Page 1

STEREO CASSETTE DECK

CT-IS21

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

Type

MY AC220-230V

NV AC230V

RBD AC110-127V/220-240V With the voltage selector

Model

CT-IS21

Power Requirement

The Voltage can be converted by

the following method.

ORDER NO.

RRV2142

CONTENTS

1. SAFETY INFORMATION

2. EXPLODED VIEWS AND PARTS LIST

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM..10

4. PCB CONNECTION DIAGRAM

5. PCB PARTS LIST

6. ADJUSTMENT

PIONEER ELECTRONIC CORPORATION 4-1, Meguro 1-Chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS SERVICE, INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER ELECTRONIC (EUROPE) N.V. Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

c

PIONEER ELECTRONIC CORPORATION 1999

...............................................

....................................................

......................................

................

..........................

18

24

27

2

3

7. GENERAL INFORMATION

7.1 DIAGNOSIS

7.1.1 POWER ON SEQUENCE

7.1.2 DISASSEMBLY

7.2 PARTS

7.2.1 IC

8. PANEL FACILITIES AND SPECIFICATIONS

............................................................

.................................................

......................................

.........................................................

T – IZM MAY 1999 Printed in Japan

................................

......................

....

31

31

31

32

33

33

34

Page 2

CT-IS21

1. SAFETY INFORMATION

This service manual is intended for qualified service technicians ; it is not meant for the casual do-ityourselfer. Qualified technicians have the necessary test equipment and tools, and have been trained

to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

WARNING

This product contains lead in solder and certain electrical parts contain chemicals which are known to the state of California to cause

cancer, birth defects or other reproductive harm.

Health & Safety Code Section 25249.6 – Proposition 65

NOTICE

(FOR CANADIAN MODEL ONLY)

Fuse symbols (fast operating fuse) and/or (slow operating fuse) on PCB indicate that replacement parts must

be of identical designation.

REMARQUE

(POUR MODÈLE CANADIEN SEULEMENT)

Les symboles de fusible (fusible de type rapide) et/ou (fusible de type lent) sur CCI indiquent que les pièces

de remplacement doivent avoir la même désignation.

(FOR USA MODEL ONLY)

1. SAFETY PRECAUTIONS

The following check should be performed for the

continued protection of the customer and service

technician.

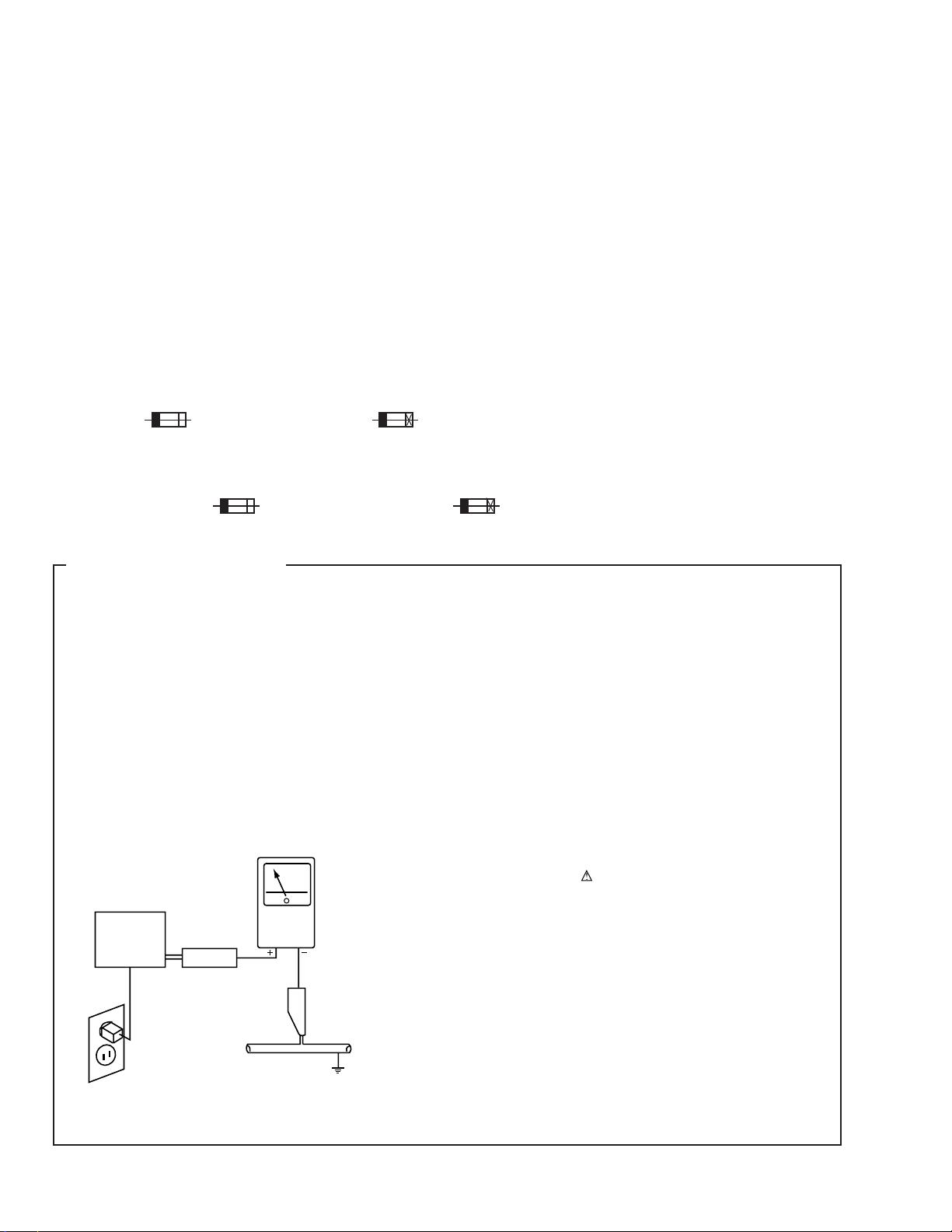

LEAKAGE CURRENT CHECK

Measure leakage current to a known earth ground (water

pipe, conduit, etc.) by connecting a leakage current tester

such as Simpson Model 229-2 or equivalent between the

earth ground and all exposed metal parts of the appliance

(input/output terminals, screwheads, metal overlays, control

shaft, etc.). Plug the AC line cord of the appliance directly

into a 120V AC 60Hz outlet and turn the AC power switch

on. Any current measured must not exceed 0.5mA.

Reading should

not be above

0.5mA

Earth

ground

Device

under

test

Also test with

plug reversed

(Using AC adapter

plug as required)

Leakage

current

tester

Test all

exposed metal

surfaces

ANY MEASUREMENTS NOT WITHIN THE LIMITS

OUTLINED ABOVE ARE INDICATIVE OF A POTENTIAL

SHOCK HAZARD AND MUST BE CORRECTED BEFORE

RETURNING THE APPLIANCE TO THE CUSTOMER.

2. PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in the appliance

have special safety related characteristics. These are

often not evident from visual inspection nor the protection

afforded by them necessarily can be obtained by using

replacement components rated for voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this Service Manual.

Electrical components having such features are identified

by marking with a

in this Service Manual.

The use of a substitute replacement component which does

not have the same safety characteristics as the PIONEER

recommended replacement one, shown in the parts list in

this Service Manual, may create shock, fire, or other hazards.

Product Safety is continuously under review and new

instructions are issued from time to time. For the latest

information, always consult the current PIONEER Service

Manual. A subscription to, or additional copies of, PIONEER

Service Manual may be obtained at a nominal charge from

PIONEER.

