Page 1

CU-V163

CMX-3000

COMPACT DISC PLAYER

CMX-3000

REMOTE CONTROLLER

CU-V163

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

Type

CMX-3000 CU-V163

Model

Power Requirement

Remarks

ORDER NO.

RRV2537

KUCXJ ‡ -

WYXJ

RLBXJ

‡ ‡ -

- ‡

AC120V

AC220- 240V

AC110-120V/ 220-240V

DC Power supply from other system

CONTENTS

1. SAFETY INFORMATION

2. EXPLODED VIEWS AND PARTS LIST

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM 12

4. PCB CONNECTION DIAGRAM

5. PCB PARTS LIST

6. ADJUSTMENT

For details, refer to "Important symbols for good services" on "service information".

................................................

.....................................................

.......................................

.................

...........................

2

5

35

50

55

7. GENERAL INFORMATION

7.1 DIAGNOSIS

7.1.1 SERVICE MODE

7.1.2 STARTING SEQUENCE

7.1.3 DISASSEMBLY

7.2 PARTS

7.2.1 IC

8. PANEL FACILITIES AND SPECIFICATIONS

...................................................

..........................................................

...........................................................

..................................

...................................

........................

.....................................

.......

57

57

57

62

63

68

68

82

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION 2001

T – ZZY NOV. 2001 Printed in Japan

Page 2

CMX-3000, CU-V163

1. SAFETY INFORMATION

This service manual is intended for qualified service technicians; it is not meant for the casual

do-it-yourselfer. Qualified technicians have the necessary test equipment and tools, and have been

trained to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

WARNING

This product contains lead in solder and certain electrical parts contain chemicals which are known to the state of California to

cause cancer, birth defects or other reproductive harm.

Health & Safety Code Section 25249.6 – Proposition 65

NOTICE

(FOR CANADIAN MODEL ONLY)

Fuse symbols (fast operating fuse) and/or (slow operating fuse) on PCB indicate that replacement parts

must be of identical designation.

REMARQUE

(POUR MODÈLE CANADIEN SEULEMENT)

Les symboles de fusible (fusible de type rapide) et/ou (fusible de type lent) sur CCI indiquent que les

pièces de remplacement doivent avoir la même désignation.

(FOR USA MODEL ONLY)

1. SAFETY PRECAUTIONS

The following check should be performed for the

continued protection of the customer and service

technician.

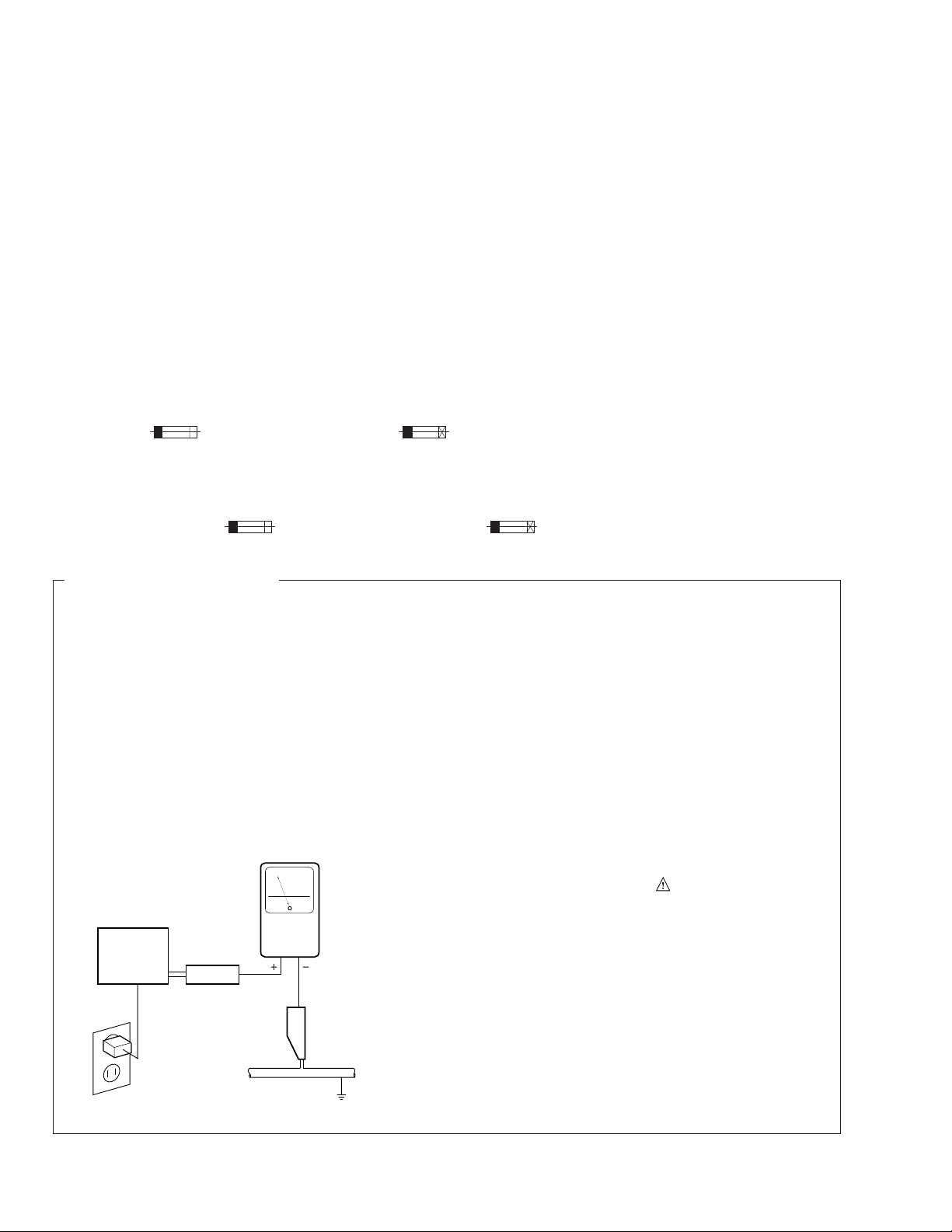

LEAKAGE CURRENT CHECK

Measure leakage current to a known earth ground

(water pipe, conduit, etc.) by connecting a leakage

current tester such as Simpson Model 229-2 or

equivalent between the earth ground and all exposed

metal parts of the appliance (input/output terminals,

screwheads, metal overlays, control shaft, etc.). Plug

the AC line cord of the appliance directly into a 120V

AC 60 Hz outlet and turn the AC power switch on. Any

current measured must not exceed 0.5 mA.

Reading should

not be above

0.5 mA

Earth ground

Device

under

test

Also test with plug

reversed

(Using AC adapter

plug as required)

Leakage

current

tester

Test all exposed

metal surfaces

AC Leakage Test

ANY MEASUREMENTS NOT WITHIN THE LIMITS

OUTLINED ABOVE ARE INDICATIVE OF A POTENTIAL SHOCK HAZARD AND MUST BE CORRECTED BEFORE RETURNING THE APPLIANCE

TO THE CUSTOMER.

2. PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in the appliance have special safety related characteristics. These

are often not evident from visual inspection nor the

protection afforded by them necessarily can be obtained by using replacement components rated for

voltage, wattage , etc. Replacement parts which have

these special safety characteristics are identified in

this Service Manual.

Electrical components having such features are

identified by marking with a

on the parts list in this Service Manual.

The use of a substitute replacement component which

does not have the same safety characteristics as the

PIONEER recommended replacement one, shown in

the parts list in this Service Manual, may create shock,

fire, or other hazards.

Product Safety is continuously under review and

new instructions are issued from time to time. For

the latest information, always consult the current

PIONEER Service Manual. A subscription to, or additional copies of, PIONEER Service Manual may be

obtained at a nominal charge from PIONEER.

on the schematics and

2

Page 3

CMX-3000, CU-V163

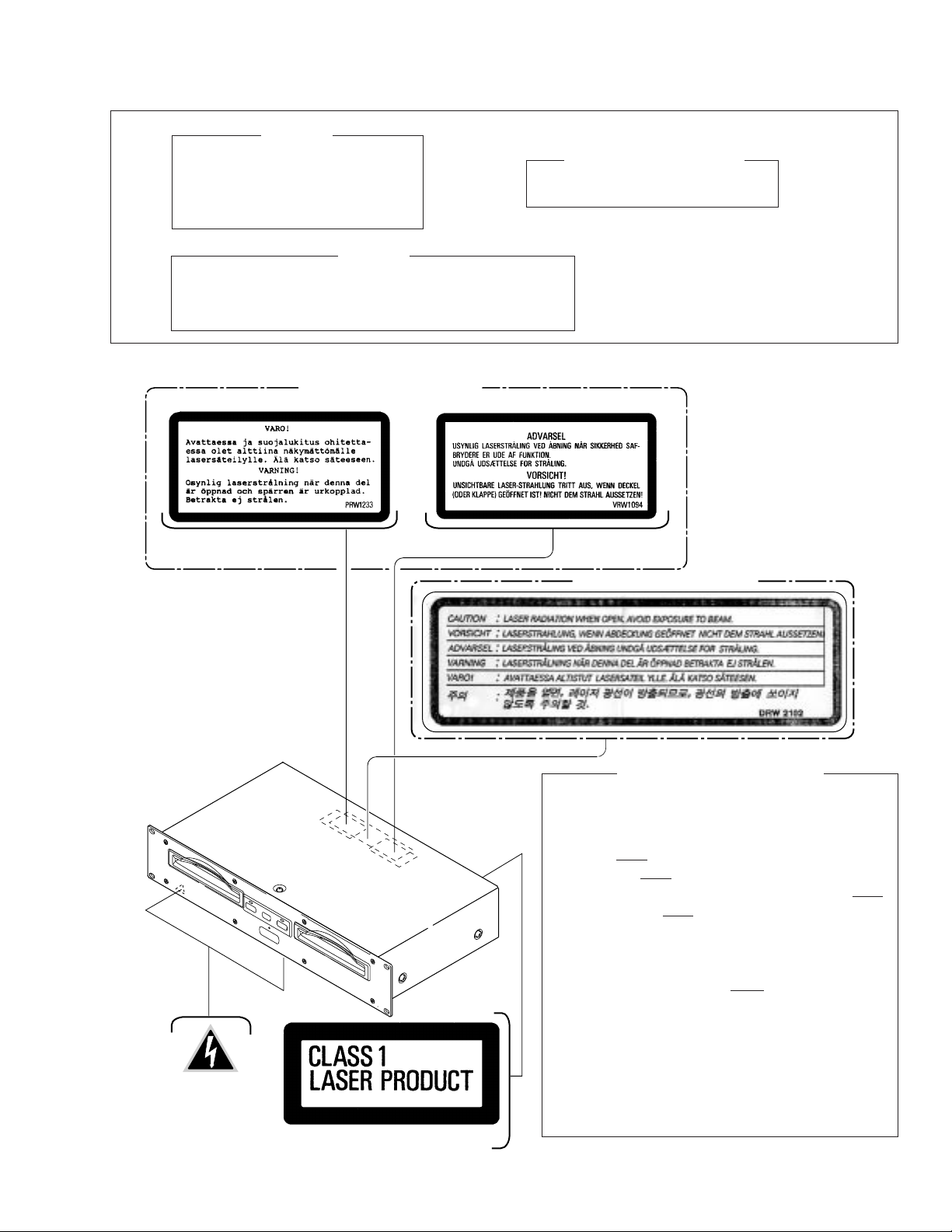

THIS PIONEER APPARATUS CONTAINS

LASER OF CLASS 1.

SERVICING OPERATION OF THE APPARATUS

SHOULD BE DONE BY A SPECIALLY

INSTRUCTED PERSON.

The AEL(accessible emission level) of the laser power output is less then CLASS 1

but the laser component is capable of emitting radiation exceeding the limit for

CLASS 1.

A specially instructed person should servicing operation of the apparatus.

LABEL CHECK

IMPORTANT

LASER DIODE CHARACTERISTICS

MAXIMUM OUTPUT POWER: 5 mW

WAVELENGTH: 780 – 785 nm

WARNING !

CMX-3000/ WYXJ type Only

CMX-3000/ RLBXJ type Only

CMX-3000/ KUCXJ type Only

Printed on the Rear Panel.

Additional Laser Caution

1. Laser Interlock Mechanism

The position of the switch (S801,S901) for detecting loading

completion is detected by the system microprocessor, and

the design prevents laser diode oscillation when the switch

is not in LPS1 terminal side (when the mechanism is not

clamped and LPS1 signal is high level.) Thus, the interlock

will no longer function if the switch is deliberately set to LPS1

terminal side. ( if LPS1 signal is low level ).

In the test mode∗ the interlock mechanism will not function.

Laser diode oscillation will continue, if pin 9 of TA2153FN

(IC1010, IC1003) on the MAIN ASSY is connected to GND,

or pin 10 of IC1010, IC1003 (LDON) is connected to low

level (ON), or else the terminals of Q1003, Q1229 are

shorted to each other (fault condition).

Note: S801, IC1010 and Q1003 (Player A Side)

S901, IC1003 and Q1229 (Player B side)

2. When the cover is opened, close viewing of the objective

lens with the naked eye will cause exposure to a Class 1

laser beam.

∗ : Refer to page 55.

3

Page 4

CMX-3000, CU-V163

SERVICE INFORMATION

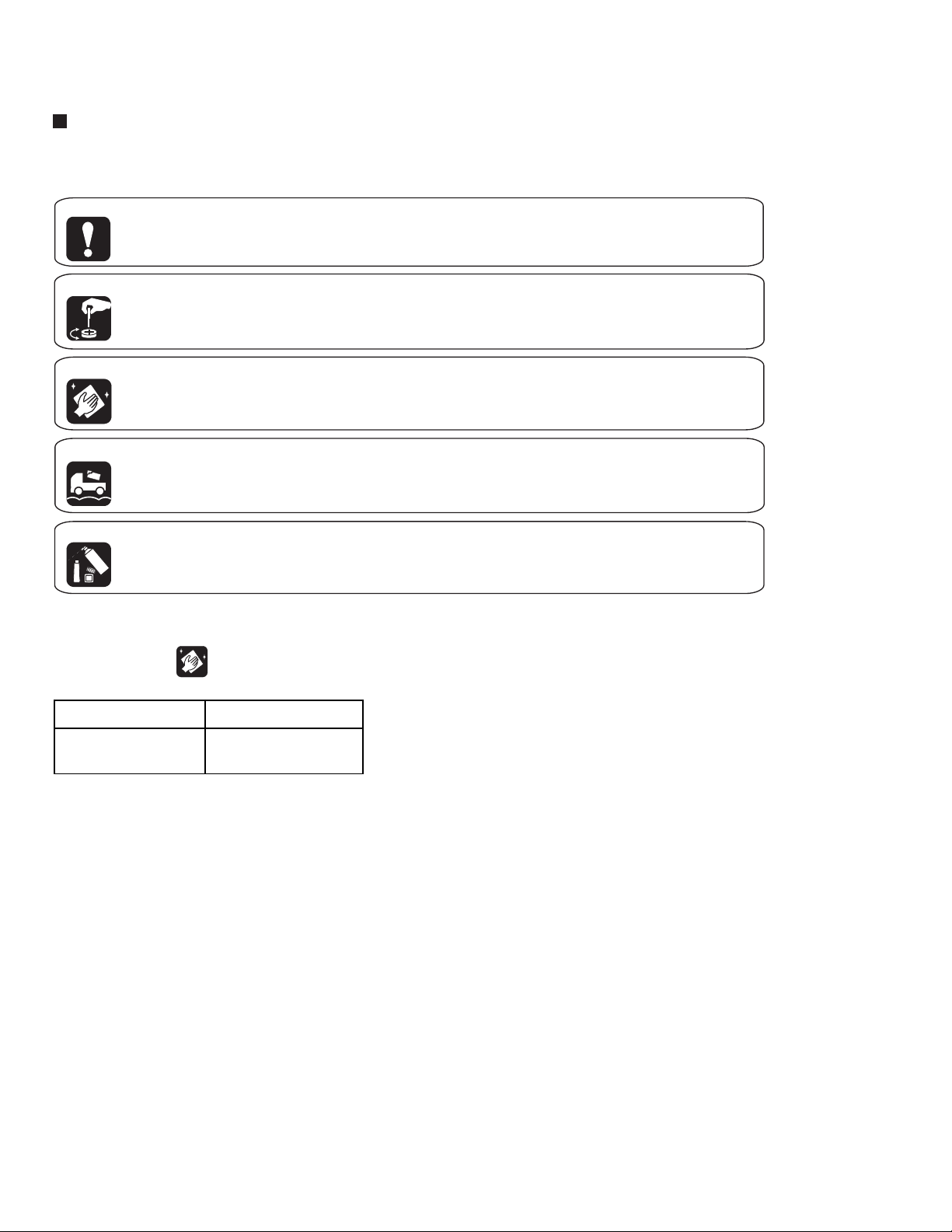

[ Important symbols for good services ]

In this manual, the symbols shown-below indicate that adjustments, settings or cleaning should be made securely.

When you find the procedures bearing any of the symbols, be sure to fulfill them:

1. Product safety

You should conform to the regulations governing the product (safety, radio and noise, and other regulations), and

should keep the safety during servicing by following the safety instructions described in this manual.

2. Adjustments

To keep the original performances of the product, optimum adjustments or specification confirmation is indispensable.

In accordance with the procedures or instructions described in this manual, adjustments should be performed.

3. Cleaning

For optical pickups, tape-deck heads, lenses and mirrors used in projection monitors, and other parts requiring cleaning,

proper cleaning should be performed to restore their performances.

4. Shipping mode and shipping screws

To protect the product from damages or failures that may be caused during transit, the shipping mode should be set or

the shipping screws should be installed before shipping out in accordance with this manual, if necessary.

5. Lubricants, glues, and replacement parts

Appropriately applying grease or glue can maintain the product performances. But improper lubrication or applying

glue may lead to failures or troubles in the product. By following the instructions in this manual, be sure to apply the

prescribed grease or glue to proper portions by the appropriate amount.For replacement parts or tools, the prescribed

ones should be used.

[ NOTES ON SERVICING ]

7 CLEARNING

Before shipping out the product, be sure to clean the following positions by using the prescribed cleaning tools:

Position to be cleaned Cleaning tools

Pickup leneses Cleaning liquid : GEM1004

Cleaning paper : GED-008

4

Page 5

CMX-3000, CU-V163

2. EXPLODED VIEWS AND PARTS LIST

NOTES:• Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

•

Therefore, when replacing, be sure to use parts of identical designation.

Screws adjacent to mark on the product are used for disassembly.

•

For the applying amount of lubricants or glue, follow the instructions in this manual.

•

(In the case of no amount instructions, apply as you think it appropriate.)

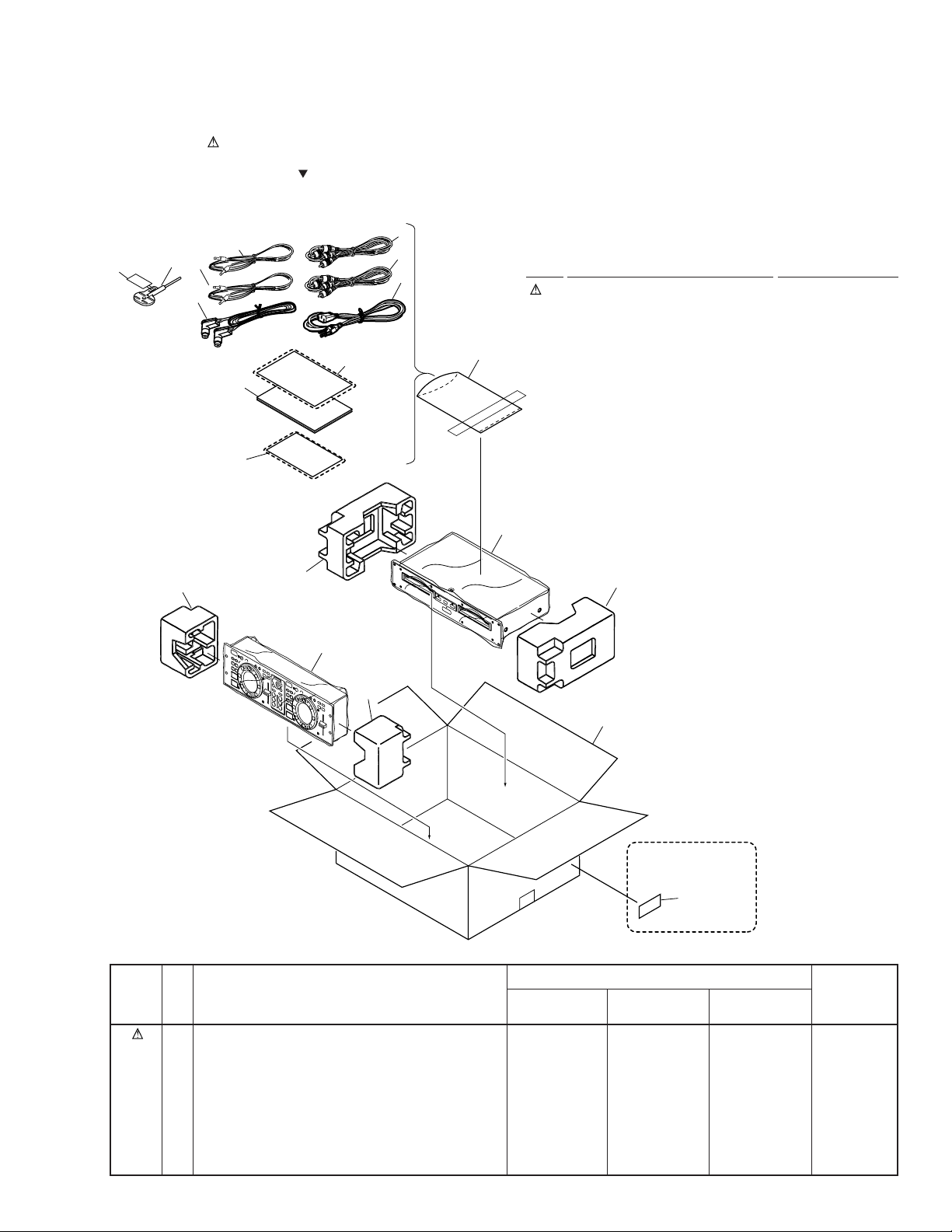

2.1 PACKING

4

6

7

3

5

14

RLBXJ type Only

7

KUXJ type Only

2

8

8

1

9

(1) PACKING PARTS LIST

Mark No. Description Part No.

