Page 1

PIONEER CORPORATION 4-1, Meguro 1-Chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS SERVICE INC. P.O.Box 1760, Long Beach, CA 90801-1760 U.S.A.

PIONEER EUROPE NV Haven 1087 Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE.LTD. 253 Alexandra Road, #04-01, Singapore 159936

C PIONEER CORPORATION 2001

K-ZZU. APR. 2001 Printed in Japan

ORDER NO.

CRT2669

HIGH POWER CD PLAYER WITH RDS TUNER

DEH-3300R-2

X1B/EW,X1P/EW

DEH-3330R-2 X1B/EW,X1P/EW

- This is the unit which has been replaced S8.1(CXK5201) CD mechanism module with S9(CXK5500).

- This service manual should be used together with the manual(s) listed below.

For the parts numbers, adjustments, etc. which are not shown in this manual,

refer to the following manual(s).

Model No. Order No. Mech. Module Remarks

CX-977 CRT2624 S9

CD Mech. Module:Circuit Description, Mech. Description, Disassembly

DEH-3300R/X1N/EW CRT2574

Page 2

2

DEH-3300R-2,3330R-2

- CD Player Service Precautions

1. For pickup unit(CXX1480) handling, please refer

to"Disassembly"(see page 24).

During replacement, handling precautions shall be

taken to prevent an electrostatic discharge(protection

by a jumper-solder).

2. During disassembly, be sure to turn the power off

since an internal IC might be destroyed when a connector is plugged or unplugged.

3. Please checking the grating after changing the service pickup unit(see page 18).

SAFETY INFORMATION

This service manual is intended for qualified service technicians; it is not meant for the casual do-it-yourselfer.

Qualified technicians have the necessary test equipment and tools, and have been trained to properly and safely repair

complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may void the warranty.

If you are not qualified to perform the repair of this product properly and safely; you should not risk trying to do so

and refer the repair to a qualified service technician.

1. Safety Precautions for those who Service this Unit.

• When checking or adjusting the emitting power of the laser diode exercise caution in order to get safe, reliable

results.

Caution:

1. During repair or tests, minimum distance of 13cm from the focus lens must be kept.

2. During repair or tests, do not view laser beam for 10 seconds or longer.

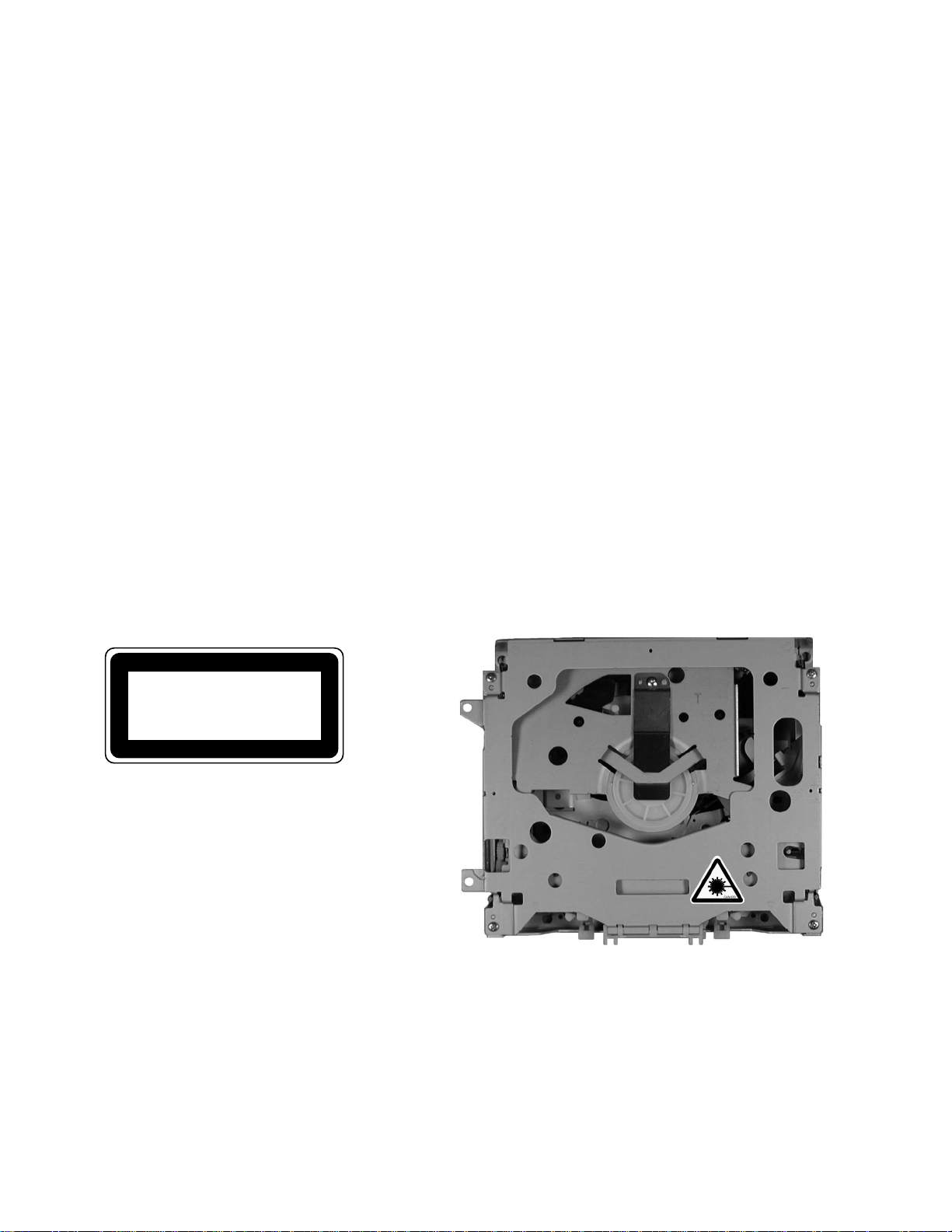

2. A “CLASS 1 LASER PRODUCT” label is affixed to the

bottom of the player.

3. The triangular label is attached to the mechanism

unit frame.

4. Specifications of Laser Diode

Specifications of laser radiation fields to which human access is possible during service.

Wavelength = 800 nanometers

CLASS 1

LASER PRODUCT

Page 3

3

DEH-3300R-2,3330R-2

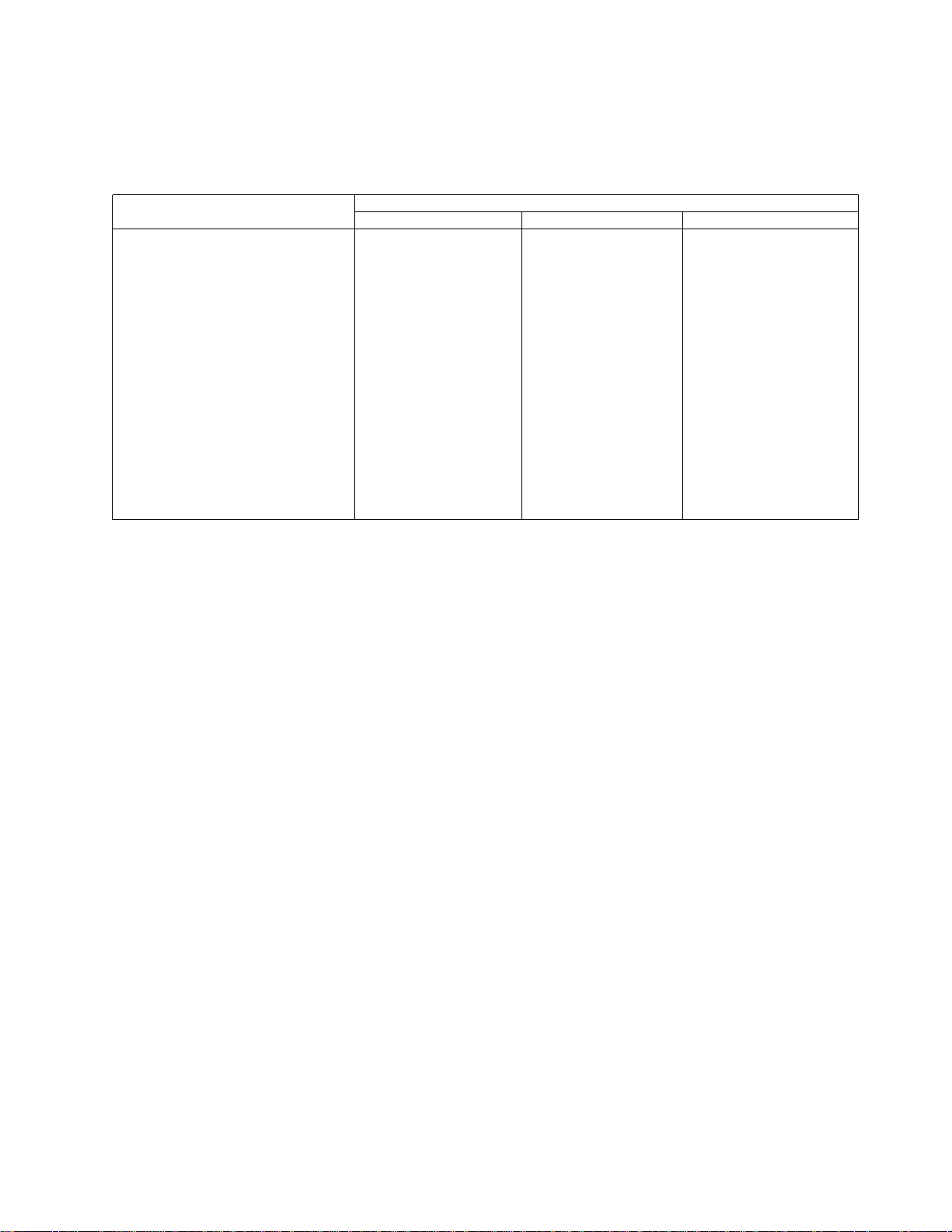

EXPLODED VIEWS AND PARTS LIST

PACKING (Page 3)

- PACKING SECTION PARTS LIST *: Non Spare Part

Part No.