on the schematics and on the parts list

AC Leakage Test

2

Page 3

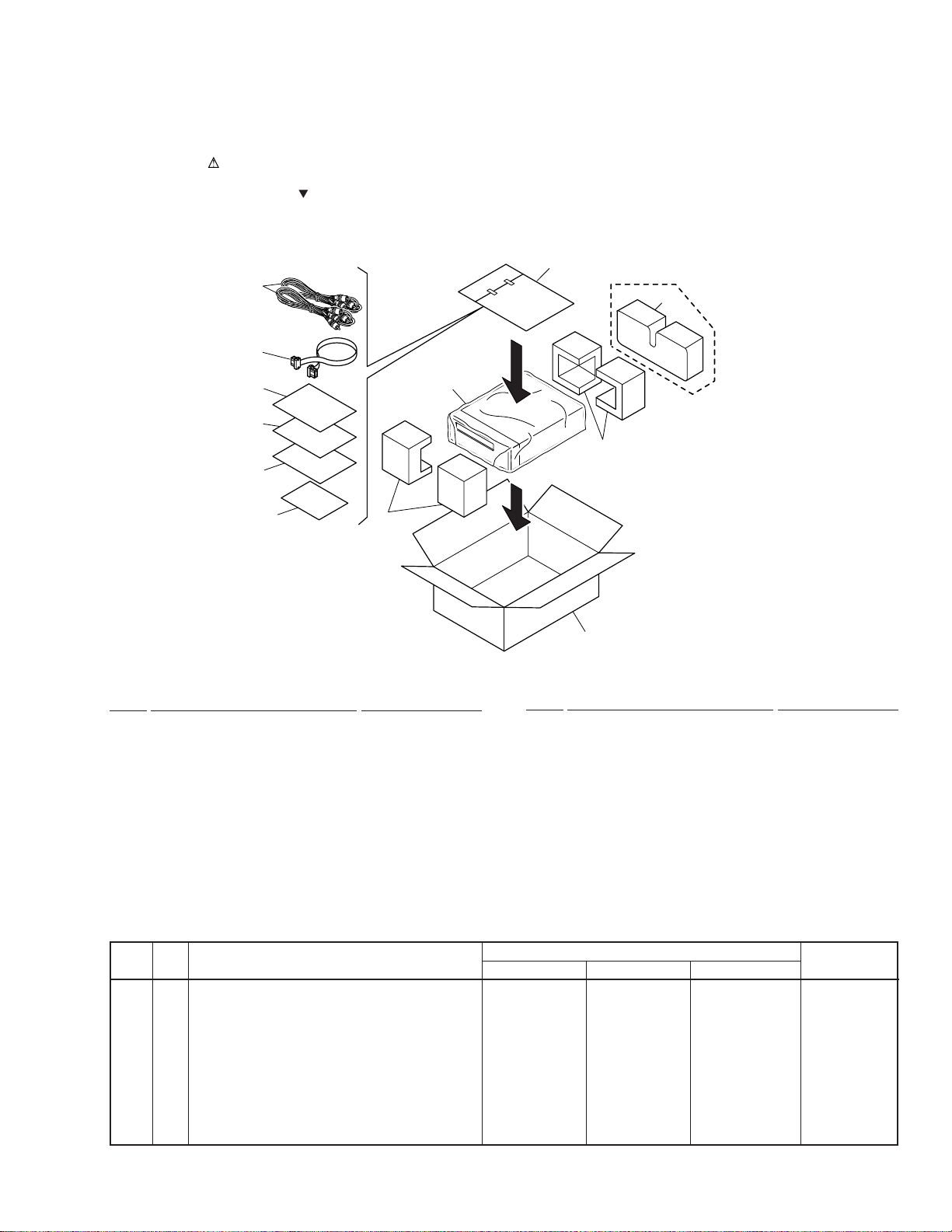

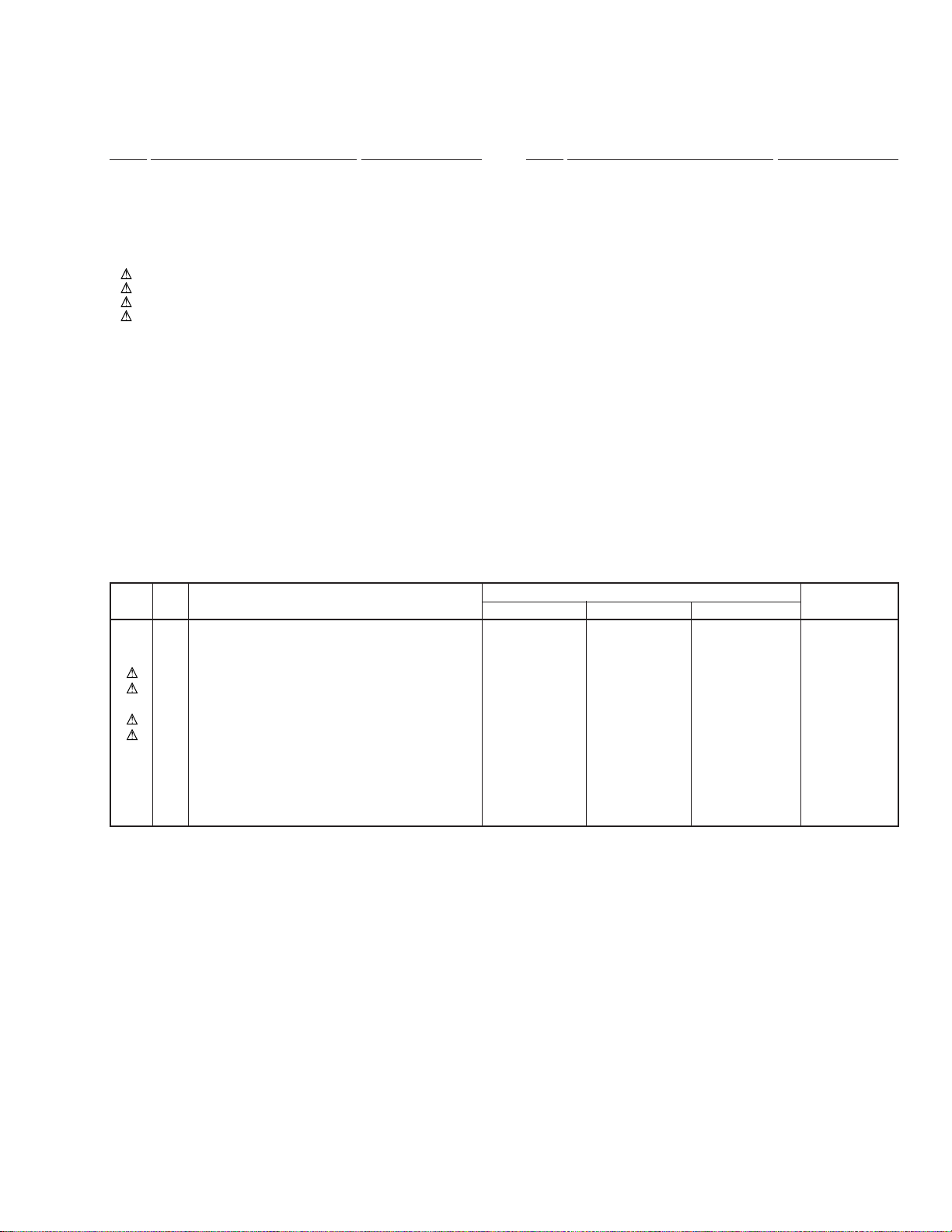

2. EXPLODED VIEWS AND PARTS LIST

NOTES:• Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

2.1 PACKING

The mark found on some component parts indicates the importance of the safety factor of the part.

•

Therefore, when replacing, be sure to use parts of identical designation.

Screws adjacent to mark on the product are used for disassembly.

•

11

6

5

NV type only

12

CT-IS21

7 (MY type

only)

8 (MY ,NV

types only)

9 (RBD type

only)

10 (MY ,NV

types only)

1

(1) PACKING PARTS LIST

Mark No. Description Part No.

1 F Pad AHA7267

2 R Pad AHA7268

3 Packing Case See Contrast table (2)

4 Mirror Mat Sheet Z23-026

5 System Cable ADE7032

6 RCA Pin-plug Stereo Cable ADE7034

7 Operating Instructions See Contrast table (2)

(Spanish/Portuguese/Dutch/Swedish)

4

2

3

Mark No. Description Part No.

8 Operating Instructions See Contrast table (2)

(English/French/German/Italian)

9 Operating Instructions See Contrast table (2)

(English/Chinese/Spanish/Arabic)

NSP 10 Warranty Card See Contrast table (2)

11 Polyethylene Bag Z21-038

(0.03 × 230 × 340)

12 Protector V See Contrast table (2)

(2) CONTRAST TABLE

CT-IS21/MY, NV and RBD are constructed the same except for the following :

Mark No. Symbol and Description

3 Packing Case Y AHD7788 Not used Not used

3 Packing Case V Not used AHD7789 Not used

3 Packing Case D Not used Not used AHD7786

7 Operating Instructions ARC7265 Not used Not used

(Spanish/Portuguese/Dutch/Swedish)

8 Operating Instructions

9 Operating Instructions (English/Chinese/Spanish/Arabic) Not used Not used ARE7235

NSP 10 Warranty Card ARY7022 ARY7022 Not used

12 Protector V Not used AHA7273 Not used

(English/French/German/Italian) ARE7234 ARE7234 Not used

MY Type NV Type RBD Type

Part No.

Remarks

3

Page 4

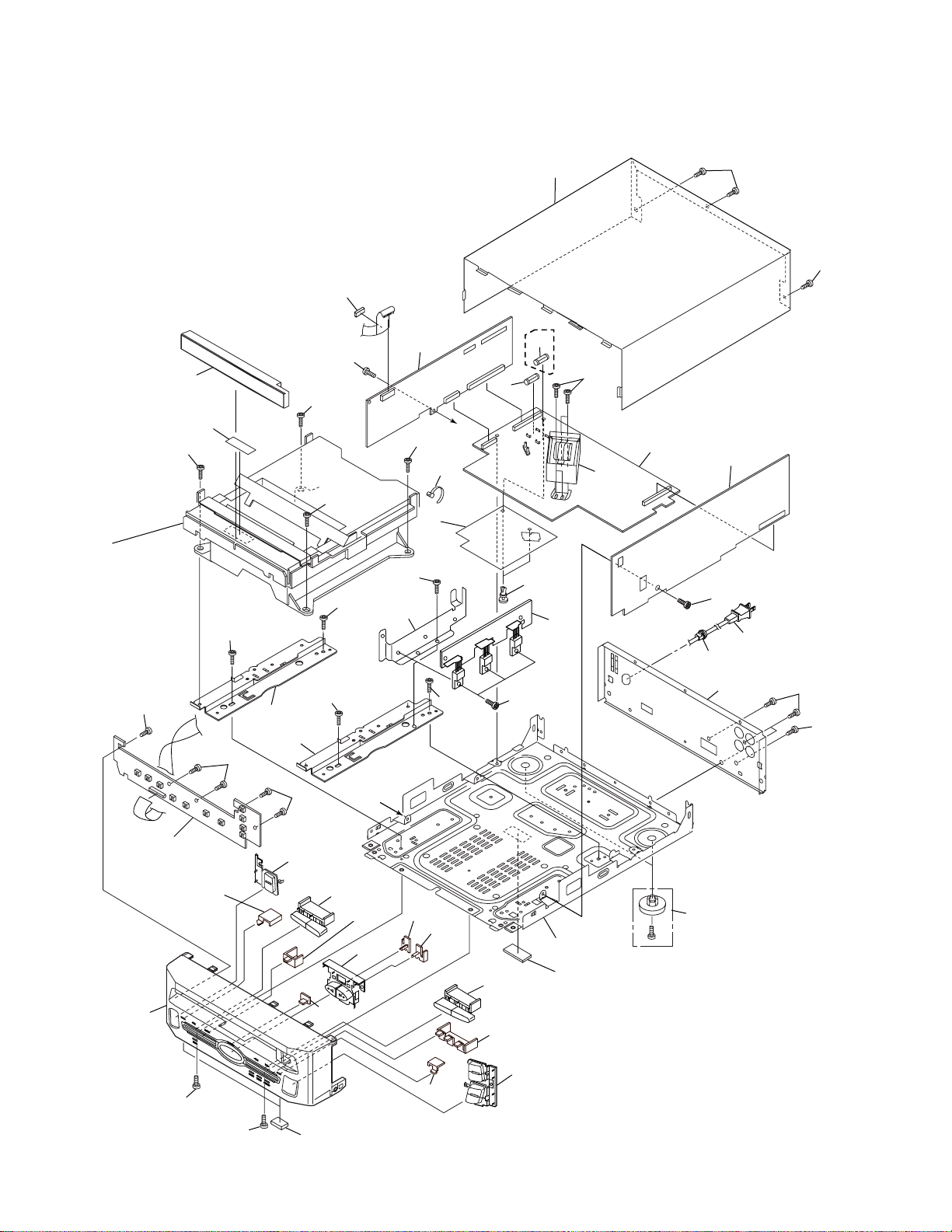

CT-IS21

2.2 EXTERIOR

25

33

6

Refer to "2.3 and

2.4 DECK MECHANISM UNIT".

34

31

32

34

17

17

33

32

33

13

32

32

18

32

33

30

RBD

2

8

type

only

7

32

33

33

A

15

35

32

4

9

14

5

33

19

32

11

1

10

33

33

29

34

3

28(3/3)

33

33

24(1/2)

28(1/3)

12

22

A

27(2/2)

23

26(1/2)

26(2/2)

28(2/3)

21

27(1/2)

20

16

36

24(2/2)

4

Page 5

(1) EXTERIOR PARTS LIST

CT-IS21

Mark No. Description Part No.

