PI miCos GmbH, Freiburger Strasse 30, 79427 Eschbach, Germany

Phone +49 7634 5057-0, Fax +49 7634 5057-99, Email info@pimicos.com, www.pi.ws

MP158E

L

-731 / V-731 Precision XY Positioner

User Manual

Version: 1.0.1

Date: 2019-03-18

This document describes the following precision

XY

positioners with 205 mm x 205 mm travel

range:

L-731.40SD:

with stepper motor, without encoder

L-731.4ASD:

with stepper motor and linear encoder,

sin/cos signal transmission

L-731.44SD:

with stepper motor and linear encoder,

A/B quadrature signal transmission

L-731.093132:

with DC motor and rotary encoder

L-731.093111:

with DC motor and linear encoder,

sin/cos signal transmission

L-731. 093112:

with DC motor and linear encoder,

A/B quadrature signal transmission

V-731.096111:

with linear motor and linear encoder,

sin/cos signal transmission

The following company names and brands are registered trademarks of Physik Instrumente (PI) GmbH & Co.

KG:

PI®, NanoCube®, PICMA®, PIFOC®, PILine®, NEXLINE®, PiezoWalk®, PicoCube®, PiezoMove®, PIMikroMove®,

NEXACT®, Picoactuator®, PInano®, NEXSHIFT®, PITOUCH®, PIMag®, PIHera, Q-Motion®

© 2019 Physik Instrumente (PI) GmbH & Co. KG, Karlsruhe, Germany. The text, photographs, and drawings in

this manual are protected by copyright. With regard thereto, Physik Instrumente (PI) GmbH & Co. KG reserves

all rights. The use of any text, images and drawings is permitted only in part and only when indicating the

source.

Original instructions

First printing: 18.03.2019

Document number: MP158D, MMa, Version 1.0.1

Subject to change without notice. This manual is superseded by any new release. The latest release is

available for download from our website (p. 3).

1 About this Document 1

1.1 Objective and Target Group of this User Manual ...................................................... 1

1.2 Symbols and Typographic Conventions...................................................................... 1

1.3 Pictures ....................................................................................................................... 2

1.4 Other Applicable Documents ..................................................................................... 2

1.5 Downloading Manuals ................................................................................................ 3

2 Safety 5

2.1 Intended Use .............................................................................................................. 5

2.2 General Safety Instructions ........................................................................................ 5

2.3 Organizational Measures ............................................................................................ 5

3 Product Description 7

3.1 Model Overview ......................................................................................................... 7

3.2 Product View .............................................................................................................. 8

3.2.1 Mechanical Parts and Protective Earth Connection ...................................... 8

3.2.2 Electrical Connections ................................................................................... 9

3.3 Direction of Motion .................................................................................................. 10

3.4 Product Labeling ....................................................................................................... 10

3.5 Scope of Delivery ...................................................................................................... 12

3.6 Suitable Controllers .................................................................................................. 12

3.7 Technical Features .................................................................................................... 13

3.7.1 Encoder ........................................................................................................ 13

3.7.2 Limit Switches .............................................................................................. 13

3.7.3 Reference Point Switch ................................................................................ 13

4 Unpacking 15

5 Installation 17

5.1 General Notes on Installation ................................................................................... 17

5.2 Attaching the L-731 / V-731 to a Surface ................................................................. 18

5.3 Connecting the L-731 / V-731 to the Protective Earth Conductor ........................... 22

5.4 Affixing the Load to the L-731 / V-731 ..................................................................... 24

5.5 Connecting the L-731 / V-731 to a Controller .......................................................... 25

6 Start-Up 27

6.1 General Notes on Start-Up ....................................................................................... 27

6.2 Starting Up the Positioner ........................................................................................ 30

6.2.1 L-731 / V-731 Entries in the Positioner Database of PI ............................... 30

Contents

7 Maintenance 31

7.1 General Notes on Maintenance ............................................................................... 31

7.2 Performing a Maintenance Run (L-731 Models) ...................................................... 31

7.3 Cleaning the L-731 / V-731 ....................................................................................... 31

8 Troubleshooting 33

8.1 Possible Causes and Remedies ................................................................................. 33

8.2 Manually Moving the Platform ................................................................................ 34

9 Customer Service 35

10 Specifications 37

10.1 Technical Data .......................................................................................................... 37

10.1.1 Data Table .................................................................................................... 37

10.1.2 Maximum Ratings ........................................................................................ 42

10.1.3 Ambient Conditions and Classifications ...................................................... 42

10.1.4 Limit Switch Specifications .......................................................................... 43

10.1.5 Reference Point Switch Specifications ........................................................ 43

10.2 Dimensions ............................................................................................................... 44

10.2.1 L-731 / V-731 Positioners ............................................................................ 44

10.2.2 Hole Pattern of the Platform ....................................................................... 45

10.3 Pin Assignment ......................................................................................................... 46

10.3.1 HD D-Sub 26 (m) .......................................................................................... 46

10.3.2 D-Sub 15 (m) ................................................................................................ 49

10.4 Tightening Torque for Screws, ISO 4762 - A2 ........................................................... 50

11 Old Equipment Disposal 51

12 EU Declaration of Conformity 53

1 About this Document

L-731 / V-731 Precision XY Positioner MP158D Version: 1.0.1 1

1.1 Objective and Target Group of this User Manual

This user manual contains the necessary information on the intended use of the L-731 / V-731.

Basic knowledge of closed-loop systems, motion control concepts, and applicable safety

measures is assumed.

The latest versions of the user manuals are available for download on our website (p. 3).

1.2 Symbols and Typographic Conventions

The following symbols and typographic conventions are used in this user manual:

DANGER

Imminently hazardous situation

If not avoided, the hazardous situation will result in death or serious injury.

Actions to take to avoid the situation

CAUTION

Dangerous situation

If not avoided, the dangerous situation will result in minor injury.

Actions to take to avoid the risk.

NOTICE

Dangerous situation

If not avoided, the dangerous situation will result in damage to equipment.

Actions to take to avoid the risk.

INFORMATION

Information for easier handling, tricks, tips, etc.

1

About this Document

1 About this Document

2 Version: 1.0.1 MP158D L-731 / V-731 Precision XY Positioner

Symbol / Label Meaning

1.

2.

Action consisting of several steps whose sequential order must be

observed

Action consisting of one or several steps whose sequential order is

irrelevant

Lists

p. 5 Cross-reference to page 5

RS-232 Labeling of an operating element on the product (example: socket of

the RS-232 interface)

Warning sign affixed to the product that refers to detailed information

in this manual.

1.3 Pictures

For better understandability, the colors, proportions and degree of detail in illustrations can

deviate from the actual circumstances. Photographic illustrations may also differ and must not

be seen as guaranteed properties.

1.4 Other Applicable Documents

INFORMATION

Current versions of manuals and data sheets can be downloadedfrom our web site www.pi.ws.

The devices and software tools from PI that are mentioned in this documentation are described

in separate manuals.

Product Document

Positioners with electric motors MP146EK Short instructions for positioners

with electric motors

C-663.11 stepper motor controller MS208E User Manual

C-663.12 Stepper Motor Controller MS241E User Manual

C-863.11 DC Motor Controller MS205E User Manual

MS205Equ User Manual Short Version

C-884 DC Motor Controller MS213E User Manual

SMC Hydra motion controller Hardware Manual

ACS SPiiPlusEC ACS SpiiPlusEC Installation Guide

ACS SpiiPlusEC IMPU Only Installation Guide

C-891 PIMag® Motor Controller C891T0001 Technical Note

1 About this Document

L-731 / V-731 Precision XY Positioner MP158D Version: 1.0.1 3

1.5 Downloading Manuals

INFORMATION

If a manual is missing or problems occur with downloading:

Contact our customer service department (p. 35).

