Page 1

PSEN opII3F Series

Operating Manual 1003504-EN-01

} PSEN sensor technology

Page 2

Preface

This document is a translation of the original document.

All rights to this documentation are reserved by Pilz GmbH & Co. KG. Copies may be made

for internal purposes. Suggestions and comments for improving this documentation will be

gratefully received.

Source code from third-party manufacturers or open source software has been used for

some components. The relevant licence information is available on the Internet on the Pilz

homepage.

Pilz®, PIT®, PMI®, PNOZ®, Primo®, PSEN®, PSS®, PVIS®, SafetyBUS p®,

SafetyEYE®, SafetyNET p®, the spirit of safety® are registered and protected trademarks

of Pilz GmbH & Co. KG in some countries.

SD means Secure Digital

Page 3

Contents

Operating Manual PSEN opII3F Series

1003504-EN-01

3

Introduction 5

Validity of documentation 5

Using the documentation 5

Definition of symbols 5

Overview 6

Unit view 8

Scope 10

Safety 11

Intended use 11

Safety regulations 12

Safety assessment 12

Use of qualified personnel 12

Warranty and liability 12

Disposal 12

Function description 13

Basic function 13

Automatic start and restart 13

Project configuration 15

Maintaining the safety distance 15

Resolution 16

Protected field perimeters 16

Ambient conditions 16

Distance from reflective surfaces 17

Minimum distance between parallel, aligned safety light grids 20

Installation of several adjacent safety light grids 21

Use of deviating mirrors 21

Dead zones 22

Installation and orientation 24

Attach the safety light grid to the installation surface 25

Orientation 28

General guidelines 28

Safety light grid alignment 29

Wiring 30

General guidelines 30

Connector pin assignment 31

Earthing the safety light grid 31

Commissioning 32

System connection 32

Checking the safety light grid 33

Page 4

Contents

Operating Manual PSEN opII3F Series

1003504-EN-01

4

Operation 35

Display elements 35

Status information 36

Safety light grid restart 38

Malfunction 38

Regular checks and maintenance 38

Checks 38

Regular check 38

Check after plant/machine modification 39

Maintenance 39

Dimensions 40

Technical details Order no. 632040-632042 42

Technical details Order no. 632043-632045 44

Technical details Order no. 632046-632048 47

Technical details Order no. 632049-632051 49

Safety characteristic data 52

Order reference 52

Order reference for safety light grids 52

Order reference for accessories 53

Order reference: Component parts 55

Appendix 56

Check list 56

EC declaration of conformity 58

Page 5

PSEN opII3F Series

Operating Manual PSEN opII3F Series

1003504-EN-01

5

Introduction

Validity of documentation

This documentation is valid for the product PSEN opII3F Series. It is valid until new documentation is published.

This operating manual explains the function and operation, describes the installation and

provides guidelines on how to connect the product.

Using the documentation

This document is intended for instruction. Only install and commission the product if you

have read and understood this document. The document should be retained for future reference.

Definition of symbols

Information that is particularly important is identified as follows:

DANGER!

This warning must be heeded! It warns of a hazardous situation that poses

an immediate threat of serious injury and death and indicates preventive

measures that can be taken.

WARNING!

This warning must be heeded! It warns of a hazardous situation that could

lead to serious injury and death and indicates preventive measures that can

be taken.

CAUTION!

This refers to a hazard that can lead to a less serious or minor injury plus

material damage, and also provides information on preventive measures

that can be taken.

NOTICE

This describes a situation in which the product or devices could be damaged and also provides information on preventive measures that can be

taken. It also highlights areas within the text that are of particular importance.

Page 6

PSEN opII3F Series

Operating Manual PSEN opII3F Series

1003504-EN-01

6

INFORMATION

This gives advice on applications and provides information on special features.

Overview

Safety light grids in the PSEN opII3F Series constitute electrosensitive protective equipment (ESPE type: 3) in accordance with DIN EN 61496-1 for work areas in which machines, robots, and automated systems could endanger the physical integrity of operators.

Unit features

} Resolution: 14 mm

} Infrared protected field is generated

} LED indicator for status information

} Optical synchronisation of transmitters and receivers

} Connection to evaluation devices

– PDP67 ION and PDP67 ION HP: 5-pin M12 two-sided connector (see Order refer-

ence for accessories, connection to PDP67 [ 54])

– all other suitable evaluation devices (see System connection [ 32]): 5-pin M12

one-sided connector and open cable end connection to clamping sleeves (see Or-

der reference for accessories, connection to other evaluation devices [ 54])

} Aluminium alloy housing

} Die-cast zinc end caps

} Shock resistance

– Bracket Swivel-Mount : 10g

– Bracket Adv Bracket Kit : 50g

} Front panel of PC

} Standard installation kit with flexible bracket (swivel mount) (included in delivery) to hold

the transmitter/receiver

– For standard application

– Transmitter/receiver remains rotatable for proper orientation

} Dead-zone-free safety light grid installation [ 22] with the

PSENopIIAdvBracketKit (available as an accessory [ 53]) as a bracket for a

transmitter/receiver

– Dead-zone-free on both sides for protected field height of 300 mm or more

– Dead-zone-free on one side for protected field height of 150 mm

– Transmitter/receiver remains rotatable for proper orientation

– Protected field heights of 150-600 mm, including: 1PSENopIIAdvBracketKit-2

(=2clamping units per transmitter and receiver)

Page 7

PSEN opII3F Series

Operating Manual PSEN opII3F Series

1003504-EN-01

7

– Protected field heights of 750-1200 mm, including: 1PSENopIIAdvBracketKit-3

(=3clamping units per transmitter and receiver)

– Protected field heights of 1350-1800 mm, including: 2PSENopIIAdvBracketKit-2

(=4clamping units per transmitter and receiver)

