1/4 scale 1936 WACO YKS-6 “Custom Cabin” ARF

Wingspan: 100 in. (2540mm)

Length: 74 in. (1880mm)

Wing Area: 2496 in². (161dm²)

Flying Weight: 352 oz. (9.98kg)

1

Introduction & History

WACO is pronounced “wah-co” It rhymes with taco. The WACO Aircraft Co has no

relation to Waco, Texas, which by the way, is pronounced “way-ko.”

“The WACO Aircraft Company of Troy, Ohio was the leading aircraft manufacturer of

civilian aircraft in the U. S. from 1928 - 1935. Beginning in 1921 as the Weaver Aircraft

Company in Lorain, Ohio, they moved to Troy in 1924 and became the Advance Aircraft

Company but kept the WACO logo. In 1929, the name was changed to simply the

WACO Aircraft Company.

WACO produced over 80 models during the years 1919 - 1946, including the large troop

carrying gliders used in all the major invasions during WWII. The best selling WACO

was the Model 10, with over 1100 being produced from 1927 - 1930. During the years

1939 - 1942, WACO also built just over 600 Model UPF-7's for the CAA and the Civilian

Pilot Training program. WACOs were also popular around the world and sold airplanes

to 37 different countries with Brazil being the largest buyer.” (WACO Air Museum online,

Oct. 2008)

Pilot-1 is pleased to announce the 1/4 scale WACO YKS-6 as part of the Golden Age

Civilian Series. The Pilot-1 WACO YKS-6 encompasses the same attributes in quality

construction and handling that made the original WACO a favorite for over 75 years.

Our engineers have spent countless hours developing a true-to-scale ARF that looks

and flies like the full-scale airplane. We know you will be pleased with its scale looks

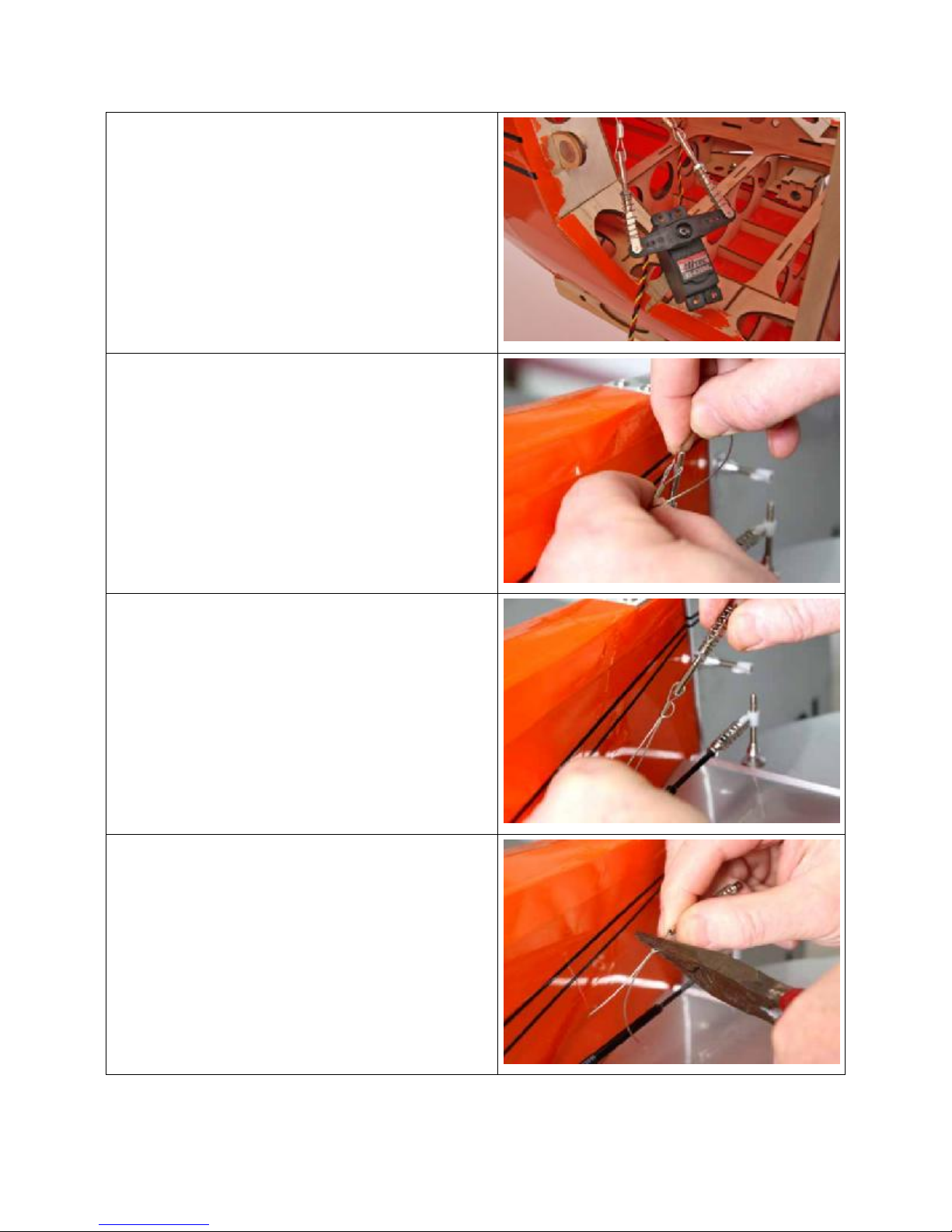

and balanced maneuverability.

2

Before starting, use the Contents list to take an inventory and make sure it is complete.

If any parts are missing or are not of acceptable quality, contact Hobby-Lobby.com

Support at 1-866-WE-FLY-RC (1-866-933-5972)

Contents List

¨ Fuselage

¨ Engine Cowl and Plywood Attachment Ring

¨ Landing Gear and Plywood Inserts

¨ Wheels, Velcro, Misc Hardware

¨ Wings and Corrugated Ailerons

¨ Tube Wing Joiners

¨ Airfoil Aluminum Wing Struts

¨ Horizontal Tail and Elevator

¨ Vertical Tail and Rudder

¨ Long Carbon Fiber Pushrods for Tail

¨ Pull-pull cable for rudder and tailwheel

Additional Items Required

(electric version)

¨ 4-channel Aircraft Radio w/ Receiver (minimum)

¨ 10 to 12 Lipo cells in series (5000-6000mah)

¨ (5) Hitec HS-635 servos for electric version (add 1 more for gas)

¨ (2) 12” servo wire extensions

¨ 77 amp Jeti SPIN Brushless ESC

¨ AXI 5345/16 Brushless Motor

¨ APC 21x12W Propeller

¨ 5-minute and 30-minute Epoxy Glue

¨ Thin CA Glue

¨ Phillips screwdriver

¨ Hex Drivers

¨ Needle Nose Pliers

¨ Hobby Knife

¨ Soldering iron and electrical solder

3

1. Locate the parts shown for the aileron

installation.