1 AF Assy See Contrast table (2)

2 U-COM Assy AWU7370

3 DISPLAY Assy AWU7373

4 MAIN Assy See Contrast table (2)

5 REG. Assy AWU7369

6 Deck Mechanism Unit See Contrast table (2)

7 FU1 Fuse (T250mA) AEK1048

8 FU2 Fuse (T315mA) See Contrast table (2)

9 T2000 Power Transformer ATT7051

10 AC Power Cord See Contrast table (2)

11 Rear Panel See Contrast table (2)

12 Rubber Sheet AEB1111

13 Spacer AEB7133

14 Nylon Rivet AEC-525

15 Insulation Sheet AEC7208

NSP 16 Chassis MD, CD ANA7092

17 Mech Angle T ANG7213

18 Heat Sink IS ANH7111

Mark No. Description Part No.

19 Strain Relief CM-22B

20 Foot Assy REC-434

21 Function Button A AAD7510

22 Function Button B AAD7511

23 Play Button AAD7534

24 O/C Button AAD7535

25 Tray Cap AAK7678

26 Play Lens AAK7679

27 REC Lens AAK7680

28 Center Lens AAK7681

29 Front Panel AMB7640

30 Bonnet IS AZN7788

NSP 31 Tray Seal RRW1162

32 Screw BBZ30P060FMC

33 Screw BBZ30P080FZK

34 Screw BPZ30P080FMC

35 Binder ZCA-SKB90BK

36 Caution Label See Contrast table (2)

(2) CONTRAST TABLE

CT-IS21/MY, NV and RBD are constructed the same except for the following :

Mark No. Symbol and Description

1 AF Assy AWU7371 AWU7371 AWU7372

4 MAIN Assy AWU7365 AWU7365 AWU7366

6 Deck Mechanism Unit AXA7073 AXA7073 AXA7082

8 FU2 Fuse (T315mA) Not used Not used AEK1049

10 AC Power Cord HE PDG1003 Not used Not used

MY Type NV Type RBD Type

Part No.

Remarks

10 AC Power Cord HB Not used VDG1062 Not used

10 AC Power Cord SD Not used Not used PDG1013

11 Rear Panel Y ANC7857 Not used Not used

11 Rear Panel V Not used ANC7858 Not used

11 Rear Panel D Not used Not used ANC7853

36 Caution Label Not used Not used ARW7036

5

Page 6

CT-IS21

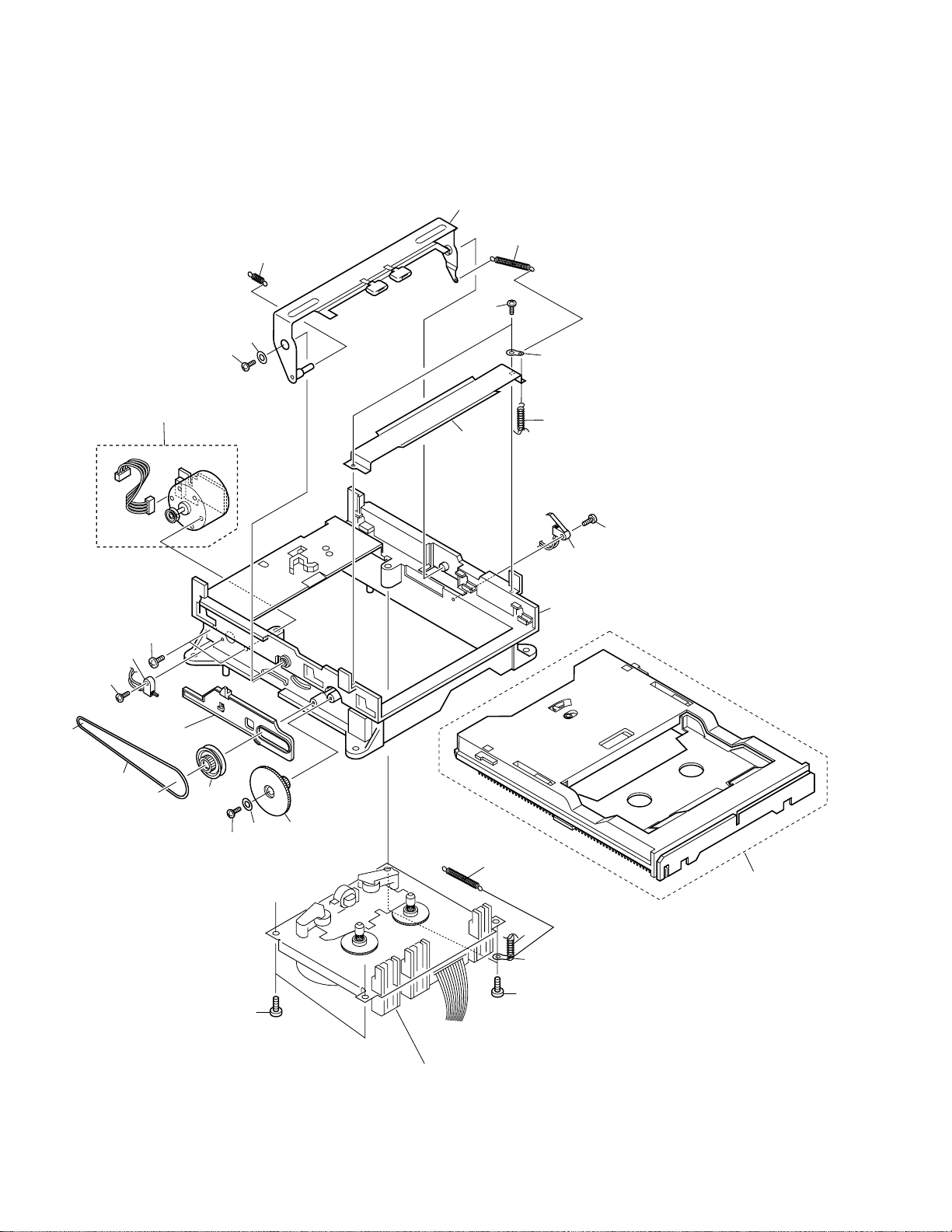

2.3 DECK MECHANISM UNIT (1/2)

17

4

16

6

5

16

19

16

12

13

14

3

1

11

9

4

16

10

20

20

16

18

8

7

20

21

2

2

Refer to "2.4. DECK MECHANISM UNIT (2/2).

6

Page 7

(1) DECK MECHANISM UNIT (1/2) PARTS LIST

Mark No. Description Part No.

1 Screw FG114-14

2 Screw UG12H-15

3 Front BKT FC64K-11

4 Washer MJ112-22

5 SP Return FK34N-11

6 Plate Hold BLK F573-258

7 Holder CST BLK F527-078

8 LDG Base FD56R-12

9 Pulley FD56T-11

10 LDG Gear FD56U-11

11 Slider FD57E-11

12 LDG Belt FF19L-12

13 Switch UE15S-14

14 MTR Reel BLK F564-313

15 • • • • •

16 Screw UG12H-28

17 SP Clamper FK34M-11

18 Switch UE18P-21

19 LUG UH12R-11

20 Earth Spring FK34S-11

CT-IS21

21 LUG UH12T-11

7

Page 8

CT-IS21

2.4 DECK MECHANISM UNIT (2/2)

39

40

19

33

15

12

31

10

4

2

32

2

8

23

5

14

31

32

7

9

3

18

34

11

6

16

24

21

43

35

37

36

30

13

20

30

41

42

27

22

26

9

17

28

1

29

1

3

25

38

8

Page 9

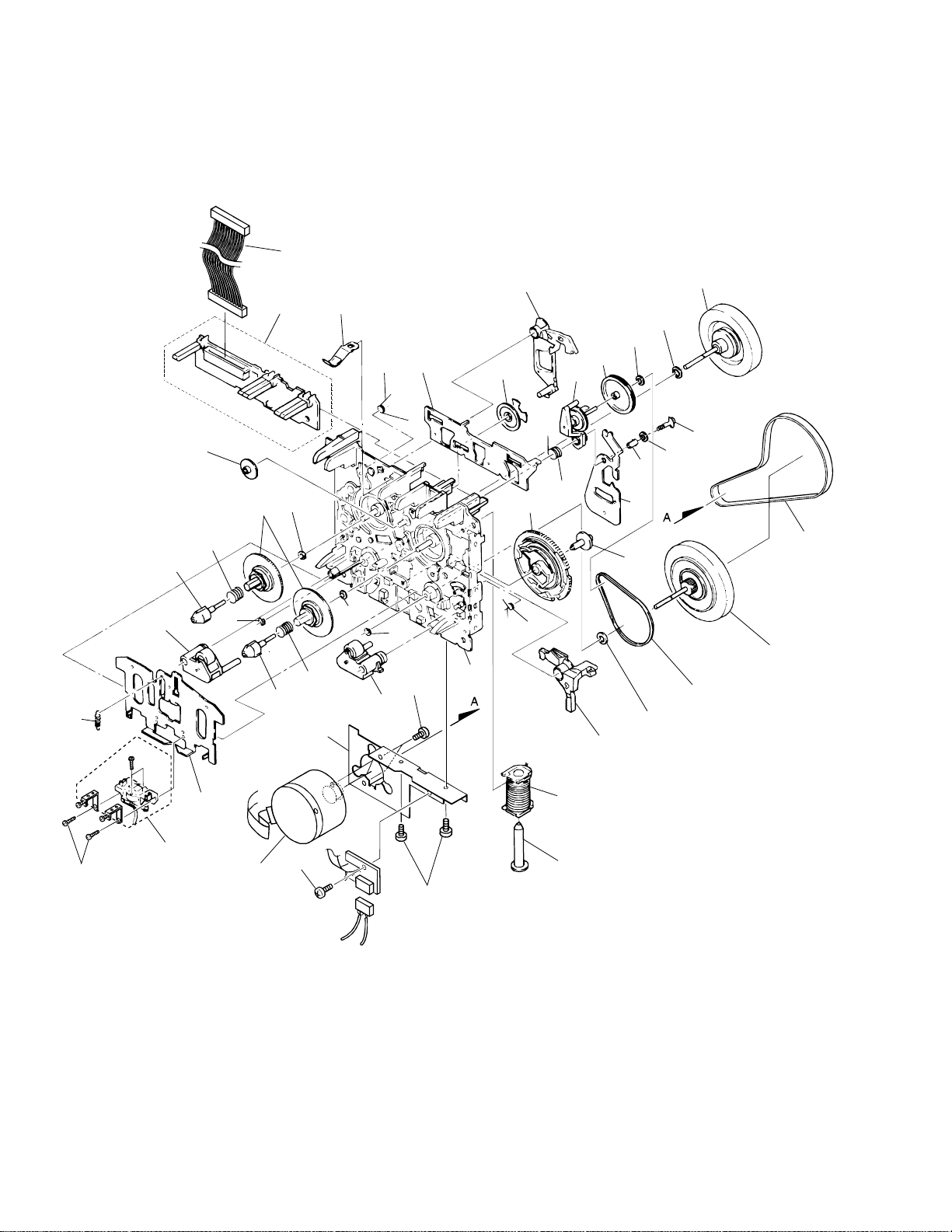

(1) DECK MECHANISM UNIT (2/2) PARTS LIST

CT-IS21

Mark No. Description Part No.

