Page 1

[o'- r,6 1

o

o

t=FT;Tit F. |-T{=T;T-TT

E

8flflfl8fl

=Es-@=

E-

E=

:

ORDER

ARPl336

STEREO DOUBLE CASSETTE TAPE DECK AMPLIFIER

DG-X772

/oE.

NO.

MODEL DC-X772 COMES

TyPe

HB AC22OV. 24OV

HE

SD

HE2

a

This service manual is

a

As

to th6 HE and SD types,

a

As to the oth€r typ€s,

AC22OV.

AC11OV, 12O-127V

AC22OV,

AC24OV only Australia

Ce manual

Este manual

a

2 4OV

24Ov

d'instruction

de servicio trata del m6tode

IN FIVE VERSIONS

Powea roquiromont

(swatchable)'

(swrrchable)*

,22OV ,24OV

(

switchable)

applicable to the

please

refbr

se

CONTENTS

1.

SPEC|F|CATTONS ......

2.

EXPLODED VIEWS AND PARTS LIST ....,.

3.

MECHANICAL

IN

OUTL

SCHEMATIC DIAGRAM

4.

P.C.BOARDS

5.

SECTION OPERATION

E

CONNECTION DIAGRAM......

DISTINGUISHED AS FOLLOWS:

United

European Continent

(switchabl€)

"

General market

Wast

HB, HE and SD typ6s.

please

refer to

pages

51.

refer to additional service

mode

au

de r6glage, en

ajuste escrito

2

9

14

6. ELECTRICAL PARTS LIST,

7, ADJUSTMENTS

7. REGLAGE

7.

AJUSTE

8. PACKING

9. FOR HE AND SD TYPES

Exoon dostination

Kingdom

Germany

change the

manual.

franqais.

en espafrol.

primary

.......

wiring,

please

refer to

page

35

40

45

50

5l

PIONEER ELECTRONIC CORPORATION 4-1. r\,4esuro 1

PIONEER

PIONEER ELECTRONICS OF CANADA, lNC. 505 Cochrane

PIOI{EER ELECTRONIC

PIONEER ELECTRONICS AUSTRALIA PTY. LTD. 178-184

ELECTRONICS SERVICE lNC. P

IEUFOPEI

N.V. Keetberglaan 1.2740

O. Box

1760.

Lono Eeach Ca

Bo!ndarv Road. Braesrde. Vrctofla3195. Australia TEL:

N4arkham,

dnve.

Beveren, BelgrumTEL 03/775 28.A8

chome, r\y'esuro,ku, Tokyo ts3, Japan

orn a 90801 U S.A.

Ontano L3R 688Canada

TEL:

14161

479 4411

580-9911

I03l

SAC)fEB

rc37 Pr'nled in

'apan

Page 2

1.

SPECTFTCATTONS

Continuous Average Power

Watts*

per

channel, min., at 8 ohms f rom

Output

is 27

40 Hertz to 20,000 Hertz. with no more

than

0.37" total harmonic distortion.

'Measured

Trcde Regulation tules on Powet

Continuous Power

40 to

1 kHz

1 kHz

Graphic equalizer trequency band .......... 100 Hz, 330 Hz,

Hum

PHONO ................ ...._......_..._._ 72

Hum and Noise

PHONO

Total Harmonic Distortion

15 Walts

o.20/o

Tape Deck

Systems

Heads ...................................

Motor ....................

Wow

Fast Winding Time ..............

pursuant

Output

20,000 Hz ......... 27 W + 27 W

(DlN)

(DlN

and Noise

................. ..... 68 dB/60

per

power)

music

(lHF,

(DlN

continuous

channel

Federcl

to the

33 W + 33

'1

kHz,

short - circu ited, A network)

(40

power

output

Ttade Commission's

Output

(T.H.D.0.3%

(T.H.D.

W

(T.H.D.

kHz, 10 kHz,

3.3

Power/5o mW)

Hz

to 20,000 Hz, 8 ohms)

..............

Section

.................

Flutter

and

4 track, 2-channel stereo

Recording/playback head x

Playback head x 1

DC servo 2 speed motor

No more than 0.13%

Approzimately 105

tape)

Claims

I

ohms)

1% 8 ohms)

50 W + 50 W

1% 8 ohms)

i7

No more than

Erasing

head x 1

(WRMS)

seconds

fol

dB

dB

dB

x 2

(C-60

Frequency Response

-20

Normal tape

CrO, ............ .. . . .

Signal to Noise Ratio

Dolby

Noise Reduction

Dolby

recording:

dB

NR OFF

B lype NR

Effect

ON

...

Hz

35

to 14,00O

Hz to

35

......................... 56 dB

...... More than 10 dB

'15.000

(at

Hz

Hz

5 kHz)

Furnished Parts

Operating

Turntable fegs

Instructions

.......................

parts

...........................................................-. 2

1

M iscellaneous

Power requirements

European model

U. K. model

Australian model .............. .

destrnation

Other

Power

European model ..........................

U.K. model

Other

1

Dimensions

Weight

Specilications and

out

Consumption

destination models .................. ..................... ... 210 W

(without

notice

due to imp@vement

models

AC 110/120-127l22O/240 V

........... ...................... 210W

360(W) x 190(H) x 283(D)

14-3l16(W) x 7-1t2\H) x 11-1l8(D) in

package)

design subject to

.................................. 6.8 kg

AC 220 V,

AC 240 V, 50/60 Hz

AC

(switchable)

possible

modtications with

Hz

50/60

240 V, 50 HZ

50/60

Hz

210 W

mm

(15

lb)

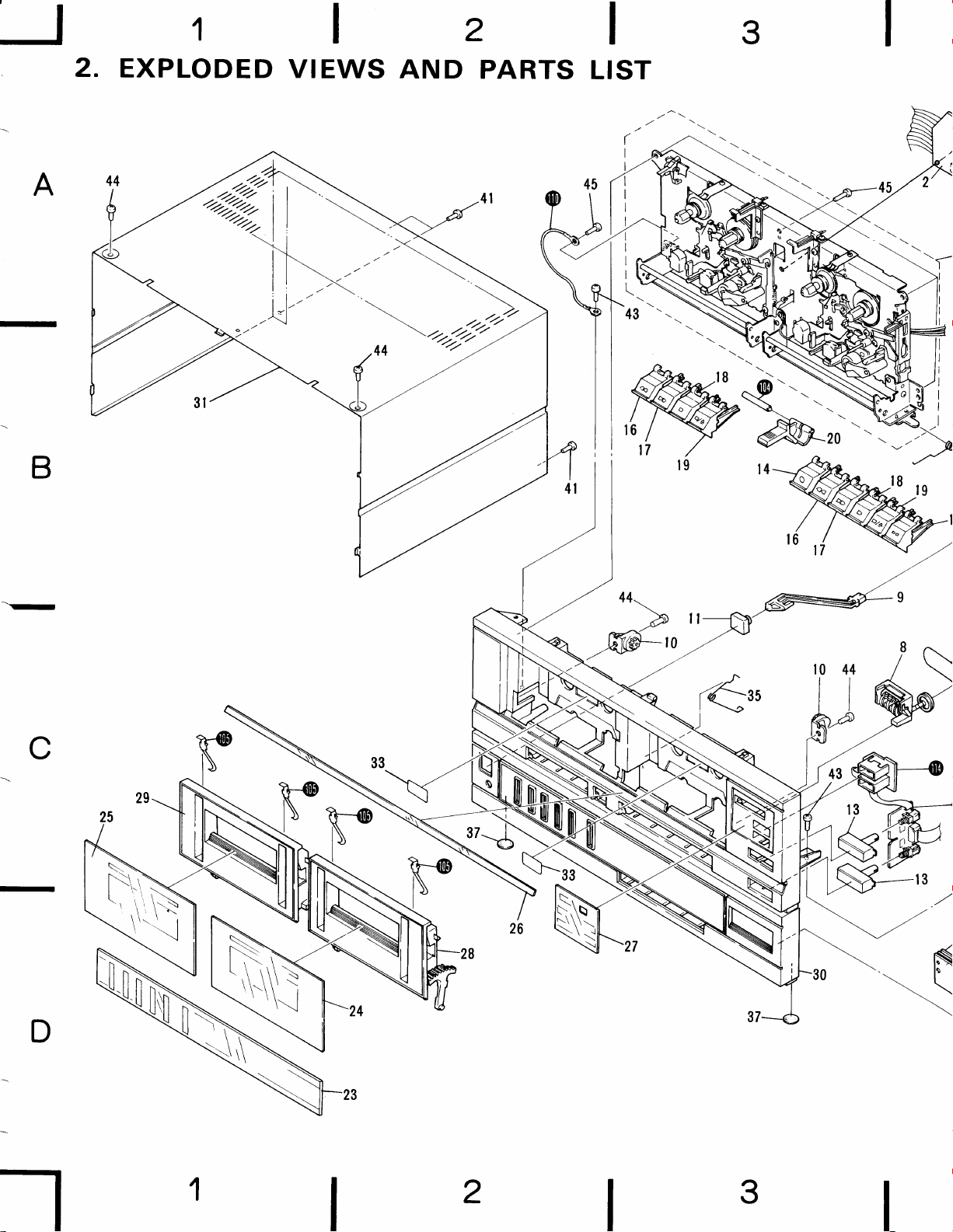

Page 3

J

llzl

2.

EXPLODED

VIEWS

AND

PARTS

3

LIST

F\.'\

tt

,'\ \'.r

\t'ti

4"

N

YNI

1

2

3

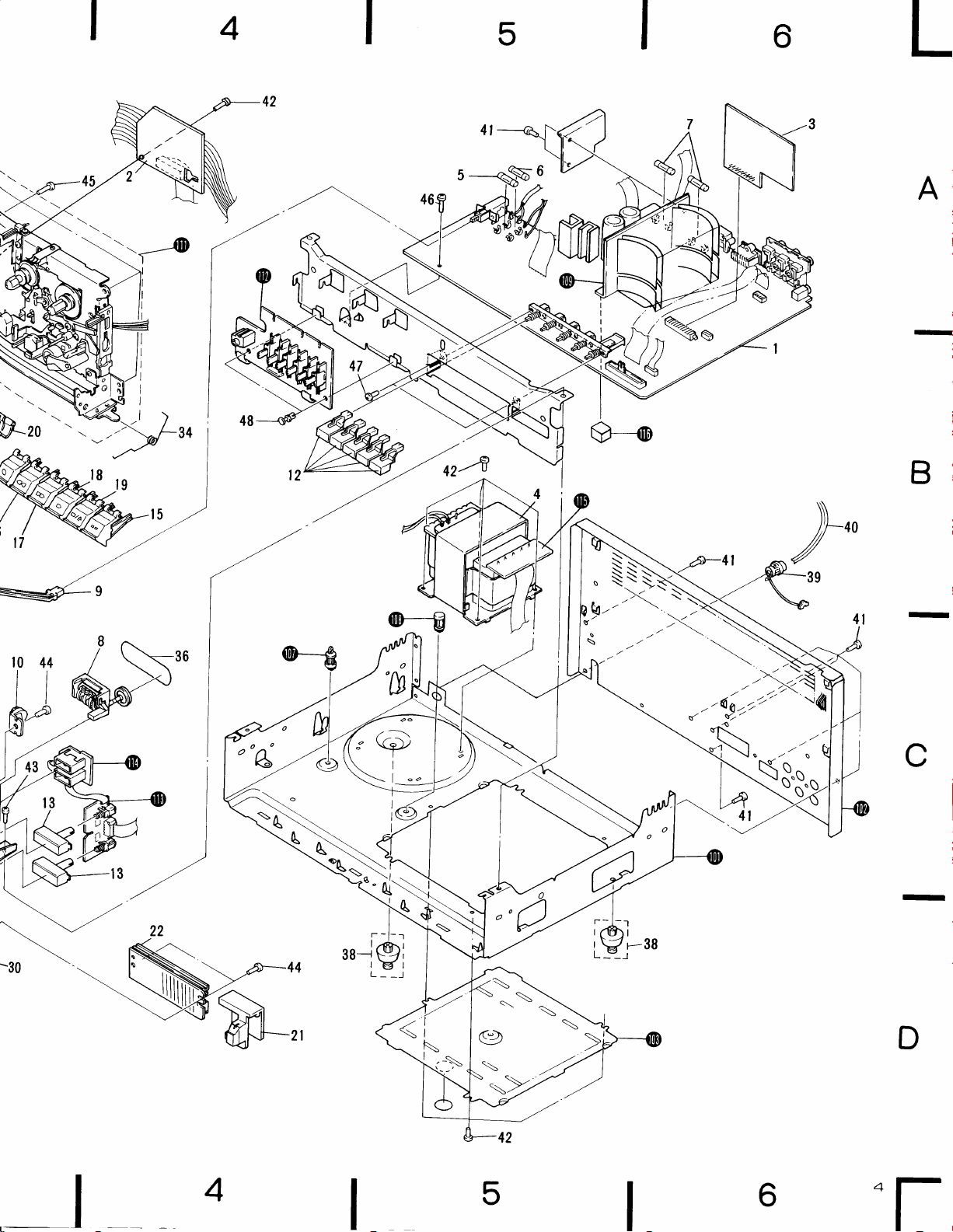

Page 4

4

5

\>vt---'

i

i

1r''%i

6

L

A

t7

<4

f0

44

qzA

"