Page 8

PSEN opII3F Series

Operating Manual PSEN opII3F Series

1003504-EN-01

8

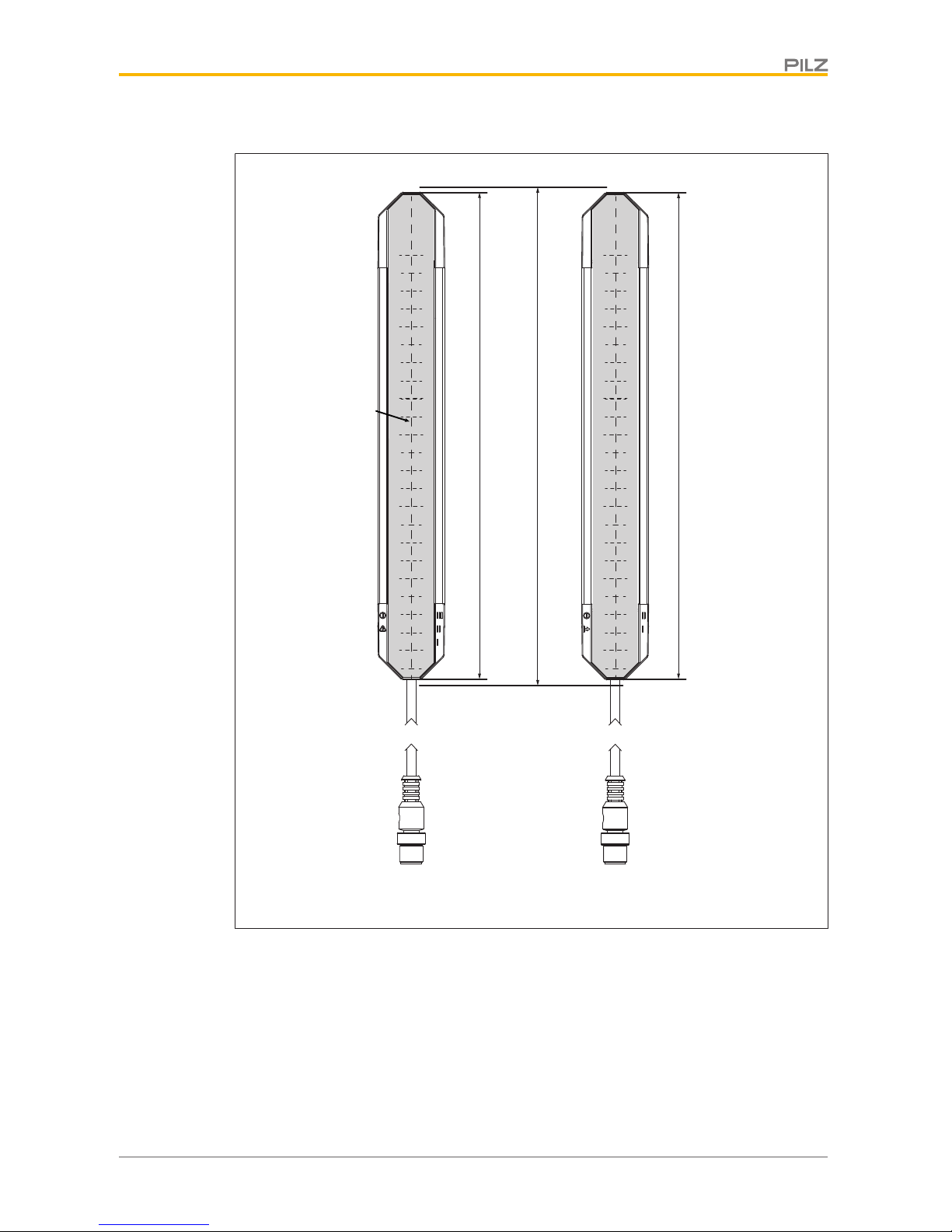

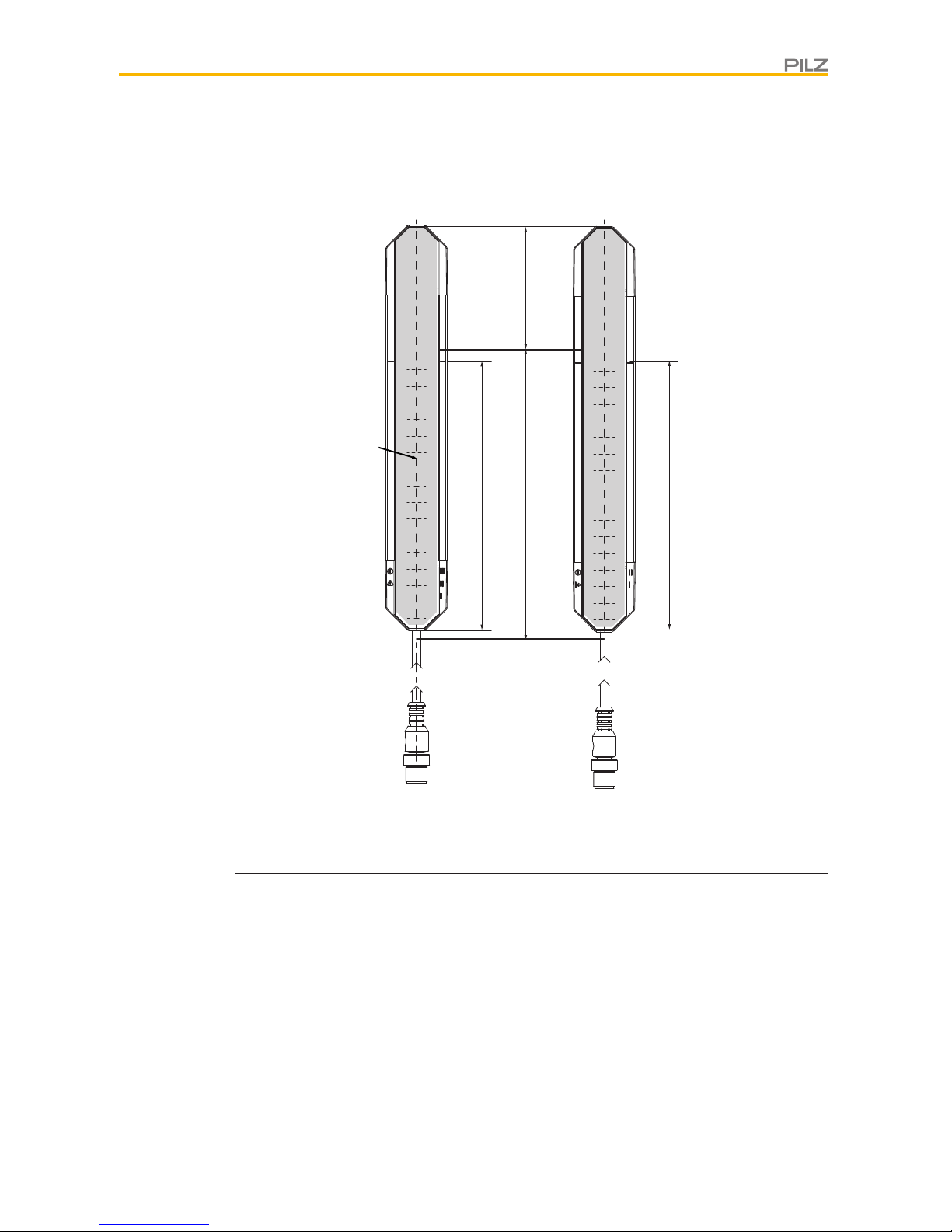

Unit view

[5]

[3]

[1]

[4] [4] [4] [4]

[5]

[3]

[6]

[2]

[1]

Receiver Transmitter

Fig.: Front view of the safety light grid transmitter and receiver, protected field height 300-1800 mm

with connection cable

Legende

[1] Protected field height

[2] Effective protected field height

[3] Tinted front panel

[4] LEDs for status information

Page 9

PSEN opII3F Series

Operating Manual PSEN opII3F Series

1003504-EN-01

9

[5] Connection cable, M12 connector

[6] Optical centre axis

[5]

[3]

[1]

[4] [4] [4] [4]

[5]

[3]

[7]

[6]

[2]

[1]

Receiver Transmitter

Fig.: Front view of the safety light grid transmitter and receiver, protected field height 150 mm with

connection cable

Legende

[1] Protected field height

[2] Effective protected field height

[3] Tinted front panel

[4] LEDs for status information

[5] Connection cable, M12 connector

[6] Optical centre axis

Page 10

PSEN opII3F Series

Operating Manual PSEN opII3F Series

1003504-EN-01

10

[7] Dead zone

The beginning of the dead zone is indicated by black lines on both sides of the

front panel

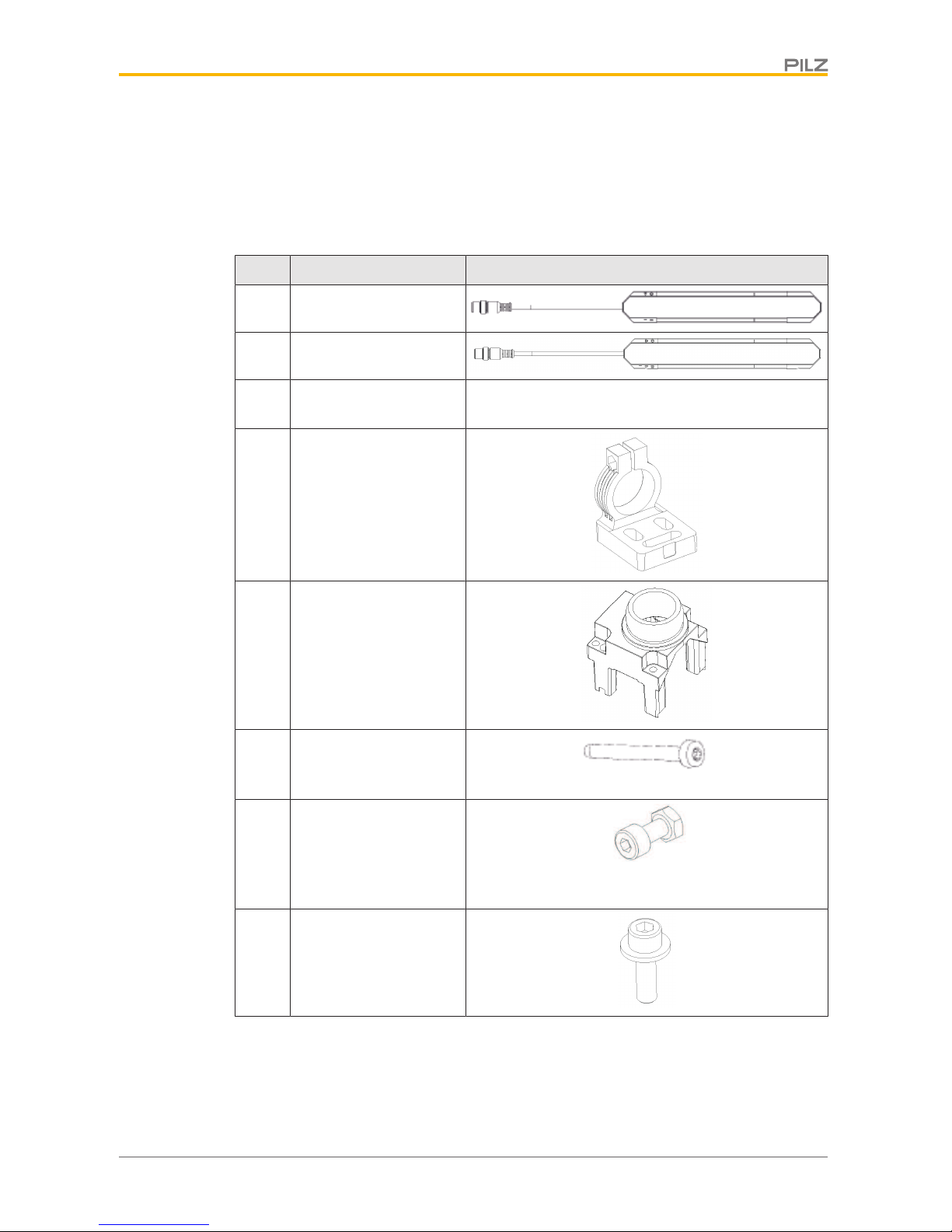

Scope

Qty Description Diagram

1 Transmitter

1 Receiver

4 Standard installation kit

consisting of:

4

} Flexible bracket

(swivel mount) in

which transmitters/receivers can be

fastened and rotated

to the proper orientation

4

} Holder for connecting

the transmitter/receiver end caps to

the flexible bracket

16

} Tightening screw

M3x33.4 oval-head

screw, self-tapping

4

} Clamping screw with

nut

ISO4762 M4x10 8.8

cylinder screw with

nut

8

} Mounting screw

ISO4762 M6x20 8.8

cylinder screw with

washer

Page 11

PSEN opII3F Series

Operating Manual PSEN opII3F Series

1003504-EN-01

11

Safety

Intended use

Safety light grids of the PSEN opII3F Series are electrosensitive protective equipment of

the 3. They are used to protect personnel and systems. The safety light grids are designed

for

} securing hazardous areas within buildings and

} securing access within buildings with a resolution of 14 mm.

The safety light grid may only be used for personal protection on machinery if

} the hazardous state can be removed by the safety light grid and

} the starting of the machine is controlled by the safety light grid and

} the safety assessment prescribes no better resolution than 14 mm.

The safety level PL d (Cat. 3 )/SIL CL 2 is only achieved if

} the safety outputs use 2-channel processing.

The safety light grid is not equipped with a restart interlock.

If the safety assessment necessitates a restart interlock, this feature must be ensured

within the plant’s programmable safety system. The system may not be started in the hazardous area following a protection violation if personnel are still in the hazardous area.

Prevent circumvention of the protected field. This means that other safety devices and safeguards may be required in addition to the safety light grid. These should be determined via

a safety assessment based on the specific application area and specific local conditions

(e.g. official specifications).

Refer to IEC/TS 62046 to determine other necessary safeguards for securing the hazardous area.

Their application must fulfil the site’s relevant national regulations (e.g.EN60204-1,

NFPA79:17-7).

The following is deemed improper use in particular:

} Any component, technical or electrical modification to the product

} Use of the product outside the areas described in this manual

} Use of the product outside the technical details (see Technical details [ 42]).

NOTICE

EMC-compliant electrical installation

The product is designed for use in an industrial environment. The product

may cause interference if installed in other environments. If installed in other

environments, measures should be taken to comply with the applicable

standards and directives for the respective installation site with regard to interference.

Page 12

PSEN opII3F Series

Operating Manual PSEN opII3F Series

1003504-EN-01

12

Safety regulations

Safety assessment

Before using a unit it is necessary to perform a safety assessment in accordance with the

Machinery Directive.

Functional safety is guaranteed for the product as a single component. However, this does

not guarantee the functional safety of the overall plant/machine. In order to achieve the required safety level for the overall plant/machine, define the safety requirements for the

plant/machine and then define how these must be implemented from a technical and organisational standpoint.

Use of qualified personnel

The products may only be assembled, installed, programmed, commissioned, operated,

maintained and decommissioned by competent persons.

A competent person is someone who, because of their training, experience and current professional activity, has the specialist knowledge required to test, assess and operate the

work equipment, devices, systems, plant and machinery in accordance with the general

standards and guidelines for safety technology.

It is the company’s responsibility only to employ personnel who:

} Are familiar with the basic regulations concerning health and safety / accident preven-

tion

} Have read and understood the information provided in this description under "Safety"

} And have a good knowledge of the generic and specialist standards applicable to the

specific application.

Warranty and liability

All claims to warranty and liability will be rendered invalid if

} The product was used contrary to the purpose for which it is intended

} Damage can be attributed to not having followed the guidelines in the manual

} Operating personnel are not suitably qualified

} Any type of modification has been made (e.g. exchanging components on the PCB

boards, soldering work etc.).

Disposal

} In safety-related applications, please comply with the mission time TM in the safety-re-

lated characteristic data.

} When decommissioning, please comply with local regulations regarding the disposal of

electronic devices (e.g. Electrical and Electronic Equipment Act).

Page 13

PSEN opII3F Series

Operating Manual PSEN opII3F Series

1003504-EN-01

13

Function description

Basic function

The safety light grid consists of a transmitter and a receiver.

Their shape and design

} protect the transmitter and receiver from external damage

} protect the safety light grid from malfunctions caused by vibration (see Technical de-

tails, environmental data section [ 42]).

The protected area is covered by infrared light beams, which are emitted from the transmitter to the receiver. The protected field thus produced is able to detect an opaque object.

