6]

[Fig. 3-1-7]

29

Page 40

INSTALLATION AND ASSEMBLY

(11) Lighting

¶ Projection screens do not reflect external light like the CRT, but the screens and their base materials may still

cause reflection if strong light of a spotlight, etc. is directly incident to them. In such a case, prevent the

illumination lighting from hitting the screen surfaces directly.

¶ Glass plates for safety protection purpose may sometimes have to be attached on the screen surfaces de-

pending on their installation location. In this case, examine the installation positions carefully so that the

front glass plates do not reflect the external light.

¶ As the actual intended images of the system may not be obtained in very bright locations, consider the

position of lighting and direction of sunlight when installing the system. Especially when the system is exposed to direct light (sunlight, etc.) from behind, the light may be reflected on the screen. Avoid such installations.

¶ Take note that in bright places, images may appear dark even when the luminance has been increased. In

addition, increasing the luminance and contrast more than required may affect the life of the system (especially the CRT).

(12) Effects of earth magnetism

¶ Due to effects of earth magnetism, the position of the image displayed will differ according to the installed

direction. Difference is about several mm in the up/down/left/right directions, but the degree of change varies

according to the strength of the earth magnetism of each area. Misconvergence may also occur due to slight

rotations.

Thus, when performing adjustments before moving the set to the place where it is to be installed, do so in the

same direction as the direction of installation, then readjust in the final position of installation.

¶ Normally perform adjustments in the final position of installation.

¶ The system is not only affected by earth magnetism but by the following magnetisms generated by various

items in its surrounding as well.

• Steel frame of building

• Power cables on the floor

• Large speaker systems

• Special equipment (Those generating magnetic force)

• Metallic installation table, frames, etc.

(13) Backyard ventilation

A temperature difference between the front and back of the screen may occur for any of a number of reasons,

such as an increase in the internal temperature of the system or a change in the effectiveness of air conditioning.

When such a temperature difference occurs, air will try to flow in order to equalize the temperatures. If there is

no path for the air to follow between the area in front of the screen and the backyard area then the screen may

warp.

You should make sure that there are paths in the backyard and in front of and behind the screen that will allow

ventilation. You should take particular care if the backyard is a closed room with no windows and powerful air

conditioning is installed.

30

Page 41

INSTALLATION AND ASSEMBLY

(14) Power supply

1 Power supply voltage

The guaranteed voltage of this system is ±10% of the rated voltage.

But if the impedance of the power wires is high, the voltage waveform will become distorted and show the same

symptoms as when voltage drops abnormally. As the following must be noted even if the voltage is within the

allowable range, check the power wiring again.

¶ The voltage drop from the switchboard to this system is great.

¶ The voltage changes greatly when the power of the system is turned on and off (Roughly 5% of the rated

voltage)

2 Power supply capacity

When calculating the capacity, assume that the maximum power consumption per multi-projection unit is 400

VA by reserving a certain headroom.

Current capacity

Multi-projection units Power capacity RM-V2550BU RM-V2550E

100 V 120V 220V 240V

1 screen 400 VA 4 A 3.3 A 1.8 A 1.7 A

4 screens 1600 VA 16 A 13.3 A 7.3 A 6.7 A

9 screens 3600 VA 36 A 30.0 A 16.4 A 15 A

The current increases as the voltage drops. Design the power supply by reserving a headroom by referring to

the connection description in 3 below. When a single power line (same power distribution panel) is used to

power another system, be careful not to exceeds the power distribution capacity by taking the power consumption of the other system in consideration.

3 Connection

¶ Each multi-projection unit has an AC OUTLET connector, which can accept the connection of up to 2 multi-

projection units in addition to the first multi-projection unit. Do not connect other equipment than multiprojection units to the AC OUTLET.

Multi-projection

unit

To power outlet

Multi-projection

unit

¶ Connect the system components so that their current consumption does not exceed the current capacity of

the power distribution panel. Always reserve a headroom when designing the system.

Multi-projection

unit

To power outlet

Multi-projection

Multi-projection

unit

unit

Multi-projection

Multi-projection

unit

unit

To power outlet

To power outlet

Multi-projection

unit

Multi-projection

unit

Multi-projection

unit

Multi-projection

unit

Multi-projection

unit

Multi-projection

unit

31

Page 42

INSTALLATION AND ASSEMBLY

4 3-pin plug

The power cord of the system has a 3-pin plug. This design aims at preventing electric shock due to leaked

current. Be always sure to connect the power plug into a 3-pole power outlet.

5 Ground-fault circuit interrupter

The system incorporates a power line filter for noise prevention and leaked current of 0.5 mA flows per multiprojection unit. If your power supply system uses a ground-fault circuit interrupter, check its sensitive current

and make sure that it is above the total current leakage of the system.

Also count in the current leakage of other equipment than the video output equipment assuming that the leaked

current of each piece of equipment is 0.5 mA.

Within Japan, the current is generally 15A~20A per circuit. It is thus imperative that you route the power supply

through a breaker.

