Page 1

Safety Mat System

Installation

and

Operation Manual

Page 2

Rev. 2.3

Page 3

NSD Safety Mat System

Installation and Operation Manual

Pinnacle Systems, Inc.

3715 Swenson Avenue

St. Charles, IL 60174

P/N: 28-045r2.3

(Please have Model #, Serial #, and Software Rev # Available)

www.pinnaclesystems.com • sales@pinnaclesystems.com • service@pinnaclesystems.com

Customer Service: 630-443-8542 (CST)

Sales and Marketing: 800-569-7697 (EST)

Page 4

Proper Use and Limitations

The NSD Safety Mat System is critical for operator

safety. Repairs should only be made by factory

authorized personnel. The manufacturer cannot be

held responsible for your repair attempts or the unit’s

subsequent safe operation.

As the NSD Safety Mat System is a single function

device, that of sensing an unauthorized intrusion into

a guarded area while simultaneously determining that

it is capable of sensing such an intrusion, any internal

malfunction will manifest itself with a RED condition

shut down. The manufacturer will not supply individual

component parts of any circuit board but will supply the

individual circuit board complete.

The information disclosed herein includes proprietary

rights of the manufacturer. Neither this document nor

the information disclosed herein shall be reproduced

or transferred to other documents, used or disclosed

to others for manufacturing purposes, or for any other

purposes, except as specifi cally authorized in writing

by the manufacturer. If this manual is supplied in

connection with the sale or delivery of manufacturer’s

equipment, it is to be used solely for maintenance, repair

or installation of such equipment.

Limitation of Liability

In the event of any claim for breach of any obligations

of manufacturer under any order, whether expressed

or implied, and particularly in the event of any claim

of a breach of the warranty or warranties contained in

the paragraph “Warranty” or of any other warranties,

expressed or implied which might, despite the paragraph

entitled “Disclaimer,” be determined to be incorporated

in any order, the company shall under no circumstances

be liable for any consequential or special damages,

either in law or in equity, or for losses or expenses or

claims for the same arising from the use of, or inability

to use, the products of the manufacturer for any purpose

whatsoever.

The manufacturer has designed this equipment to

the very highest performance and safety standards

known to the current technological state of the art.

However, the installation, usage, suitability, and fi tness

of our equipment for any purpose, known or unknown,

is interdependent upon the performance of other

equipment not manufactured, installed, secured or

maintained by the manufacturer. W e cannot and do not

accept responsibility for any overall system performance

when factors, such as these, are beyond our control.

Warnings and Warranty

Manufacturer warrants that this product will be free

from defects in material and workmanship for a period

of two years from the date of shipment thereof. Within

the warranty period, manufacturer will repair or replace

such products which are returned with shipping charges

prepaid and which will be disclosed as defective upon

examination by the manufacturer. This warranty will not

apply to any product which will have been subject to

misuse, negligence, accident, restriction, and use not

in accordance with manufacturer’s instructions or which

will have been altered or repaired by person’s other than

the authorized agent or employees of the manufacturer.

Disclaimer

The provisions of the “Warranty” paragraph above are

the sole obligations of the manufacturer and exclude

all other warranties of merchantability, expressed or

implied. Further, there are no warranties which extend

beyond the above warranty.

WARNING: The entire machine safety system

must be tested at the start of every shift. Machine

testing should include: (1) proper machine

operation and stopping capability; and (2)

verifi cation of proper installation and settings of

all point of operation guards and devices before

the operation is released for production.

Page 5

Table of Contents

Overview

Circuit Description ...................................................................................................................................................1

Specifi cations .......................................................................................................................................................... 2

Dimensions

1. NSD-TR-01 (Metal Box) Controller ..............................................................................................................3

2. NSD-DR-01 (Basic DIN-rail) and NSD-DR-04 (DIN-rail with diagnostics) Controllers ...............................3

Installation and Operation

Mat Installation ........................................................................................................................................................4

Controller Installations

NSD-TR-01 (Metal Box) Controller ...................................................................................................................4

NSD-DR-01 (Basic DIN-rail) Controller ...........................................................................................................5

NSD-DR-04 (DIN-rail with diagnostics) Controller ............................................................................................5

Operation

1. Stop Circuit (application) .............................................................................................................................6

2. Manual/Automatic Reset .............................................................................................................................6

3. External Relay Checking .............................................................................................................................6

Wiring Diagrams

1. NSD-TR-01 (Metal Box) Controller ..............................................................................................................7

1. NSD-TR-01 (Metal Box) Controller - Older boards PRIOR to Rev 10 .........................................................8

2. NSD-DR-01 (Basic DIN-rail) Controller .......................................................................................................9

3. NSD-DR-04 (DIN-rail with diagnostics) Controller .....................................................................................10

NSD-DR-04 (DIN-rail with Diagnostics) Accessible Connections .........................................................................11

NSD-DR-04 (DIN-rail with Diagnostics) Board Connector Layout ........................................................................12

Appendix A: Troubleshooting

NSD-TR-01 (Metal Box) and NSD-DR-01 (Basic DIN-rail) Controllers .............................................................AA-1

NSD-DR-04 (DIN-rail Controller with diagnostics) ............................................................................................AA-1

DeviceNet (for NSD-DR-04 only) ......................................................................................................................AA-3

Appendix B: Saftey Guidelines for Management

Operational Safety ............................................................................................................................................AB-1

Safety Enforcement ..........................................................................................................................................AB-2

Supervisor Training ...........................................................................................................................................AB-2

Operator Training ..............................................................................................................................................AB-2

- I -

Page 6

Overview

NSD Safety Mat System

Overview

The NSD Safety Mat System contains two independent

control circuits which allow for shut down due to any

single failure in one of the control circuits. The N.O.

output circuit is controlled by two captivated contact

relays in series which are both monitored. If the contact

in one relay should stick closed (i.e., contact weld) the

other relay will shut down and an LED will indicate the

fault, even if the contact on the bad relay opens back up

you must reset the power to clear the fault. The relay

contact monitoring provides a high degree of user safety .

