OS2X CHECKOUT SCALE

USER MANUAL

Pinnacle Technology Corp.

CONTENTS

1. SUMMARIZATION ............................................................................................................................... 1

1.1 ADVANCED FUNCTIONS ........................................................................................................ 1

1.2 EXCELLENT FUNCTIONS ....................................................................................................... 1

2. TECHNICAL SPECIFICATION ............................................................................................................ 2

3. APPEARANCE ...................................................................................................................................... 3

4. DIMENSION .......................................................................................................................................... 5

5. HOW TO FIX CUSTOMER DISPLAY TO CHECKOUT SCALE....................................................... 7

6. HOW TO INSTALL DISPLAY POLE ................................................................................................... 8

7. POWER CONNECTIONS ..................................................................................................................... 9

8. POWER ON/OFF ................................................................................................................................. 11

9. KEY EXPLANATION ......................................................................................................................... 11

10. WARNING ........................................................................................................................................ 12

11. SOFTWARE OPERATION .............................................................................................................. 12

12. USB VIRTUAL SERIAL PORT DRIVER INSTALLATION .......................................................... 13

13. COMMUNICATION PROTOCOL .................................................................................................. 15

1

1. SUMMARIZATION

1.1 ADVANCED FUNCTIONS

※ Communication platter which adopts patent insect-proof design can prevent the machine from

defects caused by insects.

※ Can be used as stand-alone, or connect with POS/ECR.

※ Imbedded design to save valuable counter space.

※ Optional wireless type,able to transmit weighting data to POS/ECR in time without lines.

※ Patent tempered glass platter, practical and good looking.

1.2 EXCELLENT FUNCTIONS

※ Two options of customer display: external or in-built, able to meet customers‟ need in all-round.

※ Tare, zero and other function keys on the display, easy to operate and convenient to check out the

weighting information.

※ Simple elegant design and compact internal process guarantee products‟ reliability and aesthetics.

※ Standard protocol, convenient to connect with POS/ECR.

※ Two optional measuring range: 15kg(e=2g/5g)or 30kg(e=5g/10g).

电

源

开

关

2

2. TECHNICAL SPECIFICATION

Specification of types

Desktop Type OS2CX

Imbedded Type OS2IX

OS2CX

OS2CXK

OS2CXB

OS2CXP

OS2IX

OS2IXD

Basic Features

without display

without keys

without display;

with two keys

with pedestal display

& three keys

with display, pole

& three keys

without display;

with two keys

With separate pole;

display & three keys

Dimension

344.93*262.54

*87.8mm

344.93*262.54

*87.8mm

344.93*343.2

*91.04mm

435.22*344.93

*337.87mm

370*288

*72.4mm

Platter

370*288*

72.4mm

Display pole

415.72*111.57

*86.35mm

Customer/Operator Display

5*8 field LCD

Weighing Capacity (Max.)

6/15kg;15/30kg

Division Value

2/5g;5/10g

Weighing Capacity (Min.)

40g;100g

Tare (Max.)

-5.998kg;-14.995kg

Internal Resolution

1/30000

Accuracy Class

Interface

RS232

Optional

USB、2.4G wifi communication

Power Supply

5V 1A

Working Temperature

0℃-40℃

Working Humidity

5%R.H.-85%R.H.

3

3. APPEARANCE

OS2CX

OS2CXK

OS2CXB

OS2IX

OS2CX is the type without display screen

& keys.

Without display screen, but with two key

(tare key and zero key)

Display screen is on the pedestal, with

three keys.

Embedded type, without display screen,

but with two keys.

4

OS2CXP

OS2IXD

With display screen and three keys.

With separate display screen, three key.

Display screen‟s position can be installed

according to actual needs.

5

4. DIMENSION

outline dimensional drawing

OS2CX/OS2CXK

OS2CXB

OS2CXP

OS2IX

6

Installing hole dimension figure of OS2IX type

OS2IXD

OS2IXD-platter

OS2IXD-display pole

7

5. HOW TO FIX CUSTOMER DISPLAY TO CHECKOUT SCALE

Please follow below steps to install the customer display, if the type you bought with it.

Insert the line to the port

Lock the screws

8

6. HOW TO INSTALL DISPLAY POLE

Please follow below steps to install the display pole, if the type you bought with it.

Lock the screws to

fix the display pole

on the pedestal

Lock the screws to

fix the display pole

on the bottom of

the platform.

