TECHNICAL MANUAL (Ver.1.0)

MULTI PROJECTION UNIT

RM-V2400NA / V2500NA

RM-V2400NE / V2500NE

PROJECTION SCREEN KIT

RMS-V4011/ V5011

PROJECTION FRAME

RMF-V4011/ V5011

PROJECTION CABINET

RMF-V4011R / V4011CR

Caution

This symbol refers to a hazard or unsafe

practice which can result in personal injury

or property damage.

Notes:

• Pioneer will not be liable for any loss caused by defects

of the parts supplied other than by Pioneer.

• An damage during shipping will be compensated for

only in the case where Pioneer's specific packing materials for shipping are used.

• The guarantee of performance is applicable only when

the assembly and adjustment described in this technical

manual and the adjustment described by the system

manual of RM-V2000 have been carried out.

• Specifications and design subject to possible modification without notice, due to improvements.

R

1

PIONEER RM-V2400 / 2500

MANUAL.

This Acrobat (IE: a PDF file) version of the Pioneer RM-V2400 / 2500 manual was made from

the original digital document and scanning an existing manual. Because of this, there are many

less then perfect pages and hand written comments.

As Pioneer is constantly working towards providing the best possible documentation for our

products, there may be an improved version of this document available. Please contact your

Pioneer representative for additional information.

Josh Kairoff

Pioneer New Media Technology.

October 27, 1997.

CONTENTS

CHAPTER 1. FEATURES OF PROJECTION CUBE SYSTEM .............................................................. 4

1. FEATURES OF SYSTEM........................................................................................................................................... 4

2. FEATURES OF MULTI PROJECTION UNIT (RM-V2400N/V2500N) ....................................................................... 4

3. FEATURES OF FRAME TYPE ................................................................................................................................... 5

4. FEATURES OF CABINET TYPE ................................................................................................................................ 5

CHAPTER 2 . GENERAL SPECIFICATIONS ......................................................................................... 6

1. SPECIFICATIONS ...................................................................................................................................................... 6

(1) Multi Projection Unit (RM-V2400N/V2500N)................................................................................................... 6

(2) Projection Screen Kit(RMS-V4011/V5011)Product Weight:11.0kg/14.0kg .................................................. 13

(3) Projection Frame (RMF-V4011/V5011)Product Weight:26.8kg/28.8kg ........................................................ 14

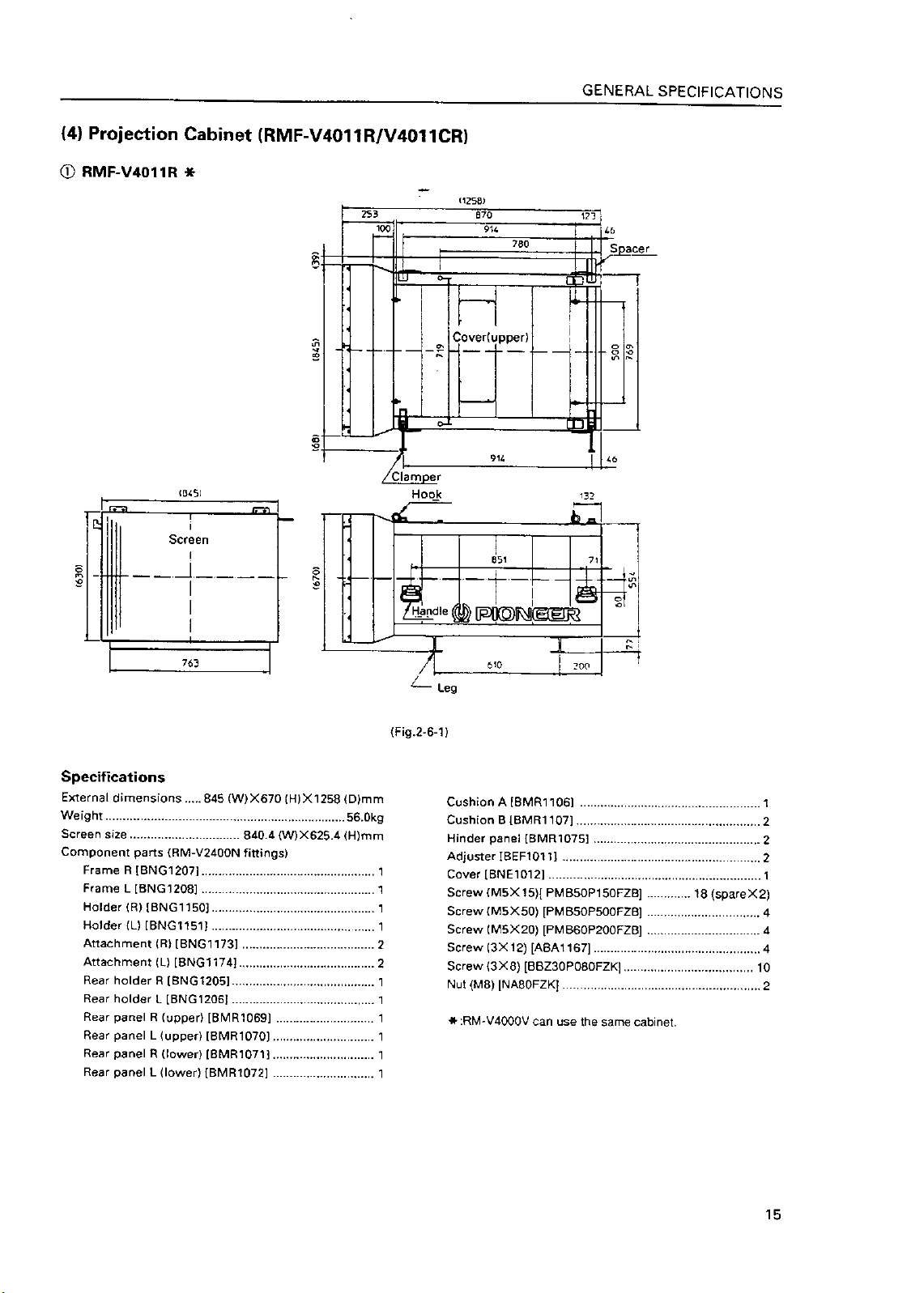

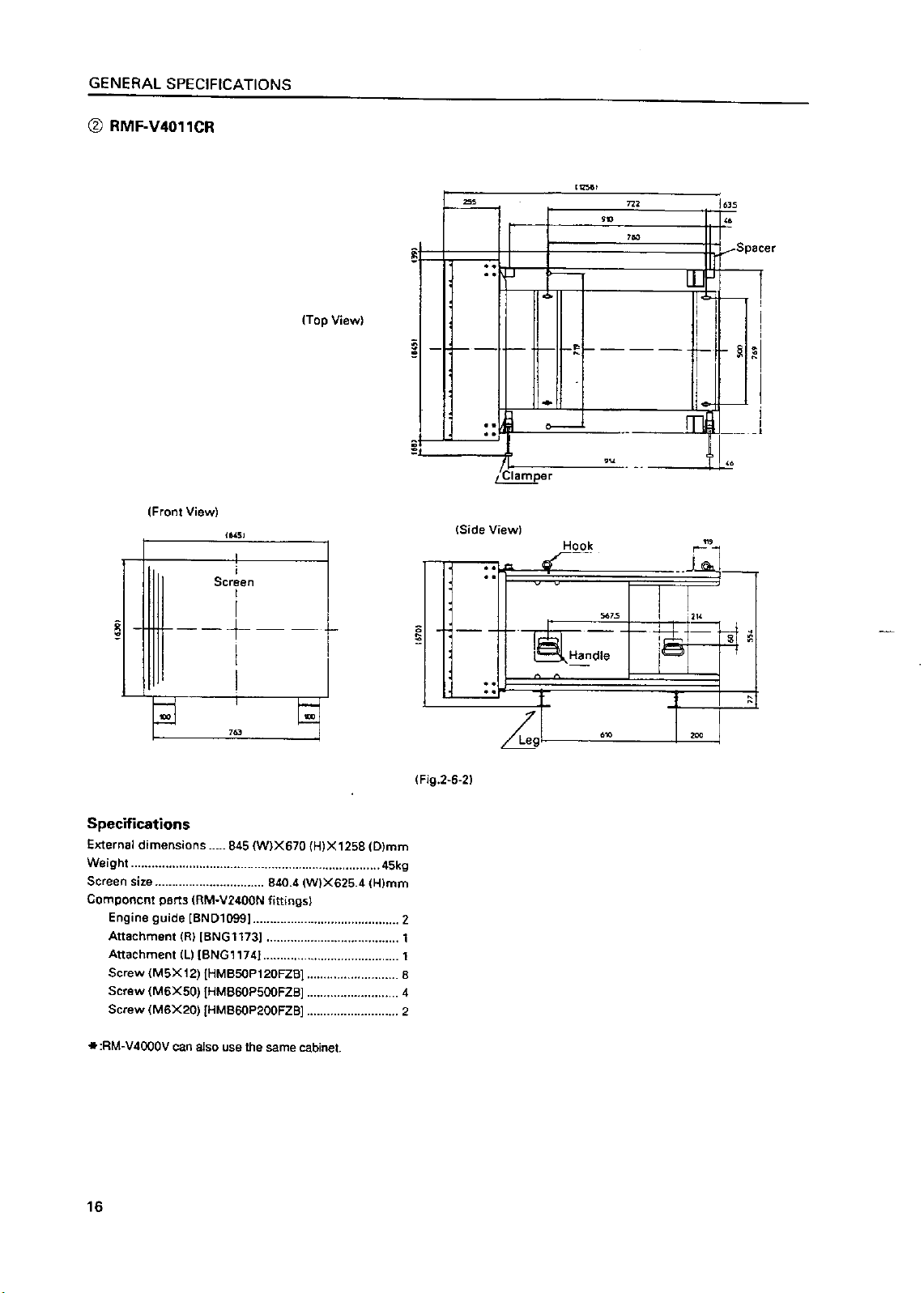

(4) Projection Cabinet(RMF-V4011R/V4011CR) .................................................................................................. 15

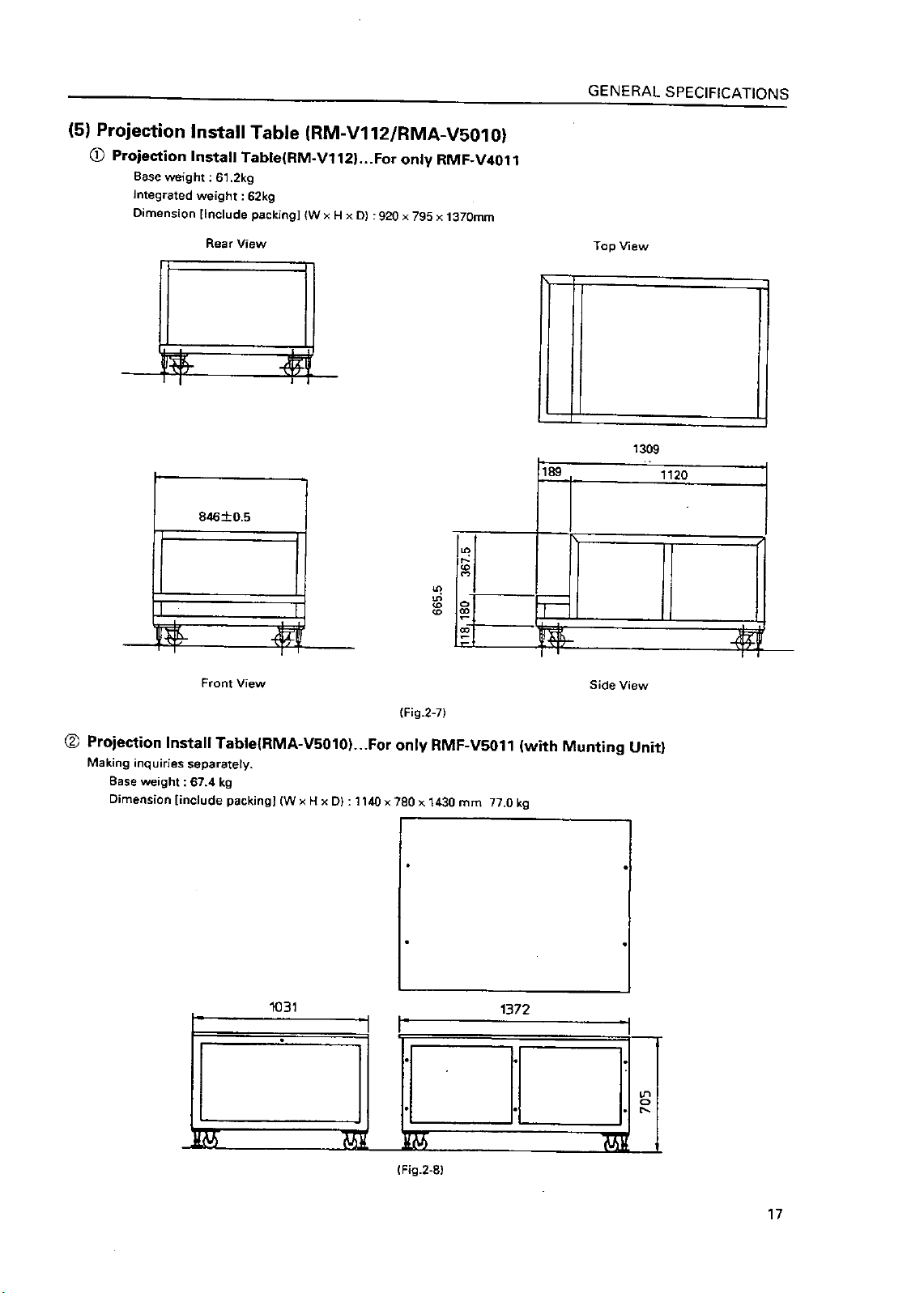

(5) Projection Install Table (RM-V112/RMA-V5010) ........................................................................................... 17

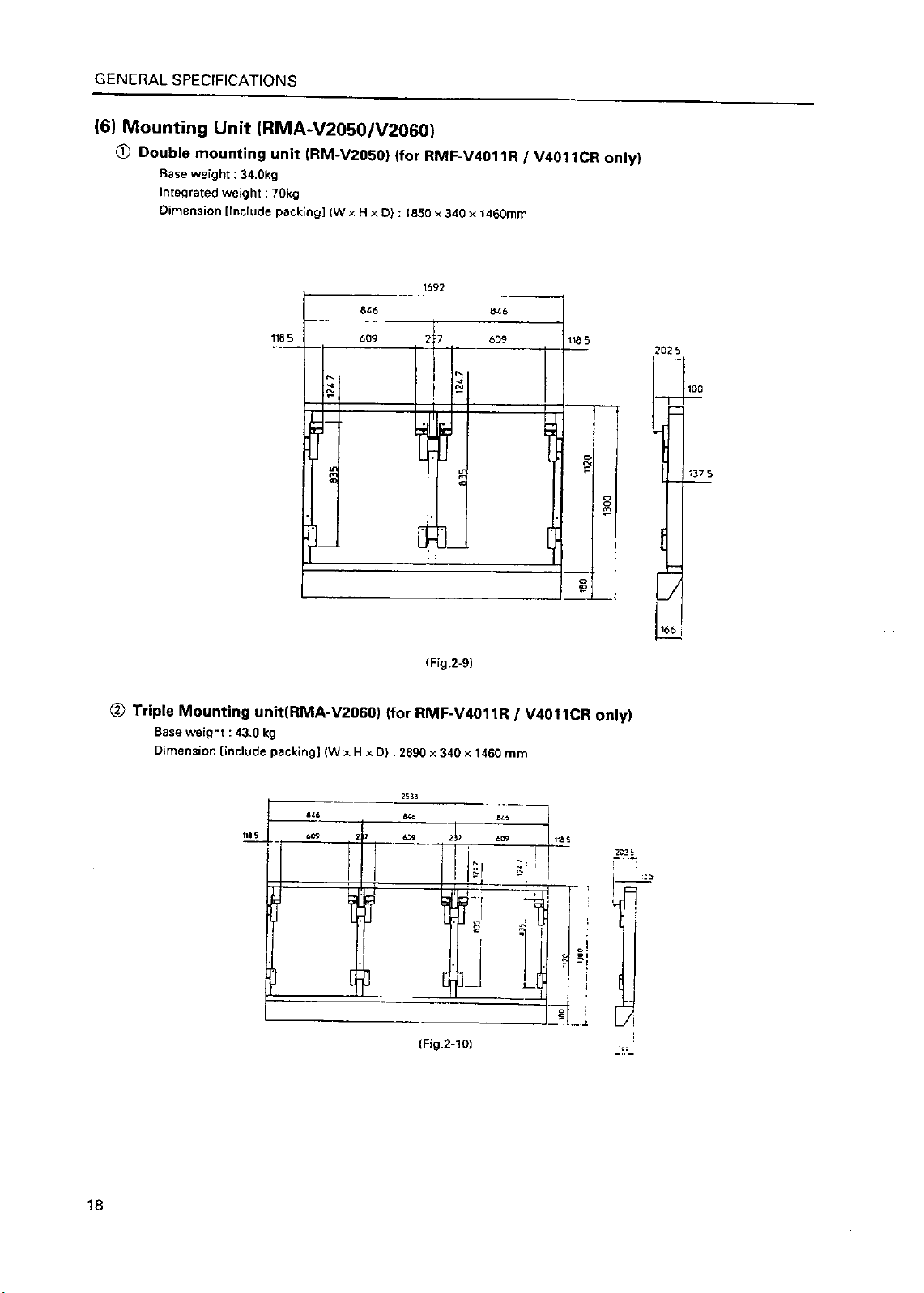

(6) Munting Unit (RMA-V2050/2060)................................................................................................................... 18

(7) Multi Video Processor(RMD-V3216/3109,RMD-V2170) ................................................................................ 19

(8) Adjustment Control Unit (RU-V107)*Option ................................................................................................ 21

(9) Projection Cabinet (RMF-V4011R) Accessories ............................................................................................ 22

