Page 1

PDrive

Motion Control PMC

User Manual – No. 21511-EN-12

Page 2

1 General Information

1.1 Copyright

Copyright 2012 Pilz GmbH & Co. KG

All rights reserved. The implementation of technical changes which improve the performance of

the product is subject to change without prior notification! The product or parts of the content

may be reproduced or transmitted in any form (by printing, photocopying, microfilm or any other

method) or stored, processed, copied or distributed by electronic means without the written

permission of Pilz GmbH & Co. KG.

1.2 Notice

Pilz GmbH & Co. KG reserves the right to make amendments to this document at any time.

The examples given serve only as illustrations. No guarantee is given for their suitability in

particular applications. Although the utmost care has been taken in the production of this

document, no liability can be accepted for any mistakes that it may contain. We welcome any

suggestions for the improvement of our products, or documentation.

1 General Information

We reserve the right to make technical changes, which lead to the improvement of the product!

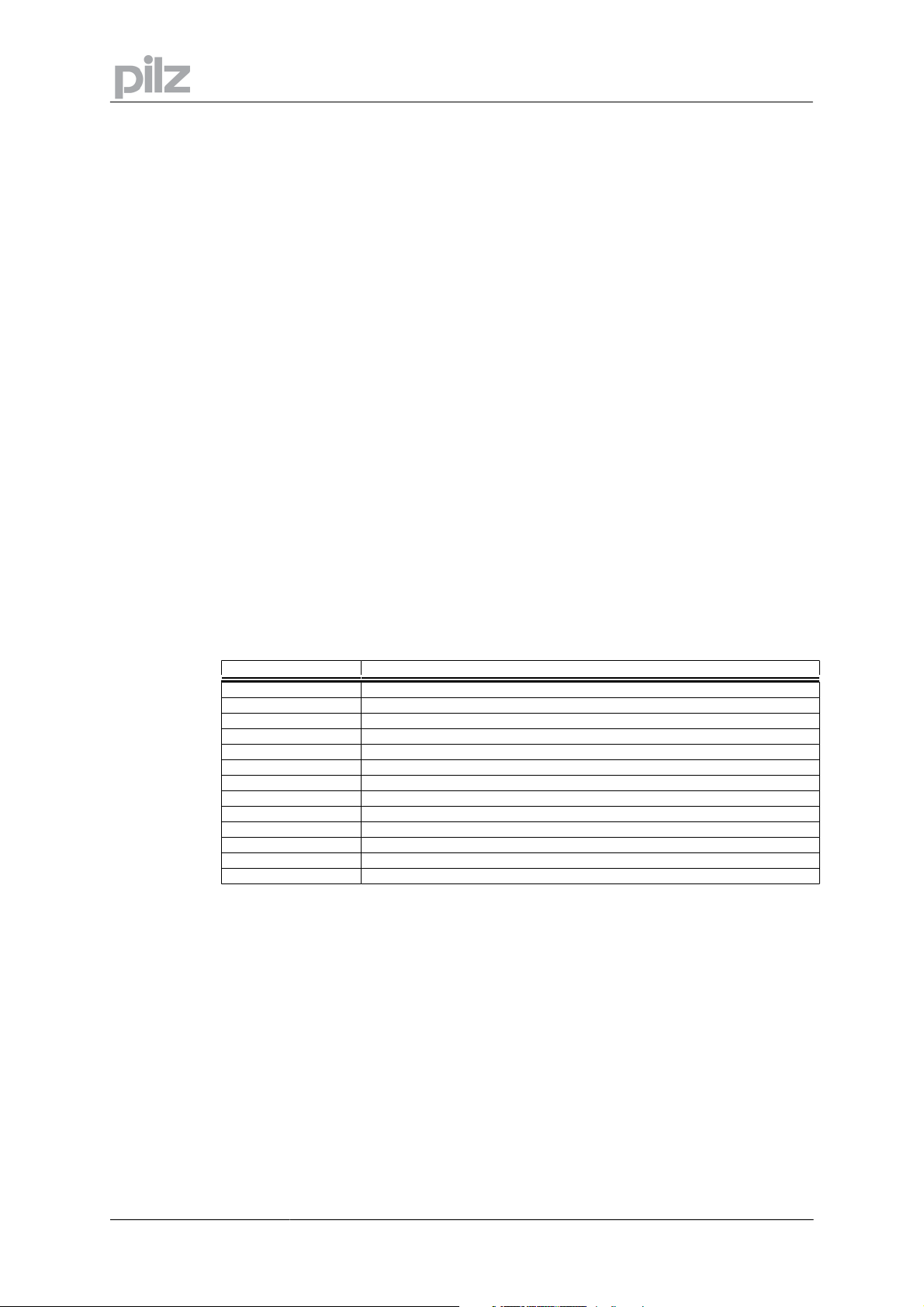

1.3 Previously published editions

Version Notes

12/2001 Initial version: valid from software version version 2.01

V1-16-07-2002 Revised version: valid from software version 2.03

V2-20-11-2002 Revised version: valid from software version 2.04

V3-10-06-2003 Revised version: valid from software version 2.05

V4-11-05-2004 Revised version: valid from software version 2.06

V5-24-02-2005 Revised version: valid from software version 2.07

V6-23-08-2005 Revised version: valid from software version 2.08

V7-16-11-2005 Revision

V8-03-05-2006 Revised version: valid from software version 3.0

V9-12-10-2007 Revised version: valid from software version 3.1

V10-18-01-2008 Revised version: valid from software version 3.2

V11-02-03-2010 Revised version: valid from software version 3.3

V12-02-04-2012 Revised version: valid from software version 3.4

Page 2 User Manual for Setup Software PDrive

Page 3

2 Table of contents

2 Table of contents

1 General Information...........................................................................................2

1.1 Copyright...........................................................................................................................2

1.2 Notice................................................................................................................................2

1.3 Previously published editions............................................................................................2

2 Table of contents................................................................................................3

3 Symbols...............................................................................................................4

4 Safety Guidelines...............................................................................................5

5 About this manual..............................................................................................6

6 Prescribed use (“Use as directed”)..................................................................7

7 Installation ..........................................................................................................8

7.1 Hardware requirements.....................................................................................................8

7.2 Installation under Microsoft Windows...............................................................................8

8 Use.......................................................................................................................9

8.1 Notes.................................................................................................................................9

8.2 Connection .......................................................................................................................9

8.3 Screen layout..................................................................................................................11

8.3.1 Title bar...........................................................................................................................12

8.3.2 Menu bar.........................................................................................................................12

8.3.3 Tool bar...........................................................................................................................14

8.3.4 Service bar......................................................................................................................15

8.3.5 Status bar........................................................................................................................16

8.3.6 Select servo amplifier......................................................................................................16

8.3.7 Project window................................................................................................................17

9 Project window.................................................................................................18

9.1 Setup...............................................................................................................................18

9.1.1 Basic setup......................................................................................................................18

9.1.2 Units................................................................................................................................19

9.1.3 CAN/Fieldbus..................................................................................................................20

9.1.4 Feedback.........................................................................................................................21

9.1.5 Motor...............................................................................................................................23

9.1.6 Current controller.............................................................................................................25

9.1.7 Speed controller..............................................................................................................26

9.1.8 Position controller............................................................................................................28

9.1.9 Electronic Gearing...........................................................................................................29

9.1.10 Encoder...........................................................................................................................30

9.1.11 Digital I/O.........................................................................................................................31

9.1.12 Analog I/O.......................................................................................................................32

9.2 Positioning.......................................................................................................................33

9.2.1 Homing............................................................................................................................33

9.2.2 Position Data...................................................................................................................40

9.2.3 Motion task......................................................................................................................42

9.2.4 Position registers.............................................................................................................47

9.3 Status..............................................................................................................................48

9.4 Monitor............................................................................................................................48

9.5 Screen page „Expansion Card“.......................................................................................49

9.5.1 Expansion card "DA1" ....................................................................................................49

9.5.2 Expansion card "D1".......................................................................................................50

9.5.3 Profibus DP Expansion card...........................................................................................51

9.5.4 Expansion card PMCprimo..............................................................................................52

9.5.5 Expansion card PMCprotego S.......................................................................................53

10 Index..................................................................................................................54

User Manual for Setup Software PDrive Page 3

Page 4

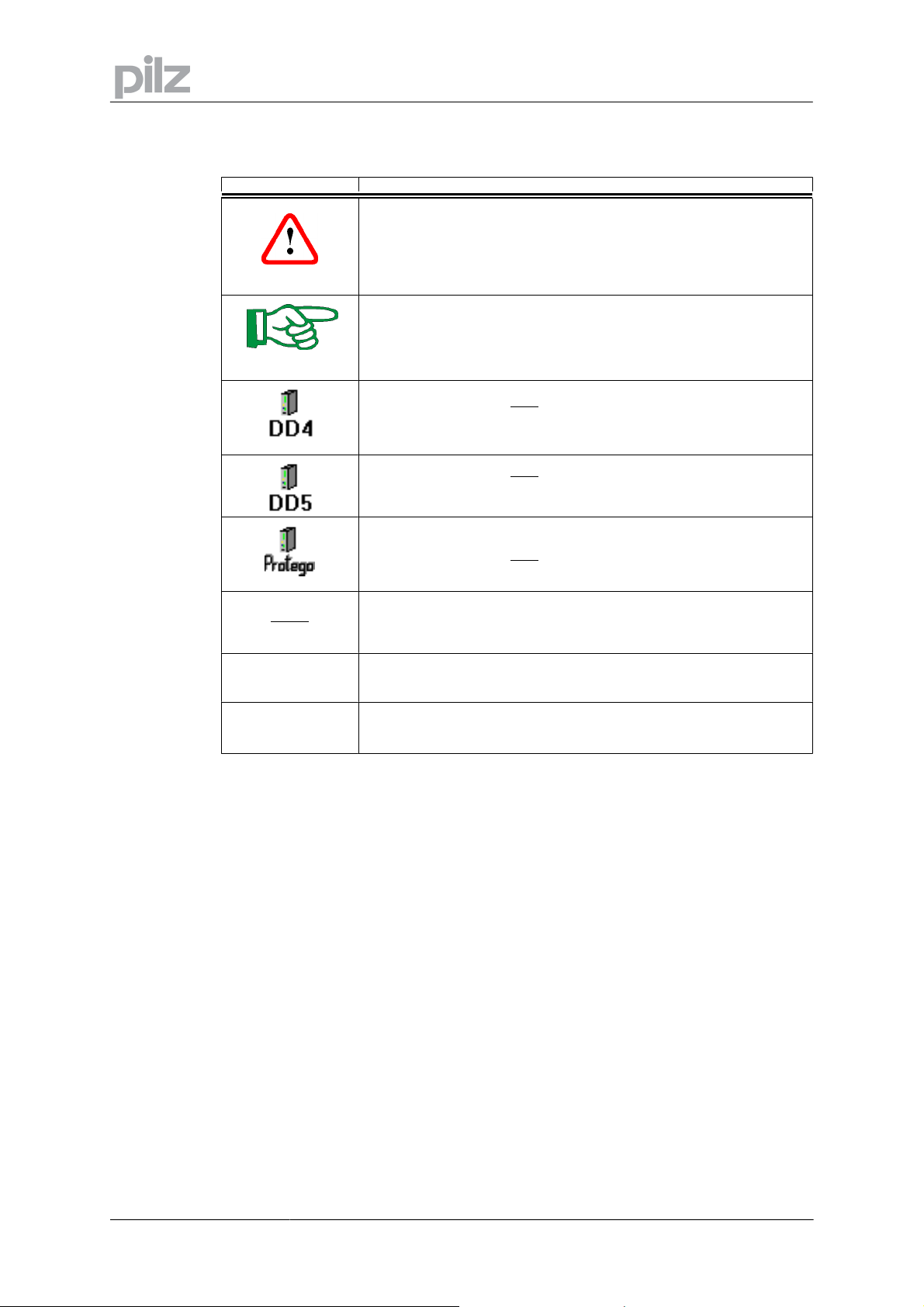

3 Symbols

Symbol Meaning

3 Symbols

This symbol indicates a possible danger, hazard, risk to life and/ or

health. Ignorance may seriously affect health and cause dangerous

injuries.