Mark No. Description DEH-3300R/X1N/EW DEH-3300R-2/X1B/EW DEH-3300R-2/X1P/EW

1 Cord Assy CDE6435 UDE6435 UDE6435

2 Case Assy CXB3520 UXB-009 UXB3520

3 Accessory Assy

*CEA2397 UEA2397 UEA2397

* 7 Polyethylene Bag E36-615 CEG-127 CEG-127

8 Polyethylene Bag CEG-162 UEG-012 UEG-012

9 Carton CHG4270 UHG4376 UHG-154

10 Contain Box CHL4270 UHL4376 UHL-107

11 Protector CHP2251 UHP2101 UHP2101

12 Protector CHP2252 UHP2102 UHP2102

13-1 Polyethylene Bag CEG1116 UEG1116 UEG1116

13-2 Owner's Manual CRD3304 URD-173 URD-173

13-3 Owner's Manual CRD3305 URD-174 URD-174

13-4 Installation Manual CRD3313 URD-176 URD-176

* 13-5 Passport CRY1013 CRY1014 CRY1014

* 13-6 Warranty Card CRY1157 URY1087 URY1087

Page 4

4

DEH-3300R-2,3330R-2

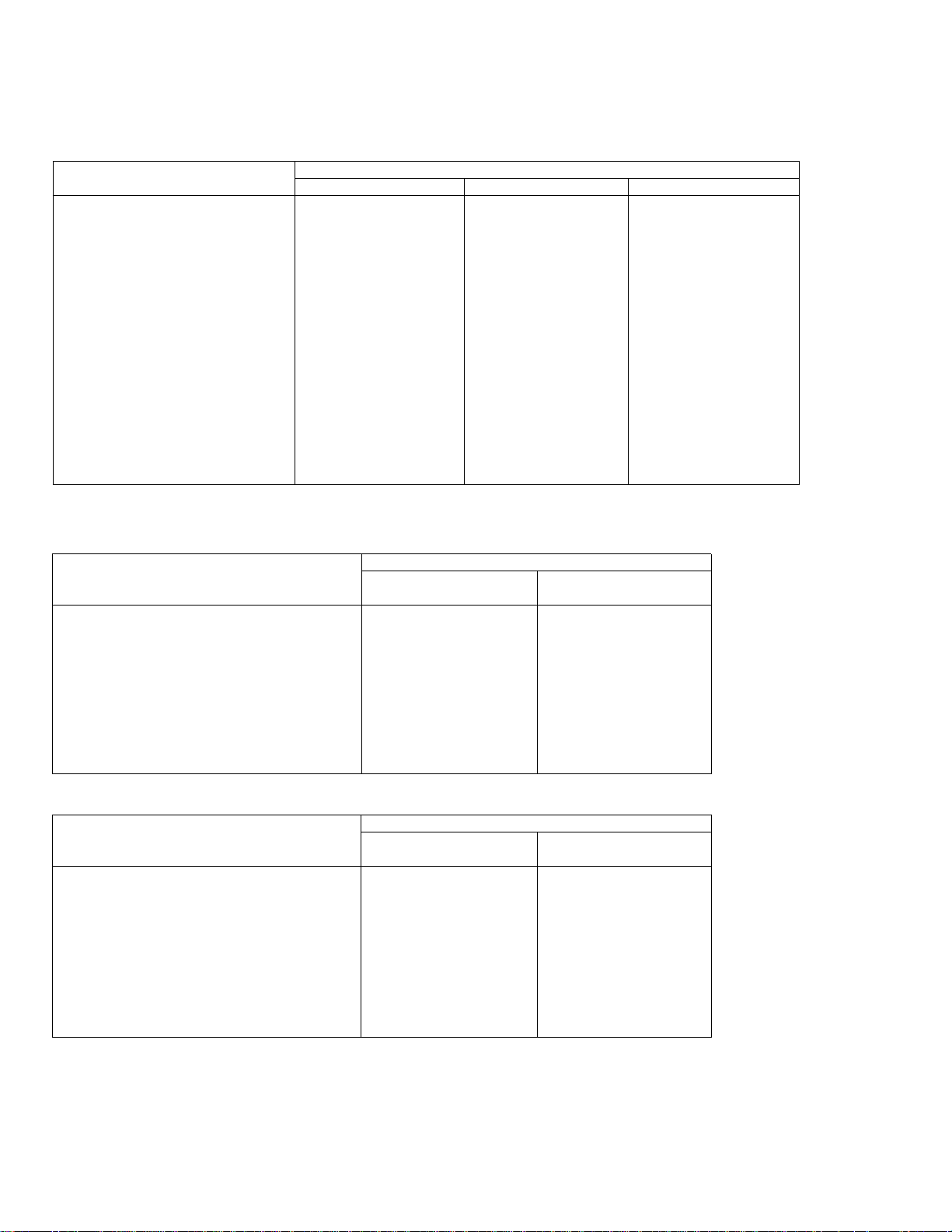

- PACKING SECTION PARTS LIST

Part No.

Mark No. Description DEH-3330R/X1N/EW DEH-3330R-2/X1B/EW DEH-3330R-2/X1P/EW

1 Cord Assy CDE6435 UDE6435 UDE6435

2 Case Assy CXB3520 UXB-009 UXB3520

3 Accessory Assy

*CEA2397 UEA2397 UEA2397

*7

Polyethylene Bag E36-615 CEG-127 CEG-127

8 Polyethylene Bag CEG-162 UEG-012 UEG-012

9 Carton CHG4271 UHG4375 UHG-153

10 Contain Box CHL4271 UHL4375 UHL-106

11 Protector CHP2251 UHP2101 UHP2101

12 Protector CHP2252 UHP2102 UHP2102

13-1 Polyethylene Bag CEG1116 UEG1116 UEG1116

13-2 Owner's Manual CRD3304 URD-173 URD-173

13-3 Owner's Manual CRD3305 URD-174 URD-174

13-4 Installation Manual CRD3313 URD-176 URD-176

* 13-5 Passport CRY1013 CRY1014 CRY1014

* 13-6 Warranty Card CRY1157 URY1087 URY1087

EXTERIOR (Page 5)

- EXTERIOR SECTION PARTS LIST

Part No.

DEH-3300R/X1B/EW

Mark No. Description DEH-3300R/X1N/EW DEH-3300R/X1P/EW

5 Cord Assy CDE6435 UDE6435

7 Cable CDE6444 CDE6610

12 Holder CNC8659 UNC8659

16 Tuner Amp Unit CWM7384 UWM7384

25 Connector(CN501) CKS4398 CKS3835

32 FM/AM Tuner Unit CWE1562 UWE1562

35 Detach Grille Assy CXB6296 UXB6296

51 Keyboard Unit CWM7406 UWM7406

58 Sub Grille Assy CXB7157 UXB7157

- EXTERIOR SECTION PARTS LIST

Part No.