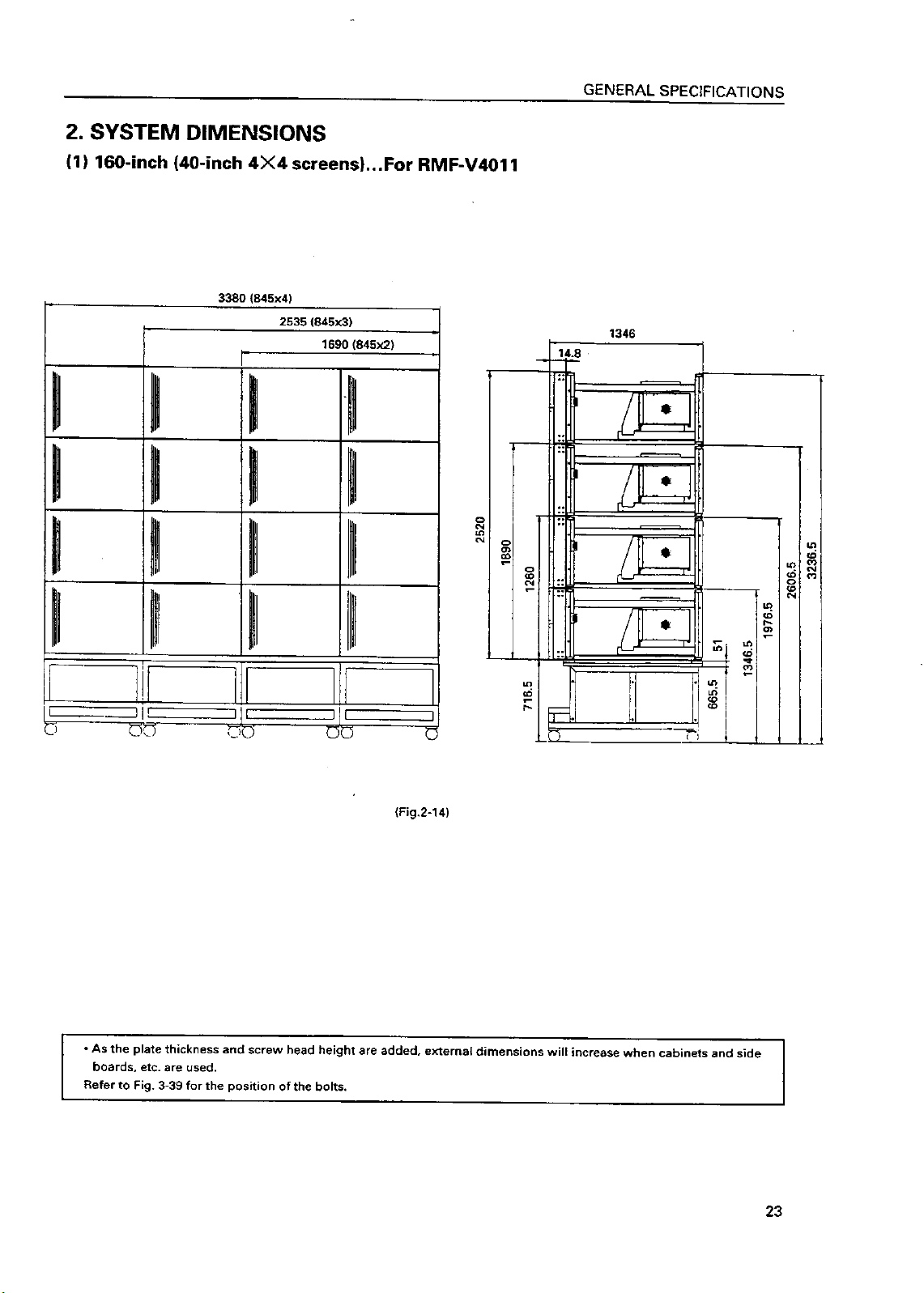

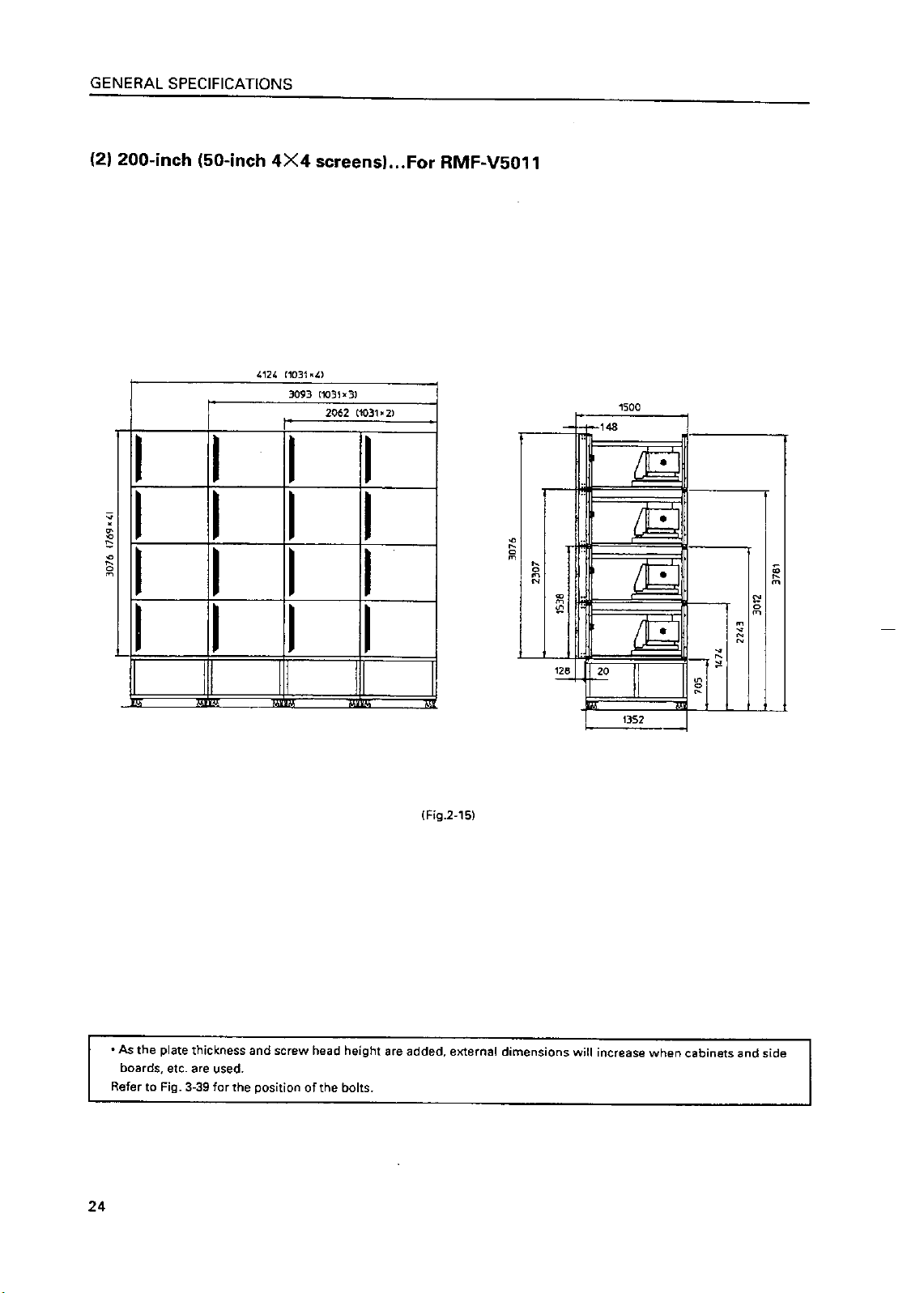

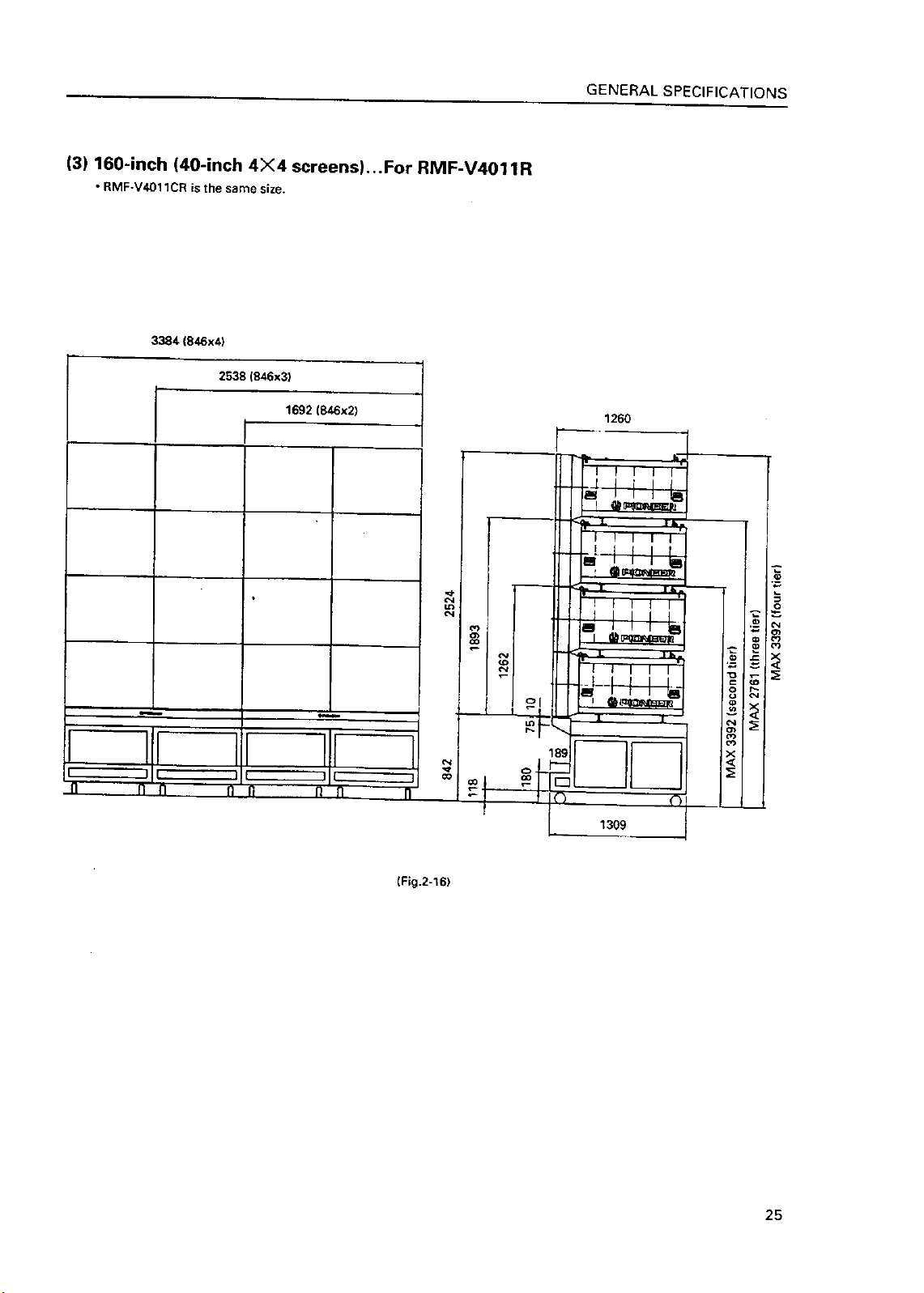

2. SYSTEM DIMENSIONS .......................................................................................................................................... 23

(1) 160-inch (40-inch 4×4screens)…For RMF-V4011 ......................................................................................... 23

(2) 200-inch (50-inch 4×4screens)…For RMF-V5011 ......................................................................................... 24

(3) 160-inch (40-inch 4×4 screens)…For RMF-V4011R...................................................................................... 25

CHAPTER 3. INSTALLATION AND ASSEMBLY ............................................................................... 26

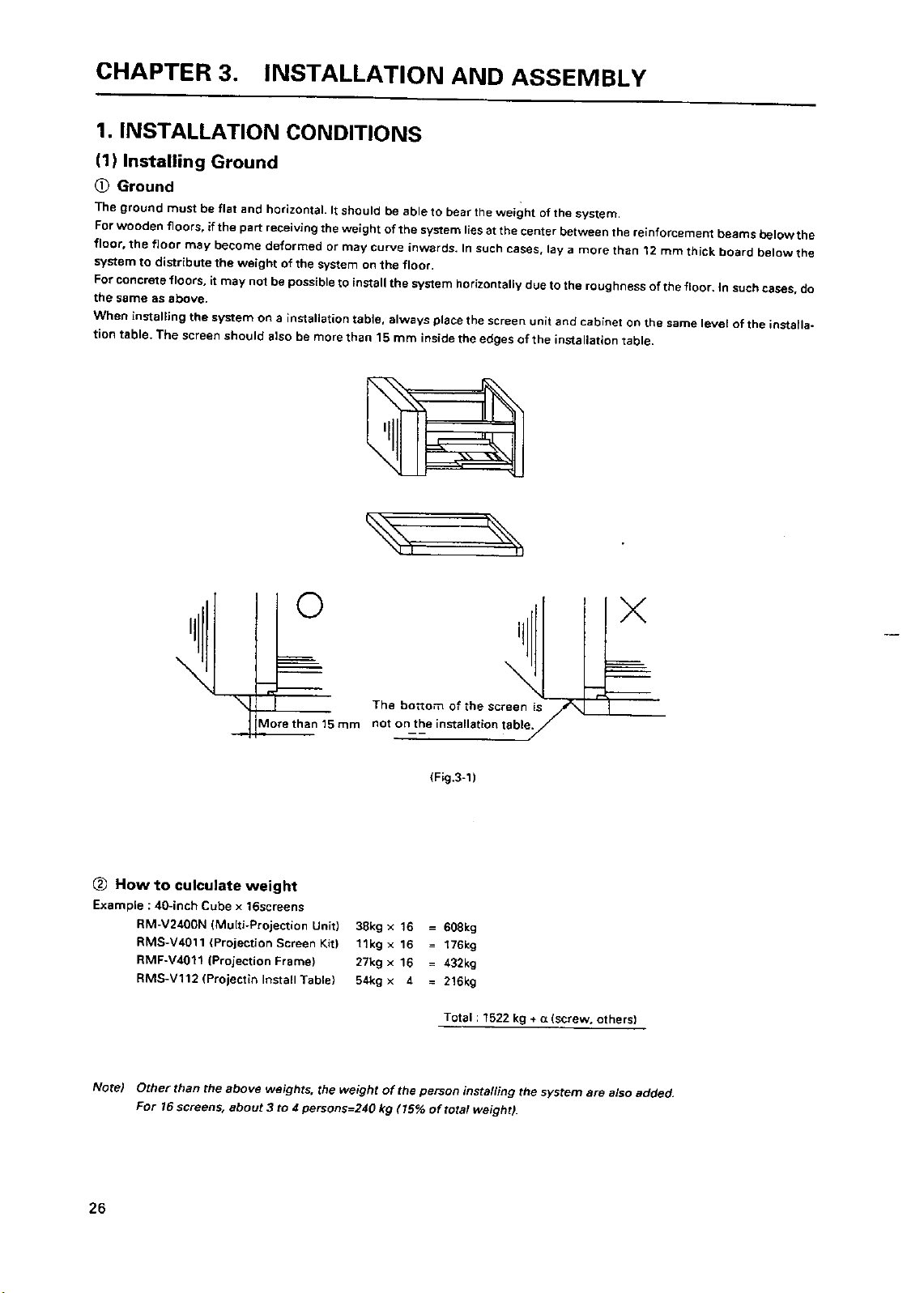

1. INSTALLATION CONDITIONS ............................................................................................................................... 26

(1) Installing Ground ............................................................................................................................................ 26

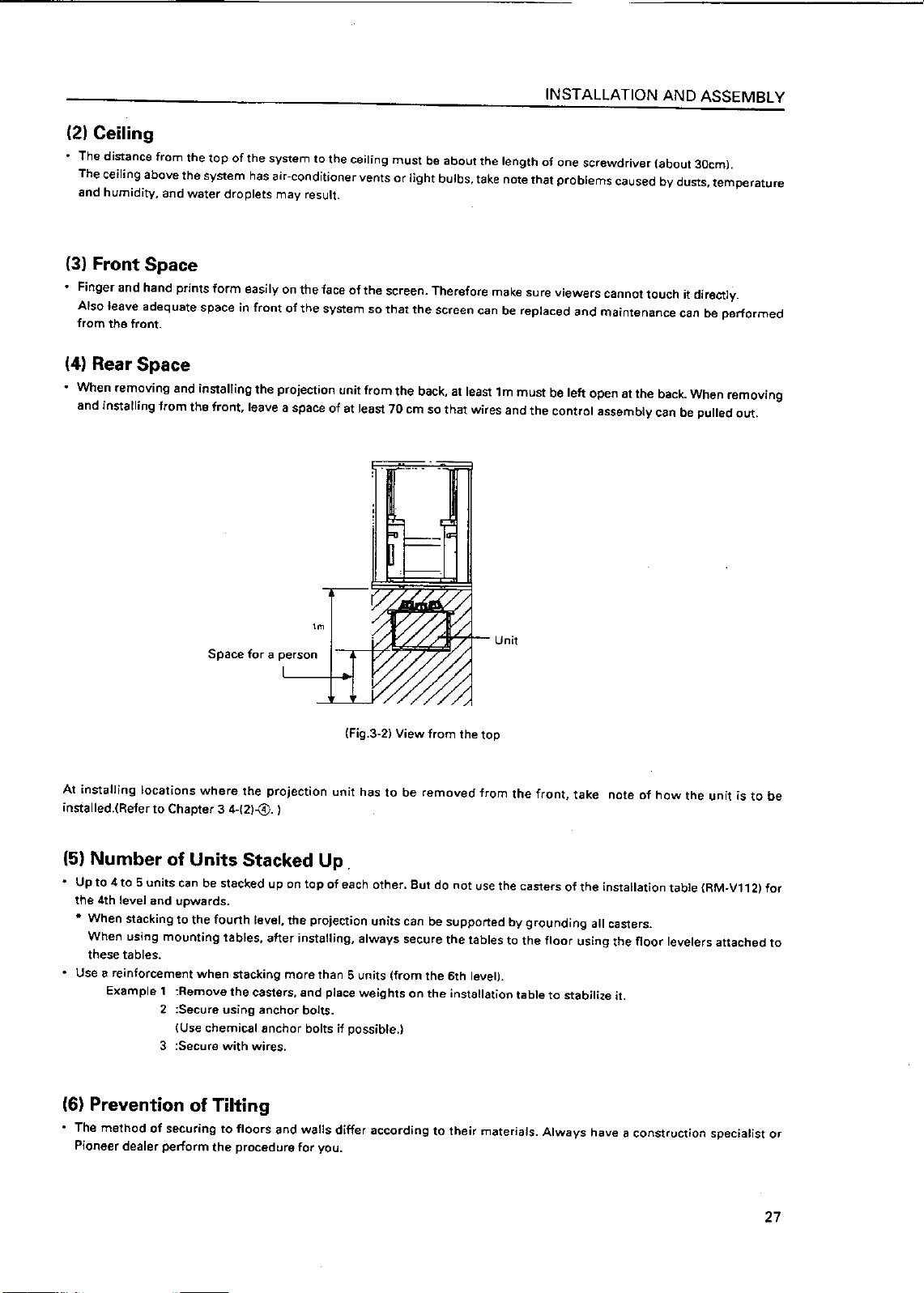

(2) Ceiling .............................................................................................................................................................. 27

