Page 1

iNEWS ControlAir

User Manual

Version 1.0.5

™

Page 2

Copyright and Disclaimer

Product specifications are subject to change without notice and do not represent a commitment on the part

of Avid Technology, Inc. The software described in this document is furnished under a license agreement.

You can obtain a copy of that license by visiting Avid's Web site at www.avid.com. The terms of that license

are also available in the product in the same directory as the software. The software may not be reverse

assembled and may be used or copied only in accordance with the terms of the license agreement. It is

against the law to copy the software on any medium except as specifically allowed in the license

agreement. Avid products or por tions thereof are protected by one or more of the following United States

patents: 4,746,994; 4,970,663; 5,045,940; 5,063,448; 5,077,604; 5,245,432; 5,267,351; 5,309,528;

5,325,200; 5,355,450; 5,396,594; 5,440,348; 5,452,378; 5,467,288; 5,513,375; 5,528,310; 5,557,423;

5,568,275; 5,577,190; 5,583,496; 5,584,006; 5,627,765; 5,634,020; 5,640,601; 5,644,364; 5,654,737;

5,701,404; 5,715,018; 5,719,570; 5,724,605; 5,726,717; 5,729,673; 5,731,819; 5,745,637; 5,752,029;

5,754,180; 5,754,851; 5,781,188; 5,799,150; 5,812,216; 5,828,678; 5,842,014; 5,852,435; 5,883,670;

5,889,532; 5,892,507; 5,905,841; 5,912,675; 5,929,836; 5,929,942; 5,930,445; 5,930,797; 5,946,445;

5,966,134; 5,977,982; 5,986,584; 5,987,501; 5,995,079; 5,995,115; 5,999,190; 5,999,406; 6,009,507;

6,011,562; 6,014,150; 6,016,152; 6,016,380; 6,018,337; 6,023,531; 6,023,703; 6,031,529; 6,035,367;

6,038,573; 6,052,508; 6,058,236; 6,061,758; 6,072,796; 6,084,569; 6,091,422; 6,091,778; 6,105,083;

6,118,444; 6,128,001; 6,128,681; 6,130,676; 6,134,379; 6,134,607; 6,137,919; 6,141,007; 6,141,691;

6,154,221; 6,157,929; 6,160,548; 6,161,115; 6,167,404; 6,174,206; 6,192,388; 6,198,477; 6,208,357;

6,211,869; 6,212,197; 6,215,485; 6,223,211; 6,226,005; 6,226,038; 6,229,576; 6,239,815; 6,249,280;

6,269,195; 6,271,829; 6,301,105; 6,310,621; 6,314,403; 6,317,142; 6,317,153; 6,317,515; D352,278;

D372,478; D373,778; D392,267; D392,268; D392,269; D395,291; D396,853; D398,912. Additional U.S.

and foreign patents pending. No part of this document may be reproduced or transmitted in any form or by

any means, electronic or mechanical, including photocopying and recording, for any purpose without the

express written permission of Avid Technology, Inc.

Copyright © 2002 Avid Technology, Inc. and its licensors. All rights reserved. Printed in USA.

The following disclaimer is required by Sam Leffler and Silicon Graphics, Inc. for the use of

their TIFF library:

Copyright © 1988–1997 Sam Leffler

Copyright © 1991–1997 Silicon Graphics, Inc.

Permission to use, copy, modify, distribute, and sell this software [i.e., the TIFF library] and its

documentation for any purpose is hereby granted without fee, provided that (i) the above copyright notices

and this permission notice appear in all copies of the software and related documentation, and (ii) the

names of Sam Leffler and Silicon Graphics may not be used in any advertising or publicity relating to the

software without the specific, prior written permission of Sam Leffler and Silicon Graphics.

THE SOFTWARE IS PROVIDED “AS-IS” AND WITHOUT WARRANTY OF ANY KIND, EXPRESS,

IMPLIED OR OTHERWISE, INCLUDING WITHOUT LIMITATION, ANY WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

IN NO EVENT SHALL SAM LEFFLER OR SILICON GRAPHICS BE LIABLE FOR ANY SPECIAL,

INCIDENTAL, INDIRECT OR CONSEQUENTIAL DAMAGES OF ANY KIND, OR ANY DAMAGES

WHATSOEVER RESULTING FROM LOSS OF USE, DATA OR PROFITS, WHETHER OR NOT ADVISED

OF THE POSSIBILITY OF DAMAGE, AND ON ANY THEORY OF LIABILITY, ARISING OUT OF OR IN

CONNECTION WITH THE USE OR PERFORMANCE OF THIS SOFTWARE.

The following disclaimer is required by the Independent JPEG Group:

Portions of this software are based on work of the Independent JPEG Group.

The following disclaimer is required by Ray Sauers Associates, Inc.:

“Install-It” is licensed from Ray Sauers Associates, Inc. End-User is prohibited from taking any action to

derive a source code equivalent of “Install-It,” including by reverse assembly or reverse compilation, Ray

Sauers Associates, Inc. shall in no event be liable for any damages resulting from reseller’s failure to

perform reseller’s obligation; or any damages arising from use or operation of reseller’s products or the

software; or any other damages, including but not limited to, incidental, direct, indirect, special or

consequential Damages including lost profits, or damages resulting from loss of use or inability to use

reseller’s products or the software for any reason including copyright or patent infringement, or lost data,

even if Ray Sauers Associates has been advised, knew or should have known of the possibility of such

damages.

Page 3

The following disclaimer is required by Videomedia, Inc.:

“Videomedia, Inc. makes no warranties whatsoever, either express or implied, regarding this product,

including warranties with respect to its merchantability or its fitness for any particular purpose.”

“This software contains V-LAN ver. 3.0 Command Protocols which communicate with V-LAN ver. 3.0

products developed by Videomedia, Inc. and V-LAN ver. 3.0 compatible products developed by third parties

under license from Videomedia, Inc. Use of this software will allow “frame accurate” editing control of

applicable videotape recorder decks, videodisc recorders/players and the like.”

Attn. Government User(s). Restricted Rights Legend

U.S. GOVERNMENT RESTRICTED RIGHTS. This Software and its documentation are “commercial

computer software” or “commercial computer software documentation.” In the event that such Software or

documentation is acquired by or on behalf of a unit or agency of the U.S. Government, all rights with

respect to this Software and documentation are subject to the terms of the License Agreement, pursuant to

FAR §12.212(a) and/or DFARS §227.7202-1(a), as applicable.

Trademarks

AirPlay, AudioVision, Avid, Avid Xpress, CamCutter, Digidesign, FieldPak, Film Composer, HIIP,

Image Independence, Marquee, Media Composer, Media Recorder, NewsCutter, OMF, OMF Interchange,

Open Media Framework, Pro Tools, and Softimage are registered trademarks and 888 I/O, AirSPACE,

AirSPACE HD, AniMatte, AudioSuite, AutoSync, AVIDdrive, AVIDdrive Towers, AvidNet,

Avid Production Network, AvidProNet, AvidProNet.com, AVIDstripe, Avid Unity, AVX, DAE, D-Fi, D-fx,

Digidesign Audio Engine, DINR, D-Verb, ExpertRender, FilmScribe, HyperSPACE, HyperSPACE HDCAM,

Intraframe, iS9, iS18, iS23, iS36, Lo-Fi, Magic Mask, make manage move | media, Matador, Maxim,

MCXpress, MEDIArray, MediaDock, MediaDock Shuttle, Media Fusion, Media Illusion, MediaLog,

Media Reader, MediaShare, Meridien, NaturalMatch, NetReview, OMM, Open Media Management,

ProEncode, QuietDrive, R&A, Recti-Fi, Review & Approval, rS9, rS18, Sci-Fi, Sound Designer II, SPACE,

SPACEShift, Symphony, Trilligent, UnityRAID, Vari-Fi, Video Slave Driver, and VideoSPACE are

trademarks of Avid Technology, Inc.