The control and monitoring of the transmitted and received infrared rays is performed by

microprocessors.

The output signal switching devices (OSSDs) switch to the OFF state when one of the following conditions is met:

} one or more light beams are interrupted by an object, a body part, or an opaque object

that is at least as large as the resolution (14 mm) covered by the safety light grid,

} an error is detected by one of the OSSDs,

} or interfering light is detected.

If an error occurs, the OSSDs remain in the OFF state. The state can be returned to the ON

state only after a successful restart [ 38] of the safety light grid.

The safety light grid of the PSEN opII3F Series offers the following functions:

} automatic start

} automatic restart

} Operation of 2 safety light grids that are parallel to one another and are installed with

the same orientation (noting the information in ambient conditions [ 20] and min-

imum separation of parallel, aligned safety light grids [ 20])

Transmitters and receivers are each electrically connected with a cable with an M12 connector that is assigned to the transmitter and receiver on the LED side.

The transmitter and receiver are optically synchronised and therefore need not be directly

connected to each other.

Information about the operating status of the safety light grid and any error state is provided

by means of LEDs.

The indicators are described in the Status Information [ 35] section.

Automatic start and restart

Automatic start

During safety light grid commissioning, the safety light grid starts automatically, and the

OSSDs switch to the ON state under the following conditions:

} both OSSDs are wired correctly and

} no error has occurred and

} the protected field is clear.

If the protected field is violated, the OSSDs switch to the OFF state.

Page 14

PSEN opII3F Series

Operating Manual PSEN opII3F Series

1003504-EN-01

14

Automatic restart

The OSSDs automatically switch to the ON state during operation under the following conditions:

} both OSSDs are wired correctly and

} no error has occurred and

} the protected field is clear and

} at least 80 ms have elapsed since the switch to the OFF state.

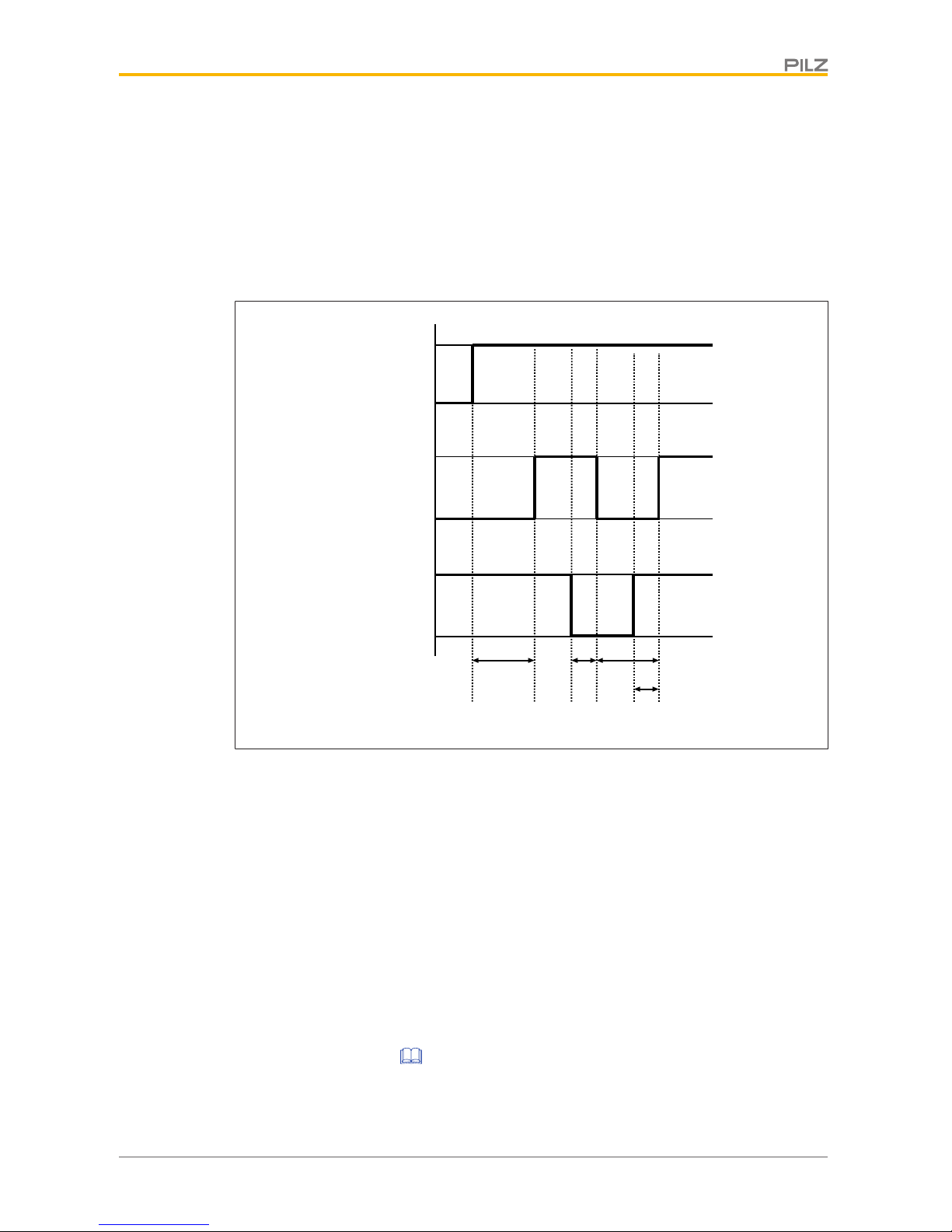

[1] [2] [3] [4] [5]

POWER

OSSD

2 3

4

[6]

t

1

tt

t

Protected

field

Free

Interrupted

ON

OFF

ON

OFF

Fig.: Automatic start and restart timing diagram

Legende

[1] Safety light grid is switched on

[2] Check completed successfully, OSSDs in the ON state

[3] Protected field broken

[4] OSSDs in the OFF state

[5] Protected field is clear again, check for errors is restarted

[6] OSSDs in the ON state

t

1

Check is begun to determine whether the protected field is clear and whether

there are errors

t

2

Response time required for the OSSDs to switch to the OFF state (see Tech-

nical details [ 42])

t

3

Minimum time that the OSSDs remain in the OFF state: 80ms

Page 15

PSEN opII3F Series

Operating Manual PSEN opII3F Series

1003504-EN-01

15

t

4

Interval between enabling of the protected field and the OSSD’s change to the

ON state

} If a synchronisation beam pair is interrupted: Response time+10ms

} If both synchronisation beam pairs (first and last light beam pair) are inter-

rupted: typically600ms (no more than4s)

Project configuration

Maintaining the safety distance

The minimum distance between the safety light grid and the hazardous machine component should be such that the operator cannot reach the hazardous area until the hazardous

machine part has come to a standstill.

In accordance with the standard

} ENISO13855

this distance depends on three factors:

} Response time of the safety light grid

Interval between interruption of the beams and the OSSD’s change to the OFF state

} Machine's stopping time

Interval between the change of the OSSD to the OFF state and the stopping of the hazardous machine movement (including the reaction time of the connected relay)

} Approach speed

The speed with which the object to be detected is nearing the hazardous area in mm/s

The general formula for calculating the minimum distance in accordance with

ENISO13855 is as follows:

S = K * (t1 + t2) + C

S Minimum distance in mm, measured from the start of the protected field to the

danger source

K Approach speed with which the object to be detected is nearing the hazardous area

in mm/s

K = 1600 mm/s when S > 500 mm

K = 2000 mm/s when S ≤ 500 mm

t1Response time of the safety light grid in seconds

Time it takes for the signal at the OSSD output on the safety light grid to change

once a protected field has been violated

t2Machine's stopping time in seconds

The time required for the machine to stop after the signal at the OSSD output

changes

C Additional distance of 0 mm for safety light grids with finger protection

Page 16

PSEN opII3F Series

Operating Manual PSEN opII3F Series

1003504-EN-01

16

Resolution

The safety light grids may only be used for protected fields in which a detection capability of

14 mm is sufficient.

Protected field perimeters

During planning, ensure sufficient protected field height to secure the hazardous area.

The protected field perimeter is defined in dimensions [ 40].

Ambient conditions

} Install the safety light grids in an environment that corresponds to the environmental

data provided in the Technical details [ 42].

} Do not install the safety light grid near particularly intense and/or flashing light sources;

this applies to the receiver in particular.

} The transmitter of one safety light grid must not interfere with the receiver of another

safety light grid.

} The transmitters and receivers of two different safety light grids must not be synchron-

ised.

} Avoid strong electromagnetic interference when operating the safety light grid.

} When operating the safety light grid, avoid the development of smoke, mist, or dust that

would reduce the grid’s operating range.

Page 17

PSEN opII3F Series

Operating Manual PSEN opII3F Series

1003504-EN-01

17

Distance from reflective surfaces

If there are reflective surfaces near the beams emitted from the safety light grid (whether

from above, below, or from the side), passive reflections can cause an object within the protected field to remain undetected (see diagrams).

This means that there must be a certain minimum distance between the safety light grid

and reflective surfaces.

[1]

[2]

[3]

[5]

[6]

[4]

[4] [4]

[4]

[7]

[8]

Fig.: Interference with the function of the safety light grid due to reflective surfaces – top view

Page 18

PSEN opII3F Series

Operating Manual PSEN opII3F Series

1003504-EN-01

18

[1]

[2] [3]

[4]

[4]

[4]

[4]

[5]

[1]

[5]

Legend

[1] Reflective surface

[2] Transmitter

[3] Receiver

[4] Half of the opening angle [ 42] (= ⍺) of the light beams emitted by the safety

light grid

[5] Minimum distance D between the safety light grid and the reflective surface

[6] Passive reflections on the surface

[7] Distance between transmitter and receiver (working distance)

[8] Hazardous area

The minimum distance D depends on two factors:

} Working distance between transmitter and receiver

} the maximum opening angle [ 42] of the light beams emitted by the safety light grid

at:

5° = ± 2.5° in relation to the optical axis

Page 19

PSEN opII3F Series

Operating Manual PSEN opII3F Series

1003504-EN-01

19

Minimum distance of the safety light grid to reflective surfaces

The formula for calculating the minimum distance D is:

} For a working distance of less than 3 m: D = 0.131 m

} For a working distance of 3 m or more: D = working distance in m x tan ⍺

[2]

0,35

0,174

0,131

0 3 4 8 [1]

Fig.: Relationship between minimum distance and working distance

Legende

[1] Working distance in m

[2] Minimum distance D to reflective surfaces in m

Page 20

PSEN opII3F Series

Operating Manual PSEN opII3F Series

1003504-EN-01

20

Minimum distance between parallel, aligned safety light grids

Please note:

Safety light grids that are installed so as to be parallel and aligned must have a minimum

spacing corresponding to the information in distance to reflective surfaces.

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[7]

Legend

[1] Transmitter from the first safety light grid

[2] Receiver from the first safety light grid

[3] Transmitter from the second safety light grid

[4] Receiver from the second safety light grid

[5] Minimum distance of 2 x D between two safety light grids that are aligned

[6] Working distance

[7] Minimum distance D, dependent on the working distance

[8] Working distance (= 3m) with constant minimum distance D=0.131m

Page 21

PSEN opII3F Series

Operating Manual PSEN opII3F Series

1003504-EN-01

21

Installation of several adjacent safety light grids

An arrangement of several adjacent safety light grids can be achieved by various methods.