1 AC Power Cord

NSP 2 Limited warranty

NSP 9 Polyethylene Bag Z21-038

13

NSP 15 Label

3 Specialized connection cable for

the remote controller (L=3 m) DDE1122

4 Forced ejection pin DEX1013

5 Operating Instructions

6 Caution Tag DRW1897

7 Control cord (L=1 m) PDE1267

8 Audio cable (L=1.5 m) VDE1064

10 Pad A DHA1529

11 Pad B DHA1530

12 Packing Case

13 Sheet RHX1006

14 Caution 220V Label

See Contrast table (2)

See Contrast table (2)

See Contrast table (2)

See Contrast table (2)

See Contrast table (2)

See Contrast table (2)

11

10

13

11

10

12

KUCXJ and WYXJ

type Only

15

(2) CONTRAST TABLE

CMX-3000/KUXJ, WYXJ and RLBXJ are constructed the same except for the following:

No.

Symbol and DescriptionMark

KUCXJ Type WYXJ Type RLBXJ Type

Part No.

Remarks

1 AC Power Cord ADG7022 ADG1154 ADG1154

NSP 2 Limited warranty ARY7043 Not used Not used

5 Operating Instructions (English) DRB1307 Not used Not used

5 Operating Instructions Not used DRB1306 Not used

(English/ French/ German/ Italian/ Dutch/ Spanish)

5 Operating Instructions (English/ Spanish/ Chinese) Not used Not used DRB1308

12 Packing Case DHG2160 DHG2158 DHG2161

14 Caution 220V Label Not used Not used ARR1003

NSP 15 Label VRW1629 VRW1629 Not used

5

Page 6

CMX-3000, CU-V163

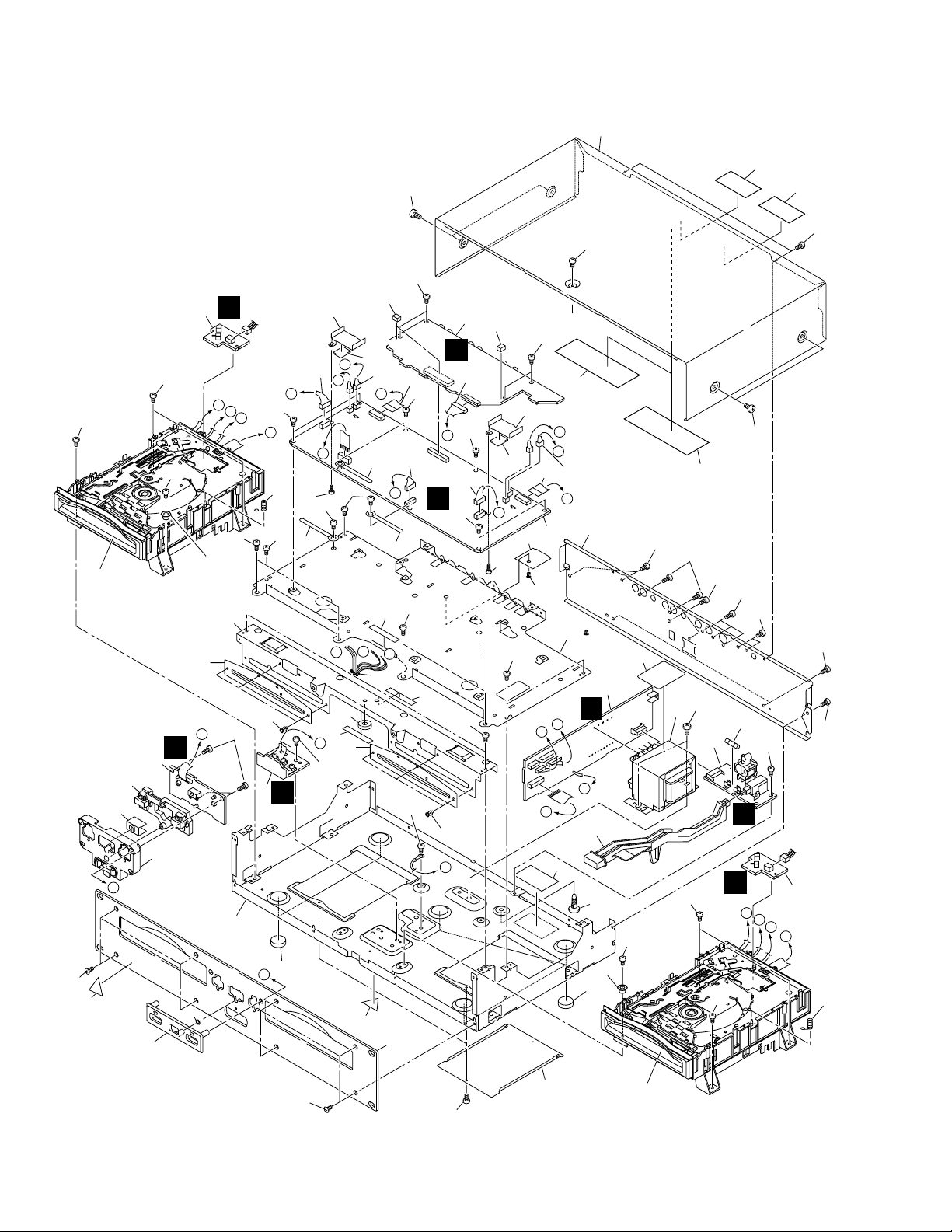

2.2 EXTERIOR SECTION

6

C

41

41

5555

39

Refer to

"2.3 SLOT-IN MECHANISM

ASSY"

20

20

B

B

5

30

36

34

A

J

24

G

21

H

45

45

47

4

J

41

I

29

41

H

40

48

12

45

C

B

41

26

28

G

B

53

20

H

41

32

49

44

50

42

42

41

17

8

17

41

18

14

I

E

9

41

13

52

26

57

47

L

M

14

9

N

22

1

37

44

41

45

41

45

41

48

28

48

41

E

11

18

12

F

A

41

K

40

45

23

F

E

54

28

41

41

47

D

41

51

2

43

F

F

E

D

C

35

10

15

3

41

G

38

D

27

55

41

K

L

41

41

7

M

N

46

56

33

58

19

A

56

31

46

25

41

39

19

Refer to

"2.3 SLOT-IN MECHANISM ASSY"

5541

29

6

Page 7

(1) EXTERIOR SECTION PARTS LIST

Mark No. Description Part No.

1 MAIN ASSY DWG1556

2 PWRB ASSY

3 ACIN ASSY

4 REGB ASSY

5 FRSW ASSY DWS1314

See Contrast table (2)

See Contrast table (2)

See Contrast table (2)

CMX-3000, CU-V163

Mark No. Description Part No.

31 Front Panel DNB1098

32 Bonnet Case DNE1409

33 Function Panel DNK3944

34 Power Knob Caver DNK3945

35 Power Knob DNK3946

6 SLM1 ASSY DWS1315

7 SLM2 ASSY DWS1316

8 JACB ASSY

9 Leadcard 16p DDD1194

10 Power Transfomer

11 Connector Ass’y PF05FE-D17

12 Connect0r Ass’y (6p) PF06PP-B47

13 Connector Assy PF09EE-D25

14 Connector Ass’y PG03KK-E15

15 Fuse (FU101)

16 • • • • •

17 Rubber Spacer DEB1455

NSP 18 Silicon Rubber D5 L DEB1456

19 Insulator DEC2348

20 Front Sheet B DEC2467

NSP 21 Chassis DNA1277

22 Rear Panel

23 PCB Frame DNH2502

24 Panel Stay DNH2503

25 Bottom Plate DNH2505

26 Heat Sink DNH2508

27 Locking Card Spacer VEC1596

28 Sheet DED1159

29 Earth Spring DBH1398

30 Eject Knob DEB1503

See Contrast table (2)

See Contrast table (2)

See Contrast table (2)

See Contrast table (2)

36 Slide SW Knob DNK3947

NSP 38 Label VRW-548

37 65 Label

39 POM Bush (M3) DEC2397

40 Screw BBZ26P060FMC

41 Screw BBZ30P060FMC

42 Screw BBZ30P060FZK

43 Screw BBZ40P060FMC

44 Screw BBZ40P060FZK

45 Screw BPZ30P080FZK

46 Screw CBZ30P080FZK

47 Rivet (Plastic) RBM-003

48 Cord Clamper (Steel) RNH-184

49 Caution Label HE

50 Caution Label

51 Trans Sheet DEC2280

52 Caution Label

53 Screw Guard DEB1447

54 Binder ZCA-SKB90BK

55 Screw BBZ30P080FMC

NSP 56 Caution Label

57 Protect Sheet

58 Spacer (PEE) DEC2470

See Contrast table (2)

See Contrast table (2)

See Contrast table (2)

See Contrast table (2)

See Contrast table (2)

See Contrast table (2)

(2) CONTRAST TABLE

CMX-3000/KUXJ, WYXJ and RLBXJ are constructed the same except for the following:

No.

Symbol and DescriptionMark

KUCXJ Type WYXJ Type RLBXJ Type

2 PWRB ASSY DWR1345 DWR1345 DWR1348

3 ACIN ASSY DWR1349 DWR1346 DWR1346

4 REGB ASSY DWR1357 DWR1347 DWR1347

8 JACB ASSY DWX2214 DWX2200 DWX2200

10 Power Transfomer (AC120V) DTT1161 Not used Not used

10 Power Transfomer (AC220-240V) Not used DTT1160 Not used

10 Power Transfomer (AC110-120V/220-240V) Not used Not used DTT1162

15 Fuse (FU101: 1.6A) REK1077 Not used Not used

15 Fuse (FU101: 1.0A) Not used REK1022 REK1022

22 Rear Panel DNC1586 DNC1585 DNC1587

37 65 Label ARW7050 Not used Not used

49 Caution Label HE Not used PRW1233 Not used

50 Caution Label Not used VRW1094 Not used

NSP 56 Caution Label DRW1975 Not used Not used

52 Caution Label Not used Not used DRW2102

57 Protect Sheet Not used DEC2466 DEC2466

Part No.

Remarks

7

Page 8

CMX-3000, CU-V163

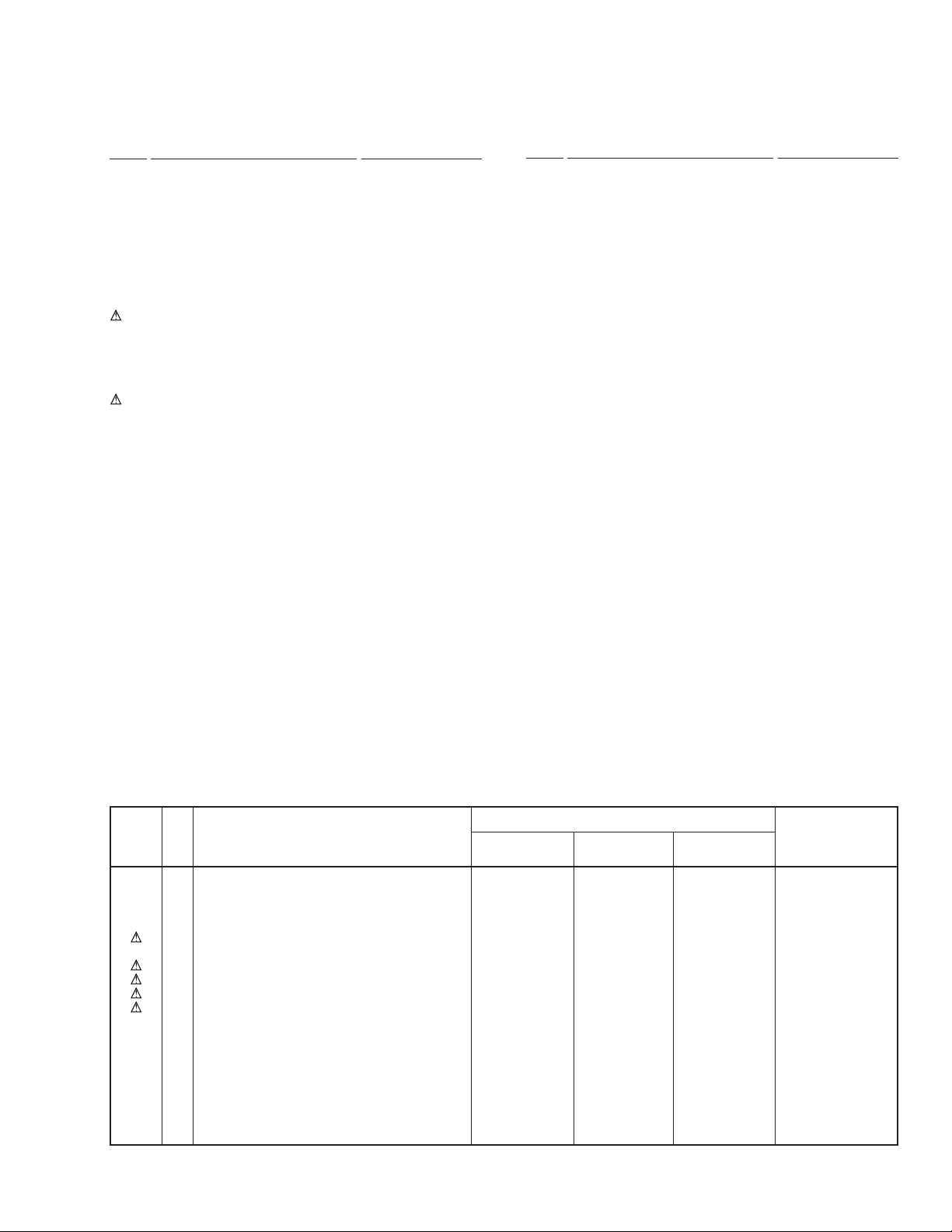

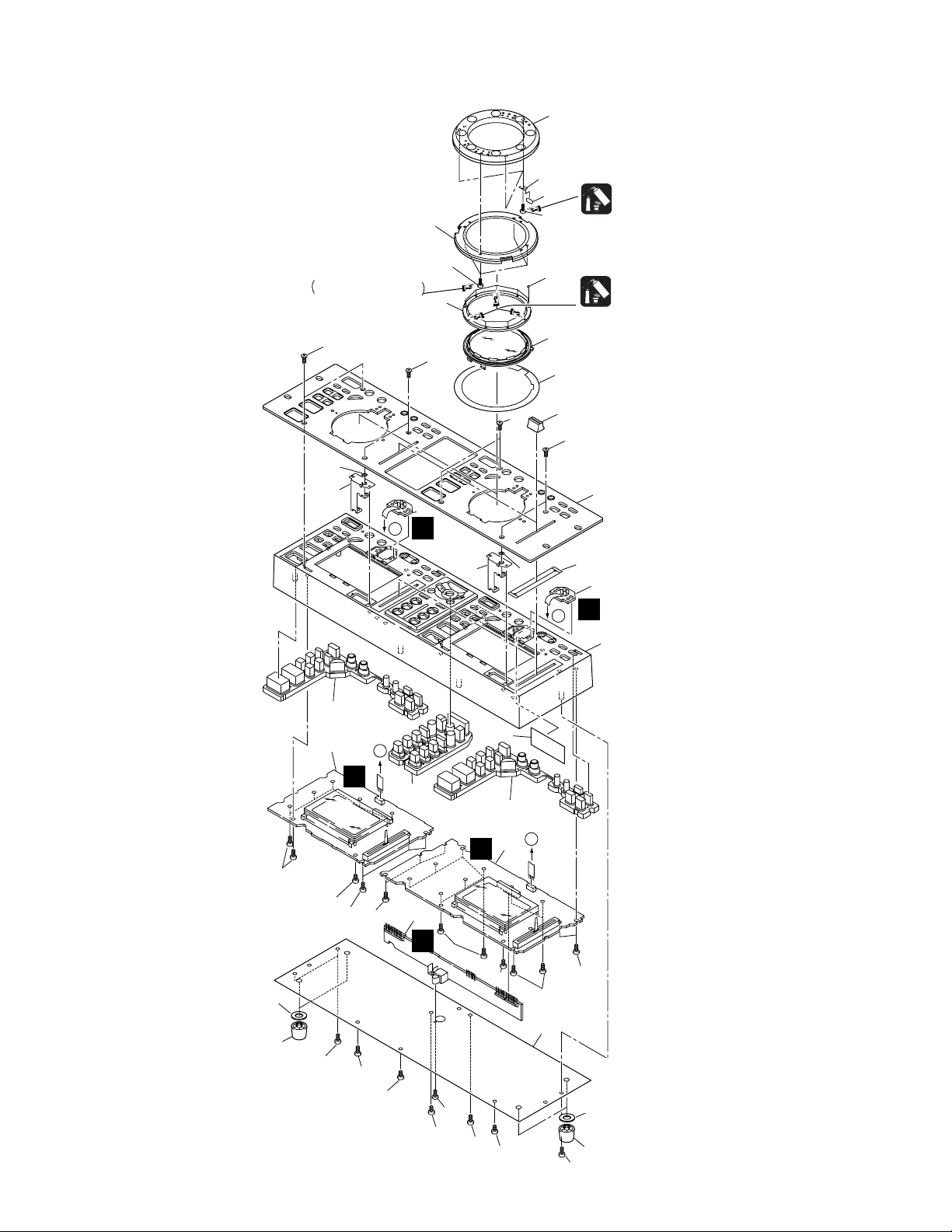

2.3 SLOT-IN MECHANISM SECTION

Paint grease the inner

surface of the wall.

11

13

Grease

Grease

(ZLB-PN397B)

(GYA1001)

10

7

Paint on side of axle.

12

22

21

Grease

Grease

(ZLB-PN397B)

(GYA1001)

9

16

15

17

23

Paint grease the inner

Paint grease the inner

surface of the wall.

surface of the wall.

Dyefree

8

Dyefree

(ZLX-ME413A)

(GEM1023)

18

19

Grease

Grease

(ZLB-PN397B)

(GYA1001)

20

1

24

To MAIN Assy

28

14

5

26

25

26

Cleaning liquid (GEM1004)

Cleaning paper (GED-008)

27

6

6

3

4

2

2

8

Page 9

SLOT-IN MECHANISM SECTION PARTS LIST

•

Mark No. Description Part No.

