Page 1

Installation Manual

for the

Metal Box Controller Module

Page 2

Rev 9-6

Page 3

Metal Box Controller Module

Installation Manual

Pinnacle Systems, Inc.

3715 Swenson Avenue

St. Charles, IL 60174

P/N: 28-006r9-6

Customer Service: 630-443-8542 (CST)

(Please have Model #, Serial #, and Software Rev # Available)

Sales and Marketing: 800-569-7697 (EST)

www.pinnaclesystems.com • sales@pinnaclesystems.com • service@pinnaclesystems.com

Page 4

Proper Usage and Limitations

The information disclosed herein includes proprietary

rights of the manufacturer. Neither this document nor

the information disclosed herein shall be reproduced

or transferred to other documents, used or disclosed

to others for manufacturing purposes, or for any other

purposes, except as specically authorized in writing by

the manufacturer. If this manual is supplied in connection

with the sale or delivery of manufacturer’s equipment, it is

to be used solely for maintenance, repair, or installation

of such equipment.

The MicroGuard was manufactured in the United States.

The Installation Manual was printed in the United States.

You must read and fully understand the following

information pertaining to the proper use and limitations of

your Microguard:

• The MicroGuard must be installed by qualified

personnel only.

• The MicroGuard must NOT be used on full revolution

presses or any machine that cannot be commanded

to stop at any time.

• You must NOT wire the Safety Output contacts of

the MicroGuard to an external relay unless you use

the External Relay Checking feature.

• Th e me chanical powe r p ress o n w hic h t he

MicroGuard is installed must meet ANSI B11.1-

1988 and OSHA 1910.217 regulations. These

include inspection and maintenance procedures

that must be followed to comply with the regulations.

The manufacturer will NOT take responsibility for

improperly maintained machinery.

• Point of operation safeguarding is dened in ANSI

B11.19-2003. This regulation is used to determine

a safe distance to place your MicroGuard. The

manufacturer takes no responsibility for injury as

a result of improper safeguarding or improper safe

distances.

• The MicroGuard may not be able to safely stop

a press which has a faulty stopping mechanism.

The manufacturer cannot be held responsible

for an improperly maintained or faulty stopping

mechanism.

• The MicroGuard must be checked before put into

operation. Follow instructions provided in this

manual for procedures on how to do this.

• The MicroGuard should never be modified or

repaired except by qualied personnel and upon

authorization of the manufacturer. Never operate

machinery that is not in full working order.

• Make sure that all maintenance people, machine

operators, die-setters, foreman, and supervisors

have read and understood this manual and all

procedures have been and will be followed.

• All procedures in this manual must be followed. The

manufacturer cannot take responsibility for operation

if all procedures and warnings in this manual are not

followed.

Warranty

Manufacturer warrants that this product will be free

from defects in material and workmanship for a period

of two years from the date of shipment thereof. Within

the warranty period, the manufacturer will repair or

replace (at our discretion) any product that is disclosed

as defective upon examination by the manufacturer and

is returned with shipping charges prepaid. This warranty

will not apply to any product that has been subjected to

misuse, negligence, accident, restriction, and use not in

accordance with manufacturer’s instructions or which will

have been altered or repaired by persons other than the

authorized agent or employees of the manufacturer.

Disclaimer

The provisions of the warranty are the sole obligations

of the manufacturer and exclude all other warranties of

merchantability, expressed or implied. Further, there are

no warranties that extend beyond the above warranty.

Limitation of Liability

In the event of any claim for breach of any obligations of

the manufacturer under any order, whether expressed

or implied, and particularly in the event of any claim

of a breach of the warranty or warranties contained in

the paragraph “Warranty” or of any other warranties,

expressed or implied which might despite the paragraph

entitled “Disclaimer,” be determined to be incorporated in

any order, the company shall under no circumstances be

liable for any consequential or special damages, either in

law or in equity, or for losses or expenses or claims for

the same arising from the use of, or inability to use, the

products of the manufacturer for any purpose whatsoever.

We have designed our equipment to the very highest

performance and safety standards known to the current

technological state of the art. However, the installation,

usage, suitability, and tness of our equipment for any

purpose, known or unknown, is interdependent upon

the performance of other equipment not manufactured,

installed, or secured or maintained by the manufacturer.

We cannot and do not accept responsibility for any overall

system performance when factors, such as these, are

beyond our control.

WARNING: The entire machine safety system must

be tested at the start of every shift. Machine testing

should include: (1) proper machine operation and

stopping capability; and (2) verification of proper

installation and settings of all point of operation

guards and devices before the operation is released

for production.

Page 5

We will not supply individual component parts of any

circuit board but will supply the individual circuit board

complete. Individual detectors or emitters are available

as a complete tested unit.

Fill this Information out Immediately

(It will be needed in the event you need assistance)

Purchase Date: _______________________________

Purchased From: ______________________________

Model No.: ___________________________________

Serial No.: ___________________________________

Options: _____________________________________

Microprocessor Revision No.: ____________________

Page 6

Table of Contents

Introduction ...........................................................................................................................................................iv

Theory of Operation ...............................................................................................................................................iv

The System ............................................................................................................................................................iv

System Safety ........................................................................................................................................................iv

Immunity to EMI/RFI ...............................................................................................................................................v

CE Approved ...........................................................................................................................................................v

Specications .......................................................................................................................................................1

Standard Features

Auxillary Output Contact ........................................................................................................................................2

Cincinnati Interface .................................................................................................................................................2

External Relay Check .............................................................................................................................................2

Standard Output Contacts .....................................................................................................................................3

Fault Relay Output .................................................................................................................................................3

Optional Features

Auto Blank ...............................................................................................................................................................4

Emergency Stop Input ............................................................................................................................................5

DeviceNet ...............................................................................................................................................................5

Floating Blank .........................................................................................................................................................5

Depth Penetration Factor ........................................................................................................................................5

Guarding Mute-Out .................................................................................................................................................6

Latching Relays ......................................................................................................................................................6

Installation Procedures .....................................................................................................................................7

Resetting the MicroGuard .......................................................................................................................................8

Alignment Procedure ..............................................................................................................................................9

Operations ............................................................................................................................................................10

ANSI Standard B11.19.2003 .................................................................................................................................11

Safeguarding with Mechanical Guards .................................................................................................................12

Light Curtain Testing Procedure ............................................................................................................................12

Controller Module Setup .......................................................................................................................................13

Single Pylon Set Controller Module Jumper Settings ...........................................................................................14

Multiple Pylon Set Controller Module Jumper Settings .........................................................................................15

Wiring ....................................................................................................................................................................16

Swivel Bracket Dimensions ...................................................................................................................................17

Pylon Dimensions (by model) (Swivel) .................................................................................................................18

Additional cable information (Swivel) ....................................................................................................................18

Fixed Bracket Dimensions ....................................................................................................................................19

Pylon Dimensions (by model) (Fixed) ...................................................................................................................19

Additional cable information (Fixed) ......................................................................................................................19

Dimensions

Physical Dimensions of Swivel Bracket ................................................................................................................17

Physical Dimensions of Swivel Bracket ................................................................................................................18

Physical Dimensions of Fixed Bracket ..................................................................................................................19

Controller Module ..................................................................................................................................................20

- i -

Page 7

Table of Contents

Accessories

Cornering Mirrors ..................................................................................................................................................21

Pedestal ................................................................................................................................................................22

Swing-Arm Mounting Bracket ...............................................................................................................................22

Appendix A: Diagnostics & Troubleshooting

Diagnostic Indicator Lights ................................................................................................................................. A-1

Obstruction or Misalignment ............................................................................................................................... A-1

Error Conditions ..................................................................................................................................................A-1

Status Display Messages ....................................................................................................................................A-2

Fault Display Messages ......................................................................................................................................A-2

Appendix B: Regulations and Guidelines

OSHA Regulations ..............................................................................................................................................B-1

Machine Control Reliability .................................................................................................................................B-1

Safety Guidelines and Management

Operational Safety .......................................................................................................................................... B-2

Power Press Guarding .................................................................................................................................... B-2

Power Press Care through Inspection and Maintenance ................................................................................ B-3

Safety Enforcement ........................................................................................................................................B-3

Supervisor Training ......................................................................................................................................... B-3

Operator Training ............................................................................................................................................ B-3