DEH-3330R/X1B/EW

Mark No. Description DEH-3330R/X1N/EW DEH-3330R/X1P/EW

5 Cord Assy CDE6435 UDE6435

7 Cable CDE6444 CDE6610

12 Holder CNC8659 UNC8659

16 Tuner Amp Unit CWM7386 UWM7386

25 Connector(CN501) CKS4398 CKS3835

32 FM/AM Tuner Unit CWE1562 UWE1562

35 Detach Grille Assy CXB6298 UXB6298

51 Keyboard Unit CWM7408 UWM7408

58 Sub Grille Assy CXB7158 UXB7158

Page 5

5

DEH-3300R-2,3330R-2

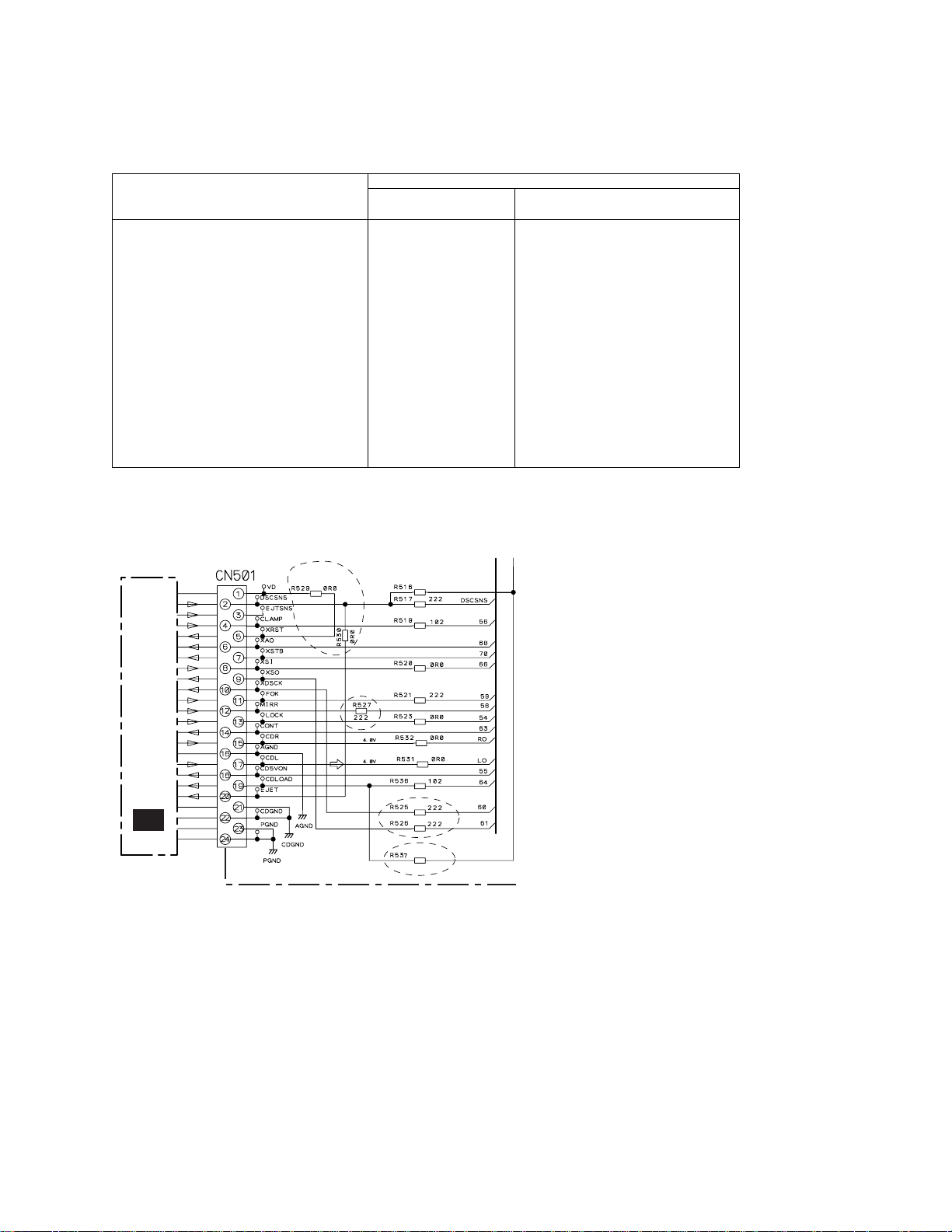

ELECTRICAL PARTS LIST(Page 34)

Tuner Amp Unit

Part No.

DEH-3300R/X1N/EW DEH-3300R-2/X1N/EW,X1M/EW

Circuit Symbol and No. DEH-3330R/X1N/EW DEH-3330R-2/X1N/EW,X1M/EW

IC601 PE5202A PE5245A

R514,R515 RS1/16S473J Not used

R516 RS1/16S473J RS1/16S104J

R518 RS1/16S222J Not used

R519 RS1/16S222J RS1/16S102J

R520 RS1/16S681J RS1/16S0R0J

R521 RS1/16S102J RS1/16S222J

R522,R524,R534,R535 RS1/16S0R0J Not used

R523 RS1/16S102J RS1/16S0R0J

R525,R526,R527 Not used RS1/16S222J

R529 Not used RS1/4PU0R0J

R530 Not used RS1/16S0R0J

R536 RS1/16S0R0J RS1/16S102J

R537 Not used RS1/16S104J

CN701

D

CONTROL UNIT

104

(1/4W)

