Page 1

efiic

CASSETTE TAPE DECK

n

Page 2

MODEL

I

Type

CT-F950 COMES

I

IN

Voltage

SIX

VERSIONS

DISTINGUISHED

I

AS

FOLLOWS:

Remarks

I

I

I

KC

I

HE

I

HB

D

DIG

0

This service manual

refer to the additional service manuals

1

I

I

AC

120vonly

AC 120v only

AC 220V and 240V (Switchable)

AC 220V and 240V (Switchable)

AC 120V. 220V and 240V (Switchable)

AC 120V. 220V and 240V (Switchable)

is

applicable to the CT.F950/KU . For servicing of the other types. please

.

I

U.S.A. model

I

Canada model

1

Europe model

I

United Kingdom

General export model

U.S. Military model

model

CONTENTS

1 . SPECIFICATION

2

.

FRONTPANEL FACILITIES

.

LEVEL DIAGRAM

3

4 . DISASSEMBLY

.

PARTS LOCATION

5

6

.

BLOCKDIAGRAM

.

CIRCUIT DESCRIPTIONS

7

7.1 Recording and playback circuit

7.2 Tape selector circuit

7.3 Level meter

7.4 Electronic counter 16

7.5 Dolby NR processor circuit 17

7.6 Control circuit

7.7 Mutingcircuit

.

MECHANICAL ADJUSTMENTS 12.1 Miscellaneous parts

8

8.1 Pinch roller pressure adjustment

8.2 Tape speed adjustment

8.3 Tape guide adjustment

9 . ELECTRICAL ADJUSTMENTS 12.5 Mother assembly (RWX-359)

9.1 Head azimuth adjustment

9.2 Playback equalizer adjustment

9.3 Playback

9.4 Level meter OdB adjustment

9.5 Approximate adjustment

9.6 Erasure current adjustment

9.7 Bias trap adjustment 33

9.8 Approximate adjustment

recording current

recording bias

.....................

.............

....................

......................

...................

...................

.......

..............

....................

...............

.........

..................

..................

......

............

.............

...........

.......

level

adjustment

..........

.........

of

.................

..........

..............

..................

of

3 9.9 Recording equalizer and variable

4

6

8

11

13

15

15

16

18

27 PATTERNS AND PARTS LIST

30 12.2 Connection diagram

30 12.3

30

31 12.6

32 12.7 Sensing assembly

32 12.8 Indicator assembly

32 12.9

33

33

9.1

9.1 1 Recording

9.12 Output

9.13 Recording dolby

9.14 Playback dolby NR adjustment 36

.

PACKING

10

.

EXPLODED

.

SCHEMATIC DIAGRAMS

12

.

34

.

13

equalizer adjustments

0

Recording and playback frequency

response adjustment 34

level

level

adjustment

..........................

11.1 Exterior

11.2 Mechanism assembly 45

11.3 Panel stay 48

Schematic diagram

12.4 Function switch assembly

Volume assembly

Indicator amplifier assembly

12.10 Integrated amplifier assembly (RWX.360) . 71

12.1 1 Power supply assembly(RWR.067)

12.12 Control assembly(RWG.103)

12.13

12.14 Tape selector assembly

12.1

TROUBLE SHOOTING

REC

5

Fuse assembly

......................

.....................

EQassembly(RWX-361) 81

.............

..............

adiustment

............

NR

adjustment

..............

P.C.

BOARD

list

............

..............

...............

................

................

...............

..................

.................

......

......

.......

..........

.........

(RWX-328) . 67

.....

.........

........

.......

.....