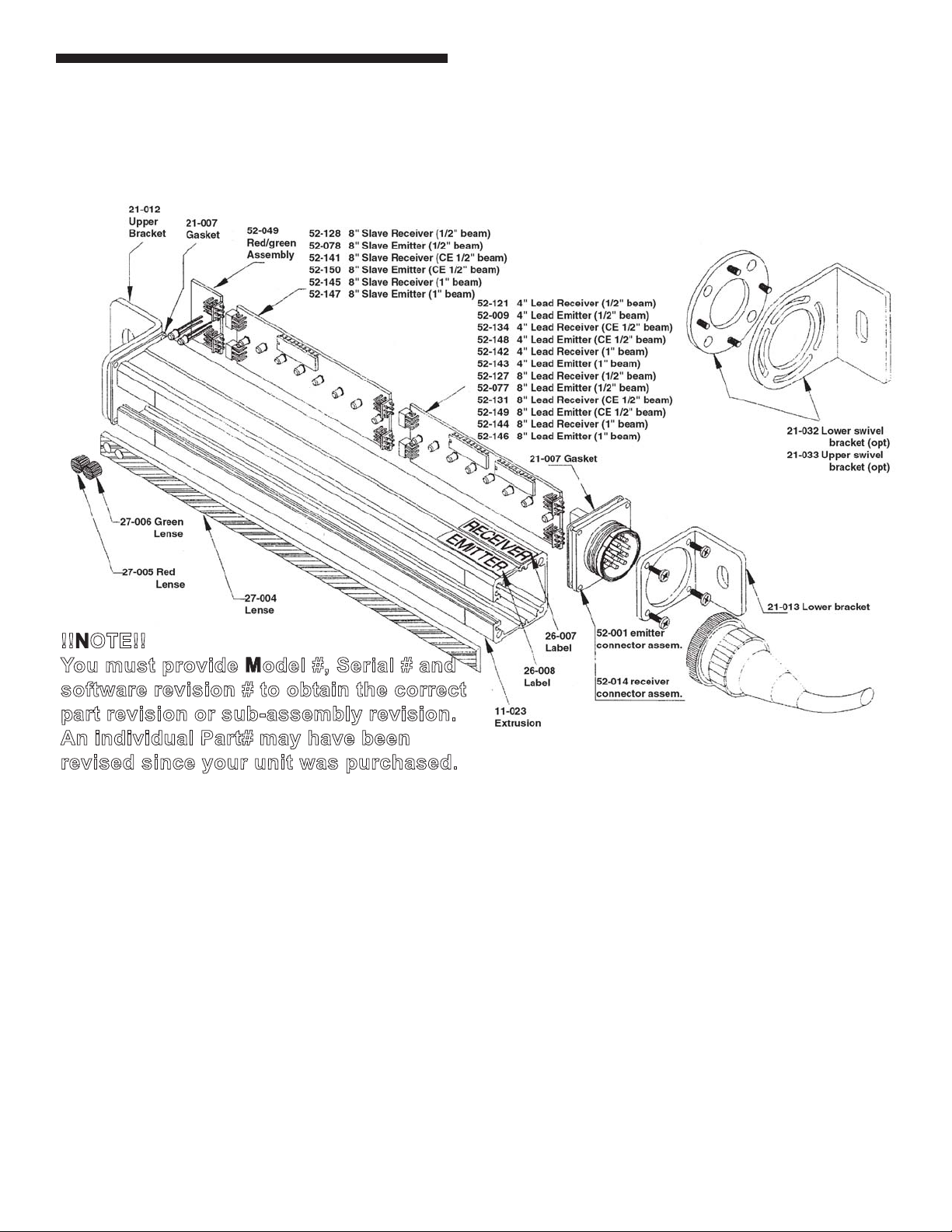

Appendix C: Replacement Parts

Controller Module Replacement Parts ................................................................................................................C-1

Pylon Replacement Parts ...................................................................................................................................C-2

Appendix D: USB Diagnostic Codes

Model MG or DR USB Diagnostic Codes ................................................................................................D-1 to D-2

- ii -

Page 8

Table of Contents

Figures

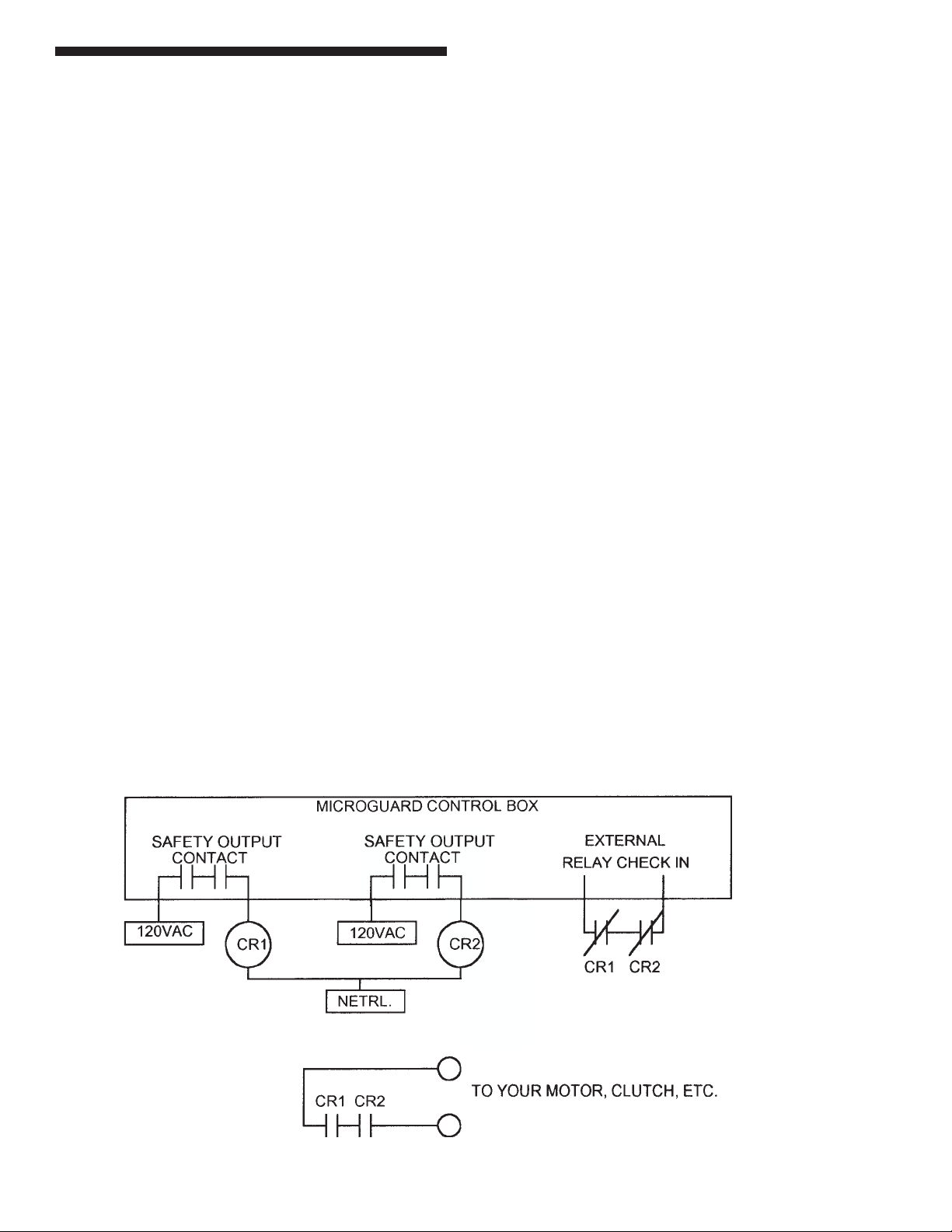

Figure 1: Wiring External Relays ........................................................................................................................2

Figure 2: Bottom Board Inside Control Box .........................................................................................................6

