Page 1

ORDER NO.

CRT3025

PUB. NO.

CRT3025

AUDIO SYSTEM

HEAD UNIT

Manufactured for TOYOTA

by PIONEER CORPORATION

VEHICLE DESTINATION PRODUCED AFTER TOYOTA PART No. ID No. PIONEER MODEL No.

LEXUS RX330 EUROPE February 2003 86120-48200 P3920 FX-MG8237ZT/EW

86120-48340 P3920 FX-MG8237ZT-91/EW

86120-48220 P3921 FX-MG8337ZT/EW

86120-48360 P3921 FX-MG8337ZT-91/EW

RX330

flashLAV

www.club-lexus.ru

Page 2

flashLAV

www.club-lexus.ru

2

1

234

12

34

F

E

D

C

B

A

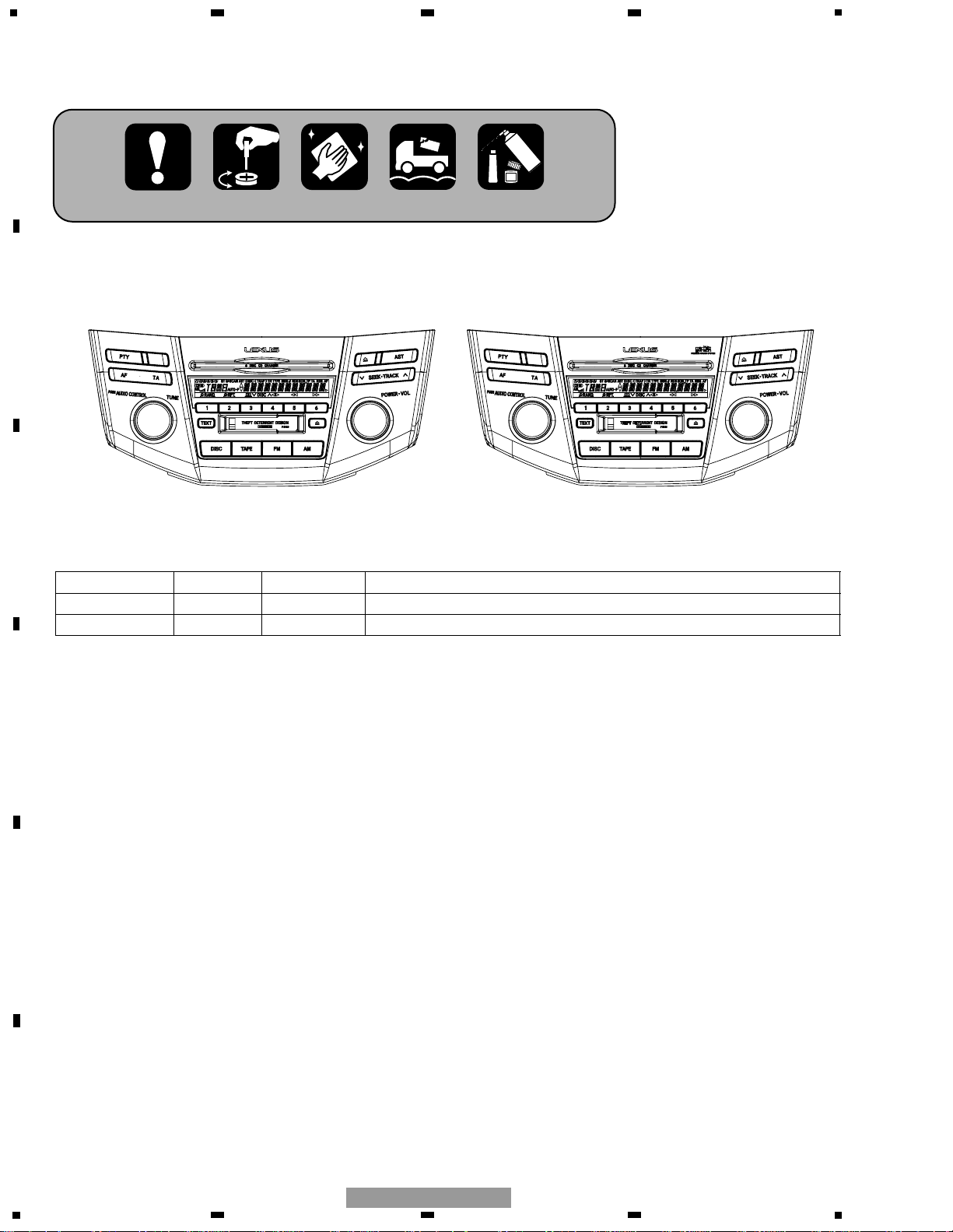

FX-MG8237ZT/EW

For details, refer to "Important symbols for good services".

FX-MG8237ZT/EW(P3920) FX-MG8337ZT/EW(P3921)

LOAD

LOAD

- This service manual should be used together with the following manual(s):

Model No. Order No. Mech. Module Remarks

CX-1011 CRT2406 3L Cassette Mech. Module:Mech.Description, Disassembly

CX-951 CRT2872 G2 CD Mech. Module:Circuit Description, Mech.Description, Disassembly

- Dolby noise reduction manufactured under license from Dolby Laboratories Licensing Corporation.

"Dolby" and the double-D symbol are trademarks of Dolby Laboratories Licensing Corporation.

Page 3

flashLAV

www.club-lexus.ru

3

5

6

7

8

F

E

D

C

B

A

5

6

7

8

FX-MG8237ZT/EW

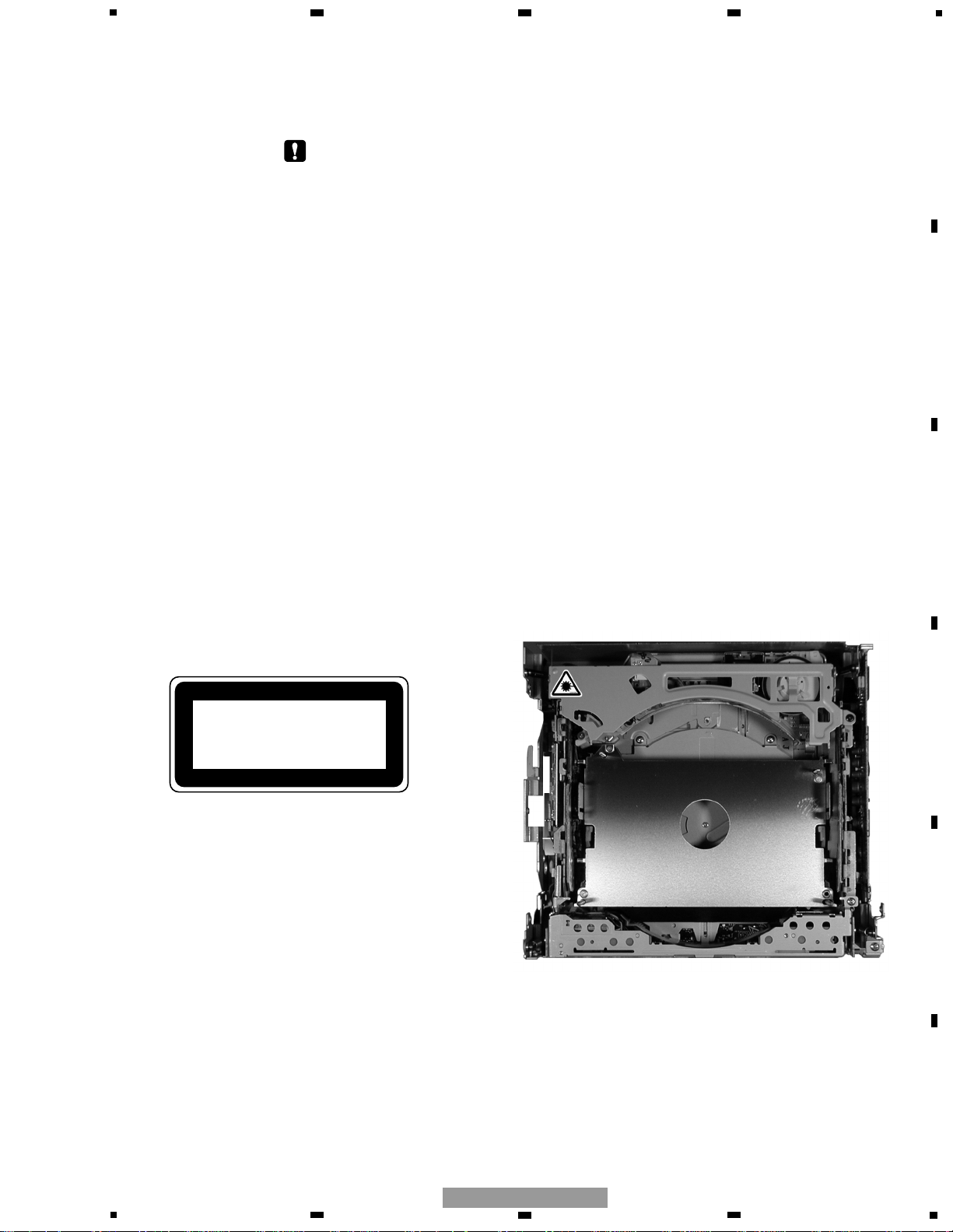

SAFETY INFORMATION

-

CD section precaution

1. Before disassembling the unit, be sure to turn off the

power. Unplugging and plugging the connectors during power-on mode may damage the ICs inside the

unit.

2. To protect the pickup unit from electrostatic discharge during servicing, take an appropriate treatment (shorting-solder) by referring to “the DISASSEMBLY” on page 83.

3. After replacing the pickup unit, be sure to check the

grating. (See p.73.)

This service manual is intended for qualified service technicians; it is not meant for the casual do-it-yourselfer.

Qualified technicians have the necessary test equipment and tools, and have been trained to properly and safely repair

complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may void the warranty.

If you are not qualified to perform the repair of this product properly and safely, you should not risk trying to do so

and refer the repair to a qualified service technician.

1. Safety Precautions for those who Service this Unit.

• When checking or adjusting the emitting power of the laser diode exercise caution in order to get safe, reliable

results.

Caution:

1. During repair or tests, minimum distance of 13cm from the focus lens must be kept.

2. During repair or tests, do not view laser beam for 10 seconds or longer.

2. A “CLASS 1 LASER PRODUCT” label is affixed to the

bottom of the player.

CLASS 1

LASER PRODUCT

4. Specifications of Laser Diode

Specifications of laser radiation fields to which human access is possible during service.

Wavelength = 800 nanometers

3. The triangular label is attached to the mechanism

unit frame.

Page 4

flashLAV

www.club-lexus.ru

4

1

234

12

34

F

E

D

C

B

A

FX-MG8237ZT/EW

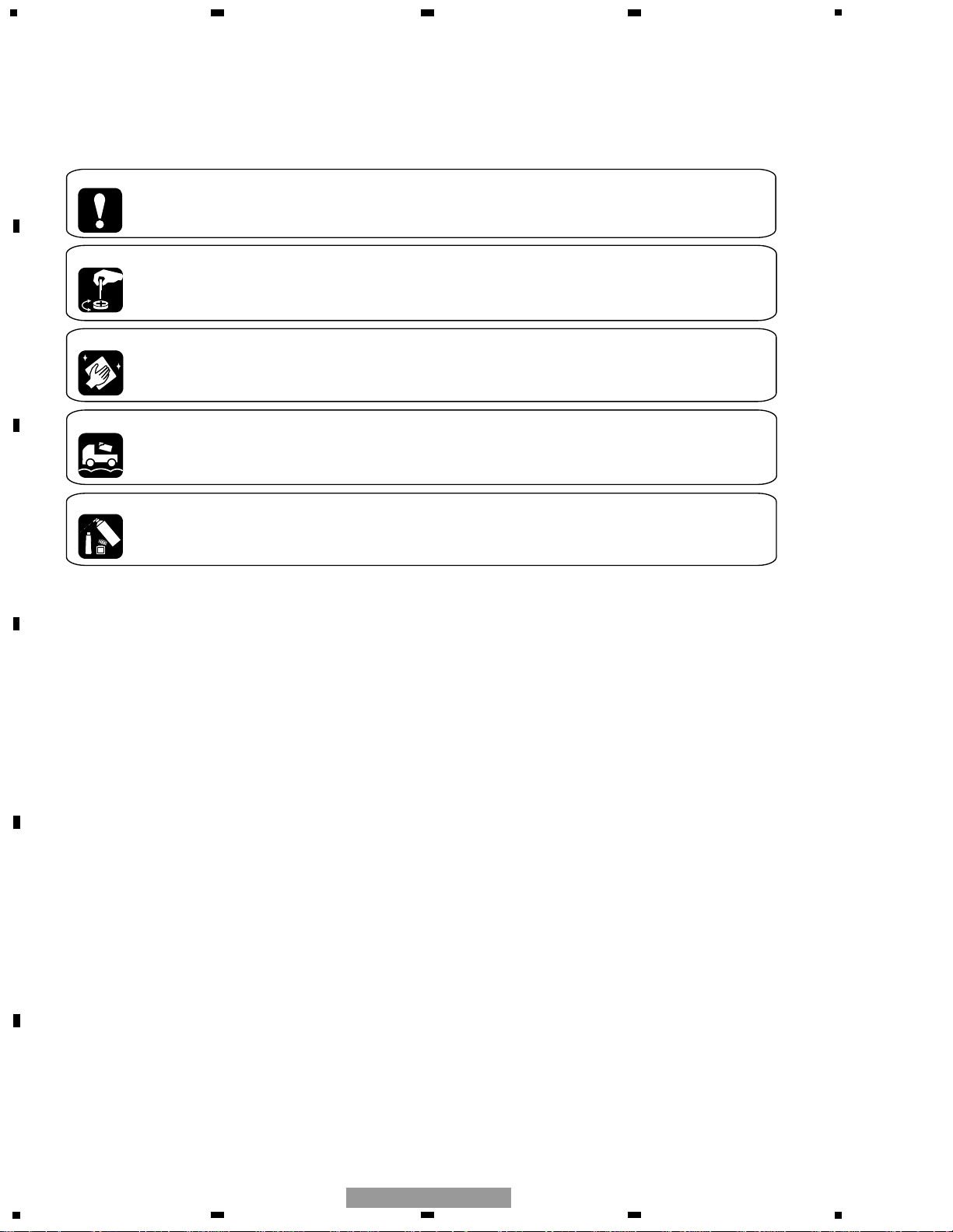

[ Important symbols for good services ]

In this manual, the symbols shown-below indicate that adjustments, settings or cleaning should be made securely.

When you find the procedures bearing any of the symbols, be sure to fulfill them:

2. Adjustments

To keep the original performances of the product, optimum adjustments or specification confirmation is indispensable.

In accordance with the procedures or instructions described in this manual, adjustments should be performed.

3. Cleaning

For optical pickups, tape-deck heads, lenses and mirrors used in projection monitors, and other parts requiring cleaning,

proper cleaning should be performed to restore their performances.

5. Lubricants, glues, and replacement parts

Appropriately applying grease or glue can maintain the product performances. But improper lubrication or applying

glue may lead to failures or troubles in the product. By following the instructions in this manual, be sure to apply the

prescribed grease or glue to proper portions by the appropriate amount.For replacement parts or tools, the prescribed

ones should be used.

4. Shipping mode and shipping screws

To protect the product from damages or failures that may be caused during transit, the shipping mode should be set or

the shipping screws should be installed before shipping out in accordance with this manual, if necessary.

1. Product safety

You should conform to the regulations governing the product (safety, radio and noise, and other regulations), and

should keep the safety during servicing by following the safety instructions described in this manual.

Page 5

flashLAV

www.club-lexus.ru

5

5

6

7

8

F

E

D

C

B

A

5

6

7

8

FX-MG8237ZT/EW

CONTENTS

SAFETY INFORMATION......................................................................................................................................................3

1. SPECIFICATIONS.................................................................................................................................................................6

2. EXPLODED VIEWS AND PARTS LIST ................................................................................................................................7

2.1 PACKING(FX-MG8237ZT-91/EW, FX-MG8337ZT-91/EW)............................................................................................7

2.2 EXTERIOR ......................................................................................................................................................................8

2.3 CD MECHANISM UNIT(1) ...........................................................................................................................................12

2.4 CD MECHANISM UNIT(2) ...........................................................................................................................................14

2.5 CASSETTE MECHANISM MODULE...........................................................................................................................16

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM.............................................................................................................19

3.1 BLOCK DIAGRAM(1) ...................................................................................................................................................19

3.2 BLOCK DIAGRAM(2) ...................................................................................................................................................20

3.3 OVERALL CONNECTION DIAGRAM(GUIDE PAGE)..................................................................................................22

3.4 KEYBOARD UNIT.........................................................................................................................................................28

3.5 CD MECHANISM MODULE(GUIDE PAGE)................................................................................................................30

3.6 CASSETTE MECHANISM MODULE...........................................................................................................................40

4. PCB CONNECTION DIAGRAM..........................................................................................................................................42

4.1 MAIN UNIT...................................................................................................................................................................42

4.2 KEYBOARD PCB ..........................................................................................................................................................46

4.3 CD MECHANISM MODULE.........................................................................................................................................48

4.4 CASSETTE MECHANISM MODULE...........................................................................................................................54

4.5 RIGHT PCB, LEFT PCB.................................................................................................................................................56

5. ELECTRICAL PARTS LIST..................................................................................................................................................57

6. ADJUSTMENT ...................................................................................................................................................................66

6.1 CONNECTION DIAGRAM............................................................................................................................................66

6.2 AUDIO, TUNER ADJUSTMENT..................................................................................................................................68

6.3 TEST MODE .................................................................................................................................................................70

6.4 CD ADJUSTMENT.......................................................................................................................................................71

6.5 CHECKING THE GRATING AFTER CHANGING THE PICKUP UNIT.........................................................................73

6.6 TEST MODE(CD)..........................................................................................................................................................75

6.7 AVC-LAN DIAGNOSIS MODE.....................................................................................................................................79

7. GENERAL INFORMATION.................................................................................................................................................83

7.1 DIAGNOSIS..................................................................................................................................................................83

7.1.1 DISASSEMBLY..........................................................................................................................................................83

7.1.2 PCB LOCATIONS ......................................................................................................................................................88

7.1.3 CONNECTOR FUNCTION DESCRIPTION................................................................................................................89

7.2 PARTS...........................................................................................................................................................................90

7.2.1 IC................................................................................................................................................................................90

7.2.2 DISPLAY....................................................................................................................................................................97

7.3 EXPLANATION.............................................................................................................................................................98

7.3.1 SYSTEM BLOCK DIAGRAM.....................................................................................................................................98

7.3.2 OPERATIONAL FLOW CHART .................................................................................................................................99

7.4 NOTES ON SERVICING.............................................................................................................................................100

7.4.1 CLEANING...............................................................................................................................................................100

7.4.2 FACTORY SETTINGS..............................................................................................................................................100

8. OPERATIONS...................................................................................................................................................................101

Page 6

flashLAV

www.club-lexus.ru

6

1

234

12

34

F

E

D

C

B

A

FX-MG8237ZT/EW

1. SPECIFICATIONS

General

Power source................13.2V(10.5V–16.0V allowable) DC

Grounding system........................................Negative type

Backup current..............................................0.3mA or less

Dimensions............................320(W) x145(H) x175(D)mm

Weight..........................................................................2.8kg

Cassette player

Tape................................Compact cassette tape(C30-C90)

Tape speed ........4.76cm/sec.(+0.14cm/sec., -0.05cm/sec.)