I

I

I

I

34

35

36

36

41

42

50

51

54

57

58

63

63

64

73

77

83

84

85

Page 3

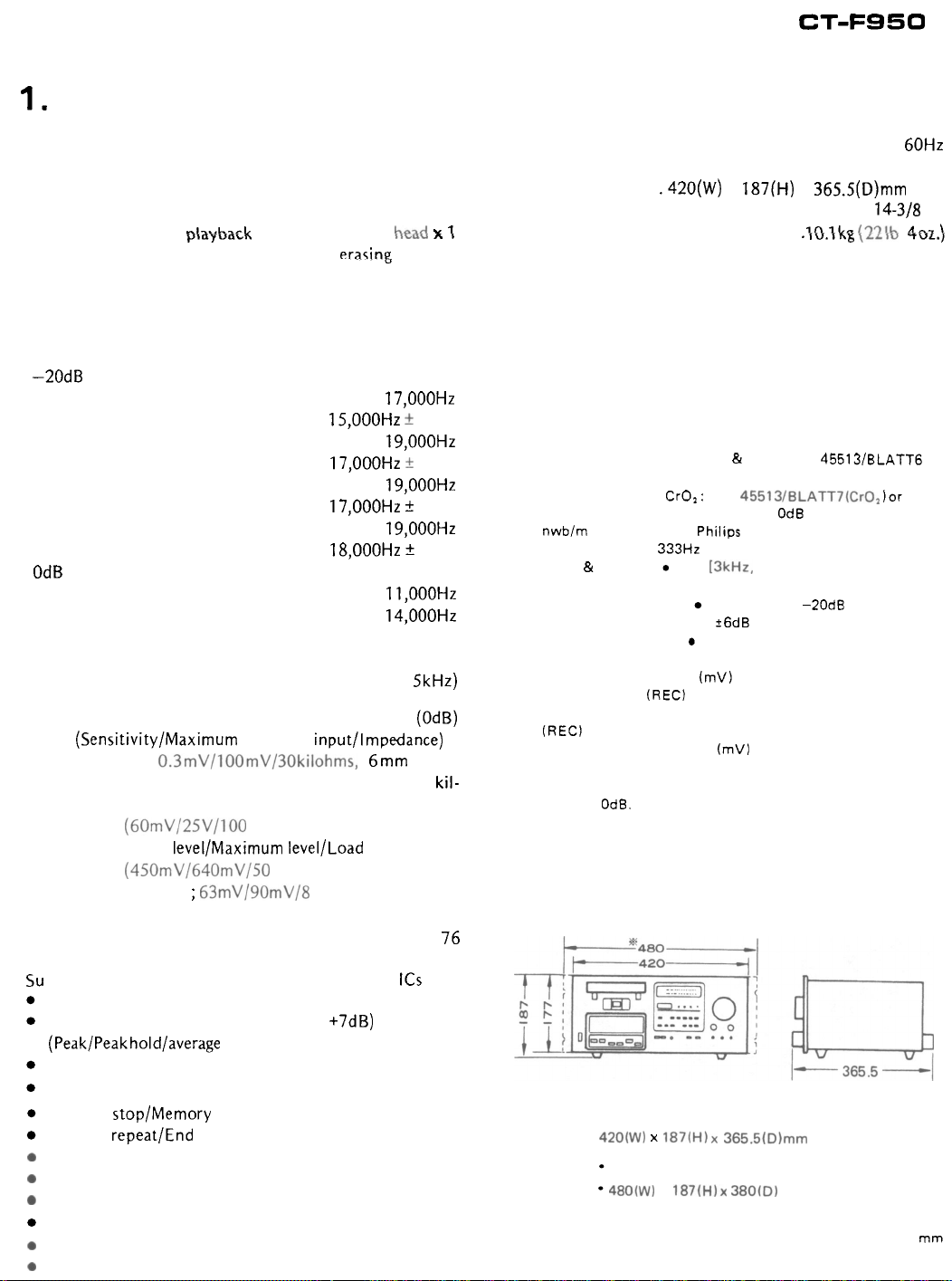

1.

SPECIFICATION

CT-F950

Systems

Motors..

............

...........

Compact cassette, 2-channel stereo

Capstan drive; DC servo motor

Reel drive; DC high torque motor x 1

Heads

.........................

phyback combination

Ferrite recording/

type

head

Praqing head

Fast Winding Time.