\:-x

B

'q

\

n"'oL"i'

B

c

4

44

2l

()\i

\.1

''o)Z,,

\Y

/'J

5

D

4l-

6

I

Page 5

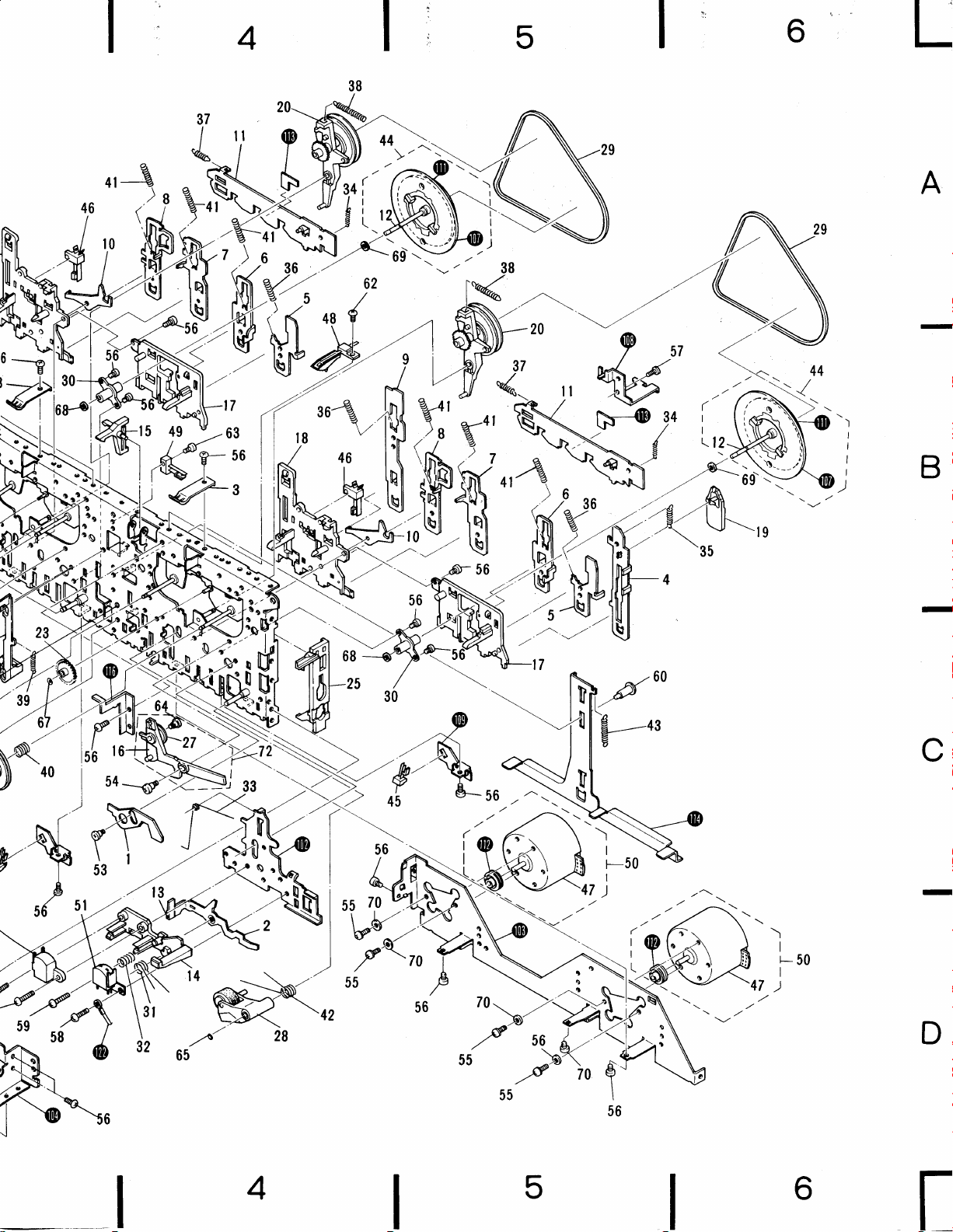

NO?XS:

.

Parts uithout

o

The

sofety

desEnotaon.

.

.

your

Fot

marks

**

CENERALLY

cld$ificatioa

This

model

Parts marked

than

port

morh

-i,

factor

A *

nutnber,

usual or lhe!

found

the

of

Potts Stoch

'l

ond

,

temperoture,

"

by

number con^ot

on aome compone^t

port.

Thercfore,

Control,

be odiusted

not always

are

unavailable.

FASTER

humidity,

MOVES

should

"

6

may be

be supplied

replocing, be 'urc

when

the

fast

THAN

b! eoch

etc.

kePt in sloclc

ports

indicotet

mouing items

*

distributot because

Theil delivery lime

the importonce

parts

to use

ate indicoted with

of identical

it depends

mat be longer

of the

the

orr

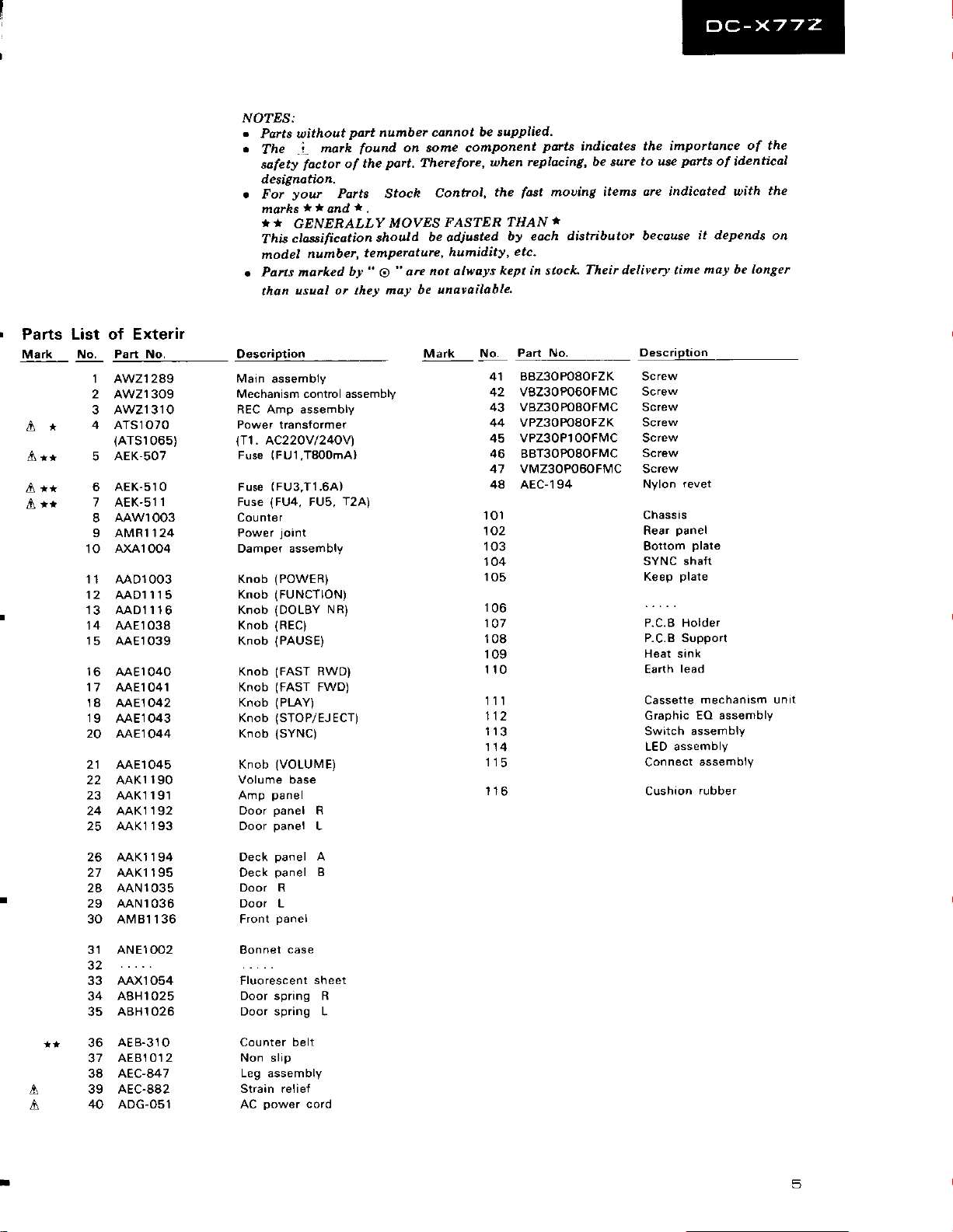

Parts List

Mark

A*

No.

10 AXAl004

11 AAD1003

12 AADl115

'13

14 AAE1038

15 AAE1039

16

17 AAEl041

18 AAEl042

19

20 AAE1044

21 AAE1045

22 AAK1190

23 AAK1191

24 AAK1192

25

of Exterir

Part No. Description

1 AWZI289

2 AWZ1309

3 AWZ1310

4 ATS1070

(Ars1065)

AEK-507

5

AEK-s10

6

7 AEK-s11

AAWl003

8

9 AMRI124

AAD1 1 16

AAE1040

AAE1043

AAK1 193

Main assembly

Mechanism control assembly

REC Amp assembly

Power transformer

l.11.

Fuse

Fuse

Fuse

Counter

Power

Damper assembly

Knob

Knob

Knob

Knob

Knob

Knob

Knob

Knob

Knob

Knob

Knob

Amp

Door

Door

^C22OV

/24OV)

(FU1,T800mA)

(FU3,T1.6A)

(FU4,

FUs,

joant

(POWER)

(FUNCTION)

(DOLBY NR)

(REC)

(PAUSE)

(FAST

RWD)

(FAST

FwD)

(PLAY)

(STOP/EJ

(SYNC)

(VOLUM

panel

panel

panel

ECT)

E)

R

L

T2A)

Part No.

No.