Wow and flutter.................................0.2% or less(WRMS)

Crosstalk ..........................................................40dB or less

Stereo Separation.........................................30dB or more

S/N .................................................................40dB or more

Distortion.............................................................3% or less

CD player

System ...................................Compact disc audio system

Usable discs ..................................................Compact disc

Signal format .....................Sampling frequency : 44.1kHz

.....................................Number of quantization : 16;linear

S/N .................................................................65dB or more

Distortion..........................................................0.3% or less

FM tuner

Frequency range........................................87.5–108.0 MHz

S/N ..........................................46dB or more(54dBµ input)

Distortion..........................................................1.5% or less

IF interference ...............................................80dB or more

Image interference........................................35dB or more

Stereo Separation ..............................25dB or more(1kHz)

MW tuner

Frequency range ..........................................522–1,611 kHz

S/N 20dB useable sensibility........................34dBµ or less

S/N .................................................................42dB or more

Distortion..........................................................1.5% or less

IF interference ...............................................55dB or more

Image interference........................................45dB or more

LW tuner

Frequency range .............................................153–279 kHz

S/N 20dB useable sensibility........................40dBµ or less

S/N .................................................................42dB or more

Distortion..........................................................1.5% or less

IF interference ...............................................55dB or more

Image interference........................................45dB or more

Page 7

flashLAV

www.club-lexus.ru

7

5

6

7

8

F

E

D

C

B

A

5

6

7

8

FX-MG8237ZT/EW

2. EXPLODED VIEWS AND PARTS LIST

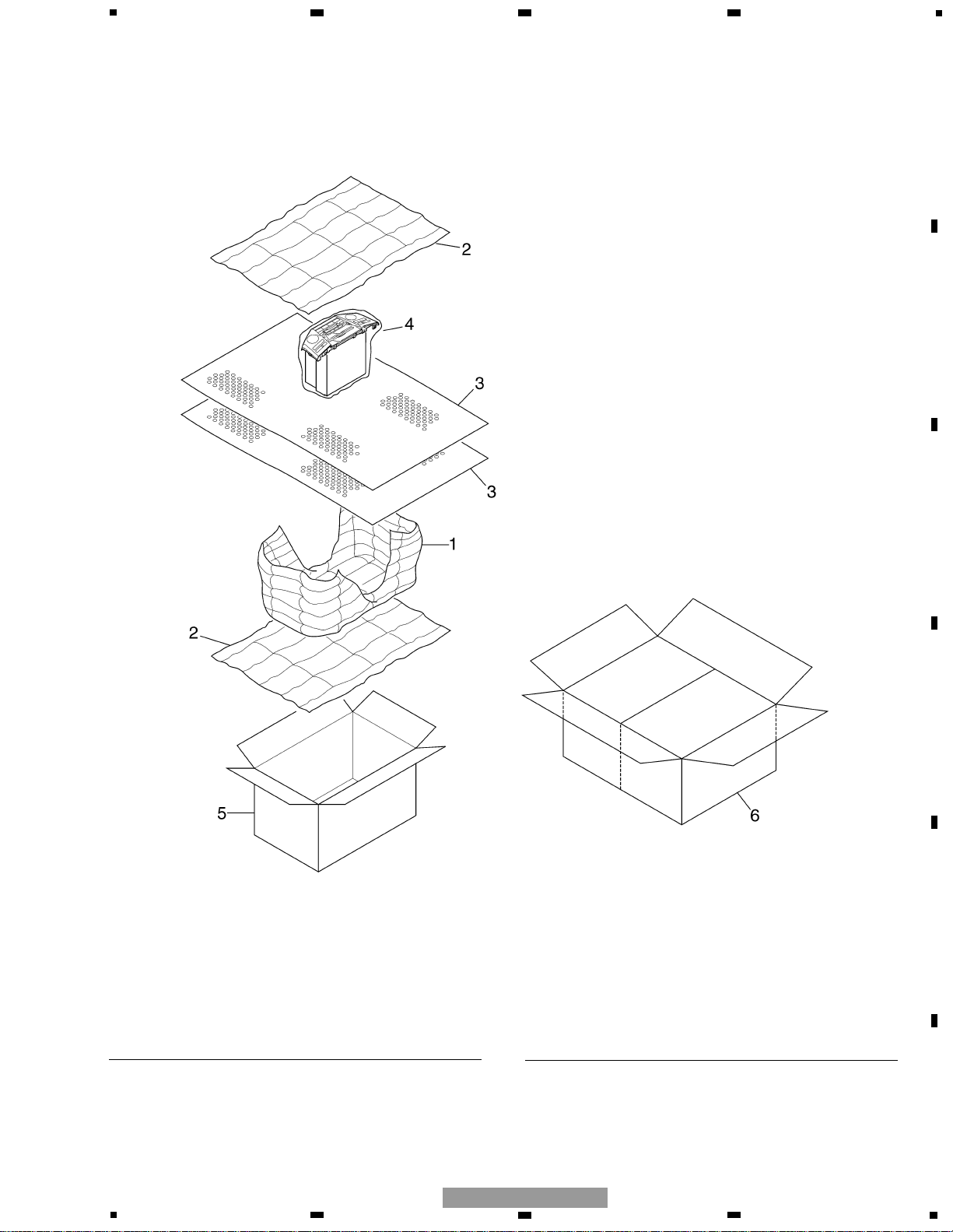

2.1 PACKING(FX-MG8237ZT-91/EW, FX-MG8337ZT-91/EW)

* 1 Air Cap CHW1945

* 2 Air Cap CHW1948

3 Cover CEG1045

4 Polyethylene Bag CEG1026

5 Carton CHG4861

6 Contain Box CHL4861

Mark No. Description Part No. Mark No. Description Part No.

NOTE:

- Parts marked by “*” are generally unavailable because they are not in our Master Spare Parts List.

- Screws adjacent to

∇ mark on the product are used for disassembly.

- For the applying amount of lubricants or glue, follow the instructions in this manual.

( In the case of no amount instructions, apply as you think it appropriate.)

- PACKING(FX-MG8237ZT-91/EW, FX-MG8337ZT-91/EW) SECTION PARTS LIST

Page 8

flashLAV

www.club-lexus.ru

8

1

234

12

34

F

E

D

C

B

A

FX-MG8237ZT/EW

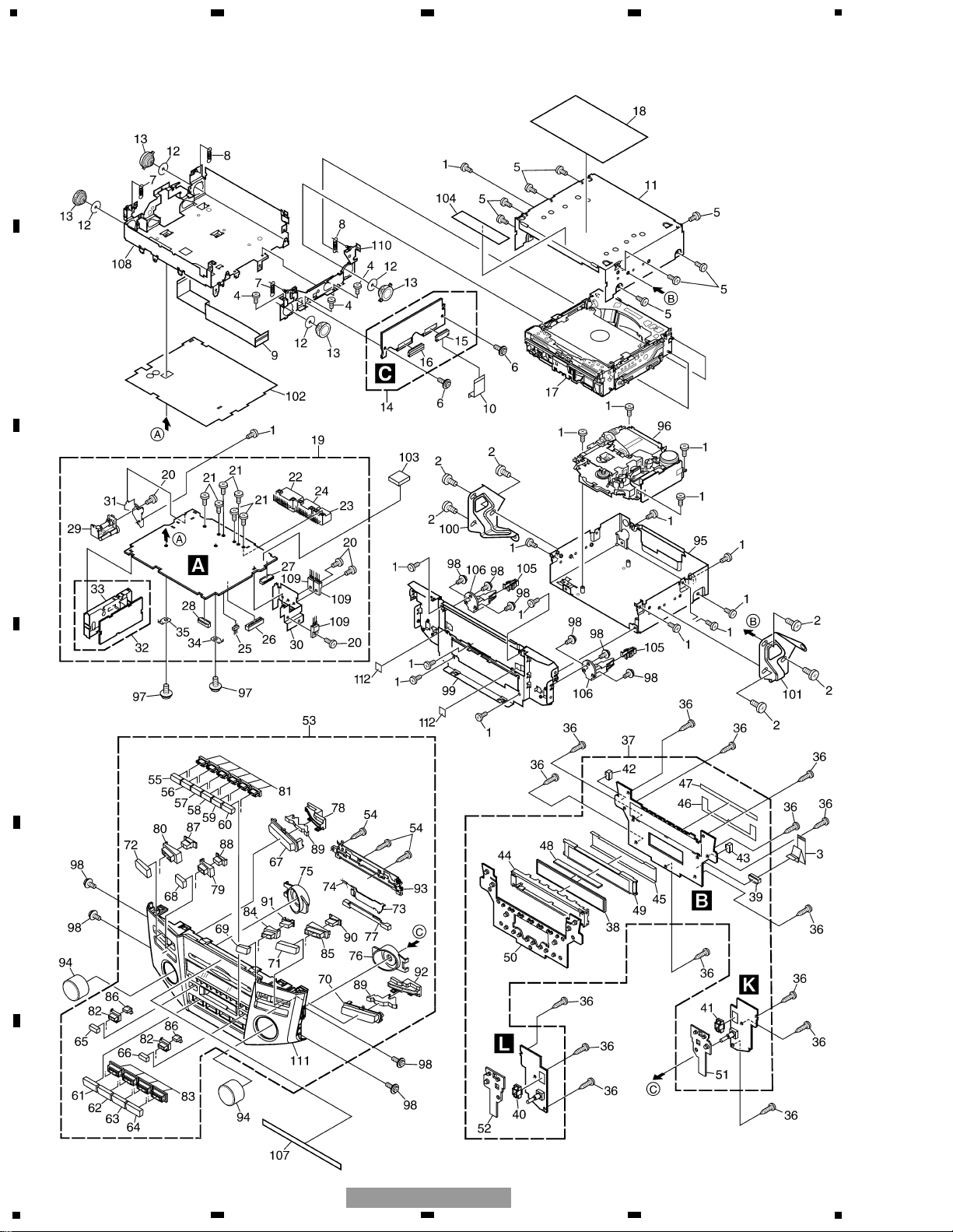

2.2 EXTERIOR

Page 9

flashLAV

www.club-lexus.ru

1 Screw BMZ26P040FTC

2 Screw

See Contrast table(2)

3 Connector CDE7260

4 Screw BMZ20P025FMC

5 Screw BMZ26P040FMC

6 Screw(M2x2.5) CBA1076

7 Spring CBH2481

8 Spring CBH2482

9 Connector CDE7020

10 Connector CDE7035

11 Case CNB2705

12 Sheet CNM5981

13 Damper CNV6608

14 Control Unit(G2T) CWX2649

15 Connector(CN601) CKS1956

16 Connector(CN101) CKS4512

17

Service Mechanism Assy(G2T) CXX1658

18 Label CRW1429

19 Main Unit

See Contrast table(2)

20 Screw BMZ30P060FTC

21 Screw(M3x6) CBA1393

22 Connector(CN801) CKM1322

23 Connector(CN473) CKM1350

24 Connector(CN472) CKM1351

25 Plug(CN354) CKS-291

26 Connector(CN353) CKS3568

27 Connector(CN351) CKS3886

28 Connector(CN804) CKS4361

29 Connector(CN501) CKX1064

30 Holder CNC9639

31 Holder CNC9701

32 FM/AM Tuner Unit CWE1633

33 Holder CNC8855

34 Terminal(CN802) VNF1084

35 Terminal(CN803) VNF1084

36 Screw BPZ20P080FTC

37 Keyboard Unit CWS1363

38 LCD(LCD901) CAW1722

39 Connector(CN901) CKS4361

40 Connector(CN904) CKS4591

41 Connector(CN905) CKS4591

42 Connector(CN902) CKS4592

43 Connector(CN903) CKS4592

44 Holder CND1021

45 Sheet CNM7958

46 Seal CNM7970

47 Seal CNM7971

48 Connector CNV7249

49 Lighting Conductor CNV7250

50 Rubber CNV7323

51 Rubber CNV7324

52 Rubber CNV7325

53 Grille Assy

See Contrast table(2)

54 Screw BPZ20P080FTC

55 Button(1) CAC7599

56 Button(2) CAC7600

57 Button(3) CAC7601

58 Button(4) CAC7602

59 Button(5) CAC7603

60 Button(6) CAC7604

61 Button(DISC) CAC7620

62 Button(TAPE) CAC7621

63 Button(FM) CAC7622

64 Button(AM) CAC7623

65 Button(TEXT) CAC7624

66 Button(TAPE EJECT) CAC7625

67 Button(AF,TA) CAC7627

68 Button(LOAD) CAC7629

69 Button(CD EJECT) CAC7628

70 Button(SEEK,TRACK) CAC7626

71 Button(AST) CAC7630

72 Button(PTY) CAC7631

73 Door

See Contrast table(2)

74 Spring CBH2663

75 Lighting Conductor CNV7251

76 Lighting Conductor CNV7252

77 Lighting Conductor CNV7253

78 Holder CNV7256

79 Holder CNV7257

80 Holder CNV7258

81 Holder CNV7259

82 Holder CNV7260

83 Holder CNV7261

84 Holder CNV7316

85 Holder CNV7317

86 Lighting Conductor CNV7319

87 Lighting Conductor CNV7320

88 Lighting Conductor CNV7321

89 Lighting Conductor CNV7330

90 Lighting Conductor CNV7467

91 Lighting Conductor CNV7469

92 Holder CNV7472

93 Door Assy CXB9033

94 Knob Unit CXB8884

95 Chassis Unit CXB9795

96

Cassette Mechanism Module EXK4295

97 Screw IMS26P040FTC

98 Screw IMS26P060FTC

99 Frame CND1789

100 86211-48030-A

See Contrast table(2)

101 86212-48030-A See Contrast table(2)

102 Insulator CNM7496

103 Spacer CNM8078

104 Seal CNM8343

105 90467-10203 CNV5641

106 Guide CNV7306

107 Label CRW1425

108 Chassis Unit CXA8029

109 Transistor(Q809,811,812) 2SB1185

110 Bracket Unit CXB8082

111 Grille Unit

See Contrast table(2)

112 Sheet CNM8435

9

5

6

7

8

F

E

D

C

B

A

5

6

7

8

FX-MG8237ZT/EW

Mark No. Description Part No. Mark No. Description Part No.

(1) EXTERIOR SECTION PARTS LIST

Page 10

flashLAV

www.club-lexus.ru

10

1

234

12

34

F

E

D

C

B

A

FX-MG8237ZT/EW

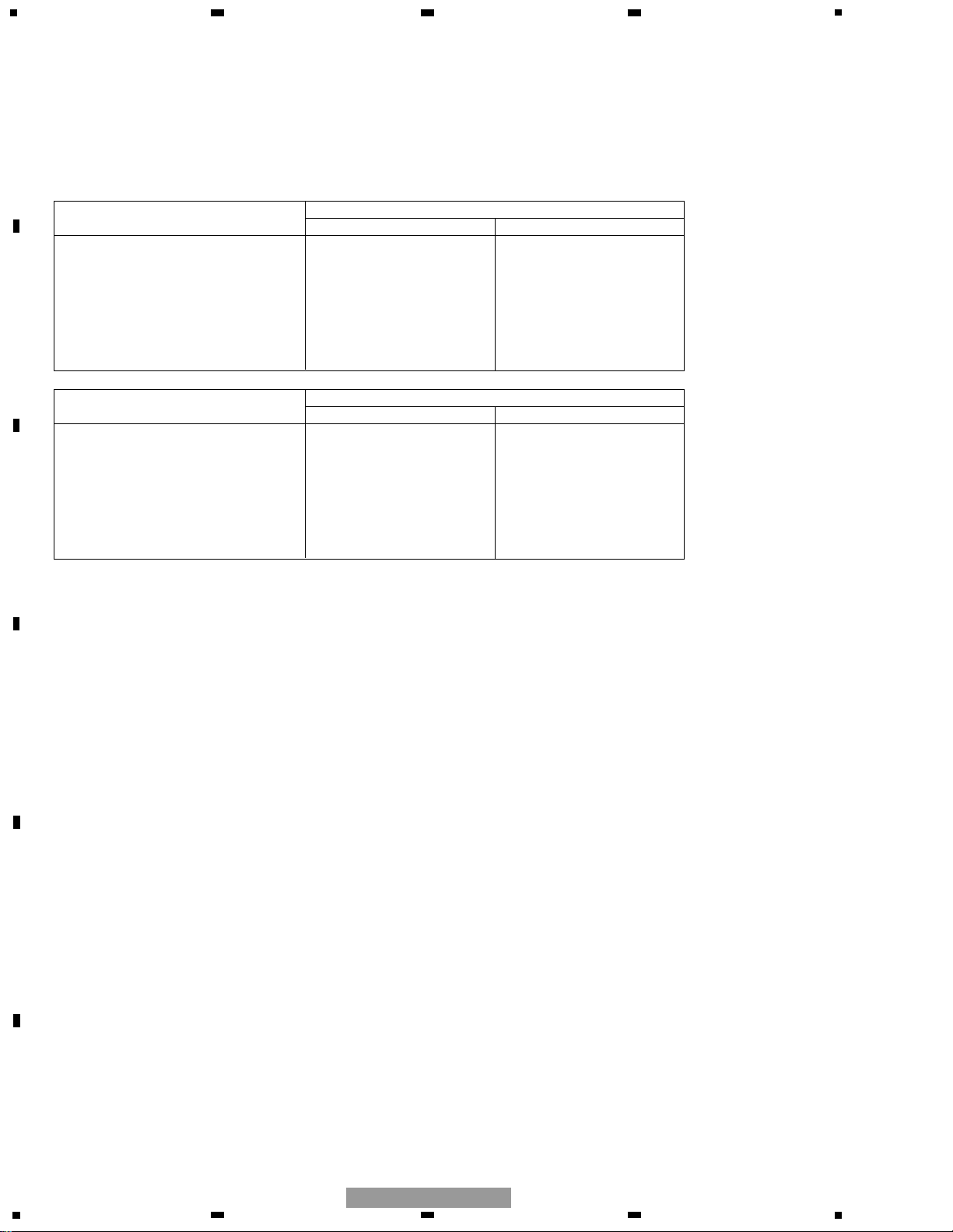

Part No.