When installing of several adjacent safety light grids, note the ambient conditions [ 16].

[1] [2] [3]

[4]

[5]

[4]

[5]

[4]

[5]

Hazardous area

Fig.: Using several adjacent safety light grids

Legende

[1] Connecting the safety light grid with an opaque surface to shield the safety light

grid on the right

[2] Connection of the safety light grid aligned with [1]

[3] Connection of safety light grid without shielding, but in the orientation opposite to

[2]

[4] Receiver

[5] Transmitter

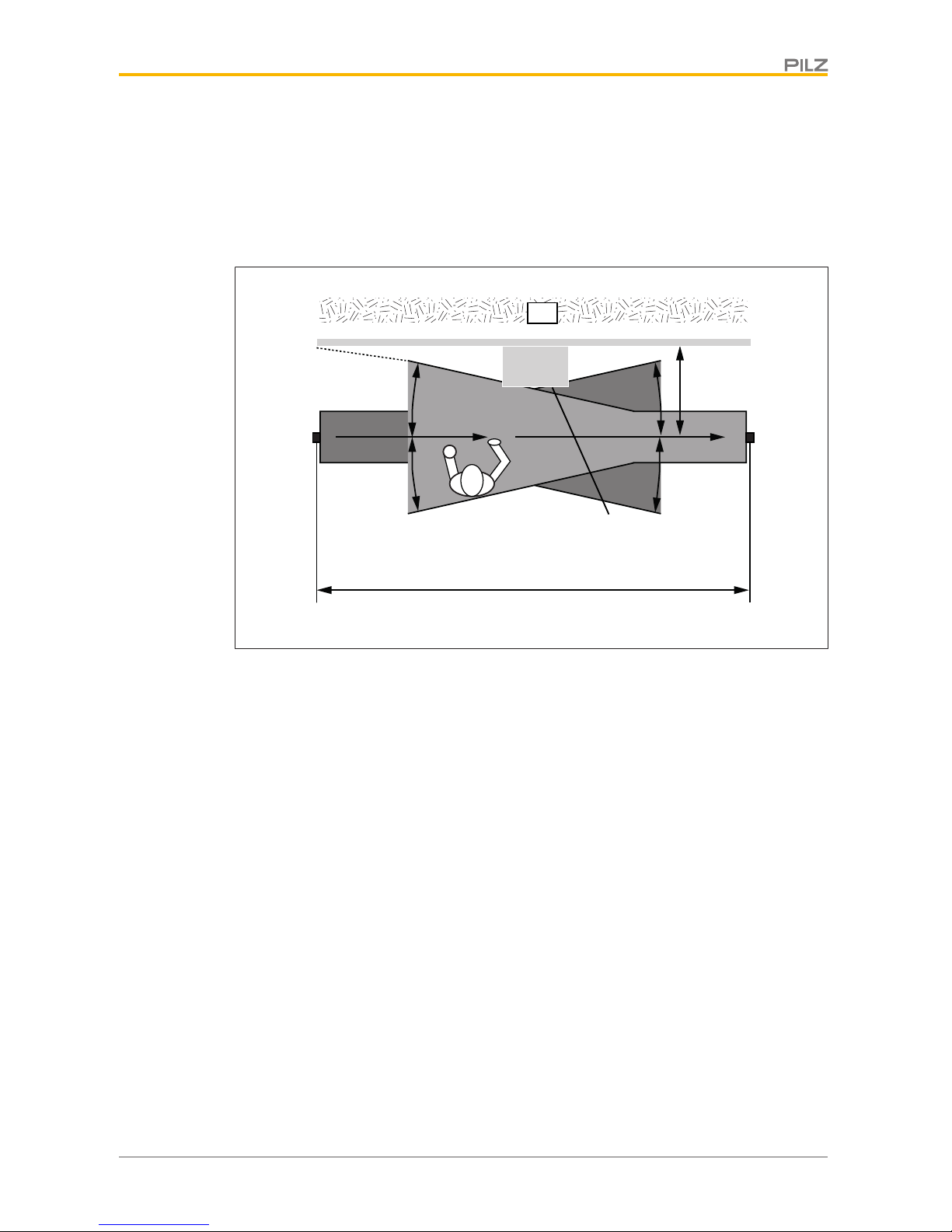

Use of deviating mirrors

Hazardous areas with different but adjacent access sides can be monitored using a safety

light grid in conjunction with deviating mirrors [ 53].

The diagram below shows an example solution for monitoring three different access sides

using two deviating mirrors. The deviating mirrors must be positioned at an angle of 45° to

the beams from the safety light grid.

When using deviating mirrors, please note:

} Even a minor angular displacement of the mirror can lead to misalignment, adversely

affecting or preventing the function of the safety light grid. Use the laser pointer PSEN

opII for alignment (see Order reference for accessories [ 53]).

} The minimum safety distance to the hazardous area must be maintained for all sections

of the light path.

} Use of a single deviating mirror reduces the operating range by about 20%. This per-

centage increases when an additional deviating mirror is used (more detailed information is provided in the technical data for the relevant mirror). Please consider this reduction when positioning the safety light grid.

} You should not use more than two mirrors per device.

} Any dust or dirt on the mirror’s reflective surface will drastically reduce the operating

range.

Page 22

PSEN opII3F Series

Operating Manual PSEN opII3F Series

1003504-EN-01

22

[1][2]

[5]

[6]

[4]

[7][8]

[3]

[4]

[5]

[5]

Fig.: Example for using deviating mirrors

Legende

[1] Transmitter

[2] Receiver

[3] Hazardous area

[4] Deviating mirrors

[5] Minimum safety distance

[6] Distance between the deviating mirrors (see the following table)

[7] Distance from transmitter to deviating mirror

[8] Distance from deviating mirror to receiver

Number of mirrors per device

Maximum operating range [ 42] in

m

1 6.4 m (8 m – 20%)

2 5.12 m (8 m – 2 x 20%)

Dead zones

Use of the standard installation kit results in a dead zone of 15.4mm on both sides of the

safety light grid.

If you want to use the safety light grid without dead zones, use the

PSENopIIAdvBracketKit for safety light grid installation (see Dead-zone-free

installation [ 6]).

Page 23

PSEN opII3F Series

Operating Manual PSEN opII3F Series

1003504-EN-01

23

Use the installation information provided in the PSENopIIAdvBracketKit operating

manual.

[1]

[2]

[3]

[4]

Fig.: Placement of the dead zones in vertical safety light grid installation

Legende

[1] Last light beam (wiring side)

[2] Last light beam (cable side)

[3] Wiring-side dead zone

[4] Cable-side dead zone

Page 24

PSEN opII3F Series

Operating Manual PSEN opII3F Series

1003504-EN-01

24

Installation and orientation

Please note:

} The optical surfaces of the transmitter and receiver must be parallel to each other and

oriented opposite to each other.

} The connection sides of the transmitter and receiver must be on the same side and at

the same height (see diagram).

[1] [2] [1] [2]

[3]

[3]

[3]

[3]

True False

Legend

[1] Transmitter

[2] Receiver

[3] Connection cable

} The distance between the transmitter and receiver must be within the operating range

of the safety light grid used (see Technical details [ 42]).

} The installation surface must be at least as wide as the standard installation kit

} The installation surface may have a flatness imperfection of no more than 1.5mm.

Page 25

PSEN opII3F Series

Operating Manual PSEN opII3F Series

1003504-EN-01

25

Attach the safety light grid to the installation surface

[2]

[3]

[1]

Please note the following when installing the

safety light grid [1]:

If the standard installation kit is used, the gap [2]

between the safety light grid [1] and the installation

surface [3] must be smaller than the safety light grid

resolution.

Prepare the installation surface.

Clean the installation surface. The installation surface must be free of dust and grease.

[1]

[1]

[2]

Mount the holder on the end cap on the connection side of the safety light grid

Feed the cable [2] through the opening in the holder.

Ensure that the holder is flush with the end cap (see

diagram).

Attach the holder to the end cap with the tightening

screws included in delivery.

[1] Torque setting 0,7 Nm

Page 26

PSEN opII3F Series

Operating Manual PSEN opII3F Series

1003504-EN-01

26

[1]

[1]

Mount the holder on the end cap on the wiring side

of the safety light grid

Ensure that the holder is flush with the end cap (see

diagram).

Attach the holder to the end cap with the tightening

screws included in delivery.

[1] Torque setting 0,7 Nm

[1]

[2]

Mount the flexible bracket (swivel mount) on the

holder on both the connection and wiring sides of

the safety light grid.

Push the flexible bracket over the holder. The flexible

bracket must lie flush with the holder.

Fix the flexible bracket in place with the clamping

screw [1] and the nut [2].

The screw connection is only tightened to the final

torque when the assembly is orientated.

[1]

[2]

[3]

[4]

a

Uneven installation surfaces can be compensated for

with the standard installation kit to a limited extent

only.

Please note the following when installing the

safety light grid [1]:

} The angle [4] of the flexible bracket [3] on the

holder [2] may not be more than 2°.

} The flexible bracket [3] must be seated on one side

of the holder [2].

Page 27

PSEN opII3F Series

Operating Manual PSEN opII3F Series

1003504-EN-01

27

14,5

6

6,3

19

Bore holes in the installation surface (two M6 screw

boreholes per flexible bracket) for mounting the flexible

brackets for the transmitter and receiver.

[1]

Fix the transmitter and receiver and their flexible

brackets in place on the installation surface.

For each bracket, use two mounting screws with washers [1] included in delivery [ 10]. If necessary,

mounting screws with deviating lengths can be used.

Transmitters and receivers can be shifted vertically

and horizontally.

The screw connection is only tightened to the final

torque when the assembly is orientated.

Ensure that the transmitters and receivers are properly

installed in a suitable place.

Ensure that the transmitters and receivers are positioned at the same height and parallel to one another.

Page 28

PSEN opII3F Series

Operating Manual PSEN opII3F Series

1003504-EN-01

28

Orientation

General guidelines

For the safety light grid to function properly, the transmitter and receiver must be correctly

aligned.

The transmitter and receiver on the safety light grid can be aligned with our without the help

of a laser alignment aid.

} Alignment with laser alignment aid: the safety light grid does not need to be switched on

} Alignment without laser alignment aid: the safety light grid must already be wired (see

chapter entitled "Wiring" in the safety grid's operating manual) and must be switched on

For alignment Pilz recommends the PSEN opII Laserpointer (see Order references for

accessories [ 53]) or another laser alignment aid.

[3]

[1]

[2]

Fig.: Transmitter/receiver modification directions during orientation

Legende

[1] Vertical: by vertical shifting of position in the elongated holes in the top and bottom

flexible brackets

[2] Horizontal: by horizontal shifting of position in the elongated holes in the top and bot-

tom flexible brackets

[3] The axis orientation can be changed by rotating the flexible bracket right or left

Pilz recommends that modifications to the orientation of the transmitter/receiver be made in

the following sequence:

1. Vertical modification

2. Horizontal modification

3. Axis orientation modification

Page 29

PSEN opII3F Series

Operating Manual PSEN opII3F Series

1003504-EN-01

29

Safety light grid alignment

Optimum alignment using a laser alignment aid

Optimum alignment with a laser alignment aid is achieved when the following conditions apply:

} Beam from the laser alignment aid on the transmitter strikes the receiver and

} Beam from the laser alignment aid on the receiver strikes the transmitter

Perform the orientation as described in the laser orientation aid’s operating manual.