Fix the pole

like the

picture shows.

9

7. POWER CONNECTIONS

There are 3 methods for OS2X to get power supply.

Method 1: Use the attached communication line to connect Aclas ECR as below picture.

Customer can self-define the length of communication line, if the line is too long,

customer can cut one end of crystal head short and follow the connection mode below to

make a new one.

PHONE4

Pin

Signal name

1

VDD

2

GND

3

TXD

4

RXD

PHONE4

Pin

Signal name

1

VDD

2

GND

3

RXD

4

TXD

Connect to

OS2X

Connect to Aclas ECR

or LP1X label printer

RS232 line

Able to self-define the length

Connection mode

10

Method 2:If the external device or PC is attached with D9 interface, customer can use a

D9-4P communication cable with USB interface from Aclas to get power supply.

Connect the OS2X with the external device as below picture. If supply power is

available from the D9 interface of external device, there is no need to connect with other

power supply.

Method 3: If you purchased USB line, you can follow below picture to connect OS2X

and other terminal with USB port.

Note: To set the communication between the OS2X and the external device that has USB

interface, users should install USB virtual serial port driver first. Please refer to related

chapter for details.

Connect to USB

port of PC or

other terminal

Connect to

OS2X

Connect to D9

port of PC or

other terminal

Communication line, connect to

OS2 (Able to self-define the length)