Mark No. Symbol and Description FX-MG8237ZT/EW FX-MG8337ZT/EW

2 Screw BMZ50P080FTC BMZ50P080FTC

19 Main Unit CWM8388 CWM8556

53 Grille Assy CXC2067 CXC2068

73 Door CAT2354 CAT2355

100 86211-48030-A CND1247 CND1247

101 86212-48030-A CND1248 CND1248

111 Grille Unit CXB9904 CXB9905

Part No.

Mark No. Symbol and Description FX-MG8237ZT-91/EW FX-MG8337ZT-91/EW

2 Screw Not used Not used

19 Main Unit CWM8388 CWM8556

53 Grille Assy CXC2067 CXC2068

73 Door CAT2354 CAT2355

100 86211-48030-A Not used Not used

101 86212-48030-A Not used Not used

111 Grille Unit CXB9904 CXB9905

(2) CONTRAST TABLE

FX-MG8237ZT/EW, FX-MG8337ZT/EW, FX-MG8237ZT-91/EW and FX-MG8337ZT-91/EW are constructed

the same except for the following:

Page 11

flashLAV

www.club-lexus.ru

11

5

6

7

8

F

E

D

C

B

A

5

6

7

8

FX-MG8237ZT/EW

Page 12

flashLAV

www.club-lexus.ru

12

1

234

12

34

F

E

D

C

B

A

FX-MG8237ZT/EW

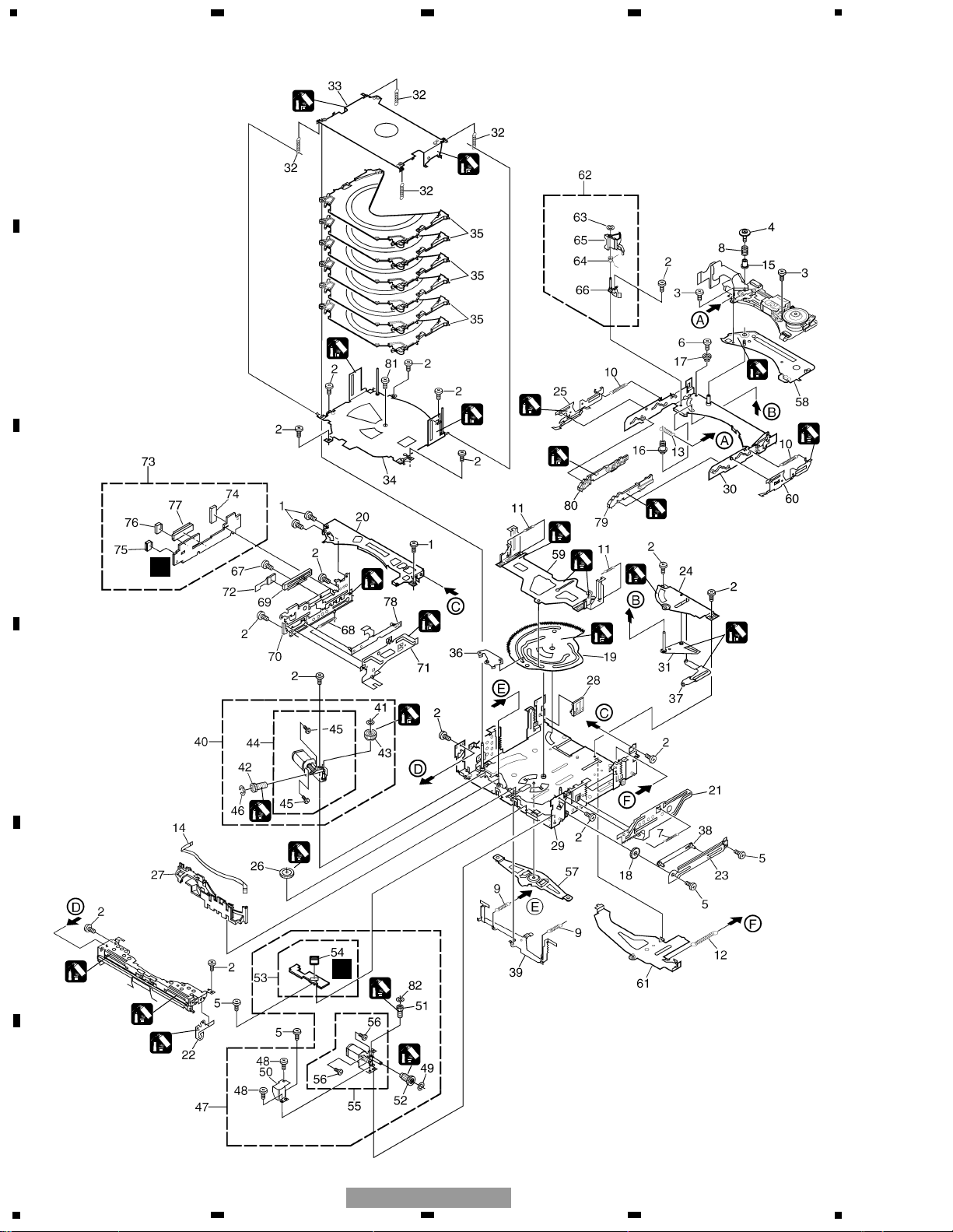

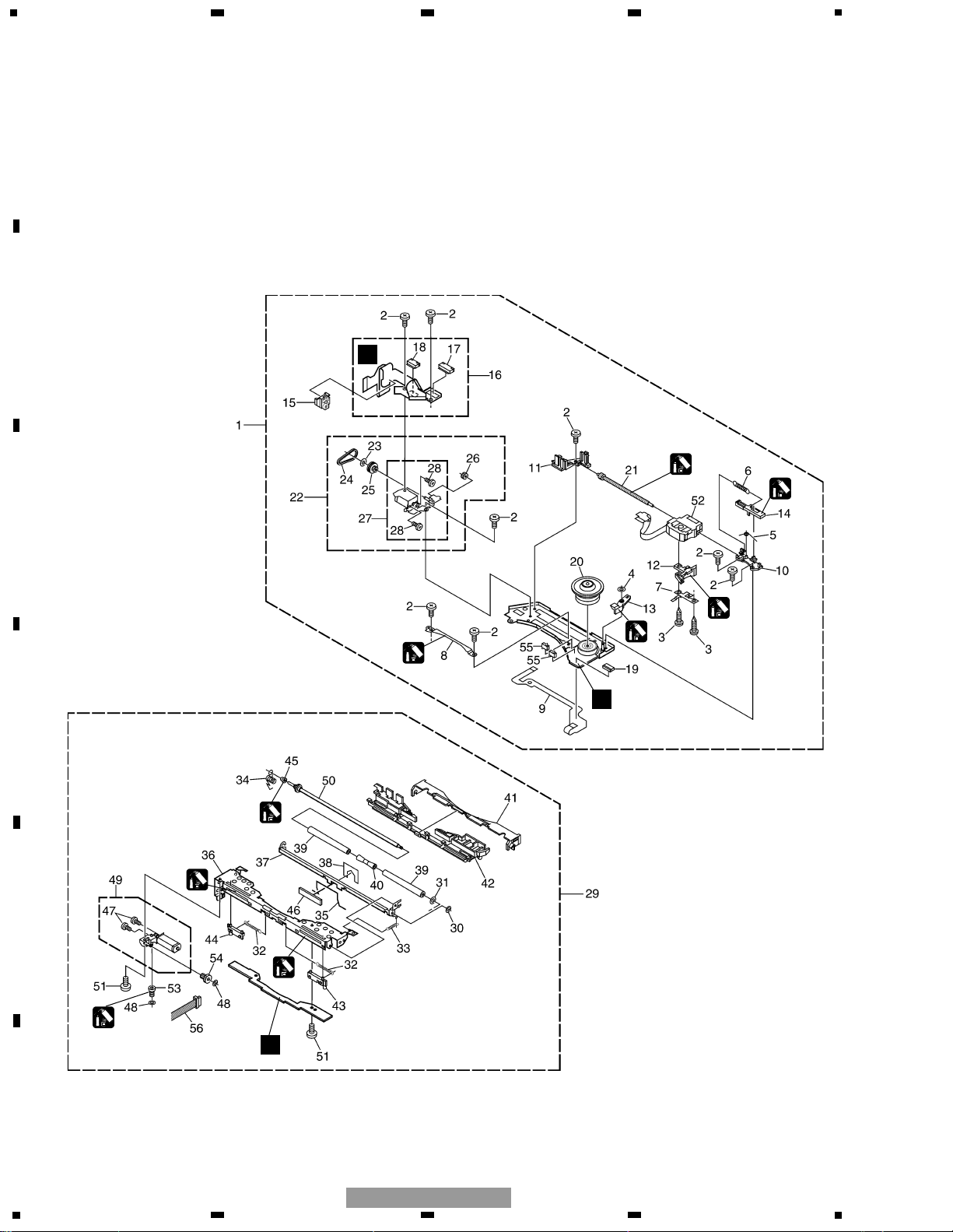

2.3 CD MECHANISM UNIT(1)

1

1

1

3

3

1

3

1

1

3

3

3

F

3

3

3

1

1

1

3

1

1

3

D

2

1

1:GEM1043

2:GEM1042

3:GEM1024

Page 13

flashLAV

www.club-lexus.ru

13

5

6

7

8

F

E

D

C

B

A

5

6

7

8

FX-MG8237ZT/EW

Mark No. Description Part No. Mark No. Description Part No.

1 Screw BMZ20P020FZB

2 Screw BMZ20P025FTC

3 Screw(M2x2) CBA1556

4 Screw(M2x2.5) CBA1626

5 Screw(M2x2.5) CBA1609

6 Screw(M2x4.5) CBA1629

7 Spring CBH2460

8 Spring CBH2461

9 Spring CBH2484

10 Spring CBH2694

11 Spring CBH2486

12 Spring CBH2487

13 Spring CBH2500

14 Connector CDE6698

15 Collar CLA4329

16 Collar CLA4330

17 Collar CLA4331

18 Gear CND1649

19 Cam Gear CND1650

20 Frame CND1651

21 Steer CND1667

22 Arm CND1657

23 Bracket CND1658

24 Bracket CND1660

* 25 Lever CNC9953

26 Gear CNV6612

27 Holder CNV6648

28 Holder CNV6738

* 29 Chassis Unit CXC1642

* 30 Frame Unit CXC1643

* 31 Arm Unit CXC1647

32 Spring CBH2488

33 Holder Unit CXC1644

34 Holder Unit CXC1646

35 Tray Unit CXB6930

36 Lever Unit CXC1648

* 37 Lever Unit CXC1649

38 Lever Unit CXC1650

* 39 Lever Unit CXC1651

40 Cam Motor Assy CXB7522

41 Washer CBF1064

42 Gear CNV6610

43 Gear CNV6611

44 Motor Unit(-A)(M1) CXC1144

45 Screw JFZ20P020FTC

46 Washer YE20FTC

47 ELV Motor Assy CXB7523

48 Screw BMZ20P025FTC

49 Washer CBF1064

50 Holder CND1668

51 Gear CNV6634

52 Gear CNV6635

53 PCB Unit(LED) CWX2614

* 54 Connector(CN31) CKS4523

55 Motor Unit(-A)(M2) CXC1145

56 Screw JFZ20P020FTC

* 57 Arm Unit CXC1653

58 Bracket Unit CXC1654

* 59 Lever Unit CXC1658

* 60 Lever Unit CXC1659

* 61 Lever Unit CXC1661

62 Arm Assy CXB8822

63 Washer CBF1038

64 Spring CBH2489

65 Arm CNV6735

66 Bracket Unit CXC1652

67 Screw BMZ20P025FTC

68 Spring CBH2459

69 Volume(VR1) CCW1023

70 Bracket CND1652

71 Steer CND1656

72 Flexible PCB CNP6368

73 PCB Unit(SIDE) CWX2613

74 Connector(CN12) CKS3991

* 75 Connector(CN14) CKS4404

76 Connector(CN13) CKS4525

77 Connector(CN11) CKS4572

78 Lever Unit CXC1645

* 79 Lever Unit CXB9121

* 80 Lever Unit CXB9122

81 Screw JFZ20P020FTC

82 Washer CBF1037

- CD MECHANISM UNIT(1) SECTION PARTS LIST

Page 14

flashLAV

www.club-lexus.ru

14

1

234

12

34

F

E

D

C

B

A

FX-MG8237ZT/EW

2

1

1

1

1

1

1

1

1

1:GEM1043

2:GEM1042

G

H

E

2.4 CD MECHANISM UNIT(2)

Page 15

flashLAV

www.club-lexus.ru

15

5

6

7

8

F

E

D

C

B

A

5

6

7

8

FX-MG8237ZT/EW

Mark No. Description Part No. Mark No. Description Part No.

1 Carriage Mech. Assy(G2T) CXB8842

2 Screw(M2x2) CBA1556

3 Screw(M2x6) CBA1628

4 Washer CBF1038

5 Spring CBH2453

6 Spring CBH2480

7 Spring CBL1521

* 8 Guide CNC9402

9 Flexible PCB CNP6217

10 Holder CNV6624

11 Holder CNV6625

12 Rack CNV6642

13 Arm CNV6731

14 Lever CNV6736

15 Holder CNV6737

16 PCB Unit CWX2611

17 Connector(CN41) CKS3785

18 Connector(CN42) CKS4508

19 Connector(CN1) CKS4508

20 Support Wheel Unit CXC1768

21 Screw Unit(-B) CXB7518

22 Carriage Motor Assy CXB7521

23 Washer CBF1038

24 Belt CNT1088

25 Pulley CNV6627

26 Gear CNV6629

27 Motor Unit(-A)(M3) CXC1143

28 Screw JFZ14P020FTC

29 Loading Mech. Assy CXB7525

30 Washer CBF1037

* 31 Washer CBF1075

* 32 Spring CBH2450

33 Spring CBH2452

* 34 Spring CBH2457

* 35 Spring CBH2580

* 36 Frame CND1653

* 37 Arm CND1654

* 38 Sheet CNM7295

39 Roller CNV6616

40 Collar CNV6617

* 41 Guide CNV6622

* 42 Holder CNV6636

* 43 Lever CNV6732

* 44 Lever CNV6733

45 Collar CNV6734

* 46 Holder CNV7144

47 Screw JFZ12P018FTC

48 Washer CBF1037

* 49 Motor Unit(-A) CXC1146

50 Shaft Unit(-C) CXB7528

51 Screw JFZ20P020FTC

52 PU Unit(PX1)(Service) CXX1569

* 53 Gear CNV6620

* 54 Gear CNV6621

55 Switch(S1,2) CSN1057

* 56 Connector CDE6674

- CD MECHANISM UNIT(2) SECTION PARTS LIST

Page 16

flashLAV

www.club-lexus.ru

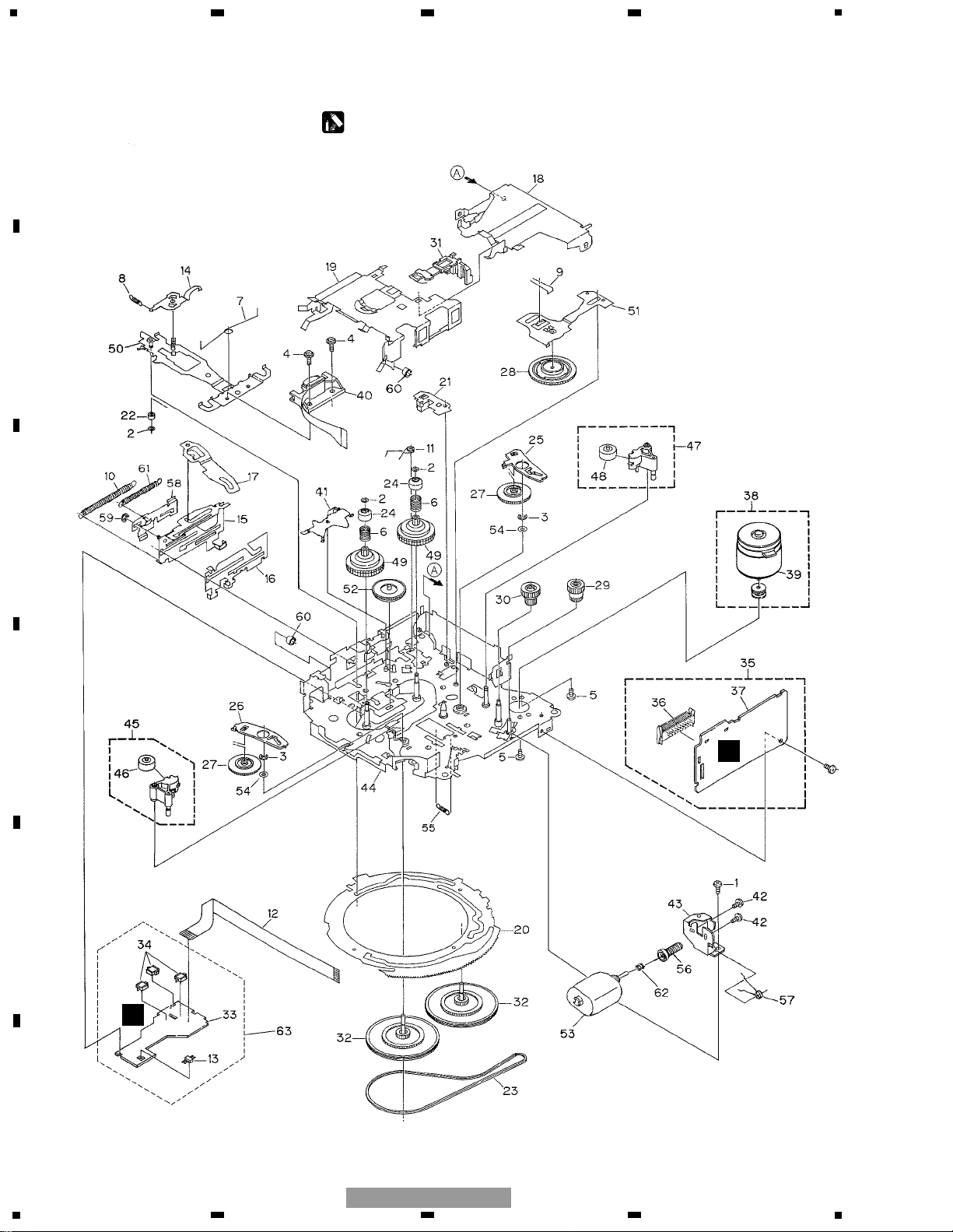

2.5 CASSETTE MECHANISM MODULE

16

1

234

12

34

F

E

D

C

B

A

FX-MG8237ZT/EW

I

J

For grease application, refer to the service manual for CX-1011 (CRT2406)

Page 17

flashLAV

www.club-lexus.ru

17

5

6

7

8

F

E

D

C

B

A

5

6

7

8

FX-MG8237ZT/EW

- CASSETTE MECHANISM MODULE SECTION PARTS LIST

1 Screw BSZ20P040FMC

2 Washer CBF1037

3 Washer CBG1003

4 Screw EBA1028

5 Screw CBA1037

6 Spring EBH1653

7 Spring EBH1642

8 Spring EBH1641

9 Spring EBH1626

10 Spring EBH1627

11 Spring EBH1648

12 Cord EDD1024

13 Photo-reflector(Q101) EGN1004

14 Arm ENC1526

15 Lever Unit EXA1610

16 Lever ENC1543

17 Arm ENC1532

18 Frame ENC1533

19 Holder ENC1547

20 Gear ENC1535

21 Arm ENC1550

22 Roller ENR1040

23 Belt ENT1027

24 Collar ENV1508

25 Arm ENV1539

26 Arm ENV1540

27 Gear ENV1569

28 Gear ENV1547

29 Gear ENR1044

30 Worm Wheel ENV1559

31 Lever ENV1551

32 Flywheel ENV1554

33 Gathering PCB ENX1073

34 Switch(S101,S102,S103) ESG1007

35 Deck Unit EWM1043

36 Plug(CN251) CKS3540

37 Gathering PCB ENX1076

38 Motor Unit(M1) EXA1618

39 Motor EXM1035

40 Head Assy(HD1) EXA1594

41 Arm ENC1537

42 Screw JGZ20P025FNI

43 Bracket ENC1559

44 Chassis Unit EXA1636

45 Pinch Holder Unit EXA1608

46 Pinch Roller ENV1518

47 Pinch Holder Unit EXA1607

48 Pinch Roller ENV1518

49 Reel Unit EXA1625

50 Head Base Unit EXA1611

51 Lever Unit EXA1587

52 Gear Unit EXA1596

53 Motor Unit(M2) EXA1623

54 Washer HBF-179

55 Spring EBH1537

56 Worm Gear ENV1564

57 Spring EBH1655

58 Lever ENC1548

59 Washer YE15FUC

60 Tube ENM1039

61 Spring EBH1645

62 Spring EBH1545

63 Sensor Unit EWM1041

Mark No. Description Part No. Mark No. Description Part No.