ControlAir, iNEWS, and Media Browse are trademarks of iNews, LLC.

iNEWS ControlAir™ User Manual Version 1.0.5

Part 0130-05583-01 Rev. A

November 8, 2002

(bbl)

Page 4

Contents

Using This Manual

Who Should Use This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Symbols and Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

If You Need Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

Related Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

If You Have Documentation Comments . . . . . . . . . . . . . . . . . . . . . . . . . vii

How to Order Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

Chapter 1 The iNEWS ControlAir™ System Overview

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Links to Other Newsroom Products . . . . . . . . . . . . . . . . . . . . . . . . . . 2

System Architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

ControlAir Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

ControlAir Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

casvr.exe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

AMCPapp.exe. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

camgr.exe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Device Managers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

ControlAir Workstation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Monitor Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

ControlAir Work Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Monitor Mode - ON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Monitor Mode - LOAD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Chapter 2 Machine Control Events

iNEWS Workspace Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Inserting Machine Control Events into Scripts . . . . . . . . . . . . . . . . . . . . 17

Character Generator (CG) and Still Store (SS) Styles . . . . . . . . . . . 19

Video Playback Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

i

Page 5

Chapter 3 The Monitor Server Utility Program

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Using the Monitor Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Monitor LOAD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Monitor Off and Unload . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Quit Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Event List Queue. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Composite Queue . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Correcting Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Chapter 4 ControlAir Workstation

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

The ControlAir User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Optional Alternative ControlAir Keyboard . . . . . . . . . . . . . . . . . . . . . 43

Using the ControlAir Workstation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Reserving a Playlist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Understanding the Event List & Event List Status . . . . . . . . . . . 44

Controlling Events Through Devices in a Playlist . . . . . . . . . . . . . . . 46

Making On-Air Changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Releasing a Playlist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Playlist is Not Received . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Red Event Display Color . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Device Polling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Chapter 5 ControlAir Configuration & Customization

Opening and Saving User Configured Options . . . . . . . . . . . . . . . . . . . . 50

Changing Default User Preference Options . . . . . . . . . . . . . . . . . . . . . . 50

Colors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Fonts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Channel Policy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Rescan Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Event Display Columns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

ii

Page 6

Using This Manual

Congratulations on your purchase of your Avid ControlAir system. You

can use your system to create broadcast-quality output incorporating every

possible production element from full-speed, high-resolution footage, to

multimedia artwork and animation, to computer-generated effects and

titling.

This publication provides information on how to use the ControlAir

system.

n

The documentation describes the features and hardware of all models.

Therefore, your system might not contain certain features and hardware

that are covered in the documentation.

Who Should Use This Manual

This manual is written for journalists, producers, directors, writers, and

various technical personnel responsible for using the ControlAir system in

a broadcast newsroom.This manual is intended for all ControlAir users,

from beginning to advanced.

It is strongly recommended that system users have prior experience in or

classroom knowledge of the Windows 2000 or NT® operating system.

Page 7

Using This Manual

About This Manual

This manual will lead you through even the most complex procedures with

task-oriented instructions, illustrated for a more realistic presentation of

the actual icons and images you will encounter. The information provides

basic user procedures, while adding a complete explanation of all the tools

and techniques required to create, apply, and adjust various settings,

including useful tips, shortcuts, and custom options.

The Table of Contents that precedes this preface lists all topics included in

the book. They are presented with the following overall structure:The

Contents lists all topics included in the book. They are presented with the

following overall structure:

• The Introduction helps you get oriented with beginning concepts and

general workflow and provides valuable pointers to keep in the back of

your mind as you proceed.

• The main body of the manual follows the natural flow of your work,

with clear and comprehensive step-by-step procedures.

• At the back of the book is a comprehensive Glossary, providing crossindustry terms and definitions.

• Finally, a detailed Index helps you quickly locate specific topics.

This manual provides instruction for your system in the following areas:

• System Architecture & Dataflow

• iNEWS Machine Control Instructions

• The Monitor Server Utility Program

• The ControlAir Workstation

• Configuration and Customization of ControlAir

Use this manual for help in using your system after you have installed

ControlAir components according to requirements and specifications.

Before installing any equipment, the site must already have a configured

network.

iv

Page 8

Symbols and Conventions

Unless noted otherwise, the material in this document applies to the

Windows 2000 operating system.

The ControlAir documentation uses the following special symbols and

conventions:

1. Numbered lists, when the order of the items is important.

a. Alphabetical lists, when the order of secondary items is important.

• Bulleted lists, when the order of the items is unimportant.

- Indented dashed lists, when the order of secondary items is

unimportant.

One arrow indicates a single-step procedure. Multiple arrows in a list

indicate that you perform one of the actions listed.

Courier Bold font identifies text that you type.

Symbols and Conventions

Look here in the

margin for tips.

n

c

w

In the margin, you will find tips that help you perform tasks more easily

and efficiently.

A note provides important related information, reminders,

recommendations, and strong suggestions.

A caution means that a specific action you take could cause harm to

your computer or cause you to lose data.

A warning describes an action that could cause you physical harm.

Follow the guidelines in this manual or on the unit itself when

handling electrical equipment.

Cross references are provided throughout this manual to give readers

locations where additional—sometimes more detailed—information on a

certain topic can be found. In some cases, the chapter name and number is

provided. In most cases, a page number is given.

For instance: See “ControlAir Work Flow” on page 8

v

Page 9

Using This Manual

See “About This Manual” on page iv for more information on what

chapters are in which sections of this manual.

In this example, information on work flows through a ControlAir system

can be found on page 8 of this manual. Chapters are numbered

consecutively with page numbers continued from the previous chapter.

Keyboard Conventions

Ctrl+x means to press and hold down the Control key and then press

another key on the keyboard, represented here by x. This is also used for

other key+combinations, such as Alt+x or Shift+x.

“Type” in a command procedure means to type the command on the

command line and then “press” the Enter key.

“Select” means to choose an operation on a menu.

“Click” means to click the left mouse button, usually in response to a

dialog box. “Right-click” means to click the right mouse button.

If You Need Help

If you are having trouble using ControlAir, you should:

1. Repeat the procedure, carefully following the instructions provided

for the task in this guide.

2. Refer to the documentation included with your hardware to review

the maintenance procedures or the hardware-related issues.

3. Check the Support section of Avid’s Web site at

http://www.avid.com/support/ for online technical publications and

additional telephone support phone numbers.

4. Maintenance Agreement contract customers can contact Av id Broadcast Customer Support personnel at any of these 24-hour global telephone numbers:

• 1 800 639 7364 in the Americas

• 44 1256 814222 in Europe, Africa, and Mid-East

vi

(All Broadcast products, ex ce p t Ne ws-

view)

Page 10

• 61 2 9963 2895 in Asia/Pacific

Or online:

•e-mail support@inewsroom.com

• http://www.avid.com/support/contact.html

For general information, call your local Avid reseller or in North America

call the Avid Broadcast Customer Relations desk at 1-800-869-7009.

Related Information

Related Information

Contact your Avid Sales representative for documentation and information

on other Avid

system, Media Browse

AirSPACE

®

products, such as the iNEWS™ newsroom computer

™

, and so forth.

™

, EditStar™, LeaderPlus™, MOS Gateway,

If You Have Documentation Comments

The Avid Broadcast Technical Publications department continually seeks

to improve its documentation. We value your comments about this manual

or other Avid-supplied documentation.

Send your documentation comments by e-mail to:

techpubs_wi@avid.com

Include the title of the document, its part number, revision, and the specific

section that you are commenting on in all correspondence. Please include

the title of the document, its part number, revision, and the specific section

you are commenting on in all correspondence.

vii

Page 11

Using This Manual

How to Order Documentation

To order additional copies of this documentation from within the United

States, call the Avid Sales department at 1-608-274-8686. If you are

placing an order from outside the United States, contact your local Avid

Sales representative.

viii

Page 12

Chapter 1

The iNEWS ControlAir

System Overview

This chapter contains the following major sections:

• Overview

• System Architecture

• ControlAir Work Flow

™

Page 13

Chapter 1 The iNEWS ControlAir™ System Overview

Overview

The iNEWS ControlAir system is a machine control system for on-air

operations, which can be integrated into the iNEWS newsroom computer

system, or into another newsroom computer system. It can also operate in a

standalone environment if the iNEWS connection is lost.

A ControlAir system normally consists of a server, one or more

workstations, and several Device Managers (DMs). Also, ControlAir:

• Directly controls production devices

• Receives information from the iNEWS Workstation as control events

are entered into production cues in scripts

• Handles several shows simultaneously, while enabling shows to be

produced back-to-back, with only a few seconds between them

Windows-based workstations, with Graphical User Interfaces (GUIs),

allow production personnel to control events on the ControlAir Server.