1 Screw KG194-36

2 Reel Feather FD57D-13

3 Screw UG11S-14

4 SP Reel(L) FK32U-12

5 SP Brake FK33B-13

6 SP Arm Play FK33P-11

7 SP Reel(R) FK32V-12

8 Spring Cassette FC65M-11

9 BKT MTR FC64M-12

10 Reel Base FD52W-12

11 Cam Gear FD52Y-23

12 Play Gear (A) FD53K-12

13 Arm Play FD53D-19

14 Plate Slide FC61L-19

15 PCB Control BLK F567-617

16 Chassis base BLK F612-231

17 Head Base FC61K-32

18 Roller Pinch BLK R F514-129

19 Roller Pinch BLK L F514-130

20 Assy F/W See Contrast table (2)

21 Clutch Assy BLK F522-037

22 Clutch Assy BLK See Contrast table (2)

Mark No. Description Part No.

23 Washer FJ111-13

24 F/R Pulley FD53F-15

25 Solenoid BLK F765-279

26 F/R Belt FF18W-12

27 Belt Main FF19H-11

28 Plate HD BLK F513-824

29 MTR MAIN BLK F525-327

30 Washer FJ111-30

31 Washer FJ111-35

32 Washer UJ16F-11

33 Lever Brake FD53P-17

34 FF Gear(A) FD53L-12

35 Cam SP FK32S-14

36 Screw UJ14A-12

37 Lever F/R FC62G-14

38 Plunger FL41S-21

39 Mecha-Cable WH65N-11

40 Spring HB FK32T-31

41 Screw UG15V-13

42 Washer MJ112-22

43 Spacer UJ15V-13

(2) CONTRAST TABLE

AXA7073 and AXA7082 are constructed the same except for the following :

Mark No. Symbol and Description

20 Assy F/W FR24S-11 FR24S-21

22 Clutch Assy BLK F522-042 F522-048

AXA7073 AXA7082

Part No.

Remarks

9

Page 10

1

23

CT-IS21

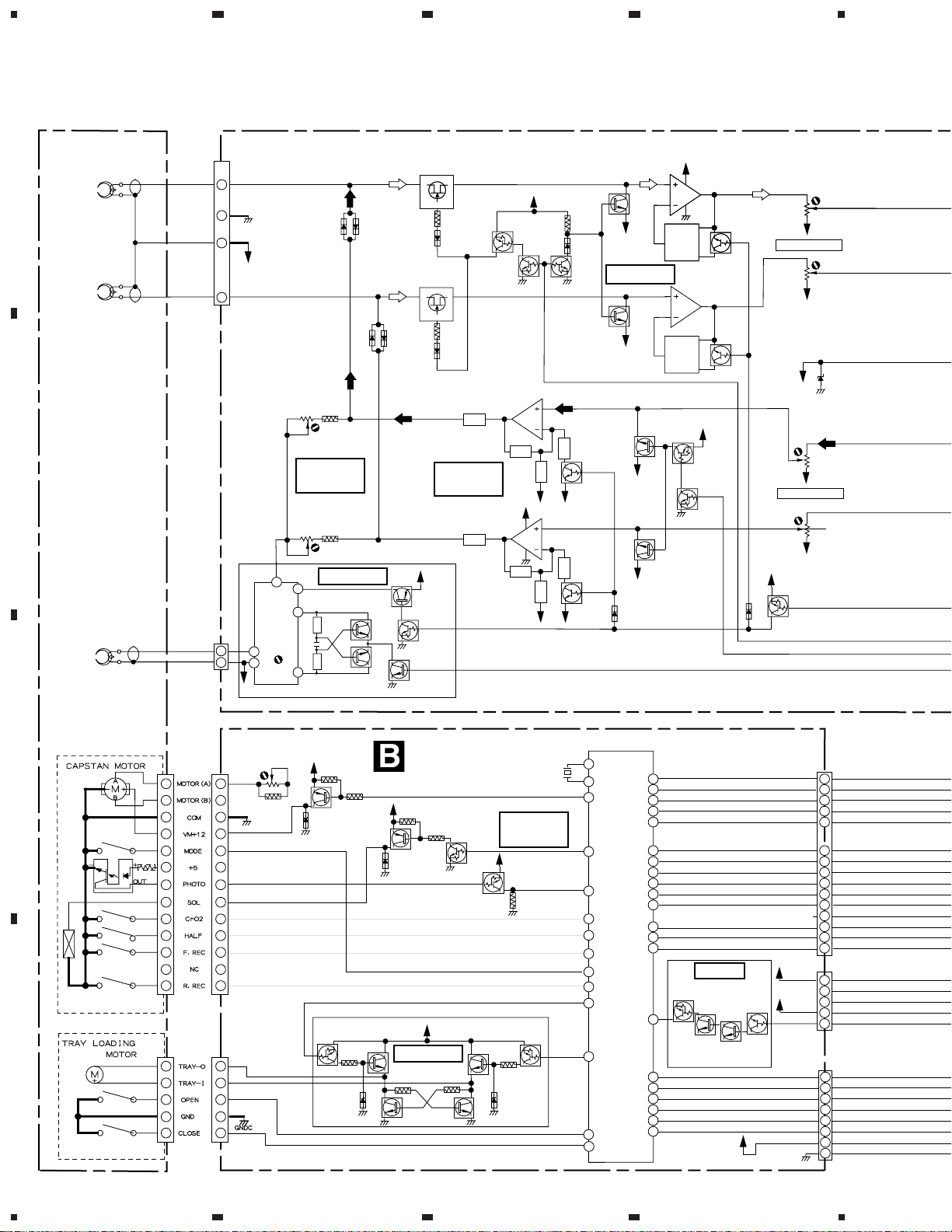

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM

3.1 BLOCK DIAGRAM

4

A

REC/PB

HEAD

DECK

MECHANISM

B

UNIT

AXA7073

(MYandNV types)

AXA7082

(RDB type)

ERACE

HEAD

CN2302

CN2301

Lch

3

4

2

Rch

1

1

2

Vref

GNDA

Vref

L2801

RTD1082

6

4

5

VR2801

PCP1032

100K-B

OFFSET

VR2802

PCP1032

100K-B

2

1

3

BIAS

BIAS OSC

Q2801

2SC1815

Q2802

2SC1815

GNDB

GNDB

Q2301

Q2301

2SK373

2SK373

D

D

G

G

Q2302

2SK373

D

G

VB12

Q2803

2SB1238X

Q2804

DTC124EK

BIAS

Q2805

2SC1815

S

S

Q2351

DTA124EK

DTC124EK

S

IC2401(1/2)

BA4558F-HT

REC EQ

AMP

IC2401(2/2)

BA4558F-HT

Q2352

GNDA

7

8

1

4

Vref Vref

VA12

VA12

DTC114TK

GNDA

Q2353

DTC124EK

PB/REC

5

6

Vref Vref

3

2

Q2303

Q2304

DTC114TK

Q2401

DTC114TK

Q2402

DTC114TK

Vref

PB AMP

Vref

Q2451

2SD2114K

Vref

Vref

VA12

3

3

2

2

EQ

EQ

5

6

EQ

GNDA

Q2452

2SD2114K

IC2301(1/2)

IC2301(1/2)

BA4558F-HT

BA4558F-HT

8

8

1

1

4

4

GNDA

IC2301(2/2)

BA4558F-HT

7

VA12

Q2460

DTA124EK

Q2453

DTC124EK

Q2305

DTC114TK

Q2306

DTC114TK

VR2401

PCP1028

4.7K-B

VR2402

PCP1028

4.7K-B

VR2301

PCP1028

4.7K-B

PB LEVEL ADJ.

VR2302

PCP1028

4.7K-B

MTZ6.2A

Vref

REC LEVEL ADJ.

VA12

Q2454

DTA124EK

RECMUTE

Vref

Vref

D2201

GNDA

Vref

Vref

CRO2

PB/REC

BIAS

VR2701

RCP1024

C

13

12

11

10

9

8

7

6

5

4

3

2

1

13

12

11

10

9

8

7

6

5

4

3

2

1

1K-B

GNDM

MODE

VM12

2SB1425

GNDM

XMOTOR

Q2701

CrO2

HALF

F.REC

MODE

R.REC R.REC

CN2701

Q2752

DTA143EK

CN2751

D

1

2

3

4

5

5

1

4

2

3

3

2

4

1

5

TOUT

OPEN

CLOSE

Q2754

GNDM

GNDM GNDM

U-COM ASSY

AWU7370

VM12

Q2702

2SB1296

GNDM

VM12

LOADING

Q2753-2756

:2SD1858X

Q2756

Q2755

DTC124EK

GNDC

DTA124EK

Q2703

Q2704

SOL

GNDC

Q2753

VSS1045

MECHA

CONT

V+5

Q2751

DTA143EK

GNDM

X2501

6MHz

SENS

CrO2

HALF

F.REC

MODE

TOUT

TIN

OPEN

CLOSE

10

11

3

µ-COM

2

16

20

21

23

17

19

47

1

40

41

IC2501

PDC059A

32

30

28

26

4

15

46

45

43

44

22

39

37

33

25

14

13

35

36

34

32

Q2060

DTA124EK

Q2059

2SC2412K

RESET

Q2058

2SC2412K

V+5

Q2057

DTA114TK

CN2501

POW

AM56

SDATA

S.REQ

S.CLK

BIAS

XCrO2

PB/XREC

RECMUTE

SYSTEM ON

DOL ON/OFF

PB MUTE

LINE MUTE

V+5

GNDD

GNDM

VM12

RESET

CN2502

CN2601

KEY2

KEY1

LEDCE

LEDCLOCK

LEDDATA

POW

V+5

GNDD

1

2

3

4

5

MS

6

7

8

9

10

11

NC

12

13

14

15

1

2

3

4

5

1

2

3

4

5

6

7

8

10

1234

Page 11

5

678

CT-IS21

Note : When ordering service parts, be sure to refer to "EXPLODED VIEWS and PARTS LIST" or "PCB PARTS LIST".