Power plug

If the line is too short, use

USB cable to prolong it

Connect PC or

power supply

11

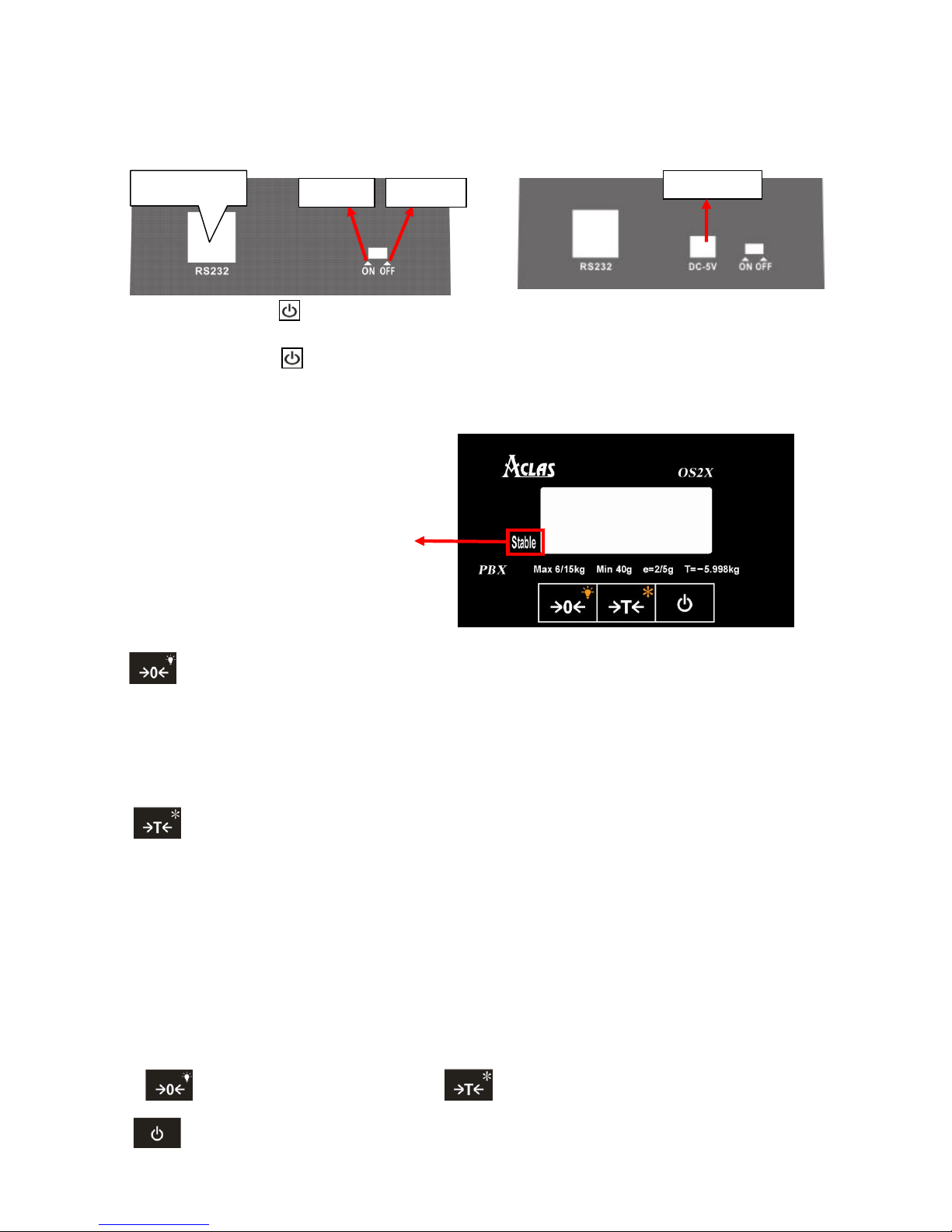

8. POWER ON/OFF

Power on: press the key to power on after soft turning off.

Power off: press the key to power off.

9. KEY EXPLANATION

: This key is to adjust the „WEIGHT‟ column to zero value.

Place the scale level steadily, if there are digits displayed on LCD when there is nothing on the

platter, you can press this key to adjust to zero.

Press this key and hold it for 1.5 seconds to turn on or turn off the backlight.

: This key is used to deduct the packing weight.

If you need to deduct the packing weight, put the container or wrapper on the scale first, and

then press this key to enter weight- deducting state. Then, take off the container and put the

commodity into the container and then place the packed goods on the pan again, now, the LCD will

display the net weight. Remove the merchandise and press this key, the scale will return to normal

weighting state.

Press this key and hold it for 1.5 seconds to enter into the unit switch function. Press the key

“ ”to shift the unit and press the key “ ” to confirm or exit the setting status.

: Press this key and hold it for 1.5 seconds to soft turn off the scale.

There is “stable” mark on the display

screen. When the weight is stable, the

triangle indicator will light which means it

is in the normal weighing status, at this

time you can put commodity on the platter

RS232 port

Power on

Power off

English version

For Mexico

Power port

12

10. WARNING

Avoid overloading.

Do not operate the printer in a humid environment.

Do not operate the scale under the place of flammability and explosive.

11. SOFTWARE OPERATION

Double click , and then below interface will pop up:

1 Select the corresponding

serial interface,baud rate9600

2Click this

button

Information

Weight display

13

12. USB VIRTUAL SERIAL PORT DRIVER INSTALLATION

If you purchased optional accessory USB line, you must install USB virtual serial

driver to realize the communication between OS2X and external equipments. If you

purchased D9 line, you can skip this chapter.

Open disk and run software“VCPDriver_V1.1_Setup.exe”:

Click“Next”

14

Click“Next”

Click“Finish”