104

F

Page 6

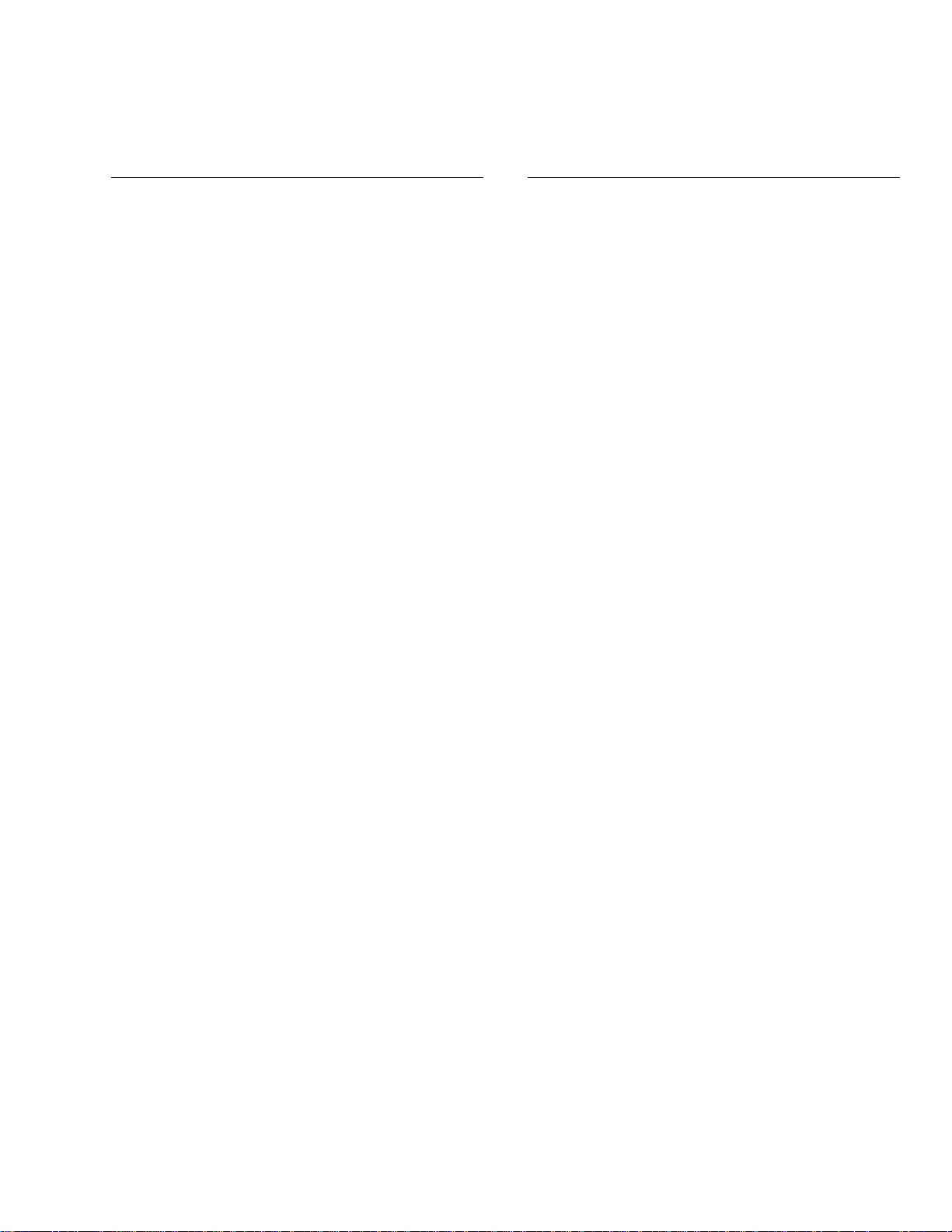

6

DEH-3300R-2,3330R-2

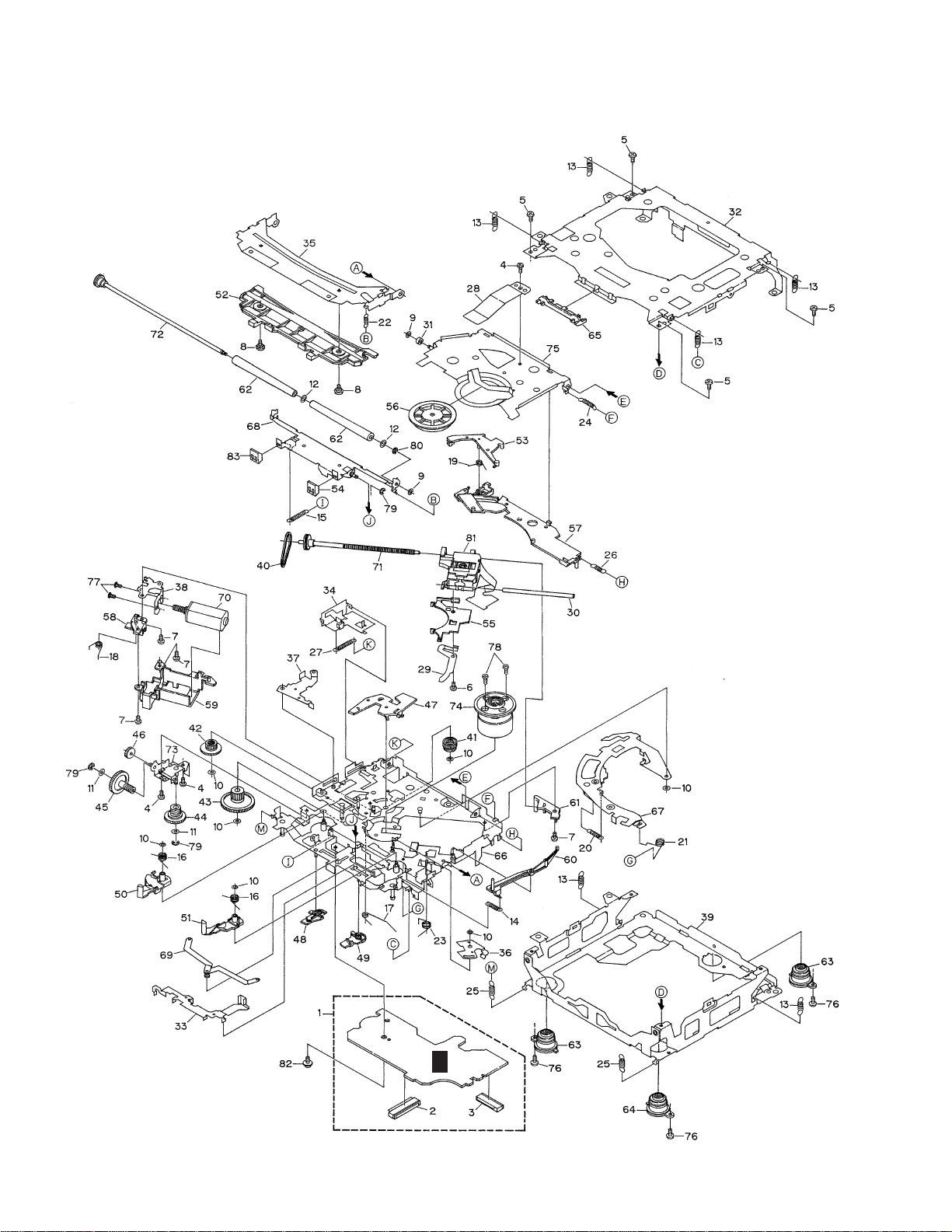

CD MECHANISM MODULE

D

F

Page 7

DEH-3300R-2,3330R-2

7

Mark No. Description Part No. Mark No. Description Part No.

1 Control Unit CWX2481

2 Connector(CN701) CKS1959

3 Connector(CN101) CKS3486

4 Screw BMZ20P025FMC

5 Screw BSZ20P040FMC

6 Screw(M2x4) CBA1362

7 Screw(M2x3) CBA1527

8 Screw CBA1545

9 Washer CBF1037

10 Washer CBF1038

11 Washer CBF1039

12 Washer CBF1060

13 Spring CBH2378

14 Spring CBH2379

15 Spring CBH2380

16 Spring CBH2381

17 Spring CBH2382

18 Spring CBH2383

19 Spring CBH2384

20 Spring CBH2385

21 Spring CBH2386

22 Spring CBH2387

23 Spring CBH2390

24 Spring CBH2391

25 Spring CBH2392

26 Spring CBH2426

27 Spring CBH2444

28 Spring CBL1494

29 Spring CBL1495

30 Shaft CLA3845

31 Roller CLA3910

32 Frame CNC8946

33 Lever CNC8948

34 Lever CNC8949

35 Arm CNC8951

36 Arm CNC9016

37 Arm CNC9017

38 Bracket CNC9123

39 Frame CNC9263

40 Belt CNT1086

41 Gear CNV6315

42 Gear CNV6316

43 Gear CNV6317

44 Gear CNV6318

45 Gear CNV6319

46 Gear CNV6320

47 Arm CNV6322

48 Arm CNV6323

49 Arm CNV6324

50 Arm CNV6325

51 Arm CNV6326

52 Guide CNV6327

53 Arm CNV6328

54 Guide CNV6329

55 Rack CNV6330

56 Clamper CNV6331

57 Arm CNV6332

58 Guide CNV6333

59 Cover CNV6334

60 Arm CNV6335

61 Guide CNV6336

62 Roller CNV6338

63 Damper CNV6339

64 Damper CNV6340

65 Guide CNV6484

66 Chassis Unit CXB5898

67 Arm Unit CXB5899

68 Arm Unit CXB5900

69 Arm Unit CXB5901

70 Motor Unit(M2) CXB5903

71 Screw Unit CXB5904

72 Gear Unit CXB5905

73 Bracket Unit CXB6006

74 Motor Unit(M1) CXB6007

75 Arm Unit CXB6237

76 Screw(M2x5) EBA1028

77 Screw JFZ20P020FMC

78 Screw JGZ17P020FZK

79 Washer YE15FUC

80 Washer YE20FUC

81 Pickup Unit(Service)(P9) CXX1480

82 Screw IMS26P030FMC

83 Guide CNV6832

- CD MECHANISM MODULE SECTION PARTS LIST

Page 8

D

F

8

DEH-3300R-2,3330R-2

1

23

4

1234

D

C

B

A

CD MECHANISM MODULE

M1 CXB6007

M2 CXB5903

LOADING/CARRIAGE

SPINDLE

RF AMP

S

ACT/MOTOR DRIVER

5V REGULATOR

CN101

CONTROL UNIT

PICKUP UNIT(SERVICE)(P9)

D

F

Page 9

D

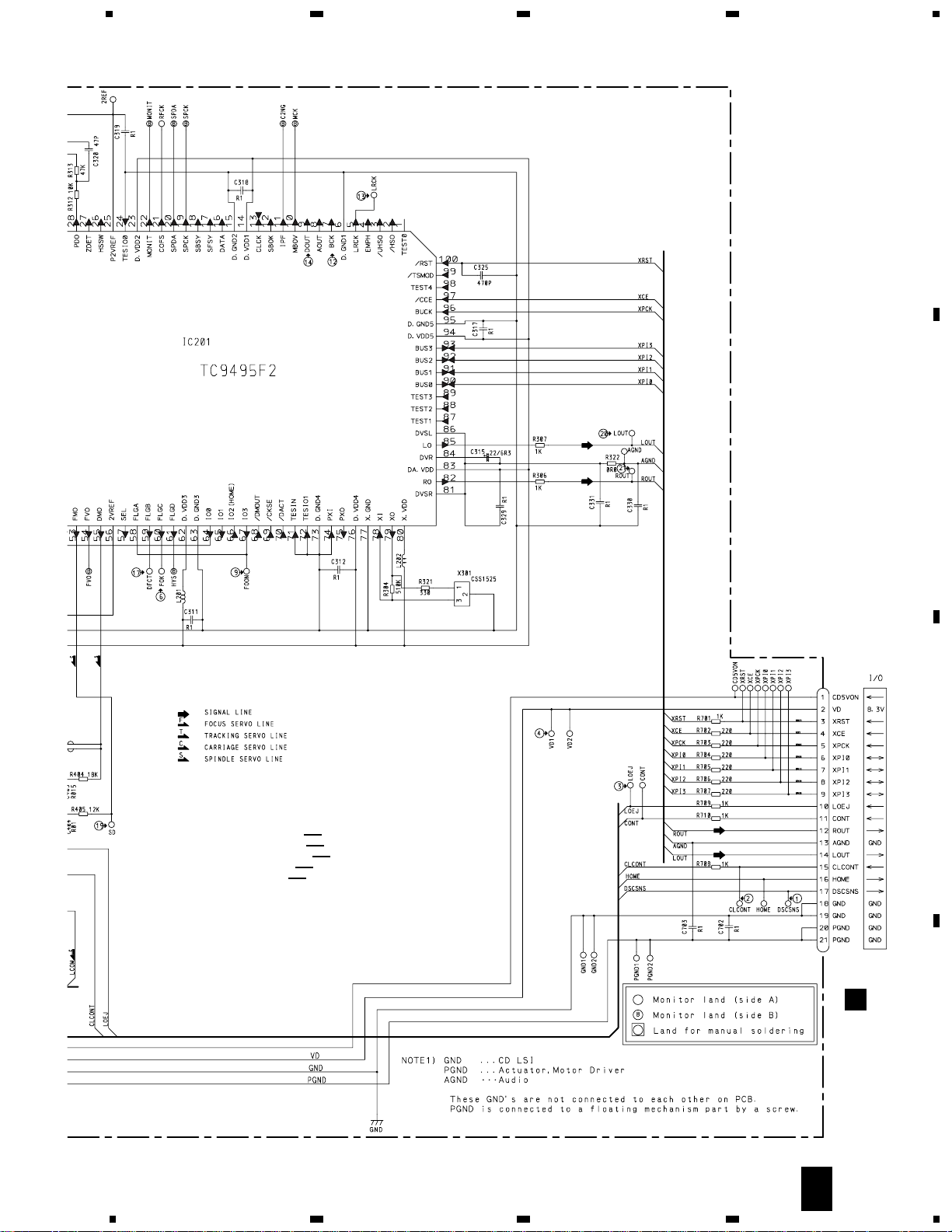

DEH-3300R-2,3330R-2

5

6

78

5

6

78

D

C

B

A

9

16.934MHz

SERVO CONTROL/DSP/DAC/LPF

CN701

SWITCHES:

CONTROL UNIT

S901 : HOME SWITCH.....ON-OFF

S902 : CLAMP SWITCH....ON-OFF

S903 : DSCSNS SWITCH....ON-OFF

S904 : 12EJ SWITCH....ON-OFF

S905 : 8EJ SWITCH....ON-OFF

The underlined indicates the switch position.

A

CN501

F

Page 10

10

DEH-3300R-2,3330R-2

@ CH1:BCK 2V/div.

During "Play"

1 CH1:DSCSNS 5V/div.

2 CH2:CLCONT 5V/div.

3 CH3:LOEJ 5V/div.

4 CH4:VD 10V/div.

When loading (8 cm CD)

500ms/div.