2. Remove the servo mounting plate from the

lower wing panels. The mounting layout is

for the Hitec HS-635 standard servo.

Adjust as necessary if you are using a

different servo.

3. Drill the wood blocks with a 1.5mm drill

(1/16”).

4. Mount aileron servo to blocks with servo

screws. Make sure the aileron is centered

using a servo centering device.

5. Add a 12” heavy-duty servo extension to

the aileron servos.

6. Add a servo plug retainer or tape the

connection to protect against accidental

disconnection.

4

7. Slide the servo extension through the wing

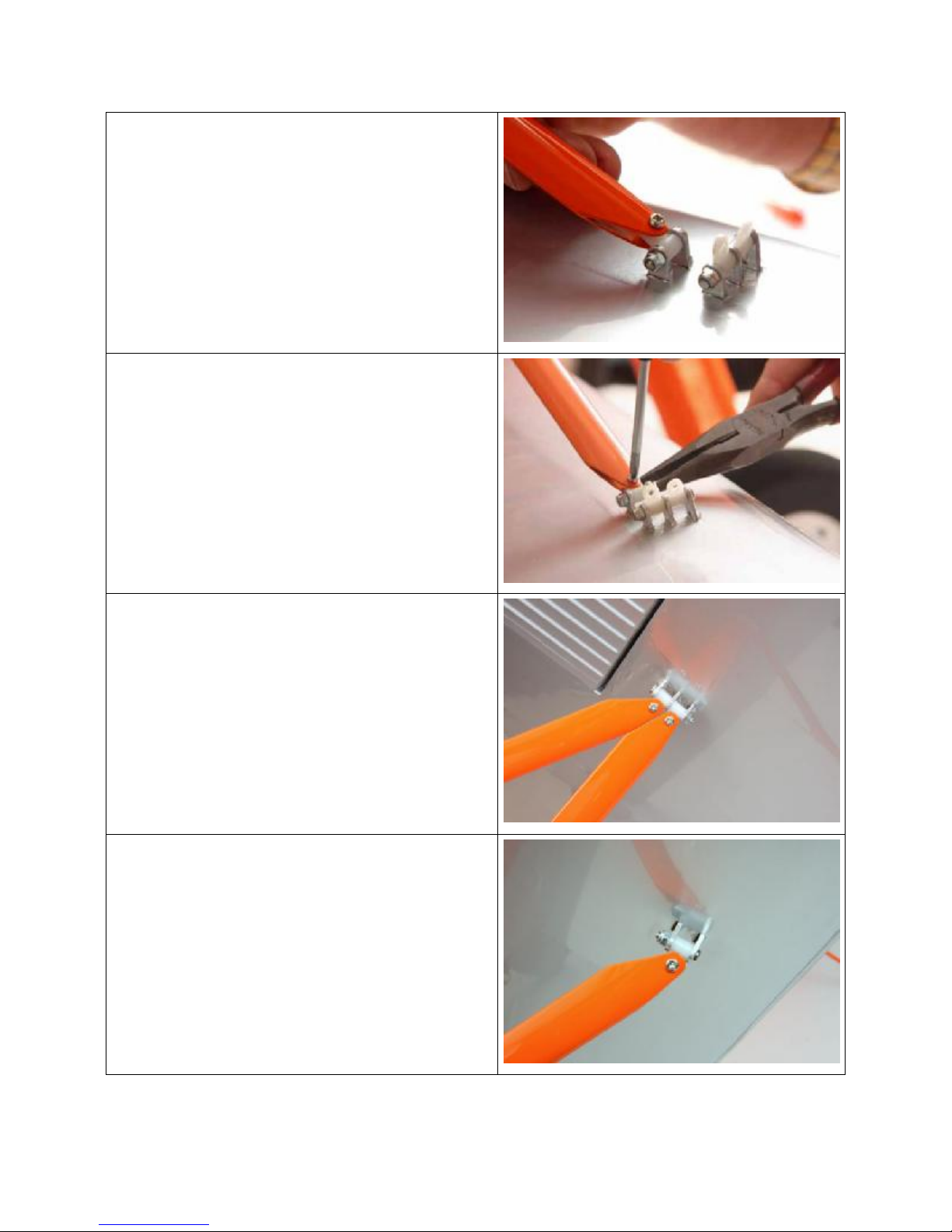

to the root.

8. Install servo mounting plate with small

sheet metal screws.

9. Untape aileron from main wing panel.

10. Locate CA hinges, four will be used for

each aileron.

11. Ailerons and their mating surface have

been pre-slotted for CA hinges.

12. Insert CA hinges to their centers in each

slot on aileron.

13. Fold the CA hinge sharply upward, This

will keep them in place when inserting the

hinges in the main wing panel.

