Page 1

Operating Manual PSSu H SB CAN(-T)

Operating Manual PSSu H SB CAN(-T)

PSSu H SB CAN(-T)

Decentralised system PSSuniversal I/O

Operating Manual — No. 21459-EN-02

Page 2

This document is a translation of the original document.

All rights to this documentation are reserved by Pilz GmbH & Co. KG. Copies may be made

for internal purposes.

Suggestions and comments for improving this documentation will be gratefully received.

Pilz®, PIT®, PMI®, PNOZ®, Primo®, PSEN®, PSS®, PVIS®, SafetyBUS p®, SafetyEYE®,

SafetyNET p®, the spirit of safety® are registered and protected trademarks of

Pilz GmbH & Co. KG in some countries.

SD means Secure Digital.

Preface

Page 3

Contents

Contents

Contents Page

Chapter 1 Introduction

1.1 Validity of documentation 1-1

1.1.1 Retaining the documentation 1-1

1.2 Overview of documentation 1-2

1.3 Definition of symbols 1-3

Chapter 2 Overview

2.1 Module features 2-1

2.2 Front view 2-2

Chapter 3 Safety

3.1 Intended use 3-1

3.2 Safety regulations 3-3

3.2.1 Use of qualified personnel 3-3

3.2.2 Warranty and liability 3-3

3.2.3 Disposal 3-3

Chapter 4 Function description

4.1 Module features 4-1

4.1.1 Integrated protection mechanisms 4-1

4.1.2 Supply voltage 4-1

4.2 SafetyBUS p 4-2

4.2.1 Connection to SafetyBUS p 4-2

4.2.2 Selector switch for setting the device

address

4.3 CANopen 4-3

4.3.1 Connection to CANopen 4-3

4.3.2 Selector switch for setting the

transmission rate

4.3.3 Selector switch for setting the station

address

4.4 USB port 4-6

Chapter 5 Installation

5.1 General installation guidelines 5-1

5.1.1 Dimensions 5-1

5.2 Installing the head module 5-2

Chapter 6 Interfaces

6.1 Interface configuration 6-1

6.1.1 Connection to SafetyBUS p 6-1

6.1.2 Connection to CANopen 6-1

6.1.3 Connection via USB 6-2

4-2

4-4

4-5

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

1

Page 4

Contents

Chapter 7 Operation

7.1 Messages 7-1

7.2 Display elements 7-3

7.2.1 Display elements for system diagnostics 7-3

7.2.2 Display elements for SafetyBUS p

7.2.3 Display elements for CANopen diagnostics 7-6

7.3 CANopen object description 7-9

7.3.1 Communication profile 7-9

7.3.2 Device profile 7-10

7.3.3 Manufacturer-specific objects 7-11

7.3.4 Object overview 7-13

7-5

diagnostics

Chapter 8 Technical details

8.1 Technical details 8-1

8.2 Order reference 8-3

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

2

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 5

1 Introduction

1.1 Validity of documentation

11000IntroductionIntroduction1-1.1Validity of docume ntation1100Validity of documenta tion1-][BA Einf Gültigkeit Kopfmodul mit SB mit T-Variante

This documentation is valid for the product PSSu H SB CAN and

PSSu H SB CAN-T. It is valid until new documentation is published.

Please also refer to the following documents:

SafetyBUS p System Description

SafetyBUS p Installation Manual

PSSuniversal System Description

Einf Einleitung

PSSuniversal Installation Manual

This operating manual explains the function and operation, describes

the installation and provides guidelines on how to connect the product .

1.1.1 Retaining the documentation

Retaining the documentation1-Einf Aufbewahren

This documentation is intended for instruction and should be retained

for future reference.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

1-1

Page 6

1 Introduction

1.2 Overview of documentation

1.2Overview of documentation1200Overview of documentation1-][BA_Einführung Übersicht Kopfmodule

1 Introduction

The introduction is designed to familiarise you with the contents, structure and specific order of this manual.

2 Overview

This chapter provides information on the module's most important features.

3 Safety

This chapter must be read as it contains important information on safety

and intended use.

4 Function Description

This chapter describes the module's individual components.

5 Installation

This chapter explains how to install the module.

6 Interfaces

This chapter describes the module's interfaces.

7 Operation

This chapter explains the display elements and advises on what to do if

a fault occurs.

8 Technical Details

This chapter contains the product's technical details and order reference.

1-2

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 7

1 Introduction

1.3 Definition of symbols

1.3Definition of symbols1300Definition of symbols1-Einfhrung Zeichen

Information that is particularly important is identified as follows:

DANGER!

This warning must be heeded! It warns of a hazardous situation

that poses an immediate threat of serious injury and death and

indicates preventive measures that can be taken.

WARNING!

This warning must be heeded! It warns of a hazardous situation

that could lead to serious injury and death and indicates preventive measures that can be taken.

CAUTION!

This refers to a hazard that can lead to a less serious or minor

injury plus material damage, and also provides information on

preventive measures that can be taken.

NOTICE

This describes a situation in which the unit(s) could be damaged

and also provides information on preventive measures that can

be taken. It also highlights areas within the text that are of particular importance.

INFORMATION

This gives advice on applications and provides information on

special features.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

1-3

Page 8

1 Introduction

1-4

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 9

2 Overview

2.1 Module features

22000OverviewOverview2-2.1Module features2100Module features2-Geraetemerkmale_Zusatz BA Einleitung

][Merkmale_Schnittstelle SB p und ST-Bus

][Merkmale_LED SB p und ST-Bus

][Merkmale_E-Module SB p und ST-Bus

][Geraetemerkmal_T

The product has the following features:

SafetyBUS p interface for

– Failsafe inputs/outputs

CANopen interface for

– Standard inputs/outputs

– Failsafe outputs with the local enable principle

USB port for connection to a PC for

– Commissioning

– Service

LEDs for:

– System status

– SafetyBUS p status

–USB status

– Status of the CANopen interface

Electronic modules that can be used for input/output:

– All failsafe modules

(PSSu E F...)

– All standard modules

(PSSu E S...)

Coated version of the module:

PSSu H SB CAN-T: for increased environmental requirements

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

2-1

Page 10

2 Overview

CANopen

PSSu H

SB CAN

Usb Dev

SB I/O

SB ADDRESS

USB

2

D -

3

D +

5

G N D

USB

0

3

6

9

x 10

0

3

6

9

x 1

312 035

0000000

HW 000

000 000

ADDRESS

OFF

ON

S1

64

32

16

8

4

2

1

S2

S2

BAUD

AUTO

OFF

500K

OFF

250K

OFF

ON

S1 OFF ONONON

BAUD

125K

Run

Err

1

2

3

4

5

6

7

8

12

10

9

11

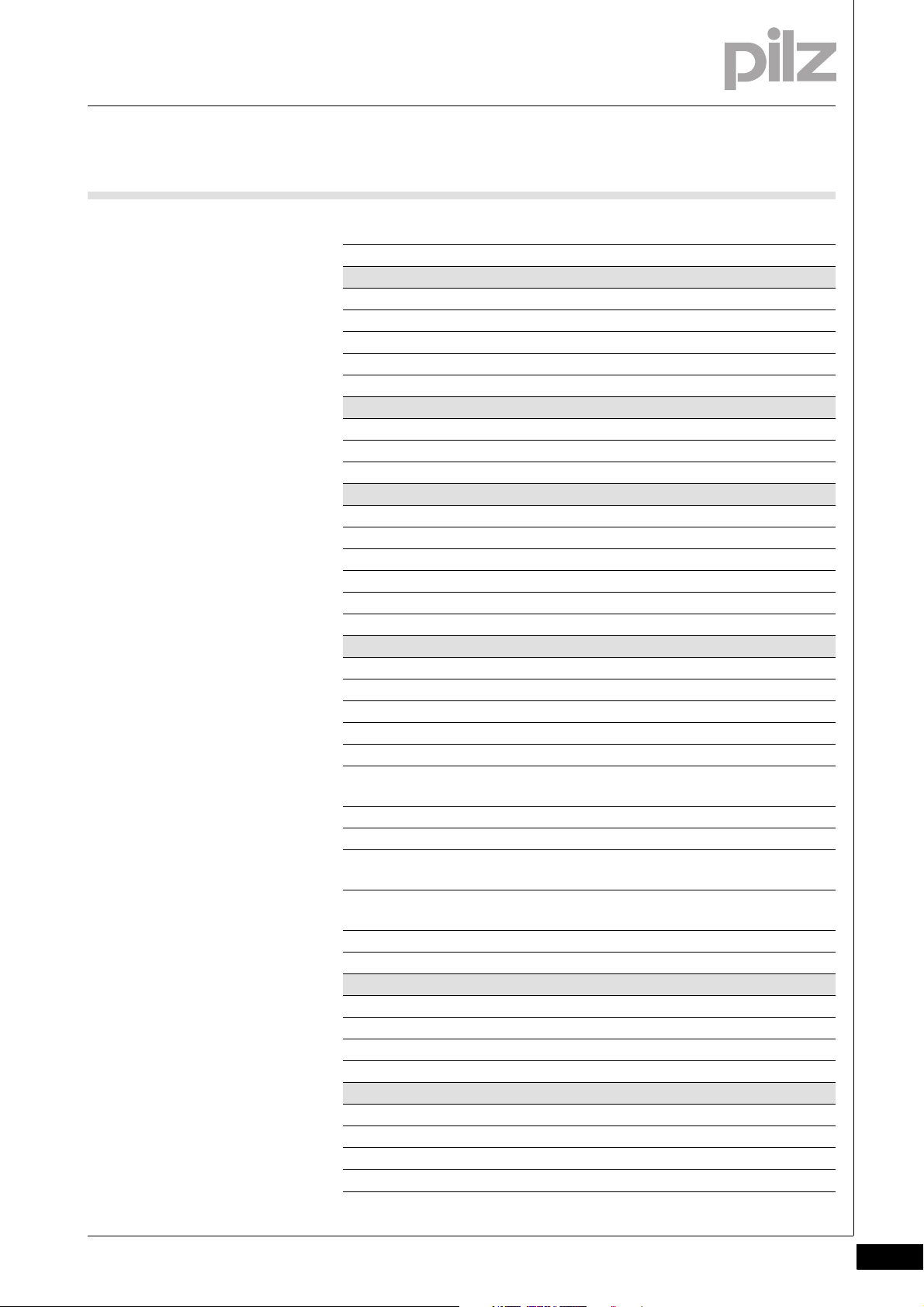

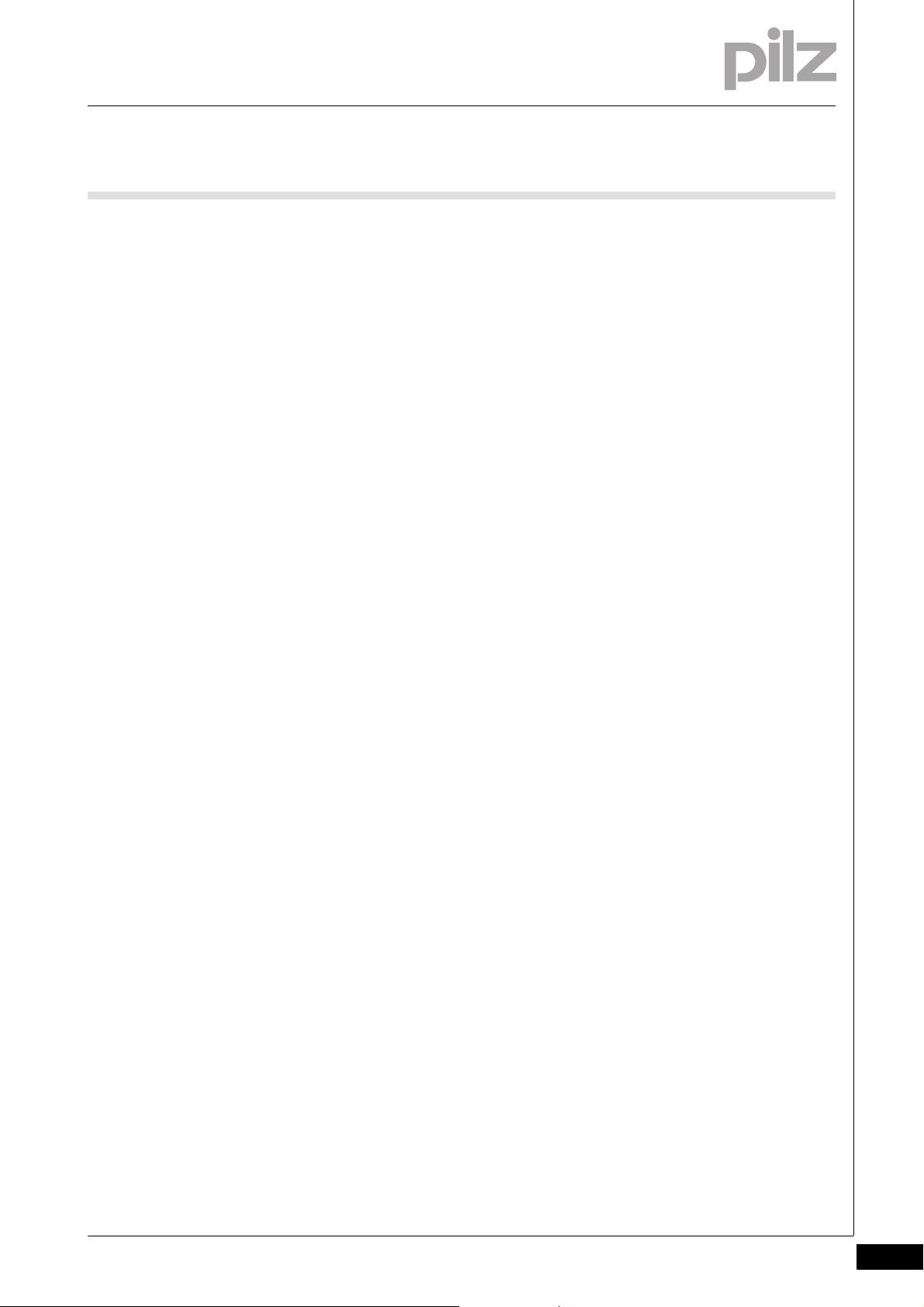

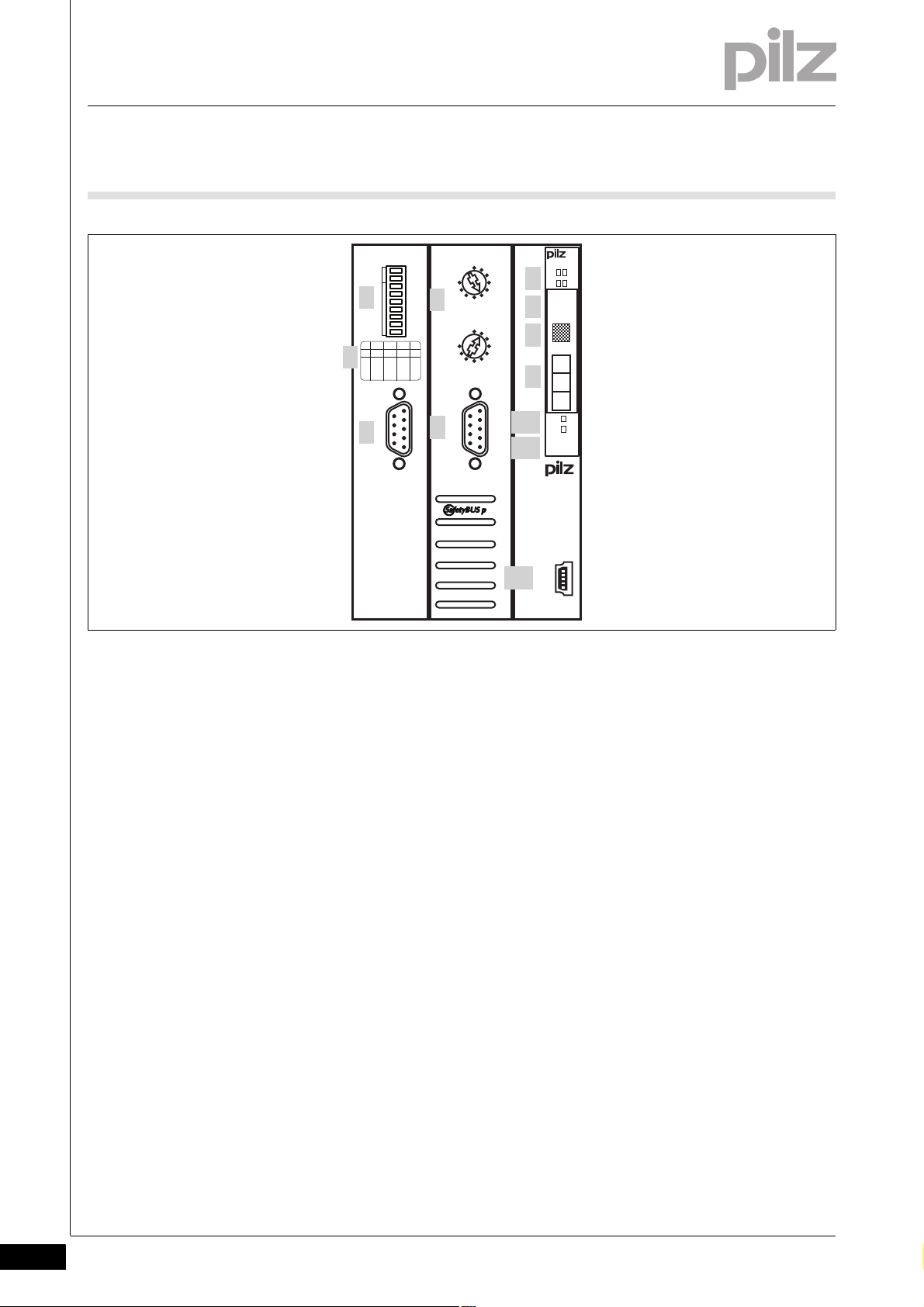

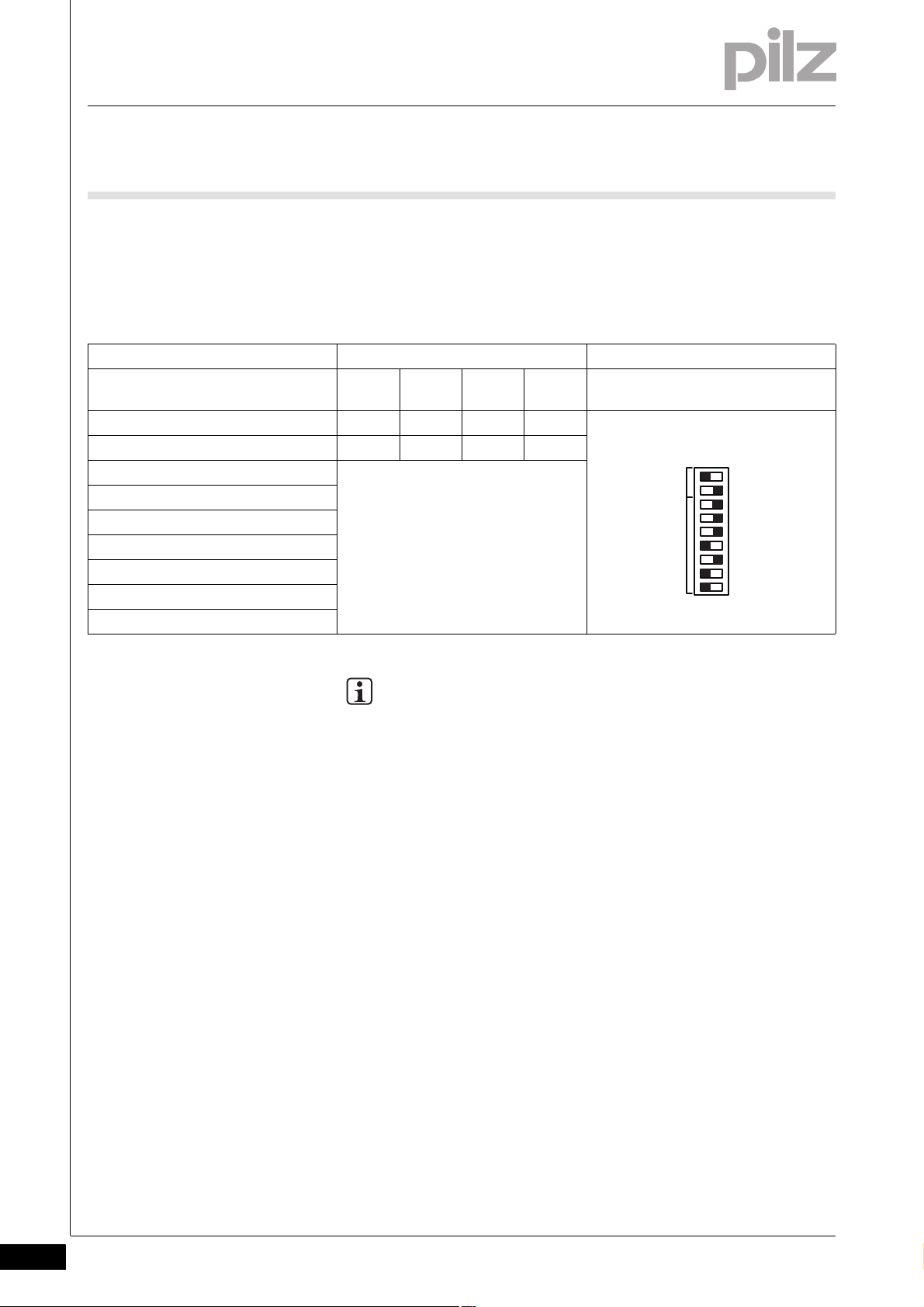

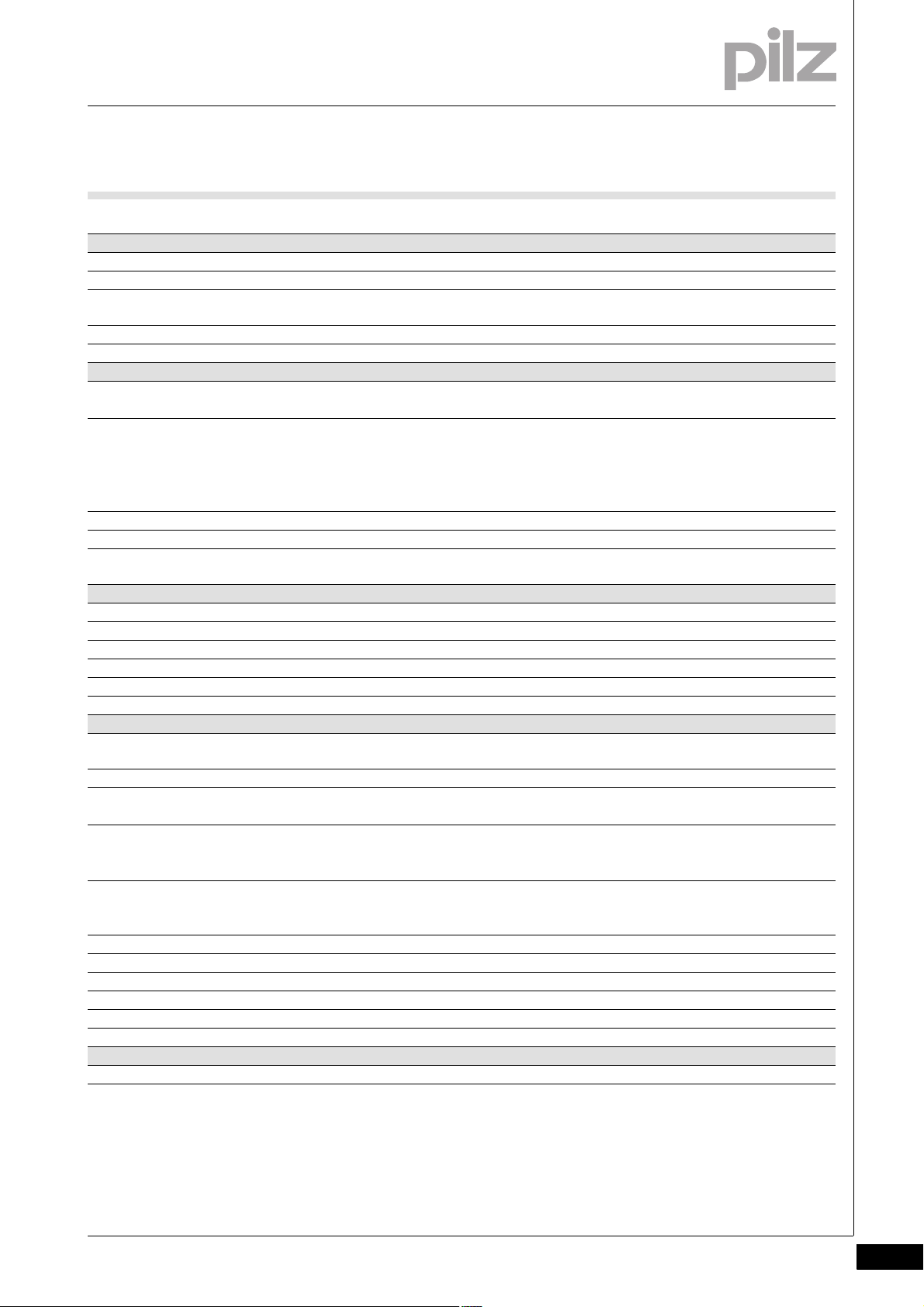

2.2 Front view

2.2Front view2200Front view2-BA_Fron tansicht

Key:

1: Selector switch for setting the station address and transmission

rate (CANopen)

2: Labelling strip with guidelines for setting the transmission rate

(CANopen)

3: CANopen interface

4: Two selector switches for setting the device address (SafetyBUS p)

5: SafetyBUS p interface

6: LEDs for system diagnostics and SafetyBUS p diagnostics

7: Labelling strip with:

– Order number

– Serial number

– Hardware version number

– Firmware version number on delivery

8: Field for 2D code

9: Labelling strip with interface configuration of the USB port

10: LEDs for CANopen diagnostics

11: Description of head module

12: USB port (Mini-B)

2-2

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 11

3 Safety

3.1 Intended use

33000SafetySafety3-3.1Intended use3100Intended use3-][Bestimmu ng SB p und ST-Bus mZust

Bestimm_Verwend_ Zusatz-(T)