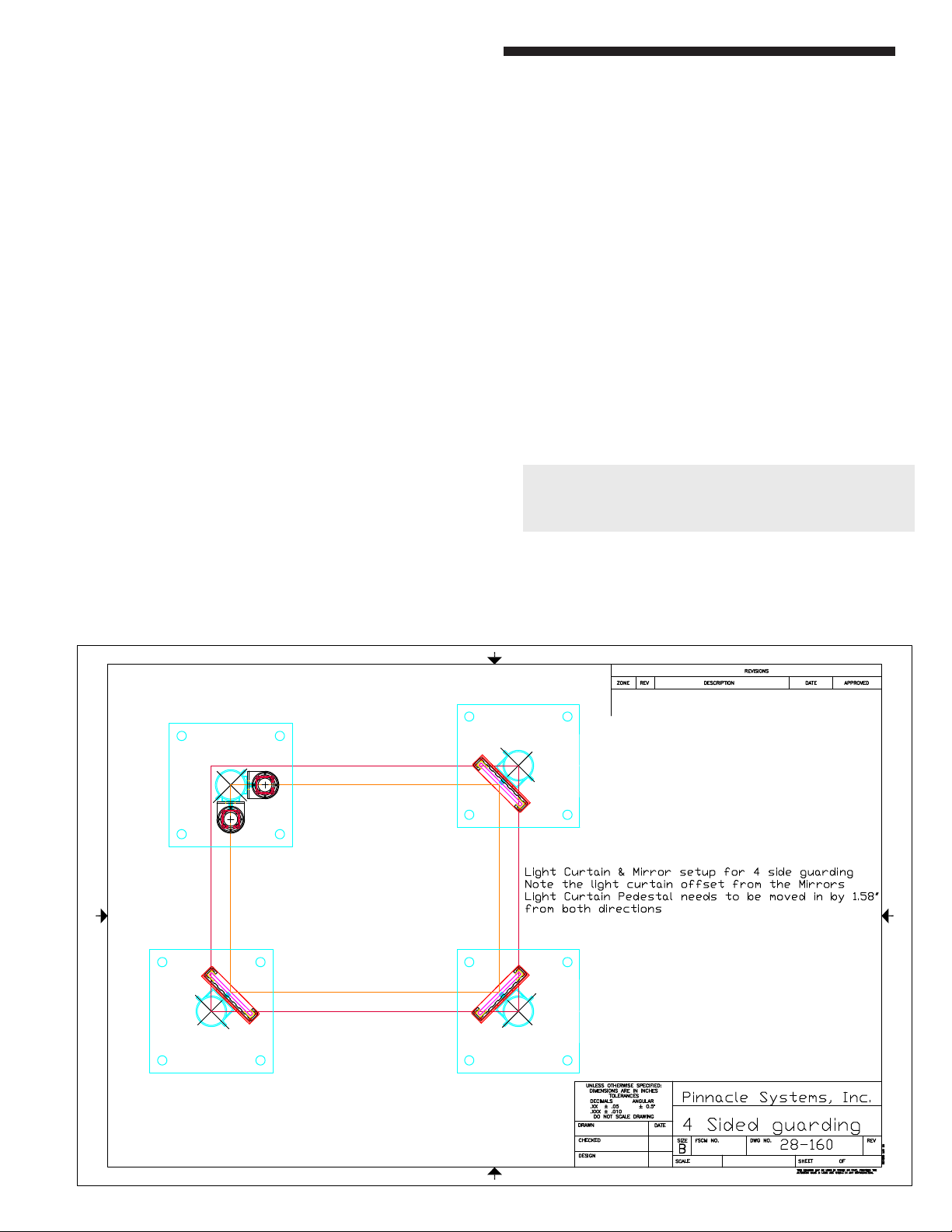

Figure 3: 4 Sided Guarding with Dual Stud Guard Brackets, TRM Mirrors and Model #8000 Pedestals ...........9

Figure 4: Minimum Object Sensitivity and D(pf) ................................................................................................ 11

Figure 5: Controller Module (Lower Board) .......................................................................................................13

Figure 6: Controller Module Jumper (Upper Board) ..........................................................................................14

Figure 7: Multi-pylon Controller Module Connector/Jumper Detail ...................................................................15

Figure 8: Controller Module Wiring Diagram .....................................................................................................16

Figure 9a: Swivel Bracket Dimensions ................................................................................................................17

Figure 9b: Swivel Bracket Dimensions, pylon dimensions (by model), and additional cable information ...........18

Figure 10: Fixed Bracket Dimensions, pylon dimensions (by model), and additional cable information .............19

Figure 11: Controller Module Dimensions ...........................................................................................................20

Figure 12: Cornering Mirror Dimensions .............................................................................................................21

Figure 13: Pedestal Dimensions .........................................................................................................................22

Figure 14: Swing-Arm Mounting Bracket Dimensions .........................................................................................22

Figure 15: Controller Module Replacement Parts .............................................................................................C-1

Figure 16: Pylon Replacement Parts ................................................................................................................C-2

Tables

Table 1a: .5” Beam Spacing Pylons .....................................................................................................................5

Table 1b: 1” Beam Spacing Pylons ......................................................................................................................5

Table 2: Mechanical Guards ............................................................................................................................12

Table 3: Controller Module Connection Chart (Lower Board) ..........................................................................13

Table 4: Single Pylon Set Controller Module Jumper Chart ............................................................................14

Table 5: Multiple Pylon Set Controller (DUAL - SC) Module Length Jumper Chart .........................................15

Table 6: Controller Module Dimensions ...........................................................................................................20

Table 7: Cornering Mirror Dimensions (MGM & TRM) .....................................................................................21

- iii -

Page 9

Introduction

The Microguard is the latest in infrared safety curtain

technology. Contained in the main housing (Controller

Module) is a diverse redundant architecture that is

designed to detect internal failures in the Emitter

pylon(s), Receiver pylon(s), and the Controller Module

which will immediately send a “STOP” command to

the machine, thus being “FAIL-SAFE.” Failures are

immediately reported on the diagnostic message display

for immediate evaluation.

Diverse redundancy means that there are at least two

ways to detect a system failure, two ways to shut it down,

and that the two methods of detection and shut down

use different techniques. This eliminates the chance

an inherent fault in one circuit will effect the other. For

example: The stop circuit output contacts run through

two relays and both are monitored for correct position

through a second set of contacts on each relay. A special

circuit monitors those contacts, but a different circuit (a

test circuit) monitors the rst circuit to make sure that it

is functioning correctly. Two different microprocessors

isolated from one another each monitor the same signals

and monitor each other. Either microprocessor can turn

off the output relays, but it requires both to turn them on.

Special watchdog circuits on the microprocessors and

on the output relay circuits prevent an unsafe condition

by turning off both outputs relays should either or both

microprocessors become erratic.

With the aid of advanced microprocessor technology, the

MicroGuard can not only detect a fault in the light curtain

but spell out the exact problem. This advancement is

a great help during alignment, use, and servicing of the

light curtain. It not only can detect shorted and open

infrared emitters, but indicate which emitters have failed,

allowing the faulty board to be replaced.

Built into the MicroGuard is an optically coupled external

relay check which can detect open or short circuits,

a Cincinnati Interface, provision for auxiliary output

contacts, and external voltage check input. The power

supply is designed to accommodate most voltage

requirements, from DC to AC (see Specications).

is placed between them, the beam is broken and the

absence of a beam is observed by the Controller Module

which de-energizes the output relays and opens the

circuit it is connected to.

The System. The MicroGuard employs infrared

technology in a small sealed NEMA 4 aluminum housing

which provides harmless invisible protection and an

unobstructed view of the guarded area. The Microguard

consists of three parts: an Emitter pylon(s), Receiver

pylon(s), and Controller Module. The Emitter pylon(s)

contains infrared light emitting diodes spaced .5” or 1”

apart down the entire length of the pylon. The Receiver

pylon(s) contains an equal number of infrared detector’s

and transistor receivers also spaced .5” or 1” apart.

The Controller Module contains diverse redundant

technology that includes two different microprocessors,

self-checking circuitry, power supply, safety output

contacts, and a diagnostics display.

System Safety. The MicroGuard employs diverse

redundant technology that provides a backup for every

system that could cause an unsafe condition. Upon

power up, all systems are checked before activating

the output relays. Once the unit passes the initial

tests and activates the system it is then tested by both

microprocessors and other circuits once per scan of

the light curtain. All signals are presented to both

microprocessors, but are isolated from one another

to prevent a failure of one microprocessor should the

other crash. Other circuits detect short circuits, open

circuits, proper voltage, proper oscillation, etc. The

use of special dual force guided safety relays assure

that if one fails, the other can safely shut down the unit.

Additionally, watchdog circuits on the relays prevent an

unsafe condition even if both microprocessors failed.

All the standard and optional features that run on the

MicroGuard are designed with safety in mind:

The Floating Blank option allows only one object to be

placed into the light curtains eld of view. Even if the

object is smaller than the allowed size, a second object

will cause the unit to go RED.

As the MicroGuard is a single function device, that of

sensing an unauthorized intrusion into a guarded area

while simultaneously determining that it is capable of

sensing such an intrusion, any internal malfunction will

manifest itself with a RED condition shut down.

Theory of Operation. The MicroGuard guards an area

by projecting a curtain of infrared light across it. It forms

a curtain by utilizing infrared emitters in line very close

together on .5” or 1” centers. This close spacing makes

it impossible to place a body part through the curtain

without detection. For every infrared emitter there is an

infrared detector directly opposite. When an obstruction

The Auto Blank option programs in the exact size and

location of an object automatically and thus can detect

any movement in the object and shut down the light

curtain, which must be reset with a key.

The External Relay Check can detect both an open or

a short in the external relay or its wiring. The standard

Cincinnati Interface provides a means to assure that

the light curtain can open up i t s o u t p u t r e l a ys

between press cycles.

- iv -

Page 10

Introduction

Immunity to EMI/RFI. The entire system is shielded,

including the pylon cables. The use of MOV’s, lters,

and chokes make it immune to the noise found in the

industrial environment. Even the software embedded

into the dual microprocessors is written to cope with a

noisy environment.

CE Approved. CE approval was third party certied by

UL / DEMKO to IEC61496-1,-2. CE approved units offer

+/-2deg beam angle, which is tighter than the standard

Microguard.