Circuit Description

The NSD-TR-01 (metal box) and NSD-DR-01 (basic

DIN-rail) are alike in that they use discrete logic circuits

to detect the mat. The NSD-DR-04 (DIN-rail with

diagnostics) is diverse redundant microprocessor driven

and has a built-in diagnostics display. A low voltage

(24VAC) signal is sent out to the safety mat(s) through

two wires. The voltage passes through the mat and back

into the NSD control unit through two more wires. Two

special optically-isolated diverse redundant circuits look

at the signals coming back from the mat(s) detecting the

presence of proper positive and negative voltage (AC)

levels and output their signals to redundant missing

pulse detectors. If the voltage coming back is too high

or low, the missing pulse detectors will drop out and

de-energize the relay circuit. If the voltage coming back

is not AC (missing either positive or negative peaks),

then the signal going to the missing pulse detector will

disappear which will, in turn, drop out and de-energize

the relay circuit.

3. If any wire going to or coming from the mat(s)

is cut and/or shorted to any other mat wire, the

signal going back into the NSD control unit is

OV, so the relays de-energize.

4. If any wire going to or coming from the mat(s)

is cut and/or shorted to an outside AC power

source (i.e., 120VAC) the signal going back

into the NSD control unit will exceed the 24V AC

signal level and the relays will de-energize.

5. If any wire going to or coming from the mat(s)

is cut and/or shorted to an outside DC power

source (i.e., 24VDC), the signal going back into

the NSD control unit will not be an AC signal

and the relays will de-energize.

6. If, when you step on the mat, either safety output

relay is stuck in the closed position, the NSD

control unit will automatically shut down the

other relay and lock out and further attempts

to reset the unit until the power is reset.

Redundant relay position detectors watch for a relay

contact stuck in the wrong position. The circuits will lock

out the reset feature of the NSD control unit if a relay

contact is closed when it should be open.

Each relay has its own driver circuit to complete the

redundancy of the circuits.

The output relays will de-energize if the voltage coming

from the mat(s) is either too high or low (12VAC to

36VAC) or is not AC (i.e., DC), including the following

reasons:

1. When you step on the mat, you are shorting

out the 24VAC signal going back into the NSD

control unit to OV, so the relays de-energize.

2. If you cut any wire going to or coming from

the mat(s), the signal going back into the NSD

control unit is OV, so the relays de-energize.

1

6

Page 7

Specifi cations

NSD Safety Mat System

Enclosure:

Input Power:

Category/Type:

Relay Style:

Relay Configuration:

Safety Relay Rating:

Reset Provisions:

Controller Response

Time:

Self-Checking

Intervals:

Number of Isolated

Zones:

Maximum Number of

Mats:

External Reset

Provision:

Indicators:

Internal (on board):

External:

NSD-TR-01

Controller

(Metal Box)

NEMA 12, 13, IP 54 NEMA 1, IP 32 NEMA 1, IP 32

120VAC +/- 10% @ 3 watts

50-60 Hz fused

4 4 4

Monitored force-guided captive

contact safety relays

2 N.O. Safety Relays (closed

when circuit activated)

1 Aux Output N.O. or N.C

4A @ 220VAC 4A @ 220VAC 4A @ 220VAC

Manual or Automatic Manual or Automatic Manual or Automatic

15 msec. 15 msec. 19 msec per mat input used

Every 20 msec. Every 20 msec. Every 20 msec.

1 to 13 (customer specified) 1 per controller 1 per controller

20 20 4 with homerun wiring

Green push button Green push button Green push button

Yellow LED

supply

Red LED = Normally dim,

brighter when mat is stepped

on. Cut wire detected when

not lit.

Green LED = Relay contact

detected closed when it should

have been open when not lit.

Must reset power to clear.

Red LED

de-energized.

Green LED = All relays are

energized.

= +5VDC power

= 1 or both relays are

24VDC +/- 20% @ 7 watts 24VDC +/- 20% @ 7 watts

Monitored force-guided captive

contact safety relays

2 N.O. Safety Relays (closed

when circuit activated)

1 Aux Output N.O. or N.C

Green LED(s) = next to

each relay (3)

Red LED

Yellow LED = +5V

Green LED

Red LED = 1 or both relays are

de-energized.

Green LED = All relays are

energized.

Yellow LEDs = 2 to show on/off

mat.

Yellow LED = relay fault if it

turns off.

NSD-DR-01

Controller

(Basic DIN-rail)

= +12V

= -5V

NSD-DR-04

Controller

(DIN-rail with Diagnostics)

Monitored force-guided captive

contact safety relays

2 N.O. Safety Relays (closed

when circuit activated)

1 Aux Output N.O. or N.C.

1 Fault Relay N.O.

20 with daisy chain wiring

Red LED = +12VDC

Green LED

Yellow LED

Green LEDs

relay (4 total)

Red LED = 1 or both relays are

de-energized.

Green LED = All relays are

energized.

Yellow LEDs = 1 for each mat

status — (4 total)

= +20VDC

= +5VDC

= one for each

Diagnostic Message

Display:

DeviceNet:

Warranty:

N/A N/A Built-in

N/A N/A Add suffix DN to Model #. See

2 years 2 years 2 years

next page for additional

information.

2

3

Page 8

Specifi cations

NSD Safety Mat System

Dimensions

NSD-TR-01 (Metal Box Controller)

Board (NSD-TR-B1): 5” x 7” plate with 4 holes 4-1/4” x 6-1/4” on center.

127mm x 177.8mm with 4 holes 107.95mm x 158.75mm on

center

Box (NSD-TR-01): 8”h x 6”w x 3.5”d (4” x 8-3/4” holes), NEMA 12, 13

203.mm x 152.4mm x 88.9mm (101.6mm x 222.25mm holes)

(NSD-TR-02): 12”h x 10”w x 5”d (8” x 12-3/4” holes), NEMA 12, 13

304.8mm x 254mm x 127mm (203.2mm x 323.85mm holes)

(NSD-TR-03/04): 16”h x 14”w x 6”d (13” x 16-3/4” holes), NEMA 12, 13

406.4mm x 355.6mm x 152.4mm (330.2mm x 425.45mm holes)

(NSD-TR-05/up): Call for sizes available.