5 CH1:FD 500mV/div.

6 CH2:FOK 5V/div.

7 CH3:MD 5V/div.

When setting up "Source On"

500ms/div.

8 CH1:FE 500mV/div.

9 CH2:FOON 5V/div.

When setting up "Source On"

500ms/div.

5 CH1:FD 500mV/div.

6 CH2:FOK 5V/div.

7 CH3:MD 5V/div.

Magnified drawing for "time"

100ms/div.

1 CH1:DSCSNS 5V/div.

2 CH2:CLCONT 5V/div.

3 CH3:LOEJ 5V/div.

4 CH4:VD 10V/div.

When loading (12 cm CD)

Ref. :

GND

Mode :

Normal

Ref. :

GND

Mode :

Normal

Ref. :

VREF

Mode :

Normal

Ref. :

VREF

Mode :

Normal

Ref. :

VREF

Mode :

Normal

Ref. :

VREF

Mode :

Normal

Ref. :

VREF

Mode :

Normal

Ref. :

VREF

Mode :

Normal

Ref. :

VREF

Mode :

Normal

Ref. :

VREF

Mode :

Test

Ref. :

VREF

Mode :

Normal

Ref. :

VREF

Mode :

Normal

500ms/div.

0 CH1:TE 500mV/div.

8 CH2:FE 500mV/div.

When setting up "Source On"

200ms/div.

1µs/div.

# CH1:LRCK 2V/div.

$ CH2:DOUT 2V/div.

During "Play"

10µs/div.

7 CH1:MD 500mV/div.

During "Play"

10µs/div.

% CH1:RFO 500mV/div.

During "Play"

0.5µs/div.

% CH1:RFO 500mV/div.

0 CH2:TE 500mV/div.

During "Tracking Open"

2ms/div.

8 CH1:FE 500mV/div.

5 CH2:FD 500mV/div.

0 CH3:TE 500mV/div.

! CH4:TD 500mV/div.

During "Play"

1ms/div.

- Waveforms

Note:1. The encircled numbers denote measuring pointes in the circuit diagram.

2. Reference voltage

VREF:2.1V

Page 11

DEH-3300R-2,3330R-2

11

% CH1:RFO 1V/div.

0 CH2:TE 500mV/div.

& CH3:DFCT 5V/div.

During inside/outside search

200ms/div.

% CH1:RFO 1V/div.

0 CH2:TE 500mV/div.

! CH3:TD 1V/div.

1 Track Jump

500µs/div.

% CH1:RFO 1V/div.

0 CH2:TE 1V/div.

! CH3:TD 1V/div.

100 Track Jump

5ms/div.

% CH1:RFO 1V/div.

0 CH2:TE 1V/div.

! CH3:TD 1V/div.

32 Track Jump

5ms/div.

5 CH1:FD 1V/div.

^ CH2:FOP 2V/div.

With no disk inserted

During "Focus Close"

200ms/div.

1 CH1:DSCSNS 5V/div.

2 CH2:CLCONT 5V/div.

3 CH3:LOEJ 5V/div.

When "Eject" (8cm CD)

200ms/div.

) CH1:LOUT 2V/div.

⁄ CH2:ROUT 2V/div.

"Play" in 1kHz, 0dB

200µs/div.

* CH1:TEY 500mV/div.

( CH2:SD 2V/div.

During inside/outside search

200ms/div.

1 CH1:DSCSNS 5V/div.

2 CH2:CLCONT 5V/div.

3 CH3:LOEJ 5V/div.

When "Eject" (12 cm CD)

200ms/div.

% CH1:RFO 2V/div.

& CH2:DFCT 5V/div.

5 CH3:FD 1V/div.

! CH4:TD 2V/div.

When reproducing black dots (800µm)

500µs/div.

Ref. :

VREF

Mode :

Test

Ref. :

VREF

Mode :

Test

Ref. :

VREF

Mode :

Normal

Ref. :

VREF

Mode :

Normal

Ref. :

VREF

Mode :

Test

Ref. :

VREF

Mode :

Test

Ref. :

VREF

Mode :

Normal

Ref. :

GND

Mode :

Normal

Ref. :

GND

Mode :

Normal

Ref. :

GND

Mode :

Normal

Page 12

12

DEH-3300R-2,3330R-2

1

23

4

1234

D

C

B

A

CD MECHANISM MODULE

CONTROL UNIT

SIDE A

M2 LOADING/CARRIAGE MOTOR

M1 SPINDLE MOTOR

PICKUP UNIT(SERVICE)(P9)

A

CN501

D

F

D

F

12EJ

DSCSNS

HOME

VREF

E

F

Page 13

DEH-3300R-2,3330R-2

1

2

34

1

2

34

D

C

B

A

13

SIDE B

CONTROL UNIT

CLAMP

8EJ

D

F

D

F

Page 14

14

DEH-3300R-2,3330R-2

ELECTRICAL PARTS LIST

NOTES:

- Parts whose parts numbers are omitted are subject to being not supplied.

- The part numbers shown below indicate chip components.

Chip Resistor

RS1/_S___J,RS1/__S___J

Chip Capacitor (except for CQS.....)

CKS....., CCS....., CSZS.....

=====Circuit Symbol and No.===Part Name Part No.

--- ------ ------------------------------------------ -------------------------

Unit Number : CWX2481

Unit Name : Control Unit

MISCELLANEOUS

IC 101 IC TA2153FN

IC 201 IC TC9495F2

IC 401 IC BA5996FM

IC 701 IC BA05SFP

Q 101 Transistor 2SD1664

Q 102 Transistor UMD2N

L 201 Inductor CTF1546

L 202 Inductor CTF1546

X 301 Ceramic Resonator 16.934MHz CSS1525

S 901 Spring Switch(HOME) CSN1051

S 902 Spring Switch(CLAMP) CSN1052

S 903 Spring Switch(DSCSNS) CSN1051

S 904 Spring Switch(12EJ) CSN1052

S 905 Spring Switch(8EJ) CSN1051

RESISTORS

R 101 RS1/16S222J

R 102 RS1/8S120J

R 103 RS1/8S100J

R 201 RS1/16S513J

R 202 RS1/16S513J

R 203 RS1/16S823J

R 204 RS1/16S823J

R 206 RS1/16S823J

R 208 RS1/16S124J

R 209 RS1/16S183J

R 210 RS1/16S153J

R 211 RS1/16S103J

R 212 RS1/16S103J

R 213 RS1/16S124J

R 215 RS1/16S0R0J

R 216 RS1/16S471J

R 301 RS1/16S333J

R 302 RS1/16S332J

R 303 RS1/16S332J

R 304 RS1/16S514J

R 306 RS1/16S102J

R 307 RS1/16S102J

R 312 RS1/16S103J

R 313 RS1/16S473J

R 315 RD1/4PU334J

R 321 RS1/16S331J

R 322 RS1/16S0R0J

R 323 RS1/16S332J

R 401 RS1/16S684J

R 402 RS1/16S103J

R 403 RS1/16S103J

R 404 RS1/16S183J

R 405 RS1/16S123J

R 407 RS1/16S622J

R 408 RS1/16S622J

R 409 RS1/16S113J

R 410 RS1/16S752J

R 701 RS1/16S102J

R 702 RS1/16S221J

R 703 RS1/16S221J

R 704 RS1/16S221J

R 705 RS1/16S221J

R 706 RS1/16S221J

R 707 RS1/16S221J

R 708 RS1/16S102J

R 709 RS1/16S102J

R 710 RS1/16S102J

R 901 RS1/16S104J

R 902 RS1/16S473J

R 903 RS1/16S273J

CAPACITORS

C 101 CEV470M6R3

C 102 CKSRYB102K50

C 103 CKSRYB104K16

C 104 CKSRYB224K16

C 105 CEV470M6R3

C 106 CKSRYB104K16

C 107 CKSRYB105K6R3

C 201 CKSRYB104K16

C 202 CCSRCH560J50

C 204 CKSRYB224K16

C 205 CKSRYB224K16

C 206 CKSRYB273K25

C 207 CKSRYB273K25

C 208 CKSRYB104K16

C 209 CKSRYB104K16

C 210 CCSRCK2R0C50

C 211 CCSRCH220J50

C 301 CKSRYB153K25

C 302 CKSRYB104K16

C 303 CKSRYB103K50

C 304 CKSRYB103K50

C 305 CKSRYB104K16

C 306 CKSRYB104K16

C 307 CKSRYB333K16

C 308 CKSRYB104K16

C 309 CKSRYB473K16

C 310 CKSRYB473K16

C 311 CKSRYB104K16

C 312 CKSRYB104K16

C 315 CEV220M6R3

C 317 CKSRYB104K16

C 318 CKSRYB104K16

C 319 CKSRYB104K16

C 320 CCSRCH470J50

C 325 CKSRYB471K50

=====Circuit Symbol and No.===Part Name Part No.

--- ------ ------------------------------------------ -------------------------

D

F

Page 15

DEH-3300R-2,3330R-2

15

C 328 CKSRYB472K50

C 329 CKSRYB104K16

C 330 CKSRYB104K16

C 331 CKSRYB104K16

C 401 CKSRYB221K50

C 402 CKSRYB221K50

C 403 CKSRYB153K25

C 404 CKSRYB103K50

C 405 CEV101M10

C 702 CKSRYB104K16

C 703 CKSRYB104K16

C 801 10µF/10V CCH1349

C 802 CEV101M10

C 803 CKSRYB224K16

Miscellaneous Parts List

Pickup Unit(Service)(P9) CXX1480

M 1 Motor Unit(SPINDLE) CXB6007

M 2 Motor Unit(LOADING/CARRIAGE) CXB5903

=====Circuit Symbol and No.===Part Name Part No.

