Pilz 20 748-03, PSS SB CPU, PSS SB 3006 DP-S, PSS SB 3006 CN-A, PSS SB 3006 IBS-S Operating Manual

...Page 1

Programmable Safety Systems

PSS-Range

PSS SB ACTIVE JUNCTION BASIS

Operating Manual

Item No. 20 748-03

Page 2

2 Operating Manual: PSS SB ACTIVE JUNCTION BASIS

Contents

Function description 3

Intended use 5

Safety 6

EMCD 6

ESD 6

Warranty and liability 6

Safety guidelines 6

Disposal 6

Bus structure with PSS SB ACTIVE JUNCTION BASIS 7

Rules for incorporation 7

Rules for bus termination 7

Determining the bus cable runs and transmission rate 8

SafetyBUS p interfaces 9

SafetyBUS p main branch 9

SafetyBUS p sub branches 9

Installation 10

Supply voltage 11

Insulation voltage test 11

Connection 12

Connecting the supply voltage 12

Earthing 12

Main branch 12

Sub branches 12

Display elements 14

Faults 14

Technical details 15

Page 3

3

Operating Manual: PSS SB ACTIVE JUNCTION BASIS

Function description

The PSS SB ACTIVE JUNCTION BASIS is a component part of the Pilz Active

Junction. An Active Junction consists of a base unit (PSS SB ACTIVE

JUNCTION BASIS) and up to two expansion modules (PSS SB ACTIVE

JUNCTION EXPANSION).

An Active Junction operates as an active junction with repeater function and is

designed for use in SafetyBUS p networks. It galvanically isolates up to 6 sub

branches from the SafetyBUS p main branch. The Active Junction can be used to

connect physically remote field devices to the SafetyBUS p main branch. The

field devices may be in either an IP20 or IP67 environment.