WARNING!

The laser beam of the laser orientation aid is harmful to the human eye

The human eye may be injured.

– Ensure that the laser beam is not directed at a human eye.

Optimal orientation without a laser orientation aid

1. Determine the maximum rotation range in when the protected field LED (OSSD status)

illuminates green.

Rotate the transmitter and receiver until the protected field LED (OSSD status) changes

from red to green.

2. Rotate the transmitter to the centre of the rotation range in which the protected field

LED illuminates green.

3. Rotate the receiver to the centre of the rotation range in which the protected field LED

illuminates green.

After the safety light grid’s transmitter and receiver have been orientated, the clamping

screws and nuts and the mounting screws must be tightened to their final torques.

} Tighten the clamping screws [1] and the nuts [2] on the flexible bracket to a torque of

1,1 Nm.

} Tighten the brackets’ mounting screws [3] on the installation surface to a torque of 3

Nm.

Page 30

PSEN opII3F Series

Operating Manual PSEN opII3F Series

1003504-EN-01

30

[1]

[2]

[3]

Legend

[1] Clamping screw

[2] Nut

[3] Mounting screws

Wiring

General guidelines

} Do not lay the connecting cable near or in contact with cables that carry high or highly

volatile currents.

} Use separate cables to connect the wires to the OSSDs on different safety light grids or

safety switches.

} Do not connect contacts OSSD1 and OSSD2 in series or in parallel.

} For supply voltage, use only PELV/SELV power supplies that have a voltage buffer in

accordance with EN60204-1.

} The power supply must be able to bridge a short (20ms) supply voltage failure in ac-

cordance with EN61496-1.

} SELV power supply

– Do not connect the safety light grid housing to the earth conductor or the protective

conductor. The transmitters and receivers must be electrically isolated from the machine/system. The use of the flexible bracket (swivel mount) provides this electrical

isolation.

} Connection to PDP67

– Use the order reference of the cable listed (see Accessories, connection to

PDP67 [ 54])

Page 31

PSEN opII3F Series

Operating Manual PSEN opII3F Series

1003504-EN-01

31

} Connection to other evaluation devices

– Use the order reference of the cable listed (see Accessories, connection to other

evaluation devices [ 54])

– The clamps for connection to the evaluation device must be kept in a locked control

cabinet. This prevents unauthorised modifications.

} Ensure compliance with permissible cable bending radii (see Technical

details [ 42]).

Connector pin assignment

Transmitter and receiver electrical connections are made with M12 connectors. These connectors are located on the bottom of the transmitters and receivers.

} Ensure that the wiring has been performed as indicated. Pins 1 and 5 must be connec-

ted to 24VDC, otherwise, the correct functionality is not guaranteed.

5-pin connector on the transmitter PIN Assignment Cable colour

1

2

3

4

5

1 +24 VDC brown

2 reserved white

3 0 VDC blue

4 reserved black

5 +24 VDC grey

5-pin connector on the receiver PIN Assignment Cable colour

1

2

3

4

5

1 +24 VDC brown

2 OSSD 1 white

3 0 VDC blue

4 OSSD 2 black

5 +24 VDC grey

Earthing the safety light grid

Please note:

} Connect the 0 V connections on all the 24 V power supplies and earth the 0 V mains at

a single point, or ensure that measures are in place to monitor for earth faults.

} The connection of the 0 V supply to the central earth bar or earth fault monitor must be

in accordance with relevant national regulations (such as EN60204-1, NFPA79:17-7,

NEC:Article250).

} Connections should be protected from corrosion.

} Flexible earthing straps should be used on moving earth parts (e.g. machine parts,

gates). Ensure these earthing straps are as short and wide as possible.

Page 32

PSEN opII3F Series

Operating Manual PSEN opII3F Series

1003504-EN-01

32

} For PELV power supplies

Connect the power supply circuit to the earth conductor.

Commissioning

System connection

Make sure that the selected evaluation device has the following properties:

} 2-channel with feasibility monitoring

} OSSD signals are evaluated

} A test pulse lasting no longer than 300 µs is bridged

Suitable Pilz evaluation devices are, for example:

} PNOZelog for monitoring safety light grids

} PNOZsigma for monitoring safety light grids

} PNOZ X for monitoring safety light grids

} PDP67 ION and PDP67 ION HP

Make the connection using one of the cables listed in the order reference (see Order

reference for accessories, connection to PDP67 [ 54]).

} PNOZmulti for safety light grid monitoring

Configure the safety light grid in the PNOZmulti Configurator with switch type 3.

} Automation system PSS 4000 for monitoring safety light grids with the FS_LightCurtain

function block

The correct connection to the respective evaluation device is described in the operating

manual for the evaluation device. Connect the evaluation device according to the specifications in the selected evaluation device’s operating manual.

Page 33

PSEN opII3F Series

Operating Manual PSEN opII3F Series

1003504-EN-01

33

5

3

1

2

4

5

3

1

0 V 24 V

24 V

0 V

24 V

OSSD 1

OSSD 2

24 V

0 V

24 V

PSENopII

receiver

PSENopII

transmitter

Evaluation device

Input circuit

External

supply voltage

Fig.: Dual-channel connection of the safety light grid to the input circuit of an evaluation device

CAUTION!

When considering the examples, please note that Pilz accepts no responsibility for the specific application. In particular, they may not be used without

testing and approval.

The system manufacturer is responsible for creating appropriate safety concepts for the overall plant and for connection to the programmable safety

system (including the user program). The applicable standards and regulations must be considered and observed.

Checking the safety light grid

Once the safety light grid has been installed and aligned, final inspections must be carried

out before it can be put into service.

INFORMATION

This inspection may only be carried out by qualified personnel.

Page 34

PSEN opII3F Series

Operating Manual PSEN opII3F Series

1003504-EN-01

34

Check the safety function of the safety light grid

Procedure

In each of the indicated checks, the OSSDs must switch to the OFF state.

The OSSD status LED on the left side of the receiver must illuminate red.

1. Move the test rod slowly through the protected field (see diagram):

– In the vicinity of the transmitter

– In the vicinity of the receiver

– In the centre of the protected field

2. Place the test rod at rest in a position in the protected field that is considered critical for

the safety assessment results

[1]

Legend

[1] Test rod

Page 35

PSEN opII3F Series

Operating Manual PSEN opII3F Series

1003504-EN-01

35

Check ambient conditions and installation

} Correct orientation and attachment

Check the seating of the mounting screw by applying pressure to edge of the safety

light grid. Neither the device status LED of the transmitter nor that of the receiver

may illuminate.

} Safety distance

The safety distance must comply with the requirements in Maintaining the safety

distance [ 15].

} Circumvention of the protected field

The hazardous zone must be secured so that it is impossible to access by circumventing the protected field

} Protected field perimeters

The protected field perimeters (see Dimensions [ 40]) must completely secure the

hazardous area, making it inaccessible.

} Response and stopping times must fulfil the requirements in Maintaining the safety

distance [ 15]

Ensure that the safety light grid's response time and the machine's stopping time fulfil

the requirements in Maintaining the safety distance [ 15].

} No intense or flashing light sources in the vicinity

There may be no especially intense or flashing light sources in the vicinity of the safety

light grid.

} Ambient conditions

Please observe the environmental conditions [ 16].

} Use of deviating mirrors

Check all areas that are bounded by a deviating mirror.

Operation

Display elements

The safety light grid’s operating status is indicated with LEDs in the end caps of the connection side of the receiver and on the transmitter.

Device status Reception quality:

III: best quality

I: worst quality

OSSD status (protected field LED)

LED indicator on the receiver

Page 36

PSEN opII3F Series

Operating Manual PSEN opII3F Series

1003504-EN-01

36

Device status Light beam error information

Light beam status

LED indicators on the transmitter

Status information

Legend

LED on

LED flashes

LED off

Displays on the receiver

Meaning

green green

Ready for operation

The current reception quality

status is indicated

green red green green green

Safety light grid is started

green red

Protected field is interrupted

red red

OSSD error.

Perform a safety light grid

restart [ 38].

red red

An error has occurred.

Perform a safety light grid

restart [ 38].

green

green

green green green

Interfering light warning

Warns of the OSSDs’ change to

the OFF state due to incident interfering light.

Page 37

PSEN opII3F Series

Operating Manual PSEN opII3F Series

1003504-EN-01

37

Meaning

red

red

green green green

Interfering light error

OSSDs have changed to the OFF

state due to incident interfering

light.

1. Install an opaque surface on

the side facing the interfering

light source or

reverse the positions of the

safety light grid’s transmitter

and receiver.

2. Perform a safety light grid

restart [ 38].

red

red

green

Overtemperature; OSSD in the

OFF state

1. Ensure that the ambient temperature corresponds to the information in the Technical

details [ 42].

2. Perform a safety light grid

restart [ 38].

red

red

green

Undervoltage; OSSD in the OFF

state

1. Ensure that the supply voltage

corresponds to the information

in the Technical

details [ 42].

2. Perform a safety light grid

restart [ 38].

Indicators on the transmitter

Meaning

green red green green

Safety light grid is started

green green

Safety light grid in operation

red red

An error has occurred.

Perform a safety light grid

restart [ 38].

Page 38

PSEN opII3F Series

Operating Manual PSEN opII3F Series

1003504-EN-01

38

Meaning

red

red

green

Overtemperature; OSSD in the OFF

state

1. Ensure that the ambient temperature

corresponds to the information in the

Technical details [ 42].

2. Perform a safety light grid

restart [ 38].

red

red

green

Undervoltage; OSSD in the OFF state

1. Ensure that the supply voltage corresponds to the information in the

Technical details [ 42].

2. Perform a safety light grid

restart [ 38].

Safety light grid restart

a Disconnect the supply voltage from the safety light grid and reconnect it. The automatic

restart [ 14] begins.

Malfunction

DANGER!

Loss of safety function due to a malfunction of the safety light grid

A safety light grid malfunction may lead to serious injury or death.

If there is a safety light grid malfunction, immediately discontinue operation

of the system components whose hazardous area the grid secures.

Regular checks and maintenance

Checks

Regular checks can bring to light changes to the plant/machine, safeguards and ambient

conditions.

Regular check

Pilz recommends that the safety light grid be checked every six months.

} Check the safety light grid’s front panel.

– Scratched front panel: Replace the safety light grid.

– Dirty front panel: Clean the front panel [ 39].

In a particularly dirty environment, front panel cleanliness should be checked more

frequently.

Page 39

PSEN opII3F Series

Operating Manual PSEN opII3F Series

1003504-EN-01

39

} Check the tightness of the safety light grid’s front panel.

All screws must be tightened to the torque specified in the Technical details [ 42].

} Check the safety function of the safety light grid (see Check the safety function of the

safety light grid [ 34]).

Check after plant/machine modification

Check the safety light grid each time the plant/machine is modified. Changing the safety

light grid or swapping safety light grid components should be regarded as a modification.