NSD-DR-01 and NSD-DR-04 (both DIN-rail Controller models)

Mounting: 35mm DIN-rail mountable or mounting screws on corners of enclosure requiring

3

4

Page 9

Installation and Operation

NSD Safety Mat System

WARNING: The entire machine safety system

must be tested at the start of every shift. Machine

testing should include: (1) proper machine

operation and stopping capability; and (2)

verifi cation of proper installation and settings of

all point of operation guards and devices before

the operation is released for production.

Mat Installation

The NSD mat system has been designed to promote

individual mat “homerun” wiring back to the mat

controller. This is suggested for easing installation

and diagnostics for maintenance troubleshooting. This

will also eliminate cumbersome “daisy chain” wiring

practices of mat systems. It also eliminates numerous

wiring connection points buried under the perimeter trim

which are time intensive to troubleshoot.

1) Sweep the fl oor area where the safety mat is to

be installed. The fl oor should be fl at and free

of foreign material.

2) Locate the safety mat in the desired location.

For future reference, install the mat with the

label side up.

3) Slide the black wire raceway component under

the mat edge (Part #M002). Refer to Figure 1

below for proper component positioning.

NOTE: The wire raceway component must be

installed whenever the surface perimeter trim

component is used.

4) Route the wire/plug assembly on the raceway

toward the mat controller location.

5) Lay the aluminum perimeter trim piece around

the mat assembly. Determine where the mat

wiring will exit the trim and notch the trim and

wire raceway for the wire to exit the assembly.

6) If surface metal raceway is used to route the

wiring (Part #M005 or M006) from the mat

assembly across the floor toward the mat

controller, it should be aligned with the notch

in the perimeter trim and anchored to the fl oor.

Route wires accordingly and snap cover plate

over the wires.

7) Slide the perimeter trim over the wire raceway

component and align over the mat edge. Drill

the perimeter trim and fl oor for securing the

perimeter trim to the fl oor with anchoring screws

and fl oor anchors.

8) If a multiple mat assembly is to be installed, use

the aluminum active coupler component (Part

#M003) to connect mats end to end or side to

side. Refer to Figure 1 below.

Controller Installation

NSD-TR-01 (Metal Box) Controller

IMPORTANT: The NSD-TR-01 Controller

provides both N.O. and N.C. output circuits, but

only Terminals 5-6 (N.O.) are safety monitored

and should be used in series with your stop

circuit. Terminals 7-8-9 are NOT monitored; this

output should only be used as an auxiliary signal

line.

Figure 1: Cross Section View of Mat Assembly Active Edging

3.025”

0.67”

0.62”

4

Page 10

Installation and Operation

NSD Safety Mat System

1) Mount the NSD-TR-01 (metal box) where you

can get access to it without having to step on

the mat.

2) Attach 120VAC to Terminals L1 and N2 and

Earth ground to GND.

3) Wire mat to terminals 1-2-3-4 (1=blue, 2=white,

3=black, 4=brown for a single 4-wire lead mat

and 1=black, 2=red, 3=red, 4=black for a two-

dual lead mat.) If your mat has two zip cords

(two wires in each cord), then one zip cord goes

to Terminals 1-2 and the other to Terminals 3-4

(it does not matter which zip cord).

4) Wire Terminals 5-6 into your STOP circuit.

Terminals 5-6 come from two N.O. contacts in

series for safety (see “important” note above).

5) Unit is setup for Manual Reset if you have the

Green button on the case.

Automatic Reset: disconnect all four wires from

Terminals 14-15-16-17.

Remote Manual Reset: Place one pole of any

D.P.N.C. button between Terminals 14-15 and

the other pole between Terminals 16-17.

6) You can use Terminals 7-8-9 for non-safety

indicating or monitoring (i.e., strobe lights, PLC).

7) External 24VDC Red Zone light goes to

Terminals 11-12; 24VDC Green Zone goes to

Terminals 12-13; Terminal 12 is 24VDC out.

NSD-DR-01 (Basic DIN-rail Controller)

IMPORTANT: You must use both Terminals 7-8

and 9-10 in your Stop circuit. If you have one

Stop circuit, you must jumper T erminal 8 to 9, then

use Terminal 7 and 10 in your Stop circuit. Do

not use Terminals 1 1-12-13 for safety circuits.

1) Mount the NSD-DR-01 (basic DIN-rail Controller)

inside an enclosure since all the wiring

terminates on the outside of the controller box.

2) Attach 24VDC to Terminals 1-2 and Earth

ground to Terminal on the right side of the DINrail controller box.

3) Wire mat to T erminals 3-4-5-6 (1=blue, 2=white,

3=black, 4=brown for a single 4-wire lead mat

and 1=black, 2=red, 3=red, 4=black for a two-

dual lead mat.)

4) Wire your Stop circuit to Terminals 7 and 10.

Place jumper between Terminals 8 and 9 (see

“important” note above).

5) Unit comes setup in manual mode with a jumper

between Terminals 2 and 16 (use the built-in

“zone reset” button to clear the zone).

Automatic Reset: Remove jumper wire from

between Terminals 2 and 16.

Remote Reset: Wire a N.C. push button in place

of the jumper wire.

6) You can use Terminals 1 1-12-13 for non-safety

indicating or monitoring (i.e., strobe lights, PLC).

7) You can install remote red and green lights

(T erminals 14-15). These terminals go to GND

when active.

NSD-DR-04 (DIN-rail Controller with diagnostics)

IMPORTANT: You must use both Terminals 4-5

and 6-7 in your Stop circuit. Do not use T ermnals

8-9-10-11-12 for safety circuits.

1) Mount the NSD-DR-04 (DIN-rail controller with

diagnostics) inside an enclosure since all the

wiring terminates on the outside of the controller

box.

2) Select the number of mats (1-4) you want to

hook up. Open the DIN-rail box and select

the proper jumper settings (see NSD-DR-04

Jumper Settings, Page 12).

3) Select Automatic or Manual Zone resetting (see

Jumper Settings, Page 12).

4) Select External relay checking (see Jumper

Settings, Page 12).