- v -

Page 11

Specications

Metal Box Controller Module

Input Power

18 to 33 VDC @ 10 W (optional)

90 to 140 VAC @ 12 W (standard)

128 to 240 VAC @ 12 W (optional)

All AC voltages work with 50 or 60 Hz

Fuses

AC power: 1 AMP Slow Blow (250VAC)

DC power: 1 AMP Fast Blow

Output Circuits (all isolated)

Terminals #12-13: N.O. (held closed when Green)

control reliable dry STOP circuit, wired through K1 &

K2 relays. 4A @ 120vac recommended max

Terminals #14-15: N.O. (held closed when Green)

control reliable dry STOP circuit, wired through K1 & K2

relays. 4A @ 120vac recommended max

Term inal s #9- 1 0-11: N.O. (hel d clo s ed wh en

Green) – common – N.C. (held open when Green)

dry auxi liar y cir cuit , wir ed th roug h K3 rela y.

4A @ 120vac recommended max

Alarm + - : N.O. (held closed when powered and NO

FAULTS) dry auxiliary circuit, wired through K4 relay.

4A @ 120vac recommended max

NOTE: For Older Control boxes prior to October 2007:

Both terminals #12-13 and #14-15 must be used to

achieve a control reliable STOP circuit. Newer control

boxes can use either or both sets of terminals.

Indicators

External:

Construction:

Control Unit: All 18 Gauge painted steel

NEMA 12 lockable box with sealed front

panel and sealed cable entry ttings (8 lbs.).

Pylons: Heavy-duty aluminum extrusion

NEMA 4. Replaceable IR lens.

Sealed bulkhead positive locking circular

connectors. (Optional polycarbonate

protective tube guards).

Cables: Emitter 20’/ Receiver 8’ (supplied

standard). Shielded PVC 22 AWG cable

(optional cable lengths available).

Temperature Range 32° to 120° F

Dimensions

Controller Module: (see Dimensions)

Pylons: 1.45” (36.83mm) square (see

Dimensions)

Beam Spacing

.5” (12.7mm) standard

1” (25.4mm) (optional). The Floating Blank

option changes the effective beam spacing.

Minimum Object Sensitivity:

.5” (12.7mm) beam spacing is .55” (14mm)

1” (25.4mm) beam spacing is 1.18” (30mm)

Response Time < 30 mSec total

Scanning Frequency 5.9 KHz

Shock Tested to withstand high vibration applications.

OK/CLEAR Green

BLOCK/FAULT Red

AUTO/FLOAT ACTIVE Yellow

SLAVE DISAGREEMENT Red

The Diagnostics Display is a four-digit

alphanumeric with scroll

Internal:

+12V (RED) D2 CINN INT. (GRN) D10

+5V (YEL) D4 EXT RELAY (GRN) D11

+5V (YEL) D3 -5V (GRN) D17

FAULT RELAY (GRN) D21

Self-Checking every 20 milliseconds

Scanning Distance All units are supplied standard

with a 20’ (6.1m) scanning capability. Extended

range units are available and must be specied -- 50’

maximum (15.2m).

Maximum Operating Distance Stated as last two

digits in model number.

1

Page 12

Standard Features

Metal Box Controller Module

Auxiliary Output Contact (K3)

Description: K3 relay uses the same driver circuitry

as the K1 relay, but has its own relay checking circuitry.

This means that you should never use the K3 relay in

series with the K1 relay unless you use K2 in another

stop circuit.

Usage: K3 has both N.O. and N.C. outputs off the

same common. This can be used in conjunction with

the standard output contacts. Never just use K3 by

itself or with K1.

N.O. contact is closed when the curtain is GREEN.

N.C. contact is open when the curtain is GREEN.

Cincinnati Interface

Description: Provided to allow an external device to

determine if the light curtain is still capable of shutting

down the safety control circuit. The Cincinnati Interface

allows an external device to override the light curtain,

initiate a RED condition, and open up the standard

output relay contacts.

Application: Cincinnati Press, PLC

Usage:

Type1: The press interface provides 24VDC when it

wants the guard to de-energize (go RED). Connect this

press signal to Terminal #5 and Ground to Terminal #6.

Type 2: The press interface provides Ground when it

wants the guard t de-energize (go RED). Connect this

signal to Terminal #6 and attach nothing to Terminal #5.

You must install the jumper J8 (bottom board).

(see Installation Procedures, “Controller Module Setup”)

External Relay Check

Description: Allows the MicroGuard to monitor a pair

of external relays in series using the external relays

secondary set of DRY contacts, provided that they are

N.C. and captive contacts. This captive or force-guided

contact will maintain the identical position as the primary

set of contacts on the external relays, except that the

secondary set of contacts are wired up to signal the

reverse of the primary. (i.e., primary are N.O., secondary

are N.C.) The circuit looks for both closure and opening

of the external relay contacts. This system is the only

safe External Relay Check.

Application: Monitoring external relay contacts for

shorts or opens.

Usage: Follow Figure 1 for wiring your external relays.

You must rst activate this feature by using the spare

jumper and placing it across J19 labeled EXT (door

board). This system requires that both N.C. relay

contacts be wired in series then back to the terminals

inside the Controller Module. Relay contacts must be

DRY contacts. Both external relay contacts must be

closed when the light curtain is RED within .25 sec or an

Figure 1: Wiring External Relays

12 13 14 15

2

Page 13

error will occur (this detects an open or a contact weld).

When the light curtain goes GREEN it will record the

opening of the external relay. If the light curtain goes

RED again without ever sensing the opening of the

external relays, an error will occur (this detects a short

or failed relay) and cause the light curtain to lock up and

must be powered down to clear the error. A Red LED

(D14) will light up when external contact is closed (see

Installation Procedures, “Controller Module Setup.” )

Captive Contact Denition: one pole inside the relay

always maintains the identical position to the other pole.

(i.e., if one pole contact welds closed, the other pole

remains closed even when the relay coil is de-energized.

NOTE: Use shielded cable for relay check inputs.

Standard Output Contacts (K1 & K2)

Description: Both K1 and K2 relays each have there

own relay driving circuitry and relay checking circuitry

and are fully independent of each other having there

own output terminals. The MicroGuard checks the

position of all the relays and shuts them all down if any

are found in the wrong position. In order for the system

to remain safe during a single failure of one relay, you

must be using the relays such that the second relay can

still shut the system down if the rst one ever fails. This

can either be by wiring both relays in series or using both

relays separately in two control circuits.

Usage: K1 and K2 have separate outputs and both

must be used either together in series with your stop

circuit or separately in two stop circuits. K1 and K2

outputs are N.O. and close when the curtain is GREEN

only.

Standard Features

Metal Box Controller Module

Fault Relay Output

Description: It will not change states due to curtain

blockage.

Application: Can be used to signal a remote station

of an unexpected machine shut down.

Usage: The fault relay provides a dry contact that is

open when good and closed when a fault or loss of

power occurs. Use the alarm contacts on the power

supply board. The dry contact is isolated up to 120VAC.

To Actviate: Install jumper on J17 (bottom board)

top 2 pins. Install jumper on J9 (door board) between

Latch and Close pins (left side). This feature will disable

remote latching. D21 will light up to show the relay is

active.

3

Page 14

Optional Features

Metal Box Controller Module

Auto Blank [patent # 5,243,183]

Description: Allows user to program the exact size and

location of an object (i.e., a conveyor, table, work piece,

etc.) automatically and can detect any movement in the

object causing the light curtain to shut down.

Application: With the obstruction in place, turn the

key swith from “OFF” to any mode of operation. If the

object(s) do not exceed the total allowable size, the unit

will energize the safety outputs.

Standard Operation: If the obstruction is moved or

removed, the unit will issue a “MOVE” fault, but will

re-energize the safety outputs when the obstruction

is returned to the original position. Standard operation

allows for a total of eight beams to be blocked anywhere

in the curtain (they do not have to be next to each other).

Optional Operation: If the obstruction is moved or

removed, the unit will issue a “MOVE” fault and lockup,

requiring you to re-program the obstruction.

Troubleshooting: If you get a “MOVE” fault when

the obstruction did not move, it is possible that you

are just barely covering a beam and either vibration or

reections are causing the beam to become uncovered.

The uncovered beam then causes a fault.

To Activate Feature: This feature must be ordered and

requires exchanging the computer chips (see Installation

Procedures, “Controller Module Setup”).

WARNING: Leave key switch in OFF/RESET

position while installing, setting up, and testing the

light curtain. Use Auto Blank only after you are

able to get a clear signal from the curtain with no

obstruction.

The term “Auto Blank” is an abbreviation which stands

for Automatic Programmable Beam Blanking. Auto

Blanking is controlled by a multi-position keyswitch and

has three distinct modes of operation:

1) Must be reset if auto blank obstruction moves

or g uard penetrated. The AUTO BLANK

obstruction must remain in its exact location

permanently. Any movement in the AUTO BLANK

obstruction and/or additional guard penetration

will latch the light curtain in a RED condition and

must be reset via the keyswitch.

