Page 1

Datasheet

Item No. R1.188.3580.0

Device for monitoring of safety-related circuits SNO 4083KM-A DC 24V

Base unit also for elevators EN 81-1/2 and heaters EN50156-1

single-channel or two-channel control, automatic or manual reset

with monitoring, cross circuit monitoring, 3 enabling current paths, 1

signalling output, DC 24 V, screw-terminals pluggable

Item No. R1.188.3580.0

EAN 4049088070884

order unit 1 Piece(s)

Datasheet

NSD Safety Mat Controller Modules

Both Modules are compliant to OSHA & ANSI Standards - EN ISO 13849-1 EN 62061 EN 81-1 EN 50156-1

NSD-3580

24 VDC

Approvals

Technical data

General

ArticlePrice udp_no_price

Function display 3 LED, green

Creepage distances and clearances between the circuits EN 60664-1

Protection degree according to DIN EN 60529 (housing) IP40

Protection degree according to DIN EN 60529 (terminals) IP20

Ambient temperature min. -25 °C

Ambient temperature max. 65 °C

Wire ranges screw terminals, fine-stranded / solid 1 x 0,14 mm² - 2,5 mm² / 2 x 0,14 mm² - 0,75 mm²

Wire ranges screw terminals,fine-stranded with ferrules 1 x 0,25 mm² - 2,5 mm² / 2 x 0,25 mm² - 0,5 mm²

Permissible torque min. 0.5 Nm

Permissible torque max. 0.6 Nm

Tightening moment 0.6 Nm

Wire range cage clamp terminals 2 x 0,25mm² - 1,5mm²

Weight 0.2 kg

Standards EN ISO 13849-1 EN 62061 EN 81-1 EN 50156-1

Suited for safety functions Yes

Category according to EN 954-1 4

Muting possible No

Feedback circuit Yes

Start contact Yes

Performance level acc. to EN ISO 13849-1 e

Rail mounting possible Yes

Connection Data

Detachable clamps Yes

Type of electric connection Screw connection

Application

Model Basic device

Suitable for monitoring of magnetic switches Yes

Suitable for monitoring of proximity switches Yes

NSD-3590

115 TO 230 VAC

Page 2

Suitable for monitoring of emergency-stop circuits Yes

Suitable for monitoring of optoelectronic protection equipment Yes

Suitable for monitoring of position switches Yes

Output circuit

Enabling paths 3

Signaling paths 1

Contact material Ag-alloy, gold-plated

Max. thermal current Ith, enabling paths 6 A

Max. thermal current Ith, signaling paths 2 A

Max. total current I2 of all current path 25 A²

Application category AC-15 (NO) Ue 230V, Ie 3A

Application category DC-13 (NO) Ue 24V, Ie 5A

Short-circuit protection (NO), max. fuse insert 6 A class gG fuse, fuse integral < 100 A²s