INFORMATION

For products that are supplied with software (CD in the scope of delivery), access to the

manuals is protected by a password. Protected manuals are only displayed on the website after

entering the password.

The password is included on the CD of the product.

For products with CD: Identify the password

1. Insert the product CD into the PC drive.

2. Switch to the Manuals directory on the CD.

3. In the Manuals directory, open the Release News (file including releasenews in the file

name).

4. Find the user name and the password in the section "User login for software download"

in the Release News.

Downloading Manuals

1. Open the website www.pi.ws.

2. If access to the manuals is protected by a password:

a) Click Login.

b) Log in with the user name and password.

3. Click Search.

4. Enter the product number up to the period (e.g., P-882) or the product family (e.g.,

PICMA® Bender) into the search field.

5. Click Start search or press the Enter key.

6. Open the corresponding product detail page in the list of search results:

a) If necessary: Scroll down the list.

b) If necessary: Click Load more results at the bottom of the list.

c) Click the corresponding product in the list.

7. Scroll down to the Downloads section on the product detail page.

The manuals are shown under Documentation.

8. Click the desired manual and save it to the hard disk of your PC or to a data storage

medium.

2 Safety

L-731 / V-731 Precision XY Positioner MP158D Version: 1.0.1 5

2.1 Intended Use

The L-731 / V-731 is a laboratory device as defined by DIN EN 61010. It is intended for indoor

use and use in an environment which is free of dirt, oil, and lubricants.

In accordance with its design, the L-731 / V-731 is intended for positioning, adjusting and

shifting of loads on two axes at various velocities. The L-731 / V-731 is not intended for

applications in areas, in which a failure would present severe risks to human beings or the

environment.

The intended use of the L-731 / V-731 is only possible when completely mounted and

connected and in a horizontal position.

The L-731 / V-731 must be operated with a suitable controller (p. 12). The controller is not

included in the scope of delivery of the L-731 / V-731.

2.2 General Safety Instructions

The L-731 / V-731 is built according to state-of-the-art technology and recognized safety

standards. Improper use of the L-731 / V-731 may result in personal injury and/or damage to

the L-731 / V-731.

Only use the L-731 / V-731 for its intended purpose, and only use it if it is in good

working order.

Read the user manual.

Immediately eliminate any faults and malfunctions that are likely to affect safety (p.

33).

The operator is responsible for the correct installation and operation of the L-731 / V-731.

2.3 Organizational Measures

User Manual

Always keep this user manual available when using the L-731 / V-731.

The latest versions of the user manuals are available on our website (p. 3) for

download.

Add all information from the manufacturer such as supplements or technical notes to

the user manual.

2

Safety

2 Safety

6 Version: 1.0.1 MP158D L-731 / V-731 Precision XY Positioner

If you give the L-731 / V-731 to other users, also include this user manual as well as all

other relevant information provided by the manufacturer.

Only use the device on the basis of the complete user manual. Missing information due

to an incomplete user manual can result in damage to equipment.

Only install and operate the L-731 / V-731 after you have read and understood this user

manual.

Personnel Qualification

The L-731 / V-731 may only be installed, started up, operated, maintained, and cleaned by

authorized and appropriately qualified personnel.

3 Product Description

L-731 / V-731 Precision XY Positioner MP158D Version: 1.0.1 7

3.1 Model Overview

Classification of the positioners

All models are precision XY positioners with linear positioner with crossed roller bearings. They

differ with respect to the drive type and encoder equipment.

L-731 / V-731

Drive type

Linear encoder: Signal

transmission

Stepper

motor

DC motor Linear motor sin/cos* A/B

quadrature

L-731.40SD +

L-731.4ASD + +

L-731.44SD + +

L-731.093132 +

L-731.093111 + +

L-731.093112 + +

V-731.096111 + +

* Separate sensor connection

Detailed model overview

Order number Product name

L-731.40SD

Precision XY positioner, 310 mm × 310 mm width, 205 mm × 205 mm

travel range, 2-phase stepper motor

L-731.4ASD

Precision XY positioner, 310 mm × 310 mm width, 205 mm × 205 mm

travel range, 2-phase stepper motor, linear encoder with sin/cos signal

transmission

L-731.44SD

Precision XY positioner, 310 mm × 310 mm width, 205 mm × 205 mm

travel range, 2-phase stepper motor, linear encoder with A/B

quadrature signal transmission

L-731.093132 Precision XY positioner, 310 mm × 310 mm width, 205 mm × 205 mm

travel range, DC motor, rotary encoder

L-731.093111 Precision XY positioner, 310 mm × 310 mm width, 205 mm × 205 mm

travel range, DC motor, linear encoder with sin/cos signal transmission

3

Product Description

3 Product Description

8 Version: 1.0.1 MP158D L -731 / V- 731 Precision XY Positioner

Order number Product name

L-731.093112 Precision XY positioner, 310 mm × 310 mm width, 205 mm × 205 mm

travel range, DC motor, linear encoder with A/B quadrature signal

transmission

V-731.096111

High-precision XY positioner, 310 mm × 310 mm width, 205 mm × 205

mm travel range, linear motor, linear encoder with sin/cos signal

transmission

For further technical data, see the specifications. (p. 37).

3.2 Product View

3.2.1 Mechanical Parts and Protective Earth Connection

Figure 1: Parts

1 Platform

2 Handle

3 ESD protection

4 Protective earth connection

5 Transport lock

3 Product Description

L-731 / V-731 Precision XY Positioner MP158D Version: 1.0.1 9

3.2.2 Electrical Connections

Connection type and assignments depend on the model (for pin assignment, see p. 46).

L-731.40SD

L-731.44SD

L-731.093112

L-731.093132

L-731.4ASD

L-731.093111

V-731.096111

Pos. Connection L-731 V-731

.40SD

.44SD

.093112

.093132

.4ASD

.093111

.096111

1 Sensor connection, X axis (D-Sub 15 panel plug) + +

2 Sensor connection, Y axis (D-Sub 15 panel plug) + +

3 Motor connection, X axis (HD D-Sub 26 panel plug) + + +

4 Motor connection, Y axis (HD D-Sub 26 panel plug) + + +

5 Protective earth connection (screw ISO 7045, M4x8) + + +

3 Product Description

10 Version: 1.0.1 MP158D L -731 / V- 731 Precision XY Positioner

3.3 Direction of Motion

Figure 2: Direction of the motion of the platform

X, Y (arrow direction:) Direction of motion on positive command

3.4 Product Labeling

3 Product Description

L-731 / V-731 Precision XY Positioner MP158D Version: 1.0.1 11

Figure 3: Product labeling (see following table)

Position Labeling Description

1

Warning symbol "Electrostatic sensitive devices"

2 Sensor X Encoder connection, X axis

3 Sensor Y Encoder connection, Y axis

4

Warning sign "Observe manual!"