The requirements of the applicable national regulations must be observed absolutely.

INFORMATION

This inspection may only be carried out by qualified personnel.

The Appendix contains a Checklist [ 56] which should help you perform the safety

check.

Maintenance

Other than cleaning the lens covers, the safety light grids requires no other form of maintenance.

CAUTION!

Improper cleaning agents can damage the safety light grid and lead to malfunctions

Moist cotton cloths should be used for cleaning.

Avoid using

} Alcohol,

} Solvents,

} Cloths made of wool,

} Cloths made of synthetic material.

Clean the lens covers during the regular check of the safety light grid [ 38].

Page 40

PSEN opII3F Series

Operating Manual PSEN opII3F Series

1003504-EN-01

40

Dimensions

M12x1

35

17,5 17,5

13,5

4,7 ±1

13,5

[1]

[2]

4,7 ±1

[3]

ø14,5

ø5

42

[4]

[5]

[6]

[7]

Fig.: Front view of the safety light grid transmitter, protected field height 300-1800 mm with connection cable

Legende

[1] Total length of transmitter (without cable)

[2] Effective protected field height

[3] Protected field height (see Technical details [ 42])

[4] Optical centre axis

[5] Cable-side beam pair for beam synchronisation

[6] Wiring-side beam pair for beam synchronisation

[7] Eye shield

35

17,5 17,5

13,5

13,5

[1]

[2]

4,7 ±1

[3]

[4]

[5]

[6]

[7]

[8]

[9]

Fig.: Front view of the safety light grid transmitter, protected field height 150 mm with connection cable

Legende

[1] Total length of transmitter (without cable)

[2] Effective protected field height

[3] Protected field height (see Technical details [ 42])

Page 41

PSEN opII3F Series

Operating Manual PSEN opII3F Series

1003504-EN-01

41

[4] Optical centre axis

[5] Cable-side beam pair for beam synchronisation

[6] Wiring-side beam pair for beam synchronisation

[7] Eye shield

[8] Dead zone 70.3 mm

[9] Protected field perimeter markings

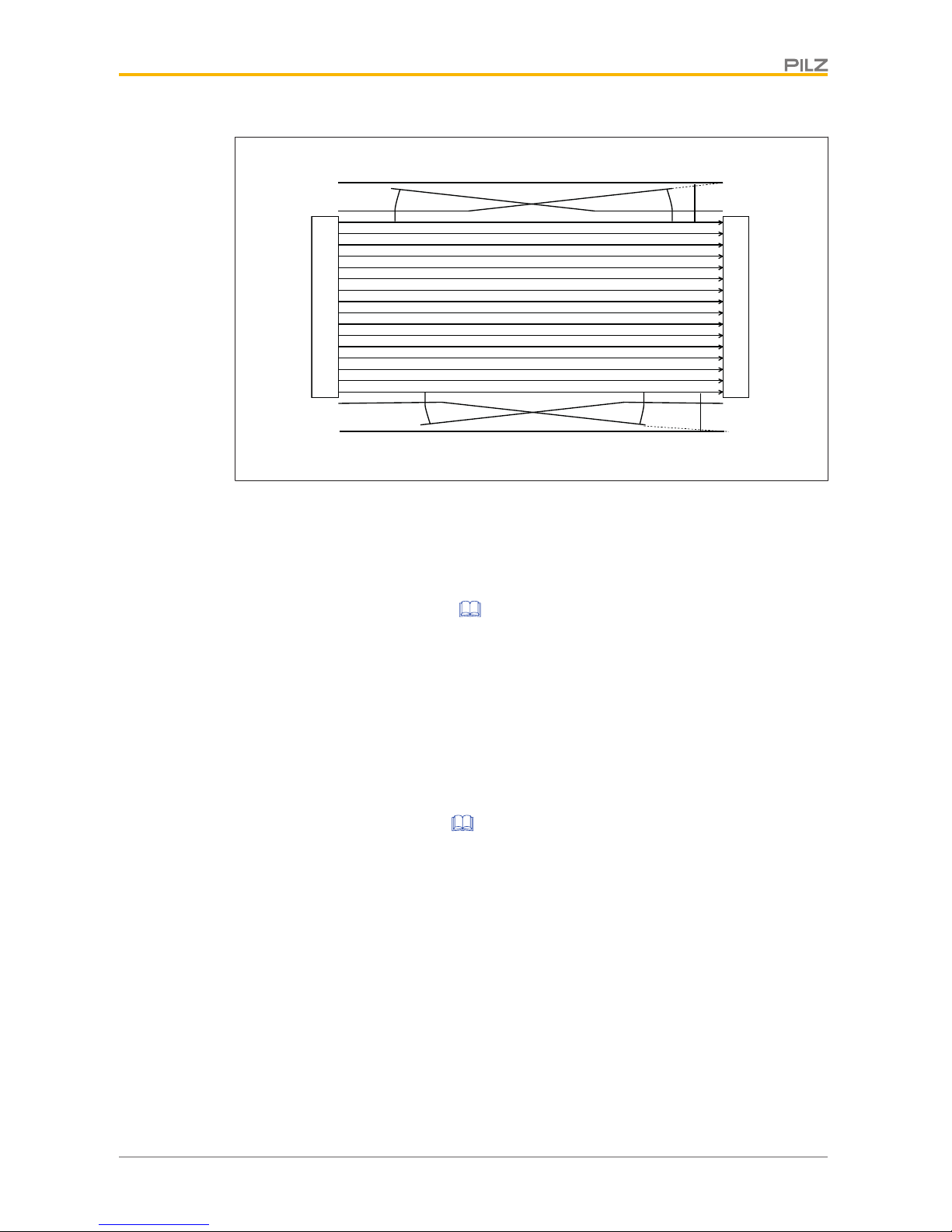

Schematic representation of the relationship between the safety light grid

dimensions and the effective protected field height

[1]

[2]

[3][4] [5][6]

[1]

Fig.: Relationship between the effective protected field height and the safety light grid dimensions

(schematic representation)

Legende

[1] Resolution

[2] Last light beams on the connection and wiring sides

[3] Protected field height

[4] Effective protected field height

[5] Transmitter

[6] Receiver

Page 42

PSEN opII3F Series

Operating Manual PSEN opII3F Series

1003504-EN-01

42

Technical details Order no. 632040-632042

General 632040 632041 632042

Approvals CE, TÜV CE, TÜV CE, TÜV

ESPE type 3 3 3

Sensor's mode of operation Infrared Infrared Infrared

Height of protected field 150 mm 300 mm 450 mm

Resolution

Operating range 0,2 - 8 m 0,2 - 8 m 0,2 - 8 m

Detection capability 14 mm 14 mm 14 mm

Electrical data 632040 632041 632042

Supply voltage

Voltage 24 V 24 V 24 V

Kind DC DC DC

Voltage tolerance -25 %/+20 % -25 %/+20 % -25 %/+20 %

Residual ripple DC 5 % 5 % 5 %

Max. power consumption

receiver 12 W 12 W 12 W

Max. power consumption

transmitter 7,2 W 7,2 W 7,2 W

Max. inductive load per

output 1 H 1 H 1 H

Optical data 632040 632041 632042

Opening angle -2,5 - 2,5 deg -2,5 - 2,5 deg -2,5 - 2,5 deg

Used wavelength range 850 nm 850 nm 850 nm

Inputs 632040 632041 632042

Max. overall line capacitance Clmax 40 nF 40 nF 40 nF

Semiconductor outputs 632040 632041 632042

OSSD safety outputs 2 2 2

Switching current per output 100 mA 100 mA 100 mA

Times 632040 632041 632042

Test pulse duration, safety

outputs 300 µs 300 µs 300 µs

Supply interruption before

de-energisation 600 µs 600 µs 600 µs

Response time t1 14 ms 14 ms 15 ms

Page 43

PSEN opII3F Series

Operating Manual PSEN opII3F Series

1003504-EN-01

43

Environmental data 632040 632041 632042

Ambient temperature

Temperature range -10 - 60 °C -10 - 60 °C -10 - 60 °C

Storage temperature

Temperature range -25 - 70 °C -25 - 70 °C -25 - 70 °C

Climatic suitability

Humidity 95 % r. h. at 50 °C 95 % r. h. at 50 °C 95 % r. h. at 50 °C

Condensation during operation Not permitted Not permitted Not permitted

EMC EN 61496-1 EN 61496-1 EN 61496-1

Vibration

In accordance with the

standard EN 60068-2-6 EN 60068-2-6 EN 60068-2-6

Frequency 10 - 150 Hz 10 - 150 Hz 10 - 150 Hz

Amplitude 0,75 mm 0,75 mm 0,75 mm

Shock stress

In accordance with the

standard EN 60068-2-27 EN 60068-2-27 EN 60068-2-27

Number of shocks 1000 1000 1000

Acceleration 10g 10g 10g

Duration 16 ms 16 ms 16 ms

Bracket Swivel-Mount Swivel-Mount Swivel-Mount

In accordance with the

standard EN 60068-2-27 EN 60068-2-27 EN 60068-2-27

Number of shocks 3 3 3

Acceleration 50g 50g 50g

Duration 11 ms 11 ms 11 ms

Bracket Adv Bracket Kit Adv Bracket Kit Adv Bracket Kit

Protection type

Housing IP65 IP65 IP65

Mechanical data 632040 632041 632042

Min. bending radius (fixed

permanently) K1 5 x Ø 5 x Ø 5 x Ø

Min. bending radius (moving) K1 10 x Ø 10 x Ø 10 x Ø

Connection type

Receiver

M12, 5-pin male connector

M12, 5-pin male connector

M12, 5-pin male connector

Transmitter M12, 5-pin male con-

nector

M12, 5-pin male connector

M12, 5-pin male connector

Max. cable length 50 m 50 m 50 m

Page 44

PSEN opII3F Series

Operating Manual PSEN opII3F Series

1003504-EN-01

44

Mechanical data 632040 632041 632042

Material

Housing Aluminium Aluminium Aluminium

End caps Zn Zn Zn

Front screen PC PC PC

Max. torque setting

Clamping screw 1,1 Nm 1,1 Nm 1,1 Nm

Installation screw 3 Nm 3 Nm 3 Nm

Fixing screw 0,7 Nm 0,7 Nm 0,7 Nm

Dimensions

Height 229 mm 304 mm 454 mm

Width 35 mm 35 mm 35 mm

Depth 40 mm 40 mm 40 mm

Weight 780 g 1.025 g 1.438 g

Where standards are undated, the 2015-12 latest editions shall apply.