Bestimmung/Gertebeschreibung Kat./SIL_PSSu

Bestimmung/Gertebeschreibung_Ausschluss

The module is designed for use in:

Safety-related applications with

– SafetyBUS p

– CANopen With local enable principle

Non-safety-related applications with

–CANopen

The module PSSu H SB CAN-T is suitable for use where there are increased environmental requirements (see Technical Details).

The module meets the requirements of EN IEC 61508 up to SIL3 and

EN 954-1 up to Category 4.

Bestimm_Verwend_Info_PSSu_ab_1.4.0_Kopf FS50/18

BA_Bestimmung Ausschluss Zusatz Kopf - E-Modul

Intended use includes making the electrical installation EMC-compliant.

Please refer to the guidelines stated in the "PSSuniversal Installation

Manual". The module is designed for use in an industrial environment. It

is not suitable for use in a domestic environment, as this can lead to interference.

The following is deemed improper use in particular:

Any component, technical or electrical modification to the module

Use of the module outside the areas described in this manual

Use of the module outside the technical details (see chapter entitled

"Technical Details")

INFORMATION

The module is supported by the PSSuniversal Configurator and

PSSuniversal Assistant from Version 1.4.0. We recommend that

you always use the latest version (download from www.pilz.de).

The module is supported by programmable safety systems with

SafetyBUS p interface, from FS operating system version 50/18.

Programmable safety systems with an older FS operating system version will have a restricted function range.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