41 BBZ30PO80FZK

42 VSZ30PO60FMC

43 VBZ30PO80FMC

44 VPZ30K)80FZK

45 VPZ30P'r

46 BBT3OPOSOFMC

47 VMZ30PO60FMC

48 AEC-194

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

OOFMC

Description

Screw

Screw

Screw

Screw

Screw

Screw

Screw

revet

Nylon

Chassis

panel

Rear

Bottom

SYNC shaft

Keep

P.C.B Holder

P.C.B Support

Heat sank

Earth

Cassette

Graphic

Switch

LED assembly

Connect

Cushaon

plate

plate

lead

mechanism unrt

EO assembly

assembly

assembly

rubber

panel

26 AAKl194

27 AAKl195

28 AAN

29

30 AMBl 136

1035

AAN1036

ANElOO2

Deck

Deck

Door R

Door L

Front

Bonnet

panel

panel

cas e

A

B

32

33

AAX1O54

34

35

36

*t

37

38 AEC-847

A

A

39 AEC-882

40 ADG-Os1

1025

A8H

ABH1026

AEB-31O

AEB1012

Fluorescent

Door spring R

Door spring L

Counter be

Non slip

Leg assembly

Straan relief

sheet

lt

Page 6

A

B

2

3

g7

L

C

,-fA<

51

/

59

5'B

,*rP

W

)

65

fl

F

.t"

,n_-/Il,

56

I

116'

-

d

A

40

lh /'

45

$

2l

..t

,.'

,f

5

-

D

-l6

2

{l

*s>

3

J,

,/

N

f

Page 7

4

5

6

L

A

B

4

5

c

D

6

I

Page 8

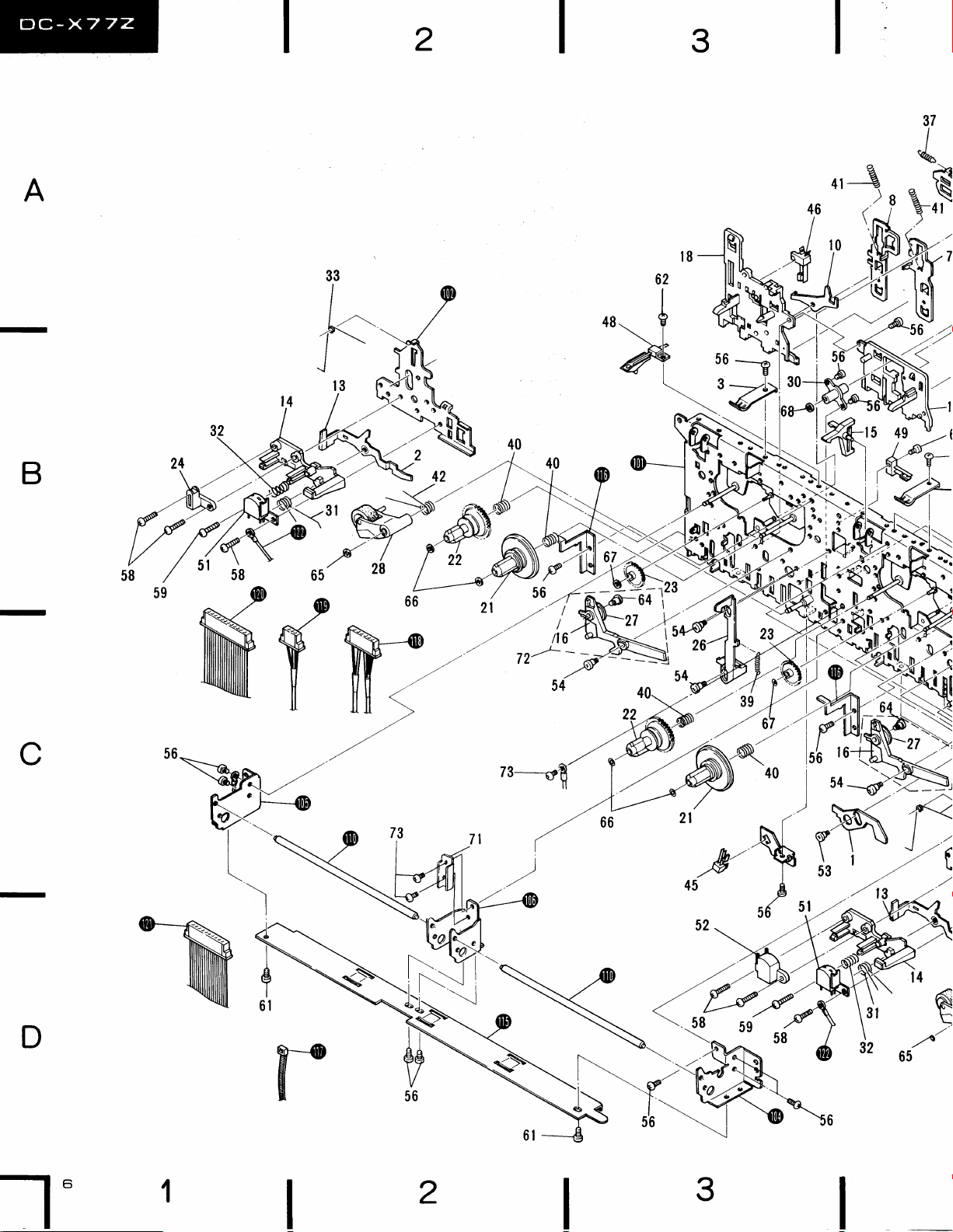

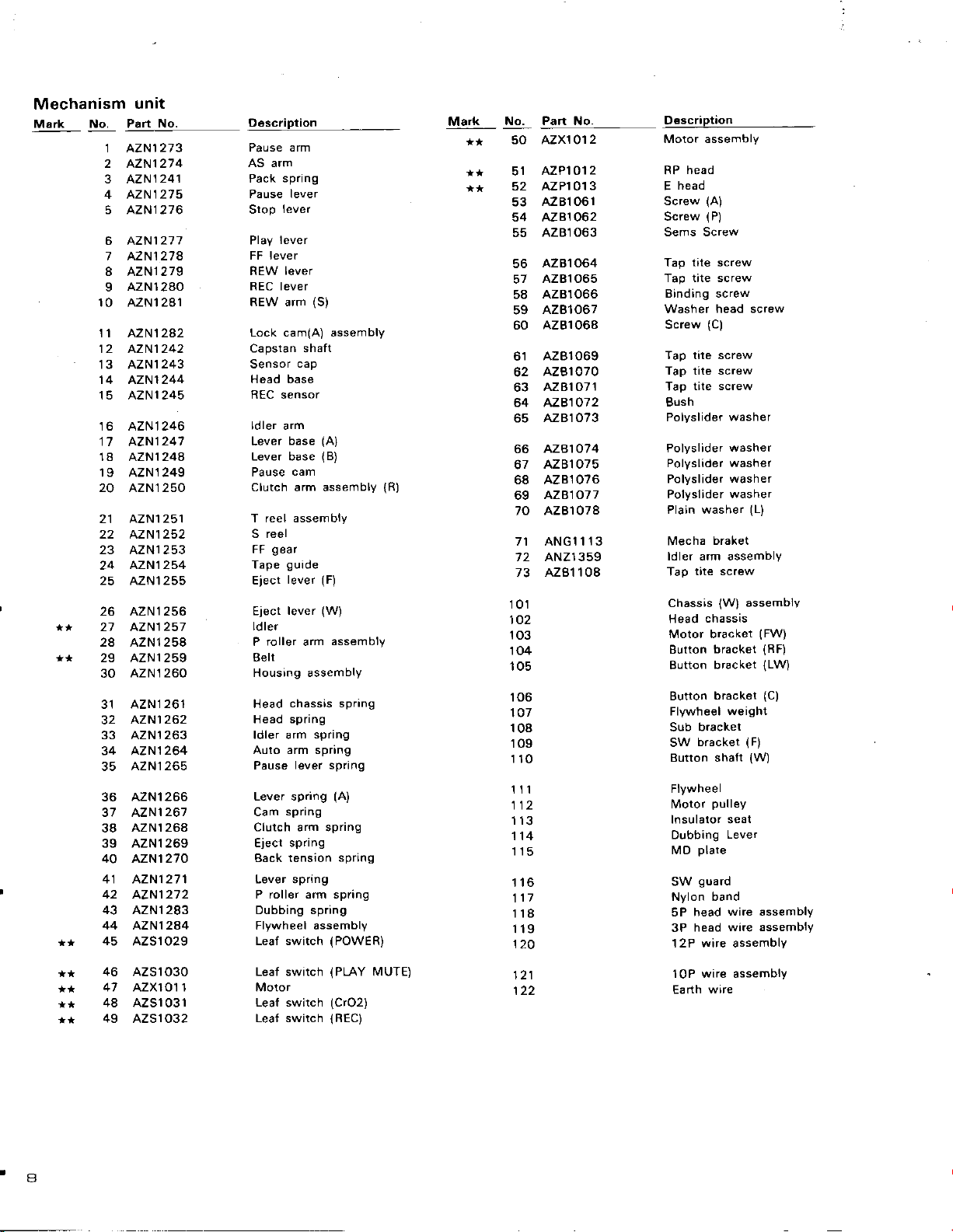

Mechanism

Mark No. Part

unit

1 AZN1273

2 AZN127

N'! 241

3 AZ

AZN1275

4

5 AZN1276

6 AZN1277

7 AZN1278

8 AZN1279

AZN1280

9

10 AZN't 281

1 1 AZN1282

12 AZN1242

13 AZN1243

14 AZN1244

15 AZNl245

16 AZNl246

17 AZN1247

18 AZNl248

l9 AZNl249

20 AZN1250

21 AZNl251

22 AZN1252

23 AZN1253

AZN1254

24

25 AZN1255

26 AZN1256

27 AZN1257

28 AZN1258

29 AZNl259

AZN1260

30

31 AZN1261

AZNI262

32

33 AZN1263

34 AZN1264

AZN1265

35

AZN1266

36

37 AZNl267

AZNl268

38

39 AZN1269

40 azN1270

41 AZN1271

42 AZN1272

43 AZNl283

44 AZN12A4

45

AZS1029

46 AZS1030

47 AZX1011

48 AZS1031

49 AZS1032

No.

Description

Pause arm

4

AS arm

spring

Pack

lever

Stop

FF lever

lever

REW

REC lever

REW arm

Lock cam(A) assembly

Capstan sh6ft

Sensor

Head base

REC sensor

ldler arm

Lever

Lever base

Palse

Clutch arm assembly

T reel assembly

S reel

FF

Tape

Eiect

Eject

ldler

P roller arm

Belt

Housing assembly

Head

Head spring

ldler arm

Auto arm spring

Pause

Lever spring

Cam

Clutch arm spring

Ejecr spring

Back tension

Lever spfing

P roller arm spring

Dubbing spring

Flywheel assembly

Leaf switch

Leaf switch

Leal switch

Leaf switch

(S)

cap

(Ai

base

(B)

cam

gear

guide

(F)

lever

(W)

lever

chassis spring

spring

lever spring

spring

{POWER)

(PLAY

{REC)

assembly

(A)

spring

MUTE)

(CrO2)

(R)

Mark

No. Part No.