1 Connector Ass’y DKP3565

2 Float Fastener DBA1139

3 Float Spring F DBH1491

4 Float Spring R DBH1492

5 Spacer Por (T3) DEB1467

6 Float Rubber DEB1506

7 Clamp Spring DBH1374

8 Guide Spring DBH1375

9 Sw.Lever Spacer (Pet) DEC2420

10 Clamp Magnet DMG1008

11 Yoke DNH2504

12 Loading Lever DNK3406

13 Main Cam DNK3407

14 Disc Guide DNK3478

15 Clamp Arm DNK3576

16 Loading Base Assy-S DEA1022

17 Eject Lever DNK3684

18 Lever AP DNK3835

NSP 20 Worm Gear DNK3410

19 Lever BP DNK3836

CMX-3000, CU-V163

21 Loading Gear DNK3409

22 Drive Gear DNK3565

NSP 24 Loading Motor DXM1173

23 Clamper DNK3949

25 Mecha Base DNK3948

26 Binder ZCA-SKB90BK

27 CD Mechanism DA11T3CNPIO

28 Loading Motor Assy-S DXX2510

9

Page 10

CMX-3000, CU-V163

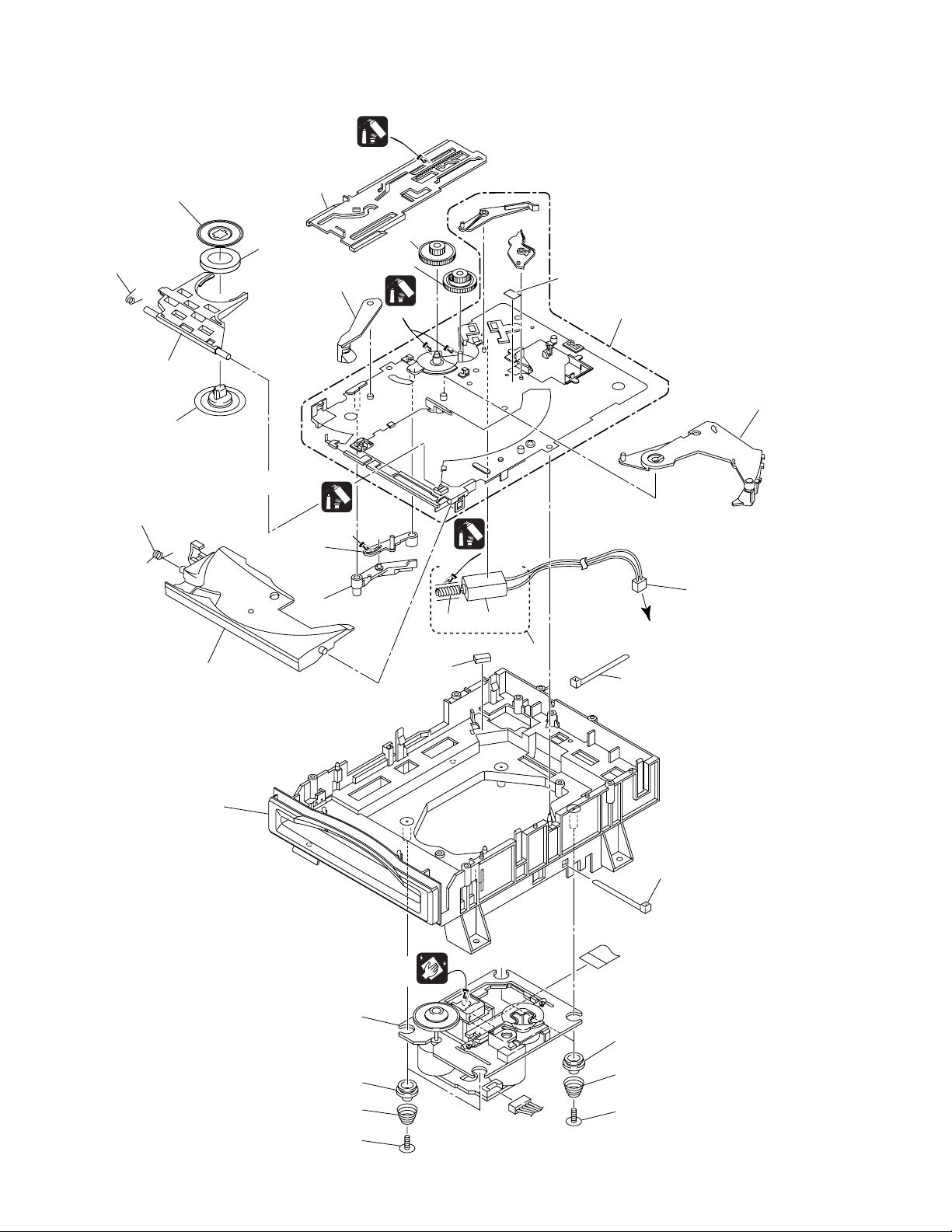

2.4 REMOTE CONTROLLER (CU-V163)

16

12

10

6

23

Super X

(GYL1004)

A hand driver fastens a screw.

The screw tightening torque

0.098 ± 0.01% [N • m]

29

30

13

A

20

1

A

6

14

29

4

29

19

24

8

25

29

Grease is applied to three

places every two pieces.

Grease

(GYA1014)

22

J

13

30

26

9

5

L

B

15

10

7

18

28

28

27

28

I

27

28

28

21

3

M

27

28

17

K

28

27

27

20

2

B

28

28

11

7

18

28

Page 11

REMOTE CONTROLLER (CU-V163) PARTS LIST

•

Mark No. Description Part No.

1 CNTA ASSY DWG1551

2 CNTB ASSY DWG1552

3 CNNB ASSY DWG1553

4 PHTA ASSY DWG1554

5 PHTB ASSY DWG1555

6 Screw ABA7022

7 CR Spacer DEB1524

8 Jog Sheet A DEC2468

9 Slide VR Packing DED1157

10 J Magnet DMG1006

11 Rear Panel DNC1590

12 Magnet Stay DNF1668

13 Earth Plate DNH2506

14 Retainer DNK3952

15 Panel Base DNK3953

16 Jog Ring DNK3954

17 Screw (Steel) PBA1096

18 Foot (Rubber) REC1263

19 Steel Ball VNX1006

20 Select Knob 1 DEB1504

CMX-3000, CU-V163

21 Select Knob 2 DEB1505

22 Control Panel DNB1099

23 Jog Dial DNK3950

24 Display Plate DNK3951

25 Slide Knob DNK3955

26 65 Label ARW7050

27 Screw BBZ30P060FMC

28 Screw BPZ30P080FZK

29 Screw CBZ30P080FZK

30 Washer WH30FUC

11

Page 12

1

23

CMX-3000, CU-V163

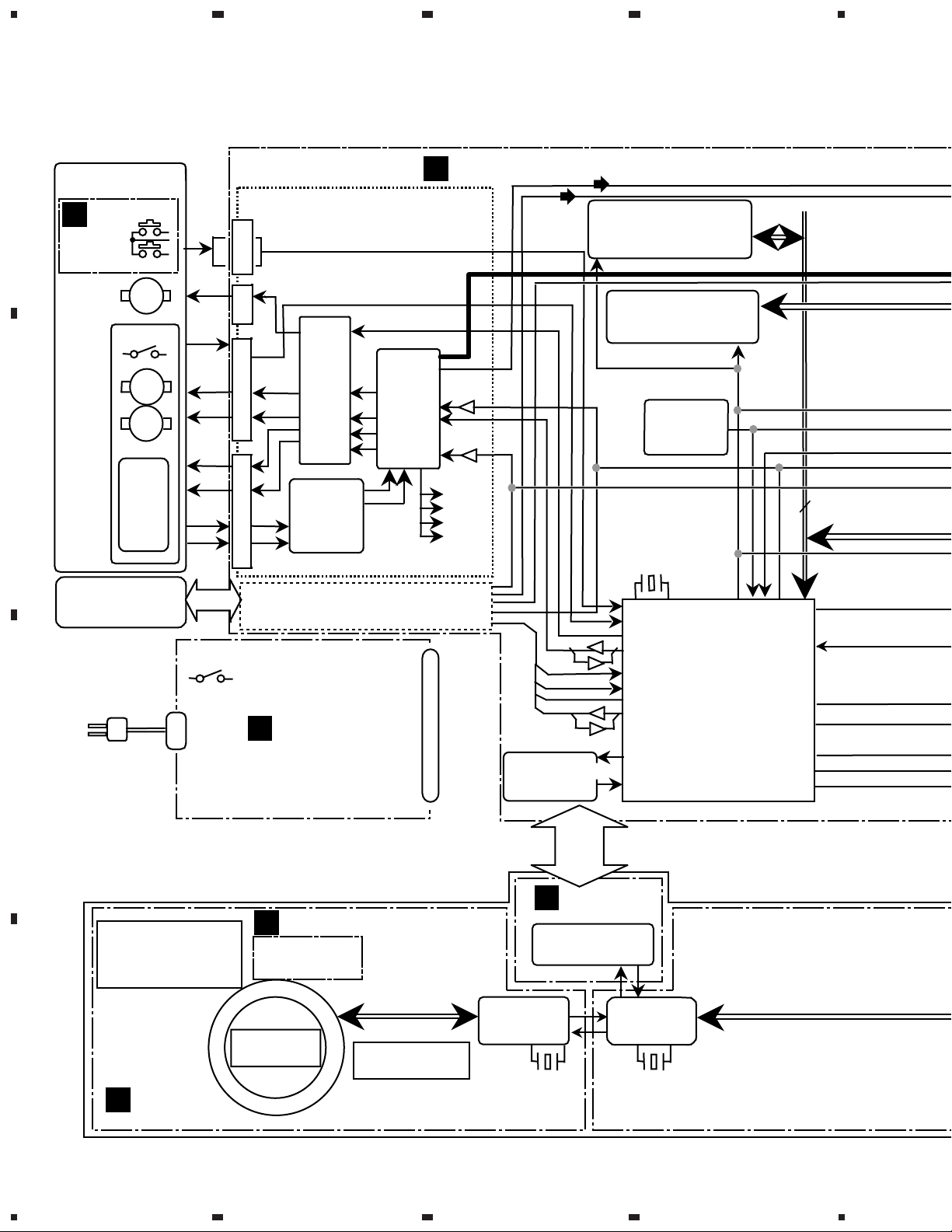

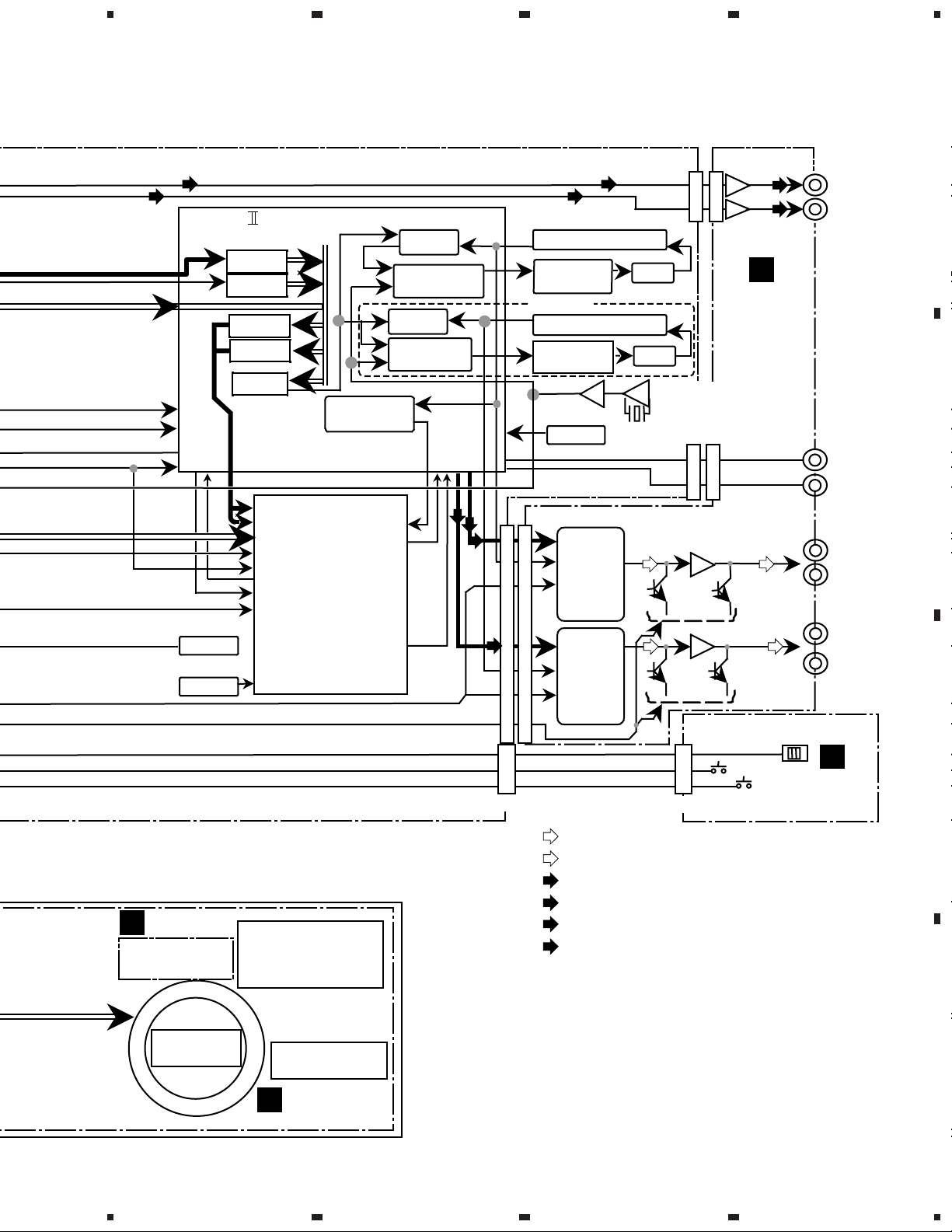

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM

3.1 BLOCK DIAGRAM

A

B

C

Slot Mecha (A)

Slot mecha

A

SLM1 ASSY

C

OP/CL

POSITION SW

Lod

M

INSIDE SW

sled

M

Spdl

M

PU

Slot mecha

B

RSA1001

Sw:

1

2

AC Power Cord

1

2

Remoto Controller Section

Function Key : A

CN801

3

2

1

J4

2

1

CN2

6

INSIDE

5

4

3

2

1

CN1

#

@

!

~

|

1

PL(A) Servo Circuit

LOAD SW

B T L

driver

IC1011

LA6562

Head AMP

IC1010

TA2153FN

PL(B) Servo Circuit

PWRB ASSY

F

Connector pin name

GNDD

GNDD

J

JOG/ENCODER

GP1S94 x2

RXD

3

V+8B

4

PHTA ASSY

Servo

processor

IC1005

TC9495F

CN105

FLAC1

5

TXD

6

A

MAIN ASSY

MCK

SBOK

SUBQ

SBSY

SFSY

toFPGA

1

V+11B

2

V+5D

3

GNDD

4

V+7A

5

GNDD

6

V+8B

7

VLOD

8

FLAC1

9

FLAC2

VLOD

7

FLAC2

8

(DOA)

(DOB)

/

4

/

4

Communication

I/F

JA701

JA207

M

CNNB ASSY

Communication

I/F

FLASH ROM(8M)

DSS1132 12.0MHz

IC1200

DYW1701

SDRAM(128M)

IC1408

K4S281632C

RESET

IC1022

M51957

48.0MHz =

Lod_Sw

INSD

LOD(A)

COM(A)

Lod_Sw

INSD

LOD(B)

COM(B)

IC1204

Micro Computer

(MINIDIN8P)

4

CLK

16

DONE

PRGM

RESET

SET

MUTE

COM

IC301 IC501

FL

D

I

CNTA ASSY

12

1234

DEL1047

Slider-

60mm

DCV1011

DSS1131

4MHz

PD5764A

DSS1131

4MHz

Control ICControl IC

Page 13

5

678

CMX-3000, CU-V163

(DOA)

(DOB)

Spartan

CLK

PRGM

DONE

RESET

MM1561

IC1208

IC1406

L

JOG/ENCODER

Reg1.8v

NJM2870F18

Reg1.8v

PHTB ASSY

GP1S94 x2

S/P I/O

S/P I/O

P/S I/O

P/S I/O

P/S

BCK/ LRC

IC1409

Gerenation

XC2S30-5TQ144C

AUDIO (A)

AUDIO (B)

CLK

RESET

Req

Valid

COM

AUDIO(A)

DSP

XCA56367

IC1402

AUDIO(B)

Function Key : B

LRCK IN

Divider

Comparator

Divider

Comparator

4

/

CN1011

AUDIO(B)

AUDIO(A)

(DA)

(DB)

MCK(A)

*

(DA)

I

_

(DB)

MCK(B)

+

I

£

909

4

3

2

(DOA)

(DOB)

P L L (A)

VCO

3 Signals

Conversion

LPF

P L L (B)

VCO

3 Signals

Conversion

LPF

IC1009

NJM2870F25

Reg2.5v

CN201

*

I

_

+

I

£

0

(DA)

(DB)

(DOA)

(DOB)

DAC

PE8001

IC201

DAC

(B)

PE8001

IC202

SIGNAL ROUTE

(A)

: PB A AUDIO SIGNAL

(B)

: PB B AUDIO SIGNAL

: DIGITAL DATA A SIGNAL

: DIGITAL DATA B SIGNAL

: DIGITAL AUDIO A SIGNAL

: DIGITAL AUDIO B SIGNAL

-

=

CN201

-

=

CN1011

JACB ASSY

Master Clock

VSS1084

16.9344MHz

CN201CN1011

^

^

&

&

¢

¢

∞

∞

IC204

NJM4558

4

3

2

EJECT sw A/B

J161CN1012

(DOA)

(DOB)

E

(A)(A)

(B)

DIGITAL OUT

On/off SW

FRSW ASSY

DIGITAL

OUT A

DIGITAL

OUT B

CONTROL A

CONTROL B

AUDIO

OUT A

AUDIO

OUT B

B

A

B

C

FL

DEL1047

5

Slider-

DCV1011

K

CNTB ASSY

60mm

D

13

6

7

8

Page 14

1

CMX-3000, CU-V163

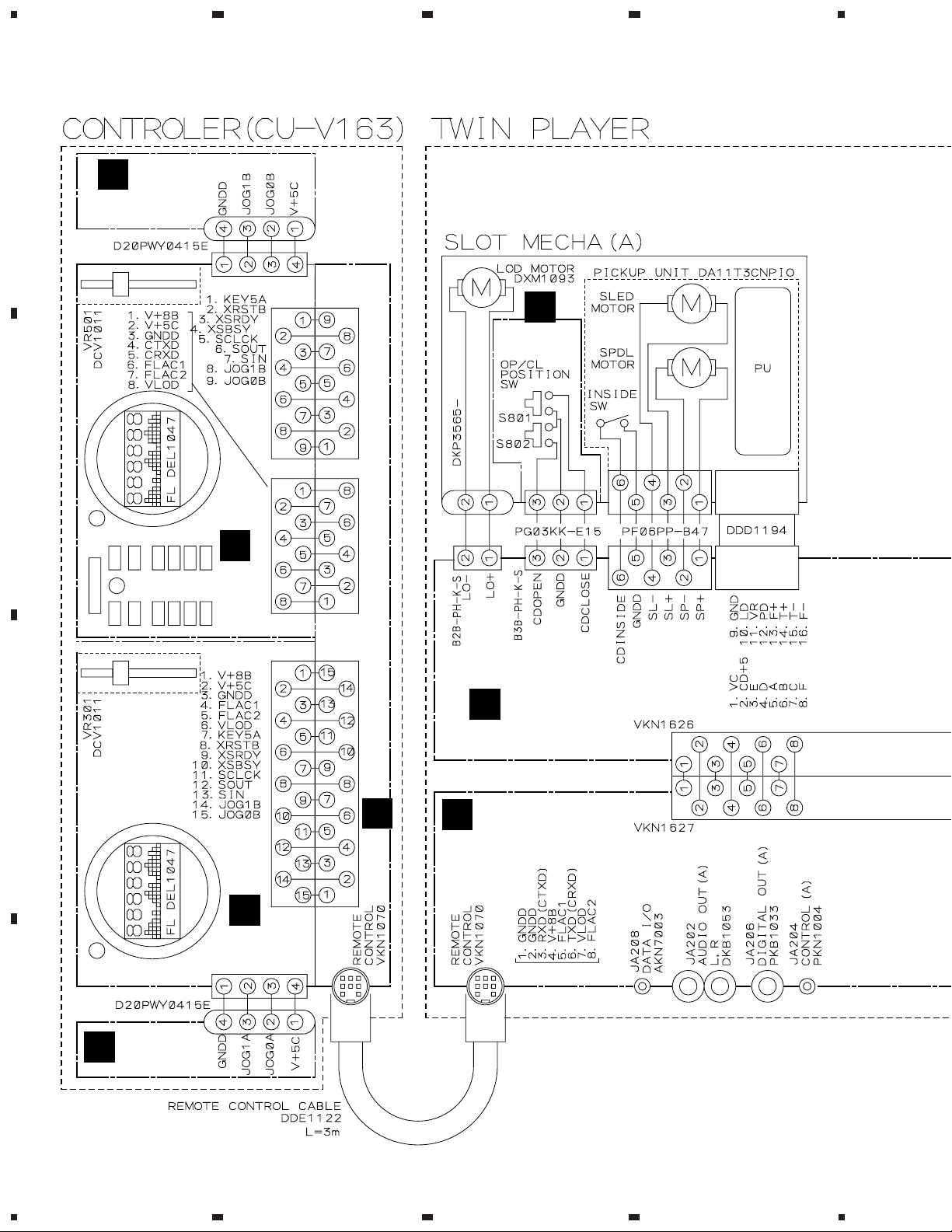

3.2 OVERALL WIRING DIAGRAM

A

L

PHTB ASSY

(DWG1555)

J502

CN501

CN503

23

CN703

C

SLM1 ASSY

(DWS1315)

4

B

CN504

CN704

J4

CN801

CN2

CN1

K

CNTB ASSY

(DWG1552)

CN1008

CN303

C

CN702

CNNB ASSY (DWG1553)

M

E

CN1006

CN1007

MAIN ASSY

A

(DWG1556)

JACB ASSY

(KUCXJ: DWX2214)

(WYXJ: RLBXJ: DWX2200)

CN1010

CN201

CN1009

I

CNTA ASSY

(DWG1551)

CN301

J302

PHTA ASSY

J

D

14

(DWG1554)

1234

JA701

JA207

Page 15

5

678

CMX-3000, CU-V163

Note : When ordering service parts, be sure to refer to "EXPLODED VIEWS and P AR TS LIST" or "PCB PARTS LIST".