(3) Front Space ..................................................................................................................................................... 27

(4) Rear Space ...................................................................................................................................................... 27

(5) Number of Units Stacked Up ......................................................................................................................... 27

(6) Prevention of Tilting ....................................................................................................................................... 27

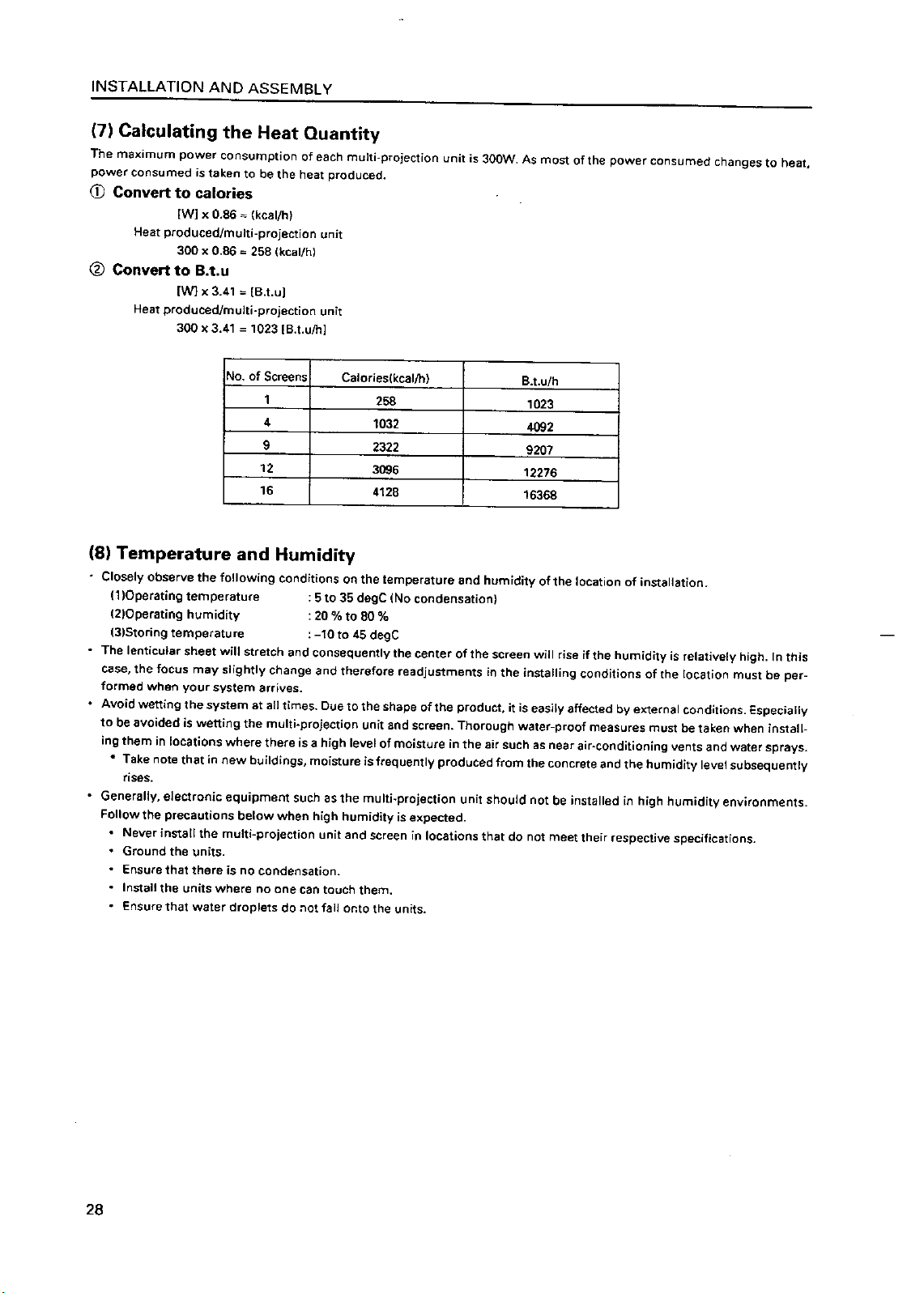

(7) Calculating the Heat Quantity ........................................................................................................................ 28

(8) Temperature and Humidity............................................................................................................................ 28

(9) Ventilation for system .................................................................................................................................... 29

(10) Condensation ................................................................................................................................................ 30

(11) Visible Angle ................................................................................................................................................. 31

(12) Lighting.......................................................................................................................................................... 34

(13) Effects of Earth Magnetism.......................................................................................................................... 34

(14) Connection with a Power Supply ................................................................................................................ 35

(15) Cables Used .................................................................................................................................................. 36

(16) Semi-outdoor Installation ............................................................................................................................ 36

(17) Precautions for Use of User-Obtained Parts .............................................................................................. 36

2. INSTALLATION AND ASSEMBLY ......................................................................................................................... 37

(1) Confirmation ................................................................................................................................................... 37

(2) Opening the Packaging .................................................................................................................................. 37

(3) Carrying the Units After Opening Packaging ............................................................................................... 43

3. PRECAUTIONS FOR TRANSPORTATION ............................................................................................................. 44

4. ASSEMBLING THE SYSTEM ................................................................................................................................. 45

(1) Assembling the Projection Frame (RMF-V4011/V5011) ............................................................................... 45

(2) Assembling the System ................................................................................................................................. 46

5. SPECIAL INSTALLATION ....................................................................................................................................... 60

(1) Wall inset ......................................................................................................................................................... 60

(2) Diagonal installation....................................................................................................................................... 60

(3) Architrave processing .................................................................................................................................... 60

(4) Upside down installation ............................................................................................................................... 60

(5) Hanging from ceiling...................................................................................................................................... 60

CHAPTER 4. ADJUSTMENTS ............................................................................................................ 61

1. ADJUSTMENT PREPARATIONS ........................................................................................................................... 61

(1) Wiring .............................................................................................................................................................. 61

(2) Wiring Handling .............................................................................................................................................. 61

(3) Aging ............................................................................................................................................................... 61

2

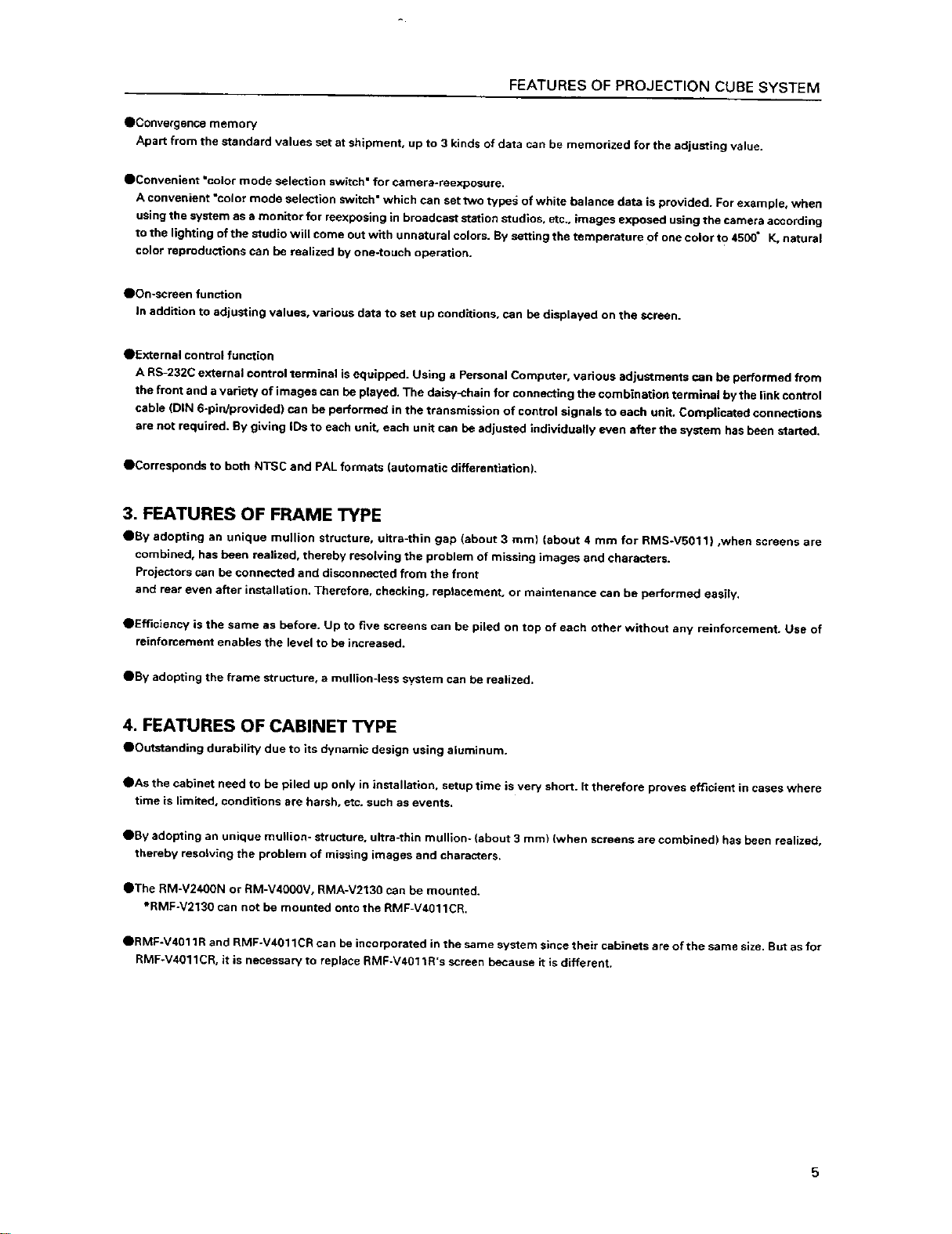

Dimensions

545

GENERAL SPECIFICATIONS

490

540

380

40

(Fig.2-1)