3

14

4

8

9

CRO2

IC2201

HA12136AF

DOLBY-B NR

-3.7dBV

-3.7dBV

-32.2dBV

-32.2dBV

6

11

IC2202(1/2)

BA4558F-HT

ALC

2SC2412K

2SC2412K

Vref

5

LINEOUT BUFFER

TP

-6.0dBV

Q2261

2SD2114K

Vref

TP

-6.0dBV

Q2262

2SD2114K

Vref

VA12

3

8

1

2

4

GNDA

VA12

Q2253

Q2251

Q2252

2SC2412K

Vref

RTF1217

RTF1217

5

6

VA12

3

2

GNDA

F2201

MPX

F2202

MPX

MPX

IC2151(1/2)

BA4558F-HT

7

IC2151(2/2)

8

BA4558F-HT

1

4

5

6

IC2101(1/2)

BA4558F-HT

351

-8.0dBV

IC2101(2/2)

BA4558F-HT

3516

-8.0dBV

IC2202(2/2)

BA4558F-HT

AF ASSY

AWU7371(MY and NV types)

AWU7372(RBD type)

Q2171

2SD2114K

Vref

Q2172

2SD2114K

Vref

7

+

MS

VA12

3

8

1

2

4

GNDA

5

7

6

INPUT BUFFER

:PLAYBACK SIGNAL ROUTE

:RECRDING SIGNAL ROUTE

LINEOUT

Lch

GNDA

LINEOUT

Rch

GNDA

Q2263

DTC143EK

GNDA

GNDA

LINEIN

Lch

LINEIN

Rch

+

+

GNDD

CN2506

Q2173

DTA124EK

CN2505

VC5

15

14

MS

3

12

13

1 GNDB

5

6

11

8

V+B

LMUTE

PBMUTE NCNC

GNDA

GNDD

ON/OFF

CrO2

MS

NC

DOL

15

14

3

12

13

1

5

6

11

8

LINEMUTE

MS

DOL

ON/OFF

CrO2

A

B

PB/REC

RECMUTE

BIAS

CN2503

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

1

2

3

4

5

CN2504

J2601

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

POW

AM56

S.DATA

S.REQ

S.CLK

MS

BIAS

XCrO2

PB/XREC

RECMUTE

NC

NC

DOL ON/OFF

PB MUTE

LINE MUTE

V+5

GNDD

GNDM

VM12

RESET

KEY2

KEY1

LEDCE

LEDCLK

LEDDATA

POW

V+5

GNDD

CN2551

4

IC2502

3

BU2092F

2

DTC143EK

9 - 16

Q2601

23451

NC

AM56

SDATA

SCLOCK

REQ/ENA

MAIN ASSY

AWU7365(MY and NV types)

AWU7366(RBD type)

DISPLAY

ASSY

AWU7373

VB12

VA12

Q2051

GNDC

UN+5

GND

2SB1238X

VC5

UN+5

IC2057

NJM78M05FA

VC5

VC5

+5V

678

Q2061

2SC2412K

GNDC GNDM

M+12

MGND

AEK7011

AEK7011

AEK7011

UN12

M+12

Q2056

2SD2395

9

10

7

2

4

IC2051

1.5A

IC2052

1.5A

IC2053

1.5A

PB/REC

RECMUTE

BIAS

B+12

VA12

TRANSFORMER

UN12

IN OUTIN OUT

IC2055

NJM7812FA

PB/REC

9

RECMUTE

10

7

2

4

POWER

ATT7051

BIAS

+12V

FU1

T250mA

MY and NV

FU1

types

FU2

AEK1049

T315mA

AEK1048

GNDA GNDB

CN2051

23451678

GND

23451

J2052

REG.

ASSY

AWU7369

FU2

RDB

type

S2001

VOLTAGE

SELECTOR

AKX7004

C

NEUTRAL

LIVE

D

11

5

6

7

8

Page 12

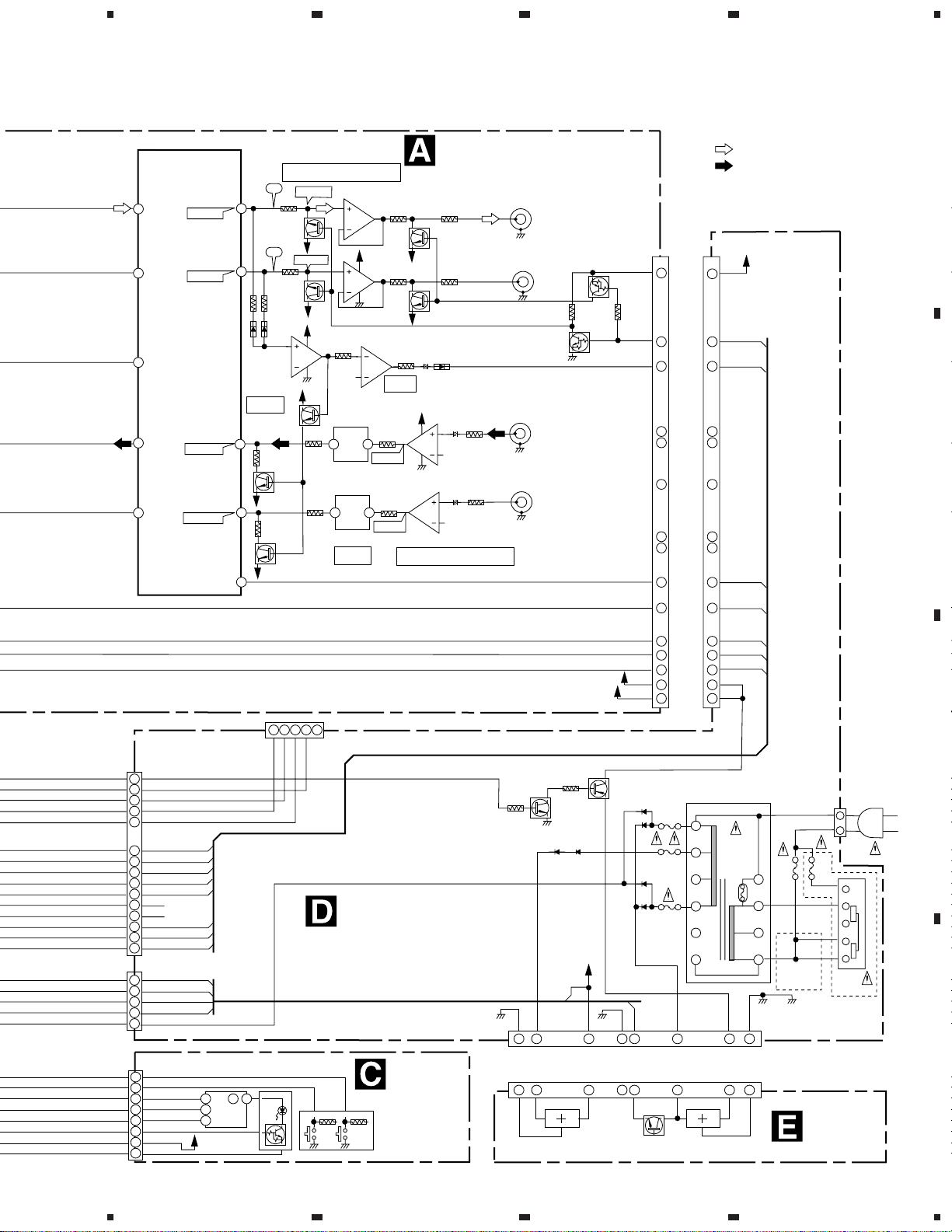

CT-IS21

3.2 AF ASSY

A

B

DECK MECHA

UNIT (1/2)

(AXA7073

:MY, NV TYPES)

(AXA7082

:RBD TYPE)

1

REC/PB

HEAD

ERASE

HEAD

CN2301

CN2302

23

AF ASSY

A

(AWU7371: MY, NV TYPES)

(AWU7372: RBD TYPE)

D2301-D2306:

1SS133

C2315,

C2321-C2324

; MY and NV

types only

4

BA4558BF-HT

C

BA4558BF-HT

PCB BINDER

D

12

A

1234

NOTES

ALL CAPACITORS ARE IN µF

UNLESS OTHERWISE SPECIFIED.

ELECT.

Page 13

5

678

CT-IS21

MTZJ6.2A

D2252-D2255:

1SS355

: PLAYBACK SIGNAL ROUTE

: RECORDING SIGNAL ROUTE

A

B

BA4558BF-HT

BA4558BF-HT

ALL RESISTORS ARE IN Ω

UNLESS OTHERWISE SPECIFIED.

1/4W UNLESS OTHERWISE SPECIFIED

: CHIP (1/10W)

ALL INDUCTORS ARE IN µF.

: The power supply is shown

with the marked box.

5

CN2506

REC

CN2101(1/4)

CN2101(2/4)

6

PLAY

CN2101(3/4)

L

L

RR

CN2101(4/4)

CN2505

D

BA4558BF-HT

BA4558BF-HT

C

D

A

7

8

13

Page 14

1

CT-IS21

3.3 U-COM AND DISPLAY ASSYS

CN2701

A

DECK MECHA

UNIT (2/2)

(AXA7073

B

:MY, NV TYPES)

(AXA7082

:RBD TYPE)

23

4

CN2751

U-COM ASSY

B

C

D2602,D2603,

D2605-D2609:

(AWU7370)

C

DISPLAY ASSY

(AWU7373)

PCB BINDER

CN2601

CABLE

HOLDER

J2601

LED DRIVER

D

PCB BINDER

14

B

C

1234

Page 15

5

678

CT-IS21

A

MTZJ6.8C

B

CN2502

CN2504

D

S2901-S2904,S2906-S2912:

ASG7013

CN2501

1SS133

CN2503

D

SWITCHES

DISPLAY ASSY

S2901 : STANDBY/ON

S2902 : ASEB

S2903 : 2

S2904 : 3

S2906 : OPEN CLOSE (0)

S2907 : ¶8

S2908 : 1

S2909 : ¡

S2910 : STOP (7)

S2911 : REVERSE MODE

S2912 : DOLBY NR

RESET

NOTES

ALL CAPACITORS ARE IN µF

UNLESS OTHERWISE SPECIFIED.