4

Old equipment disposal

4 Country of origin: Germany Country of origin

4 WWW.PI.WS Manufacturer's address (website)

4 L-731.4ASD Complete product code (example)

4

CE conformity mark

4 415002159 Serial number (example), individual for each

L-731 / V-731

Meaning of the places (counting from left):

1 = internal information,

2 and 3 = year of manufacture,

4 to 9 = consecutive numbers

5 X Motor connection, X axis

6 Y Motor connection, Y axis

7, 4

Manufacturer's logo

8

Protective earth conductor connection (p. 22)

9, 4 L-731 / V-731 Product series

10

Warning symbol”Risk of crushing”

10

10

3 Product Description

12 Version: 1.0.1 MP158D L -731 / V- 731 Precision XY Positioner

3.5 Scope of Delivery

Item number Component

L-731.xxxxxx or

V-731.xxxxxx

Positioner according to order (p. 7)

Motor cable and if necessary, sensor cable according to the controller and

positioner ordered

MP146EK Short instructions for positioners with electric motors

6303500012 Mounting accessories:

• 4 socket head screw, ISO 4762* M6x35

• 2 dowel pins, ISO 8734** - 6 m6 x 16

* Corresponds to DIN 912

** Corresponds to DIN 6325

3.6 Suitable Controllers

C-663.12*

SMC

Hydra

C-863*

C-891*

C-884

C-885

with

C-663.

12C885

C-885

with

C-891.

10C885

C-885

with

C-863.

20C885

Modular

ACS

controller

Motion axes

per controller

(max.)

1 2 1 1 6

20

20

40

PC interfaces

USB, RS-

232, daisy

chain

network

RS-232,

LAN

USB, RS-

232, LAN

RS-232,

LAN

RS-232,

LAN

USB, LAN

USB, LAN

USB, LAN

USB, LAN

Multiple

controllers on

the same PC

+ + + + + + + + +

L-731.40SD + + + +

L-731.44SD + + + +

L-731.4ASD + +

L-731.093111 + + + +

L-731.093112 + + + +

L-731.093132 + + + +

V-731.096111 + + + +

* 2 controllers of this type are required for operation.

PC software is in the scope of delivery of the controllers from PI. The operation of the

controllers is described in the corresponding user manuals.

3 Product Description

L-731 / V-731 Precision XY Positioner MP158D Version: 1.0.1 13

3.7 Technical Features

3.7.1 Encoder

The L-731.4ASD, L-731.44SD, L-731.093111, L-731.093112, and V-731.096111 models are

equipped with an optical linear encoder. Optical linear encoders measure the actual position

directly (direct metrology). Errors occurring in the drive, such as nonlinearity, backlash or elastic

deformations cannot influence the measurement of the position.

The L-731.093132 model is equipped with an optical rotary encoder. A rotary encoder is

implemented at a rotating point in the drivetrain, e.g., the motor shaft.

Refer to the table in the "Specifications" section for the encoder resolution (p. 37).

The L-731.40SD model does not have an encoder.

3.7.2 Limit Switches

The positioner is equipped with optical limit switches.

Each limit switch sends its signal to the controller on a dedicated line. The controller then stops

the motion. If the controller does not stop the motion in time, the positioner runs into the hard

stop.

See "Limit Switch Specifications" for more information (p. 43).

3.7.3 Reference Point Switch

The positioner is equipped with a direction-sensing reference point switch (see "Reference

Point Switch Specifications" (p. 43)).

The commands that use the reference signal are described in the user manual of the controller

and/or in the corresponding software manuals.

4 Unpacking

L-731 / V-731 Precision XY Positioner MP158D Version: 1.0.1 15

1. Unpack the L-731 / V-731 with care.

2. Compare the contents with the items listed in the contract and the packing list.

3. Inspect the contents for signs of damage. If there is any sign of damage or missing parts,

contact PI immediately.

4. Keep all packaging materials in case the product needs to be returned.

4

Unpacking

5 Installation

L-731 / V-731 Precision XY Positioner MP158D Version: 1.0.1 17

5.1 General Notes on Installation

DANGER

For V-731 models: Magnetic fields!

Magnetic fields may damage or interfere with sensitive devices and objects (e. g. cardiac

pacemakers, EC-cards, magnetic data carriers). The fields are also effective when the

positioner is not connected to the controller/electric power.

Lo

ose magnetizable objects (e.g. made of iron, steel) may be attracted and cause damages. The

corresponding pull might not be manually compensated.

If applicable, note the usual precautions for applying pacemakers.

Remove loose magnetizable objects and sensitive devices from the installation site.

Ensure that hazardous areas are marked correspondingly and that the usual precautions

are applied.

Keep sufficient distance from the positioner.

Apply corresponding precautions also for storage and transport of the positioner.

CAUTION

Risk of crushing by moving parts!

There is a risk of minor injury from crushing between the moving parts of the positioner or the

load and a fixed part or obstacle.

Use protective structures to keep limbs away from areas in which they could be caught by

moving parts.

Observe the safety distances in accordance with DIN EN ISO 13857 when installing

protective structures.

NOTICE

Cable break!

A cable break leads to failure of the positioner.

Install the positioner so that the cable is not bent too strongly or crushed.

NOTICE

Heating up of the L-731 / V-731 during operation!

The heat produced during operation of the L-731 / V-731 can affect your application.

Install the L-731 / V-731 so that the application is not impaired by the dissipated heat.

5

Installation

5 Installation

18 Version: 1.0.1 MP158D L-731 / V-731 Precision XY Positioner

NOTICE

Damage due to removed caps or screws!

Removing caps and screws can lead to contamination and failure of the L-731 / V-731.

Do not loosen screws on the positioner, except when removing the transport lock (p. 20).

Do not remove any caps other than the ESD protection.

Remove the ESD protection only when connecting to the controller.

INFORMATION

For optimal repeatability, all components must be connected firmly together.

If possible, simulate the positioner motions with a mounted load or make suitable

calculations to detect collisions or unfavorable center of gravity constellations.

If necessary, take suitable constructive measures to avoid collisions and instability in

the overall system.

Avoid or mark danger zones that result from the installation of the positioner and the

application, in accordance with the legal regulations.

5.2 Attaching the L-731 / V-731 to a Surface

NOTICE

Warping of the L-731 / V-731 due to mounting on uneven surfaces!

Mounting the L-731 / V-731 on an uneven surface can warp the L-731 / V-731. Warping

reduces the accuracy.

Mount the L-731 / V-731 on

to an even surface. The recommended flatness of the surface is

≤5 µm.

For applications with large temperature changes:

Only mount the L-731 / V-731 on surfaces that have the same or similar thermal expansion

properties as the L-731 / V-731.

NOTICE

Damage to the V-731 by impact of the platform with hard stops!

The V-731 has a linear drive without self-locking. When the XY positioner is tipped, the

platform can hit the hard stops without braking.

Only mount the V-731 onto absolutely horizontal surfaces.

Remove the transport lock just before mounting onto the surface.

5 Installation

L-731 / V-731 Precision XY Positioner MP158D Version: 1.0.1 19

Requirements

You have read and understood the general notes on installation (p. 17).

You have provided a suitable surface (for the required position and depth of the

holes for accommodating the screws and locating pins, see "Dimensions" (p. 44)):

− For mounting from above: 4 threaded holes M6 are provided.

− If you use locating pins to align the positioner: Two 6 mm Ø locating holes are

present.

− The flatness of the surface is ≤5 µm.

− For applications with large temperature changes: The surface should have the

same or similar thermal expansion properties as the L-731 / V-731 (e.g., surface

made of aluminum).

You have accounted for the space required to route cables without bending and

according to regulations.