Links to Other Newsroom Products

The iNEWS ControlAir system also provides efficient links to other Avid

products for additional scripting and video capabilities, such as Digital

News Gathering (DNG), a disk-based production system, which stores

digital video, audio, and graphics data in a single central library. That data

is then accessible by workstations for recording, editing, and playback.

Another feature is the iNEWS CG Title Entry, which enables newsroom

personnel to simulate character-generated graphics on the iNEWS

Workstation.

The iNEWS product set is constructed on a modular, open architecture,

enabling its components to work efficiently not only with other Avid

products, but also with third-party hardware and software. The iNEWS

newsroom computer system operates on industry-standard technologies,

including Windows

Silicon Graphics

protocols.

2

®

-based operating systems, Intel®-based PCs, Intel and

®

-based servers, and TCP/IP Internet networking

Page 14

Avid publishes open Applications Programming Interfaces (APIs) for

ControlAir that enables integration with third-party software and hardware.

System Architecture

There are three groups of software in the iNEWS ControlAir system.

• The ControlAir Server (which includes the casvr.exe and

AMCPapp.exe executable programs)

•Device Managers (DMs)

• ControlAir Workstation

Typically, ControlAir Server software and device managers are installed on

the ControlAir Server, while the ControlAir Workstation is installed on

computers in each of the control rooms where ControlAir will be operated.

ControlAir architecture consists of:

System Architecture

n

• ControlAir Server

- Avid Machine Control Protocol application (AMCPapp.exe)

- ControlAir Server application (casvr.exe)

- ControlAir Manager application (camgr.exe)

•Device Managers

• ControlAir Workstation(s)

• The monitor server utility program - running on the iNEWS Server.

ControlAir software can be installed on either the Mirror Net or the House

Net of the iNEWS hosts. If ControlAir components need access to other

station networking services than just iNEWS Servers, then they should be

placed on the House network. In either case, static IP addresses and local

hosts files should be used for all ControlAir components.

3

Page 15

Chapter 1 The iNEWS ControlAir™ System Overview

ControlAir Components

There are several components that make up the ControlAir system,

including the ControlAir Server program (casvr.exe), AMCP

application (AMCPapp.exe), ControlAir Manager program

(camgr.exe), device managers, and ControlAir Workstation, which are

explained in this section.

ControlAir Server

The ControlAir Server is a computer that runs the casvr.exe,

AMCPapp.exe, and camgr.exe programs, as well as any device

managers (DMs) that are controlled by that server. It is also possible to run

ControlAir Workstation software on this computer, if desired, but it is not

required. For more information on hardware requirements for the

ControlAir Server, see the iNEWS ControlAir Installation and Operations

Manual.

casvr.exe

The executable program called casvr.exe is the central program that runs

on the ControlAir Server.

The ControlAir Server program:

• Routes status and messages between AMCPapp.exe, device

managers, and ControlAir Workstations

• Creates and manages playlists and downloads them to their respective

devices

• Tracks which components have playlists and devices reserved

• Directs control commands from ControlAir Workstation to the

appropriate device manager (DM).

w

4

If ControlAir Server program (casvr.exe) fails or is stopped, other

components, such as DMs, must also be restarted. If the ControlAir

Manager program is set up, it will monitor the ControlAir Server

program and components and restart them should they stop running.

Each DM will reconnect at start up to the ControlAir Server and to

the device(s) it controls. If ControlAir Manager is not used,

Page 16

System Architecture

components of the ControlAir system must be restarted manually. Any

playlists loaded at the time the ControlAir Server program is stopped

should be reloaded after the program is restarted.

AMCPapp.exe

The executable program called AMCPapp.exe is the interface between

Avid’s iNEWS newsroom computer system and the ControlAir Server

running casvr.exe. It translates Avid Machine Control Protocol (AMCP)

data coming in from iNEWS—or other newsroom computer system—into

data that the ControlAir system can manage.

camgr.exe

The executable program named camgr.exe is known as the ControlAir

Manager. It monitors ControlAir components, including device managers,

on the ControlAir Server. If a component stops running, the ControlAir

Manager will restart it automatically.

n

Device Managers

ControlAir Manager can also monitor third-party device managers.

A device manager (DM) is an executable program that connects directly or

via the network to casvr.exe. When the connection is made to

casvr.exe, the DM will accept playlists from iNEWS and commands

from ControlAir Workstation. Although DMs can run on other computers,

Avid recommends they be installed on the ControlAir Server—the same

computer running the casvr.exe program.

Each DM is designed to control a specific machine. For instance,

LouthDM.exe is a DM designed to control any video server that

correctly supports the Louth video device control protocol (VDCP)—such

as Avid’s AirSPACE series of video servers.

There are existing DMs that allow the ControlAir operator to control the

following machine types used for broadcast production:

• Character Generator (CG)

5

Page 17

Chapter 1 The iNEWS ControlAir™ System Overview

• Still stores

• Video playback devices

ControlAir Workstation

See Chapter 4 for more

information.

Monitor Server

See Chapter 3 for more

information.

The ControlAir Workstation provides the operator with a Graphical User

Interface (GUI) that allows control of broadcast events. From the

ControlAir Workstation, the ControlAir operator can view playlists that

have been downloaded from iNEWS, get device and event status, and

control the broadcast production devices.

The ControlAir Workstation software can run on the same computer as the

casvr.exe program, or on a separate computer.

The monitor server is not an actual part of ControlAir software, but is a

utility program on the iNEWS Server. For ControlAir, it is used to scan

stories in the rundown, searching for machine control events to build event

lists (playlists) for the production devices. It continues monitoring the

rundown for changes to machine control events and sends them to the

ControlAir system until the show goes off the air.