3-1

Page 12

3 Safety

3.1 Intended use

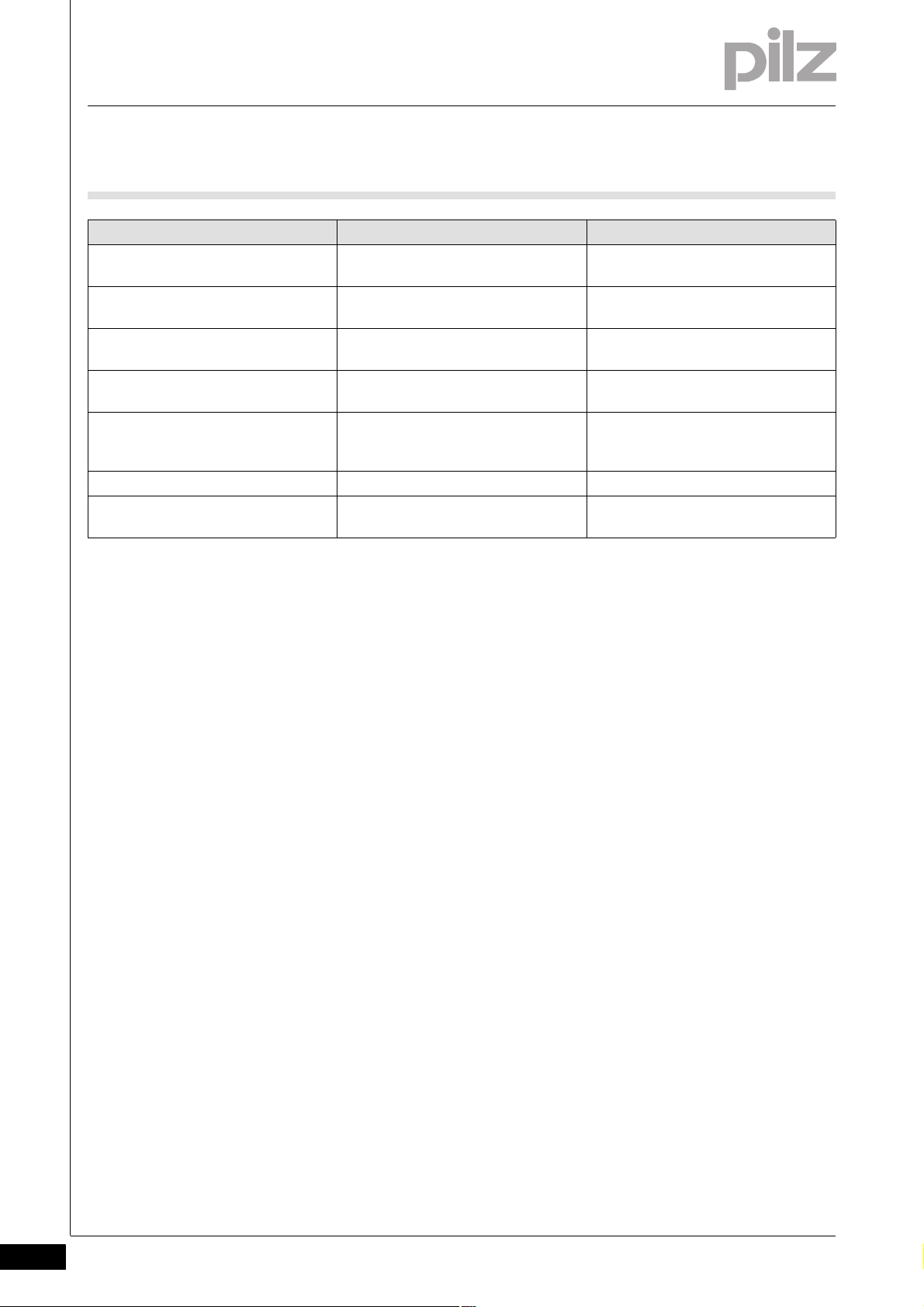

The head module may be used in conjunction with the following elec-

][BA_Sicherheit E-Module FS /ST

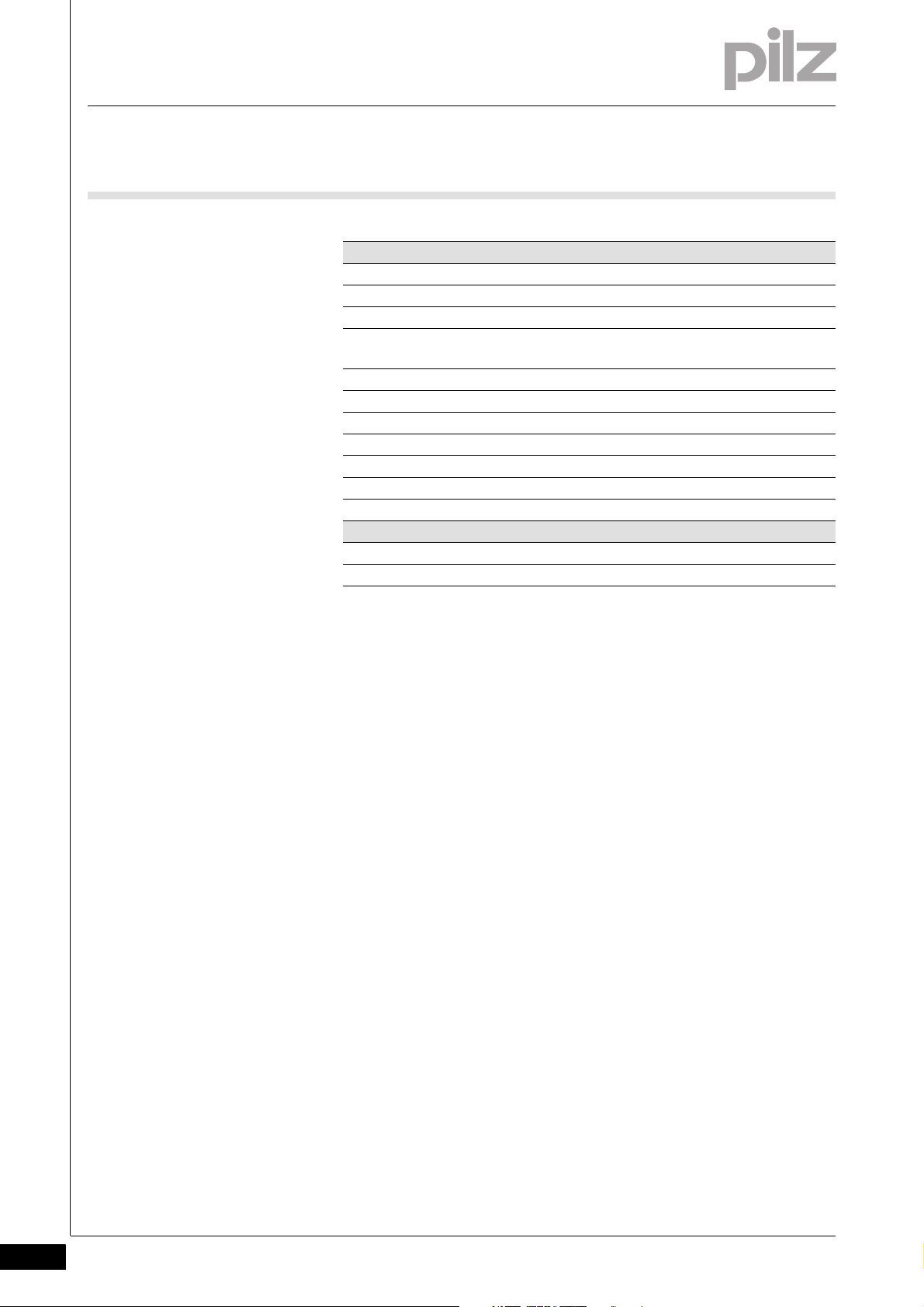

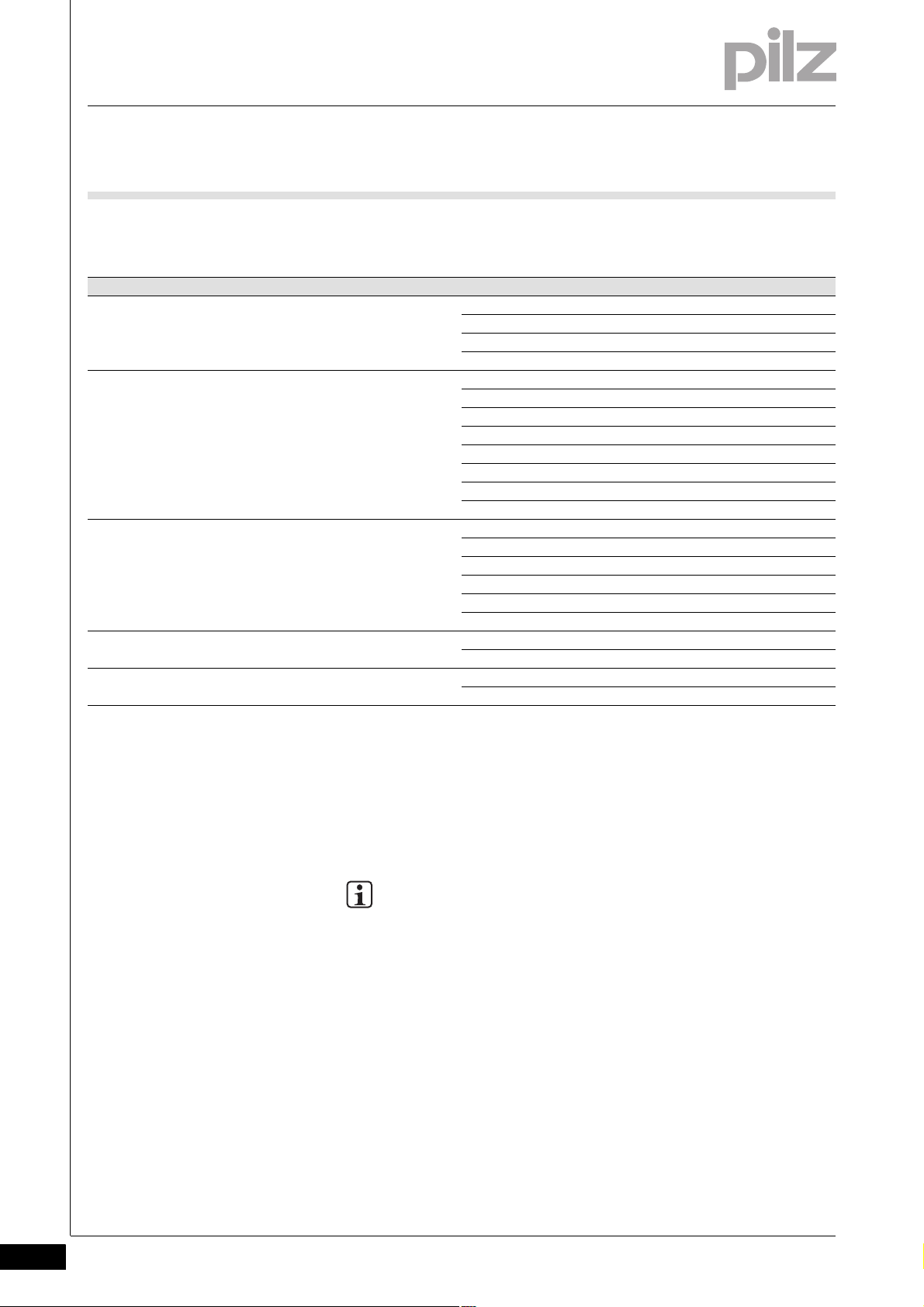

Module type Module name

Voltage supply PSSu E F PS(-T)

Digital input/output modules PSSu E S 4DI(-T)

Analogue input/output modules PSSu E S 2AI I se(-T)

Counter modules PSSu E S ABS SSI(-T)

Voltage distribution PSSu E PD(-T)

][BA Bestimmung Firmware

tronic modules:

PSSu E F PS1(-T)

PSSu E F PS-P(-T)

PSSu E F BSW(-T)

PSSu E S 4DO 0.5(-T)

PSSu E S 2DO 2(-T)

PSSu E F 4DI(-T)

PSSu E F 4DO 0.5(-T)

PSSu E F 2DO 2(-T)

PSSu E F 2DOR 8(-T)

PSSu E F DI OZ 2(-T)

PSSu E S 4AI U(-T)

PSSu E S 2AI U(-T)

PSSu E S 2AO I(-T)

PSSu E S 4AO U(-T)

PSSu E S 2AO U(-T)

PSSu E S INC(-T)

PSSu E PD1(-T)

The module's firmware can be updated to a later version using the

Firmware Manager on the PSSuniversal Assistant. For the reason, the

module's actual firmware version may not always match the firmware

version printed on the front of the unit. Updating the firmware can also

expand the module's functionality.

INFORMATION

The module's actual firmware version can only be established

using the Firmware Manager on the PSSuniversal Assistant.

3-2

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 13

3 Safety

3.2 Safety regulations

3.2Safety regulations3200Safety regulations3-

3.2.1 Use of qualified personnel

Use of qualified personnel3-Sich Qualif. Personal

The products may only be assembled, installed, programmed, commissioned, operated, maintained and decommissioned by competent persons.

A competent person is someone who, because of their training, experience and current professional activity, has the specialist knowledge required to test, assess and operate the work equipment, devices,

systems, plant and machinery in accordance with the general standards

and guidelines for safety technology.

It is the company's responsibility only to employ personnel who:

Are familiar with the basic regulations concerning health and safety /

accident prevention

Have read and understood the safety guidelines given in this descrip-

tion

Have a good knowledge of the generic and specialist standards ap-

plicable to the specific application.

3.2.2 Warranty and liability

Warranty and liability3-Sich Gewhrleistung

3.2.3 Disposal

Disposal3-Si ch Entsorgung

All claims to warranty and liability will be rendered invalid if:

The product was used contrary to the purpose for which it is intended

Damage can be attributed to not having followed the guidelines in the

manual

Operating personnel are not suitably qualified

Any type of modification has been made (e.g. exchanging compo-

nents on the PCB boards, soldering work etc.).

In safety-related applications, please comply with the mission time t

M

in the safety-related characteristic data.

When decommissioning, please comply with local regulations regard-

ing the disposal of electronic devices (e.g. Electrical and Electronic

Equipment Act).

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

3-3

Page 14

3 Safety

3-4

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 15

4 Function description

4.1 Module features

44000Function descriptionFunction description4-4.1Module features4100Module features4-

4.1.1 Integrated protection mechanisms

Integrated protection mechanisms4-][Schutzmechanismen H SBUS + ST-BUS

The module has the following protection mechanisms:

Multi-channel diverse processor section

Cyclical self tests

Potentially isolated SafetyBUS p interface

Potentially isolated CANopen interface

When the PSSu E F PS1(-T) is used to supply the system, the module

supply is buffered for 20 ms if the supply voltage is interrupted.

