Page 1

Operating Manual PMCprimo C

Operating Manual PMCprimo C

PMCprimo C

Motion Controller

Operating Manual — No. 1002242-EN-01

Page 2

This document is a translation of the original document.

All rights to this documentation are reserved by Pilz GmbH & Co. KG. Copies may be made

for internal purposes.

Suggestions and comments for improving this documentation will be gratefully received.

Pilz®, PIT®, PMI®, PNOZ®, Primo®, PSEN®, PSS®, PVIS®, SafetyBUS p®, SafetyEYE®,

SafetyNET p®, the spirit of safety® are registered and protected trademarks of

Pilz GmbH & Co. KG in some countries.

SD means Secure Digital.

Preface

Page 3

Contents

Contents

Contents Page

Chapter 1 Introduction

1.1 Validity of the documentation 1-1

1.1.1 Retaining the documentation 1-1

1.2 Overview of documentation 1-2

1.3 Definition of symbols 1-3

Chapter 2 Overview

2.1 Unit features 2-1

2.2 Front view 2-2

2.3 Type code 2-3

2.4 Scope of supply 2-4

Chapter 3 Security

3.1 Intended use 3-1

3.2 Safety regulations 3-2

3.2.1 Use of qualified personnel 3-2

3.2.2 Warranty and liability 3-2

3.2.3 Disposal 3-2

3.3 Standards 3-3

Chapter 4 Function description

4.1 Device properties 4-1

4.1.1 Controller 4-1

4.1.2 Supply voltage 4-2

4.1.3 Digital inputs 4-3

4.1.4 Digital outputs 4-3

4.1.5 Interfaces 4-3

4.1.5.1 Overview 4-3

4.1.5.2 CANopen 4-5

4.1.5.3 PROFIBUS DP 4-6

4.1.5.4 Ethernet 4-6

4.1.5.5 SafetyNET p (in preparation) 4-7

4.1.6 Encoder 4-7

4.1.7 Reset button 4-8

4.2 Software 4-9

Chapter 5 Installation

5.1 General requirements 5-1

5.2 Dimensions 5-2

5.3 Installing the unit 5-3

5.4 Installing the fieldbus junction box 5-4

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

1

Page 4

Contents

Chapter 6 Wiring

6.1 Wiring guidelines 6-1

6.2 Connector pin assignment X40 6-2

6.3 Supply voltage 6-3

6.4 Digital inputs 6-4

6.5 Digital outputs 6-5

6.6 Interfaces 6-6

6.6.1 Overview 6-6

6.6.2 CANopen, PROFIBUS DP 6-6

6.6.2.1 Wiring guidelines for the CANopen inter-

6.6.2.2 Two CANopen interfaces 6-8

6.6.2.3 CANopen/PROFIBUS DP interface 6-8

6.6.3 Ethernet 6-9

6.6.4 SafetyNET p (in preparation) 6-9

6.7 Encoder 6-10

6.7.1 Supply voltage 6-10

6.7.2 Incremental encoder with TTL signal 6-11

6.7.3 Absolute encoder with SSI interface 6-12

6-6

face

Chapter 7 Commissioning

7.1 Safety guidelines 7-1

7.2 Commissioning the PMCprimo C 7-2

7.2.1 Preparing for commissioning 7-2

7.2.2 Establish communication PMCprimo C <> PC

7.2.3 Adapt basic configuration of PMCprimo 7-7

7.2.4 Configure servo amplifier 7-8

7.2.5 Operate PMCprimo C 7-9

7.3 Install CoDeSys 7-12

Chapter 8 Operation

8.1 Operating states and changes in operating

status

8.1.1 Status graph 8-1

8.1.2 Operating states 8-2

8.1.2.1 "Power Off" operating status 8-2

8.1.2.2 "Startup" operating status 8-2

8.1.2.3 "Boot Menu" operating status 8-2

8.1.2.4 "RUN" operating status 8-3

8.1.2.5 "STOP" operating status 8-3

8.1.2.6 "Fatal Error" operating status 8-3

8.1.3 Change in operating status 8-4

8.2 Reset, restart, start and stop options 8-7

8.2.1 Overview 8-7

7-3

8-1

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

2

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 5

Contents

8.2.2 Cold start, "Startup" 8-7

8.2.3 Reset commands 8-8

8.2.3.1 Warm reset 8-8

8.2.3.2 Cold reset 8-8

8.2.3.3 Original Reset 8-8

8.2.4 Start and stop commands 8-9

8.3 Functions of the reset button 8-10

8.4 Messages 8-11

8.5 Display elements 8-12

Chapter 9 Technical details

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

3

Page 6

Contents

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

4

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 7

1 Introduction

1.1 Validity of the documentation

11000IntroductionIntroduction1-1.1Validity of the documentation1100Validity of th e documentation1-Einf Gltigkeit der Dokumentation

This documentation is valid for the product PMCprimo C. It is valid until

][BA_Einfhrung_Einleitung

Einf_Dokumente

new documentation is published.

This operating manual explains the function and operation, describes

the installation and provides guidelines on how to connect the product

PMCprimo C.

Please also refer to the following documents from the motion control

range:

The online help for the PDrive commissioning software describes how

to set the parameters for the servo amplifiers from the PMC product

area.

Guidelines regarding installation and environmental conditions can be

found in the operating manual for the servo amplifier PMCprotego D.

The configuration and programming software for motion control de-

vices (e.g. CoDeSys, PTerm, PScope, PMotion) can be found on the

CD-ROM "Motion Control Tools".

The manuals for Pilz products from the PMC product area are availa-

ble on the supplied CD-ROM "Documentation Motion Control".

You will need to be conversant with the information in these documents

in order to fully understand this manual.

1.1.1 Retaining the documentation

Retaining the documentation1-Einf Aufbewahren

This documentation is intended for instruction and should be retained

for future reference.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

1-1

Page 8

1 Introduction

1.2 Overview of documentation

1.2Overview of documentation1200Overview of documentation1-Einf_Uebersicht_Doku

1 Introduction

The introduction is designed to familiarise you with the contents, structure and specific order of this manual.

2 Overview

This chapter provides information on the product's most important features.

3 Safety

This chapter must be read as it contains important information on safety

and intended use.

4 Function Description

This chapter describes the product's individual functions.

5 Installation

This chapter explains how to install the product.

6 Wiring

This chapter describes the product's wiring.

7 Commissioning

This chapter describes how to commission the product.

8 Operation

This chapter describes the display elements, explaining their operation

and diagnostics.

1-2

9 Technical Details

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 9

1 Introduction

1.3 Definition of symbols

1.3Definition of symbols1300Definition of symbols1-Einfhrung Zeichen

Information that is particularly important is identified as follows:

DANGER!

This warning must be heeded! It warns of a hazardous situation

that poses an immediate threat of serious injury and death and

indicates preventive measures that can be taken.

WARNING!

This warning must be heeded! It warns of a hazardous situation

that could lead to serious injury and death and indicates preventive measures that can be taken.

CAUTION!

This refers to a hazard that can lead to a less serious or minor

injury plus material damage, and also provides information on

preventive measures that can be taken.

NOTICE

This describes a situation in which the unit(s) could be damaged

and also provides information on preventive measures that can

be taken. It also highlights areas within the text that are of particular importance.

INFORMATION

This gives advice on applications and provides information on

special features.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

1-3

Page 10

1 Introduction

1-4

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 11

2 Overview

2.1 Unit features

22000OverviewOverview2-2.1Unit features2100Unit features2-Uebersicht_System_PMCprimo_C

PMCprimo C is a motion controller used to automate multi-axis motion

sequences. The device contains a PLC with the functionality of a logic

and motion controller.

Logic controller universally programmable in accordance with

IEC 61131-3

Motion controller

– Speed axes

– Positioning axes

– Synchronisation axes (electrical cam disk)

– Path axes (interpolation)

– Technological functions

Digital inputs and outputs

– 6 digital inputs, each one can be used as a quick reference input

– 6 single-pole digital outputs

Encoder

– Incremental encoder with TTL signal

– Absolute encoder with SSI interface

Interfaces

– Ethernet TCP/IP

– SafetyNET p RTFN (in preparation)

– SafetyNET p RTFL (in preparation)

Depends on unit type

– 2 CANopen interfaces

– 1 CANopen/ 1 PROFIBUS DP interface

Supply voltages for

– Device plus digital outputs

–Encoder

Memory for

– Operating system

–Data

– Device project with user program

Reset button

– To change between operating states

– For a hardware reset (cold start)