Mechanical life 107 switching cycles

Control circuit

Nominal output voltage DC 22.5 V

Input current (safety circuit / reset circuit) 25 mA

max. peak current (safety circuit / reset circuit) 100 mA

Response time tA1 250 ms

Response time tA2 250 ms

Min. switch-on time 60 ms

Recovery time tW 120 ms

Release time tR 20 ms

Synchronous time tS 1.5 s

Permissable test pulse time tTP 0.8 ms

max. resistivity, per channel

Type of switch function of the inputs Normally open contact

Evaluation inputs 2-channel

Supply circuit

Nominal voltage UN DC 24 V

Rated consumption DC 1.6 W

Operating voltage min. 22.4 V

Operating voltage max. 26.4 V

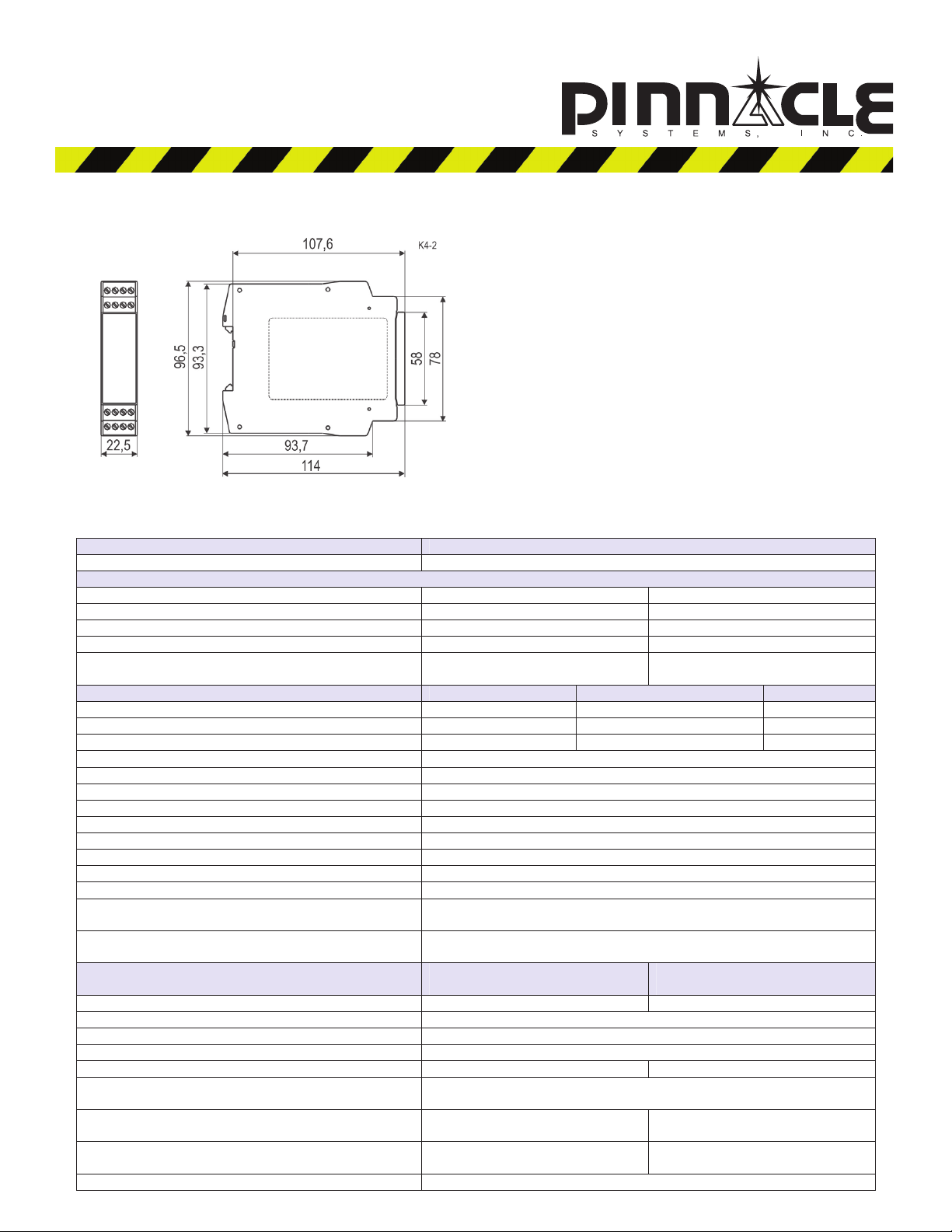

Dimensions

Depth 114 mm

Width 22.5 mm

Height 96.5 mm

(5 + (1,176 x UB / UN - 1) x 100)

≤

Ω

www.pinnaclesystems.com2

Page 3

Instructions

(Translation of the original instructions)

SNO 4083KM

Wieland Electric GmbH

Brennerstraße 10-14

D-96052 Bamberg

Tel. +49 (0) 951 / 9324 -0

Fax +49 (0) 951 / 9324 -198

www.wieland-electric.com

Wieland Electric GmbH

Brennerstraße 10-14

D-96052 Bamberg

Tel. +49 (0) 951 / 9324 -0

Fax +49 (0) 951 / 9324 -198

www.wieland-electric.com

Basic device for EMERGENCY STOP and safety door applications

• Basic device according to EN 60204-1:2007 and EN ISO 13849-1:2007 for single or

two-channel EMERGENCY STOP monitoring.