Wow and Flutter

..........

.........

Approximately

85

seconds

(C

-

60 tape)

No more than 0.04% (WRMS)

Frequency Response

-20dB Recording

Standard, LH tapes

..............

20

to 17,000Hz

(25 to 15,000Hz * 3dB)

Ferrichrome tape

...............

Chromium dioxide tape

(25

...........

20 to 19,000Hz

to

17,000Hz 2 3dB)

20 to 19,000Hz

(25 to 17,000Hz t 3dB)

Metal tape

...................

.20 to 19,000Hz

(25 to 18,000Hz t 3dB)

OdB Recording

Chromium dioxide tape

Metal tape

Signal-to

...................

-

Noise Ratio. . Dolby NR OFF; More than 59dB

...........

20

to 11,000Hz

.20

to 14,000Hz

Dolby NR ON; More than 69dB

(over 5kHz)

Harmonic Distortion

.........

No more than 1.2% (OdB)

Inputs (Sensitivity/Maximum allowable input/lmpedance)

MIC (L, R); 0.3mV/100mV/30kilohms, 6mm diam.

jack (Reference MIC impedance; 250 ohms to 30

ohms)

LINE

x

2; (60mV/25V/100 kilohms) Pin jack

Outputs (Reference

x

LINE

2; (450mV/640mV/50 kilohms) Pin jack

HEADPHONES x

level/Maximum level/Load impedance)

1

;

63mV/90mV/8 ohms, 6mm diam.

jack

Semiconductors

.....................

Transistors x 76

Diodes x 84, Photo interrupter

Su bfunctions

ICS

Dolby NR system (ON-OFF) with LED indicator lamp

Fluorescent tube level meter

(-20

to +7dB)

(Peak/Peakhold/average selector)

Fluorescent tape counter

Bias fine adjusting control knob

Memory stop/Memory play

Counter repeat/End repeat

0

Input selector

0

Automatic tape slack canceller

0

Cassette compartment illumination

Standby mechanism with unattended recording

0

Tape Selector 4 position.

0

Click Stop. Output VR.

x

x

x

x

kil-

x

13

Power Requirements

1

1

1

Power Consumption

Dimensions

Weight

......

.........................

Furnished parts

................. AC 120V 60Hz

......................

.420(W) x 187(H) x 365.5(D)mm Max.

16

-

9/16 x 7-3/8 x 14-318 in.

.\O.\kg

Stereo connecting cords

Head cleaning swabs

Operating instructions x

.54 watts

{22\b

4ozz.)

with

pin plugs x

2

x

3

1

NOTE:

Specifications and the design subject to possible modifi

-

cation without notice due to improvements.

NOTES:

1. Reference Tapes: Standard

equiv.

:

2. Reference Recording Level: Meter

nwb/m magnetic level = Philips cassette reference level)

3. Reference Signal:

4. Wow

5.

6. Signal

7.

8.

9.

10.

81

Flutter:

(weighted), rms value]

Frequency Response: Measured at -20dB level, DOLBY

NR

OFF,

level deviation

to

Noise Ratio: 0 Measured at the third harmonic distor

tion 3% level, weighted.

Sensitivity: Input level (mV) required for reference recording

level with input

Maximum Allowable Input: While decreasing settings of input

(REC) level controls and increasing level at input jacks, this

the

maximum

amplifier output waveform becomes clipped.

Reference Output Level: Playback output level when meter

indicates

Maximum Output Level: Playback

reference recording level when

are

set

OdB.

to

maximum.

CrO,: DIN 45513/BLATT7(Cr02 )or equiv.

333Hz

(REC)

input

&

LH: DIN 45513/BLATT6 or

OdB indicating level (160

JIS

[BkHz, with acoustic compensation

is

26dB without indication.

controls set

level (mV) at the point where recording

to

maximum.

output

output

level with respect

(PLAY) level controls

-

is

to

1

420(W) x 187(H)x 365.5(D)mm Max.

with rackmount adaptor JA-R102

480(W) x 187(H)x 380(D)

mm

Max,

Unit:

mm

Page 4

2.