4.1.2 Supply voltage

Supply voltage4-][Funktionsbeschreibung Module Supply

Module supply

The module supply provides the module with voltage.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

4-1

Page 16

4 Function description

SB ADDRESS

0

3

6

9

x 10

0

3

6

9

x 1

4.2 SafetyBUS p

4.2SafetyBUS p4200SafetyBUS p4-

4.2.1 Connection to SafetyBUS p

Connection to SafetyBU S p4-][Funktion_BA_Zusatz SB p Kopplung

A PSSu with SafetyBUS p interface is regarded as a bus subscriber in a

SafetyBUS p network.

The “SafetyBUS p Installation Manual” and the “SafetyBUS p System

Description” apply for subscribers in a SafetyBUS p network.

Detailed descriptions for commissioning are available in the online help

for the PSS WIN-PRO system software. Step-by-step instructions can

be found in the manual: "Getting Started: Full version of PSS WIN-PRO".

4.2.2 Selector switch for setting the device address

Selector switch for setting the device address4-][Funktion_BA_Zusatz SB p Wahlschalter

The device address of a PSSu is set via the two rotary switches “x 10”

and “x 1”.

Permitted device addresses are in the range 32

plies if the PSSu system is configured for SafetyBUS p 1 in the Safety-

BUS p Configurator on the PSS WIN-PRO system software. The offset

of 100

for device addresses on SafetyBUS p 1 is calculated automati-

D

cally from the bus configuration.

Rotary switch “SB ADDRESS”:

Switch designation

x 10 Set the tens

x 1 Set the units

Key Example:

... 95D. The same ap-

D

Device address 51

D

4-2

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 17

4 Function description

CANopen

Master

CANopen

Slave 1

PSSu

CANopen

Slave 2

CANopen

Slave n

4.3 CANopen

4.3CANopen4300CANopen4-

4.3.1 Connection to CANopen

Connection to CANopen4-][Funktionsbeschreibung_BA_Zusatz CAN Kopplung

A PSSu system with CANopen interface is a passive subscriber (Slave)

of the CANopen fieldbus.

The basic communication functions with CANopen conform to CiA DS301 V3.0. The central controller (Master) reads input information from

the slaves and writes output information to the slaves as part of each

cycle.

Bus termination must be activated on both ends of the bus.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

4-3

Page 18

4 Function description

ADDRESS

OFF

ON

S2

S1

32

16

8

4

2

1

BAUD

64

4.3 CANopen

4.3.2 Selector switch for setting the transmission rate

Selector switch for setting the transmission rate4-][Funktionsbeschreibung_BA_Zusatz CAN Übertragung

The transmission rate of a PSSu is set via the “BAUD” DIP switches S1

and S2.

“BAUD” DIP switch Key Example:

Switch designation AUTO 500

KBit/s

S2 OFF OFF ON ON

S1 OFF ON OFF ON

64

32

16

8

4

2

1

Station address

250

kBit/s

125

kBit/s

Transmission rate

500 kBit/s

INFORMATION

The transmission rate should only be set when the module is

switched off (no voltage applied).

The settings are only transferred when booting. Any changes

made to the settings during operation will not be transferred.

If the PSSu station has lots of telegrams to send via the CANopen fieldbus, make sure that the transmission rate is high enough, e.g. when several analogue input/output modules are used. If the transmission rate is

too low, the PSSu may not be able to establish a connection to the

CANopen fieldbus.

4-4

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 19

4 Function description

ADDRESS

OFF

ON

S2

S1

32

16

8

4

2

1

BAUD

64

4.3 CANopen

4.3.3 Selector switch for setting the station address

Selector switch for setting the station address4-][Funktionsbeschreibung_BA_Zusatz CAN Station

The station address of a PSSu (“Node ID”) is set via the “ADDRESS” DIP

switches (“1”, “2”, “4”, “8”, “16”, “32” and “64”). The DIP switches are

binary coded. Permitted station addresses are in the range 0

A station address is set via a combination of the relevant binary coded

switches:

“ADDRESS” DIP switch Key Example

Switch designation OFF ON Station address 116

S2 Transmission rate

S1

64 0 64

32 0 32

16 0 16

808

404

202

101

D

D

D

D

D

D

D

... 127D.

D

D

INFORMATION

The station address should only be set when the module is

switched off (no voltage applied).

The settings are only transferred when booting. Any changes

made to the settings during operation will not be transferred.

Each station address on a CANopen network must be unique.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

4-5

Page 20

4 Function description

4.4 USB port

4.4USB port4400USB port4-][Funktion_BA_Zusatz USB

The following functions are available via the USB port:

Show actual hardware

Comparison of actual/registered hardware

Display and update firmware versions

Setting the parameters for the ST section

Parameters for the module's ST section can either be set via the fieldbus

interface or via the USB port. Parameter setting via the USB port has priority over parameter setting via the fieldbus interface. Once parameters

for the the head module have been set via the USB port, the ability to set

parameters for the module via the fieldbus interface is disabled. The disable can be lifted in the PSSuniversal Assistant.

Procedure for connecting the head module via the USB port:

Connect PC to head module via USB cable.

Install USB driver.

View the actual hardware registry in the PSSuniversal Assistant and

call up other functions.

This way it is possible to copy and edit an existing configuration in the

PSSuniversal Assistant.

INFORMATION

The USB driver can be found on the PSSuniversal Assistant

CD-ROM, in the subdirectory \bin\PILZ_USB_DRIVER

4-6

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 21

5 Installation

56,4 mm

125,6 mm

72,6 mm

75,2 mm

69,2 mm

2,8 mm

21,6 mm

(2.448")(2.22")

(0.11")

(4.945")

(2.858")

(0.85")

(2.96")

5.1 General installation guidelines

55000InstallationInstallation5-5.1General installation guidelines5100General installation guidelines5-][Montage BA Kopfmodul Allgemein

Please also refer to the PSSuniversal Installation Manual.

The description below assumes that the mounting rail is already in-

Montage_EMV ESD

stalled.

CAUTION!

Damage due to electrostatic discharge!

Electrostatic discharge can damage components. Ensure

against discharge before touching the product, e.g. by touching

an earthed, conductive surface or by wearing an earthed armband.

5.1.1 Dimensions

Dimensions5-][Abmessungen SB p und ST-Bus

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

5-1

Page 22

5 Installation

[2]

[1]

5.2 Installing the head module

5.2Installing the head module5200Installing the head module5-][Montage Kopfmodul

Prerequisite:

The mounting rail must be installed.

Procedure:

Install an end bracket to the left of the head module or leave enough

space for one.

Slot the groove on the head module on to the mounting rail from be-

low [1].

Push the head module back [2] until you hear it lock into position.

Schematic representation:

5-2

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 23

6 Interfaces

1

5

6

9

1

5

6

9

1

5

6.1 Interface configuration

66000InterfacesInterfaces6-6.1Interface configuration6100Interface configuration6-][A nschluss SB CAN

SafetyBUS p Layout

Male 9-pin D-SUB connector 1: n.c.

2: CAN_L (brown)

3: CAN_GND (white)

4: n.c.

5: CAN_SHLD

6: n.c.

7: CAN_H (green)

8: Supply voltage for fibre-optic couplers from Pilz

9: n.c.

CANopen Layout

Male 9-pin D-SUB connector 1: n.c.

2: CAN_L

3: CAN_GND

4: n.c.

5: CAN_SHLD

6: GND

7: CAN_H

8: n.c.

9: n.c.

USB Layout

Mini-B USB connector 1: n.c.

2: D- USB Data –

3: D+ USB Data +

4: n.c.

5: GND Ground

n.c. = not connected

(1)

(1)

Not required for operation

6.1.1 Connection to SafetyBUS p

Connection to SafetyBU S p6-][BA_Verdrah tung SB p

Please refer to the SafetyBUS p Installation Manual.

6.1.2 Connection to CANopen

Connection to CANopen6-][BA_Ve rdrahtung CAN

The connection cable must conform to the requirements of CiA DS 102

V2.0.

Only shielded cable should be used as the CANopen connection cable.

Connect the cable shield on the CANopen connection cable to Pin 5 of

the 9-pin D-Sub connector. The relationship of the cable runs to the bit

rate must be maintained.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

6-1

Page 24

6 Interfaces

6.1 Interface configuration

6.1.3 Connection via USB

Connection via USB6-][ BA_Verdrahtung USB

Please note the requirements of the USB standard for USB 2.0 and for

Mini-B USB ports.

The maximum cable runs for USB connection cable are 5 m.

6-2

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 25

7 Operation

7.1 Messages

77000OperationOperation7-7.1Messages71 00Messages7-][BA_ Betrieb Meldungen SB p

All errors and faults detected by the electronic modules on a PSSu are

signalled to the head module and entered in the head module's error

stack. You can read the head module's error stack using the

][BA_Betrieb Tabelle Meldungen FS+ST Sys A

Module error Statement Remedy

Start-up error Error as the PSSu system starts up Change faulty module

Configuration error Incorrect module type configured The configured hardware registry does

FS communication error Error during FS communication Change faulty module

ST communication error Error during ST communication Change faulty module

Bus termination error There is no terminating plate or there is

Temperature error: too warm (

Temperature error: too hot (1) Ambient temperature too high:

Output error Error during cyclical output test for

Test pulse error Possible causes: Short circuit be-

Relay control error Error during cyclical monitoring test of

Relay error A relay position is faulty;

Block switching output error Error during cyclical monitoring test of

Error in the feedback loop FS input detects an error in the feed-

Error in the local enable principle FS output has reacted incorrectly or

Input error Error during the cyclical input test;

Overload/short circuit Load on output too high Rectify overload or short circuit

1

) Ambient temperature too high:

PSS WIN-PRO system software (SafetyBUS p, Domain 0).

not match the actual hardware registry

Install a terminating plate with inte-

a bad contact with the module bus

Error stack entry

Reset the module and stop the affected I/O-Groups (SafetyBUS p)

short circuit. Possible causes: Short

circuit, or output defective

tween a test pulse and a supply voltage, or a defective module

the relay coils

possible cause: Defective relay contact

the relay contacts;

possible external cause: Voltages being fed back to the relay contacts

back loop or FS input is defective

unexpectedly

possible cause: Input defective

grated end bracket or insert the base

modules together correctly

Ensure there is sufficient ventilation in

the control cabinet or prevent overload

Ensure there is sufficient ventilation in

the control cabinet or prevent overload

Rectify the short circuit or change the

faulty module

Rectify the short circuit or change the

faulty module

Change faulty relay module

Change faulty relay module

Check the supply voltage and the wiring

Check FS input, check the configuration of the feedback loop, check the

signals, or check the wiring and contacts

Check the configuration of the FS output, or check the fieldbus signals in

the FS and ST section

Change faulty module

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

7-1

Page 26

7 Operation

7.1 Messages

Module error Statement Remedy

Overload of the supply voltage for encoder

Overvoltage error A system voltage or infeed is too high Stabilise the supply or change the

Undervoltage error A system voltage or infeed is too low Stabilise the supply or change the

Error in the overvoltage protection diodes

Timeout error on the output No data has been received for the out-

Polarity error Polarity of the periphery supply Correct the polarity

Error in the periphery supply Lower voltage limit exceeded on the

Supply voltage for encoder overloaded or short-circuited

Overvoltage protection diodes are defective

put from the module bus for longer

than 50 ms.

periphery supply

Rectify overload or short circuit

faulty supply voltage module

faulty supply voltage module

Change faulty supply voltage module

Check ST communication or configuration

Ensure there is a sufficient supply

(1) There are two levels of overtemperature.