7

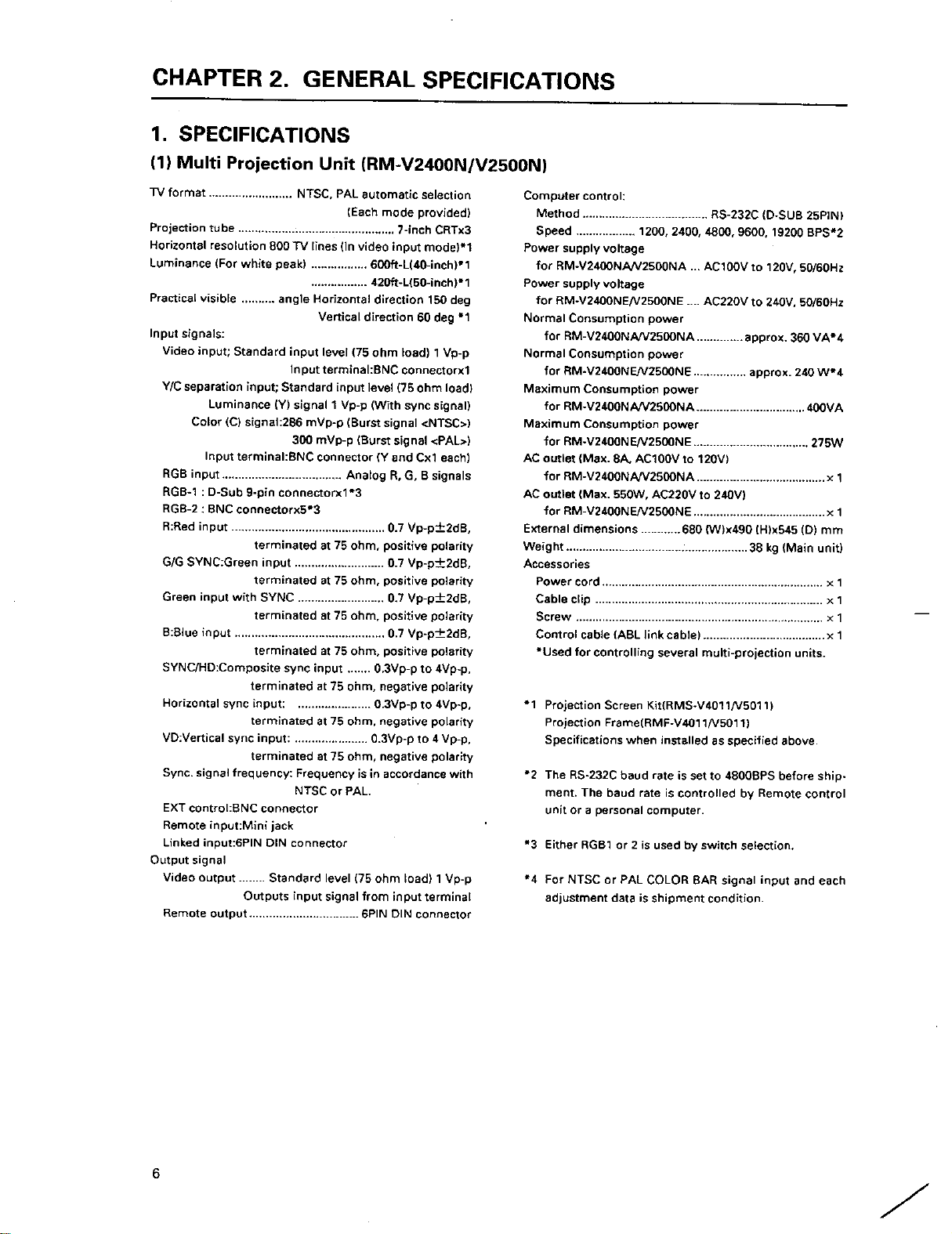

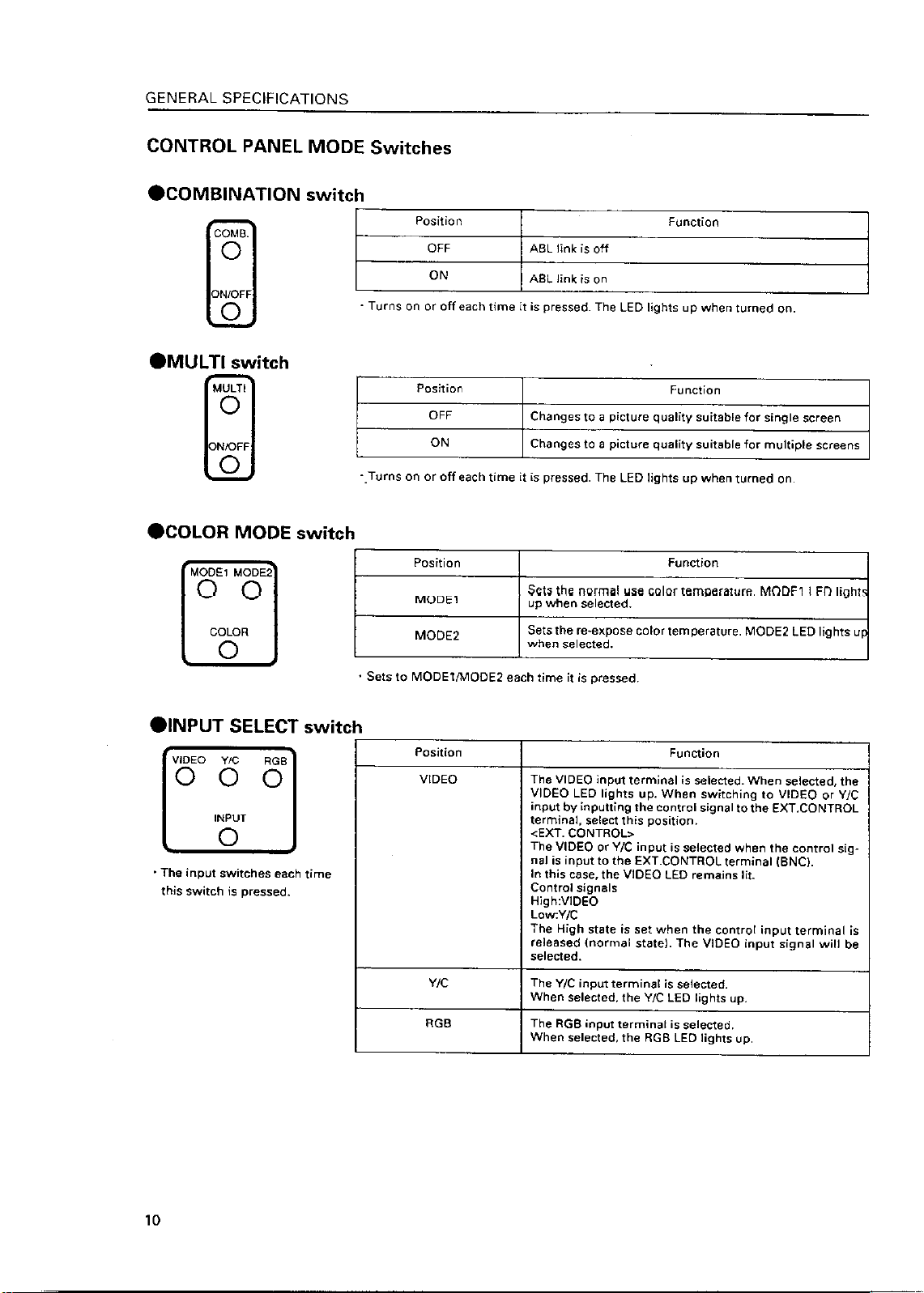

GENERAL SPECIFICATIONS

Power Supply Panel

1

3

3

1

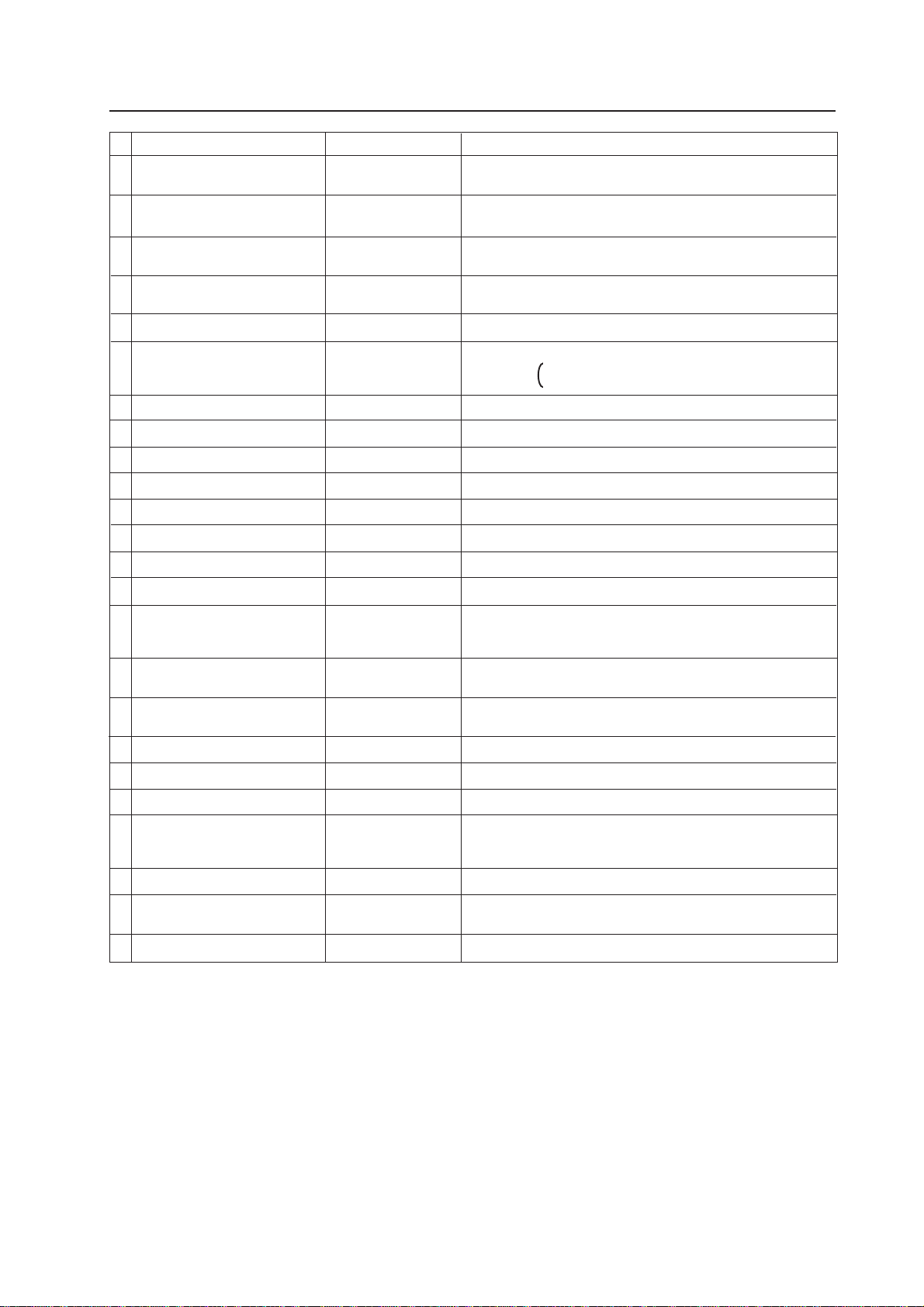

No.

1

2

3

Main power switch

4

Name

AC inlet

AC outlet

RM-V2400NA/V2500NA

2

See-saw switch

Type

RM-V2400NE/V2500NE

4

(Fig. 2-2)

Connects AC power cord.

Connects other multi-projection units. Not linked to main power

switch. Note 1)

Turns on and off the power supplied to the main unit. Sets into

the standby state when turned on.

2

Function

4

Note 1) Refer to page 35 [(14) Connection with a power supply 3 Connection].

Fuse holder

Stores the fuse. No-one except serviceman should touch this part.

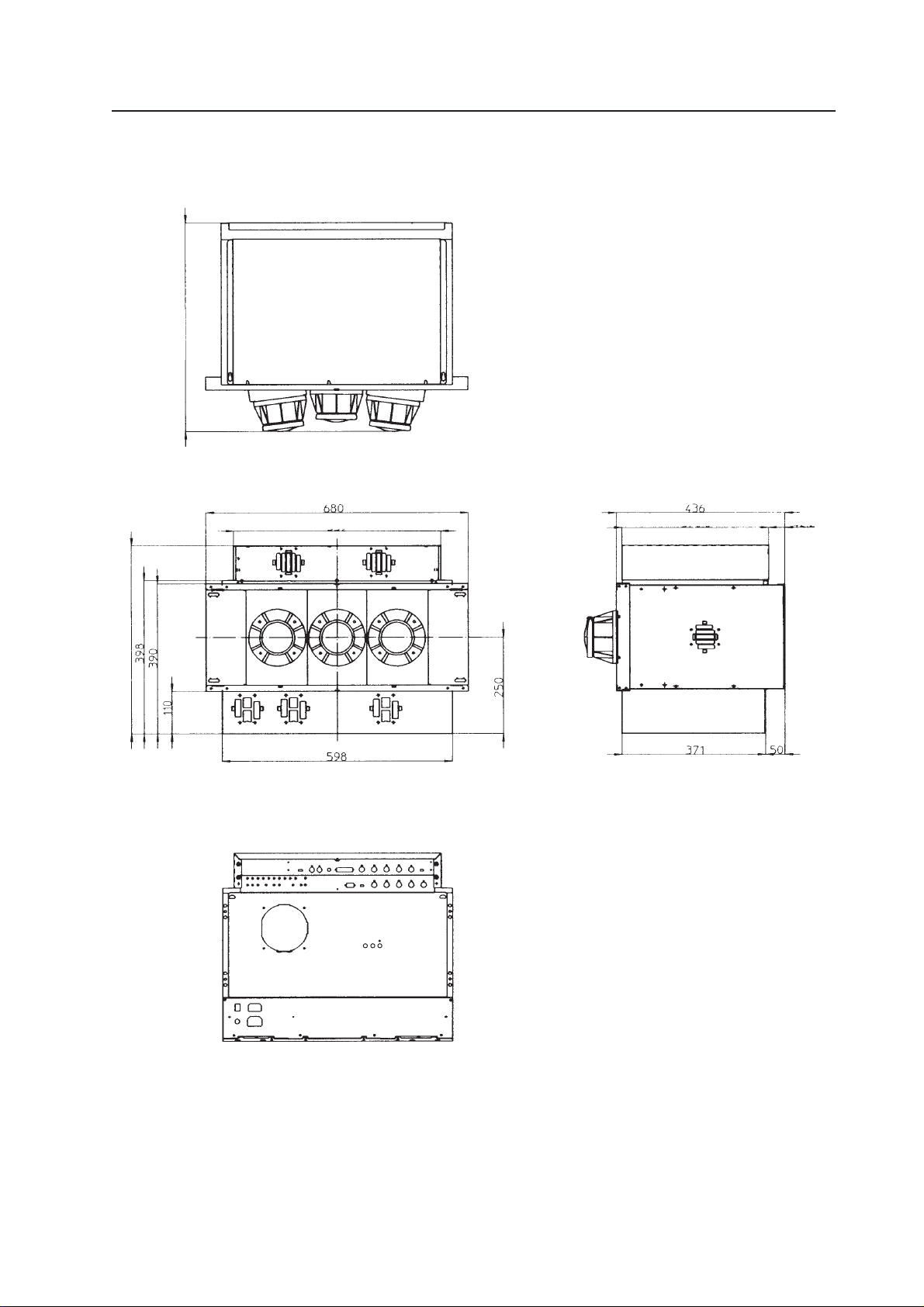

Control Panel

(Fig. 2-3)

8

GENERAL SPECIFICATIONS

No.

1

ABL link switch

2

Linked input terminal

3

Linked output terminal

4

Remote control connection terminal

5

RS-232C port

6

Control input terminal

7

Y (Luminance) input terminal

8

C (Color) input terminal

9

Video input terminal

0

Video output terminal

-

TERMINATE switch

=

COMBINATION switch

~

MULTI switch

!

COLOR MODE switch

@

INPUT switch

Name

Type

Slide switch

DIN 6PIN

DIN 6PIN

Mini jack

D-sub 25 PIN (Female)

BNC connector

BNC connector

BNC connector

BNC connector

BNC connector

Slide switch

Tact switch

Tact switch

Tact switch

Tact switch

Function

Used for switching the control level of the ABL link control voltage

when ABL link is ON.

Input terminal of ABL signal, remote control signal and RS-232C

signal

Output terminal of ABL signal, remote control signal, and RS-232C

signal

Connected to adjusting remote control (optional)

RS-232C communication connector

Video input and Y/C input external switching control signal input

terminal Normal(video signal input) : Open

Select Y/C input : Low(0V)

Luminance signal input terminal

Color signal input terminal

Video signal input terminal

Video input terminal 9 through-out terminal

Turns on when terminates the video input terminal 9 at 75 ohm

Turns on when linked to ABL

Turns on when used on multi screen

Switches the color temperature. 1:Normal use. 2:Re-exposure

Switches VIDEO input, Y/C input, RGB input.

Switches VIDEO input and Y/C input with the external control signal

6 at VIDEO position

#

POWER switch

$

STATUS switch

%

RGB input terminal

^

RGB input select switch

&

RGB input terminal (Vertical sync)

*

RGB input terminal

(Horizontal sync/composite

sync)

(

RGB input terminal (B)

)

RGB input terminal

(G/composite sync)

_

RGB input terminal (R)

• To turn off the power, use the POWER switch - of the unit, the RS-232C control, or wired remote control (optional). (If turned

off using the main POWER switch or by disconnecting the power cable from the outlet, the settings of the above = to @

switches and the state of the TV SYSTEM and convergence memory will not be recorded on the memory.)

Consequently when starting up or stopping the whole system by AC ON/OFF in setup conditions for a demonstration, it is

necessary to turn off the power using the above method to record each setting in the memory.

(Refer to "CHAPTER 4. ADJUSTMENTS, (5)Equipment Required for Adjustments".)

Tact switch

Tact switch

D-sub 9PIN (Male)

Slide switch

BNC connector

BNC connector

BNC connector

BNC connector

BNC connector

Power OFF : STANDBY (Red LED) lights up

Power ON : ON (Green LED) lights up

Accumulated duty time: * Switch which displays setting states of

each switch on the screen.

RGB signal input terminal

Switches RGB signal input terminal type

RGB signal vertical sync input terminal

RGB signal horizontal sync and composite sync (Only for input sig-

nal H/V sync) input terminal

RGB signal B input terminal

RGB signal G and composite sync (Input signal G on sync) input

terminal

RGB signal R input terminal

* : Accumulated duty time

Counts only when the power is ON.

9

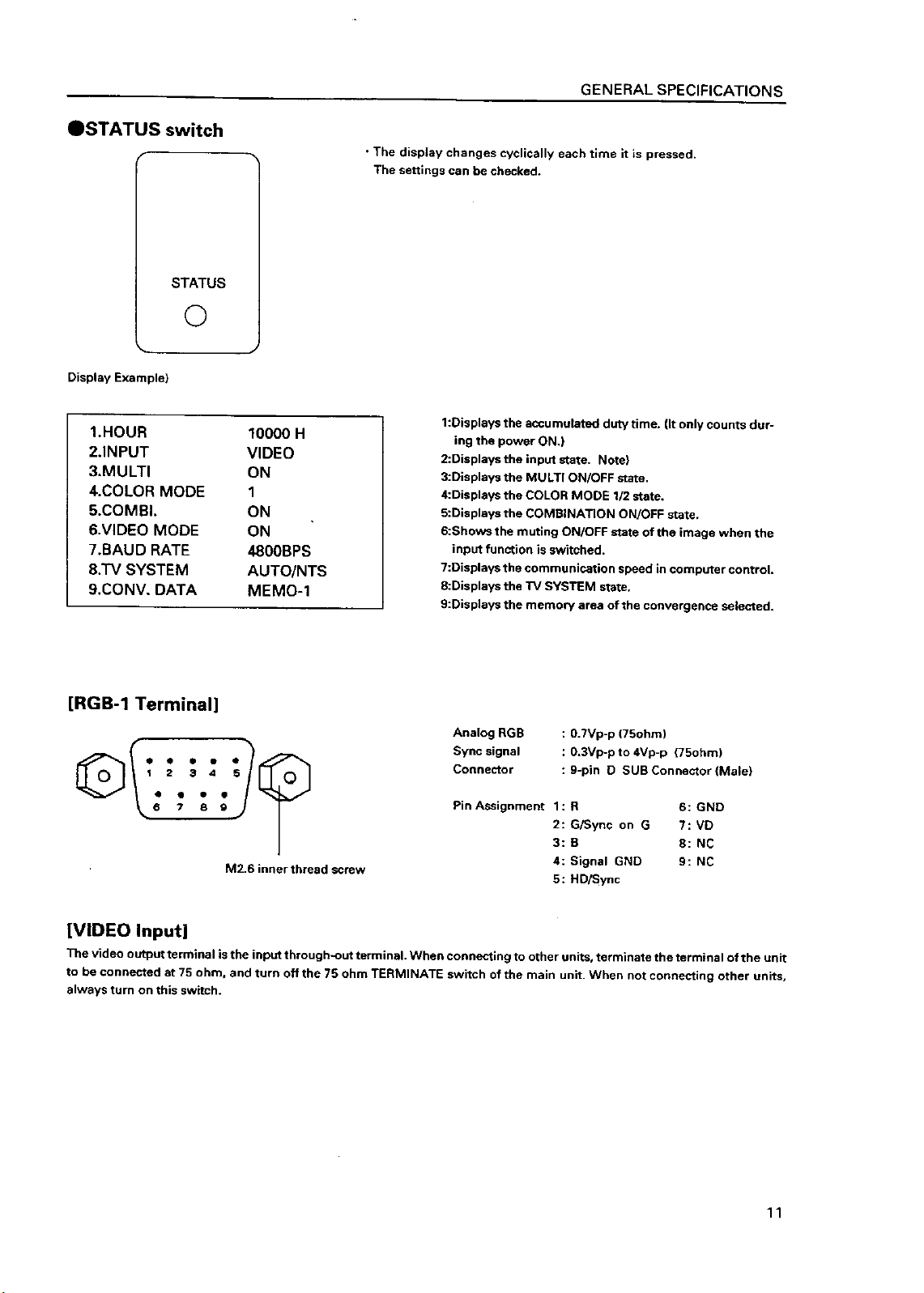

GENERAL SPECIFICATIONS

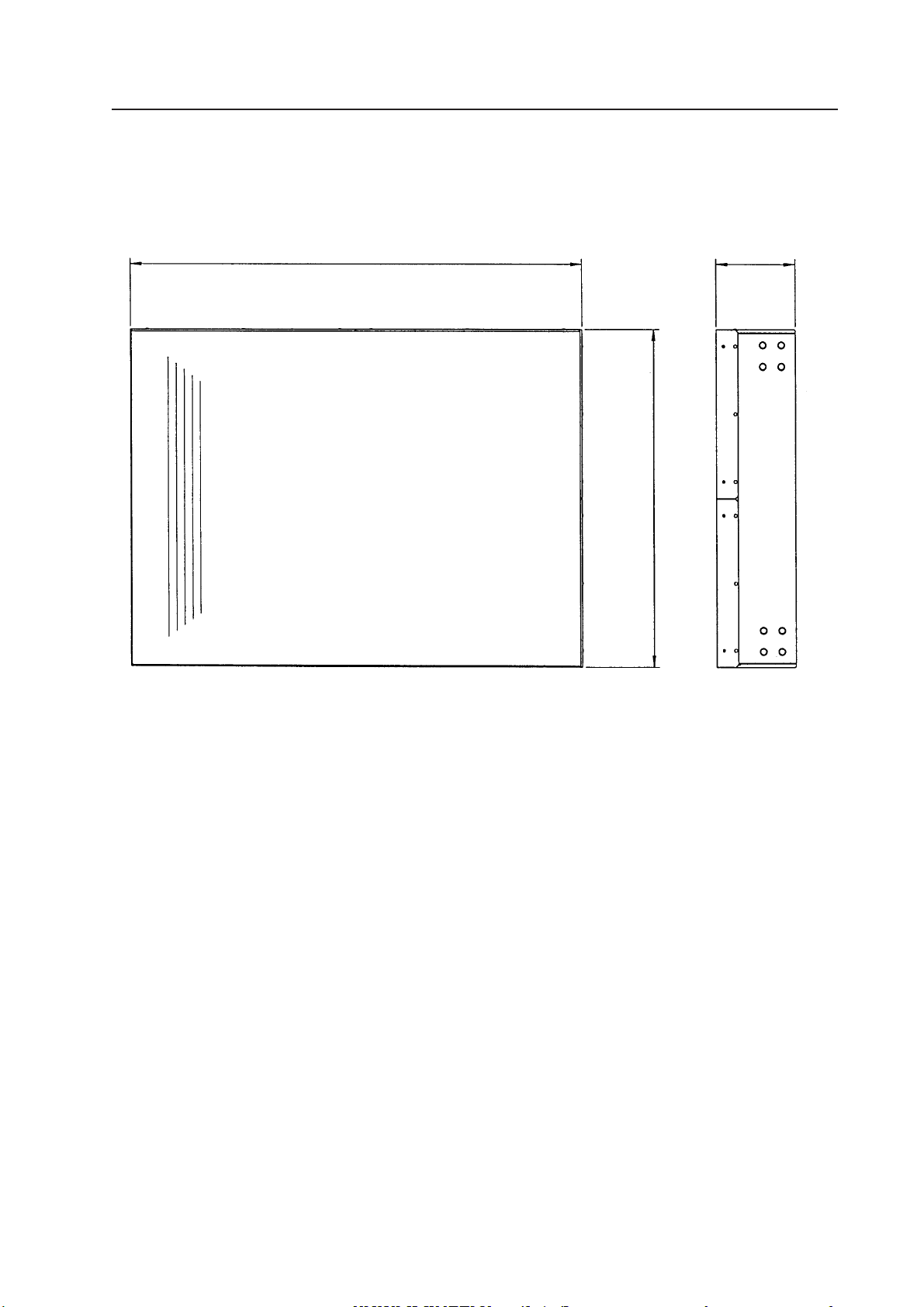

(2) Projection Screen Kit (RMS-V4011/V5011) Product Weight : 11.0 kg/14.0kg

845

(1031)

148

(148)