ELECT.

ALL RESISTORS ARE IN Ω

UNLESS OTHERWISE SPECIFIED.

: CHIP (1/10W)

: The power supply is shown

with the marked box.

C

D

B

5

6

7

C

8

15

Page 16

1

CT-IS21

3.4 MAIN AND REG. ASSYS

AC POWER CORD

A

PDG1003 (MY TYPE)

VDG1062 (NV TYPE)

PDG1013 (RBD TYPE)

CN2001

AC IN

AWU7366

ONLY

FU1 250mA/250V

AEK1048

23

4

S2001

VOLTAGE

SELECTOR

AKX7004

B

AC220-240V

AC110-127V

FU2 315mA/250V

AEK1049

AWU7365

ONLY

T2000

POWER TRANSFORMER

ATT7051

SCREW

TERMINAL

CN2551

D

MAIN ASSY

(AWU7365: MY, NV TYPES)

(AWU7366: RBD TYPE)

SYSTEM

C

D

16

D

1234

CN2505

CN2506

A

Page 17

5

678

CT-IS21

A

REGULATOR

CN2051

PCB BINDER

J2052

CABLE HOLDER

E

REGULATOR

REG. ASSY

(AWU7369)

B

CN2501

B

C

CN2503

NOTES

ALL CAPACITORS ARE IN µF

UNLESS OTHERWISE SPECIFIED.

ELECT.

ALL RESISTORS ARE IN Ω

UNLESS OTHERWISE SPECIFIED.

1/4W UNLESS OTHERWISE SPECIFIED

: CHIP (1/10W)

• NOTE FOR FUSE REPLACEMENT

CAUTION -

5

FOR CONTINUED PROTECTION AGAINST RISK OF FIRE.

REPLACE WITH SAME TYPE AND RATINGS ONLY.

CN2502

B

CN2504

D

D

6

7

E

8

17

Page 18

1

2

23

CT-IS21

4. PCB CONNECTION DIAGRAM

4.1 AF ASSY

A

SIDE A

A

B

4

AF ASSY

NOTE FOR PCB DIAGRAMS :

1. Part numbers in PCB diagrams match those

in the schematic diagrams.

2. A comparison between the main parts of PCB

and schematic diagrams is shown below.

Symbol In PCB

Diagrams

BCE

C

D

3. The parts mounted on this PCB include all

necessary parts for several destinations.

For further information for respective destinations,

be sure to check with the schematic diagram.

4. View point of PCB diagrams.

Connector

BCE

Symbol In Schematic

Diagrams

BCEBCE

BCE

BCE

DGS

DGGSS

Capacitor

Part Name

Transistor

Transistor

with resistor

Field effect

transistor

Resistor array

3-terminal

regulator

SIDE A

SIDE B

AF ASSY

A

CN2505

D

P.C.Board

D

18

A

Chip Part

1234

SIDE B

Q2171

Q2172

IC2151

IC2101

Q2261Q2263Q2173

Q2262

IC2202

Q2252

Q2251

Q2254

Q2253

Q2255

IC

Page 19

5

Q

678

CT-IS21

VR2301

VR2302

VR2401

VR2402

(ANP7329-B)

Q2301 Q2801

Q2805Q2302

Q2802

Q2803

VR2801

VR2802

REC/PB

HEAD

A

B

ERASE

HEAD

2254

Q2253 IC2201

Q2460

Q2453

Q2353 Q2351

Q2305

Q2402Q2452

Q2401Q2451

IC2301

IC2401

DECK MECHA UNIT

Q2456

Q2455Q2303

Q2804Q2304Q2306Q2352Q2454Q2255

(ANP7329-B)

C

D

5

6

7

A

8

19

Page 20

1

23

CT-IS21

4.2 U-COM AND DISPLAY ASSYS

4

A

DISPLAY ASSY

C

CAPSTAN

MOTOR

DECK

MECHA

UNIT

B

TRAY

LOADING

MOTOR

U-COM ASSY

B

VR2701

D

CN2503

Q2701

Q2702

Q2753

Q2754

Q2755

Q2756

D

CN2504

C

D

(ANP7329-B)

(ANP7329-B)

SIDE A

20

B C

1234

Page 21

1

U-COM ASSY

B

234

CT-IS21

DISPLAY ASSY

C

A

Q2703

Q2752

Q2751

Q2704

Q2057

Q2058

Q2059

Q2060

Q2561

IC2502

B

Q2601

C

IC2501

Q2563

Q2564

Q2562

D

(ANP7329-B)

(ANP7329-B)

SIDE B

B

1

2

3

C

4

21

Page 22

1

23

CT-IS21

4.3.MAIN AND REG. ASSYS

4

B

CN2502

A

MAIN ASSY

D

AC IN

NEUTRAL

B

REG. ASSY

E

LIVE

B

CN2501

IC2051

IC2052

IC2053

C

IC1

IC2054

Q2051

D

(ANP7329-B)

A

CN2506

(ANP7329-B)

SIDE A

22

D E

1234

Page 23

1

MAIN ASSY

D

234

CT-IS21

A

B

Q2061

REG. ASSY

E

C

Q2052

(ANP7329-B)

(ANP7329-B)

D

SIDE B

D E

1

2

3

4

23

Page 24

CT-IS21

Mark No. Description Part No.

Mark No. Description Part No.

5. PCB PARTS LIST

NOTES:•Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

•

Therefore, when replacing, be sure to use parts of identical designation.

When ordering resistors, first convert resistance values into code form as shown in the following examples.

•

Ex.1 When there are 2 effective digits (any digit apart from 0), such as 560 ohm and 47k ohm (tolerance is shown by J=5%,

and K=10%).

560 Ω→56 × 10

47k Ω→47 × 103→ 473 ........................................................ RD1/4PU 4 7 3 J

0.5 Ω→R50 ..................................................................................... RN2H

1 Ω→1R0 ..................................................................................... RS1P

Ex.2 When there are 3 effective digits (such as in high precision metal film resistors).

5.62k Ω→ 562 × 10

LIST OF HOLE PCB ASSEMBLIES

Mark Symbol and Description

NSP COMPLEX ASSY

AF ASSY

U-COM ASSY

DISPLAY ASSY

MAIN ASSY

REG. ASSY

1

→ 561 ........................................................ RD1/4PU 5 6 1 J

R 5 0

1 R 0

1

→ 5621 ...................................................... RN1/4PC 5 6 2 1 F

Part No.

CT-IS21/MY CT-IS21/NV CT-IS21/RBD

AWM7463

AWU7371

AWU7370

AWU7373

AWU7365

AWU7369

AWM7463

AWU7371

AWU7370

AWU7373

AWU7365

AWU7369

AWM7464

AWU7372

AWU7370

AWU7373

AWU7366

AWU7369

K

K

Remarks

PCB PARTS LIST

Mark No. Description Part No.

AF ASSY

A

(1) CONTRAST TABLE

AWU7371 and AWU7372 are constructed the same except

for the following :

Mark Symbol and Description

C2323,C2324 CCSQCH100D50 Not used

C2321,C2322 CCSQCH470J50 Not used

C2315 CKSQYB102K50 Not used

AWU7371 AWU7372

(2) PARTS LIST FOR AWU7371

SEMICONDUCTORS

IC2101,IC2151,IC2202 BA4558F-HT

IC2301,IC2401 BA4558F-HT

IC2201 HA12136AF

Q2254 2SA1037K

Q2803 2SB1238X

Q2801,Q2802,Q2805 2SC1815

Q2251-Q2253 2SC2412K

Q2171,Q2172,Q2261,Q2262 2SD2114K

Q2451,Q2452 2SD2114K

Q2301,Q2302 2SK373

Q2173,Q2351,Q2454,Q2460 DTA124EK

Q2303-Q2306,Q2401,Q2402 DTC114TK

Q2255,Q2352,Q2353,Q2453,Q2804

Q2263 DTC143EK

D2256,D2301-D2306 1SS133

D2252-D2255,D2307,D2308,D2401

D2201 MTZJ6.2A

Part No.

Remarks

DTC124EK

1SS355

Mark No. Description Part No.

COILS AND FILTERS

L2802 LFA121J

L2801 OSC COIL RTD1082

L2401,L2402 COIL 10mH RTF1004

L2403,L2404 COIL 4.7mH RTF1021

F2201,F2202 MPX FILTER RTF1217

CAPACITORS

C2301,C2302,C2323,C2324 CCSQCH100D50

C2423,C2424 CCSQCH221J50

C2253 CCSQCH271J50

C2321,C2322 CCSQCH470J50

C2153,C2154,C2203,C2207 CEAT100M50

C2215 CEAT101M16

C2251 CEAT220M50

C2216 CEAT221M16

C2254 CEAT2R2M50

C2407 CEAT330M50

C2107,C2161,C2425 CEAT470M16

C2221,C2222,C2261,C2262 CEAT4R7M50

C2204,C2311,C2312 CEJA100M16

C2103,C2104,C2201,C2202

C2217,C2218,C2255,C2403,C2404

C2419,C2420 CEJA1R0M50

C2309,C2310,C2408,C2805,C2806

C2314,C2807 CEJA470M16

C2208 CEJAR10M50

C2205,C2206 CEJAR22M50

C2151,C2152,C2315 CKSQYB102K50

C2431,C2432 CKSQYB122K50

C2211,C2212 CKSQYB152K50

C2303,C2304 CKSQYB681K50

C2108 CKSQYF104Z50

CEJA1R0M50

CEJA1R0M50

CEJA330M16

24

Page 25

CT-IS21

Mark No. Description Part No.