Too warm:

If a module's temperature exceeds a threshold value, the module

sends a warning to the head module. If the temperature drops back

below the threshold value, the module sends an all-clear.

Too hot:

If a module's temperature exceeds a further threshold value, the module sends an error message to the head module and triggers an I/OGroup stop.

Further information on PSSu error messages is available in the online

help for the system software.

7-2

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 27

7 Operation

Usb Dev

--- - --

DevUsb

7.2 Display elements

7.2Display elements72 00Display elements7-Anzeige Legende 3x

Legend:

7.2.1 Display elements for system diagnostics

Display elements for system diagnostics7-][BA_Anzeige System

The module has LEDs to display various PSSu states (“Usb” LED and

“Dev” LED).

LED on

LED flashes

LED off

LED Key

Description Colour Status

Usb - - - No data is being

transmitted via

the USB port

Green Data is being

transmitted via

the USB port

Dev - - - PSSu system

error, no startup

Green PSSu running

without error

Red Error in the

head module

Red Error on the

module bus (*1)

1

) An error on the module bus (flashing red LED) may be due to one of

(*

the following reasons, which are stored in the error stack:

1. The head module cannot determine the registered hardware. Possible

causes:

Module bus is incomplete

Terminating resistor is missing.

A module is defective

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

A module does not have valid software.

Invalid hardware registry

Too many modules

7-3

Page 28

7 Operation

7.2 Display elements

Remedy: Correct the hardware registry.

2. Error: A module is missing. Possible cause:

The module has been removed.

The module has an error and is no longer registering after a reset.

The module has an error and switches to a system stop.

The module no longer has a voltage supply.

Remedy: Rectify the above points.

7-4

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 29

7 Operation

SB ADDRESS

0

3

6

9

x 10

Usb Dev

SB I/O

I/OSB

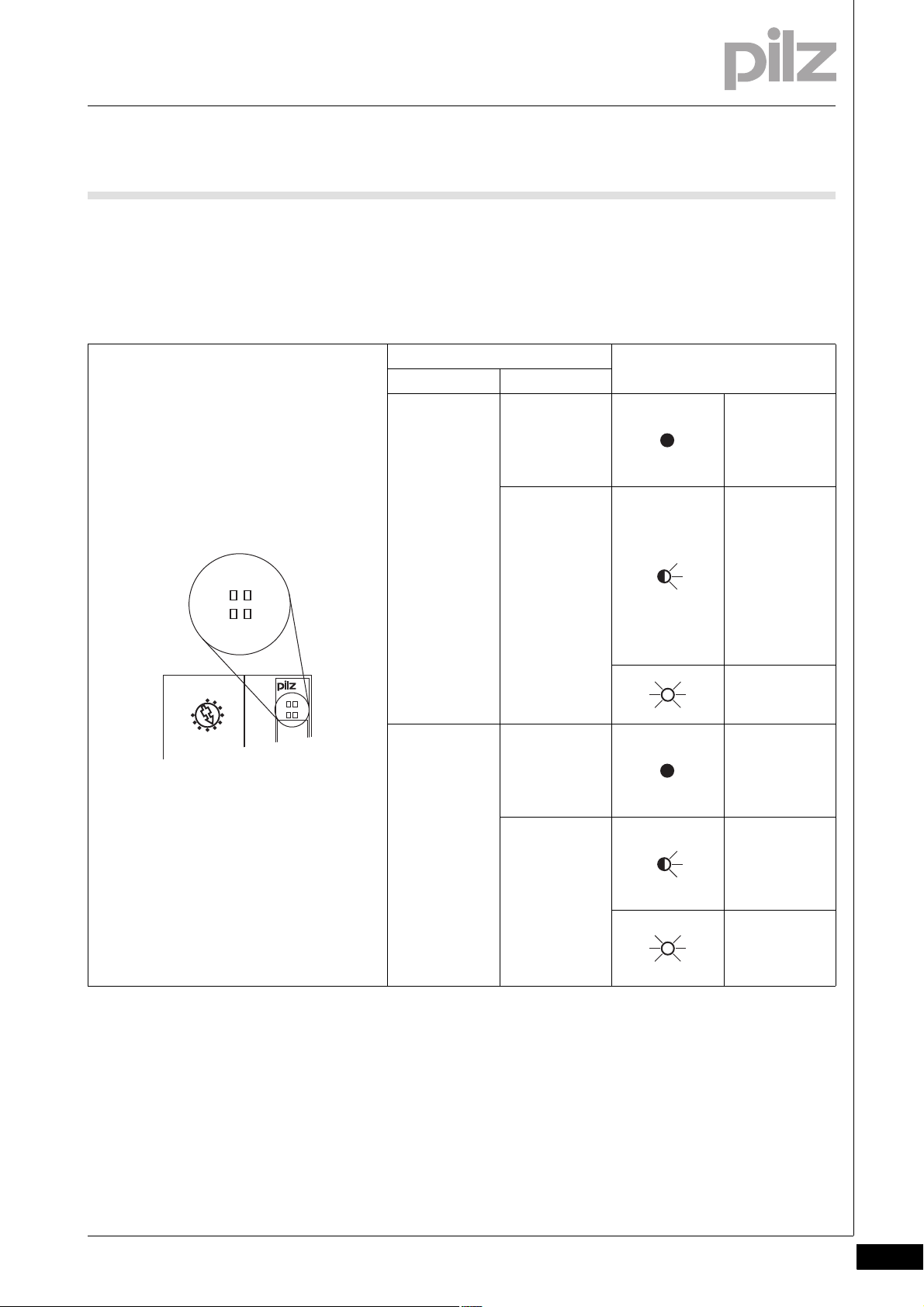

7.2 Display elements

7.2.2 Display elements for SafetyBUS p diagnostics

Display elements for SafetyBUS p diagnostics7-][BA_ Anzeige SB p

The module has LEDs to display various SafetyBUS p states (“SB” LED

and “I/O” LED).

LED Key

Designation Colour

SB - - - No contact with

Green There is contact

I/O - - - All the SBp-De-

Green One of the SBp-

SafetyBUS p

(MD is not running or SBp wiring is faulty)

with

SafetyBUS p,

but the MD

does not recognise the SBpDevice. (faulty

device address

or SBp configuration)

Connection to

MD is running

correctly.

vice's I/OGroups are in a

STOP condition.

Device's I/OGroups is in a

STOP condition.

All the SBp-Device's I/OGroups are in a

RUN condition

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

7-5

Page 30

7 Operation

1

2

3

4

7.2 Display elements

7.2.3 Display elements for CANopen diagnostics

Display elements for CANopen diagnostics7-][BA_Anzeige CAN

The module has LEDs to display various CANopen states (“Run” LED

and “Err” LED).

Key:

LED off Permanently off

LED flashes once 50 ms on, 50 ms off

LED flashes once 200 ms on, 1000 ms off

LED flashes twice On twice for 200 ms, off for 200 ms in between, then off for 1000 ms

LED flashes three times On three times for 200 ms, off for 200 ms in between, then off for 1000 ms

LED flashes four times On four times for 200 ms, off for 200 ms in between, then off for 1000 ms

LED flashes 200 ms on, 200 ms off

LED on Permanently on

7-6

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 31

7 Operation

Run

Err

SB ADDRESS

0

3

6

9

x 10

0

3

6

9

x 1

PSSu H

xx CAN x

Usb Dev

SB I/O

USB

2

D -

3

D +

5

G N D

USB

Run

Err

31...

0000000

HW 000

000 000

CANopen

ADDRESS

OFF

ON

S1

64

32

16

8

4

2

1

S2

S2

BAUD

AUTO

OFF

500K

OFF

250K

OFF

ON

S1 OFF ONONON

BAUD

125K

1

7.2 Display elements

“RUN” LED

LED Key

Designation Colour

Run - - - No data transfer

green Automatic bit rate

detection is running

(together with “Err”

LED).

green Module in “Pre-Op-

erational” status

green Module in

“STOPPED” status

green Module in “Opera-

tional” status

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

7-7

Page 32

7 Operation

Run

Err

SB ADDRESS

0

3

6

9

x 10

0

3

6

9

x 1

PSSu H

xx CAN x

Usb Dev

SB I/O

USB

2

D -

3

D +

5

G N D

USB

Run

Err

31...