To prevent voltage dropping, current waveform degradation and noise induction in the middle of the circuit,

always supply power directly from the power distribution panel.

Do not use an existing wall outlet etc. to supply power as this is extremely dangerous.

It is extremely dangerous to supply power from existing wall outlets, etc.

Install the system near the outlet for connecting the units of the system as much as possible.

Set the current capacity slightly greater-about more than 25% of the total consumption power.

(15) Cables used

Use a coaxial cable for the external input cable. Normally use a 3C-2V for less than 15m long. Use 5C-2V for

greater lengths. Adjust the length of the cables. The distance between the transmission system and MPJ should

be as short as possible. When the distance is great, consider the thickness of the cable and electrical compensation carefully.

The limit is as shown when using the cables to connect the transmission final output terminal and the system.

3C-2V: 15m

5C-2V: 30m

To use a longer cable, the VIDEO signal must be corrected.

NOTE) To install the system up against the wall, use L-shaped BNC conversion adapters.

(16) Semi-outdoor installation

This system is basically designed for use indoors. When the system is installed in semi-outdoor locations, the

following problems may occur. Take the following measures before using the system.

• Waterproof and rustproof measures

• Temperature difference and humidity difference

• Light on the screen (So that it is not exposed to direct sunlight.)

• Wind containing salt

(17) Caution for use of user-prepared parts

We basically recommend that the user uses the projection stands manufactured and recommended by us.

However, if you want to prepare them by yourself, use care in the following point.

¶ Install the stands so that the system is maintained level. Be sure to calculate the floor strength and take

sufficient measures to prevent the system from tumbling down. When not using a Pioneer-recommended

stand, Pioneer will accept no responsibility for accidents or damage due to improper installation or mounting

or to natural disasters.

32

Page 43

INSTALLATION AND ASSEMBLY

(18) Ventilation

To prevent the rise in the internal temperature, the system is equipped with a vent and a vent with a fan on the

top panel and vents on the bottom and rear panels. [Fig. 3-1-8]

Vent with a fan

Vent

Vent

Vent (Bottom)

Vent (Bottom)

[Fig. 3-1-8]

Be careful not block these vents. Otherwise heat will be stagnated inside the system and may result in a fire

hazard.

When the system is used in a 2-stage configuration or is installed up against the wall, reserve spaces of at least

10 cm (4 inches) to the left and right sides of the system. When it is used in a 3-stage configuration, also make

sure that there is a clearance of at least 5cm (2 inches) between the rear panel and wall and at least 10 cm (4

inches) on the sides. [Fig. 3-1-9]

(With these conditions, it is assumed that there is a space of at least 10cm between the system and the ceiling.)

5 cm

Wall

Set

10 cm 10 cm

2-stage configuration

Wall

Set

10 cm 10 cm

3-stage configuration

[Fig. 3-1-9]

33

Page 44

INSTALLATION AND ASSEMBLY

2. INSTALLATION AND ASSEMBLY

(1) Confirmation

1 Decide the position for installing the system according to the installation conditions in

Chapter 3.

Check items

[1] Dimensions of installing position, space at the back, distance to the ceiling

[2] Floor flatness, strength, roughness

[3] Position of power supply

[4] Installing location

Necessity for special measures for floor or wall (reinforcement covers, sheets, planks, etc.), route by

which set is to be moved in and out, width of route, availability of elevator, size and weight restrictions of

elevator, air-conditioning air currents, etc.

[5] Position, specifications, and structure of a transmission equipment, and image type

[6] Model number of equipment used, and their quantity (perform according to list).

Check if there is enough equipment for each unit

* These procedures must be performed by only one person.

(2) Unpacking

1 Packaging specifications

[1] Screen : 1 RM-V2550S 1149(W) x 174(H) x 903(D) mm 17.5 kg

2 RM-V2550S2 1149(W) x 174(H) x 903(D) mm 12 kg

[2] Cabinet : 1130(W) x 1309 (H) x 825(D) mm 88 kg

2 Unpacking tips

[1] Begin with unpacking the largest carton. place smaller cartons in the vacant carton of the larger items, and

dispose of the packing material while unpacking the cartons.

After unpacking, arrange the items in order of assembly to facilitate the later assembly operation.

Move the vacant cartons to another place so that they do not come in the way of assembly, and reserve as

wide a space as possible for the assembly.

* By placing opened cartons upside down, they can easily be distinguished from non-opened cartons.

Manage the accessories, warranty cards, etc. so as not to lose them.

[2] The cabinet is designed with a structure that is easy to tumble down. It should be unpacked in as close as

possible location to the system installation position.

The under-carton can be used to prevent the cabinet from tumbling down because will not tumble down in

that location. After unpacking the cabinet from the under-carton, immediately place the cabinet on the stand

(when a stand is used) and fix using bolts.

34

Page 45

INSTALLATION AND ASSEMBLY

3 RM-V2550BU's cabinet and RM-V2550E unpacking procedure [Fig. 3-2-1]

[1] Remove the upper carton and place it upside down.