[ VER ]

•

⇒

This symbol indicates an important hint regarding the correct use of the

product. Ignorance may affect the performance of the machinery

and/or the surrounding.

This parameter applies only to a PMCtendo DD4 and

PMCprimo Drive2

This parameter applies only to a PMCtendo DD5 and

PMCprimo Drive3

This parameter applies only to a PMCprotego D.

Reference to the according command in the onlne help (example

command „VER“)

Emphasis

see page (cross reference)

Page 4 User Manual for Setup Software PDrive

Page 5

4 Safety Guidelines

4 Safety Guidelines

● When commissioning, you must ensure that neither the controllers nor the amplifiers

present any risk to persons, plant or machinery. Appropriate protection and

precautionary measures must be put in place.

● To avoid personal injury and material damage, only qualified, trained personnel should

work on the devices.

● Only specialist staff with extensive knowledge of drive technology and control

engineering should be permitted to program a running drive online. Data stored on

data media is not protected from unintended changes by third parties. Data must be

checked for accuracy before it is loaded on to the hardware.

● The installation and operating instructions must be read carefully and all safety

regulations observed before installation and initial operation as danger to personnel and

damage to machinery may be caused.

● Only qualified and well-trained specialists who are familiar with the transportation,

installation, initial operation, maintenance and operation of the units as well as with the

relevant standards may carry out the corresponding works.

● Technical data and indications (Type tag and documentation) are to be kept absolutely.

User Manual for Setup Software PDrive Page 5

Page 6

5 About this manual

This documentation explains the use of the PDrive.exe setup software for setting

parameters and configuring servo amplifiers of the PMCtendo DD4/5, PMCprimo Drive2/3 and

PMCprotego D series.

The series PMCprimo Drive2/3 differ from the series PMCtendo DD4/5 only in the motion

control functionality.

For this reason the series PMCprimo Drive2/3 is not mentioned furthermore in this

manual. Parameters for the PMCtendo DD4 are concerning the PMCprimo Drive2 too and

parameters for the PMCtendo DD5 the PMCprimo Drive3.

Detailed descriptions of functions and parameters are located in the Object Reference Guide.

The setup software must be installed on a personal computer (PC). The PC is connected

to the servo amplifier by a communication cable. The setup software initiates the

communication

between PC and servo amplifier.

With very little effort you can alter parameters and instantly observe the effect on the servo

amplifier, since there is a continuous (online) connection to the amplifier. At the same time,

important actual values are read out from the servo amplifier and displayed on the monitor of

the PC.

5 About this manual

Any interface modules (expansion cards), which may be built into the servo amplifier, are

automatically recognized and the additional parameters required for position control or motionblock definition are made available.

You can save sets of data on data media (archiving), and load them again. You can also

print out the data sets.

We provide you with default sets of motor-specific data for all the reasonable combinations of

servo amplifier and motor. In most applications you will be able to commission your drive

without any problems, just by using these default values.

Knowledge of the Microsoft Windows operating system and the use of a personal

computer is assumed.

You must follow the safety, installation and commissioning instructions in the

installation manual for the servo amplifier that is used.

We provide training and familiarization courses on request.

Page 6 User Manual for Setup Software PDrive

Page 7

6 Prescribed use (“Use as directed”)

6 Prescribed use (“Use as directed”)

The setup software PDrive is intended to be used for altering or storing the operational

parameters for the servo amplifiers of the PMCtendo DD4/5, PMCprimo Drive2/3 and

PMCprotego D series. The servo amplifier that is connected is commissioned with the aid of

the software - whereby the drive can be directly controlled by the setup and service functions.

The characteristic nature of a PC means that these functions are not functionally safe

without further measures. A PC-program might be unexpectedly disturbed or stopped,

so that in the event of a malfunction any movements that have already been initiated

cannot be stopped from the PC.

The manufacturer of the machine must carry out a hazard analysis for the machine, and

is responsible for the functional, mechanical and personnel safety aspects of the

machine. This applies especially to the initiation of movements with the aid of functions

in the commissioning software.

Only personnel who have extensive knowledge in the fields of drive technology and

control technology are permitted to carry out online parameter setting of a drive that is

running.

Sets of data that are stored on data media are not safe from undesirable alteration by

third parties. So after you have loaded a set of data, you must check all the parameters

before enabling the servo amplifier.

The servo amplifiers are components that are built into electrical equipment or

machines, and can only be operated as integral components of such equipment.

The BTB/RTO contact must be wired into the safety loop of the system. The safety loop,

and the Stop and Emergency Stop functions must fulfil the requirements of EN 60204,

EN 292 and VDI 2853.

User Manual for Setup Software PDrive Page 7

Page 8

7 Installation

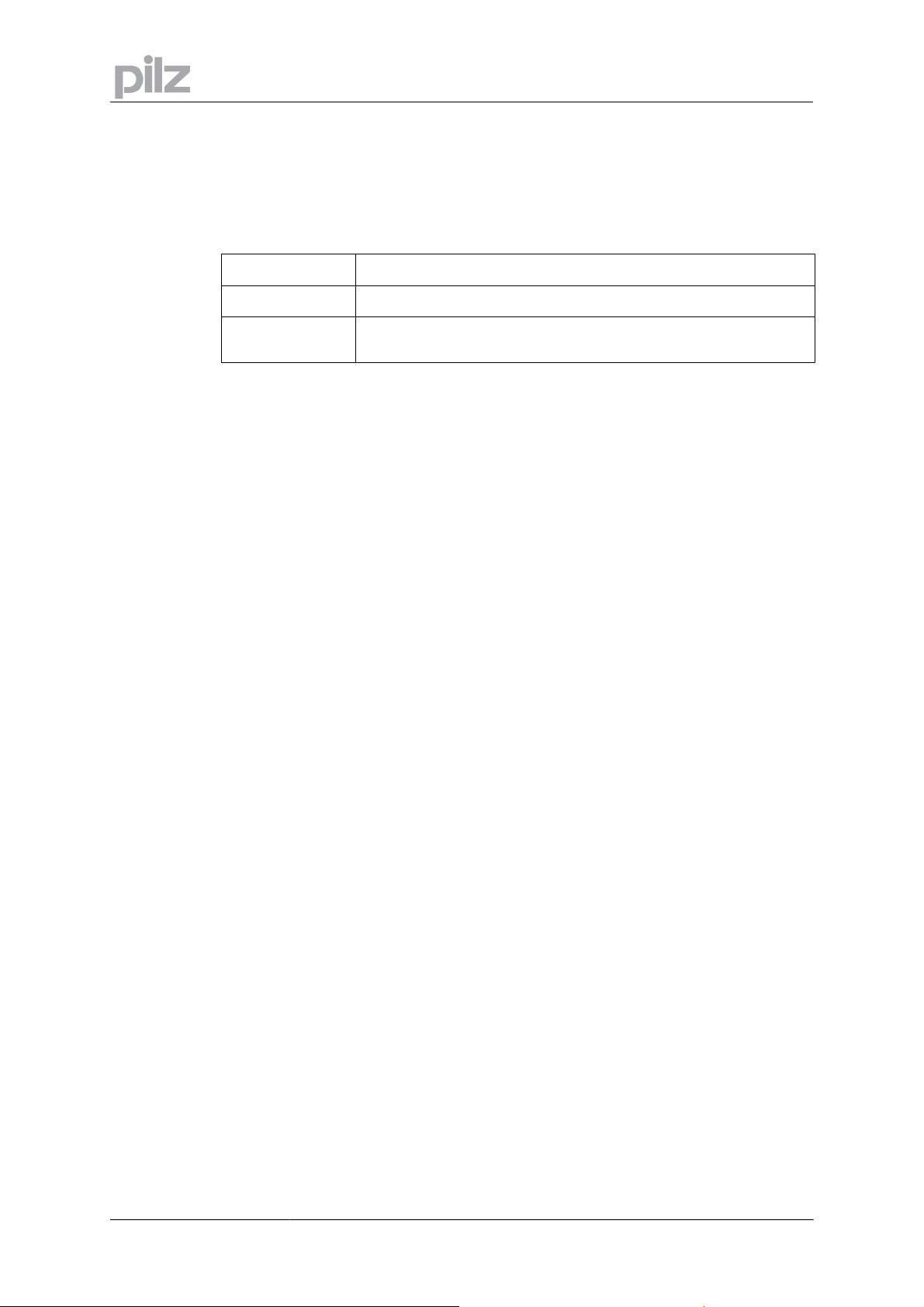

7.1 Hardware requirements

Minimum specification for the PC:

7 Installation

Operating system

Hardware

Interface

Windows 2000, XP, Vista or 7

Minimum requirements of operating system

one free serial interface

Ethernet interface (optional)

7.2 Installation under Microsoft Windows

The PC interface (X6, RS232) of the servo amplifier is connected to the serial interface of the

PC.

You can order the necessary programming cable from us or make one up yourself. The pin

assignment can be found in the installation manual of the servo amplifiers.

Start your PC and insert the Motion Control Tools-CD into the CD-ROM drive. The installation

software will start automatically. Otherwise start MInstall.exe on the CD-ROM.

Click on „Install Motion Control Tools“ and follow the instructions.

Page 8 User Manual for Setup Software PDrive

Page 9

8 Use

8 Use

8.1 Notes

The setup software is basically used in the same way as other Windows programs. Use a

decimal point as the decimal symbol, do not use a comma.

Please note that, after an alteration in a parameter on a screen page, you must first press

„Return“ or select an other parameter on the page, so that the parameter is transferred

to the RAM of the servo amplifier.