LED display for device's operating status

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

2-1

Page 12

2 Overview

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

STAT

RESET

680050 12

100001

X45

X44

X43

X42

X41

X40

1

3

4

5

6

2

7

10

1

4

8

9

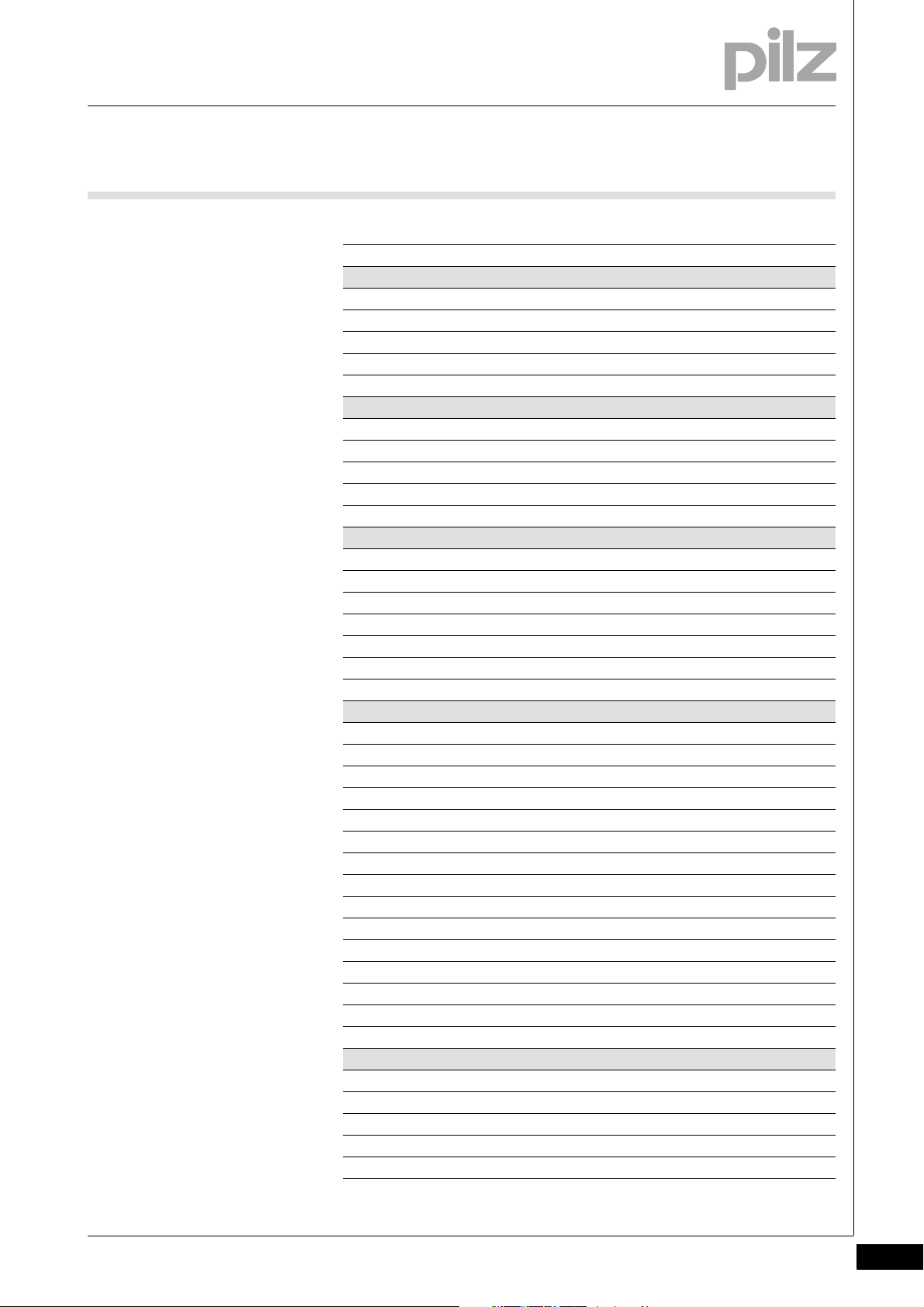

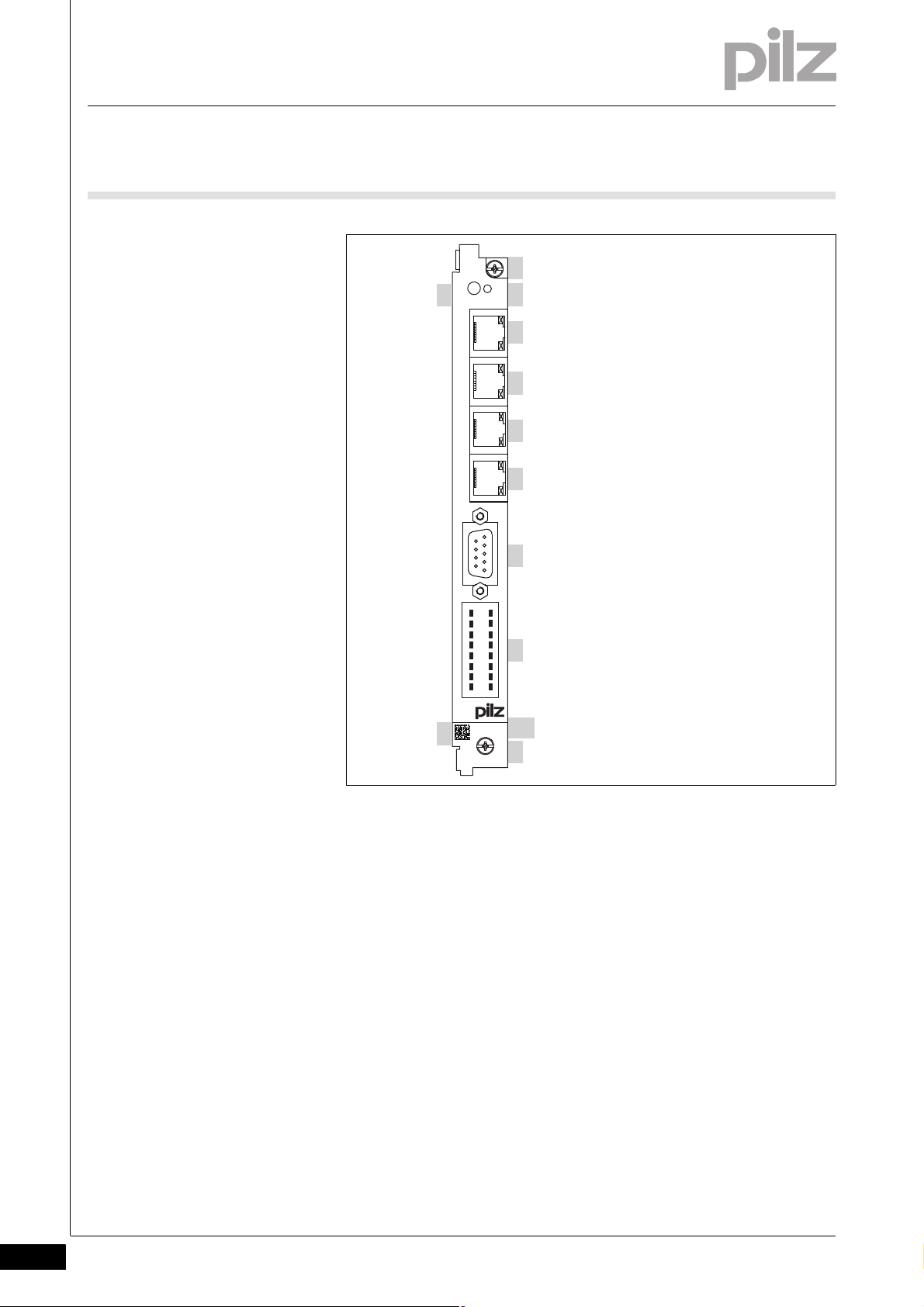

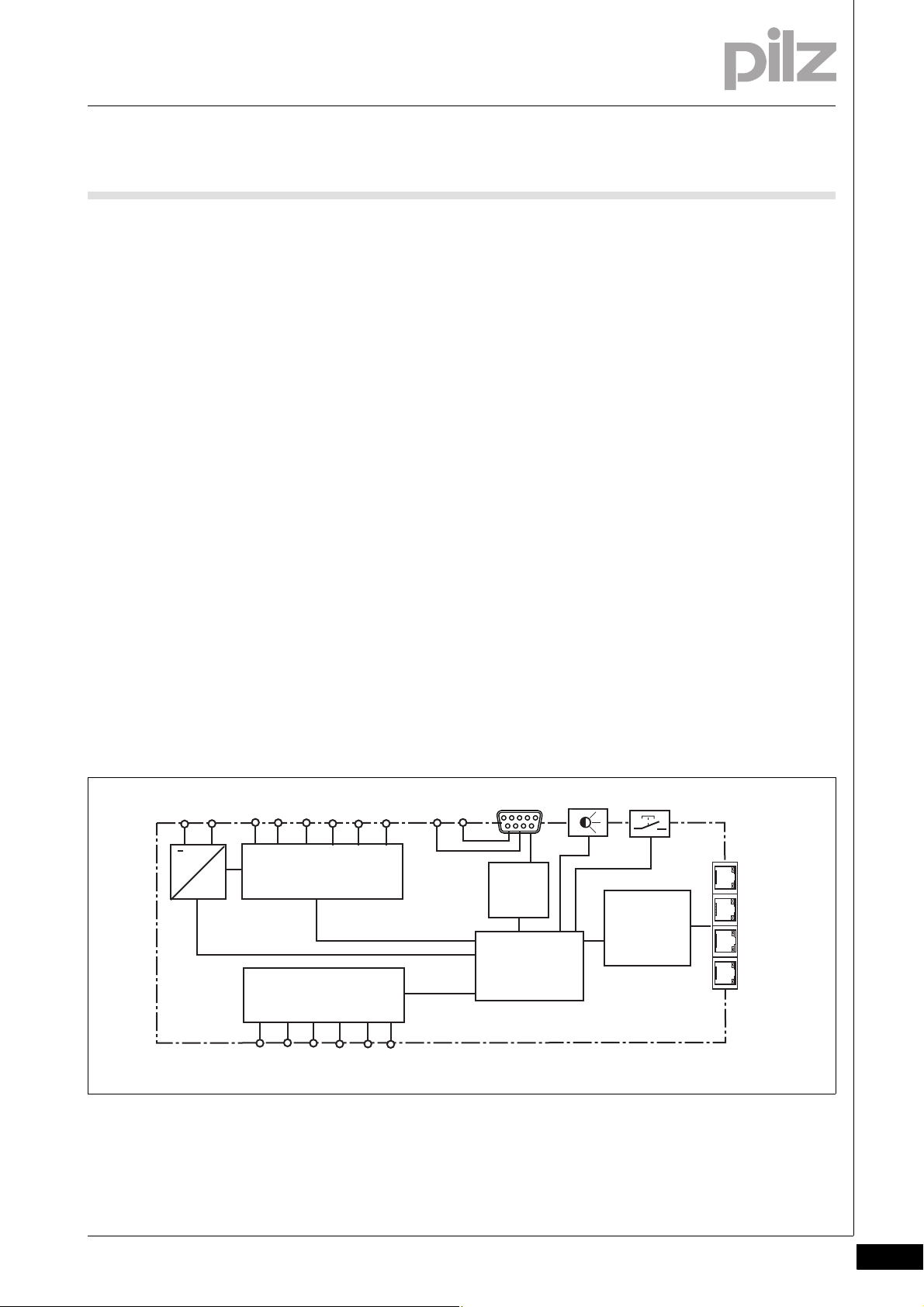

2.2 Front view

2.2Front view2200Front view2-Übersicht_Front

Uebersicht_Front_Legende

Legend:

1: Screw for attachment to the servo amplifier

2: Reset button

3: LED to display operating states

4: SafetyNET p RTFL interface

5: SafetyNET p RTFN/Ethernet TCP/IP interface

6: CANopen/PROFIBUS DP interface

7: Connection for encoder

8: Digital inputs/outputs and supply voltages

9: 2D code

10: Labelling strip with:

– Order number

2-2

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

– Serial number

– Number of device version

Page 13

2 Overview

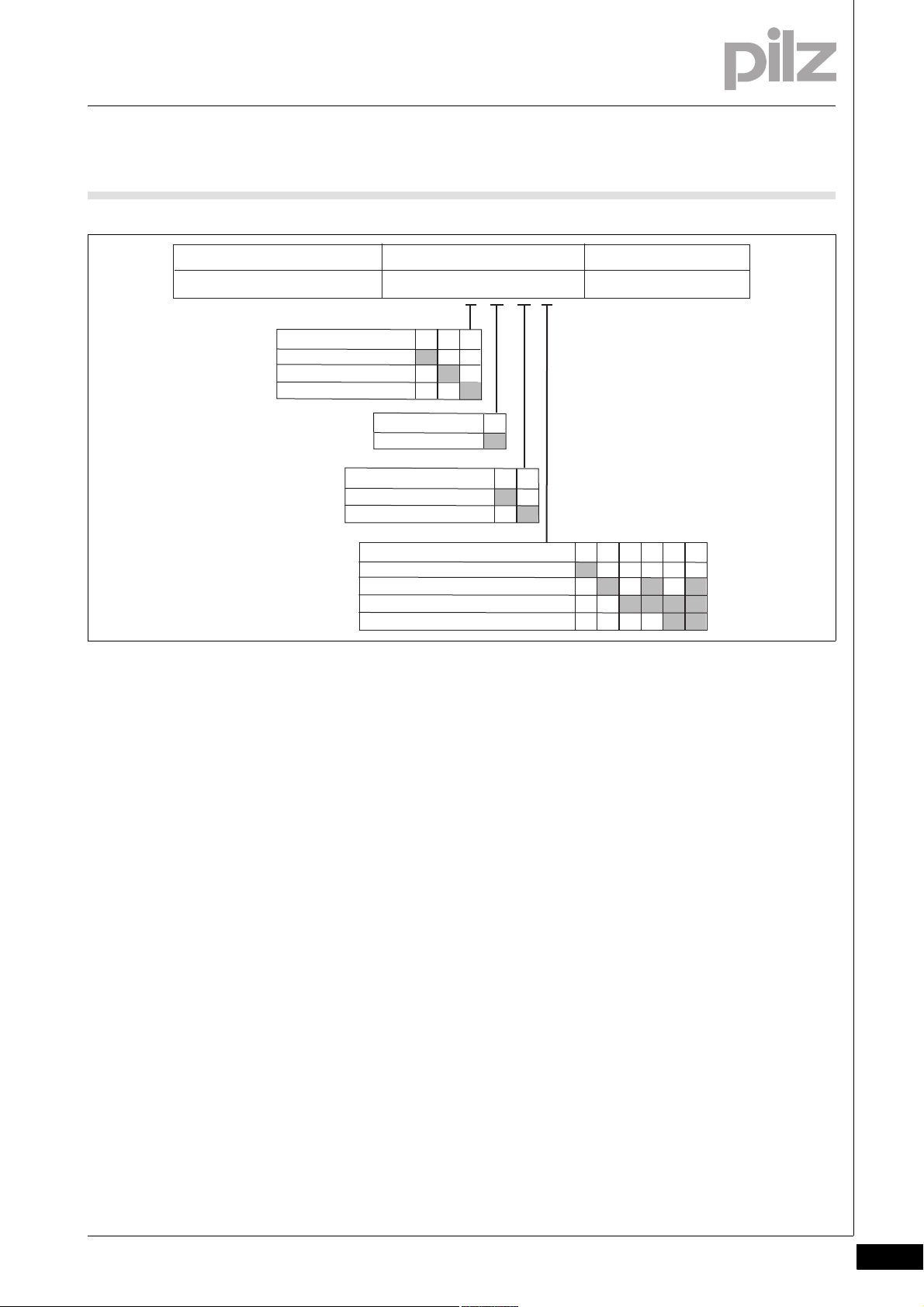

Always state when ordering Type

Supply voltage

Order number PMCprimo C. _ / _ / _ / _ 24 VDC

Hardware

CANopen/CANopen

CANopen/PROFIBUS DP

A B

CPU

0.6 GHz

A

Software

None

Dynamic curve calculation

IEC 61131-3 programming

Path interpolation

2 34567

Servo amplifier

None

PMCprotego D.01-24

PMCprotego D.48-72

012

2.3 Type code

2.3Type code2300Type code2-Typenschlüssel

Fig. 2-1: Type code for PMCprimo C

Explanation of type code

Servo amplifier

Type of servo amplifier in which the PMCprimo C is installed

CPU

Clock frequency of processor

Hardware

– A: Two CANopen interfaces

– B: One CANopen and one PROFIBUS DP Slave interface

Software

– 2: Software options not enabled

– 3, 5, 7: Dynamic curve calculation enabled

The dynamic curve calculation is a calculation program for allocation tables. The allocation table is defined through variables and

scaling. The dynamic curve calculation reads in the variables and

calculates an allocation table.