--- ------ ------------------------------------------ -------------------------

Page 16

16

DEH-3300R-2,3330R-2

CD ADJUSTMENT

1) Precautions

• This unit uses a single power supply (+5V) for the regulator. The signal reference potential, therefore, is

connected to VREF(approx. 2.1V) instead of GND.

If VREF and GND are connected to each other by mistake during adjustments, not only will it be impossible to measure the potential correctly, but the servo

will malfunction and a severe shock will be applied to

the pick-up. To avoid this, take special note of the following.

Do not connect the negative probe of the measuring

equipment to VREF and GND together. It is especially

important not to connect the channel 1 negative

probe of the oscilloscope to VREF with the channel 2

negative probe connected to GND.

Since the frame of the measuring instrument is usually at the same potential as the negative probe, change

the frame of the measuring instrument to floating status.

If by accident VREF comes in contact with GND,

immediately switch the regulator or power OFF.

• Always make sure the regulator is OFF when connecting and disconnecting the various filters and wiring

required for measurements.

• Before proceeding to further adjustments and measurements after switching regulator ON, let the player

run for about one minute to allow the circuits to stabilize.

• Since the protective systems in the unit's software are

rendered inoperative in test mode, be very careful to

avoid mechanical and /or electrical shocks to the system when making adjustment.

• The RFI and RFO signals are easy to oscillate because

of a wide band. When observing them, insert a resistor of about 1 kΩ to the series.

• This equipment will not guarantee the load ejection

operation when the mechanical unit is turned upside

down. In particular, if the ejection operation is incorrectly performed and recovery is disabled, the recovery is enabled by resetting a product or turning ACC

off to on.

2) Test Mode

This mode is used for adjusting the CD mechanism

module of the device.

• Test mode starting procedure

Reset while pressing the 4 and 6 keys together.

• Test mode cancellation

Switch ACC, back-up OFF.

• After pressing the EJECT key, do not press any other

key until the disk is completely ejected.

• If the ] or [ key is pressed while focus search is in

progress, immediately turn the power off (otherwise

the actuator may be damaged due to adhesion of the

lenses).

• Jump operation of TRs other than 100TR continues

after releasing the key. CRG move and 100TR jump

operations are brought into the “Tracking close” status when the key is released.

• Powering Off/On resets the jump mode to “Single

TR(91)”, the RF AMP gain setting to 0 dB, and the

automatic adjustment value to the initial value.

Page 17

DEH-3300R-2,3330R-2

17

*1)

+12dB

TRK12 MIN12 SEC

12

TYP

TRK MIN SEC

*2) S. curve check setting

TRK01 MIN01 SEC

01

Focus Close setting

TRK00 MIN00 SEC

00

or

TRK99 MIN99 SEC

99

*8) CRG motor voltage = 2 [V]

*3)

T.Offset

Display

Switch to the order of the original display

F.Offset

Display

*7)

F.AGC

Gain

RF AGC

Gain

TRK/MIN/SEC

T.AGC

Gain

*5

Single TR

TRK

91

MIN

91

SEC

91

or

TRK

81

MIN

81

SEC

81

32TR

TRK

92

MIN

92

SEC

92

or

TRK

82

MIN

82

SEC

82

100TR

TRK

93

MIN

93

SEC

93

or

TRK

83

MIN

83

SEC

83

CRG Move

TRK

94

MIN

94

SEC

94

or

TRK

84

MIN

84

SEC

84

*4) 1TR/32TR/100TR

*6) Only at the time of CRG move or 100TR jump

[BAND]

Power On

(T. offset is adjusted)

TRK

00

MIN

00

SEC

00

[CD] or [SOURCE]

Source On

TRK MIN

[4]+[6]+Reset

Test Mode In

[3]

Power On

(T. offset is not adjusted)

TRK

99

MIN

99

SEC

99

[2]

RF AMP

Gain switching

*1

TRK

GG

MIN

GG

SEC

GG

[BAND]

Power Off

TRK MIN SEC

[BAND]

Power Off

TRK MIN SEC

[BAND]

Power Off

TRK MIN SEC

[BAND]

Power Off

TRK MIN SEC

[3]

Focus Close /

S. curve check

TRK

91

MIN

91

SEC

91

[6]

Focus Mode switching

*2

TRK

0x

MIN

0x

SEC

0x

[1]

Tracking Servo

Close

TRK

00

MIN

00

SEC

00

or

TRK

99

MIN

99

SEC

99

[[]

CRG-

*8

TRK

00

MIN

00

SEC

00

or

TRK

99

MIN

99

SEC

99

[]]

CRG+

*8

TRK

00

MIN

00

SEC

00

or

TRK

99

MIN

99

SEC

99

[6]

New Test Mode

[2]

Automatic adjustment value

display switching

*3

TRK

??

MIN

??

SEC

??

[1]

T.CLS and F,T AGC

and RF AGC and

Applicable servomechanism

TRK

xx

MIN

xx

SEC

xx

[6]

T.Close and

Applicable servomechanism

TRK

xx

MIN

xx

SEC

xx

[3]

RF AGC /

RF AGC coefficient display

TRK

??

MIN

??

SEC

??

[]]

CRG+

TRK

8x

MIN

8x

SEC

8x

or

TRK

9x

MIN

9x

SEC

9x

[[]

CRG-

TRK

8x

MIN

8x

SEC

8x

or

TRK

9x

MIN

9x

SEC

9x

[2]

T.Balance adjustment /

T.Balance coefficient display

TRK

??

MIN

??

SEC

??

[1]

F,T,RF AGC /

F.Bias display switching

*7

TRK

??

MIN

??

SEC

??

[3]

F,T AGC,F.Bias

and RF AGC

TRK

xx

MIN

xx

SEC

xx

[6]

CRG/TR jump value

*5

switching

TRK

xx

MIN

xx

SEC

xx

[]]

CRG+/TR Jump+

*4

TRK

xx

MIN

xx

SEC

xx

[[]

CRG-/TR Jump-

*4

TRK

xx

MIN

xx

SEC

xx

[2]

Tracking Open

TRK

8x

MIN

8x

SEC

8x

or

TRK

9x

MIN

9x

SEC

9x

[2]

Tracking Open

TRK

8x

MIN

8x

SEC

8x

or

TRK

9x

MIN

9x

SEC

9x

F. EQ measurement setting

TRK02 MIN02 SEC

02

[Key]

[BAND]

[]]

[[]

[1]

[2]

[3]

[6]

-

-

Power On/Off

CRG +/TR Jump+

(Direction of the external surface)

CRG -/TR Jump(Direction of the internal surface)

T.CLS and AGC and Applicable servomechanism/

AGC,AGC display switching

RF Gain switching/Offset adjustment display/

T.Balance adjustment/T.OPN

F.CLS,S.Curve/Rough Servo and RF AGC/

F,T,RF AGC

SPDL 1X/2X switching

(Double-speed compatibility only)

Error rate measurement

F.Mode switching/T.CLS/CRG,TR

Jump switching

Test Mode New Test Mode

Operation

Error occurrence time/

cause display switching

TRK+/FF

TRK-/REV

SCAN

MODE

(ITP)

-

-

Auto/Manual switching

F.Bias

[KEY]

Contents

Display

- Flow Chart

Page 18

18

DEH-3300R-2,3330R-2

• Note :

The grating angle of the PU unit cannot be adjusted after the PU unit is changed. The PU unit in the CD mecha-

nism module is adjusted on the production line to match the CD mechanism module and is thus the best adjusted

PU unit for the CD mechanism module. Changing the PU unit is thus best considered as a last resort. However, if

the PU unit must be changed, the grating should be checked using the procedure below.

• Purpose :

To check that the grating is within an acceptable range when the PU unit is changed.

• Symptoms of Mal-adjustment :

If the grating is off by a large amount symptoms such as being unable to close tracking, being unable to perform

track search operations, or taking a long time for track searching.

• Method :

• Measuring Equipment • Oscilloscope, Two L.P.F.

• Measuring Points • E, F, VREF

• Disc • ABEX TCD-784

• Mode • TEST MODE

• Checking Procedure

1. In test mode, load the disc and switch the 5V regulator on.

2. Using the ] and [ buttons, move the PU unit to the innermost track.

3. Press key 3 to close focus, the display should read "91". Press key 2 to implement the tracking balance adjust-

ment the display should now read "81". Press key 3. The display will change, returning to "81" on the fourth

press.

4. As shown in the diagram above, monitor the LPF outputs using the oscilloscope and check that the phase differ-

ence is within 75° . Refer to the photographs supplied to determine the phase angle.

5. If the phase difference is determined to be greater than 75° try changing the PU unit to see if there is any

improvement. If, after trying this a number of times, the grating angle does not become less than 75° then the

mechanism should be judged to be at fault.

• Note

Because of eccentricity in the disc and a slight misalignment of the clamping center the grating waveform may be

seen to "wobble" ( the phase difference changes as the disc rotates). The angle specified above indicates the average angle.

• Hint

Reloading the disc changes the clamp position and may decrease the "wobble".