NOTE: If no obstructions were programmed in, the

guard will still latch in a RED condition should the

guard be penetrated.

2) Must be reset if auto blank obstruction moves.

The Auto Blank obstruction must remain in its

exact location permanently. This works like Mode

1 except guard penetrations will not latch in a RED

condition.

3) Mode 2 with oating blank. This mode works

like Mode 2 with the addition of a Floating Blank

which is set to allow a one beam float (see

Optional Features, Floating Blank”).

NOTE: If no obstructions were programmed in, the

guard will still allow a one beam oat.

Programming: To program, turn the keyswitch into the

OFF/RESET position and place the obstruction(s) in the

guarded area. Now, turn the keyswitch into the desired

mode of operation. The exact size and location of the

object(s) are now in memory. The Depth Penetration

Factor D(pf) must be set to account for the one beam

oat (see Optional Features, “Floating Blank”).

Diagnostics Display

AB Auto Blank detected an object (the number

indicates the size of the object).

RDY No objects programmed in, keyswitch in

Mode 1 or 2.

FB No objects programmed in, keyswitch in

Mode 3

SIZE Obstruction size exceeded a total of eight

beams.

PENT Penetration of the light curtain occurred

while keyswitch was in Mode 1.

MOVE Auto Blank obstruction moved.

IMPORTANT: Place Auto Blank keyswitch into

OFF/RESET position and remove any obstructions

while aligning light curtain. Do not use Auto Blank

until light curtain is correctly aligned (see Installation

Procedures, “Alignment Procedure”).

The keyed selector switch is designated to be supervisory

controlled. After installation, the safety key should be

removed and controlled only by the safety supervisor or

authorized plant personnel.

4

Page 15

Optional Features

Metal Box Controller Module

Emergency Stop Input(s)

Description: This option utilizes two normally-closed

emergency stop contacts to achieve a Catagory 4

safety level, per EN 954-1. If either or both emergency

stop contacts open, power to the safety output relays is

removed, causing the relays to de-energize and send

a stop signal to the guarded machine.

Application: This protects against a safety switch

contact failure or wiring fault. A contact failure or wiring

short will inhibit the system reset, causing the system’s

Diagnostic Message Display to indicate an Emergency

Stop Input Failure.

Usage: Wire one N.C. contact between Terminal #1 and

#4. Wire the second N.C. contact between Terminal #3

and #4 (located on power supply board). This option

cannot be used with Mute-Out. Alterative option: Wire

rst N.C. contact between Terminal #6 and #4. Wire

second N.C. contact between Terminal #7 and #8. This

option cannot be used with Cincinnati or External relay

checking features. To reset ESTOP: Close both ESTOP

inputs, then use the latching relay reset input to clear

ESTOP fault (cycle closure between Terminal #2 and 4).

DeviceNet

Description: Optional external board that is mounted

to the door board inside the Metal Box Controller

Module. External board comes with its own directions.

™

Depth Penetration Factor is the number used to

compute the distance the light curtain should be placed

from the point of operation (see Installation Procedures,

“ANSI Standard B11.19-2003”).

Diagnostics Display:

RDY Keyswitch is in the lowest position (Floating

Blank is off).

FB Indicates Floating Blank active and the

number of blocked beams.

OBST A second object found in the curtain (only

one obstruction is allowed to oat).

Table 1a: .5” Beam Spacing Pylons

Display

Minimum

Object

Sensitivity, S

D(pf) Depth

Penetration

Factor

Max. Floating

object size

less than

Inches/Millimeters Inches/Millimeters Inches/Millimeters

RDY (oat off) 0.55” / 14mm 0.935” / 23.8mm 0.00” / 0.0mm

FB1 (1 beam oat) 1.18” / 30mm 3.077” / 78.2mm 0.45” / 11.4mm

FB2 (2 beam oat) 1.75” / 45mm 5.015”/129.2mm 0.95” / 24.1mm

FB3 (3 beam oat) 2.36” / 60mm 7.089”/180.2mm 1.45” / 36.8mm

FB4 (4 beam oat) 2.95” / 75mm 9.095”/231.2mm 1.95” / 49.5mm

FB5 (5 beam oat) 3.54” / 90mm 11.101”/282.2mm 2.45” / 62.2mm

FB6 (6 beam oat) 4.13” /105mm 13.107”/333.2mm 2.95” / 74.9mm

Floating Blank

Description: On a press brake, the Floating Blank permits

the work piece to be placed in the guarded area and can

be moved around as long as it does not exceed the object

sensitivity selected. A keyswitch by default allows for

zero, one, two, or three beams to be blocked anywhere

in the curtain as long as all the blocked beams are next

to each other. The customer may request different

blanking sizes for different applications. The Minimum

Object Sensitivity (MOS) and the Depth Penetration

Factor (DPF) change when the key switch position

is changed. The DPF is used to compute the safety

distance.

Location of the light curtain from the point of operation

must include the depth penetration factor D(pf)

equivalent to the beam spacing.

Minimum Object Sensitivity indicates the minimum

size required to cause the light curtain to detect an

object even if it is moving (oating). If the obstruction is

slightly smaller (less than .25”) than the stated number,

the light curtain may blink RED/GREEN when the

object is moving in the eld of view. If the obstruction

is smaller than the stated number by at least .25”, then

the light curtain will stay GREEN as long as there are

no additional obstructions.

Table 1b: 1” Beam Spacing Pylons

Minimum

Display

Inches/Millimeters Inches/Millimeters Inches/Millimeters

Rdy (oat off) 1.18” / 30mm 3.077” / 78.2mm 0.00” / 0.0mm

FB1 (1 beam oat) 2.36” / 60mm 7.089” /180.2mm 0.95” / 24.1mm

FB2 (2 beam oat) 3.54” / 90mm 11.101” /282.2mm 1.95” / 49.5mm

FB3 (3 beam oat) 4.72” / 120mm 15.113” /384.2mm 2.95” / 74.9mm

Object

Sensitivity, S

D(pf) Depth

Penetration

Factor

Max. Floating

IMPORTANT: Place Floating Blank keyswitch

in lowest position and remove any obstructions

while aligning light curtain. Do not use Floating

Blank until light curtain is correctly aligned (see

Installation Procedure, “Alignment Procedures”).

The keyed selector switch is designated to be

supervisory controlled. After installation, the safety

key should be removed and controlled only by the

safety supervisor or authorized plant personnel.

5

object size

less than

Page 16

Optional Features

Figure 2: Bottom board inside Control Box

Metal Box Controller Module

Guarding Mute-Out

Description: The Guarding Mute-Out option is the

only fault-tolerant method of by-passing the light curtain

during the nonhazardous portion of your machine cycle

(i.e., up stroke of press).

Application: Allows any object to pass through the light

curtain without opening the stop circuit and interrupting

the machine cycle (i.e., the curtain stays GREEN).

Usage: The Guarding Mute-Out portion of the cycle

occurs between the pinch point and top stop (about

180° to 300°) or any non-hazardous portion of your

machine cycle.

You must power up the MicroGuard out of the Guarding

Mute-Out condition, any other condition will cause an

error to occur and you will have to power down the guard

to reset it. When in Guarding Mute-Out, the MicroGuard

will display “MUTE.” If LS4 or LS5 limit switches are ever

caught out of sequence, the guard will fault and issue

an error message of “MUTE-OUT SWITCH FAULT” or

“SLV MUTE-OUT SWITCH FAULT.”

Use only the shielded cable provided! Do not route

cable along with high voltage lines.

1) Connect one side of LS4 and LS5 to Terminal

4 inside MicroGuard.

2) Connect other side of LS4 to Terminal 1 inside

MicroGuard.

4) Connect other side of LS5 to Terminal 3 inside

MicroGuard.

If both signals remain in the same state (i.e., both

closed or both open) for more than 100mSec a fault

will be issued.

NOTE: To by-pass this feature, jumper LS5 (terminal

3) to terminal 4.

To Activate Feature: This feature must be ordered and

requires exchanging the computer chips (see Controller

Module Setup section for a diagram).

Latching Relays

Description: Light curtain wil stay in a RED condition

when blocked, even when the blockage is removed and

the guard is clear, until signalled to try and reset back

to GREEN (unblocked).

If you have Auto-Blank, this option allows you to reset

penetration without reprogramming the Auto-Blank.

Application: This is used for guarding an area against

intrusion. Without this option the light curtain would only

stay RED (safe) as long as the intrusion was detected

(i.e., nger, hand, etc.).

Usage: Wire a N.O. button between Terminals 2 and 4. You

can remote this button if you want. This feature must be

ordered and requires exchanging the computer chips.

Also, install jumpers on J15 and J17 on bottom 2 pins

of each (bottom board).