630

(769)

(Fig.2-4)

Accessory

Screw rivet ........................................................................................................................... 6

Unit:mm

The number in parentheses is

the dimentsion for RMS-V5011

13

GENERAL SPECIFICATIONS

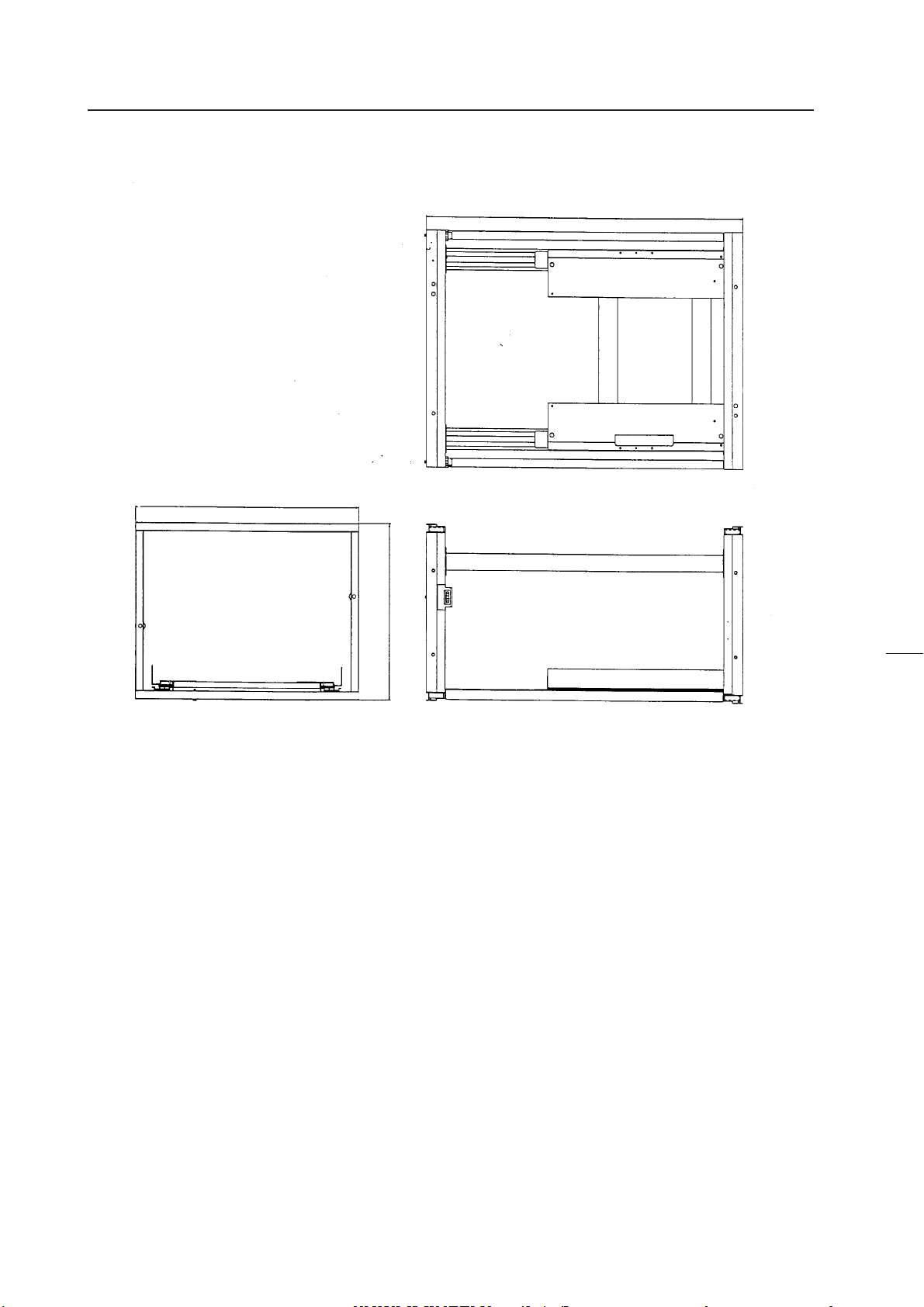

(3) Projection Frame (RMF-V4011/V5011) Product Weight : 26.8kg/28.8kg

1201(1352)

845(1031)

630

(769)

(Fig.2-5)

Accessories

Metal fixture (R) ................................................................................................................... 1

Metal fixture (L) ................................................................................................................... 1

Stopper ................................................................................................................................. 2

Screw M5x10 ................................................................................................................. 38+2

Screw M5x35 ....................................................................................................................... 6

Screw M5x50 ....................................................................................................................... 4

Hexagon head bolt (with washer) M8x45 ..........................................................................8

Shield.................................................................................................................................... 1

Rivet ...................................................................................................................................... 2

Unit:mm

The number in parentheses is

the dimension for RMS-V5011

14

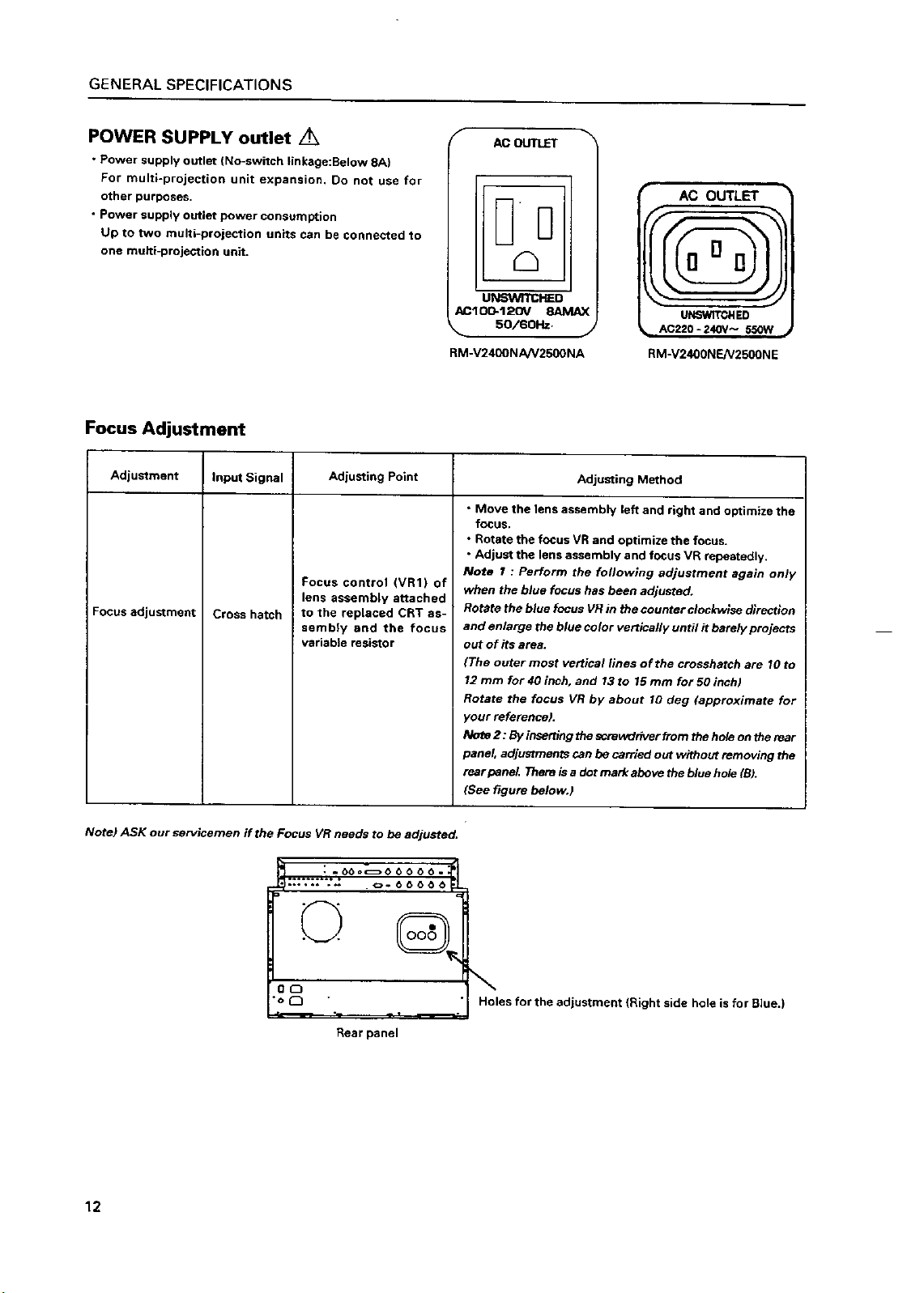

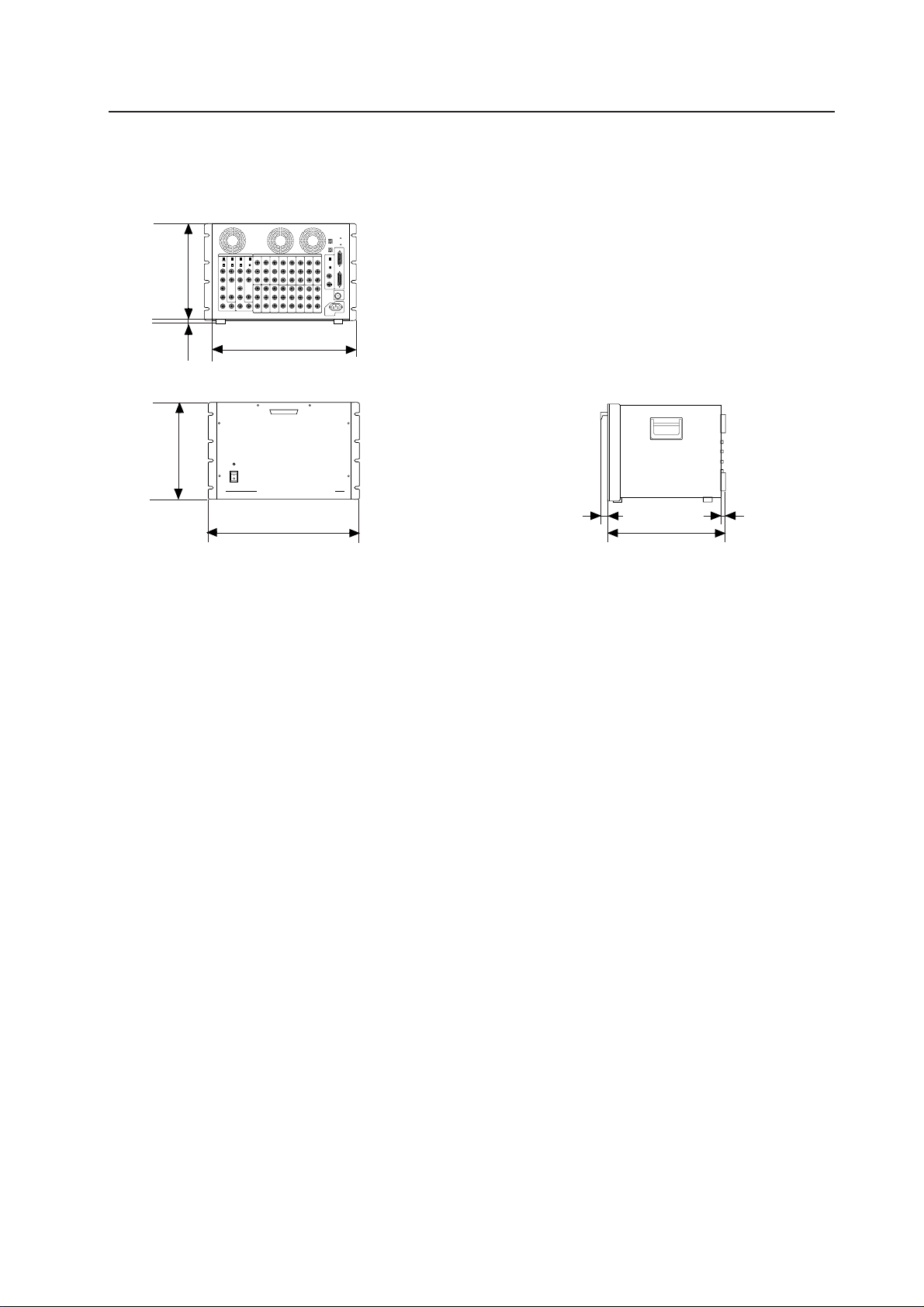

(7) Multi Video Processor (RMD-V3216/V3109, RMD-V2170)

1 Multi Video Processor (RMD-V3216/V3109)

Rear View

0

0

299

15

430

D

GENERAL SPECIFICATIONS

314

POWER

ON

OFF

MULTI VIDEO PROCESSOR RMD-V3216

482.6

Front View

Main Specifications of Multi Video Processor

(RMD-V3216/V3109)

Input signal

Input video signal (Can be expanded up to four systems)

2-line (RMD-V3216), 1-line (RMD-V3109).... BNC terminal

1 Composite video signal ...........................................

....................................... 1.0 Vp-p (75ohm terminated)

2 Y/C separation signal

Y (With sync)................................ 1.0Vp-p (75ohm)

C burst level ............................ 0.286 Vp-p (75ohm)

*1 or 2 signal format can be selected

*Only 1 has a terminate switch, throughout

Input standard sync signal.......................... BNC terminal

1 Composite sync signal ................ 0.286 to 4.0 Vp-p

2 Composite video signal

Video level ...................... 0 to 0.714 Vp-p (75ohm)

Single level ............................. 0.286 Vp-p (75ohm)

*Terminate switch, throughout

RS-232C control input 25-pin D-SUB

Output signal

Output video signal

16-line (RMD-V3216), 9-line (RMD-V3109)... BNC terminal

1 Composite sync signal ................ 1.0 Vp-p (75ohm)

2 Y/C separation signal

Y (With sync)................................. 1.0Vp-p (75ohm)

C (With burst) Burst level ....... 0.286 Vp-p (75ohm)

*1 and 2 signal formats are output simultaneously.

(Fig.2-11)

16

19

420

Side View

3 RGB signal

Green (Sync on Green) ...............................1.0 Vp-p

SYNC ........................................................... 0.3 Vp-p

B.R................................................................ 0.7 Vp-p

Output reference composite sync signal BNC terminal

TTL level

(Or input reference sync signal throughout)

Others

Power supply.............................. AC100 to 120V (50/60 Hz)

Power consumption.............................................................

............................ (RMD-V3216, RMD-V3109) 350W, 700VA

Operating temperature and humidity range ......................

........................................................................... 5 °C to 35 °C

Below 85% (No condensation)

External dimensions (RMD-V3216, RMD-V3109) ...............

................... 482.6 (Width)x420 (Depth)x314 (Height) (mm)

(Excluding handle)

Weight

RMD-V3216 ............................................................... 22.5 kg

RMD-V3109 ............................................................... 22.0 kg

Accessories

Rack mounting screw M5.................................................. 8

Rack mounting washer...................................................... 8

19

GENERAL SPECIFICATIONS

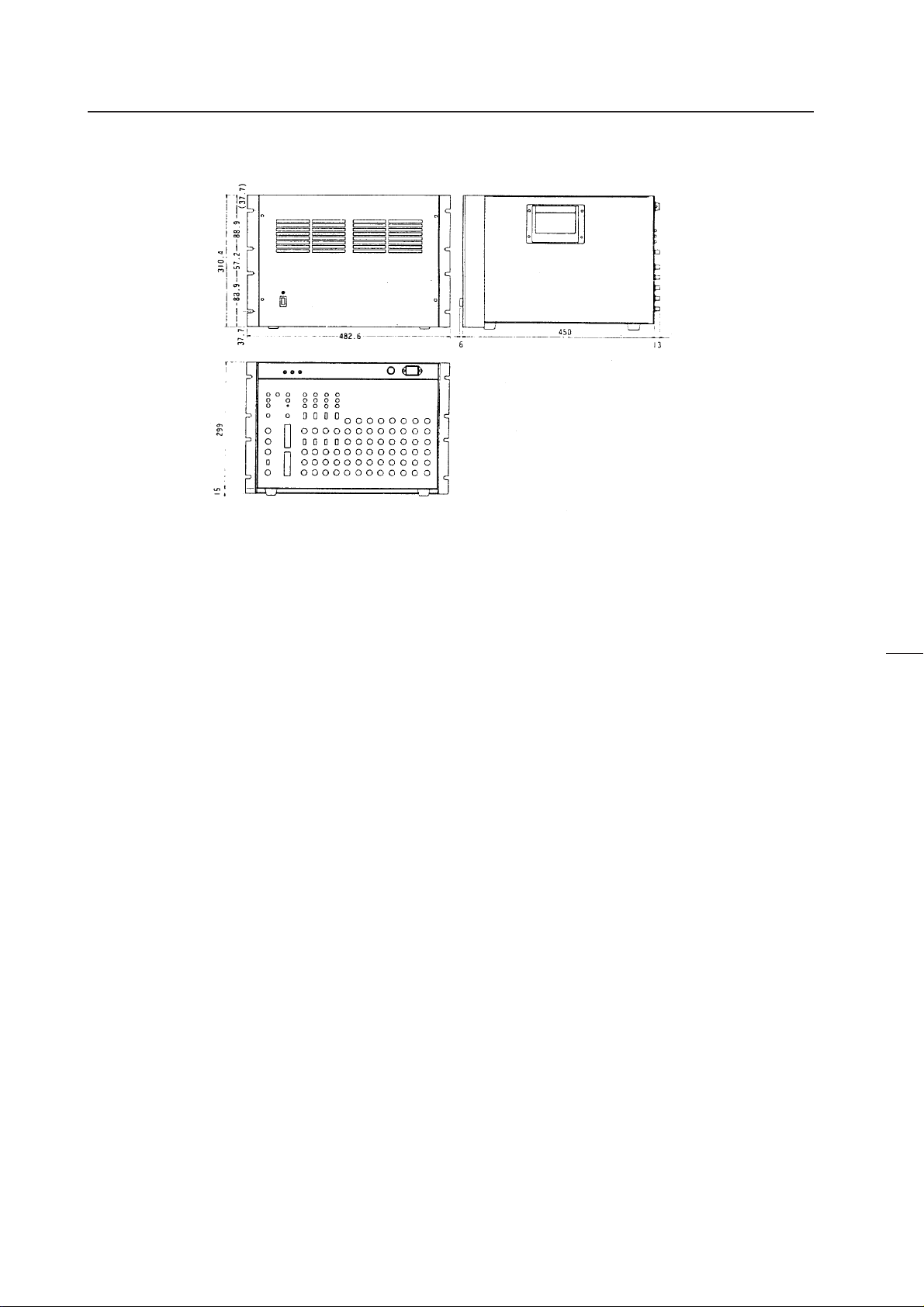

2 Multi Video Processor (RMD-V2170)

Front View

Rear View

(Fig.2-12)

Main Specifications of Multi Video Processor (RMD-V2170)

Input video signal ......................................... NTSC format

Input signal band ...................................... Above 4.2 MHz

Output

Video output

Input

Video input

Input signal ..............................................................