6

Page 18

System Architecture

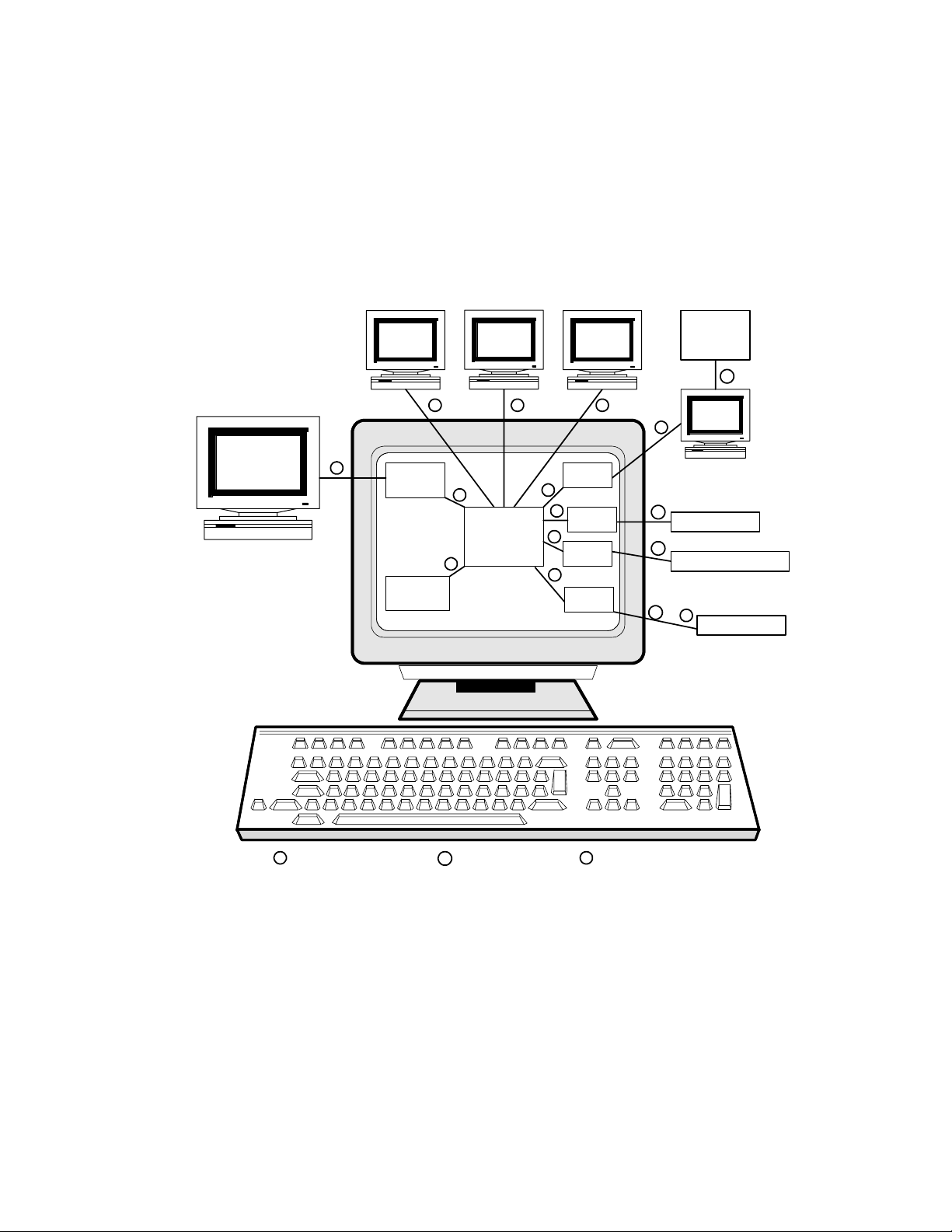

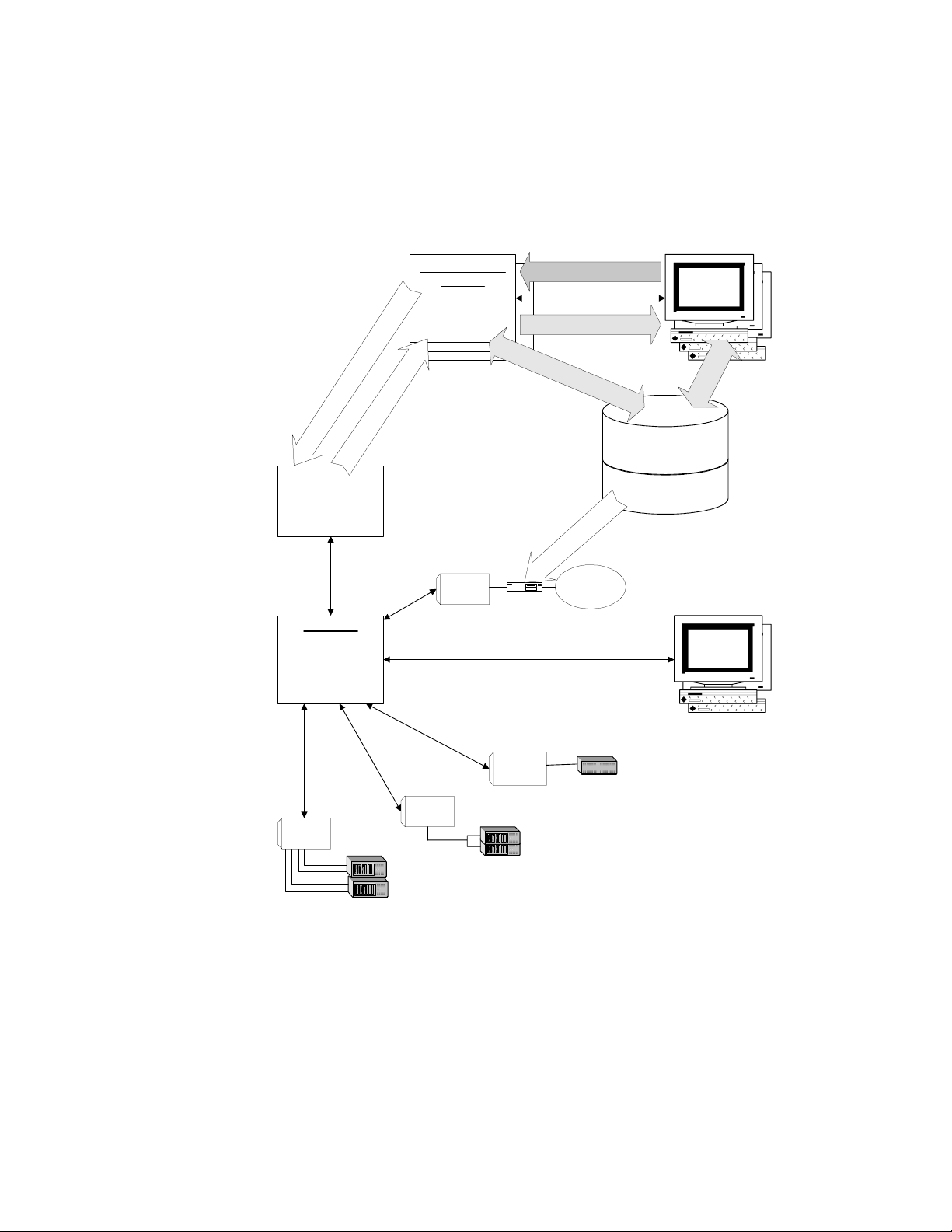

Figure 1 depicts how connections are made from iNEWS, through the

AMCP application (AMCPapp.exe), to the ControlAir Server program

(casvr.exe), then to the ControlAir Workstation, device managers, and

devices

Still Store,

N

CG, Cart, &

other Video

Devices

S

ControlAir

Workstation

ControlAir

Workstation

ControlAir

Workstation

N NN

iNEWS

newsroom computer system

Network Serial

N

AMCP

Application

C

ControlAir

Server

Application

(casvr.exe)

C

ControlAir

Workstation

S

Device

Manager

C

C

C

C

Device

Manager

Device

Manager

Device

Manager

Communication between

CN

S

Still Store

S

CharacterGenerator

S

or

N

programs in computer

Figure 1 ControlAir Component Associations

MCS-PC

Video

7

Page 19

Chapter 1 The iNEWS ControlAir™ System Overview

ControlAir Work Flow

After the news staff has entered machine control events in scripts, the

producer can download rundowns to ControlAir using the monitor server

in iNEWS.

n

See Chapter 2 for more

information.

Monitor Mode - ON

For more information on creating monitor servers, see the iNEWS

ControlAir Installation and Operations Manual.

From the ControlAir Workstation, production personnel, such as the

ControlAir operator, can access playlists for downloaded rundowns and

control associated production devices to cue, play, and stop the production

events requested.

When your newsroom staff builds a show, they insert special keywords into

scripts, known as machine control events. These items include a word to

identify the specific machine or a machine type, such as CG or SS, and

some information to indicate what they want that machine to display.

The following example shows a machine control event that instructs the

character generator to display two lines of text using a saved template

named LOC2:

*CG LOC2

Bob Willhouser

Washington DC

See Chapter 3 for more

information.

8

When the monitor server is turned on—usually by the producer, from the

iNEWS Workstation’s Tools menu—it will read all machine control events

in the rundown and build playlists, also known as event lists, for each

device.

After the monitor server is turned on, it continues to monitor the rundown,

examining every saved story for deleted, new, or updated events in the

playlist.

The monitor server performs as much error checking as it can without

communicating with any broadcast equipment.

Page 20

ControlAir Work Flow

The iNEWS ControlAir system is not yet involved. Playlists can be printed

and distributed to the equipment operators, who can control devices, such

as the CG, using traditional methods.

Figure 2 shows communication paths after the monitor server is turned on

from the iNEWS Workstation.

n

For more information about iNEWS utility programs known as monitor

servers, see the iNEWS ControlAir Installation and Operations Manual.

9

Page 21

Chapter 1 The iNEWS ControlAir™ System Overview

,

s

t

s

i

l

y

a

l

P

e

t

a

d

p

U

/

d

a

o

l

n

w

o

D

e

v

E

AMCPapp

Protocol converter

Maintains link to each

loaded monitor server

casvr.exe

Retains all loaded playlists,

playlist & event status,

status of attached DM and

ControlAir workstations.