Technical details Order no. 632043-632045

General 632043 632044 632045

Approvals CE, TÜV CE, TÜV CE, TÜV

ESPE type 3 3 3

Sensor's mode of operation Infrared Infrared Infrared

Height of protected field 600 mm 750 mm 900 mm

Resolution

Operating range 0,2 - 8 m 0,2 - 8 m 0,2 - 8 m

Detection capability 14 mm 14 mm 14 mm

Electrical data 632043 632044 632045

Supply voltage

Voltage 24 V 24 V 24 V

Kind DC DC DC

Voltage tolerance -25 %/+20 % -25 %/+20 % -25 %/+20 %

Residual ripple DC 5 % 5 % 5 %

Max. power consumption

receiver 12 W 12 W 12 W

Max. power consumption

transmitter 7,2 W 7,2 W 7,2 W

Max. inductive load per

output 1 H 1 H 1 H

Page 45

PSEN opII3F Series

Operating Manual PSEN opII3F Series

1003504-EN-01

45

Optical data 632043 632044 632045

Opening angle -2,5 - 2,5 deg -2,5 - 2,5 deg -2,5 - 2,5 deg

Used wavelength range 850 nm 850 nm 850 nm

Inputs 632043 632044 632045

Max. overall line capacitance Clmax 40 nF 40 nF 40 nF

Semiconductor outputs 632043 632044 632045

OSSD safety outputs 2 2 2

Switching current per output 100 mA 100 mA 100 mA

Times 632043 632044 632045

Test pulse duration, safety

outputs 300 µs 300 µs 300 µs

Supply interruption before

de-energisation 600 µs 600 µs 600 µs

Response time t1 15 ms 16 ms 17 ms

Environmental data 632043 632044 632045

Ambient temperature

Temperature range -10 - 60 °C -10 - 60 °C -10 - 60 °C

Storage temperature

Temperature range -25 - 70 °C -25 - 70 °C -25 - 70 °C

Climatic suitability

Humidity 95 % r. h. at 50 °C 95 % r. h. at 50 °C 95 % r. h. at 50 °C

Condensation during operation Not permitted Not permitted Not permitted

EMC EN 61496-1 EN 61496-1 EN 61496-1

Vibration

In accordance with the

standard EN 60068-2-6 EN 60068-2-6 EN 60068-2-6

Frequency 10 - 150 Hz 10 - 150 Hz 10 - 150 Hz

Amplitude 0,75 mm 0,75 mm 0,75 mm

Page 46

PSEN opII3F Series

Operating Manual PSEN opII3F Series

1003504-EN-01

46

Environmental data 632043 632044 632045

Shock stress

In accordance with the

standard EN 60068-2-27 EN 60068-2-27 EN 60068-2-27

Number of shocks 1000 1000 1000

Acceleration 10g 10g 10g

Duration 16 ms 16 ms 16 ms

Bracket Swivel-Mount Swivel-Mount Swivel-Mount

In accordance with the

standard EN 60068-2-27 EN 60068-2-27 EN 60068-2-27

Number of shocks 3 3 3

Acceleration 50g 50g 50g

Duration 11 ms 11 ms 11 ms

Bracket Adv Bracket Kit Adv Bracket Kit Adv Bracket Kit

Protection type

Housing IP65 IP65 IP65

Mechanical data 632043 632044 632045

Min. bending radius (fixed

permanently) K1 5 x Ø 5 x Ø 5 x Ø

Min. bending radius (moving) K1 10 x Ø 10 x Ø 10 x Ø

Connection type

Receiver

M12, 5-pin male connector

M12, 5-pin male connector

M12, 5-pin male connector

Transmitter M12, 5-pin male con-

nector

M12, 5-pin male connector

M12, 5-pin male connector

Max. cable length 50 m 50 m 50 m

Material

Housing Aluminium Aluminium Aluminium

End caps Zn Zn Zn

Front screen PC PC PC

Max. torque setting

Clamping screw 1,1 Nm 1,1 Nm 1,1 Nm

Installation screw 3 Nm 3 Nm 3 Nm

Fixing screw 0,7 Nm 0,7 Nm 0,7 Nm

Dimensions

Height 604 mm 754 mm 904 mm

Width 35 mm 35 mm 35 mm

Depth 40 mm 40 mm 40 mm

Weight 1.850 g 2.263 g 2.675 g

Where standards are undated, the 2015-12 latest editions shall apply.

Page 47

PSEN opII3F Series

Operating Manual PSEN opII3F Series

1003504-EN-01

47

Technical details Order no. 632046-632048

General 632046 632047 632048

Approvals CE, TÜV CE, TÜV CE, TÜV

ESPE type 3 3 3

Sensor's mode of operation Infrared Infrared Infrared

Height of protected field 1.050 mm 1.200 mm 1.350 mm

Resolution

Operating range 0,2 - 8 m 0,2 - 8 m 0,2 - 8 m

Detection capability 14 mm 14 mm 14 mm

Electrical data 632046 632047 632048

Supply voltage

Voltage 24 V 24 V 24 V

Kind DC DC DC

Voltage tolerance -25 %/+20 % -25 %/+20 % -25 %/+20 %

Residual ripple DC 5 % 5 % 5 %

Max. power consumption

receiver 12 W 12 W 12 W

Max. power consumption

transmitter 7,2 W 7,2 W 7,2 W

Max. inductive load per

output 1 H 1 H 1 H

Optical data 632046 632047 632048

Opening angle -2,5 - 2,5 deg -2,5 - 2,5 deg -2,5 - 2,5 deg

Used wavelength range 850 nm 850 nm 850 nm

Inputs 632046 632047 632048

Max. overall line capacitance Clmax 40 nF 40 nF 40 nF

Semiconductor outputs 632046 632047 632048

OSSD safety outputs 2 2 2

Switching current per output 100 mA 100 mA 100 mA

Times 632046 632047 632048

Test pulse duration, safety

outputs 300 µs 300 µs 300 µs

Supply interruption before

de-energisation 600 µs 600 µs 600 µs

Response time t1 17 ms 18 ms 19 ms

Page 48

PSEN opII3F Series

Operating Manual PSEN opII3F Series

1003504-EN-01

48

Environmental data 632046 632047 632048

Ambient temperature

Temperature range -10 - 60 °C -10 - 60 °C -10 - 60 °C

Storage temperature

Temperature range -25 - 70 °C -25 - 70 °C -25 - 70 °C

Climatic suitability

Humidity 95 % r. h. at 50 °C 95 % r. h. at 50 °C 95 % r. h. at 50 °C

Condensation during operation Not permitted Not permitted Not permitted

EMC EN 61496-1 EN 61496-1 EN 61496-1

Vibration

In accordance with the

standard EN 60068-2-6 EN 60068-2-6 EN 60068-2-6

Frequency 10 - 150 Hz 10 - 150 Hz 10 - 150 Hz

Amplitude 0,75 mm 0,75 mm 0,75 mm

Shock stress

In accordance with the

standard EN 60068-2-27 EN 60068-2-27 EN 60068-2-27

Number of shocks 1000 1000 1000

Acceleration 10g 10g 10g

Duration 16 ms 16 ms 16 ms

Bracket Swivel-Mount Swivel-Mount Swivel-Mount

In accordance with the

standard EN 60068-2-27 EN 60068-2-27 EN 60068-2-27

Number of shocks 3 3 3

Acceleration 50g 50g 50g

Duration 11 ms 11 ms 11 ms

Bracket Adv Bracket Kit Adv Bracket Kit Adv Bracket Kit

Protection type

Housing IP65 IP65 IP65

Mechanical data 632046 632047 632048

Min. bending radius (fixed

permanently) K1 5 x Ø 5 x Ø 5 x Ø

Min. bending radius (moving) K1 10 x Ø 10 x Ø 10 x Ø

Connection type

Receiver

M12, 5-pin male connector

M12, 5-pin male connector

M12, 5-pin male connector

Transmitter M12, 5-pin male con-

nector

M12, 5-pin male connector

M12, 5-pin male connector

Max. cable length 50 m 50 m 50 m

Page 49

PSEN opII3F Series

Operating Manual PSEN opII3F Series

1003504-EN-01

49

Mechanical data 632046 632047 632048

Material

Housing Aluminium Aluminium Aluminium

End caps Zn Zn Zn

Front screen PC PC PC

Max. torque setting

Clamping screw 1,1 Nm 1,1 Nm 1,1 Nm

Installation screw 3 Nm 3 Nm 3 Nm

Fixing screw 0,7 Nm 0,7 Nm 0,7 Nm

Dimensions

Height 1.054 mm 1.204 mm 1.354 mm

Width 35 mm 35 mm 35 mm

Depth 40 mm 40 mm 40 mm

Weight 3.088 g 3.500 g 3.913 g

Where standards are undated, the 2015-12 latest editions shall apply.

Technical details Order no. 632049-632051

General 632049 632050 632051

Approvals CE, TÜV CE, TÜV CE, TÜV

ESPE type 3 3 3

Sensor's mode of operation Infrared Infrared Infrared

Height of protected field 1.500 mm 1.650 mm 1.800 mm

Resolution

Operating range 0,2 - 8 m 0,2 - 8 m 0,2 - 8 m

Detection capability 14 mm 14 mm 14 mm

Electrical data 632049 632050 632051

Supply voltage

Voltage 24 V 24 V 24 V

Kind DC DC DC

Voltage tolerance -25 %/+20 % -25 %/+20 % -25 %/+20 %

Residual ripple DC 5 % 5 % 5 %

Max. power consumption

receiver 12 W 12 W 12 W

Max. power consumption

transmitter 7,2 W 7,2 W 7,2 W

Max. inductive load per

output 1 H 1 H 1 H

Page 50

PSEN opII3F Series

Operating Manual PSEN opII3F Series

1003504-EN-01

50

Optical data 632049 632050 632051

Opening angle -2,5 - 2,5 deg -2,5 - 2,5 deg -2,5 - 2,5 deg

Used wavelength range 850 nm 850 nm 850 nm

Inputs 632049 632050 632051

Max. overall line capacitance Clmax 40 nF 40 nF 40 nF

Semiconductor outputs 632049 632050 632051

OSSD safety outputs 2 2 2

Switching current per output 100 mA 100 mA 100 mA

Times 632049 632050 632051

Test pulse duration, safety

outputs 300 µs 300 µs 300 µs

Supply interruption before

de-energisation 600 µs 600 µs 600 µs

Response time t1 19 ms 20 ms 20 ms

Environmental data 632049 632050 632051

Ambient temperature

Temperature range -10 - 60 °C -10 - 60 °C -10 - 60 °C

Storage temperature

Temperature range -25 - 70 °C -25 - 70 °C -25 - 70 °C

Climatic suitability

Humidity 95 % r. h. at 50 °C 95 % r. h. at 50 °C 95 % r. h. at 50 °C

Condensation during operation Not permitted Not permitted Not permitted

EMC EN 61496-1 EN 61496-1 EN 61496-1

Vibration

In accordance with the

standard EN 60068-2-6 EN 60068-2-6 EN 60068-2-6

Frequency 10 - 150 Hz 10 - 150 Hz 10 - 150 Hz

Amplitude 0,75 mm 0,75 mm 0,75 mm

Page 51

PSEN opII3F Series

Operating Manual PSEN opII3F Series

1003504-EN-01

51

Environmental data 632049 632050 632051

Shock stress

In accordance with the

standard EN 60068-2-27 EN 60068-2-27 EN 60068-2-27

Number of shocks 1000 1000 1000

Acceleration 10g 10g 10g

Duration 16 ms 16 ms 16 ms

Bracket Swivel-Mount Swivel-Mount Swivel-Mount

In accordance with the

standard EN 60068-2-27 EN 60068-2-27 EN 60068-2-27

Number of shocks 3 3 3

Acceleration 50g 50g 50g

Duration 11 ms 11 ms 11 ms

Bracket Adv Bracket Kit Adv Bracket Kit Adv Bracket Kit

Protection type

Housing IP65 IP65 IP65

Mechanical data 632049 632050 632051

Min. bending radius (fixed

permanently) K1 5 x Ø 5 x Ø 5 x Ø

Min. bending radius (moving) K1 10 x Ø 10 x Ø 10 x Ø

Connection type

Receiver

M12, 5-pin male connector

M12, 5-pin male connector

M12, 5-pin male connector

Transmitter M12, 5-pin male con-

nector

M12, 5-pin male connector

M12, 5-pin male connector

Max. cable length 50 m 50 m 50 m

Material

Housing Aluminium Aluminium Aluminium

End caps Zn Zn Zn

Front screen PC PC PC

Max. torque setting

Clamping screw 1,1 Nm 1,1 Nm 1,1 Nm

Installation screw 3 Nm 3 Nm 3 Nm

Fixing screw 0,7 Nm 0,7 Nm 0,7 Nm

Dimensions

Height 1.504 mm 1.654 mm 1.804 mm

Width 35 mm 35 mm 35 mm

Depth 40 mm 40 mm 40 mm

Weight 4.325 g 4.738 g 5.150 g

Where standards are undated, the 2015-12 latest editions shall apply.