50 AZX1012

AZPl012

51

52 AZP1013

AZB'I 06r

53

54 Az81062

AZB1063

55

AZB1064

56

AZB1065

57

AZB1066

58

AZB1067

59

60 AZ81068

AZB1069

61

AZe1070

62

AZB1 OT

63

AdB107

64

AZB1073

65

AZB1074

66

AZ81075

67

68 AZ81076

AZB1077

69

70 AZB1078

71 ANG1 1

72 ANZ1359

AZB1 108

73

101

102

103

104

105

106

107

104

109

110

111

112

113

114

115

17

18

19

20

121

122

l

2

13

D€scription

Motor assembly

head

RP

head

E

(A)

Screw

(P)

Screw

Sems Screw

tite

Tap

Tap tite screw

Binding scrow

Washer

Screw

Tap tite screw

Tap tite screw

Tap

Bush

Polyslider

Polyslider

Polyslider washer

Polyslider

Polyslider

Plain washer

Mech6

ldler arm assembly

Tap

Chassis

Head

Motor bracket

Bution

Button

Bufion

Flywheel

Sub

SW

Button shaft

screw

head screw

(C)

tite screw

washer

washer

washer

washer

(L)

braket

tite screw

assembly

{W)

chassis

bracket

bracket

pulley

Motor

lnsulator seat

Dubbing

plate

MD

guard

SW

Nylon band

5P head

head

3P

12P wire assembly

10P wire assembly

wire

Earth

(FW)

bracket

bracket

bracket

(RF)

lLW)

(C)

weight

(F)

(W)

Lever

wire assembly

wire assembly

a

Page 9

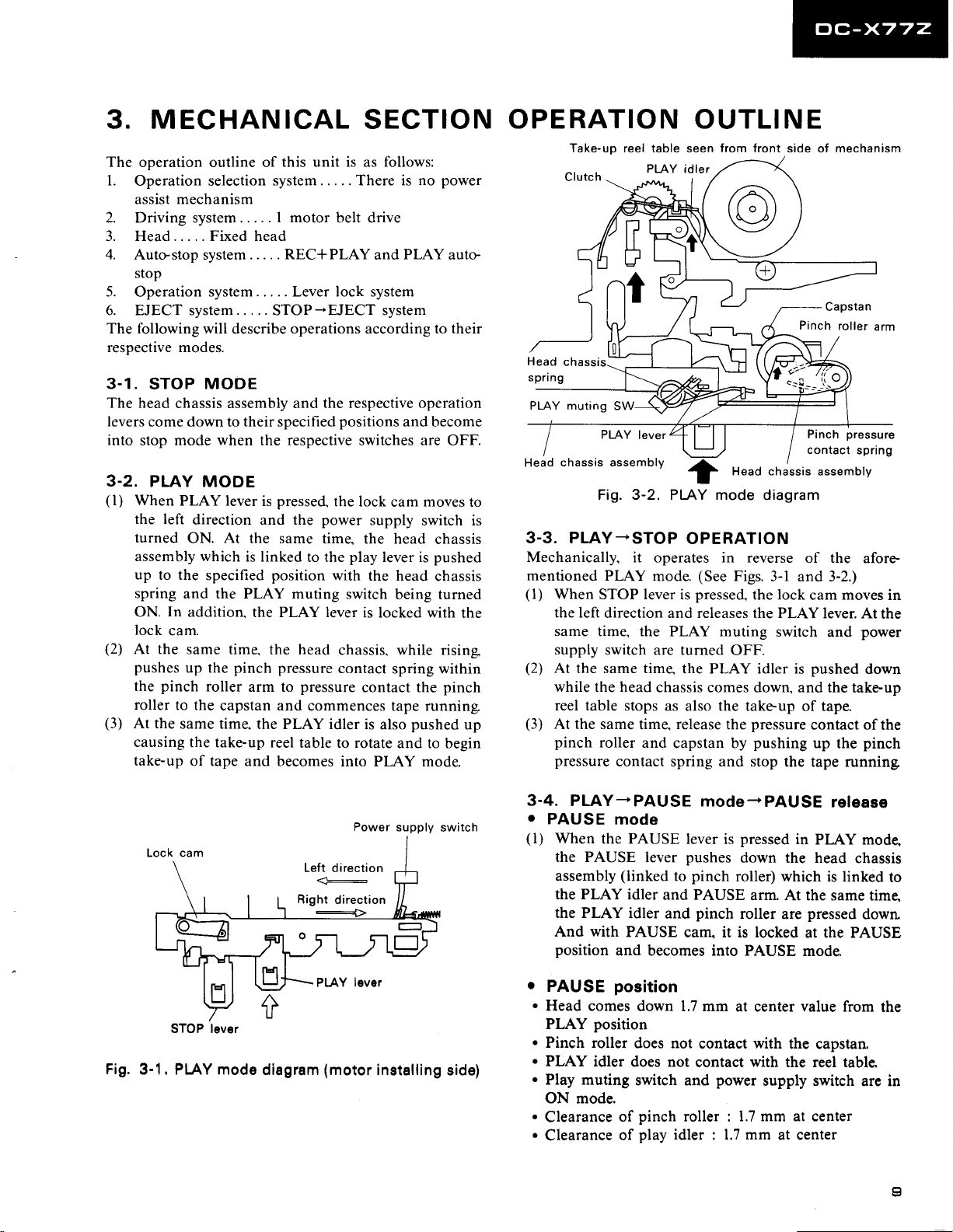

3. MECHANICAL SECTION

The operation outline of this

l.

Operation selection

assist mechanism

2. Driving system.....

3. Head.....Fixedhead

4.

Auto-stop system.....

stop

5.

Operation

6. EJECT system..

The following will

respective modes.

3.1.

STOP

The head

levers come down to their specified

into

stop mode when the respective switches are OFF.

3.2.

PLAY MODE

(l)

When

the

turned

assembly which

up

to the

spring

ON.

lock

(2)

At the

pushes

pinch

the

roller

(3)

At the

causing

take-up

system. . . . . Lever lock system

. ..

describe

MODE

chassis assembly and

PLAY lever

left

direction and the

ON.

specifred

and the PLAY muting

In

addition.

cam.

same time,

up

the

roller

to the

same time,

the take-up reel

of tape and

is

At

the same

is linked

the PLAY lever

pinch

arm to

capstan and

the PLAY idler

unit is

system . . . . . There is

I motor

REC+PLAY

STOP-EJECT system

pressed.

position

the head

pressure

becomes into PLAY mode.

belt drive

operations according to their

the respective operation

the lock

power

time, the head

to the

with

pressure

commences tape running

table to rotate

follows:

as

power

no

and PLAY auto-

positions

play

switch

chassis. while rising

contact

and become

moves

cam

supply

the head

is locked with

contact the

is also

switch is

chassis

lever is

pushed

chassis

being turned

spring within

pinch

pushed

and to

begin

the

OPERATION

to

up

Take-up

Head

chassis

spnng

PLAY muting

chassis assemblv

Head

reel table seen

PLAY idler

SW

PLAY

lever

Fig. 3-2. PLAY mode

3-3. PLAY-STOP

Mechanically,

mentioned PLAY

(l)

When

the left

same

supply

(2)

At

the same time,

while

reel table

(3)

At the same

pinch

pressure

it operates in reverse

mode.

STOP lever is

direction and releases the PLAY

time, the PLAY muting

switch are turned

the head

roller

chassis comes down, and

stops as

time,

and

capstan by

contact spring and

OUTLINE

front side of mechanism

Head chassis

diagram

OPERATION

(See

Figs.

3-l and 3-2.)

pressed,

the PLAY idler is

also

release

the lock

switch

OFF.

the

take.up of tape.

pressure

the

pushing

stop the tape

Capsta

Pinch

roller

Pinch

contact

assembly

of the

moves

cam

lever. At

and

pushed

the take'up

contact of

up

the

n

arm

pressure

spflng

afore-

in

the

power

down

the

pinch

running

STOP lever

Fig.

3-1. PLAY mode

Left

Right

diagram

(motor

Power supply

direction

direction

installing side)

switch

3-4.

PLAY-PAUSE

o

PAUSE

(l)

When

the PAUSE

assembly

the PLAY

the PLAY

And with

position

o

PAUSE

.

Head comes

PLAY

.

Pinch roller

.

PLAY idler

.

Play muting

position

ON mode.

.

Clearance

.

Clearance

mode

the PAUSE

(linked

idler and PAUSE

idler

PAUSE

and becomes into

position

down 1.7 mm

does not

does not

switch and

pinch

of

play

of

lever is

pushes

lever

pinch

to

pinch

and

cam, it is locked

contact with

contact

roller :

idler

mode-PAUSE

pressed

down

roller)

roller

PAUSE mode.

at center value from

power

1.7 mm at center

mm

: 1.7

in

PL,AY mode,

the head

which is linked

arm. At the same

pressed

are

at the PAUSE

the capstan"

with

the reel table,

supply switch

at center

release

chassis

to

timg

down

the

are in

Page 10

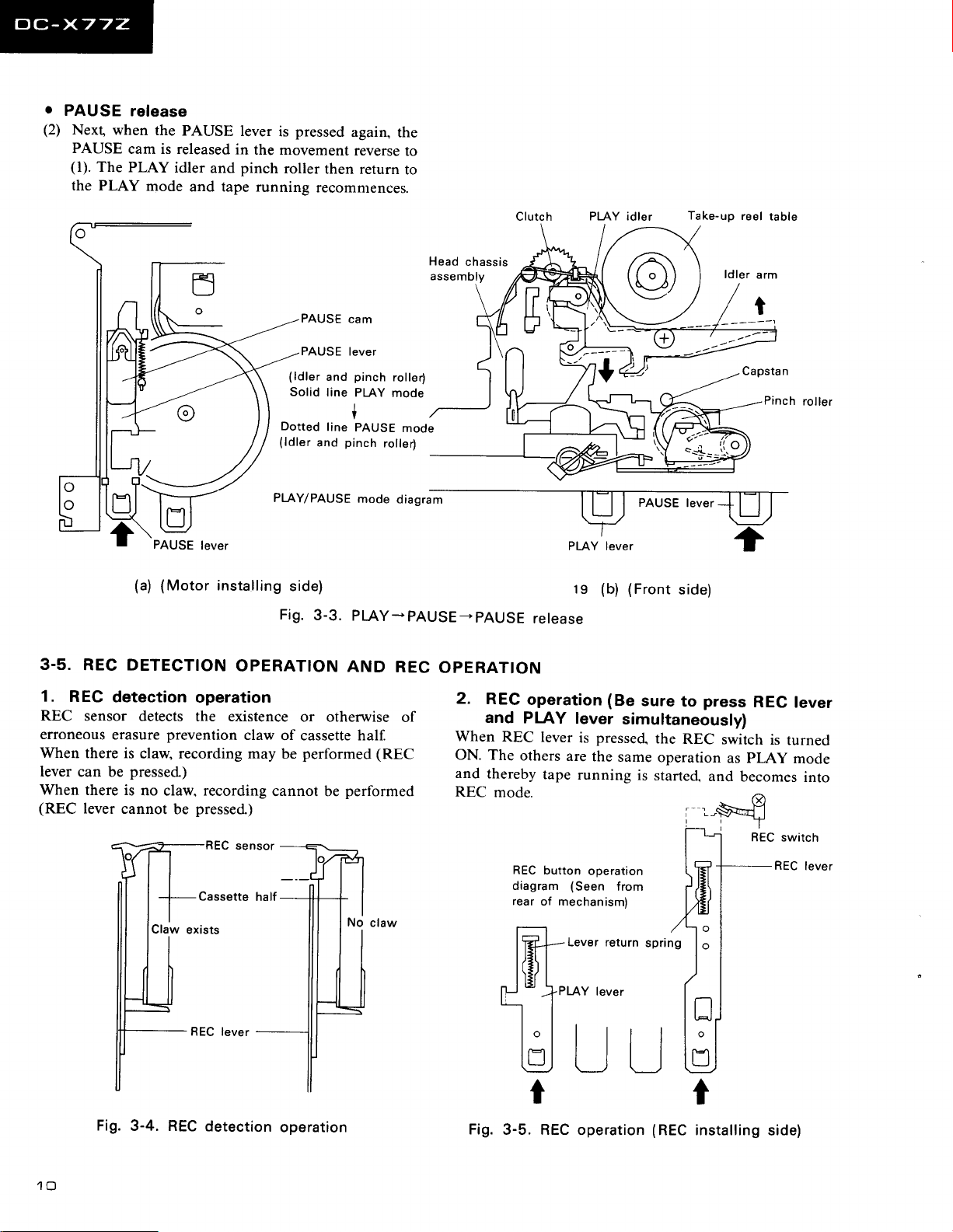

o

PAUSE

(2)

Nexg

PAUSE

(l).

the PLAY

release

when

the

cam is released

The

PLAY

mode

PAUSE

idler

and tape running

lever

in the movement

pinch

and

pressed

is

roller

then

recommences.

again,

reverse

return

the

to

to

3.5.