15

13. COMMUNICATION PROTOCOL

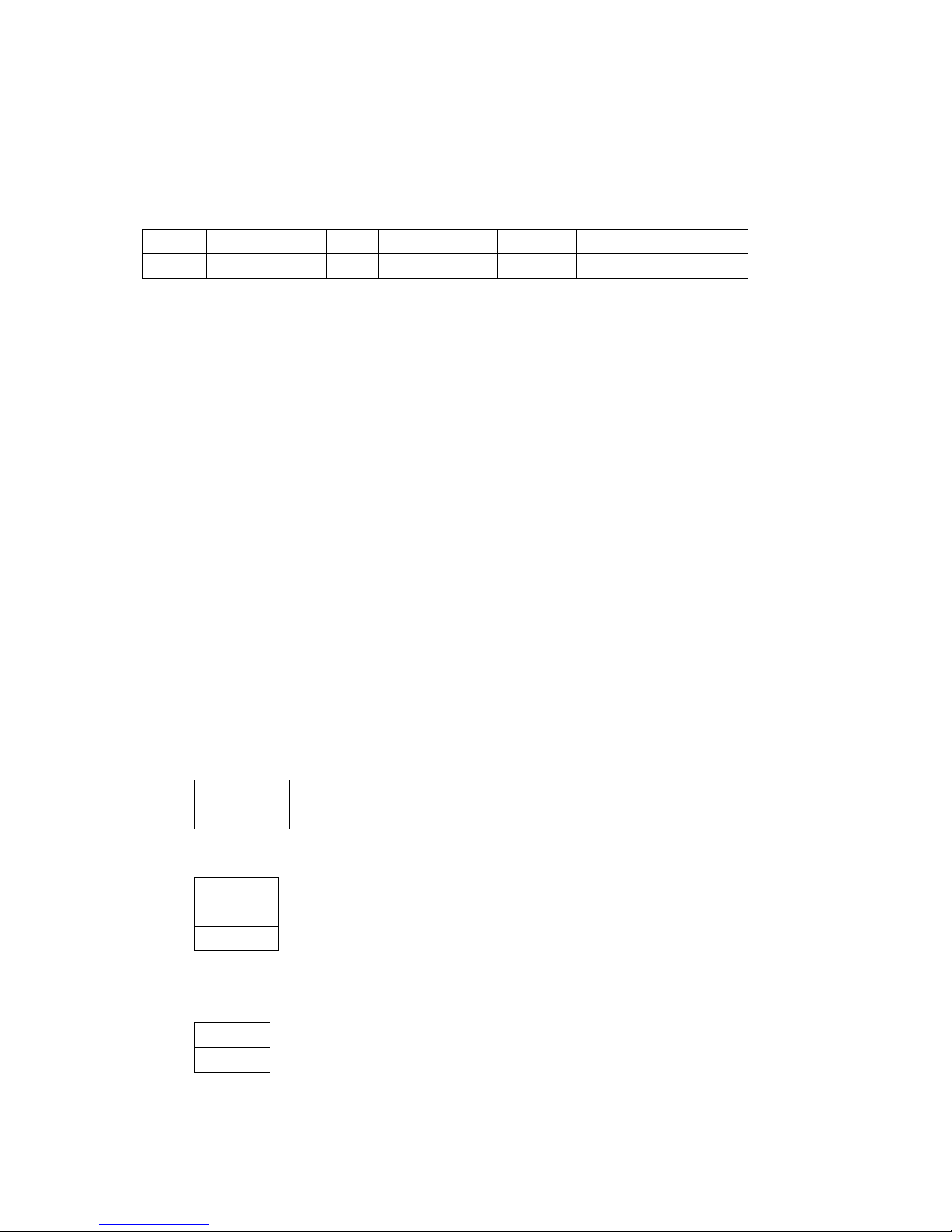

Send communication protocol actively :

Default send 10 times/s when power on. Frequency can be adjusted and the adjusting method is

same with OP box.

sending content is as follows:

Head1

Head2

Flag1

Sign

Weight

Unit

CheckSum

Tail1

Tail2

Flag2 0 1 2 3

4~9

10,11

12

13

14

15

Head1:1 byte,fixed as 0x01.

Head2:1 byte,fixed as0x02.

Flag1:1 byte,status: F’: Weight is beyond the range or haven‟t startup to zero.

‘S’: Weight is stable.

‘U’: Weight is unstable.

Sign:1 byte,sign: ‘-’:Weight is negative.

‘ ’: Weight is positive.

Weight:6 bytes,weight

Unit:2 bytes,unit

CheckSum: 12 bytes in front of the vision exclusive or and.

Tail1:1 byte,fixed as 0x03.

Tail2:1 byte,fixed as 0x04.

Flag2:1 byte,status:

Bit4:1: The current weight is zero. 0:The current weight is not zero.

Bit5:1: current in the tare mode 0: Not in tare mode.

Bit6:1: Weight is beyond the range or haven‟t startup to zero. 0: Weight is in normal and has

startup to zero.

Send communication protocol passively

1>PC Request the connection firstly

PC Send one byte command 0x05 firstly.

command

0x05

Scale response one byte command 0x06.

PC can confirm the scale has connected via these two commands firstly.

comman

d

0x06

2>PC Request to receive the weighing result.

PC sends one byte command 0x11.

command

0x11

scale response weighing result,response data format and the format of sending actively is basically the

same, just miss Flag2.

16

Head1

Head2

Flag1

Sign

Weight

Unit

CheckSum

Tail1

Tail2 0 1 2 3

4~9

10,11

12

13

14

Head1:1 byte,fixed as 0x01.

Head2:1 byte, fixed as 0x02.

Flag1:1 byte,status: ‘F’: Weight is beyond the range or haven‟t startup to zero.

‘S’: Weight is stable.

‘U’: Weight is unstable.

Sign:1 byte,sign: ‘-’:Weight is negative.

‘ ’: Weight is positive.

Weight:6 bytes,weight

Unit:2 bytes,unit

CheckSum:12 bytes in front of the vision exclusive or and.

Tail1:1 byte,fixed as 0x03.