– 4-7: IEC 61231-3 programming enabled

PLC functionality is programmed with CoDeSys.

– 6, 7: Path interpolation enabled

PLC functionality and path interpolation

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

2-3

Page 14

2 Overview

2.4 Scope of supply

2.4Scope of supply2400Scope of supply2-Lieferumfang

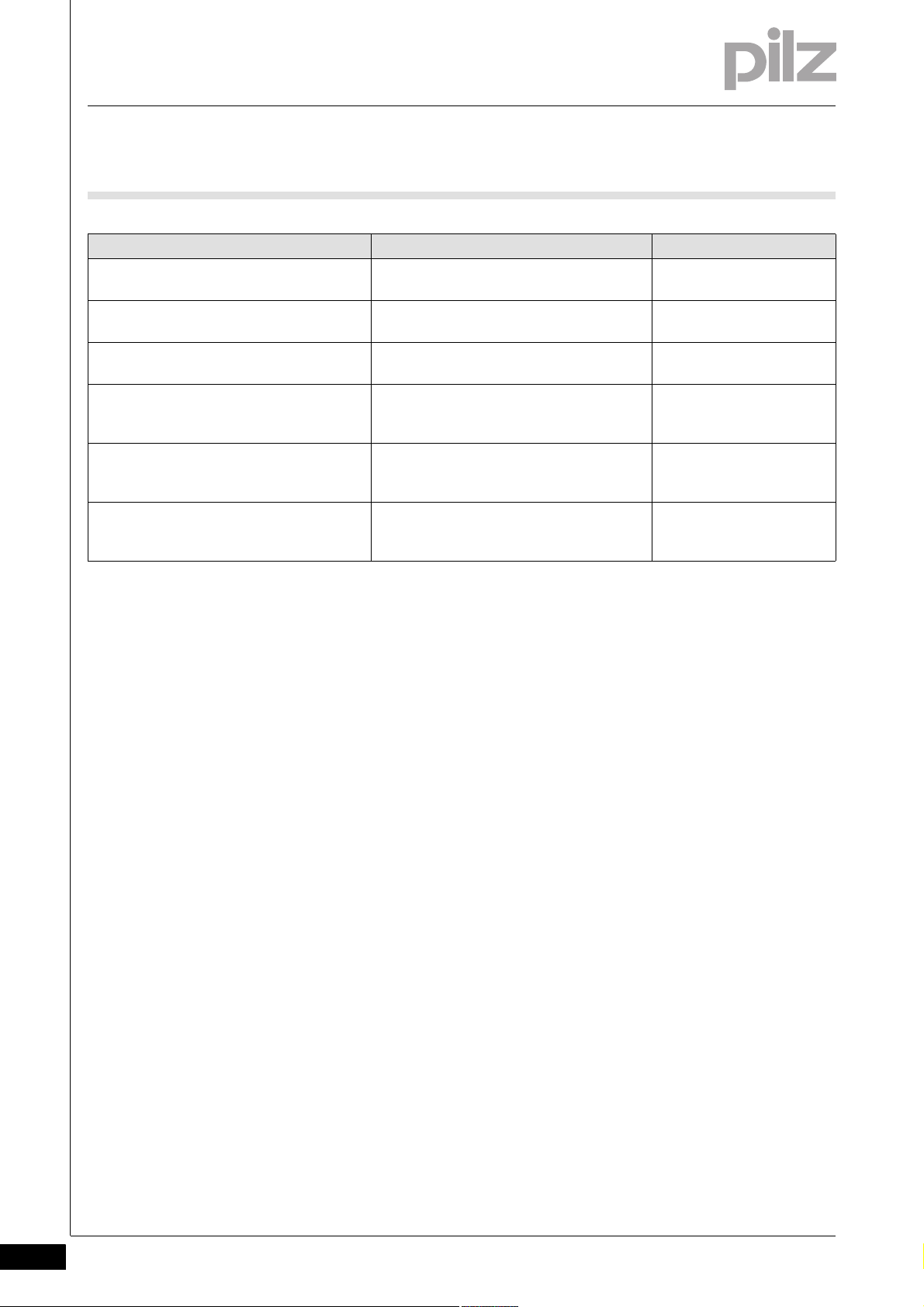

Order reference Description Order number

PMCprimo C Expansion card for motion controller (for

function range see "Type code")

PMCprotego D.CAN-CANbus Adapter 0124A incl. RJ45 connection cable

PMCprotego D.CAN-CANbus Adapter 4872A incl. RJ45 connection cable

PMCprotego D.CAN-PROFIBUS Adapter

01-24A incl. RJ45 connection cable

PMCprotego D.CAN-PROFIBUS Adapter

48-72A incl. RJ45 connection cable

CD-ROM "Documentation Motion Control" Operating manual PMCprimo C,

Fieldbus junction box with two CANopen

interfaces for PMCprotego D.01 … D.24

Fieldbus junction box with two CANopen

interfaces for PMCprotego D.48/D.72

Fieldbus juction box with one CANopen interface and one PROFIBUS interface for

PMCprotego D.01 … D.24

Fieldbus juction box with one CANopen interface and one PROFIBUS interface for

PMCprotego D.48/D.72

Manuals for Pilz products from the PMC

product area

See "Type code"

680040

680042

680041

680043

---

2-4

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 15

3 Security

3.1 Intended use

33000SecuritySecurity3-3.1Intended use3100Intended use3-BA_Sicherh eit_Bestimmung

The motion controller PMCprimo C is suitable for use in logic and motion control applications.

Examples of typical application areas for the product are

Clocked production machinery

Continuous manufacturing processes (winding, flying saw, cross cut-

ter)

Machine tools

Packaging machines

Pick and place applications

The motion controller is installed in the servo amplifier PMCprotego D.

Once installed, the environmental conditions of the servo amplifier PMCprotego D apply, e.g. the lower storage temperature (see "Technical

Details" in the operating manual for the servo amplifier).

Bestimmung/Gerätebeschreibung_EMV+Ausschluss

Please note that the PMCprimo C has no internal electrical connection

to the servo amplifier PMCprotego D. When installing and operating the

device, you must refer to the operating manuals for the servo amplifiers,

in particular the safety guidelines.

Intended use includes making the electrical installation EMC-compliant.

The product is designed for use in an industrial environment. It is not

suitable for use in a domestic environment, as this can lead to interference.

The following is deemed improper use in particular:

Any component, technical or electrical modification to the product

Use of the product outside the areas described in this manual

Use of the product outside the technical details (see chapter entitled

“Technical Details”)

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

3-1

Page 16

3 Security

3.2 Safety regulations

3.2Safety regulations3200Safety regulations3-

3.2.1 Use of qualified personnel

Use of qualified personnel3-Sich Qualif. Personal

The products may only be assembled, installed, programmed, commissioned, operated, maintained and decommissioned by competent persons.

A competent person is someone who, because of their training, experience and current professional activity, has the specialist knowledge required to test, assess and operate the work equipment, devices,

systems, plant and machinery in accordance with the general standards

and guidelines for safety technology.

It is the company's responsibility only to employ personnel who:

Are familiar with the basic regulations concerning health and safety /

accident prevention

Have read and understood the safety guidelines given in this descrip-

tion

Have a good knowledge of the generic and specialist standards ap-

plicable to the specific application.

3.2.2 Warranty and liability

Warranty and liability3-Sich Gewhrleistung

3.2.3 Disposal

Disposal3-Si ch Entsorgung nur Standard

All claims to warranty and liability will be rendered invalid if:

The product was used contrary to the purpose for which it is intended

Damage can be attributed to not having followed the guidelines in the

manual

Operating personnel are not suitably qualified

Any type of modification has been made (e.g. exchanging compo-

nents on the PCB boards, soldering work etc.).

When decommissioning, please comply with local regulations regard-

ing the disposal of electronic devices (e.g. Electrical and Electronic

Equipment Act).

3-2

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 17

3 Security

3.3 Standards

3.3Standards3300Standards3-BA_Sicherheit_Normen

To use the device correctly you will need to have a good knowledge of

the relevant standards and directives. The following standards are relevant:

EN 61131-1:2003: Programmable controllers – Part 1: General infor-

mation

EN 61131-2:2003: Programmable controllers – Part 2: Equipment re-

quirements and tests

EN 61131-3:2003: Programmable controllers – Part 3: Programming

languages

Please note this is not an exhaustive list of safety standards and directives.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