Page 52

PSEN opII3F Series

Operating Manual PSEN opII3F Series

1003504-EN-01

52

Safety characteristic data

NOTICE

You must comply with the safety-related characteristic data in order to

achieve the required safety level for your plant/machine.

Operating

Mode

EN ISO

13849-1:

2015

PL

EN ISO

13849-1:

2015

Category

EN 62061

SIL CL

EN 62061

PFHD [1/h]

IEC 61511

SIL

IEC 61511

PFD

EN ISO

13849-1:

2015

TM [year]

Sensor with

N/C contacts PL d Cat. 3 SIL CL 2 2,00E-07

–

2,00E-03 20

All the units used within a safety function must be considered when calculating the safety

characteristic data.

INFORMATION

A safety function's SIL/PL values are not identical to the SIL/PL values of

the units that are used and may be different. We recommend that you use

the PAScal software tool to calculate the safety function's SIL/PL values.

Order reference

Order reference for safety light grids

Product type Features Order no.

PSEN opII3FS-14-015

Safety light grid for finger protection, protected field height of 150 mm 632 040

PSEN opII3FS-14-030

Safety light grid for finger protection, protected field height of 300 mm 632 041

PSEN opII3FS-14-045

Safety light grid for finger protection, protected field height of 450 mm 632 042

PSEN opII3FS-14-060

Safety light grid for finger protection, protected field height of 600 mm 632 043

PSEN opII3FS-14-075

Safety light grid for finger protection, protected field height of 750 mm 632 044

PSEN opII3FS-14-090

Safety light grid for finger protection, protected field height of 900 mm 632 045

Page 53

PSEN opII3F Series

Operating Manual PSEN opII3F Series

1003504-EN-01

53

Product type Features Order no.

PSEN opII3FS-14-105

Safety light grid for finger protection, protected field height of 1050

mm

632 046

PSEN opII3FS-14-120

Safety light grid for finger protection, protected field height of 1200

mm

632 047

PSEN opII3FS-14-135

Safety light grid for finger protection, protected field height of 1350

mm

632 048

PSEN opII3FS-14-150

Safety light grid for finger protection, protected field height of 1500

mm

632 049

PSEN opII3FS-14-165

Safety light grid for finger protection, protected field height of 1650

mm

632 050

PSEN opII3FS-14-180

Safety light grid for finger protection, protected field height of 1800

mm

632 051

Order reference for accessories

Standard installation kit

Product type Features Order No.

PSEN opII Bracket

Kit

Standard installation with flexible bracket 632 015

Expanded mounting kit

Product type Features Order No.

PSEN opII Adv

Bracket Kit-2

Four-piece expanded mounting kit with three degrees of freedom for

dead-zone-free conditions for protected field heights between 150 mm

and 600 mm (inclusive)

632 016

PSEN opII Adv

Bracket Kit-3

Six-piece expanded mounting kit with three degrees of freedom for

dead-zone-free conditions for protected field heights between 750mm

and 1200mm (inclusive)

632 017

Laser orientation aid

Product type Features Order No.

PSEN opII laser

pointer

Laser orientation aid for safety light grids from the PSENopII series 632 014

Page 54

PSEN opII3F Series

Operating Manual PSEN opII3F Series

1003504-EN-01

54

Protective columns

Product type Features Order No.

PSEN op Protective

Column-060/1

Protective column for safety light grid, H=600mm 630 950

PSEN op Protective

Column-090/1

Protective column for safety light grid, H=900mm 630 951

PSEN op Protective

Column-120/1

Protective column for safety light grid, H=1200mm 630 952

PSEN op Protective

Column-165/1

Protective column for safety light grid, H=1650mm 630 953

PSEN op Protective

Column-190/1

Protective column for safety light grid, H=1900mm 630 954

Test object

Product type Features Order no.

PSEN opII Testpiece F 14 mm

Test rod for safety light grid with finger protection, ⌀14 mm 632 018

Connection to PDP67

Product type Connection 1 Connection 2 Length Order No.

PSS67/PDP67 cable

M12-5sf M12-5sm

straight, M12, 5-pin, socket straight, M12, 5-pin, con-

nector

3 m 380 208

5 m 380 209

10 m 380 210

20 m 380 220

30 m 380 211

Connection to other evaluation devices

Product type Connection 1 Connection 2 Length Order No.

PSEN op cable

M12-5sf

unshielded, straight,

M12, 5-pin, socket

Open cable 3 m 630 310

5 m 630 311

10 m 630 312

20 m 630 298

30 m 630 297

50 m 630 364

Page 55

PSEN opII3F Series

Operating Manual PSEN opII3F Series

1003504-EN-01

55

Order reference: Component parts

Transmitter

Product type Features Order No.

PSEN opII3Fs-14-015 emitter

For safety light grid for finger protection, protected field height of 150mm632240

PSEN opII3Fs-14-030 emitter

For safety light grid for finger protection, protected field height of 300mm632241

PSEN opII3Fs-14-045 emitter

For safety light grid for finger protection, protected field height of 450mm632242

PSEN opII3Fs-14-060 emitter

For safety light grid for finger protection, protected field height of 600mm632243

PSEN opII3Fs-14-075 emitter

For safety light grid for finger protection, protected field height of 750mm632244

PSEN opII3Fs-14-090 emitter

For safety light grid for finger protection, protected field height of 900mm632245

PSEN opII3Fs-14-105 emitter

For safety light grid for finger protection, protected field height of 1050mm632246

PSEN opII3Fs-14-120 emitter

For safety light grid for finger protection, protected field height of 1200mm632247

PSEN opII3Fs-14-135 emitter

For safety light grid for finger protection, protected field height of 1350mm632248

PSEN opII3Fs-14-150 emitter

For safety light grid for finger protection, protected field height of 1500mm632249

PSEN opII3Fs-14-165 emitter

For safety light grid for finger protection, protected field height of 1650mm632250

PSEN opII3Fs-14-180 emitter

For safety light grid for finger protection, protected field height of 1800mm632251

Receiver

Product type Features Order No.

PSEN opII3Fs-14-015 receiver

For safety light grid for finger protection, protected field height of 150mm632340

PSEN opII3Fs-14-030 receiver

For safety light grid for finger protection, protected field height of 300mm632341

PSEN opII3Fs-14-045 receiver

For safety light grid for finger protection, protected field height of 450mm632342

PSEN opII3Fs-14-060 receiver

For safety light grid for finger protection, protected field height of 600mm632343

Page 56

PSEN opII3F Series

Operating Manual PSEN opII3F Series

1003504-EN-01

56

Product type Features Order No.

PSEN opII3Fs-14-075 receiver

For safety light grid for finger protection, protected field height of 750mm632344

PSEN opII3Fs-14-090 receiver

For safety light grid for finger protection, protected field height of 900mm632345

PSEN opII3Fs-14-105 receiver

For safety light grid for finger protection, protected field height of 1050mm632346

PSEN opII3Fs-14-120 receiver

For safety light grid for finger protection, protected field height of 1200mm632347

PSEN opII3Fs-14-135 receiver

For safety light grid for finger protection, protected field height of 1350mm632348

PSEN opII3Fs-14-150 receiver

For safety light grid for finger protection, protected field height of 1500mm632349

PSEN opII3Fs-14-165 receiver

For safety light grid for finger protection, protected field height of 1650mm632350

PSEN opII3Fs-14-180 receiver

For safety light grid for finger protection, protected field height of 1800mm632351

Appendix

Check list

The checklist below is intended as an aid in for the following work on a safety light grid of

PSEN opII3F Series:

} commissioning,

} recommissioning, and

} running the specified regular check.

Note that the check list is not intended to replace the plant-specific safety analysis required

for commissioning/recommissioning, nor the resulting inspections and actions.

INFORMATION

Commissioning, recommissioning and regular inspection may only be carried out by qualified personnel.

We recommend that you keep the completed check list and store it with the machine documentation for reference.

Page 57

PSEN opII3F Series

Operating Manual PSEN opII3F Series

1003504-EN-01

57

No. Action OK NOT OK Notes

1 Check the category/standards

Does the category of the safety light grid

match the category required for the plant/

machine?

Have the standards applicable for the plant/

machine been considered?

2 Check the safety light grid ambient con-

ditions

Have the environmental conditions been

met (see Ambient conditions [ 16])?

Have the technical details been met for all

the safety light grid components?

3 Check access to the hazardous area

Are all access points to the danger zone

safeguarded by either safety light grids or

mechanical safeguards?

4 Check the minimum distance to hazard-

ous area

Has the minimum distance been calculated

in accordance with the applicable standards?

Has the calculated minimum distance been

maintained at all points?

5 Check protected field

Has the ability to creep underneath the protected field undetected been excluded?

6 Check safety light grid

Make sure that there are no objects in front

of the safety light grid (trailing cable, crossbeams, struts, covers, etc.).

Make sure that there are no transparent materials between the monitored protected

field and the safety light grid (such as the

glass panel).

Are all the mechanical connections on the

safety light grid attached correctly?

Are all the electrical connections to the

safety light grid wired correctly?

Page 58

PSEN opII3F Series

Operating Manual PSEN opII3F Series

1003504-EN-01

58

No. Action OK NOT OK Notes

7 Check the effectiveness of the safety

light grid during the hazardous movement

Is the safety light grid effective throughout

the whole of the plant/machine's hazardous

movement?

8 Check the output circuitry of the pro-

grammable safety and control system

Have OSSDs been incorporated as required

for the desired safety category?

Are the switching elements that are connected to the OSSDs (valves, contactors, etc.)

monitored with feedback loops?

Does the wiring of the OSSDs match the circuit diagram?

9 Check guard function for protected field

of the safety light grid:

Violate the protected field at various points:

The hazardous movement must be shut

down.

10 Switch off safety light grid

Is the hazardous movement stopped immediately when you switch off?

EC declaration of conformity

This product/these products meet the requirements of the directive 2006/42/EC for machinery of the European Parliament and of the Council. The complete EC Declaration of

Conformity is available on the Internet at www.pilz.com/downloads.