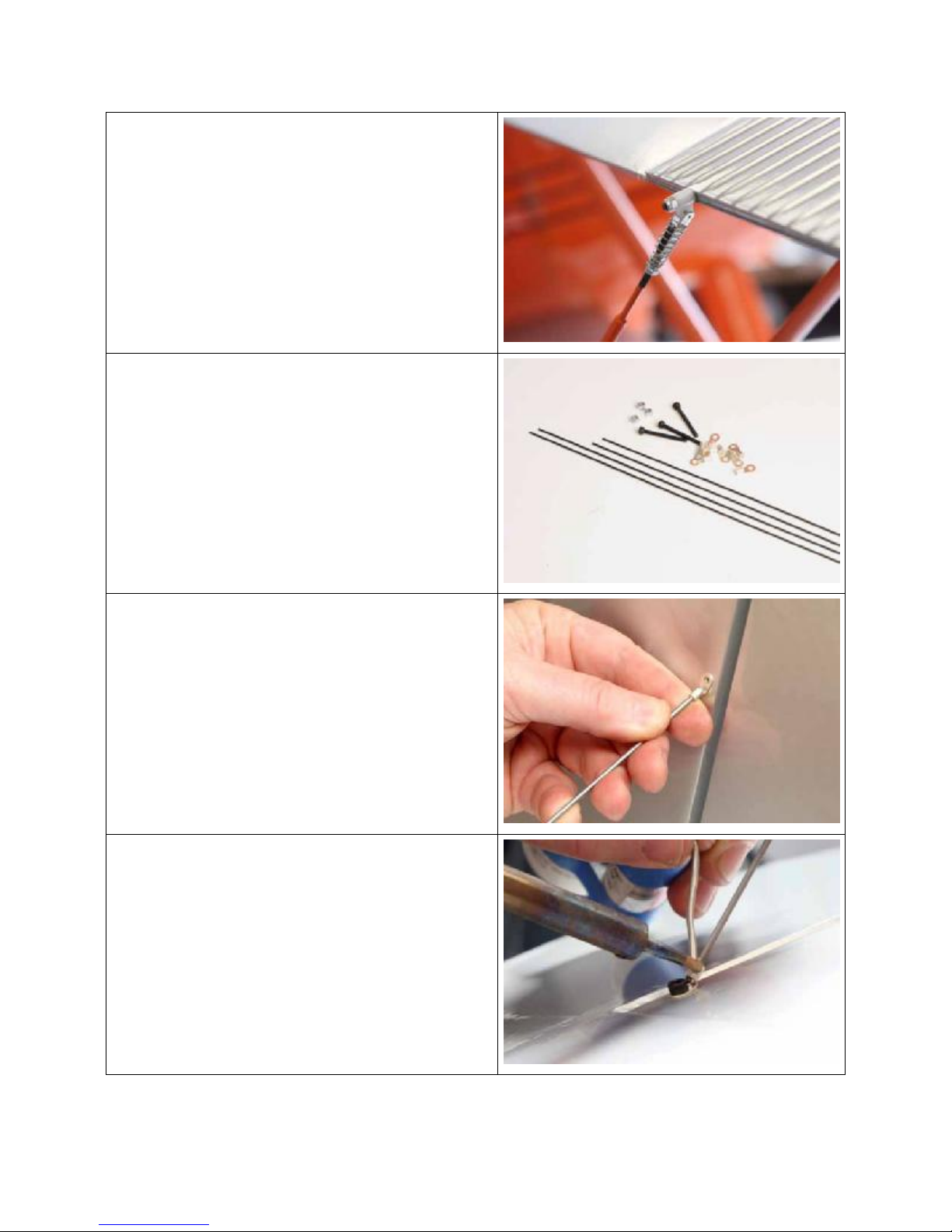

14. Install the aileron into position on the main

wing panel. Make sure to check the gap at

the root of the aileron and the fit at the tip.

15. With the aileron tight against wing and

deflected downward, use 3 drops per

hinge of thin CA to assure strong bonds.

Use paper towel to remove any excess CA

before drying.

5

16. Deflect aileron upwards and repeat

application for bottom of wing. Note very

small gap between aileron and wing.

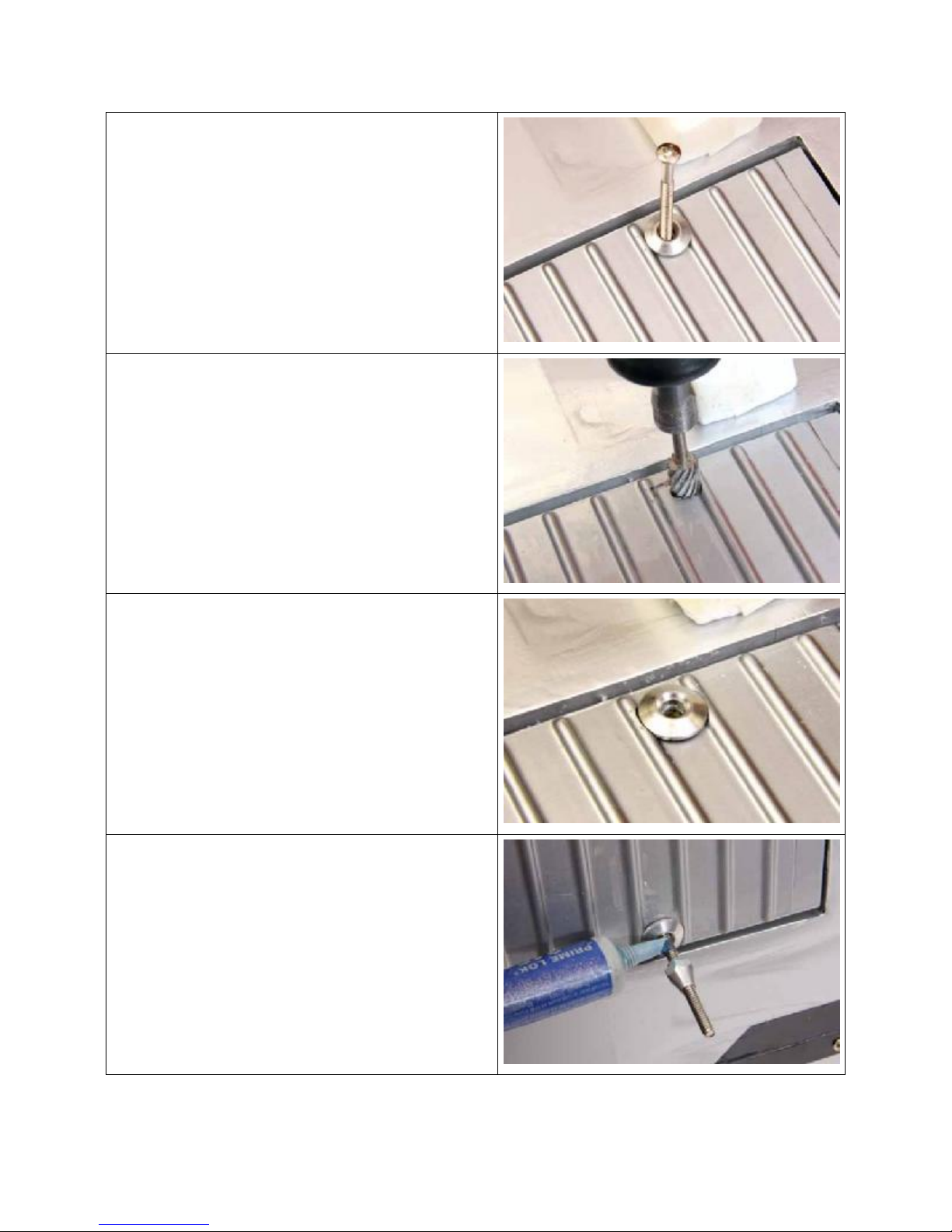

17. From the top of the wing install the aileron

control horn with its washer. DO NOT

tighten yet. Relieve the areas where the

washer touches the corrugations. This is

most easily accomplished with a Dremel.

18. After marking the location of the washer

use a Dremel to trim the corrugations.

19. Work carefully to maintain a close fit to the

washer. (See Photo)

20. Repeat the process for the underside of

the aileron.

21. Assemble the aileron control horn and use

a drop of thread locker to avoid the unit

loosening due to vibration. Snug the nut

tight but do not overtighten.