• PL e / category 4 according to EN ISO 13849-1:2007

• SILCL 3 according to DIN EN 62061:2005

• Stop category 0 according to DIN EN 60204-1

• Manual or automatic start

• With / without crossover detection

• Feedback circuit for monitoring external contactors

• Three enabling current paths, one messaging current path

• Evaluation unit for BWS 4 according to EN 61496-1

• Usage according to EN 81-1 and EN 50156-1

• For connection in series with a pressure sensitive mat according to EN 1760-1

Device versions

R1.188.3580.0—SNO 4083KM-A DC 24 with screw terminals, pluggable

R1.188.3590.0—SNO 4083KM-A AC 115-230 V with screw terminals, pluggable

R1.188.3600.0—SNO 4083KM-C DC 24 V with spring-loaded terminals, pluggable

R1.188.3610.0—SNO 4083KM-C AC 115-230 V with spring-loaded terminals, pluggable

R1.188.3830.0—SNO 4083KM-A 0,5S DC 24 V with screw terminals, pluggable

R1.188.3840.0—SNO 4083KM-A 0,5S AC 115-230 V with screw terminals, pluggable

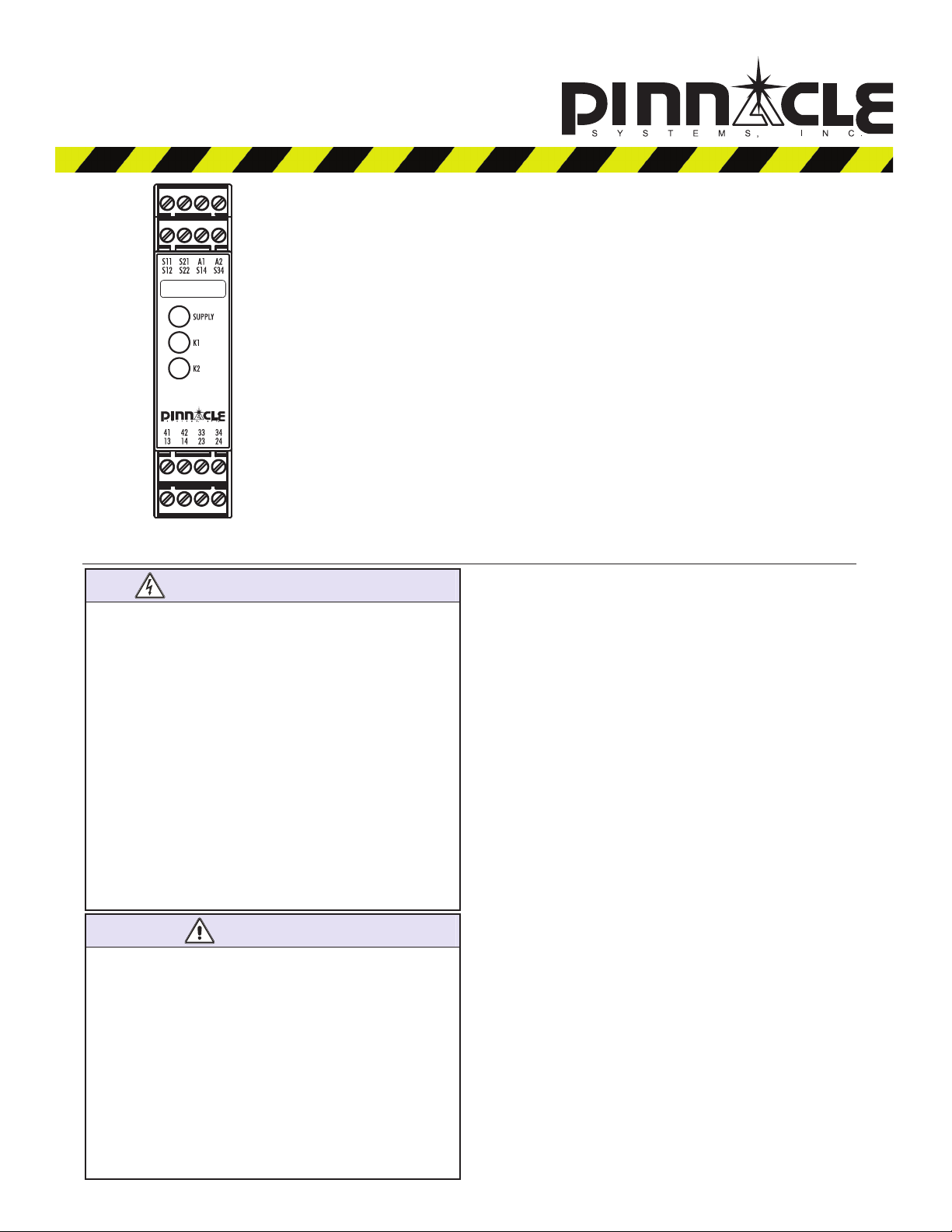

Front view

Basic device for Emergency Stop and Safety Mat applications

Basic device for EMERGENCY STOP and safety door applications

• Basic device according to EN 60204-1:2007 and EN ISO 13849-1:2007 for single or

two-channel EMERGENCY STOP monitoring.