FRONT PANEL FACILITIES

@POWER SWITCH

The power comes on when the POWER switch

level meter and tape counter, and the cassette compartment

illumination will then come on.

is

depressed. The

@DUST COVER

When you are not using the deck, always keep this cover in place

to prevent dust and dirt from adhering to the head section and

rotating parts.

@REMAINING TAPE MARKER

If

this marker

ina for several minutes of recording or playback.

is

visible,

it

means that there

is

enough tape remain-

@INPUT (RECORDING LEVEL) CONTROLS

Use these to adjust

jacks or rear panel INPUT jacks.

Turning these controls to the right increases the level.

The controls are coupled to the left and right channels, but

you

can also

the left channel (front) independently.

the

level

of

the input signals from the

use

them to adjust the right channel (back) and

@OUTPUT (PLAYBACK LEVEL) CONTROLS

Use these to adjust the output signal level during playback. Turn

ing the controls to the right increases the level. The controls are

coupled when turned but it

channel (back) and the

When playing back

playback level

click stop position.

(OdB)

a

is

is

left

reference tape

obtained with these controls

also possible to adjust the right

channel (front) independently.

(160

nwb/m), a reference

set

to the

@TAPE SELECTOR

This selector allows the bias and equalizer characteristics to be

selected during recording and the equalizer characteristics during

playback in line with the type of tape you are using.

METAL: For using metal tapes

LH

STD:

CrO,: For using chrome tapes

Fe

For using ordinary or

-

Cr: For using ferrichrome tapes

tapes

@MlC JACKS

These are the input jacks for microphone recording. Plug the

channel microphone into the L jack and the right channel micro

phone into the R jack.

@HEADPHONES JACK

This is the output jack for your stereo headphones. You will

able to hear sound from signals selected by the MONITOR switch

es.

Use this jack when

recording or when

CT-FgSO. Adjust the output level with the

NOTES:

Use low-impedance headphones.

Y

O

model,

You

HEADPHONESjack by mistake.

U

will damage tht. microphone

BINPUT SELECTOR SWITCH

Use this switch to select the program source which you intend to

MIC

-

"6"

record.

LINE:

MIC:

NOTE:

LINE switch is depressed euen when the microphones are

plugged into the

Set

which

Set

phone, or microphones, connected to the MIC jacks.

You

will be able to record signals from the INPUT jacks

@DOLBY* NR SWITCH

Set

this switch to ON for recording with the built-in

reduction system and for the playback of tapes which have been

recorded using the Dolby

@BIAS CONTROL

Use this control to adjust the bias in accordance with the

characteristics of the tape being used.

(click stop) position corresponds to the standard bias.

@MONITOR SWITCHES

You will be able to listen to the recorded signals (playback sound)

if

you

depress the TAPE

left

You will be able to listen to the signals (recording input) just

before they are recorded if you depress the SOURCE. Use these

switches to monitor your recording. Depress the TAPE during

-

play back.

you

want to monitor the quality

want to listen to a tape privately on the

you

OUTPUT

If

you

will not be able to obtain sufficient volume.

to this position for recording a program source

is

connected to the rear panel INPUT jacks.

to this position for recording signals from a micro

MIC

jacks.

NR

system.

while you are recording a program.

use a high-impedance

if

you

It

is

plug

set

so

that the center

controls.

it

into the

Dolby

of

if

the

noise

be

-

a

-

*Manufactured under license from Dolby Laboratories.

OD

*Dolby and

are trademarks

of

Dolby Ldboratorie5.

Page 5

CT-FS50

I

1

3-HEAD

I

CLOSED

2

LOOPDUAL CAPSTAN

MOTOR TAPE TRANSPORT

L

SYSTEM

@OPE RAT1 NG SWITCH ES

II

(REW):

W

(FF):

I

(STOP):

b

(PLAY):

REC:

PAUSE

:

NOTES’

When any

responding indicator (except

signifying that the deck is set to that respective mode.