3-3

Page 18

3 Security

3-4

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 19

4 Function description

X45

X44

X43

X42

715

Power

=

~

X40

1 2 3

Inputs

SafetyNET p

Ethernet

CANopen

PROFIBUS

9 10 11

4 5 6

12 13 14

Outputs

816

Power

Encoder

Logic

Motion Control

Encoder

X40

X41

STAT RE SET

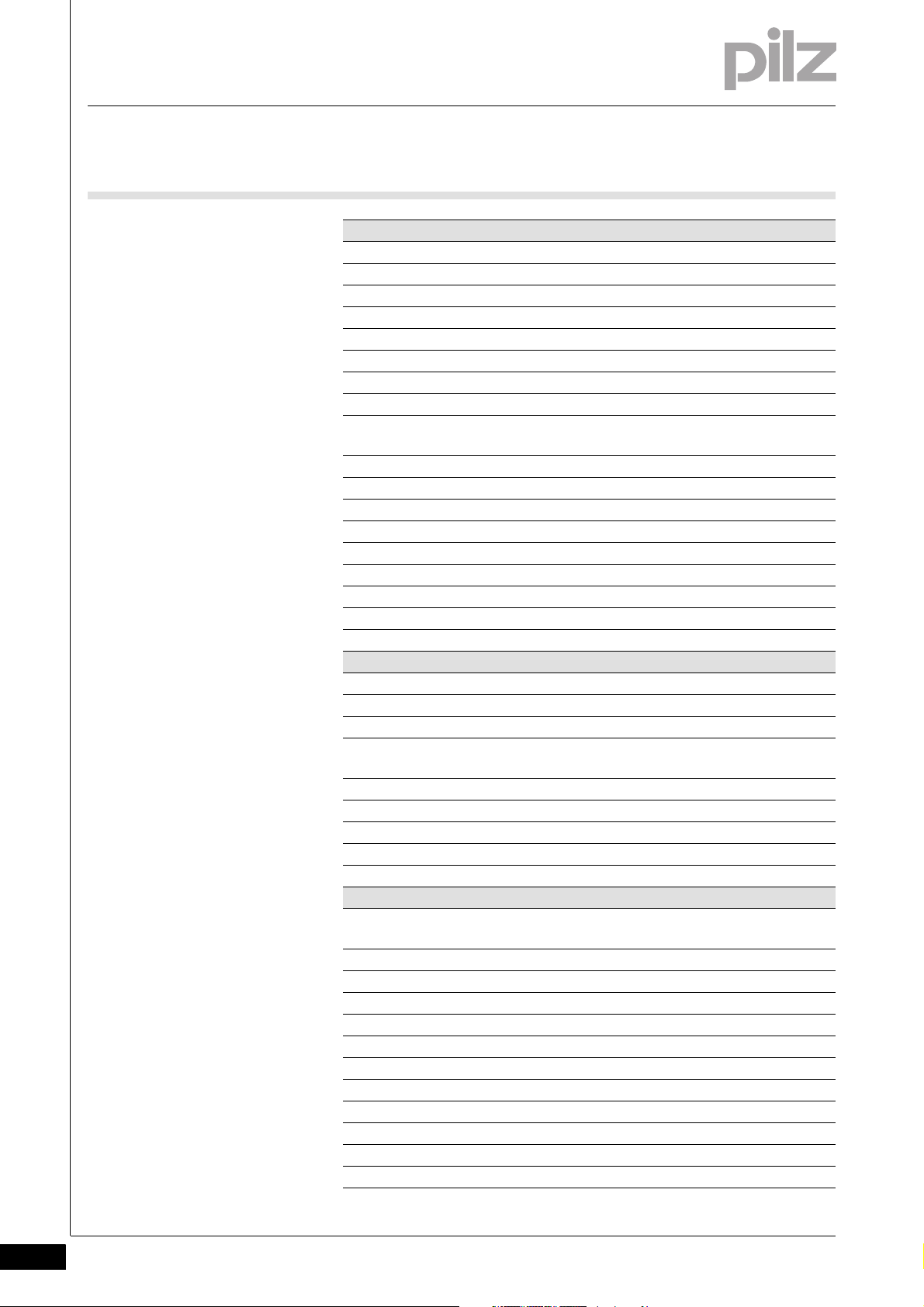

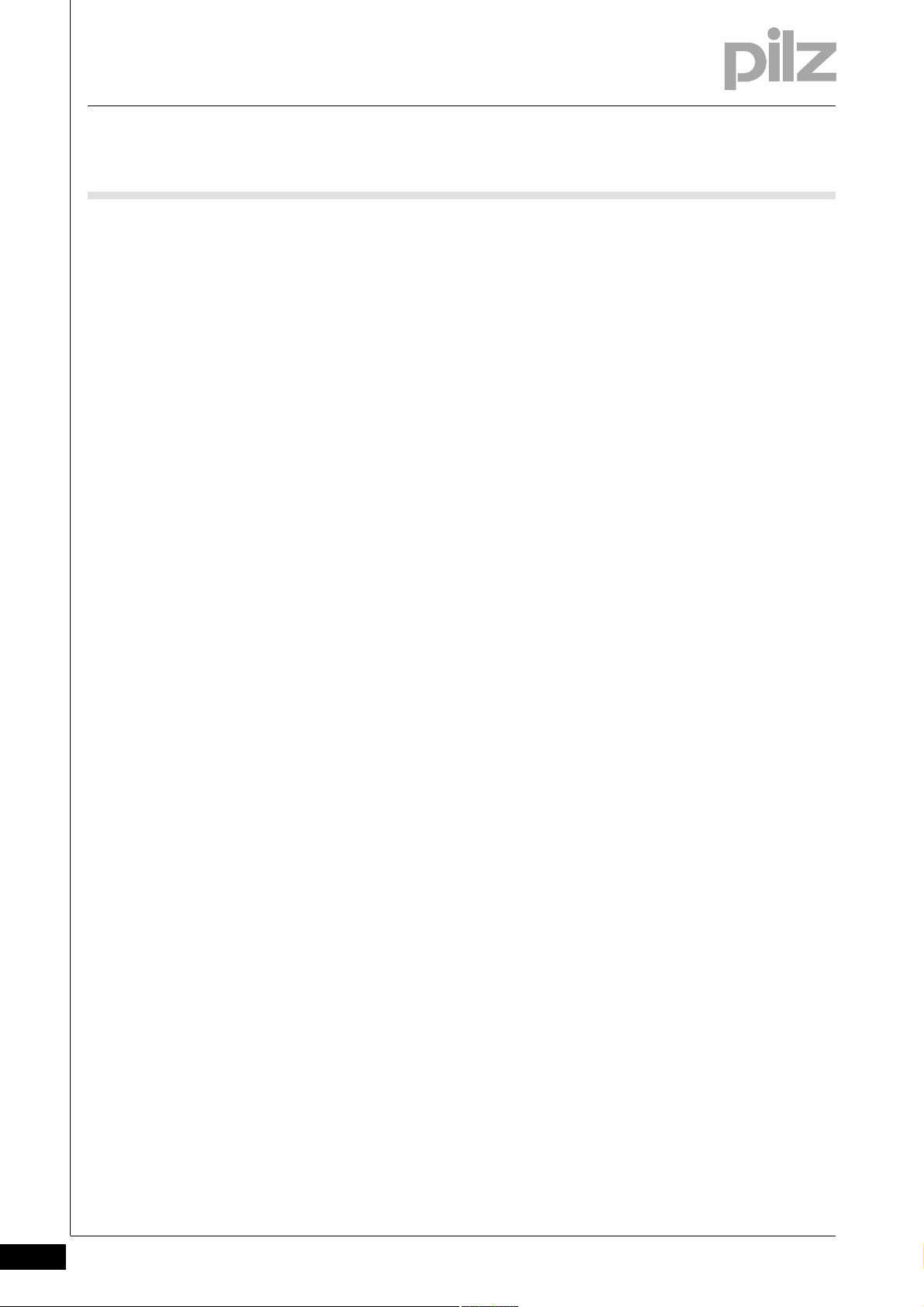

4.1 Device properties

44000Function descriptionFunction description4-4.1Device properties4100Device properties4-

4.1.1 Controller

Controller4-Funktion_PMCprimo_C

The PMCprimo C is a drive-integrated programmable logic controller

with motion control functionalities. The controller has volatile and nonvolatile memory for the operating system, the data and the device

project with the user program.

It can be used for logic and motion control of intelligent drives.

User programs can be programmed in the main IEC 61131-3 languages.

The software CoDeSys is used to program the PLC functionality. The

controller runs as an independent task.

The motion controller has 6 digital inputs and 6 single-pole digital outputs. The inputs and outputs are read cyclically. The cycle times are ≤

1ms. It can also access inputs and outputs on networked servo amplifiers from the PMC product area.

Funktion_PMCprimo_C_Blockschaltbild

The motion controller has fieldbus interfaces for communication with the

periphery.

An additional encoder can be connected (incremental encoder with TTL

signal or absolute encoder with SSI interface).

An LED provides information about the controller's operating states.

Funktion_PMCprimo_C_Umfeld

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Fig. 4-1: Block diagram PMCprimo C

4-1

Page 20

4 Function description

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

START

RESET

680050 12

100001

X45

X44

X43

X42

X41

X40

X42

X6B

CANopen 1

CANopen 2

PROFIBUS DP

X6C

1

1

Ethernet

X43

3

2

4.1 Device properties

The motion controller PMCprimo C (1) is installed in a servo amplifier

PMCprotego D (3). A fieldbus junction box PMCprotego D.CAN-CANbus Adapter or PMCprotego D.CAN-PROFIBUS Adapter (2) is used for

networking (CANopen, PROFIBUS DP).

4.1.2 Supply voltage

Supply voltage4-Funktion_Versorgung

Fig. 4-2: Installation of the motion controller in a servo amplifier PM-

Cprotego D

The PMCprimo C has two supply voltages:

X40/7,15

Supply voltage for the device and the digital outputs (24 VDC)

X40/8,16

Supply voltage for the encoder (5 V, 24 VDC)

The voltage is connected directly to the female 9-pin D-Sub connec-

tor X41/4,9.

Internally the two supply voltages are galvanically isolated. The two

earths can be connected externally.

4-2

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 21

4 Function description

4.1 Device properties

4.1.3 Digital inputs

Digital inputs4-Funktion_Eingaenge

The device has 6 digital inputs.

The inputs are compatible with EN 61131-2, Type 1.

The time behaviour of the digital inputs depends on the method of use:

With normal use, the inputs have a filter time of ≤ 600 μs.

If the inputs are used as reference inputs, the reaction time to 0/1 or

1/0 pulse edges is < 5μs.

The inputs can be used as reference inputs, to poll the position of the

encoder for example.

4.1.4 Digital outputs

Digital outputs4-Funktion_Ausgaenge

4.1.5 Interfaces

Interfaces4-

The device has 6 single-pole digital outputs.

Signals at the output

"0" signal (0 V) at the output:

– Output is high impedance

– No current to the load

"1" signal (+24 V) at the output:

– Output is low impedance

– Current is supplied to the load

– The maximum current strength per output is 0.5 A.

All digital outputs are protected against short circuit and overload.

The outputs can be used to connect relays, valves or inputs from another controller, for example.

4.1.5.1 Overview

Overview4-Funktion_Schnittstellen_PMCprimo_C

The motion controller PMCprimo C has various fieldbuses for communication with the periphery. These are available on four RJ45 sockets on

the front of the device. The interfaces are suitable for the following applications:

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

4-3

Page 22

4 Function description

4.1 Device properties

CANopen

– Real-time capable networking between CAN devices and the mo-

tion controller

– Suitable for applications

–with (≤ 32) subscribers

– with cycle time (≥ 1ms)

– in existing networks (e.g. with PMCtendo DD5).

– Connection to the servo amplifier PMCprotego D via the fieldbus

junction box PMCprotego D.CAN-CANbus Adapter (supplied with

the device)

PROFIBUS DP Slave

– Networking between the motion controller and a PROFIBUS Mas-

ter.

– Suitable for data exchange with a third party controller.

– Connection to the servo amplifier PMCprotego D via the fieldbus

junction box PMCprotego D.CAN-PROFIBUS Adapter (supplied

with the device)

Ethernet

– Ethernet TCP/IP

– Communication between the programming device and the mo-

tion controller

– Suitable for configuration, programming, commissioning

– Modbus TCP/IP

– Communications protocol based on Industrial Ethernet (TCP/IP

over Ethernet).

– Suitable for networking between the motion controller and a vis-

ualisation device or a PSS 4000, for example.

SafetyNET p (in preparation)

– SafetyNET p RTFN

– Communication based on Standard Ethernet.

– Networking between controllers or cells and SafetyNET p RTFL

devices.

– Standard communication

– Basic topology: Star

– SafetyNET p RTFL

– Real-time capable networking between SafetyNET p RTFL de-

vices and the motion controller PMCprimo C and automation

system PSS 4000.

– The RTFL transport layer enables cycle times to be optimised,

enabling it to be used in extremely time-critical applications.

– Standard communication

– Basic topology: Linear

4-4

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 23

4 Function description

4.1 Device properties

4.1.5.2 CANopen

CANopen4-Funktion_CANopen

The CANopen interface is suitable for networking drive components at

field level. It meets the requirements defined in the communications protocol DS-301.

The following device classes with CANopen device profiles are supported:

I/O modules DS-401

Electrical drives DS-402

Funktion_CANopen_PMCprimo_C

Encoders DS-406

The CAN network is designed as a linear structure. The CANopen communication protocol is based on CAN.

CAN networking with the motion controller is suitable for applications

with a maximum subscriber number of ≤ 32 and a cycle time ≥ 1ms.