C2252 CKSQYF105Z16

C2808 CQHA822J2A

C2209,C2210 CQMA103J50

C2801 CQMA123J50

C2421,C2422 CQMA152J50

C2409,C2410 CQMA223J50

C2417,C2418 CQMA393J50

C2803,C2804 CQMA472J50

C2307,C2308,C2802 CQMA682J50

C2405,C2406 CQMA683J50

RESISTORS

R2805 RD1/2VM161J

R2806 RD1/2VM201J

R2803 RD1/2VM4R7J

VR2301,VR2302,VR2401,VR2402 PCP1028

(4.7kΩ)

VR2801,VR2802 (100kΩ) PCP1032

Other Resistors RS1/10S J

OTHERS

CN2101 PIN JACK(4P) AKB7015

CN2302 KR CONNECTOR 2P B2B-PH-K-S

CN2301 KR CONNECTOR 4P B4B-PH-K-S

CN2506 15P SOCKET KP200TA15L

PCB BINDER VEF1040

U-COM ASSY

B

SEMICONDUCTORS

IC2501 PDC059A

Q2702 2SB1296

Q2701 2SB1425

Q2058,Q2059 2SC2412K

Q2753-Q2756 2SD1858X

Mark No. Description Part No.

OTHERS

CN2601 8

CN2701 KR CONNECTOR 13P B13B-PH-K-S

CN2751 KR CONNECTOR 5P B5B-PH-K-S

CN2501 15P SOCKET KP200TA15L

CN2502 5P SOCKET KP200TA5L

PCB BINDER VEF1040

X2501 CERAMIC RESONATOR VSS1045

(6.00MHz)

DISPLAY ASSY

C

P JUMPER CONNECTOR

52151-0810

SEMICONDUCTORS

IC2502 BU2092F

Q2601 DTC143EK

D2602,D2603,D2605-D2609 SLP3118C51H

D2601,D2604 SLP9118C51H

SWITCHES

S2901-S2904,S2906-S2912 ASG7013

CAPACITORS

C2601 CKSQYB102K50

C2604 CKSQYF104Z25

RESISTORS

All Resistors RS1/10S J

OTHERS

8P CABLE HOLDER 51048-0800

J2601 JUMPER WIRE 8P D20PYY0825G

PCB BINDER VEF1040

Q2057 DTA114TK

Q2060,Q2704 DTA124EK

Q2751,Q2752 DTA143EK

Q2562,Q2563 DTC114TK

Q2561 DTC115TK

Q2564,Q2703 DTC124EK

D2062 1SS133

D2751,D2752 MTZJ5.6C

D2501 MTZJ6.8C

D2701,D2702 S5688G

COIL

L2501 LAU220J

CAPACITORS

C2561,C2562 CCSQCH101J50

C2703 CEAT221M16

C2066 CEJA220M25

C2502 CEJA470M16

C2501,C2503,C2504,C2506-C2510

C2563,C2702,C2751 CKSQYB103K50

C2505 CKSQYB471K50

RESISTORS

R2751-R2754 RD1/4PU391J

R2708 RD1/4PU751J

VR2701 (1kΩ) PCP1024

Other Resistors RS1/10S J

CKSQYB103K50

MAIN ASSY

D

(1) CONTRAST TABLE

AWU7365 and AWU7366 are constructed the same except

for the following :

Mark Symbol and Description

H2001,H2002 Fuse Clip Not used AKR1003

S2001 Voltage Selector Not used AKX7004

Part No.

AWU7365 AWU7366

Remarks

(2) PARTS LIST FOR AWU7365

SEMICONDUCTORS

IC2051-IC2053

Q2051 2SB1238X

Q2061 2SC2412K

D2066,D2068 MTZJ15C

D2067 MTZJ6.8C

D2051-D2054,D2056,D2057 S5688G

PROTECTOR (1.5A)

AEK7011

CAPACITORS

C2555-C2558 CCSQCH101J50

C2065 CEAT100M50

C2058-C2060 CEAT331M16

C2052 CEAT332M25

C2051 CEAT332M35

RESISTORS

All Resistors RS1/10S J

25

Page 26

CT-IS21

Mark No. Description Part No.

OTHERS

CN2051

CN2551 5P SOCKET AKP7042

H2003,H2004 FUSE CLIP AKR1003

CN2503,CN2505 15P PLUG KM200TA15

CN2504 5P PLUG KM200TA5

TERMINAL RKC-061

PCB BINDER VEF1040

SCREW PLATE VNE1948

REG. ASSY

E

8P JUMPER CONNECTOR

52147-0810

SEMICONDUCTORS

IC2055 NJM7812FA

IC2057 NJM78M05FA

Q2056 2SD2395

CAPACITORS

C2049,C2054 CEJA1R0M50

RESISTORS

All Resistors RS1/10S J

OTHERS

8P CABLE HOLDER 51048-0800

J2052 JUMPER WIRE 8P D20PYY0810G

Mark No. Description Part No.

26

Page 27

6. ADJUSTMENT

6.1 TEST MODE

CT-IS21

How to Enter the Test Mode

Receive "A15F" (Bus code 1C5F) with the remote control unit or

plug the power cord into the AC socket with the TEST MODE JP

(W101 and W102) on the U-COM Assy short-circuited.

TEST MODE

Short point

W102

W101

Front

U-COM ASSY

SIDE A

3. When pressing the ASES key, the Auto-recording/playback

operation mode is reached and perform the following operation.

1 Function is set to AUX.

2 FWD recording is performed for 4 seconds.

3 REV recording is performed for 4 seconds.

4 FWD playback is performed for 4 seconds. (Function becomes

TAPE).

5 Stop

4. The same operation as before can be performed with the key except

for the REVERSE MODE and ASES keys.

However, the REVERSE mode should endless fix for ageing.

LINE MUTE (PB MUTE) is opened in the REC pause and

recording status.

Cancellation of the Test Mode

Press the "STANDBY/ON" key or disconnect the AC power cord.

About the Mechanism Ageing Mode

When pressing the ASES and STOP keys for 3 seconds in the wall

outlet on, Deck power is on and the ageing mode is reached.

PLAY indicator starts flashing when enter the ageing mode.

Fig. 6-1 Test mode

Operation of the Test Mode

1. LED check mode

When pressing the REVERSE MODE key, LED indication

changes as follows.

→ Normal display → All LED lights → All LED lights out

∗ STANDBY LED is not able to controlled with the microcomputer

because of it's lighted with the hardware.

2. When pressing the EJECT key, the Cassette mecha. SW check

mode is reached and LED displays as follows.

LED

DIR FWD

DIR REV

PLAY

REC

SW ON OFF

FWD REC SW

REV REC SW

HALF SW

TAPE TYPE

Enable the FWD

recording

Enable the REV

recording

Tape exist

NORMAL

Disenable the FWD

recording

Disnable the REV

recording

No Tape

CrO

2

6.2 ADJUSTMENT

Adjustment Condition

(1) Clean the heads and demagnetize them using a head eraser.

(2) Set the measurement level to 0 dBV = 1 Vrms.

(3) Use the specified tape for adjustment. Use the labeled (A) side

of the test tape.

NCT–111 : For Tape Speed Adjustment

: For Head Azimuth Adjustment

STD-331E : For Playback Level Adjustment

: For Playback Frequency Adjustment

STD–632 : Normal blank tape

STD–622 : CrO

(4) Provide yourself with the following measuring devides:

• AC millivoltmeter

• Low-frequency oscillator

• Attenuator

• Oscilloscope

(5) Adjust both right and left channels unless otherwise specified.

(6) Turn the DOLBY NR switch off unless otherwize specified.

(7) Warm up the unit for several minutes before adjustment. In

particular, be sure to warm up the unit in the REC/PLAY mode

for 3 to 5 minutes before starting recording/playback frequency

characteristics adjustment.

(8) Always follow the indicated adjustment order.

Otherwise, a complete adjustment may not be achieved.

2 blank tape

27

Page 28

CT-IS21

List of Adjustment

¶ Playback Section

(1) Tape Speed Adjustment

(2) Head Azimuth Adjustment

(3) Playback Level Adjustment

(4) Playback Frequency Characteristics Confirmation

¶ Recording Section

(1) Recording Bias Adjustment

(2) Recording Level Adjustment

(3) Recording Frequency Characteristics Confirmation

Dolby noise reduction manufactured under license from Dolby

Laboratories Licensing Corporation.

“DOLBY” and the double-D symbol are trademarks of Dolby

Laboratories Licensing Corporation.

0 dB

30s

315 Hz

0 dB: 315 Hz, 250 nwb/m

30 s 30 s 30 s 10s 10s .......................................................................................................... 10s

6.3 kHz 10 kHz 315 Hz 14 kHz

12.5

kHz

PLAY BACK

RECORDING

10 kHz

8 kHz 4 kHz2 kHz

250

3dB

250

3dB

Fig. 6-2 Frequency Characteristics

6.3

kHz

1 kHz

500Hz250Hz125

10k

3dB 4dB

10k

3dB

Hz

12.5k

12.5k

5dB

–20 dB

63 Hz 40 Hz

Fig. 6-3 Test Tape STD-331E

6.2.1 Playback Section

(1) Tape Speed Adjustment

No. Mode Input Signal/Test Tape Adjustment Points Measurement Points Adjustment Value Remarks

PLAY1

NCT-111 (3 kHz)

VR2701 (AF Assy)

(Refer to Fig. 6-4)

LINE OUT

(L, R ch)

(AF Assy)

(2) Head Azimuth Adjustment

• This unit is equipped with auto tape selector.

• Do not switch between forward and reverse operation with the screwdriver inserted.

No. Mode Input Signal/Test Tape Adjustment Points

PLAY1

STD-331E

(10 kHz, –20dB)

Head azimuth

adjustment Screw

(Fig. 6-4)

Measurement

Points

LINE OUT

(L, R ch)

(AF Assy)

3000 Hz ±10Hz

Adjustment

Value

Max. Playback

signal level

FWD adjustment

REV Confirmation

( 3000 Hz ± 40Hz )

Remarks

After adjustment, apply silicon

bond to the head azimuth

adjustment screw.

28

Page 29

(3) Playback Level Adjustment

• Since this adjustment determines playback DolbyNR level, Perform it carefully.

Measurement

Points

Adjustment

Value

CT-IS21

RemarksNo. Mode Input Signal/Test Tape Adjustment Points

PLAY1

STD-331E test tape

(Playback: 315 Hz, 0 dB)

L ch

R ch VR2302

VR2301

LINE OUT

(L, R ch)

(AF Assy)

–6.0 dBV

(4) Playback Frequency Characteristics Confirmation

Measurement

Points

PLAY1

STD-331E test tape

LINE OUT

(L, R ch)

(AF Assy)

Adjustment

Value

Check that the frequency

characteristics is within the

range of Fig. 6-2.