Tail2:1 byte,fixed as 0x04.

tare zero by active or passive way

1. Tare or zero

PC sends

STX

Cmd

ETX1

ETX2

0

1,2

3

4

STX:1 byte,fixed as 0x3C.

Cmd:2 bytes, tare fixed as 0x54, 0x4B.

zero fixed as 0x5A ,0x4B.

ETX1:1 byte,fixed as 0x3E.

ETX2:1 byte,fixed as 0x09.

Pinnacle scale DigitOpBox protocol

1)Communication package format:

1.Communication package format:

A:without data column‟s format(not including DATA and DT SUM)

STX

ID

CMD

PARA

PGNO

LEN

SUM

0

1,2,3,4

5,6

7,8 9 10,11

12

SUM = Byte0 + Byte1 + Byte2 + … + Byte10 + Byte11

B:with data column‟s format(LEN > 0)

STX

ID

CMD

PARA

PGNO

LEN

SUM

DATA

DT SUM

0

1,2,3,4

5,6

7,8 9 10,11

12

13 ~ (13+LEN-1)

(13+LEN ),

(14+LEN)

SUM = Byte0 + Byte1 + Byte2 + … + Byte10 + Byte11

DT SUM = CRC16 ( Byte13 ~ Byte[13+LEN-1] )

Note:

1.When LEN is 0, DATA column and DT SUM are empty, at this time, data Packet total

length is 13 bytes.

17

2.When LRN is not 0, DT SUM‟s CRC checksum is only related with DATA column, and

is not related to the prior 13 bytes, at this time, data package total length is (13+LEN+2)

byte.

3.High order is in front and the low order is in rear to multi-byte column.

2. Communication package format explanation:

3. .communication command:

CMD1

CMD2

PARA1

PARA2

EXPLANATION

0x80

0x00

Baud Rate

0x00

Set communication baud rate

0x80

0x01

Frq

0x00

set measuring result sending frequency

0x80

0x02

0x00

0x00

read measuring result

0x80

0x03

0x00

0x00

start zero device

0x80

0x04

0x00

0x00

start tare device

0x80

0x05

Tare

start or stop preset tare device

0x80

0x06

Unit

0x00

set measuring unit

0x80

0x0d

0x00

0x00

The response of OP box(Command failure)

0x80

0x0e

0x00

0x00

The response of OP box(Command success )

2)Command explanation:

4. Set communication baud rate:( Successful response 0x800E,Failure response 0x800D)

STX

ID

CMD

PARA

PGNO

LEN

SUM

0xAB

0x00000000

0x8000

0xXX00

0

0x00

X

Default the baud rate is 9600bps when power on. When the command is received successfully, change

baud rate by parameter PARA1.

XX = 0x01 : 115200 bps

XX = 0x02 : 57600 bps

XX = 0x03 : 38400 bps

XX = 0x06 : 19200 bps

XX = 0x0C : 9600 bps

Command use method:PC use the default baud rate 9600bps to send this command to OP box firstly, and

then continue to use 9600bps baud rate to response after OP box received the command. Then switch the

S/N

items

explanation

length(bytes)

mark

1

STX

Package head

1

Communications packet starting marks 0xAB

2

ID

Scale number

4

keep,fill all with 0

3

CMD

command 2 Command classification

4

PARA

parameter

2

Parameter related with command

5

PGNO

Package

number

1

Data package number(single/last one fill with0)

6

LEN

length

2

data length

7

SUM

checksum

1

The sum form item1to item6, total 12 bytes

8

DATA

data

LEN

Command data,Max 49 bytes

9

DT

SUM

Data

checksum

2

CRC checksum of 8

18

baud rate to the corresponding baud rate again after response data sending finished.

5. set measuring result sending frequency:( Successful response 0x800E,Failure response 0x800D)

STX

ID

CMD

PARA

PGNO

LEN

SUM

0xAB

0x00000000

0x8001

0xXX00

0

0x00

X

Default frequency is sending 10 times measuring result in each second actively. When the

command is received successfully, change the frequency according to parameter PARA1.

XX = 0x0A : 10Hz

XX = 0x09 : 9Hz

XX = 0x08 : 8Hz

………

XX = 0x01 : 1Hz

XX = 0x00 : send measuring result passively, at this time you can achieve the measuring

result via the command “read measuring result”.

6.Read measurement results:

STX

ID

CMD

PARA

PGNO

LEN

SUM

0xAB

0x00000000

0x8002

0x0000

0

0x00

X

When initiative sending frequency is set as 0, achieve the measurement results: via this

command.