.....................NTSC composite video signal (BNC)

Input system ...................................................4-line

Standard input level.................... 1Vp-p (75 load)

Y/C separation

Input signal .... NTSC Y/C separation signal (BNC)

Input system ...................................................4-line

Standard input level............... Y:1 Vp-p (75 load)

.................... C:286 mVp-p (75 load burst signal)

*The video input or Y/C separation input is to be

selected by the switch on the rear panel.

Reference sync signal input

Input signal ............................. Composite sync (BNC)

Standard input level .....................................................

...................................... Composite sync 0.3 to 4 Vp-p

Control input

Input signal .... Conforms to RS-232C (25-pin, D-sub)

Y/C separation output

Test signal output

Output signal .................................................................

............................ NTSC composite video signal (BNC)

Standard output level ....................... 1Vp-p (75 load)

Sync signal output............................... TTL level (BNC)

Power supply voltage ...................... 100 to 120V, 50/60 Hz

Power consumption ....................................... 300W/500VA

External dimensions ............483 (W)x314 (H)x469 (D) mm

Weight.......................................................................... 33 kg

Side View

Output signal ............................................................

...................... NTSC composite video signal (BNC)

Output system ............................................... 16-line

Standard output level .................. 1Vp-p (75 load)

Output signal ...NTSC Y/C separation signal (BNC)

Output system ............................................... 16-line

Standard output level ...............Y1 Vp-p (75 load)

......................C286 mVp-p (75 load, burst signal)

*Line up series of RMD-V2110 with 9 OUTPUT CIRCUITS.

20

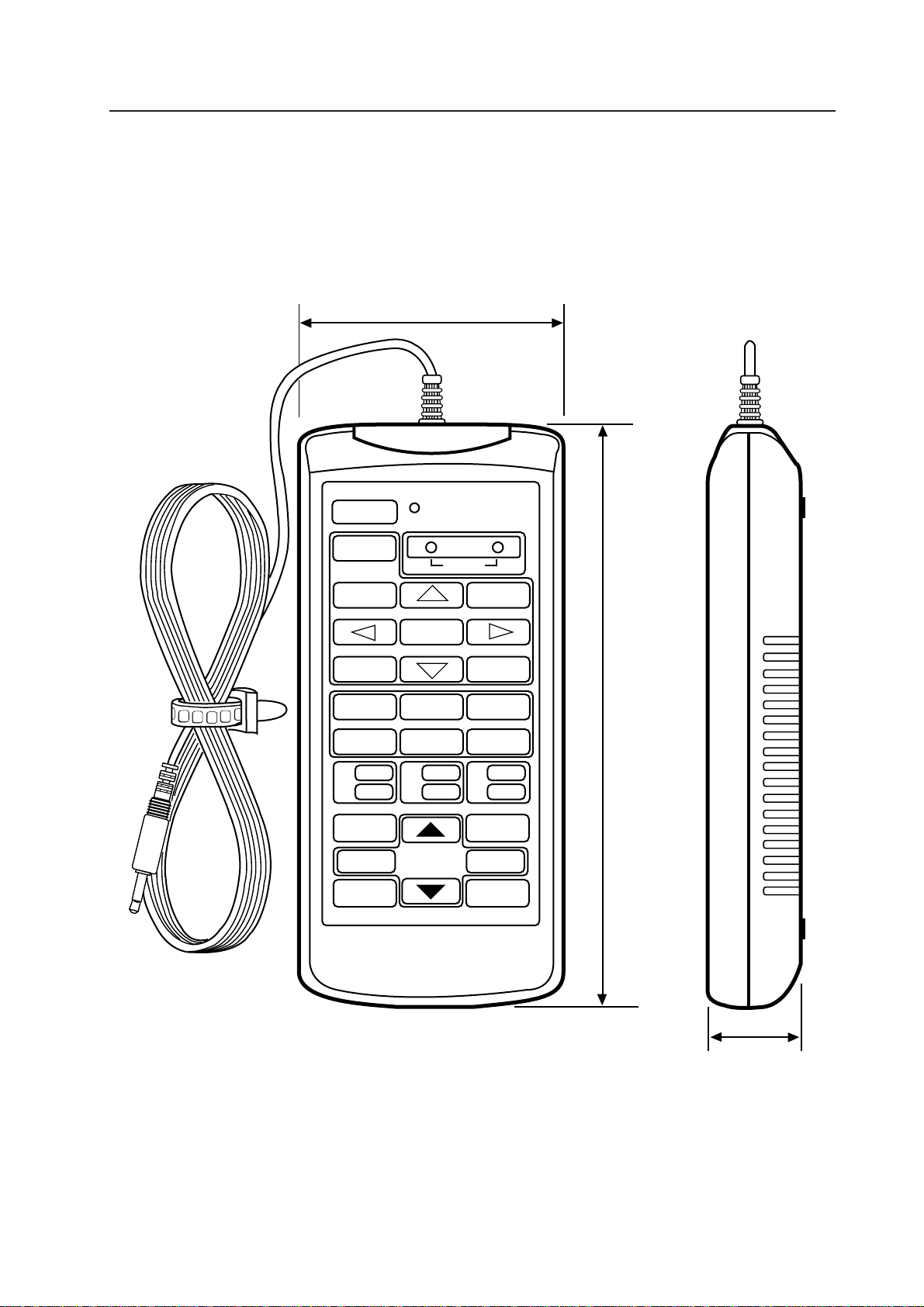

(8) Adjustment Control Unit (RU-V107)*Option

84

GENERAL SPECIFICATIONS

POWER

0

13

46

79

D

ADJUSTMENT CONTROL UNIT

RU-V107

ADJ IN

2

5

8

Î

ABC

DEF

ADJ ADJ ADJ

RGB

ON/OFF ON/OFF ON/OFF

INPUT SEL

2

//

–+

DISP CALL

MAIN MENU

3

ADJ OUT

187

Cable length : 5m

(Fig.2-13)

Accessories

AA dry battery (IEC R6P)......................................................................................................2

Cable (5m) ............................................................................................................................ 3

29

21

GENERAL SPECIFICATIONS

(9) Projection Cabinet (RMF-V4011R) Accessories

To attach the multi-projection unit (RM-V2400N) to the conventional RM-V2000A, the RMF-V4011R accessories (metal fixtures) are required. The following lists the required parts. For details of attaching the multi-projection unit, refer to Chapter 3.

"4-(2)Assembling the System".

Frame R (BNG1207) ....................................................................................................... 1

Frame L (BNG1208) ....................................................................................................... 1

Holder (R) (BNG1150) .................................................................................................... 1

Holder (L) (BNG1151) .................................................................................................... 1

Attachment (R) (BNG1173)............................................................................................2

Attachment (L) (BNG1174) ............................................................................................ 2

Rear holder R (BNG1205) .............................................................................................. 1

Rear holder L (BNG1206) .............................................................................................. 1

Rear panel R (upper) (BMR1069) .................................................................................. 1

Rear panel L (upper) (BMR1070) .................................................................................. 1

Rear panel R (lower) (BMR1071) .................................................................................. 1

Rear panel L (lower) (BMR1072)................................................................................... 1

Cushion A (BMR1106) ................................................................................................... 1

Cushion B (BMR1107)....................................................................................................2

Hinder panel (BMR1075) ...............................................................................................2

Adjuster (BEF1011) ........................................................................................................2

Screw (M5x15) (PMB50P150FZB) ...............................................................18 (Spare 2)

Screw (M5x50) (PMB50P500FZB) ................................................................................. 4

Screw (M6x20) (PMB60P200FZB) ................................................................................. 4

Screw (3x12) (ABA1167)................................................................................................4

Screw (3x8) (BBZ30P080FZK) ..................................................................................... 10

Nut (M8) (NA80FZK) ......................................................................................................2

Note : RM-V4000V can assemble with the same accessories.

22

INSTALLATION AND ASSEMBLY

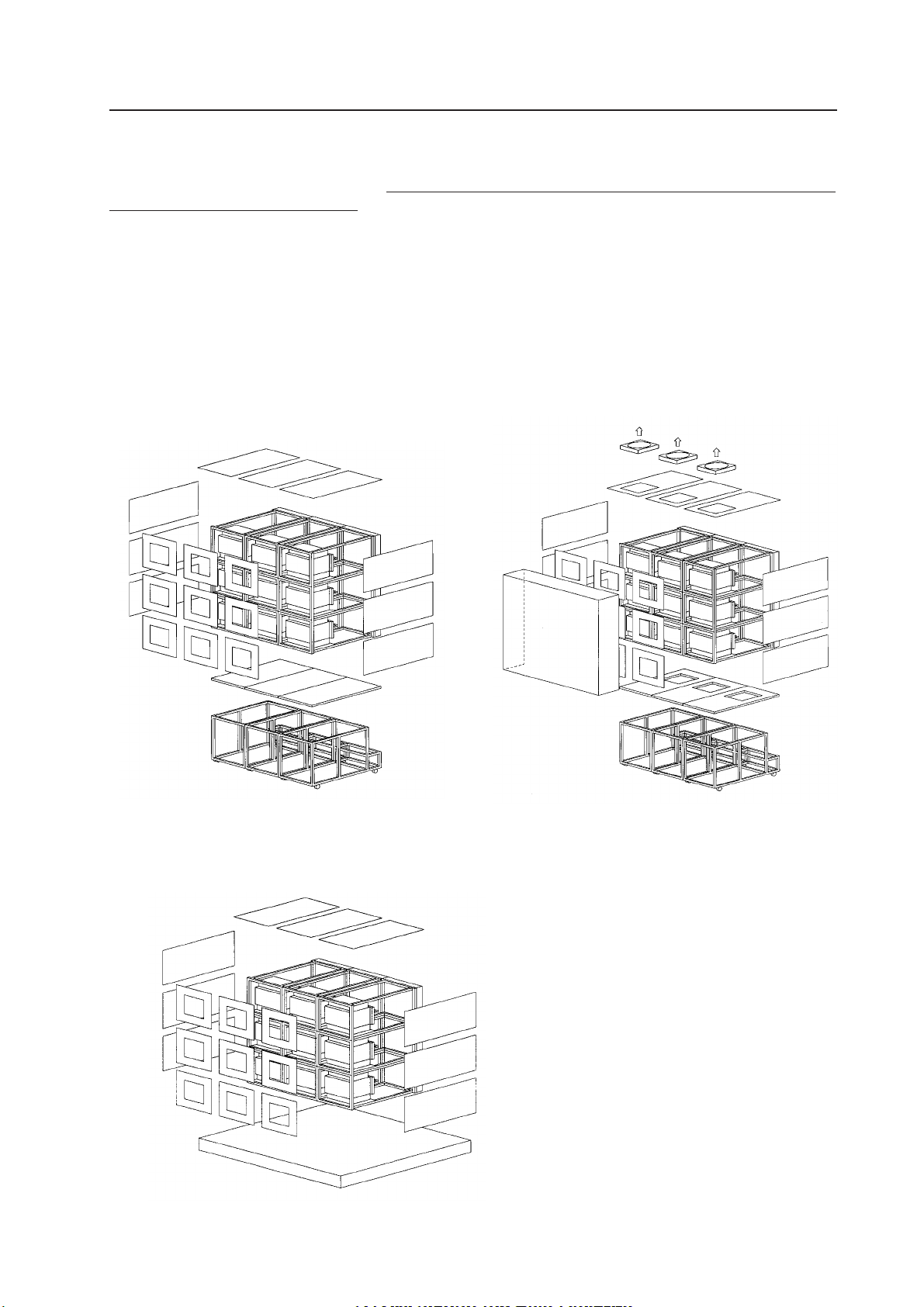

(9) Ventilation for system

The ventilation method differs according to where the system is installed. The following shows how to provide ventilation for

the units according to the place of installation. Refer to these and keep the installation condition in the previous section [(8)

Temperature and Humidity] at the system.

But when installing your unit, consult your dealer.

1 When there are no walls on all sides (within 1m)

As shown in Fig. 3-3, attach the top panel, side panel, and rear panel.

(Note)

When attaching the rear panel, be careful not to block the vents for the fan of the projection unit.

2 When there is a wall at the back *

As shown in Fig. 3-5, mount a large fan to the top panel, provide vents for inhaling air at the bottom panel to blow out air

inside. Always leave more than 300 mm between the wall and the back of the unit.

(Fig. 3-3)

3 When blocking the bottom (when placing the projection unit on the floor directly) *

Same as 1. (Fig. 3-6)

<Note>

*: There should be no obstacles within the 1m area of the

unit except for the rear and bottom. If this condition is

not followed, construct your own ventilation system

(large fan, low temperature by air-conditioning, etc.)

(Fig. 3-6)

according to the site of use.

(Fig. 3-5)

29

INSTALLATION AND ASSEMBLY

(10) Condensation

One problem that occurs in the winter season is "Condensation". When the temperature of the room in which the multiprojection unit system is installed rises suddenly, condensation occurs on the screen and lens, thereby the system cannot

display its best performance. In such cases, turn off the power once, leave the system off for one hour, and turn on the power

again. Increasing the room temperature gradually is another method.

30

INSTALLATION AND ASSEMBLY

4 3P Plug

The power cord of this unit has a 3P plug. This is to prevent electric shocks caused by leaked currents. Always connect it to a

3P outlet.

5 Leak Breaker

The unit is incorporated with the power line filter to reduce noise. Therefore a 0.5 mA leakage current will flow with each unit.

If a leak breaker is equipped, check that its sensitive level is above the total leakage current of the system.

Also calculate each unit such as image transmission unit, etc. as 0.5 mA.

It is extremely dangerous to supply power from existing wall outlets, etc.

Position the final outlet connected to each unit of this system as near as possible to the system.

Set the current capacity slightly greater-about more than 25% of the total consumption power.

(15) Cables Used

Use coaxial cables. Normally use a 3C-2V for less than 20m long. Use 5C-2V for greater lengths. 5C-2V is recommended for

high-vision.

Adjust the length of the cables. The distance between the transmission system and multi-projection unit should be as short as

possible. When the distance is great, consider the thickness of the cable and electrical compensation carefully.

The limit is as shown when using the cables to connect the transmission final output terminal and the system.

3C-2V: 15m

5C-2V: 30m

To use a longer cable, the VIDEO signal must be corrected.

(16) Semi-outdoor Installation

This system is basically designed for use indoors. However, if it has to be installed outdoors, take note of the following.

• Waterproof and rustproof measures

• Temperature difference and humidity difference

• Light on the screen (So that it is not exposed to direct sunlight.)

• Wind containing salt

(17) Precautions for Use of User-Obtained Parts

It is recommended that Pioneer products be used for the projection stand, mount unit, etc. Users obtaining these parts separately by themselves should take note of the following.

• When obtaining stands and mount units separately, make sure that the system can be installed horizontally. Also calculate

strength properly and take adequate measures against tilting of the screen. If the recommended stand and mount unit are

not used, Pioneer will bear no responsibility whatsoever for accidents and injuries incurred due to incomplete connections

and mounting, natural disasters, etc.

• When mounting top board, side board, rear panel obtained separately, use the holes for mounting the Pioneer stand and

projection frame. (Refer to Fig. 3-39)

36

INSTALLATION AND ASSEMBLY

2.INSTALLATION AND ASSEMBLY

(1) Confirmation

1 Decide the position for installing the system according to the installation conditions in Chapter 3.

Check Items

[1] Dimensions of installing position, space at the back, distance to the ceiling

[2] Floor flatness, strength, roughness

[3] Position of power supply

[4] Installing location

Necessity ti strengthen the floor, wall, etc.(reinforcement cover, sheet, plank, etc.), path used to transport the system,

width of passage, if elevator is available , its size and maximum bearing weight, etc.

[5] Position, specifications, and structure of a transmission equipment, and image type

[6] Model number of equipment used, and their quantity (perform according to list).

Check if there is enough equipment for each unit

*These procedures must be performed by only one person.

(2) Opening the Packaging

1 Packaging specifications

[1] Multi Projection Unit (RM-V2400N/V2500N) : 770(W) × 630(H) × 670(D) 43.5kg

[2] Projection Screen Kit (RMS-V4011) : 940(W) × 230(H) × 730(D) 15.7kg

(RMS-V5011) : 1126(W) × 230(H) × 879(D) 20.2kg

[3] Projection Frame (RMF-V4011) : 950(W) × 180(H) × 1300(D) 31.2kg

(RMF-V5011) : 1160(W) × 250(H) × 1475(D) 35.4kg

[4] Projection Cabinet (RMF-V4011R) : 1006(W) × 859(H) × 1454(D) 68.0kg

(RMF-V4011CR) : 1007(W) × 867(H) × 1393(D) 58.0kg

2 Opening the packaging

Open from the big ones first and put the small packagings inside the empty big packagings. Also dispose or store the

packagings.

Do not mix up the opened items with those still in the packaging.

Move the empty packagings somewhere else so that they will not come in the way. Next, obtain an assembly space that is as

wide as possible.

* Turn down the opened packagings upside down to differentiate them from those not opened.

Do not lose accessories, the warranty card, etc.

37

INSTALLATION AND ASSEMBLY

3 Multi Projection Unit (RM-V2400N/V2500N)

[1] Open the upper carton.

[2] Remove the upper carton.

[3] Remove the upper pad and remove the AC power cord, ABL cable and instruction manual provided.

[4] Take out the unit (must be taken out by two persons).

[1]

[3]

Upper carton

[2]

Upper pad

[4]

Accessories

38

(Fig.3-12)

INSTALLATION AND ASSEMBLY

4 Projection Screen Kit (RMS-V4011/V5011)

* Projection screen kit is double-packaged to maintain its performance. After removing the middle cover protecting its screen,

make sure the screen does not get scratched or dirty.

[1] Remove the top cover.

[2] Remove the band securing the middle cover and remove the middle cover.

[3] Gently peel off the black tape pasted at the four sides of the screen.

Be careful not to damage the lenticular sheet.

[4] Take out the screen unit from the box and stand it on a flat floor, paying attention to its top and bottom.