REGB ASSY

(WYXJ, RLBXJ: DWR1347)

(KUCXJ:DWR1357)

D

SLM2 ASSY

(DWS1316)

H

J151

A

FRSW ASSY

(DWS1314)

J161

CN1012

B

J4

CN1004

CN901

CN1002

CN2

CN1003

CN1

CN1005

CN1218 CN104

CN202

CN106

CN105

F

CN102CN103

ACIN ASSY

G

B

(KUCXJ: DWR1349)

(WYXJ: RLBXJ: DWR1346)

C

AN101

PWRB ASSY

(KUCXJ, WYXJ: DWR1345)

(RLBXJ: DWR1348)

POWER

REQUIREMENT

REK1022

REK1022

REK1077

5

6

AC220- 240V

60Hz

AC110- 120V/ 220-240V

50/ 60Hz

AC120V

50/ 60Hz

7

15

8

D

Page 16

1

CMX-3000, CU-V163

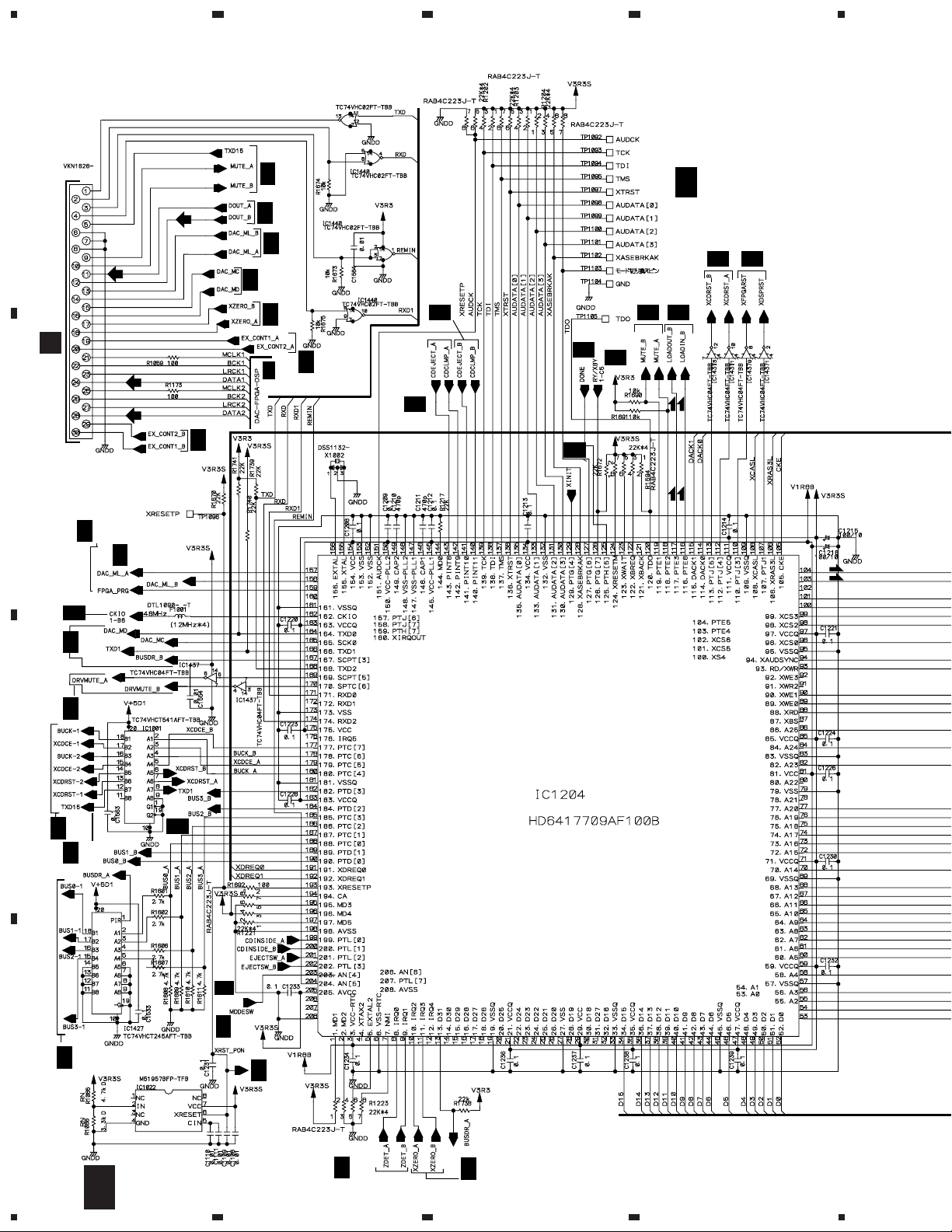

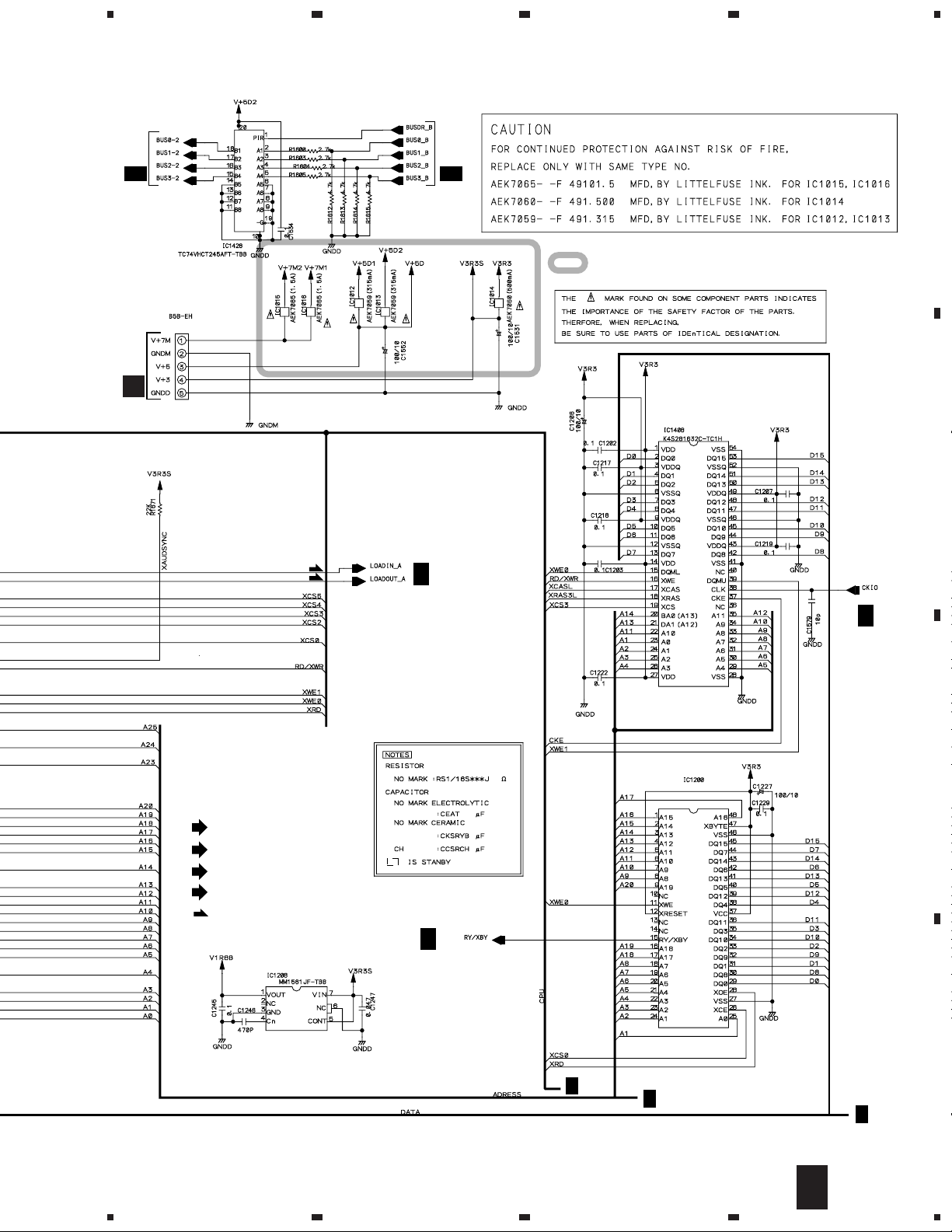

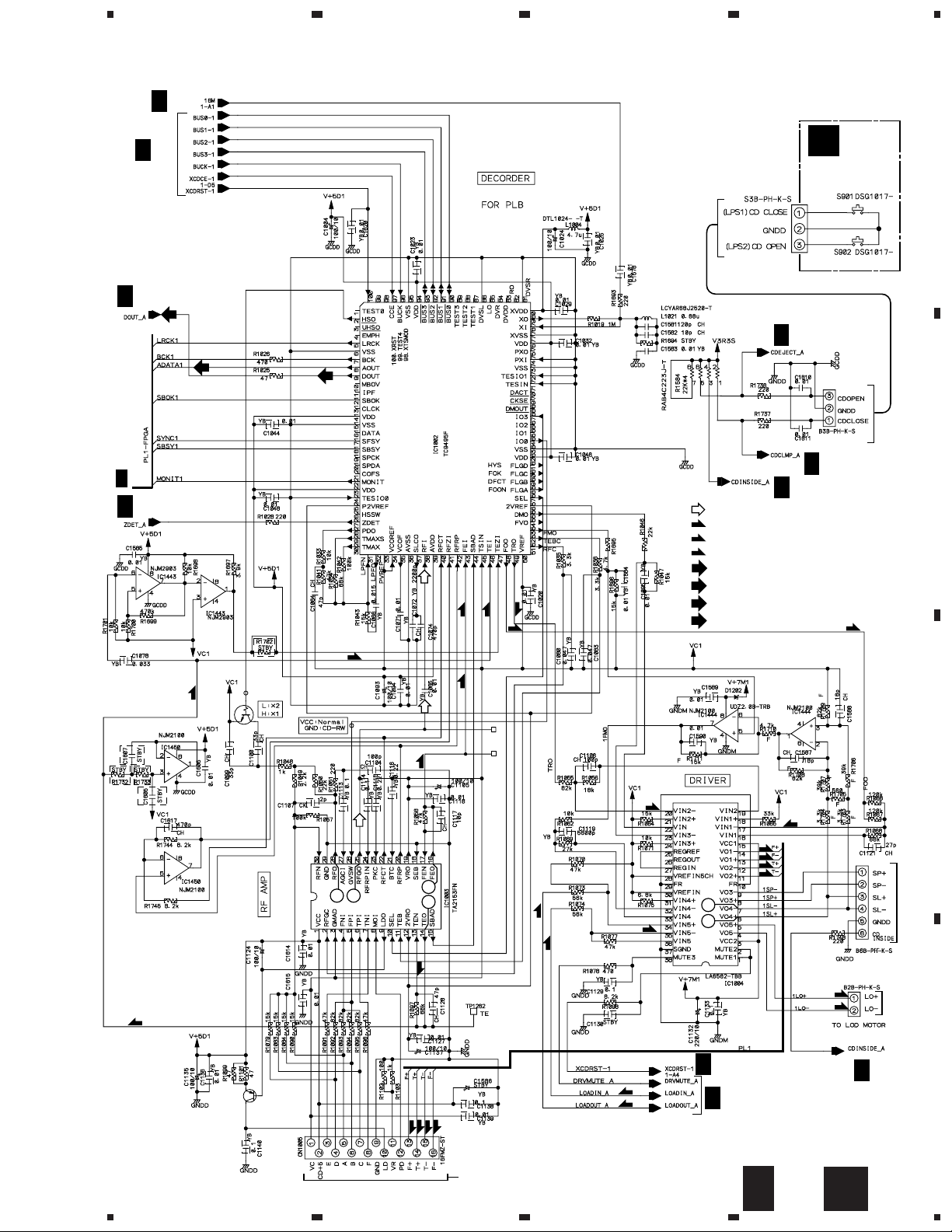

3.3 MAIN (1/3) ASSY

A

CN1010

(DOB)

CN201

E

(DB)

(DA)

B

(IC1204: 118pin)

(IC1204: 119pin)

(DOA)

(IC1204: 158pin)

(IC1204: 157pin)

(IC1204: 165pin)

(IC1204: 164pin)

(IC1204: 11pin)

(IC1204: 10pin)

A 2/3

A 1/3

A 3/3

A 1/3

A 1/3,2/3

A 1/3

A 2/3

A 2/3

23

A 1/3

A 3/3

A 2/4

A 1/3

(L)

(L)

A 3/3

A 2/3

A 3/3

A 2/3

4

MAIN ASSY

(DWG1556)

A 1/3

A 2/3

(L)

(L)

A 2/3

A 1/3

(L)

(L)

A 1/3,2/3

A 1/3

A 3/3

C

A 3/3

A 1/3

A 1/3

A 2/3,3/3

A 2/3

D

A 3/3

16

A 2/3

A 3/3

1/3

A

1234

A 1/3

Page 17

5

678

CMX-3000, CU-V163

A 3/3

CN1218

CN104

F

A 1/3

: The power supply is shown with the marked box.

(L)

(L)

A 3/3

A

B

SIGNAL ROUTE

(DA)

: DIGITAL DATA A SIGNAL

(DB)

: DIGITAL DATA B SIGNAL

(DOA)

: DIGITAL OUT A SIGNAL

(DOB)

: DIGITAL OUT B SIGNAL

(L)

: LOADING MOTOR SIGNAL

A 1/3

C

DYW1701

A 1/3

D

A 2/3

A 2/3

A 2/3

1/3

A

5

6

7

8

17

Page 18

1

23

CMX-3000, CU-V163

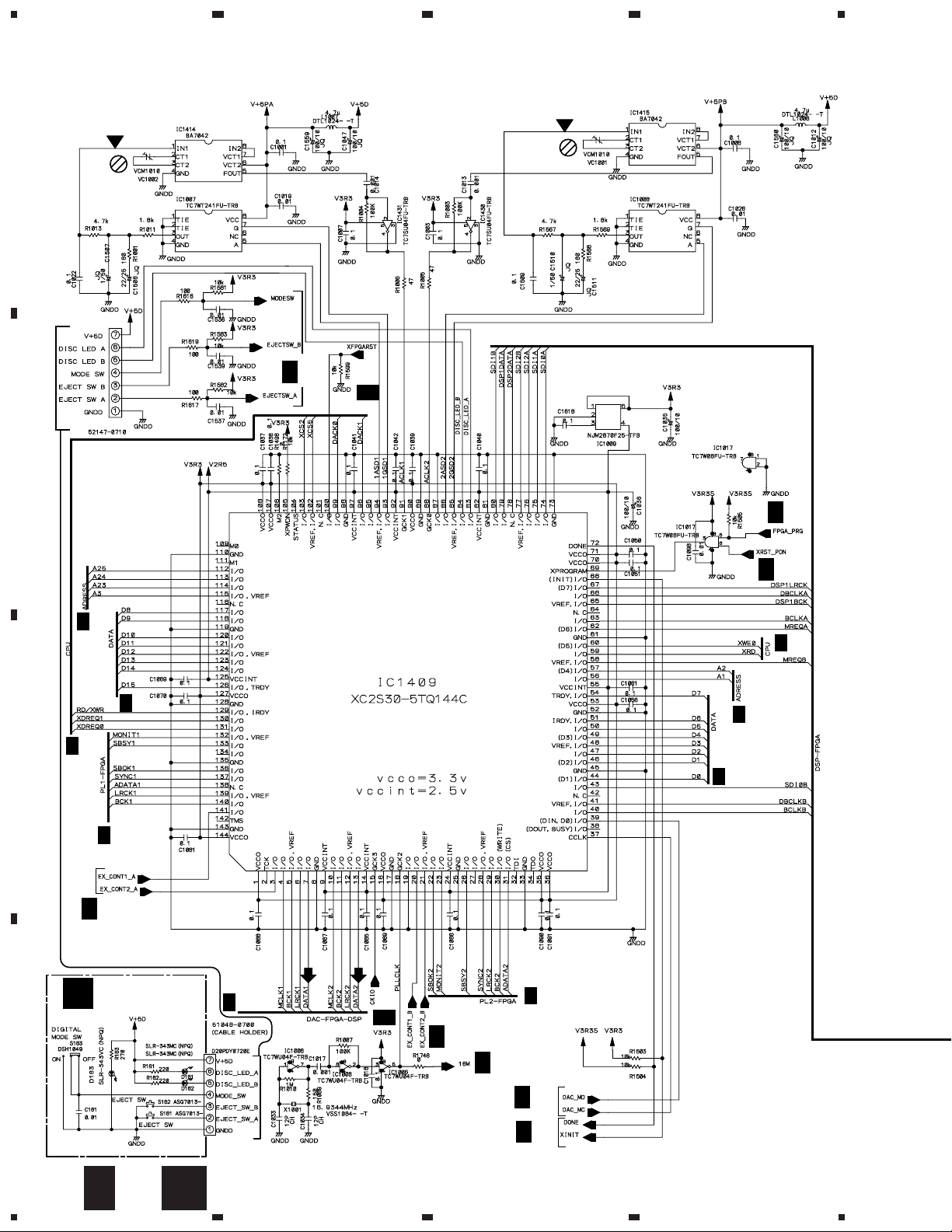

3.4 MAIN (2/3) and FRSW ASSYS

4

A

VCO Adjust -b

VCO Adjust -a

I

A 1/3

A 1/3

CN1012

B

A 1/3

A 1/3

A 1/3

A 1/3

A 1/3

A 1/3

C

A 1/3

A 1/3

A 1/3

A 1/3

(DA)

A 3/3

FRSW ASSY

B

(DWS1314)

(DB)

A 1/3, 2/3

A 1/3, 3/3

J161

D

A 1/3

A 3/3

18

A 1/3

A 1/3

2/3

A

1234

B

Page 19

5

678

CMX-3000, CU-V163

A 2/3

MAIN ASSY

(DWG1556)

A

B

A 1/3

SIGNAL ROUTE

(DA)

: DIGITAL DATA A SIGNAL

: DIGITAL DATA B SIGNAL

(DB)

A 1/3

C

A 2/3

A 1/3

A 1/3

A 1/3

D

2/3

A

5

6

7

8

19

Page 20

1

23

CMX-3000, CU-V163

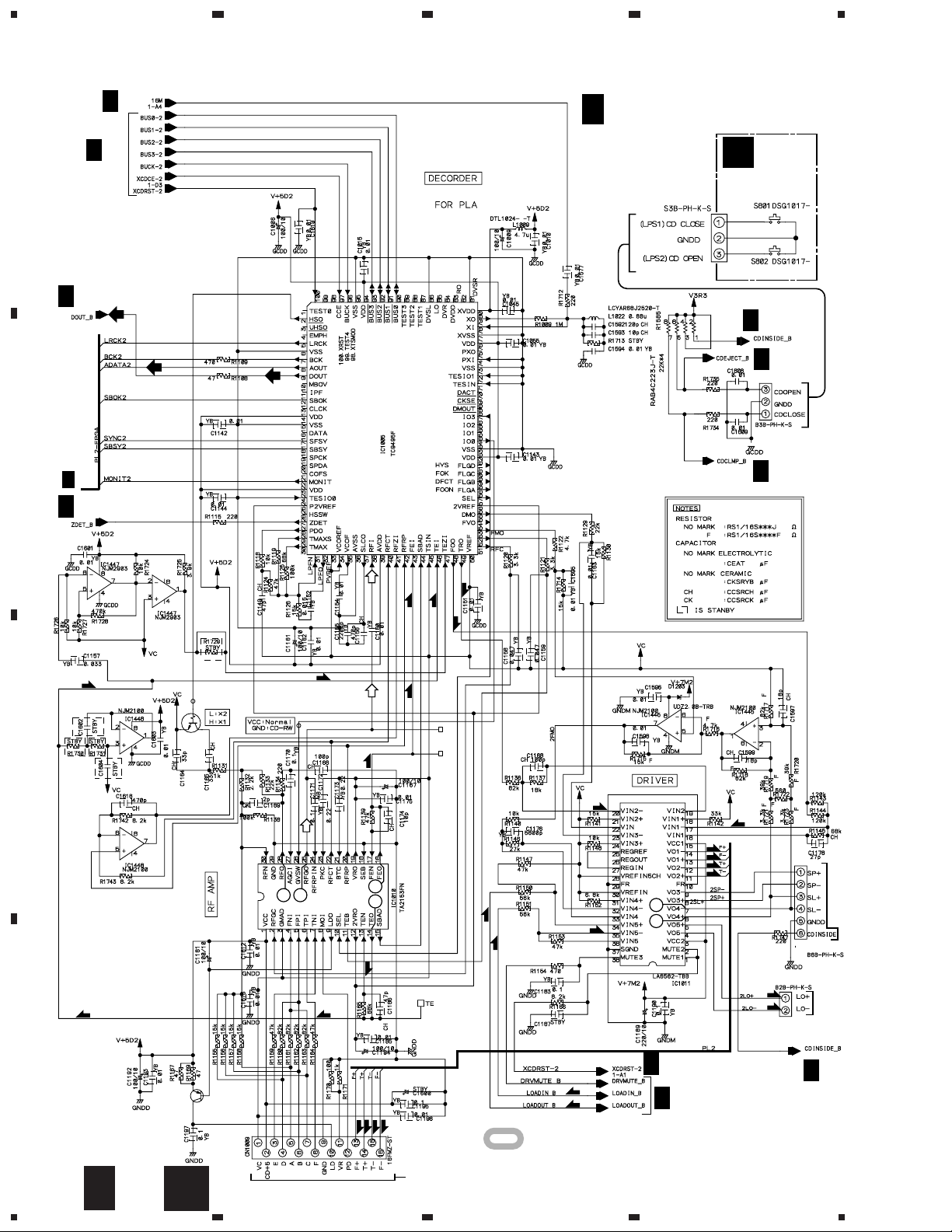

3.5 MAIN (3/3), SLM1 and SLM2 ASSYS

4

A 2/3

A

A 1/3

A 3/3

MAIN ASSY

(DWG1556)

C

SLM1 ASSY

(DWS1315)

A 1/3

CN801

(DOA)

A 1/3

A 1/3

(DA)

B

A 2/3

(DOA)

CN1006

A 1/3

A 1/3

(TS)

(RF)

(FS)

(TS)

B

E

C

Q1002

C

(TS) (TS)

DTC114TK

(TS)

(RF)

(FS)

(RF)

3

4

1

2

(TS)

(FS)

(FS)

(TS)

(FS)

RF

FE

(TS)

(FS)

(FS)

(FS)

(TS)

(TS)

6

(L)

(L)

(L)

5

CN1007

CN1008

(L)

(L)

Searvo Mecha

To Slot Mecha (A)

Loading Motor

To Slot Mecha (A)

D

E

B

C

Q1003

2SA1036 (QR)

(FS)

(TS)

(TS)

(FS)

(L)

(L)

A 3/3

A 1/3

A 1/3

: The power supply is shown with the marked box.