Distributes Commands,

updated status, event

changes & messages.

iNEWS Monitor

Servers

ON: Watch for added,

deleted, or Modified

Machine Control Events

s

t

LOAD: Send playlists and

n

e

v

updates to ControlAir

E

,

s

e

i

r

o

t

S

s

e

g

a

s

s

e

M

r

o

r

r

E

,

s

u

t

a

t

S

t

n

MCSDM

O

B

MCSPC

Monitor Commands

(ON, LOAD, UNLOAD, OFF)

(progress, errors, warnings)

N

:

G

e

t

u

s

i

l

y

d

s

P

t

e

l

m

a

y

i

l

n

i

s

t

,

W

r

i

t

e

r

f

t

r

a

t

s

w

e

o

R

d

Any MCS Legacy

Playbackdevice

Messages

f

o

,

P

a

r

s

e

E

R

v

e

u

n

n

t

d

L

o

i

s

w

t

q

u

e

u

e

Rundown & Event List queues

System Map & Resource queues

o

t

S

W

s

E

r

e

N

i

v

i

r

m

d

o

d

a

o

l

n

Workstations

n

,

s

iNEWS DB

iNEWS Software

Monitor Server

MCSPC Legacy Drivers

iNEWS

,

s

n

w

s

o

t

d

n

n

e

v

u

E

R

r

e

e

t

t

a

n

e

r

E

C

ControlAir

Workstations

10

Chyron DM

Chyron

Leitch DM

Louth DM

10base-T

ASC 300's

RS-422

Video Servers

Figure 2 Monitor Mode - ON Communication Paths

Page 22

Monitor Mode - LOAD

As air time nears and the newsroom staff completes the rundown,

someone—usually the producer or equipment (ControlAir) operator—will

instruct the monitor server to load the playlist into the ControlAir system

(via the AMCP application program). See the iNEWS ControlAir

Installation and Operations Manual.

As the rundown is downloaded to the ControlAir Server, the casvr.exe

program loads it to the ControlAir Workstation, and loads individual event

lists or playlists to the appropriate device manager (DM). That DM

establishes a connection to the device (if it has not already done so) and

begins its assigned task, such as inserting CG text, checking for availability

of video clips, and so forth.

Each DM sends to the ControlAir Server program (casvr.exe) the

status of devices and individual playlists, such as whether video is

available, and so forth. The ControlAir Server then forwards the data to the

ControlAir Workstation and iNEWS monitor server (via AMCPApp.exe).

Error messages are returned to the iNEWS user who loaded the rundown

and the ControlAir operator. The monitor server also displays status for

video clips, such as whether the clip is available, into stories in the

rundown and event lists located in the iNEWS database.

ControlAir Work Flow

The ControlAir operator may now take control of the playback devices and

take the show to air.

Figure 3 shows communication paths after the monitor server is instructed

to load playlists, commands, status, and user messages between ControlAir

components; note the direction of flow for the four different kinds of data.

11

Page 23

Chapter 1 The iNEWS ControlAir™ System Overview

AMCPapp

Protocol converter

Maintains link to each

loaded monitor server

Playlist, Event Updates

Messages (progress, errors, warnings)

casvr.exe

Retains all loaded playlists,

playlist & event status,

status of attached DM and

ControlAir workstations.

Distributes Commands,

updated status, event

changes & messages.

P

l

a

S

t

a

t

u

s

|

Status | Messages

Playlists | ControlAir Cmds

Louth DM

iNEWS Monitor

Servers

ON: Watch for added,

deleted, or Modified

Machine Control Events

LOAD: Send playlists and

updates to ControlAIr

A

f

t

e

r

L

A

l

o

r

t

n

o

C

|

s

t

s

i

l

a

y

s

a

l

s

e

P

Event Status, Messages

y

l

i

s

t

s

|

C

o

n

t

r

o

l

A

M

i

r

e

C

s

s

a

g

e

s

M

|

s

u

t

ta

S

⇒

Messages Progress, errors, warnings

⇐⇐⇐⇐ Playback Commands (Channel, Play, Stop, etc.) ⇐⇐⇐⇐

P

l

a

y

l

i

s

t

s

|

C

o

S

n

t

a

t

r

t

o

u

l

s

A

|

M

e

s

s

a

g

e

s

m

d

s

O

B

O

A

D

:

E

v

e

n

t

S

s

d

m

C

r

i

s

e

g

⇒

Device & Event Status

⇒

Playlist, Event Updates

i

r

C

m

d

s

MonitorCommands

(ON, LOAD, UNLOAD, OFF)

(progress, errors, warnings)

N

:

G

e

t

u

s

i

l

y

d

s

P

t

e

l

m

a

y

l

i

i

n

s

t

,

W

r

i

t

u

s

(

A

v

MCSDM

(client)

e

a

i

l

a

b

l

e

,

C

t

a

t

ChyronDM

Messages

f

o

,

P

a

r

s

e

E

v

R

e

u

n

n

t

d

L

o

i

s

w

t

q

u

e

u

e

u

e

s

d

,

e

t

c

.

)

Rundown & Event List queues

System Map & Resource queues

MCS-PC

⇒

⇒

⇒

Chyron

n

,

iNEWS DB

Any MCS Legacy

Playback device

iNEWS

Workstations

,

s

n

w

s

o

t

d

n

n

e

v

u

E

R

r

e

t

e

t

a

n

e

r

E

C

ControlAir

Workstations

Leitch DM

10base-T

ASC 300's

12

RS-422

Video Servers

Figure 3 Monitor LOAD Communication Paths

Page 24

Monitor Mode - Unload

After the show airs, someone—typically the producer or equipment (ControlAir) operator—will instruct the monitor server to unload the playlist

from the ControlAir system. The unload mode allows the user to disconnect from the ControlAir Server without turning off the monitor server.

See “Using the Monitor Server” on page 26 and Figure 9 on page 27 for

more information about various modes of the monitor server.

ControlAir Work Flow

13

Page 25

Chapter 1 The iNEWS ControlAir™ System Overview

14

Page 26

Chapter 2

Machine Control Events

This chapter contains the following major sections:

• iNEWS Workspace Overview

• Inserting Machine Control Events into Scripts

- Character Generator (CG) and Still Store (SS) Styles

- Video Playback Device

Page 27

Chapter 2 Machine Control Events

iNEWS Workspace Overview

The iNEWS workspace consists of three main panels: the Directory panel,

the Queue panel, and the Story panel. The Story panel displays the story

text; however, it may be split, as shown in Figure 4, to also show an

Instruction panel for production cues, a Story Form panel, as well as the

Story Text panel. It depends on the view specified.

Story Form Panel

Queue Panel

Directory

Panel

16

Story

Panel

Instruction Panel Story Text Panel

Figure 4 iNEWS Workspace

Page 28

Inserting Machine Control Events into Scripts

Inserting Machine Control Events into Scripts

To insert a machine control event into a script in iNEWS, do the following:

1. Open the script into the Story panel.

2. Click in the Story panel at the location where the production cue is to

be placed.

3. Press Alt+Insert.

An Instruction panel appears to the left of the Story Text panel.The

Instruction panel has a Production Cue text box where the cursor is placed

so that a production cue, may be entered. A production cue containing a

command for a device is known as a machine control event.

A production cue marker (also known as a grommet, shown at left) is

inserted in the script text at the cursor position.

In the example shown in Figure 5, the Story panel is split to show both the

Instruction and Story Text panels, but not the Story Form panel.

Each command is preceded by an asterisk (*) and should be written in a

special format.

The format for machine control events, following the asterisk, starts with a

command for the name of device manager the instruction is for, such as CG

for a character generator, or SS for a still store device. After the command,

the format specifies a particular item or template. If additional comments

or information is required it would follow on succeeding lines in the same

Production Cue text box.

17

Page 29

Chapter 2 Machine Control Events

A machine control event for a 2-line character generator graphic may look

like the one shown in Figure 5.

Figure 5 Machine Control Event Example

n

n

In the example shown in Figure 5, the Take VO production cue is just

information for the director; it is not a machine control event. The machine

control event for the character generator is in the second Production Cue

text box.

Machine control event formats will vary based on styles set up by your

system administrator. Check with your system administrator for a list of

styles used at your location.

Production cues may include the following: Take VO, On Camera, Take

SOT, and Take Live. When using ControlAir, production cues may include

machine control events to character generators (CGs), still stores (SS),

video playback devices, such as Betacart machines (CART), digital video

playback.

By default, iNEWS generally refers to all video playback devices as

“CART” type devices, including high resolution video servers, such as an

AirSPACE video server.

Some typical machine control events in a script are shown in Figure 6.

18

Page 30

Inserting Machine Control Events into Scripts

Figure 6 Machine Control Events in a Script

Machine control events are easily identified in a script; they appear in the

Instruction panel, are preceded by an asterisk, and are colored blue.