Only CAN devices that are known to the controller or support a cor-

responding device profile can be operated in the motion controller's

CAN network.

CAN devices detected by the motion controller are ready for opera-

tion immediately after the initial network run-up. No complex configuration of the CAN devices is required.

The overall cable length and the length of the stub lines depend on the

transmission rate.

Process data objects (PDO) are defined for each CAN device type and

cannot be customised by the user.

For servo amplifiers, the "FS" command can be used to set which

process data is to be exchanged between the motion controller and

the servo amplifier (see "PMCprimo Programming Manual").

The signal lines must be terminated with resistors (120 Ohm) on the

first and last subscriber. The resistors are generally integrated within

the connected devices and can be activated there. For a

PMCprimo C, a terminating resistor can be activated in the fieldbus

junction box PMCprotego D.CAN-CANbus Adapter or

PMCprotego D.CAN-PFOFIBUS Adapter.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

4-5

Page 24

4 Function description

4.1 Device properties

4.1.5.3 PROFIBUS DP

PROFIBUS DP4-Funktion_PROFIBUS

PROFIBUS is an open fieldbus standard. Communication is defined in

IEC 61158 and IEC 61784. Further provisions have been defined in

specifications published by the PROFIBUS User Group. These specifications are available from PROFIBUS International.

On a certain unit type, the PROFIBUS interface is available together with

Funktion_PROFIBUS_primo_C

a CANopen interface on an RJ45 socket (X42).

Properties:

The PROFIBUS is configured using the CD command: Slave address,

address range, see PMCprimo Programming Manual.

A total of up to 108 bus variables can be read and written (see PMCp-

rimo Programming Manual):

– Address space of bus variables: $B1 to $Bx108 (can be set using

the CD command).

– Data width: 16 Bit including sign

– Value range: -32768 to 32767 (Hex: 0x0000 to 0x7FFF).

When changing the variable content, any programs can be started if

the bus variables have been defined as trigger variables.

PROFIBUS_Hinweis_Nutzerorganisation

4.1.5.4 Ethernet

Ethernet4-Funktion_Gigabit_Ethernet

INFORMATION

The GSD file is available on the supplied CD-ROM. The name of

the description file can be found in the "Technical Details".

INFORMATION

Please also refer to the installation guidelines published by the

PROFIBUS User Group.

The Gigabit Ethernet interface (X43) connects the PMCprimo C to a pro-

gramming device for configuration, programming and commissioning.

The interface can also be used to connect a visualisation device.

The Gigabit Ethernet interface is compatible with 1000Base-T (Standard

Gigabit Ethernet). Data exchange is possible via Modbus TCP/IP.

4-6

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 25

4 Function description

4.1 Device properties

4.1.5.5 SafetyNET p (in preparation)

SafetyNET p (in preparation)4-Funktion_SN

The components at field level are connected to the Ethernet-based multi-master bus system SafetyNET p. Higher speeds are required, so the

RTFL transport layer is used. The RTFL transport layer enables scan

times to be optimised and can therefore be used in extremely time-critical applications, such as drive controllers.

Two SafetyNET p interfaces are available for connection to a

SafetyNET p network (X44, X45).

Functions

The PMCprimo C receives signals from other network subscribers; it

processes these signals in the user program and passes them on to

the connected components.

Hinweis_PSS4000

4.1.6 Encoder

Encoder4-Funktion_Geber

MAC address

The MAC address is a factory-set default. The address can be read

with the PTerm software, using the "VN1" command

INFORMATION

Further information is available in the "System Description PSS

4000".

A rotary encoder can be connected to the 9-pin D-Sub socket X41.

The following encoder systems are supported:

Incremental encoder with TTL signal

Absolute encoder with SSI interface

The encoder's supply voltage is connected to separate terminals on the

unit (X40/8,16). The size of the voltage depends on the encoder (e.g. 5 V,

10 - 30 VDC).

INFORMATION

Refer to the chapter entitled "Wiring" for details of how to connect the supply voltage.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

4-7

Page 26

4 Function description

4.1 Device properties

4.1.7 Reset button

Reset button4-Funktion_Reset_Taster

The "RESET" button is mounted in a recess on the front of the unit. It can

only be accessed using an appropriate tool (e.g. a pin).

The following actions can be triggered by pressing the "RESET" button:

Change from "Startup" operating status to "Boot Menu"

Hardware reset (cold start): Change from "RUN" or "STOP" operating

status to "Startup"

Change from "RUN" operating status to "STOP"

Change from "STOP" operating status to "RUN"

INFORMATION

Further information on the reset button can be found in the

chapter entitled "Operation".

4-8

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 27

4 Function description

4.2 Software

4.2Software4200Software4-Uebersicht_System_PMCtools

Various tools are available for planning, configuration, programming and

commissioning. They are used to create a project:

Motion control tools

The motion control tools are a software package used to operate and

commission the motion control systems.

–Terminal program PTerm

PTerm can be used to send commands directly to the hardware. It

can also be used for firmware updates and for basic configuration

of the motion controller.

– Oscilloscope function PScope

PScope is a PC-based oscilloscope with up to 4 channels. It can

be used to record and visualise signals from controllers and servo

amplifiers.

– Elliptical curve construction PMotion

PMotion is a tool for constructing elliptical curves.

– Commissioning software PDrive

PDrive is used to parameterise and commission the servo amplifier

PMCprotego D.

CoDeSys

CoDeSys is a development environment for programming controllers

in accordance with IEC 61131-3. Additional commands for motion

Funktion_Version_CoDeSys_2.3.9

sequences have been added.

INFORMATION

For programming in accordance with IEC 61131-3 you will need

CoDeSys Version 2.3.9. This software is available on the current

CD-ROM "Motion Control Tools".

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

4-9

Page 28

4 Function description

4-10

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 29

5 Installation

5.1 General requirements

55000InstallationInstallation5-5.1General requirements5100General requirements5-Montage

Montage_EMV ESD

Montage_Einbau

Please also refer to the operating manual for the servo amplifier.

CAUTION!

Damage due to electrostatic discharge!

Electrostatic discharge can damage components. Ensure

against discharge before touching the product, e.g. by touching

an earthed, conductive surface or by wearing an earthed armband.

NOTICE

The motion controller is installed in the servo amplifier

PMCprotego D. Once installed, the environmental conditions of

the servo amplifier PMCprotego D apply (see "Technical Details"

in the operating manual for the servo amplifier).

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

5-1

Page 30

5 Installation

18,4

(0.72'')

2,5

(0.098'')

175 (6.89'')

97,4 (3.83'')

5.2 Dimensions

5.2Dimensions5200Dime nsions5-Montage

Fig. 5-1: Dimensions, stated in mm (")

5-2

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 31

5 Installation

PMCprotego D.01

PMCprotego D.03

PMCprotego D.06

PMCprotego D.12

PMCprotego D.24 PMCprotego D.48

PMCprotego D.72

Slot 1/2

Slot 1/2

Slot 1/2

5.3 Installing the unit

5.3Installing the unit5300Installing the unit5-Montage_primo_C

The PMCprimo C is installed in slots 1 and 2 of the servo amplifier

PMCprotego D. When installing, please note the guidelines given under

"Installation" in the operating manual for the servo amplifier.

Fig. 5-2: Slots 1 and 2 for installing the PMCprimo C

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

5-3

Page 32

5 Installation

START

RESET

X45

X6D

X6

5.4 Installing the fieldbus junction box

5.4Installing the fieldbus junction box5400Installing the fieldbus junction box5-Montage_Feldbusverteiler

A fieldbus junction box is included with the PMCprimo C. The fieldbus

junction box is plugged into the servo amplifier.

INFORMATION

Pin assignment, wiring and assembly are described in the operating manual for the fieldbus junction box.

To install the fieldbus junction box, follow the instructions below:

Switch off the mains voltages and 24 V supply!

Connect the 9-pin female D-Sub connector X6D to the male connec-

tor X6 on the servo amplifier.

Montage_Feldbusverteiler_Abb

Turn the screws into the thread on the housing.

5-4

Fig. 5-3: Installing the fieldbus junction box on a servo amplifier

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 33

6 Wiring

6.1 Wiring guidelines

66000WiringWiring6-6.1Wiring guidelines6100Wiring guidelines6-Verdr_Leiterquerschnitte

Please note:

Cable cross sections for field connection terminals in mm

Verdr_Allgemein

Inputs

Appropriate wiring must be used to exclude short circuits between

Cables must be shielded if the signals are used as reference inputs.

Outputs

If short circuits occur between the cable from the output to the load

Use appropriate wiring to exclude short circuits between the outputs!

The actuators may be connected using unshielded cables.

The outputs do not need suppression for inductive loads.

2

:

– Digital inputs/outputs, supply voltage: 0.5 (AWG20) ... 1.0

(AWG18), AEH without plastic collar, in accordance with DIN

46228/1

the inputs or to a supply line!

Other signal lines do not need to be shielded.

and a supply line, it will no longer be possible to switch off the load.

Possible remedy: Use separate multicore cable for supply voltages.

Cable material

Use copper wiring.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

6-1

Page 34

6 Wiring

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

6.2 Connector pin assignment X40

6.2Connector pin assignment X406200Connector pi n assignment X406-Verd r_primo_C_X40_Klemmenbelegung

Connector X40 Pin Designation Description

1 I1:1 Digital input 1

2 I1:2 Digital input 2

3 I1:3 Digital input 3

4 O1:1 Digital output 1

5 O1:2 Digital output 2

6 O1:3 Digital output 3

7 +24 V Supply voltage for unit and digital outputs (24

V)

8 Encoder Supply Supply voltage for encoder

9 I1:4 Digital input 4

10 I1:5 Digital input 5

11 I1:6 Digital input 6

12 O1:4 Digital output 4

13 O1:5 Digital output 5

14 O1:6 Digital output 6

15 0 V Supply Supply voltage for unit and digital outputs,

reference earth for digital inputs and outputs

(0 V)

16 0 V Encoder Supply voltage for encoder (0 V)

6-2

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 35

6 Wiring

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

L3

7

X40

L1

L2

15

+24 V

0 V Supply

PE

+24 V

6.3 Supply voltage

6.3Supply voltage6300Supply voltage6-Verdr_Versorgung

Verdr_Versorgung_Warnung

The digital outputs and the unit need a 24 VDC supply.

When selecting the power supply, please refer to the requirements

stated under “Technical Details”.

The power supply must be able to bridge a power outage of 20 ms.

WARNING!

Electric shock!

Safe electrical isolation must be ensured for the external power

supply that generates the supply voltage. Failure to do so could

result in electric shock. The power supplies must comply with

EN 60950-1, 05/2006, EN 61558-2-6, 11/1997.

Verdr_primo_C_X40_Versorgung

Connector pin assignment

Connector X40 Pin Designation Description

7 +24 V Supply voltage + 24 VDC

15 0 V Supply Earth for supply voltage

Connection

24 V connection isolated from external power supply, e.g. with isolating

transformer

Noise suppression filter integrated

within the unit

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

6-3

Page 36

6 Wiring

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

1

2

3

9

0V

10

24 V

I/O-GND

X40

11

15

I1:1

I1:6

I1:5

I1:4

I1:3

I1:2

ShieldServo Drive

Shield

6.4 Digital inputs

6.4Digital inputs6400Digital inputs6-Verdr_primo_C_X40_Inputs

Connector pin assignment

Connector X40 Pin Designation Description

1 I1:1 Digital input 1

2 I1:2 Digital input 2

3 I1:3 Digital input 3

9 I1:4 Digital input 4

10 I1:5 Digital input 5

11 I1:6 Digital input 6

15 0 V Supply Reference earth for digital inputs

Connection

Input circuit Digital input

24 VDC, referenced to earth (X40/15)

Cables must be shielded if the signals are used as reference inputs.