5) Attach 24VDC to T erminals 1-2 and Earth ground

to Terminal 3 of Power/Output connector.

6) Wire mat to terminals 1-2-3-4 of each mat

connector (1=blue, 2=white, 3=white, 4=brown

for a single 4-wire lead mat and 1=black,

2=red, 3=red, 4=black for a single two-dual

lead mat.)

7) Wire your Stop circuit to Terminals 4 and 7.

Place jumper between 5 and 6 (see “important”

note above).

8) You can use Terminals 8-9-10-11-12 for nonsafety indicating or monitoring (i.e., strobe

lights, PLC).

NOTE: Canadian market wiring is black, red, red, black with 18-guage wiring size.

5

Page 11

Installation and Operation

NSD Safety Mat System

9) You can install remote red and green lights

(Terminals 7 and 8 of I/O connector). These

terminals go to GND when active.

10) Remote Zone reset connects to Terminal 3 of

I/O connector.

1 1) If you need to use external relays, then connect

external relays to T erminals 1-2 of I/O connector

(see below for explanation).

Operation

If you have manual reset (standard), you must push the

RESET button to reset the NSD controller.

If you have automatic reset, the NSD Controller will go

GREEN when you step off the mat. Automatic reset

should not be used in applications where there is no

barrier past the mat.

Stop Circuit (application)

Anyone stepping on the mat(s) will automatically shut

the machine off. This circuit allows for multiple numbers

of mats to be wired in series to protect a very large

area around dangerous equipment with only one NSD

Controller.

NSD-DR-04 (DIN-rail with diagnostics): If you select

manual, you will have to go to the control box and press

the zone reset button each and every time you step on

any mat(s). Place jumper across JP3 to activate this

feature.

To remote the zone reset, place a N.O. button between

T erminal 3 of the Input/Outputs connector and Terminal

2 of the Power Connector.

If you select automatic, the zone will clear itself when

you have stepped off the mat(s). Remove jumper across

JP3 to activate this feature.

Note: This setting changes all mats. You cannot

change some mats to manual and others to

automatic.

External Relay Checking

NSD-DR-04 (DIN-rail with diagnostics): This option is

selected when you have to switch a large load. This

feature allows the NSD to monitor your external relays.

This system requires that you use two force-guided

relays for the external switching and that the secondary

pole of each relay (N.C.) be tied in series back to the

NSD control external relay input terminals for each

particular zone. Place jumper across JP4 EXT to

activate this feature (see Page 10 for wiring diagram).

Manual/Automatic Reset

NSD-TR-01 (Metal Box): If nothing is attached to

Terminals 14-15-16-17, then the NSD Controller will

automatically reset itself. If you have a push button,

simply remove all four of these wires from their terminals.

If a 2 pole N.C. push-button contact is placed across

Terminals 14-15 and the second pole is placed across

Terminals 16-17, then you must use the push-button to

manually reset the NSD Controller unit.

NSD-DR-01 (Basic DIN-rail): If you select manual, you

will have to go to the control box and press the zone

reset button each and every time you step on any mat(s).

This requires a jumper wire between Terminals 2 and

16. To remote the zone reset, place a N.C. button in

place of the jumper wire.

If you select automatic, the zone will clear itself when

you have stepped off the mat(s). Remove the jumper

wire from between Terminals 2 and 16.