• PL e / category 4 according to EN ISO 13849-1:2007

• SILCL 3 according to DIN EN 62061:2005

• Stop category 0 according to DIN EN 60204-1

• Manual or automatic start

• With / without crossover detection

• Feedback circuit for monitoring external contactors

• Three enabling current paths, one messaging current path

• Evaluation unit for BWS 4 according to EN 61496-1

• Usage according to EN 81-1 and EN 50156-1

• For connection in series with a pressure sensitive mat according to EN 1760-1

Device versions

Front View

R1.188.3580.0—SNO 4083KM-A DC 24 with screw terminals, pluggable

Supply LED green, power supply indicator

R1.188.3590.0—SNO 4083KM-A AC 115-230 V with screw terminals, pluggable

K1, K2 LED green, operation and status indicator for relays K1 and K2

R1.188.3600.0—SNO 4083KM-C DC 24 V with spring-loaded terminals, pluggable

R1.188.3610.0—SNO 4083KM-C AC 115-230 V with spring-loaded terminals, pluggable

R1.188.3830.0—SNO 4083KM-A 0,5S DC 24 V with screw terminals, pluggable

R1.188.3840.0—SNO 4083KM-A 0,5S AC 115-230 V with screw terminals, pluggable

Front view

Supply LED green, power supply indicator

K1, K2 LED green, operation and status indicator for relays K1 and K2

SAFETY REGULATIONS

• Installation, commissioning, modification and retrofitting

must only be performed by a qualified electrician.

• Disconnect the device/the system from the power supply

before starting work. In the case of installation and system

errors, mains voltage can be present on the control circuit in

1 Proper use

The devices are safety switching devices. They must only be

used as components of safety equipment on machines that is

intended for the protection of persons, material, functions and

machinery.

the case of non-galvanically isolated devices.

• Observe the electrotechnical and professional trade associa-

2 Function

tion safety regulations for installation of the equipment.

• Opening the case or other manipulation voids any war-

ranty.

• In the case of improper use or any use other than for the

intended purpose, the device must no longer be used and

any warranty claim is void. Invalidating causes can be:

strong mechanical loading of the device, such as occur

when falling or voltages, currents, temperatures, humidity

outside the specifications.

• Always check all safety functions in accordance with the

applicable regulations during initial commissioning of your

machine/system and observe the specified inspection cycles for safety devices.

ATTENTION

• Take the following safety precautions before starting

installation / assembly or dismantling:

1. Disconnect the device / the system from the power

supply before starting work.

2. Secure the machine / system against being switched on

again.

3. Confirm that no voltage is present.

4. Ground the phases and short to ground briefly.

5. Cover and shield neighbouring live parts.

6. The devices must be installed in a switch cabinet with a

protection class of at least IP54.

• Limited contact protection! Protection class according to

EN 60529:

− Case/terminals: IP40/IP20.

− Finger-proof according to EN 50247.

The device is a two-channel safety switching device for EMERGENCY STOP equipment according to EN 60204-1. It performs

self-monitoring during each ON-OFF cycle and is equipped with

positively driven relays. The device is suitable for connection in

series with short-circuiting pressure sensitive mats, pressure

sensitive bumpers or switching edges with 4-wire technology

(without a monitoring resistor).

Basic function: After applying the supply voltage to the

terminals A1/A2 and closed safety inputs, the enabling current

paths are closed when a valid reset signal is established at S34.

The enabling current paths are opened when the safety inputs

are opened/de-energised.

Operating modes / System functions

• Single-channel or two-channel actuation

• With or without crossover detection

• Manual start (triggering with falling edge)

• Automatic start

• Evaluation of signal transmitters featuring equivalent or non-

equivalent switching

Page 4

• The performance level (PL) and safety category in accor-

NOT E

dance with EN ISO 13849-1 depend on the external wiring,

the application case, the choice of control device and how

this is physically arranged on the machine.

• The user must carry out a risk assessment in accordance

with ISO 14121-1.

• The entire system/machine must undergo validation in

accordance with the applicable standards on the basis of

this.