To Slot Mecha (A)

Pickup Assy

20

3/3

A

1234

C

Page 21

A 2/3

5

678

CMX-3000, CU-V163

A 1/3

A 1/3

A 2/3

A 1/3

(DOB)

(DB)

(DOB)

(TS)

(RF)

(FS)

(TS)

(FS)

(TS)

CN901

(RF)

: RF SIGNAL ROUTE

(L)

: LOADING MOTOR SIGNAL

(FS)

: FOCUS SERVO SIGNAL

(TS)

: TRACKING SERVO SIGNAL

(DA)

: DIGITAL DATA A SIGNAL

(DB)

: DIGITAL DATA B SIGNAL

: DIGITAL OUT A SIGNAL

(DOA)

: DIGITAL OUT B SIGNAL

(DOB)

D

SLM2 ASSY

(DWS1316)

A 1/3

CN1002

A 1/3

A 1/3

A

B

(FS)

(TS)

(TS)

B

E

C

Q1228

DTC114TK

E

C

2SA1036 (QR)

B

Q1229

(FS)

(RF)

RF

(FS)

(RF)

3

4

1

2

(TS)

FE

(TS)

(FS)

(FS)

(FS)

(TS)

(TS)

6

(L)

(L)

(L)

5

CN1003

C

Searvo Mecha

To Slot Mecha (B)

CN1004

(L)

(L)

Loading Motor

To Slot Mecha (B)

(FS)

(TS)

(TS)

(FS)

A 3/3

(L)

(L)

A 1/3

A 1/3

D

To Slot Mecha (B)

Pickup Assy

3/3

A

5

6

7

D

8

21

Page 22

1

CMX-3000, CU-V163

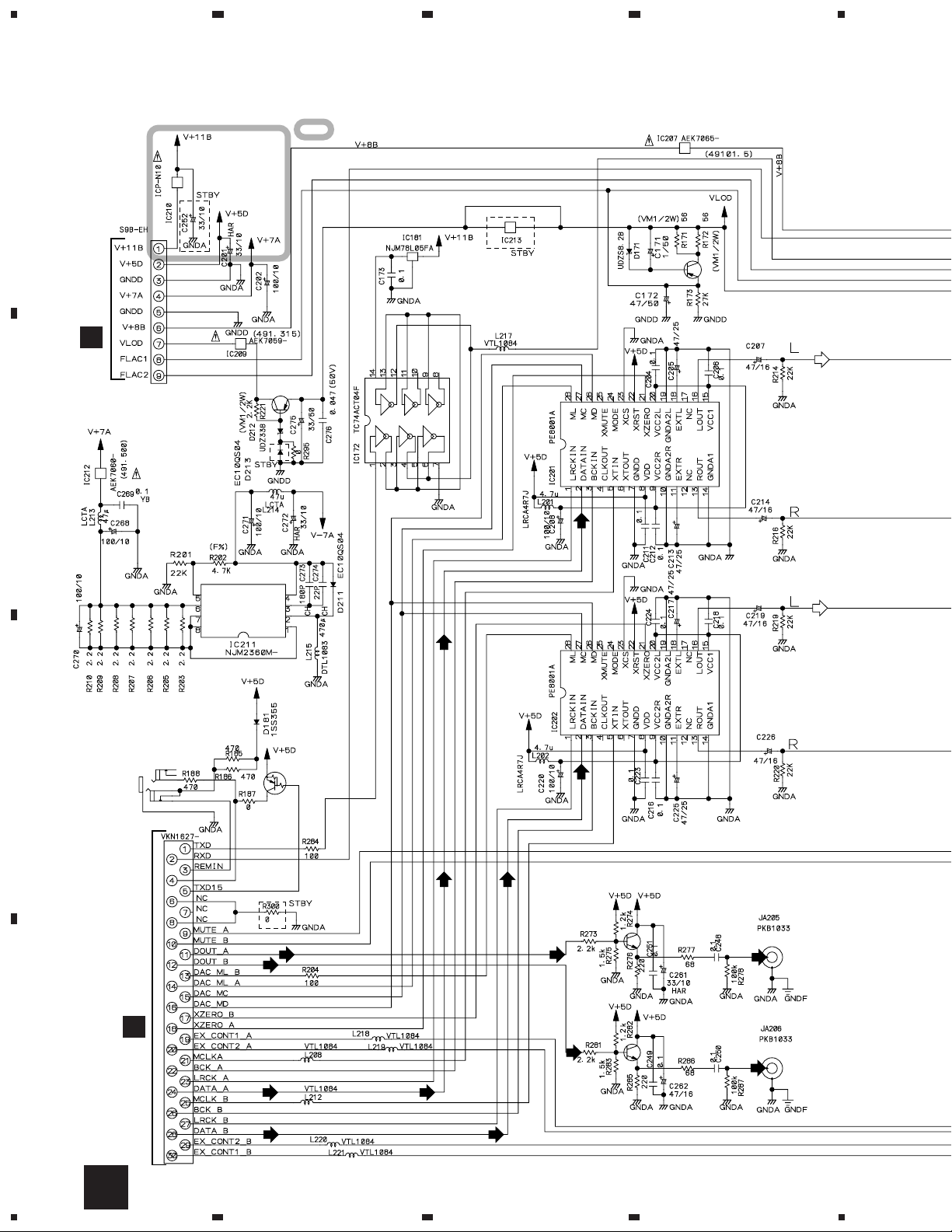

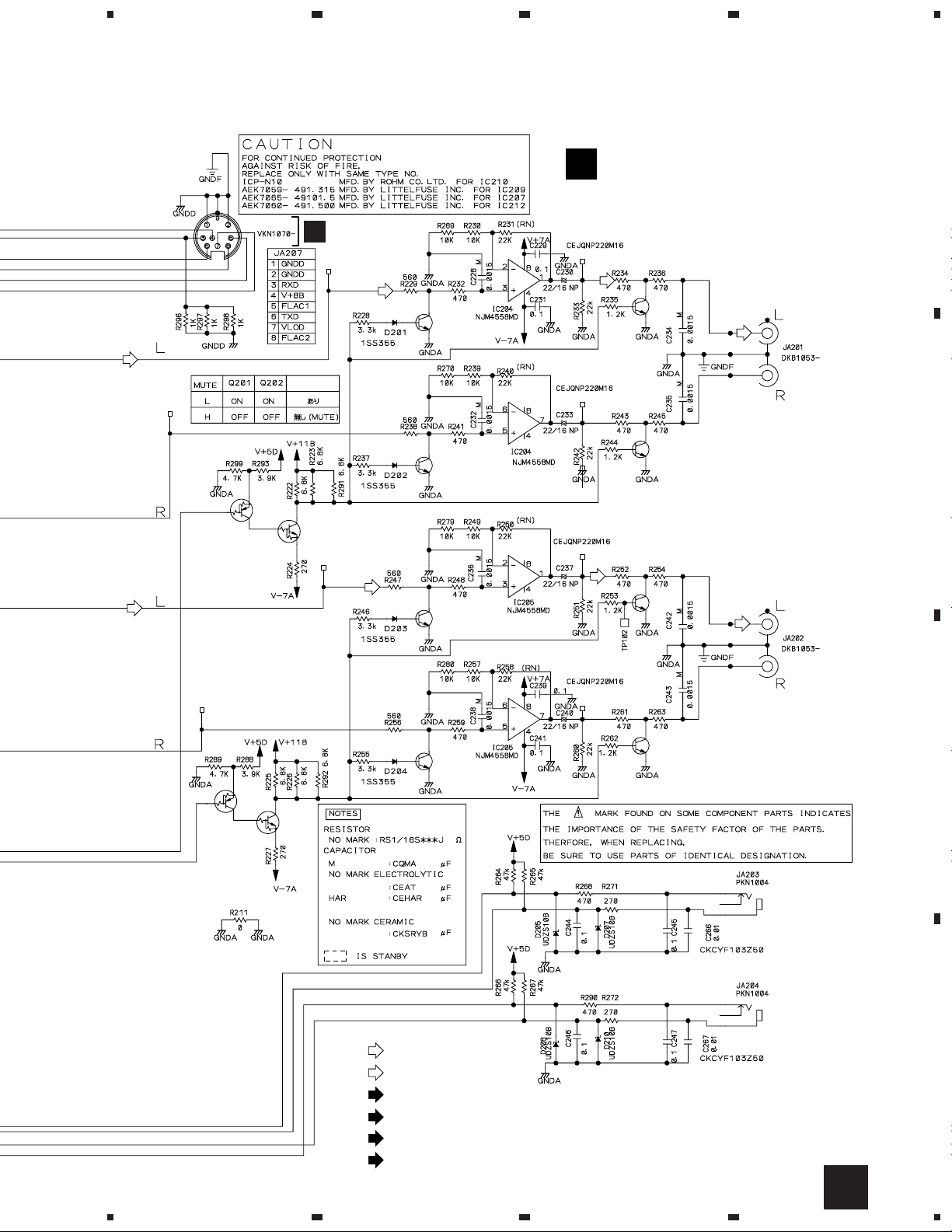

3.6 JACB ASSY

23

4

: The power supply is shown with the marked box.

(1.5A)

A

(0.4A)

CN202

Q171

2SB1237

CN105

F

(500mA)

(315mA)

Q215

2SB1375

B

(DB)

(A)

(B)

(DB)(DB)

JA208

C

AKN7003-

DATA I/O

Q182

DTA143EUA

(DA)

CN201

(DOA)

(DOB)

(DA)

(DOB)

Q213

2SD2412K (RS)

DIGITAL OUT (B)

(DOB)

CN1010

Q214

A

D

(DB)

(DB)

(DOA)

2SD2412K (RS)

DIGITAL OUT (A)

(DOA)

22

(DA) (DA)

E

1234

Page 23

5

678

CMX-3000, CU-V163

JACB ASSY

E

(KUCXJ: DWX2214)

A

(WYXJ: RLBXJ: DWX2200)

JA207

(A)

TP3

Q201

DTA124EUA

(B)

M

AUDIO OUT

Q202

DTC124EUA

JA701

TP1

TP5

(B)

TP2

(A)

Q205

2SD2114 K (VW)

Q207

2SD2114 K (VW)

Q209

2SD2114 K (VW)

(A)

TP4

TP6

TP6

(B)

2SD2114 K (VW)

Q206

Q208

2SD2114 K (VW)

2SD2114 K (VW)

Q210

(A)

AUDIO OUT (B)

B

(B)

AUDIO OUT (A)

TP7

Q203

DTA124EUA

Q204

DTC124EUA

Q211

2SD2114 K (VW)

SIGNAL ROUTE

(A)

: PB A AUDIO SIGNAL

(B)

: PB B AUDIO SIGNAL

(DA)

: DIGITAL DATA A SIGNAL

: DIGITAL DATA B SIGNAL

(DB)

(DOA)

: DIGITAL OUT A SIGNAL

(DOB)

: DIGITAL OUT B SIGNAL

TP8

Q212

2SD2114 K (VW)

C

CONTROL (B)

CONTROL (A)

D

E

5

6

7

8

23

Page 24

1

CMX-3000, CU-V163

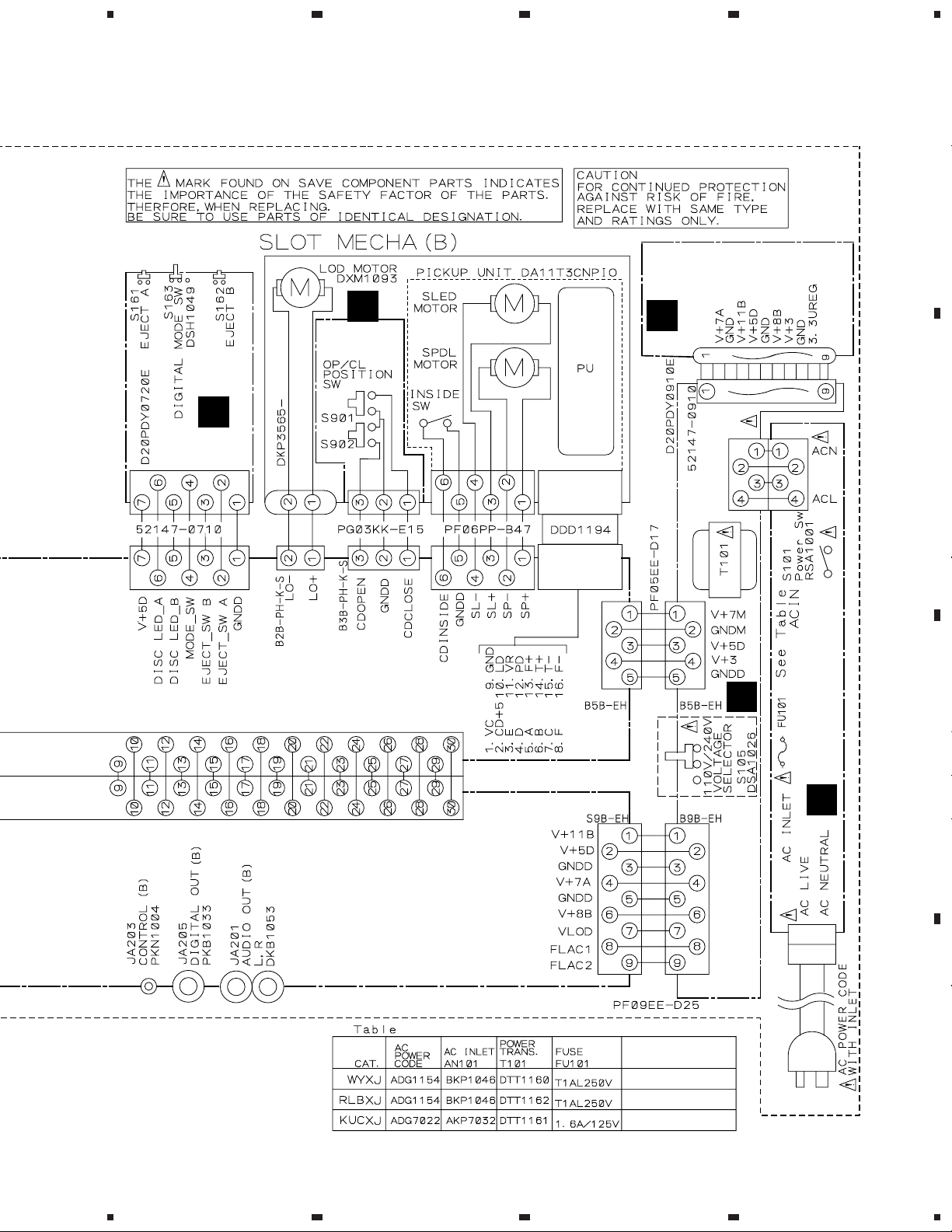

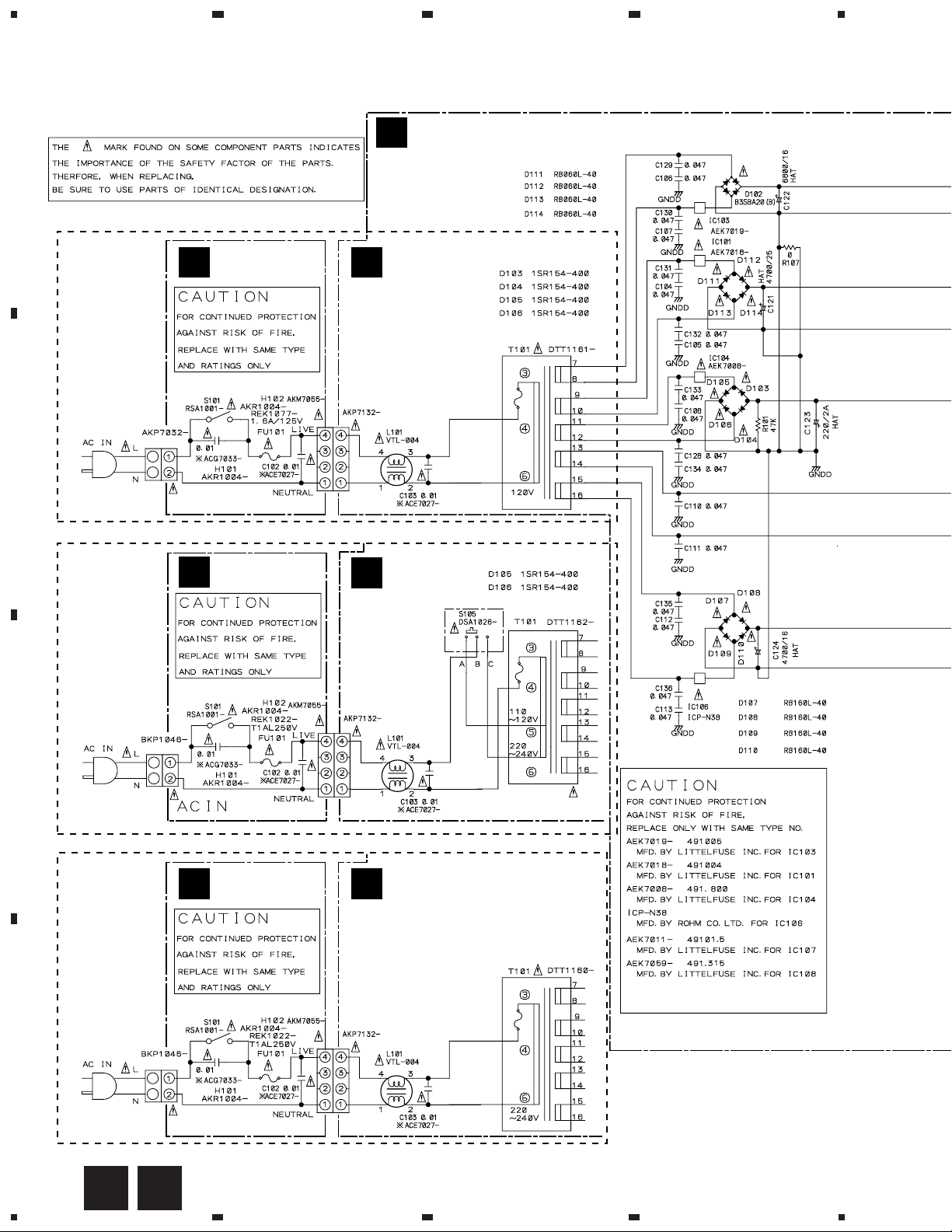

3.7 PWRB, REGB and ACIN ASSYS

A

KUCXJ type

AN101

B

AC CORD: ADG7022AC120V 60Hz

G

ACIN ASSY

(DWR1349)

CN102

23

F

PWRB ASSY

(KUCXJ: DWR1345)

(WYXJ: DWR1345)

(RLBXJ: DWR1348)

PWRB ASSY

F

(DWR1345)

CN103

4

(5A)

(4A)

(800mA)

RLBXJ type

AN101

C

AC CORD: ADG1154AC110-120V/ 220-240V

50/ 60Hz

WYXJ type

G

G

ACIN ASSY

(DWR1346)

CN102

ACIN ASSY

(DWR1346)

F

CN103

F

PWRB ASSY

(DWR1348)

PWRB ASSY

(DWR1345)

(800mA)

(1.5A)

CN102

D

AC CORD: ADG1154AC220-240V 50/ 60Hz

24

F

AN101

G

1234

CN103

Page 25

5

678

CMX-3000, CU-V163

A

CN106 J151

B

(315mA)

(1.5A)

CN104

CN105

CN1218

A

CN202

E

REGB ASSY

(KUCXJ: DWR1357)

H

(WYXJ, RLBXJ: DWR1347)

C

D

H

5

6

7

8

25

Page 26

1

23

CMX-3000, CU-V163

3.8 CNTA and PHTA ASSYS

M

4

CN702

A

CN303

Q369 2SC4081 (R/S)

Q361 2SC4081 (R/S)

Q372 2SC4081 (R/S)

Q373 2SC4081 (R/S)

Q368 2SC4081 (R/S)

B

Q370 2SC4081 (R/S)

Q371 2SC4081 (R/S)

Q362 2SC4081 (R/S)

Q363 2SC4081 (R/S)

Q364 2SC4081 (R/S)

Q365 2SC4081 (R/S)

Q366 2SC4081 (R/S)

Q367 2SC4081 (R/S)

C

SWITCHES

S301 : 1

S302 : ¡

S303 : 4

S304 : ¢

S305 : TIME MODE/ AUTO CUE

S306 : CD TEXT/ WAVE

S307 : PITCH BEND [ + ]

S308 : PITCH BEND [ - ]

S311 : MASTER TEMPO

S312 : TEMPO RANGE

S313 : 0 (EJECT)

S341 : 6

S342 : CUE

S343 : IN/REALTIME CUE

D

S344 : OUT/ OUT ADJ

S345 : JOG MODE

S346 : EXIT/RELOOP

S347 : EMERGENCY LOOP

26

I

1234

Page 27

5

678

CMX-3000, CU-V163

: The power supply is shown with the marked box.