6

Page 12

Installation and Operation

NSD Safety Mat System

Wiring Diagrams

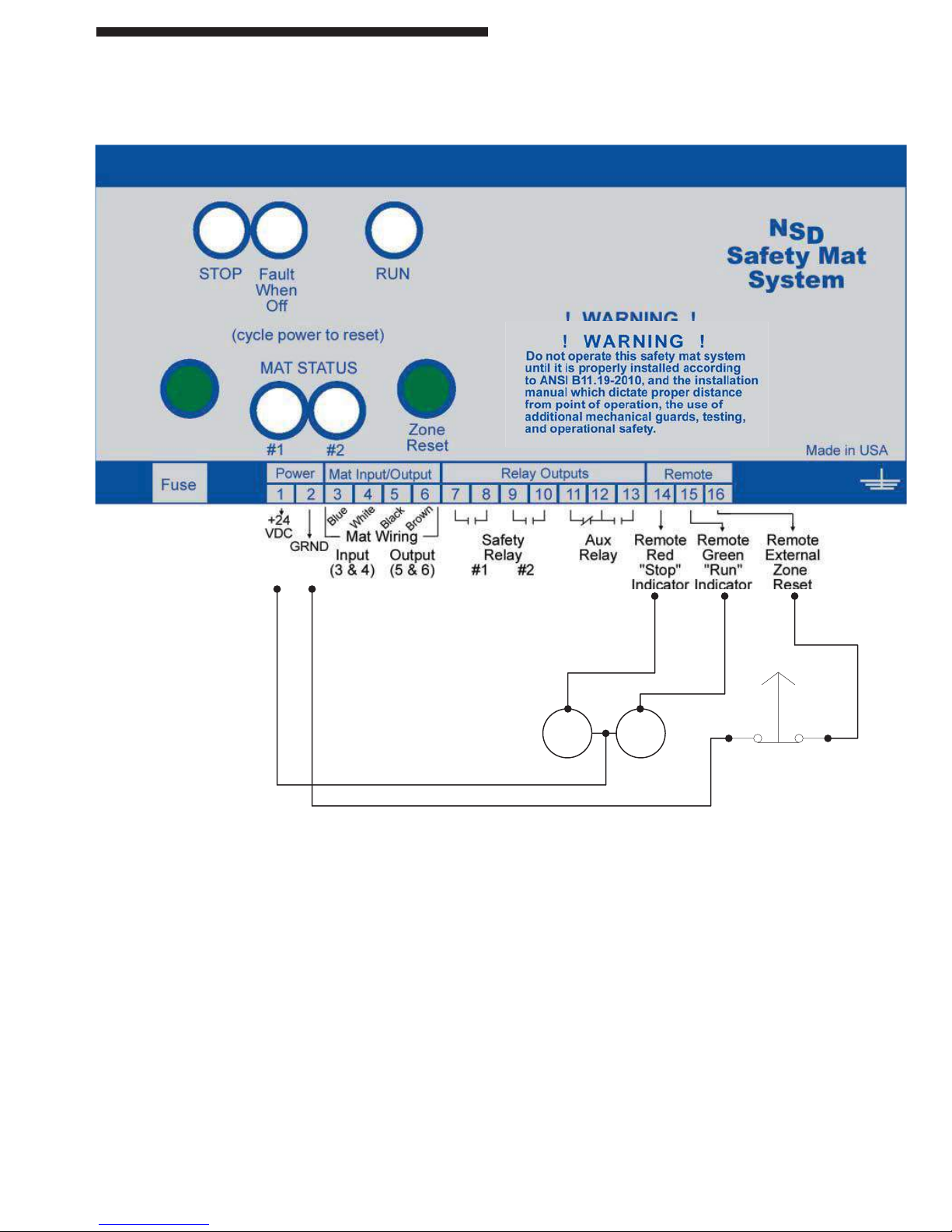

NSD-TR-01 (Metal Box Controller)

4 mounting holes (#8

screws)

Power ON

5.0"

4.25"

7.0"

6.25"

Push “Clear” button to Reset

mat control.

Mat Control willAuto-Reset

is both N.C.contacts are

disconnected.

External Status

Indicators

GRN

24vdc

120vac

power

Connect either ofthe 2 wire pairs

to Terminal#1 , and the other

pair to Terminal#3& #4 (as

shown)

Earth

Ground

NOTE: If you daisy chain mats, the blue/white is one

pair and should go to Terminals #1 and #2. The black/

brown is the other and should go to the blue/white pair

of the second mat, and so on. The black/brown pair of

the last mat goes back to Terminals #3 and #4.

If the mat has two lamp cords, then either pair can go

to Terminals #1 and #2 and so on.

Mat #1

Mat #2

AB

2 Independent

Safety Outputs

A&B:

Wire each in

series with each

STOP circuit in

a DUAL STOP

system.

NOTE:

These are N.O.

Held Closed

outputs

Replacement

Safety Relay

32-101

Relay Fault LED’s D14,D18

On Mat LED’s D10,D12

NOTE: Canadian market wiring is black, red, red,

black with 18-guage wiring size.

7

door are LED’s

resistors set for

NC-C-NO

Aux Output:

for status only

Replacement

relay 32-001

NSD Mat Wiring:

Style “X” or “E”

1 Black, 2Red, 3 Black, 4 Red

Or Style “W” or “P”

1 Blue, 2White, 3 Black, 4 Brown

White Steel

mounting plate

is used to

support the PCB

(ON=good, OFF=Relay stuck on FAULT)

(ON=ON mat, OFF=OFF mat)

RED

Indicators on

with internal

24vdc

Page 13

Installation and Operation

NSD Safety Mat System

Wiring Diagrams

NSD-TR-01 (Metal Box Controller) - Diagram below is for older boards PRIOR to Rev 10.

4 mounting holes (#8

5.0"

screws)

7.0"

6.25"

Power ON

4.25"

Push “Clear” button to Reset

Mat Control will Auto-Reset

is both N.C. contacts are

24vdc

mat control.

disconnected.

External Status

Indicators

GRN

120vac

power

Ground

Connect either of the 2 wire pairs

to Terminal#1 & #2, and the other

pair to Terminal#3 & #4 (as

shown)

Earth

Mat #1

Mat #2

Safety Output:

Wire in series

with STOP

circuit.

This is a N.O.

Held Closed

output

Test

NC C NO

Aux Output: for

status only

NSD Mat Wiring:

Style “X” or “E”

1 Black, 2 Red, 3 Black, 4 Red

Or Style “W” or “P”

1 Blue, 2 White, 3 Black, 4 Brown

Indicators on

door are LED’s

with internal

resistors set for

White Steel

mounting plate

is used to

support the PCB

RED

24vdc

NOTE: If you daisy chain mats, the blue/white is one

pair and should go to Terminals #1 and #2. The black/

brown is the other and should go to the blue/white pair

of the second mat, and so on. The black/brown pair of

the last mat goes back to Terminals #3 and #4.

If the mat has two lamp cords, then either pair can go

to Terminals #1 and #2 and so on.

Relay Fault LED’s D14,D18

(ON=good, OFF=Relay stuck on FAULT)

On Mat LED’s D10,D12

(ON=ON mat, OFF=OFF mat)

NOTE: Canadian market wiring is black, red, red,

black with 18-guage wiring size.

8

Page 14

Installation and Operation

NSD Safety Mat System

NSD-DR-01 (Basic DIN-rail Controller)

Optional Remote 24vdc

Status indicator lights

NOTE:

Mat Wiring for Mat Styles “W” and “P” are

shown above (Blue, White, Black, Brown)

Mat Wiring for Mat Styles “X” and “E” are

Black, Red, Red, Black

(and are wired in that order)

Canadian market wiring is black, red, red,

black with 18 gauge wiring size.

NOTE:

Safety Relay outputs are N.O. (Held Closed)

and are wired into your STOP circuit(s).

Aux Relay should only be used for indicator

lights.

Red Grn

Manual Relay Latching Reset:

Wire Terminal #2 to #16 and use the Green ZONE

RESET button to reset

Optional Remote Latching Relay Reset:

Use a N.C. push button wired as shown above

LED indictors:

STOP: Safety Relays OFF (OPEN)

RUN: Safety Relays ON (CLOSED)

MAT STATUS: OFF = ON Mat

Fault When Off: OFF = Relay Fault

9

Page 15

NSD-DR-04 (DIN-rail Controller with diagnostics)

Installation and Operation

NSD Safety Mat System

External Relay Checking (optional usage)

NOTE: Terminal #6 (INPUT/OUTPUT PLUG) is internally connected to Terminal #1 (POWER/OUTPUT)

plug. This allows Terminal #6 to provide +24v to the lights for the RSD (Remote Status Display).

NOTE: Canadian market wiring is black, red, red, black with 18-guage wiring size.