Character Generator (CG) and Still Store (SS) Styles

The machine control event command *CG is followed by the style used

for the caption. Styles are specific to individual stations and are generally

set up by the system administrator.

There is a unique style for each type of CG that is used during the

broadcast. For instance, in the following example, 2line, 1line, place name.

*CG 2line TONY BLAIR

Prime Minister

*CG 1line NATHANIEL LOYD

*CG place NORTH WALTHAM

Following the style is the actual text that ControlAir will send to the

character generator to build the CG.

19

Page 31

Chapter 2 Machine Control Events

A full frame CG can be recalled by replacing the style with a page number,

as in the following example:

*CG 888

The preceding example will recall page 888 from the character generator,

without writing any text to the page.

The *SS command is also followed by either a style (logo-right) or still

store number (1234), as shown in Figure 6. The system administrator sets

up the styles for frequently used graphics and assigns numbers used to

create new graphics daily.

ControlAir will use the style or number to recall the particular still in the

proper manner during the broadcast.

Video Playback Device

Use the Story Form panel to enter the Video ID into iNEWS. This allows

the Video ID to be viewed from the rundown. During the broadcast,

ControlAir will report the video event status to the Event Status field of the

iNEWS rundown, in the Queue panel.

20

When the Video ID is entered in the Video ID field in the Story Form

panel, those video events will appear first on ControlAir and in the

composite playlist. They appear ahead of CG or still store’s in the script,

regardless of whether a CG needs to be taken before rolling the tape.

When an accurate, sequential listing of all events on ControlAir and in the

composite list is required, the events must be entered in the body of the

script as production cues. If they are not put into form fields, ControlAir is

unable to report the status back to the Event Status field on the iNEWS

rundown in the Queue panel. Also, the ability to use the color rules in the

rundown to alert to an empty Video ID field is lost.

Page 32

Inserting Machine Control Events into Scripts

For instance, if a story contains a presenter on set with a still store graphic

over the shoulder, then the presenter's name gets superimposed onair. Next,

a tape is rolled, and a locator CG (super) is inserted. The script would need

production cues in the following order, so all events appear in the order that

they are required during the show.

*SS ots 1001

*CG 2line

Amy Anchor

Newswatch Eleven on Your Side

*CART 23456

*CG loc

Downtown Boston

If the cart number was placed in a Video ID field instead of in the body of

the script, the ControlAir Workstation and composite list would show the

following order:

cart 23456

ss 1001

cg Amy Anchor

cg Downtown Boston

If you want the tape number in the Video ID field for status feedback

purposes, the still store graphic and CG event containing the presenter’s

name could be in a separate script, such as a Lead-In or Intro. Then, the

tape number is placed in the Video ID field, with the next CG inside the

story. In this case, the ControlAir Workstation and composite list would

show the following order:

ss 1001

cg Amy Anchor

cart 23456

cg Downtown Boston

21

Page 33

Chapter 2 Machine Control Events

Figure 7 iNEWS Rundown

The control room staff can quickly see from the rundown, which items still

require a Video ID while the show is being prepared. When the Video ID is

entered, the entire line changes color. When using more than one video

channel during the broadcast, there are a number of ways to assign the

playout channel for each item. Playout channels may be assigned by the

device itself, from the iNEWS rundown, or by ControlAir, either manually

or automatically.

22

For video servers, such as AirSPACE, or for video playback devices, the

channel may be assigned through the iNEWS rundown in the Video ID

column. It may also be done in the rundown by adding the playout channel

to the Video ID Form field . For example: 72951*A—as shown in

Figure 8—instructs ControlAir to play a video with an ID of 72951

through video output channel A on a video playback device or video

server.

If no channel is assigned by the script, the video event will be assigned a

channel by the DM or ControlAir depending on your local configuration

which is determined by the iNEWS system administrator.

Page 34

Inserting Machine Control Events into Scripts

Figure 8 Channel Assignment Through a Script

23

Page 35

Chapter 2 Machine Control Events

24

Page 36

Chapter 3

The Monitor Server Utility

Program

After the iNEWS ControlAir software is installed, monitor servers must be

set up on iNEWS Servers to use ControlAir.

This chapter contains the following sections:

• Overview

• Using the Monitor Server

• Monitor LOAD

• Monitor Off and Unload

• Quit Time

• Event List Queue

• Composite Queue

• Correcting Errors

Page 37

Chapter 3 The Monitor Server Utility Program

Overview

Monitor server is a utility program—running on the iNEWS newsroom

computer system—that checks a show’s event requests for errors, creates

composite and event lists, and sends playlists to ControlAir.

The monitor server is turned on when a user at an iNEWS Workstation

turns it on. When on, monitor server checks its assigned rundown for

machine control events, and builds playlists. It continues to monitor the

rundown for changes and performs as much error checking as it can—by

comparing machine control events with styles located in the

SYSTEM.RESOURCE queue—without communicating with any broadcast

equipment, including ControlAir. See “Monitor Mode - ON” on page 8

and “Monitor Mode - ON Communication Paths” on page 10 for more

information.

The monitor server loads data to the ControlAir system when a user

instructs it to do so from an iNEWS Workstation. The communication

paths between monitor server and ControlAir, at this point, are explained

in more detail in “Monitor Mode - LOAD” on page 11. See also “Monitor

LOAD Communication Paths” on page 12.

n

It is recommended that producers or production assistants turn the monitor

server on as show time approaches so it can check the rundown queue

throughout much of the show’s development. Monitor server scans through

the scripts and builds Event Lists for CG, CART, and SS if these events are

present in the scripts. Monitor Server will also create a Composite list if

configured to do so. Instructing the monitor server to load data should be

done later such as, just before taking the show to air.

Using the Monitor Server

This section provides some basic user information about the iNEWS

feature called monitor server. Procedures include how to turn the monitor

server on and off, as well as how to instruct it to load or unload machine

control event data.

26

Page 38

Using the Monitor Server

To use the monitor server, log in to an iNEWS Workstation, and do the

following:

1. Open the appropriate rundown queue.

2. Click Tools > Monitor.

For more information

on Quit Time, see “Quit

Time” on page 30.

The Monitor Queue dialog box appears. The Quit Time or automatic

shut-off time appears at the bottom of the dialog box.

Figure 9 Monitor Queue Dialog Box

3. Select a monitor mode based on the following options:

• On - Turns the monitor server on and creates an event list for

each device in the rundown queue.

• Load - Instructs the monitor server to load event lists to

devices you select. See “Monitor LOAD” on page 29

for more information.

• Unload - Disconnects from the selected device or server without

turning the monitor server off. (If all devices/servers

are unloaded, the monitor server returns to the On

mode. See “Monitor Off and Unload” on page 29 for

more information.

27

Page 39

Chapter 3 The Monitor Server Utility Program

• Off - Turns the monitor server off, overriding the Quit Time

The Devices section of the Monitor Queue dialog box displays a list of

available devices.

The list could include:

- Specific devices, such as those connected through an MCS-PC

or PC-PCU

- Servers, such as the ControlAir Server and/or MOS Gateway

Server

If you select Load, specify the device or server to load from the

Devices list, or select the All Devices checkbox to load all devices

associated with the rundown queue. To select up to three devices from

the list, without selecting all, press the Ctrl key while you click on each

item. If you select a server, the data will be loaded to all devices

associated with that server.

If you select the MOS Gateway Server that is interfacing with a device

that has multiple channels, such as an OmniBus automation system, a

second dialog box will appear, allowing you to select the channel from

a drop-down list.

setting. See “Monitor Off and Unload” on page 29 for

more information.

28

Click OK to return to the previous dialog box.

4. Click OK.

Page 40

Using the Monitor Server

n

Monitor LOAD

For more information on the monitor server, refer to the iNEWS ControlAir

Installation and Operations Manual.

Before ControlAir is able to view the list of machine control events and

control them for playback, they must be loaded from the rundown in

iNEWS. The procedure for using monitor server to load events is on page

26.

Events are loaded from iNEWS to ControlAir and then communicated to

appropriate devices. After ControlAir receives the entire lists, it will notify

the user that it has received the list by sending a message to the iNEWS

Workstation. Confirmation messages may look like the following:

LIST RECEIVED “SHOW.5P.Rundown

SHOW.5P.RUNDOWN: Download Complete

If the monitor server is not on, loading events will automatically switch the

monitor server on.