6

22. Screw nylon control horn linkage to the

control horn. The distance from the bottom

of the aileron to the center of the hole on

the nylon part should be about 28mm

(1-1/8”).

23. Prepare 3 full size servos for installation,

we recommend the Hitec HS-635.

24. Install the servo arms as shown in the

photo.

25. Locate the 2 long elevator pushrods.

26. Install 2-HS-635 Hitec servos into outer

mount locations with arms pointing toward

center of fuselage. (See Photo) A short

Phillips screwdriver is required.

27. Slide the elevator pushrods into position

and install each clevis into servo arm

about 25mm (1”) from the center.

28. We will come back to the rudder servo

installation in a few steps.

29. Locate the parts for the tailwheel

assembly.

7

30. Mount the aluminum plate to the bottom of

the fuselage with 3 screws. The bend in

the aluminum plate goes down.

(See photo)

31. Locate horizontal stabilizer and elevators

along with 6 CA hinges. Repeat the

assembly process similar to the ailerons.

Make sure to adjust the gaps in the hinge

line as well as the end gaps prior to

gluing.

32. Epoxy horizontal tail into position on the

fuselage making sure to center accurately.

33. Prepare the vertical fin and rudder for

installation. Install CA hinges in rudder

and fin.

34. NOTE: Tail wheel must be installed at the

same time as the rudder.

35. Epoxy vertical fin and rudder in place

along with the tailwheel steering arm.

(See photo)

36. Locate the Pull-Pull rudder control parts.

2 lengths of cable, 4 metal clevises and 4

metal crimp tubes.

8

37. Thread the bare end of each cable into

fuselage at rear. A tube is a pre-installed

for you. Pull all but a few inches of cable

to the front. Tape the rear of the cables so

that they remain accessible.

38. Install clevises at the front end of the

cables. Order of assembly: slide crimp on

wire, thread wire through hole in clevis,

return through crimp, loop end around

through front of crimp again.

39. It is easiest to complete the cable setup at

the servo end prior to installing the servo

in the fuselage.

40. Install servo in center hole in fuselage.

41. Un-tape the cables at the rear of the

fuselage and thread the pull-pull cables

through the clevises. Just get the basic

cable threading done but DO NOT crimp

yet.

42. Install the pull-pull control horn through

the rudder and center. Use thread locker

to keep the unit tight.

43. Install the nylon horns on the threaded

rod.

44. TIP: Connect the rudder servo to a servo

centering device and center the servo.

Leave connected during the cable

adjusting process.

45. After you are satisfied that you have the

cable lengths correct for centering your

rudder, and that the servo is still in its

neutral position, crimp the wire in position.

9

46. Photo shows the elevator and rudder

controls. Tighten the lock nut to maintain

the settings.

47. Clip the excess wire in front of the crimp.

48. Locate the pre-painted wire landing gear

parts as well as the 2 wooden fillers and

the 2 nylon landing gear straps and

screws.

49. Insert the landing gear into the pockets on

the fuselage making sure to avoid

puncturing the covering with the rear

landing gear wire.

50. Seat gear fully into position and insert the

rear wire in the pre-drilled hole near the

front edge of the lower wing. (See photo)

51. Spread epoxy on the sides and edges of

the wooden fillers.

10

52. Insert glued filler in position. Have a small

hammer handy to tap the block in place.

53. When fully sheeted the wooden block will

still protrude a small amount.

54. Use a paper towel and rubbing alcohol to

remove an epoxy that has squeezed out.

55. Repeat process for the other side.

56. Place the nylon landing gear strap in

position. (See photo)

57. Drill a pilot hole for the mounting screws.

58. Screw strap into position.

11

59. After the epoxy has cured sand the

wooden filler blocks flush with the

fuselage. This is most easily accomplished

by using a Dremel with a sanding drum.

Work carefully to not damage the finished

fuselage.

60. Once satisfied with the fillers, cut 2

patches from the supplied orange

covering to hide the installation.

61. Using a covering iron with a sock on it,

iron the covering into position.

62. Locate the gear leg covers and their

inserts.

12

63. After trial fitting, epoxy the gear legs into

position.

64. Insert balsa strips into the groove to finish

the inside of the gear leg.

65. Once satisfied with the position of the

fillers, CA them in place with thin CA.

66. Cut lengths of orange covering to finish

the interior of the gear legs. Iron one edge

of the covering into position.

13

67. Slit the covering to go around the smaller

wire and complete the ironing process.

68. Locate the scale wheels.

69. Slip one wheel collar on the axel then the

wheel and another wheel collar.

70. Tighten wheel collars.

NOTE: The nuts on the wheel disc face the

inside of the model. (see photo)

14

71. Install the 2 wing tubes. The longer one

(approx. 25”) is the bottom tube. The

shorter tube (approx. 21-1/2”) is for the

upper wing.

72. Slide the 4 wing panels into position.

73. Locate the 4 hitch pins. The wing panels

are held in place with these pins, no

screws of bolts are required.

74. Press the hitch pin into position to hold the

wing panel in place.

NOTE: For convenience and to avoid the

chance of forgetting or losing the pins, we

suggest that you use a short length of string

and tether each of the pins near where they

are to be used.

15

75. Locate the 8 pre-painted airfoiled

aluminum wing struts.

76. Locate the hardware for the struts.

16 Nylon fittings pre-drilled.

4- 3x30mm screws (shorten to 25mm)

8- 3x15mm screws

16- 3x10mm screws

28- 3mm nylock nuts

77. Install 2 nylon fittings with on 3x25mm

screw and one 3mm nyloc nut. Orient the

nuts toward the middle of the wing.

78. For the single fitting locations use the

3x15mm screw and 3mm nylock nut.

16

79. When all fittings are installed on the wings

begin to install the struts with the long

diagonal strut.

80. Attach the bottom of the strut to the single

fitting on the leading edge of the bottom

wing, make sure to align the airfoil with the

thick end forward. Use a 3x10mm screw

and a 3mm nylock nut.

81. Hold the nut with a pair of needle nose

pliers while you screw the Phillips head in

place. Repeat at the upper end.

82. The N struts are 3 different lengths with

the longest at the rear, the shortest in the

middle (the diagonal) and the middle

length strut at the front. The photo shows

the upper connection of the N struts at the

rear of the wing.

83. Photo shows the upper connection of the

N strut at the front of the wing.

17

84. Photo from the rear of the diagonal strut

and the N struts at the front of the lower

wing.

85. Photo of the rear N strut connection at the

rear of the lower wing.

86. Install all hardware and snug each nut, do

not over tighten.

87. Locate the hardware for the aileron

interconnection.