Page 18

flashLAV

www.club-lexus.ru

18

1

234

12

34

F

E

D

C

B

A

FX-MG8237ZT/EW

Page 19

flashLAV

www.club-lexus.ru

19

5

6

7

8

F

E

D

C

B

A

5

6

7

8

FX-MG8237ZT/EW

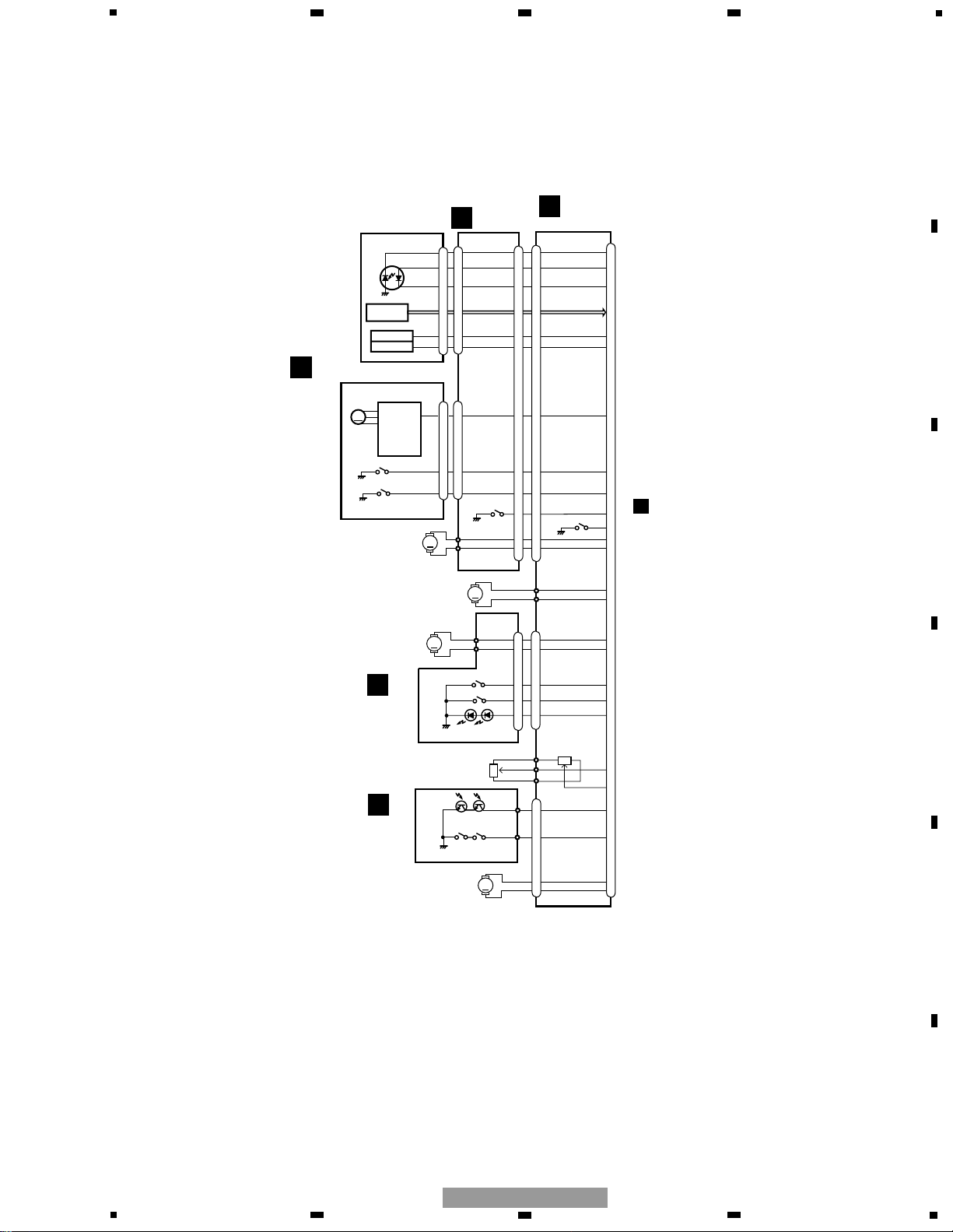

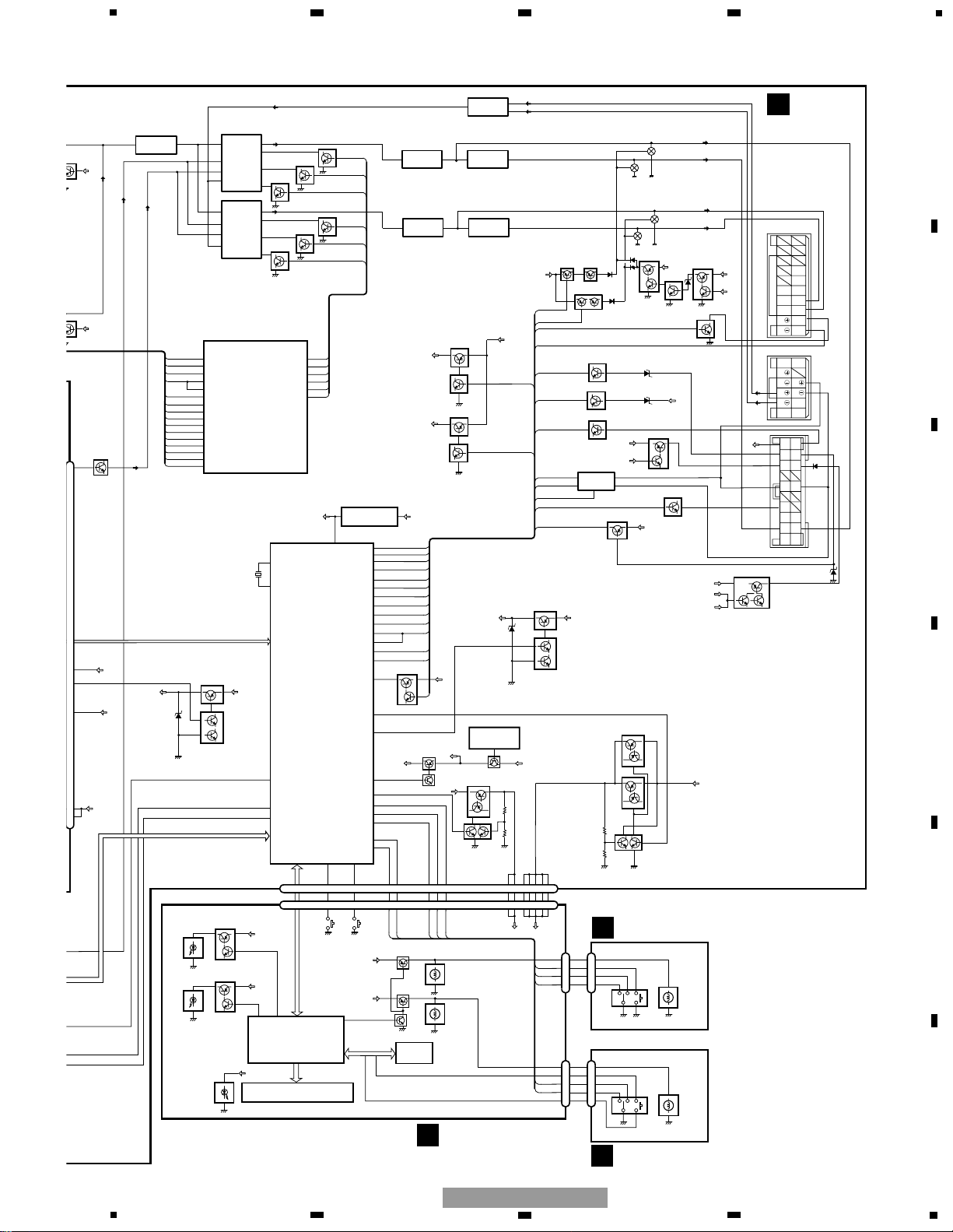

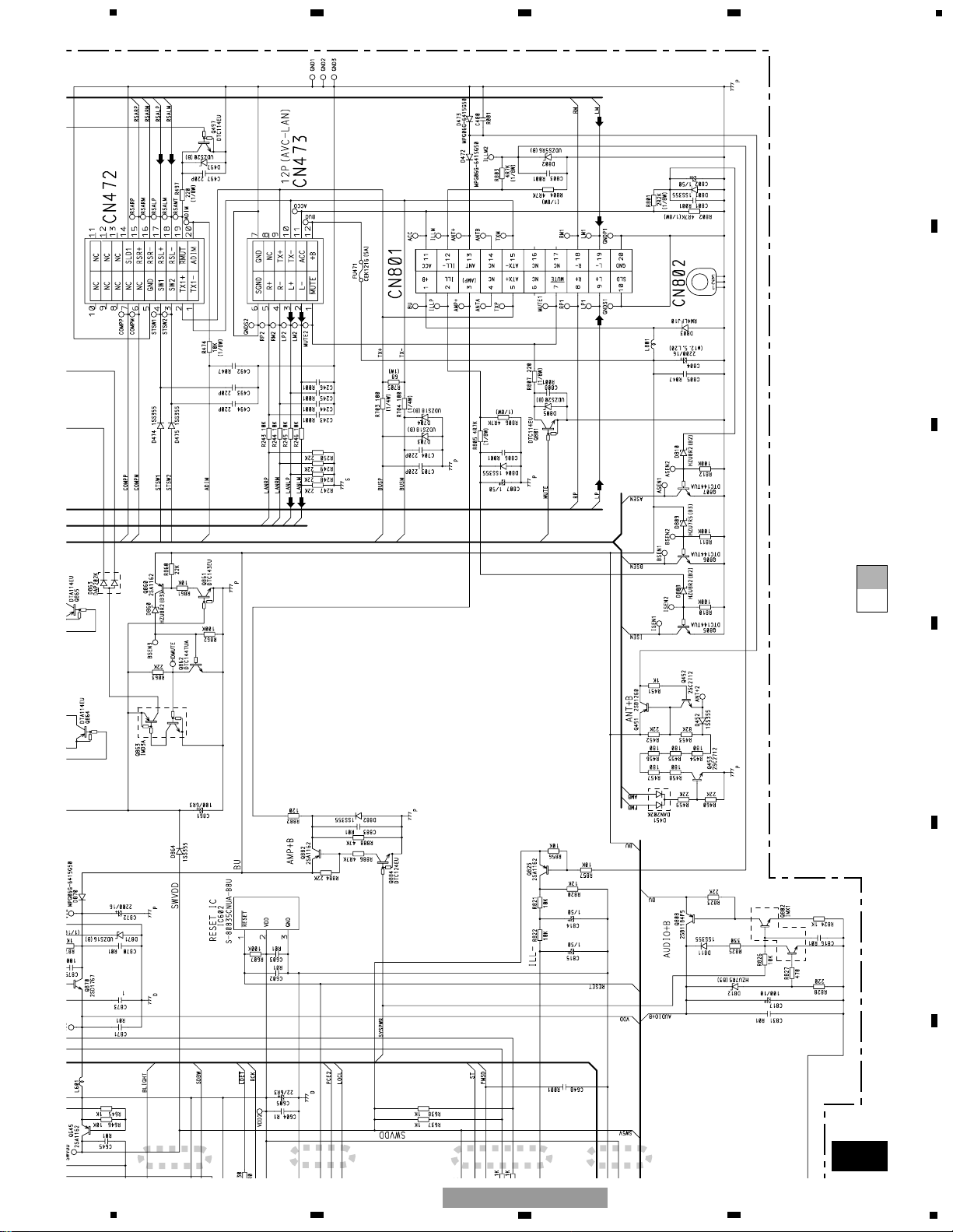

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM

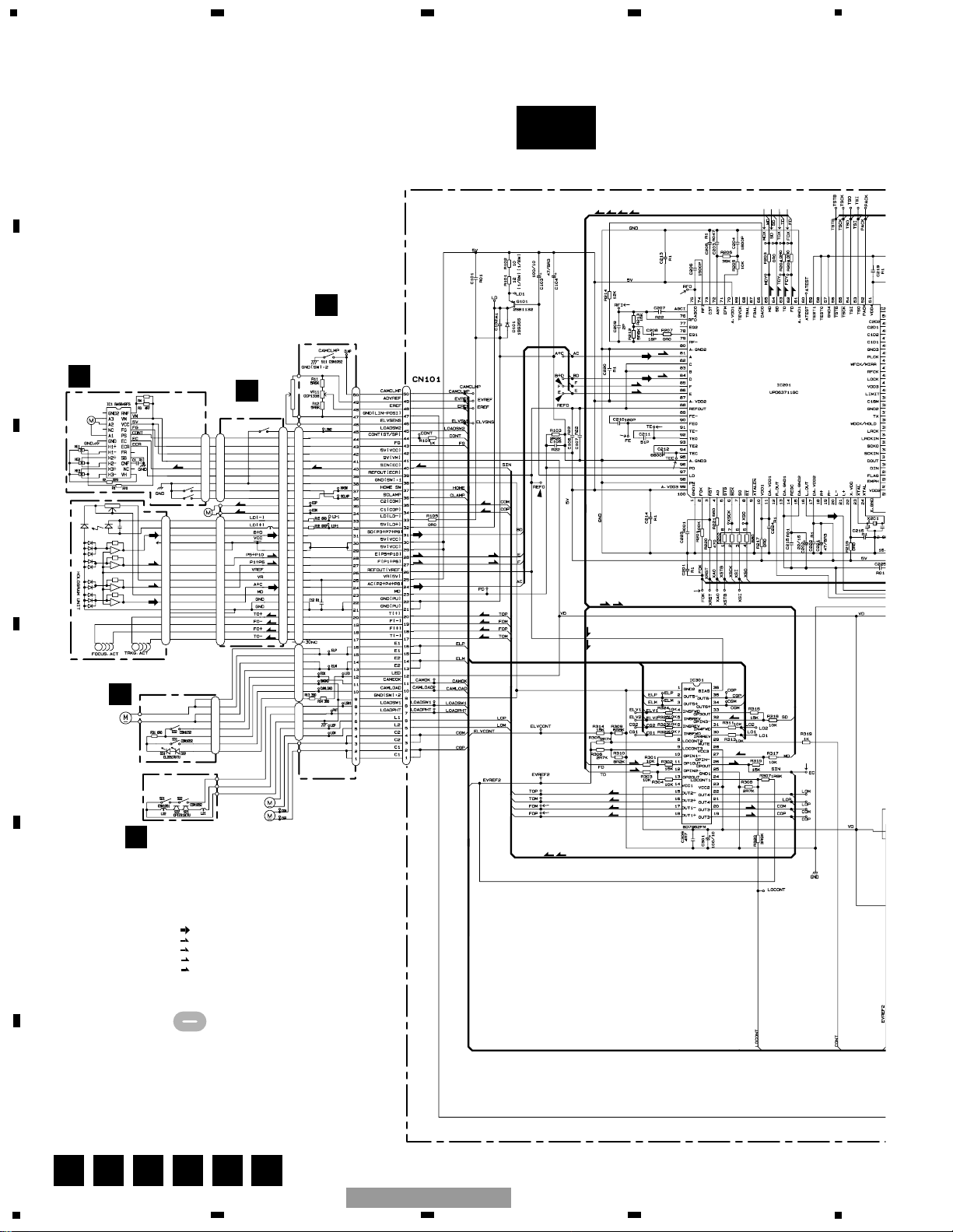

3.1 BLOCK DIAGRAM(1)

M

LOADING

VR1 ELV SENSE

VR11

S31 CAMLOAD

PU UNIT(SERVICE)(PX1)

PCB UNIT(M2 UNIT)

HOLOGRAM

UNIT

FOCUS ACT

TRACKING ACT

MD

LD+

LD-

LD

MD

FO+

TO+

CN41

M

M

SPINDLE

M3 CARRIAGE

CLAMP

10

2

1

16

14

A+C,B+D,

E,F

2

A3

3

5

A2

A1

IC 1

BA6849FS

MOTOR

DRIVER

CN1

EC

19

S2 CLAMP

HOME

S1 HOME

5

2

1

5

2

1

CN42

S41 LOAD3

PCB UNIT

23

14

13

28

26

6

9

10

1

11

12

23

14

13

28

26

6

9

10

1

11

12

PCB UNIT(SIDE)

CN12

S11 CAMCLMP

M

M1 CAMGEAR

CN31

M

M2 ELV

S32 CAMEOK

D31

D32

PCB UNIT

(LED)

CN14

CN13

Q22 Q21

S21 LOAD1

S22 LOAD2

PCB UNIT

(LOAD)

2

1

4

5

CN11

MD

23

32

33

LD+

LD-

FOP

18

TOP

20

SIN(EC)

40

CLAMP

36

HOME

37

LOADSW2

45

50

COP

34

COM

35

CGM

3

CGP

1

ELP

15

ELM

13

CAMOK

11

CAMLOAD

10

LED

12

ELVSNS

46

EREF

48

LOADPHT

7

LOADSW1

8

LOP

6

LOM

5

G

F

H

D

E

1

1

2

2

5

5

7

7

8

8

C

CN101

Page 20

flashLAV

www.club-lexus.ru

20

VDCNT2

R

CN501

SUB

ANTENNA

16

13

10

11

2

AUDIO+B

SWVDD

MAIN

ANTENNA

IC 501

LA1061M

5

6

Q501

DIVERSITY

COMP

IC561

HA12181FP

AM NOISE CANCELER

CN351

SUB

MAIN

1

NIN

39

FMSD

FML

Q401

MFIX

13

CSL

BU

8

4

19

20

3

CN353

IC 3

EEPROM

28

27

FM/AM 1ST IF 10.7MHz

T51 Q51 CF51

CF52 CF53

IC1

MIXER, IF AMP, DET.