If a reset of the servo amplifier is necessary to activate a function, this will be recognized by the

setup software, which will make a reset after a software confirmation request.

The currently valid data set must be saved in the EEPROM of the servo amplifier, in order to be

permanently stored. So execute the Save Data to EEPROM function on the service bar before

you switch off the servo amplifier or quit processing the data set.

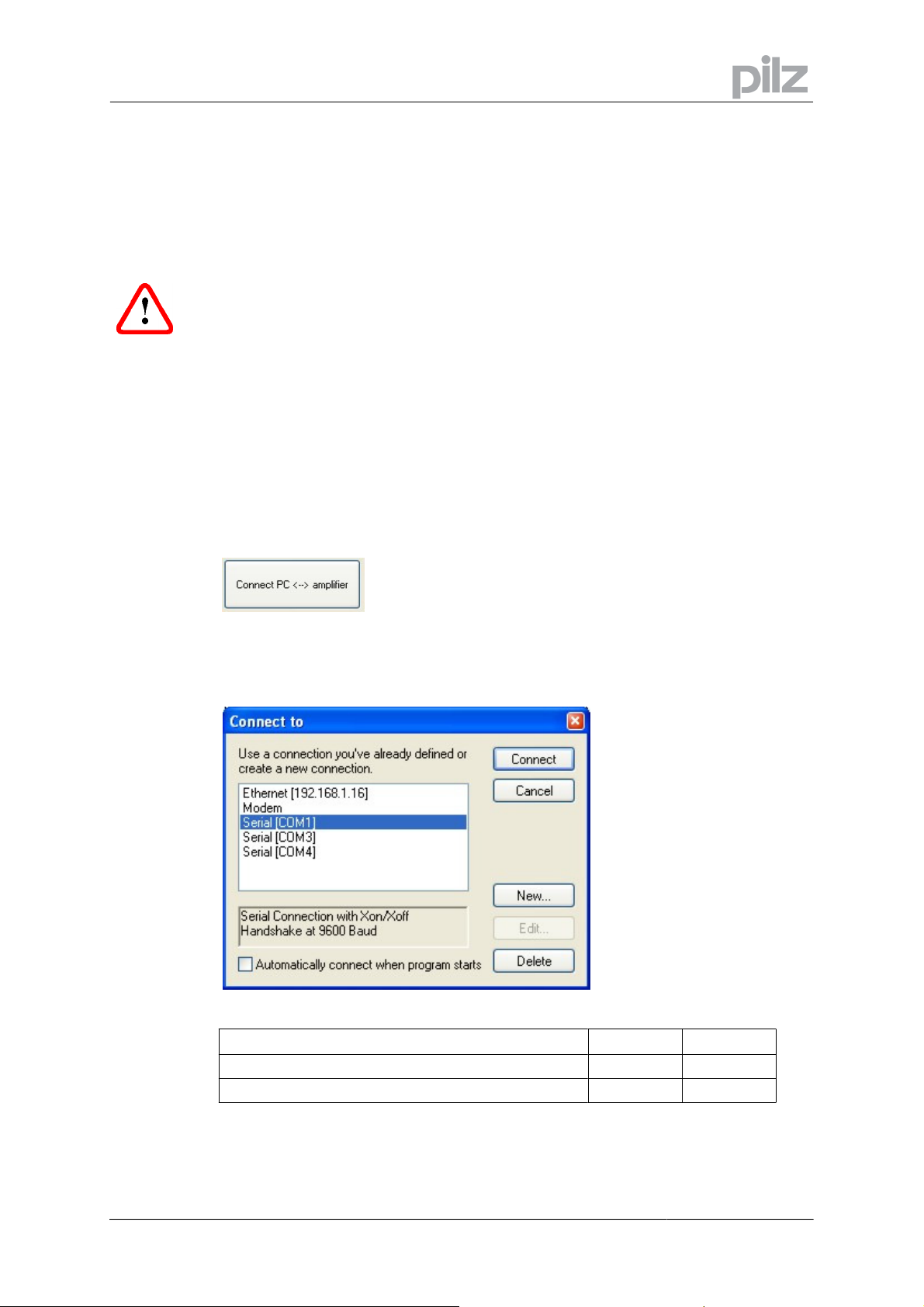

8.2 Connection

Connect the interface cable to a serial interface on your PC and to the serial interface of the

servo amplifier.

Start PDrive.exe and click to the button:

PDrive is trying to read data from the servo amplifier.

If you have never started a communication before, you have to configure the communication

parameters first (PTerm):

Choose a connection, set the

connection parameters and click

to „Connect“.

Connection parameter:

Device Baud rate Handshake

PMCtendo DD4 / PMCprimo Drive2 9600 XON/XOFF

PMCtendo DD5 / PMCprimo Drive3 / PMCprotego D 38400 XON/XOFF

User Manual for Setup Software PDrive Page 9

Page 10

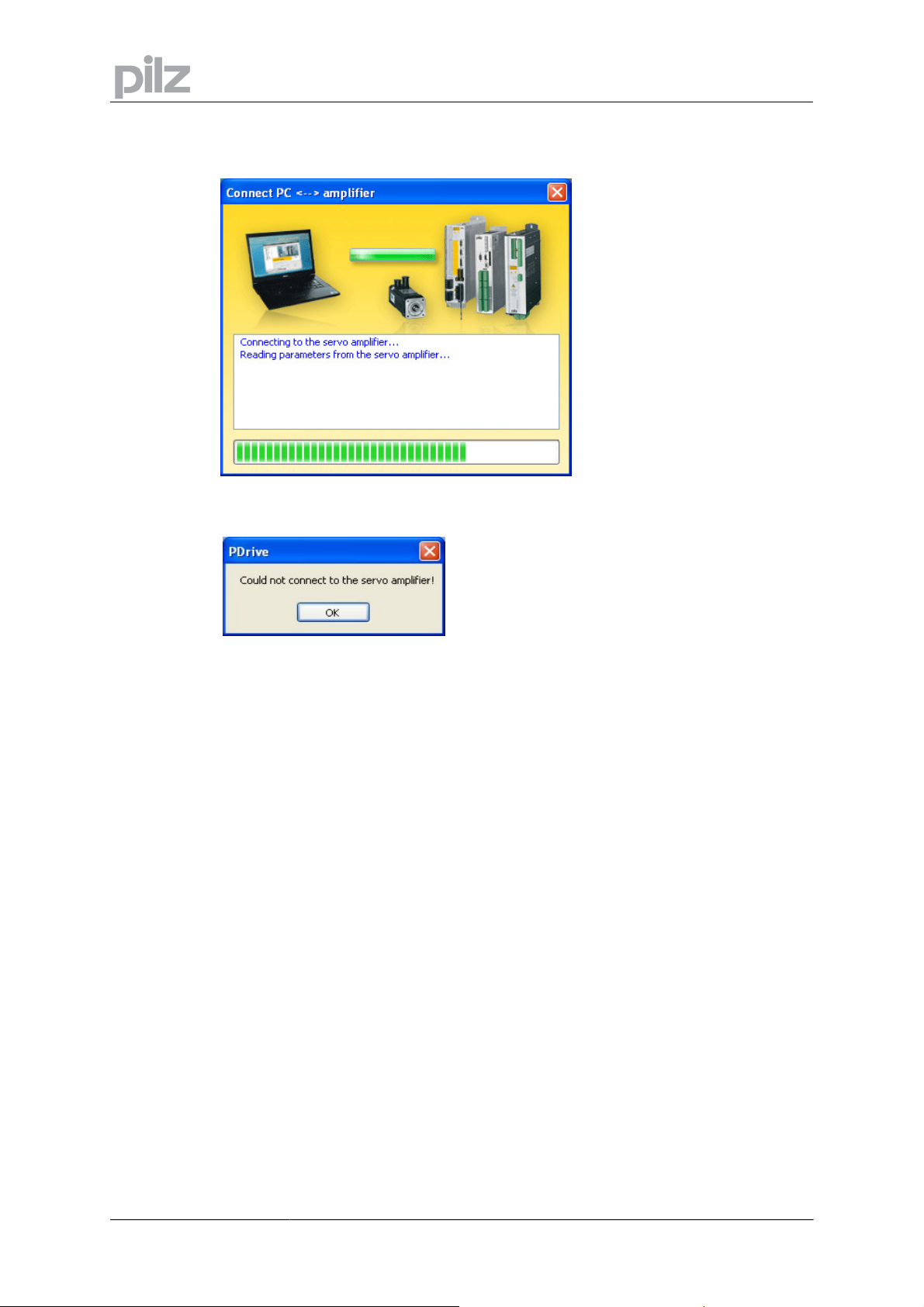

8 Use

PDrive is now reading the actual parameters of the servo amplifier.

A previously opened data set in PDrive will be overwritten with the new data.

If there is no communication possible, you will receive this message:

In this case check the following:

1. Is the servo amplifier's 24V supply voltage connected?

2. Has the correct PC interface been selected?

3. Has the correct servo amplifier interface been selected?

4. Has an incorrect connection cable been used?

5. Has the correct baud rate been set?

Find the error, rectify it and then restart the connection.

Page 10 User Manual for Setup Software PDrive

Page 11

8 Use

8.3 Screen layout

Title bar

Tool bar

Menu bar

Project window

Main window

Service bar

Status bar

Title bar The program name and the name of the currently opened document are displayed in the title

bar.

Furthermore the connection status will be shown ("connected" or "not connected").

Tool bar The typical Windows-style buttons can be used for a direct start of individual functions.

Menu bar Access to several program functions using Windows menus.

Main view The main frame allows changing parameters, monitoring actual values of the servo amplifier

and selecting functions.The lower part of this window shows the communication status, the

operate mode, the expansion cards and the axis status. In a network the servo amplier can be

changed in this window, too.

Service bar Service functions for operating the servo amplifier.

Status bar Current information about the data communication is shown here.

Project window In a structure similar to Windows Explorer, links to all screen pages are listed that you need for

setup, optimizing and monitoring of the servo amplifier. The selected screen is shown in the

main frame. The top level of the tree shows the name of the connected servo amplifier.

User Manual for Setup Software PDrive Page 11

Page 12

8.3.1 Title bar

The program name and the name of the currently opened document are displayed in the title

bar.

Furthermore the connection status will be shown ("connected" or "not connected").

8.3.2 Menu bar

File

New Creates a new parameter file.

Open... Opens a parameter file: A parameter data set is read from the

Save parameters Saves the current parameter data set to a data medium (hard

Save parameters as... Saves the current parameter data set to a data medium (hard

Export as FB for

SoftPLC

Print... The current data set will be printed out. You can choose whether

Print preview /

Print setup...

Send... Sends the actual data file via E-mail.

Exit Terminates the program.