Example: Reference inputs I1:1 and

I1:2 (Pin 1, 2)

6-4

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 37

6 Wiring

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

DI 5

5

6

12

X40

DI 4

4

DI 2

DI 1

DI 3

14

O1:1

13

DI 6

O1:2

O1:3

O1:4

O1:5

O1:6

7

15

+24 V

0 V

+24 V

I/O-GND

6.5 Digital outputs

6.5Digital outputs6500Digital outputs6-Verdr_primo_C_X40_Outputs

Connector pin assignment

Connector X40 Pin Designation Description

4 O1:1 Digital output 1

5 O1:2 Digital output 2

6 O1:3 Digital output 3

7 +24 V Supply voltage for digital outputs

12 O1:4 Digital output 4

13 O1:5 Digital output 5

14 O1:6 Digital output 6

15 0 V Supply Reference earth for digital outputs

Connection

Output circuit Digital output

24 VDC, referenced to earth (X40/15)

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

6-5

Page 38

6 Wiring

X45

X44

X43

X42

8

1

8

1

8

1

8

1

6.6 Interfaces

6.6Interfaces6600Interfaces6-

6.6.1 Overview

Overview6-Verdr_primo_C_X42_X45_Uebersicht

Four RJ45 sockets with interfaces are available on the front.

Socket assignment

Socket X42 Connector Description

X45 SafetyNET p interface

X44 SafetyNET p interface

X43 Ethernet interface

X42 Depending on the unit type:

- 2 CANopen interfaces

- 1 CANopen/ 1 PROFIBUS DP interface

6.6.2 CANopen, PROFIBUS DP

CANopen, PROFIBUS DP6-Verdr_ primo_C_X42_Varianten

Depending on the unit type, socket X42 is assigned to

A combined CANopen/PROFIBUS DP interface

Two CANopen interfaces

6.6.2.1 Wiring guidelines for the CANopen interface

Wiring guidelines for the CANopen interface6-CANopen_Leitungen

The CAN network is designed in a linear structure.

The overall cable length and the length of the stub lines depend on the

transmission rate and on the cable properties (cable resistance and

cable capacitance).

The signal lines must be terminated with resistors on the first and last

subscriber.

A characteristic impedance of 120 Ohm is acceptable for bus lengths

up to 40 m.

6-6

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 39

6 Wiring

Node 1

Node 2

Node n-1

Node n

RT [

W

]

l

a

Node 3

A

A

RT [

W

]

6.6 Interfaces

Fig. 6-1: Overall length and length of the stub lines on a CAN net-

work.

Legend:

Node: CANopen subscriber

a: Length of stub line

A: Branch

R

: Terminating resistor

T

Relationship between transmission rate, bus length and length of stub

lines:

Transmission

rate [kBit/s]

1000 25 1,5 7,5

500 100 5,5 27,5

250 250 11 55

125 500 22 110

Bus length l [m] Length of stub

line a [m]

Overall length of

all stub lines [m]

The following table provides an approximate overview of the size of the

terminating resistor R

with different cable lengths. In each specific

T

case, details of the characteristic impedance can be found in the cable

specification .

CANopen_Hinweis_Nutzerorganisation

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Bus length l [m] Terminating resistor RT [Ohm]

0 – 40 120

40 – 300 150 - 300

300 - 500 150 - 300

6-7

Page 40

6 Wiring

8

1

8

1

6.6 Interfaces

INFORMATION

Please also refer to the installation guidelines published by the

CANopen User Group.

6.6.2.2 Two CANopen interfaces

Two CANopen interfaces6-Verdr_primo_C_X42_CANopen_CANopen

There are two CANopen interfaces on the same socket. The two CANopen interfaces use the same operating earth (GND).

Socket assignment

Socket X42 Pin Designation Description

1n.c.

2n.c.

3GND Earth

4 CAN2_H CAN2 high signal

5 CAN2_L CAN2 low signal

6GND Earth

7 CAN_H CAN1 high signal

8 CAN_L CAN1 low signal

n.c. = not connected

6.6.2.3 CANopen/PROFIBUS DP interface

CANopen/PROFIBUS DP interface6-Verdr_primo_C_X42_CANopen_PROFIBUS

The PROFIBUS and CANopen interface are on the same socket. The

PROFIBUS and CANopen interface use the same operating earth (GND).

Socket assignment

Socket X42 Pin Designation Description

1 CNTR-P (RTS) PROFIBUS RTS

2 n.c. n.c.

3GND Earth

4 RxD/TxD-N PROFIBUS A-line

5 RxD/TxD-P PROFIBUS B-line

6GND Earth

7 CAN_H CAN high signal

8 CAN_L CAN low signal

n.c. = not connected

PROFIBUS_Hinweis_Nutzerorganisation

6-8

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 41

6 Wiring

8

1

8

1

6.6 Interfaces

INFORMATION

Please also refer to the installation guidelines published by the

PROFIBUS User Group.

6.6.3 Ethernet

Ethernet6-Verdr_primo_C_X43_Ethernet

Socket assignment

Socket X43 Pin Designation Description

1D1+ TX D1+

2D1- TX D1-

3D2+ RX D2+

4D3+ BI D3+

5D3- BI D3-

6D2- RX D2-

7D4+ BI D4+

8D4- BI D4-

The Ethernet interface is compatible with 1000Base-T (Standard Gigabit

Ethernet)

Recommended cable: Cat 5e SF/UTP

6.6.4 SafetyNET p (in preparation)

SafetyNET p (in preparation)6-Verdr_primo_C_X44_45_SN

SafetyNET p is an Ethernet interface. Further information can be found

in the "System Description PSS 4000".

Socket assignment

Socket X44, X45 Pin Designation Description

1 TD+ (yellow) Transmit+

2 TD- (orange) Transmit-

3 RD+ (white) Receive+

4n.c.

5n.c.

6 RD- (blue) Receive-

7n.c.

8n.c.

n.c. = not connected

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

6-9

Page 42

6 Wiring

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

8

X40

L1

0 V

16

+V

PE

X41

4

9

0 V

+V

6.7 Encoder

6.7Encoder6700Encoder6-

6.7.1 Supply voltage

Supply voltage6-Verdr_Versorgung_Warnung

WARNING!

Electric shock!

Safe electrical isolation must be ensured for the external power

supply that generates the supply voltage. Failure to do so could

result in electric shock. The power supplies must comply with

EN 60950-1, 05/2006, EN 61558-2-6, 11/1997.

Verdr_primo_C_Encoder_Versorg

Connector pin assignment

Connector X40 Pin Designation Description

8 Encoder Supply Supply voltage for external encoder

16 0 V Encoder Supply Supply voltage for external encoder (0 V)

Supply voltage

Connection

X40/8 is linked internally to X41/4

and X40/16 to X41/9

6-10

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 43

6 Wiring

1

5

6

9

1

6

2

X41

3

Incremental encoder

7

8

9

V+

0 V

0 V

4

B

B\

A

A\

Z

Z\

B

B\

A

A\

Z

Z\

V+

X40

0 V

V+

8

16

6.7 Encoder

6.7.2 Incremental encoder with TTL signal

Incremental encoder with TTL signal6-Verdr_primo_C_X41_Inkremental

If the cable length is > 50 m, please speak to our Customer Support.

Socket assignment

Socket X41 Pin Designation Description

1 A Channel A

2 B Channel B

3 Z Reference pulse Z

4 V+ Supply voltage

5n. c.

6 A\ Channel A inverted

7B\ Channel B inverted

8 Z\ Reference pulse Z inverted

9 0 V Supply voltage 0 V

n. c. = not connected

Connection

Input circuit Incremental encoder

Twisted pair, shielded

Shield connection in the housing

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

6-11

Page 44

6 Wiring

1

5

6

9

2

7

1

X41

4

Encoder

6

9

CLOCK

CLOCK\

DATA

DATA\

CLOCK

CLOCK\

DATA

DATA\

0 V

Vcc

V+

0 V

X40

0 V

V+

8

16

6.7 Encoder

6.7.3 Absolute encoder with SSI interface

Absolute encoder with SSI interface6-Verdr_primo_C_X41_SSI

If the cable length is > 50 m, please speak to our Customer Support.

Socket assignment

Socket X41 Pin Designation Description

1 CLOCK Pulse signal

2DATA Data

3n.c. ---

4 V+ Supply voltage

5n.c. ---

6 CLOCK\ Pulse signal inverted

7 DATA\ Data inverted

8n.c. ---

9 0 V Supply voltage 0 V

n c.: not connected

Connection

Input circuit Absolute encoder with SSI interface

Shielded

Shield connection in the housing

6-12

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 45

7 Commissioning

7.1 Safety guidelines

77000CommissioningComm issioning7-7.1Safety guidelines71 00Safety guidelines7-Inbetrieb_Sicherheit_primo_C

This chapter describes the communication between a PMCprimo C and

a servo amplifier PMCprotego D during initial commissioning.

Further information on commissioning the servo amplifier can be found

in the operating manual.

][Inbetrieb_Sicherheit

Please note the following safety guidelines during commissioning:

When commissioning, you must ensure that the control systems do

To avoid personal injury and material damage, only qualified, trained

Prior to commissioning the machine manufacturer must produce a

Only specialist staff with extensive knowledge of drive technology

Data stored on data media is not protected from unintended changes

Prior to installation and commissioning, information in this operating

It is essential to comply with the technical details and specifications

Life-threatening voltages up to 900 V are present. Check that all live

The heat sink and front plate temperature on the amplifier may reach

CAUTION!

not present a risk to persons, plant or machinery. Appropriate protection and precautionary measures must be put in place.

personnel should work on the devices. Qualified technical staff are

those who are familiar with the transport, installation, commissioning,

maintenance and operation of the device. They will be familiar with

the relevant standards and regulations.

hazard analysis for the machine and take appropriate measures to ensure that unexpected movements do not cause injury to people or

damage to equipment.

and control engineering should be permitted to program a running

drive online.

by third parties. Data must be checked for accuracy before it is downloaded to the control system.

manual, and in particular the safety guidelines, must be carefully read

and considered (see Chapter entitled “Safety”). Personal injury and

material damage may result if devices are handled incorrectly.

(type label and documentation).

connections are safely protected against contact.

80°C during operation. Check (measure) the temperature of the heat

sink. Wait until the heat sink has cooled to 40°C before touching it.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

7-1

Page 46

7 Commissioning

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

START

RESET

680050 12

100001

X45

X44

X43

X42

X41

X40

X42

1

X43

X40

+24 V

0 V

L3

7

L1

L2

15

PE

X4A

1

2

4

5

6

3

+24 V

0 V

1

2

PMCprimo C

PMCprotego D

Ethernet

CANopen 2/PROFIBUS DP

PMCprotego D.CAN-CANbus-Adapter

L3

L1

L2

PE

CANopen 1

7.2 Commissioning the PMCprimo C

7.2Commissioning the PMCprimo C7200Commissioning the PMCprimo C7-

7.2.1 Preparing for commissioning

Preparing for commissioning7-Inbetrieb_vorbereiten_primo_C

Install the PMCtools

The following PMCtools are available on the supplied CD-ROM:

PTerm

PDrive

PScope

PMotion

PEdit

PVIS PMC Configurator

CoDeSys with Target Support Package (TSP)

The CD also contains:

Operating manuals for the respective software

ASCII help files from Danaher/Kollmorgen

1. Insert the "Pilz Motion Control" CD into the drive on your PC.

The CD starts automatically.

2. Select the

The software is installed on your PC.

Motion Control Tools

menu.

7-2

Connect PMCprimo C and PMCprotego D

Fig. 7-1: Connect PMCprimo C and PMCprotego D

Prerequisites:

The motion controller PMCprimo C must be installed in a servo am-

plifier.

A fieldbus junction box PMCprotego D.CAN-CANbus Adapter or

PMCprotego D.CAN-PROFIBUS Adapter must be inserted.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 47

7 Commissioning

7.2 Commissioning the PMCprimo C

Establish the following connections:

Connect X42 on the motion controller to X6E on the fieldbus junction

box using the supplied RJ45 cable.