6

21

18

LDET

COMP

222510 14 12 15 16 8 13 2 3 4

CF202

VDD

VCC

DI/DO

CE2CKCE1

SDBWSLFMSD

NL1

NL2

IC 2 FM MPX

AMANT

FMANT

ATT

ATT

AMRF

FMRF

IMG ADJ

RF ADJ

X901

10.25MHz

ANT ADJ

LOCL

23

LOCH

AMDET

MPXREF 41kHz

AM 2ND IF

450kHz

19

CREQ

11

DGND

1

STIND

L ch

5

R ch

924

AMDET

FMLOCL

20

177

AMPNS

WC

26

RFGND

AMIN

Q561

IC252

PM4009A

X251

RDS

DECODER

1211

20

8

AM

Q402

VDD

Q404

Q351

LDET

RDSMUTE

FMSD

1

CD9V

11

AUDIO+B

RDT

5

Q403

Q406

AMB

Q405

FMB

Q252

NL2

Q502

AUDIO+B

LOCL

Q504

SWVDD

STBY

B.U

MUTE

MTL

LOAD

5

1

4

2

1

3

4

11

9

20

19

8

I

DECK UNIT

IC251

HA12216F

IC351

PA2020A

EQ AMP

MECHANISM

DRIVER

CN251

CN252

CN254

CN255

CN253

6

16

TAPE+B

Lch

10

12

FWD

L-ch

REV

L-ch

37

38

39

18

19

17

3

15 6

8

7

10

CN256

3

15 6

S101

LOAD

S102

MODE

Q101

REEL

SENSE

M

M

M2

SUB

MOTOR

M1

MAIN

MOTOR

5

2

1

SENSOR UNIT

S103

70µs

4

4

J

I

23

32

33

18

20

40

36

37

45

50

34

35

3

1

15

13

11

10

12

46

48

7

8

6

5

CONTROL UNIT(G2T)

Q101

96

PD

CD CONTROL

97

LD

A+C,B+D,E,F

L-OUT

16

IC504(1/2)

TC74VHCT08AFT

3 1,2

IC 201

UPD63711GC

6 4,5

33

LRCKIN

31

SCKIN

3.3V - 5V CONVERTER

5V - 3.3V CONVERTER

IC505(1/2)

TC74VHC541FT

DOUT,LRCK,

SCKO,RADV,

SBSY

15

ZLRCK

14

ZSCK

IC501

SM5903BFP

SHOCK PROOF

CONTROLLER

10

V+5

22

3V

IC507

MSM51V17400F6TFT

IC702

PD5748E

MECH.

CONTROLLER

IC504(2/2)

TC74VHCT08AFT

IC505(2/2)

TC74VHC541FT

YMDATA,

YMLD,

YMCLK

21

ZSENSE

9,10

8

98

ZSENSE

BUFFER RAM

14

VDD

VCC2

3+3ch

DRIVER

IC 301

BD7962FM

ELV1,ELV2,ELVCONT,LD1,LD2,

LOCONT,CG1,CG2

9

29

CONT

MUTE

MOTOR CONTROL

14

VD

XSI,XSO,XSCK,XSTB,XAO,XRST,FOK,LOCK,

TSI,TSO,TSCK,TSTB,PACK,SBSY

SERVO DSP I/F

SERVO EQUALIZER OUTPUT

FD,TD,SD,MD

18

15

OUT1+

OUT2-

Q602

Q603

CD MUTE

VD

Q601

74

CDMUTE

CN101

CN501

BSI,BSO,BSCK,BRXEN,BSRQ,BRST

10

reset

LOUT

37

VDCONT

9

6

3

RESET

VDCONT

VDD

VD

VD

17

18

IC 303

BA05SFP

5V REGULATOR

4

2

V+5

S-818A33AUC-BGN

3V REGULATOR

1

5

IC 302

3V

92

TEMP

94

VDIN

VD

26

OPOUT

COP

COM

ELP

ELM

LOP

LOM

CGM

CGP

19

20

2

3

21

22

34

35

OUT3+

OUT3-

OUT5OUT5+

OUT4+

OUT4OUT6+

OUT6-

VD

CLAMP

HOME

LOADSW2

CAMCLMP

ELVSNS

EREF

72

79

82

23

91

92

HOME2

HOME

LOADSW2

CAMCLMP

EREFF

CAMOK

21

CAMOK

CAMLOAD

22

CAMLOAD

LOADPHT

89

LOADPHT

LOADSW1

81

LOADSW1

ELVSENS

C

F

CN11

8

FM/AM TUNER UNIT

1

234

12

34

F

E

D

C

B

A

FX-MG8237ZT/EW

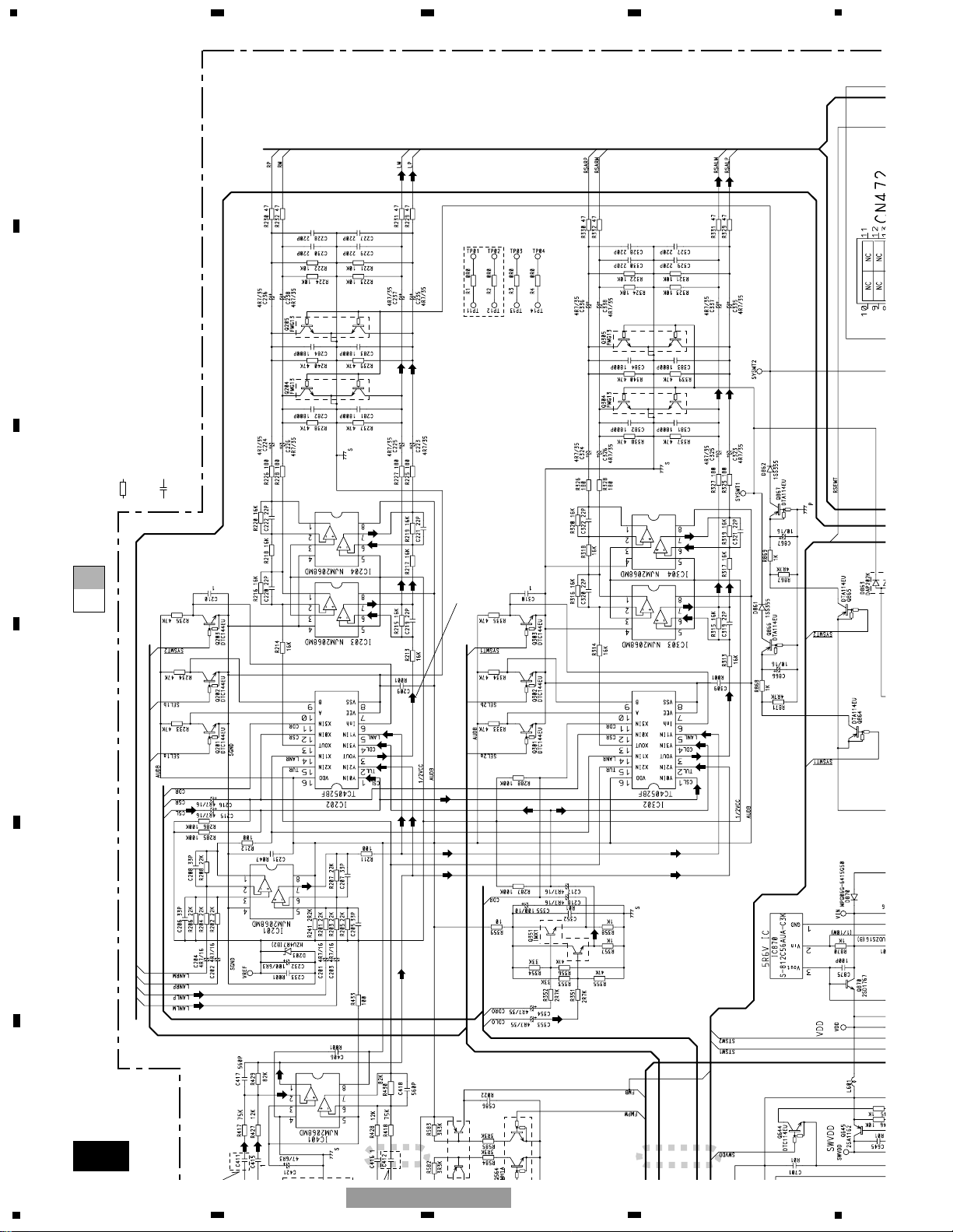

3.2 BLOCK DIAGRAM(2)

Page 21

flashLAV

www.club-lexus.ru

21

13

XOUT

X601

VDCNT2

17 23

17

20 74

23 21 22

19

21 22

19

20

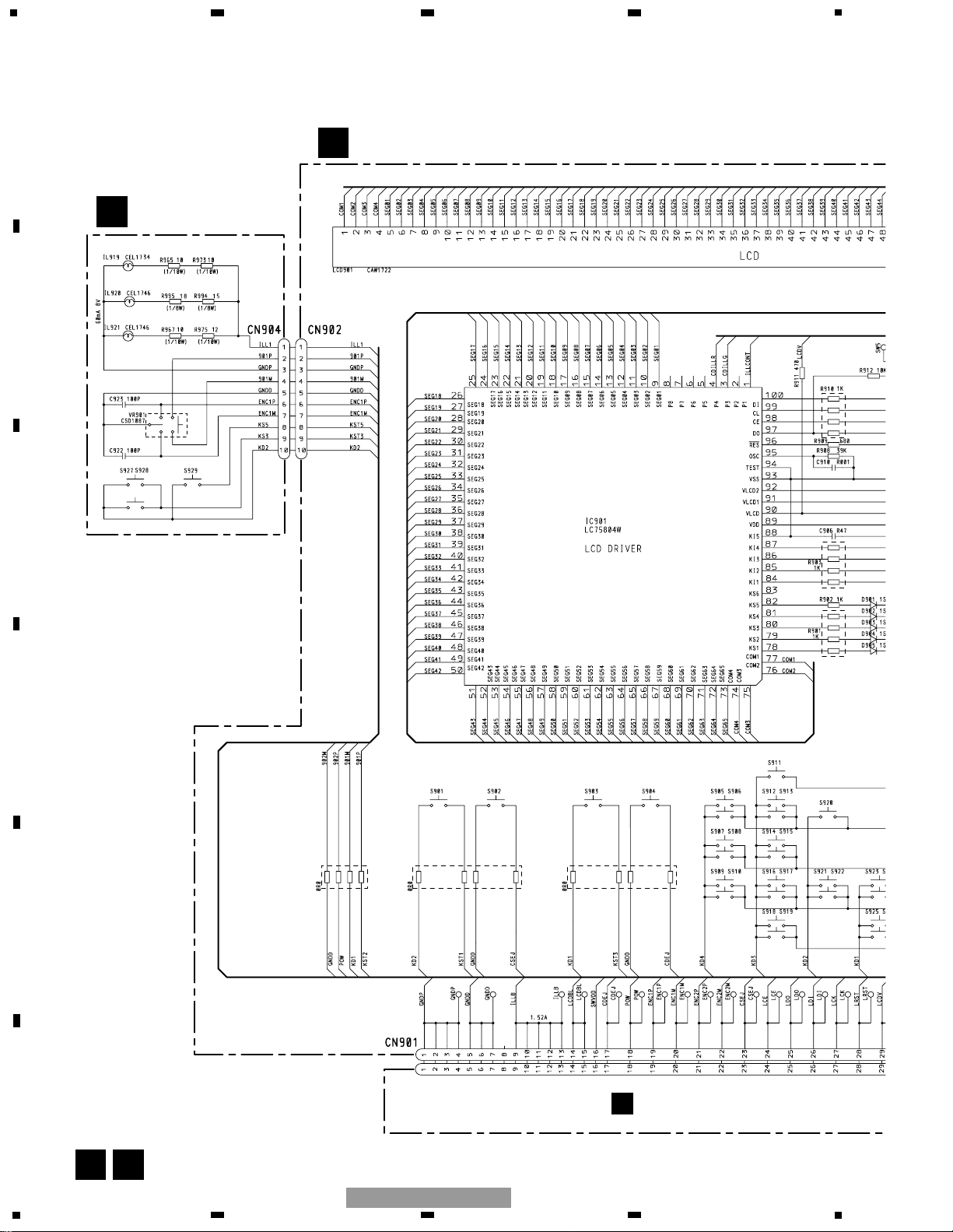

LC75804W

IC 901

LCD901

20

14,15

14,1599

CD

EJECT

TAPE

EJECT

VDD

IC 602

S-80835CNUA-B8U

53

12

12

RESET

RESET

RESET

15

XIN

13

XOUT

RESET

75

73

28

BLIGHT

83

82

ENC1+

85

ENC2-

84

ENC2+

65

CONTROLLER

SYSTEM

IC 601(2/2)

KEY

MATRIX

CN804

CN902

VDD

KEYBOARD PCB

ENC2P

ENC2M

ENC1P

pwr

LCDBL

ILLB

cdej

csej

asens

bsens

Q818

Q819

BU

Q816

Q808

KEY CONTROLLER

LCD DRIVER

16

13

10

11

2

VR902

POWER•VOL

VR901

AUDIO CONTROL•TUNE

ENC1-

power

81

18

18

ENC1M

ILLB

101011

11

AVC-LAN BUS DRIVER

UNBALANCE TO BALANCE CONVERTER

IC701

HA12187FP

6

BU

AVC-LAN MUTE

Q801

ISENS

Q805

BSENS

Q806

ASENS

Q807

5

Q812

Q814

4

LAMP

Q802

Q809

Q815

CD9V

AUDIO+B

VDCONT2

SYSPWR

Q865

Q867

IC401

NJM2068MD

TUNER

MIXING AMP

1

IC203

NJM2068MD

67

IC204

NJM2068MD

67

Q864

Q205

sysmute

30

29

21

TX

RX1

RX2

isens

22

IPPW

1

2

8

bsens

TX

RX

isens

IPPW

MUTE

RX

56

LANMUTE

CN351

Q811

Q813

BU

AUDIO +B REGULATOR

CD 9V REGULATOR

BU

Q563(1/2)

Q564(1/2)

Q563(2/2)

Q564(2/2)

AUDIO+B

FMB

AMB

42

AMPW

41

FMPW

FML

CSL

CDL

B

SWVDD

IC202

TC4052BF

IC302

TC4052BF

2

2

3

1

1

4

4

BALANCE TO UNBALANCE CONVERTER

IC303

NJM2068MD

67

IC304

NJM2068MD

67

3

ACC+B

R

L

R

SGND

mute

GND

TX

BU+B

TX

L

CN473

SW2

SW1

TX1

TX1

GND

ADIM

SLD1

CN472

RSR+

RSR-

RSL+

RSL-

rmut

ACC

+B

ILL-

ILL

ANT

AMP

TX-

TX+

mute

R-

R+

L-

L+

GND

SLD

CN801

Q351

Q204

Q305

Q304

IC870

S-812C56AUA-C3K

3

VDD

VDD5V REGULATOR

BU

Q870

1

1

CD9V

UNBALANCE TO BALANCE CONVERTER

SELECTOR

SELECTOR

IC201

NJM2068MD

7

5

5

5

LANL

Q866

52

sysmute@

asens

Q451

Q452

Q453

AMB

FMB

ANT+B

Q645

SWVDD

Q644

55

SWVDD

43

SYSPWR

CONTROLLER

IC 601(1/2)