8 Use

data medium (hard drive, floppy disk). If there is an active

connection, the data set is downloaded to the servo amplifier.

disk, diskette) while keeping the file name, if the data set already

has a name. If the data set has not yet got a name, you will be

prompted to enter a name and storage location.

disk, diskette). You will be prompted to enter a name and storage

location.

Exports the actual parameters into a EXP file. This file can be

imported in the windows program CoDeSys for a Software-PLC.

the print data are sent to the system printer or saved to a file.

Use these functions in the same way as for any other Windows

software.

Communication

Connect / Disconnect

PC ↔ amplifier

Save parameters to

EEPROM

Load default

parameters to RAM /

EEPROM

View

Toolbar

Status bar

Service bar

Programs

PTerm

PScope

PEdit

PMotion

Connect or disconnect PDrive and servo amplifier.

Saves the current parameter data set permanent in the EEPROM

of the servo amplifier.

Reset all parameters and load the default parameters to RAM /

EEPROM.

Switch to show/hide the toolbar (above) or the service bar and

status bar (below).

Starts the tools PTerm (terminal program) ,PScope (scope

function), PEdit (text editor) or PMotion (motion generator).

Page 12 User Manual for Setup Software PDrive

Page 13

8 Use

Service

STOP amplifier Stops the current service function.

ENABLE amplifier Enables the servo amplifier by software.

DISABLE amplifier Disables the servo amplifier by software.

RESET amplifier Software reset of servo amplifier.

CLRFAULT Clears the current errors and warnings.

Tools

Options Settings for using the program.

- Show tooltips.

- Default values for PMCprimo Drive.

User Manual for Setup Software PDrive Page 13

Page 14

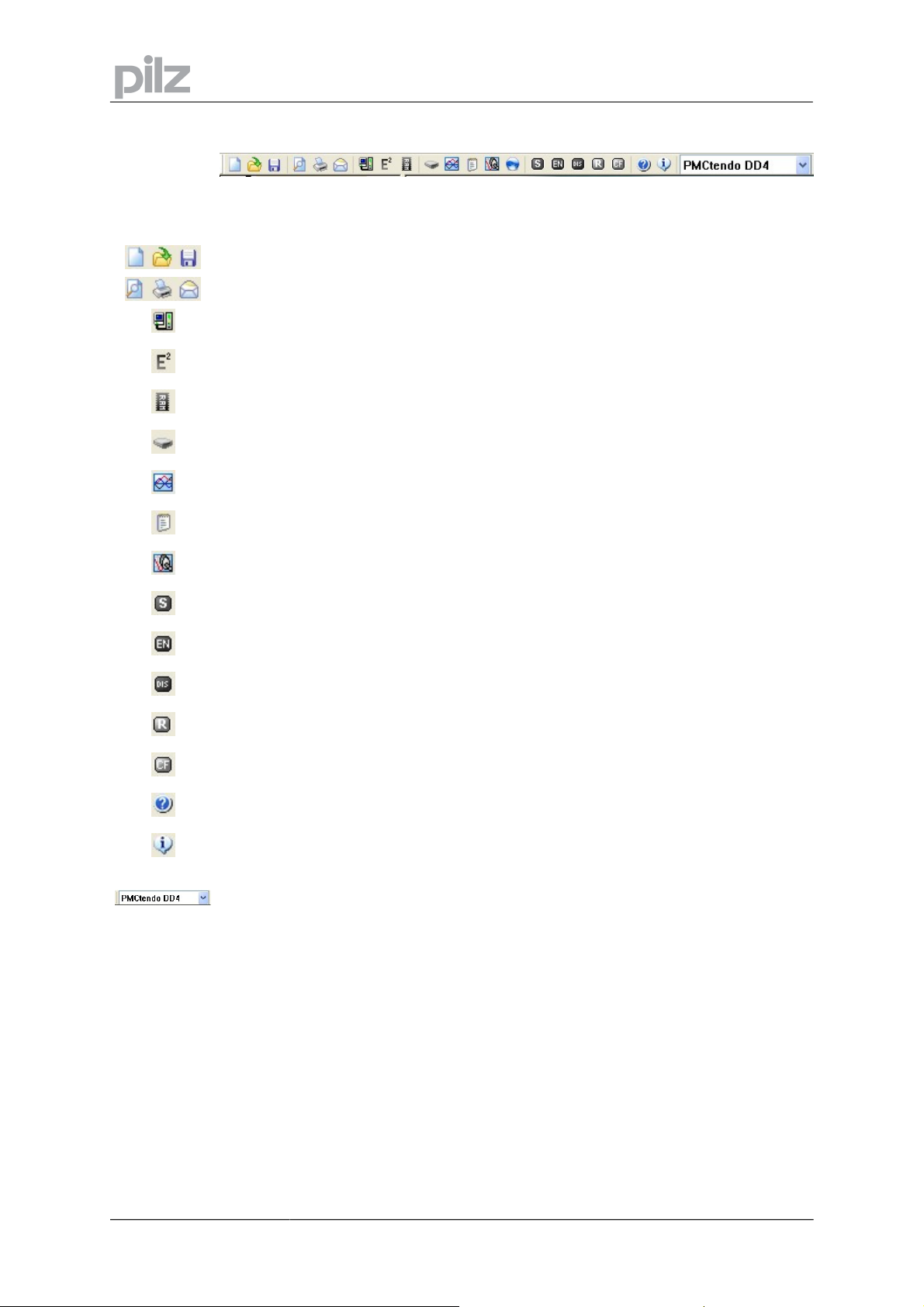

8.3.3 Tool bar

All symbols of the toolbar and their meaning:

Standard Windows:

New – open – save

Search – print – send

Connect / Disconnect PC <--> amplifier:

Reads actual parameters from the amplifier. Clicking again diconnects the communication.

Save parameters to EEPROM:

Saves the current parameter data set permanent in the EEPROM of the servo amplifier.

Load default parameters to RAM / EEPROM:

Reset all parameters and load the default parameters to RAM / EEPROM.

PTerm:

Starts PTerm.exe.

PScope:

Starts PScope.exe.

PEdit:

Starts PEdit.exe.

PMotion:

Starts PMotion.exe.

STOP amplifier:

Stopps the current service function and disables power stage.

ENABLE:

Enables power stage.

DISABLE:

Disables power stage.

RESET amplifier:

Software reset of servo amplifier.

Clear Fault:

Clears the current errors and warnings.

Help topics:

Starts online help for PDrive.

Info:

Displays program information, version number and copyright of PDrive.

Current device:

In offline mode, selection as to whether a DD4, DD5 or PMCprotego D parameter file is to be

created. In online mode, displays whether there is a connection to DD4, DD5 or

PMCprotego D.

8 Use

Page 14 User Manual for Setup Software PDrive

Page 15

8 Use

8.3.4 Service bar

With the service bar you have a direct access to important service functions of the servo

amplifier.

PTerm:

Starts PTerm.exe.

PScope:

Starts PScope.exe.

PEdit:

Starts PEdit.exe.

Save:

Saves the current parameter/motion task data set to a data medium (hard drive, floppy disk). If

the data set does not yet have a file name, you will be prompted to enter a name and storage

location.

Load:

Opens a parameter file: A parameter data set is read from the data medium (hard drive, floppy

disk). If there is an active connection, the data set is downloaded to the servo amplifier.

Save data in EEPROM:

Non-volatile storage of the currently valid parameter set in the EEPROM of the servo amplifier.

In this way you can permanently save all the parameter changes that you have made since the

last switch-on/reset of the servo amplifier.

Load default parameters to RAM / EEPROM:

Cancel all the parameters that have been set up, and load the manufacturer’s default values.

STOP amplifier:

Stop the currently active service function and disables the power stage.

ENABLE:

Enables the power stage.

DISABLE:

Disables the power stage.

RESET amplifier:

Software-reset of the servo amplifier.

Clear Fault:

Clear the present errors and warnings.

User Manual for Setup Software PDrive Page 15

Page 16

8.3.5 Status bar

Current information about the data communication is shown here.

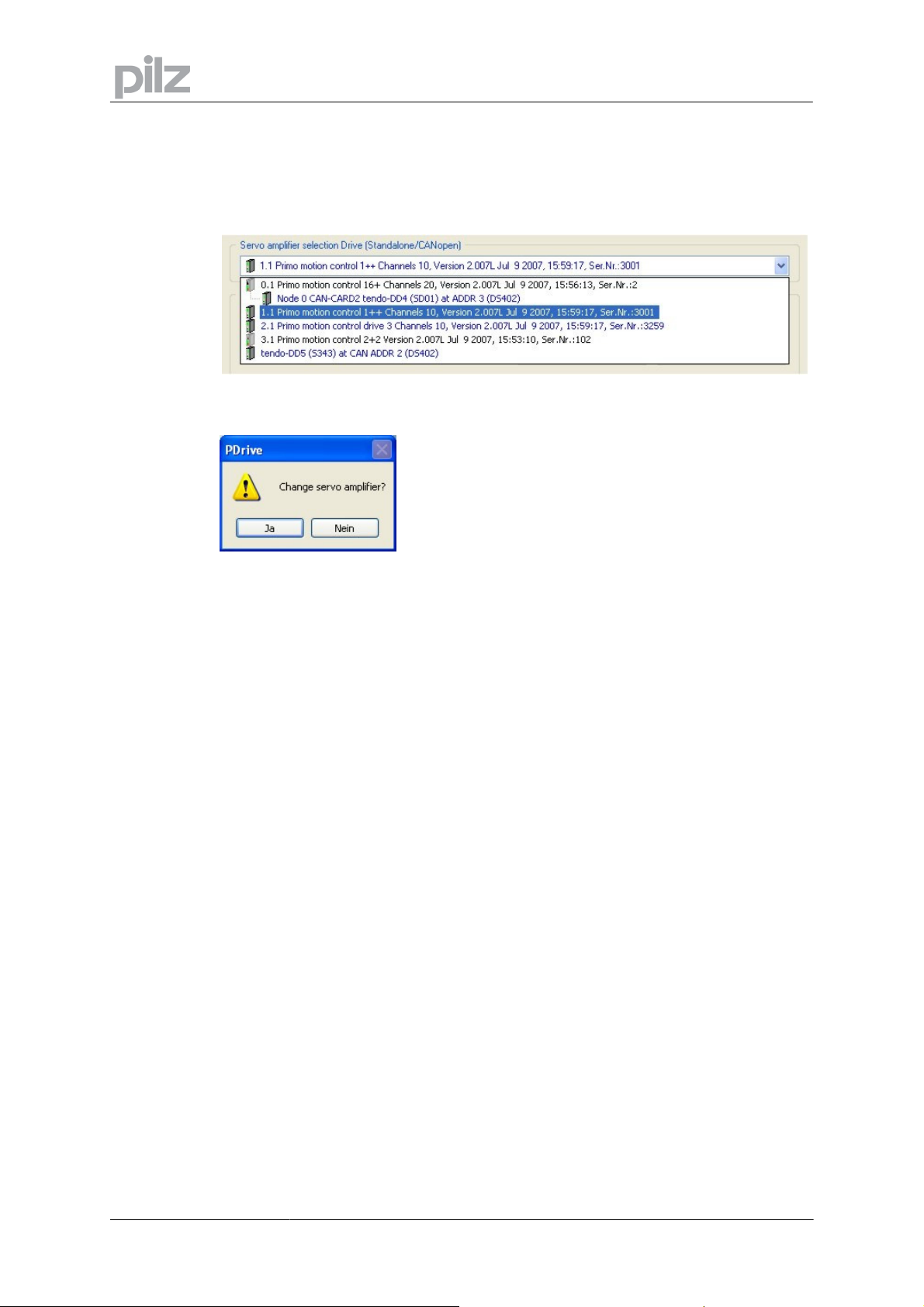

8.3.6 Select servo amplifier

In a network you can change the actual servo amplifier here.