*All

the operating switches are released

when the

Depress this switch to rewind the tape. (The tape

will travel at high speed from right to left.)

Depress this switch to send the tape forward at

high speed. (The tape will travel from left to

right.)

Depress this switch to stop the tape run and to

release

the operating switches.

Depress this switch when playing back

(The tape will travel from left to right.)

Depress this switch together with the PLAY

switch for recording.

This switch will not

loaded or when the erasure prevention tabs of

loaded cassette have been broken off.

Depress this switch to stop the tape temporarily

during recording or playback.

allow the tape

of

the operating switches ore depressed. the cor

POWER

switch

is

work when a cassette

tc continue to travel

STOP

turned

OFF.

Depres5 it again to

mode) will come

(OFF)

as

to

@COUNTER RESET BUTTON

Depress this button to reset the tape counter display to

Q

TAPE

COUNTER

This indicates the position

“000”

when the power is switched on.

of

the tape run. The counter reset to

@LEVEL METER

This indicates the input level during recording and the output level

during playback.

By

operating the METER switches, it can be made to function

as a peak meter, a peak hold meter or as a level meter.

The input signal level

SOURCE has been depressed, and the

indicated when the MONITOR switch TAPE has been depressed.

@DOLBY

This lights up when the DOLBY NR switch

indicates that a tape

Dolby NR system.

NR

is

indicated when the MONITOR switch

playback‘output level

INDICATOR

is

being recorded or played back with the

is

set to

@TAPE INDICATORS

METAL: This light comes on when the TAPE selector is

CrO,: This light comes on when the TAPE selector is

METAL.

CrO,.

7

a

tape.

is

not

before.

on

stop mode

“000.”

ON

and it

set

to

set

to

@+-\I

s

.....

...............

0

@

MEMORY/REPEAT INDICATOR

This indicator comes on when the MEMORY/REPEAT switches

are

depressed, signifying that the deck

mode.

@MEMORY/REPEAT SWITCHES

:

MEMORY

a

REPEAT

COUNTER:

-

@METER SWITCHES

PEAK:

PEAK

AVERAGE:

@TIMER START SWITCHES

Depress these switches when

tape with the use of a timer.

REC:

is

PLAY:

OFF:

Depress this switch and the tape will be rewound to

STOP

that spot at which the tape counter was preset to

“000”

during rec/play, when the REW switch

depressed at any position

PLAY:

Depress this switch and the tape will be rewound to

that spot at which the tape counter was preset to

“000”

during rec/play, and playback will start from

that spot, when

position

tape during playback or recording from the point

end of the tape.

END:

OFF:

recording to release the MEMORY and REPEAT

switches.

HOLD:

When this switch is depressed, the deck will autom2tical-

ly

be

and recording will begin, Use

FM programs when

wise occupied.

When this switch

ly

be

and playback will begin. Use this switch for wake

playback instead of an alarm clock.

Always depress

record or playback

release the REC and PLAY switches of TIMER

START.)

you

like.

Depress this switch when

which the tape counter was

Depress this switch when

tape from the beginning to the end of that tape.

Depress this switch during normal tape playback or

The meter functions

this switch is depressed.

The meter functions as a peak level meter and

the highest level of

this switch

The meter functions

switch

set

to the recording mode at the preset timer time,

set

to the playback mode at the preset timer time,

is

is

depressed.

is

depressed, the deck will automatical

this

............

I!)

0

is

set

to the respective

you

like.

the

REW switch

as

the

depressed.

you

as

are playing back or recording

you

are

switch when

a

tape using the timer. (This will

is

depressed at any

you

want to play back

set

to

“000”

up to the

you

want to play back

a peak level meter when

signals

is

indicated when

a level meter when this

this

switch for recording

out

of the house or other

you

do not intend to

is

a

at

a

a

-

-

-

up

Page 6

3.