SYSTEM

FMSD

RDSMUTE

LDET

DI/DO

CE2

CK

CE1

SL

1

FMSD

3

RDSMUTE

19

ldet

32

PDI

11

PDO

33

PCE2

34

pck

93

PCE1

31

SL

MAIN UNIT

A

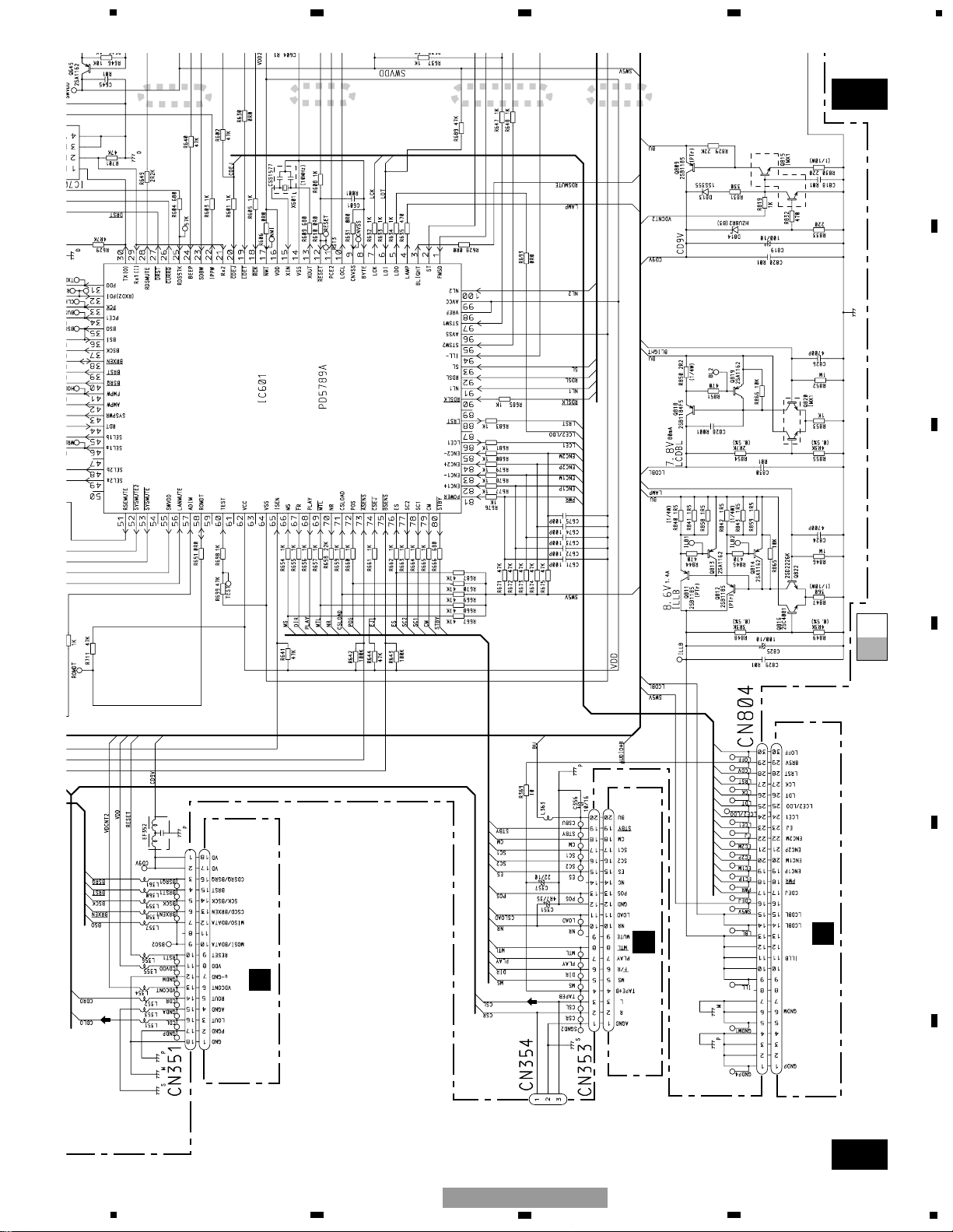

PD5789A

PD5789A

80

stby

69

mtl

71

CSLOAD

RDT

44

RDT

BU

ADIM

Q721

Q722

57

ADIM

SW5V

ADIM

1

2

6

7

1

2

6

7

ILLCONT

Q901

Q902

Q903

ILLB

ILLB

Q907

Q908

ILLB

Q905

Q906

ILLB

34

CDILLRCDILLG

LCDBL

LCDBL

1

2

6

7

1

2

6

7

ILL2

ILL1

LEFT PCB

L

RIGHT PCB

K

4

4

KST2

KDT1

ENC2P

ENC2M

ENC1P

pwr

ENC1M

ENC2P

ENC2M

ENC1P

pwr

ENC1M

CN904 CN902

CN905CN903

LDO,LCK,LCE,LDI,LRST

Q820

Q882

Q884

BU

SYSPWR

ILLB REGULATOR

ILL-

Q825

SWVDD

ILL-

94

ILL-

sysmute

sysmute@

Q860

Q861

AMPW

FMPW

Q863

BU

SWVDD

SWVDD

Q862

Q497

RSEMT

RSEMT

51

RSEMUTE

Q301

Q302

Q303

6

9

10

INH

B

A

SEL2b

SEL2a

sysmute

Q201

Q202

Q203

6

9

10

INH

B

A

SEL1b

SEL1a

sysmute@

45

SEL1b

46

SEL1a

48

SEL2b

49

SEL2a

53

sysmute

52

sysmute@

2

Q406

AMB

Q405

FMB

NL1

91

NL1

NL2

100

NL2

LOCL

10

LOCL

6

121213

13

BU

LANLP

LANLM

BU

Q822

CREQ

26

currq

ST

2

ST

SDBW

23

SDBW

5

6

7

8

F

E

D

C

B

A

5

6

7

8

FX-MG8237ZT/EW

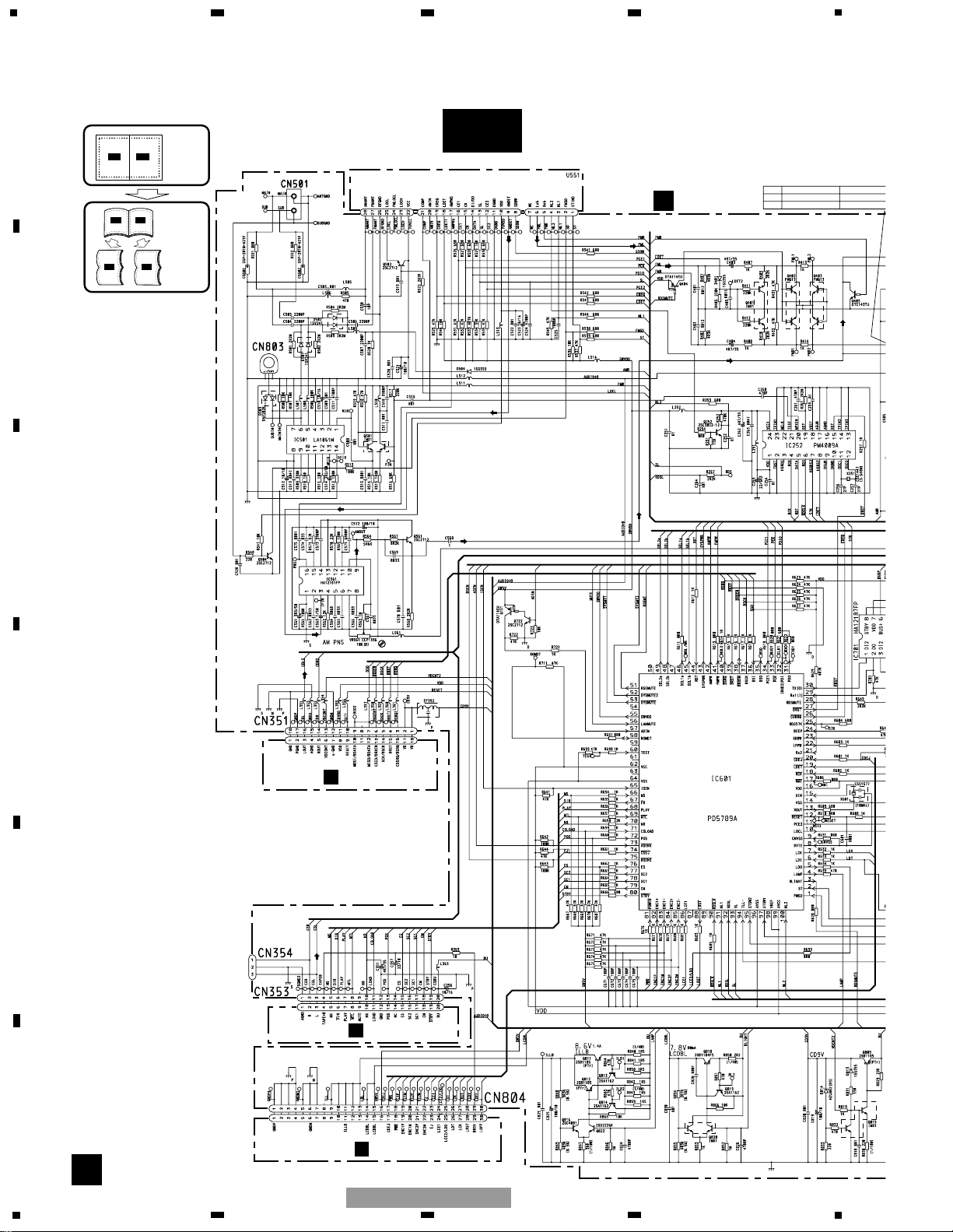

Page 22

flashLAV

www.club-lexus.ru

A-a A-b

A-a

A-b

A-b

A-a

Large size

SCH diagram

Guide page

Detailed page

Note: When ordering service parts, be sure to refer to " EXPLODED VIEWS AND PARTS LIST" or

"ELECTRICAL PARTS LIST".

A-a

A

FM/AM TUNER UNIT

C

CN501

I

CN251

B

CN901

A

MAIN UNIT

FX-MG8337ZT/E

R022

R022

FX-MG8237ZT/EW

R1

R1

C411

C412

SYSTEM CONTROLLER

FM(30%,400Hz):-24.9dBs

AM(30%,400Hz):-11.8dBs

CD(1kHz):+3.6dBs

TAPE(1kHz):-7.5dBs

431

5

2

431

52

6

431

52

6

4

3

1

5

2

6

4

3

1

5

2

6

4

3

1

5

2

4

3

1

5

2

5

2

TUNER MUTE

FM DIVERSITY

RDS DECODER

ANTENNA

JACK

22

1

234

12

34

F

E

D

C

B

A

FX-MG8237ZT/EW

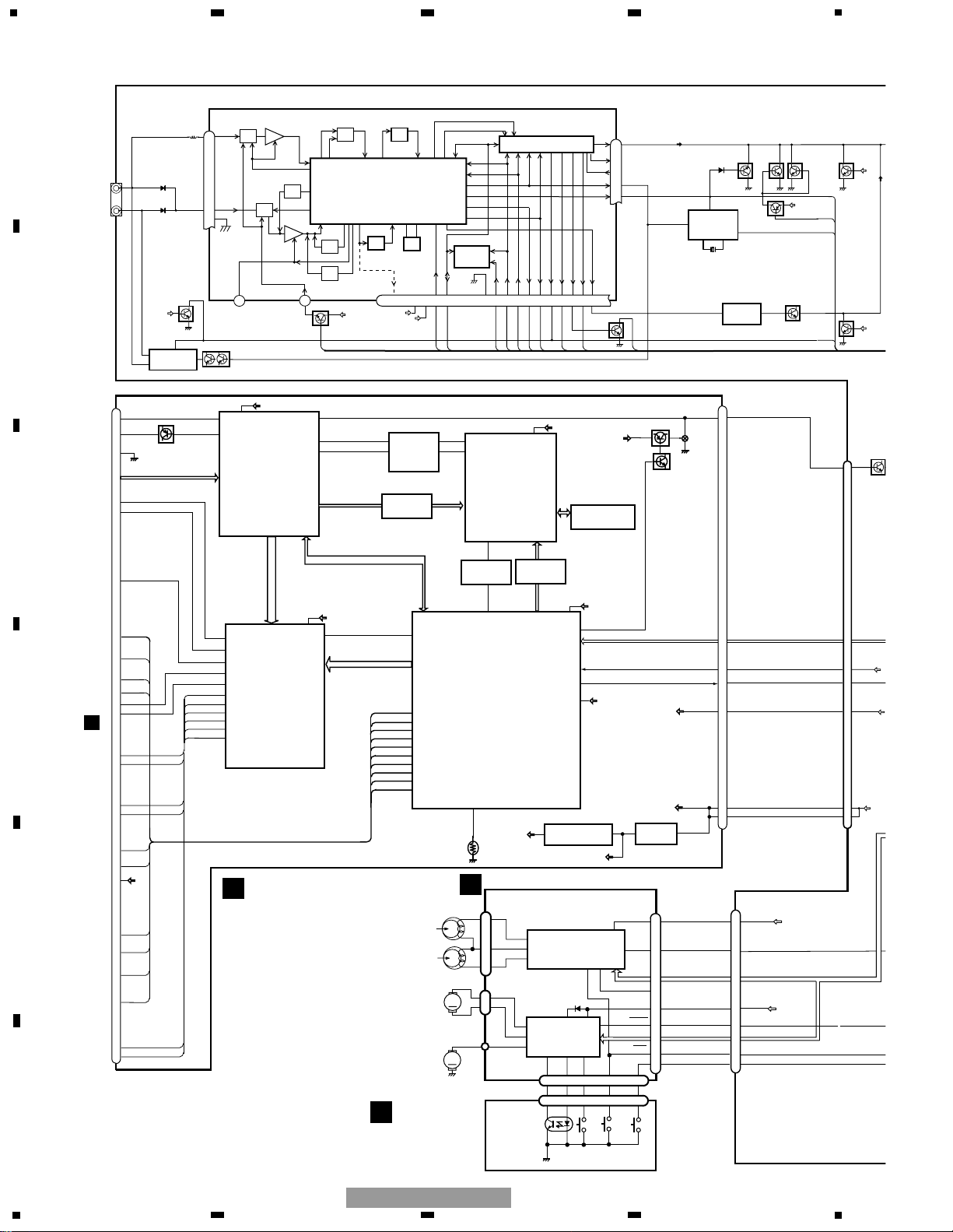

3.3 OVERALL CONNECTION DIAGRAM(GUIDE PAGE)

Page 23

flashLAV

www.club-lexus.ru

A-b

A

Decimal points for resistor

and capacitor fixed values

are expressed as :

2.2 2R2

0.022 R022

←

←

The > mark found on some component parts indicates

the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of

identical designation.

Symbol indicates a resistor.

No differentiation is made between chip resistors and

discrete resistors.

NOTE :

Symbol indicates a capacitor.

No differentiation is made between chip capacitors and

discrete capacitors.

FX-MG8337ZT/EW

R022

R022

FX-MG8337ZT/EW

>

350µH

FM: -9.6dBs

AM:-11.5dBs

TAPE: -7.5dBs

CD: +2.3dBs

FM: -3.9dBs

AM: -5.8dBs

TAPE: -1.9dBs

CD:+8.0dBs

4

3

1

5

2

6

4

3

1

5

2

6

4

3

1

5

2

6

431

52

6

4

3

1

5

2

4

3

1

5

2

4

3

1

5

2

4

3

1

5

2

4

3

1

5

2

6

4

3

1

5

2

6

4

3

1

5

2

6

TUNER MIXING AMP

BALANCE TO UNBALANCE

UNBALANCE TO BALANCE

UNBALANCE TO BALANCE

AUDIO SELECTOR

FOR RSA

AUDIO SELECTOR

FOR AMP

SYSTEM MUTE

SYSTEM MUTE

ASENSEBSENSEISENSE

23

5

6

7

8

F

E

D

C

B

A

5

6

7

8

FX-MG8237ZT/EW

Page 24

flashLAV

www.club-lexus.ru

A-a

A-b

A-a

A-a

A-b

1

2

FM/AM TUNER UNIT

A

MAIN UNIT

FX-MG8337ZT/EW

R022

R022

FX-MG8237ZT/EW

R1

R1

C411

C412

FM(30%,400Hz):-24.9dBs

AM(30%,400Hz):-11.8dBs

4

3

1

5

2

4

3

1

52

6

4

3

1

5

2

6

4

3

1

5

2

4

3

1

5

2

4

3

1

5

2

6

4

3

1

5

2

4

3

1

2

6

TUNER MUTE

FM DIVERSITY

RDS DECODER

TUNER

ANTENNA

JACK

24

1

234

12

34

F

E

D

C

B

A

FX-MG8237ZT/EW

Page 25

flashLAV

www.club-lexus.ru

A-a

A-b

A-a

A-a

A-b

3

4

5 6

C

CN501

I

CN251

B

CN901

SYSTEM CONTROLLER

CD(1kHz):+3.6dBs

TAPE(1kHz):-7.5dBs

4

3

1

52

6

4

3

1

5

2

6

25

5

6

7

8

F

E

D

C

B

A

5

6

7

8

FX-MG8237ZT/EW

Page 26

flashLAV

www.club-lexus.ru

A-a

A-b

A-b

1

2

Decimal points for resistor

and capacitor fixed values

are expressed as :

2.2 2R2

0.022 R022

←

←

Symbol indicates a resistor.

No differentiation is made between chip resistors and

discrete resistors.

NOTE :

Symbol indicates a capacitor.

No differentiation is made between chip capacitors and

discrete capacitors.

FX-MG8337ZT/EW

FM: -9.6dBs

AM:-11.5dBs

TAPE: -7.5dBs

CD: +2.3dBs

4

1

2

6

4

3

1

5

6

4

3

1

5

2

4

3

1

5

2

4

3

1

5

2

4

3

1

5

2

4

3

152

6

TUNER MIXING AMP

BALANCE TO UNBALANCE

UNBALANCE TO BALANCE

UNBALANCE TO BALANCE

AUDIO SELECTOR

FOR RSA

AUDIO SELECTOR

FOR AMP

SYSTEM MUTE

SYSTEM MUTE

26

1

234

12

34

F

E

D

C

B

A

FX-MG8237ZT/EW

Page 27

flashLAV

www.club-lexus.ru

A-a

A-b

A-b

3

4

5 6

The > mark found on some component parts indicates

the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of

identical designation.