The following message box appears:

8 Use

After clicking „Yes“ PDrive reads the data of the chosen servo amplifier.

Page 16 User Manual for Setup Software PDrive

Page 17

8 Use

8.3.7 Project window

In a structure similar to Windows Explorer, links to all screen pages are listed that you need for

setup, optimizing and monitoring of the servo amplifier.

The selected screen is shown in the main frame.

The top level of the tree shows the name of the

connected servo amplifier

(PMCprimo Drive2[MOTOR3] in the example).

Below there is a summary of all pages for

parametrization and setup of the servo amplifier

(„Setup“).

„Positioning“ combines all pages which deal with

moving and motion tasks .

Under „Expansion Card“ you can setup

expansion cards.

„Status“ and „Monitor“ display the current status of

the servo amplifier and important parameters.

User Manual for Setup Software PDrive Page 17

Page 18

9 Project window

9.1 Setup

9.1.1 Basic setup

9 Project window

Regeneration resistor [ PBALRES ]

Internal The internal regeneration resistor is used.

External An external regeneration resistor, connected to the terminals +R

used.

Ohm - PMCtendo DD5 and PMCprotego D only

Sets the value of the regeneration resistor in unit Ohm.

Max. Regeneration Power [ PBALMAX ]

Set the maximum Regen Power.

Max. Mains Voltage [ VBUSBAL ]

This parameter is used to adjust the regeneration and switch-off levels of the servo amplifiers

to suit the mains power supply voltage or the system conditions for multi-axis systems with

parallel-connected DC-link circuits.

Response to Loss of Input Phase [ PMODE ]

Handles the message „Phase missing“.

Hardware [ HVER ]

Display the version and revision level of the servo amplifier hardware.

Firmware [ VER ]

Display the version and revision level of the servo amplifier firmware.

Name [ ALIAS ]

Here you can assign a name (8 chars max.) to the servo amplifier.

and -RB , is

bext

Serial Number [ SERIALNO ]

Display the serial number of the servo amplifier.

Run Time [

Display the operational time of the servo amplifier, saved at 8 min. intervals.

Page 18 User Manual for Setup Software PDrive

TRUN ]

Page 19

9 Project window

Ambient temperature switch off threshold [ MAXTEMPE ]

Definition of the threshold for the maximum permitted ambient temperature. If this value is

exceeded, an error is triggered.

Set Software-Enable on Bootup [ AENA ]

Definition of the status of the software-enable on switching on the instrument, or after using

“Reset“ to clear errors.

Quick-Boot [ BOOT ]

This can be used to change the behaviour of the amplifier during the initialisation phase. If

Quick-Boot is activated, the internal servo amplifier settings will only be recompiled when

changes are made.

9.1.2 Units

Position [ PUNIT ]

Definition of the global unit for all position-dependent parameters of the position controller.

Velocity [ VUNIT ]

Definition of the global dimensional unit for speed and velocity. This unit applies to all

speed/velocity dependent parameters of the speed/position controllers.

Acceleration [ ACCUNIT ]

Definition of the dimensional unit for acceleration. This unit is used for the ramps of the

trajectory generator as well as for the braking/acceleration ramps of the speed controller.

Resolution counts / Motor Revs [ PGEARI ] [ PGEARO ]

You can use the entry fields in this equation to determine the transmission ratio.

User Manual for Setup Software PDrive Page 19

Page 20

9.1.3 CAN/Fieldbus

9 Project window

Address [ ADDR ]

The entry is the station address (1...63) of the servo amplifier. This number is required by the

fieldbus and for the parameter setting of the servo amplifier in multi-axis systems for an

unambiguous identification of the servo amplifier within the system.

External Watchdog [ EXTWD ]

Definition of the monitoring (watchdog) time for fieldbus/slot communication. This monitoring is

only active when the value is greater than 0 and the output stage is enabled.

Source for fieldbus synchronization [ SYNCSRC ]

Defines the synchronisation source, if the control loop is synchronised via an interface.

FPGA functionality [ FPGA ] – PMCtendo DD4 only

Defines the FPGA program that is to be loaded in the initialisation phase.

Baud Rate CAN open [ CBAUD ]

The entry is the transmission rate of the servo amplifier.

Page 20 User Manual for Setup Software PDrive

Page 21

9 Project window

9.1.4 Feedback

Warning !

An incorrect setting can cause the motor to run away, even with a speed setpoint n=0 !!

Feedback Type [ FBTYPE ]

The FBTYPE command is used to select the type of feedback device that is used for the

commutation and velocity controller.

Offset [ MPHASE ]

Compensates for a mechanical position error of the resolver/encoder in the motor. Change this

only while the amplifier is disabled.

If an encoder with EnDat or Hiperface® is used as a feedback unit, the offset is automatically

transmitted to the servo amplifier.

Number of Poles [ MRESPOLES ] – resolver only

Standard resolvers have 2 poles.

Encoder Lines [ ENCLINES ] – Hiperface/EnDat only

ENCLINES sets the resolution (number of lines) of the encoder input channel using an

ENCODER as feedback unit. In case of Rotary Motors it is the number of lines per revolution, in

case of linear Motors it is the number of lines per pole pitch. W ith an ENDAT or Hiperface

Encoder ENCLINES is read automatically during the initialization process.

Count Direction [ DIR ] – PMCtendo DD5 and PMCprotego D only

Defines the direction of rotation of the motor shaft in relation to the polarity of the set value.

Bandwidth [ MRESBW ]

With a wide bandwidth, the drive will respond more rapidly to control-loop deviations => smaller

following error. A very wide bandwidth only makes sense with low moments of inertia, low KP,

and very high values of acceleration. A narrower bandwidth produces a filter effect. The speed

and positional control are smoother (the encoder emulation is quieter as well).

Observer-Feedforward [ VLO ]

This parameter applies a dynamic pre-control to the actual-value detection (Luenberger

monitor), particularly for resolver feedback. It reduces the phase-shift in the detection of the

actual value, thus improving the stability of the speed control.

With VLO = 1 the pre-control is set to optimum, with VLO = 0 the monitor is switched off.

Feedback Filer Mode [ FLTMODE ] – PMCtendo DD4 only

Feedback Filter Mode.

User Manual for Setup Software PDrive Page 21

Page 22

9 Project window

Number of multi-turn bits [ SSIREVOL ] – PMCtendo DD5 and PMCprotego D only

Defines the number of multi-turn bits in an SSI communication.

Number of SSI bits to read [ SSIRXD ] – PMCtendo DD5 and PMCprotego D only

Establishes the number of SSI bits to read

Resolver Signal [ RK ]

The RK parameter can be used to correct any amplitude difference that may exist between the

sine and cosine signals from the resolver.

Press the button “Calculate RK” for automatic calculation.

No overvoltage surveillance [DRVCONFIG] (Bit 6)

Monitoring of the maximum voltage of the sine/cosine encoder at X1 is deactivated.

No overflow surveillance [DRVCONFIG] (Bit 7)

Overflow monitoring of a multi-turn encoder is switched off.

Single turn executed as multi turn encoder [DRVCONFIG] (Bit 8)

A single-turn encoder is treated as a multi-turn encoder. The absolute position within a

revolution is taken on power-up. A reference run is not required.

Angle of rotation

Shows the mechanical angle of rotation.

Page 22 User Manual for Setup Software PDrive

Page 23

9 Project window

9.1.5 Motor

Motor Type [ MTYPE ]

MTYPE sets the amplifier's control algorithms to different motor types.

I0 [ MICONT ]

The standstill current is the r.m.s. current value that the motor requires at standstill to produce

the standstill torque (defines the maximum value for the entry of Irms in the current controller).

I

[ MIPEAK ]

0max

The peak current (r.m.s. value) should not exceed 4 x the rated current of the motor. The actual

value is also determined by the peak current of the servo amplifier that is used (defines the

maximum value for the entry of Ipeak in the current controller).

El. Therm. Time Constant [ MTIME ] – PMCtendo DD5 and PMCprotego D only

Motor thermal time constant to calculate MI2T with MICONT.

Maximum Speed [ MSPEED ]

Maximum permissible speed of the motor. Limits the entry for the parameter SPEED LIMIT.

Number of Poles [ MPOLES ]

The number of motor poles per turn of the motor.

L [ ML ] -PMCtendo DD5 and PMCprotego D only

Inductance of the motor (phase-phase). You can take this value from the motor manual.

L [ L] – PMCtendo DD4 only

Inductance of the motor (phase-phase). You can take this value from the motor manual.

Stator Wind. Resistance [ MRS ]

The parameter describes the stator winding resistance phase-phase in Ohm.

Brake [ MBRAKE ]

If you want to operate a 24V holding brake in the motor directly from the servo amplifier, this

parameter can be used to enable the brake function.

Velocity threshold commutation error [ VCOMM ]

Defines the velocity threshold for commutation error monitoring.

Motor Unit [ MUNIT ] – PMCtendo DD4 only

Unit for all speed-dependent motor parameters.

User Manual for Setup Software PDrive Page 23

Page 24

9 Project window

Current Advance [ MTANGLP ] – not for Induction Motor

A current-dependent phase advance, to make use of the reluctance torque for motors with

magnets embedded in the rotor.

Limit Phi [ MVANGLF ] – not for Induction Motor

Velocity-dependent Lead (Limit Phi).

Start Phi [ MVANGLB ] – not for Induction Motor

Velocity-dependent Lead (Start Phi).

Rated Speed [ MVR ] – Induction Motor only

In asynchronous motor mode, the parameter MVR must be set to the rated speed of the motor.

This is the threshold for the start of field attenuation.

Rotor Time Constant [ MTR ] – Induction Motor only

Defines the rotor time constant under rated load (Tr = Lh/Rr). Lh is die magnetizing inductance

and Rr is the rotor resistance.

Field Level [ MIMR ] – Induction Motor only

Magnetizing Current (Induction Motor).

KP [ GF ] – Induction Motor only

Proportional gain (P) of the flux controller. The flux controller is implemented as a PI controller.