0000000

HW 000

000 000

CANopen

ADDRESS

OFF

ON

S1

64

32

16

8

4

2

1

S2

S2

BAUD

AUTO

OFF

500K

OFF

250K

OFF

ON

S1 OFF ONONON

BAUD

125K

1

2

3

4

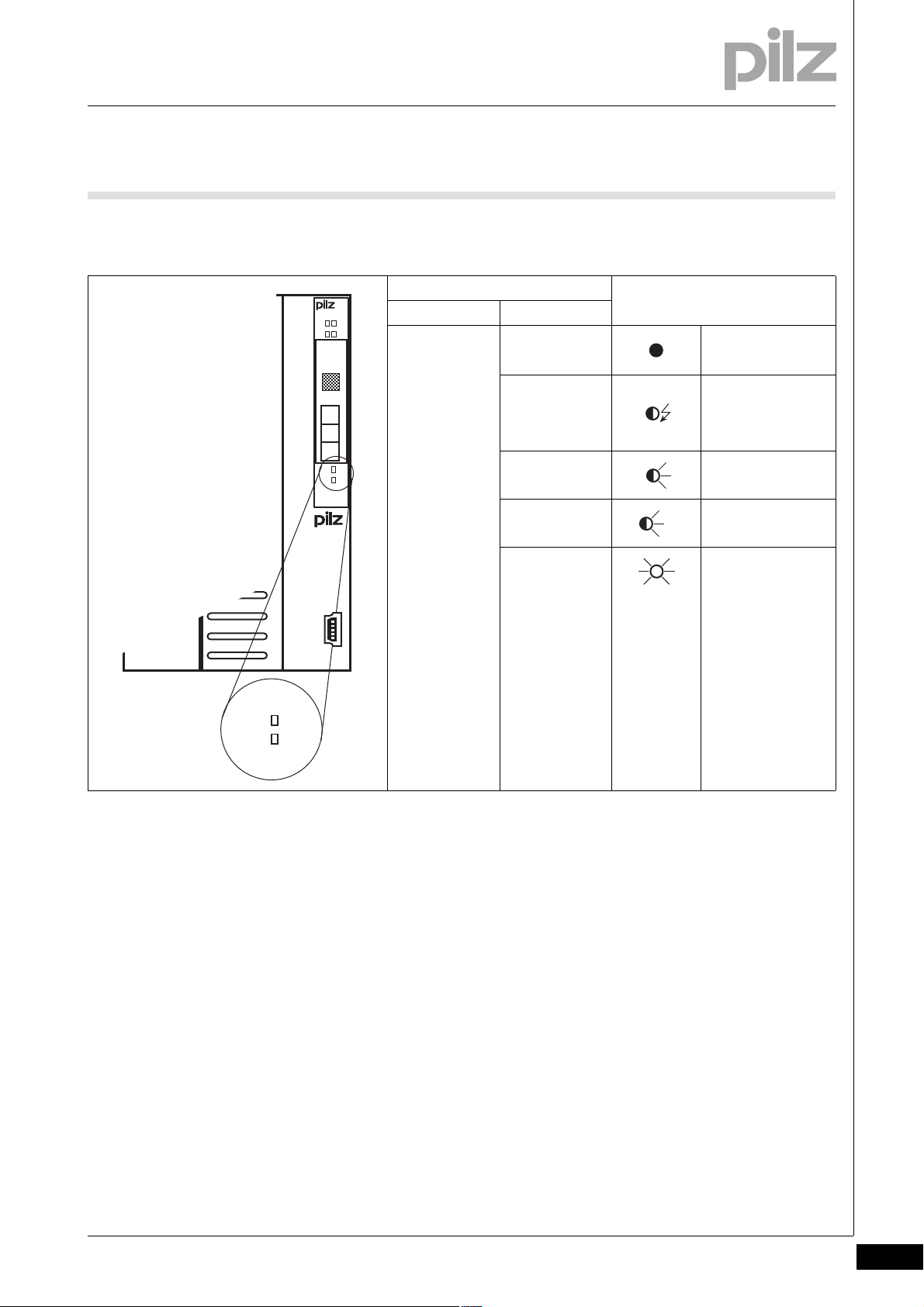

7.2 Display elements

“Err” LED

LED Key

Designation Colour

Err - - - No fault

red Automatic bit rate

detection is running

(together with

“Run” LED).

red Invalid configura-

tion

red Error threshold val-

ue has been

reached, the CAN

controller has received too many error telegrams.

red Monitoring error,

addressing MasterSlave monitoring

error, e.g. heartbeat

monitoring

red Error in “Synchroni-

sation” status, synchronisation

telegram not within

the configured time.

red Error in event timer

7-8

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

red CANopen isn't run-

ning

Page 33

7 Operation

7.3 CANopen object description

7.3CANopen object description7300CANopen ob ject description7-

7.3.1 Communication profile

Communication profile7-][BA_Betrieb CANopen Kommunikation

In accordance with CiA 301 Application Layer and Communication Profile Version 4.1

Object Index Description

Device Type 1000 Device Classification

Error Register 1001 1-Byte error register, indicates the presence of a device error and its

type.

Manufacturer Status Register 1002 Error register for displaying the manufacturer-specific error

COB-ID-SYNC 1005 CAN identifier for the SYNC message

Manufacturer Device Name 1008 Manufacturer-specific details

Manufacturer HW Version 1009 Manufacturer-specific details

Manufacturer SW Version 100A Manufacturer-specific details

Guard Time 100C Time interval for the node guarding protocol

Life Time Factor 100D Timeout for the node guarding protocol

COB-ID EMCY 1014 CAN identifier for the EMCY message

Consumer Heartbeat Time 1016 Time interval for the heartbeat protocol

Producer Heartbeat Time 1017 Timeout for the heartbeat protocol

Identity Objekt 1018 Contains general information about the device (e.g. CANopen Ven-

dor ID).

Module List 1027 List of the module identifiers in slot sequence

(actual configuration)

Error Behaviour 1029 Specifies the status in which a device should be set if a device error

or communication error occurs.

Server SDO Parameter 1200–127F Parameter für Server-SDO

Rx PDO Parameter 1400–15FF Communication parameter for Receive-PDO

Rx PDO Mapping 1600–17FF Mapping parameter for Receive-PDO

Tx PDO Parameter 1800–19FF Communication parameter for Send-PDO

Tx PDO Mapping 1A00–1BFF Mapping parameter for Send-PDO

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

7-9

Page 34

7 Operation

7.3 CANopen object description

7.3.2 Device profile

Device profile7-][BA_Betrieb CANopen Gerte

In accordance with CiA 401 Device Profile for Generic I/O Modules Version 3.0

Object Index Description

8-Bit Digital Input 6000 Digital input data: Grouping 8 input channels into one byte

Global Interrupt Enable 6005 Global interrupt enable, without having to adapt the interrupt masks

Interrupt Mask Any Change 8-Bit 6006 Specifies which I/O channels trigger an interrupt at any signal change.

Interrupt Mask Low-to-High 8-Bit 6007 Specifies which I/O channels trigger an interrupt when the signal

changes from low to high.

Interrupt Mask High-to-Low 8-Bit 6008 Specifies which I/O channels trigger an interrupt when the signal

changes from high to low.

8-Bit Digital Output 6200 Digital output data: Grouping 8 output channels into one byte

Error Mode Output 8-Bit 6206 Defines whether an output is to assume a predefined error value in the

case of an error or "Stop Remote Node".

Error Value Output 8-Bit 6207 If the corresponding error mode is activated, the outputs are set to the

preset values in the case of an error.

Analogue Input 16-Bit 6401 Object for up to 16 Bit wide analogue input values

Analogue Input Interrupt Trigger Se-

lection

Analogue Input Interrupt Source 6422 Determines which channels have triggered an interrupt.

Analogue Input Global Interrupt Ena-

ble

Analogue Input Interrupt Upper Limit

Integer

Analogue Input Interrupt Lower Limit

Integer

Analogue Input Interrupt Delta Un-

signed

Analog Input Interrupt Negative Delta

Unsigned

Analog Input Interrupt Positive Delta

Unsigned

Analogue Output 16-Bit 6411 Object for up to 16 Bit wide analogue output values

Analogue Output Error Mode 6443 Object defines whether an output is to assume a predefined error val-

Analogue Output Error Value Integer 6444 If the corresponding error mode is activated, the outputs are set to the

6421 Determines the events/triggers that initiate an interrupt for a specific

channel.

6423 Global interrupt enable, without having to adapt the interrupt masks

6424 If activated, an interrupt is triggered if the input value is equal to or

greater than the specified value.

6425 If activated, an interrupt is triggered if the input value is lower than the

specified value.

6426 Indicates the relative difference to the last reference value, where an

interrupt is triggered if the value exceeds or drops below that refer-

ence value.

6427 Indicates the relative difference to the last reference value, where an

interrupt is triggered if the value drops below that reference value.

6428 Indicates the relative difference to the last reference value, where an

interrupt is triggered if that reference value is exceeded.

ue in the case of an error or "Stop Remote Node".

preset values in the integer format.

7-10

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 35

7 Operation

7.3 CANopen object description

7.3.3 Manufacturer-specific objects

Manufacturer-specific objects7-][BA_Betrieb CANopen Herstellerspez.

Manufacturer-specific

Object Index

(hex)

2000 1–64 Digital FS input byte 1–64 Input byte for FS module on slot 0–63

2200 1–64 Digital FS output byte 1–64 Output byte for FS module on slot 0–63

2300 1–32 Analogue ST inputs status channel 1–32 Status byte for ST analog input channel 1–32

2500 (1) 1–12 Absolute encoder ST input status 1–12 Status byte for absolute encoder 1–12

2501 (

2510 (1) 1–7 Incremental encoder ST input status 1-7 Status byte for incremental encoder input 1–7

2511 (

2512 (1) 1–7 Incremental encoder ST output function 1-7 Byte for function calls from the incremental en-

2513 (1) 1–7 Incremental encoder ST output value 1-7 4 Bytes of counter data each for incremental

2F01 1–64 PII (complete) Byte 1–64 Byte 1–64 of the process image of all inputs

2F11 1–64 PIO (complete) Byte 1–64 Byte 1–64 of the process image of all outputs

3001 (

3100 Output format 1. Head parameter (Intel/Motorola)

3101 Output sequence 2. Head parameter (slot-oriented)

3200 1–64 Open circuit diagn. Byte 1–64 Open circuit diagnostics for slot 0–63

3300 (

3301 1–32 Channel operating mode analogue input

3302 1–32 Channel operating mode analogue output

3303 (1) 1–12 Channel operating mode absolute encoder

3304 (1) 1–7 Channel operating mode incremental en-

3320 1–32 ADC-HW Preset Word 1–32 ADC hardware preset for analogue input chan-

3321 1–32 Manufacturer switch-on value word 1–32 Manufacturer switch-on value for analogue out-

3322 1 User switch-on value word 1–32 User switch-on value for analogue output chan-

3330 1–32 Underrange-Limit Word 1–32 Underrange limit for analogue input channel

3331 1–32 Overrange-Limit Word 1–32 Overrange limit for analogue input channel

Object

Subindex

(decimal)

1

) 1–12 Absolute encoder ST input value 1–12 4 Bytes of counter data each for absolute en-

1

) 1–7 Incremental encoder ST input value 1 8 Bytes of counter data each for incremental

2

) 1–64 Set configuration word 1–64 Registered hardware for slot 0–63

3

) 1–64 Module operating mode Byte 1–64 Module operating mode for slot 0–63

Contents Description

coders 1–12

encoder input 1–7

coder output 1–7

encoder output 1–7

Channel operating mode for analogue input

word 1–32

word 1–32

word 1–12

coder word 1-7

channel 1–32

Channel operating mode for analogue output

channel 1–32

Channel operating mode for absolute encoder

1–12

Channel operating mode for incremental en-

coder 1-7

nel 1–32

put channel 1–32

nel 1–32

1–32

1–32

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

7-11

Page 36

7 Operation

7.3 CANopen object description

Manufacturer-specific (continued)

Object Index

(hex)

3332 1–32 Limit value1 Word 1–32 Lower limit value for analogue input channel 1–

3333 1–32 Limit value2 Word 1–32 Upper limit value for analogue input channel 1–

3340 1–32 Manufacturer Scaling Offset Analogue Input

3341 1–32 Manufacturer Scaling Offset Analogue Out-

3345 1–32 Manufacturer Scaling Gain Analogue Input

3346 1–32 Manufacturer Scaling Gain Analogue Output

3350 1–32 User Scaling Offset Analogue Input Word 1–32User scaling offset for analogue input channel

3351 1–32 User Scaling Offset Analogue Output Word

3355 1–32 User Scaling Gain Analogue Input Word 1–32User scaling gain for analogue input channel 1–

3356 1–32 User Scaling Gain Analogue Output Word 1–32User scaling gain for 1–32 analogue output

4000 Fieldbus diagnostics 5 Byte fieldbus diagnostic data

Object

Subindex

(decimal)

Contents Description

32

32

Manufacturer scaling offset for analogue input

Word 1–32

put Word 1–32

Word 1–32

Word 1–32

1–32

channel 1–32

Manufacturer scaling offset for analogue output

channel 1–32

Manufacturer scaling gain for analogue input

channel 1–32

Manufacturer scaling gain for analogue output

channel 1–32

1–32

User scaling offset for analogue output channel

1–32

32

channel 1–32

(1) in development

2

(

) You can find the configuration of the electronic modules in the EDS

file for the PSSuniversal CANopen interface under [3001sub0].