>

350µH

FM: -3.9dBs

AM: -5.8dBs

TAPE: -1.9dBs

CD:+8.0dBs

4

3

1

5

2

6

4

3

152

6

ASENSEBSENSEISENSE

27

5

6

7

8

F

E

D

C

B

A

5

6

7

8

FX-MG8237ZT/EW

Page 28

flashLAV

www.club-lexus.ru

28

B L

R917

R919

R921

B

KEYBOARD PCB

L

LEFT PCB

A

CN804

SEEK•TRACK

DOWN

DISCTAPE

AM FM

4321

56

TAPE EJECTTEXT CD EJECTLOAD

TA

AFPTY

AUDIO

CONTROL•

TUNE

1

234

12

34

F

E

D

C

B

A

FX-MG8237ZT/EW

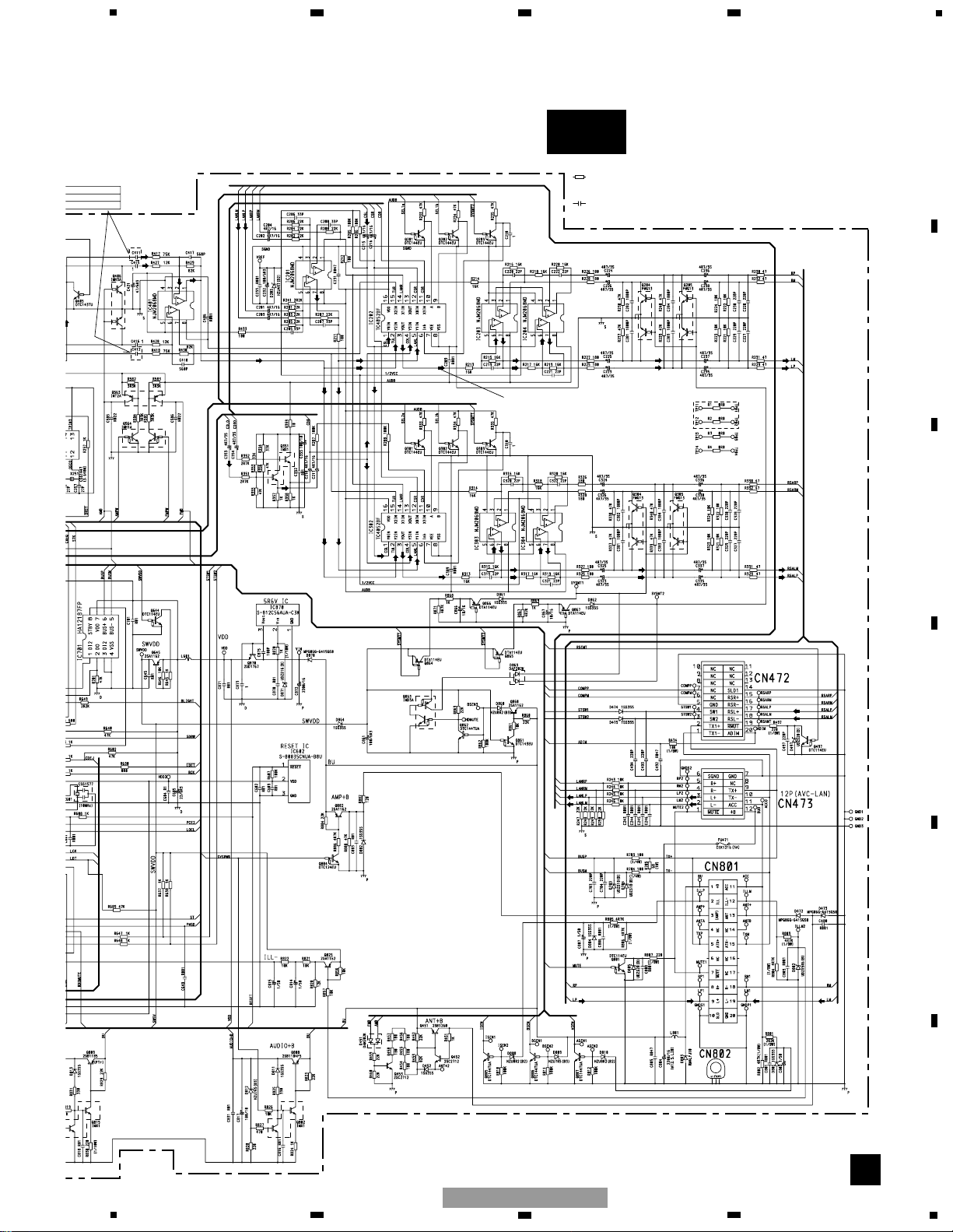

3.4 KEYBOARD UNIT

Page 29

flashLAV

www.club-lexus.ru

29

B K

2SC4116

R998

4R7K

R999

10K

K

RIGHT PCB

KEYBOARD UNIT

Consists of

KEYBOARD PCB

RIGHT PCB

LEFT PCB

1

5

POWER•VOL

SEEK•TRACK

UP

AST

5

6

7

8

F

E

D

C

B

A

5

6

7

8

FX-MG8237ZT/EW

Page 30

flashLAV

www.club-lexus.ru

C-a

C

D E

F

G H

VR1

ELVSENSE

CCW1023

10K

LOAD1

LOAD2

CAMGEAR MOTOR

M1 CXC1144

LOADING MOTOR

ELEVATION MOTOR

M2 CXC1145

CAMEOK

CAMLOAD

L1

LOAD3

S41

CSN1051

CRG MOTOR

M3 CXC1143

CLAMP

HOME

S2

S1

CSN1057

CSN1057

1

5

12

24

13

SPINDLE

MOTOR

MOTOR DRIVER

CD CONTROL

3+3ch

DRIVER

1K(B)

VCC

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

CN11

CN12

1

2

3

4

5

CN14

CN13

GR

BL

CN31

RE

WH

6

7

8

9

5

4

3

2

1

6

7

8

9

5

4

3

2

1

CN42

CN1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

CN41

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

F

PCB UNIT

(SIDE)

G

PCB UNIT

H

PCB UNIT

(M2 UNIT)

D

PCB UNIT

(LED)

E

PCB UNIT(LOAD)

PU UNIT(SERVICE)(PX1)

F

T

C

S

SIGNAL LINE

FOCUS SERVO LINE

TRACKING SERVO LINE

CARRIAGE SERVO LINE

SPINDLE SERVO LINE

SL

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

1

2

3

4

5

6

7

8

1

2

3

1

2

3

4

5

6

7

8

T

T

T

T

T

T

T

T

T

T

SL

SL

SL

SL

SL

SL

SL

SL

S

C

C

C

C

C

C

C

C

C

C

S

S

S

S

S

S

S

S

C

F

T

F

T

F

T

F

T

T

T

F

F

T

F

F

T

T

F

F

T

SL

F

F

3

2

4

!

7

9

6

0

5

@

)81

: The power supply is shown with the marked box.

30

1

234

12

34

F

E

D

C

B

A

FX-MG8237ZT/EW

3.5 CD MECHANISM MODULE(GUIDE PAGE)

Page 31

flashLAV

www.club-lexus.ru

C-b

C

SHOCK PROOF

MEMORY

CONTROLLER

BUFFER RAM

3.3V-5V CONVERTER

5V-3.3V CONVERTER

MECHANISM CONTROLLER

5V REGULATOR

3.3V REGULATOR

MUTE

A

CN351

C

CONTROL UNIT(G2T)

SL

SL

SL

#

$

%

^

&

(

*

31

5

6

7

8

F

E

D

C

B

A

5

6

7

8

FX-MG8237ZT/EW

Page 32

flashLAV

www.club-lexus.ru

A-a

C-b

C-a

C-a

C-b

F

G H

1

VR1

ELVSENSE

CCW1023

10K

L1

LOAD3

S41

CSN1051

CRG MOTOR

M3 CXC1143

CLAMP

HOME

S2

S1

CSN1057

CSN1057

1

5

12

24

13

SPINDLE

MOTOR

MOTOR DRIVER

CD CONTROL

3+3ch

DRIVER

1K(B)

VCC

123456789

101112131415161718192021222324252627282930

CN11

CN12

CN14

678954321

678954321

CN42

CN1

123456789

10111213141516

17

CN41

123456789

10111213141516

17

F

PCB UNIT(SIDE)

G

PCB UNIT

H

PCB UNIT

(M2 UNIT)

PU UNIT(SERVICE)(PX1)

123456789

101112131415161718192021222324252627282930

123

4

T

T

T

T

T

T

T

T

T

T

SL

SL

SL

SL

SL

SL

SL

SL

S

C

C

C

C

C

C

S

S

S

S

S

C

F

T

F

T

F

T

TFF

T

TFF

T

SL

F

F

!

7

9

6

0

5

@

)

8

1

32

1

234

12

34

F

E

D

C

B

A

FX-MG8237ZT/EW

Page 33

flashLAV

www.club-lexus.ru

A-a

C-b

C-a

C-a

C-b

D E

2

3

LOAD1

LOAD2

CAMGEAR MOTOR

M1 CXC1144

LOADING MOTOR

ELEVATION MOTOR

M2 CXC1145

CAMEOK

CAMLOAD

3+3ch

DRIVER

30

12345

CN14

CN13

GR

BL

CN31

RE

WH

17

D

PCB UNIT

(LED)

E

PCB UNIT(LOAD)

PU UNIT(SERVICE)(PX1)

30

1234567

8

123

1234567

8

F

T

C

S

SIGNAL LINE

FOCUS SERVO LINE

TRACKING SERVO LINE

CARRIAGE SERVO LINE

SPINDLE SERVO LINE

SL

: The power supply is shown with the marked box.

C

C

C

C

S

S

S

F

F

T

TTF

F

3

2

4

33

5

6

7

8

F

E

D

C

B

A

5

6

7

8

FX-MG8237ZT/EW

Page 34

flashLAV

www.club-lexus.ru

C-a

C-b

C-b

1

SHOCK PROOF

MEMORY

CONTROLLER

BUFFER RAM

3.3V-5V CONVERTER

5V-3.3V CONVERTER

3.3V REGULATOR

MUTE

A

CN351

C

CONTROL UNIT(G2T)

SL

SL

SL

SL

%

^

&

(

*

34

1

234

12

34

F

E

D

C

B

A

FX-MG8237ZT/EW

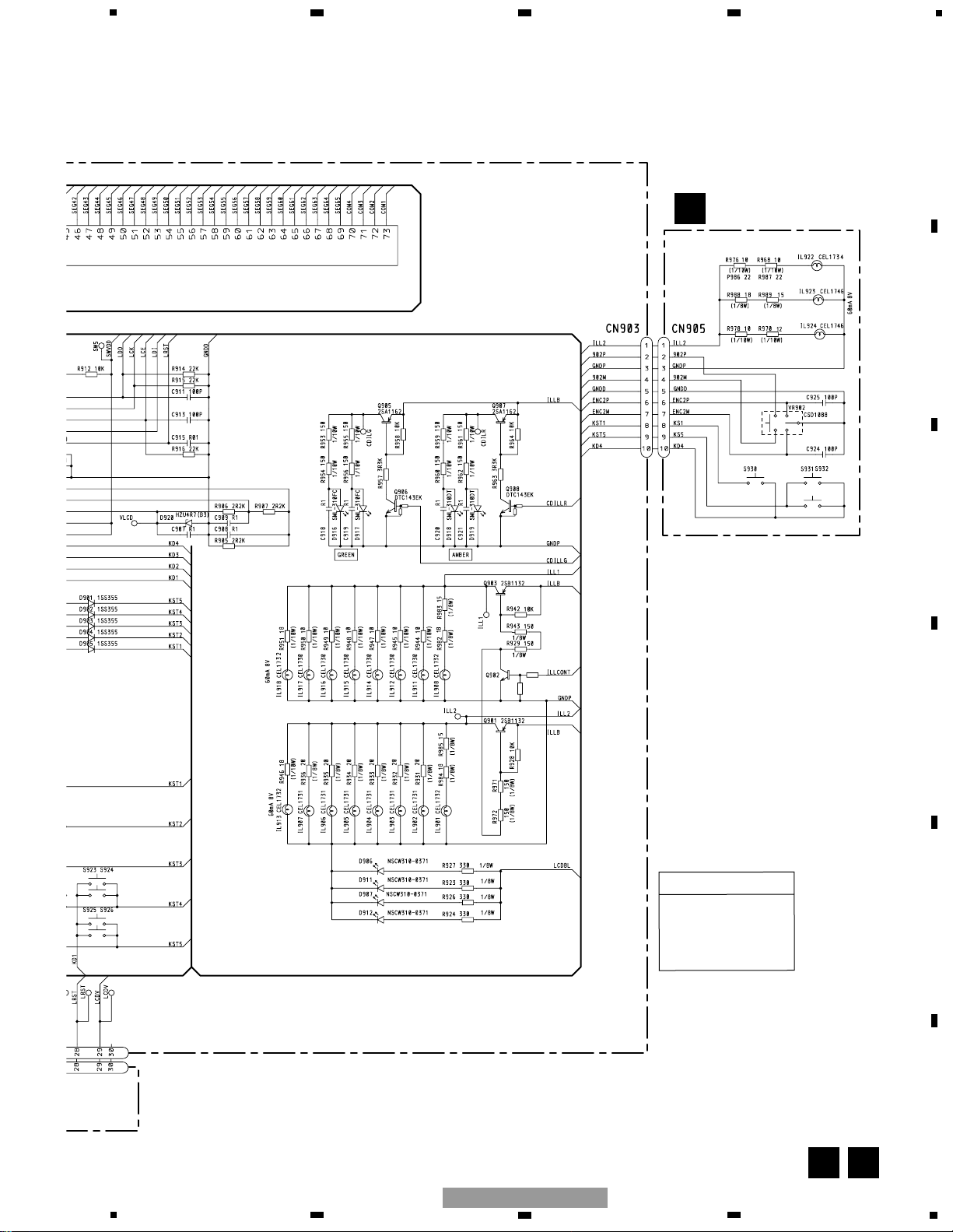

Page 35

flashLAV

www.club-lexus.ru

C-a

C-b

C-b

2

3

MECHANISM CONTROLLER

5V REGULATOR

3.3V REGULATOR

#

$

35

5

6

7

8

F

E

D

C

B

A

5

6

7

8

FX-MG8237ZT/EW

Page 36

flashLAV

www.club-lexus.ru

36

1

234

12

34

F

E

D

C

B

A

FX-MG8237ZT/EW

Note: The encircled numbers denote measuring points in the circuit diagram.

CH1 : 1 FDX

Mode:Test

CH2 : 2 FOP

CH3 : 3 FOM

CH1 : 5 RFO

CH2 : 6 TE

CH3 : 7 TEC

Mode:Test

CH4 : 4 EC

Focus search mode

CH1 : 5 RFO

Mode:Test

CH2 : 6 TE

CH3 : 8 TDX

1 Track Jump

Tracking open

CH1 : 5 RFO

CH2 : 6 TE

CH3 : 8 TDX

4 Track Jump

Mode:Test

CH1 : 5 RFO

CH2 : 6 TE

CH3 : 8 TDX

10 Track Jump

Mode:Test

CH1 : 5 RFO

CH2 : 6 TE

CH3 : 8 TDX

32 Track Jump

Mode:Test

Page 37

flashLAV

www.club-lexus.ru

37

5

6

7

8

F

E

D

C

B

A

5

6

7

8

FX-MG8237ZT/EW

CH1 : 6 TE

Mode:Normal

CH2 : 9 FE

CH3 : 0 RFI

Focus close

CH1 : $ STSMO

Mode:Normal

CH2 : 6 TE

Memory capacity (remaining) at the starting of PLAY

CH1 : 1 FDX

CH2 : ! FOK

CH3 : @ MDX

CH4 : # FG

Setup

CH1 : 9 FE

CH2 : 1 FDX

CH3 : 6 TE

CH4 : 8 TDX

During "Play"

Mode:Normal

Mode:Normal

CH1 : $ RFO

Mode:Normal

CH2 : 6 TE

Memory capacity (remaining) during PLAY

CH1 : % LRCK

Mode:Normal

CH2 : ^ SCKO

CH3 : & DOUT

Digital audio data(x2 speed)

Page 38

flashLAV

www.club-lexus.ru

38

1

234

12

34

F

E

D

C

B

A

FX-MG8237ZT/EW

CH1 : * LOUT

CH2 : ( ROUT

Mode:Normal

CH1 : 6 TE

CH2 : 8 TDX

Mode:Normal

CH3 : ) SD

Audio output(1kHz , 0dB)

CH1 : 1 FDX

Mode:Normal

CH4 : 4 EC

During inside / outside search

CH2 : ! FOK

CH3 : @ MDX

CH4 : # FG

DISC stop

Page 39

flashLAV

www.club-lexus.ru

39

5

6

7

8

F

E

D

C

B

A

5

6

7

8

FX-MG8237ZT/EW

Page 40

flashLAV

www.club-lexus.ru

DECK UNIT

MUTE

HA12216F

11

12

13

14

15

16

17

18

19

20

40

39

38

37

36

35

34

33

32

31

30

292827

26

252423

22

21

1

234

5

678

9

10

R256

180

R287

0R0

C271

1/50

R284 0R0

R283 0R0

R282 0R0

C254 390P

C253 390P

C252 390P

C251 390P

R281 0R0

R255

180

C256

R01

R258

18K

R402

3R3K

R403 910

C272

R1

R288

0R0

R285 0R0

HD1

HEAD ASSY

EXA1594

TEST TAPE

NCT-150

(400Hz, 200nWb/m)

RL

RR

FR

FL

C302

R1

VR302

33K(B)

-8.24dBs(300mV)±1dB

Fwd-R

Fwd-L

Rev-R

Rev-L

NFI(L)

RIN(L)

RIP

FIN(L)

GND

GND

FIN(R)

VREF

RIN(R)

NFI(R)

M-OUT(R)

EQOUT(R)

TAI(R)

BIAS

RAI(R)

PBOUT(R)

DET(L)

MUTE

MSGV(R)

MAOUT

MSI

MSDET

MSGV

F/R

120/70

NR

MOUT(L)

EQOUT(L)

TAI(L)

NC

RAI(L)

PBOUT(L)

NC

DET(L)

MSGV(S)

CN252

CN251

DOLBY B NR

IC251

VR301

33K(B)