TN [ GFTN ] – Induction Motor only

Reset (I) time of the flux controller.

Field Correct Factor [ MCFW ] – Induction Motor only

Correction factor for field-weakening.

The correction factor compensates for non-linearity of the motor inductance with reducing

magnetizing current by increasing speed during field-weakening.

Slip Correct Factor [ MCTR ] – Induction Motor only

Correction factor for the rotor (armature) time constant, increases the torque in the fieldweakening range /stationary range.

Rated Frequency [ MFR ] – PMCtendo DD5 and PMCprotego D with asynchronous motor only

Rated frequency of the asynchronous motor.

Rated Voltage [ MUR ] – PMCtendo DD5 and PMCprotego D with asynchronous motor only

Rated voltage of the asynchronous motor.

Initial Voltage Factor [ VSTART ] – PMCtendo DD5 and PMCprotego D with async. motor only

Initial voltage as a fraction of the rated voltage.

Power Factor [ MCOSPHI ] – PMCtendo DD5 and PMCprotego D with async. motor only

Power factor of the asynchronous motor.

Page 24 User Manual for Setup Software PDrive

Page 25

9 Project window

9.1.6 Current controller

Ipeak (pos.) [ IPEAK ]

Sets the required pulse current (r.m.s. value). The value that can be entered is limited to the

rated peak current of the motor or amplifier (the lower of the two values).

Ipeak (neg.) [ IPEAKN ]

Sets the intended pulse current (r.m.s. value) for the negative range.

Homing IPeak [ REFIP ]

The REFIP parameter can be used to set the peak current for homing to a stop.

Irms [ ICONT ] – PMCtendo DD4 only

Sets the rated output current that is required. The adjustment is usually made to I0 , the

standstill current for the motor that is connected. The value that can be entered is limited to the

rated current of the servo amplifier or the standstill current of the motor Io (the lower of the two

values).

Proportional Gain (Kp_i) [ MLGQ ]

Determines the proportional gain of the current controller.

Integral Time (Tn_i) [ KTN ]

Determines the integral-action time (integration time constant) of the current controller.

I 2 t-Warning [ I2TLIM ]

Sets the level, as a percentage value of the r.m.s. current, above which a message will be sent.

User Manual for Setup Software PDrive Page 25

Page 26

9.1.7 Speed controller

9 Project window

Speed Limit (pos.) [ VLIM ] – PMCtendo DD4 only

Limits the motor speed. The maximum value also depends on the used motor and encoder.

Speed limit (pos.) [ VLIMP ] – PMCtendo DD5 and PMCprotego D only

Limits the motor speed. The maximum value also depends on the used motor and encoder.

Speed limit (neg.) [ VLIMN ]

The VLIMN parameter defines the maximum velocity for the negative direction.

Overspeed [ VOSPD ]

Determines the upper limit for the motor speed. If this limit is exceeded, the servo amplifier

switches into the fault condition.

Count direction [ DIR ] – PMCtendo DD4 only

Fixes the direction of rotation of the motor shaft, referred to the polarity of the setpoint.

Acc. Ramp [ ACC ]

Limits the rate of increase of the internal setpoint processing during acceleration to the speed

limit (valid for both directions). A jump or step in the setpoint that is provided will be turned into

a smoother, more favourable transition.

Dec. Ramp [ DEC ]

Limits the rate of decrease of the internal setpoint processing during braking to the zero speed

(valid for both directions). A jump or step in the setpoint that is provided will be turned into a

smoother, more favourable transition.

Emerg. Dec. Ramp [ DECSTOP ]

The breaking ramp for emergency breaking.

Disable Dec. Ramp [ DECDIS ]

When the output stage is disabled (removal of the hardware or software enable), the internal

speed setpoint is set to 0, using the preset DECDIS ramp.

PI-Plus [ GVFR ]

With the default setting, the speed controller functions as a standard PI-controller with slight

overshoot in the step response.

Prop Gain Kp_v [ GV ]

Determines the proportional gain.

Int. Time Tn_v [

Page 26 User Manual for Setup Software PDrive

GVTN ]

Page 27

9 Project window

Determines the integral-action time / integration time constant.

PID-T2 [ GVT2 ] – PMCtendo DD4 only

Affects the proportional gain (P-gain) at medium frequencies.

Feedback [ GVFBT ] – PMCtendo DD4 only

If necessary, the time constant for the PT1-filter in the actual speed feedback (tachometer

smoothing) can be altered.

LP-Frequency [ ARLPF ] – PMCtendo DD5 and PMCprotego D only

Frequency limit low pass filter.

HP-Frequency [ ARHPF ] – PMCtendo DD5 and PMCprotego D only

Frequency limit high pass filter.

User Manual for Setup Software PDrive Page 27

Page 28

9.1.8 Position controller

9 Project window

Feedback [ EXTPOS ]

The EXTPOS command defines the feedback source for the drive position control loop.

Prop Gain Kp_p [ GP ]

Determines the proportional gain for the position controller.

Tn [ GPTN ] – PMCtendo DD4 only

Determines the integral-action time (integration time constant) for the position controller.

Prop Gain Kp_v [ GPV ]

Determines the proportional gain for the speed section of the controller.

FF-Faktor Speed [ GPFFV ]

Determines the feed-forward factor for the position controller.

FF-Faktor Current [ GPFFT ] – PMCtendo DD4 only

Position control loop: feed forward for the current command.

Count Direction [ DIR ] – PMCtendo DD5 and PMCprotego D only

The DIR variable defines the count direction for feedback information.

Resolution [ ENCIN / EGEARO / EGEARI ] – PMCtendo DD5 and PMCprotego D only

ENCIN sets the resolution (number of pulses) of the encoder input channel using a digital

encoder as feedback unit.

In case an external feedback system is used the ratio can be set by EGEARI and EGEARO.

The feedback turn are set by EGEARI the motor turn by EGEARO.

Page 28 User Manual for Setup Software PDrive

Page 29

9 Project window

9.1.9 Electronic Gearing

External Gearing Source [ GEARMODE ]

The servo amplifier can be controlled through different interfaces and from various sources.

Ratio [ GEARO ] / [ GEARI ]

You can use the entry fields in this equation to determine the transmission ratio.

Input Filter [ GEARFILT ] – PMCtendo DD5 and PMCprotego D only

This command GEARFILT can be used to configure the filter and determine the corresponding

frequency of the electronic gearing filter.

Count Direction [ DIR ] – PMCtendo DD5 and PMCprotego D only

The DIR variable defines the count direction for feedback information.

Lines per Revolution [ ENCIN ] – PMCtendo DD4 only

ENCIN sets the resolution (number of pulses) of the encoder input channel using a digital

encoder as feedback unit.

User Manual for Setup Software PDrive Page 29

Page 30

9.1.10 Encoder

9 Project window

Encoder-Emulation [ ENCMODE ]

Selection of the digital encoder channel.

Resolution [ ENCOUT ]

Determines the number of increments per turn that are output (ROD).

Zero Pulse Offset [ ENCZERO ]

Determines the position of the zero (marker) pulse when A=B=1. The entry is referred to the

zero-crossing of the feedback unit.

Transmit Timeout SSI [ SSITOUT ] – PMCtendo DD5 and PMCprotego D only

The command SSIOUT sets the monoflop - timeout of the SSI – transmission.

No. of Bits (Multi-/Single -Turn) [ SSIREVOL ] – PMCtendo DD5 and PMCprotego D only

Command ‘SSIREVOL’ sets the number of turns (MultiTurn) for SSI – Transmission.

Baud Rate [ SSIOUT ] – PMCtendo DD4 only

Determines the serial transmission rate. Change this only while the amplifier is disabled.

SSI-Takt [ SSIINV ] – PMCtendo DD4 only

Determines whether the output level is normal, or inverted. Change this only while the amplifier

is disabled.

SSI Code [ SSIGRAY ]

Determines whether the output is in binary or GRAY code. Change this only while the amplifier

is disabled.

Number of SSI bits to read [ SSIRXD ] – PMCtendo DD5 and PMCprotego D only

Establishes the number of SSI bits to read

Input Edge [ ENCCAPT ] – PMCtendo DD4 only

Determines the triggering edge and thus the quiescent level of the clock line. Change this only

while the amplifier is disabled.

SSI-Mode [ SSIMODE ] – PMCtendo DD4 only

Determines the encoder type (Single turn or Multi turn).

Page 30 User Manual for Setup Software PDrive

Page 31

9 Project window

9.1.11 Digital I/O

Input 1 – Input 4 [ IN1MODE – IN4MODE ]

The command is used to configure the function of the digital inputs.

Var. x [ IN1TRIG – IN4TRIG ]

Auxiliary trigger variable for the digital inputs.

Output 1 – Output 2 [ O1MODE – O2MODE ]

You can combine the following standard pre-programmed functions with the digital outputs.

Var. x [ O1TRIG – O2TRIG ]

Auxiliary variable for the digital outputs.

User Manual for Setup Software PDrive Page 31

Page 32

9.1.12 Analog I/O

9 Project window

Analog-Inputs – Function [ ANCNFG ]

The ANCNFG command configure the analog inputs.

Offset [ ANOFF1 - ANOFF2 ]

Adjust the axis to standstill while the setpoint SW =0V.

Filter [ AVZ1 - AVZ2 ]

You can enter a filter time constant here, for setpoint 1 (clock rate 8 kHz)

(1st order filter).

Velocity Scale [ VSCALE1 - VSCALE2 ]

Scaling of the speed setpoint value.

Current Scale [ ISCALE1 - ISCALE2 ]

Scaling of the torque setpoint value.

Velocity Deadband [ ANDB ]

Suppresses small input signals.

Analog Output 1+2 [ ANOUT1 – ANOUT2 ] – PMCtendo DD4 only

Configuration of the analog outputs.

Page 32 User Manual for Setup Software PDrive

Page 33

9 Project window

9.2 Positioning

9.2.1 Homing

Reference traversing (homing) is an absolute task that is used to zero the drive for

subsequent positioning operations. You can choose between various types of homing.

After homing, the drive reports "InPosition" and then enables the position controller in the

servo amplifier.

The limit switch functions: 2, PSTOP and 3, NSTOP must be activated for digital inputs 3

or 4 to achieve full homing functionality.

Be sure that the zero point of the machine (reference point) is in a position that allows

the subsequent positioning operations. The software limit-switches that were set as

parameters may be ineffective. The axis could move to the hardware limit-switch or even

the mechanical stop. There is a risk of damage.

If the reference point (zero point of the machine) is approached with excessive velocity,

(for instance, because of high moments of inertia), it may be overshot and, in the worst

case, move to the hardware limit-switch or even the mechanical stop. There is a risk of

damage.

The position controller cannot be operated without first making a reference traverse

(homing). A homing/reference traverse must be made after the 24 V supply voltage has

been switched on. The start signal must not be removed during homing. The start signal

must remain present until the "InPosition" message appears.