(a) (Motor

REC

DETECTION

F

PAUSE

PLAY/PAUSE

lever

installing

OPERATION

PAUSE

AUSE lever

(ldler

Solid

Dotted

(ldler

side)

Fig.

3-3.

Head

assembly

cam

pinch

and

line

line

and

pinch

roller)

PLAY

mode

lt

PAUSE

PLAY-PAUSE-PAUSE

AND

roller)

mode

mode

diagram

REC

OPERATION

chassis

ts

release

PLAY idler

(b) (Front

Take-up

side)

reel

ldler

Capsta n

arm

t

Pinch

table

roller

1.

REC

REC

sensor detects

erroneous

When

there is

lever

can be

When

there is

(REC

lever

Fig.

detection

erasure

prevention

claw, recording

pressed)

no

claw,

cannot

be

3-4. REC

operation

the existence

claw

of cassette half

may be

recording

pressed)

REC

Cassette

detection

cannot be

operation

or otherwise

performed (REC

performed

of

2.

REG

and

When

ON. The

and

REC

REC

thereby

mode.

JB!,-Y

--t

Fig.

3-5. REC operation

operation (Be

PLAY

others

REC

diagram

rear

r_-l

Il5ff

lever

lever

tape

button

of mechanism)

pressed.

is

are

the

running

ooeration

(Seen

Lever return

'ever

I

tij

t_r

t

to

press

sure

simultaneously)

the

REC

switch

same

from

operation

is

started"

as

and

/

sprins

r_l

t

(REC

installing

REC

tever

is

turned

pLAy

becomes

REC

side)

mode

switch

REC

into

lever

Page 11

3-6. REC

Function

PAUSE

(r)

(2)

3.7.

(l)

(2)

same

-

PAUSE RELEASE)

-

REC

REC

SW and PLAY

PAUSE

REC function

REC-STOP

When

STOP lever is

lever

and PLAY lever

and REC lever

the REC

OFF.

The

other

operation

-

PAUSE

to the

PAUSE

_

PAUSE RELEASE

starts

-

description in item

SW

again.

OPERATION

pressed

are

returned

are

switch

and PLAY muting

operations

are the same

PAUSE

except for the followings.

keep

and the locks

released

by the return

RELEASE

(PLAY

5

REC

condition.

of REC

the PLAY lever

spring

switch

are turned

as PLAY-STOP

and

Stop mode

clutch

-

Reel

arm spring

gear

FF

sear

{

Clutch

arm

clutch arm orotrusion

diagram

gear

F/R

Supply

)

reel

Power

gear

supply

switch

-\--

cam

-

Lock

_JL

3-8. FFIREW

o

FF

operation

(l)

When the FF lever

(2)

o

(l)

(2)

REW

direction,

is locked

At

becomes

F/R gear

engages

the

operation.

Lock

lever

ON

At the

linked

direction

F/R

nearing

gear

rotate

the

with the lock

the

same

in

is

the F/R gear

reel

begins

operation

cam moves

pressed"

is

and is locked

same

to the

the

gear

is

the

with

the

and

becomes

OPERATTON

pressed

is

power

supply

time,

free

state

moved

time, when

simultane-ously

supply

by nearing

to rotate

in the

the

with

REW lever, pushes

protrusion

reel

supply reel

into

cam.

protrusion

the

due

with

left

power

the lock

the

of the

gear

gear.

REW

switch is

to the

FF

and

direction

supply

REW

lock

cam moves

shape

it

to the

gear

(reel

becomes

when

switch

cam.

arm

clutch arm.

moved in

and

engages the F/R

Then

the reel

operation.

turned

of

clutch

of FF

FF

gear).

(S),

in

to the

the

in left

ON and

arm

lever.

gear

and

Then

into

FF

the REW

is turned

which

left

Then

the

direction

begins to

(a)

STOP

REW

is

(b)

mode

REW

FF

mode

diagram

REW lever

mode

agram

/\

1,\0

,.'

\'1

C

!q-l

JHI

itot I I

-u

!l(tJl?....1

FF

(c)

,R

t'k

/1.

'r:t

ttl

----)

lever

FF mode

?

E

:

E

ILJ

til

r-5'r

.Y

ti

lFJ-

l(

r

3-6. FFlREW operation

Fig.

(Seen

from rear of mechanism)

(Motor

installing side)

Page 12

3.9.

AUTO

After

the

tape

playback

operations,

the linking parts

become

(l)

(2)

(3)

(4)

into

STOP

Auto

sensor

the

tape

end

At

the

same

AS

arm.

At

the

same

flywheel,

lever,

the lock

and releases

Thereafter,

REC-STOP

From

front

(Cassette

half

STOP

has

OPERATION

been

taken

the

auto sensor

release

the

mode.

becomes

time,

time,

lowered

the auto

the

auto

cam

PLAY

perform

they

and PLAY-STOP.

side

of mechanism

existsl

Auto

sensor

up

lock

arm

arm

shifts

lever

the

by the

cam

by the

is

contacts

toward

and

same

psta

Ca

recording

detects

and

the

tape

pushed

REC lever.

operations

n

them.

Then

operations

tension

up

by

the

claw

releasing

and

of

the

of

of

as

3-1O.

In

always

STOP*EJECT

case

go

operation.

Solid

line

Dotted

lines

PLAY,

through

denotes

denote

(Rear

REC,

FF

STOP mode

STOp

moqe

during

side

surface

MECHANISM

and

REW

lever

before

EJECT

operation

Eject

of mechanism)

enterins

It is

lever

lever

are locked.

EJECT

mechanism

on

the right.

ejecl

Fig.

3-7.

AUTO

and

(Cassette

Arrow

shifting direction

Auto

AS

PLAY

half

points

sensor

arm

lever

E head

STOP linkage

playback)

exists)

to

R/p

head

diagram

.'----_==-X..tlywheel

Capstan

/

6,1

Pinch

roller

(Recording

\

.-""*

"".

Auto arm

\

\\

'\

lj

(A)

Right

side surface

(B)

Motor installing

surface

Stop lever

of mechanism)

side

Fig.

3-8. AUTO

(Partial

cannot

playback)

and

sections

be

seen)

STOP linkage

of

auto

arm,

flywheel

diagram

(Recording

and

AS

arm

Fig.

3-9.

STOP-EJECT

mechanism

121

Page 13

3.11.

(l)

ONE TOUCH

STOP-One

Since the

mechanism,

to set

the P mechanism

mechanism

lever.

Moreover,

returns

differing

to the

completion

touch

PI-AY

and REC

into

REC mode

stop

of the

DUBBING

dubbing

levers

from

operation.

of P

lever

into

other levers,

position

OPERATION

operation

mechanism

are interlinked,

PLAY

pressing

by

without

mode

only

the

and

possible

it is

and R"/p

the dubbing

dubbing

locking

Vp

lever

after

(2)

Dubbing-STOP

After

completion

completion

STOP

function

possible

only upon

Moreover,

the

course

respective

Thereafter,

and

REC-STOP

operation

playback

of

of recording

of the individual

take

when

suspending

of

operation,

mechanisms.

the

operations

operations.

of P

mechanism

of

R/P mechanism,

mechanisms

up completion

the

dubbing

press

the

STOP levers

are same

as PLAY*STOp

and after

becomes

of the

operation

AUTO

tape.

in

of

R/P

mechanism

R/P

mechanism

R/P

STOP lever

mechanism

PLAY lever

Fig.

One touch

Solid line

Dotted

3-10.

dubbing

denotes

lines

REC lever

Dubbing

One touch

(Motor

denote

installing

operation

STOP mode.

during one touch

lever P

dubbing

side)

diagram

mechanism

operation

dubbing

operation

P mechanism

STOP

(1)

PLAY lever

lever

P mechanism

,1

2t

Fig.

3-11.

One touch

dubbing

operation

(2)

to

Page 14

2

3

4. SCHEMATIC

DIAGRAM

MECHANISM CONTROL ASSEMBLY AWZI3O9

cr,r

!

^li

-

o&!-6oorMoroR

coNTRoL

I

|

ELRA

I

3

Page 15

o2o7,2O8: HrGH SPEED SrTCH

o2@.2ro:TAPE I SWTTCH

02il.212:TAPE2SW|TCH

O2t3.2I4:PB

MUTING

5

6

tl

L_

o221,

R?.zs

fr:Ll

)2€

.

a2t7,214

FILTER AMP

02t5,216

:

ALC

DOL€Y

rol5o

V R535

4

tczo1,2o4,ez27-zz9t

'i

s

5

0232-236 Brasosc

R!i9

6

I -J

I

REc

t_

Page 16

7

I

REC AMP

IC5Ot:

H|GH SPEEO

osostsi

I

SWTTCH

czao

c279

|

,sE

i

a, t-@

vR2o7l

I

47or - 47ok

i336

vF2q

ilechanjsn

s60z/0603

0604-0606

a601

D6o2

D601,0604

vR6O1

VR602,VR604

Contort

,VR60l

F537 220

AssembrY

2SA933S

2SC1740S

2SC337l

Ro6'2Esn

1ss1ll

vRlF6H102

vRld6H202

REC

IC50l

!c502

s501-a504

a505-0508

0503

0501

1501,1502

R5!s-:?'{fll

,5r

Amp Assenbly

.D502,0504

rnducto.

'"1

| | |

stlTcB

s201.s202

a??5

D??6

O5O7,3OA:

tcm2 : cr&

AssemblY

NORMAL SPEED SWTCH

EO

AEL.44]

AELIO]J

I

7

8

I

Page 17

GRAPHIC EQ ASSEMBLY

(I/2}

11

tc4o!,4o2:

GEO AMP

c4i9

0.15

/10

12

MAIN ASSEMBLY

I

r+

1i

F-r

ilr

"l

_d_

'EF

AWZ12A9

rcloiiPHoilo

12/21

Eo atP

rcl02:

BUFFER I. MIX

AMP

,10

11

TUNER

12

rcto4, !05:

REGU

Page 18

.l?

t\,

14

15

frain Asserbty

rc201

r c202

rc101.rc102

IC103

r c203

tc204,Ic205

rc104

rc105

422 6

0

1

2 0

O 2 0 2 . 0

2 0 '

.

a2?9,0231

.a?32

s 2l0

0234

a101

o 1 0 2 , 0 1

0 I , a 2 0 9 - o 2 1

a???

,a??1 ,a227

0217,A218

a104,0235,q216

0203,a204

01 10

Dl OE

0102-0107

01 01

s101

RYlO]

s102

t ?D1

20?

.F

1101,1102

L?05,1206

!203,1204

TZOl

L2O1,t202

1207

c27 A

cl45,C116

c135

c137.C13A

vR101

-VR206

vR201

vR207,VR208

-

o

o

2 0 6

.