LEVEL

PLAYBACK

DIAGRAM

-60-

-80-

-?4dBV

(0.2mV)

-36dBV

PB AMP Gain

49dB

1

VR Loss

I

IdB

Note;

.

OdBV=IV

. Frequency

:

333Hz

Page 7

RECORDING

MIC

!I?

-

20

I

I

I

I

I

I

I

LINE

MIC

IICAMP

A

6

I

VR

1201-1

I

>

m

0

-

J

W

>

W

J

-

-

-

0

20

40

60

-

I

i

IOdBV

(0.31V)

-

'R

Max.

-245

dBV

59.5rnk

60dBV

IrnV)

-

?OdE\r

0.32mk

I

I

I

I

-32dBV (25.lmV)I

VR

Max.

.42dBV -42dBv

(7.9 m V) (7.9 m\

MIC

28

I

I

I

I

I

I

I

I

I

I

I

__

AMP Gain

dB

I

!R

Max.

-

7dBV

(

0.4

LINE AMP Goin

40dE

VR

Loss

I

OdB

DOLBY iMP

4

V)

Gain

4dB

VRLasr

2368

I

I

I

-26dBV

(50.lrnV)

I2.dB

1

OdBV= IV

Frequency

:

333Hx

Page 8

4.

DISASSEMBLY

External

1,

Remove the bonnet by undoing screws 0 to

2.

Remove the front. panel by undoing screws

@to

3.

Remove the bottom plate by undoing screws

CD

CD.

to

Components

a$.

0.

4.

The function switch assembly is mounted onto

the chassis by means of rubber bushes. Remove

it by gently raising it up.

Fig.

4-1

Disassembly

of

exterior parts

i

Q

Page 9

CT-FS

5

0

Mechanical Assembly

After removing the front panel, undo screws

OtoO.

0

Fig.

Sub-head Assembly, Pinch-roller Arm Assembly

and Pressure Arm

1.

Remove the sub-head base assembly by undoing

screws

bolt.

2.

Remove the feed side pinch-roller arm assembly

by loosening the height adjuster (unt).

3.

Remove the take-up side pinch-roller arm

assembly by taking off E

4.

Remove the pressure arm by taking

0

When the pinch pressure spring is replaced

with a new one, take care to ensure that the

Remove the mechanism assembly

4-2

0

and @ and the socket-head hexagonal

-

washer

0.

off E-

washer

new spring

of the sub

adjustments” (Page

is

properly seated. The requirements

-

section entitled “Pinch roller pressure

30)

included in the section

“Mechanical adjustments” shall be satisfied.

Fluorescent Indicator Tube

1.

Remove the indicator lens assembly by undoing

screwsOtoO.

2.

Remove the indicator amplifier assembly by

8

to

undoing screws

3.

The fluorescent indicator tube is mounted on

@.

the indicator assembly. Remove it by means of

a soldering iron.

the indicator tube

Indicator assembly

Fig.

Remove the fluorescent indicator tube

4-3

Take great care when handling

so

as

to avoid damaging it.

n

Indicator amplifier assembly

Indicator lens assembly

I

Pinch-roller arm assembly

B

Height adjuster (nut)

Socket

Remove the sub-head assembly, pinch-roller arm assembly and pressure arm

4-4

Fig.

-

head

P

Pinch

-

roller arm assembly

Page 10

Mechanical

Assembly

When replacing a motor or a belt, be careful

the sequence of disassembly and reassembly

various components concerned.

1.

Remove the capstan motor by undoing screws

\Oto

0.

2.

Remove solenoid A by undoing screws

0

to

of

of

the

0.

3.

Remove the plunger chassis assembly by undoing

@to

screws

4.

Remove the sub-chassis assembly by undoing

screws

5.

Remove the take-up motor by undoing screws

CD

and

screws

Sub-chassis assembly

Q).

CD

to

@.

(D,

and remove solenoid B by undoing

@

and

@.

UL

cord clamper

Fig.

4-5

D

Disassembly

of

mechanism assembly

Supply pulley assembly

Loading...

Loading...