REMOTE STATUS DISPLAY

Green: Terminal #8 (INPUT/OUTPUT)

Red: Terminal #7 (INPUT/OUTPUT)

Black: Terminal #1 (POWER/OUTPUT)

White/Black: Terminal #3 (INPUT/OUTPUT) / Terminal #2 (POWER/OUTPUT)

12cond cable: J1 (on left side of diagnostics display)

10

Page 16

Installation and Operation

NSD Safety Mat System

NSD-DR-04 (DIN-rail Controller with diagnostics)

Accessible Connections

J1 Diagnostics display plug (used by remote status display option)

The Plug is located under the top cover on the left side of the controller

External:

POWER/OUTPUT PLUG

Terminal No. Usage

1,2,3 +POS, -NEG, EARTH GROUND (24VDC ONLY)

4,5 Safety relay N.O. output (dry contact) (held closed when GREEN)

6,7 Safety relay N.O. output (dry contact) (held closed when GREEN)

8,9,10 Auxiliary relay N.C., COM, N.O.

11,12 Fault relay N.O. (open when faulted)

INPUT / OUTPUT PLUG

Terminal No. Usage

1,2 +pos, -neg External relay checking (option)

24vdc applied across these terminals when external relay is de-energized

3 Remote external zone reset (Ground to reset zone)

4,5 Auxiliary inputs (Ground to activate feature)

6 +24vdc input (Common for terminals 3,4,5) (jumper from term #1 Power/Output)

7 Optional remote RED “STOP” indicator output (Grounded when RED)

8 Optional remote GREEN “RUN” indicator output (Grounded when GREEN)

MAT 1,2,3,4 INPUT

Terminal No. Usage

1,2 20VDC output to mat (1=blue, 2=white)

voltage between 1 & 2 alternates

(1=black, 2=red for single two-dual lead mats)

3,4 Return from mat (3=black, 4=brown)

(3=red, 4=black for single two-dual lead mats)

DEVICENET PLUG (DB-9 female)

Terminal No. Usage

2,7 CANL, CANH (twisted pair data lines)

3,6 Ground

NOTE: Canadian market wiring is black, red, red, black with 18-guage wiring size.

11

Page 17

NSD-DR-04 (DIN-rail Controller with diagnostics)

Board Connector Layout

J2,J26 MAT INPUT #1 thru #4 JP1,2 NUMBER OF MATS SELECTION

J1 DIAGNOSTICS DISPLAY (remote) JP3 MANUAL

J120 POWER/OUTPUT JP4-6 EXT, AUX1, AUX2

D13,14 Safety relay output on (closed) D3 +12v supply

D16 Auxiliary relay output on D1 +5v supply

D15 Fault relay output on (closed) D23 +20v supply

Installation and Operation

NSD Safety Mat System

NSD-DR-04 (DIN-rail Controller with Diagnostics)

Jumper Settings

1= jumper install

Number of Mats:

JP2 JP1

0 0 1 mat

1 0 2 mats

0 1 3 mats

1 1 4 mats

JP3

1= Manual relay reseting

0= Automatic relay reseting

JP4

1= External relay checking enabled

0= Disabled

JP5

Not used at this time

JP6

Not used at this time

12

Page 18

Appendix “A”

Troubleshooting

NSD-TR-01 (Metal Box) and

NSD-DR-01 (Basic DIN-rail) Controllers

PROBLEM: No indicators are lit

Cause(s): 1) Incorrect line voltage OR no line

voltage.

2) Incorrectly wired.

3) Blown fuse.

4) Bad regulator.

Cure: Check fuse, then make sure you

have line voltage present at the

correct terminals and that its within

specifi cations. If it all checks out, then

the control board must be replaced.

PROBLEM: NSD control will not go green when

reset, relay fault LED is off

Cause(s): 1) Noise on the power line caused a

glitch in the NSD control.

2) Relay contact stayed closed when

user stepped on mat.

3) One of the redundant control

circuits is faulty.

Cure: Remove power to unit for 30 seconds,

apply power and hit the RESET button.

This should reset the circuits and the

NSD control should come back up.

Check the relays for signs of contact

pitting. Also, it’s possible that large

voltage spikes on the power line could

have caused a glitch in the NSD control

and it shut down. If the unit continues

have this problem, install MOV’s on the

power terminals of any nearby motors,

or solenoids. These devices cause

noise on the power line and the MOV’s

can usually cure this.

PROBLEM: NSD control will not go green when

reset, wire fault LED is off

Cause(s): 1) Wires from mat have not been

installed correctly.

2) One or more of the four wires going

out to the mat has been cut.

Cure(s): 1) See wiring diagram page for mat

wire colors and terminals.

2) Repair or replace cut wires.

PROBLEM: NSD control will not go green when

reset, all internal indicators are on

Cause(s): 1) Object on mat is keeping control

RED.

2) Short in either the mat or external

wires going to the mat.

3) You forgot to press the RESET

button to reset the mat.

Cure: Remove the mat wires from the control

unit and use an OHM meter to check for

a short between the wires or between

each pair of wires on the mat. If there

is a short, check for physical signs of

damage to the wiring or the mat. The

mat will require replacement if the short

is not in the wiring.

NSD-DR-04

(DIN-rail Controller with diagnostics)

PROBLEM: Mat wiring fault

Cause(s): 1) Low voltage on input that should

be ground.

2) High voltage on input that should

be ground.

Cure: Bad wiring, bad comparator, or bad mat.

PROBLEM: Circuit fault

Cause(s): 1) Voltage to mat below low setpoint.

2) V oltage to mat below high setpoint.

3) One of the redundant circuits

indicates ON mat, the other

indicates OFF mat.

4) One of the redundant circuits

indicates OFF mat, the other

indicates ON mat.

5) High voltage on input that should

be ground.

Cure: Bad wiring, bad comparator, or bad mat.

PROBLEM: Zone # out of sequence

Cause: The master and slave processors

disagree on which sequence they are

on.

Cure: An external electrical noise could be

causing one of the processors to loose

sequence.

AA - 1

Page 19

Appendix “A”

Troubleshooting

PROBLEM: Zone 1 relay off, should be on

Cause(s): Relay found in the wrong state; circuitry

failure or relay failure.

Cure: Call for assistance.