4-Nylon connectors

4-3mm nylock nuts

2-Pre-painted inter connectors

88. Screw the nylon part to the pre-installed

threaded stud at the trailing edge of the

ailerons, secure with 3mm nylock nut.

89. Install aileron inter connector celvis to the

nylon part.

18

90. Adjust the length of the inter connector so

that both upper and lower aileron are in

neutral position.

91. Connect and tighten lock nuts to secure.

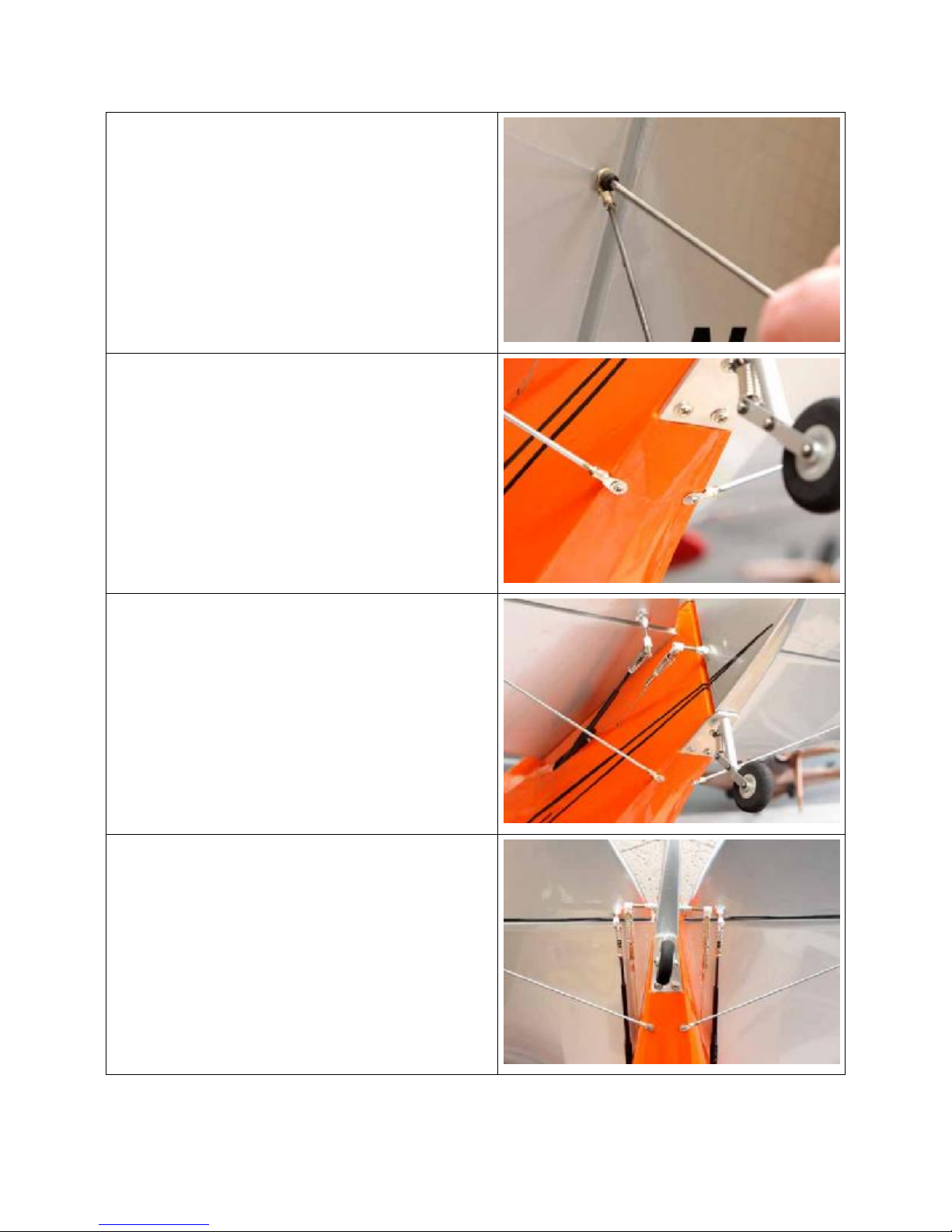

92. Locate the tail brace wires and solder on

electrical ends as well as the 3-3mm allen

head screws and 3mm nylock nuts.

93. You will be soldering the ring electrical

connectors to the ends of the brace wires.

94. Pre-bend one of the solder-on connectors

as shown in the photo.

95. Solder the connector to the brace wire.

96. Adjust the length of the brace wire and

solder it in place with the connector held

with the bolt. (See photo)

19

97. Tighten the 3 threaded allen head bolts.

98. On the bottom brace wires solder the

terminal so that a wood screw can be

used to attach it to the fuselage. Pre-drill

the fitting before installing the screws.