Connect the Ethernet interface X43 on the motion controller to the

PC.

Connect the supply voltages

Servo amplifier:

– PMCprotego D.01 … D.24

X4A/1: 24 V

X4A/2: 0 V

– PMCprotego D.48 or PMCprotego D.72

X4/1: 24 V

X4/3: 0 V

PMCprimo C:

– X40/7: 24 V

– X40/15: 0 V

Apply the supply voltages

Switch on the supply voltages for the motion controller and the servo

amplifier's control element.

Start the units. The motion controller PMCprimo C scans the network for

subscribers.

Logical axes are automatically assigned to the servo amplifiers in the

motion controller if

No configuration is stored on the motion controller.

New servo amplifiers are detected in the existing configuration.

7.2.2 Establish communication PMCprimo C <-> PC

Establish communication PMCprimo C <-> PC7-Inbetrieb_primo_C_PC

The following steps describe how to establish a connection between the

PC and motion controller via the Ethernet interface.

Prerequisite:

The motion controller PMCprimo C must be installed in a servo am-

plifier PMCprotego D.

The software tools must be installed on the PC.

The supply voltages (24 VDC) must be present on the servo amplifier

and PMCprimo C.

The configuration PC must be connected to the Ethernet interface

X43 on the PMCprimo C.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

7-3

Page 48

7 Commissioning

7.2 Commissioning the PMCprimo C

Establish the connection

1. Open the terminal program

PTerm

.

Inbetrieb_primo_C_PC_alt1

Inbetrieb_primo_C_PC_alt2

2. Select

The

Connect via

File -> Connect

.

… window opens.

You can now connect to a known network subscriber. If you do not

know the IP address, you can browse the network for subscribers.

Alternative 1: The IP settings are known

Prerequisite: The PMCprimo C and PC must be accessible in the

same network or via a Router

1. Select

2. Select

3. Enter the

New…

The

New Connection

Ethernet Connection

The

Select Telnet Connection

The

Connect via…

IP address

and select OK.

window opens. The network subscribers are list-

window opens.

.

window opens.

ed. The network subscriber that has just been entered is highlighted

in the list of connections.

4. Select

Connect

.

The network subscriber is connected

Inbetrieb_primo_C_status

Alternative 2: The IP settings are unknown

Prerequisite: The PMCprimo C and the PC are in the same broadcast

domain.

1. Select

Search…

in the

Connect via…

window

The system searches for network subscribers. The

work Search

window opens.

PMCprimo Net-

2. From the list, select the subscriber to which you wish to connect.

Please note: Click on

3. Select

Configuration…

4. Enter the IP settings and then select

Search

5. Select

window opens.

Connect

Ping

to identify the device's hardware.

The

Device Configuration

OK

. The

window opens.

PMCprimo Network

.

The network subscriber is connected.

The motion controller reports on the configuration, once the Ethernet

connection has been established.

7-4

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 49

7 Commissioning

7.2 Commissioning the PMCprimo C

START

SOFTWARE

Firmware: 3.0.2_T04, Apr 18 2012, 11:11:50

Motion: INSTALLED

IEC PLC: INSTALLED

Interpolation: NOT AVAILABLE

ETHERNET

IP address 192.168.0.11

Netmask 255.255.255.0

Gateway 192.168.0.1

CHANNELS

Number 1...30

HARDWARE

Type: PMCprimo C 0.6GHz 2xCAN

Mat.Nr.: 680055

Ser.Nr.: 111

Pr.Ver.: 1.0

Inputs: 6

Outputs: 6

Virtual-Inputs: 56

Virtual-Outputs: 56

Analogue Inputs: 0

Analogue Outputs: 0

DEVICES in CAN Network:

PMCtendo DD4 (SD03) at CAN2 ADDR 9 found (DS402)

Inputs: 2

Outputs: 0

PMCprotego D (S706) at CAN1 ADDR 10 found (DS402)

Inputs: 5

Outputs: 1

Virtual-Inputs: 17

Virtual-Outputs: 19

Analogue Inputs: 2 inputs linked to channel from 0.1 to 0.2

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

7-5

Page 50

7 Commissioning

7.2 Commissioning the PMCprimo C

0.1: hw2

STATE OF DEVICES:

Device Network Addr CH FS VN State

---------------------------------------------------------------------------------

PMCprimo C --- --- --- --- 3.0.2_T04 ACTIVE

PMCtendo DD4 CAN2 9 0.2 27 5.180 FAULT

PMCprotego D CAN1 10 0.3 27 5.260 ACTIVE

0.1:

The motion controller is ready for operation. It reports with the command

prompt

0.1:. Key:

Character

0 Address of the control-

. Decimal point

1 Number of current axis

: Status indicator of cur-

Meaning Details

ler (always 0 on

PMCprimo C)

rent axis

> Control loop closed

: Control loop open

A Axis executes compensatory move-

ment

C Axis executes coupling process

I Initialisation running

M Axis executes positioning

S Axis executes stop command

V Axis is in speed control

W Axis is in standby

X Position assignment is active on the

axis

7-6

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 51

7 Commissioning

7.2 Commissioning the PMCprimo C

7.2.3 Adapt basic configuration of PMCprimo

Adapt basic configuration of PMCprimo7-Inbetrieb_Basis_primo_C

The basic configuration of the motion controller can be amended in the

terminal program PTerm using the "CD" command.

Alternatively select

0.1: cd

0.1:

A C T U A L C O N F I G U R A T I O N:

Operate Mode: STANDALONE

(24) Cycle Time: 1000 µs

( 4) Actual IP address: 192.168.0.11

( 4) Actual Netmask: 255.255.255.0

( 4) Actual Gateway: 192.168.0.1

(12) Number of Channels: 30

( 8) CAN Cycle time: 4 ms

( 9) CAN node address: 50

( 3) CAN1 baudrate: 1000 Kbit

(21) CAN2 baudrate: 1000 KBit

(23) CAN2 cycle time: 4ms (equal CAN1)

(22) CAN-mode: CAN1: Master CAN2: Master

(20) Display error number: with no offset

(26) PmcProtego with SD-Card: 10

(11) PROFIBUS Address: 25

( 5) PROFIBUS IN/OUT Length: 20 (Words)

( 6) PROFIBUS Offset: 0

*****************************************

Tools -> Basis Controller Configuration

in PTerm.

0: Exit menu

2: Delete application data

3: Change CAN1 baudrate

4: Change Ethernet

5: Change in/out length for Profibus

6: Change offset for Profibus

8: Set CAN Cycle time

9: Set CAN address

11: Change Profibus address

12: Change number of channels

21: Change CAN2 baudrate

22: Enable slave mode for CAN1/2

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

7-7

Page 52

7 Commissioning

7.2 Commissioning the PMCprimo C

23: Set CAN2 cycle time

24: Change cycle time of system

26: Set address for PmcProtego with SD-Card

Choice [Return; ESC exits menu]:

Once you exit the menu the basic configuration is active and saved, if

changes have been made. It may be necessary to reboot the motion

control system for the changes to take effect.

7.2.4 Configure servo amplifier

Configure servo amplifier7-Inbetrieb_protego

Parameters for the servo amplifiers available in the CANopen network

can be set using the software tool PDrive.

Please note the following prerequisites:

The servo amplifier must not be enabled (ENABLE = 0).

The mains voltage for the servo amplifier's power element must be

switched off.

The 24 VDC supply voltage for the servo amplifier's control element

must be present

The terminal program PTerm must be connected to the motion con-

trol system.

The CANopen network must be configured for the motion control sys-

tem and servo amplifier.

The section below only describes the procedure in principle. Further information is available in the manual for the software tool and the operating instructions for the servo amplifier.

Open the software tool

PDrive

.

Select the servo amplifier

From the

Servo amplifier selection

list, select the servo amplifier for

which you wish to set the parameters.

7-8

Set the basic parameter settings

1. In the project window, select

The

Basic Setup

window appears. This contains information about

the servo amplifier (hardware, firmware, serial number, operating

hours).

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Setup -> Basic Setup

.

Page 53

7 Commissioning

7.2 Commissioning the PMCprimo C

2. Change the entries.

If necessary, you can change the following fields, for example:

– Name: Identification for servo amplifier

– Maximum mains voltage: 230 V, 400 V or 480 V

Select motor from motor database

Select

Send parameter file to servo amplifier

Click

Tools -> Motor Database…

The

Pilz Motor Database

motor for a certain servo amplifier.

Apply

to send the parameter file to the servo amplifier.

window appears. You can select a suitable

7.2.5 Operate PMCprimo C

Operate PMCprimo C7-Inbetrieb_bedienen_primo

You can operate the motion controller in PTerm by issuing commands

in the command language.

HW1 - Show Hardware

0.1: hw1

0.1:

SOFTWARE

Firmware: 3.0.2_T04, Apr 18 2012, 15:49:14

Motion: INSTALLED

IEC PLC: INSTALLED

Interpolation: NOT AVAILABLE

ETHERNET

IP address 192.168.0.12

Netmask 255.255.255.

Gateway 192.168.0.1

0

CHANNELS

Number 1...30

HARDWARE

Type: PMCprimo C 600MHz CAN/CAN

Mat.Nr.: 680050

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

7-9

Page 54

7 Commissioning

7.2 Commissioning the PMCprimo C

Ser.Nr.: 100004

Pr.Ver.: 0.1

Inputs: 6

Outputs: 6

Virtual-Inputs: 56

Virtual-Outputs: 56

Analogue Inputs: 0

Analogue Outputs: 0

DEVICES in CAN Network:

PNOZmulti (DS401) at CAN1 ADDR 14 found.

Inputs 24

Outputs 24

CAN-I/O (DS401) at CAN1 ADDR 23 found: PSSuniversal

Inputs: 32

Outputs: 36

Analogue Inputs: 2 inputs linked to channel from 0.1 to 0.2

Analogue Outputs: 2 outputs linked to channel from 0.1 to 0.2

PMCprotego D (S703) at CAN1 ADDR 31 found (DS402)

Inputs: 4

Outputs: 2

Virtual-Inputs: 18

Virtual-Outputs: 18

Analogue Inputs: 2 inputs linked to channel from 0.3 to 0.4

PMCprotego D (S703) at CAN1 ADDR 32 found (DS402)

Inputs: 18

Outputs: 10

Virtual-Inputs: 4

Virtual-Outputs: 10

Analogue Inputs: 2 inputs linked to channel from 0.5 to 0.6

7-10

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 55

7 Commissioning

7.2 Commissioning the PMCprimo C

HW2 - Show Hardware State

0.1: HW2

0.1:

STATE OF DEVICES:

Device Network Addr CH FS VN State

--------------------------------------------------------------------------------------

PMCprimo C --- --- --- --- 3.0.2_T04 ACTIVE

PNOZmulti CAN1 14 --- --- --- ACTIVE

CAN-I/O CAN1 23 --- --- --- FAULT

PMCprotego D CAN1 31 --- --- 5.260 ACTIVE

PMCprotego D CAN1 31 --- --- 5.260 ACTIVE

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

7-11

Page 56

7 Commissioning

7.3 Install CoDeSys

7.3Install CoDeSys7300In stall CoDeSys7-Inbetrieb_CoDeSys_installieren

The development environment for programming in accordance with

IEC 61131-3 CoDeSys can be found on the CD-ROM "Motion Control

Tools".

1. Start the CD-ROM "Motion Control Tools"

Funktion_Version_CoDeSys_2.3.9

2. Select the

CoDeSys

menu.

Installation will start. Follow the instructions.

The following components are installed:

PMCprimo Target Packages

Primo.dll

This library combines CoDeSys with PMCtools, enabling curves

(PMotion) and parameters for the servo amplifier and motors (PDrive)

to be edited.

Primo base project

The base project can be found in the CoDeSys directory under

Projects\primo.