Figure 2: Bottom Board Inside Control Box

1 2 3 4 - +

LS4 LS5 CONDITION DISPLAY

OPEN CLOSED GUARDED RdyM

CLOSED OPEN MUTE-OUT MUTE

OPEN OPEN FAULT Mute out switch fault

CLOSED CLOSED FAULT Mute out switch fault

N.O.

MUTE-LS4

Latching

Reset

Button

NOTE: To turn off this option (for alignment purposes)

short the 3 left pins of J4 together. Remove the shorted

pins when done with the guard alignment.

ALARM

Dry contact

MUTE-LS5

6

Page 17

Installation Procedures

Metal Box Controller Module

WARNING: The entire machine safety system

must be tested at the start of every shift. Machine

testing should include: (1) proper machine

operation and stopping capability; and (2)

verication of proper installation and settings of

all point of operation guards and devices before

the operation is released for production.

CAUTION: The MicroGuard should be mounted

in a manner so that only authorized personnel can

change the mounting or location.

CAUTION: Additional guards may be required to

prevent the operator from standing between the

light curtain and the point of operation.

1) Test the unit before you mount it on your equipment

by running the light curtain with the pylons butted

up to and facing each other. Each cable and pylon

is labeled “EMITTER” or “RECEIVER”. You will

feel a snap when the plug is fully seated and

locked onto the connector. Attach a line cord to

the power terminals for testing. If the light curtain

goes GREEN, you are ready to proceed with the

next step. If the light curtain stays RED, call your

dealer for help in determining the problem.

2) Determine the Safety Distance of the light curtain

from the point of operation (see Installation

Procedure, “ANSI Standard B11.19-2003”).

3) Determine if any part of the Microguard is to be

directly subjected to either excessive shock and/

or vibration. If so, mount the subjected parts to

your equipment using shock-mounted devices

(such as Part# 21-019). Shock and/or Vibration

damage is not covered under warranty.

4) Place the Controller Module in an accessible

location where the cables can reach the pylons.

Dress the cables to avoid crushing, kinking, or

cutting (see Dimensions, “Controller Module“).

5) Wire power to the proper terminals and check that

the voltage is correct (see Installation Procedures,

“Controller Module Setup”).

Power for the MicroGuard should not be down

stream of noisy inductive devices (i.e., motors,

solenoids, etc.), it should be in front of them.

6) Interface the light curtain standard relay output

contacts to the safety stop circuit(s). You must use

both K1 and K2 output contacts. Do not use an

external relay(s) unless you use the external

relay checking feature.

7) Interface any remaining optional input or output

lines to their proper terminals (see Optional

Features).

8) Align the light curtain (see Installation Procedures,

“Alignment Procedure”).

9) Use a round test piece (i.e., dowel rod) that has a

diameter equal to the minimum object sensitivity.

Check and assure stop of machine when signal of

penetration is made. Minimum object sensitivity

goes up if you use Auto or Floating Blank options.

10) Mechanical guarding may also be required

from reaching around the light curtain to the

point of operation (see Installation Procedures,

“Safeguarding with Mechanical Guards”).

11) For installation assistance, please call your

dealer.

NOTE: For location of pylons in relation to the hazard

area, see Appendix B: Regulations and Guidelines,

“Federal Register 1910.217 (c) (3) (iii) (e)” and Installation

Procedures, “Safeguarding with Mechanical Guards”.

4) Mount both pylons with the connector side in the

same direction mechanically aligned with one

another. Locate pylons so the working zone

is guarded from reaching around, over, and

under the light curtain system to the point

of operation or hazard zone (see Installation

Procedures, “Safeguarding with Mechanical

Guards”).

NOTE: For location of pylons in relation to the

hazard area, refer to Appendix B: Regulations

and Guidelines, “Federal Register 1910.217

(c) (3) (iii) (e).”

7

Page 18

Installation Procedures

Metal Box Controller Module

Resetting the MicroGuard

Error messages are stored in a nonvolatile memory

(EEPROM). To clear error messages, press the RESET

button. DO NOT hold in the button or hit it twice,

just one hit. The unit will not reset until it is nished

displaying the entire error message.

If you remove power from the unit without clearing the

error message, the message will reappear when you

power back up. Hit the RESET button to clear this error

from memory.

The RESET button is located inside the MicroGuard

Controller Module on the door circuit board, left hand

side, or the lower circuit board underneath the gray

ribbon cable to start up the light curtain.

You can review all previous error messages recorded

by holding down the RESET button while turning on the

power to the unit, for two seconds. Each error message

will scroll by, last error rst. When you see the message

“NO MORE CODES,” hit the RESET button to start up

the curtain. Up to 45 previous error messages can be

displayed. You can shut down the curtain during normal

operation by pressing the RESET button.

8

Page 19

Installation Procedures

Metal Box Controller Module

Alignment Procedure

1) Both pylons should be placed so that they are

mechanically aligned to one another. Make sure

that both ends of each pylon line up with each

other.

2) Slightly loosen the mounting bracket screws to

allow for slight rotational movement of Receiver

pylon.

3) Move the Receiver pylon to nd its midpoint (or

sweet spot) where the unit goes from RED to

GREEN to RED.

4) Tighten the screws once you nd the midpoint

and repeat the operation for the Emitter pylon.

If you still cannot get the unit to go GREEN

5) Recheck mechanical alignment.

6) The diagnostics display will indicate the distance

(in inches) of the rst missing beam from the

connector end of the guard and the total number

of missing beams (i.e., 12 4 = rst missing beam

is 12” from connector and a total of 4 beams are

missing or 015A = rst missing beam is 1.5” from

connector and 10 beams are missing)

7) Loosen the mounting bracket corresponding to

the end of the pylon closest to the missing beam

and adjust it to get the unit to go GREEN.

If you are using mirrors, refer to Figure 3

8) Every mirror you use will increase the difculty of

alignment and will reduce the overall maximum

optical distance you can achieve. A loss of 5%

per mirror should be used to determine the total

optical distance (i.e., 15’ through two mirrors =

16.5’ with losses).

9) You may have to rotate all mirrors in turn (starting

from the Emitter end) to nd the true optical path

of infrared light. Also, you may have to toe in one

end of the mirror due to irregularities in the mirror

brackets.

NOTE: Make sure you do not exceed the total

optical path distance of 20’ or the curtain distance

that was specied.

Figure 3: 4 Sided Guarding with Dual Stud Guard Brackets, TRM Mirrors and Model #8000 Pedestals

9

Page 20

Installation Procedures

Metal Box Controller Module

Operations

NOTE: Examine the MicroGuard on a daily basis to

make sure that no one has moved the light curtain pylons

closer to the pinch point or removed any mechanical

guards from around the curtain.

NOTE: If it is possible for someone to go through the

light curtain and remain in a dangerous area without

having to block the light curtain, you must order the

Resettable Latching Relays option which keeps the

curtain RED even after you are no longer blocking the

curtain. The Latchout reset button is mounted away

from the dangerous area and must be cycled to reset

the curtain.

1) Power up the light curtain. If a fault occurred the

last time the unit was powered and was never

RESET, it will appear as a “SLAVE FOUND” error

message and you will have to push the RESET

button to clear the fault message and start the

curtain.

2) When GREEN the curtain will display “RDY” or

“rdy “ depending on any options that were set (see

Appendix A: Diagnostics and Troubleshooting for

Descriptions).

3) When RED due to blockage, the display will

indicate the location of the rst obstruction(s) and

the total size of the obstruction(s) (see Appendix

A: Diagnostics and Troubleshooting). If you have

Floating Blank, then this is indicating that your

object is too large for the oating size you have

selected. If you increase the Floating Blank size,

you must recalculate the safety distance formula

since the object sensitivity will be larger. If you

have the Resettable Latchout option, the display

will show “PENT” to indicate penetration. You

must cycle the Latchout RESET button to clear

the curtain (see Optional Features, “Resettable

Latching Relays”).

6) Auto Blank. The display will show “AB” to indicate

that an object is programmed in and its size (in

beams) is shown as the next digit. If you keep

getting a “MOVE” message and your object is

not moving, try repositioning the object slightly

(+/- 1/4”) and reprogram it back into memory. If

you get a “SIZE” message, you must either get

new software to allow a larger object or reduce

your object size.

7) Floating Blank. The display will show “FB” to

indicate the allowed blanking size in beams. Once

an object penetrates the curtain, any second

object will cause the curtain to display “OBST” to

indicate that a second obstruction is in the curtain.

This is done in case you select a Floating Blank

size much larger than the actual object size.

4) When RED due to a fault, the display will scroll

the error message that caused the fault and the

board and beam number (if it can be pin pointed).

You must rst correct the fault and then push the

RESET button to clear the fault from memory,

even powering down the unit will not clear the

fault from memory (see Appendix A: Diagnostics

and Troubleshooting).