• The stated performance level will only be achieved if, taking

into account the prevailing device load (see EN ISO 13849-1

Table C.1) and the application case, an average number of

switching cycles per year is not exceeded (see EN ISO

13849-1, C.2.3 and Table K.1). Assuming that the B10d

value is 400,000 for the maximum load, the maximum cycle

number would be 400,000 / 0.1 x 30 = 133,333 switching

cycles per year.

• The safety-related characteristics only apply when the relays

are switched at least once per year.

• Operating the device other than specified can result in

malfunctions or destruction of the device.

• The device must be checked to ensure it is in perfect

working order before commissioning, after replacement of

modules and/or in the case of changes to an installation that

has already undergone acceptance.

• For operation at 115–230 VAC, the operating equipment of

the control circuits must be designed for a rated voltage of

300 V. Basic isolation between supply and control circuits.

• The specified times must always be adhered to when

operating the device; otherwise, the device may become

locked. Locking may be reversed by opening the safety

inputs in the proper manner.

NOT E

• The expansion units of the SNE series or external contactors

with positively-driven contacts can be used for duplicating

the enabling current paths

• The contacts must be fused with maximum 6 A operating

class gG.

• Control outputs S11 and S21 are equipped with overload

protection (for short circuits). Once the cause of the error

has been rectified, the device is ready for operation again

after approx. 3 s.

• The control inputs and outputs are only used for the con-

nection of control devices and not for the connection of

external consumers such as lamps, relays or contactors.

• External loads must be equipped with a suitable protection

circuit for the load (e.g. RC elements, varistors, suppressors,

etc.) in order to reduce electromagnetic interference and

increase the service life of the output switching elements.

• The application-specific standards must be observed when

installing and operating the device.

• The safety functions have not been checked by UL. The

certification process has been carried out in accordance

with the requirements for general applications as stipulated

by UL508.

3 Mounting

Mounting Dismantling

1. Attach the device to the DIN

rail.

2. Snap the device on to the

DIN rail by applying slight

pressure in the direction of

the arrow.

3. Press the device down in

the direction of the arrow.

4. While pressed down,

detach the device from the

latching (in the direction

indicated by the arrow) and

remove it from the DIN rail.

4 Terminal diagram

www.pinnaclesystems.com4

Page 5

A

5 Function diagrams

Equivalent actuation with manual start (installation 1, 2, 3, 4, 5, 8)

A1

S11

S12 (CH1)

S22 (CH2)

S34 (Reset)

13/14

23/24

33/34

41/42

S12 (CH1)

S22 (CH2)

S34 (Reset)

13/14

23/24

33/34

41/42

t

tS tBR tMt

B

A

t

R1

t

W

Non-equivalent actuation with automatic start (installation 6, 7)

1

S11

t

tA

B

t

R1

t

W

t

tBR tMtA

S

t

R2

t

t

S

A

t

R2

Page 6

6 Installation

1 – EMERGENCY STOP button, single-channel 2 – EMERGENCY STOP button, two-channel without

crossover detection

S12

3 – Safety light curtain BWS type 4, two-channel with

crossover detection by BWS1)

BWS type 4

S22 S21

Note: Not for 110-230 VAC

S11 S14

with OSSD

S12

5 – Pressure sensitive mat, two-channel with crossover

detection

S22 S21

S11

S14

Safety mat

S11

S21 S22

S12 S14

S12

4 – EMERGENCY STOP button, two-channel with

crossover detection

S11

6 – Solenoid switch, two-channel, non-equivalent, with

crossover detection

Type SMA

actuated

S22

S12 S21

S11

S21

S21 S12

S11

S22 S14

S14

S22 S14

7 – Reset, automatic, with and without feedback circuit

K11 ... K13

S11

S34

S11

S34

www.pinnaclesystems.com6

8 – Reset, manual, monitored, with and without feedback

circuit

K11 ... K13

S21

S34

S21

S34

Page 7

9 – Power supply 10 – Outputs

]

i

hi

[A]

L+/L1

L+ / L1 M / N

A1

A2

7 Contact load derating

I² – Total current

I² [A²]