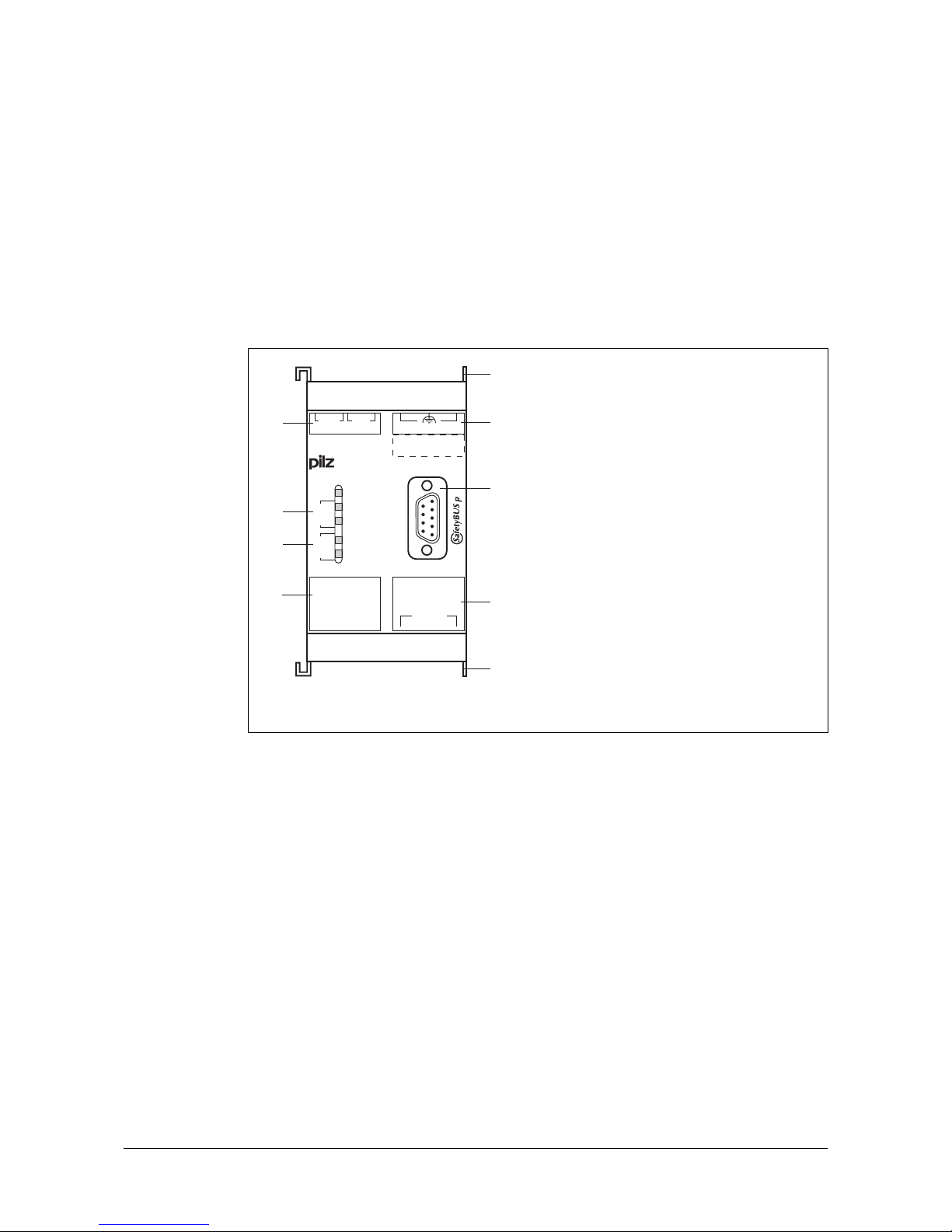

Fig. 1: Elements on the PSS SB ACTIVE JUNCTION BASIS (front view)

If the field devices are in an IP67 environment, the supply voltage for the field

devices can be provided via the Active Junction. In this case, special bus cable

will be required. This is designed for an IP67 environment and contains the lines

for the supply voltage for the field devices as well as the data lines. The

maximum extension of a sub branch is limited by a number of different factors

(number of bus subscribers in the sub branch, transmission rate, current

consumption of the connected field devices etc.).

The base unit PSS SB ACTIVE JUNCTION BASIS is designed for the formation

of two sub branches. If more than two sub branches are required, the expansion

module PSS SB ACTIVE JUNCTION EXPANSION can be used. It is possible to

connect a max. of two expansion modules. Each expansion module can be used

to connect two additional sub branches via the base unit to the SafetyBUS p main

branch.

Power

Traffic

Supply

Traffic

Supply

Sub-Br.Sub-Br.

1

2

ACTIVE JUNCTION

CAN_L

GND

CAN_H

VCC

1... ...4

-X1-

-X2-

1... ...4

-X3-

-X4-

SHIELD

1... ...4

-X5-

Note:

1... ...4

-X0-

24V

0V

BASIS

6

7

8

4

3

2

1

5

5

1: Supply voltage terminal

2: Display elements sub

branch 1

3: Display elements sub

branch 2

4: SafetyBUS p interfaces

(sub branches)

5: Element for attaching an

expansion module

6: Functional earth

connection

7: SafetyBUS p interface

(main branch)

8: Terminals for connecting

the cable screening

Page 4

4 Operating Manual: PSS SB ACTIVE JUNCTION BASIS

I/OD

I/OD

MD

LD

PSS SB ACTIVE JUNCTION BASIS

main branch

sub branch (2)sub branch (1)

IP20

or

IP67

drop line

IP20

1 1

2

3

3 3

4 4 4

5

1 Terminating resistor in

the main branch

(terminator)

2 Terminating resistor for

each sub branch of the

Active Junction

(integrated into the unit)

3 Field devices

4 T-connectors

5 Terminating resistor for

the sub branch

(terminator)

Fig. 2: Bus structure with PSS SB ACTIVE JUNCTION BASIS (principle)

The Active Junction is one of the non-safety-related devices on SafetyBUS p. It

is not assigned a Device Address. Although the Active Junction is not registered

as a bus subscriber, it must be regarded as a bus subscriber when establishing

the transmission rate.

If there is a short circuit in the supply voltage to a sub branch near to the Active

Junction (up to ca. 10 m cable runs), the supply voltage to the sub branch will be

switched off. The “Supply” LED for the relevant sub branch will turn red (see

sections entitled “Display elements” and “Faults”).

If a signal error occurs within a sub branch (permanent dominant signal level),

the sub branch will be ignored. The “Traffic” LED for the relevant sub branch will

turn red (see sections entitled “Display elements” and “Faults”).

Page 5

5

Operating Manual: PSS SB ACTIVE JUNCTION BASIS

Intended use

The PSS SB ACTIVE JUNCTION BASIS is designed for use in SafetyBUS p

networks. It is suitable for connecting physically remote field devices (e.g. light

guards) to the SafetyBUS p main branch. Using the unit allows you to build a star

or tree structure, rather than the linear topology specified for SafetyBUS p.