C310

R1

C309

R1

R321

0R0

VCC

CCP1280

CCP1280

NC

MSOUT

NC

NC

R260

13K

R262

270K

C401

3900P

R401

15K

R276

100K

C402

R33

C404

R01

C403

R022

R273

0R0

R272

0R0

C40

Q271

2SC4116

R271

18K

C301

R1

R259

13K

C255

R01

R257

18K

R261

270K

A

I

CN353

R292

0R0

R286 0R0

R296

0R0

I

40

1

234

12

34

F

E

D

C

B

A

FX-MG8237ZT/EW

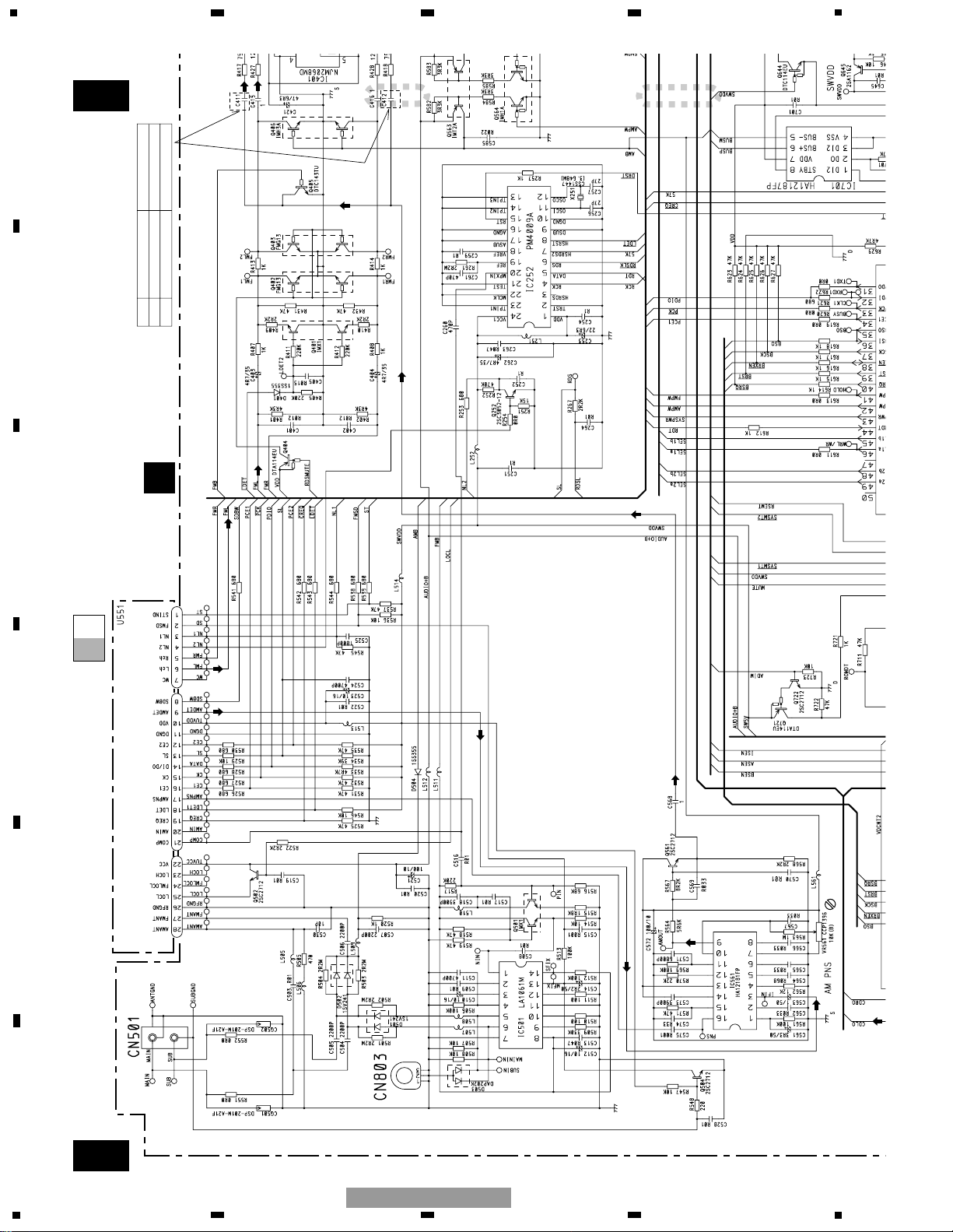

3.6 CASSETTE MECHANISM MODULE

Page 41

flashLAV

www.club-lexus.ru

41

5

6

7

8

F

E

D

C

B

A

5

6

7

8

FX-MG8237ZT/EW

SWITCHES:

SENSOR UNIT

S101:LOAD SWITCH..........EJECT-PLAY

S102:MODE SWITCH............ON-OFF

S103:70µs SWITCH...............ON-OFF

The underlined indicates the switch position.

R275

47K

R351 1K

R352 1K

R353 1K

R354 1K

R373 0R0

R355

270K

C352

3900P

R362 300

C351 R22

C353 R01

C354 R01

R374 0R0

C356 R01

C355 R1

D352 1SS355

M1 MOTOR UNIT

(MAIN MOTOR)

EXA1618

M2

MOTOR UNIT

(SUB MOTOR)

EXA1623

RS3

RS2

RS1

SC2

SC1

TAB

MC

CE

VCC2

NC

VCC

MCS

RRS

FRS

RSB

C

TAB

MS2

NC

NC

MM

SM1

RSB

GND

RS

mtl

MCS

load

CN255

CN253

CN254

MECHANISM

DRIVER

IC351 PA2020A

R375 0R0

R404

270K

C405

R033

R277

220K

R278

100K

Q271

2SC4116

SENSOR UNIT

S101

LOAD

ESG1007x3

S102

MODE

Q101

EGN1004

CN256

S103

70µs

J

L101

L102

JI

Page 42

flashLAV

www.club-lexus.ru

42

Capacitor

Connector

P.C.Board

Chip Part

A

A

MAIN UNIT

SIDE B

SIDE A

NOTE FOR PCB DIAGRAMS

1.The parts mounted on this PCB

include all necessary parts for

several destination.

For further information for

respective destinations, be sure

to check with the schematic dia gram.

2.Viewpoint of PCB diagrams

C

CN501

B

CN901

I

CN251

CAR HA

76859

4

1

234

12

34

F

E

D

C

B

A

FX-MG8237ZT/EW

4. PCB CONNECTION DIAGRAM

4.1 MAIN UNIT

Page 43

flashLAV

www.club-lexus.ru

43

A

SIDE A

FRONT

FM/AM TUNER UNIT

CAR HARNESS CAR HARNESS

CAR HARNESS

ANTENNA

SUB

MAIN

11112213314415516617718819920

10

111012913814715616517418319220

1

76859410311212

1

5

6

7

8

F

E

D

C

B

A

5

6

7

8

FX-MG8237ZT/EW

Page 44

flashLAV

www.club-lexus.ru

44

A

A

MAIN UNIT

1

234

12

34

F

E

D

C

B

A

FX-MG8237ZT/EW

Page 45

flashLAV

www.club-lexus.ru

45

A

SIDE B

5

6

7

8

F

E

D

C

B

A

5

6

7

8

FX-MG8237ZT/EW

Page 46

flashLAV

www.club-lexus.ru

B

B

KEYBOARD PCB

SIDE A

SEEK•TRACK

DOWN

CD EJECT

TAPE EJECT

1 1 2 2 3 3 4 45 56 6

TEXT

LOAD

TA

DISC

DISC

TAPE

TAPE

FM

AM

AM

FM

46

1

234

12

34

F

E

D

C

B

A

FX-MG8237ZT/EW

4.2 KEYBOARD PCB

Page 47

flashLAV

www.club-lexus.ru

B

B

KEYBOARD PCB

SIDE B

A

CN804

K

CN905

L

CN904

47

5

6

7

8

F

E

D

C

B

A

5

6

7

8

FX-MG8237ZT/EW

Page 48

flashLAV

www.club-lexus.ru

48

C

C

CONTROL UNIT (G2T)

SIDE A

IC,Q

A

CN351

F

CN11

REFO

E

F

1

234

12

34

F

E

D

C

B

A

FX-MG8237ZT/EW

4.3 CD MECHANISM MODULE

Page 49

flashLAV

www.club-lexus.ru

49

C

C

CONTROL UNIT (G2T)

SIDE B

IC,Q

5

6

7

8

F

E

D

C

B

A

5

6

7

8

FX-MG8237ZT/EW

Page 50

flashLAV

www.club-lexus.ru

D

D

PCB UNIT (LED)

E

PCB UNIT (LOAD)

E

F

CN14

M

M2

ELEVATION

RE

WH

CAMOK

CAMLOAD

5

6

7

8

LOAD2

LOAD1

F

CN13

50

1

234

12

34

F

E

D

C

B

A

FX-MG8237ZT/EW

Page 51

flashLAV

www.club-lexus.ru

F

F

PCB UNIT (SIDE)

F

PCB UNIT (SIDE)

SIDE A

SIDE B

E

M

LOADING

VR1

ELV SENSE

1

2

3

4

5

D

CN31

C

CN101

G

8

GR

BL

M

M1

CAMGEAR

51

5

6

7

8

F

E

D

C

B

A

5

6

7

8

FX-MG8237ZT/EW

Page 52

flashLAV

www.club-lexus.ru

M

M3

CRG

1

30

F

CN12

1

9

CN42

1

17

CN41

S41

LOAD3

H

CN1

PU UNIT(SERVICE)(PX1)

L1

G

G

PCB UNIT

52

1

234

12

34

F

E

D

C

B

A

FX-MG8237ZT/EW

Page 53

flashLAV

www.club-lexus.ru

H

H

PCB UNIT(M2 UNIT)

M

SPINDLE

S1

HOME

S2

CLAMP

1

9

CN1

G

CN42

C1

R2

R1

IC1

1

5

1012

13 15

20

24

R4

R3

HE3

HE2

HE1

53

5

6

7

8

F

E

D

C

B

A

5

6

7

8

FX-MG8237ZT/EW

Page 54

flashLAV

www.club-lexus.ru

I

I

DECK UNIT

SIDE A

SIDE B

I

DECK UNIT

CN251

2 4 6 8 10 12 14 16 18 20

1 3 5 7 9 11 13 15 17 19

IC,Q

IC251

Q351

Q352

ADJ

VR302

VR301

IC351

CN252

CN254

CN253

CN255

M1

M2

HEAD ASSY

CN256

21

22

1

10

11

20

21

30

31

40

5

15

25

35

R292

Q271

E

R278

R276

R277

R404

C405

C403

C402

C401

C310

C272

R273

R272

R275

R285

R286

R258

C404

R403

R402

R401

C271

IC251

VR302

R283

R282

R281

R284

C253

R253

C252

R252

R287

R296

R321

R288

R255

R261

C255

R257

R259

C301

R271

C309

VR301

C254

R251

C251

R254

C302

R260

C256

R262

R256

R354

R352

R351

R353

E

E

1

Q271

A

CN353

J

54

1

234

12

34

F

E

D

C

B

A

FX-MG8237ZT/EW

4.4 CASSETTE MECHANISM MODULE

Page 55

flashLAV

www.club-lexus.ru

J

1

2

3

4

5

6

S101

LOAD

S102

MODE

S103

70µs

CN256

Q101

REEL SENSE

L101

L102

I

CN253

J

SENSOR UNIT

55

5

6

7

8

F

E

D

C

B

A

5

6

7

8

FX-MG8237ZT/EW

Page 56

flashLAV

www.club-lexus.ru

K

L

LEFT PCB

SIDE A

L

LEFT PCB

SIDE B

K

RIGHT PCB

SIDE A

K

RIGHT PCB

SIDE B

L

B

CN902

B

CN903

PTY

AST

AST

SEEK•TRACK

UP

PTY

AF

AUDIO CONTROL

•TUNE

POWER•VOL

56

1

234

12

34

F

E

D

C

B

A

FX-MG8237ZT/EW

4.5 RIGHT PCB, LEFT PCB

Page 57

flashLAV

www.club-lexus.ru

Unit Number : CWM8388(FX-MG8237ZT/EW)

Unit Number : CWM8556(FX-MG8337ZT/EW)

Unit Name : Main Unit

MISCELLANEOUS

IC 201 IC NJM2068MD

IC 202 IC TC4052BF

IC 203 IC NJM2068MD

IC 204 IC NJM2068MD

IC 252 IC PM4009A

IC 302 IC TC4052BF

IC 303 IC NJM2068MD

IC 304 IC NJM2068MD

IC 401 IC NJM2068MD

IC 501 IC LA1061M

IC 561 IC HA12181FP

IC 601 IC PD5789A

IC 602 IC

S-80835CNUA-B8U

IC 701 IC HA12187FP

IC 870 IC

S-812C56AUA-C3K

Q 201 Transistor DTC144EU

Q 202 Transistor DTC144EU

Q 203 Transistor DTC144EU

Q 204 Transistor FMG13

Q 205 Transistor FMG13

Q 252 Transistor 2SC3052-12

Q 301 Transistor DTC144EU

Q 302 Transistor DTC144EU

Q 303 Transistor DTC144EU

Q 304 Transistor FMG13

Q 305 Transistor FMG13

Q 351 Transistor IMX1

Q 401 Transistor IMX1

Q 402 Transistor FMG13

Q 403 Transistor FMG13

Q 404 Transistor DTA114EU

Q 405 Transistor DTC143TU

Q 406 Transistor IMH3A

Q 451 Transistor 2SB1260

Q 452 Transistor 2SC2712

Q 453 Transistor 2SC2712

Q 497 Transistor DTC114EU

Q 501 Transistor IMX1

Q 502 Transistor 2SC2712

Q 504 Transistor 2SC2712

Q 561 Transistor 2SC2712

Q 563 Transistor IMT2A

Q 564 Transistor IMH1A

Q 644 Transistor DTC114EU

Q 645 Transistor 2SA1162

Q 721 Transistor DTA114EU

Q 722 Transistor 2SC2712

Q 801 Transistor DTC114EU

Q 802 Transistor IMX1

Q 805 Transistor DTC144TUA

Q 806 Transistor DTC144TUA

Q 807 Transistor DTC144TUA

Q 808 Transistor 2SB1184F5

Q 809 Transistor 2SB1185

Q 811 Transistor 2SB1185

Q 812 Transistor 2SB1185

Q 813 Transistor 2SA1162

Q 814 Transistor 2SA1162

Q 815 Transistor IMX1

Q 816 Transistor 2SC4081

Q 818 Transistor 2SB1184F5

Q 819 Transistor 2SA1162

Q 820 Transistor IMX1

Q 822 Transistor 2SD2226K

Q 825 Transistor 2SA1162

Q 860 Transistor 2SA1162

Q 861 Transistor DTC143EU

Q 862 Transistor DTC144TUA

Q 863 Transistor IMD3A

Q 864 Transistor DTA114EU

Q 865 Transistor DTA114EU

Q 866 Transistor DTA114EU

Q 867 Transistor DTA114EU

Q 870 Transistor 2SD1767

Q 882 Transistor 2SA1162

Q 884 Transistor DTC124EU

D 203 Diode HZU4R7(B2)

D 401 Diode 1SS355

D 451 Diode DAN202K

D 452 Diode 1SS355

D 472 Diode MPG06G-6415G50

D 473 Diode MPG06G-6415G50

D 474 Diode 1SS355

D 475 Diode 1SS355

D 497 Diode UDZS20(B)

D 501 Diode 1SV241

D 502 Diode 1SV241

D 503 Diode DAP202K

D 504 Diode 1SS355

D 703 Diode UDZS18(B)

D 704 Diode UDZS18(B)

D 801 Diode 1SS355

D 802 Diode UDZS5R6(B)

D 803 Diode RM4LFJ10

D 804 Diode 1SS355

D 805 Diode UDZS20(B)

D 808 Diode HZU8R2(B2)

D 809 Diode HZU7R5(B3)

D 810 Diode HZU8R2(B2)

D 811 Diode 1SS355

D 812 Diode HZU7R5(B3)

D 813 Diode 1SS355

D 814 Diode HZU8R2(B3)

D 860 Diode HZU8R2(B3)

D 861 Diode 1SS355

57

5

6

7

8

F

E

D

C

B

A

5

6

7

8

FX-MG8237ZT/EW

5. ELECTRICAL PARTS LIST

NOTES:

- Parts whose parts numbers are omitted are subject to being not supplied.

- The part numbers shown below indicate chip components.

Chip Resistor

RS1/_S___J,RS1/__S___J

Chip Capacitor (except for CQS.....)

CKS....., CCS....., CSZS.....

=====Circuit Symbol and No.===Part Name Part No.

--- ------ ------------------------------------------ -------------------------

=====Circuit Symbol and No.===Part Name Part No.

--- ------ ------------------------------------------ -------------------------

A

Page 58

flashLAV

www.club-lexus.ru

D 862 Diode 1SS355

D 863 Diode DAP202K

D 864 Diode 1SS355

D 870 Diode MPG06G-6415G50

D 871 Diode UDZS16(B)

D 882 Diode 1SS355

L 251 Inductor LCTA101J2520

L 252 Inductor LCTC100K3216

L 351 Inductor LCTC2R2K1608

L 352 Inductor LCTC2R2K1608

L 353 Inductor LCTC2R2K1608

L 354 Inductor LCTC2R2K1608

L 355 Inductor CTF1578

L 356 Inductor LCTC2R2K1608

L 357 Inductor CTF1306

L 358 Inductor CTF1306

L 359 Inductor CTF1306

L 360 Inductor CTF1306

L 361 Inductor CTF1306

L 363 Inductor LFEA4R7J

L 505 Ferri-Inductor LAU4R7K

L 506 Coil CTB1102

L 507 Inductor LCTC6R8K3216

L 508 Inductor LCTC6R8K3216

L 509 Inductor LCTC6R8K3216

L 510 Inductor LCTA561J4532

L 511 Inductor LCTA4R7J2520

L 512 Inductor LCTA1R0J2520

L 513 Inductor LCTA1R0J2520

L 514 Inductor LCTA1R0J2520

L 561 Inductor LCTA4R7J2520

L 601 Inductor LCTA100J3225

L 801 Coil 350µH CTH1276

CG 501 Surge Protector DSP-201M-A21F

CG 502 Surge Protector DSP-201M-A21F

X 251 Crystal Resonator 3.648MHz CSS1447

X 601 Radiator 10.0MHz CSS1577

VR 561 Semi-fixed 10kΩ(B) CCP1396

FU 471 Fuse 5A CEK1216

FM/AM Tuner Unit CWE1633

EF 352 EMI Filter CCG1163

RESISTORS

R 1 (FX-MG8337ZT/EW) RS1/16S0R0J

R 2 (FX-MG8337ZT/EW) RS1/16S0R0J

R 3 RS1/16S0R0J

R 4 RS1/16S0R0J

R 201 RS1/16S223J

R 202 RS1/16S223J

R 203 RS1/16S223J

R 204 RS1/16S223J

R 205 RS1/16S223J

R 206 RS1/16S223J

R 207 RS1/16S223J

R 208 RS1/16S223J

R 211 RS1/16S101J

R 212 RS1/16S101J

R 213 RS1/16S163J

R 214 RS1/16S163J

R 215 RS1/16S163J

R 216 RS1/16S163J

R 217 RS1/16S163J

R 218 RS1/16S163J

R 219 RS1/16S163J

R 220 RS1/16S163J

R 221 RS1/16S103J

R 222 RS1/16S103J

R 223 RS1/16S103J

R 224 RS1/16S103J

R 225 RS1/16S181J

R 226 RS1/16S181J

R 227 RS1/16S181J

R 228 RS1/16S181J

R 229 RS1/10S470J

R 230 RS1/10S470J

R 231 RS1/10S470J

R 232 RS1/10S470J

R 233 RS1/16S473J

R 234 RS1/16S473J

R 235 RS1/16S473J

R 237 RS1/16S473J

R 238 RS1/16S473J

R 239 RS1/16S473J

R 240 RS1/16S473J

R 241 RS1/16S222J

R 243 RS1/16S103J

R 244 RS1/16S103J

R 245 RS1/16S103J

R 246 RS1/16S103J

R 247 RS1/16S223J

R 248 RS1/16S223J

R 249 RS1/16S223J

R 250 RS1/16S223J

R 251 RS1/16S153J

R 252 RS1/16S474J

R 253 RS1/16S681J

R 254 RS1/16S0R0J

R 257 RS1/16S102J

R 261 RS1/16S225J

R 267 RS1/16S222J

R 285 RS1/16S104J