3

(

) You can find the operating modes of the analogue electronic modules

in the EDS file for the PSSuniversal CANopen interface under [3300].

7-12

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 37

7 Operation

7.3 CANopen object description

7.3.4 Object overview

Object overview7-][BA_Betrieb CANopen Objekt bersicht

Inputs/outputs

Object Index Object Subind-exContents Description

6000 1–64 Digital ST inputs 64 x PII Byte (digital) for ST modules

6200 1–64 Digital ST outputs 64 x PIO Byte (digital) for ST modules

2300 1–32 Analogue ST inputs (status) Analogue PII for 32 ST word channels

6401 1–32 Analogue ST inputs (value) Status bytes for 32 ST/FS word channels

6411 1–32 Analogue ST outputs Analogue PIO for 32 ST word channels

2000 1–64 Digital FS inputs 64 x PII Byte (digital) for FS modules

2200 1–64 Digital FS outputs 64 x PIO Byte (digital) for FS modules

2500 1–12 (

2501 1–12 (1) ST absolute encoder (value) 12 x 4 Bytes counter data

2510 1–7 (

2511 1–7 (1) ST incr. encoder input (value) 7 x 8 Bytes counter data

2512 1–7 (1) ST incr. encoder output (function) 7 x 1 Byte for function calls

2513 1–7 (

1

) ST absolute encoder (status) 12 x 1 status byte

1

) ST incr. encoder input (status) 7 x 1 Status Byte

1

) ST incr. encoder output (value) 7 x 4 Bytes counter data

Complete process images

Object Index Object Subind-exContents Description

2F01 1–64 PII (complete) 64 x PII Byte

2F11 1–64 PIO (complete) 64 x PIO Byte

Configurations

Object Index Object Subind-exContents Description

1027 1–64 Actual configuration 64 x Word actual hardware registry

3001 1–64 Set configuration 64 x Word set hardware registry

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

7-13

Page 38

7 Operation

7.3 CANopen object description

Parameters

Object Index Object Subind-exContents Description

3100 Output format

3101 Output sequence

3200 1–64 Open circuit diagnostics Open circuit diagnostics for max. 64 slots

3300 1–64 Module operating mode Module operating mode for max. 64 slots

3301 1–32 Channel operating mode AI Parameter for max 32 i/p analogue channels

3302 1–32 Channel operating mode AO Parameter for max 32 o/p analogue channels

3303 1–12 (

3304 1–7 (1) Channel operating mode INC Parameter for max 7 INC modules

3320 1–32 ADC Hardware Preset Parameter for max 32 i/p analogue channels

3321 1–32 Manufacturer switch-on value Parameter for max 32 o/p analogue channels

3322 1–32 User switch-on value Parameter for max 32 o/p analogue channels

3330 1–32 Underrange Limit Parameter for max 32 i/p analogue channels

3331 1–32 Overrange Limit Parameter for max 32 i/p analogue channels

3332 1–32 Limit value 1 Parameter for max 32 i/p analogue channels

3333 1–32 Limit value 2 Parameter for max 32 i/p analogue channels

3340 1–32 Manufacturer Scaling Offset AI Parameter for max 32 i/p analogue channels

3341 1–32 Manufacturer Scaling Offset AO Parameter for max 32 o/p analogue channels

3345 1–32 Manufacturer Scaling Gain AI Parameter for max 32 i/p analogue channels

3346 1–32 Manufacturer Scaling Gain AO Parameter for max 32 o/p analogue channels

3350 1–32 User Scaling Offset AI Parameter for max 32 i/p analogue channels

3351 1–32 User Scaling Offset AO Parameter for max 32 o/p analogue channels

3355 1–32 User Scaling Gain AI Parameter for max 32 i/p analogue channels

3356 1–32 User Scaling Gain AO Parameter for max 32 o/p analogue channels

1

) Channel operating mode ABS Parameter for max 12 ABS modules

7-14

Status information

Object Index Object Subind-exContents Description

1002 Device status Status byte

4000 1–5 Fieldbus diagnostics 5 Byte diagnostic data

(1) in development

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 39

8 Technical details

8.1 Technical details

88000Technical detailsTechnical details8-8.1Technical details8100Technical details8-][Technische Daten PSSu Kopf SBUS+ST-BUS mZust

Technical details

Application range Standard/Failsafe

Maximum achievable category in accordance with

EN 954-1

Maximum achievable SIL value SIL3

Module's device code 0224h

Electrical data

Internal supply voltage

Supply voltage range of module supply 4.9 - 5.1 V

Current and power consumption from module supply

Module's current consumption without FO connection 320 mA

FO connection's current consumption 120 mA

Module's power consumption without FO connection 1.60 W

FO connection's power consumption 0.60 W

Max. power dissipation of the module 1.60 W

Potential isolation between module supply and CANopen 700 V

Potential isolation between module supply and

SafetyBUS p

SafetyBUS p

Application range Failsafe applications

Device address 32d ... 95d

Max. transmission rate 500 kBit/s

Cable runs 3,500 m

Transmission type differential two-wire cable

Connection Male 9-pin D-SUB connector

CANopen

Application range Standard applications

Device type Slave

Station address 1 .. 127d

Set via DIP switch

Maximum data length of the fieldbus interface: Input 64 Byte

Maximum data length of the fieldbus interface: Output 64 Byte

Maximum data length of the fieldbus interface: Diagnostics 5 Byte

Transmission rates 1 MBit/s, 10 kbit/s, 100 kBit/s, 125 kBit/s, 20 kbit/s,

Set via automatic/DIP switch

Connection Male 9-pin D-SUB connector

Protocol CANopen Standard 4,0

Operating modes Slave Mode

Certification CiA

Description file PSSuCO.eds

Manufacturer's ID 0189h

USB

Connection Mini-B connector

4

700 V

Failsafe applications with local enable principle

250 kBit/s, 50 kbit/s, 500 kBit/s, 800 kbit/s

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

8-1

Page 40

8 Technical details

8.1 Technical details

Environmental data

Climatic suitability EN 60068-2-14, EN 60068-2-1, EN 60068-2-2,

EN 60068-2-30, EN 60068-2-78

Ambient temperature 0 - 60 °C

-40 - 70 °C coated version (-T)

Storage temperature -25 - 70 °C

-40 - 70 °C coated version (-T)

Climatic suitability in accordance with EN 60068-2-78 93 % r. h. at 40 °C

Condensation no

yes coated version (-T)

Max. operating height above sea level 5000 m coated version (-T)

EMC EN 61000-4-2, EN 61000-4-3, EN 61000-4-4,

EN 61000-4-5, EN 61000-4-6, EN 61000-6-2,

EN 61000-6-4

Vibration to EN 60068-2-6

Frequency 10 - 150 Hz

Max. acceleration 1g

Shock stress

EN 60068-2-27 15g

11 ms

EN 60068-2-29 10g

16 ms

Protection type

Mounting (e.g. cabinet) IP54

Housing IP20

Airgap creepage in accordance with EN 60664-1

Overvoltage category II

Pollution degree 2

Mechanical data

Housing material

Front PC

Bottom PC

Dimensions

Height 128.4 mm

Width 75.2 mm

Depth 79.4 mm

Weight 170 g

8-2

SI-Kennzahlen_PSSu_Kop f

Safety characteristic data

Unit Operating mode

EN ISO 13849-1PLEN 954-1

Category

EN IEC 62061

SIL CL PFH [1/h] tM [year]

Logic --- PL e (Cat. 4) Cat. 4 SIL CL 3 2.88E-09 20

Si_Kennzahlen_Erläuterung

All the units used within a safety function must be considered when cal-

Technische Daten_Satz No rmen

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

culating the safety characteristic data.

Page 41

8 Technical details

8.2 Order reference

8.2Order reference8200Order reference8-Bestelldaten

Order reference

Description Order no.

PSSu H SB CAN

(Head module with SafetyBUS p interface and CANopen

interface)

PSSu H SB CAN-T

(Head module with SafetyBUS p interface and CANopen

interface, coated version)

312 035

314 035

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

8-3

Page 42

8 Technical details

8-4

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 43

...

21459-EN-02, 2011-06 Printed in Germany

© Pilz GmbH & Co. KG, 2011

+49 711 3409-444

support@pilz.com

Pilz GmbH & Co. KG

Felix-Wankel-Straße 2

73760 Ostfildern, Germany

Telephone: +49 711 3409-0

Telefax: +49 711 3409-133

E-Mail: pilz.gmbh@pilz.de

Internet: www.pilz.com

Technical support

In many countries we are

represented by our subsidiaries

and sales partners.

Please refer to our homepage

for further details or contact our

headquarters.

InduraNET p

®

, Pilz

®

, PIT

®

, PMCprotego

®

, PMI

®

, PNOZ

®

, Primo

®

, PSEN

®

, PSS

®

, PVIS

®

, SafetyBUS p

®

, SafetyEYE

®

, SafetyNET p

®

, the spirit of safety

®

are registered and protected trademarks

of Pilz GmbH & Co. KG in some countries. We would point out that product features may vary from the details stated in this document, depending on the status at the time of publication and the scope

of the equipment. We accept no responsibility for the validity, accuracy and entirety of the text and graphics presented in this information. Please contact our Technical Support if you have any questions.

Contact address

Loading...

Loading...