100kΩ

390pF

100kΩ

390pF

E

VREF

F

VREF

Xch Ych

L.P.F.

L.P.F.

VREF

E

F

CHECKING THE GRATING AFTER CHANGING THE PICKUP UNIT

CONTROL UNIT

Oscilloscope

Page 19

DEH-3300R-2,3330R-2

19

Grating waveform

Ech → Xch 20mV/div, AC

Fch → Ych 20mV/div, AC

45°

0°

75°

60°

30°

90°

Page 20

20

DEH-3300R-2,3330R-2

GENERAL INFORMATION

TEST MODE

- Error Messages

If a CD is not operative or stopped during operation due to an error, the error mode is turned on and cause(s) of the

error is indicated with a corresponding number. This arrangement is intended at reducing nonsense calls from the

users and also for facilitating trouble analysis and repair work in servicing.

(1) Basic Indication Method

1) When SERRORM is selected for the CSMOD (CD mode area for the system), error codes are written to DMIN (minutes display area) and DSEC (seconds display area). The same data is written to DMIN and DSEC. DTNO remains

in blank as before.

2) Head unit display examples

Depending on display capability of LCD used, display will vary as shown below. xx contains the error number.

8-digit display 6-digit display 4-digit display

ERROR–xx ERR–xx E–xx

(2) Error Code List

Code Class Displayed error code Description of the code and potential cause(s)

10 Electricity Carriage Home NG CRG can't be moved to inner diameter.

SERVO LSI Com- CRG can't be moved from inner diameter.

munication Error → Failure on home switch or CRG move mechanism.

Communication error between microcomputer and SERVO LSI.

11 Electricity Focus Servo NG Focusing not available.

→ Stains on rear side of disc or excessive vibrations on REWRITABLE.

12 Electricity Spindle Lock NG Spindle not locked. Sub-code is strange (not readable).

Subcode NG → Failure on spindle, stains or damages on disc, or excessive vibrations.

A disc not containing CD-R data is found.

Turned over disc are found, though rarely.

CD signal error.

17 Electricity Setup NG AGC protection doesn't work. Focus can be easily lost.

→ Damages or stains on disc, or excessive vibrations on REWRITABLE.

30 Electricity Search Time Out Failed to reach target address.

→ CRG tracking error or damages on disc.

44 Electricity ALL Skip Skip setting for all track.

(CD-R/RW)

50

Mechanism CD On Mech Error Mechanical error during CD ON.

→ Defective loading motor, mechanical lock and mechanical sensor.

A0 System Power Supply NG Power (VD) is ground faulted.

→ Failure on SW transistor or power supply (failure on connector).

Remarks: Mechanical errors are not displayed (because a CD is turned off in these errors).

Unreadable TOC does not constitute an error. An intended operation continues in this case.

Upper digits of an error code are subdivided as shown below:

1x: Setup relevant errors, 3x: Search relevant errors, Ax: Other errors.

Page 21

DEH-3300R-2,3330R-2

21

- New Test Mode

S-CD plays the same way as before.

If an error such as off focus, spindle unlocking, unreadable sub-code, or sound skipping occurs after setup, its

cause and time occurred (in absolute time) are displayed.

During setup, operational status of the control software is displayed.

These displays and functions are prepared for enhancing aging in the servicing and efficiency of trouble analysis.

(1) Shifting to the New Test Mode

1 Turn on the current test mode by starting the reset from the key.

2 Select S-CD for the source through the specified procedure including use of the [SOURCE] key, and inserting the

disc. Then, press the [Jump Mode Selector] key while maintaining the regulator turned off.

3 After the above operations, the new test mode remains on irrespective of whether the S-CD is turned on or off.

You can reset the new test mode by turning on the reset start.

(2) Key Correspondence

Key Test mode New test mode

Regulator Off Regulator On In-play Error Production

BAND To regulator on To regulator off – Time/Err.No. switching

] – FWD-Kick FF/TR+ –

[ – REV-Kick REV/TR- –

1 – Tracking Close Scan –

2 – Tracking Open Mode –

3 – Focus Close ––

–– Focus Open ––

–– Jump Off ––

6 To new test mode Jump mode switching Auto/Manu –

Note: Eject and CD on/off is performed in the same procedure as that for the normal mode.

(3) Cause of Error and Error Code

Code Class Contents Description and cause

40 Electricity Off focus detected. FOK goes low.

→ Damages/stains on disc, vibrations or failure on servo.

41 Electricity Spindle unlocked. LOCK = Low continued for 150 msec.

→ Damages/stains on disc, vibrations or failure on servo.

42 Electricity Sub-code unreadable. Sub-code was unreadable for 500 msec.

→ Damages/stains on disc, vibrations or failure on servo.

43 Electricity Sound skipping detected. Last address memory function was activated.

→ Damages/stains on disc, vibrations or failure on servo.

Note: Mechanical errors during aging are not displayed.

Page 22

22

DEH-3300R-2,3330R-2

(4) Display of Operational Status during Setup

Status No. Contents Protective action

21 Focus search start Focus search timeout.

22 Focus search 2 Focus search timeout.

23 Focus search 3 Focus search timeout.

24 Focus search 4 Focus search timeout.

25 Focus search(Setup protection) Focus slips off.

26 Focus search(Fast recovery) Focus slips off.

27 RF detection Focus slips off.

28 Spindle rough servocontrol Focus slips off.

29 Tracking balance adjustment start Focus slips off.

30 Tracking balance adjustment 2 Focus slips off.

31 Tracking balance adjustment 3 Focus slips off.

32 Tracking close start(Spindle stationary servocontrol setting)

Focus slips off.

33 Tracking close 2 Focus slips off.

34 Tracking close 3 Focus slips off.

35 Focus/Tracking AGC start Focus slips off.

36 Focus/Tracking AGC 2 Focus slips off.

37 Focus/Tracking AGC 3 Focus slips off.

38 Focus/Tracking AGC 4 Focus slips off.

39 Focus/Tracking AGC 5 Focus slips off.

40 Focus/Tracking AGC 6 Focus slips off.

41 Focus/Tracking AGC 7 Focus slips off.

42 Focus/Tracking AGC 8 Focus slips off.

43 FE bias start Focus slips off.

44 FE bias 2 Focus slips off.

45 RF AGC start Focus slips off.

46 RF AGC 2 Focus slips off.

47 Lock check start Focus slips off.

48 Lock is being checked Focus slips off.

49 Subcode check start Focus slips off, spindle lock is not performed.

50 Subcode is being checked Focus slips off, no subcode can be read.

Page 23

DEH-3300R-2,3330R-2

23

(5) Display Examples

1) During Setup

8-digit display, 6-digit display 4-digit display(Auto setting) 4-digit display(Manual setting)

TNO. Min Sec TNO. Min Sec

11 11' 11" 11 11' 11"

2) During Operation (TOC read, TRK search, Play, FF and REV)

The same as in the normal mode.

3) When a Protection Error Occurred

(A) Error display ((A)←→(B), (C) : BAND key)

8-digit display 6-digit display 4-digit display

ERROR-xx ERR-xx E-xx

(B) Error occurrence timing display in track no. ((B)←→(C) : Auto/Manual key)

8-digit display, 6-digit display 4-digit display(Auto setting)

TNO. Min Sec TNO.

10 40' 05" 10

(C) Error occurrence timing display in absolute time. ((B)←→(C) : Auto/Manual key)

8-digit display, 6-digit display 4-digit display(Manual setting)

TNO. Min Sec Min Sec

10 40' 05" 40' 05"

Page 24

24

DEH-3300R-2,3330R-2

- How to hold the Mechanical Unit

1.Hold the top and bottom frame.

2.Do not squeeze top frame's front portion too tight,

because it is fragile.

- How to remove the Top and Bottom Frame

1.When the disk is "clamp" state, unlock Spring A (6

pieces) and Spring B (2 pieces), and unscrew screws

(4 pieces).

2.Unlock each 1 of pawl at the both side of the frame,

then remove the top frame.

3.Remove the Carriage Mechanical part in such way

that; you remove the mechanical part from 3 pieces

of Damper while slowly pulling up the part.

4.Now, the top frame has been removed, and under

this state, fix the genuine Connector again, and eject

the disk.

(Caution)

When you reassemble the Carriage Mechanical part,

apply a bit of alcohol to Dampers.

- How to remove the Guide Arm Assy

1.Unlock the spring (1 piece) at the right side of the

assembly.

2.Unscrew screws (2 pieces), then remove the Screw

Gear Bracket.

3.Shift the Guide Arm Assy to the left and slowly rotate

it to the upper direction.

4.When the Guide Arm Assy rotates approximately 45

degree, shift the Assy to the right side direction and

remove it.

Top Frame

Bottom Frame

Damper

Spring

Screw Gear Bracket

Guide Arm

Assy

Carriage

Mechanical

Part

Do not squeeze.

DISASSEMBLY

Page 25

DEH-3300R-2,3330R-2

25

- How to remove the Control Unit

1.Give jumper-solder treatment to the Flexible Wire of

the Pickup unit, then remove the wire from the

Connector.

2.Remove all 4 points of solder-treatment on the Lead

Wire. Also, unscrew the screw(1 piece).

3.Then, Remove the Control unit.

(Caution)

Be careful not to damage SW when you reassemble

the Control Unit into the device.

- How to remove the Loading Arm Assy

1.Unlock the spring (1 piece) and remove the E ring (1

piece) of the Fulcrum Shaft.