Please refer to note 1 about the returned data analysis.

7.Zero command:( successful response 0x800E,failure response 0x800D)

STX

ID

CMD

PARA

PGNO

LEN

SUM

0xAB

0x00000000

0x8003

0x0000

0

0x00

X

Sensor starts zero device after sending this command.

8.Tare command:( successful response 0x800E,failure response 0x800D)

STX

ID

CMD

PARA

PGNO

LEN

SUM

0xAB

0x00000000

0x8004

0x0000

0

0x00

X

Sensor starts tare device after sending this command.

9.Start or stop preset tare device:( successful response 0x800E,failure response 0x800D)

STX

ID

CMD

PARA

PGNO

LEN

SUM

0xAB

0x00000000

0x8005

Tare 0 0x00

X

Sensor starts or stop preset tare device after sending this command.

The range of tare is 0~ the maximum tare value allowed.

When tare is 0, it will stop preset tare device. When tare is not 0, it will start preset tare

device.

10. Change measuring unit:( successful response 0x800E,failure response 0x800D)

STX

ID

CMD

PARA

PGNO

LEN

SUM

0xAB

0x00000000

0x8006

0xXX00

0

0x00

X

The default unit is kg when power on, when command is received successfully, change

the unit according to the parameter PARA1.

XX = 0:standard unit(kg)

19

XX = 1: standard unit(g)

XX=6:British unit(pound)

XX=7:British unit(ounce)

Note 1:

The sensor returned the measured results of data format:

1.Data

STX

ID

CMD

PARA

PGNO

LEN

SUM

0xAB

0x00000000

0x8002

0x8300

0xXXXX

0

0x00

X

When adopting 0x8002 command achieve measurement results, answering CMD is

0x8002.

When sensor is set for the certain frequency and sent measurement results automatically,

CMD is 0x8300.

PARA:the current temperature AD.

2.Data in data area

Flag

Mode

Unit

Decimal Digit

Net Value

Tare Value

Gross Value

0 1 2 3 4,5,6,7

8,9,10,11

12,13,14,15

Flag: Bit0: 0 means weight is unstable 1 means weight is stable

Bit1: 0 means weight is in its range. 1 means weight is beyond the range.

Bit2: 0 means have startup to zero. 1 mean haven‟t startup to zero.

Bit3: 0means the current weight is more than the minimum weighing range

1 means the current weight is less than the minimum weighing range

Bit4: 1 the current OP box is soft unlock 0 the current OP box is not soft unlock

Bit5: 1 the current OP box hardware is unlock 0 the current OP box hardware is not

unlock

Bit6: 1 the lowest order of the result is always zero. 0 the lowest order of the result maybe

not zero.

Bit7: retain

Mode: 0:It stands for net weight weighing mode, at this time, tare and gross weight

column not transmission.

1:It stands for tare weighing mode.

2:It stands for Pre-set tare weighing mode.

Unit:

0: "Gram",

1: "kg",

2: "Tonne",

13: "Ounce",

14: "Pound",

15: "Kilo pound (kip)",

Decimal digits

Each weight value occupies 4 bytes, high-order in the front, and low in the rear. The highest Bit is the

sign bit. For example:

Flag

Mode

Unit

Decimal Digit

Net Value

0x01

0x00

0x01

0x03

0x80,0x00,0x04,0xD2

20

When receive the above data, it means: weight is stable, net weight weighing model, unit

kg, 3 decimal places, symbol is negative, -1.234 kg.

Flag

Mode

Unit

Decimal Digit

Net Value

0x00

0x00

0x00

0x00

0x00,0x00,0x04,0xD2

When receive the above data, it means: weight is unstable, net weight weighing model, unit

g, 0 decimal places, symbol is positive, 1234 g.

5) Protocol change

1. PC sends replacement protocol

STX

Cmd

ETX1

ETX2 0 1,2

3

4

STX:1 byte,fixed as 0x3C.

Cmd:2 bytes, OS2passively sends communication protocol fixed as 0x41, 0x4C.

OS2 actively sends communication protocol fixed as 0x50, 0x42.

Pinnacle scale DigitOpBox protocol fixed as 0x44, 0x42.

ETX1:1 byte,fixed as 0x3E.

ETX2:1 byte,fixed as 0x09.

DOS201ENV0-OS2X-09

Loading...

Loading...