5 Installation

20 Version: 1.0.1 MP158D L-731 / V-731 Precision XY Positioner

Tools and accessories

Mounting accessories; in the scope of delivery (p. 12)

− 4 socket head cap screws, ISO 4762 M6x35

− 2 dowel pins, ISO 8734 - 6 m6 × 10, for use as locating pins

Allen wrench AF 5

Hex key, AF 3

Mounting the positioner onto a surface

Figure 4: Remove the handle and the transport lock

1 Screw for the handle

2 Handle

3 Perforated plate for the transport lock

4 Wing screw for the transport lock

5 Screw for the transport lock

1. Remove both handles: Loosen the screws for the handles (see figure above).

2. Remove the screw and both wing screws of the transport lock (see figure above).

3. If you use locating pins to align the positioner:

a) Insert the locating pins into the respective holes in the surface.

b) Place the positioner on the surface so that the locating pins are inserted into the

corresponding locating holes on the other side.

5 Installation

L-731 / V-731 Precision XY Positioner MP158D Version: 1.0.1 21

4. Move the platform in the X direction so that two of the fixing holes (through-holes)

become accessible (see figure below).

Figure 5: Position of the through-holes for mounting the positioner (schematic)

It is possible to move the platform accordingly.

Alternatively, to move the platform via a spindle:

Figure 6: Position of the drive screw access

a) Insert a hex key AF3 into the drive screw access until you sense a mechanical

resistance.

b) Turn the hex key clockwise or counterclockwise to move the platform in the

positive or negative X direction.

5. Align the positioner on the surface so that the corresponding mounting holes in the

positioner and the surface overlap.

6. Tighten all screws in the mounting holes selected. Pay attention to the permissible

tightening torques (p. 50)

5 Installation

22 Version: 1.0.1 MP158D L-731 / V-731 Precision XY Positioner

7. Repeat steps 4 to 6 for all remaining mounting holes.

8. Check that the positioner is affixed firmly to the surface.

5.3 Connecting the L-731 / V-731 to the Protective Earth Conductor

INFORMATION

It is only necessary to connect the L-731 / V-731 to the protective earth conductor when both

of the following conditions are met:

The load on the platform of the L-731 / V-731 must be connected to the protective earth

conductor, but it is not possible to connect the protective earth conductor directly to the

load.

The load and the platform are connected conductively to each other.

INFORMATION

Observe the applicable standards for connecting the protective earth conductor.

A protective earth connection is located on front side of the L-731 / V-731 (see also Figure 1,

p.8).

Figure 7: Protective earth connection set-up (explosive view)

1 Screw, M4x8, ISO 7045

2 Flat washer

3 Safety washer

4 M4 mounting hole

5 Installation

L-731 / V-731 Precision XY Positioner MP158D Version: 1.0.1 23

Figure 8: Mounting of the protective earth conductor (profile view)

1 Base body of the L-731 / V-731 (front side)

2 Flat washer

3 Safety washer

4 Screw, M4x8, ISO 7045

5 Cable lug

6 Protective earth conductor

Requirements

You have read and understood the general notes on installation (p. 17).

Tools and accessories

Suitable protective earth conductor: Cross-sectional area of the cable ≥ 0.75 mm

2

PH1 screwdriver or similar tool

Connecting the L-731 / V-731 to the protective earth conductor

1. If necessary, attach a suitable cable lug to the protective earth conductor.

2. Remove the screw and the safety and flat washers of the protective earth connection

(p. Figure 7).

3. Tighten the screw (together with the safety and flat washers) to affix the cable lug of

the protective earth conductor to the protective earth connection (p. Figure 8)

4. Tighten the screw with a torque of 1.2 Nm to 1.5 Nm.

5. Make sure that the contact resistance at all connection points relevant for mounting

the protective earth conductor is <0.1 Ω at 25 A.

5 Installation

24 Version: 1.0.1 MP158D L-731 / V-731 Precision XY Positioner

5.4 Affixing the Load to the L-731 / V-731

NOTICE

Impermissibly high load on the positioner!

An impermissible high load impairs the motion of the platform and can damage the positioner.

When considering the mass and mounting method of the load, pay attention to the

specified maximum permissible forces, that are permitted to act on the platform (p. 37).

Requirements

You have read and understood the general notes on installation (p. 17).

You have mounted the positioner properly onto a surface (p. 18).

The positioner is not connected to the controller.

You have prepared the load so that it can be affixed to the mounting holes on the

platform (p.45):

− The distance between the center of gravity of the load and the center of the

platform is as small as possible in all directions.

− At least two points are provided for affixing the load to the platform (ideally: three

attachment points).

Tools and accessories

At least 2 M6 screws of suitable length

Suitable tool for tightening the screws.

Optional: Dowel pins, ISO 8734 - 6 m6 x 16 (locating pins)

Affixing the load

1. If you use locating pins for aligning the load: Insert the locating pins into the holes

provided in the platform (p.45).

2. Align the load so that the selected mounting holes in the platform can be used to affix

it.

3. Use the screws to affix the load to the selected mounting holes in the platform.

4. Check that the load is affixed firmly to the platform of the positioner.

5 Installation

L-731 / V-731 Precision XY Positioner MP158D Version: 1.0.1 25

5.5 Connecting the L-731 / V-731 to a Controller

NOTICE

Damage if an incorrect controller or motor cable is connected!

Connecting a positioner to an unsuitable controller or using an unsuitable motor cable can

cause damage to the positioner or controller.

Only connect the positioner to a suitable controller (p. 12).

To connect the positioner to the controller, only use a motor cable that is suitable for

the controller (see following table).

C-663.11 C-663.12 C-863 SMC Hydra

L-731.40SD 2x C-815.LSM1 2x C-815.00UP0100-

0300

- 2x C-815.LSH1

L-731.44SD - 2x C-815.00UP0100-

0300

- 2x 720090669-0300

L-731.4ASD - - - 2x C-815.LSH1

and

2x 7210920211-

0300

L-731.093111 - -

-

2x 720190600-0300

and

2x 7210920211-

0300

L-731.093112 - - 2x C-815.LDM1 2x 720190500-0300

L-731.093132 - - - 2x C-815.VLH1

and

2x 7210920211-

0300

Requirements

You have read and understood the general notes on installation (p. 17).

You have installed the controller.

You have read and understood the user manual of the controller.

The controller is switched off.

Tools and accessories

Cable from the scope of delivery of the positioner (p. 12)

Suitable tools for tightening the screws to the connections

5 Installation

26 Version: 1.0.1 MP158D L-731 / V-731 Precision XY Positioner

Connecting the L-731 / V-731 to a Controller

1. Remove the ESD protection from all connections of the L-731 / V-731.

2. Connect the L-731 / V-731 and the controller to each other:

3. Use the integrated screws to secure the connections against accidental disconnection.

6 Start-Up

L-731 / V-731 Precision XY Positioner MP158D Version: 1.0.1 27

6.1 General Notes on Start-Up

DANGER

For V-731 models: Magnetic fields!

Magnetic fields may damage or interfere with sensitive devices and objects (e. g. cardiac

pacemakers, EC-cards, magnetic data carriers). The fields are also effective when the

positioner is not connected to the controller/electric power.

Loose magnetizable objects (e.g. made of iron, steel) may be att

racted and cause damages. The

corresponding pull might not be manually compensated.

If applicable, note the usual precautions for applying pacemakers.

Remove loose magnetizable objects and sensitive devices from the installation site.

Ensure that hazardous areas are marked correspondingly and that the usual precautions

are applied.

Keep sufficient distance from the positioner.

Apply corresponding precautions also for storage and transport of the positioner.

CAUTION

Risk of crushing by moving parts!

There is a risk of minor injury from crushing between the moving parts of the positioner or the

load and a fixed part or obstacle.