0 2 1 9

6

,

.92?8,a233

2 ? 3 , D

-

gat416BL

HA12O86NT

il5?16P

tc4001BP

1C4069U8P

UPCTE[123

!Pc78128

DTA124ES

(

r

1

2 q E

5

Dtct4lEs

2SA9lls

2SBE34

2 S C 1 7 4

0 S

2SC1740SLN

25C3377

2SK573

Hls15L

RDl3EB

s5566

ASG1005

(ASG1007)

ASR1005

(ASR-111)

suJ8L22224L

ATF-?10

ATH-133

ATn-037

ATil1OO1

aTx-035

LAU?21K

LTAlO2J

ACE-1

34

ACG1002

ACG1005

acut

002

vRTil6V20l

G.aphic ES Assenblt

IC401.rC402

vR401-VR405

0401-D404

BA]8121

ACU1011

RDlOESB

RESISTORS:

Indrcated In

nored k; t0, M; Mn.

CAPACITORS:

Indrcated In

Indrcarion

VOLTAGE,

f:li

E,

€

@l;

OTHEAS:

The-A

fte safery facior

pans

N

The undenrned

This rs the

rmprovemenis r.

SWITCHES:

THE UNOERIINED INDICATES

s101 P09ER

s102-1 PH0N0

s102-? cD

s102-l vtDE0

s102-4

S102.5

Sritch

sz0- DoLaY !F

s202

1/4W.

Q,

1/6w

(F)j

a1%.

(pF)/volrage

capacity

w(hout voltage rs

CURRENT:

Sisnal vohase ar 30 w + 30 w,

(V)

Dc vohage

raled

mA

DC curenl at no ,npur

Slsnar vollase ,t FM 4oO Hz t 75

S,snal .o!le.

;

i>

Adtwtire

I

A

ma,k

rdentical

ot

marked

at no Inpul

powei.

potnl

lound

on some component

pan.

of lhe

designanon

capacitors and resistors have

Indicales the

basic schemarc d'egram,

des19n.

TUrER

TAPE

Assenbty

Hj-SPEED oN-QII

1/8W

and

J5% tote.ance lntess otheturse

t2%,

r1o%.

8a ourpui

kHu DEV

Ind'Lares

pans

.umbers.

F F

a2o% rote.adce

{M)j

(1

kHzl

(

,s DC voltase

)

rhe ,mponance

{G);

lK);

(V)

!nless otheMrse noted

50V ercept electrotyric capactror.

sisnal Valle In

s,gnal

pads

The.elore,

when replacing, be

positron.

swnch

bur the actual crrcuil may vary due ro

THE SWITCH POSITION

-_91,L

0 N

!!-0

-_91_!

0 N

--Qlf

N

0

-.911

N

0

N--qr[

0

0\-0.1

sure

p: pF.

ro

ar

o'

use

DCl?V

OUTPUT

GRAPHIC EO ASSEMELY

I2l2)

PHONES

F,]M;---__-l

wi..

sP- oded

I

:

rw

I

-l

L

J

-l

R

Aac

AOG-051

SPEAKERS

powen

F;,;l

ac240v

5O/6OH2

cono

2

13

14

L----J

T! PowER TRANSFoRMER

A

ats ro70 r ATsio63t

I

15

Page 19

16

17

I

I

I

NOTE:

The indicated

only. Other alternatiue

are listed in

semiconductors

parts

the

are

semiconductors

list.

representatiue ones

may be

used and

External

2SA933S

2SC17405

2sctz+cuN61

Appearance

1'o'No-f\SI1'l

*1ffi"'*

B

llrl

P.C.BOARDS

CONNECTION

3

DIAGRAM

F

1

2

3

Page 21

rl

5

6

ctta

atu

a-

o

tr

aDa

o8

tctor

ClOl

cta

cttt

rctol

ctto

otaa

e''

clol

rctot

c22'

cttt

octo -ra

ctta

cltl

rctoa

rcto.t

.Cta

cto

ctrt

ctto

ctot

caa

ctll

tc-a

att

ctat

et.

atll

at

C'

rr?

I{

4

5

6

Page 22

o|oa oios

7

REC

AMP ASSEMBLY

8

AWZI3IO

rc

30t

olor

O22t

o22l

rc203

o230

o22t

o2a2

O2Ol

o222

o223

o220 0at9

o221

Q22l

rc205

rc204

o254

o20l

Q2t2

o 2ro

O2t5

o2l

O2O2

tc20r

i

o20f

o2i5

02l

o2l

o2rt

o217

4

I

o2rc

CASSETTE

|

*ar^*, ",

xEcilirtt

I

ll

MECHANISM

ASSEMBLY

MECHANISM

tl

L ci

+

ici

Er^sE

i

CONTROL

AWZt309

ASSEMBLY

REC

Cr

O2

XUTI

NOTE

1. Thir P.C.8

2.

t.C.8.

Th.

wirh

paa

dr.

p.srn

EO

cffapq|dint

7

ffidid

hia

*rich

di.arh indlc.llo

OSOI

a

O O

o-o2o3-o

-o

0-12!7

/c513 \

@'.

i

Ecs|lE

Oth.r3

t.C.B.

panain

diat.m indicatior

tc

s

FY

L

F

VR

3.

Th.

cOeitq frfrind m*t.d witho(&!U.

L

Th. diod. mind

5.

Th.

tr.di.td tmin.l ro whkh

m..td wlth

di{..m b viMd f.6

b-n |dntd on tfr lbdd o ba nplac.d with

ririrt

rymbolr

Cdiioo(tnf

pd

nontad.id..

tti

ll.i.d in th. tolbri|rr T$L.

pan

rymbol

fHl':fgl

P]ffir

D20l

o---{a<

R257

rVVt-<

"#1"

'JF

Prt

Nm

tc

gf,iictt

F.l.y

Coil

Filt.l

VatiabL radator

S.mi-flx.d

ldo.rt||

O

E i. .fflx.d dffi th. .mittf,.

or

cblol

circl-l .h{ n

circlil $w o'tod. .kt .

tliv.

thd Ailn

PmNm

T.a6iabr

F.dilor typ.

tr6iabr

Diod.

R6irtor

Capacitor

(PohriW)

C+-itor

(Nd{oLritV}

tmi.d.

I

7

I

I

9

Page 23

6.

ELECTRICAL

NOTES:

.

o

wilhout

Parts

Parts marked by

part

number connot

"A"

able.

The

mork

A,

found

replacing, be sure to use

your pans

For

' *

GENERALLY MO'ES FASTER THAN

Stock Control, the

This classifcation shall be

When ordering resistors,

Ex. I When there are 2 elfective digits

5'%.andK: I0'b.

5fl9 56x101 56,t..........................RD1/1PS66[ll

17kQ

47xt0t 173..........................RD1/4PS@A6J

0.54 0R5...............................................RN2HO88K

1!> 010................................................ Rs/P o t!

Ex. 2

When

there are 3 effective digis

'62k9 562x tqt 562t ........................ RN1/4SR tr 6 E E

Miscellaneous Parts

P.C.BOARD

Mark

ASSEMBLIES

Symbol & Description Part No. Mark Symbol & Oescription Pan No.

Main

assembly

Mechanism control assembly

REC Amp

Graphic EO assembly

Switch assembly

LED

Connect assembly

assembly

assembly

PARTS LIST

b? supplied.

not always kept in stock. Their delivery time may be longer thon usual or they

are

on some

parts

component

of itlentical .lesig,nation.

fast

par$

moving

indicotes the impormnce of the

items are indicated

with

*

adjusted by each distributor because it depends on model

conve rcsistonce

frrst

(any

values into code

digit opaft

from

form

0), such as 5(fl ohm and 47k ohm

o K

(such

AWZl 289

AWZl 309

AWZ1 310

as in high

precision

metal

tt

*t

tt

*r

*r

the marks

as shown in the

0230

4234

0101

0102, O'l03, O209-O216,

0219-0222.

4224.4233

4217 , 4218

frlm

F

safety

factor

*

*

ond * .

number, temperature, humidiry, etc.

following

resistors).

4224, A227

pa

of the

examples.

(tolerance

may be unavail-

. Therefore, when

is shown by J

DTC! 43 ES

2SA933S

2S8834

2SC1740S

,

2SC1740SLN

-

OTH ER S

Mark

A

A

A

A

Main Assembly

SEM ICO N

Mark Symbol & O6sc.ipiion

A

Symbol & Dosc.iption

T1

r

r*

r*

r.*

Power t€nsformer

l^c22ov

FU'! Fuse

FU3 Fuse

FU4, FUs Fuse

AC

/24ovl

Power cord

DUCTO RS

lC2O1

*r

lC2O2

rt

lC1

at

r*

t*

1C102

01

,

|c103

IC203

tc204, tc205

rcl

04

tcl

05

4226

0201

0202, 0205-0208,

,

4223.4229-4232

(TSOOmA)

(T1.64)

(T2A)

(AW21289)

Part No.

ATS1070

(Ars1065)

AEK-507

AEK.51O

AEK.s1 1

ADG-051

Part No.

84341 6 BL

HA12086NT

M5218P

sTK414'l

TC4001 BP

TC4O69U BP

pPC78M12H

pPC7A12H

DTA124ES

DTC124ES

O1O4, 0235, 0236

*r

o2O3. A2o4

*t

D11O

r

0108

r

Dl02-D107

*

A

* D109, D2O1-D21O,

D213-0224, D227

D101

r

A

SWITCHS & RELAY

Mark

Ar*

Symbol & O€sc.iption

sl01 Push switch

RY101 Relay

5102 Push switch

(PHONO,

TAPE)

CD, VIDEO, TUNER,

-D240

lPowER)

2SC3377

2SK373

HZS15L

RD13EB

1SS131

4D4B'44

Parl No.

ASG1005

(ASG1007)

ASRl OO5

(ASR-111)

suJat22224L

Page 24

COILS, TRANSFORMER

Mark Symbol

F2O1 , F2O2

L101, L102 AF choke coil

1205, L2O6 Trap coil

L2O3, L2O4 Trap coil

T201 Bias OSC translormer

1201, L2O2 Inductor

L2O7 lnductor

Do.cription

a

DOLBY Filter

CAPAC ITORS

Mark

Symbol & Dosc.iption

(680PF/630V)

c278

C145. C146

Cl35

C137, C1 38

c209,

c101.

cl19. C] 20,

c207,

(O.01pF/AC125V)

pFlAC1sOV

{0.01

\33OOpF/a2vl

c210

c102. cl05,

C203. C204.

c204. c215,

cl53. C154

c279. C2AO

7

c27

c147,

C1

4A

ct 28

c127

c123. C1 24

c129

c134

c269

c249. C250

c117,

C11a. C213,

c235. C236.

c136. C243.

c256,

C257

C244,

C261. C262,

c267, C270

c140.

c125, C126

f1t1 f1)) aa11

c1

41

C't 43.

,

c251 . C252

c224,

C241. C242,

c2 59

cl30

c133, C217,

c239.

C21a. C225,

C240

c139

cl13. Cl 14,

c221.

c264. C26a,

c107.

c142, C271.

C223. C226,

C237. C238,

C283, C284

c108. c1 15,

C272

c260

AND

C106.

C216.

c2't

,

c2

c144

c234,

c258.

C263.

16.

C1

FILTERS

)

4.

66,

Part No.

ATF-210

ATH.133

ATM.O37

ATMI OO1

ATX.O35

LAU221 K

LTAl

02J

Part No.