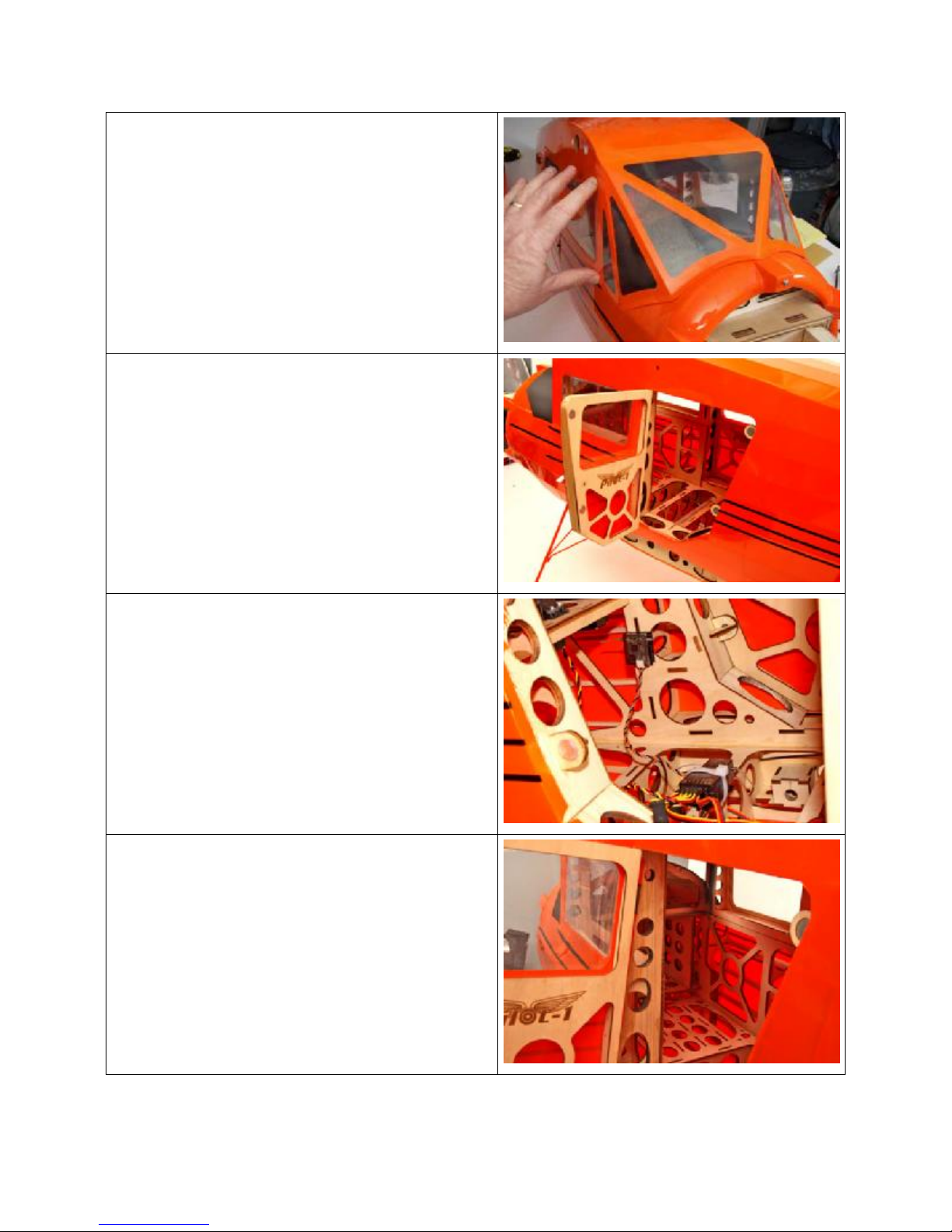

99. See photo for the location of the brace

wires.

100. Photo shows the general layout of tail

parts.

101. Bottom view of elevator pushrods, pullpull rudder with tail wheel steering and the

lower mount points for the tail brace wires.

20

102. You may wish to paint the interior of

the fiberglass cowl with a matt finish black

paint.

103. Put the dummy motor into the cowl but

DO NOT glue in place at this time.

104. The cowl mounting ring is pre-installed

at the factory. Installation is by placing the

cowl over the cowl mount screws and

rotating slightly in a counter-clockwise

direction to hold in place.

105. Before flying you may choose to

tighten several of the screws by using a

long Phillips screwdriver from the front of

the cowl.

106. Locate the wooden AXI motor mounts

107. There is a light line burned on the 2

side pieces, this line is 15mm from one

edge of the plywood. If you are using a

5330 series motor, assemble the parts

without modification.

108. If you are using the 5345 series motor

you will need to cut off 15mm of each side

to achieve the proper motor distance from

the firewall.

109. Install the motor on the front mount

and screw the front face to the sides, do

not glue the front plate to the sides.

110. Epoxy this unit to the firewall box using

the centering reference that is burned into

the firewall.

111. If you wish to screw this mount to the

firewall block, pre-drill some pilot holes

and screw the mount in place from inside

the fuselage.

21

112. Photo shows AXI5345/16 motor and a

Jeti 99A SPIN ESC. The ESC is screwed

to the side of the motor mount and it is in

the airflow inside the cowl.

113. The power wires are routed back to a

Series connector in the battery box inside

the fuselage. This series connector has 3

male Deans connectors, 2 for connection

to flight batteries and 1 to be used with a

jumper female Deans as an arming plug.

114. Photo shows cowl mounted and the

dummy radial engine with the center

relieved for the electric motor. Dummy

motor has been detailed with some paint

and self-stick aluminum tape on the

pushrods. Propeller is an APC 21x12W

electric prop.

115. A pre-assembled and painted

instrument panel is provided.

116. There is a printed sheet with the

instruments at the rear of the manual. You

can cut this out and attach it to the rear of

the panel.