Use protective structures to keep limbs away from areas in which they could be caught by

moving parts.

Observe the safety distances in accordance with DIN EN ISO 13857 when installing

protective structures.

NOTICE

Damage due to collisions!

Collisions can damage the positioner, the load to be moved, and the surroundings.

Make sure that no collisions are possible between the positioner, the load to be moved,

and the surroundings in the motion range of the positioner.

Do not place any objects in areas where they can be caught by moving parts.

Stop the motion immediately if a controller malfunction occurs.

If possible, adapt the travel range limits of your mechanical system in the software that

you use for commanding the motion.

6

Start-Up

6 Start-Up

28 Version: 1.0.1 MP158D L-731 / V-731 Precision XY Positioner

NOTICE

Damage if an incorrect controller or motor cable is connected!

Connecting a positioner to an unsuitable controller or using an unsuitable motor cable can

cause damage to the positioner or controller.

Only connect a positioner to a suitable controller (page 12).

To connect the positioner to the controller, only use a motor cable that is suitable for

the controller (see following table).

C-663.11 C-663.12 C-863 SMC Hydra

L-731.40SD 2x C-815.LSM1 2x C-815.00UP0100-

0300

- 2x C-815.LSH1

L-731.44SD - 2x C-815.00UP0100-

0300

- 2x 720090669-0300

L-731.4ASD - - - 2x C-815.LSH1

and

2x 7210920211-

0300

L-731.093111 - -

-

2x 720190600-0300

and

2x 7210920211-

0300

L-731.093112 - - 2x C-815.LDM1 2x 720190500-0300

L-731.093132 - - - 2x C-815.VLH1

and

2x 7210920211-

0300

NOTICE

Operating voltage excessively high or incorrectly connected!

Operating voltages that are excessively high or incorrectly connected can cause damage to the

L-731 / V-731.

Do not exceed the operating voltage range (p. 42) that is specified for the L-731 / V-731.

Only operate the L-731 / V-731 when the operating voltage is properly connected; see "Pin

Assignment" (p. 45).

6 Start-Up

L-731 / V-731 Precision XY Positioner MP158D Version: 1.0.1 29

NOTICE

Damage or considerable wear due to high accelerations!

High accelerations can cause damage to or considerable wear on the mechanical system.

Stop the motion immediately if a controller malfunction occurs.

Ensure that the end of the travel range is approached at low velocity.

Determine the maximum velocity for your application.

NOTICE

Unintentional motions!

Unintentional motion of the L-731 / V-731 is possible when it is connected to the controller.

Defective software or incorrect operation of the software can also result in unintentional

motion.

Do not place any objects in areas where they can be caught by moving parts.

Before connecting the L-731 / V-731, check whether a macro is defined as the start-up

macro in the controller, and cancel the selection of the start-up macro if necessary.

INFORMATION

The maximum velocity for an L-731.4xSD should be determined in the application. If the

commanded velocity is too high, the stepper motor might stop without the controller detecting

this state.

INFORMATION

The repeatability of the positioning is only ensured when the reference point switch is always

approached from the same side. Controllers from PI fulfill this requirement as a result of the

automatic direction sensing for reference moves to the reference point switch.

6 Start-Up

30 Version: 1.0.1 MP158D L-731 / V-731 Precision XY Positioner

6.2 Starting Up the Positioner

Requirements

You have read and understood the general notes on start-up (p. 27).

For starting up with a load or in a multi-axis system: You have properly installed the

positioner (p. 17).

You have read and understood the user manual of the controller used.

You have read and understood the manual of the PC software used.

The controller and the required PC software have been installed. All connections on the

controller have been set up (see "Connecting the L-731 / V-731 to the Controller"

(p. 25) and the user manual of the controller).

Starting up the positioner

1. Start up the controller(s) (see user manual of the controller).

Configure the controller(s) during start-up using the PC software for the positioner used

(see user manual of the controller, and the PC software): Select the entry in the

positioner database that exactly matches the positioner model used.

2. Start a few motion cycles for testing purposes (see user manual of the controller

model).

6.2.1 L-731 / V-731 Entries in the Positioner Database of PI

For PI controllers, you can select the connected positioner from a positioner database in the

corresponding PC software. The appropriate operating parameters are thus loaded to the

controller. You can find a detailed description in the user manual for the controller or in the

manual for the PC software used.

7 Maintenance

L-731 / V-731 Precision XY Positioner MP158D Version: 1.0.1 31

7.1 General Notes on Maintenance

NOTICE

Damage due to improper maintenance!

Removing caps and screws can lead to contamination and failure of the L-731 / V-731.

Do not loosen screws on the positioner.

Do not remove any caps other than the ESD protection.

7.2 Performing a Maintenance Run (L-731 Models)

Depending on the operating conditions and the period of use of the L-731, the following

maintenance measures are required:

Maintenance Run

The maintenance run serves to distribute the existing lubricant.

After 500 operating hours or at least after 1 year, perform a maintenance run over the

entire travel range, in order for the lubricant present to be evenly distributed.

If the L-731 is to be operated continuously in an industrial environment over a small

travel range (<20 % of the entire travel range), perform a maintenance run across the

entire travel range every 5000 motion cycles.

Lubrication

Under laboratory conditions, the positioner needs extra lubrication in exceptional cases only.

For continuous industrial use, the lubrication intervals must be defined individually.

If you have any questions, contact our customer service department (p. 35).

7.3 Cleaning the L-731 / V-731

Requirements

You have disconnected the positioner from the controller.

Cleaning the Positioner

If necessary, clean the surfaces of the positioner with a cloth that is dampened with a

mild cleanser or disinfectant.

7

Maintenance

8 Troubleshooting

L-731 / V-731 Precision XY Positioner MP158D Version: 1.0.1 33

8.1 Possible Causes and Remedies

Problem Possible causes Solution

Reduced positioning

accuracy

Warped base body

Mount the L-731 / V-731 onto an even

surface. The recommended flatness of the

surface is ≤ 5 µm.

Increased wear due to small

motions over a long period of

time

Carry out a maintenance run over the

entire travel range.

Functional impairment

after system

modification

Controller was replaced.

L-731 / V-731 was replaced by

another model.

Load the parameters from the positioner

database that correspond to the

combination of controller and the L-731 /

V-731 model.

Mechanical system

does not move; no

operating noise can be

heard.

Controller not correctly

connected or defective.

Check all connecting cables.

Check the controller.

If necessary, check the power supply of the

positioner.

For L-731.4xSD models:

Actual position

deviates from the

displayed position.

The motor is overloaded by an

external load torque or the mass

to be driven in the case of strong

acceleration or deceleration.

The motor skips steps. The information on the

current position is lost without the controller

detecting the state.

Determine the maximum velocity for a

positioner with a stepper motor in the

application.

Start a new reference move.

If the problem that occurred with your system is not listed in the table above or cannot be

solved as described, contact our customer service department (p. 35).

8

Troubleshooting

8 Troubleshooting

34 Version: 1.0.1 MP158D L-731 / V-731 Precision XY Positioner

8.2 Manually Moving the Platform

INFORMATION

It is necessary to repeat the reference move after moving manually and connecting to the

controller.

V-731: The platform can be easily moved by hand without aid.

L-731: The platform can be moved with more force by hand without aid. Alternatively, the

spindle can be used to move the platform without damaging the drive.

This can be necessary when the platform is stuck at the beginning or the end of the travel range

(has reached the hard stop).

Figure 9: Position of the spindle accesses for the Y direction (left arrow) and X direction (right arrow)

Requirements

The positioner is not connected to the controller.