If the field devices are in an IP67 environment, suitable cable and connection

materials must be used. The information in the guideline: “SafetyBUS p - IP67

Physical Layer Concept”, published by the SafetyBUS p Club International e.V.,

is binding.

Precise details on the PSS SB ACTIVE JUNCTION BASIS are provided in the

“Technical details” section. Use of the device outside the specifications given

here will be deemed as improper use. Any component, technical or electrical

modifications will be deemed as improper use.

Use of the PSS SB ACTIVE JUNCTION BASIS outside the areas described in

this manual will be deemed as improper use. Intended use includes following the

information in this documentation.

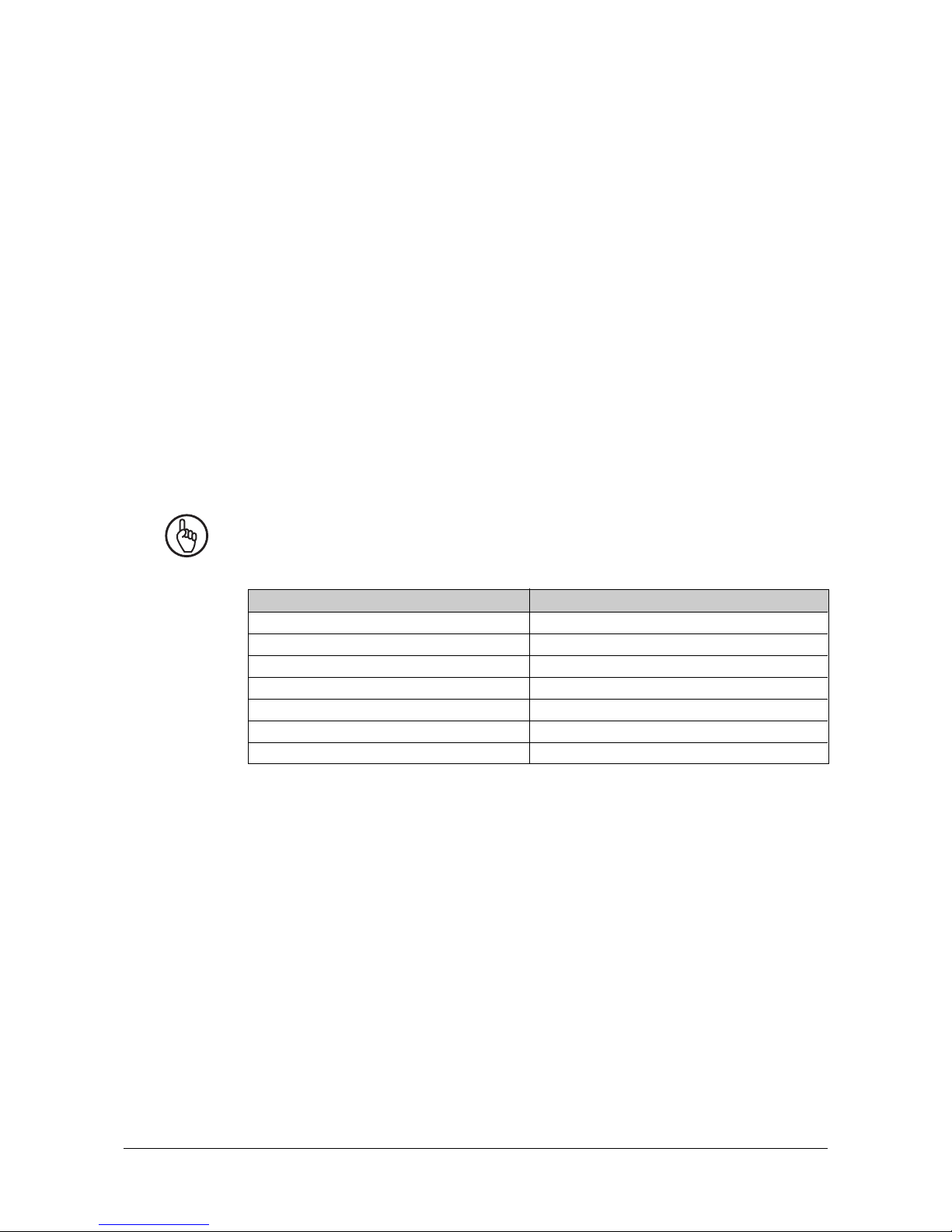

NOTICE

SafetyBUS p subscribers in the following table only support the PSS SB ACTIVE

JUNCTION BASIS from the stated version number onwards:

Table 1

From version

3.0

2.0

2.0

2.0

1.7

2.0

2.0

SafetyBus p module

PSS SB CPU

PSS SB 3006 CN-A

PSS SB 3006 DP-S

PSS SB 3006 IBS-S

PSS SB DI8O8

PSS SB DI16

PSS SB Router1

Page 6

6 Operating Manual: PSS SB ACTIVE JUNCTION BASIS

Safety

The PSS SB ACTIVE JUNCTION BASIS is not a safety-related device.