Monitor Off and Unload

Monitor Off is used after the show is over. Switching the monitor server off

stops the system from scanning scripts for updates and sending those

updates to ControlAir.

If ControlAir has already reserved the show, the broadcast may continue

but no updates from iNEWS will be received. If ControlAir has not

reserved the show, switching the monitor server off removes the playlist

from the ControlAir Workstation.

Monitor Unload clears the ControlAir playlist, if ControlAir has not

reserved the show, but continues to scan the scripts and update the event

lists with changes.

29

Page 41

Chapter 3 The Monitor Server Utility Program

Quit Time

Monitor server uses a large amount of system resources. If monitor servers

are left on after the end of their shows, they could degrade the efficiency of

the iNEWS system.

To protect system resources, a Quit Time may be set by the system

administrator. This will automatically switch off the monitor server at the

specified time, ensuring the integrity of the system. However, for the best

results, Avid recommends that monitor servers be manually turned off at

the end of each show.

The Quit Time or automatic shut-off time appears at the bottom of the

Monitor Queue dialog box, as shown in Figure 9 on page 27.

Event List Queue

After the monitor server is on for a few seconds, event lists are built. The

Event List queues are generally built in the same folder as the rundown,

such as:

30

Rundown: SHOW.6PM.RUNDOWN

CG Event List: SHOW.6PM.CG

SS Event List: SHOW.6PM.SS

CART Event List: SHOW.6PM.CART

Page 42

Composite Queue

Any script or rundown changes will be picked up automatically by the

monitor server, which will then make the appropriate changes in the event

lists. All changes must be made in the rundown queue, not in the event

build queues. The following Figure 10 shows a CG event queue for a

rundown, listing the CGs for that show.

Figure 10 Rundown Queue

Composite Queue

It is possible to configure iNEWS to also create a Composite List queue.

This is a single queue that contains a list of all machine control events in

the rundown that are required during the show. This list represents what

will be seen on the ControlAir Workstation. The Composite List Queue is

usually found in the same folder as the rundown, such as:

Composite List Queue: SHOW.6PM.COMPOSITE

31

Page 43

Chapter 3 The Monitor Server Utility Program

Figure 11 Composite List Queue

Correcting Errors

Message alerts are sent to the iNEWS Workstation when monitor server is

on and finds errors in scripted events. After a show is loaded, if the monitor

server finds an error, it also sends a message to the ControlAir

Workstation. No indication is sent to ControlAir if the show is not loaded.

There are a number of reasons for the monitor server to see errors in

events. For instance, the monitor server may not recognize the style used or

there may be errors in the device name.

n

32

The monitor server will not detect spelling mistakes in a CG text. Run the

spell check over the scripts to find these types of errors.

Events must be corrected in the script, not in the Event List queue, which is

only written to by the monitor server and should be read only to the user.

Page 44

Correcting Errors

In iNEWS, when opening a script containing an error, the left-hand side of

the script—known as the Instruction panel—will appear red, and the

production cue containing the erroneous machine control event, will be

highlighted in yellow.

Figure 12 Correcting Errors in Scripts

After correcting an error, save the script and the monitor server will make

the appropriate changes to the Event List queue.

33

Page 45

Chapter 3 The Monitor Server Utility Program

34

Page 46

Chapter 4

ControlAir Workstation

This chapter explains how to use the ControlAir Workstation. This chapter

is made up of the following sections

• Overview

• Using the ControlAir Workstation

• Troubleshooting

Page 47

Chapter 4 ControlAir Workstation

Overview

The ControlAir system allows the user to control the machine control

events in a show.

To start the ControlAir Workstation, do the following:

1. Double-click on the ControlAir Workstation icon on the Windows

desktop.

The Connect to Server dialog box appears as shown in Figure 13.

Figure 13 Connect to Server Dialog Box

The dialog box prompts for the name of the ControlAir Server to use.

The first time the ControlAir Workstation is launched, this dialog box

will contain the workstation’s local machine name by default.

2. Enter the server name in the ControlAir Server text box.

3. Click OK.

The ControlAir Workstation is displayed and ready for use.

The ControlAir User Interface

The ControlAir Workstation graphic user interface (GUI) is shown in

Figure 14.

36

Page 48

Overview

Title Bar

Expand or

Menu Bar

Show Loaded

Message History List

Collapse Control From iNEWS

Figure 14 ControlAir Workstation GUI

The Title bar displays the name of the ControlAir Workstation file

currently open.

The Menu bar displays the ControlAir Workstation menus: File, Broadcast,

View, and Help.

The File menu contains the following selections:

• Open—allows access to other CAW files—that is, files with the tag

.caw. CAW files allow operators to save and recall their own

preferences.

• Save—saves changes to the current *.caw file.

• Save As—saves the current *.caw file with another name.

• Exit—exits the ControlAir Workstation.

37

Page 49

Chapter 4 ControlAir Workstation

n

In earlier versions of the ControlAir software, the tag for these files was

.bcw

depends on which version of software a site has. For the purposes of this

manual, CAW is used.

The Broadcast menu contains the following selections:

• Cue—cues an event to get ready to play.

• Play—plays an event.

• Pause—pauses the event that is playing. To restart the event, use the

• Stop—stops an event.

• Reserve Playlist—reserves a playlist ready to broadcast.

• Release Playlist—releases a playlist from the reserve status.

• Cycle Channels—changes channel assignment to the next channel

• Change Channel—allows manual channel selection from an offered

• Rescan a Device—allows rescanning an Avid AirPlay connected to a

not

.caw

, so they were known as BCW files. Which tag is used

Pause command a second time or the Play command.

according to ControlAir Workstation setup.

list.

Media Server to detect new media in the bins.

38

• Connect to Server—allows selection of a ControlAir Server or to

reconnect to a server if a connection has been lost.

• Options—allows access to configure and customize the ControlAir

Interface.

The View menu determines what portions of the ControlAir Workstation’s

graphic user interface is displayed on screen. It contains the following

selections:

• Toolbar—contains control buttons for some broadcast commands

including, Play, Cue, Stop, Pause.

• Status Bar—allows viewing of the bottom status bar giving the

connection status of the ControlAir Workstation to the ControlAir

Server.

• Clocks Bar—allows viewing of the Elapsed Time, Time Left, Playlist

Devices and Local Time Toolbars.

Page 50

Overview

• Device Bar—allows viewing of the Device Status Bar.

• Clear Error Log—clears errors from the Message History list, shown

in Figure 14.

• View Error Log—allows viewing of the Message History list.

The Help menu contains the following selections:

• Help Topic—provides access to the ControlAir Workstation online

help system.

• About—displays ControlAir Workstation version number of the

product.

The main toolbar as shown in Figure 15, has a list—known as the Message

History list—that provides a historical list of the past 21 system messages,

such as initialization and disconnect notices, with the most recent

appearing on screen It also displays any errors associated with the

ControlAir Server, AMCP application and ControlAir Workstation.The

button located to the left of this text box, marked X, may be used to clear

messages.

Toolbar

Message History List

Elapsed Time Section

Figure 15 Partial View of the ControlAir WorkstationScreen

Playlist Devices Section

Device Bar

39

Page 51

Chapter 4 ControlAir Workstation

The ControlAir Workstation toolbar is used to play, cue, stop, rescan, and

pause an event.The button located to right of these buttons, marked X, may

be used to clear messages that appear in the Message History list.

The Elapsed Time displays the amount of time that has elapsed during the

playout of a video event.The Time Left displays the time remaining in a

CG animation or video event currently playing.

The Playlist Devices, as shown in Figure 15, displays a list of the devices

being used by ControlAir and their status.The names in the status section

correspond to the name of the device managers. The status conditions may

be one of the following: On-Line, Off-Line, Ready, In Use, Unknown and

Busy.

When the ControlAir Workstation starts, the Device bar will not appear

automatically in the window. It appears after the iNEWS monitor server

loads a rundown. At that time, the monitor server checks the show’s list of

devices in the SYSTEM.MAP story and verifies whether device managers

(DMs) are running on the ControlAir Server for each device; Their status is

then displayed on the Device bar, as shown in Figure 15.

40

The Device bar will remain displayed even after the first rundown is

unloaded and as long as the ControlAir Workstation window remains open,

but the black status fields of the bar are cleared.