The SW-enable is set automatically when homing starts. Homing is only started in

OPMODE 8. However, the SW-enable is set in all OPMODEs. The drive can be accelerated

by an analog setpoint that is applied, if the START command is executed in OPMODE 1

or 3.

User Manual for Setup Software PDrive Page 33

Page 34

9.2.1.1 Homing [NREF]

You can choose which type of reference traverse should be performed.

No Function Reference point is...

0 Set Home Reference

immediately

1 Home Switch and Zero

Pulse

2 Limit Switch and Zero

Pulse

3 Home Switch without Zero

Pulse

4 Limit Switch without Zero

Pulse

5 within one Revolution and

Zero Pulse

6 Set Ref.Point immediately

on Position Command

7 Move to Mechanical Stop

(Ref. Ipeak) and Zero Pulse

8 Move to an absolute SSI-

Position

9 Move to Mechanical Stop

(Ref. Ipeak) without Zero

Pulse

9 Project window

the setpoint position

the first feedback zero-mark outside the home

switch

the first feedback zero-mark outside the limit

switch

the edge of the home switch

the edge of the limit switch

the next feedback zero-mark

the actual position

the first feedback zero-mark outside the mechanical stop.

Peak current is limited to Homing Ipeak during

the movement. (see screen page "Current

Loop").

the read position from the SSI input at the

beginning of the homing

the actual position, when the drive is at the mechanical

stop and the following error reaches

50% of the max. allowable following error.

Peak current is limited to Homing Ipeak during

the movement. (see screen page "Current

Loop").

Direction of Motion [ DREF ]

Determines the direction of motion for homing. The setting "distance-dependent" is only

relevant for Homing 5 (within one turn). In this case, the direction is chosen to give the

shortest distance to the zero-mark. This parameter also defines the direction of motion

for a Modulo type of axis.

Homing Speed [ VREF ]

Speed for the homing operation. The sign is automatically fixed by the selected direction

of motion.

Reference Offset [ ROFFS ]

With the reference offset you can assign an absolute position value other than 0 to the

reference point. With an offset for the reference position, you are not actually making a

physical change, but the offset is used as a reference value within the position control of

the servo amplifier. Homing to the reference switch does not finish at zero, but at the

preset reference offset value.

The reference offset must be set before homing is started.

Acceleration Ramp [ ACCR ]

Acceleration ramp for homing operation. This ramp is also valid for jog mode.

Deceleration Ramp [ DECR ]

Deceleration ramp for the homing operation. This ramp is also valid for jog mode. This

deceleration ramp is only used if the operating mode allows it. For homing to a hardware

limit-switch, the emergency ramp is used.

Page 34 User Manual for Setup Software PDrive

Page 35

9 Project window

9.2.1.2 Homing type 0

Sets the reference point to the setpoint position (the following error is lost). The load

does not move.

9.2.1.3 Homing type 1

Before starting homing, check the safety of the system since the load may move even if

the limit-switches are disconnected or defective.

Homing without limit switches, with homing switch, with feedback zero:

Negative traverse, positive count direction, Negative traverse, negative count direction

Homing with limit switches, with homing switch, with feedback zero

Negative traverse, positive count direction

Positive traverse, positive count direction

The meanings of the abbreviations in the drawings are:

Limit switch NSTOP

N

Homing switch

R

Limit switch PSTOP

P

preset velocity

vref

Start position

SP

feedback zero mark

NM

User Manual for Setup Software PDrive Page 35

Page 36

9.2.1.4 Homing type 2

Homing with limit switches, without homing switch, with feedback zero

Negative traverse, positive count direction

Positive traverse, positive count direction

9 Project window

The meanings of the abbreviations in the drawings are:

Limit switch NSTOP

N

Homing switch

R

Limit switch PSTOP

P

preset velocity

vref

Start position

SP

feedback zero mark

NM

Page 36 User Manual for Setup Software PDrive

Page 37

9 Project window

9.2.1.5 Homing type 3

Before starting homing, check the safety of the system, since the load may move, even if

the limit-switches are disconnected or defective.

Homing with limit switches, with homing switch, without feedback zero

Negative traverse, positive count direction

Positive traverse, positive count direction

9.2.1.6 Homing type 4

Homing with limit switches, without homing switch, without feedback zero

Negative traverse, positive count direction

Positive traverse, positive count direction

User Manual for Setup Software PDrive Page 37

Page 38

9.2.1.7 Homing type 5

Behavior for successively repeated starts of Homing 5:

The position controller can only hold the motor in the zero position by passing the zero

mark by ± 1 count. On a repeated start of Homing 5, depending on the position (1 count

in advance of or 1 count behind the zero-mark) and the count direction, the movement

may be a full motor turn!

Homing with limit switches, without homing switch, with feedback zero

Negative traverse, positive count direction Positive traverse, positive count direction

9 Project window

9.2.1.8 Homing type 6

Sets the reference point to the actual position (the following error is not lost). The load does not

move.

9.2.1.9 Homing type 7

Using this type of homing can damage the mechanical stop on the machine. The peak

current, Ipeak, and the continuous current, Irms, are limited for the duration of the

homing run. A more severe limiting of the current is possible. (see parameter Homing

Ipeak on screen page "Current Loop").

Mechanical stop, without limit switches, without homing switch, with feedback zero.

Negative traverse, positive count direction Positive traverse, positive count direction

The meanings of the abbreviations in the drawings are:

Limit switch NSTOP

N

Homing switch

R

Limit switch PSTOP

P

preset velocity

vref

Start position

SP

feedback zero mark

NM

Page 38 User Manual for Setup Software PDrive

Page 39

9 Project window

9.2.1.10 Homing type 8

Prerequisite: an absolute encoder (SSI) is connected to to the encoder input X1 of the servo

amplifier. When the homing starts, the absolute position is read at connector X1. The reference

point is set to this position. The load does not move..

9.2.1.11 Homing type 9

Using this type of homing can damage the mechanical stop on the machine. The peak

current, Ipeak, and the continuous current, Irms, are limited for the duration of the

homing run. A more severe limiting of the current is possible. (see parameter Homing

Ipeak on screen page "Current Loop").

Mechanical stop, without limit switches, without homing switch, without feedback zero

Negative traverse, positive count direction Positive traverse, positive count direction

The meanings of the abbreviations in the drawings are

Limit switch NSTOP

N

Homing switch

R

Limit switch PSTOP

P

preset velocity

vref

Start position

SP

feedback zero mark

NM

User Manual for Setup Software PDrive Page 39

Page 40

9.2.2 Position Data

9 Project window

Axis type [ POSCNFG ] :

Here you select whether the axis is to be operated as a linear or a rotary axis.

Linear axis A linear axis is an axis with a limited range of travel. A linear axis moves

Modulo axis Axis with a limited range of movement. The minimum position is SRND and

Max. Following Error [ PEMAX ]

The following error is the maximum difference (+/- window) between the position setpoint and

the actual position that is permitted during processing. If the value leaves this window, then the

position controller generates an error message and brakes the drive, using the emergency

ramp.

In-Position window [ PEINPOS ]

Sets the InPosition window. Determines at which distance from the set position the „InPosition“

message should be reported. The drive moves precisely to the target position.

Modulo Start-Position [ SRND ]

The SRND parameter is used to define the start of the range of movement for a modulo axis.

within the traversing limits that are given by the software limit-switches, both

absolutely and relatively. A reference point must be set.

the maximum position is ERND-1. If the maximum position ERND-1 is

reached, it automatically switches over to SRND. The absolute target

positions have to be in the defined range. If a motion task is started, which

has a absolute position outside the range, a warning "n08" is displayed

(wrong motion task). Relative moves are calculated in a way, that the target

position always is in the defined range. A positioning in a axis like this, gives

two possibilities of direction to the target position. DREF gives the possibility

to restrict the direction. This axis type also needs a homing move.

Modulo End-Position [ ERND ]

The ERND parameter is used to define the end of the range of movement for a modulo axis.

V max(pos.) [ PVMAX ]

This parameter is used to adjust the maximum speed of movement to suit the limits of the

operative machinery.

V max(neg.) [ PVMAXN ]

The parameter PVMAXN defines the maximum velocity (in the negative direction) that is

permitted for a motion task.

Page 40 User Manual for Setup Software PDrive

Page 41

9 Project window

a-max [ PTMIN ]

A drive is always so dimensioned that it can provide more power than the application requires.

This parameter determines the limit for the maximum mechanical acceleration time to v_max,

that must not be exceeded by the drive.

1 Neg.-SW-limit switch – 2.Pos.-SW-limit switch [ SWCNFG ]

Configuration variables for the position register. SWCNFG is a binary-coded bit-variable, and is

transferred to the ASCII terminal program as a decimal number.

at Position [ SWE1 – SWE2 ]

The variable contains the position value for the position register.

User Manual for Setup Software PDrive Page 41

Page 42

9.2.3 Motion task

9.2.3.1 Overview

9 Project window

For each positioning task, you must define motion tasks. These motion tasks are selected by a

motion task number and stored in the servo amplifier.

Motion task No. Memory Precondition Note

1 .. 180 EEPROM output stage disabled permanently stored

192 .. 255 RAM none volatile storage

When the servo amplifier is switched on, the RAM motion tasks are automatically initialized

with the parameters of the EEPROM motion tasks 1 .. 64.

Motion task No. Memory Precondition Note

1 .. 200 EEPROM output stage disabled permanently stored

201 .. 300 RAM none volatile storage

When the servo amplifier is switched on, the RAM motion tasks are automatically initialized

with the parameters of the EEPROM motion tasks 1 .. 100.

All motion tasks are represented in tabular form. All motion task parameters can be

entered in the table directly. The standard Windows operations are available (Cut, Copy,

Paste, Delete).

The clipboard operations cut, copy and paste are only possible for complete rows so, for

these operations, the appropriate row must be selected. A line can be selected either by

clicking on the row number, or through the keyboard shortcuts <Shift>+<Space>. Doubleclicking a line number in the table opens the screen page for the associated

motion task.

The SW-enable is automatically set when the motion task starts.

The motion task is only started in OPMODE 8. However, the SW-enable is set in all

OPMODEs.

The drive can be accelerated by an analog setpoint that is applied, if the START

command is executed in OPMODE 1 or 3. The motion task is not started if the target

position is beyond the defined SW-limit switches (warning messages n06/n07 and n08).

Page 42 User Manual for Setup Software PDrive

Page 43

9 Project window

9.2.3.2 Edit

Number

Displays the active motion task number.

Unit

Unit for path and speed entries. See screen page "Units/Mechanical".

Type

This selection determines whether the motion task is interpreted as a relative or an

absolute task.