5) If you have the Guarding Mute-Out option, the

display will show “MUTE” during the up stroke.

If you have the Cincinnati Interface hooked up,

the display will show “CINN” during the up stroke

(see Optional Features, “Guarding Mute-Out”).

10

Page 21

Installation Procedures

Installation Procedures

Metal Box Controller Module

The following formula should be used when calculating

the safety distance:

Ds = K x (Ts + Tc + Tr + Tbm) + D(pf)

Ds = Minimum safety distance between the

device and the nearest point of operation

hazard (in inches).

K = Hand speed constant. This value has been

determined by various studies and, although

these studies indicate speeds of 63 in/sec to

over 100 in/sec, they are not conclusive

de termination s. Th e emplo yer sho uld

determine this value by considering all factors,

including physical ability of the operator.

Ts = Stop time of the machine tool measured by a

stop time measurement device.

Tc = Response time of the control system (usually

is taken care of by the measurement device).

Tr = Response time of the presence-sending

device and it’s interface, if any, as stated by

the ma nufactu rer or measur ed by th e

employer.

Tbm = Additional time allowed for the brake monitor

to compensate for variations in normal

stopping time.

D(pf) = Depth Penetration Factor. Added distance as

indicated by Figure 2. The minimum object

sensitivity is stated by the manufacturer. If a

Floating Blank is used, use the Dpf numbers

found on Tables 2 and 3.

Penetration factor, Dpf, for presence-sensing

devices used in a vertical application with object

sensitivity less than 64 mm (2.5 inches)

Dpf, the distance added to the safety distance due to

the penetration factor compensates for varying object

sensitivities of electro-optical presence-sensing

devices.

When blanking features are used and when the

blanked area is not completely filled by the workpiece

or part, or by mechanical guarding, the minimum

d B11.19-2003d B11.19-2003

d B11.19-2003d B11.19-2003

d B11.19-2003

or calculaor calcula

or calculaor calcula

or calcula

ting safting saf

ting safting saf

ting saf

ety distanceety distance

ety distanceety distance

ety distance

tains frtains fr

tains frtains fr

tains fr

om hazarom hazar

om hazarom hazar

om hazar

dous pointdous point

dous pointdous point

dous point

aa

aa

a

tion.tion.

tion.tion.

tion.

Metal Box Controller Module

ANSI Standard B11.19-2003

Formula for calculating safety distance

of light curtains from hazardous point

of operation.

The effective sensing eld of the device shall be located

at a distance from the nearest recognized hazards such

that the operator or others cannot reach the hazard with

a hand or other body part before cessation of motion

during the hazardous portion of the machine cycle.

The point at which a device responds to an intrusion may

vary. The devices should be located or adjusted such

that the device always responds to the intrusion at or

prior to the safety distance. Care should be exercised

when installing the device to ensure that it does not

detect false signals from other devices in the area.

Usually the electro-optical presence-sensing device is

used in a manner that provides a protected zone in front

of the primary work area with auxiliary devices or guards

used to protect secondary access areas. In some cases,

however, mirrors may be used in conjunction with the

device to provide 2-, 3-, or 4-sided protection.

The machine stop time should be measured with the

machine running at its fastest speed with its heaviest

die or tooling and the stop time being measured at the

90° position in the downstroke.

Figure 4: Minimum Object Sensitivity and D(pf)

Minimum

Object

Dpf = 3.4 (S-7) mm

(Dpf = 3.4 (S-0.275) in)

The following formula should be used when calculating

the safety distance:

Ds = K x (Ts + Tc + Tr + Tbm) + D(pf)

Ds = Minimum safety distance between the

device and the nearest point of operation

hazard (in inches).

K = Hand speed constant. This value has

been determined by various studies and,

although these studies indicate speeds of

Ts = Stop time of the machine tool measured by

Tc = Response time of the control system (usually

Tr = Response time of the presence-sending

Tbm = Additional time allowed for the brake

D(pf) = Depth Penetration Factor. Added distance

Penetration factor, Dpf, for presence-sensing

devices used in a vertical application with object

sensitivity less than 64 mm (2.5 inches)

Dpf, the distance added to the safety distance due

to the penetration factor compensates for varying

object sensitivities of electro-optical presence-sensing

devices.

When blanking features are used and when the

blanked area is not completely lled by the workpiece

or part, or by mechanical guarding, the minimum

object sensitivity can be calculated as:

Object sensitivity = size of the blanked area plus

minimum object sensitivity without blanking.

Once this value is found, then determine Dpf.

If the entre blanked area is lled with mechanical

11

guarding or other xed material or guards, use the

device’s object sensitivity to determine Dpf.

63 in/sec to over 100 in/sec, they are not

conclusive determinations. The employer

should determine this value by considering

all factors, including physical ability of the

operator.

a stop time measurement device.

is taken care of by the measurement

device).

device and it’s interface, if any, as stated

by the manufacturer or measured by the

employer.

monitor to compensate for variations in

normal stopping time.

as indicated by Figure 4 on this page. The

minimum object sensitivity is stated by the

manufacturer. If a Floating Blank is used,

use the Dpf numbers found in the Floating

Blank section of this manual.

Page 22

Installation Procedures

Metal Box Controller Module

Safeguarding with Mechanical Guards

When a light system is used to protect the operator or

passerby from penetration, it must be mounted and

properly sized (grid length) so it is impossible to reach

under, around, or over into the hazardous point of

operation zone. Infrared light systems normally guard

the front or feed area of a machine. The sides or the

areas where the light screen does not guard must be

guarded by some other means.

If the position of the safety light curtain will allow the

operator or others to place themselves between the

sensing eld and the hazardous area, auxiliary guards or

devices such as safety mats, barrier guards, or devices

should be used in conjunction with the safety light

curtain to prevent the operator or others from exposure

to the hazardous area. If mechanical guards such as

polyurethane, expanded or perforated metal, hairpins,

etc. are used to guard these areas, the opening must

comply with the OSHA safety distance in relationship

to the openings.

After installation of point of operation guards and before

a job is released for operation, a check should be made

to verify that the guard will prevent the operators hands

from reaching into the point of operation or any hazard

zone.

Table 2 outlines the distances that guards should be

positioned from the nearest point-of-operation hazards.

The various openings are such that for average-sized

hands, an operator’s ngers will not reach the point of

operation.

After installation of point-of-operation guards and before

a job is released for operation, a check should be made

to verify that the guard will prevent the operator’s hands

or other body parts from reaching the point of operation.

Light Curtain Test Procedure

Use a dowel rod (or similar object) with a diameter

equal to the M.O.S. (Minimum Object Sensitivity) of

the guard you are testing. Move the rod through the

eld of the curtain (i.e. top to bottom for vertically

mounted curtains). Repeat this test close to the Emitter pylon, close to the Receiver pylon, in the middle

between the pylons, and most importantly in front of

the operator position.

Make sure the curtain indicates a “Blocked” condition

(RED light) when the rod is in the eld of the curtain.

Check and make sure the machine cannot move

when the curtain shows “Blocked”. If the machine can

operate while the curtain shows a “Blocked” condition,

then re-examine your wiring.

NOTE: Always use both safety relays in your STOP

circuit(s).

If the curtain does not show “Blocked” when the rod

is in the eld: Check to make sure the rod is truly in

the curtain’s eld, and re-check the curtain’s Minimum

Object Sensitity (including AutoBlank and Floating

blank options that change the M.O.S.).

Infrared light from the curtain may be reecting

around the rod due to reective material too close

to the curtain’s eld. In this case, you will have to

move the curtain pylons back away from the reective

material and repeat the test over again. The curtain’s

power level can also be reduced by the factory.

Table 2: Mechanical Guards

Distance of opening Maximum width

from point of operation of opening

hazard (inches) (inches)

1/2 to 1-1/2 1/4

1-1/2 to 2-1/2 3/8

2-1/2 to 3-1/2 1/2

3-1/2 to 5-1/2 5/8

5-1/2 to 6-1/2 3/4

6-1/2 to 7-1/2 7/8

7-1/2 to 12-1/2 1-1/4

12-1/2 to 15-1/2 1-1/2

15-1/2 to 17-1/2 1-7/8

17-1/2 to 31-1/2 2-1/8

12

Page 23

Controller Module Setup

Table 3: Controller Module Connection Chart (Lower Board)

Installation Procedures

Metal Box Controller Module

1 Mute-Out Input LS4 (optional)

2 Remote Latch reset input

3 Mute-Out LS5 (optional)

4 Ground for Terminals

5 Cincinnati Interface + Input

6 Cincinnati Interface – Input

7 External relay monitor input

8 External relay monitor input

9 Aux relay K3 (N.O.) close when Green

Figure 5: Controller Module (Lower Board)

NOTE:

If K1 & K2 Safety Relays

are clear, blue or white,

you m u s t use b o th

Safety Outputs 12-13

& 14-15 together. If K1

& K2 Safety Relays are

Green, you can use one

or both Safety Outputs.