ACE-134

ACG1002

ACG1005

ACH-249

cccsL100 D50

cccsLl01

J50

cccsLr 0l K500

cccsL221J50

cccs 1470J50

Pl

CEAN

CEAN P22O M50

CEAN P33O M25

CEANP4TO M50

cEASR4T M1

CEASR4T M5O

CEASR6S M5O

cEASO10M50

CEASl OOMSO

CEAS101

cEAS101 M25

CEAS2R2M5O

cEAS220M't 6

CEAS221M1O

CEAS221 M16

cEHAO332

CEAS4RTM5O

cEAS470 Mr 6

CEAS471 M16

OO M50

00

M1 6

M25

Symbol & Descriprion

c245, C246,

c213. C274

c2aa

c247,

C24A,

c221 , C222

c219,

c103,

c231 , C232

c253. C254

R ESISTO RS

Symbol

vR1Ol

R166, R167 RD1/2 PMFL1

R168, Rl70, R171 RD1/2PMtrtrtrJ

R149, R150, R152-R154 RDl/4PMFLtr D OJ

R155, R156, Rl69 RD1/4PMFtr D !J

R145-R148, R151. R159. RD1/4pMtr ! DJ

R1

60,

Rl 62 RSl LMF51 1J

R164, R165

VR201-VR206(20k

VR207.

Other resistors

OTH E RS

M6rk

Mechanism

Symbol & Doscription Psn No.

Jack 6P

Terminal

(DCl20V

Jack

Control Assembly

SEMICONDUCTORS

Mark

Symbol e Description

0602, 0603

*t

0604-0606

tt

0601

**

D602

r

0603, D604

r

CAPAC ITO RS

Mark Symbol

c604

c601-c603

RESISTORS

Ma.k Symbol

vR6O1. VR6O3

vR6O2, VR6O4

Other resistors

c275, C276

C220,

c229, C230

c104,

c205, c206.

D€scription Part No.

&

(1O0kX2)

R319

VR2O8(5O0k Semi fixed)VRTM6V504

(PHONO,

4P

{SPEAKERI

Oosc.iption

&

Oescription Parl No.

&

Part No.

coMA103K50

cKcYX104M25

coMA153K50

coM4223K50

coMA273 K50

CEJAOl OM5O

CEJAl OO M1

ACU1O02

RS2LMFtr O OJ

lixed)VRTM6V203

Semi

RD1/8PMC

CD, VIDEO) AKB-Og5

OUTPUT) AKN-034

AKE-109

(AWZI

Part No.

2SA933S

2SC1740S

25C337 7

RD6,2 ESB

'|

ss131

Peri No.

3O9)

cEAS'r 00M25

cKCYX473 M25

(1k

(2k

fixed)VRTM6H

Semi

lixed)VRTM6H2O2

Semi

RD1/8PM tr tr trJ

102

6

OoJ

tr

trJ

c109. c1 1 0

c201

c202

,

c111, C112

c211. C212,

c131. C132,

c149,

C150,

c2a1 . c2a2

c151

c22a

cKcYBl 52 K50

cKcY8561 K50

cKcYB562 K50

cKcY868l K50

cKcYF473Z50

cKcYX473 M25

Page 25

R

EC Amp Assembly

SEM ICO NDUCTO RS

Symbol & Description

rc501

rc502

-0504

o501

o505-o508

D503

D501, D502. D504

cotL

Ma.k

CAPACITORS

Mark

R

ES ISTO

Mark

Symbol

L501, L5O2

Description Pan No.

t

Symbol & Description

c507. c508

c501 , c502

c521

c503, c504

c505, c506

c519, C520

c513. C514

c511,

C512.

c509, c510,

RS

Symbol & D€scription

All resistors

(AWZ1

Inductor

c515, C516

c517, C518

31 O)

Parl No.

M52181

M74LSo5P

2SC1740S

DTCl

R D5.6 ESB

1 SSI 31

LTA392J

Part No.

CEASR33 M5O

cEASO10M50

CEAS101

C EA54R7 M5O

cEAS470M16

coMA153J50

coMA223J50

coMA392J50

coMA822J50

Part No.

RD1/8 PM

24ES

M 10

tr tr

trJ

RES ISTOR S

Mark Svmbol & Doscription

VR401-VB4O5

r

r

VR406

(30k)

130kX2)

R407, R408

Other resistors

OTHER

Mark Symbol

Jack

Switch

Maik

Assembly

Symbol & Ooscription

5201, S2O2 Push swrtch ASG-424

r*

(DOLBY

Oasc.iptaon

&

(PHONES)

NR, Hi.SPEED)

Part

ACUI 01 1

ACUl01

RD1/2PM331 J

RDl

Part No.

AKN

Part No.

R ES ISTO R

M

ark Symbol & Description Part No.

R327

RD1/8 PM103J

LED Assembly

SEM ICON D U CTO RS

Mark Symbol & Description

D225

t

R

ESISTOB S

Mark Svmbol & D€sc.iption

R329

R328

Pan No.

AEL-443

AEL1O33

Part No.

RD1/8PM471J

RD1/8 PM681 J

No.

3

PM tr D OJ

/8

1OO7

Graphic EO Assembly

ICO

SEM

Mark

CAPACITORS

Mark Symbol

N DUCTO RS

Symbol & Description

lc4o1, lc4o2

rt

D401 - D404

&

c419,

C420

c42t, c422

c425.

C426

c401

c402. c427

,

c435

c423, C424

c403. c404

c433,

C434

c43t, c432

c409,

c410

c407.

c408

c4't 5, c416

c413.

C4t4. C429,

c411,

C412

c417 , C41A

c405, c406

c437, C438

Doscription

Part No.

843812 L

RDl

OESB

Part

No.

CEJARl SM50

CEJAR6SM5O

c42a CEJA4R7M50

.

CEJA1 Ol M1O

CEJA4TOMI6

cKcY8331 K50

cKcY839't K50

cKcY856l K50

cKcYF472250

coMA153K50

coMA182K50

coMA183K50

c430

coMA333K50

coMA392K50

coMA393K50

coM4682K50

cccsLl0l K50

Connect

No

supply

Assembly

part

inside.

Page 26

7, ADJUSTMENTS

Tape

l.

2. Turn

3. Mount

4.

5.

6.

7. Put

speed

Connect

(Dolby

Short-circuit

on the

adiustment

the frequency

TP:

L-ch)

the tape

the

tape

switch

test tape

between

assembly

mode.

(STD-301

Adjust

frequency

Release

TP5

and TP6.

the

VR60l

play

is

with

VR602

of deck

the short-circuit

deck

I into

so

that

becomes 30lOHz

(Note

l:

Be sure

ing

the

normal

speed

countr

on

the

on.

STD-301

terminals

and

backed in

so

that

I become

play

playback

the

+l0Hz.

not to

turn

adjustment)

to the TPI

complex

onto deck I.

TP4,

put

the deck

double

the

6020H2

between

mode

signal

VR602

assembly.

playback

terminals

and

while

terminal

TP5

and Tp6

I into

speed)

signal

+20H2.

adjust with

frequency

perform-

play

Tp4,

8. At

this

flutter

mal

speeds.

9. Mount

10.

Short-circuit

on the

mode.

(STD-301

11. Adjust

frequency

deck I.

12.

Release the

TP5

13.

Put the

VR603

deck

(Note:

the normal

14. At this

flutter

mal

speeds.

point,

are

be sure to

within

0.390 both in the double

confirm that the

the test tape STD-301

between

tape

assembly

play

is

with VR604

of

deck II becomes

short-circuit

terminals

and

backed

so that

put

in double

between

onto deck II.

TP4. TP5

the

deck II into

playback

the

+20H2

wow

and nor-

and TP6

speed)

signal

against that of

terminals TP4.

and TP6.

deck

II into

so

that the

II becomes

Be sure

not

speed

point,

be sure to confirm that the

play

playback

+l0Hz

to turn

against

VR604

adjustment)

mode

signal

and

frequency

that

while

adjust with

of

deck I.

performing

wow

are within 0.390 both in the double and nor-

and

play

of

and

(Note)

Short-circuit

(double

speed)

VR604

@ @

between

adjustment.

VR603

MECHAN

Tp4

VR6O1

@ @

ISM

CONTROL

and TP5

R60

,"ro,'Ho

I:r

during

tape

ASSEMBLY

AWZ1309

\rgrl

speed

VR2O3

@

Fig.

7-1

Adjustment

Point

Page 27

Electrical

Prior

to

firm the

system adjustment

the electrical system adjustment,

following itesm.

1. The mechanical adjustment should

2. Perform cleaning of the

tion of

The level

3.

=

head with the head eraser.

during

measurement is determined at OdBv

lV.

4. The specified tape should

the test tape has A side and

Since

with label.

side

STD-331B:

STD-608A:

For

Normal

STD-620: CrOz blank

Prepare the

5.

following measuring

AC millivoltmeter,

and oscilloscope.

ator,

For

6.

7. Turn the

the adjustment,

otherwise specified.

unless

Dolby

NR

head

and

be used for adjustment.

playback

system adjustment

tape

blank

tape

low frequency

perform

switch

both

to off

instruments.

oscillatore,

L and

specified.

be sure to con-

be completed.

the demagnetiza-

B side, use the

A

attenu-

R channels

unless otherwise

8. Prior to the

the set

ing the

quency

adjustment, be sure to

for

several

adjustment of the

characteristics, aging should be

REC/PLAY mode for

The-adjustment

9.

with

the adjustment order. If the order is not

it may

cause the

which induces

Deck I

Head

l.

2.

azimuth

Playback

level adjustment

Deck ll

l. Head

2. Playback level

3.

4. Adjustment

azimuth adjustment

Adjustment

of recording and

characteristics

of

minutes. Especially

recording

3 to 5

should be

failure

inferior

the

performed

of the complete adjustment

function of the unit.

adjustment

adjustment

recording level

perform

prior

and

minutes.

in

playback

aging of

to enter-

playback

fre-

performed

accordarrce

kept.

frequency

in

30s

3l5Hz

kHz lOkHz

6.3

315Hz

Fig. 7-2

Test tape

12.5

okH 8

kH2

STD-331 B

kHz

,3kH

3t5Hod B

lkHz

16Onwb/m

kHz

I kHz

2

OOHi

25H

;3 H2 lOHz

Page 28

AdjUStment

1. Head

Procedure

2. Playback

Procedure

1

1

azimuth

Tape

selector

(AUTO)

NORM

level

Tape

selector

(AUTO)

NORM

AdjUStment

1. Head

Procedure

2. Playback

Procedure

'l

1

azimuth

I

ape

selector

(AUrO)

NORM

level

Tape

selector

(AUTO)

NoRM

|

I

3.

Adilttmontlt tacotding

fruqu!.rcy

Procedure

1

2

3

'

Sefect the test

4. Recording

Procedure

1

2 NORM

3

chaaetarlldc!

Tape

selector

(AUrO)

NORM

NORM

NORM

lovel

Tape

selector

(AUTO)

NORM

CrOz REC/PLAY

Of DgCk I

adiustment

adiustment

Of DgCk

adiustment

adiustment

I

I I

PEC/PLAY

tape, tape

adiustment

REC/PLAY

*This

Mode

PLAY

Input

Play

on test

*

Perform

Mode

PLAY

Input

Play

on test tape

*This

II

Mode

PLAY

Mode

pt-lv

dd

Mode

REC

REC

Input

Play

on test

*

Perform

Input

phy

I

test tap6 sTp-3318

phybld(

Input

STD-6O8A

REC mode.

Apply

to the

the CD

Record

315H2

tape

selector,

Mode

and

'

Set the

Input

REC Apply

to the CD terminal

the

Record

31 SHz

sTD-608A.