80

70

60

50

40

30

13

23

33

41

K1

K2

14

K11 K12

M/N

24

34

K13

42

20

10

30

20 40

-10

-20

10

0

8 Relay service life

ng current

tc

w

50

TA[°C

60

T

A,max

Switching cycles

Page 8

SNO 4083KM-A screw terminal SNO 4083KM-C spring-loaded terminal

9 Dimensions

SNO 4083KM-A screw terminal SNO 4083KM-C spring-loaded terminal

9 Dimensions

10 Technical data

NSD-3580

24 VDC

Function EMERGENCY STOP relay

Function indicator 3 LEDs, green

Power circuit

Rated voltage UN 24 V DC 115–230 VAC

Operating voltage range UB: 0.85–1.1 × UN 20.4 to 26.4 VDC 97 to 253 VAC

Rated power 1.6 W 1.8 W / 4.0 VA

Nominal frequency 50-60 Hz

Electrical isolation between supply and control

circuits

Control circuits S11/S21 S12/S22 S14/S34

Rated output voltage 22.5 V DC

Input current 25 mA 3 mA

Max. peak current 100 mA 5 mA

Response time (manual start tA1, autom. start tA2) 250 ms

Minimum activation time tM (manual start) 125 ms

Recovery time tW 120 ms

Release time tR 20 ms

Synchronous time monitoring tS 0.5 s / 1.5 s

Test pulse length tT 4 ms

Test pulse interval T

Permissible test pulse time tTP < 0.8 ms

Test pulse length tTR, of the incoming test pulse < 16 ms

Delay time tD (time between test pulse and incoming

test pulse)

Max. line resistance per channel 2) 24 VDC (5 + (1.176 × UB / UN – 1) × 100) Ω

115–230 VAC 12 Ω

Output circuits Enabling current paths

Contact Normally open Normally closed

Contact type Positively driven

Contact material Ag alloy, gold plated

Rated switching voltage U 230 VAC

Max. thermal permanent current ITH 6 A 2 A

Max. total current I

65°C 9 A2

Utilisation category AC-15 Ue 230 V, Ie 5 A

DC-13 Ue 24 V, Ie 5 A

Short circuit protection 6 A class gG fuse,

Mechanical service life 107 switching cycles

200 ms

TEST

< 48 ms

2

55°C 25 A2

N

13/14, 23/24, 33/34

fuse integral < 100 A²s

Yes

www.pinnaclesystems.com8

NSD-3590

115 TO 230 VAC

Messaging current paths

41/42

Page 9

Terminals and connection data Screw terminals Spring-loaded terminals

Single-core or finely stranded 1 × 0.14–2.5 mm²

2 × 0.2-1.5 mm²

2 × 0.14-0.75 mm²

Finely stranded with wire-end ferrule according to

DIN 46228

1 × 0.25-2.5 mm²

2 × 0.25-0.5 mm²

2 × 0.25–1.5 mm² (trapezoid

crimping)

AWG conductor size (only use Cu wires) 26–14 24–16

Maximum tightening torque 0.5–0.6 Nm (5–7 lbf-in)

Stripping length Max. 8 mm

General data

Air gap and creepage paths between the circuits EN 60664-1

Protection class according to EN 60529

IP40/IP20

case/terminals

Ambient operating temperature –25 to +65 °C

Storage temperature –25 to +75 °C

Weight 0.2 kg

Standards EN ISO 13849-1, EN 62061, EN 81-1, EN 50156-1

Certifications TÜV, cULus (in progress)

11 Error codes and correction

Flashing

code

2 Crossover, can be rectified during operation

3 Process error, failure to observe the correct sequence for two-channel actuation, can be rectified during opera-

tion by repeating the actuation sequence correctly

4 Synchronous time error, synchronous time exceeded in the case of two-channel actuation, can be rectified

during operation by adhering to the synchronous time

5 Maximum reset actuating time exceeded, can be rectified during operation by repeating the reset with the

correct time

6 Configuration error, can be rectified by ensuring the correct terminal assignment for the required configuration,

the device has to be switched off and on again

7 Permissible input voltage limits undershot/overshot S12 and S22, can be rectified by setting the supply voltage

correctly, the device has to be switched off and on again

8 Device temperature too high, can be rectified by reducing the contact loads or the ambient temperature, the

device has to be switched off and on again

≥ 12 Internal monitoring event, please replace the device and contact after sales service

If an error is still indicated even after the cause has been rectified, inputs S12, S22, S14 and S34 must be kept open during

power-on (e.g. pull out the connector). The error should then be cleared and you can perform a restart with the required installation by means of a power-off and power-on operation.

Loading...

Loading...