117. Scale instruments with raised bezels

and clear faces in color are available from

Hobby Lobby. The holes in the panel are

designed for these instruments. HL part#

PP41008 American Aircraft of the 30’s

22

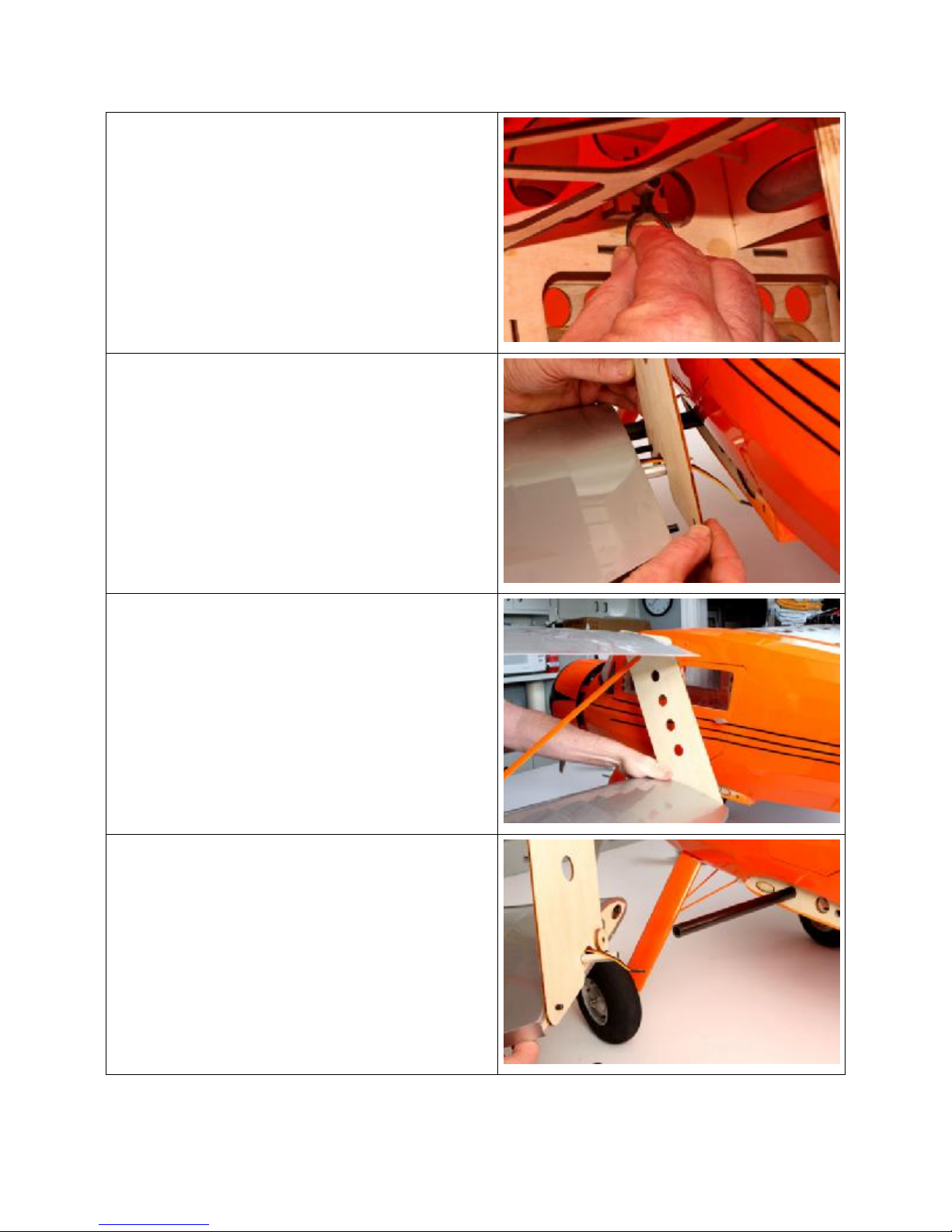

118. Fit the windshield and attach either

with small screws or canopy glue.

119. Access to the radio system and the

batteries is through the operable doors.

120. In addition to flight batteries you will

need to supply your radio system with

power. Use an external BEC like the Jeti

JE512 combined with a 2-cell 21002500mAh Lipo pack. The BEC can be set

to 6V output for stronger servo response.

121. Secure this system to the front of the

cabin with Velcro and cable ties.

122. Locate your radio receiver on the floor

of the cabin with easy access. 6” servo

extensions on the 2 aileron channels of

the receiver will make connecting the

ailerons easier.

123. Make sure to label them so that an

inadvertent misconnection is avoided.

124. Flight batteries are installed in the

inside of the motor box in the nose of the

aircraft. You will need to build a platform

on which to attach the batteries. The exact

dimensions of this will be determined by

your choice of batteries. Make sure that

they are secure before flight.

125. Two 6-cell 5000mAh Thunder Power

packs balanced our airplane without any

additional ballast.

23

126. To remove the wing panels as sets first

remove the hitch pins.

127. Unplug the aileron extensions from

your receiver and slide the wings away

from the side of the fuselage about 2-3”.

128. Slip the provided plywood wing jig into

place one both the lower and upper root

ribs.

129. With the ply jig in place slide the wing

set the rest of the way off of the tube

joiners.

130. The operation should take less than a

minute per side of the aircraft.

24

131. The wings transport easily beside the

fuselage for quick and pain free assembly

at the flying field.

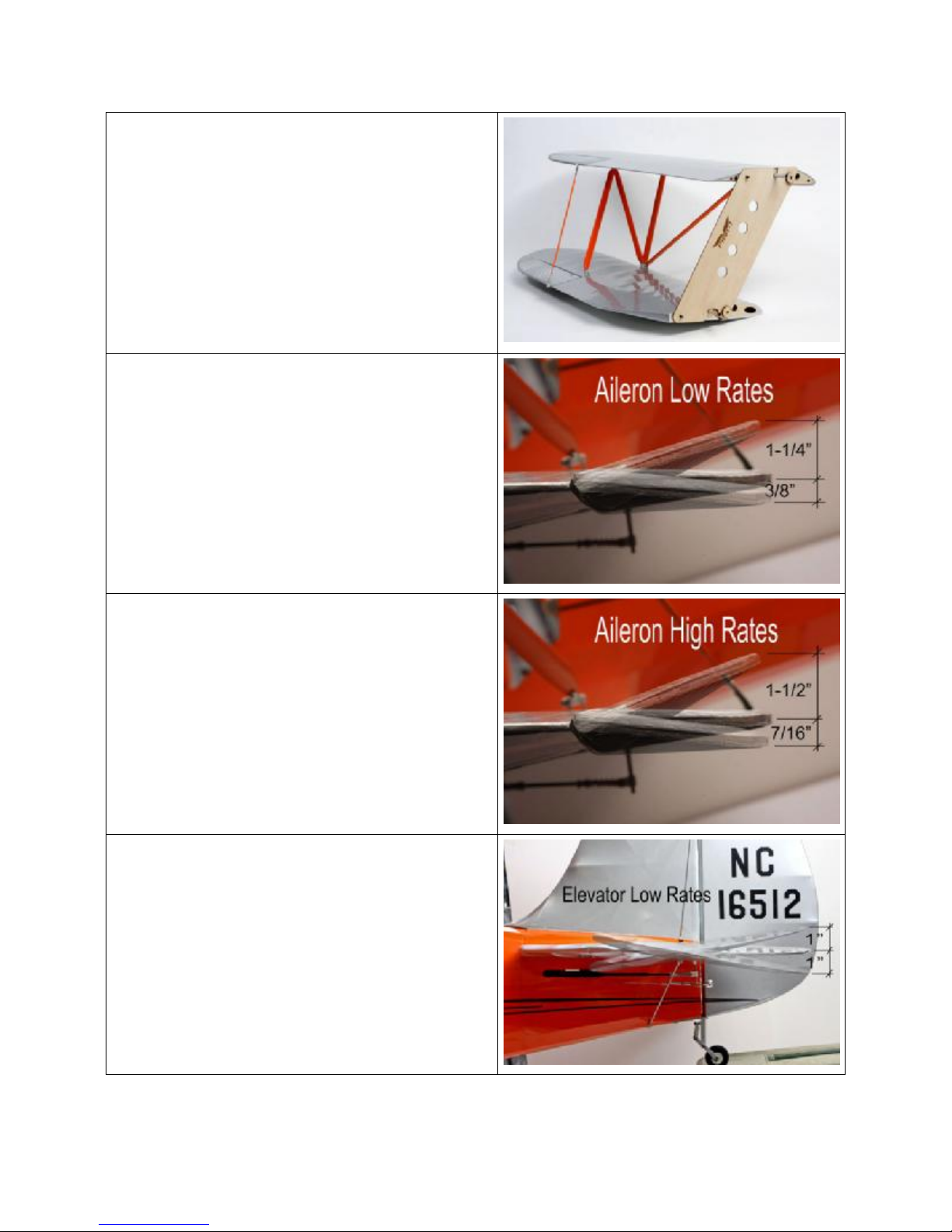

Aileron Low Rates:

1-1/4” UP

3/8” DOWN

Aileron High Rates

1-1/2” UP

7/16” DOWN

Elevator Low Rates

1” UP

1” DOWN

25

Elevator High Rates

1-3/4” UP

1-3/4” DOWN

Rudder Low Rates

1” in each direction

Rudder High Rates

1-1/2” in each direction

CG

6” back from the leading

edge of the upper wing where

it meets the fuselage

NOTE: This is about in line with the leading

Edge of the lower wing

26

Instrument panel can be cut out and installed behind the wooden panel.