PROBLEM: External relay contact welded/cut

Cause: External relay check input remained

open (0 volts) while the zone was deenergized.

Cure: When the zone is de-energized (RED),

your external relay must close within

1/4 second.

PROBLEM: External relay contact short

Cause: External relay check input remained

closed (voltage applied) while the zone

was energized.

Cure: When the zone is energized, the

secondary pole of your external relay

(N.C.) must open up within 1/4 second.

PROBLEM: Mat # out of sequence

PROBLEM: Serial data corrupted

Cause: Electrical noise getting into the control

box causing one of the computer to

reset.

Cure: Place MOV’s across the coil of any

device (outside this control) switched

on/off by the relay outputs of this

controller.

PROBLEM: Serial data transmission incomplete

Cause: Electrical noise getting into the control

box causing one of the computer to

reset.

Cure: Place MOV’s across the coil of any

device (outside this control) switched

on/off by the relay outputs of this

controller.

PROBLEM: Master relay on, Slave relay off

Cause(s): The master processor disagrees with

the slave.

Cure: Call for assistance.

Cause: The master and slave processors

disagree on which sequence they are

on.

Cure: Could have an electrical noise problem

causing one of the processors to loose

sequence.

PROBLEM: Ram failure

Cause: Microprocessor failed the internal

memory test.

Cure: Call for assistance.

PROBLEM: Power failure

Cause: Circuitry failure; brown out.

Cure: Call for assistance.

PROBLEM: Watchdog failure

Cause: Watchdog circuitry failure.

Cure: Call for assistance.

PROBLEM: Slave relay on, Master relay off

Cause: The slave processor disagrees with the

master.

Cure: Call for assistance.

AA - 2

Page 20

Appendix “A”

Troubleshooting

DeviceNet

Applicable for the DIN-rail (with diagnostics) only

Vendor ID code = 0459

Diagnostics Display

“OK U”

Devicenet unconnected (may be unplugged from

network)

“OK C”

Devicenet connected but not allocated (passed

duplicated mac id check)

“OK A”

Devicenet allocated (in service)

“OK F”

Devicenet faulted out (mat controller will work, but

not devicenet)

User adjustable MAC_ID

(default = 63)

If the NSD controller fi nds a duplicate MAC_ID,

it will go off-line and display the current MAC_ID

on the diagnostics display. Use the Fault Reset

button to decrement the MAC_ID to a new (unused)

value. Hold the button in for 2 sec to program it

permanently.

The NSD controller will now check for duplicate

MAC_ID’s using the new ID.

Network adjustable BAUD_RATE

(default = 125Kb/s)

If your network runs at different baud rate, you can

adjust the NSD controller using standard DeviceNet

set commands. The NSD controller supports 125,

250, and 500Kb/s rates. After you change the Baud

rate, you must cycle power to NSD to re-enable

Devicenet.

Network settable CONNECTION

(default= offl ine)

Network adjustable EPR_RATE timer

(default= 10sec for explicit connection, none for

bit-strobe)

The EPR (Extendend packet rate) timer is set in

250msec increments. A value of less than 250 will

keep the connection forever.

Bit_Strobe Return Values: (4 bytes returned)

BYTE 0: Status Code

Value Defi nition

0 Off all mat

1 On at least one mat

5 Waiting for Fault Reset button to be

pushed

6 Fault reset button held down

10-19 Mat fault codes

21-26 Relay fault codes

27-32 External relay fault codes

34 Ram failure

35 Power on reset

36 Clock / watchdog failure

37 Data exchange with Slave computer

corrupted

38 Data exchange with Slave not

completed

Byte 1: Zone Status

Defi nition:

0=relays off / contacts open;

1=relays on / contacts closed

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Zone Zone Zone

#3 #2 #1

Byte 2: Mat Status

Defi nition: 0=on mat;1=off mat

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Mat Mat Mat Mat Mat Mat Mat Mat

#8 #7 #6 #5 #4 #3 #2 #1

Byte 3: Options Enabled

Defi nition: 0=disabled, 1=enabled

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Re- Re- Re- Aux Aux Mute- Ext. Manual

served served served #2 #1 out Relay Reset

Ckg.

The NSD controller will allow EXPLICIT and BIT_

STROBE connections only

AA - 3

Page 21

Appendix “B”

Safety Guidelines for Management

Safety Guidelines for Management

Operational Safety

1. Appoint a Safety Coordinator to be responsible

for safety regulations, requirements, and

suggestions. He must review and investigate

all accidents and “close calls.”

2. Establish and issue safety rules. Inform each

employee of his responsibilities. Make sure he

understands them and knows what is expected

of him.

3. A thorough review and an early inspection must

be made of existing presses, dies, and point

of operation guarding to attain the degree of

responsibility required by ANSI B11.1-2009

Safety Standards and Federal State laws.

Review what mandatory modifications are

necessary.

4. Equipment that is no longer safe and that cannot

be economically upgraded should be destroyed.

5. Never allow persons legally under age to

operate or assist in the operation of machinery .

6. All personnel must be properly trained to

eliminate accidents and injuries.

7. Regardless of the operator’s experience,

education, or language barrier, it is the

responsibility of the supervisor to give him

a thorough explanation with each new job

assignment.

8. No employee should be given a work assignment

that he does not fully understand. Only properly

instructed and thoroughly trained personnel

should be assigned to work on or with any

machine.

9. It shall be the responsibility of the employer

to provide an adequate, clean, safe, and

uncluttered work area around each machine.

10. If a malfunction is reported, stop the machine

immediately , correct the problem, then resume

production.

11. Investigate all accidents and close calls.

Analyze the reason for occurrence. T ake action

to prevent recurrence. Keep records of the

investigation and preventative steps that were

taken.

12. Only employees who understand the machines,

operation and safety requirements, and who are

able to communicate this knowledge should

be given the responsibility of instructing and

training others to perform as operators.

13. Management must decide that personnel

protective safety equipment is required to

perform each job safely. Items such as safety

glasses, shoes, gloves, helmets, hand pads,

spats, protective sleeves and material handling

equipment are common in the metal working

industry . If noise levels are excessive, protective

headsets and earmuffs are recommended.