EMCD

The device is designed for use in an industrial environment. Interference may

occur if used within a domestic environment.

ESD

CAUTION!

Electrostatic discharge can damage components on the device. Ensure against

discharge before touching the device, e.g. by touching an earthed, conductive

surface or by wearing an earthed armband.

Warranty and liability

All claims to warranty and liability will be rendered invalid if:

• The system was used contrary to the purpose for which it is intended

• Damage can be attributed to not having followed the guidelines in the

documentation

• Operating personnel are not suitably qualified.

• The housing was opened

• Any type of modification has been made (e.g. exchanging components on the

PCB boards, soldering work etc.)

Safety guidelines

The information and requirements stipulated in the “SafetyBUS p Installation

Manual” are valid when using the PSS SB ACTIVE JUNCTION BASIS (see

SafetyBUS p System Manual). Failure to comply with these stipulations will

render all warranty and liability claims invalid.

The guidelines in the “SafetyBUS p - IP67 Physical Layer Concept” of the

SafetyBUS p Club International e. V. must also be met.

Disposal

The device must be disposed of properly when it reaches the end of its service

life.

Page 7

7

Operating Manual: PSS SB ACTIVE JUNCTION BASIS

Bus structure with PSS SB ACTIVE JUNCTION BASIS

Rules for incorporation

The Active Junction (base unit and expansion module) is transparent for all

telegrams on the main branch and sub branches. If a signal error occurs within a

sub branch (permanent dominant signal level), the sub branch will be ignored.

Please note the following rules:

• The physical arrangement of the Active Junction on the main branch can be

freely selected. However, bear in mind that run time delays on the signals must

be considered when using an Active Junction. These run time delays can be

expressed as constant virtual cable runs (see section entitled “Determining the

bus cable runs and transmission rate”).

• Using the Active Junction allows you to build a star or tree structure, rather than

the linear topology specified for SafetyBUS p. This reduces the effective

electrical cable runs (no return line needed).

• The relationship of the cable runs to the transmission rate should be

maintained.

• Where possible, plan to use only complete I/O-Groups in a sub branch. This

increases the availability if an error occurs.

Rules for bus termination

Each branch (main branch and sub branches) must be fitted with terminating

resistors.

• The signal lines (CAN_L and CAN_H) on the first and last bus subscribers on

the main branch should be fitted with terminating resistors (120 Ohm).

• The Active Junction is the first bus subscriber on a sub branch. The device has

an integral terminating resistor for each sub branch. The signal lines (CAN_L

and CAN_H) on the last bus subscriber on each sub branch should therefore

be fitted with a terminating resistor (120 Ohm). If necessary use special IP67

terminators.

Page 8

8 Operating Manual: PSS SB ACTIVE JUNCTION BASIS

Determining the bus cable runs and transmission rate

NOTICE

Please read the information in chapter "Designing a SafetyBUS p network" of the

"SafetyBUS p Installation Manual".

If you are using Active Junction please also note:

• Examine every connection combination between the first and last bus

subscriber across all branches (see Fig. 3)

• If the line under examination contains Active Junctions, account for them with

the virtual cable runs as shown in Table 2:

Number of

Active Junctions

1

2

Virtual cable runs

(total)

50 m

100 m

90 m

Cable runs l

Distance

between

adjacent Active Junctions

in the main branch

---

l

Distance

< 10 m

l

Distance

≥ 10 m

MD

LD

I/OD

I/OD

I/OD I/OD

main line

l

Distance

Active Junctions

I/OD I/OD

main branch

l

Distance

l

Distance

Fig. 3: Active Junction arrangement (example)

Table 2

INFORMATION

If possible place all Active Junctions on the main branch (see Fig. 4). This will

guarantee that a maximum of 2 Active Junctions with virtual cable runs will impact

on the main line.