The DMs listed on the bar are not necessarily used by the current rundown

queue; that is, the rundown may or may not have a playlist for the device

associated with the DM. Those actually used by the loaded rundown are

shown in the Playlist Devices section when the rundown is reserved from

the ControlAir Workstation. In either case, the device name and its status

appear.

Page 52

Overview

There are several status possibilities that are color-coded for easy visual

recognition

Table 1 Status of Devices

Status Color Explanation

On-Line Green Indicates the DM for the named device is

running, connected to the ControlAir Server,

and communicating with the device. However,

control of the device has not yet been reserved

by a ControlAir Workstation.

In-Use Green Indicates the DM for the named device is

running, connected to the ControlAir Server,

communicating with the device, and control

of the device is reserved by this ControlAir

Workstati on.

Busy Green Indicates the same things as In-Use, except

that control of the device is reserved by

another ControlAir Workstation.

Ready Yellow Indicates a DM for a certain device is running

on the ControlAir Server and ready to

communicate with the device, but no

communication between DM and device has

happened.

Ready does not indicate an actual connection between the

n

device and ControlAir Server.

Off-Line Purple Indicates ControlAir can communicate with

the DM for this device, but the device is not

available to be controlled by ControlAir; can

indicate problems with the DM’s connection

to the device.

Unknown Red Indicates a DM for this device is not running

or is no longer connected to the ControlAir

Server. It can also indicate a mismatched

device name; ensure that the device names in

the SYSTEM.MAP file and device manager’s

DMP file are correct.

41

Page 53

Chapter 4 ControlAir Workstation

The Local Time display shows the workstation’s local time.

Expand and Collapse buttons. Clicking on the plus sign (+) will expand the

show to reveal the individual broadcast events. The plus sign (+) will

become a minus sign (-) when the event is expanded.

Column headers appear above the name of the show as shown in Figure 16.

42

Figure 16 ControlAir Event Display Expanded Show

The following may appear:

• Page—displays the page number and story number assigned to the

story on the iNEWS rundown.

• Slug/Description—displays the story title from the iNEWS rundown.

Page 54

Using the ControlAir Workstation

• Status—displays the status of an event. Event status, default colors and

descriptions are shown in Figure 2 on page 4-45.

• Channel—displays the channel that this event will play on, as reported

by the device manager.

• Duration—displays the duration in hh:mm:ss format of the video

event as reported back from the device.

• Media ID—displays the different types of event IDs such as, tape

names for Betacarts or the media clip names for video servers.

• Device displays the name of the device such as,CG, SS or Cart used for

an event.

• Inventory—indicates the status of video events where more than one

video channel is configured on a video server(s) under the control of

one Device Manager. A Full Block indicates Video is not available on

that channel and a Thin Block indicates Video is available on that

channel. A half filled Block indicates an incomplete event.

When a Character Generator (CG) is used there may be headers such as,

Style, Format, and Effect that pertain to colors, fonts, or special effects

used by the CG operator.

Optional Alternative ControlAir Keyboard

An optional piece of equipment that may be included in a ControlAir

Workstation may be an alternative keyboard, such as the type

manufactured by Genovation. This keyboard is smaller and eliminates the

need for a standard sized keyboard in the production area. It is mapped to

the keys on the number pad on the standard keyboard.

Using the ControlAir Workstation

Using ControlAir to control a show consists of three primary tasks:

• Reserving a Playlist

• Controlling Events Through Devices in a Playlist

• Releasing a Playlist

43

Page 55

Chapter 4 ControlAir Workstation

Reserving a Playlist

After ControlAir Workstation has started and a show is downloaded from

iNEWS, ControlAir displays a list. Confirmation of the download is seen

in the ControlAir Workstation Message History list, as shown in Figure 17.

Figure 17 Download Confirmation Message

Controlling events in the show for playback is not enabled until the playlist

is reserved for that show.

To reserve the playlist for the show, do one of the following:

a. Select the show by clicking on the show name—such as,

b. Select Broadcast > Reserve Playlist.

SHOW.6PM RUNDOWN—then, press the R key.

-OR-

To verify confirmation of the playlist reservation, Reserved by

controlair-2 now appears next to the show name, as shown in

Figure 14 on page 4-37.

After the playlist is reserved, double clicking on the show name will

display the event list. An event may now be played by placing the cursor on

the event and clicking the Play button or pressing the Enter key. There is

also a Play option located in the Broadcast menu. After the show is

reserved no other ControlAir Workstation may take control of that show.

n

Understanding the Event List & Event List Status

44

It is possible to override control of a playlist from another ControlAir

Workstation with a password. See Table 3 and “Controlling Events

Through Devices in a Playlist” on page 46 for more information.

Tab le 2 shows the types of event status, their default color representations,

and a description of the type status.

Page 56

Using the ControlAir Workstation

Table 2 Event Status, Default Colors, & Descriptions

Type of Event Status Default Color Representation Status Description

Cued Yellow The event is prepared to play.

Pause Yellow The video is paused, press pause or

play to resume.

?Cued? Yellow An intermediate status before a

video is cued.

Playing Green An event is playing.

Standby Yellow The next event to be cued on a

channel.

Unavailable Magenta An event cannot be located or does

not exist. Corrective action is

required.

Unknown Red An event has just arrived and the

Device Manager has not yet

processed the event request. From

an Unknown status, an event can

go to either Available or

Unavailable.

The event list displayed on the ControlAir Workstation includes the page

number and slug for every story in the rundown. When a story has events,

these will be listed under the story title, one line for each event. Character

Generator (CG) events display the text, the CG page number, status, and

device name. Video events display nothing in the Slug/Description column

but display their Media ID, status, channel, duration, device name, and

inventory.

45

Page 57

Chapter 4 ControlAir Workstation

Controlling Events Through Devices in a Playlist

In order to control an event the cursor must be on it. Tabl e 3 shows the type

of control and how to issue the control command.

Table 3 Type of Event Control & Command Instruction

Type of Event Control Command Instruction

Cueing an Event Press Delete on the keypad.

Playing an Event Press Enter on the keypad.

Pausing an Event Press the number 1(one) on the

keypad.

Stopping an Event Press the number 0(zero) on the

keypad.

Overriding a Channel Assignment Press the numeric key on the

keyboard, corresponding with the

channel you want. For instance,

press 1 for channel A, 2 for B, and

so forth.

46

Rescanning a Device (AVID

AirPlay ONLY)

It may be necessary to rescan a device when a device has failed

n

to load properly. From the Broadcast menu choose Rescan

Device or press Insert on the keyboard. Before rescanning a

device, the device must be identified in the Rescan Device tab.

Override Control of a Playlist Reserve the already reserved

Press the Insert key on the keypad

playlist. The Override dialogue

box appears requesting a

password. Enter the password.

During a broadcast, as events are played by pressing Enter on the keypad,

the cursor will automatically advance to the next event in the show. If an

event that is playing needs to be re-cued, it must first be paused first.

Page 58

Making On-Air Changes

When a producer makes changes to an iNEWS rundown, it is reflected on

the ControlAir Workstation event display. When stories are floated, they

disappear from the ControlAir Workstation display. When a story's events

are Cued, ControlAir will automatically Cue the events for the next story.

When floated stories are reinstated, they reappear on the ControlAir

Workstation display. Reinstated story's events will be re-cued according to

their position in the rundown.

When a story is deleted from the iNEWS rundown, the item disappears

from the ControlAir Workstation display. If a story that has an event

currently playing is deleted from the iNEWS rundown, the event will

continue to play. When the event is stopped or finishes playing the item is

deleted from the ControlAir Workstation display.

When a story is inserted in the iNEWS rundown, it will appear on the

ControlAir Workstation display even if it contains no events. Machine

instructions are passed to the ControlAir Server when the story is saved.

Using the ControlAir Workstation

Changes to the order of the stories are also reflected on the ControlAir

Workstation display.

Releasing a Playlist

It is not possible to release a playlist if any of the events are playing.

To release a playlist, do the following:

1. Release the playlist by clicking on the show name and press the letter

U on the keyboard.

Exiting the program by clicking on the X button in the upper-right-corner

of the window will also release the playlist.

47

Page 59

Chapter 4 ControlAir Workstation

Troubleshooting

Status