Record

31

SHz to the test

sTD-620.

provided

deck is

signal/test

back lOkHz/-2OdB

tape

STD-3318

this

adjustment

signal/test

back 31SH2/OdB

STD-331B

deck is

signal/test

back 315H2/OdB

tape STD-3318

this adjustment

signal/test

back 3l sHz/odB on I vnzo+

'

This adiustm€nt is

cis€d not

signal/test

and

the signal

CD terminal

switch on.

play

and

lOkHz

and

STD-6O8

Dolby

NR

switch and satisfy the

graphic

signal/test

the

signal of 315H2

with

an auto-tape-setector mechanism.

tape

Adjusting

Head

adjusting screw

(Fig.7-3)

precisely

tape Adjusting

vR2O2

vR201

provided

with an auto-tape-setector

tape Adjusting

Head

adjusting

(Fis.

precisely

tape

|

Adjusting

vR203

p€rfom6d

to worcen rh€ distortion ratio

tape Adjusting

put

into

of 315H2

Bias

frequency

T201

Input

and turn

back

on test

equalizer and

tape Adjusting

VR2O8

VR2O7

balance volume to

Input

since this

7-3)

since this adjustment

and turn

CD switch on.

play

and

and

play

back

back

to the test tape

VR2O6

VR2O5

tape

point

azimuth

point

(R)

(L)

point

azimuth

screw

point

1a1

{L}

point

oscillator

signal level

(R)

(L)

frequency

point

signal level

(R)

(L)

Measuring

TP'I

1P2

adjustment

is

Measuring

TP1

TP2

mechanism.

Measuring

rPl

rP2 (R)

is Dolby level

Measuring

rrr

|

rp2

|

in ord6r to adjBt

due to und€r bia6.

Measuring

Between@and@

in

Fig. 7-2

TP1

rP2

TP1

TP2

characteristic

the center

Measuring

TPl

TP2

TP1 (L)

TPl (L)

TP2

point

(L)

(R)

Dolby level

point

(L)

(R)

point

(L)

point

lq T-13jdB"

{F)

Adjustment value

Maximum

level

signal

setting during

Adjustment

-13.5

dBv

Adjustment

Maximum

signal level

setting

during

Adjustment

|

the recording bia6. Th€r€tore,

point

(L)

(R)

(Ll

(R)

zone

and the mike mixing

point

(L)

(R)

(R)rP2

(R)

Adjustment value

Confirm that the

cillation

1O5 kHz

-33.5

Repeat recording

pensate

lOkHz

as shown in

Adjustment

-13.5

Repeat recording

pensate

315H2 becomes

Confirm

becomes

dBv

against

Figs. 7-5

volume

playback

After completion,

lock

playback.

value Remark

+O.5

dB

value

playback

After

lock

playback.

value

to^5 dBT-

|

caution shoutd bs €x€F

os-

kHz.

dB

315H2

and 7-8.

-13.S

playback

dBv

and

playback

and

playback

playback,

(11.0

When it is

within the

dard,

standard

justing

playback,

becomes O*O.5dB.

frequency

+1

+O.5

so

that the

to the source

value

dBv

so that the

that the

-13.5

the screw

the screw.

put

side.

Remark

dBv

level

dB).

Remark

Remark

completion.

Remark

Remark

not

stan-

it into

by

ad-

T2O1.

and com-

level

of

and com-

level

of

(to.S

dB).

315H2

of

the

37

Page 29

,"ro,

""ffiE

@

VR2O5

uHo

VR2O3

@

uV^,p^,o,

Fig. 7-4 Head

.

ll(l ll

azimuth

7-3 Arrangement diagram

Fig.

rr

>

,)ll

lltl^ll

adjustment

of adjusting

Test tape STD.331 B

DOLBY

NR switch

The right

at 63 Hz to compensate for edge effect.

7-5 Playback

Fig.

position

channel

parts

OFF

is

corrected

by

-O.5

frequency response tolerance

125 Hz

at

and

-1

dB

zone

Jd

Page 30

Test tape

DOLBY NR

switch

sTD-608A

OFF

Test tape STD-6O8A

DOLBY NR switch

ON

5

3

2

1

o

-l

-2

-3

-4

-5

€

Test tape

DOLBY

5

5

4

3

I

o

-l

-3

-5

40 63 16

63

NR

1@

switch

125

250 315 500

Fig. 7-6

STD.62O

OFF

125 25O 315 5OO

Fig. 7-7

lk 2k 4t

Recording

1t 2k 4k

Recording

playback

&

playback

&

6.31 10k 12k

15r

frequency response

Test tape

DOLBY

6.3t g t2k

t5k

frequency

4

I

o

I

3

5

Q 63 1@ 125 250 315 500

tolerance zone

NR

switch

5

4

I

o

l

2

3

5

40 63

t@

125

25O

315

response tolerance

STD-620

ON

5OO

zone

lk 2k

(NORM)

lt 2k

(CrO2)

4k

6.3k 10* t2k 15k

41

6.3t

fr

!2r 1*

Test

tape

DOLBYNR

5

5

4

3

I

o

switch

Test tape

DOLBY NR

6

5

l

o

-3

€ 63 tm 125 { 63

switch

Fig.

STD.6O8A Test tape

OFF

STD.62O

OFF

z5o 3r5 soo

7-8

rk zr

Copy mode recording

*

d\-ia 15r

g

playback

&

DOLBY

Test tape

DOLBY

-l

-3

-5

(HIGH

llxrCH

SPEED

--l

4r

SeeeO

+r\l rzr r5r

purposes)

STD.6O8A

NR

switch

3

2

1

o

-l

-3

-6|||||,a-----

4

63

lOO

r25

OFF

250 315 500 1t 2'

sTD-620

NR

switch

5

3

1

o

r@

125 250

frequency response

OFF

315 500 rk 2k

(for

reference

COPY)

r2r

COeVI

6.3k

rct

l*

39

Page 31

8. PACKING

Parts List of Packing

Mark No. Pan

1 AR81050

2 AHA|

3 AHAl063

4

5

6

7 ABA1003

No. Doscription

062

AHDl 173

AMRl060

AMRl06l

Operating instructions

(English)

pad

Side

Side

Packing case

Player stand L

Player stand R

Screw

Packing sheet

pad

L

R

Page 32

9. FOR

HE AND

SD TYPES

CONTRAST

NOTES:

.

Parts without

.

Pa s marked

able.

o

The

b.

replacing,

.

yow parts

For

* '

GENERALLY

This classifrcation

.

When

Ex. I When

OF MISCELLANEOUS

pa

number cannot

by " Q ' are not always

mark

found

be sure to use

Stock

shall be adjustetl

ordering rcsistors,

there are 2 efective

5'/,'.andK:10"/").

5flA

47kQ

0.54 0R-5...............................................RN2Ho8trK

56 x t0t -56./..........................

47t t0'

ta u0................................................Rs"tpoo@K

Ex. 2 When

there arc -1 effective

5.62k4

562 x I0t

The DC'X772/HE

sections.

Mark

A

A

A

Symbol & O.scription

lMlC

T1 Poller

tAc220t240v

lAcl

AC

be supplied.

kept in stock. Thei

on some component

parts

of klentical designation.

Contol, the

MO'ES FASTER

convert resistance

first

and

SD types

Amp Assembly

translormer

1

1 20-1

Ol

power

cord

moving items

fast

THAN

by each distributor

digits

473..........................

digis

562t ........................ RN//4SR

are the

I

27

/22O/240\4

PARTS

parls

indicates the

are intlicated with the

,

(ony

values inb code

digit apartfrom 0),

(such

as in

high

same as the DC-X77/HB

delivery time may

importance oJ the

because it depends on model

t'orm

such as 560 ohm

RDt/4pSE@E

RDI/4pSE A E J

precision

metal

tr 6 E tr F

be longer than usual

safety

marks, * and

as shown in the

end 17k ohm

J

resistors).

film

type with the

Parta No,

DC-XI72

HB typB

ATSl070

'^::::''

AOG{)51

ATS1070

'^:l::''

ADG1O19

or they may be unavail-

part.

of the

factor

*.

number, temperatnre,

following

examples.

(tolerance

exception of the following

HE

typ€ SD type

ATS1066

(A.Ts1064

ADG 1016

Therefore,

humidity, etc.

is shown byJ

t

when

-

R€marks

A

A

A

A

A

A

A

r*

51 Voltag€

*r

F1 Fuse

**

F3 Fuse

**

**

F4,F5

*r

F2 Fuse

*r

selector switch

1

o / t 20- 1 2J

lacl

(T800mA)

(

1A)

(T1.6A)

(1.64)

(T2A)

Fuse

(2.5A)

(1A)

Operating instructions

(

E nglish/German/French/lral

(German)

Terminal

Knob

Front

Packing

(GND)

{MlC

panel

case

MIXING)

/22O/

(English)

24OV'l

ian)

AEK.5O7

^il

ll'

^il

'

ll

ARBl O5O

AMB1136

AH O't 173

AEKO3l

^ii

i*

^::"1'

AR E 1 0il4

AMB1136

AHD1173

AKX,5O7

AEK.l19

"i*-iir

AE K.l23

AEK.119

^::l:'

ARC1032

1016

AAB

AMB1137

AHD1212

Page 33

Schematic

diagram

-^--A

\ro-

A

FU4

----{

-r-v-a

FUSE

FUSE

FUSE

(Tr.6A

(T2A

IT2A)

for

)

)

HE type

Voltage

Line

Line voltage

1. Disconnect

2. Remove

3. Change the

(Connect

4.

Stick the line voltage

22OY

24OY

Selection

can be changed

the

the

Bonnet case.

connection

as shown in Fig.)

label AAX.I93

label AAX.I92

(For

Power

AC

of the

label on the rear

with

cord.

HE

and

following

primary

HB types)

steps.

lead

wires.

panel.

$rr

Schematic

------J

n

eowen

ATStOT0

diagram

I

TRANSFoRMER

(ATS|O65

)

for

SD

--<n

--4'o-

type

-P-

-4.r-

A

FU3

A

FU4

fu5

FUSE ( 2.5A

AC PowER

A

AoGro,r9

lj_\

)

CORD

ac 220v

50,/

60 Hr

a:1"',l,"

CONNECT

ASSEMBLY

--t

MAIN

ASSEMBLY

AWZ,I289

/\

T.I

POWER TRANSFORMER

(

ATS rO66

ATS rO64

I

tl

)

Ac

PowER

coRo

ac 1to / 120 - 127

50l6Otlz

/

220 /

240V

.,4

VOLTAGE SELECTOR

AKX-307

t2O-127 / tg/

l24O /

22ovl

a

&l ADG tor6

Page 34

2

Schematic

MIC

diagram

AMP ASSEMBLY

of

MIC

AMP Assembly

(SD

Wpe

only)

MAIN

ASSEMBLY

AWZ12A9

l'-

I

q1g6_

'''[RjH

-

tr -on,

-|Il------IIE-

|

ffis

j:ii

W 7

22/16.

R7o6

1OO

47k

I I *A;i

//

CT|O

/

22tro

R705

4

P.C. Boards Patterns

of MIC

AMP Assembly

(SD

type

only)

1

2

3

Page 35

Parts list of M lC

Amp Assembly

SEMICONDUCTORS

Mark

CAPAC ITO RS

Mark

Symbol & O€scription

|CTOt

*t

rr O7O1, O7O2

O7O1. D7O2

*

Symbol & Descriplion

c703

c702. c70a

c704, c709

c706, c710

c707,

c711

(SD

type only)

Part No.

M5218PF

2SC17405

1

SS131

Part No.

cccsL101 J50

CEASOl OM50

cEAS100M25

cEAS220M16

cEAS470M16

External Appearance of

2SC17406 M5218PF

Transistor and

lCs

R ESISTO R

*

OTH ER

Mark

c705

c701

S

sy]!!ql3_9-91S!pqon

VR7O1

resistors

Other

Symbol

Jack

&

(MlC)

Description

cKcY8471K50

cKcY8681K50

Pan

No.

ACS-012

RD1/8 PM tr O trJ

Pan No.

AKNlOO5

Loading...

Loading...