Page 9

9

Operating Manual: PSS SB ACTIVE JUNCTION BASIS

SafetyBUS p interfaces

SafetyBUS p main branch

Connection to the SafetyBUS p main branch is via a male 9-pin D-Sub connector.

Fig. 4: Configuration of the interface to the SafetyBUS p main branch

SafetyBUS p sub branches

Connection to the SafetyBUS p sub branches is via 4-pin screw connectors.

1: n.c.

2: CAN_L (brown)

3: CAN_GND (white)

4: n.c.

5: CAN_SHLD

6: n.c.

7: CAN_H (green)

8: Supply voltage for fibre-optic couplers

from Pilz

9: n.c.

n.c. = not connected

1

9

5

6

Male 9-pin D-Sub connector

9-pin

1234

X1

1234

X2

Fig. 5: Configuration of the interface to the SafetyBUS p sub branches

4-pin screw connectors

(X1/X2)

1: CAN_L (brown)

2: GND (white)

(CAN_GND and VCC_GND)

3: CAN_H (green)

4: VCC (red)

(carried supply voltage 24 V)

Page 10

10 Operating Manual: PSS SB ACTIVE JUNCTION BASIS

75 (2.95")

94 (3.70")

121 (4.76")

45

(1.77")

87 (3.42")

49,2

(1.94")

5

(0.196")

Installation

INFORMATION

Please refer also to the chapter entitled “Installation and Assembly” in the

“SafetyBUS p Installation Manual”.

The PSS SB ACTIVE JUNCTION BASIS is enclosed in a 45 mm P99 housing,

suitable for DIN rail mounting.

• The device should be installed in a control cabinet with a protection type of at

least IP54.

• There are two notches on the back of the unit for DIN rail attachment.

• If you are installing the unit on to a vertical DIN rail, ensure that it is mounted

securely by using a retaining bracket or an end angle.

Fig. 6: Dimensions

Page 11

11

Operating Manual: PSS SB ACTIVE JUNCTION BASIS

Supply voltage

For details of the power supply please refer to the “Technical details” section.

Remember to take into account that the power supply experiences a brief inrush

current (ca. 2 A above current consumption) due to input capacitance.

CAUTION!

• The tolerance on the supply voltage is +25 % or -3 % maximum. Safe operation

cannot be guaranteed outside this range.

• The supply voltage at the field devices must not drop below 20.4 V, otherwise

safe operation cannot be guaranteed.

• Overvoltage or interference voltage can damage or even destroy the electronics

on the device. If this occurs, the affected I/O-Groups will switch to a STOP

condition and all the outputs in the affected I/O-Groups will be switched off. You

should therefore take note of the relevant EMC measures.

• The supply voltage to a sub branch can take a max. 3 A load.

WARNING!

Safe electrical isolation must be ensured for the external 24 V supplies. Failure to

do so could result in electric shock. Power supplies must conform to EN 60742,

9/95 (DIN VDE 0551) or EN 50178, 10/97.

To achieve the lowest possible residual ripple, we recommend that you install a

three-phase bridge rectifier or regulated supply.

Insulation voltage test

Pilz bus subscribers are connected to functional earth via protection elements

on the voltage supply.

Insulation voltage tests are only possible with voltages up to ca. 42 V.

Page 12

12 Operating Manual: PSS SB ACTIVE JUNCTION BASIS

Connection

Connecting the supply voltage

• Connect the 24 V on the power supply to terminal contact 1/2 on terminal block

X0.

• Connect the 0 V on the power supply to terminal contact 3/4 on terminal block

X0.

NOTICE

If the Active Junction is being used to separate sections of the plant, each Active

Junction should be fed through a separate power supply. This will stop a short

circuit in the supply to one plant section affecting the other plant sections.

Earthing

NOTICE

Ensure that the cable screening is connected throughout in each branch. Ensure

the connection for the IN/OUT bus cable is made correctly in each bus

connector.

Please read the information in chapter "Installation and Assembly" of the

"SafetyBUS p Installation Manual".

Main branch

• Connect the cable screening with low impedance to the screen bar or earth bar;

this only needs to be done once for the whole main branch (Fig 8).

• Please refer to the information in the chapter entitled “Installation and

Assembly” in the “SafetyBUS p Installation Manual”.

Sub branches

• Connect each sub branch cable screen to one of the connections on the two

terminal blocks X3/X4 (SHIELD) on the base unit. X3/X4 is connected internally

to X5.

• Connect the X5 terminal block connections (

) on the base unit with low

impedance to the screen bar or earth bar (Fig. 8).