CNTA ASSY

I

(DWG1551)

CN301

J302

PHTA ASSY

J

(DWG1554)

A

B

C

Q410

2SC4081 (R/S)

2SC4081 (R/S)

D

7

I

J

8

27

Q409

Q408

Q406

Q404

2SC4081 (R/S)

2SC4081 (R/S)

Q403

5

2SC4081 (R/S)

2SC4081 (R/S)

6

Page 28

1

23

CMX-3000, CU-V163

3.9 CNTB and PHTB ASSYS

4

M

CN704

M

CN703

A

CN504 CN503

Q569 2SC4081 (R/S)

Q561 2SC4081 (R/S)

Q572 2SC4081 (R/S)

Q573 2SC4081 (R/S)

Q568 2SC4081 (R/S)

B

Q570 2SC4081 (R/S)

Q571 2SC4081 (R/S)

Q562 2SC4081 (R/S)

Q563 2SC4081 (R/S)

Q564 2SC4081 (R/S)

Q565 2SC4081 (R/S)

Q566 2SC4081 (R/S)

Q567 2SC4081 (R/S)

C

SWITCHES

S501 : 1

S502 : ¡

S503 : 4

S504 : ¢

TIME MODE/ AUTO CUE

S505 :

S506 : CD TEXT/ WAVE

S507 : PITCH BEND [ + ]

S508 : PITCH BEND [ - ]

S511 : MASTER TEMPO

S512 : TEMPO RANGE

S513 : 0 (EJECT)

S514 : BPM S SYNC

S515 : RELAY PLAY

S521 : HOT CUE 1 - B

S522 : HOT CUE 2 - B

S523 : HOT CUE 3 - B

S524 : HOT CUE REC - B

S525 : AUTO - B

S526 : TAB - B

S531 : HOT CUE 1 - A

S532 : HOT CUE 2 - A

S533 : HOT CUE 3 - A

S534 : HOT CUE REC - A

S535 : AUTO - A

D

S536 : TAB S541 : 6

S542 : CUE

S543 : IN/ REALTIME CUE

S544 : OUT/ OUT ADJ

S545 : JOG MODE

S546 : EXIT/ RELOOP

S547 : EMERGENCY LOOP

28

K

1234

Page 29

5

678

CMX-3000, CU-V163

CNTB ASSY

K

(DWG1552)

: The power supply is shown with the marked box.

CN501

J502

PHTB ASSY

L

(DWG1555)

A

B

Q601

2SC4081 (R/S)

Q602

2SC4081 (R/S)

5

Q603

2SC4081 (R/S)

Q604

2SC4081 (R/S)

Q606

2SC4081 (R/S)

Q608

2SC4081 (R/S)

Q609

2SC4081 (R/S)

6

Q610

2SC4081 (R/S)

Q611

2SC4081 (R/S)

Q612

2SC4081 (R/S)

Q613

2SC4081 (R/S)

7

Q614

2SC4081 (R/S)

Q615

2SC4081 (R/S)

Q616

2SC4081 (R/S)

K

Q617

2SC4081 (R/S)

L

8

Q618

2SC4081 (R/S)

29

C

D

Page 30

1

CMX-3000, CU-V163

3.10 CNNB ASSY

A

CN504

K

B

CN704

CN703

23

: The power supply is shown with the marked box.

CNNB ASSY

M

(DWG1553)

4

CN503

K

CN702

CN303

I

C

D

30

M

1234

Page 31

Waveforms

1

2

1

2

IC1010- 16pin (FE)

IC1003- 16pin (FE)

V: 0.5V/div. H: 5mS/div.

IC1010- 14pin (TE)

IC1003- 14pin (TE)

V: 1V/div. H: 5mS/div.

Mode: Focus IN

2

2

IC1010- 14pin (TE)

IC1003- 14pin (TE)

V: 1V/div. H: 2mS/div.

Mode: Tracking Open

2

2

IC1010- 14pin (TE)

IC1003- 14pin (TE)

V: 0.5V/div. H: 2mS/div.

Mode: 1 Track Jump

3

3

IC1010- 28pin (RFO)

IC1003- 28pin (RFO)

V: 500mV/div. H: 500nS/div.

Mode: RF (Play Mode x1)

3

3

IC1010- 28pin (RFO)

IC1003- 28pin (RFO)

V: 500mV/div. H: 200nS/div.

Mode: RF (Play Mode x2)

4

4

IC1010- 25pin (RFGO)

IC1003- 25pin (RFGO)

V: 500mV/div. H: 500nS/div.

Mode: AGC RF (Play Mode x1)

4

4

IC1010- 25pin (RFGO)

IC1003- 25pin (RFGO

V: 500mV/div. H: 200nS/div.

Mode: AGC RF (PLAY MODE x2)

2

5

2

5

6

IC1010- 14pin (TE)

IC1003- 14pin (TE)

V: 1V/div. H: 0.2S/div.

IC1011- 6pin (SL+)

IC1004- 6pin (SL+)

V: 2V/div. H: 0.2S/div.

6

IC1011- 7pin (SL-)

IC1004- 7pin (SL-)

V: 2V/div. H: 0.2S/div.

Mode: 1 Track = 16 Track Serch

MAIN ASSY

3/3

A

CMX-3000, CU-V163

31

Page 32

CMX-3000, CU-V163

Voltage (1/3)

IC1200 (DYW1701)

Pin No. Voltage (V)

1 0 to 3.2

2 0 to 3.2

3 0 to 3.2

4 0 to 3.2

5 0 to 3.2

6 0 to 3.2

7 0 to 3.2

8 0 to 3.2

9 0 to 3.2

10 0.7

11 0.7

12 0 to 3.2

13 0.7

14 0.7

15 3.1

16 0 to 3.2

17 0 to 3.2

18 0 to 3.2

19 0 to 3.2

20 0 to 3.2

21 0 to 3.2

22 0 to 3.2

23 0 to 3.2

24 0 to 3.2

25 0 to 3.2

26 3.2

27 0

28 0 to 3.2

29 0 to 3.2

30 0 to 3.2

31 0 to 3.2

32 0 to 3.2

33 0 to 3.2

34 0 to 3.2

35 0 to 3.2

36 0 to 3.2

37 3.1

38 0 to 3.2

39 0 to 3.2

40 0 to 3.2

41 0 to 3.2

42 0 to 3.2

43 0 to 3.2

44 0 to 3.2

45 0 to 3.2

46 0

47 3.1

48 0 to 3.2

IC1022 (M51957BFP)

Pin No. Voltage (V)

1 0

2 0

3 0

4 0

5 1.3

6 3.2

7 3.2

8 0

A

1/3

MAIN ASSY

IC1204 (HD6417709AF100B)

Pin No. Voltage (V)

1 3.2

2 0

3 1.8

4 1.6

5 0

6 0

7 0

8 0

9 0

10 3.3

11 3.2

12 3.3

13 0 to 3.3

14 0

15 0

16 0

17 3.3

18 3.3

19 0

20 0

21 3.3

22 0

23 0

24 0

25 0

26 0

27 0

28 0

29 1.8

30 0

31 0

32 0

33 0

34 0 to 3.3

35 3.2

36 0 to 3.3

37 0 to 3.3

38 0 to 3.3

39 0 to 3.3

40 0 to 3.3

41 0 to 3.3

42 0 to 3.3

43 0 to 3.3

44 0 to 3.3

45 0

46 0 to 3.3

47 3.3

48 0 to 3.3

49 0 to 3.3

50 0 to 3.3

51 0 to 3.3

52 0 to 3.3

53 0 to 3.3

54 0 to 3.3

55 0 to 3.3

56 0 to 3.3

57 0

58 0 to 3.3

59 3.3

60 0 to 3.3

61 0 to 3.3

62 0 to 3.3

63 0 to 3.3

64 0 to 3.3

65 0 to 3.3

66 0 to 3.3

67 0 to 3.3

68 0 to 3.3

69 0

70 0 to 3.3

71 3.3

72 0 to 3.3

73 0 to 3.3

74 0 to 3.3

75 0 to 3.3

76 0 to 3.3

77 0 to 3.3

78 0 to 3.3

79 0

80 0

81 1.8

82 0 to 3.3

83 0

84 0 to 3.3

85 3.3

86 0 to 3.3

87 3.2

88 0 to 3.3

89 0 to 3.3

90 0 to 3.3

Pin No. Voltage (V)

91 3.2

92 3.2

93 0 to 3.3

94 3.2

95 0

96 3.3

97 3.3

98 0 to 3.3

99 0 to 3.3

100 0 to 3.3

101 3.2

102 3.2

103 3.2

104 3.2

105 3.2

106 0 to 3.3

107 0 to 3.3

108 0 to 3.3

109 0

110 0

111 3.2

112 0

113 0

114 0 to 3.3

115 0 to 3.3

116 3.2

117 3.2

118 0

119 0

120 3.3

121 3.2

122 3.2

123 3.2

124 3.2

125 3.2

126 3.1

127 3

128 3.2

129 2.8

130 0

131 0

132 0

133 3.2

134 1.8

135 3.2

136 3.0

137 3.0

138 3.0

139 3.0

140 3.1

141 0

142 3.0

143 0

144 0

145 1.8

146 0.7

147 0

148 0

149 0.7

150 1.8

151 1.9

152 0

153 0

154 1.8

155 1.6

156 1.1

157 3.2

158 3.2

159 3.2

160 0 to 3.2

161 0

162 0 to 3.2

163 3.2

164 0

165 3.2

166 3.2

167 0 to 3.2

168 0 to 3.2

169 0

170 0

171 3.2

172 3.2

173 0

174 0 to 3.2

175 1.8

176 3.0

177 0 to 3.2

178 0 to 3.2

179 0 to 3.2

180 0 to 3.2

Pin No. Voltage (V)

181 0

182 0 to 3.2

183 3.2

184 0 to 3.2

185 0 to 3.2

186 0 to 3.2

187 0 to 3.2

188 0 to 3.2

189 0 to 3.2

190 0 to 3.2

191 0 to 3.2

192 0 to 3.2

193 3.2

194 3.1

195 0

196 3.1

197 0

198 0

199 3.0

200 3.0

201 3.2

202 3.2

203 3.1

204 0

205 3.2

206 0.7

207 0.7

208 0

IC1408 (K4S281632)

Pin No. Voltage (V)

1 3.2

2 0 to 3.3

3 3.2

4 0 to 3.3

5 0 to 3.3

6 0

7 0 to 3.3

8 0 to 3.3

9 3.2

10 0 to 3.3

11 0 to 3.3

12 0

13 0 to 3.3

14 3.2

15 0 to 3.3

16 0 to 3.3

17 0 to 3.3

18 0 to 3.3

19 0 to 3.3

20 0 to 3.3

21 0 to 3.3

22 0 to 3.3

23 0 to 3.3

24 0 to 3.3

25 0 to 3.3

26 0 to 3.3

27 3.2

28 0

29 0 to 3.3

30 0 to 3.3

31 0 to 3.3

32 0 to 3.3

33 0 to 3.3

34 0 to 3.3

35 0 to 3.3

36 0

37 3.2

38 0 to 3.3

39 0 to 3.3

40 0.7

41 0

42 0 to 3.3

43 3.2

44 0 to 3.3

45 0 to 3.3

46 0

47 0 to 3.3

48 0 to 3.3

49 3.2

50 0.7

51 0 to 3.3

52 0

53 0 to 3.3

54 0

32

Page 33

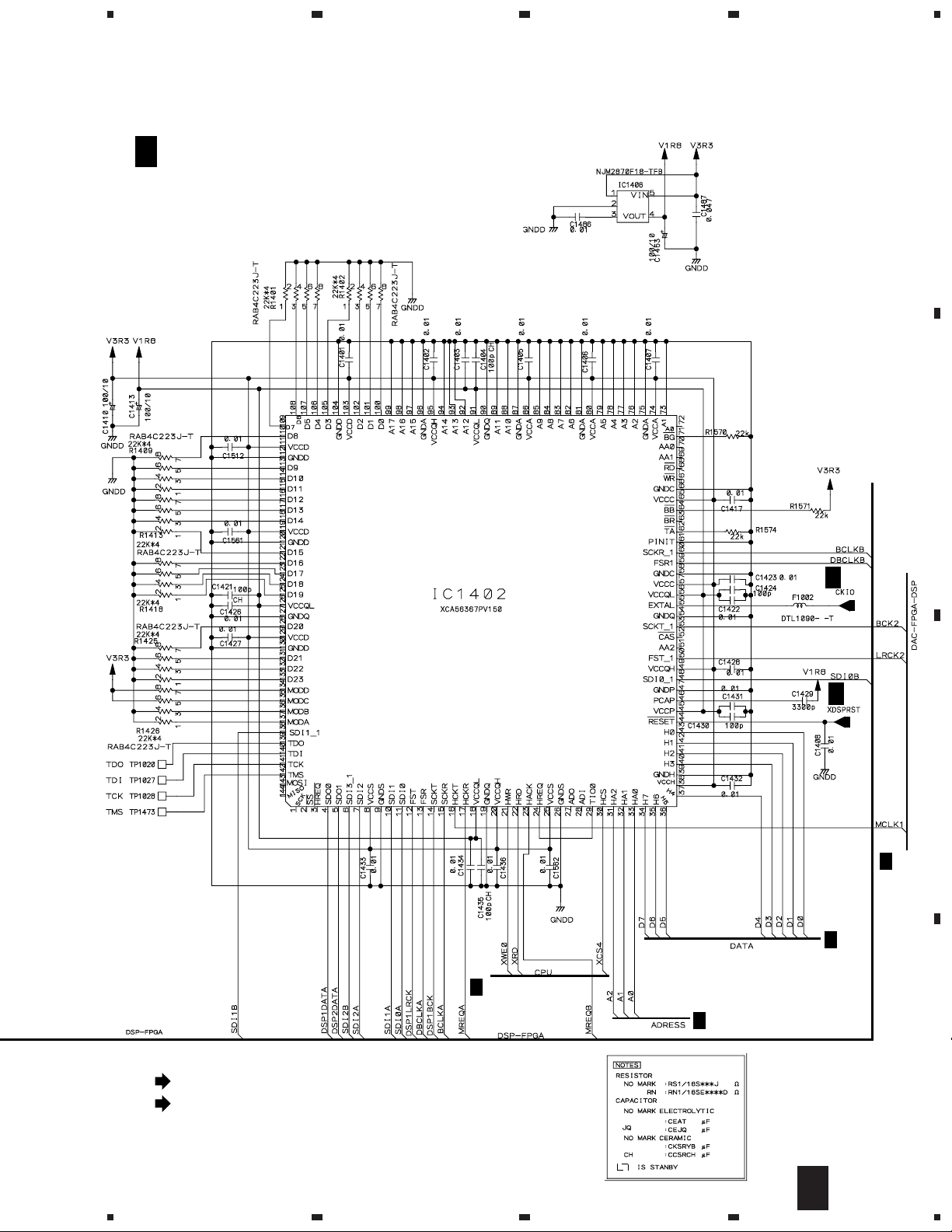

Voltage (2/3)

IC1402 (XCA56367PV150)

Pin No. Voltage (V)

1 1.1

2 0.7

3 0.6

4 0 to 3.2

5 0 to 3.2

6 0 to 3.2

7 0 to 3.2

8 3.2

9 0

10 0 to 3.2

11 0 to 3.2

12 0 to 3.2

13 0 to 3.2

14 0

15 0 to 3.2

16 0 to 3.2

17 0 to 3.2

18 1.8

19 0

20 3.3

21 0 to 3.2

22 0 to 3.2

23 0 to 3.2

24 0

25 3.2

26 0

27 0

28 0.7

29 0

30 3.2

31 3.2

32 0.8

33 0 to 3.2

34 0 to 3.2

35 0 to 3.2

36 0 to 3.2

37 0 to 3.2

38 3.2

39 0

40 0 to 3.2

41 0 to 3.2

42 0 to 3.2

43 0 to 3.2

44 3.2

45 1.8

46 0.9

47 0

48 0 to 3.2

49 3.2

50 0 to 3.2

51 0.9

52 0.7

53 3.2

54 0 to 3.2

55 0

56 0 to 3.4

57 1.8

58 0

59 0 to 3.2

60 0 to 3.2

61 0.7

62 0

63 3.2

64 3.1

65 3.2

66 0

67 0.7

68 0.7

69 0.7

70 0.7

71 0

72 0.7

73 0

74 3.2

75 0

76 0

77 0

78 0

79 0

80 3.2

81 0

82 0

83 0

84 0

85 0

86 3.2

87 0

88 0

89 0

90 0

Pin No. Voltage (V)

91 1.8

92 0

93 0

94 0

95 3.2

96 0

97 0

98 0

99 0

100 0

101 0

102 0

103 3.2

104 0

105 0

106 0

107 0

108 0

109 0

110 0

111 3.2

112 0

113 0

114 0.6

115 0.6

116 0

117 0

118 0.6

119 0.7

120 0.7

121 0

122 0

123 0

124 0

125 0

126 0

127 0

128 0

129 3.2

130 0

131 0

132 0

133 0

134 2.6

135 0

136 0

137 0

138 1 to 3.2

139 0

140 0

141 0

142 0

143 0

144 0.6

A

2/3

MAIN ASSY

IC1409 (XC2S30-5TQ144C)

Pin No. Voltage (V)

1 3.2

2 2.4

3 3.1

4 0.4 to 2.1

5 0 to 3.1

6 0 to 3.1

7 0 to 3.1

8 0

9 0

10 0.4 to 2.9

11 0 to 3.1

12 0 to 3.1

13 0 to 3.1

14 2.5

15 0 to 3.1

16 0.7

17 0.6

18 0.6

19 0.6

20 0.6

21 3.2

22 0.6

23 0 to 4.9

24 2.5

25 0.6

26 0.6

27 0

28 0 to 4.9

29 0 to 4.9

30 11 to 3.8

31 0 to 4.9

32 2.4

33 0.6

34 0.6

35 3.2

36 0.6

37 3.2

38 0

39 0

40 0 to 3.0

41 0 to 3.2

42 0

43 0 to 3.2

44 0 to 3.2

45 0

46 0 to 3.2

47 0 to 3.2

48 0 to 3.2

49 0 to 3.2

50 0 to 3.2

51 0 to 3.2

52 0

53 3.2

54 0 to 3.2

55 2.5

56 0 to 3.2

57 0 to 3.2

58 0 to 3.2

59 0 to 3.2

60 0 to 3.2

61 0

62 0

63 0 to 3.0

64 0

65 0 to 3.0

66 0 to 3.1

67 2.9

68 2.9

69 3.2

70 3.2

71 3.2

72 3.2

73 0

74 0 to 3.1

75 0 to 3.1

76 0 to 3.1

77 0.6

78 0 to 3.1

79 0 to 3.1

80 0 to 3.1

81 0

82 2.5

83 0.6

84 0

85 0

86 3.2

87 0

88 0.7 to 2.6

89 0

90 0.6

Pin No. Voltage (V)