Absolut movement to an absolute target position, relative to the reference

Relativ soll relative to last target (setpoint) position (in connection with motion

Relativ ist relative to actual position at start (in connection with motion block

Relativ In-Pos when the load is in the InPosition window: relative to last target position

Relativ Latch pos contact our applications department

Relativ Latch neg contact our applications department

x_cmd

This parameter defines the distance or the target position, depending on the motion type.

V_cmd_Source

The velocity can be defined in the motion block, or provided as an analog setpoint.

digital: digital setpoint provision through v_cmd.

Analog IN1:analog setpoint provision at input An In 1 (terminals X3/4-5, is used. The

value is read at the start of the motion task.

point

block changeover: e.g., summing operation)

changeover: e.g., register control)

when the load is not in the InPosition window: relative to actual position

at start

V cmd

This parameter determines the velocity of movement for digital setpoint provision. If

v_max is set to a value less than v_cmd at a later time, the position controller uses the

smaller value.

User Manual for Setup Software PDrive Page 43

Page 44

9 Project window

Page 44 User Manual for Setup Software PDrive

Page 45

9 Project window

t_acc_total

This parameter determines the acceleration ramp steepness, depending on the selected

units.

t_dec_total

This parameter determines the deceleration ramp steepness, depending on the selected

units.

Ramp

Determines which type of acceleration/braking ramp is used to carry out a motion task.

Trapeze The drive is given a constant linear acceleration/deceleration to the

target speed.

Sine² To limit any jolting, the drive is accelerated/decelerated within the

acceleration time along an acceleration ramp without any disruptions.

The resulting speed characteristic corresponds to a sine² curve. The

profile is stored in a table in the servo amplifier.

variable The acceleration/braking ramps can be adjusted.

Acc. Ramp (T1)

This parameter determines the acceleration time to v_cmd.

Dec. Ramp (T2)

This parameter determines the deceleration (braking) time from v_cmd to zero.

User Manual for Setup Software PDrive Page 45

Page 46

9.2.3.3 Next Motion Task

Select whether a new motion task should be started automatically, after the present task

is complete. The „InPosition“ signal is only enabled when the last motion task (no further

task) is processed.

You can use the output function "16, Next-InPos" to generate a signal at a digital output

when each target position within a sequence of motion tasks has been reached.

Next Number

The number of the next task, which starts automatically after the current task is

complete.

Acc/Dec

Select the action to be taken when the target position for the present motion task is

reached.

on v=0 The drive brakes to a stop in the target position. The next motion task is then

beginning at

target position

complete at

target position

started.

The drive moves at v_cmd of the present motion task to the target position,

and then accelerates through to v_cmd of the next task.

The changeover to the next task is brought so far forwards, that the v_cmd of

the next task is already achieved by the time the target of the present motion

task has been reached.

9 Project window

Start Condition

immediately The next task is started as soon as the target position is reached.

I/O The next task is started by a signal at a digital input (one of the terminals

Time The next task is started with a defined delay after the target position has been

I/O or Time The next task is started by a signal at a digital input (one of the terminals

Start by I/O Edge

The logic for the digital input that has the function "15, Start next Motion Task" assigned

to it.

LOW-level: 0 ... 7 V HIGH-level: 12 ...3 0 V / 7 mA

Delay Time

The entry (in ms) for the delay time between reaching the target position and starting the

next task.

X3/11...14).

This is only meaningful with "Acceleration/Deceleration to v=0".

Condition: the digital input must have the function „15, Start_MT Next“

assigned, and the target position must have been reached.

You can pre-select the logic with the „Start with“ parameter.

reached. You can enter the delay time with the „Delay time“ parameter.

This is only meaningful with "Acceleration/Deceleration to v=0".

X3/11...14) or after a defined delay.

This is only meaningful with "Acceleration/Deceleration to v=0".

The trigger is the event that occurs first (the start signal or the end of the

delay time).

Condition: the digital input must have the function “15, Start_MT Next“

assigned, and the target position must have been reached.

You can pre-select the logic with the „Start with“ parameter, and enter the

delay time with the „Delay time“ parameter.

Page 46 User Manual for Setup Software PDrive

Page 47

9 Project window

9.2.4 Position registers

Exceeding or falling of up to 16 position values in the motion way can be monitored.

The actual position is visible as well.

Enable Positionsregisters [ WPOS ]

The fast position registers are enabled by WPOS.

No. active 1 – 16 [ WPOSE ]

Enable Fast Position Registers 1 ... 16.

check [ WPOSX ]

Mode of Fast Position Registers 1 ... 16.

Signal, [ WPOSP ]

Polarity of Fast Position Registers 1 ... 16.

if Position... [ P1 - P16 ]

The variables P1 ... P16 contain the position values for the position thresholds 1 ... 16.

User Manual for Setup Software PDrive Page 47

Page 48

9.3 Status

9 Project window

The actual error status and the run time monitor of the servo amplifier are displayed

here. Compare to the runtime status you can simply calculate when an error occurs.

Top left is the error history with the time (run time) when the error occured. Top right is

information about the frequency for every error. Below these frames, the actual errors

and warnings are listed.

You can find a list of all warnings and error messages in the installation manual of the

servo amplifier.

9.4 Monitor

All important parameters are displayed.

Additionally, you can see the value of 5 parameters. Fill in the ASCII names of the parameters

you want to see.

Page 48 User Manual for Setup Software PDrive

Page 49

2

9 Project window

9.5 Screen page „Expansion Card“

The design of screen page "expansion card" depends on the installed expansion card:

9.5.1 Expansion card "DA1"

The expansion card DA1 is available only for PMCtendo DD4 with a special firmware

version.

For getting information please consult our applications department.

CAM 1 / CAM 2 [ CAM1 / CAM2 ]

Position cams for the digital outputs O1 and O2.

Syntax: CAMx number Start offset length

number: number of signals in one cycle (max. 30)

Start offset: Start position 1st CAM

Length: CAM length

Example: CAM1 5 1000 500

Output O1; 5 CAM; 1st CAM starts at 1000; each CAM 500 units long

Number = 0 deletes the definition

Cycle length [ CYCLES ]

Defines the whole cam cycle in

Position mode [ CYCLEMODE ]

0 normal positioning: Rotating direction depends on the actual position.

1 shortest positioning: The cycle length is considered; the axis takes the shortest

way to the position.

2 only positive positioning: The axis moves only in positive direction.

3 only negative positioning: The axis moves only in negative direction.

CYCLES

motor cycles.

User Manual for Setup Software PDrive Page 49

Page 50

9.5.2 Expansion card "D1"

9 Project window

This screen is available only if an I/O extension card is inserted into the servo amplifier.

The status of the 14 additional inputs and 8 outputs is displayed here.

Page 50 User Manual for Setup Software PDrive

Page 51

9 Project window

9.5.3 Profibus DP Expansion card

This screen is available only if a PROFIBUS extension card is inserted into the servo

amplifier.

The PROFIBUS-specific parameters, the bus status, and the data words in the transmit

and receive directions (as seen by the bus-master) are displayed on this screen page.

This page is helpful when searching for errors and commissioning the bus communication.

The data for input/output are only transferred, if the threshold monitoring for the servo

amplifier is active in the master’s hardware configuration.

Instrument Control:

On this screen page, the bit states are displayed for the control word (STW) and the

status word (ZSW). The instrument state given by the status word is made visible in the

state machine. The present state is shown in black. All other states are shown in gray. In

addition, the previous state is indicated by accentuation of the number for the corresponding

arrow symbol.

User Manual for Setup Software PDrive Page 51

Page 52

9.5.4 Expansion card PMCprimo

If a PMCprimo MC1P expansion card is installed in the servo amplifier (servo amplifier edition

PMCprimo Drive2/3) several parameters have to be set on defined values and therefore they

cannot be edited by the user. When connecting PDrive to the servo amplifier those parameters

are checked and set automatically on their defined values. After that the access to these

parameters is denied for the user. The following message appears while saving the parameters

on the servo amplifier:

PMCprimo default values:

- Analog Outputs 1 / 2: ANOUTx = 6

- Digital Inputs 1 / 2 / 3 / 4: INxMODE = 0

- Setpoint Ramp + / -: ACC / DEC = 1

- Ambient Temperature Switch off Threshold MAXTEMPE = 65

- FPGA functionality FPGA = 0

- Source for fieldbus synchronization SYNCSRC = 0

9 Project window

Attention:

The automatically loading of PMCprimo default values can be deselected in the menu „Tools“

-> „Options“.

Changing the PMCprimo default values can cause unexpected effects in the amplifier!

Page 52 User Manual for Setup Software PDrive

Page 53

9 Project window

9.5.5 Expansion card PMCprotego S

In online mode, this view displays status information along with the error stack from a built-in

PMCprotego S expansion card. The expansion card is configured using the software

"PASconfig SDrive". If PDrive detects an installation of the PMCprotego S configuration

software, a button to start/activate PASconfig SDrive will automatically be displayed.

User Manual for Setup Software PDrive Page 53

Page 54

10 Index

10 Index

A

ACC.........................................................26, 52

ACCR............................................................34

ACCUNIT......................................................19

ADDR............................................................20

AENA.............................................................19

ALIAS............................................................18

Analog I/O.....................................................32

ANCNFG.......................................................32

ANDB............................................................32

ANOFF1........................................................32

ANOFF2........................................................32

ANOUT..........................................................52

ANOUT1........................................................32

ANOUT2........................................................32

ARHPF..........................................................27

ARLPF...........................................................27

AVZ1.............................................................32

AVZ2.............................................................32

B

Basic setup....................................................18

BOOT............................................................19

C

CAM1............................................................49

CAM2............................................................49

CAN/Fieldbus................................................20

CBAUD..........................................................20

Communication.............................................12

CYCLEMODE................................................49

CYCLES........................................................49

Expansion Card.............................................49

Expansion card "DA1....................................49

Expansion card PMCprimo............................52

Expansion card PMCprotego S.....................53

EXTPOS........................................................28

EXTWD.........................................................20

F

FBTYPE.........................................................21

File.................................................................12

FLTMODE.....................................................21

FPGA.......................................................20, 52

G

GEARFILT.....................................................29

GEARI...........................................................29

GEARMODE..................................................29

GEARO..........................................................29

GF..................................................................24

GFTN.............................................................24

GP.................................................................28

GPFFT...........................................................28

GPFFV...........................................................28

GPTN.............................................................28

GPV...............................................................28

GV.................................................................26

GVFBT...........................................................27

GVFR.............................................................26

GVT2.............................................................27

GVTN.............................................................26

H

HVER.............................................................18

D

D1..................................................................50

DA1...............................................................49

DEC.........................................................26, 52

DECDIS.........................................................26

DECR............................................................34

DECSTOP.....................................................26

Digital I/O.......................................................31

DIR..............................................21, 26, 28, 29

DREF.............................................................34

E

EGEARI.........................................................28

EGEARO.......................................................28

Electronic Gearing.........................................29

ENCCAPT.....................................................30