Tools and accessories

Hex key AF 3

Manually moving the platform

Insert the hex key into the corresponding spindle access.

Turn the hex key as far as necessary:

− Clockwise rotation: Platform moves in a positive direction

− Counterclockwise rotation: Platform moves in a negative direction

9 Customer Service

L-731 / V-731 Precision XY Positioner MP158D Version: 1.0.1 35

For inquiries and orders, contact your PI sales engineer or send us an email (mailto:info@pi.de).

If you have questions concerning your system, have the following information ready:

− Product and serial numbers of all products in the system

− Firmware version of the controller (if present)

− Version of the driver or the software (if present)

− Operating system on the PC (if present)

If possible: Take photographs or make videos of your system that can be sent to our

customer service department if requested.

The latest versions of the user manuals are available on our website (p. 3) for download.

9

Customer Service

10 Specifications

L-731 / V-731 Precision XY Positioner MP158D Version: 1.0.1 37

10.1 Technical Data

The specified data applies to a temperature of 20 °C (±3 °C) and horizontal installation.

You can download current versions of data sheets from our web site www.pi.ws.

10.1.1 Data Table

L-731.40SD / L-731.44SD / L-731.4ASD

L-731.40SD L-731.44SD L-731.4ASD Unit Tolerance

Active axes X, Y X, Y X, Y

Motion and positioning

Travel range 205 × 205 205 × 205 205 × 205 mm

Integrated sensor – Incremental linear

encoder with A/B

quadrature signal

transmission

Incremental linear

encoder with

sin/cos signal

transmission

Sensor resolution – 10 10*

nm

Sensor signal period – 20 µm

Minimum incremental motion 1 0.05 0.05 µm typ.

Unidirectional repeatability 1 0,05 0,05 µm typ.

Bidirectional repeatability ±2.5 ±0.5 ±0.5 µm typ.

Backlash 3 0.1 0.1 µm

Pitch xry / yrx ±50 / ±40 ±50 / ±40 ±50 / ±40 µrad typ.

Yaw ±30 ±30 ±30 µrad typ.

Straightness / flatness ±2 ±2 ±2 µm typ.

Velocity 45 45 45 mm/s max.

Reference and limit switches optical optical optical

Mechanical properties

Load capacity 200 200 200 N

Permissible torque in θX, θY 125 125 125 Nm

Permissible torque in θZ 125 125 125 Nm

Moved mass in X 12 12 12 kg

Moved mass in Y 3.5 3.5 3.5 kg

Overall mass

15.5

15.5

15.5

kg

Guiding Crossed roller guide with anti-creep system

10

Specifications

10 Specifications

38 Version: 1.0.1 MP158D L-731 / V-731 Precision XY Positioner

L-731.40SD L-731.44SD L-731.4ASD Unit Tolerance

Drive properties

Motor Type 2-phase stepper motor

Spindle pitch 2 2 2 mm

Motor power/axis 5 5 5 W

Operating voltage 24

48

24

48

24

48

V

V

nom.

max.

Miscellaneous

Operating temperature range 10 to 50 10 to 50 10 to 50 °C

Humidity 20 … 90 % rel., not condensing

Material Aluminum, black anodized

Connection Motor

connection:

2 × HD D-Sub 26

(m)

Motor and sensor

connection: 2 ×

HD D-Sub 26 (m)

Motor

connection:

2 × HD D-Sub 26

(m)

Recommended controller

2 × C-663: Mercury Step motion

controller,

SMC Hydra: motion controller for 2

axes

Modular ACS controller

SMC Hydra:

motion controller

for 2 axes

Modular ACS

controller

10 Specifications

L-731 / V-731 Precision XY Positioner MP158D Version: 1.0.1 39

L 731.093111 / L 731.093112 / L 731.093132

L 731.093111 L 731.093112 L 731.093132 Unit Tolerance

Motion and positioning

Active axes X, Y X, Y X, Y

Travel range 205 × 205 205 × 205 205 × 205 mm

Integrated sensor Incremental linear

encoder with

sin/cos signal

transmission

Incremental linear

encoder with A/B

quadrature signal

transmission

Incremental

rotary encoder

Sensor resolution

10

10

nm

20000

cts/rev

Sensor signal period 20 – - µm

Minimum incremental motion 0,1 0,5 0,8 µm typ.

Unidirectional repeatability

0,1

0,5

0,8

µm typ.

Bidirectional repeatability ±0,5 ±0,5 ±2,5 µm typ.

Pitch xry / yrx ±50 / ±40 ±50 / ±40 ±50 / ±40 µrad typ.

Yaw ±30 ±30 ±30 µrad typ.

Straightness / flatness ±2 ±2 ±2 µm typ.

Velocity 50 50 90 mm/s max.

Reference and limit switches optical optical optical

Mechanical properties

Load capacity 200 200 200 N

Permissible torque in θX, θY 125 125 125 Nm

Permissible torque in θZ 125 125 125 Nm

Moved mass in X 12 12 12 kg

Moved mass in Y 3.5 3.5 3.5 kg

Overall mass 16 16 16 kg

Guiding Crossed roller guide with anti-creep system

Drive properties

Motor Type DC motor

Spindle pitch

2 2 2

mm

Operating voltage 24

48

24

48

24

48

V

V

nominal

max.

Motor power/axis 60 60 60 W nominal

10 Specifications

40 Version: 1.0.1 MP158D L-731 / V-731 Precision XY Positioner

L 731.093111 L 731.093112 L 731.093132 Unit Tolerance

Miscellaneous

Operating temperature range 10 … 50 10 … 50 10 … 50 °C

Humidity 20 … 90 % rel., not condensing

Material Aluminum, black anodized

Connection Motor

connection:

2 × HD D-Sub 26

(m)

Motor and sensor

connection: 2 ×

HD D-Sub 26 (m)

Motor

connection:

2 × HD D-Sub 26

(m)

Recommended controller SMC Hydra:

motion controller

for 2 axes

Modular ACS

controller

2 × C-863: Mercury servo controller,

C-884: 4-ch motion controller

Modular ACS controller

10 Specifications

L-731 / V-731 Precision XY Positioner MP158D Version: 1.0.1 41

V 731.096111

V-731.096111 Unit Tolerance

Motion and positioning

Active axes X, Y

Travel range 205 × 205 mm

Integrated sensor Incremental linear encoder

Sensor resolution* 1 nm

Sensor signal period 20 µm

Minimum incremental motion 0.02 µm typ.

Unidirectional repeatability 0.1 µm typ.

Bidirectional repeatability ±0.25 µm typ.

Pitch xry / yrx ±50 / ±40 µrad typ.

Yaw ±30 µrad typ.

Straightness / flatness ±2 µm typ.

Velocity 200 mm/s max.

Reference and limit switches optical

Mechanical properties

Load capacity 50 N

Permissible torque in θX, θY 125 Nm

Permissible torque in θZ 125 Nm

Moved mass in X 15.4 kg

Moved mass in Y 5.6 kg

Overall mass 19.4 kg

Guiding Crossed roller guide with anti-creep

system

Drive properties

Motor type Linear motor, ironless

Operating voltage 48 V max.

Peak force 100 N typ.

Nominal force 29 N typ.

Peak current, effective 5 A typ.

Nominal current, effective 1.5 A typ.

Force constant, effective 19.9 N/A typ.

Resistance phase-phase 11 Ω typ.

Inductivity phase-phase 3.6 mH typ.

Back EMF phase-phase 16 Vs/m max.