Preflight

If you are new to flying R/C aircraft, or a seasoned modeler, we recommend you have a fellow R/C

modeler help you with the first flight. Some items you will need to complete on your first preflight are:

1. Aircraft assembled correctly and ready for flight.

2. All control throws and expos are set per this manual.

3. Transmitter fully charged and on correct model.

4. Aircraft balances at the recommended location.

5. Flight Battery is fully charged and secure.

6. All electronics are operating correctly, proper direction, and secure.

7. Complete a radio Range Check per your radio manual.

8. Balance propeller and make sure it is secure.

9. Wait for a calm or light wind day for first flights.

Flying

You will soon find out the Pilot-1 Cabin WACO YKS-6 is a real pleasure to fly. Takeoffs, landings, and

scale aerobatics are easy and well behaved. Even if you have never flown a tailwheel airplane before, the

Pilot-1 Cabin WACO YKS-6 should be an easy transition. Landings are best accomplished by “threepointing.” This means that all three wheels should touch at the same time and a little up-elevator is held

until the aircraft comes to a complete stop. Except for takeoff and climb, you will only use about 1/2

throttle to maintain a scale flying speed. You can expect flight times of 8+ minutes depending on battery

used and throttle management.

We hope you enjoy your Pilot-1 Cabin WACO YKS-6 as much as we do!

Happy Landings!

27

WARNING – THIS IS NOT A TOY!

Radio controlled model aircraft are capable of inflicting serious injury and/or property damage if not assembled, operated, and

maintained in a competent and safe manner. If you are not already experienced with radio controlled models, we strongly suggest

Hobby-Lobby guarantees this kit to be free from defects in both material and workmanship at the date of purchase. This warranty

does not cover any component parts damaged by use or modification. In no event shall Hobby-Lobby’s liability exceed the original

that you find an experienced modeler to assist you.

Warranty

cost of the purchased kit.

2008 Official Academy of Model Aeronautics National Model Aircraft Safety Code

1. A model aircraft shall be defined as a non-human-carrying device capable of sustained flight in the atmosphere. It shall

not exceed limitations established in this code and is intended to be used exclusively for recreational or competition

activity.

2. The maximum takeoff weight of a model aircraft, including fuel, is 55 pounds, except for those flown under the AMA

Experimental Aircraft Rules.

3. I will abide by this Safety Code and all rules established for the flying site I use. I will not willfully fly my model aircraft in a

reckless and/or dangerous manner.

4. I will not fly my model aircraft in sanctioned events, air shows, or model demonstrations until it has been proven airworthy.

5. I will not fly my model aircraft higher than approximately 400 feet above ground level, when within three (3) miles of an

airport without notifying the airport operator. I will yield the right-of-way and avoid flying in the proximity of full-scale

aircraft, utilizing a spotter when appropriate.

6. I will not fly my model aircraft unless it is identified with my name and address, or AMA number, inside or affixed to the

outside of the model aircraft. This does not apply to model aircraft flown indoors.

7. I will not operate model aircraft with metal-blade propellers or with gaseous boosts (other than air), nor will I operate

model aircraft with fuels containing tetranitromethane or hydrazine.

8. I will not operate model aircraft carrying pyrotechnic devices which explode burn, or propel a projectile of any kind.

Exceptions include Free Flight fuses or devices that burn producing smoke and are securely attached to the model aircraft

during flight. Rocket motors up to a G-series size may be used, provided they remain firmly attached to the model aircraft

during flight. Model rockets may be flown in accordance with the National Model Rocketry Safety Code; however, they

may not be launched from model aircraft. Officially designated AMA Air Show Teams (AST) are authorized to use devices

and practices as defined within the Air Show Advisory Committee Document.

9. I will not operate my model aircraft while under the influence of alcohol or within eight (8) hours of having consumed

alcohol.

10. I will not operate my model aircraft while using any drug which could adversely affect my ability to safely control my model

aircraft.

11. Children under six (6) years old are only allowed on a flightline or in a flight area as a pilot or while under flight instruction.

12. When and where required by rule, helmets must be properly worn and fastened. They must be OSHA, DOT, ANSI,

SNELL or NOCSAE approved or comply with comparable standards.

GENERAL

RADIO CONTROL

1. All model flying shall be conducted in a manner to avoid over flight of unprotected people.

2. I will have completed a successful radio equipment ground-range check before the first flight of a new or repaired model

aircraft.

3. I will not fly my model aircraft in the presence of spectators until I become a proficient flier, unless I am assisted by an

experienced pilot.

4. At all flying sites a line must be established, in front of which all flying takes place. Only personnel associated with flying

the model aircraft are allowed at or in front of the line. In the case of airshows demonstrations straight line must be

established. An area away from the line must be maintained for spectators. Intentional flying behind the line is prohibited.

5. I will operate my model aircraft using only radio-control frequencies currently allowed by the Federal Communications

Commission (FCC). Only individuals properly licensed by the FCC are authorized to operate equipment on Amateur Band

frequencies.

6. I will not knowingly operate my model aircraft within three (3) miles of any preexisting flying site without a frequency-

management agreement. A frequency management agreement may be an

allocation of frequencies for each site, a day-use agreement between sites, or testing which determines that no

interference exists. A frequency-management agreement may exist between two or more AMA chartered clubs, AMA

clubs and individual AMA members, or individual AMA members. Frequency-management agreements, including an

interference test report if the agreement indicates no interference exists, will be signed by all parties and copies provided

to AMA Headquarters.

7. With the exception of events flown under official AMA rules, no powered model may be flown outdoors closer than 25 feet

to any individual, except for the pilot and located at the flightline.

8. Under no circumstances may a pilot or other person touch a model aircraft in flight while it is still under power, except to

divert it from striking an individual.

28

9. Radio-controlled night flying is limited to low-performance model aircraft (less than 100 mph). The model aircraft must be

equipped with a lighting system which clearly defines the aircraft's attitude and direction at all times.

10. The operator of a radio-controlled model aircraft shall control it during the entire flight, maintaining visual contact without

enhancement other than by corrective lenses that are prescribed for the pilot. No model aircraft shall be equipped with

devices which allow it to be flown to a selected location which is beyond the visual range of the pilot.

Hobby Lobby International, Inc.

5614 Franklin Pike Circle

Brentwood, TN 37027

1-866-WE-FLY-RC

(1-866-933-5972)

www.hobby-lobby.com

29

Loading...

Loading...