10 Aux relay K3 (common)

11 Aux relay K3 (N.C.) close when Red

12-13 Safety Output #1 N.O. close when Green

14-15 Safety Output #2 N.O. close when Green

16 Case Ground (Earth)

17-18 Neutral (-) and Line (+)

alarm Dry relay opens on fault or loss of power

13

Page 24

Installation Procedures

Metal Box Controller Module

Table 4: Single Pylon Set Controller Module Jumper Chart

Auto Blank / Floating Blank Keyswitch.................................................................................................................. J4

Pylon Length Selector ...........................................................................................................................................S3

1 = Jumper

4" 8" 12" 16" 20" 24" 28" 32" 36" 40" 44" 48" 52" 56" 60" 64"

D0 1 1 1 1 1 1 1 1

D1 1 1 1 1 1 1 1 1

D2 1 1 1 1 1 1 1 1

D3 1 1 1 1 1 1 1 1

D4 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

68" 72" 76" 80" 84" 88" 92" 96" 100" 104" 108" 112" 116" 120"

D0 1 1 1 1 1 1 1

D1 1 1 1 1 1 1 1 1

D2 1 1 1 1 1 1 1 1

D3 1 1 1 1 1 1 1 1

D4

For pylons with 1” beam spacing, install the Jumper plug (just below D4)

For pylons with 1/2” beam spacing, remove the Jumper plug (just below D4)

EXT (Activates External Relay Check, see Standard Features) .......................................................................... J9

FLASH (Doubles response time of light curtain allow for Arc Weld Flash near light curtain ................................ J9

LATCH (Activates remote latch resetting (see Resettable Latching Relays) ....................................................... J9

FAULT RESET BUTTON (Push button to reset faults, do not hold button in) .......................................................S2

Figure 6: Controller Module Jumper — Upper Board

14

Page 25

Installation Procedures

Metal Box Controller Module

Table 5: Multiple Pylon Set Controller (DUAL - SC) Module Length Jumper Chart

Auto Blank / Floating Blank Keyswitch................................................................................................................ J40

Pylon Length Selector ..................................................................................................................................S3 & S4

1 = Jumper

4" 8" 12" 16" 20" 24" 28" 32" 36" 40" 44" 48" 52" 56" 60" 64"

D0/L0 1 1 1 1 1 1 1 1

D1/L1 1 1 1 1 1 1 1 1

D2/L2 1 1 1 1 1 1 1 1

D3/L3 1 1 1 1 1 1 1 1

D4/L4 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

68" 72" 76" 80" 84" 88" 92" 96" 100" 104" 108" 112" 116" 120"

D0/L0 1 1 1 1 1 1 1

D1/L1 1 1 1 1 1 1 1 1

D2/L2 1 1 1 1 1 1 1 1

D3/L3 1 1 1 1 1 1 1 1

D4/L4

For pylons with 1” beam spacing, install the Jumper plug (just Left of D4/L4)

For pylons with 1/2” beam spacing, remove the Jumper plug (just Left of D4/L4)

EXT (Activates External Relay Check, see Standard Features) .......................................................................... J9

FLASH (Doubles response time of light curtain allow for Arc Weld Flash near light curtain ................................ J9

LATCH (Activates remote latch resetting (see Resettable Latching Relays) ....................................................... J9

FAULT RESET BUTTON (Push button to reset faults, do not hold button in) .......................................................S2

Figure 7: Multiple Pylon Controller Module Connector/Jumper Detail

15

Page 26

Installation Procedures

Figure 8: Controller Module Wiring Diagram

Metal Box Controller Module

Wiring

Figure 8: Controller Module Wiring Diagram

16

Page 27

Pylon Dimensions

Dimensions

Metal Box Controller Module

Figure 9a: Swivel Bracket Dimensions

Dimensions

Metal Box Controller Module

17

Page 28

Dimensions

Metal Box Controller Module

Pylon Dimensions

Figure 9b: Swivel Bracket Dimensions, pylon dimensions (by model), and additional cable information

18

Page 29

Dimensions

Metal Box Controller Module

Pylon Dimensions

Figure 10: Fixed Bracket Dimensions, pylon dimensions (by model), and additional cable information

19

Page 30

Dimensions

Metal Box Controller Module

Controller Module

The Emitter cable plugs into a bulkhead connector on

the bottom right of the controller. The Receiver cable

plugs into a bulkhead connector on the bottom middle of

the controller. All other signals, including power, enter

through the knockout provided on the bottom left of the

controller. The bulkhead connectors are water/dust/oil

tight. Cables lock onto the bulkhead connectors with

a ¼ turn.

Tol. +/- 0.10” / 2.54mm

Table 6: Controller Module Dimensions

Dim Single Multiple

(in/mm) (in/mm)

A 7” / 177.8 8” / 203.2

B 4” / 101.6 7” / 177.8

C 8” / 203.2 9” / 228.6

D 4” / 101.6 4” / 101.6

E 8.65” / 215.9 9.85” / 248.9

Figure 11: Controller Module Dimensions

20

Page 31

Cornering Mirrors

Accessories

Metal Box Controller Module

Through the use of cornering mirrors, multiple sides or

work envelopes can be guarded which enhance safety

and down-time related to mechanical and electrical

interlock systems. Be sure to include a reectivity

loss per mirror (15% for MGM, 10% for TRM) when

calculating total scanning distance of light curtain.

WARNING: If you are using Auto Blank or Floating

Blank options, you may unknowingly create a hole

around your machine. Do not use mirrors with

blanking unless you need blanking on all guarded

sides.

Table 7: Cornering Mirror Dimensions

MODEL DIM A (in/mm) DIM B (in/mm) DIM C (in/mm)

(hole to hole (mirror length) (total length)

distance)

TRM-04 / MGM-04 7.45 / 189 6.25 / 159 8.50 / 216

TRM-08 / MGM-08 11.45 / 240 10.25 / 260 12.50 / 318

TRM-12 / MGM-12 15.45 / 392 14.25 / 362 16.50 / 419

TRM-16 / MGM-16 19.45 / 494 18.25 / 464 20.50 / 521

TRM-20 / MGM-20 23.45 / 595 22.25 / 565 24.50 / 622

TRM-24 / MGM-24 27.45 / 697 26.25 / 667 28.50 / 724

TRM-28 / MGM-28 31.45 / 799 30.25 / 768 32.50 / 826

TRM-32 / MGM-32 35.45 / 900 34.25 / 870 36.60 / 927

TRM-36 / MGM-36 39.45 / 1002 38.25 / 971 40.50 / 1029

TRM-40 / MGM-40 43.45 / 1104 42.24 / 1073 44.50 / 1130

TRM-44 / MGM-44 47.45 / 1208 46.25 / 1175 48.50 / 1232

TRM-48 / MGM-48 51.45 / 1307 50.25 / 1276 52.50 / 1334

TRM-52 / MGM-52 55.45 / 1408 54.25 / 1378 56.50 / 1435

TRM-56 / MGM-56 59.45 / 1510 58.25 / 1480 60.50 / 1537

TRM-60 / MGM-60 63.45 / 1612 62.25 / 1581 64.50 / 1638

TRM-64 / MGM-64 67.45 / 1713 66.25 / 1683 68.50 / 1740

NOTE: Mirrors are surface coated. Wipe surface

using only a damp, clean, soft 100% cotton cloth.

To replace broken or scratched glass, remove end

bracket and slide mirror out with gasket.

Tolerance: +/- 0.10 inches / .025cm

Figure 12: Cornering Mirror Dimensions

TRM DimensionsMGM Dimensions

21

Page 32

Accessories

Metal Box Controller Module

Pedestal

The heavy duty, all-welded steel pedestal oor mounts

can be used for mounting either the MicroGuard Metal

Box or DIN-rail Controller Module light curtain or

cornering mirrors. Sliding mounts on the pedestal are

universal in design and are supplied standard. Unique

oating base on pedestal is designed to compensate

for uneven oors. Pedestal is fabricated from 12 gauge

steel, the base is ¼” steel plate, and the entire unit is

painted OSHA yellow.

Standard height = 72” (model 8000)

Optional height = 96” (model 8096)

NOTE: Do not mount pedestal to oor until you have

fully installed your guarding system and know it is

operating properly in its current position on the oor.

WARNING: Pedestals must be bolted to the oor

after installation; they must not be movable.

11-183 Standard Single mounting bracket

(shown)

Figure 13: Pedestal Dimensions

Stud is 3/8”-16 x 10/16” long

11-184 Special Dual pedestal mounting

bracket. Has two mounting studs 90

deg apart. Allows both Emitter and

Receiver pylon on one pedestal.

Requires SMB option on pylons.

Model 9000 and 9500

Excellent method of mounting the light guard for press brakes or when the light guard is to be moved for die setups