Magnetic periods 30 mm

10 Specifications

42 Version: 1.0.1 MP158D L-731 / V-731 Precision XY Positioner

V-731.096111 Unit Tolerance

Miscellaneous

Operating temperature range 10 … 50 °C

Humidity 20 … 90 % rel., not condensing

Material Aluminum, black anodized

Motor connector 2 × HD D-Sub 26 (m)

Sensor connection 2 × D-Sub 15 (f)

Recommended controller SMC Hydra

C-891

Modular ACS controller

10.1.2 Maximum Ratings

The L-731 / V-731 positioners are designed for the following operating data:

Model Maximum operating

voltage

Operating frequency Maximum power

consumption*

L 731.093111

L 731.093112

L 731.093132

48 V 0 Hz 60 W

L-731.4xSD 48 V 0 Hz 5 W

V-731.096111 48 V 0 Hz 3 W

* per axis

10.1.3 Ambient Conditions and Classifications

The following ambient conditions and classifications must be observed for the L-731 / V-731:

Area of application For indoor use only

Maximum altitude 2000 m

Relative humidity 20% … 90%, not condensing

Storage temperature 10 °C … 50 °C

Transport temperature 10 °C … 50 °C

Supply fluctuations Max. ±10 % of the nominal voltage

Degree of pollution 2

Degree of protection according to IEC 60529 IP00

10 Specifications

L-731 / V-731 Precision XY Positioner MP158D Version: 1.0.1 43

10.1.4 Limit Switch Specifications

Type Optical sensor

Supply voltage +5 V/GND, supplied via the motor connector

Signal output Open Collector (other models)

Signal logic The signal level changes when passing the limit switch. The signal

logic is active high. That means:

Normal motor operation: low (0 V)

Limit switch reached: high (+5 V)

10.1.5 Reference Point Switch Specifications

Type Optical sensor

Supply voltage +5 V/GND, supplied by the motor controller through the motor

connector.

Signal output Open Collector (other models)

Signal logic Direction sensing by means of different signal levels on the left and

right side of the reference point switch: The signal level changes

from 0 to +5 V when the reference point switch is passed.

Hysteresis 0.2 … 0.4 mm (when arriving from the positive or negative direction)

10 Specifications

44 Version: 1.0.1 MP158D L-731 / V-731 Precision XY Positioner

10.2 Dimensions

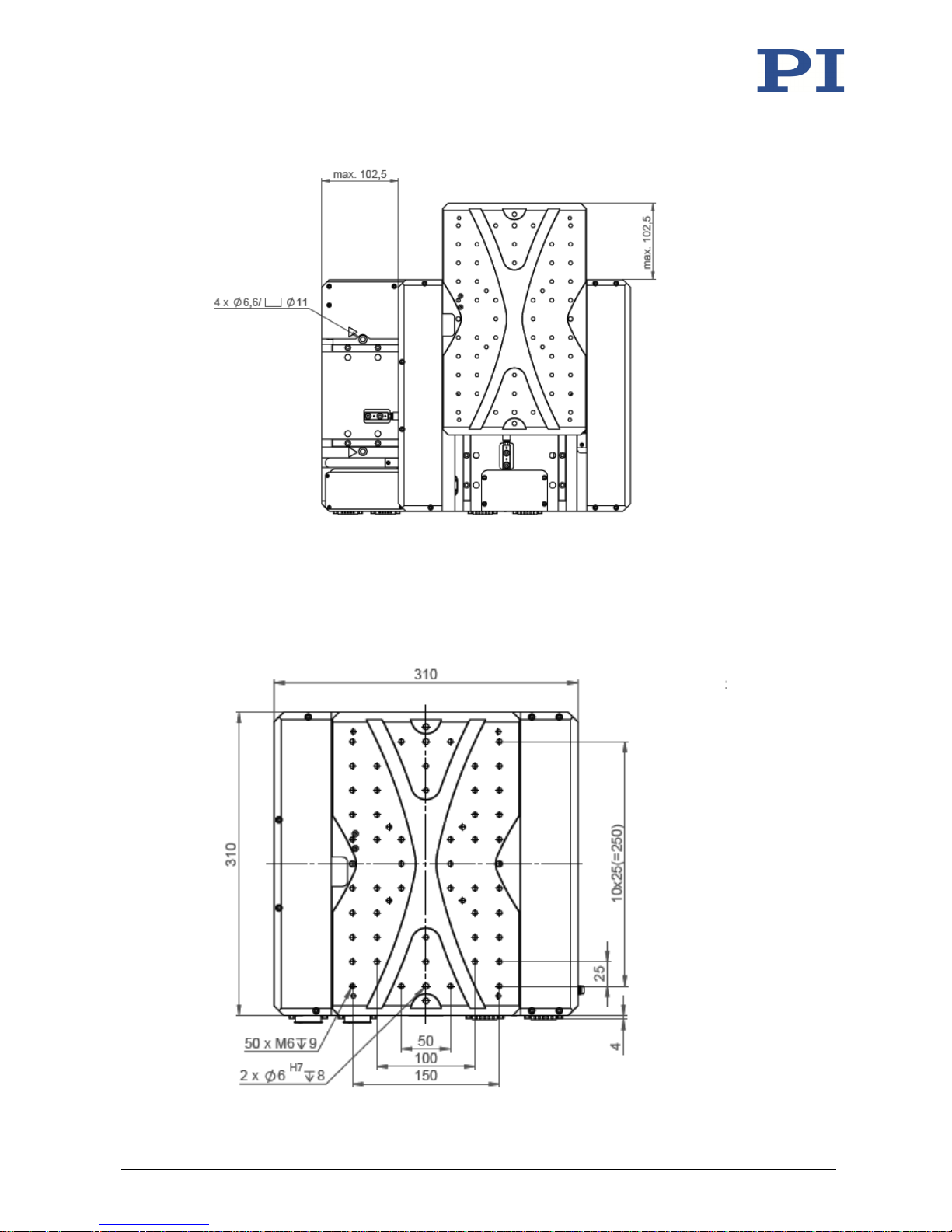

10.2.1 L-731 / V-731 Positioners

Dimensions in mm. Note that the decimal places are separated by a comma in the drawings.