[5] Remove the eight screws for transportation (gold), four protection panels, white sheet at the back of the screen, and the

bag containing accessories attached to the top of the frame.

* The protection panel is attached with the transportation screws. Keep the removed panel if required. When storing

the system, do not remove the outermost protection panel.

[6] When opening the packagings of several units first, after opening them, place them in a different place to protect them

from damage, and place a sheet over them to protect them from dusts.

[1]

[3]

Transportation screws (Eight : Gold)

Protection panel

Top cover

Black tape

[2]

[4]

Flat floor

Bag containing

accessories

Instruction manual

Middle cover

Band

Bag containing

accessories

Top

Right side

[5]

White sheet

(Fig.3-13)

39

INSTALLATION AND ASSEMBLY

5 Projection Frame (RMF-V4011/V5011)

[1] Open the upper carton and cut the PP bands (eight) securing the internal parts.

[2] Remove the two horizontal frame assemblies (packaged in a card box), fixtures (R) and (L).

[3] Remove the H-shape frame assembly (L).

[4] Remove the base assembly.

[5] Remove the H-shape frame assembly (R).

[6] Remove the shield attached to the under carton, bag containing accessories, and instruction manual.

Upper carton

Bag containing accessory

Fixture (R)

H-shape frame assembly (L)

Base assembly

Band A

Horizontal assembly

Fixture (L)

H-shape frame assembly (R)

Shield

40

(Fig. 3-14)

6 Projection Cabinet (RMF-V4011R)

[1] Open the upper carton and remove packings B and C, and the instruction manual.

[2] Remove the upper carton.

[3] Remove the top sheet B and peel off the front and back sheets B.

[4] Remove the cabinet. (Hold the handle of the cabinet by two persons.)

[5] Remove sheet B.

[6] Remove the parts from the under carton.

Upper carton

INSTALLATION AND ASSEMBLY

Pat

Pat

Sheet B

Sheet B

Under carton

(Fig. 3-15)

41

INSTALLATION AND ASSEMBLY

7 Projection Cabinet (RMF-V4011CR)

[1] Open the upper carton and take out pats A and B and the Instruction Manual.

[2] Remove the upper carton.

[3] Remove the upper sheet.

[4] Take out the cabinet.

(This should always be performed by two persons holding the handle. As the front of the cabinet is heavy, be careful not

to scratch the screen when taking it out.)

[5] Remove the lower sheet.

[6] Remove the parts from the under carton.

Upper carton

Pat A

Under carton

Pat B

Sheet

Sheet

42

(Fig. 3-16)

INSTALLATION AND ASSEMBLY

(3) Carrying the Units After Opening Packaging

To carry the screen unit and multi-projection unit after opening the packaging, hold them by the parts shown in the figure, and

lift and move them.

Handle position

Screen Unit

(Lifted by one or two persons)

Hold the parts indicated by

(Fig. 3-17)

• Never drag the system along the floor when moving the units.

• The lenticular sheet damages very easily as it is very thin. Therefore move it gently and do not apply excessive shock or

vibration to it.

• As the panels supporting the screen are very thin and deform easily, be careful that they do not hit or get hooked onto

surrounding objects when moving them.

Multi-Projection Unit

(Must be lifted by two persons)

43

INSTALLATION AND ASSEMBLY

4. ASSEMBLING THE SYSTEM

(1) Assembling the Projection Frame (RMF-V4011/V5011)

Assemble the projection frame as follows.

[1] Mount the stopper onto the base assembly and tighten the screws (M5 × 35). (2 × 2 points)

[2] Mount the H-shape frame assemblies (R) and (L), and tighten the screws (M5 × 10). (4 × 4 points)

[3] Mount the horizontal frame assemblies (two) and tighten the screws (M5 × 10). (4 × 4 points)

* As for the positions for tightening the screws in steps [2] and [3], push the frame against the corner fixtures in the two

directions indicated by the arrow.

[4] Attach the shield to the H-shaped frame assembly (L) using rivet, and paste the magic tape on the H-shaped frame

assembly (L) according to the magic tape pasted on the shield.

[5] Attach the fixtures (R) and (L) and tighten the screws (M5 × 10). (3 × 2 points)

[6] Place the projection unit on the base assembly, and secure the fixtures (R) and (L) and projection unit to each other with

the screws (M5 × 10). (2 × 2 points)

[7] Secure the movable part of the base assembly with the two screws (M5 × 35).

3 Horizontal frame assembly

H-shape frame assembly (L)

4 Rivet

5 Shield

2 H-shape frame assembly (L)

1 Screw (M5 × 35)

1 Stopper

A-5

Holder (L)

Table

2 H-shape frame

assembly (R)

A-7

B-6

Screw (M5 × 35)

A-5 Holder (R)

B-5 Guide fixture

(Fig. 3-19)

1 Base assembly

45

INSTALLATION AND ASSEMBLY

(2) Assembling the System

The basic procedure for assembling the system is as follows.

1 Assemble the projection install table (RM-V112/RMA-V5010).

2 Mount a one-link mount unit . (40-inch only)

3 Assemble the projection frame (RMF-V4011/V5011). (Refer to Fig. 3-20)

4 Mount the multi-projection unit (RM-V2400N/V2500N).

5 Mount the projection screen kit (RMS-V4011/V5011). (Refer to Fig. 3-21, 22)

6 Mount the top board , side board , rear panel.

7 Mount the projection unit (RM-V2400N) to the projection cabinet (RMF-V4011R).

Mount the frame on the install table by 4 screws.

(Fig. 3-20 50 inch)

Difference

Screen side

Screen side has the difference between the board and frame.

(Fig. 3-21 40 inch)

Screen side has

the difference.

(Fig. 3-22 50 inch)

The basic procedure for assembling the system for rental-use is as follows.

1 Assemble the projection stand (RM-V112).

2 Mount the 2-link/3-link mount unit (RMA-V2050/V2060).

3' Mount the multi-projection unit (RM-V2400N) to the projection cabinet (RMF-V4011R/V4011CR).

4' Mount the projection cabinet (RMF-V4011R/V4011CR).

7' Mount the projection unit (RM-V2400N) to the projection cabinet (RMF-V4011CR).

The above procedure is recommended. It is explained below.

Rear side

1 Projection Install Tables (RM-V112/RMA-V5010)

Place the installation tables (RM-V112/RMA-V5010) at the specified position and link them together with the bolts and nuts

specified.

First tighten the bolts and nuts temporarily, and after all have been linked, check their height differences and if they are

horizontal before tightening the nuts and bolts firmly.

Do not tighten the adjusters at the legs as their final positions have to be adjusted after assembling all units.

To install at a height greater than the installation table when not using this table, make sure the strength is greater than

required.

46

INSTALLATION AND ASSEMBLY

4 Multi Projection Unit (RM-V2400N/V2500N)

The Multi-Projection Unit is designed to be mounted from the back of the cabinet normally. If sufficient space cannot be left at

the back, it can be mounted from the front.

Mount from front

(Fig.3-27)

Mount from back

a When mounting from the back

[1] Pull the table of the cabinet to the back. (Fig. 3-28)

[2] Insert the (M5 × 35) into the holes (Fig. 3-29) on the table. (To prevent the table from moving when placing the projection

unit.)

[3] Place the multi-projection unit on the table and decide the position.

The position should be so that the front of the multi-projection unit will touch the metal fixtures while the sides touch the

guide fixtures (right side as viewed from the screen side). (Fig. 3-30)

[4] Secure the multi-projection unit to the metal fixtures of the cabinet with the four (M5 × 50). (Fig. 3-31)

[5] Remove the inserted into the table at step [2], and push in until the table touches the stopper.

48

Table

(Fig. 3-29)(Fig. 3-28)

(Fig. 3-31)(Fig. 3-30)

INSTALLATION AND ASSEMBLY

b When mounting from the front

[1] Remove the two stoppers and two metal fixtures from the cabinet. (Fig. 3-32)

[2] Pull the table to the front.

[3] Insert the screws (M5 × 35) into the holes on the table.

[4] Place the multi-projection unit on the table.

[5] Attach the metal fixtures to the table.

[6] Decide the position of the multi-projection unit and attach it to the metal fixture with the four (M5 × 10). (Fig. 3-33)

[7] Remove the screws inserted into the table at step [3], and push in until the stopper can be attached.

*As there are no stoppers at the back, be careful not to push the table in excessively.

[8] Re-tighten the stopper at the initial position.

[9] Pull out the table until it touches the stopper.

[10] Secure the cabinet table to the cabinet with the two (M5 × 35).

Metal fixtures

(Fig.3-32) (Fig.3-33)

49

INSTALLATION AND ASSEMBLY

5 Projection Screen Kit (RMS-V4011/V5011)

[1] Mount the screen unit serving as the reference. Basically, mount from the center unit at the bottom.

a If the number of units arranged are odd (E.g.: 3 × 3=9 screens)

• Adjust the screen unit to the cabinet at the center of the bottom level and temporarily tighten the linking bolts. (Do not

tighten tightly.)

• Adjust the left and right balance with your hand and tighten the linking bolts tightly so that the two centers coincide.

Top view

Projection Frame

Reference Unit

Linking bolt

Adjust the left and

right balance with

your hand.

(Fig. 3-34)

Projection screen

Linking bolt

Adjust the left and

right balance with

your hand.

b If the number of units arranged are even (E.g.: 4 × 4=16 screens)

• Adjust the screen unit to the right cabinet (or left cabinet) at the center two cabinets of the bottom level and temporarily

tighten the linking bolts. (Do not tighten tightly.)

• Adjust the left side of the screen unit attached and left side of the cabinet (rights sides if the screen unit was attached to the

left cabinet at the center) so that they are aligned precisely with your hand, and tighten the linking bolts.

• Join the left side (or right side) screen unit to the unit mounted first as closely as possible.

50

Adjust so that they are aligned precisely

Reference Unit

(Fig.3-35)

INSTALLATION AND ASSEMBLY

[2] Join the next screen beside the screen mounted as the reference and mount the remaining screens in order. (Stack them

from the bottom to the top.)

[3] If necessary, attach the screw rivet (BEC1082) provided as the accessory of RMS-V4011. (Fig. 3-36)

(Fig. 3-36)

* This part is used to shield the light leaking from the big hole (ø 8) on the outermost side of the left and bottom projection

units (diagonally shaded part in Fig. 3-37) after installing the system. Use it if necessary.

Screen units with this rivet cannot be attached outside the area indicated by the standing lines in fig. 3-37.

(It will not connect to the adjoining units.)

(Fig. 3-37)

<Note>

• Do not mistake the top and bottom of the screen unit. The side with the longer screw projecting out (side with transportation

screw) is the top and the side with the 8 mm hole is the bottom.

• Before mounting the screen unit to the cabinet, check that the transportation screw, protection panel, and black tape have

been removed. (Do not remove the protection panel on the outer-most side when installing the system.)

• Always tighten the linking bolts of the cabinet and screen unit with your hands, and tighten them as firmly as possible.

• Put on gloves when stacking the screen units for protection and perform in twos.

• To prevent the lenticular sheet from damage, mount the screen unit gently and do not subject it to vibration and shock.

• When the screen units are stacked, the head of the panel fixing screws and 8 mm holes will engage. When stacking the

upper screen unit, make sure that it does not brush the lower screen unit as it has panel screws projecting out.

51

INSTALLATION AND ASSEMBLY

6 Top panel, Side panel, Rear panel

As this system is of the rear projection type, it must be enclosed to avoid exposure to external light. (Fig.3-38)

Side panel

Top panel

Side panel

(Fig. 3-29)

Rear panel

(Fig. 3-38)

52

INSTALLATION AND ASSEMBLY

3' Attaching the Multi Projection Unit (RM-V2400N) to the Projection Cabinet (RMF-

V4011R)

The figure shows the assembling procedure of the left attachment. Assemble the right attachment in the same way. The parts

on the right side of the screen are R and those on the left side are L from the view point against the screen.

(1) Attach the attachments R and L (BNG1173, 1174) to the

front of frames R and L (BNG1207, 1208) using the

screw (M5 ×15).

Frame L

(BNG1208)

Screw

Attachment L

(BNG1174)

(2) Insert the claws of holders R and L (BNG1150, 1151)

into the slits of frames R and L, rotate them as shown

in the figure, and attach using the screws (M5 × 15). (2

pieces × 2 locations).

(M5 ×15)

Holder L

(BNG1151)

(3) Insert the claws of the attachments R and L into the

rear slits of the multi-projection unit, and attach using

the screws (M5 × 15). (1 piece × 2 locations).

Attachment L

(BNG1174)

*Drop the screw-lock fluid to screws so as not to

loosen.(Right and left)

(4) Attach the parts assembled at steps (1) and (2) onto

the multi-projection unit. Attach the attachments R

and L to frames R and L.

Using the screw (M5 × 15) as shown in the figure, and

attach the attachments R and L to the rear of the projection unit using the screws (M5 × 50).

(2 screws × 2 locations).

Screw

(M5 × 15)

54

Screw

(M5 × 15)

Screw

(M5 × 50)

4

INSTALLATION AND ASSEMBLY

(5) Paste cushion A (BMR1106) to the top board of the

multi-projection unit and cushion B (BMR1107) to the

two sides at the

23

position shown in the figure after

peeling off the seal.

Cushion A

(BMR1106)

* Paste after adjusting the

center of the top board to

that of cushion A.

Cushion B

(BMR1107)

* Paste without cover-

ing the fan.

(7) Attach the attachments R and L to the unit through the

top board of the unit using the screws (M6 × 20) and

then attach attachments R and L to the unit from the

back using screws (M6 × 20). (2 screws × 2 locations).

Screws

(M6 × 20)

Screws

(M6 × 20)

*Drop the screw-lock fluid to screws so as not to loosen.

(4 points)

(6) Insert the multi-projection unit from the rear of the

unit in this state.

Unit

(8) Check the Focus and readjust if necessary.

(9) Attach the cover (BNE1012) to the top board of the unit

using the four screws (M5 × 15).

Screw (M5 × 15)

Cover

(BNE1012)

55

INSTALLATION AND ASSEMBLY

(10) Attach the adjuster (BEF1011) attached with a nut

(M8) to the rear holders R and L (BNG1205, 1206).

Adjuster

(BEF1011)

nut

(M8)

Rear holder L

(BNG1205)

(12)Attach each rear panel (BMR1069, 1070, 1071, 1072) to

the unit and the rear holders R and L using the screws

(3 × 8). Furthermore, to cover up the gap at the top of

the projection unit, paste the hinder panel (BMR1075)

over the top board and projection unit.

Hinder panel

(BMR1075)

Rear panel L (upper)

(BMR1070)

Rear panel L (lower)

(BMR1072)

(11)While tilting the parts assembled at step 10, insert it

into the holes on the shoulder of the multi-projection

unit and attach with the screws (3 × 12). (2 screws × 2

locations). Furthermore, pull up the adjuster to the top

of the unit while rotating it, and pull down the nut to

the rear holders R and L while rotating it to secure the

projection unit.

* Tighten the nuts tightly.

screws

(M3 × 12)

Screw : M3 × 8

[After Completion]

4' Mounting the Projection Cabinet (RMF-V4011R)

Projection cabinet can mount to use the conventional method. For details, refer to the RM-V2000A technical manual.

56

INSTALLATION AND ASSEMBLY

7'

Mount the multi-projection unit (RM-V2400N) to the Projection Cabinet (RMF-V4011CR)

The figure shows how the left side attachment is assembled. Assemble the right attachment in the same way.

To differentiate the R and L of the parts, those on the right side of the screen as seen from the front are R and those on the left

are L.

(1) Attach the engine guide to the projection unit with

screws.

Attach the engine guide so that the distance between

the top edge of the engine guide and the top edge of

the unit and the distance between the bottom edge of

the engine guide and the bottom edge of the unit are

equal.

Screw (M6 × 50)

Engine guide (BND1099)

(3) Insert the projection unit from the rear of the cabinet.

(4) Attach fixtures R and L and the engine guide to the

projection unit with screws.

* Secure the M6 × 20 with a screw-locking compound.

(2) Insert the claws of fixtures R (BNG1173) and L

(BNG1174) into the slits at the back of the projection

unit.

* Secure the screws with a screw-locking compound.

Fixtures L (BNG1174)

Screw (M5 × 12)

Screw (M5 × 12)

Screw (M6 × 20)

57

9 Removal of RM-V2400N

Perform the following steps to remove RM-V2400N from

RMF-V4011CR.

[1] When removing from the rear

1) Remove the screws of the engine guide and fixtures R

and L attached to the cabinet.

INSTALLATION AND ASSEMBLY

2) Remove the screen (Refer to Replacing the Screen in

“Chapter 5.1. Maintenance”.)

3) Remove the screws attaching the projection unit and

engine guide.

2) Pull out the projection unit.

Leave the engine guide and fixtures R and L attached

to the projection unit.

(Note) The projection unit should be removed by more

than two persons always.

[2] When removing from the screen side

• Excluding exceptional cases, remove the projection

unit from the rear.

1) Before assembling the cabinet, remove the screws at

the side securing the fixtures R and L to the projection

unit.

Keep these screws carefully because they are to be attached again when transporting the cabinet.

4) Push out the projection unit. Leave the engine guide

and fixtures R and L attached to the cabinet.

(Note)

If the screws at the side securing the fixtures R and

L to the projection unit have not been removed at

step 1) :

a) Remove the screws securing the fixtures R and L to the

cabinet.

b) Lift up the rear of the projection unit, and pull it out

from the screen side. In this case, the fixtures R and L

are attached to the projection unit.

59

INSTALLATION AND ASSEMBLY

5. SPECIAL INSTALLATION

(1) Wall inset

• If removing the screen after installing the system, the person must go behind the screen (diagonally shaded part of the

figure). Therefore when insetting the unit in the wall, careful take this into account before installation.

Screen

(Fig. 3-43)

• When fixing the screen into the wall, space for placing your hand inside the wall at the top, bottom, right, and left will be

required in addition to the above in order to attach and remove the screen.

(2) Diagonal installation

• This system cannot be placed facing upwards or downwards and diagonally. Always place it horizontally.

However, Multiprojection unit (RM-V4000NA/V5000NA) alone can be tilted at the up to 45 deg. Installation of special order

screens and cabinets should also become possible in the near future.

(3) Architrave processing

• When enclosing the screen with a frame, etc., add 15 mm to the dimensions of the assembled screen at the top, bottom, left,

and right.

* Perform framing constructions after assembling the screen.