• Follow the guidelines in the “SafetyBUS p - IP67 Physical Layer Concept”

published by the SafetyBUS p Club International e.V.

Page 13

13

Operating Manual: PSS SB ACTIVE JUNCTION BASIS

Fig. 7: Earthing

Legend, Fig. 8:

➀ Cable screening

➁ Galvanic isolation

➂ Base unit PSS SB ACTIVE JUNCTION BASIS

➃ Field device

➄ Screen bar/earth bar

Functional earth

X0

X3 X4

X5

X1 X2

MD

LD

I/OD

I/OD

I/OD

2

3

sub branch (1)

sub branch (2)

X0

X3 X4

X5

X1 X2

2

3

main branch

4

4

4

4

24 V

0 V

5

24 V

0 V

sub branch (1)

sub branch (2)

Page 14

Display elements

Table 3

Faults

If a unit is defective or there is a wiring error, all the outputs in the affected I/OGroup are switched off and the I/O-Group switches to a STOP condition. An error

telegram is then sent to SafetyBUS p and the error is entered in the error buffer

of the controlling PSS.

An error message appears on the display of the controlling PSS. The error stack

display in the programming device and the display elements on the PSS SB

ACTIVE JUNCTION BASIS or PSS SB ACTIVE JUNCTION EXPANSION can be

used to locate the error.

LED

POWER

sub branch 1

sub branch 2

Signal

Lights green

Flickers green

Lights red

Lights green

Lights red

Flickers green

Lights red

Lights green

Lights red

Key

Supply voltage present (screw connector

X0)

Data traffic in

sub branch 1

Signal error in sub branch 1

(permanent dominant signal level)

Supply voltage present in sub branch 1

(screw connector X1)

Short circuit in supply voltage sub branch 1

Data traffic in

sub branch 2

Signal error in sub branch 2

(permanent dominant signal level)

Supply voltage present in sub branch 2

(screw connector X2)

Short circuit in supply voltage sub branch 2

Traffic

Supply

Traffic

Supply

Page 15

Technical details

Electrical data

Supply voltage

Tolerance range

Current consumption

Galvanic isolation

Connection

Sub branches

Virtual cable runs of an Active Junction

SafetyBUS p

Transmission rate

Cable runs

Transmission type

Mechanical data

Max. cross section of external conductors

Torque setting for connection terminals

Dimensions (H x W x D)

Weight

Environmental data

Protection type (EN 60529, 09/00)

Mounting position

Ambient temperature

(EN 60068-2-14, 11/99)

Storage temperature

(EN 60068-2-1/-2, 07/94, 03/93)

Climatic suitability

(DIN IEC 68-2-3, 12/86)

Condensation

Vibration (EN 60068-2-6, 04/95)

Shock (EN 60068-2-27, 03/93)

EMC

24 VDC

23.4 ... 30 VDC including residual ripple of

max. ± 1.2 V

120 mA plus load currents from the

sub branches (max. 6 A) and load currents for

fibre-optic couplers

(max. 25 mA per fibre-optic coupler)

Yes (optocoupler), between the

SafetyBUS p

®

main branch and the

sub branches

SafetyBUS

®

:

Male 9-pin D-Sub connector

Supply and sub branches:

4-pin screw connector

Max. 3 A load current per sub branch,

electronic short circuit protection,

integral terminating resistor (120 Ohm) per sub

branch

50 m

Max. 500 kBit/s

Max. 3500 m

Differential two-wire cable

1 x 2.5 mm2 or 2 x 1.5 mm

2

Single-core or multi-core with

crimp connectors

1.2 Nm (screws)

94 x 49.2 x 126 mm

250 g

IP20

Any

0 ... +60 °C

-25 ... +70 °C

Max. 93 % r.h.

Not permitted

Frequency range: 10 ... 150 Hz

Amplitude: 0.075 mm, max. 1g

30g, 11 ms

EN 61000-6-2, 03/00

EN 55011, 05/00

Page 16

...

www

www.pilz.com

+49 711 3409-444

Pilz GmbH & Co. KG

Sichere Automation

Felix-Wankel-Straße 2

73760 Ostfildern, Germany

Telephone: +49 711 3409-0

Telefax: +49 711 3409-133

E-Mail: pilz.gmbh@pilz.de

In many countries we are

represented by our subsidiaries

and sales partners.

Please refer to our Homepage

for further details or contact our

headquarters.

Technical support

20 749-02-06/04 Printed in Germany

Loading...

Loading...