2.Shift the arm to the left side direction and unlock pins

(2 pieces).

- How to remove the Pickup Unit

1.Unscrew 2 pieces of screws, then remove the Pulley

Cover.

2.Remove the Feed Screw unit from the pawl of the

Feed Screw Guide (The pawl is located inside the

guide).

3.Remove the belt from the Pulley, then remove the

Pickup unit.

(Caution)

Make sure not to stain the belt with grease when you

fix the belt.

Control Unit

Jumper-Solder

Solder

Loading Arm Assy

Pickup Unit

Pulley Cover

Feed Screw Guide

Belt

Grease Application

Grease Application

Grease Application

Page 26

26

DEH-3300R-2,3330R-2

115

16 30

- Pin Functions(TA2153FN)

Pin No. Pin Name I/O Function and Operation

1 VCC Power supply voltage terminal

2 RFGC I RF amplitude adjustment control signal terminal

3 GMAD I AGC amplifier frequency characteristic adjustment terminal

4 FNI I Main beam amplifier input terminal

5 FPI I Main beam amplifier input terminal

6 TPI I Sub beam amplifier input terminal

7 TNI I Sub beam amplifier input terminal

8 MDI O Monitor photodiode amplifier input terminal

9 LDO I Laser diode amplifier output terminal

10 SEL I APC circuit ON/OFF signal, LDO terminal control input terminal and bottom

and peak detection frequency switching terminals

11 TEB I Tracking error balance adjustment signal input terminal

12 2VRO O Reference voltage (2VRO) output terminal

13 TEN I Tracking error signal generation amplifier reverse phase input terminal

14 TEO O Tracking error signal generation amplifier output terminal

15 SBAD O Sub beam addition signal output terminal

16 FEO O Focus error signal generation amplifier output terminal

17 FEN I Focus error signal generation amplifier reverse phase input terminal

18 SEB I RFRP generation circuit mode switching terminal

19 VRO O Reference voltage (VREF) output terminal

20 RFRP O Signal generation amplifier output terminal for track count

21 BTC I Bottom detection time constant adjustment terminal for RFCT signal

generation

22 RFCT O RFRP signal center level output terminal

23 PKC I Peak detection time constant adjustment signal for RFCT signal generation

24 RFRPIN I Signal generation amplifier input terminal for track count

25 RFGO O RF signal amplitude adjustment amplifier output terminal

26 GVSW I AGC, FE or TE amplifier gain switching terminal

27 AGCIN I RF signal amplitude adjustment amplifier input terminal

28 RFO O RF signal generation amplifier output terminal

29 GND I GND terminal

30 RFN2 I RF signal generation amplifier input terminal

TA2153FN

IC

Page 27

27

DEH-3300R-2,3330R-2

- Pin Functions(TC9495F2)

Pin No. Pin Name I/O Function and Operation

1 TESTO Test mode terminal

2 hso O Replay speed flag output terminal

3 uhso O Replay speed flag output terminal

4 EMPH O Emphasis flag output terminal for sub code Q data

5 LRCK O Channel clock (44.1 kHz) output terminal

6 VSS Digital ground terminal

7 BCK O Bit clock output terminal

8 AOUT O Digital audio data output terminal

9 DOUT O Digital out output terminal

10 MBOV O Buffer memory over signal output terminal

11 IPF O Correction flag output terminal

12 SBOK O CRCC decision result output for sub code Q data

13 CLCK I/O Clock input/output terminal for sub code P-W data read

14 VDD Digital + power supply terminal (5 V)

15 VSS Digital ground terminal

16 DATA O Sub code P-W data output terminal

17 SFSY O Replay-system frame sync signal output terminal

18 SBSY O Sub code block sync output terminal

19 SPCK O Clock for processor status signal read

20 SPDA O Processor status signal output terminal

21 COFS O Correction-system frame clock (7.35 kHz) output terminal

22 MONIT O LSI internal signal output terminal

23 VDD Digital + power supply terminal (5 V)

24 TESIO0 I Test input/output terminal

25 P2VREF PLL-system only 2VREF terminal

26 HSSW O The VREF voltage is reached for double or quad speed.

27 ZDET O One-bit DAC zero detection flag output terminal

28 PDO O Phase error signal issue between the EFM and PLCK signals

29 TMAXS O TMAX detection result output terminal

30 TAMX O TMAX detection result output terminal

31 LPFN I Reverse input terminal of amplifier for lowpass filter

32 LPFO O Output terminal of amplifier for lowpass filter

33 PVREF PLL-system only VREF terminal

34 VCOREF I VCO center frequency reference level terminal

35 VCOF O Filter terminal for VCO

36 AVSS Analog-system ground terminal

37 SLCO O Output terminal of DAC for data slice level generation

38 RFI I RF signal input terminal

39 AVDD Analog-system power supply terminal (5 V)

40 RFCT I RFRP signal center level input terminal

41 RFZI I Input terminal for RFRP signal zero cross

42 RFRP I RF ripple signal input terminal

43 FEI I Focus error signal input terminal

44 SBAD I Sub beam addition signal input terminal

45 TSIN I Test input terminal

46 TEI I Tracking error input terminal

47 TEZI I Input terminal for tracking error or zero cross

48 FOO O Focus equalizer output terminal

49 TRO O Tracking equalizer output terminal

50 VREF Analog reference power supply terminal

51 RFGC O RF amplitude adjustment control signal output terminal

52 TEBC O Tracking balance control signal output terminal

53 FMO O Feed equalizer output terminal

54 FVO O Speed error signal or feed search EQ output

55 DMO O Disc equalizer output terminal

56 2VREF Analog reference power supply terminal

57 SEL O APC circuit ON/OFF signal output terminal

Page 28

28

DEH-3300R-2,3330R-2

Pin No. Pin Name I/O Function and Operation

58-61 FLGA-D O External flag output terminal for internal signal monitor

62 VDD Digital + power supply terminal (5 V)

63 VSS Digital ground terminal

64 IO0 O RF amplifier gain switching terminal

65 IO1 O Not used

66 IO2 I HOME detection switch input terminal

67 IO3 O FocusDrv and signal output terminal

68 dmout I Field equalizer PWM output terminal for IO0 and IO1

Disc equalizer PWM output terminal for IO2 and IO3

69 ckse I Usually open

70 dact I DAC test mode terminal

71 TESIN I Test input terminal

72 TESIO1 I Test input/output terminal

73 VSS Digital ground terminal

74 PXI I DPS-system clock oscillator circuit input terminal

75 PXO O DPS-system clock oscillator circuit output terminal

76 VDD Digital + power supply terminal (5 V)

77 XVSS Ground terminal for system clock oscillator circuit

78 XI I System clock oscillator circuit input terminal

79 XO O System clock oscillator circuit output terminal

80 XVDD For system clock oscillator circuit + power supply terminal

81 DVSR R channel D/A converting unit power supply terminal

82 RO O R channel data forward rotation output terminal

83 DVDD D/A converting unit power supply terminal (5 V)

84 DVR Reference voltage terminal

85 LO O L channel forward rotation output terminal

86 DVSL L channel D/A converting unit power supply terminal

87-89 TEST1-3 I Test mode terminal

90-93 BUS0-3 I/O Data input/output terminal for microcomputer interface

94 VDD Digital + power supply terminal (5 V)

95 VSS Digital ground terminal

96 BUCK I Clock terminal for microcomputer interface

97 cee I Chip enable signal for microcomputer interface

98 TEST4 I Test mode terminal

99 tsmod I Test mode terminal

100 rst I Reset signal input terminal

30

31

50

51

80

81

100

1

*TC9495F2

IC's marked by* are MOS type.

Be careful in handling them because they are very

liable to be damaged by electrostatic induction.

Page 29

29

DEH-3300R-2,3330R-2

- Pin Functions(BA5996FM)

Pin No. Pin Name Function and Operation

1 VR Input pin for reference voltage

2 OPIN2(+) Input pin for non-inverting input for CH2 preamplifier

3 OPIN2(-) Input pin for inverting input for CH2 preamplifier

4 OPOUT2 Output pin for CH2 preamplifier

5 OPIN1(+) Input pin for non-inverting input for CH1 preamplifier

6 OPIN1(-) Input pin for inverting input from CH1 preamplifier

7 OPOUT1 Output pin for CH1 preamplifier

8 GND Ground pin

9 MUTE Mute control pin

10 POWVCC1 Power supply pin for CH1, CH2, and CH3 at "Power" stage

11 VO1(-) Driver CH1 - Negative output

12 VO1(+) Driver CH2 - Positive output

13 VO2(-) Driver CH2 - Negative output

14 VO2(+) Driver CH2 - Positive output

15 VO3(+) Driver CH2 - Positive output

16 VO3(-) Driver CH2 - Negative output

17 VO4(+) Driver CH4 - Positive output

18 VO4(-) Driver CH4 - Negative output

19 POWVCC2 Power supply pin for CH4 at "Power" stage

20 GND Ground pin

21 CNT Control pin

22 LDIN Loading input

23 OPOUTSL Output pin for preamplifier for thread

24 OPINSL Input pin for preamplifier for thread

25 OPOUT3 CH3 preamplifier output pin

26 OPIN3(-) Input pin for inverting input for CH3 preamplifier

27 OPIN3(+) Input pin for non-inverting input for CH3 preamplifier

28 PREVCC PreVcc

BA5996FM

114

15 28

Loading...

Loading...