15 mm

15 mm

15 mm

15 mm

(Fig. 3-44)

• If light leaks from the rear space after constructions, place a blind plate over the rear.

• No one should climb onto the top board. (RMF-V4011/V5011)

(4) Upside down installation

• Not possible

(5) Hanging from ceiling

• Not possible

60

CHAPTER 4. ADJUSTMENTS

1. ADJUSTMENT PREPARATIONS

(1) Wiring

1 Connection of Power Supply

• The power supply can be connected to up to 3 units in a series using the AC outlets of Multi projection units. Connect the

three units as one system to the external outlet.

• The AC plug of Multi projection unit is a 3P with a ground pin. When connecting it to a normal outlet, use an exclusive 3P AC

adapter.

• The AC plug of Multi projection unit is a 3P with a ground pin. To prevent electric shocks, connect the ground pin to the

ground when connecting the power supply.

2 Connection of signal cable

• Use coaxial cables. Normally, if less than 15m, use 3C-2V. If less than 30m, use 5C-2V.

The signal transmission equipment and Multi projection units should be as close as possible to each other.

3 Connection of ABL link cable

• By connecting the ABL link cables in cascade form, control signals (RS-232C, remote control signal) can be transmitted to all

the units.

Personal Computer

or

Remote control unit

(Up to 16 units can be operated using the remote control unit at one time using the link cable.)

RS-232C

Multi Projection

Unit

OUT

Link cable

Multi Projection

Unit

IN

OUT

Link cable

Multi Projection

Unit

IN

OUT

(2) Wiring Handling

• Except for short-term installations such as events, etc., in normal long-term installations, adjust the length of the wiring

appropriately taking into consideration the overall route to be wired.

• Make sure the connection terminals are not subjected to direct weight and force. Tie the wires up in short-term use and bind

them up properly in long-term use.

(3) Aging

• After turning on the power, input the 100% white signal or moving images, and perform aging until Multi projection unit

stabilizes (about 1 hour). If adjustments are performed without aging, as it takes time until Multi projection unit will warm

up and stabilize, convergence and white balance will become incorrect.

61

ADJUSTMENTS

(2) TV System

The TV system determines the control of the whole unit (convergence, OSD display select, video system select, deflection)

according to the signal input.

Set it according to the signal input.

When TV SYSTEM is set to AUTO

• The mode is automatically set to NTSC or PAL according to the input signal (NTSC/PAL).

When the TV SYSTEM is set to NTSC

• The mode is set to NTSC regardless of the input signal.

When the TV SYSTEM is set to PAL

• The mode is set to PAL regardless of the input signal.

[Precaution to use]

Normally, the TV SYSTEM is set to AUTO. If the signals cannot be differentiated between NTSC and PAL (or they are differentiated incorrectly : VCR signal repeatedly dubbed or part of CATV converter, etc.), the TV SYSTEM is set to NTSC or PAL

according to the input signal.

When the input signal is NTSC or PAL, and the TV SYSTEM is set to NTSC or PAL, it can enable the input to be switched

smoothly (little screen noises), and prevent signals from being differentiated incorrectly due to signal disturbances and cuts.

In some cases, even if the same TV format is used, more than two types of convergence data will be required. (For example,

when there are signal phase differences for every input source, etc.) In such cases, use two types of memories. Switch them

using the personal computer.

64

ADJUSTMENTS

(6) Giving IDs

When several Multi projection units are used to compose the 9 screens or 16 screens (multi-screen), the ID is used to differentiate between Multi projection units. When the units are given IDs, by connecting the ABL link cable, commands can be

transmitted by specifying the ID, and it is possible to operate only Multi projection unit corresponding to that ID by remote

control operations.

<Giving IDs using Personal Computer>

Commands: IDC (IDC CLEAR) ;Clears the ID given

IDS (ID SET) ;Gives an ID

The IDS is valid only when no ID has been given. It will be valid from units nearest to the personal

computer (remote control).

(Example) 4 screens • When giving IDs first using Personal Computer.

Personal Computer

**AJY

11 IDS

↓

**AJY

12 IDS

↓

**AJY

21 IDS

↓

**AJY

22 IDS

By sending commands in this order, IDs can be given to each Multi Projection Unit (connect ABL link cables as above example).

The characters that can be used for the IDs are 0 to 9 and A to F, and * (capital and small letters are not differentiated).

The * can be used in the following way.

** IDC :Clears IDs given to all units

*1AJY :Only units which have IDs whose 2nd digit is 1 enter the adjustment mode.

2* IN1 :The input function of only units which have IDs whose 1st digit is 2 is set to VIDEO.

Multi Projec-

tion Unit

ID=11 ID=12

Multi Projec-

tion Unit

Multi Projec-

tion Unit

ID=21 ID=22

Multi Projec-

tion Unit

66

9

ADJUSTMENTS

<Giving IDs Using the Remote Control>

[1] Press the

[2] The main menu will be displayed. Press the

ADJ IN

key to set the whole screen into the adjustment mode.

1

key.

Select ”1. ID SET/CLEAR/SELECT”

[3] Check that the ID display at the top left of the screen is “– –” and press the

1

key.

Select “1.ID SET”.

If an ID has already been given, press the

key, select “0. ID CLEAR” of the main menu, return to “[1] Enter the

0

adjustment mode.” and give the ID.

[4] As the ID input standby state is set, press the

to

0

,

to

A

keys, and input the ID.

F

[5] To use the multi-screen unit, return to “[1] Enter the adjustment mode.” and given an ID to the next unit.

Note) To return the whole screen to the main menu after giving IDs to the whole screen, press the

ADJ IN

key.

<Selecting the ID Using the Remote Control>

Select the screen to be adjusted using the remote control.

Example) Select the ID at the bottom left side of the screen (ID=21) as shown

ID = 12ID = 11

in the figure on the right.

key.

ADJ IN

key .

ID = 21

ID = 22

[1] Set all screens to the adjustment mode using the

[2] Select [1. ID SET/CLEAR/SELECT using the

[3] Select [2. ID SELECT] using the

[4] Press the

2

and

1

2

keys (ID=21).

1

key.

[5] Only the bottom left side of the screen shows the main menu. The other screens will set into the standby state

POWER

(

,

ADJ IN

• To return to the main menu after completing ID SELECT, press the

Pressing the

ADJ IN

ADJ OUT

,

keys only are accepted).

MAIN MENU

key to keep the ID SELECT state.

key will also return to the main menu, but it also clear the ID SELECT state, making it necessary to

repeat from step [1] again.

To select other screens, press the

MAIN MENU

key to return to the main menu, and change the ID number set at step [4] above.

Note : When the wrong ID has been specified

Repeat the above steps [1] to [5].

Perform the same steps when an inappropriate ID (Example : ID=33, etc. in the above screen) has been input. In this case, all

screens will set into the standby state.

<Precautions for Giving IDs using the Remote Control and Personal Computer>

Communication cannot be performed with units connected using the ABL link cable, after units whose IDs have been

cleared. When the command “** IDC” shown in the figure on the previous page is performed, only the first unit can be

controlled. Using the command “11 IDS” will enable the 2nd unit and onwards to be controlled.

When IDs are set as this, the unit connected next can be controlled.

67

ADJUSTMENTS

3.EXAMPLES OF MAIN USES OF MULTI-PROJECTION UNITS

(1) Expansion/Individual Switching at Multi Video Processor Side - General example

Source

NTSC

or PAL

TV SYSTEM) AUTO

Converter data required at display) One

Multi Video

Processor

NTSC

or PAL

Multiprojection Unit

(2) When Switching Source Inputs to Multi Video Processor

LDP-1

LDP-2

* There is phase difference

between LDP1 and 2

TV SYSTEM) AUTO

Converter data required for display) Two

* For example, adjust LDP-1 with MEMORY 1 and LDP-2 with MEMORY 3 and switch data by

external control when switching LDP .

Multi Video

Processor

* Only one image

frame data

NTSC

or PAL

Multiprojection Unit

68

ADJUSTMENTS

4. SCREEN ADJUSTMENTS

(1) Adjustment Flowchart

The following shows the order for performing the adjustments generally required in the setup of the multi-projection system.

For details, see the descriptions on the next page and later.

1 Give ID

↓

2 Adjust the size of each screen

↓

3 Adjust the convergence of each screen

↓

4 Adjust the joining of the screens

(Adjust with the multi-video processor)

↓

5 Check that there is no information missing and color deviation on the moving image.

If information is missing or color has deviated, return to 2 and readjust.

↓

6 Adjust the white balance of each screen.

↓

7 Adjust the ABL level

↓

8 Check the ABL level and white balance using the video actually transmitted.

If there is deviation, return to 6 and readjust

↓

9 Adjust the color tone using the video actually transmitted.

↓

0 Recheck 6 to 8

69

(2) Convergence Adjustment Flowchart

ADJUSTMENTS

1

(P. 70)

2

(P. 70)

3

(P. 70)

4

(P. 71)

Find the center of the screen

Input the adjustment signal

Using only green, adjust the

center of V STATIC GH STATIC

Adjust the size of V SIZE V LIN

H SIZE GH LIN

Is the Horizontal size

standard (93%)?

YES

NO

8

(P. 85)

Adjust H BLK-L and

H BLK-R

5

(P. 72)

6

(P. 72)

7

(P. 72)

Adjust joining of peripheral screens

in green point convergence mode

Adjust linearity of green

point convergence mode

Adjust green, red, blue color deviation in point convergence mode

70

ADJUSTMENTS

(3) Convergence Adjustment Contents

1 Measurement of screen center

The center can be found easily by pasting threads in the

spaces of the protection panels at the screen frame.

The & numbers correspond to the numbers in the flowchart.

2 Adjustment signal input

For adjusting size...Frame size picture(EX.LD Test disc GGT1072, FRAME No. 5941),Monoscope, etc.

For screen joining, linearity, color adjustment...Use adjustment signals such as , cross-hatch, etc.

(EX. LD Test disc GGT1072, FRAME No. 7081,etc.)

If signals are created in the multi video processor, use them.

Input the above adjustment signals via the Multi Video Processor actually used.

Note : For the particulars about the FRAME No.,etc. of LD Test disc GGT1072,refer to the disc manual differently.

3 Center adjustment

Center

Set to only green and adjust the center with V STATIC

GH STATIC .

V STATIC

GH STATIC

71

ADJUSTMENTS

4 V SIZE, V LIN, H SIZE Adjustment

1 V SIZE adjustment

Set to only green, observe the top part of the screen , and

adjust the data amount in the vertical direction using

V SIZE .

Do not observe the bottom part of the screen.

2 H SIZE adjustment

Observe here

Set to only green, observe the right side of the screen ,

and adjust the data amount in the horizontal direction using H SIZE .

Do not observe the left side of the screen.

3 V SIZE, V LINEARITY, H SIZE, GH LINEARITY adjustment

Those familiar with the convergence adjustment can adjust the bottom part of the screen in addition to the top part of the screen

using V SIZE and V LINEARITY . Also it can adjust the left side of the screen in addition to the right side of the screen using

H SIZE and GH LINEARITY .

Observe

here

Reference Information

To adjust the NTSC input for horizontal 93% and vertical 92%, use the frame size screen of the LD test disc GGT1072

(frame No. 5941).

Horizontal : Adjust so that the sixth 92.5% line from the inside can be seen completely.

Vertical : Adjust so that the sixth 92.5% line from the inside can be seen only slightly.

72

ADJUSTMENTS

Movement of screen by point convergence adjustment

Movement of screenOSD display

Observe here

Use especially when adjusting the horizontal size of the left side of the screen .

In addition, there are nine other area adjustments. It is a convenience to adjust deviation of circumference screens.

74

ADJUSTMENTS

75

ADJUSTMENTS

76

ADJUSTMENTS

In adjustment step 5 , observe the external part of the screen, adjust the 16 adjusting points there, taking note of linearity in

the peripheral area such as joining with other screens, crosshatch, etc.

(Ignore the distortion inside the screen.)

In adjustment step 6 , adjust the inside of the screen and produce linearity.

The following are examples of adjusting points in point convergence adjustments and their movements on the screen.

77

ADJUSTMENTS

Displayed OSD

Movement on screen

78

ADJUSTMENTS

79

ADJUSTMENTS

80

ADJUSTMENTS

81

ADJUSTMENTS

82

ADJUSTMENTS

NOTE

If only one point is moved greatly in the point convergence mode, it may not move in areas smaller than the

desired adjusting area.

In this case, adjust while moving the other points

slowly.

Does not move to the set position

5 2

4 1

6 3

83

ADJUSTMENTS

8 H BLK L and H BLK R Adjustments

H BLK L and H BLK R adjustments are performed to obtain the optimum convergence adjustment wave form when the

display range changes due to changes in the H SIZE.

Video signal

Display range

Convergence adjustment wave

form

Video signal

Convergence adjustment wave

form

Display

range after size

changed

Color deviation

When size is increased with H BLK L and H BLK R not

adjusted.

No color deviation

Convergence adjustment wave

form

86

Adjustment by

H BLK L

Image after H BLK L and H BLK R has been adjusted.

Adjustment by

H BLK R

ADJUSTMENTS

H BLK R Adjustment

Output all three colors R, G, B, observe

the right side of the screen , and adjust with H BLK R so

that the color stops deviating.

RGB

RGB

Observe here

BGR

When H BLK R adjustment is not properly performed

H BLK L adjustment

Output all three colors R, G, B, observe the

left side of the screen , and adjust with H BLK L so that

the color stops deviating.

Observe here

NOTE

There are points at which the screen does not move even through the H BLK L value changes. This is not a malfunction.

RGB

87

Confirming the Optimum H BLK L, H BLK R Values

Optimum H BLK R value

ADJUSTMENTS

OSD display

A

When point A is lowered by point convergence, point B should not move.

Confirming the Optimum H BLK L Value

C

Movement on screen

B

D

When point C is lowered by point convergence, point D should not move.

Note

Convergence can be adjusted even if the optimum values are slightly different from the above optimum values during adjustments.

But, if the screen changes markedly, re-adjust H BLK L or H BLK R, and adjust the convergence.

88

ADJUSTMENTS

5 Rough Adjustments

(1) Black level adjustment Signal:White 10%

Adjust R LOW, G LOW, and B LOW to the point where the CRT starts lighting up.

(2) HI LIGHT adjustment Signal:White 50%

Adjust R HI, G HI, and B HI so that the CRT becomes white. First, adjust so that the brightness of R, G, and B becomes the same,

and while maintaining that brightness, balance R, G, and B, and adjust so that the CRT becomes white.

(3) LOW LIGHT adjustment Signal:White 20%

Adjust R LOW, G LOW, and B LOW so that the CRT becomes gray.

(4) Convergence adjustment Signal:White 50%, 20%

Repeat (2) to (3) and converge the light. If the HI LIGHT of

R, G, and B is moved, their LOW LIGHT will change greatly. Therefore, pay special attention to the value of the LOW LIGHT.

Hi UP

Amount of Hi UP

Amount of

Low DOWN

Low Down

Low Light starts to

deviate

92

ADJUSTMENTS

6 LINEAR WHITE adjustment

When white peak signals such as WINDOW are input, due to the characteristics of the Blue CRT, there is a tendency for the

peak to become yellow compared to other colors. The linear white adjustment is performed to correct this tendency.

Blue becomes weak when data is set to UP and strong when set to DOWN. If Linear White is added excessively, the ABL

voltage becomes unbalanced and the medium luminance of blue may be erased, etc.

Also make sure that the blue is not blur when MULTI ON is set because the top left and bottom left of the screen are affected

first.

LINEAR WHITE

becomes effective

LINEAR WHITE Down

7 ABL GAIN adjustment (White 100%)

The ABL GAIN adjustment adjusts the white 100% luminance of a unit to other units after low luminance and medium luminance have been adjusted.

Normally, when white 100% is input, ABL is imposed and the current is controlled so that the current flowing in the CRT does

not exceed a certain level. Even if the current flowing in the CRT of each unit is the same, the difference in the characteristics

of each CRT will cause their luminance to become inconsistent. The ABL GAIN adjustment converges this inconsistency. It

adjusts the ABL current flowing virtually.

In white 100% inputs, as the ABL works efficiently, the luminance drops, when the ABL GAIN of a unit with high luminance is

decreased, use this adjustment to adjust its luminance to the other units.

Turn off the ABL in the adjustment.

Normally set the ABL GAIN to maximum.

8 ABL LEVEL adjustment (White 100%)

The ABL LEVEL adjustment controls the inconsistency of the ABL control voltage of each unit when ABL is on.

[1] Set the ABL of all units to ON.

[2] Turn on and off the ABL of each unit to change the luminance.

[3] For units whose luminance becomes dark when ABL is ON, turn UP the ABL level and set to the point where the

luminance stops changing by turning on and off the ABL.

[4] For units whose luminance does not change, turn DOWN the ABL level to the point just before the luminance

becomes dark.

[5] Perform steps (2) to (4) for all the units, change white from 0 to 100% and check that the ABL does not work

abnormally.

93

ADJUSTMENTS

(6) External Control by RS-232C

As Multi projection unit is equipped with a RS-232C port, various controls and, white balance and convergence adjustments

can be performed by an external computer.

By programming software ,it is possible not only to adjust White Balance,Convergence but to save and control the adjustment data of each source.

1 Interface

1]Connector

D-sub 25-pin

2]Pin assignment

PIN No.

Symbo;

Signal Name

1

2

3

5

7

[3]Baud rate

4800 bps (1200, 2400, 9600, 19200 bps can also be

selected)

[4]Data format

Start:1-bit

Data:8-bit

Parity:0 (No parity)

Stop:1-bit

[5]Connection

COMPUTER

FG 1

TXD 2

RXD 3

CTS 5

GND 7

FG

RXD

TXD

CTS

GND

Straight cable

Frame Ground

Received Data

Transmitted Data

Clear To Send

Signal Ground

Multi projection unit

1 FG

2 RXD

3 TXD

5 CTS

7 GND

COMPUTER

(IBM PC)

TXD 3

RXD 2

CTS 8

GND 5

Multi projection unit

2 RXD

3 TXD

5 CTS

7 GND

1 FG

[6]Protocol

Multi projection unit from computer

stx

ID

COMMAND

stx

stx

ID

ID

COMMAND

COMMAND

96

ID : 2-Byte(ASC ll)COMMAND : 3-Byte(ASC ll)

etx

COMMAND COMMAND

ARGUMENT

stx=02h etx=03h

*

etx

etx

ARGUMENT : 3-Byte(ASC ll)

Up to 3 commands possible

Note : * In case of the numeral direct command

Loading...

Loading...