Figure 10: Dimensions; platform in reference position

10 Specifications

L-731 / V-731 Precision XY Positioner MP158D Version: 1.0.1 45

Figure 11: Dimensions; platform moved out

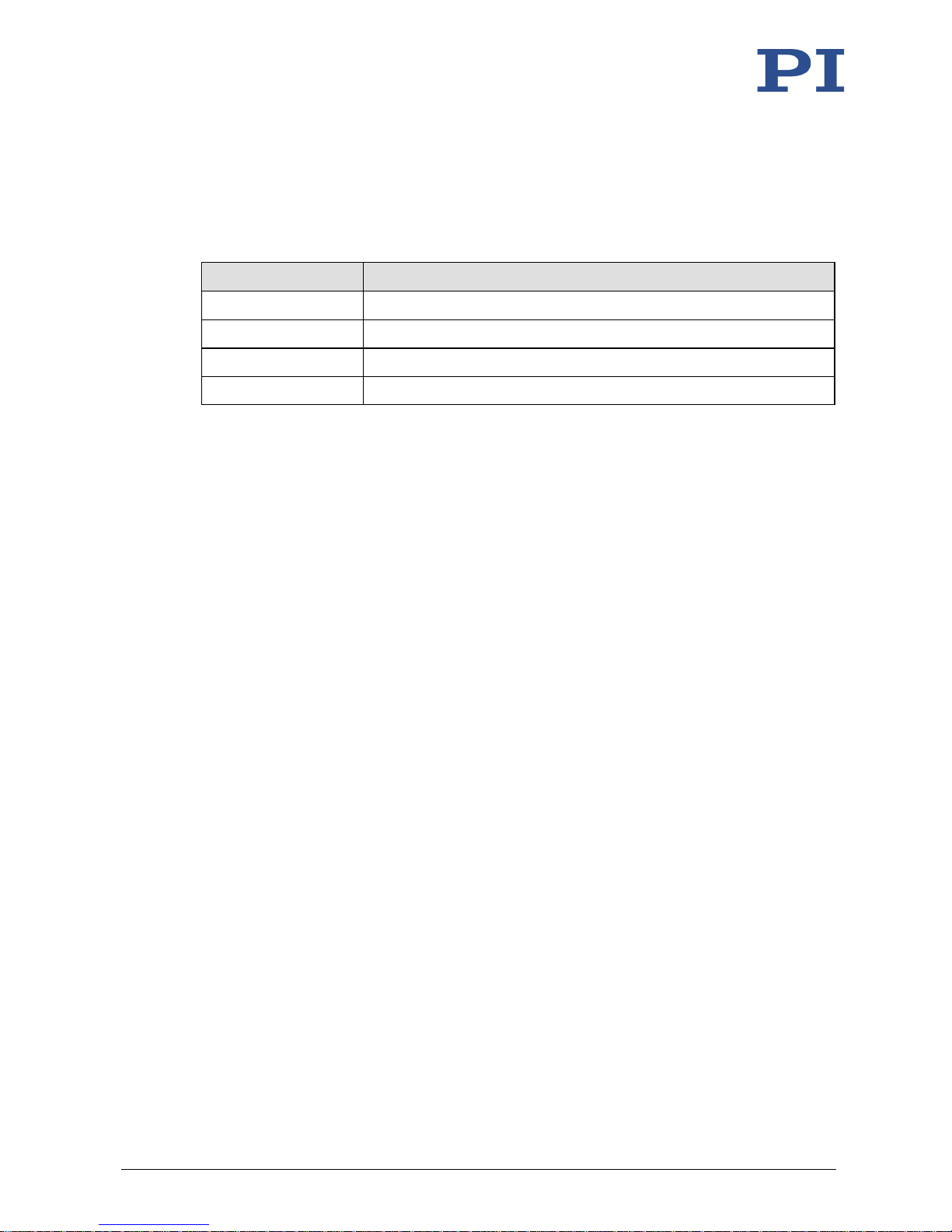

10.2.2 Hole Pattern of the Platform

Figure 12: Hole pattern

10 Specifications

46 Version: 1.0.1 MP158D L-731 / V-731 Precision XY Positioner

10.3 Pin Assignment

10.3.1 HD D-Sub 26 (m)

Figure 13: HD D-Sub 26 panel plug

L 731.093132 / L 731.093111 / L 731.093112

Pin Signal Direction

1 Motor + Input

2 Motor + Input

3 Motor - Input

4 Motor - Input

5 - -

6 - -

7 - -

8 - -

9 - -

10 REF Output

11 Limit neg. Output

12 Limit pos. Output

13 - -

14 - -

15 - -

16 - -

17 ID I/O Bidirectional

18 Limit Power (+5 V) Input

19 Encoder A+ Output

20 Encoder A- Output

21 Encoder B+ Output

22 Encoder B- Output

23 Encoder C+ Output

24 Encoder C- Output

25 GND -

26 Encoder Power 5 V DC Input

10 Specifications

L-731 / V-731 Precision XY Positioner MP158D Version: 1.0.1 47

L-731.4xSD

Pin Signal L-731.40SD / L-731.44SD Signal L-731.4ASD Direction

1 Motor A+ Motor + / Motor A+ / U Input

2 Motor A+ Motor + / Motor A+ / U Input

3 Motor A- Motor - / Motor A- / V Input

4 Motor A- Motor - / Motor A- / V Input

5 Motor B+ Motor B+ / W Input

6 Motor B+ Motor B+ / W Input

7 Motor B- Motor B- Input

8 Motor B- Motor B- Input

9 - - -

10 REF REF Output

11 Limit neg. Limit neg. Output

12 Limit pos. Limit pos. Output

13 - - -

14 - - -

15 - - -

16 - - -

17 ID I/O ID I/O Bidirectional

18 Limit Power (+5 V) Limit Power (+5 V) Output

19 Encoder A+ Encoder A+ Output

20 Encoder A- Encoder A- Output

21 Encoder B+ Encoder B+ Output

22 Encoder B- Encoder B- Output

23 Encoder C+ Encoder C+ Output

24 Encoder C- Encoder C- Output

25 GND GND -

26 - - -

10 Specifications

48 Version: 1.0.1 MP158D L-731 / V-731 Precision XY Positioner

V-731

Pin Signal Direction

1 Motor A+ / Phase 1 Input

2 Motor A+ / Phase 1 Input

3 Motor A- / Phase 2 Input

4 Motor A- / Phase 2 Input

5 Motor B+ / Phase 3 Input

6 Motor B+ / Phase 3 Input

7 Motor B- Input

8 Motor B- Input

9 - -

10 REF Output

11 Limit neg. Output

12 Limit pos. Output

13 - -

14 - -

15 - -

16 - -

17 ID I/O Bidirectional

18 Limit Power (+5 V) Input

19 - -

20 - -

21 - -

22 - -

23 - -

24 - -

25 GND -

26 - -

10 Specifications

L-731 / V-731 Precision XY Positioner MP158D Version: 1.0.1 49

10.3.2 D-Sub 15 (m)

Figure 14: D-Sub 15 panel plug

Pin Signal Direction

1 Power 5 V DC Input

2 GND -

3 sin + Output

4 sin - Output

5 Temp GND -

6 cos + Output

7 cos - Output

8 Limit neg. Output

9 NTC Output

10 REF + Output

11 PTC Output

12 REF - Output

13 - Output

14 GND -

15 Limit pos. Output

10 Specifications

50 Version: 1.0.1 MP158D L-731 / V-731 Precision XY Positioner

10.4 Tightening Torque for Screws, ISO 4762 - A2

The following tightening torques for screws according to ISO4762 (corresponds to DIN 912) - A2

may not be exceeded.

Value Maximum tightening torque

M3 1.5 Nm

M4 2 Nm

M5 2.5 Nm

M6 3 Nm

11 Old Equipment Disposal

L-731 / V-731 Precision XY Positioner MP158D Version: 1.0.1 51

In accordance with EU law, electrical and electronic equipment may not be disposed of in EU

member states via the municipal residual waste.

Dispose of your old equipment according to international, national, and local rules and

regulations.

In order to fulfil the responsibility as the product manufacturer, PI miCos GmbH undertakes

environmentally correct disposal of all old PI miCos equipment made available on the market

after 13 August, 2005 without charge.

Any old PI miCos equipment can be sent free of charge to the following address:

PI miCos GmbH

Freiburger Strasse 30

79427 Eschbach, Germany

11

Old Equipment Disposal

12 EU Declaration of Conformity

L-731 / V-731 Precision XY Positioner MP158D Version: 1.0.1 53

An EU Declaration of Conformity has been issued for the L-731 / V-731 in accordance with the

following European directives:

• EMC Directive

• RoHS Directive

The applied standards certifying the conformity are listed below.

• EMC: EN 61326-1

• Safety: EN 61010-1

• RoHS: EN 50581

12

EU Declaration of Conformity

Loading...

Loading...