When a mat system is used to protect the operator or passerby from penetration, it must be mounted and

properly sized so it is impossible to reach under, around, or over into the hazardous point of operation zone.

Safety mat systems normally guard the front or feed area of a machine. The sides of the areas where the

safety mat does not guard must be guarded by some other means or by additional safety mats.

If the position of the safety mat(s) will allow the operator or others to place themselves between the sensing

fi eld and the hazardous area, auxiliary guards or devices such as safety light curtains, barrier guards or

devices should be used in conjunction with the safety mat(s) to prevent the operator or others from exposure

to the hazardous area.

If mechanical guards such as: polyurethane, expanded or perforated metal, hairpins, etc., are used to guard

these areas, the opening must comply with the OSHA safety distance in relationship to the openings.

After installation of point of operation guards and before a job is released for operation, a check should be

made to verify that the guard will prevent the operators hands from reaching into the point of operation or any

hazard zone. Always refer to the applicable OSHA & ANSI standard in order to assure proper compliance to

the subject machine.

! ! ! CAUTION ! ! !

AB - 1

Page 22

Appendix “B”

Safety Guidelines for Management

14. When designing point of operation guarding,

the manufacturing process should be weighed

heavily in favor of operational safety.

15. Establish safe and convenient material handling

methods and procedures.

16. Post in convenient areas the names, addresses,

and phone numbers of physicians and hospitals,

and members of the organization who are to be

called in case of emergency.

17. All equipment must be electrically connected

according to the National Electric Code and be

consistent with other accepted practices.

18. Provide adequate and proper fi re protection

equipment.

Safety Enforcement

In order to have an effective safety program,

management at all levels must enforce every safety

rule and regulation. Strong disciplinary measures are

sometimes required. They should consist of a warning,

written reprimand, work suspension, transfer, demotion,

or possibly a dismissal. All infractions must be reported

and recorded. Once an infraction in noted, it shows

that an unsafe practice or condition has existed. This

may be the result of poor planning or improper training

and instructing. The reason for the infraction should be

analyzed in order to take corrective action.

Supervisor Training

It should be the responsibility of management to instruct

their supervisors on safety, giving job instructions,

supervising operators, determining accident causes, and

building safety attitudes among the machine operators.

Accidents can occur due to inadequate training of

supervisors.

Operator Training

It shall be the responsibility of management to insure

proper training of operators. A specifi c training program

should be instituted to instruct the operator in safety,

proper usage of the equipment, and correct operational

procedure in performing each and every job. In addition

to the supervisor, the operator should be familiar with the

proper guarding of the point of operation. Never permit

an operator to start a job without complete instructions

from his immediate supervisor.

AB - 2

Page 23

WARRANTY

Manufacturer warrants that this product will be free from

defects in material and workmanship for a period of one

year from the date of shipment thereof. Within the warranty

period, manufacturer will repair or replace such products

which are returned to it with shipping charges prepaid and

which will be disclosed as defective upon examination

by the manufacturer. This warranty will not apply to any

product which will have been subject to misuse, negligence,

accident, restriction, and use not in accordance with

manufacturer’s instructions or which will have been altered

or repaired by persons other than the authorized agent or

employees of the manufacturer.

DISCLAIMER

The provisions of the paragraph “Warranty” are the sole

obligations of the manufacturer and exclude all other

warranties of merchantability, expressed or implied.

Further, there are no warranties which extend beyond the

above warranty.

LIMITATION OF LIABILITY

In the event of any claim or breach of any obligations

of manufacturer under any order, whether expressed or

implied, and particularly in the event of any claim or a breach

of the warranty or warranties contained in the paragraph

“Warranty” or of any other warranties, expressed or implied

which might, despite the paragraph entitled “Disclaimer,” be

determined to be incorporated in any order, the company

shall under no circumstances be liable for any consequential

or special damages, either in law or in equity, or for losses

or expenses or claims for the same arising from the use of,

or inability to use, the products of the manufacturer for any

purpose whatsoever.

The entire machine safety

system must be tested at the start of every shift.

Machine testing should include: (1) proper machine

operation and stopping capability; and (2) verifi cation

of proper installation and settings of all point of

operation guards and devices before the operation

is released for production.

DISCLAIMER

Pinnacle Systems, Inc. does not assume liability for the

contents of this publication or the use of any products

described. Pinnacle Systems, Inc. reserves the right to

make changes to the products or any catalogs without

further notice.

ERRORS AND OMISSIONS

Information presented by Pinnacle Systems, Inc. has

been checked and is believed to be accurate; however,

no responsibility is assumed for clerical, typographical or

proofreading errors or omissions.

CHANGE IN SPECIFICATIONS

Product specifi cations and accessories may be changed

at any time based on improvements and other reasons.

It is our practice to change part numbers when published

ratings or features are changed, or when signifi cant con-

struction changes are made. However, some specifi ca-

tions of the Product may be changed without any notice.

When in doubt, special part numbers may be reassigned

to fi x or establish key specifi cations for your application.

Please consult the factory.

Page 24

Sales and Marketing Offi ces

Customer Service: (630) 443-8542

United States

Pinnacle Systems, Inc.

P.O. Box 100088

Pittsburgh, PA 15233

Toll Free Number: 800-569-7697

Direct Number: 412-262-3950

Fax: 412-262-4055

Canada

Pinnacle Systems, Inc.

8-1734 Orangebrook Court

Pickering, Ontario L1W 3G8

Toll Free Number: 888-285-8885

Direct Number: 905-831-1111

Fax: 905-831-4064

We have designed our equipment to the very highest

performance and safety standards known to the

current technological state of the art, as evidenced by

our U.S.A. and foreign patents issued and pending.

However, the installation, usage, suitability , and fi tness

of our equipment for any purpose, known or unknown,

is interdependent upon the performance of other

equipment not manufactured, installed, secured or

maintained by Pinnacle Systems, Inc.

We cannot and do not accept responsibility for any

overall system performance when factors, such as

these, are beyond our control.

www.pinnaclesystems.com

sales@pinnaclesystems.com

service@pinnaclesystems.com

Loading...

Loading...