91 0

92 2.5

93 0

94 3.2

95 0

96 0 to 3.2

97 2.5

98 0

99 0 to 3.2

100 3.2

101 0

102 3.2

103 0 to 3.2

104 0.6

105 0.6

106 0

107 3.2

108 3.2

109 2.5

110 0

111 2.5

112 0 to 3.2

113 0 to 3.2

114 0 to 3.2

115 0 to 3.2

116 0

117 0 to 3.2

118 0 to 3.2

119 0

120 0 to 3.2

121 0 to 3.2

122 0 to 3.2

123 0 to 3.2

124 0 to 3.2

125 0.6

126 3.2

127 0

128 0.7

129 0.7

130 0 to 3.2

131 0 to 3.2

132 0 to 4.9

133 0.7

134 0

135 0

136 0 to 4.9

137 0 to 4.9

138 0 to 4.9

139 0 to 4.9

140 1 to 3.8

141 3.2

142 2.4

143 0

144 3.2

CMX-3000, CU-V163

IC1414 (BA7042)

Pin No. Voltage (V)

1 0

2 2.3

3 0

4 0

5 2.5 to 4.5

6 5.0

7 2.6

8 2.6

33

Page 34

CMX-3000, CU-V163

Voltage (3/3)

A

3/3

MAIN ASSY

IC1005 (TC9495F)

Pin No. Voltage (V)

1 4.4

2 0

3 5.0

4 0

5 0 to 4.9

6 0

7 0.3 to 4.4

8 0 to 4.9

9 0

10 0

11 0

12 5.0

13 0 to 4.2

14 5.0

15 0

16 0 to 4.9

17 0 to 4.9

18 0 to 4.9

19 0.3 to 4.2

20 0 to 4.7

21 0 to 4.9

22 0 to 4.5

23 4.9

24 0

25 4.2

26 2.1

27 0 to 4.9

28 5.0

29 0

30 4.2

31 2.1

32 2.0

33 2.1

34 2.1

35 1.3

36 0

37 2.1

38 1.6 to 2.6

39 5.0

40 3.0

41 3.1

42 2.5 to 2.9

43 2.5 to 2.9

44 2.5

45 2.1

46 1.4 to 2.9

47 0 to 4.1

48 0.7 to 2.2

49 1.4 to 3.4

50 2.1

51 0.4 to 2.1

52 2.1

53 0.4 to 2.1

54 2.1

55 0 to 4.2

56 4.2

57 2.1

58 0 to 5.0

59 5.0

60 5.0

61 0

62 5.0

63 0

64 5.0

65 0

66 0

67 0 to 5.0

68 4.9

69 4.9

70 4.9

71 0

72 0

73 0

74 0

75 5.0

76 5.0

77 0

78 1.0 to 3.0

79 0.5 to 4.5

80 5.0

81 0

82 0.4

83 0

84 0

85 0.4

86 0

87 4.8

88 4.8

89 4.8

90 0 to 5.0

Pin No. Voltage (V)

91 0 to 5.0

92 0 to 5.0

93 0 to 5.0

94 5.0

95 0

96 5.0

97 0 to 5.0

98 4.7

99 4.7

100 5.0

IC1010 (TA2153FN)

Pin No. Voltage (V)

1 4.9

2 1.8

3 2.1

4 2.1

5 2.1

6 2.0

7 2.1

8 0

9 4.3

10 0

11 2.1

12 4.1

13 2.1

14 2.1

15 1.2

16 2.1

17 2.1

18 0.0

19 2.1

20 1.1

21 1.8

22 1.1

23 0.5

24 2.0

25 2.1

26 0

27 2.2

28 1.0 to 2.1

29 0

30 2.1

IC1011(LA6562)

Pin No. Voltage (V)

1 4.3

2 4.3

3 7.3

4 3.3

5 3.3

6 3.4

7 3.2

8 2.5

9 3.5

10 0

11 3.7

12 3.4

13 3.8

14 3.7

15 7.3

16 2.0

17 2.0

18 2.0

19 2.0

20 2.0

21 2.0

22 2.0

23 2.0

24 2.0

25 1.0

26 0.6

27 1.0

28 2.0

29 0

30 2.0

31 2.0

32 2.0

33 2.0

34 2.5

35 2.5

36 2.0

37 0

38 3.2

IC201 (PE8001)

Pin No. Voltage (V)

1 0 to 3.1

2 0 to 3.1

3 0 to 3.1

4 0.3 to 4.4

5 0.5 to 2.7

6 0.8 to 4.8

7 0

8 5.0

9 5.0

10 0

11 0 to 2.5

12 0

13 2.5

14 0

15 5.0

16 2.2

17 0.7

18 0

19 0

20 5.0

21 3.0

22 0

23 0

24 0

25 0 to 4.9

26 0

27 0.5

28 3.2

IC301 (PD5764A)

Pin No. Voltage (V)

1 0

2 0

3 0

4 0

5 5.0

6 5.0

7 0

8 0

9 0

10 0 to 5.0

11 0 to 5.0

12 0 to 5.0

13 0 to 5.0

14 0 to 5.0

15 0 to 5.0

16 0 to 5.0

17 0

18 5.0

19 0 to 5.0

20 0 to 5.0

21 0

22 0 to 4.3

23 0 to 5.0

24 5.0

25 0

26 0

27 0

28 0

29 0 to 5.0

30 0 to 5.0

31 0 to 5.0

32 0 to 5.0

33 5.0

34 5.0

35 5.0

36 5.0

37 -31 to 5.0

38 -31 to 5.0

39 -31 to 5.0

40 -31 to 5.0

41 -31 to 5.0

42 -31 to 5.0

43 -31 to 5.0

44 -31 to 5.0

45 -31 to 5.0

46 -31 to 5.0

47 -31 to 5.0

48 -31 to 5.0

49 -31 to 5.0

50 -31 to 5.0

JACB ASSY

E

CNTA ASSY

I

Pin No. Voltage (V)

IC211 (NJM2360M)

Pin No. Voltage (V)

1 7.1

2 0 to 5.6

3 -7.5

4 -7.9

5 0.5

6 6.9

7 6.9

8 6.9

51 -31 to 5.0

52 -31 to 5.0

53 -31 to 5.0

54 -31 to 5.0

55 -31 to 5.0

56 -31 to 5.0

57 -31 to 5.0

58 -31 to 5.0

59 -31 to 5.0

60 -31 to 5.0

61 -31 to 5.0

62 -31 to 5.0

63 -31 to 5.0

64 -31 to 5.0

65 -31 to 5.0

66 -31 to 5.0

67 -31 to 5.0

68 -31 to 5.0

69 -31 to 5.0

70 -31 to 5.0

71 -31 to 5.0

72 -31 to 5.0

73 -31

74 -31

75 -31

76 -31 to 5.0

77 -31 to 5.0

78 -31 to 5.0

79 -31 to 5.0

80 -31 to 5.0

81 -31 to 5.0

82 -31 to 5.0

83 -31 to 5.0

84 -31 to 5.0

85 -31 to 5.0

86 -31 to 5.0

87 -31 to 5.0

88 -31 to 5.0

89 -31

90 0 to 5.0

91 0 to 5.0

92 0 to 5.0

93 1.3

94 0 to 5.0

95 0 to 5.0

96 0

97 0

98 5.0

99 2.5

100 0 to 5.0

IC501 (PD5764A)

Pin No. Voltage (V)

1 5.0

2 5.0

3 5.0

4 5.0

5 5.0

6 5.0

7 0 to 5.0

8 0 to 5.0

9 0

10 0 to 5.0

11 0 to 5.0

12 0 to 5.0

13 0 to 5.0

14 0 to 5.0

15 0

16 0

17 0

18 5.0

19 0

20 0

21 0

22 0 to 4.0

23 0 to 5.0

24 0 to 5.0

25 5.0

26 0 to 5.0

27 0 to 5.0

28 0 to 5.0

29 0 to 5.0

30 0 to 5.0

31 0 to 5.0

32 0 to 5.0

33 5.0

34 5.0

35 0 to 5.0

36 0 to 5.0

37 -31 to 5.0

38 -31 to 5.0

39 -31 to 5.0

40 -31 to 5.0

41 -31 to 5.0

42 -31 to 5.0

43 -31 to 5.0

44 -31 to 5.0

45 -31 to 5.0

46 -31 to 5.0

47 -31 to 5.0

48 -31 to 5.0

49 -31 to 5.0

50 -31 to 5.0

CNTB ASSY

K

Pin No. Voltage (V)

51 -31 to 5.0

52 -31 to 5.0

53 -31 to 5.0

54 -31 to 5.0

55 -31 to 5.0

56 -31 to 5.0

57 -31 to 5.0

58 -31 to 5.0

59 -31 to 5.0

60 -31 to 5.0

61 -31 to 5.0

62 -31 to 5.0

63 -31 to 5.0

64 -31 to 5.0

65 -31 to 5.0

66 -31 to 5.0

67 -31 to 5.0

68 -31 to 5.0

69 -31 to 5.0

70 -31 to 5.0

71 -31 to 5.0

72 -31 to 5.0

73 -31

74 -31

75 -31

76 -31 to 5.0

77 -31 to 5.0

78 -31 to 5.0

79 -31 to 5.0

80 -31 to 5.0

81 -31 to 5.0

82 -31 to 5.0

83 -31 to 5.0

84 -31 to 5.0

85 -31 to 5.0

86 -31 to 5.0

87 -31 to 5.0

88 -31 to 5.0

89 -31

90 0 to 5.0

91 0 to 5.0

92 0 to 5.0

93 5.0

94 0 to 5.0

95 0 to 5.0

96 5.0

97 0

98 5.0

99 2.5

100 0 to 5.0

34

Page 35

4. PCB CONNECTION DIAGRAM

NOTE FOR PCB DIAGRAMS :

1. Part numbers in PCB diagrams match those in the schematic

diagrams.

2. A comparison between the main parts of PCB and schematic

diagrams is shown below.

Symbol In PCB

Diagrams

BCE

BCE

Symbol In Schematic

Diagrams

BCEBCE

BCE

BCE

Part Name

Transistor

Transistor

with resistor

CMX-3000, CU-V163

3. The parts mounted on this PCB include all necessary parts for

several destinations.

For further information for respective destinations, be sure to

check with the schematic diagram.

4. View point of PCB diagrams.

Connector

Capacitor

SIDE A

DGGSS

D

DGS

Field effect

transistor

Resistor array

3-terminal

regulator

P.C.Board

Chip Part

SIDE B

35

Page 36

1

234

CMX-3000, CU-V163

4.1 MAIN, FRSW, SLM1 and SLM2 ASSYS

A

SLM1 ASSY

C

FRSW ASSY

B

SIDE A

(DNP2002-C)

To Slot Mecha (A)

pick up Assy (CN1)

MAIN ASSY

B

A

CN1012

A

(DNP2002-C)

CN201

E

To Slot Mecha (A) Loading Motor (J4)To Slot Mecha (A) Servo Mecha

C

D

(DNP2003-B)

IC1011

IC1445

IC1448IC1447

IC1005

IC1010

Q1003

Q1002

IC1428

IC1013

IC1006

IC1409

IC1408

IC1406

IC1015 IC1012

B

J161

IC1415 IC1414

IC1431IC1430IC1008 IC1007

36

A B C

1234

Page 37

5

67

8

CMX-3000, CU-V163

A

SLM2 ASSY

D

201

(DNP2002-C)

To Slot Mecha (B)

Servo Mecha

To Slot Mecha (B)

Loading Motor (J4)

SIDE A

To Slot Mecha (B)

pick up Assy (CN1)

B

C

D

IC1450

IC1002

Q1229

IC1003

DA

8

Q1228

37

IC1208IC1001IC1440

IC1204IC1408

7

IC1200

IC1009 IC1014 IC1427IC1022IC1017

5

CN104

F

6

IC1437 IC1444

IC1016

7

IC1004

IC1443

Page 38

1

CMX-3000, CU-V163

A

SIDE B

MAIN ASSY

A

B

MAIN ASSY

A

234

C

D

38

A

1234

Page 39

5

67

8

CMX-3000, CU-V163

A

SIDE B

B

C

(DNP2003)

D

5

6

7

8

A

39

Page 40

1

CMX-3000, CU-V163

4.2 PWRB, REGB and ACIN ASSYS

A

REGB ASSY

H

(DNP2002-C)

SIDE A

F

B

234

CN1218

A

PWRB ASSY

IC103

IC104

IC106IC101

C

ACIN ASSY

G

D

(DNP2002-C)

40

F

ACIN

G

1234

H

(DNP2002-C)

Page 41

1

23

4

CMX-3000, CU-V163

A

JACB ASSY

E

JA701

M

IC209

IC212

IC210

IC207

SIDE A

IC213

Q171

Q215

B

C

(DNP2002-C)

1

D

2

3

4

E

41

Page 42

1

CMX-3000, CU-V163

JACB ASSY

E

A

IC172

SIDE B

B

234

Q213

Q214

Q201

Q202

Q208

C

Q206

Q207

IC201IC204

Q205

Q212

Q211

D

42

E

IC205 IC202

Q209

Q210

1234

Q203

Q204

(DNP2002-C)

Page 43

1

23

4

CMX-3000, CU-V163

REGB ASSY

H

A

(DNP2002-C)

SIDE B

PWRB ASSY

F

B

C

D

(DNP2002-C)

F

1

2

3

H

4

43

Page 44

1

CMX-3000, CU-V163

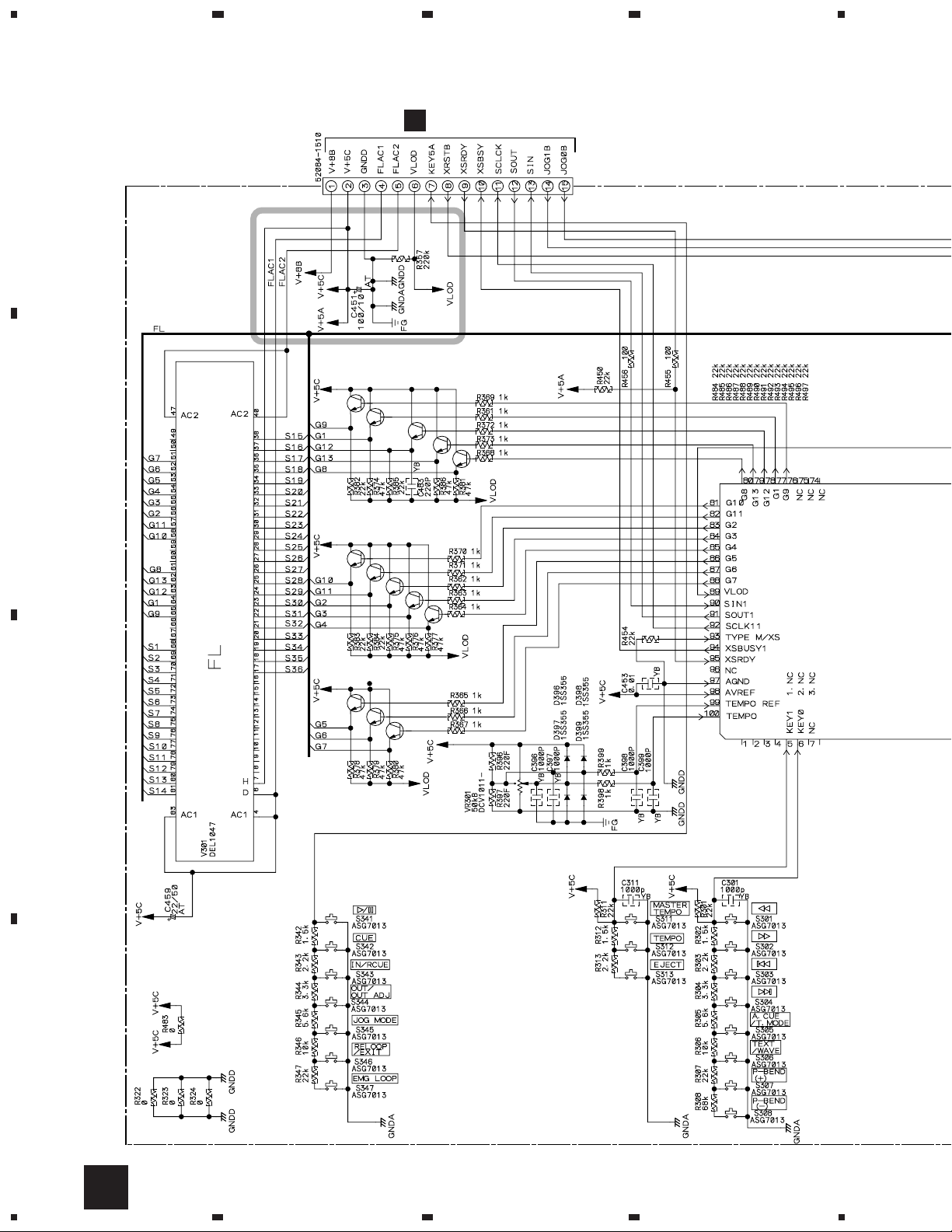

4.3 CNTA and PHTA ASSYS

A

234

I

CNTA ASSY

SIDE A

B

J

PHTA ASSY

C

(DNP2004-B)

CN702

M

D

(DNP2004-B)

44

I

SWITCHES FUNCTION

S301 : 1

S302 : ¡

S303 : 4

S304 : ¢

S305 : AUTO CUE/ TIME MODE

S306 : TEXT/ WAVE

S307 : PITCH BEND [ + ]

S308 : PITCH BEND [ - ]

S311 : MASTER TEMPO

S312 : TEMPO

S313 : 0 (EJECT)

S341 : 6

S342 : CUE

S343 : IN/REALTIME CUE

S344 : OUT/ OUT ADJ

S345 : JOG MODE

S346 : RELOOP/ EXIT

S347 : EMERGENCY LOOP

J

1234

Page 45

1

I

CNTA ASSY

SIDE B

23

CMX-3000, CU-V163

4

A

J

PHTA ASSY

(DNP2004-B)

B

C

D

Q369

Q408

Q409

1

IC305Q410

2

IC304

IC303

Q368

Q361 Q370

Q372

Q371

Q373 Q362

Q406 Q403 Q404

Q363

Q364

Q365

Q366

Q367

IC301

(DNP2004-B)

I

3

J

4

45

Page 46

1

H

CMX-3000, CU-V163

4.4 CNTB and PHTB ASSYS

A

SIDE A

234

P

L

CNTB ASSY

K

(DNP2002-B)

B

C

SWITCHES FINCTION

S501 : 1

S502 : ¡

S503 : 4

S504 : ¢

S505 :

AUTO CUE/ TIME MODE

S506 : TEXT/ WAVE

S507 : PITCH BEND [ + ]

S508 : PITCH BEND [ - ]

D

46

K

1234

S511 : MASTER TEMPO

S512 : TEMPO RANGE

S513 : 0 (EJECT)

S514 : BPM SYNC

S515 : RELAY PLAY

S521 : HOT CUE 1 - B

S522 : HOT CUE 2 - B

S523 : HOT CUE 3 - B

S524 : HOT CUE REC - B

S525 : BPM AUTO - B

S526 : BPM TAP - B

S531 : HOT CUE 1 - A

S532 : HOT CUE 2 - A

S533 : HOT CUE 3 - A

S534 : HOT CUE REC - A

S535 : BPM AUTO - A

S536 : BPM TAP - A

S541 : 6

S542 : CUE

S543 : IN/ REALTIME CUE

S544 : OUT/ OUT ADJ

S545 : JOG MODE

S546 : RELOOP/ EXIT

S547 : EMERGENCY LOOP

Page 47

P2002-B)

PHTB ASSY

L

5

67

8

CMX-3000, CU-V163

A

SIDE A

B

C

IC502

5

6

(DNP2002-B)

D

7

K

L

8

47

Page 48

1

CMX-3000, CU-V163

4.5 CNTB, PHTB and CNNB ASSYS

A

PHTB ASSY

L

SIDE B

234

CNNB ASSY

M

SIDE A

B

C

CNTB ASSY

K

(DNP2004-B)

D

(DNP2004-B)

48

K

1234

L

M

Q569Q561Q572Q573

Q568Q570Q571Q562

Q563IC501 Q564Q565Q566Q567

Q608Q609

Q60IC503

Page 49

5

IC701

E

67

CMX-3000, CU-V163

JA207

(DNP2004-B)

SIDE A

I

8

A

CN303

B

SIDE B

C

Q606 Q615 Q611

Q603

Q604

Q616

Q618

5

Q601Q602

Q612

Q613Q614Q617

6

D

7

K

M

8

49

Page 50

CMX-3000, CU-V163

5. PCB PARTS LIST

NOTES:•Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

• LIST OF WHOLE PCB ASSEMBLIES (FOR CMX-3000)

Mark

NSP POWB ASSY DWM2130 DWM2127 DWM2131

1: Although DWR1357 and DWR 1347 are different in part number, they consist of the same components.