6.2.2 Recording Section

(1) Recording Bias Adjustment

• After the adjustment, caution should be exercised so as not to become under bias by checking the distortion rate.

No. Mode Input Signal/Test Tape Adjustment Points

REC/

1

PAUSE

REC =

2

PLAY

Input a 315Hz (–26 dBV) signal to

the LINE INPUT.

Load the STD–632 test tape and

record/playback the 315Hz and

10kHz signals. (see the Note below)

L ch

R ch VR2802

VR2801

Measurement

Points

LINE OUT

(L, R ch)

(AF Assy)

Adjustment

Value

–26 dBV

Repeat adjustment until playback level of

the 10kHz signal is within 0dB ± 0.5dB

from that of the 315Hz signal.

RemarksNo. Mode Input Signal/Test Tape Adjustment Points

Remarks

Note: Set the 10kHz input signal level to the same value as the 315Hz input signal level of step 1.

(2) Recording Level Adjustment

No. Mode Input Signal/Test Tape Adjustment Points

REC/

1

PAUSE

REC =

2

PLAY

Input a 315Hz signal to the LINE

INPUT.

• STD–632 test tape and record/

playback the 315Hz signal.

• DOLBY NR : OFF

Input signal level

L ch

R ch VR2402

VR2401

Measurement

Points

LINE OUT

(L, R ch)

(AF Assy)

(3) Recording Frequency Characteristics Confirmation

No. Mode Input Signal/Test Tape Adjustment Points

REC =

1

PLAY

• STD–632, STD-622 test tape

• Record with –26.0 dBV

• DOLBY NR : ON/OFF

Note : Impedance of LINE IN/OUT are as follows :

• LINE IN : 53 kΩ

• LINE OUT : 2 kΩ

Measurement

Points

LINE OUT

(L, R ch)

(AF Assy)

Adjustment

Value

Remarks

–10 dBV

Repeat recording, playback and

adjustment until playback level of the

315Hz signal becomes –

Adjustment

Value

Check that the frequency

characteristics is within the

range of Fig. 6-2.

10dBV ± 0.5dB

Remarks

.

29

Page 30

CT-IS21

Front

W102

W101

TEST MODE

Jumper

MECHANISM UNIT

U-COM ASSY

SIDE A

TAPE SPEED

VR2701

FWD Azimuth

Adjustment Screw

Front

REV Azimuth

Adjustment Screw

AF ASSY

PB LEVEL

VR2302

(R ch)

SIDE A

VR2301

(L ch)

VR2402

(R ch)

REC LEVEL

BIAS LEVEL

VR2802

(R ch)

VR2401

(L ch)

VR2801

(L ch)

30

Fig. 6-4 Adjustment and Measuring Points

Front

Page 31

7. GENERAL INFORMATION

7.1 DIAGNOSIS

7.1.1 POWER ON SEQUENCE

• STANDBY/ON key is pressed.

• Receive the system power on

information with the sytem bus.

Go to Power ON

CT-IS21

Note : Pin No. shows the Pin No. of µ-COM PDC059A.

Perform the mechanism initialization every time it power on.

(When the AC outlet is pulled out

while raising up the Head Base or

the gear comes off, perform the

initialization every time because the

normal movement can't be done.)

No

Is Tray open ?

Yes

Tray close

200mS WAIT

Is MODE SW

OFF ?

No

SOL 50mS ON

MOTOR ON

150mS WAIT

Yes

(port Pin 2 )

(port Pin 3 )

Check the mecha. switch (port Pin 40 and Pin 41 )

CLOSE Pin 40 = H , Pin 41 = L

OPEN Pin 40 = L , Pin 41 = H

Close it if the tray is opened (port Pin 1 and Pin 47 )

CLOSE Pin 1 = L , Pin 47 = H

OPEN Pin 1 = H , Pin 47 = L

Check that the mecha. is stop

condition (port Pin 17 = L)

MOTOR ON

500mS WAIT

No

Is MODE SW

OFF ?

No

Is it fifth

times ?

No

Is MODE SW

OFF ?

Yes

300mS WAIT

MOTOR OFF

END

Yes

:ERROR

(port Pin 3 )

Yes

ERROR

Is it second

times ?

Yes

:Give up

Initialize end

Deck motor off

(port Pin 3 = L)

No

31

Page 32

CT-IS21

7.1.2 DISASSEMBLY

FRONT PANEL

3

Bonnet IS

MAIN ASSY

1

×3

MAIN Assy

7

CN2051

3

×4

U-COM Assy

1

×4

9

4

6

AF Assy

2

About

30°

2

Deck Mechanism

Unit

REG. Assy

8

CN2302

5

AF Assy

CN2601

Unhook

CN2301

Rear Panel IS

MAIN Assy

(SIDE B)

10

4

6

AF Assy

8

5

×2

7

Unhook

Note : These screws are loosened.

Connect the above connectors.

Then, diagnose the MAIN Assy.

32

Page 33

CT-IS21

No. Pin Name I/O Pin Function No. Pin Name I/O Pin Function

1 TIN O Loader mechanism motor close 25 POFF I AC input detection

2 SOL O Solenoid control 26 S.R/E I/O System bus request

3 XMOTOR O Cassette mechanism motor control 27 S.DOUT O System bus output data

4 S.CLK I System bus clock 28 S.DIN I System bus input data

5 XRESET I Reset input 29 NC − Not used

6 E+5V I Connect to VDD 30 AM56 I System 5.6 input

7NC − Not used 31 XTEST I Test mode detection input

8 E+5V I Connect to VDD 32 POWER O Power control

9 GNDD − GND 33 LINEMUTE O Line mute control

10 6MHz I

Connect a crystal resonator

34 LEDDATA O IC DATA output for LED control

11 6MHz O 35 LEDCE O IC OK output for LED control

12 E+5V − Power supply +5V 36 LEDCLK O IC output for LED control

13 KEY1 I

AD key data input

37 PB MUTE O CLK (Not used)

14 KEY2 I 38 MODEL I Model switch input

15 MS I MS audio signal input 39 DOLBY O DOLBY NR control

16 SENSE I Sensing pulse input 40 XOPEN I Loader mechanism open SW control

17 XMODE I Cassette mechanism mode SW input 41 XCLOSE I Loader mechanism close SW input

18 NC − Not used 42 NC − Not used

19 XRECR I REV REC detection SW input 43 PB/XREC O DOLBY PB/REC control

20 XCrO

2

(SW) I CrO2 position detection SW input 44 RECMUTE O REC MUTE control

21 XHALF I Tape detection SW input 45 XCrO

2

O Normal / CrO2 control

22 NC 0 Non connection 46 BIAS O BIAS control

23 XRECF I FWD REC detection SW 47 TOUT O Loader mechanism motor open

24 NC − Not used 48 NC − Not used

7.2 PARTS

7.2.1 IC

• The information shown in the list is basic information and may not correspond exactly to that shown in the schematic diagrams.

PDC059A (U-COM ASSY : IC2501)

• System Microcomputer

Pin Function

•

33

Page 34

CT-IS21

8. PANEL FACILITIES AND SPECIFICATIONS

PANEL FACILITIES

34

Page 35

Accessories

System Cable ×1

(ADE7032)

RCA Pin-plug Stereo Cable ×2

(ADE7034) (L=50 cm)

White

Red

1 STANDBY/ON button and standby indicator

This is the power switch.

ON : When set to the ON position, power is supplied and the

STANDBY : When set to the STANDBY position, the main power flow

unit becomes operational.

is cut and the unit is no longer fully operational. A min ute

flow of power feeds the unit to maintain operation readiness.

Energy-Saving Design

This product has been designed to reduce energy consumption when the unit is in the power off (standby)

mode.

¶ Consult the Specifications for the power consumption

in standby mode.

NOTE:

When the Stereo Cassette Deck CT-IS21 is connected to

the XC-IS21MD or XC-IS21T via the system cable, the unit’ s

power will be switched on/off (standby) automatically by

operating the ST ANDBY/ON b utton of either of the connected

units.

2 Recording-pause button (¶8)

3 REC (recording) indicator

4 ASES button

5 Play indicator

6

Play buttons and direction indicators

(2, 3)

7 Reverse mode indicators

8 Fast forward/re ver se b uttons( 1, ¡)

9 Cassette tray

0 OPEN/CLOSE button (0)

- STOP button(7)

= DOLBY* NR button and indicator

*

¶

Dolby noise reduction manufactured under license from

Dolby Laboratories Licensing Corporation.

¶

“DOLBY” and the double-D symbol are trademarks of

Dolby Laboratories Licensing Corporation.

~ REVERSE MODE button

CT-IS21

SPECIFICATIONS

System ......................................................4-track, 2-channel stereo

Heads.................................................................... “Har d Permalloy”

recording/playback head × 1

“Ferrite” erasing head × 1

Motor ................................................................ DC servo motor × 2

Wow and Flutter........................................................*0.1% (WRMS)

Frequency Response

–20 dB recording:

TYPE II (High/CrO2) tape.............. *35 Hz to 15,000 Hz ±4 dB

TYPE I (Normal) tape ...................*35 Hz to 14,000 Hz ±4 dB

Signal-to-Noise Ratio

Dolby NR OFF............................................................. *55 dB

(peak recording level, audible compensation TYPE II)

Noise Reduction Effect

Dolby NR ON .......................... 10 dB compensation at 5 kHz

Input (Sensitivity)

REC ...................................100 mV (Input impedance 53 kΩ)

Output (Reference lev el)

PLAY ..................................... 0.5 V (Output impedance 2 kΩ)

Pow er Requirements

NV type ............................................................. AC 230 V, 50/60 Hz

MY type ................................................... AC 220 ~ 230 V, 50/60 Hz

RBD type ................................................ AC 110 ~ 127/220 ~ 240 V

(switchable), 50/60 Hz

Power Consumption ................................................................ 12 W

Power Consumption in standby mode........................................ 3 W

Dimensions...................................... 210 (W) × 75 (H) × 290 (D) mm

Weight (without package) ....................................................... 2.6 kg

* Values measured in accordance with EIAJ standards.

Accessories

Operating instructions

NV type ..........................................................................................1

MY type ..........................................................................................2

RBD type ........................................................................................1

RCA pin-plug stereo cable ..............................................................2

System cable ..................................................................................1

NOTE:

Specifications and design subject to possible modifications without

notice, due to improvements.

35

Loading...

Loading...