INFORMATION

For programming in accordance with IEC 61131-3 you will need

CoDeSys Version 2.3.9. This software is available on the current

CD-ROM "Motion Control Tools".

7-12

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 57

8 Operation

1

1

3

4

5

2

Startup

0

1

Power Off

X40/7 = 0 V

RUN

X40/7 = 0 -> 24 V

Press reset

button

Boot Menu

Exit Boot

Menu

Command?

Fatal Error

Error detected

STOP

No user

program

HW reset:

- RS1

- Reset button

- RS3 or

reset button

- RS4

- RS5

- RS6

Automatic

HW reset

User

program

available

HW reset:

- RS1

- Reset button

X40/7 = 24 -> 0 V

2

1

1

3

2

1

Error detected

3

2

1

Error detected

22

RS2 or

reset button

1

1

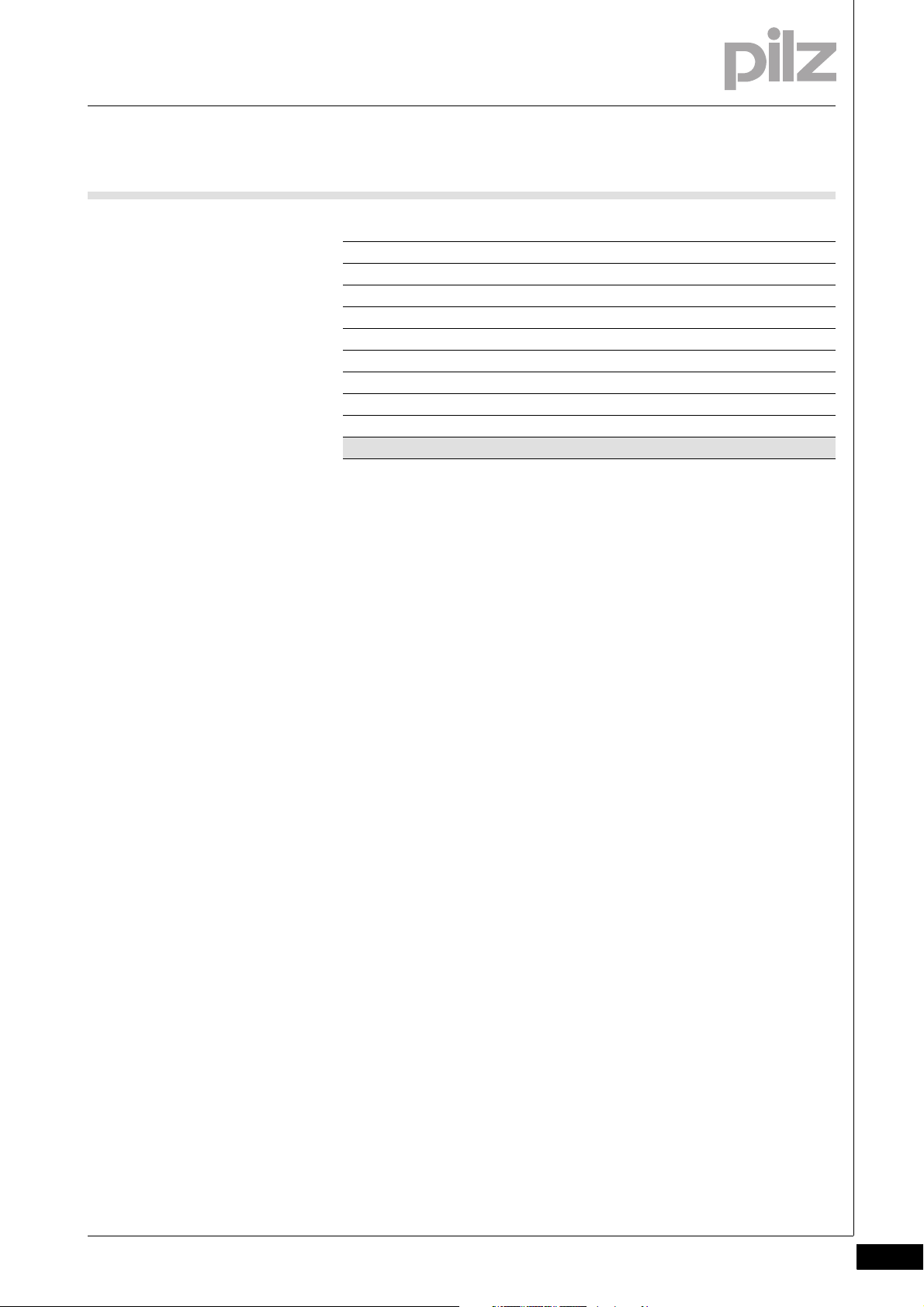

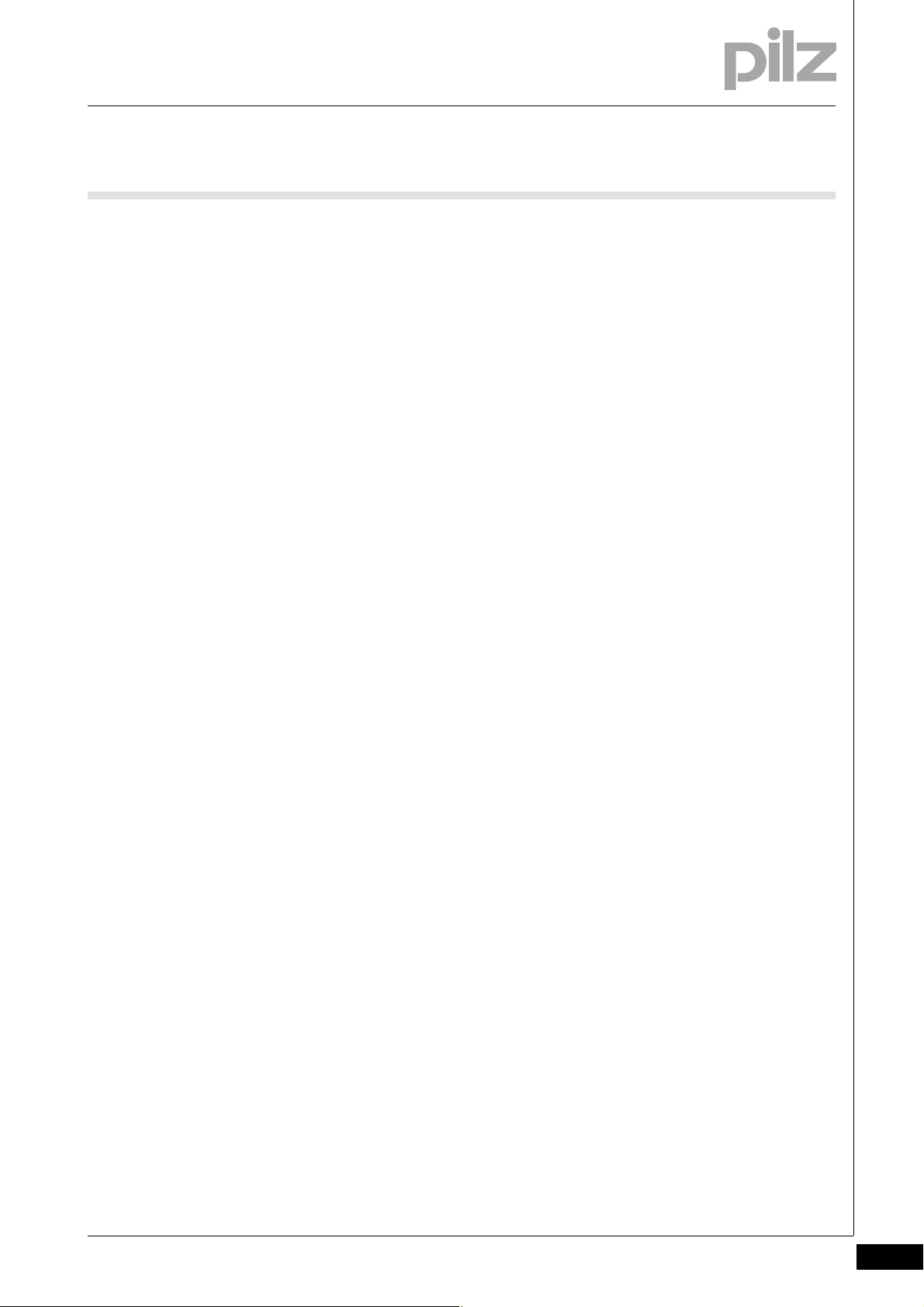

8.1 Operating states and changes in operating status

88000OperationOperation8-8.1Operating states and changes in operating status8100Operating states and changes in operating status8-

8.1.1 Status graph

Status graph8-Betriebzustand_Uebersicht

The following status graph shows the operating states and changes in

operating status. The priority of a transition is indicated by a number in

a small square in the middle of the transition arrow. The operating states

Betriebszustand_Zustandsgraph_primo_C

and changes in operating status are described in detail below.

Fig. 8-1: Operating states and changes in operating status of the

motion controller

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

8-1

Page 58

8 Operation

8.1 Operating states and changes in operating status

8.1.2 Operating states

Operating states8-

8.1.2.1 "Power Off" operating status

"Power Off" operating status8-Betriebszustand_Power_Off_primo_C

In the "Power Off" operating status, the motion controller PMCprimo C

is voltage-free. By switching on the supply voltage, the system changes

to the "Startup" operating status.

8.1.2.2 "Startup" operating status

"Startup" operating status8-Betriebszustand_Startup_primo_C

The following steps are performed in the "Startup" operating status:

Initialise hardware

Initialise fieldbus interfaces

Load operating system

Load user program

If no errors are detected during "Startup", the controller changes to

"RUN" status, if a user program has been loaded.

"STOP" status, if no user program has been loaded.

Status of LED:

LED flashes rapidly.

The LED lights for 4 s continuously after "Startup" has been run. Dur-

ing this time it's possible to change to "Boot Menu" operating status.

Change to "Boot Menu":

Press the reset button while the LED is lit continuously.

8.1.2.3 "Boot Menu" operating status

"Boot Menu" operating status8-Betriebszustand_Boot_Menu_primo_C

In the "Boot Menu" operating status, the operating parameters for the

motion controller can be configured in the command language in the terminal program PTerm using the command CD, e.g.

Configure the interfaces

Delete the user program

8-2

Prerequisite:

The PC and motion controller must be connected via the Ethernet in-

terface.

Status of LED:

The LED is lit continuously.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 59

8 Operation

8.1 Operating states and changes in operating status

8.1.2.4 "RUN" operating status

"RUN" operating status8-Betriebszustand_RUN_primo_C

In "RUN" operating status

All system sections are in a RUN condition and are operating fault-

lessly.

A PLC user program is run as part of each cycle.

Status of LED:

The LED flashes slowly.

8.1.2.5 "STOP" operating status

"STOP" operating status8-Betriebszustand_STOP_primo_C

In "STOP" operating status

No user program is run.

It is possible to communicate with the motion contoller in the terminal

program PTerm via the command language.

Status of LED:

The LED is lit continuously.

8.1.2.6 "Fatal Error" operating status

"Fatal Error" operating status8-Betriebszustand_Fatal_Error_primo_C

"Fatal Error" operating status is reached when an error occurs.

The operating status is adopted temporarily.

The motion controller automatically changes back to "Startup" oper-

ating status.

The error is entered in the error stack.

Status of LED:

The LED is switched off.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

8-3

Page 60

8 Operation

1

0

1

1

2

1

3

1

4

1

5

8.1 Operating states and changes in operating status

8.1.3 Change in operating status

Change in operating status8-Betriebszustandswechsel_primo_C

--> All operating states change to "Power Off"

The system changes to "Power Off" operating status when the 24 VDC

supply voltage has been switched off.

--> Change from "Power Off" to "Startup"

The system changes to "Startup" operating status when the 24 VDC

supply voltage has been switched on.

--> Change from "Startup" to "Boot Menu"