*

2: Although DWX2214 and DWX2200 are different in part number, they consist of the same components.

*

The mark found on some component parts indicates the importance of the safety factor of the part.

•

Therefore, when replacing, be sure to use parts of identical designation.

When ordering resistors, first convert resistance values into code form as shown in the following examples.

•

Ex.1 When there are 2 effective digits (any digit apart from 0), such as 560 ohm and 47k ohm (tolerance is shown by J=5%,

and K=10%).

560 Ω→56 × 10

47k Ω→47 × 10

0.5 Ω→R50 ..................................................................................... RN2H

1 Ω→1R0 ..................................................................................... RS1P 1 R 0 K

Ex.2 When there are 3 effective digits (such as in high precision metal film resistors).

5.62k Ω→ 562 × 10

Symbol and Description

MAIN ASSY DWG1556 DWG1556 DWG1556

PWRB ASSY DWR1345 DWR1345 DWR1348

ACIN ASSY DWR1349 DWR1346 DWR1346

REGB ASSY DWR1357 DWR1347 DWR1347

FRSW ASSY DWS1314 DWS1314 DWS1314

SLM1 ASSY DWS1315 DWS1315 DWS1315

SLM2 ASSY DWS1316 DWS1316 DWS1316

JACB ASSY DWX2214 DWX2200 DWX2200

1

→ 561 ........................................................ RD1/4PU 5 6 1 J

3

→ 473 ........................................................ RD1/4PU 4 7 3 J

R 5 0

1

→ 5621 ...................................................... RN1/4PC 5 6 2 1 F

Part No.

CMX-3000/

KUCXJ

CMX-3000/

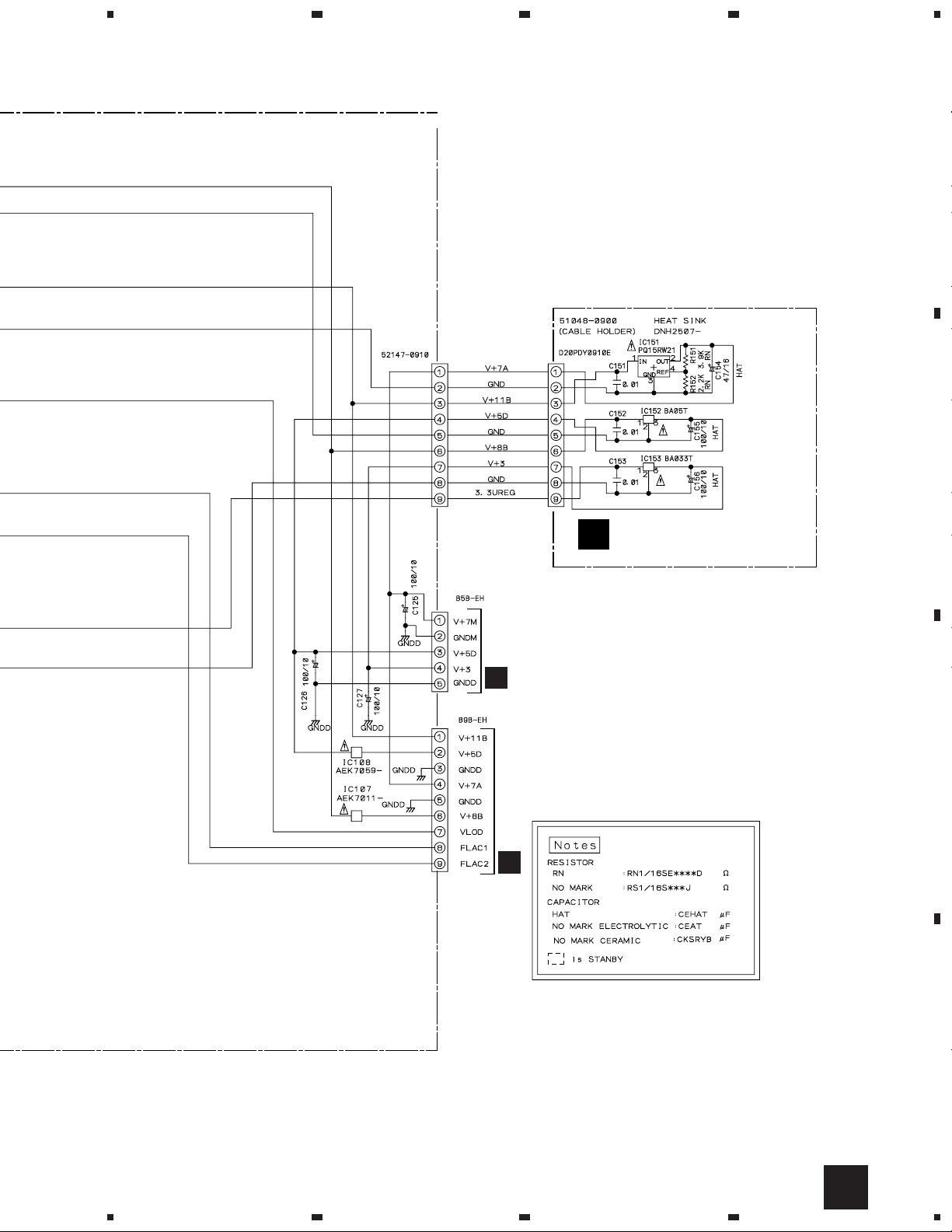

WYXJ

CMX-3000/

RLBXJ

K

1

*

2

*

Remarks

• LIST OF PCB ASSEMBLIES (FOR CU-V163)

NSP CONT ASSY DWM2129

CNTA ASSY DWG1551

CNTB ASSY DWG1552

CNNB ASSY DWG1553

PHTA ASSY DWG1554

PHTB ASSY DWG1555

• CONTRAST OF PCB ASSEMBLIES

PWRB ASSY

F

DWR1345 and DWR1348 are constructed the same except for the following:

Mark

ACIN ASSY

H

Symbol and Description

DWR1345 DWR1348

S105 (Voltage Selector) Not used DSA1026

DWR1349 and DWR1346 are constructed the same except for the following:

Mark

Symbol and Description

DWR1349 DWR1346

AN101 (Power Socket) AKP7032 Not used

AN101 (1P AC Inlet) Not used BKP1046

Part No.

Part No.

Remarks

Remarks

50

Page 51

CMX-3000, CU-V163

• PARTS LIST FOR CMX-3000/ KUCXJ

Mark No. Description Part No. Mark No. Description Part No.

MAIN ASSY

A

SEMICONDUCTORS

IC1012, IC1013 (315 mA) AEK7059

IC1014 (500 mA) AEK7060

IC1015, IC1016 (1.5 A) AEK7065

IC1414, IC1415 BA7042

IC1200 DYW1701

IC1204 HD6417709AF100B

IC1408 K4S281632C-TC1H

IC1004, IC1011 LA6562

IC1022 M51957BFP

IC1208 MM1561JF

IC1444, IC1445, IC1448, IC1450 NJM2100M

IC1406 NJM2870F18

IC1009 NJM2870F25

IC1443, IC1447 NJM2903M

IC1003, IC1010 TA2153FN

IC1440 TC74VHC02FT

IC1437 TC74VHC04FT

IC1427, IC1428 TC74VHCT245AFT

IC1001 TC74VHCT541AFT

IC1430, IC1431 TC7SU04FU

IC1017 TC7W08FU

IC1007, IC1008 TC7WT241FU

IC1006 TC7WU04FU

IC1002, IC1005 TC9495F

IC1409 XC2S30-5TQ144C

IC1402 XCA56367PV150

Q 1003, Q 1229 2SA1036K

Q 1002, Q 1228 DTC114TK

D1202, D1203 UDZ2.0B

COILS AND FILTERS

L1004, L1006, L1007, L1009 DTL1024

F1001, F1002 DTL1090

L1021, L1022 LCYAR68J2520

CAPACITORS

C1117, C1174, C1579, C1582, C1593 CCSRCH100D50

C1104, C1106, C1166, C1168, C1404 CCSRCH101J50

C1421, C1424, C1430, C1435 CCSRCH101J50

C1033, C1034 CCSRCH120J50

C1581, C1592 CCSRCH121J50

C1587, C1588, C1597, C1599 CCSRCH180J50

C1121, C1178 CCSRCH270J50

C1099, C1100, C1164, C1165 CCSRCH330J50

C1064, C1128, C1149, C1186 CCSRCH470J50

C1074, C1156, C1616, C1617 CCSRCH471J50

C1107, C1169 CCSRCK2R0C50

C1004, C1006, C1009, C1024 CEAT101M10

C1035, C1036, C1093, C1105, C1124 CEAT101M10

C1135, C1137, C1161, C1167, C1181 CEAT101M10

C1192, C1194, C1206, C1215, C1216 CEAT101M10

C1227, C1410, C1413, C1453, C1531 CEAT101M10

C1552 CEAT101M10

C1132, C1189 CEAT221M10

C1012, C1047, C1559, C1560 CEJQ101M6R3

C1507, C1510 CEJQ1R0M50

C1508, C1511 CEJQ220M25

C1013, C1014, C1017 CKSRYB102K50

C1010, C1015, C1019, C1020, C1023 CKSRYB103K50

C1025, C1026, C1029, C1032 CKSRYB103K50

C1044-C1046, C1048, C1055, C1065 CKSRYB103K50

C1071, C1094, C1095, C1098 CKSRYB103K50

C1108-C1111, C1118, C1127, C1136 CKSRYB103K50

C1139, C1142-C1144, C1150, C1151 CKSRYB103K50

C1154, C1162, C1163, C1175, C1185 CKSRYB103K50

C1193, C1196, C1401-C1403 CKSRYB103K50

C1405-C1408, C1417, C1422, C1423 CKSRYB103K50

C1426-C1428, C1431-C1434, C1436 CKSRYB103K50

C1486, C1512, C1533, C1534 CKSRYB103K50

C1536, C1537, C1539, C1554 CKSRYB103K50

C1561-C1564, C1577, C1578 CKSRYB103K50

C1583-C1585, C1589, C1590 CKSRYB103K50

C1594-C1596, C1598, C1601, C1603 CKSRYB103K50

C1606, C1608-C1615, C1619, C1620 CKSRYB103K50

C1001, C1003, C1007, C1008, C1018 CKSRYB104K25

C1022, C1037-C1042, C1050, C1051 CKSRYB104K25

C1056, C1061, C1069, C1070, C1081 CKSRYB104K25

C1085-C1091, C1113, C1114, C1129 CKSRYB104K25

C1133, C1138, C1140, C1170, C1171 CKSRYB104K25

C1183, C1190, C1195, C1197 CKSRYB104K25

C1202, C1203, C1207-C1209 CKSRYB104K25

C1212-C1214, C1217-C1224, C1226 CKSRYB104K25

C1228-C1234, C1236-C1239, C1245 CKSRYB104K25

C1509, C1618 CKSRYB104K25

C1066, C1152 CKSRYB153K50

C1072, C1155 CKSRYB222K50

C1115, C1116, C1172, C1173 CKSRYB224K16

C1429 CKSRYB332K50

C1078, C1157 CKSRYB333K16

C1210, C1211, C1246 CKSRYB471K50

C1080, C1083, C1158, C1159, C1247 CKSRYB473K50

C1487 CKSRYB473K50

C1119, C1176 CKSRYB562K50

VC1001, VC1002 (40P) VCM1010

RESISTORS

R1202-R1204, R1221, R1223 RAB4C223J

R 1401,R 1402,R 1409,R 1413,R 1418 RAB4C223J

R 1425,R 1426,R 1584,R 1585,R 1594 RAB4C223J

R1086 RN1/16SE3301D

R1085 RN1/16SE4701D

R1711, R1715 RS1/16S1502F

R1703, R1704, R1721, R1723 RS1/16S3301F

R1706, R1707, R1719, R1720 RS1/16S3902F

R1710, R1716 RS1/16S4701F

R1705, R1722 RS1/16S5600F

R1708, R1709, R1717, R1718 RS1/16S8202F

Other Resistors RS1/16S&&& J

OTHERS

CN1005, CN1009 FPC CONNECTOR 16FMZ-ST

CN1012 7P JUMPER CONNECTOR 52147-0710

CN1004, CN1008 CONNECTOR POST B2B-PH-K-S

CN1002, CN1006 CONNECTOR POST B3B-PH-K-S

CN1218 5P TOP POST B5B-EH

51

Page 52

CMX-3000, CU-V163

Mark No. Description Part No.

CN1003, CN1007 CONNECTOR B6B-PH-K-S

X1002 CRYSTAL RESONATOR(12MHz) DSS1132

CN1010 CONNECTOR VKN1626

X1001 CRYSTAL RESONATOR(16.9MHz) VSS1084

FRSW ASSY

B

SEMICONDUCTORS

D 161 ,D 162 SLR-343MC(NPQ)

D163 SLR-343VC(NPQ)

SWITCHES

S161, S162 ASG7013

S163 DSH1049

CAPACITORS

C161 CKSRYB103K50

RESISTORS

Other Resistors RS1/16S&&& J

OTHERS

161 7P CABLE HOLDER 51048-0700

J 161 JUMPER WIRE D20PDY0720E

SLM1 ASSY

C

SWITCHES AND RELAYS

S801, S802 DSG1017

Mark No. Description Part No.

Q 202 ,Q 204 DTC124EUA

D181, D201–D204 1SS355

D211 EC10QS04

D212 UDZ33B

D 205 ,D 207 ,D 208 ,D 210 UDZS10B

D214 UDZS5.1B

D171 UDZS8.2B

COILS AND FILTERS

L215 DTL1083

L213, L214 LCTA470J2520

L201, L202 LRCA4R7J

L208, L212, L217–L221 VTL1084

CAPACITORS

C273 CCSRCH181J50

C274 CCSRCH220J50

C202, C208, C220, C268 CEAT101M10

C270, C271 CEAT101M10

C171 CEAT1R0M50

C275 CEAT330M50

C207, C214, C219, C226, C262 CEAT470M16

C205, C213, C217, C225 CEAT470M25

C172 CEAT470M50

C201, C261, C272 CEHAR330M10

C230, C233, C237, C240 CEJQNP220M16

C266, C267 CKCYF103Z50

C248, C250 CKSRYB103K50

C173, C204, C206, C211, C212 CKSRYB104K25

C216, C218, C223, C224, C229 CKSRYB104K25

OTHERS

CN801 CONNECTOR POST S3B-PH-K-S

SLM2 ASSY

D

SWITCHES AND RELAYS

S901, S902 DSG1017

OTHERS

CN901 CONNECTOR POST S3B-PH-K-S

JACB ASSY

E

SEMICONDUCTORS

IC209 (315 mA) AEK7059

IC212 (500 mA) AEK7060

IC207 (1.5 A) AEK7065

IC210 (0.4 A) ICP-N10

IC211 NJM2360M

IC204, IC205 NJM4558MD

IC181 NJM78L05A

IC201, IC202 PE8001A

IC172 TC74ACT04F

Q171 2SB1237X

Q215 2SB1375

Q213, Q214 2SC2412K

Q205–Q212 2SD2114K

Q 201 ,Q 203 DTA124EUA

Q182 DTA143EUA

C231, C239, C241, C244–C247 CKSRYB104K25

C249, C251, C269 CKSRYB104K25

C276 CKSRYB473K50

C228, C232, C234–C236, C238 CQMA152J50

C242, C243 CQMA152J50

RESISTORS

R221 RD1/2VM222J

R171, R172 RD1/2VM560J

R231, R240, R250, R258 RN1/16SE2202D

R201 RS1/16S2202F

R202 RS1/16S4701F

Other Resistors RS1/16S&&& J

OTHERS

208 JACK AKN7003

JA201, JA202 2P JACK DKB1053

JA205, JA206 JACK BOARD PKB1033

JA203, JA204 JACK/12V PKN1004

207 I/O JACK VKN1070

CN201 B TO B CONNECTOR 30P VKN1627

0 SCREW PLATE VNE1948

PCB BINDER VEF1040

52

Page 53

CMX-3000, CU-V163

Mark No. Description Part No.

PWRB ASSY

F

SEMICONDUCTORS

IC104 (800 mA) AEK7008

IC107 (1.5 A) AEK7011

IC101 (4 A) AEK7018

IC103 (5 A) AEK7019

IC108 (315 mA) AEK7059

IC106 (1.5 A) ICP-N38

D 103 -D 106 1SR154-400

D102 D3SBA20(B)

D111–D114 RB060L-40

D107–D110 RB160L-40

COILS AND FILTERS

L101 VTL-004

CAPACITORS

C103 (0.01 µF/ AC275V ) ACE7027

C 125 -C 127 CEAT101M10

C123 CEHAT221M2A

C124 CEHAT472M16

C121 CEHAT472M25

C122 CEHAT682M16

C104–C108, C110–C113 CKSRYB473K50

C128–C136 CKSRYB473K50

Mark No. Description Part No.

REGB ASSY

H

SEMICONDUCTORS

IC153 BA033T

IC152 BA05T

IC151 PQ15RW21

CAPACITORS

C155, C156 CEHAT101M10

C154 CEHAT470M16

C151–C153 CKSRYB103K50

RESISTORS

R152 RN1/16SE2201D

R151 RN1/16SE3901D

OTHERS

151 9P CABLE HOLDER 51048-0900

J 151 JUMPER WIRE D20PDY0910E

0 REGURATOR PLATE DNH2507

SCREW BBZ30P060FMC

RESISTORS

Other Resistors RS1/16S&&& J

OTHERS

CN106 9P JUMPER CONNECTOR 52147-0910

CN103 SOCKET 4P AKP7132

CN104 5P TOP POST B5B-EH

CN105 9P TOP POST B9B-EH

0 SCREW PLATE VNE1948

ACIN ASSY

G

SWITCHES AND RELAYS

S101 RSA1001

CAPACITORS

C102 (0.01µF/ AC275V ACE7027

C101 (10000PF/AC250V) ACG7033

OTHERS

CN102 PLUG 4P AKM7055

AN101 POWER SOCKET AKP7032

H101, H102 FUSE CLIP AKR1004

53

Page 54

CMX-3000, CU-V163

Mark No. Description Part No. Mark No. Description Part No.

CNTA ASSY

I

SEMICONDUCTORS

IC301 PD5764A

IC305 TC74HC14AF

IC303, IC304 TC7S86F

Q361–Q373, Q403, Q404 ,Q406 2SC4081

Q408–Q410 2SC4081

D301, D302, D396–D399 1SS355

D411, D412 SLI-343URCW(RST)

D415–D420 SLI-343YCW(RST)

D407–D410 TLGE68TG(NP)

SWITCHES

S301–S308, S311–S313 ASG7013

S341–S347 ASG7013

CAPACITORS

C451 CEAT101M10

C458 CEAT1R0M50

C459 CEAT220M50

C301, C311, C396–C399 CKSRYB102K50

C452–C455, C457 CKSRYB103K50

SWITCHES

CAPACITORS

RESISTORS

D623–D628, D631–D636 SLI-343YCW(RST)

D607–D610 TLGE68TG(NP)

D590 UDZS5.1B

S501–S508, S511–S515 ASG7013

S521–S526, S531–S536 ASG7013

S541–S547 ASG7013

C651 CEAT101M10

C658 CEAT1R0M50

C659 CEAT220M50

C501, C511, C521, C531, C541 CKSRYB102K50

C596–C599, C656 CKSRYB102K50

C652–C655, C657 CKSRYB103K50

C683–C700 CKSRYB221K50

R596, R597 RS1/16S2201F

VR501 (50kΩ-B x2) DCV1011

Other Resistors RS1/16S&&& J

C483–C500 CKSRYB221K50

C461, C462 CKSRYB471K50

RESISTORS

R396, R397 RS1/16S2201F

VR301 (50kΩ-B x2) DCV1011

Other Resistors RS1/16S&&& J

OTHERS

CN303 CONNECTOR 52084-1510

CN301 4P JUMPER CONNECTOR 52147-0410

V301 VACUUM FL DISPLAY DEL1047

X301 CERAMIC RESONATOR DSS1131

FL HOLDER DNK3956

PHTA ASSY

J

SEMICONDUCTORS

D391, D392 GP1S94

CAPACITORS

C391 CKSRYB103K50

RESISTORS

Other Resistors RS1/16S&&& J

OTHERS

J 302 JUMPER WIRE D20PWY0415E

CNTB ASSY

K